Page 1

USERGUIDE

UGH003-0102

Thermolater® vacuTrac

Positive/Negative Pressure Water Temperature

Controller with TW-1 or TW-2 Microprocessor

www.conairgroup.com

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 2

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equi pment and the date you

received it in the User Guide. Our service department uses this information, along with the manual

number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engine ering prints and parts lists together for

documentation of your equipment.

Date:

ual Number: UGH003-0102

Man

Serial Number(s):

Model Number(s)

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental, consequential

damages in connection with the furnishing, performance or use of this information. Conair makes no warranty

of any kind with regard to this information, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

Copyright 2002 l Conair l All rights reserved

Corporate Office: 724.584.5500 Instant Access 24/7 (Parts and Service): 800.458.1960 Parts and Service: 814.437.6861

Page 3

TEMPERATURE CONTROL UNITS

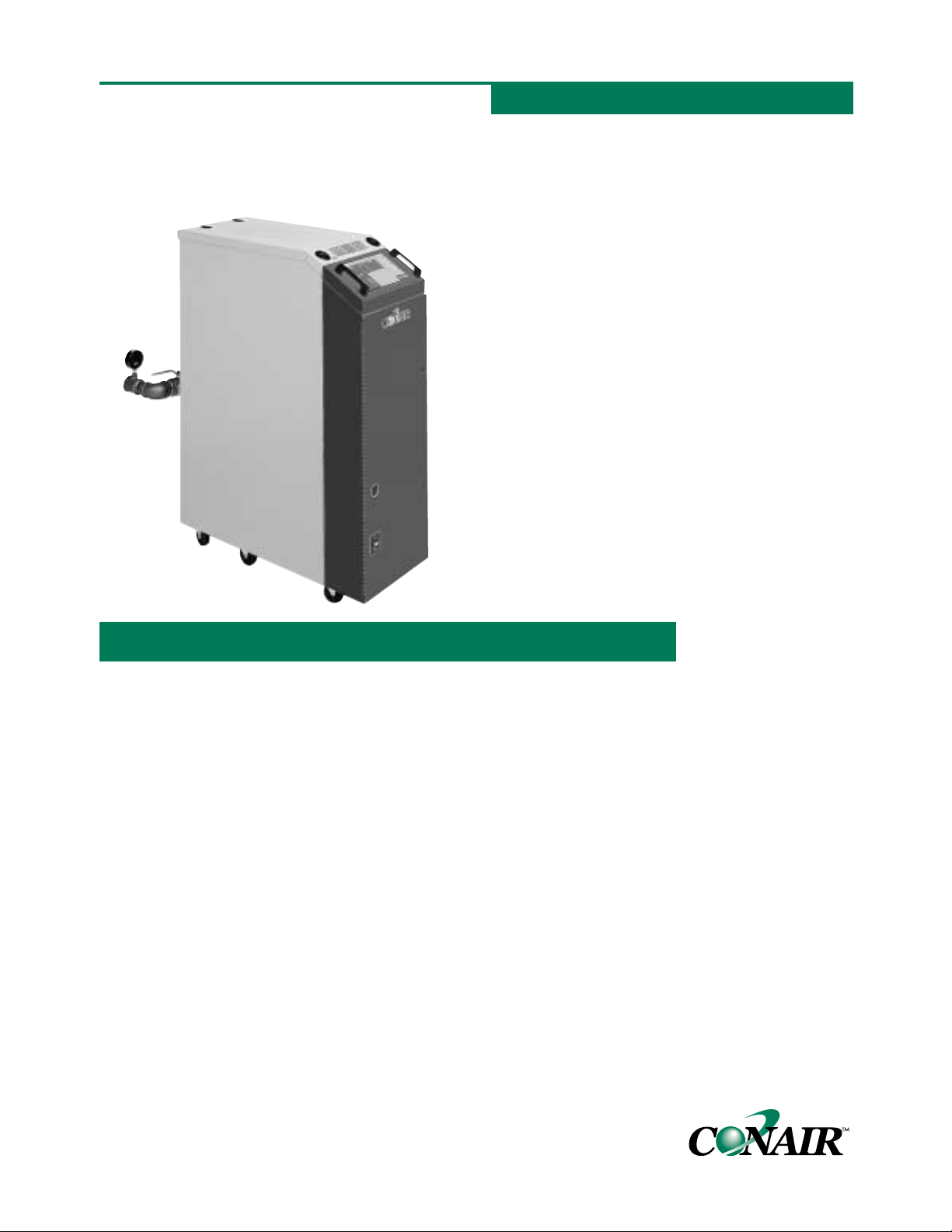

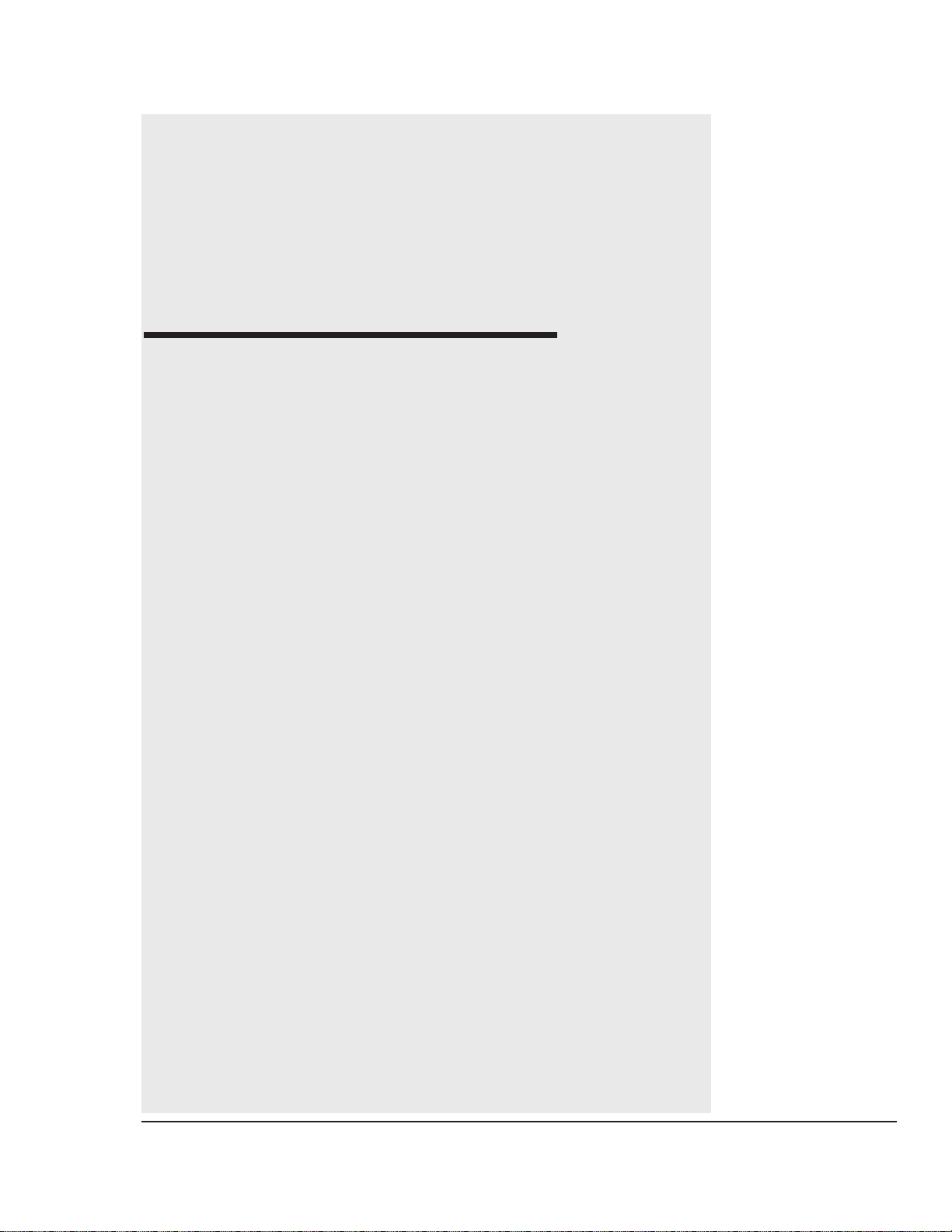

Thermolator®vacuTrac (VTR1-DI and VTR2-DI)

Positive/Negative Pressure

One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

TPHM011/1101

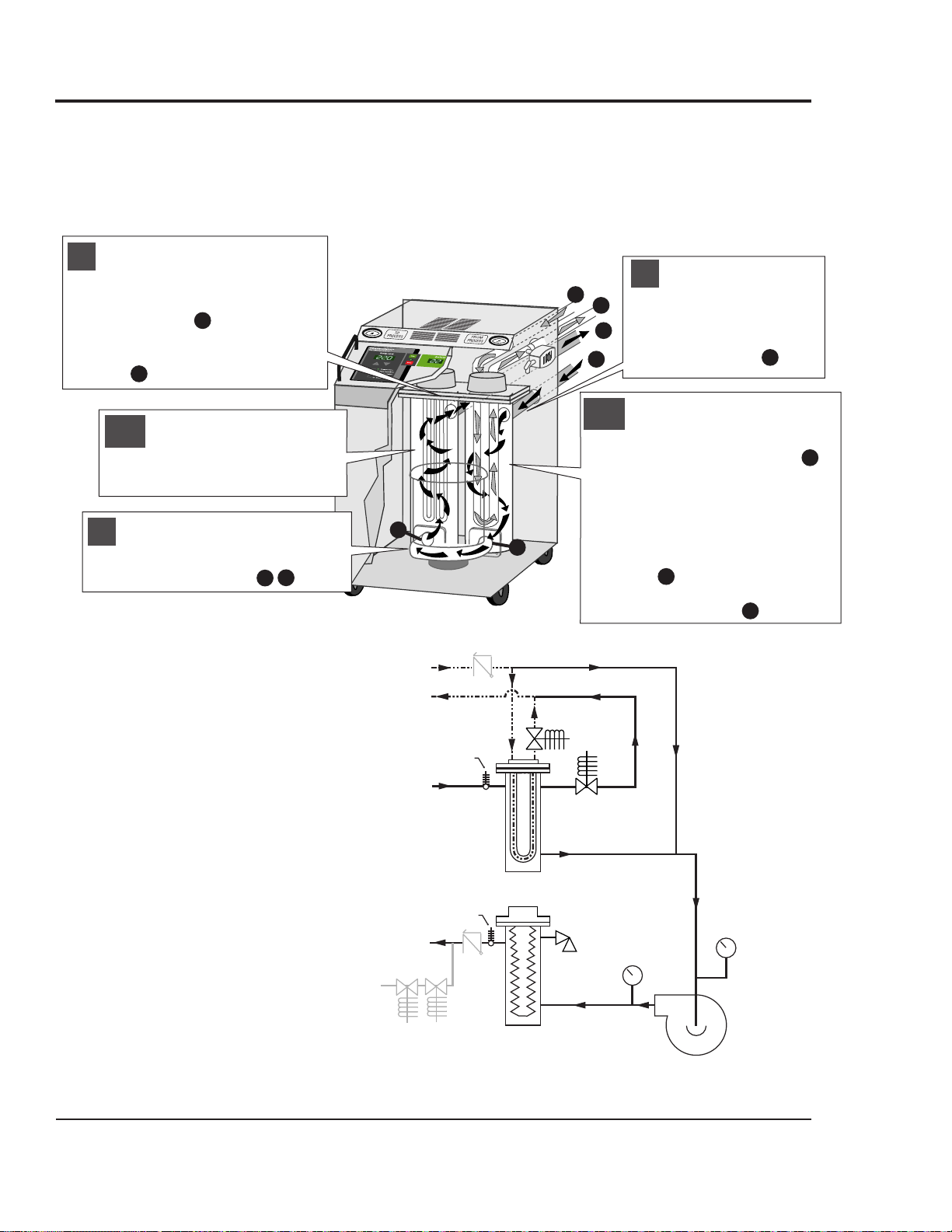

Keep your operation up and running with the

Thermolator vacuTrac water temperature controller. This

positive/negative pressure unit can be used as a temporary fix for a leaky mold or bad O-rings.

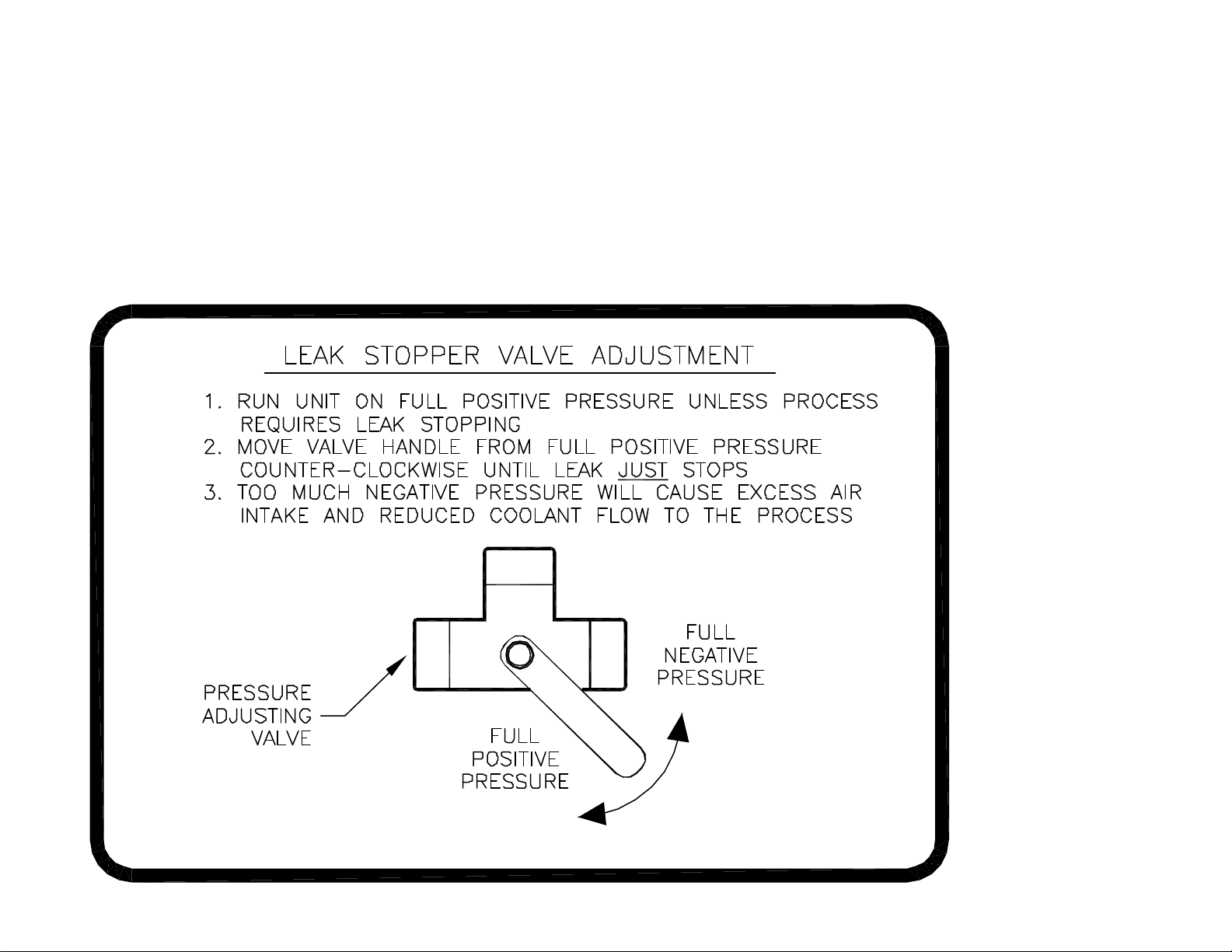

The vacuTrac is equipped with a manual three-way

ball valve that allows you to change the unit from positive pressure to negative pressure by moving the valve

handle on the back of the unit counterclockwise.

Changing the unit to operate with negative pressure

allows the unit to draw air into the mold effectively stopping leaks.

■ INCOLO Y HEATERS

Standard on the vacuTrac, Incoloy heaters resist damage

from high temperatures and chemicals.

■THREE-WAY B ALL VALVE

Quick and easy changeover from standard positive pressure

to negative pressure operation.

■ LIFT-OFF ACCESS PANELS

Convenient, tool-free access to internal components.The

cabinet lifts away for easy maintenance and servicing.

■ STA TE-OF-THE-ART CONTROLS

Easy to use microprocessor controls provide accurate temperature control. Auto-tuning of the PID control parameter

provides uniform temperature control regardless of light or

heavy external loading.

■COMP ACT ,STURDY DESIGN

Small footprint. Designed for efficient use of your valuable

floor space.

CONTROL

TEMPERATURE

AND STOP

MOLD LEAKS

Single or dual zone models available

Use the vacuTrac to produce negative pressure in the from process

lines. Otherwise, the unit functions

like a direct injection temperature

control unit and can be used when

your application requires process

temperatures up to 180° F.

The unit is equipped with a highcapacity, heavy-duty jet pump/venturi. Choose 9 or 12 kW heaters

and pumps from 2 to 7.5 Hp.

Specify single zone if you need

one temperature throughout your

mold, or dual zone if two different

setpoints are required.

You have a choice of two

advanced microprocessor control

systems. Other options include bell,

strobe or piezo horn for alarm conditions.

Page 4

TPHF017/1101

FEATURES

One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

TEMPERATURE CONTROL UNITS

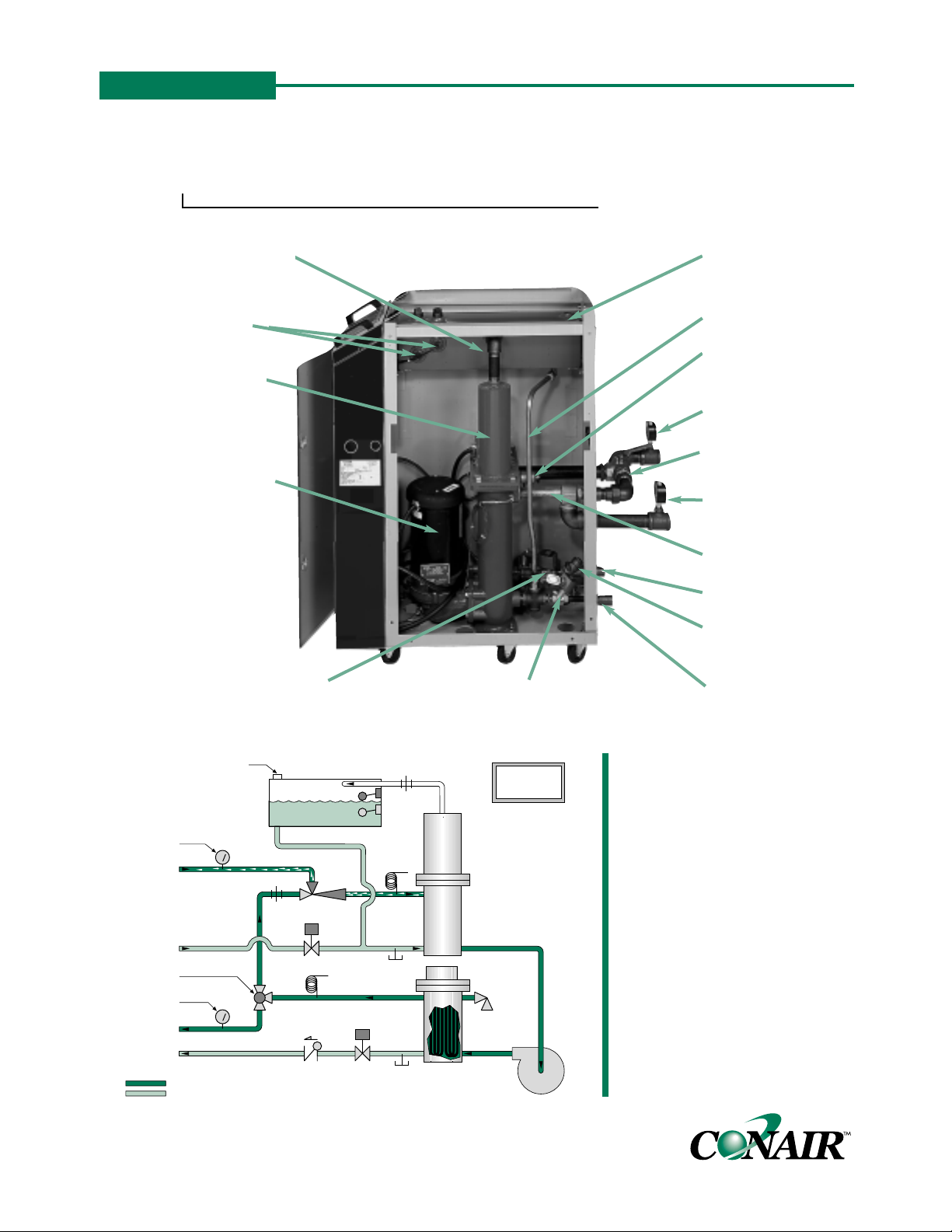

Thermolator®vacuTrac (VTR1-DI and VTR2-D2)

Positive/Negative T emperature Controller

FEATURES

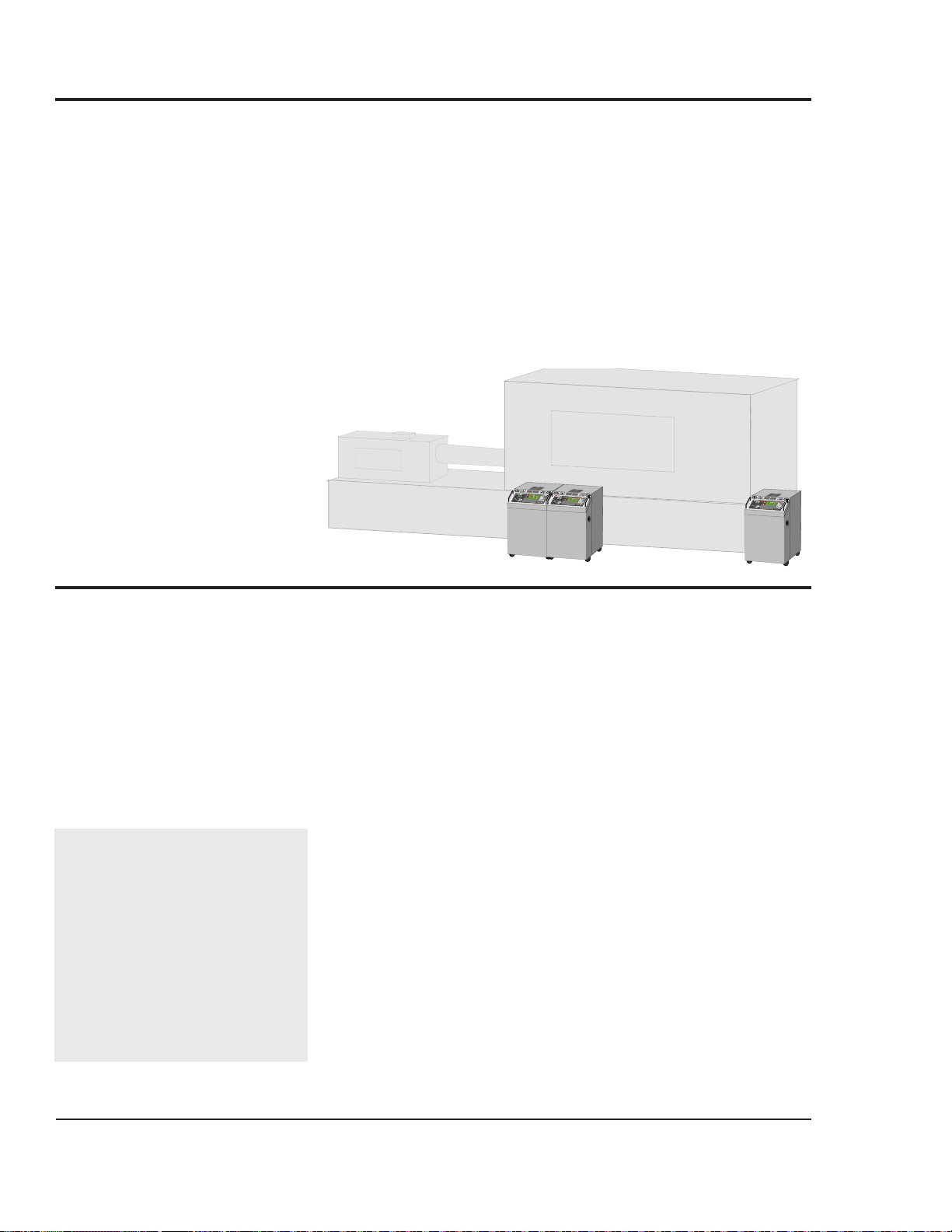

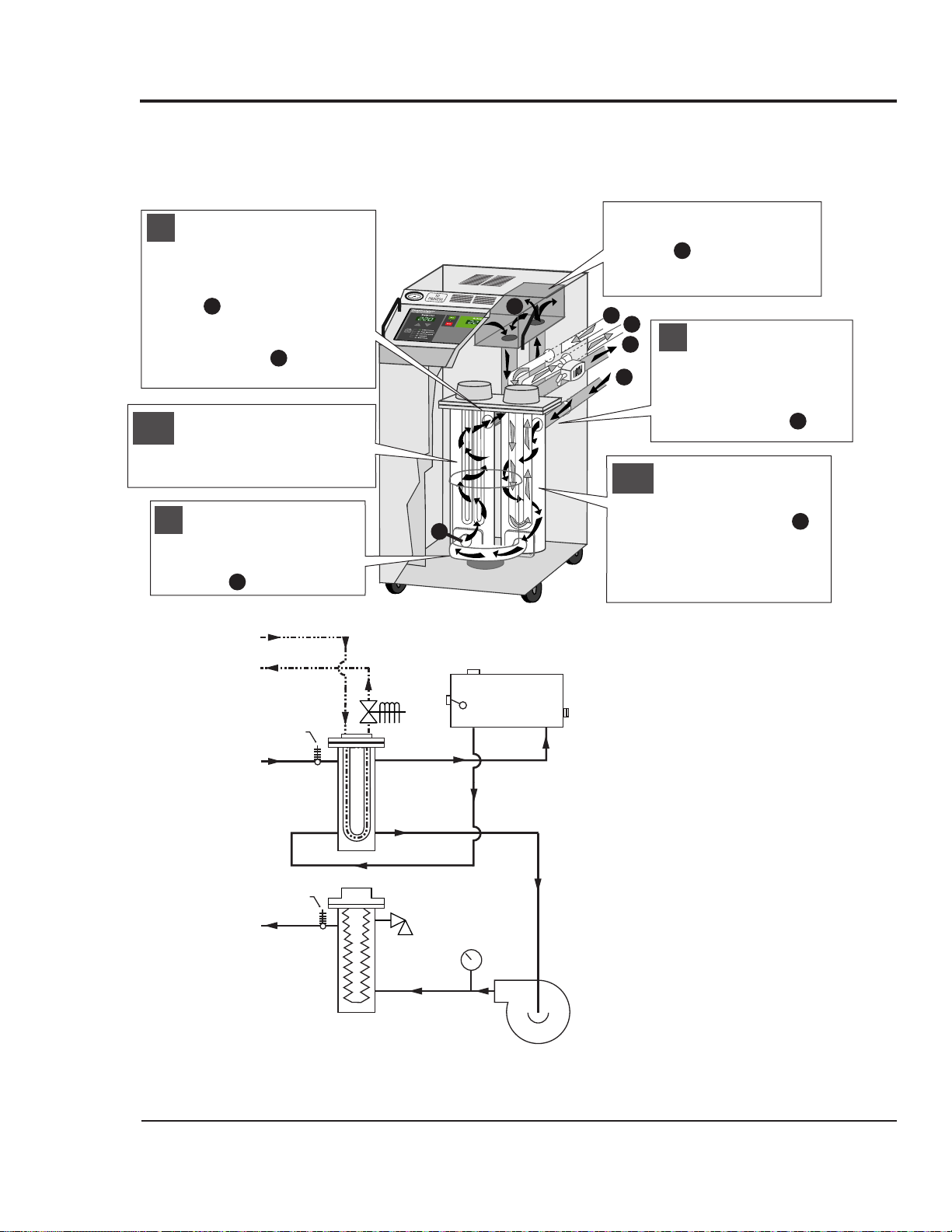

Expansion/fluid reservoir

accepts thermal expansion

of fluid when heated.

High efficiency pump

pushes fluid through

the system.

Air/water separation

tank allows entrapped

air to escape to the

expansion tank.

Pressure relief valve

prevents system

over pressurization.

Venting line prevents

trapped air in system.

Cooling check valve

prevents coolant back

flow into the vacuTrac.

Level switches

control tank fluid level.

Make-up solenoid valve

maintains tank level.

Cooling solenoid valve

lets hot fluid out of system.

Vacuum generating jet

pump/venturi

To process

pressure gauge

Three-way ball valve

diverts flow to

generate vaccuum.

From process

pressure gauge

Overflow connection

relieves system static

pressure.

Cooling water outlet

Cooling water inlet

Positive/negative pressure

units use a jet pump/venturi to

produce negative pressure in

the “from process” lines.

Water at positive pressure

will leak out of mold cracks or

bad o-rings. During negative

pressure operation, however,

air is drawn through the lines,

and the mold operates without

leaking. A manual three-way

ball valve can be closed to

make these units into standard direct injection units.

Because the units use water

and vent to the atmosphere,

they have a maximum process

temperature of 180° F.

From Process

Pressure Gauge

From Process

Cooling In

and Make-Up

Manual Three-Way

Ball Valve

To Process

Pressure Gauge

To Process

Cooling Out

Vent and Overflow

Connection

3 Gallon

Reservoir

Union

Make-Up Solenoid

Process Piping

Cooling Water/Make-Up Piping

Make-Up Switch

Low Level Switch

Jet Pump/

Venturi

Valve

Supply

Temperature

Thermocouple

Check

Valve

Cooling

Solenoid

Valve

Union

Return

Temperature

Thermocouple

Drain

Drain

Air

Vent

Line

Air/Water

Separation

Tank

Pressure

Relief

Valve

Heater Tank

(9 or 12 kW)

Pump

Note:

Maximum Set

Point is 180°F

Page 5

TPHO017/1101

FEATURES

One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

TEMPERATURE CONTROL UNITS

Thermolator® vacuTrac (VTR1-DI and VTR2-D2)

Positive/Negative Pressure

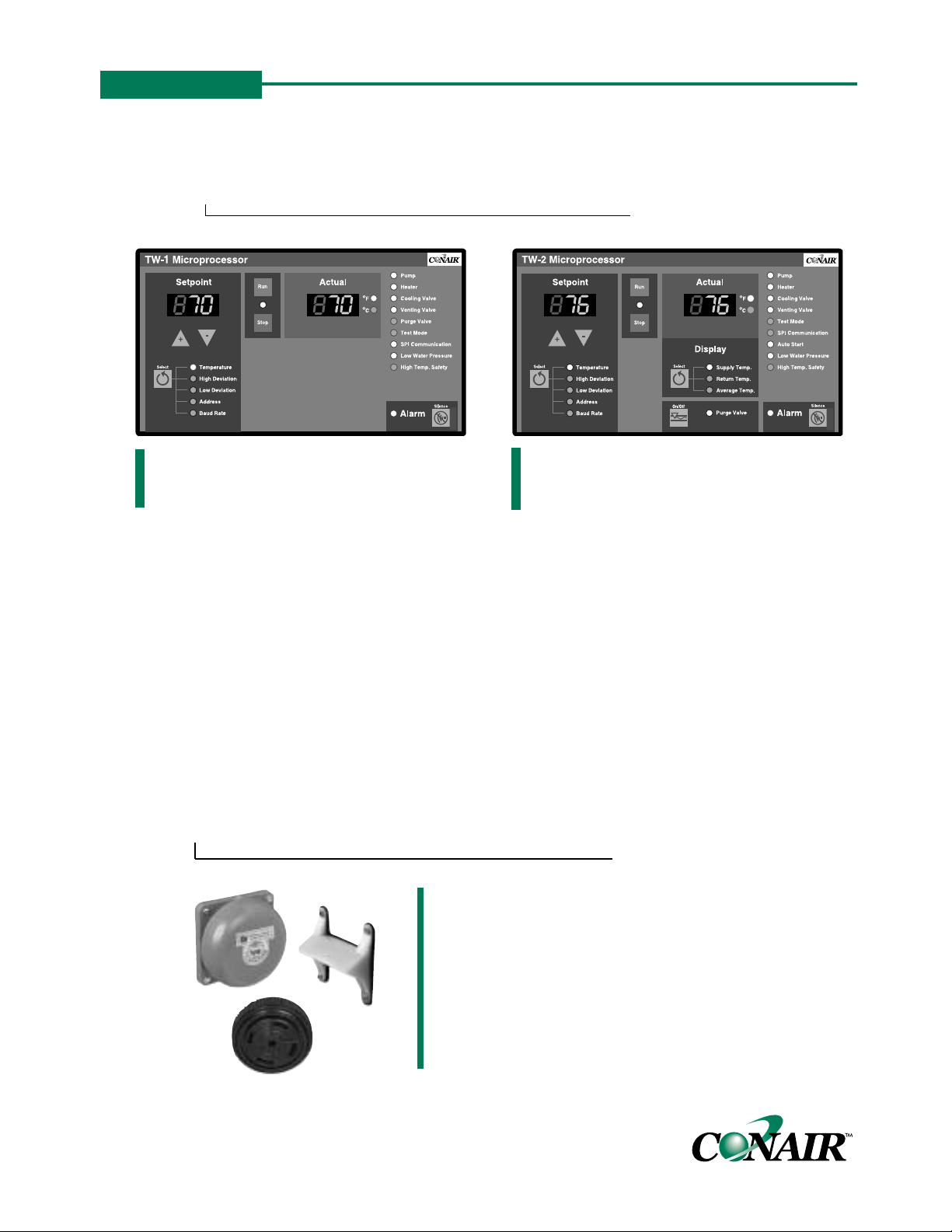

CONTROLS

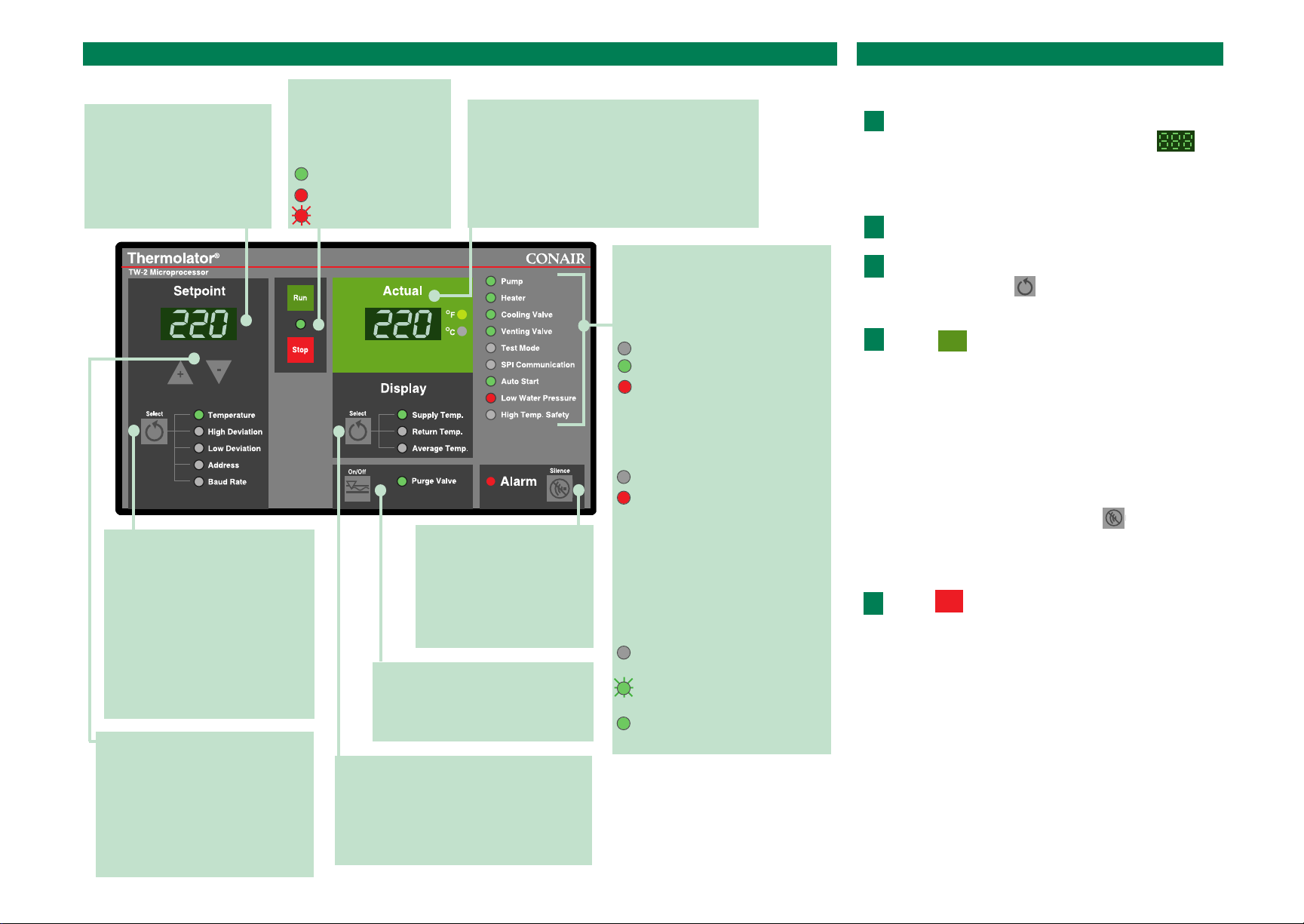

vacuTrac Plus Control (TW-2)

Includes all of the features of the standard

vacuTrac control, PLUS:

● Autostart capability for convenient pre-

heating of molds.Works with external

timers or switches.

● Choice of temperature control points

allows you to monitor and control from the

process supply or process return temperature, or from an average of the two.

● Phase detection circuit indicates incorrect

pump rotation or an open electrical leg.

● Remote control up to 50 feet.Magnetic

panel back allows you to place the controls

where you need them. Comes with 15-foot

cable.Lengths of 30 or 50 feet optional.

Note:The purge option is not available on

the vacuTrac positive/negative pressure

water temperature controllers.

vacuTrac Control (TW-1)

Our waterproof, durable control is operator

friendly and smart. Standard features:

● Automatic fine-tuning of PID control para-

meters provides uniform temperature control

regardless of external loading.

● Adjustable high/low deviation warnings

track with your setpoint temperature. Preprogrammed acceleration feature speeds up

setting parameters.

● 18 operating and fault indicator lights,

including 7 bi-color LEDs, tell you the status

of critical components and parameters.

● Password entr y prevents unauthorized or

accidental changes to operating parameters.

● RS485 communication using SPI protocol.

Baud rates and addresses are programmable on the operator panel.

OPTIONS

Alarm packages

Call attention to alarm conditions

with a light and horn package.

Page 6

One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

TPHS017/1101

SPECIFICATIONS

TEMPERATURE CONTROL UNITS

Thermolator®vacuTrac (VTR1-DI and VTR2-DI)

Positive/Negative Pressure

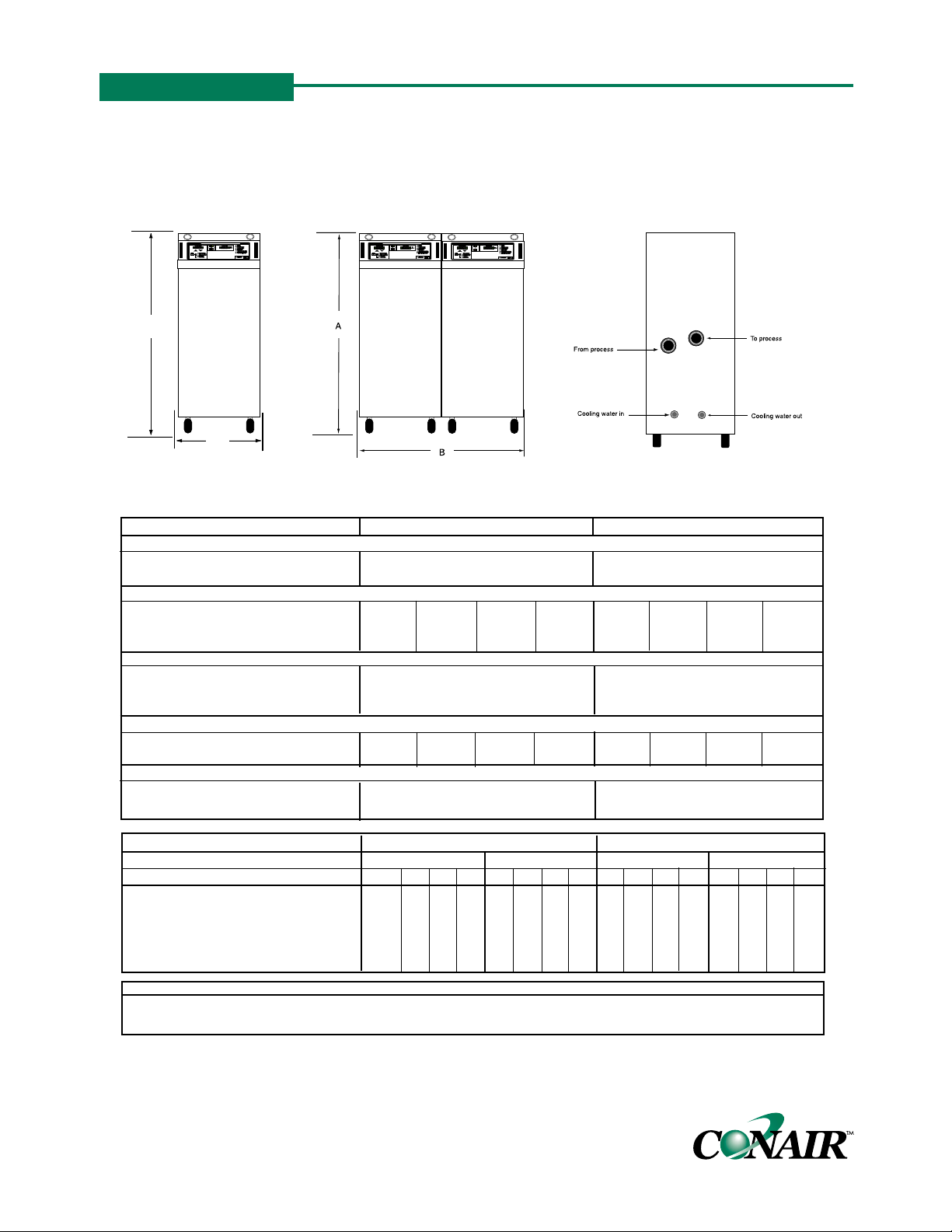

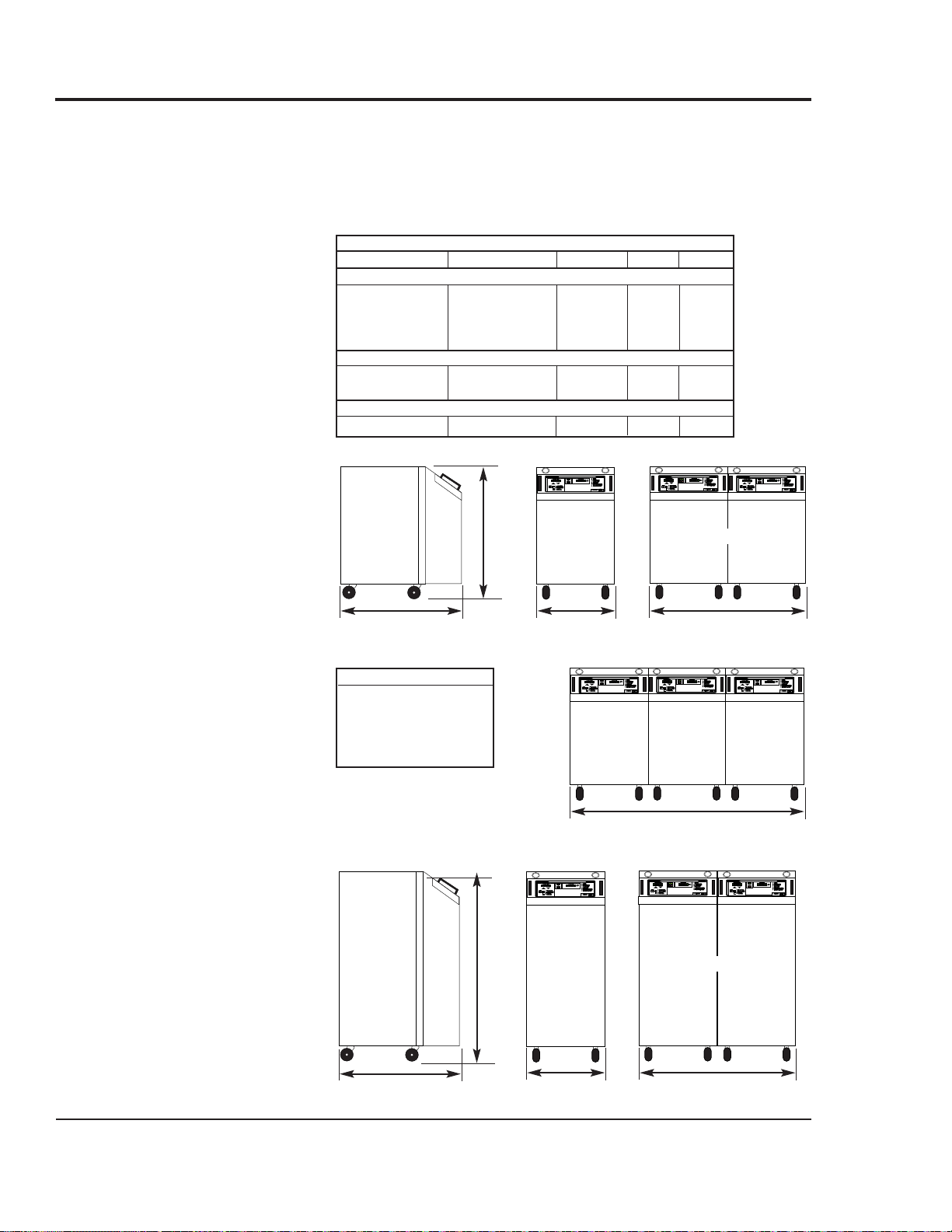

VTR1-DI (single zone) VTR2-DI (dual zone)

VTR1-DI rear view and connections

MODELS

VTR1-DI VTR2-DI

Performance Characteristics

Minimum setpoint 32 °F {0 °C} 32 °F {0 °C}

Maximum setpoint 180 °F {82 °C} 180 °F {82 °C}

Pump Performance per zone

Pump Size Hp {kW}

2 {1.49} 3 {2.24} 5 {3.73} 7.5 {5.59} 2 {1.49} 3 {2.24} 5 {3.73} 7.5 {5.59}

Nominal flow gpm {l/min}

55 {208} 80 {303} 100 {379} 115 {435} 55 {208} 80 {303} 100 {379} 115 {435}

Pressure @ nominal flow psi {bar}

31 {2.2} 35 {2.5} 43 {3} 51 {3.6} 31 {2.2} 35 {2.5} 43 {3} 51 {3.6}

Dimensions inches {mm}

A -Height

43 {1090} 43 {1090}

B- Width

14 {355} 28 {710}

C- Depth

31.5 {800} 31.5 {800}

Weight Ib {kg}

Operating

300 {136} 305 {138} 310 {141} 320 {145} 600 {272} 610 {277} 620 {281} 640 {290}

Shipping

470 {213} 475 {216} 480 {218} 490 {222} 770 {349} 780 {354} 790 {358} 810 {367}

Water Connections NPT inches (Female)

To/From Process 1.25 1.25

Cooling Water Inlet/Outlet 0.75 0.75

ELECTRICAL REQUIREMENTS - full load amps

†

VTR1-DI VTR2-DI

Heater 9 kW 12 kW 9 kW 12 kW

Voltage

208V 230V 460V 575V 208V 230V 460V 575V 208V 230V 460V 575V 208V 230V 460V 575V

Pump sizes

2 Hp {1.49 kW} 31.8 28.8 14.4 11.5 40.2 36.4 18.2 14.6 63.6 57.6 28.8 23.0 80.4 72.8 36.4 29.1

3 Hp {2.24 kW} 34.7 31.4 15.7 12.6 43.1 39.0 19.5 15.6 69.3 62.8 31.4 25.1 86.1 78.0 39.0 31.2

5 Hp {3.73 kW} 38.5 34.8 17.4 13.9 46.8 42.4 21.2 17.0 76.9 69.9 34.8 27.8 93.7 84.8 42.4 33.9

7.5 Hp {5.59 kW} 45.7 41.4 20.7 16.6 54.1 49.0 24.5 19.6 91.5 82.8 41.4 33.1 108.3 98.0 49.0 39.2

SPECIFICATIONS NOTES:

†

All voltages are 3 phase, 60 Hz.

Specifications can change without notice. Check with a Conair representative for the most current information.

A

B

Page 7

CONAIR THERMOLATOR VTR POSITIVE/NEGATIVE OPERATION

1.0 PROCESS WATER CONNECTIONS

PROCESS CONNECTIONS

Connect the FROM PROCESS and TO PROCESS connections on the back of the Thermolator using 1-

1/4”

NPT piping. Viewed from the rear, the FROM PROCESS connection is located on the left hand side of the

unit, and is clearly marked “FROM PROCESS”. The TO PROCESS connection is located on the right hand

side of the unit, and is marked “TO PROCESS” in close proximity on the back panel.

OVERFLOW/VENT CONNECTION

Connect the OVERFLOW/VENT piping on the reservoir tank, located at the top rear of the unit, to an open

drain or vented, covered container. This connection must be piped with a clean break in order to prevent

back flow and pressure in the PROCESS piping. This is where a VTR vents air out of the PROCESS piping

since the unit is operating at times in a vacuum mode, and can be introducing small amounts of air into

the PROCESS piping.

Note: Always use a back-up wrench to support the piping when making connections to the unit.

1.1 COOLING/MAKE-UP WATER CONNECTIONS

COOLING CONNECTIONS

Connect the COOLING WATER IN /MAKE-UP and COOLING WATER OUT piping to the Thermolator using ¾”

NPT pipe. Viewed from the rear, the COOLING IN /MAKE-UP hookup is in the lower left hand side through

the back panel and is marked “COOLING WATER IN”. The COOLING WATER OUT hookup is in the lower

right hand side through the back panel and is marked “COOLING WATER OUT”.

Note: The cooling water out connection is piped with a swing check that must not be turned on to its

side when the connection is made.

1.2 COOLING/MAKE-UP WATER PRESSURES

COOLING /MAKE-UP SUPPLY & RETURN WATER PRESSURES

Cooling /make-up SUPPLY and RETURN water pressure must have net pressures of between 25 PSI and 75

PSI. A net pressure less than 25 PSI may not provide sufficient cooling for the process. The net pressure

is the difference between the cooling SUPPLY and RETURN pressures.

1.3 SEQUENCE OF OPERATION

SEQUENCE OF OPERATION

VTR1 units control process water temperature. When the controller signals the unit to heat, the electric

immersion heater is energized raising the PROCESS water temperature. When the controller signals the

unit to cool, the COOLING WATER OUT (1/4”) solenoid valve is energized. This allows the hot PROCESS

water out of the process piping. When sufficient water has been pumped out of the unit, the MAKE-UP

Page 8

water level float switch will make, opening the COOLING/MAKE-UP (3/8”) solenoid valve, replacing the

hot discharged water with cooler water.

This unit’s operation is similar to a TW-DI unit except that a VTR unit has a reservoir tank that is open to

the atmosphere, which allows a maximum 180° F PROCESS water temperature.

Notes: 1. The DIN units do not have pressure switches. They use float switches instead

2. The make up water level float switch is the higher one in the reservoir tank. The low

water level cut-out float switch is the lower one in the reservoir tank.

3. Anytime the three phase power is turned on to the unit the cooling/make-up water is

(3/8”) solenoid valve may energize.

The VTR unit operates in either a positive or negative pressure mode. Upon energizing the unit, if the

make-up level float switch is in the made position, the COOLING/MAKE–UP water in (3/8”) solenoid valve

will open and begin to fill the unit’s PROCESS piping and reservoir tank. As the water level rises in the

reservoir tank, or if it is sufficiently full to begin with, the low water level float switch will make, turning

off the (LOW WATER PRESSURE) light on the operator panel.

STARTING UP THE UNIT

The start button may now be pressed to energize the unit. The negative pressure mode of operation is

initiated by turning the 3-way valve (See Figure 1.) at the back of the unit counter clock-wise. Negative

pressure in the process piping is caused by diverting some of the flow from the pump through the eductor.

The water bypassed to the eductor creates a high velocity flow at the eductor nozzle which then causes a

suction on the from process line.

Never turn the valve all the way to “negative” (counter clockwise), because all the flow will bypass the

process, and there will be no temperature control of the mold. When the unit is running in a negative

pressure mode, any leak that was in the system will now be drawing air in to the process piping.

The air and water mixture is separated in the separation tank located on the suction side of the pump. The

air is vented from the unit through the overflow connection on the back of the reservoir tank. If this vent

becomes plugged, the unit will not work properly.

1.4 TROUBLESHOOTING A VTR UNIT

A few things may cause the VTR unit to act erratically. If glycol is present in a heavy concentration

within the process water, it may foam and back up into the reservoir tank. This can cause the reservoir

tank to overflow, or the float switches to stick. This problem may be eliminated by using an anti-foaming

agent in the water, and periodically opening the (1”) pipe plugs on top of the tank to clean the switches

with a soft haired paint brush.

An inability to get desired cooling can be a problem with a VTR unit. If the cooling water out line

pressure is greater than the unit’s pump discharge pressure, there is no way for the unit to cool. A change

in the installation will be required in order to provide a reduced cooling water out line pressure.

If the reservoir tank continuously overflows there is a chance that either a float switch has stuck or the

cooling/make-up valve has stuck open from a piece of dirt.

Page 9

Figure 1.

Page 10

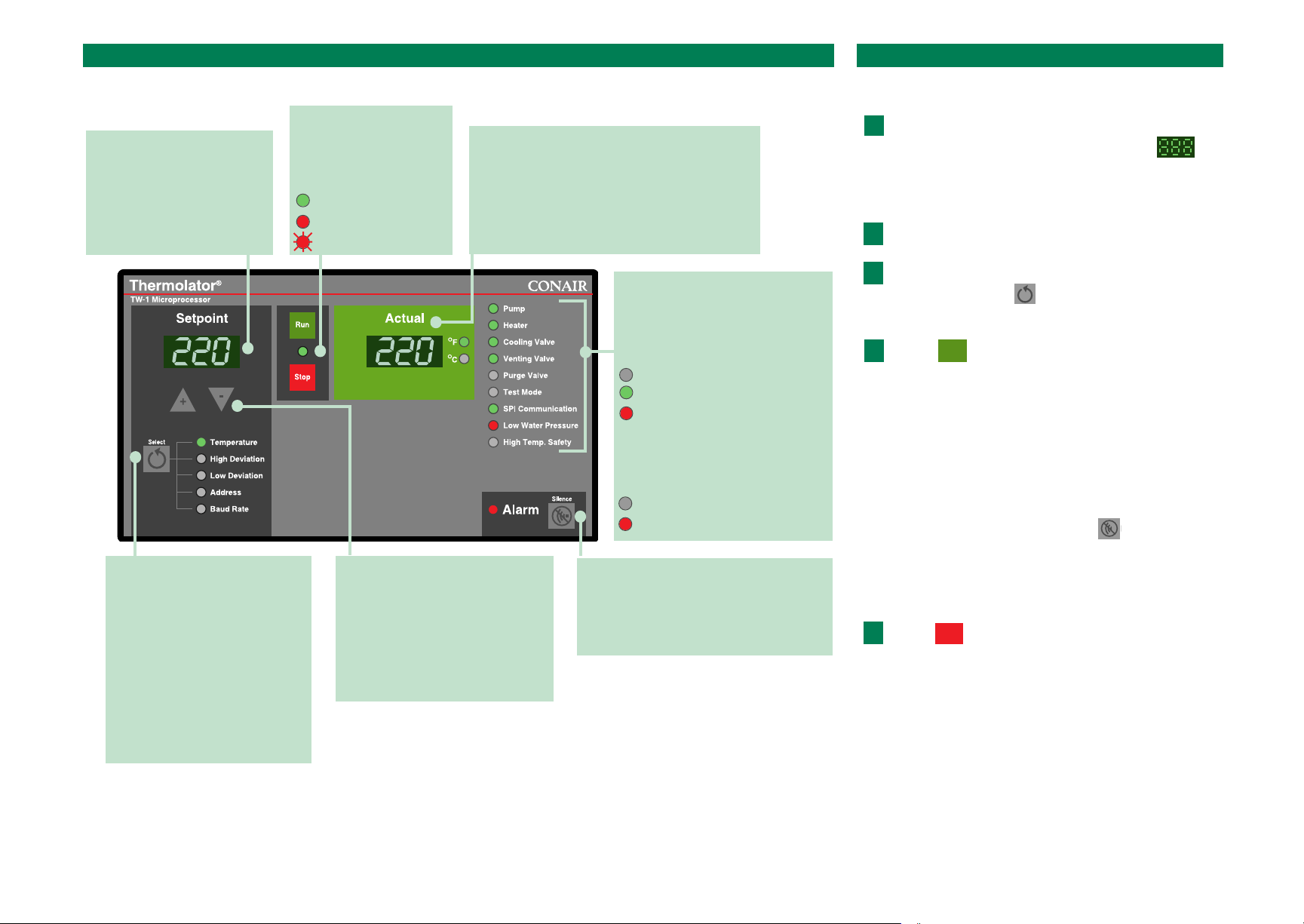

OPERATIONTHE TW-1 CONTROL

Actual values display

The green window displays the temperature

at the middle of the mold. This temperature

is calculated as an average of the temperatures of the supply water and return water.

The lights indicate whether the temperature

is in degrees Fahrenheit or Celsius.

Alarm

Press to acknowledge the alarm light

and silence the optional audible alarm.

The alarm light will flash until the

cause of the alarm condition is fixed.

Starting the Thermolator®.

Turn on main power to the Thermolator®.

◆ Setpoint and actual windows display for

three seconds, then display the most recently

entered setpoint temperature and the current

actual temperature.

◆ Indicator lights blink green, then red.

Turn on water supply to the unit.

If the water supply is on, go to Step 3.

Enter the temperature setpoint.

Press the Setpoint until the green light appears

next to Temperature. Press

▲ to increase the set-

point or

▼ to decrease.

Press .

◆ The RUN/STOP light turns green.

◆ The unit initiates a 60-second venting

sequence. Cooling and venting valves are

active for 60 seconds. The pump is active for

the final 30 seconds.

◆ Normal operation begins. The heater turns on

if the actual temperature is below setpoint.

The cooling valve remains active if the actual

temperature is above setpoint.

If the Alarm light turns on, press to silence an

audible alarm and go to the Troubleshooting section.

Stopping the Thermolator®.

Press .

◆ The RUN/STOP light turns red.

Setpoint display

The window displays the

setpoints entered for the

fluid temperature, the high

and low temperature deviation alarms, the SPI baud

rate and the SPI address.

1

2

3

Status lights

The lights indicate the operating

status of the listed components.

Except in Test Mode and Auto

Start, the lights indicate:

= Off or inactive

= On or active

= Alarm condition

Test Mode is used for initial programming. When test mode is

enabled, normal operation is

disabled.

= Test Mode off

= Test Mode on; unit dis-

Setpoint Select button

Press repeatedly until a green

light appears next to the parameter you want to program or

view.

NOTE: Default settings for the deviation setpoints are:

High = setpoint + 10˚ F

Low = setpoint - 10˚ F

A warning alarm occurs (indicator

light turns red) whenever the actual

temperature is outside this setpoint

range. Recommend setting: ± 2-10˚.

Setpoint adjustment

buttons

Press ▲ or ▼ to enter temperature and SPI parameters. Press

▲ to increase a value. Press ▼

to decrease a value.

TIP: Press and hold the button for

faster scrolling speed.

Run/Stop

Press the RUN button to

start normal operation.

Press STOP to stop the

temperature control unit.

= Running

= Stopped

= Alarm (flashing)

4

Run

Stop

1

Page 11

Actual temperature of water supplied to the mold is

higher than the setpoint deviation limit allows.

1. High deviation temperature is set too low. Increase.

2. Water has stopped flowing between supply outlet and

return inlet. Check for plugged pipe or failed cooling

valve.

3. The heater contact failed. Replace the contactor.

4. The heater and lines may be too

large for this application.

Actual temperature of water supplied to

the mold is higher than the programmed

190˚ F safety limit.

1. Water has stopped flowing between supply outlet and

return inlet. Check for closed valve or plugged line.

2. The heater contactor failed. Replace contactor.

Actual temperature of water supplied to

the mold is below the programmed 20˚ F

safety limit.

1. The cooling valve is stuck open. Clean valve.

2. The heater has failed. Check for a bad heating element,

or a heater contact that failed in the open position.

The incoming power is out of phase. A

leg may have failed or is disconnected.

1. The pump is rotating in the wrong direction. Reverse any

two leads on the power connection.

2. Check fuses or circuits at the main power supply.

The return line temperature probe failed.

Check for loose connections, or replace.

The supply line temperature probe failed.

Check for loose connections, or replace.

The pump fuse failed.

Replace the fuse on the motherboard.

NOTE: See the Thermolator User Guide for additional alarm messages regarding fuses and controller errors.

TROUBLESHOOTING

Shut down alarms

The Thermolator has shut down automatically to prevent

damage to equipment or personnel. To resume normal

operation, press , fix the problem, then press .

The pump overload has tripped. Contact is open.

1. Verify that the correct voltage is supplied to the motor.

2. Water flow may be more than the pump can handle.

Check current draw against motor rating. Decrease flow

as needed.

The supply water level is low.

1.Verify that the water supply is turned on.

NOTE: The low water pressure alarm does not require manual

reset. It will reset automatically when the water level is sufficient.

The actual temperature of water supplied to the mold

exceeds the 190˚ F temperature safety switch limit.

1. The unit is not running. Start the Thermolator.

2. Water has stopped flowing between supply outlet and

return inlet. Check for closed valve or plugged line.

3. The heater contactor failed. Replace contactor.

If there is a problem, the Thermolator®activates the red Alarm light

and changes the RUN/STOP light from green to flashing red.

Press to silence the optional audible alarm.

Check the indicator lights and messages

to help determine the cause of the problem.

Warning alarms

The Thermolator continues operating, but this problem

could lead to a shutdown condition if not corrected.

Actual temperature of water supplied to the mold is

lower than the setpoint deviation limit allows.

1. Low deviation temperature is set too low. Increase.

2. The heater failed. Check for a bad heating element or a

heater contact that failed in the open position.

3. The cooling valve is stuck open. Clean valve as needed.

Stop Run

WARNING: Before servicing the Thermolator

®

Allow the unit to cool to below 100˚ F. Disconnect and lockout

the main power source. Disconnect water and air supply lines.

!

1

2

Low Deviation

High Deviation

SPI Communication

FUS

002

PbS

Err

Pbr

Err

Hi

SAF

Lo

SAF

PHS

Err

Pump

Pump

High Temp. Safety

Low Water Pressure

QCH005/1197 © 1997

Positive/Negative Water

Temperature Controller

with TW-1 Microprocessor

Quick Card

Thermolator

®

vacuTrac

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412) 312-6001

Basic

Operation

Troubleshooting

Instant Access Parts

& Service:

(800) 458-1960

(814) 437-6861

www.conairnet.com

Page 12

Page 13

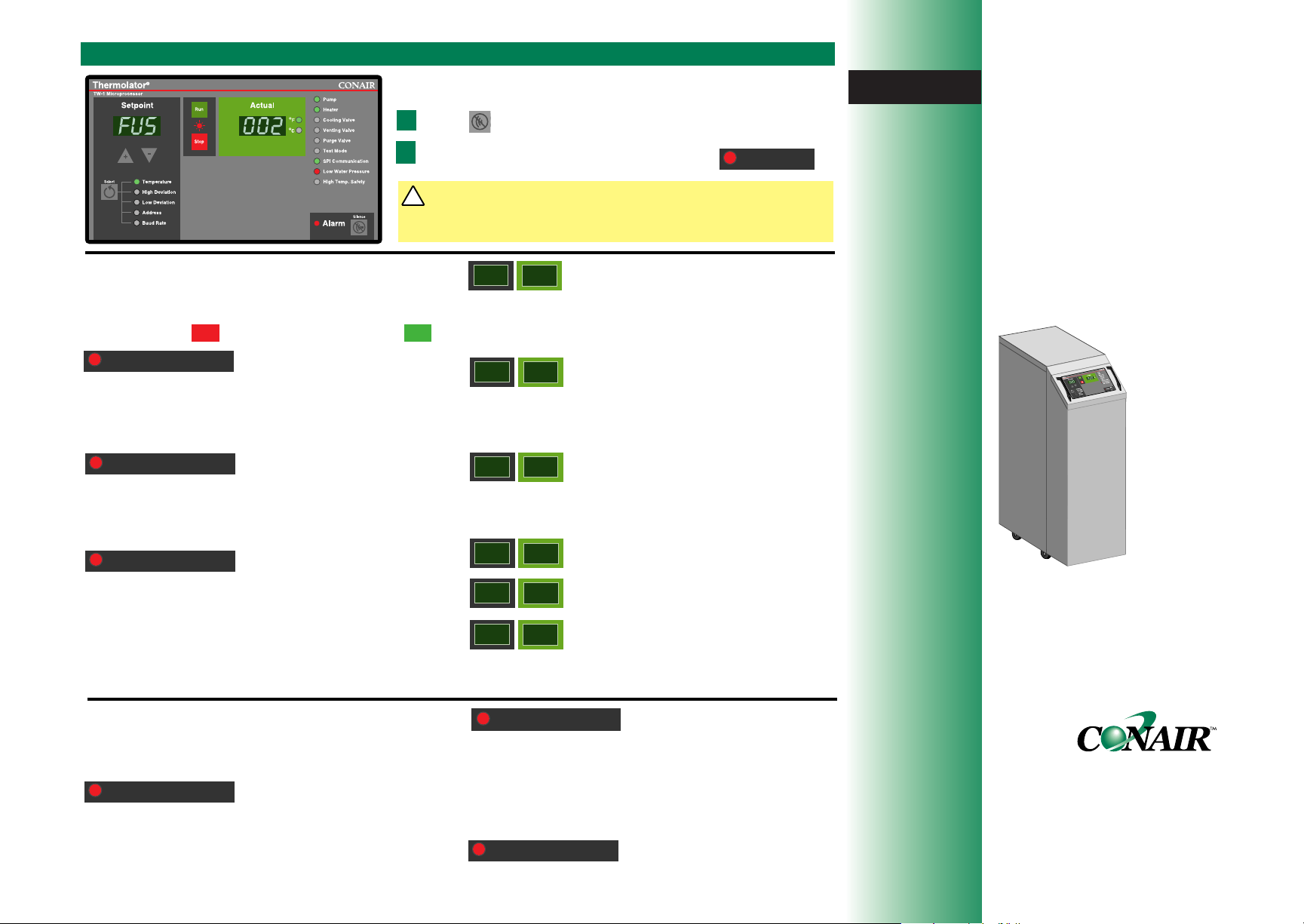

OPERATIONTHE TW-2 CONTROL

Actual values display

The green window displays the temperature

at the middle of the mold. This temperature

is calculated as an average of the temperatures of the supply water and return water.

The lights indicate whether the temperature

is in degrees Fahrenheit or Celsius.

Alarm

Press to acknowledge the

alarm light and silence the

optional audible alarm.

The alarm light will flash

until the cause of the

alarm condition is fixed.

Starting the Thermolator®.

Turn on main power to the Thermolator®.

◆ Setpoint and actual windows display for

three seconds, then display the most recently

entered setpoint temperature and the current

actual temperature.

◆ Indicator lights blink green, then red.

Turn on water supply to the unit.

If the water supply is on, go to Step 3.

Enter the temperature setpoint.

Press the Setpoint until the green light appears

next to Temperature. Press

▲ to increase the set-

point or

▼ to decrease.

Press .

◆ The RUN/STOP light turns green.

◆ The unit initiates a 60-second venting

sequence. Cooling and venting valves are

active for 60 seconds. The pump is active for

the final 30 seconds.

◆ Normal operation begins. The heater turns on

if the actual temperature is below setpoint.

The cooling valve remains active if the actual

temperature is above setpoint.

If the Alarm light turns on, press to silence an

audible alarm and go to the Troubleshooting section.

Stopping the Thermolator®.

Press .

◆ The RUN/STOP light turns red.

Setpoint display

The window displays the

setpoints entered for the

fluid temperature, the high

and low temperature deviation alarms, the SPI baud

rate and the SPI address.

1

2

3

Status lights

The lights indicate the operating

status of the listed components.

Except in Test Mode and Auto

Start, the lights indicate:

= Off or inactive

= On or active

= Alarm condition

Test Mode is used for initial programming. When test mode is

enabled, normal operation is

disabled.

= Test Mode off

= Test Mode on; unit disabled

Auto Start allows you to start

and stop the Thermolator

®

from

a remote switching or timing

device, such as the processing

machine control. This feature

can only be enabled by configuring a dip switch on the control

motherboard.

= Disabled; Auto Start not

available

=

(flashing) Enabled; unit can

start at any time

= On and under control of

Setpoint Select button

Press repeatedly until a green

light appears next to the parameter you want to program or view.

NOTE: Default settings for the deviation setpoints are:

High = setpoint + 10˚ F

Low = setpoint - 10˚ F

A warning alarm occurs (indicator

light turns red) whenever the actual

temperature is outside this setpoint

range. Recommend setting: ± 2-10˚.

Setpoint adjustment

buttons

Press ▲ or ▼ to enter temperature and SPI parameters. Press

▲ to increase a value. Press ▼

to decrease a value.

TIP: Press and hold the button for

faster scrolling speed.

Run/Stop

Press the RUN button to

start normal operation.

Press STOP to stop the

temperature control unit.

= Running

= Stopped

= Alarm (flashing)

4

Display Select button

Press repeatedly until a green light

appears next to the parameter you want

to program or view in the Actual values

window. See the User Guide for programming information.

Run

Purge On/Off

The purge option is not available

on positive/negative pressure

water temperature controllers.

Stop

1

Page 14

Actual temperature of water supplied to the mold is

higher than the setpoint deviation limit allows.

1. High deviation temperature is set too low. Increase.

2. Water has stopped flowing between supply outlet and

return inlet. Check for plugged pipe or failed cooling

valve.

3. The heater contact failed. Replace the contactor.

4. The heater and lines may be too

large for this application.

Actual temperature of water supplied to

the mold is higher than the programmed

190˚ F safety limit.

1. Water has stopped flowing between supply outlet and

return inlet. Check for closed valve or plugged line.

2. The heater contactor failed. Replace contactor.

Actual temperature of water supplied to

the mold is below the programmed 20˚ F

safety limit.

1. The cooling valve is stuck open. Clean valve.

2. The heater has failed. Check for a bad heating element,

or a heater contact that failed in the open position.

The incoming power is out of phase. A

leg may have failed or is disconnected.

1. The pump is rotating in the wrong direction. Reverse any

two leads on the power connection.

2. Check fuses or circuits at the main power supply.

The return line temperature probe failed.

Check for loose connections, or replace.

The supply line temperature probe failed.

Check for loose connections, or replace.

The pump fuse failed.

Replace the fuse on the motherboard.

NOTE: See the Thermolator User Guide for additional alarm messages regarding fuses and controller errors.

TROUBLESHOOTING

Shut down alarms

The Thermolator has shut down automatically to prevent

damage to equipment or personnel. To resume normal

operation, press , fix the problem, then press .

The pump overload has tripped. Contact is open.

1. Verify that the correct voltage is supplied to the motor.

2. Water flow may be more than the pump can handle.

Check current draw against motor rating. Decrease flow

as needed.

The supply water level is low.

1.Verify that the water supply is turned on.

NOTE: The low water pressure alarm does not require manual

reset. It will reset automatically when the water level is sufficient.

The actual temperature of water supplied to the mold

exceeds the 190˚ F temperature safety switch limit.

1. The unit is not running. Start the Thermolator.

2. Water has stopped flowing between supply outlet and

return inlet. Check for closed valve or plugged line.

3. The heater contactor failed. Replace contactor.

If there is a problem, the Thermolator®activates the red Alarm light

and changes the RUN/STOP light from green to flashing red.

Press to silence the optional audible alarm.

Check the indicator lights and messages

to help determine the cause of the problem.

Warning alarms

The Thermolator continues operating, but this problem

could lead to a shutdown condition if not corrected.

Actual temperature of water supplied to the mold is

lower than the setpoint deviation limit allows.

1. Low deviation temperature is set too low. Increase.

2. The heater failed. Check for a bad heating element or a

heater contact that failed in the open position.

3. The cooling valve is stuck open. Clean valve as needed.

Stop Run

WARNING: Before servicing the Thermolator

®

Allow the unit to cool to below 100˚ F. Disconnect and lockout

the main power source. Disconnect water and air supply lines.

!

1

2

Low Deviation

High Deviation

SPI Communication

FUS

002

PbS

Err

Pbr

Err

Hi

SAF

Lo

SAF

PHS

Err

Pump

Pump

High Temp. Safety

Low Water Pressure

QCH006/1197 © 1997

Positive/Negative Water

Temperature Controller

with TW-2 Microprocessor

Quick Card

Thermolator

®

vacuTrac

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412) 312-6001

Basic

Operation

Troubleshooting

Instant Access Parts

& Service:

(800) 458-1960

(814) 437-6861

www.conairnet.com

Page 15

Page 16

Page 17

Thermolator

®

TW-1 and TW-2

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412)-312-6320

Water Temperature Control Units

UGH015/0100

Installation

Operation

Maintenance

Troubleshooting

Page 18

It’s a good idea to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Please keep this User Guide and all manuals, engineering

prints and parts lists together for documentation of your

equipment.

Date:

Manual Number: UGH015/0100

Serial number(s):

Model number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Please record your

equipment’s model and

serial number(s) and

the date you received it

in the spaces provided.

Copyright 1999

All rights reserved

THE CONAIR GROUP, INC.

Page 19

UGH015/0100 Thermolator TW-1 and TW-2

TABLE OF

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . .1-1

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . .1-2

Your responsibility as a user . . . . . . . . . . . . . . . . . . . . . . .1-2

ATTENTION: Read this so no one gets hurt . . . . . . . . . . .1-3

D

ESCRIPTION . . . . . . . . . . . . . . . . . . . .2-1

What is the Thermolator TW Series? . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How it works: Direct Injection . . . . . . . . . . . . . . . . . . . . . .2-3

How it works: Closed Circuit . . . . . . . . . . . . . . . . . . . . . . .2-4

How it works: Isolated Circuit . . . . . . . . . . . . . . . . . . . . . .2-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Features and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

INSTALLATION . . . . . . . . . . . . . . . . . . . .3-1

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Connecting the water supply . . . . . . . . . . . . . . . . . . . . . . .3-4

Optional purge valve hookups . . . . . . . . . . . . . . . . . . . . . .3-5

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . .3-6

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Initial setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Changing temperature units . . . . . . . . . . . . . . . . . . . . . . . .3-9

Enabling and disabling passcode protection . . . . . . . . . . .3-10

Selecting the temperature control point

(TW-2) . . . . . . . . . .3-12

Entering setpoint deviation parameters . . . . . . . . . . . . . . .3-14

Activating SPI communication . . . . . . . . . . . . . . . . . . . . .3-15

Enabling the Auto Start feature

(TW-2) . . . . . . . . . . . . . . . .3-16

OPERATION . . . . . . . . . . . . . . . . . . . . . .4-1

TW-1 control features . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

TW-2 control features . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Positioning the control panel . . . . . . . . . . . . . . . . . . . . . . .4-4

Starting the Thermolator . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Entering passcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Stopping the Thermolator . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Using the manual purge option . . . . . . . . . . . . . . . . . . . . .4-8

Using the TW-2 purge feature . . . . . . . . . . . . . . . . . . . . . .4-9

Performing an Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . .4-10

MAINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Preventative maintenance schedule . . . . . . . . . . . . . . . . . . .5-2

To access the Thermolator enclosure . . . . . . . . . . . . . . . . .5-3

Checking fluid level in the reservoir

(IC) . . . . . . . . . . . . . . .5-4

i

Page 20

Thermolator TW-1 and TW-2 UGH015/0100

TABLE OF

CONTENTS

MAINTENANCE . . . . . . . . . . . . . . .(continued)

Performing System Tests . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

The Key/Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Input Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Output Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Disabling and Enabling Outputs . . . . . . . . . . . . . . . . . . . . .5-9

Calibrating Temperature Sensors . . . . . . . . . . . . . . . . . . .5-10

Logging Operating Hours . . . . . . . . . . . . . . . . . . . . . . . .5-11

T

ROUBLESHOOTING . . . . . . . . . . . . . . . .6-1

Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

A Few Words of Caution . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

How to Identify the Cause of a Problem . . . . . . . . . . . . . . .6-3

DIAGNOSTICS

Shut Down Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Warning Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

System Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Thermolator Will Not Power Up . . . . . . . . . . . . . . . . . . .6-12

REP

AIR

Checking and Replacing Fuses . . . . . . . . . . . . . . . . . . . . .6-13

Resetting and Replacing Overloads . . . . . . . . . . . . . . . . .6-14

Replacing the Motherboard . . . . . . . . . . . . . . . . . . . . . . .6-15

Replacing the Heater Contactor . . . . . . . . . . . . . . . . . . . .6-16

Checking and Replacing Thermocouples . . . . . . . . . . . . .6-17

Repairing Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . .6-18

Replacing Heater Elements . . . . . . . . . . . . . . . . . . . . . . .6-20

Removing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Disassembling and assembling 3/4 to 2 HP Pumps . . . . . .6-23

Disassembling and assembling 3 to 7.5 HP Pumps . . . . . .6-24

APPENDIX

Customer Service Information . . . . . . . . . . . . . . . . . . . . . .A-1

Warranty/Guarantee Information . . . . . . . . . . . . . . . . . . . .A-2

Plumbing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Thermolator SPI commands . . . . . . . . . . . . . . . . . . . . . . .D-1

PARTS/DIAGRAMS

Spare Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PD-1

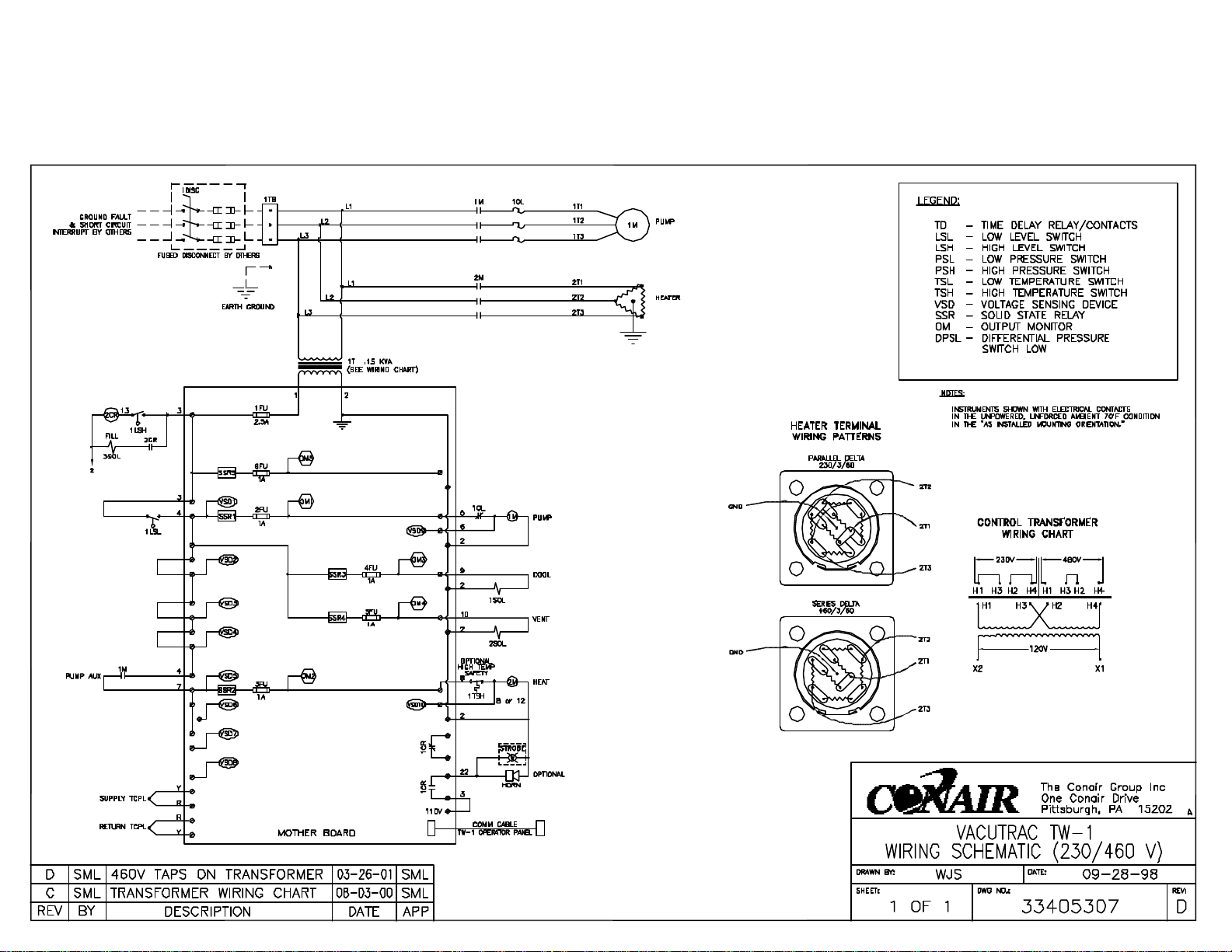

TW-1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PD-5

TW-1 Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . .PD-6

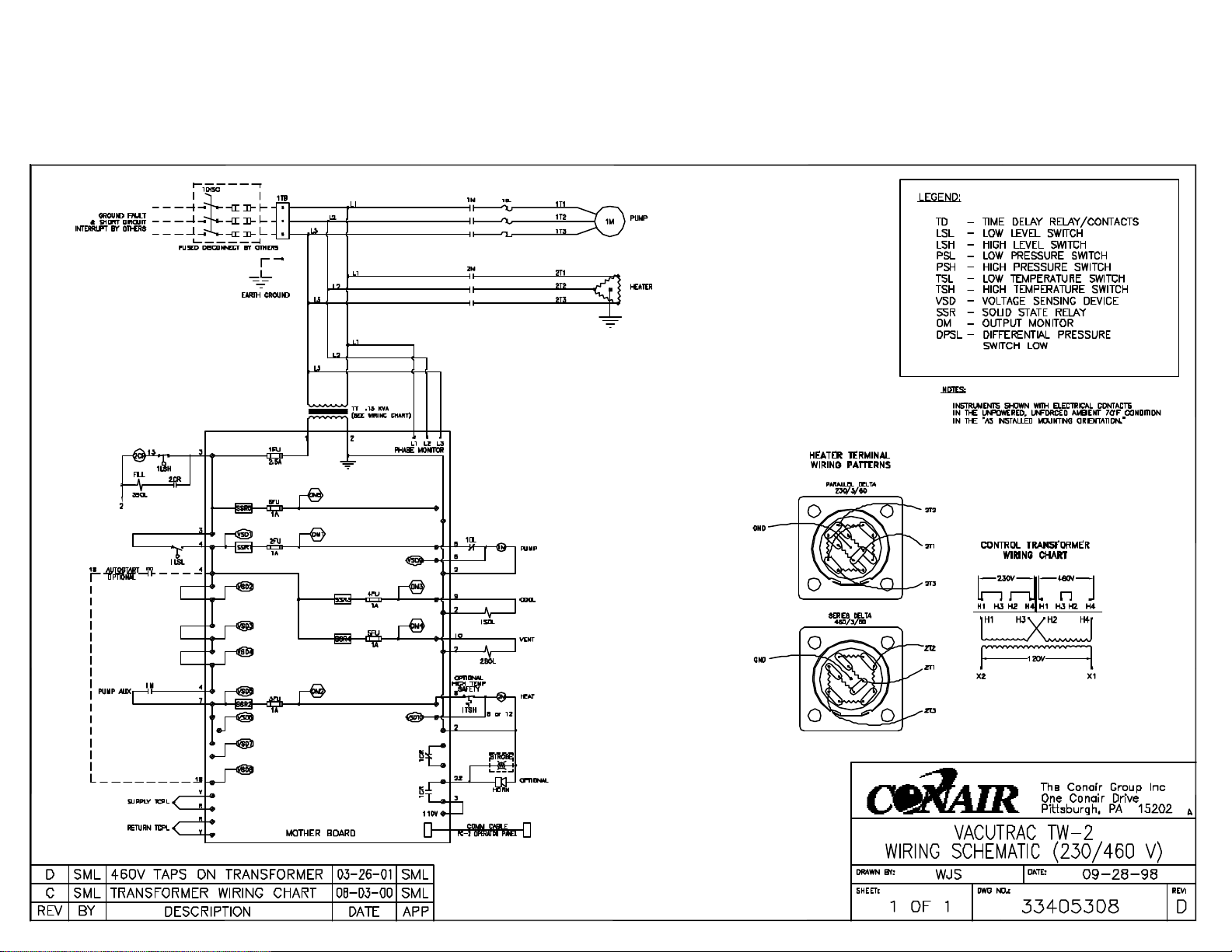

TW-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PD-7

TW-2 Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . .PD-8

ii

Page 21

1-1

UGH015/0100 Thermolator TW-1 and TW-2

●●

Purpose of the User Guide . . . .1-2

●●

How the guide is organized . . . .1-2

●●

Your responsibilities as a user .1-2

●●

ATTENTION: Read this so

no one gets hurt . . . . . . . . . . .1-3

INTRODUCTION

Page 22

Thermolator TW-1 and TW-2 UGH015/0100

1-2 INTRODUCTION

This User Guide describes the Conair Thermolator®TW-1 and

TW-2 water temperature control units and explains step-bystep how to install, operate, maintain and repair this equipment.

Before installing this product, please take a few moments to

read the User Guide and review the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This

review won’t take long, and it could save you valuable installation and operating time later.

Symbols have been used to help organize the User Guide and

call your attention to important information regarding safe

installation and operation.

Symbols within triangles warn of conditions that could

be hazardous to users or could damage equipment.

Read and take precautions before proceeding.

Numbers within shaded squares indicate tasks or steps

to be performed by the user.

A diamond indicates the equipment’s response to an

action performed by the user.

An open box marks items in a checklist.

A shaded circle marks items in a list.

You must be familiar with all safety procedures concerning

installation, operation and maintenance of this equipment.

Responsible safety procedures include:

● Thorough review of this User Guide, paying particular

attention to hazard warnings, appendices and related diagrams.

● Thorough review of the equipment itself, with careful

attention to voltage requirements, intended uses and

warning labels.

● Thorough review of instruction manuals for associated

equipment.

● Step-by-step adherence to instructions outlined in this

User Guide.

P

URPOSE OF

T

HE USER

GUIDE

HOW THE

G

UIDE IS

ORGANIZED

1

◆

❒

●

YOUR

RESPONSIBILITY

ASAUSER

Page 23

UGH015/0100 Thermolator TW-1 and TW-2

INTRODUCTION 1-3

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by

following the procedures outlined below and elsewhere in the

User Guide.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

CAUTION: Hot surfaces

Surface temperatures inside the Thermolator

can exceed 250° F (121° C). Always allow the

unit to cool to below 100° F (38° C) before

opening, servicing or disassembling the unit.

WARNING: Electrical shock hazard

This equipment is powered by three-phase

main voltage, as specified on the machine serial tag and data plate.

Always disconnect and lock out the incoming

main power source before opening the electrical enclosure or performing non-standard operating procedures, such as troubleshooting or

maintenance. Only qualified personnel should

perform procedures that require access to the

electrical enclosure while power is on.

WARNING: Improper installation,

operation or servicing may result in

equipment damage or personal injury.

This equipment should be installed, adjusted,

and serviced by qualified technical personnel

who are familiar with the construction, operation and potential hazards of this type of equipment.

All wiring, disconnects and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. A properly

sized conductive ground wire from the incoming

power supply must be connected to the chassis

ground terminal inside the electrical enclosure.

Improper grounding can result in personal

injury and erratic machine operation.

Do not operate the equipment at power levels

other than what is specified on the the equipment serial tag and data plate.

Page 24

WARNING: Hazardous substance

The electrical contactors in the

Thermolator have mercury contactors.

Mercury is considered a hazardous substance and must be dealt with accordingly. Material Safety Data Sheet (#7439-

97) has been included in the instruction

packet. This sheet explains the potential

hazards, how to avoid them and how to

clean up and dispose of the mercury if it

spills.

ATTENTION:

R

EAD THIS SO NO

ONE GETS HURT

Thermolator TW-1 and TW-2 UGH015/0100

1-4 INTRODUCTION

Page 25

2-1

UGH015/0100 Thermolator TW-1 and TW-2

●●

What is the Thermolator

TW Series?

. . . . . . . . . . . . . . .2-2

●●

Typical applications . . . . . . . . . .2-2

●●

How it works:

Direct Injection (DI) models . . .2-3

●●

How it works:

Closed Circuit (CC) models . . .2-4

●●

How it works:

Isolated Circuit (IC) models . . .2-5

●●

Specifications . . . . . . . . . . . . . .2-6

●●

Features and options . . . . . . . . .2-8

DESCRIPTION

Page 26

The Thermolator TW models circulate water at a temperature

higher than the available water supply, to add or remove heat

as needed to maintain a uniform temperature setpoint in the

process. The TW-2 offers an enhanced control, with additional

diagnostic features and autostart capabilities.

Both the TW-1 and TW-2 models are available in single or

multiple-zone configurations, using direct injection or closed

circuit process heating and cooling. Multiple-zone models can

control up to three temperatures at different locations in the

process. Two- and three-zone models have common cooling

water manifolds and electrical connections.

The best model for your application depends on the process

temperature you need to maintain and the quality of the cooling water supply.

Direct injection (DI) models control the temperature by

discharging heated process water and adding cooling water

directly from the water supply. DI models are designed for:

● Process temperatures up to 250°F (121°C).

● Use with chiller water or properly treated and filtered tower

or city water.

Closed circuit (CC) models add cooling water to the process

loop only during the initial filling or when make-up water is

needed. CC models are recommended for:

● Process temperatures 180°F (82°C) to 250°F (121°C).

● Use with contaminated cooling water, or with properly

treated and filtered tower or city water..

Isolated circuit (IC) models separate the cooling water from

the process fluid, which is held in a reservoir. IC models are

recommended for:

● Process temperatures up to 180°F (82°C).

● Use with contaminated cooling water or a process fluid

mixture of water and glycol.

WHAT IS THE THERMOLATOR ?

Thermolator TW-1 and TW-2 UGH015/0100

2-2 DESCRIPTION

T

YPICAL

A

PPLICATIONS

IMPORTANT: Do not use

deionized water or glycol

mixtures containing additives

in a Thermolator. Softened

water or glycol mixtures with

additives, such as automotive fluids, can damage the

Thermolator. Glycol/water

process loop mixtures should

use industrial-grade ethylene

glycol only.

Page 27

Direct injection models maintain the process temperature

by electrically heating and injecting cool water supplied to

the Thermolator by a chiller, tower or other water source.

HOW IT WORKS:

D

IRECT INJECTION

UGH015/0100 Thermolator TW-1 and TW-2

DESCRIPTION 2-3

A

B

The temperature of the process fluid is measured

as it leaves the unit’s heater tank. The fluid then

flows through the “To Process” line to the mold

or process. The fluid returns to the unit through the

“From Process” line for reheating or cooling.

1

A

B

C

D

If the process

temperature is

below the setpoint, the heater

elements inside

the heater tank

are energized.

E

F

4

The pump moves water from the mixing

tank to the heater tank. Pressure is

measured before and after the pump .

NOTE: Some higher kW models have an

additiona heater in the mixing tank

E

F

The temperature of the process

fluid is measured as it flows into

the mixing tank through the

“From Process” line .

2

B

If the average temperature is

above the setpoint value, the cooling valve opens. Cool water enters

the bottom of the mixing tank via

the “Cooling In” line . Warm

water flows out of the top of the

tank via the “Cooling Out” line .

C

D

3b

3a

Cooling Water Out

From Process

Cooling Water In

To Process

Purge Valve

(optional)

Check

Valve

Thermocouple

Thermocouple

Check

Valve

Cooling

Valve

Mixing

Tank

Heater

Supply

Pressure

Relief

Valve

Gauge

Direct Injection

Check valves included only with

optional mold purge.

Return

Pressure

Gauge

Pump

Page 28

HOW IT WORKS:

C

LOSED CIRCUIT

Thermolator TW-1 and TW-2 UGH015/0100

2-4 DESCRIPTION

A

B

The temperature of the process

fluid is measured as it leaves

the unit’s heater tank. The fluid

then flows through the “To

Process” line to the mold or

process. The fluid returns to the

unit through the “From Process”

line for reheating or cooling.

1

A

B

C

D

3b

If the process temperature

is below the setpoint, the

heater elements inside the

heater tank are energized.

E

F

4

The pump moves water from the

mixing tank to the heater tank.

Pressure is measured before

and after the pump .

E

F

The temperature of

the process fluid is

measured as it flows

into the cooling tank

through the “From

Process” line .

2

B

3a

If the temperature is above

the setpoint value, the cooling

valve opens. Cool water

enters the cooling piping

and circulates through a tube

heat exchanger to cool the

process fluid. The cooling

valve allows warm fluid to

escape through the process

vent line via the “Cooling Out”

line and cooling make-up

water to enter through the

“Cooling In” line .

C

D

Closed Circuit models maintain the process temperature by

heating and cooling fluid for the process circuit. Cooling

water supplied by a chiller, tower or other water source, is

mixed with the process fluid only during the initial filling

or when water is needed to make up process fluid loss.

C

Cooling Water In

Cooling Water Out

Check

Valve

Process Vent/Fill Line

Process Vent Line

Cooling

Valve

Return Thermocouple

From Process

Vent

Valve

Cooling Heat

Exchanger

Heater

Relief

Valve

Supply

Pressure

Gauge

Compressed

Air Connection

Supply Thermocouple

To Process

Check

Valve

Mold Purge

Solenoid Valves

(optional)

Closed Circuit

Check valves included only with

optional mold purge.

Return

Pressure

Gauge

Pump

Page 29

HOW IT WORKS:

I

SOLATED CIRCUIT

UGH015/0100 Thermolator TW-1 and TW-2

DESCRIPTION 2-5

Isolated Circuit models maintain the process temperature

by heating and cooling fluid for the process circuit. The

process fluid, which is stored in a reservoir, is isolated from

cooling water supplied by a chiller, tower or other source

A

B

The temperature of the

process fluid is measured

as it leaves the unit’s heater

tank. The fluid then flows

through the “To Process”

line to the mold or

process. The fluid returns to

the unit through the “From

Process” line for reheating or cooling.

1

A

B

C

D

If the process temperature

is below the setpoint, the

heater elements inside the

heater tank are energized.

E

4

The pump moves water

from the mixing tank to

the heater tank. Pressure

is measured after the

pump .

E

The temperature of

the process fluid is

measured as it flows

into the cooling tank

through the “From

Process” line .

2

B

If the temperature is

above the setpoint

value, the cooling valve

opens. Cool water

enters the cooling piping

and circulates through a

tube heat exchanger to

cool the process fluid.

C

G

The vent line allows warm

process fluid to expand to the

reservoir . The reservoir

supplies process fluid through

a make-up line as needed.

G

3b

3a

Cooling Water In

Cooling Water Out

Return Thermocouple

From Process

Cooling

Valve

Vent Line

Manual Fill

and Vent Port

3 Gal. Reservoir

Low Level

Switch

Level

Sight Glass

Cooling Heat

Exchanger

Make-Up Line

Supply Thermocouple

To Process

Heater

Relief

Valve

Supply

Pressure

Gauge

Pump

Isolated Circuit

NOTE: There is a 180˚ F operating temperature

limit on isolated circuit units.

Page 30

SPECIFICATIONS

Thermolator TW-1 and TW-2 UGH015/0100

2-6 DESCRIPTION

CABINET STYLE REFERENCE

Heater Voltage Selection Single Zone 2 Zone 3 Zone

Direct Injection (DI)

9, 12, 18 or 24 kW 208, 230, 460, 575 A B C

36 kW 208 or 230 D E N/A

36 kW 460 or 575 A B C

48 kW 208, 230, 460, 575 D E N/A

Closed Circuit (CC)

9 or 12 kW 208, 230, 460, 575 A B C

18 or 24 kW 208, 230, 460, 575 D E N/A

Isolated Circuit (IC)

9, 12, 18 or 24 kW 208, 230, 460, 575 D E N/A

A

B

C

D

E

Dimensions and performance characteristics vary according to

the model, voltage and components selected. See the cabinet

style reference chart to determine dimensional information for

your specific model. Additional technical information can be

found in the Appendix of this User Guide.

Height

Width

Single Zone

Width

2- Zone

Width

3-Zone

Depth

Width

Single Zone

Width

2- Zone

Height

Depth

NOTE: 2-zone and 3-zone

models have common wiring

and plumbing.

WATER CONNECTIONS

All models

NPT inches (female)

From process 1.25

Cooling water in/out 0.75

Page 31

SPECIFICATIONS

UGH015/0100 Thermolator TW-1 and TW-2

DESCRIPTION 2-7

TW1

TW2

Zones

(1, 2 or 3)

Direct Injection (DI)

Closed Circuit (CC)

Isolated Circuit (IC)

PERFORMANCE CHARACTERISTICS -

*Lower operating temperatures can be obtained with larger cooling valves. Consult your Conair representative.

Models TW1 -DI or TW2 -DI TW1 -CC or TW2 -CC TW1 -IC or TW2 -IC

Minimum Setpoint Temperature °F {°C} 32 {0} 32 {0} 32 {0}

Maximum Setpoint Temperature °F {°C} 250 {121} 250 {121} 180 {82}

Minimum Operating Temperature °F {°C} Approximately 20° {11°} above the cooling water inlet temperature*

Standard Cooling Valve Size inches {mm} 1/4 {6.35} 3/4 {19.05} 3/4 {19.05}

Available pump sizes 0.75, 1, 2, 3, 5 or 7.5 Hp {0.56, 0.75, 1.49, 2.24, 3.73 or 5.59 kW}

Available heater sizes 9, 12, 18, 24, 36 or 48 kW 9, 12, 18 or 24 kW

PUMP PERFORMANCE - Consult your Conair representative for pump performance characteristics at other operating points.

Pump 3/4 HP {0.56 kW} 1 HP {0.75 kW} 2 HP {1.49 kW} 3 HP {2.24 kW} 5 HP {3.73 kW} 7.5 HP {5.59 kW}

Nominal Flow gpm {lpm} 40 {151} 45 {170} 55 {208} 80 {303} 100 {379} 115 {435}

Pressure@ Nominal Flow psi {kg/cm2} 17 {1.2} 18 {1.3} 31 {2.2} 35 {2.5} 43 {3} 51 {3.6}

TOTAL FULL LOAD AMPS PER ZONE All voltages are 3 phase, 60 Hz.

Heater 9 kW 12 kW 18 kW 24 kW 36 kW 48 kW

Voltage

208V 230V 460V 575V 208V 230V 460V 575V 208V 230V 460V 575V 208V 230V 460V 575V

Pump

0.75 HP {0.56 kW} 28.9 26.2 13.1 10.5 37.3 33.8 16.9 13.5 54.0 48.8 24.4 19.5 70.7 64.0 32 25.6

1 HP {0.75 kW} 29.4 26.6 13.3 10.6 37.8 34.2 17.1 13.7 54.4 49.2 24.6 19.7 71.2 64.4 32.2 25.8

2 HP {1.49 kW} 31.8 28.8 14.4 11.5 40.2 36.4 18.2 14.6 56.8 51.4 25.7 20.6 73.6 66.6 33.3 26.6

3 HP {2.24 kW} 34.7 31.4 15.7 12.6 43.1 39.0 19.5 15.6 59.7 54.0 27.0 21.6 76.5 69.2 34.6 27.7

5 HP {3.73 kW} 38.5 34.8 17.4 13.9 46.9 42.4 21.2 17.0 63.4 57.4 28.7 23 80.2 72.6 36.3 29.0

7.5 HP {5.59 kW} 45.7 41.4 20.7 16.6 54.1 49.0 24.5 19.6 70.7 64.0 32.0 25.6 87.5 79.2 39.6 31.7

SHIPPING WEIGHT RANGES lbs {kg} Weights vary depending on cabinet size and cooling type (DI, CC or IC).

Single Zone 2 Zone 3 Zone

Pump Min Max Min Max Min Max

0.75 HP {0.56 kW} 240 {109} 300 {136} 480 {218} 600 {272} 720 {327} 840 {381}

1 HP {0.75 kW} 240 {109} 300 {136} 480 {218} 600 {272} 720 {327} 840 {381}

2 HP {1.49 kW} 250 {113} 310 {141} 500 {226} 620 {282} 750 {336} 870 {396}

3 HP {2.24 kW} 260 {118} 320 {145} 520 {236} 640 {290} 780 {354} 900 {408}

5 HP {3.73 kW} 270 {122} 330 {150} 540 {244} 660 {300} 810 {366} 930 {423}

7.5 HP {5.59 kW} 280 {127} 340 {154} 560 {254} 680 {308} 840 {381} 960 {435}

DIMENSIONS in. {mm}

Cabinet Style A B C D E

Height 28.0 {710} 28.0 {710} 28.0 {710} 43.0 {1090} 43.0 {1090}

Depth 22.5 {570} 22.5 {570} 22.5 {570} 31.5 {800} 31.5 {800}

Width 13.75 {350} 27.5 {700} 41.25 {1050} 14.0 {355} 28.0 {710}

208V 230V 460V 575V 208V 230V 460V 575V

104.0 94.0 47.0 37.6 137.0 124.0 62.1 49.7

104.3 94.4 47.2 37.8 137.7 124.6 62.3 49.6

106.7 96.6 48.3 38.6 140 126.8 63.4 50.7

109.6 99.2 49.6 39.7 143 129.4 64.7 51.8

113.4 102.6 51.3 41.0 146.7 132.8 66.4 53.1

120.7 109.2 54.6 43.7 154 139.4 69.7 55.8

MODEL DESIGNATIONS

TOTAL FULL LOAD AMPS PER ZONE All voltages are 3 phase, 60 Hz.

Heater 0 heaters

Voltage

208V 230V 460V 575V

Pump

0.75 HP {0.56 kW} 3.9 3.6 2.3 1.5

1 HP {0.75 kW} 4.4 4.0 2.5 1.6

2 HP {1.49 kW} 6.8 6.2 3.6 2.5

3 HP {2.24 kW} 9.7 8.8 4.9 3.6

5 HP {3.73 kW} 13.5 12.2 6.6 4.9

7.5 HP {5.59 kW} 20.7 18.8 9.9 7.6

NOTE: Thermolators

can be ordered

without heaters for

certain applications.

Page 32

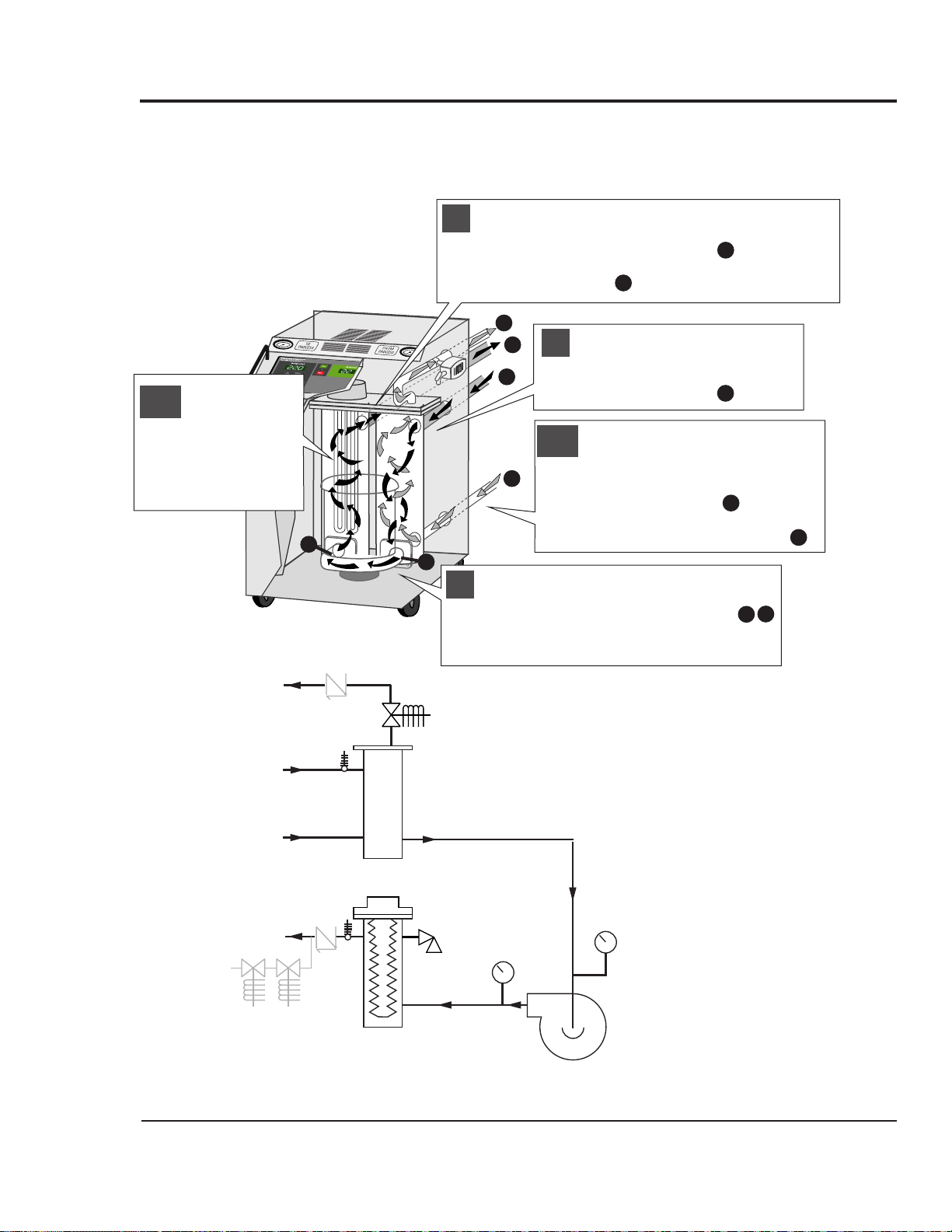

High efficiency pumps

from 3/4 to 7.5 Hp. Silicon

carbide seals are standard.

Pump seal flush line

continuously cleans the

pump seal for extended life.

Incoloy heaters

minimize chemical and

high temperature damage

Built-in sediment trap

settles contaminants away

from the pump seals.

Motor drip cover

protects motor windings

from moisture damage.

Two-piece cast

construction

Alarm packages

The Thermolator control includes an output

relay that can be connected to an optional

external alarm package to call attention to

alarm conditions.

Motorized Cooling Valve

Eliminates thermal shock from your process

circuit by modulating the cooling water.

Compressed Air Mold Purge

Quickly evacuates fluid from the process

circuit, allowing for faster, cleaner disconnection of the temperature controller from

molds and hoses.

Stacking Rack

Save floor space by stacking Thermolators

two-high. The stacking rack can be used

only with single-zone models in 28-inch

high cabinets.

OPTIONS

Thermolator TW-1 and TW-2 UGH015/0100

2-8 DESCRIPTION

FEATURES AND OPTIONS

Page 33

3-1

UGH015/0100 Thermolator TW-1 and TW-2

●●

Unpacking the boxes . . . . . . . . .3-2

●●

Preparing for installation . . . . . .3-3

●●

Connecting the water supply . .3-4

●●

Optional purge valve hookups .3-5

●●

Connecting the main power . . .3-6

●●

Testing the installation . . . . . . . .3-7

●●

Initial setup . . . . . . . . . . . . . . . .3-8

●●

Changing temperature units . . .3-9

●●

Enabling and disabling

passcode protection . . . . . . .3-10

●●

Selecting the temperature

control point

(TW-2)

. . . . . . . . .3-12

●●

Entering setpoint

deviation parameters . . . . . . .3-14

●●

Activ

ating SPI

comm

unication . . . . . . . . . . . .3-15

●●

Installing the Auto Start

feature . . . . . . . . . . . . . . . . . .3-16

INSTALLATION

Page 34

UNPACKING THE BOXES

Thermolator TW-1 and TW-2 UGH015/0100

3-2 INSTALLATION

Carefully remove the Thermolator and compo-

nents from their shipping containers, and set upright.

Remove all packing material, protective paper,

tape, and plastic. Check inside the electrical enclosure

and behind the side panels for accessories or hardware

that may have been placed there for shipping.

Carefully inspect all components to make sure no

damage occurred during shipping, and that you have all

the necessary hardware. If damage is found, notify the

freight company immediately.

Take a moment to record serial numbers and

specifications in the blanks provided on the back of the

User Guide’s title page. The information will be helpful if

you ever need service or parts.

You are now ready to begin installation.

Complete the preparation steps on the next page.

Remote control cord

(TW-2 only)

Thermolator

1

2

3

4

5

Thermolator TW models come fully assembled. If they were

specified at the time of the order, the optional purge valve or

motorized cooling valve is factory-installed.

Motorized cooling valve

(optional)

Compressed air mold purge

(optional)

Page 35

UGH015/0100 Thermolator TW-1 and TW-2

INSTALLATION 3-3

The Thermolator is easy to install, if you plan the location and

prepare the area properly.

Position the Thermolator as close to the process

machine as possible.

Make sure the installation area provides:

❒❒

A three-phase power source supplying the correct

current for your Thermolator model. Check the serial tag

on the side of the electrical enclosure for the required voltage, phase, frequency, full load amps, disconnect fuse size

and minimum wire connection size. Field wiring should be

completed by qualified personnel to the planned location

for the Thermolator. All electrical wiring should comply

with your region’s electrical codes.

❒❒

A clean, well-ventilated environment.

The room temperature should not exceed 120° F (48° C)

with 95% non-condensing humidity and should not fall

below 32° F (0° C).

❒❒

Minimum clearance for safe operation and

maintenance. The diagram at right shows

minimum clearance for operation. You also

need enough clearance in the rear for

water hookups. For maintenance, you

should move the Thermolator to

provide at least 36 inches on any side

of the Thermolator.

❒❒

A source of water for cooling.

City, tower or chiller water may be used, as long as the

supply pressure is at least 25 psi and not more than 85 psi.

Install plumbing for process and cooling lines.

You will need two 1

1

/

4

-inch NPT male fittings for the

process inlet and outlet and two 3/4-inch NPT male fittings for the cooling inlet and outlet. Larger line sizes are

acceptable as long as they are reduced at the Thermolator

connections. Smaller line sizes are not recommended.

PREPARING FOR INSTALLATION

1

2

Process machine

Thermolator

Alternate

locations

3

12 inches

(305 mm)

12 inches

(305 mm)

20 inches

(508 mm)

Page 36

Motorized Cooling Valve

If you have the optional motorized

cooling valve, connect the cooling

water supply to the female

3

/

4

inch

NPT fitting on the valve. except as

noted, all other connections should

be made as described above.

The Thermolator process inlets and outlets must be connected

to the plumbing that will circulate the temperature-controlled

water or fluid through the process. Cooling water inlets and

outlets are connected to the cooling water supply.

Remove the shipping pipe plug from the female

connections on the back of the Thermolator.

Install pipe to the rear of the Thermolator.

Use male 1

1

/

4

-inch NPT piping for process connections

and male

3

/

4

inch NPT piping for water connections. Pipe

and pipe threads must be clean and new. Clean threads

with solvent, removing all oil, grease and dirt. Allow the

threads to dry before proceeding.

Coat the pipe threads with thread sealant.

Follow the sealant manufacturer’s directions.

Connect the male pipe to the appropriate

female connection on the back of the unit

. Start

by hand until the threads engage, then use a pipe wrench

to tighten the connection only enough to prevent leaks.

Do not over-tighten!

CONNECTING PROCESS AND WATER SUPPLY LINES

Thermolator TW-1 and TW-2 UGH015/0100

3-4 INSTALLATION

1

2

3

4

Tools for installation:

❒ Pipe wrench large enough

for a 2-inch pipe

❒ Premium quality Teflon

thread sealant

NOTE: We recommend

that you install an

external ball valve on

the cooling water inlet

of the Thermolator. This

valve is required when

the purge valve option

is installed.

From

process

To

process

From

process

To

process

Cooling water out

Cooling water out

Cooling water in

Cooling water out

Cooling water in

DIRECT INJECTION

CLOSED CIRCUIT

ISOLATED CIRCUIT

From

process

To

process

Page 37

A purge valve is available as an option on Direct Injection and

Closed Circuit units only. This valve quickly evacuates fluid

from the process circuit, allowing faster disconnection of the

temperature controller from molds and hoses. An optional

manual purge button controls this valve on TW-1 models.

TW-2 models have a purge button on the control panel.

If this option is ordered with the Thermolator, purge control

wiring and installation of the valve on the process line outlet

of the unit is completed at the factory. You still must connect

process and cooling water inlets and outlets, as well as a supply of non-lubricated compressed air.

Remove the shipping pipe plug from the female

connections on the back of the Thermolator.

Install an external ball valve on the cooling

water inlet of the Thermolator.

This valve is

required when a purge valve is used.

Install pipe to the rear of the Thermolator.

Use male 1

1

/

4

-inch NPT piping for process connections

and male

3

/

4

inch NPT piping for water connections. Pipe

and pipe threads must be clean and new. Clean threads

with solvent, removing all oil, grease and dirt. Allow the

threads to dry before proceeding.

Coat the pipe threads with thread sealant.

Follow the sealant manufacturer’s directions.

Connect the male pipe to the appropriate

female connection on the back of the unit

.

Connect cooling water lines as indicated on the previous

page. Connect process lines as indicated below. Start by

hand until the threads engage, then use a pipe wrench to

tighten the connection only enough to prevent leaks. Do

not over-tighten!

Connect the purge

valve to the compressed

air supply.

The air pressure

should not exceed 100 psi.

UGH015/0100 Thermolator TW-1 and TW-2

O

PTIONAL

PURGE VALVE

HOOKUPS

INSTALLATION 3-5

From

process

To

process

Compressed air

fitting

1

2

3

4

5

6

Page 38

Thermolator TW-1 and TW-2 UGH015/0100

Before beginning, note the electrical specifications on the

nameplate mounted to the side of the unit. The electrical

hookup must match these specifications with +/- 10% maximum voltage variance. An improper power supply could

damage the unit as well as seriously injure an operator.

The electrical hookup also should run through a fused disconnect sized for the nameplate amperage and conforming to

Article 250 of the National Electrical Code.

Open the unit’s electrical enclosure.

Insert the main power wire

through the knockout

hole in the right side of the enclosure.

Secure the power wire with a rubber compression fitting or strain relief.

Connect the power wires to the terminals.

Connect the three hot

wires to L1, L2, and L3

on the terminal block.

Connect the ground

wire

to the copper

grounding mount.

If you have installed a

disconnect device, follow

the manufacturer’s wiring

instructions.

1

2

3

4

5

CONNECTING

T

HE MAIN

POWER

SUPPLY

3-6 INSTALLATION

WARNING: Electrical shock hazard

This equipment is powered by three-phase main

voltage. Always disconnect and lock out the main

power source before performing any work

involving electrical connections. All wiring,

disconnects and fusing should conform to your

region’s electrical codes and should be installed

only by qualified personnel.

IMPORTANT: Always refer

to the wiring diagrams that

came with your temperature

control unit before making

electrical connections. The

diagrams show the most

accurate electrical component information.

IMPORTANT! Before initiating

power to the unit:

❒ Check the system for leaks.

❒ Verify that the voltage, phase,

frequency, amperage, disconnect fuse

and minimum wire size meet the

specifications stated on the nameplate mounted on the side of the unit.

❒ Verify that resistance to ground on

each phase is at least 1 meg ohm.

Page 39

UGH015/0100 Thermolator TW-1 and TW-2

INSTALLATION 3-7

Turn on the cooling water supply and check for

leaks.

If any leaks appear, stop the test and fix the problem before continuing. The cooling water must be at least

25 PSI or the unit will not function. The LOW WATER

PRESSURE light will come on when power is applied.

The light goes off when the pressure is correct.

Apply power to the unit.

◆ Indicator lights on the control panel blink green, then

red, to test operation of the LEDs.

◆ Setpoint and actual windows will display for

three seconds, followed by the software version. The

windows then display the factory default setpoint of

100° F and the actual temperature.

Check the rotation of the pump. Remove the top

access panel and the pump motor drip cover. Verify that

the pump rotation matches the direction indicated on the

rotation sticker on top of the pump.

NOTE: If the rotation is incorrect, stop the test and

disconnect power to the unit. Open the electrical

enclosure and switch any two of the three power

source wires on the terminal block. Return to Step 2

and check rotation again.

Replace the drip cover and top access panel.

Press the RUN key to start the unit.

If everything is working correctly:

◆ The RUN/STOP light turns green.

◆ The unit initiates a 60-second venting sequence.

Cooling and venting valves are active for 60 seconds.

The pump is active for the final 30 seconds. Indicator

lights will energize when the device is active.

◆ Normal operation begins. The heater turns on if the

actual temperature is below setpoint. The cooling valve

is active if the actual temperature is above setpoint.

The test is over. Proceed to initial setup if the unit operated

normally; refer to the

T

ROUBLESHOOTING

section if it did not.

TESTING THE INSTALLATION

1

2

3

4

5

WARNING: Only qualified personnel

should perform this procedure.

Parts of this test require opening the unit while it is

energized. Only qualified personnel who have been

trained in the use of electrical testing devices and

in avoiding the safety hazards involved in safely

troubleshooting this type of equipment should perform this test procedure.

Page 40

Thermolator TW-1 and TW-2 UGH015/0100

3-8 INSTALLATION

INITIAL

SETUP

The factory-set parameters and operating modes will satisfy

most applications. But you can change some settings and

enable or disable features as needed.

You can modify the parameters for high and low process temperature deviation warnings from the control panel. See

S

ETTINGSETPOINTDEVIATIONPARAMETERS

.

Dip switches on the motherboard inside the TW-1 and

TW-2 electrical enclosure allow you to:

❒ Select the units of measure for tem-

perature displays.

❒ Enable password protection.

❒ Enable the Auto Tune.

❒ Enable the Auto Start feature.

❒ Enable the Test Mode.

❒ Select the source point of tempera-

ture control.

To change the dip switch settings, see the appropriate topic

on the following pages.

Dipswitch Configuration

No. OFF ON

1 Display units in °F Display units °C

2 Auto Tune disabled Auto Tune enabled

3 Passcode protect Password reset/modify

4 * Auto Start disabled Auto Start enabled

5 * Control point protect Control point source select

6 Test Mode disabled Test mode enabled

7

†

Controller type selection Controller type selection

8

†

Controller type selection Controller type selection

* Available only on TW-2 models.

† Switches 7 and 8 must be ON for Direct Injection and Closed Circuit

models. Switches 7 and 8 must be OFF for Isolated Circuit models. Do

not change these settings.

WARNING: Electric shock hazard

This equipment is powered by high voltage. Always

disconnect and lock out the main power source

before opening the unit or the electrical enclosure to

modify factory settings. Failure to disconnect and

lock out the main power source can result in severe

personal injury.

NOTE: All dip switch illustrations in this manual show

switches 7 and 8 set to ON.

If you have an Isolated

Circuit model, these switches should be set to OFF. Do

not change the factory settings of these dip switches.

876

54321

Page 41

UGH015/0100 Thermolator TW-1 and TW-2

CHANGING TEMPERATURE UNITS

The temperature units are factory-set as degrees Celsius or

degrees Fahrenheit, as specified when the unit was ordered.

When the Thermolator is on, the indicator lights to the right

of the Actual temperature display on the control panel will

show which temperature unit has been set.

To change this setting, move Dip Switch 1 on the control

circuit board.

Disconnect and lock out main power to the