Page 1

Installation

Maintenance

Operation

Troubleshooting

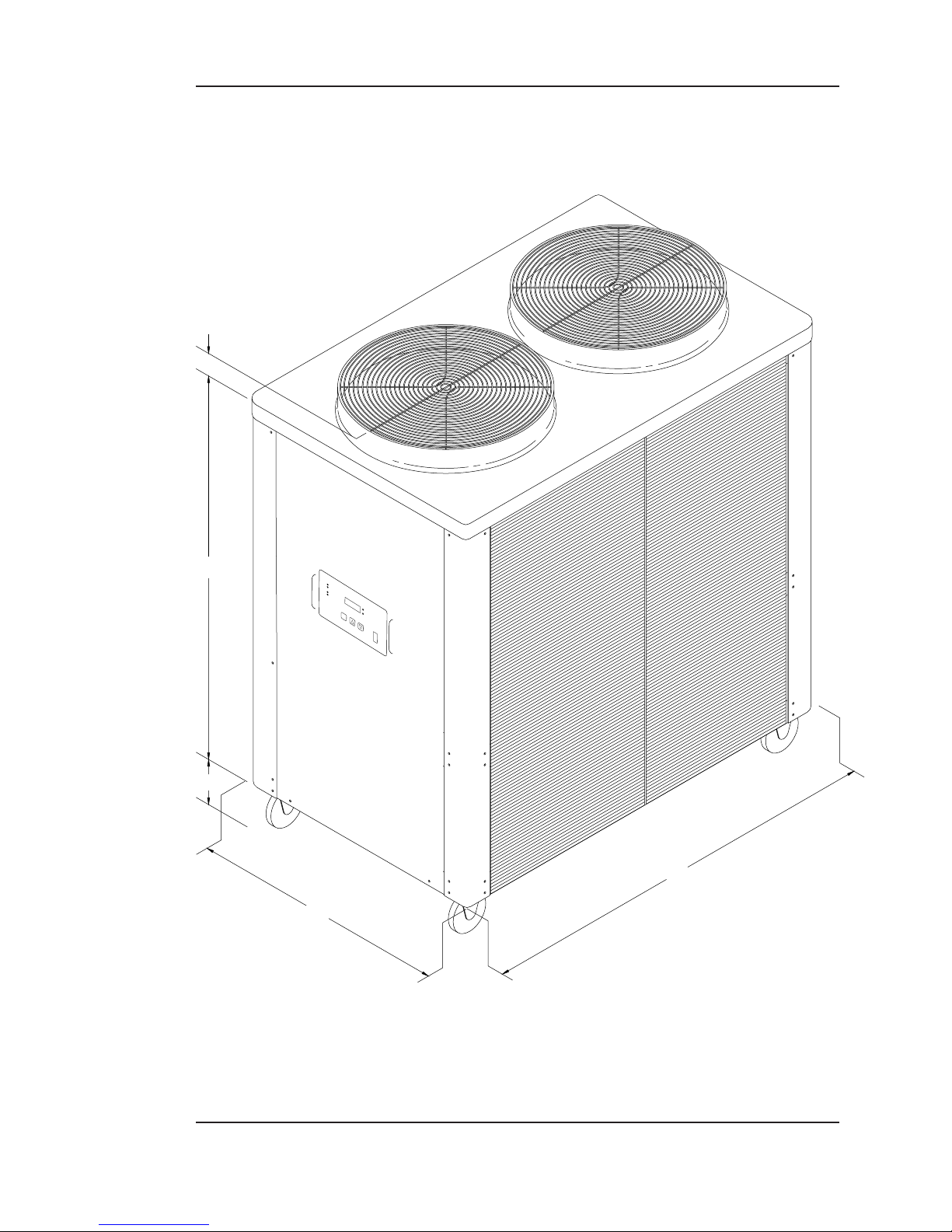

Portable Chillers

VL Series Air-Cooled and Water-Cooled

with Capacities from 2 to 40 tons

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412)-312-6227

UGH021/0301

Page 2

It’s a good idea to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Please keep this User Guide and all manuals, engineering

prints and parts lists together for documentation of your

equipment.

Date:

Manual Number: UGH021/0301

Serial number(s):

Model number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Please record your

equipment’s model and

serial number(s) and

the date you received it

in the spaces provided.

Copyright 2001 All rights reserved

THE CONAIR GROUP, INC.

Page 3

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 3

TABLE OF CONTENTS

1.0 GENERAL 5

1.1 Introduction 6

1.2 Unit location for air cooled models 6

1.3 Unit location for water cooled models 6

1.4 Efficiency 6

1.5 Safety 7

1.6 Clean air act 7

1.7 Miscellaneous 7

Chiller features identified 8

2.0 INSTALLATION 9

2.1 General 10

2.2 To and From process connections 10

2.3 Water supply connection 11

2.4 Air cooled condenser 11

2.4 Water cooled condenser 13

2.5 Electrical connection 13

3.0 OPERATIONS 17

3.1 General 18

3.2 Start up/operations procedure 18

3.3 Instrument operation 23

3.4 Shut down procedure 26

4.0 TROUBLESHOOTING 27

4.1 Sensors 28

4.2 Process pump 28

4.3 Compressor 28

4.4 Blower/fan 28

4.5 Low flow 28

4.6 High Pressure 29

4.7 Low pressure 29

4.8 Freezestat 29

4.9 Oil pressure 30

4.10 Crankcase heater 30

4.11 Electronics 30

5.0 MAINTENANCE 31

5.1 Warranty service procedure 32

5.2 Periodic preventative maintenance 32

5.3 Special maintenance 33

5.4 Solenoid valve service 34

5.5 Pump seal service 36

5.6 Checking the refrigerant charge 39

5.7 Proper cleaning procedure for brazed plate evaporators 40

6.0 COMPONENTS 43

6.1 Water system 44

6.2 Refrigeration system 44

Page 4

Page: 4

7.0 RELATED DRAWINGS 47

7.1 VLA-5/7.5/10 mechanical schematic 48

7.2 VLA-15/20/25/30 mechanical schematic 49

7.3 VLA-5 physical 50

7.4 VLA-7.5/10 physical 51

7.5 VLA-15/20/25/30 physical 52

7.6 Duct schematic for air cooled chillers 53

7.7 VLA-5/ 7.5/ 10 electrical 54

7.8 VLA-15/ 20/ 25/ 30 electrical 55

7.9 VLW-5/7.5/10 ton mechanical schematic 56

7.10 VLW-15/20/25/30 ton mechanical schematic 57

7.11 VLW-5/7.5/10 physical 58

7.12 VLW-15/20/25/30 ton physical 59

7.13 VLW-5/ 7.5/ 10 ton electrical 60

7.14 VLW-15/ 20/ 25/ 30 ton electrical 61

8.0 APPENDIX 63

8.1 Specifications 64

8.2 Operations below 48°F 66

8.3 Water quality control 68

8.4 Inhibited propylene glycol 68

8.5 Maintaining proper water flow 70

8.6 Low flow bypass circuits 71

8.7 Overhead piping kit 72

8.8 Chiller capacity and derate chart 73

8.9 Pressure-temperature chart for R-22 refrigerant 74

8.10 Engineering formulas 75

8.11 Spare parts list- water-cooled models 76

8.12 Spare parts list- air-cooled models 77

A-1 Service Information 79

A-2 Warranty information 80

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page 5

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 5

1.0 GENERAL

1.1 INTRODUCTION

1.2 UNIT LOCATION FOR AIR COOLED MODELS

1.3 UNIT LOCATION FOR WATER COOLED MODELS

1.4 EFFICIENCY

1.5 SAFETY

1.6 CLEAN AIR ACT

1.7 MISCELLANEOUS

Page 6

Page: 6

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

1.1 INTRODUCTION

A. This manual covers most ‘VL’ series portable chiller models. Most

‘VL’ series portable chillers are basically identical with exception of

the type of condenser (air cooled or water cooled).

B. All instructions in this manual apply to most ‘VL’ series portable

chiller models regardless of the type of condenser or

instrumentation. Specific instructions relating only to air cooled

condensers, water cooled condenser, or instrumentation are

identified and should be noted by the operator.

C. When calling for assistance from the Conair Service Department, it

is important to know the model and serial number of the particular

unit. The model number encodes critical unit information which is

helpful in any attempt to troubleshoot operating difficulties. The

serial number allows the service team to locate manufacturing and

testing records which can have additional information relating to a

particular unit.

1.2 UNIT LOCATION FOR AIR COOLED MODELS

A. The ‘VL’ air cooled portable chiller is designed for indoor use only.

For most efficient operation, locate the chiller in a clean, dry and

well ventilated environment.

B. The ‘VL’ air cooled portable chiller has an air cooled refrigerant

condenser. For air cooled condensers, a motor driven fan (on

models from 2 to 10 tons) or a centrifugal blower (on models from

15 to 30 tons) generates air flow through the condenser to remove

heat from the refrigerant system. The air cooled condenser on the

‘VL’ portable chiller will discharge a maximum of 15,000 BTU’s per

hour per ton of cooling.

C. The ‘VL’ air cooled portable chiller must have a minimum entering

air temperature of 60°F and a maximum entering air temperature of

95°F for efficient operation.

D. The ‘VL’ air cooled portable chiller must have a minimum of two

feet clearance at the air intake and six feet at the vertical exhaust air

discharge.

1.3 UNIT LOCATION FOR WATER COOLED MODELS

A. The ‘VL’ water cooled portable chiller is designed for indoor use

only. For most efficient operation, locate the chiller in a clean, dry

and well ventilated environment.

1.4 EFFICIENCY

A. Long term efficiency of operation is largely determined by proper

maintenance of the mechanical parts of the unit and the water

Page 7

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 7

quality. Conair recommends filtering where required to prevent

solids from plugging critical parts (pumps, heaters, seals for

example). Conair highly recommends the services of a competent

water treatment specialist be obtained and his recommendations

followed. Conair accepts no responsibility for inefficient operation,

or damage caused by foreign materials or failure to use adequate

water treatment.

1.5 SAFETY

A. It is important to become thoroughly familiar with this manual and

the operating characteristics of the Conair ‘VL’ series portable

chiller.

B. It is the owner’s responsibility to assure proper operator training,

installation, operation, and maintenance of the Conair ‘VL’ series

portable chiller.

C. Observe all warning and safety placards applied to the chiller.

Failure to observe all warnings can result in serious injury or death

to the operator and severe mechanical damage to the unit.

1.6 CLEAN AIR ACT

A. The ‘VL’ series portable chiller contains HVLC-22

(chlorodifloromethane). This is a class 2 substance.

B. Effective July 1, 1992, it is unlawful for any person in the course of

maintaining, servicing, repairing, or disposing of refrigeration

equipment to knowingly vent or otherwise dispose of any class 2

substance used as a refrigerant in the manner which permits such

substance to enter the atmosphere.

C. De minimis releases associated with good faith attempts to

recapture, reclaim or recycle such substance shall not be subject to

the prohibition set forth in the preceding paragraph.

1.7 MISCELLANEOUS

A. The ‘VL’ series portable chiller is designed to circulate temperature

stabilized fluid through the process resulting in process temperature

control.

B. The ability of the ‘VL’ series portable chiller to maintain process

temperature control is significantly affected by the method of

installation as outline in section 2 of this manual.

C. If the operator has any questions concerning the location and

operation of the ‘VL’ series portable chiller, contact the Conair

Service Department at 800-458-1960 or 814-437-6861.

Page 8

Page: 8

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

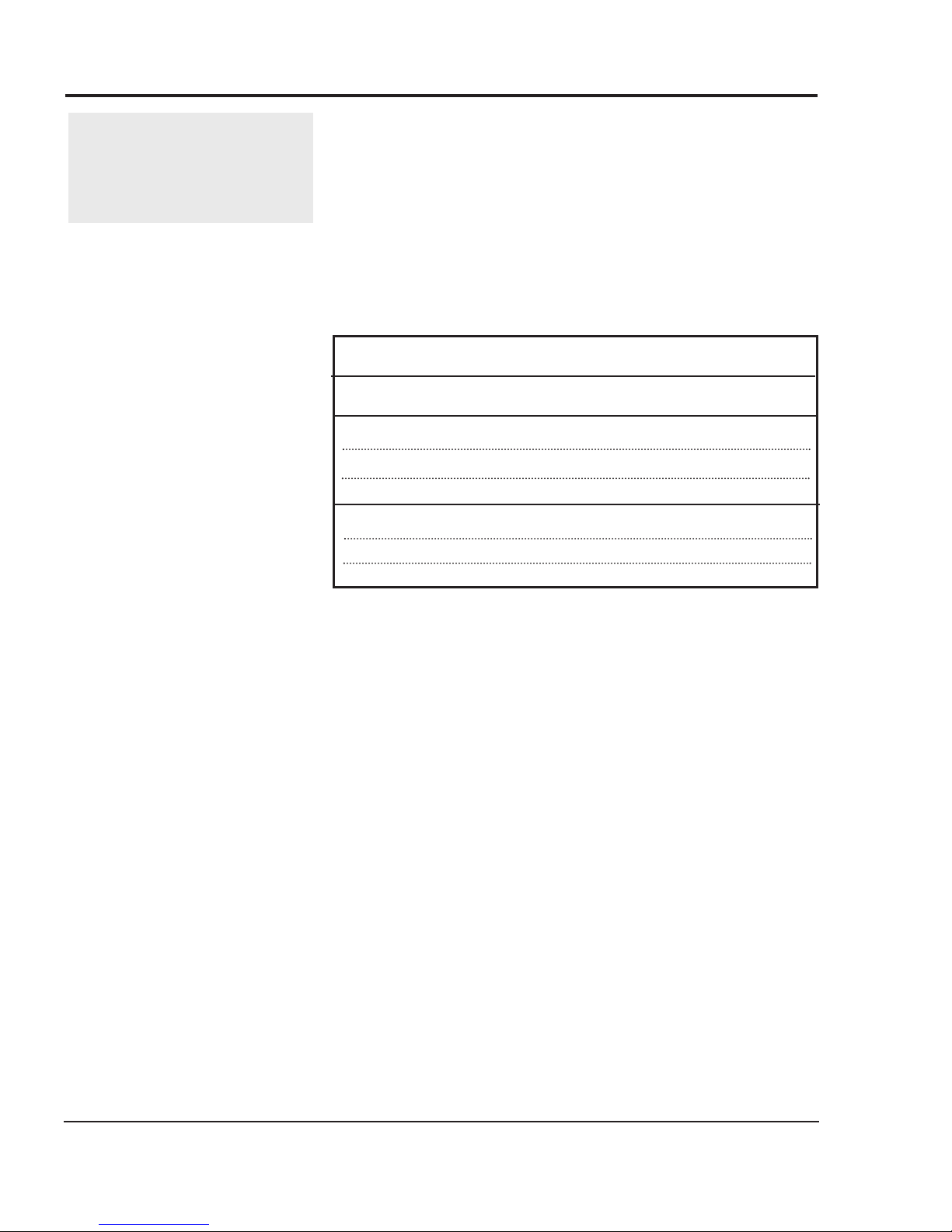

To Process

Connection

From Process

Connection

Hot Gas

Bypass

Valve

VLA-10

pictured

Compressor

Expansion

Valve

Liquid Line

Solenoid

Refrigerant

Sight Glass

Insulated

Fiberglass

Reservoir

Centrifugal

Pump

Electrical

Cabinet

Galvanized

Steel Frame

Fan Motor

Air Cooled

Condenser

Fiberglass Fan Shroud

Caster

Filter-Drier

To Process

Connection

From Process

Connection

VLW-10

pictured

Condenser Supply

Condenser

Condenser Return

Condenser

Expansion

Valve

Liquid Line

Solenoid

&

Hot Gas

Bypass Valve

&

Filter-Drier

(not visible in

photograph)

Refrigerant

Sight Glass

Insulated

Fiberglass

Reservoir

Centrifugal

Pump

Electrical

Cabinet

Galvanized

Steel Frame

Caster

Compressor

Condenser

Page 9

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 9

2.0 INSTALLATION

2.1 GENERAL

2.2 TO AND FROM PROCESS CONNECTIONS

2.3 WATER SUPPLY CONNECTION

2.4 AIR COOLED CONDENSER

2.5 WATER COOLED CONDENSER CONNECTION

2.6 ELECTRICAL CONNECTION

Page 10

Page: 10

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

2.1 GENERAL

A. All process piping materials (such as hose, rigid piping, valves or

filters) used in process water piping circuitry must be rated for

100°F minimum temperature and 100 PSI minimum pressure.

B. All such materials must have the equivalent or larger diameter of

the particular process connection that length of process water

piping is connected to.

2.2 TO AND FROM PROCESS CONNECTIONS

(see figures 2.2A & 2.2B)

A. Connect the ‘TO PROCESS’ to the ‘water in’ manifold on the mold

or process.

B. Connect the ‘FROM PROCESS’ port to the ‘water out’ port on the

process manifold.

C. Process water piping circuitry should be designed to avoid an

excessive use of elbows and/or lengths of pipe or hose. If hose is

the material of choice, avoid tight twists or curls and excessive

lengths.

D. Valves and filters may be installed in the process water piping

circuitry to facilitate service and maintenance provided that such

devices maintain the full inside diameter of the process connection.

If installed, all such devices must be open and clean during unit

operation.

To process connection:

connect to “water in” on process manifold

From process connection:

connect to “water out” on process manifold

Condenser water in

connection:

connect to tower or city water supply

Condenser water out

connection:

connect to tower or city water return

Water supply connection:

(not shown on this unit)

connect to plant’s city water source

Figure 2.2A

Typical process connections

for water cooled chiller

Page 11

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 11

To process connection:

connect to “water in” on process manifold

From process connection:

connect to “water out” on process manifold

Water supply connection:

(not shown on this unit)

connect to city water source

Figure 2.2B

Typical process connections

for air cooled chiller

2.3 WATER SUPPLY CONNECTION

A. The automatic water supply make-up system continually monitors

the reservoir tank and fills it when needed. Connect as follows:

1. Connect the chiller’s ‘WATER SUPPLY’ port to the plant’s

city water source.

2. Minimum water supply pressure requirement is identified

on the equipment data plate. This is normally 20 psi.

3. Be certain to use a water supply line equipped with a back

flow prevention device to prevent contamination of potable

water.

2.4 AIR COOLED CONDENSER

A. Air cooled condensers require ambient air temperatures between

60°F and 95°F for efficient operation. Operating above above 95°F

may result in elevated condensing pressures and eventual shutdown on the high pressure safety switch. In such cases, a water

assist unit may be necessary for operations. Air temperatures below

60°F may result in below normal condensing pressures and poor

condensing. In such cases, a low-ambient damper assembly is

required. Check with the Conair service department for more

information on operating with ambients air temperatures above

95°F or below 60°F.

Page 12

Page: 12

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

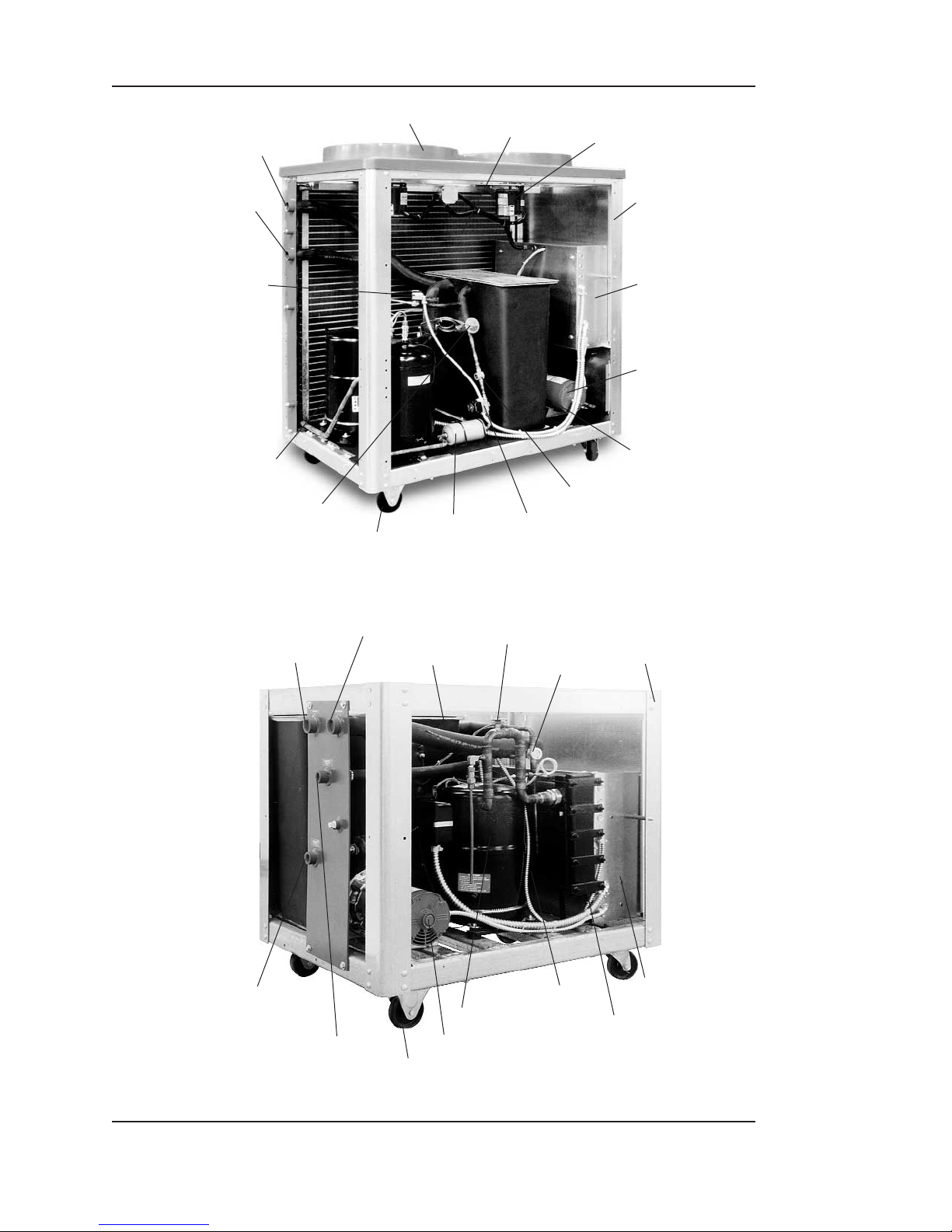

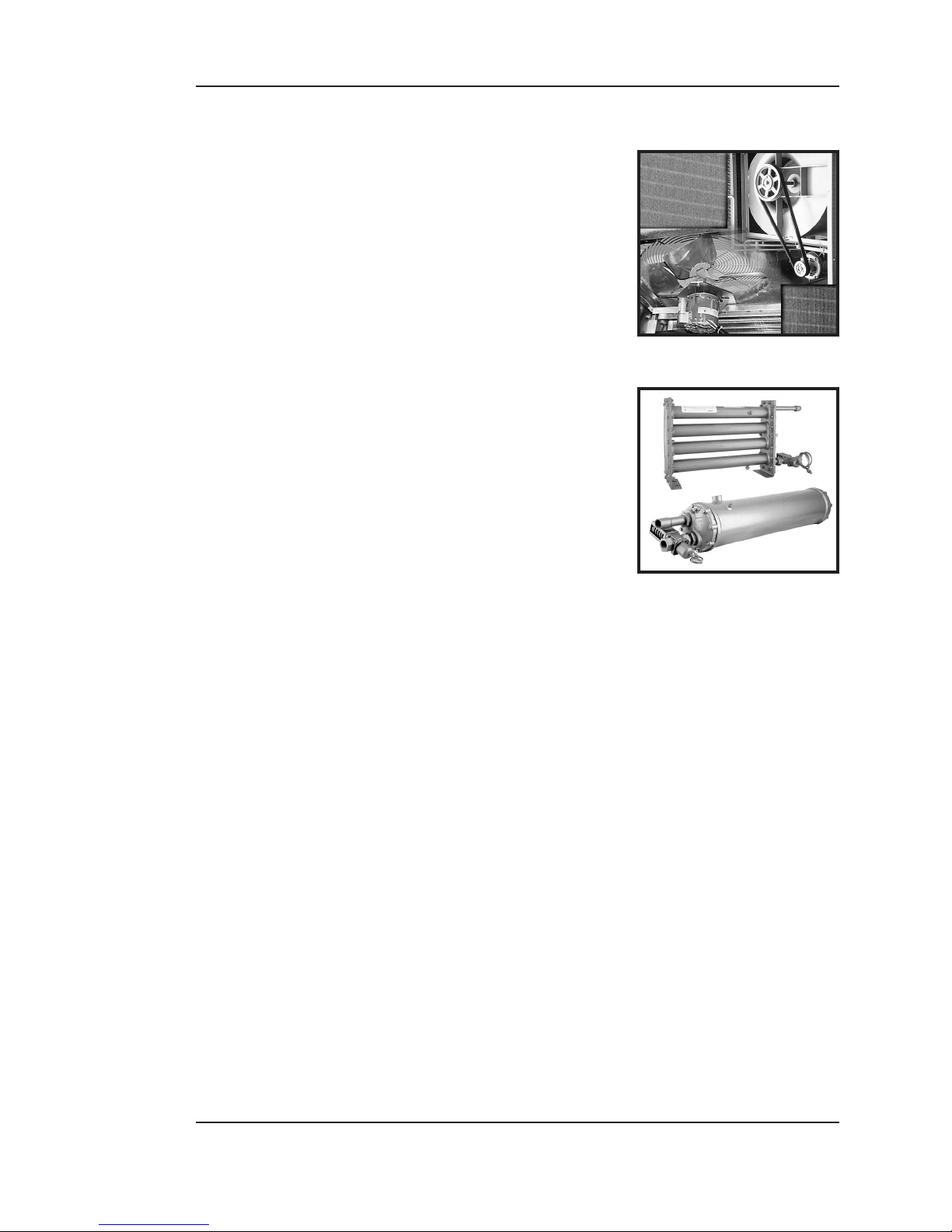

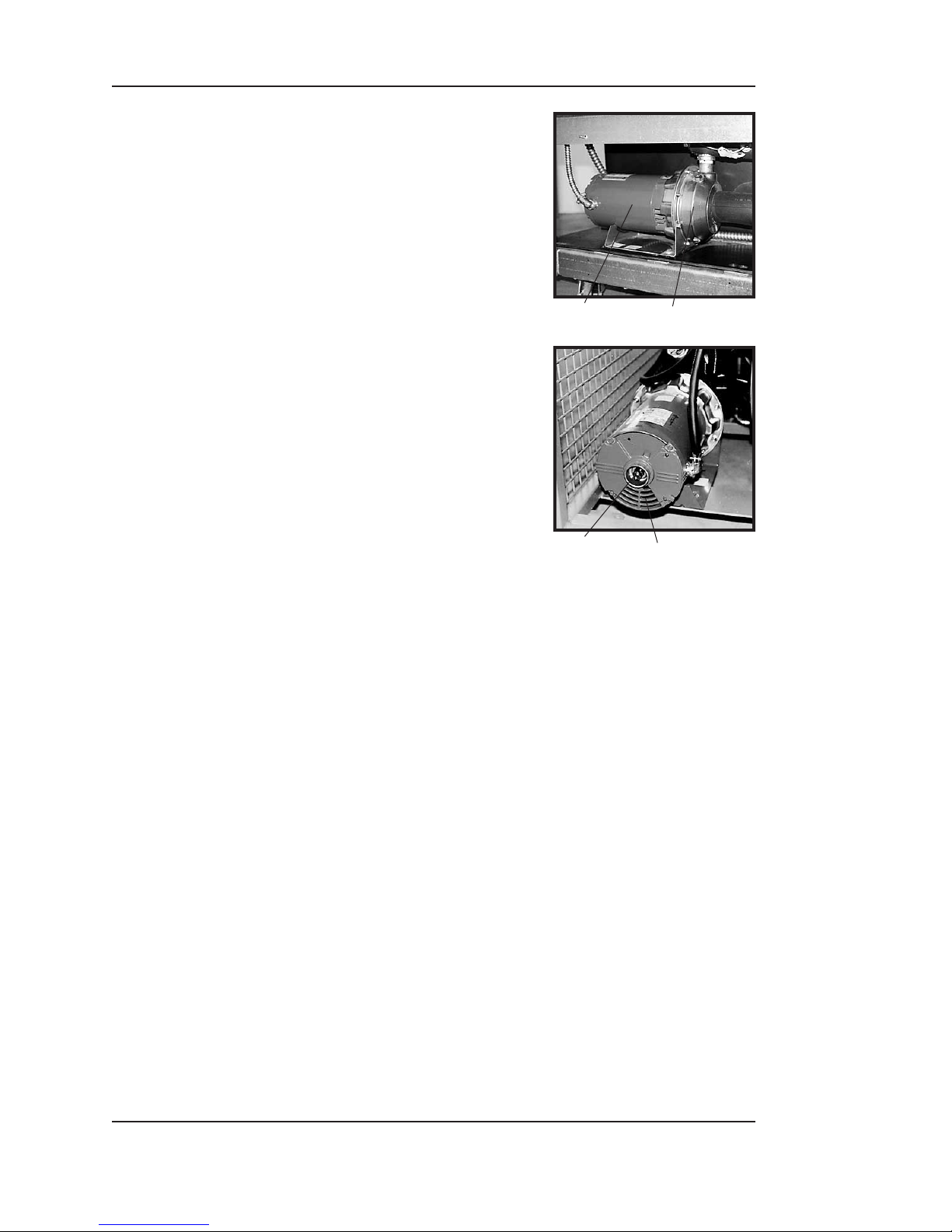

B. Air flow is generated by the motor

driven fans (figure 2.4A) or

centrifugal blowers (figure 2.4B). Air

flow is from the outside of the

chiller, through the condenser and

exhausted through the top of the

unit. On centrifugal blowers models,

exhaust air can be ducted outside of

the plant’s interior environment.

Special duct work is required and a

HVAC contractor should be

consulted for sizing and material

specifications. Exhaust air can not be

ducted on motor driven fan models.

C. A free air space of at least two (2)

feet is required at the condenser

intake and six (6) feet at the

condenser discharge to allow for

proper air flow.

D. At full load, the chiller will discharge

approximately 15,000 BTU’s per

hour per ton of cooling.

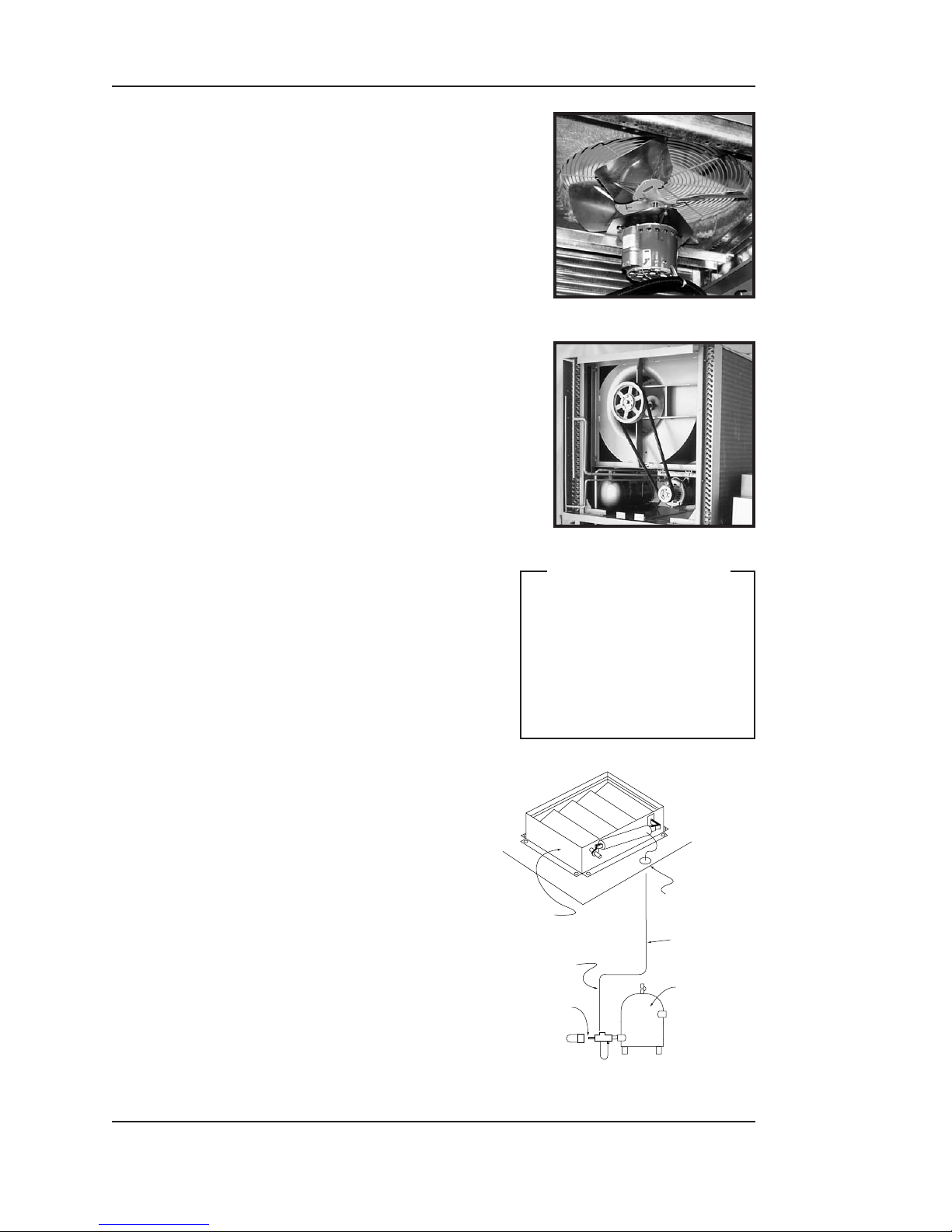

E. On blower units, air discharge

duct work should be sized by

a qualified HVAC engineer.

Sizing shall be according to

rated VLM at the static

pressure of .90 inches of

water. See figure 2.4C at right.

F. On blower units, a damper

control assembly is required in

low ambient

temperature areas or

when outdoor air

make-up is used. The

assembly works in

conjunction with

refrigerant head

pressure to regulate

air flow to maintain

proper refrigerant

head pressure when

condenser intake air

temperature will be

less than 60°F. See

figure 2.4D to the

right.

Figure 2.4C

Figure 2.4D

Figure 2.4A

Typical fan assembly

Figure 2.4B

Typical blower assembly

MODEL CFM

VLA-15 15,000

VLA-20 20,000

VLA-25 25,000

VLA-30 30,000

CFM RATINGS

Damper assembly

1/4" copper line connection

Angle valve and cap

Punch hole

in top panel

1/4" Copper line

Liquid receiver

(located inside

chiller on base)

Page 13

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 13

2.5 WATER COOLED CONDENSER CONNECTION

A. Connect the ‘CONDENSER WATER

IN’ port to the plant’s city water

supply or tower system supply.

1. Required consumption from

a city water source is 1.5

gpm at 65°F per ton of

rated capacity.

2. Required consumption for a

tower water source is 3 gpm

at 85°F per ton of rated

capacity.

B. Connect the chiller’s ‘CONDENSER

WATER OUT’ port to the plant’s

drain or tower system return.

1. Note: if dumping to the

plant’s open drain, drainage

shall be done according to

local codes.

C. The pressure differential requirement

between the condenser “water in”

and the condenser “water out” lines

must be 30 psi for adequate efficiency.

D. The installation of a strainer in the condenser “water in” line is

recommended. This removes solids from the water supply and

serves to protect the water saver (regulator) valve.

E. An optional water saver (regulator) valve may be installed in the

condenser “water in” line. During winter months, or cold seasons,

the valve will throttle the water flow through the condenser. The

amount of flow is based on the refrigerant head pressure and the

regulator will modulate the valve’s orifice to maintain a head

pressure of 210 psig for best efficiency.

2.6 ELECTRICAL CONNECTION

A. NEMA 1 MODELS

1. Electrical power supply requirements for Nema 1 units are

identified on the equipment data plate. Determine the

plant’s voltage supply is the same as the unit’s voltage

requirements. WARNING: Do not connect the unit to a

voltage supply not equal to the unit’s voltage

requirements as specified on the unit’s data plate. Use

of incorrect voltage will void the unit’s warranty and

Figure 2.5A

Condenser connections 30 ton unit - optional regulator

valve shown

Figure 2.5B

Condenser connections 10 ton unit- optional regulator

valve shown

Page 14

Page: 14

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

cause a significant hazard that may result in serious

personal injury and unit damage.

2. A customer supplied, four conductor cable is required for

connection to a customer supplied fused disconnecting

means. The fused disconnecting means shall be sized and

installed according to the unit’s power supply requirements

and local electrical codes. See figure 2.5A (next page) for

details on water cooled power cable routing.

3. Connect the four conductor power cable to power entry

terminal block on the unit’s electrical panel. Then connect

the power cable to the fused disconnect switch.

B. NEMA 12 MODELS

1. NEMA 12 units are constructed with a dust tight electrical

enclosure and branch circuit fusing. Electrical power supply

requirements are identified on the equipment data plate.

Determine the plant’s voltage supply is the same as the

unit’s voltage requirements. WARNING: Do not connect

the unit to a voltage supply source not equal to the

unit’s voltage requirements as specified on the unit’s

data plate. Use of incorrect voltage will void the unit’s

warranty and cause a significant hazard that may result

in serious personal injury and unit damage.

2. Appropriate conduit and fittings should be selected which

will maintain the integrity of the cabinet.

3. Supply a power conductor sized according to the unit’s

power supply requirements. Connect the power conductor

to the unit’s power supply entry terminal block or the fused

disconnect switch. Some Nema 12 models may be supplied

with an optional disconnect switch. The owner supplied

fused disconnecting means shall be sized and installed

according to the unit’s power supply requirements and

local electrical codes.

C. CONTROL CIRCUIT WIRING

1. The unit’s supplied control circuit is 110 volt, 1 phase, 60

cycle. The control circuit is supplied by the factory installed

transformer. An inline control circuit fuse is provided.

D. GENERAL

1. Make certain all ground connections to the unit are

properly affixed.

2. Make certain power conductor, disconnecting means, and

fusing are properly sized according to the unit’s power

supply requirements.

Page 15

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 15

3. Make certain all electrical connections are tightly affixed.

Any loose wiring connections must be tighten before

engaging the power supply.

4. Make certain no moisture or standing water is present

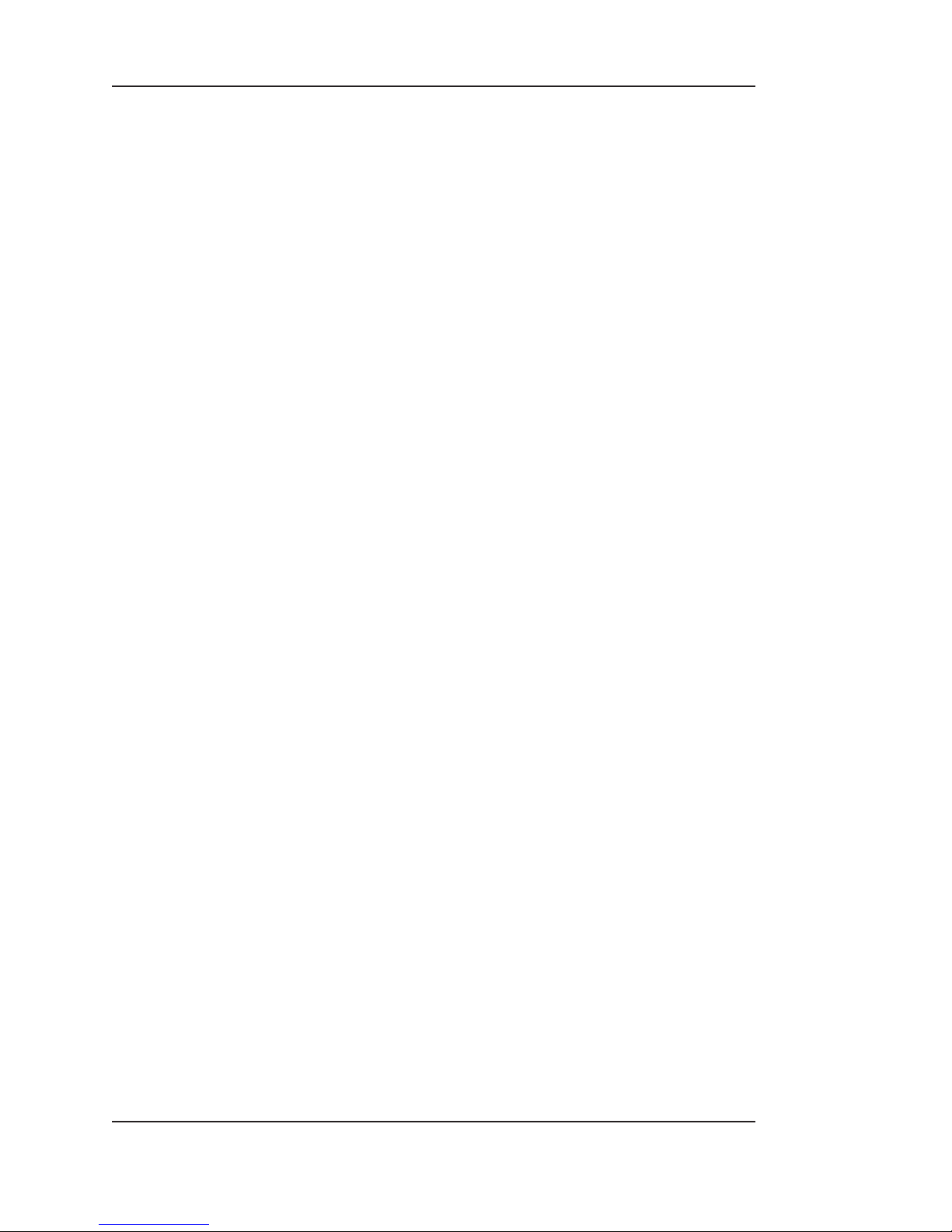

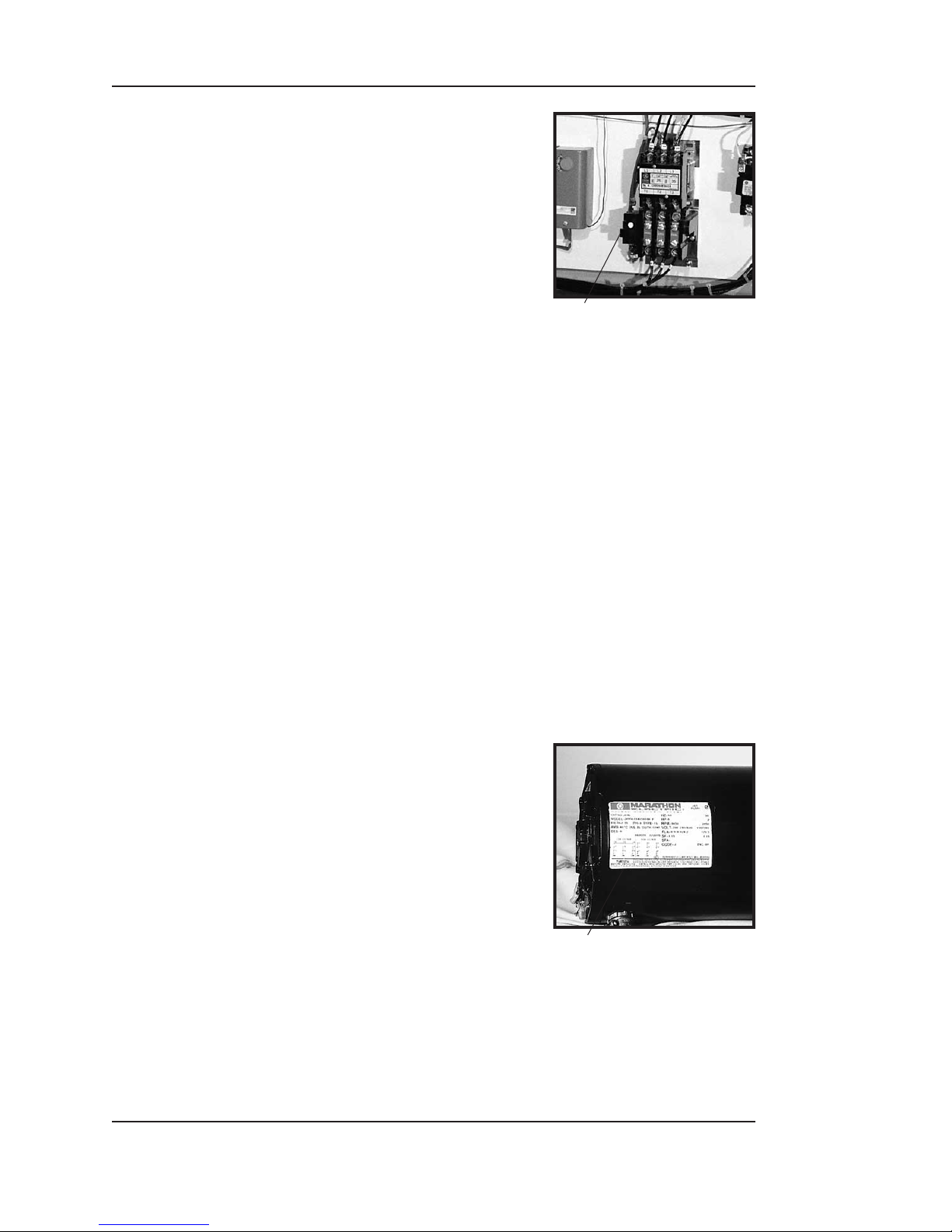

inside the electrical cabinet (figure 2.5B).

Refrigerant High

Pressurestat

Refrigerant Low

Pressurestat

Fuse Block

Transformer

Power Entry

Freezestat

Cabinet Door

Figure 2.6B Typical electrical cabinet detail.

Motor Starter

Overload Relay

Compressor Starter

Figure 2.6A

5 THRU 10 TON MODELS

ELECTRICAL CABINET

MICROPROCESSOR

CONTROLLER

5 THRU 10 TON MODELS

WATER COOLED

WATER COOLED

ROUTE POWER CORD

OUT OPEN BACK OF UNIT

TO DISCONNECT

ELECTRICAL CABINET

MICROPROCESSOR

CONTROLLER

WATER COOLED

WATER COOLED

15 THRU 30 TON MODELS

15 THRU 30 TON MODELS

TO DISCONNECT

ROUTE POWER CORD

OUT OPEN BACK OF UNIT

Page 16

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

Page: 16

THIS PAGE INTENTIONALLY BLANK

Page 17

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 17

3.0 OPERATIONS

3.1 GENERAL

3.2 START UP/OPERATIONS PROCEDURE

3.3 INSTRUMENT/OPERATION

3.4 SHUT DOWN PROCEDURE

Page 18

Page: 18

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

3.1 GENERAL

A. Failure to follow the factory required operations procedure may

adversely affect the unit’s ability to adequately control process

temperature and may create a hazardous operating condition

which may result in serious operator injury and/or unit damage.

B. IMPORTANT: each chiller is equipped with a crankcase heater on

the compressor. While the compressor is idle, the crankcase heater

prevents freon vapor from migrating to and condensing in the

compressor crankcase. If freon is allowed to condense in the

crankcase, it can be drawn into the cylinders upon start up. This

can cause catastrophic damage to the connecting rods, pistons,

and valve plates. To avoid this, BEFORE THE UNIT IS STARTED,

THE POWER SUPPLY SHOULD BE APPLIED TO THE UNIT FOR AT

LEAST 12 HOURS, OR UNTIL THE BOTTOM OF THE

COMPRESSOR IS WARM TO THE TOUCH. If the power has been

disconnected more than two hours, the power should be applied

for six hours before restarting. Power should be applied to the unit

continuously, except for service purposes. The crankcase heater

should be checked for proper operation on a regular basis.

C. The OPERATIONS segment of this manual is divided into the

following sections:

3.2 Start up/operations - follow this segment to start the unit

after the initial install to the process system or to restart the

unit after reinstallation to the same or different process

system. This section includes information on system fill,

electric motor phasing (pump rotation) and process flow

adjustments.

3.3 Instrument - follow this segment to start up and operate

the instrument. This section includes information on

setpoint selection and adjustment, and feature

explanations.

3.4 Shut down procedure - follow this segment to shut down

the unit. This segment includes information on system shut

down, electrical power supply precautions, and

disconnection from system.

3.2 START UP/OPERATION PROCEDURE

A. SYSTEM FILL

1. The VL series portable chiller has an internal reservoir which

must be filled and maintained for proper operation. All VL

series chillers have a level switch mounted at the proper

water level in the reservoir.

Page 19

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 19

2. Conair recommends the addition of 20% inhibited

propylene glycol to the process fluid. This should help

prevent the process fluid from freezing and internal

components from rusting. A biocide must be added to the

water to prevent organism growth in the chilled water

system. See water treatment section in section 8 of this

manual for more information.

3. FOR AUTOMATIC FILL (IF

EQUIPPED): engage the

water supply to unit. The

level switch will activate the

make-up solenoid (figure

3.2A), which will open and

the water supply will fill the

reservoir tank. During

operations, with the water

supply source “on”, the unit

will automatically maintain

the correct reservoir level.

4. MANUAL FILL: disconnect the electrical power supply and

remove all necessary cover panels to access the reservoir

tank. Add fluid directly to the reservoir tank. When the

pump is first started, as process lines are filled and air is

purged, additional fluid may be required to restore the

reservoir to the correct level.

B. ELECTRIC MOTOR PHASING (PUMP ROTATION)

1. The operator must determine the unit is phased correctly.

This is done by visually inspecting the rotation of the pump

motor shaft and is outlined below. Incorrect phasing results

in poor operation and eventual damage to the unit.

a. Supply electrical power to the unit by engaging the

unit’s disconnect switch. Once the correct voltage

is supplied to the unit, the POWER light on the

unit’s instrument display will illuminate.

b. Remove the necessary covers panel to access the

pump motor. Note that electrical power is

engaged at this point and caution must be

observed while the electrical supply is engaged

and cover panels are removed.

c. Locate the electric motor (figure 3.2B) The operator

must identify the motor shaft inside the electric

motor housing. The motor shaft can be seen

through the vent slots in the motor housing or by

removing the shaft cover (figure 3.2C).

Figure 3.2ATypical make-up solenoid valve

Page 20

Page: 20

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

d. Toggle the CHILLER

ON switch. This will

quickly cycle the

electrical motor

“on” and then “off”.

e. Observe the motor

shaft. When the

CHILLER ON switch

is turned “on”, the

motor shaft will

rotate. When the

CHILLER ON switch

is turned “off”, the

motor shaft will

slowly “coast” to a

stop. As the shaft

slows to a stop, the

operator must

identify its rotation.

Correct rotation

(correct phase) is

“clockwise”, when

viewed from the

rear of the motor.

Incorrect rotation is “counterclockwise” (incorrect phase) when viewed from the

rear of the motor. If the shaft does not rotate when

the PUMP switch is toggled, the operator must

identify the cause as outlined in this manual’s

troubleshooting and repair section.

f. If the motor shaft is phased correctly (shaft turns in

a clockwise direction), continue with step C. If the

motor shaft is NOT phased correctly (shaft turns in

a counter-clockwise direction), continue the

procedure with step 2.

2. If the motor shaft is NOT phased correctly, the operator

must:

a. Disengage the electrical power supply to the unit at

the disconnect switch. Follow proper lockout

procedures before proceeding. Verify the POWER

light on the instrument display is off.

b. With the electrical power supply is disengaged,

reverse any two power leads of the power cord at

the disconnect terminals.

c. Note: reversing any two power leads of the power

cord will correctly phase an incorrectly phased

Figure 3.2C

Motor shaft

Vent slots

Figure 3.2B

Electric motor

Pump

Page 21

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 21

power supply. The operator must reverse the

power leads at the disconnect switch only and

NOT at the power entry terminals on the unit’s

electrical panel. The unit’s internal electrical

system wiring is phased correctly at the factory and

must not be altered in the field.

d. Visually inspect the rotation of the motor as

outlined step 1 to determine the unit is phased

correctly.

C. PROCESS FLOW ADJUSTMENTS

1. The operator must determine and set proper water flow

rate for the most efficient and trouble free operation.

a. Water flow rate through the process is determined

by the pressure losses in the process loop.

Generally, higher flow rates result in turbulent flow

achieving maximum temperature control and lower

maintenance. Since the evaporator in most liquid

chillers is flow sensitive, the efficiency of operation

is directly related to the flow of liquid.

b. Maximum chiller efficiency is obtained at

approximately 2.4 gpm per ton of rated capacity.

Low liquid flow can reduce efficiency and in some

cases allow ice to form in the evaporator which can

damage the evaporator. Excessive flow will trip the

motor overload protection circuit.

2. Activate the CHILLER ON rocker switch on the display to

activate the process pump. Wait a few moments to allow air

to be purge from system. Two items the operator must look

for are low or excessive flow conditions.

3. LOW FLOW... to allow operation under a low flow

condition, it is necessary to install a flow bypass system in

the process circuitry. This will allow a portion of the flow to

bypass the process and return directly to the chiller. This

keeps the total flow above the cutoff point. Figure 3.2D

illustrates a typical bypass loop.

Figure 3.2D Typical low flow by-pass loop

21 GPM 5 GPM

BYPASS

CHILLER PROCESS

THROTTLING

VALVE 16 GPM

5 GPM21 GPM

Page 22

Page: 22

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

4. EXCESSIVE FLOW... excessive

flow can overload the

process pump motor and

cause eventual failure. This is

a result of the process loop’s

ability to flow water at a

great rate than can be

provided by the process

pump. This eventually

results in tripping the

thermal motor overload

relay (overload relays open)

and the unit will shut down.

a. If an excessive flow situation is encountered and

the motor overload circuit has tripped, the operator

must manually reset the overload relay (figure 3.2E)

before operations can continue. This is done by

opening the electrical panel cover, identifying the

reset lever on the overload relay, and pushing the

reset lever “in” until the overloads are reset

(evidenced by a “clicking” sound as the overloads

reset).

5. To overcome an excessive flow condition, the operator

should set the process flow rate according to the motor

amperage:

a. Remove electrical cover panel. Note that the

electrical power is engaged at this point and

caution must be observed while the cabinet

panel is open.

b. Identify the motor

starter block. This

block consists of

the motor starter

contactor and the

overload relay.

c. Place an amp

meter on a single

power lead

emanating from

the overload relay.

d. Locate the electric pump motor. Identify

the motor name plate on the motor housing (figure

3.2F). The full load amp rating for the motor is

listed on the name plate.

e. Engage the electrical power supply and start the

motor by switching ‘on’ the CHILLER ON rocker

switch.

Figure 3.2E

Reset level on overload relay

Motor name plate

Figure 3.2F

Page 23

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 23

f. The amp meter will display the motor amps.

Compare the actual motor amps as displayed on

the amp meter to the full load amp rating as listed

on the motor name plate.

g. If the amp draw is excessive (higher than the listed

name plate amp rating), a throttling valve must be

installed in the “from process” circuit line. The

preferred throttling valve is a ball valve.

h. With the throttling valve installed, fully close the

valve and then engage the pump. Slowly open the

throttling valve and monitor the motor amps as

displayed on the amp meter until the actual motor

amps equals the listed full load amp rating of the

motor.

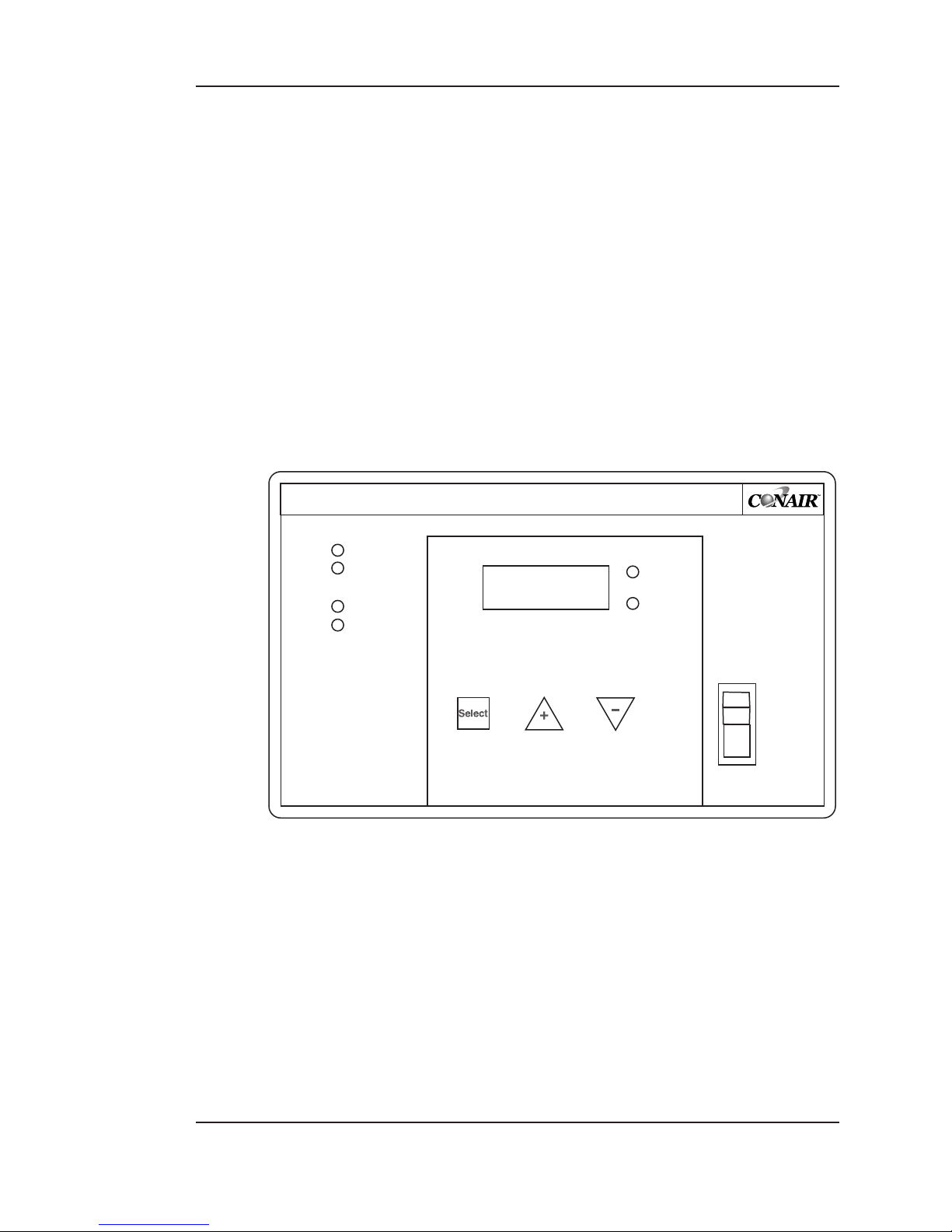

3.3 INSTRUMENT OPERATION

A. INSTRUMENT START-UP

1. When the correct electrical power and adequate water

supply pressure are supplied to the unit, it is possible to

start the unit for temperature control duty.

2. When the electrical power supply is engaged to the unit,

the instrument (figure 3.3A) will momentarily illuminate all

indicating lights and digits on the display head. After a

short delay, the instrument will display the software version

number. At this time, the operator can verify that all lights

and digits are functioning properly. If the operator

VL Chiller Control

Power

Pump

Compressor

Hot Gas Bypass

Temperature

To Process

Setpoint

On

Off

Page 24

Page: 24

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

determines an indicating light or digit does not illuminate,

the instrument must be removed and sent to the factory for

repair. When power is supplied to the unit, the POWER

light will illuminated.

3. Toggle ‘on’ the CHILLER ON rocker switch to activate the

chiller. The operator can stop process operations

(refrigerant and coolant circuits) by switching ‘off’ the

CHILLER ON switch.

4. To select the operating setpoint, use the SELECT key to

index through the TO PROCESS and SET POINT

temperature functions until the SET POINT light is

illuminated.

5. When the SET POINT light is illuminated, the setpoint

temperature is shown in the temperature display window.

Use the UP and DOWN ARROW keys to change the

setpoint temperature.

6. PRECAUTIONS: the instrument is programmed from the

factory with a setpoint range of 48° to 70°F. To operate

below 48°F, the addition of inhibited propylene glycol and

modification of the safety control settings are required.

Diligent monitoring of the water/glycol solution is

mandatory to prevent freezing of the evaporator. Freezing

may cause the evaporator to rupture allowing water and

freon to mix which will cause major damage to the

refrigeration system. Operating above 70°F requires the

addition of a refrigerant crankcase pressure regulating (CPR)

valve. The CPR valve is necessary to prevent overloading of

the compressor which can cause premature failure. Contact

your local refrigeration contractor or the factory for further

information. The operating range of the instrument may be

changed to 20°F - 90°F by adjustment of the CPU DIP

switch. Refer to the technical section of this manual for

more information. The instrument is set up from the factory

to give an alarm light and a 115 volt alarm output if the

temperature to process deviates more than 10° from the

setpoint.

7. After selecting the setpoint temperature, the operator may

leave the display in the SET POINT state. The display will

automatically return to the TO PROCESS temperature state

after twenty seconds of inactivity.

8. The operator can stop operations by switching ‘off’ the

CHILLER ON rocker switch. This will disengage the

refrigerant and coolant circuits.

Page 25

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 25

B. INSTRUMENT OPERATION

1. When the CHILLER ON rocker switch is toggled on, the

instrument will begin temperature control operations and

the ‘to process’ temperature will begin to drop.

2. When the ‘to process’ temperature drops 1° below the

setpoint, the instrument will activate the capacity control

system to match the cooling capacity to the present load,

as indicated by the HOT GAS BYPASS light (figure 3.3A).

3. If the load is less than the minimum capacity of the chiller,

the ‘to process’ temperature will continue to drop. At 3°

below setpoint the compressor will stop and enter a three

minute time delay period before restarting at 1° above

setpoint. The time delay is to prevent short cycling damage

to the compressor.

C. INSTRUMENT CONTROLS

1. CHILLER ON SWITCH: this rocker switch

engages/disengages electrical supply to the compressor and

pump circuit.

2. SELECT: depress to index through the TO PROCESS and

SET POINT temperatures.

3. UP ARROW: depress and hold this push button to increase

the setpoint temperature. If this push button is pressed

momentarily the setpoint value is incremented by one

degree. If the push button is held down for more than one

second, the setpoint will increase slowly at first and then

faster after about two seconds.

4. DOWN ARROW: depress and hold this push button to

decrease the setpoint temperature. If this push button is

pressed momentarily the setpoint value is incremented by

one degree. If the push button is held down for more than

one second, the setpoint will increase slowly at first and

then faster after about two seconds.

D. INSTRUMENT STATUS DISPLAY

1. POWER: illuminates when the proper supply of electrical

power is applied to the unit.

2. PUMP: illuminates when the CHILLER ON rocker switch is

turned on and the pump is operating. Even with the

CHILLER ON rocker switch on, the PUMP light will not

illuminate if a safety fault condition exists.

3. COMPRESSOR: illuminates when the instrument engages

Page 26

Page: 26

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

the compressor contactor. Engaging the compressor

contactor supplies electrical current to the compressor. This

action will decrease process water temperature.

4. CAPACITY CONTROL: illuminates when the instrument has

engaged the capacity control system.

E. TEMPERATURE DISPLAY

1. A three digit display window indicates the appropriate

temperature in Fahrenheit. The window also displays the

numeric value for the setpoint temperature. A red light will

illuminate beside the parameter currently being displayed.

a. TO PROCESS: indicates liquid temperature being

delivered from the chiller.

b. SETPOINT: indicates selected temperature control

point.

3.4 SHUT DOWN/DISCONNECT SEQUENCE

A. PRECAUTIONS/WARNINGS

1. The operator must precisely follow all shut down

procedures outlined in this manual. If the operator fails to

follow precisely all procedures outlined in this manual, an

unsafe condition can develop resulting in damage to the

unit or personal injury.

B. UNIT SHUT DOWN

1. To shut down the unit: toggle off the CHILLER ON rocker

switch. Maintain electrical power to the unit at all times

except for service purposes. If the unit is to be

disconnected from the process, disengage the voltage

supply before removing power cord and process lines.

Page 27

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 27

4.0 TROUBLESHOOTING

4.1 SENSORS

4.2 PROCESS PUMP

4.3 COMPRESSOR

4.4 BLOWER/FAN

4.5 LOW FLOW

4.6 HIGH PRESSURE

4.7 LOW PRESSURE

4.8 FREEZESTAT

4.9 OIL PRESSURE

4.10 CRANKCASE HEATER

4.11 ELECTRONICS

Page 28

Page: 28

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

4.1 SENSORS

A. The sensor is a solid state temperature transducer which converts

temperature input to proportional current output.

B. To quickly test for a defective probe, switch connections between

the defective probe and a probe known to be working properly.

4.2 PROCESS PUMP

A. The centrifugal pump is designed to operate at a specific flow and

pressure at the maximum run load amp draw of the motor. Too

much flow can overload the motor and cause the overload circuit

to open and stop the pump.

B. If the overload trips, check for electrical shorts, loose wires, or

blown fuses. If these check OK, reset the overload circuit and restart

the chiller.

C. Check the amperage and if excessive, partially close the ‘from

process’ valve until the amperage is reduced to the proper level.

4.3 COMPRESSOR

A. Semi-hermetic compressors are protected by an external overload

device (Klixon switch, solid state module, etc.). If the safety switch

opens, this indicates an overload condition exists.

B. Check for electrical shorts, loose wires, bad fuses, or bad motor

starter contacts. If these check ok, check for a defective protection

device.

C. Hermetic compressors have internal protection.

4.4 BLOWER/FAN

A. Check for an electrical short, loose wires, bad fuses, or bad motor

starter contacts.

B. Check the blower for defective bearings or other forms of drag on

the blower wheel.

4.5 LOW FLOW

A. One pump chillers require 100% of the process flow to circulate

through the evaporator.

B. In some process conditions the minimum flow required cannot be

maintained making it necessary to install a bypass line between the

to and from process lines.

Page 29

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 29

4.6 HIGH PRESSURE

A. If the refrigerant high pressure safety switch has opened, this switch

must be manually reset after the problem has been resolved.

B. Refrigerant high pressure will vary with ambient temperature from a

minimum of 190 psi to as high as 280 psi. Check for restricted

filters, broken or loose blower drive belts, restricted air flow.

C. On air-cooled models: maintain at least four feet of clearance for

each condenser intake.

D. On air-cooled models: check if the discharge duct work (if installed)

is undersized and restricting air flow.

4.7 LOW PRESSURE

A. If the refrigerant low pressure safety switch has opened, the cause

of the problem must isolated and resolved.

B. The switch will automatically reset when the pressure rises above

the cut-in pressure. If this does not occur contact the Conair service

department for instructions.

C. The low pressure switch is set to cut-out at 58 psi and cut-in at 63

psi. If a low pressure condition exists for more than five seconds the

compressor will stop and a “L-P” fault will appear in the display

window.

D. After the refrigerant pressure rises above the cut-in pressure, a three

minute time delay will occur before the compressor restarts. This

will protect the evaporator and compressor from damage should a

problem occur in the refrigeration system or if the chiller is

operated under circumstances which could cause damage to the

refrigeration system.

E. If a low pressure fault occurs, check for blockage in the evaporator

water inlet. If a blockage is found, back flush the evaporator and

flush complete process water system.

F. Check for low freon. The refrigerant sight glass should appear clear

when the unit is operating at 100% cooling capacity. Constant

foam or bubbles indicate a loss of freon.

G. Check to see if the condensing media is too cold. On air condensed

units, the ambient air at the condenser intake must be at least

60°F. If this is not possible, a damper control assembly package may

be required.

4.8 FREEZESTAT

A. The freezestat sensor bulb is located at the evaporator water outlet

Page 30

Page: 30

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

port. If the water out temperature of the evaporator reaches the

freezestat setting the switch will open and stop the refrigeration

compressor.

B. Check for restricted water flow and add a bypass line if necessary.

C. The setpoint is adjusted too low for the safety switch settings.

D. The freezestat is adjusted incorrectly or is defective.

4.9 OIL PRESSURE (Semi-hermetic Compressors)

A. This switch must be manually reset after the problem is resolved.

B. Check for low oil level in the compressor crankcase or insufficient

compressor warm up before start-up.

C. Defective crankcase heater, internal compressor damage causing

the compressor to pump too much oil through the system,

defective oil pump, or plugged pick up screen in compressor oil

sump. Note: only semi-hermetic compressors 15-30 tons have an

oil pressure safety switch.

4.10 CRANKCASE HEATER (Semi-hermetic Compressors)

A. If the crankcase heater is not drawing current during the

compressor off cycle, check for a defective crankcase heater,

defective fuses or defective interlock on the compressor starter.

4.11 ELECTRONICS

A. The Display/CPU is used for all normal set ups, diagnostics,

temperature readout and operational information. This is not

normally a field repairable part. It is designed to be easily removed

and replaced if a problem arises.

Page 31

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 31

5.0 MAINTENANCE

5.1 WARRANTY SERVICE PROCEDURE

5.2 PERIODIC PREVENTATIVE MAINTENANCE

5.3 SPECIAL MAINTENANCE

5.4 SOLENOID VALVE SERVICE

5.5 PUMP SEAL SERVICE

5.6 CHECKING THE REFRIGERANT CHARGE

5.7 PROPER CLEANING PROCEDURE FOR BRAZED PLATE EVAPORATOR

Page 32

Page: 32

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

5.1 WARRANTY SERVICE PROCEDURE

A. In the event of a problem with a chiller that can not be resolved by

normal troubleshooting procedures, the customer is invited to

consult the Conair service department for assistance. The correct

model number and serial number of the chiller must be available.

The service department will attempt to isolate the problem and

advise repair procedures. Often times, with the customer’s input

and with the machine diagnostics, problems can be determined

with “over-the-phone” consultation.

B. If the problem is beyond the scope of “over-the-phone”

consultation, and if the warranty status of the machine is valid,

Conair will contact the nearest authorized service contractor and

provide authorization to conduct an “on-site” inspection of the unit

in order to determine the course of repair. If the chiller is not

covered by the warranty, Conair will advise on the repair and

recommend available service contractors.

C. Conair manufactures a complete line of heat transfer equipment. It

is of the utmost importance that Conair have the correct model

number and serial number of the machine in question. This will

allow Conair to obtain the correct manufacturing records which

will help the service department to properly troubleshoot the

problem and obtain the proper replacement parts when they are

required. This information is stamped on the metal data tag that is

attached to the machine.

D. The Conair service department must be notified prior to any repair

or service of a warranty nature. Warranty claims will not be honored

without prior authorization.

5.2 PERIODIC PREVENTATIVE MAINTENANCE

A. Lubricate all motors. Note that some motors are supplied with

sealed bearings.

B. Tighten all wire terminals.

C. Clean and check motor starter and contactor contacts.

D. Check safety switch settings.

E. Clean condenser fins of dust and dirt.

F. Back flush evaporator.

G. Check glycol/water solution ratio for operating temperature.

H. Check system for leaks.

Page 33

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 33

I. Refrigerant sight glass: check for bubbles when compressor is

operating at 100%. Check the moisture indicator for a color other

than green.

J. Clean unit.

5.3 SPECIAL MAINTENANCE

A. Any service of the refrigeration system must be accomplished by a

certified refrigeration technician.

1. Vacuum check compressor.

2. Addition of compressor oil.

3. Addition of refrigerant.

4. Repair of a refrigerant leak.

5. Adjustment of super heat.

6. Changing of filter-drier or drier core.

7. Repair of a refrigeration solenoid.

8. Valve plate replacement on compressor. (Semi-hermetic

compressors only)

Page 34

Page: 34

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

5.4 SOLENOID VALVE SERVICE

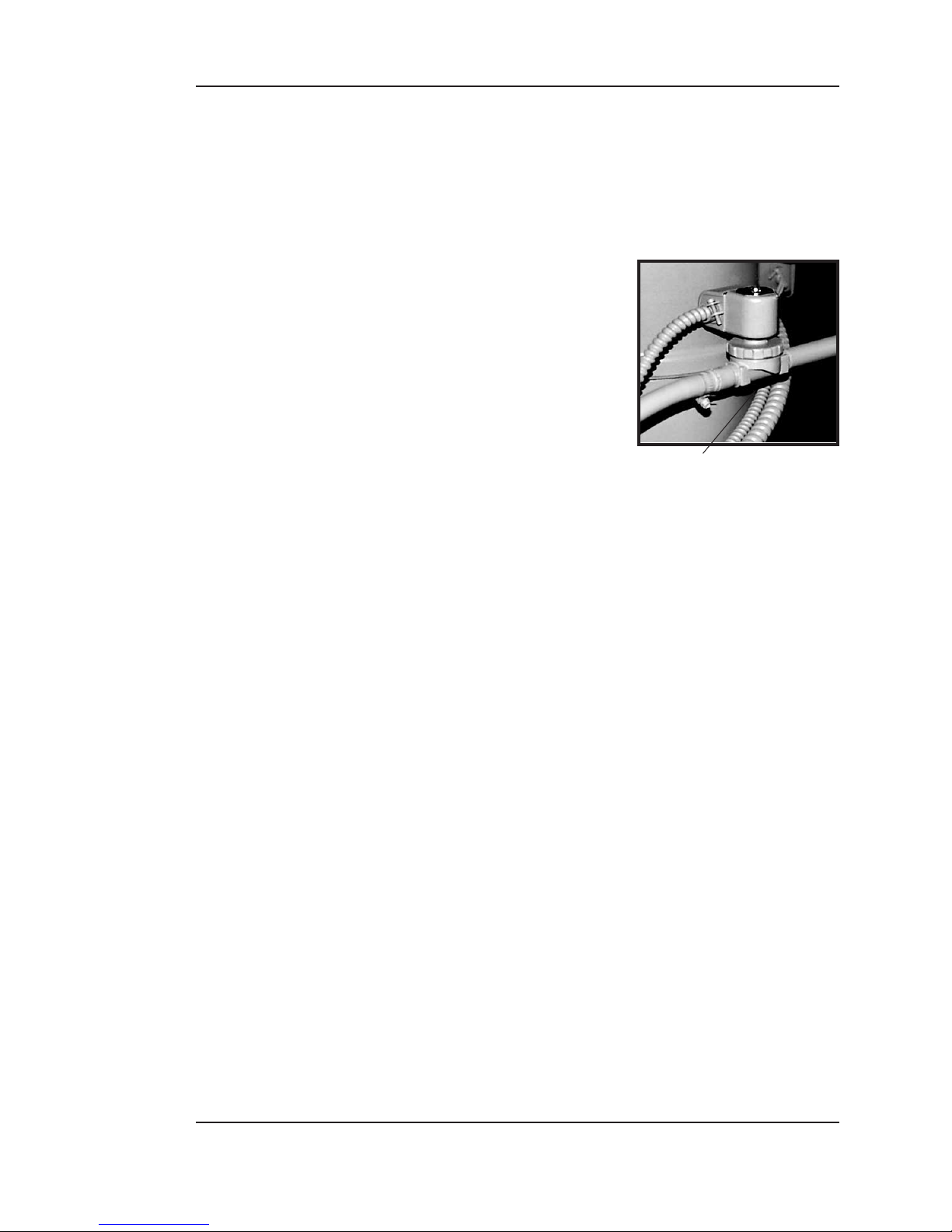

A. VLA units with the water make-up

system use a solenoid valve (figure

5.4A) to regulate the level in the

reservoir tank. The solenoid valve is

controlled by the float switch.

B. Generally, solenoid valves fail due

to poor water quality, low water

flow, or defective valve elements.

C. The operator should follow this

procedure to service the make-up

solenoid valve:

1. Disengage process operations according to the procedure

outlined in section 3.4. The operator must be certain

process fluid temperature is under 100°F and pressure is

relieved (pressure gauge reads “0”) and water system flow

is shut off and all pressure relieved.

2. Disengage main power supply. The operator must verify the

POWER light on the display is “off”.

3. Remove or open any access cover panel and set aside to

gain access to the solenoid valve.

4. The operator must be certain all water supply system

pressure is relieved.

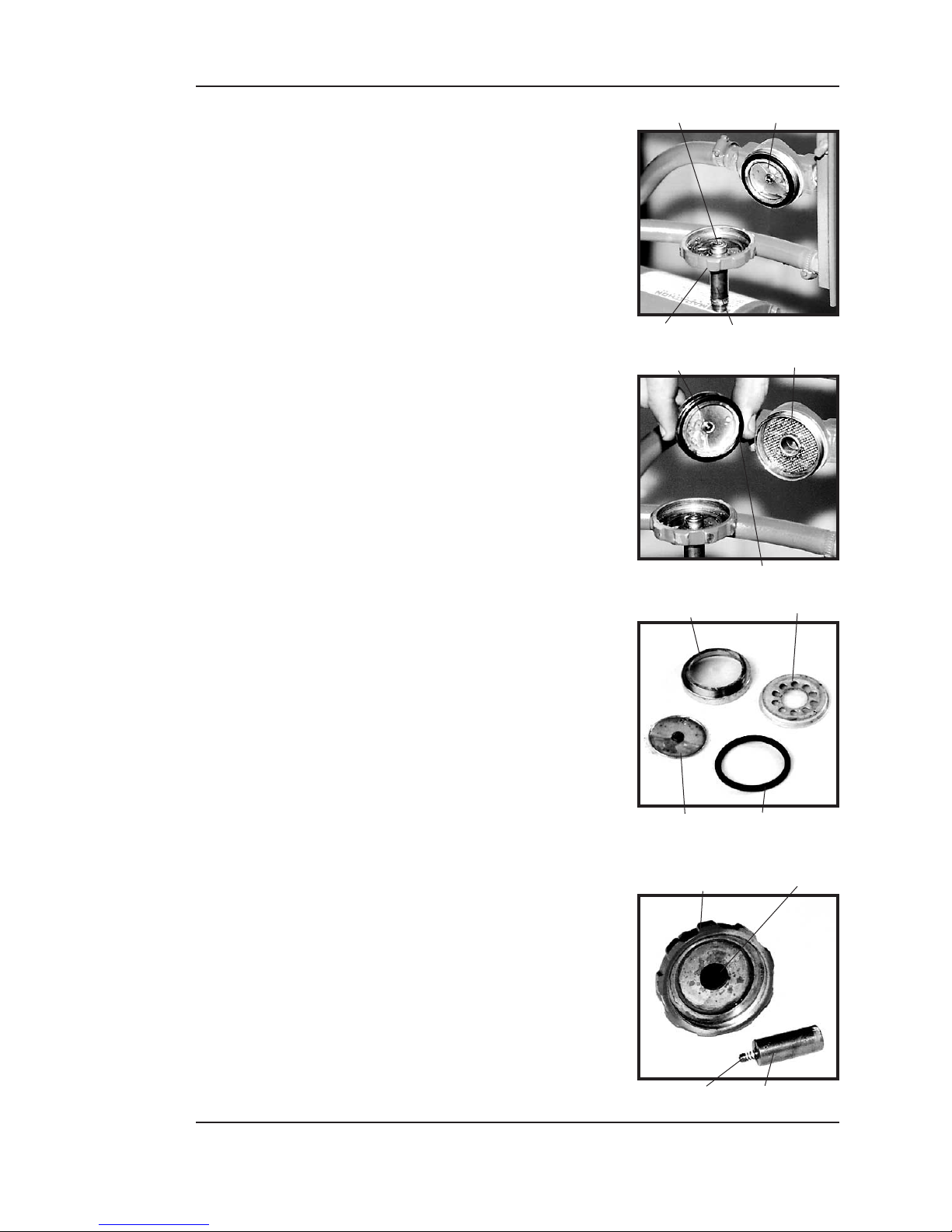

5. Identify the retaining screw (figure 5.4B) on the solenoid

valve coil. Remove the screw. Keeping all electrical

connections intact, lift the coil off of the enclosure tube and

set aside.

6. Use a pair of channel lock pliers or a pipe wrench to

separate the bonnet assembly from the valve body. The

plunger is “loose” inside the enclosing tube. Be certain it is

retained in the enclosure tube as the bonnet is removed

(figure 5.4C).

7. Identify the diaphragm

assembly. Gently remove

the assembly from the

valve body (figure 5.4D).

8. Identify the mesh screen.

Gently removed the mesh

Coil

Figure 5.4B

Retaining screw

Typical water make-up

solenoid valve

Figure 5.4A

Page 35

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 35

screen and clean or replace

as necessary.

9. Clean the valve body.

10. Reset the mesh screen into

the valve body.

11. If a new diaphragm

assembly was obtained,

continue with step 12. If

not, disassemble the

diaphragm assembly and

note component order

(figure 5.4E). Clean the

valve port, plate, collar and

O-ring. Once cleaned,

reassemble the diaphragm.

12. Set the reassembled

diaphragm assembly or the

new assembly back into the

valve body. The stem

should be facing out of the

valve body.

13. Inset the plunger with

spring first into the

enclosing tube of the top

bonnet (figure 5.4F).

Holding the plunger in the

enclosure tube, set the top

bonnet onto the valve

body and tighten.

14. Place the coil onto the top

bonnet and replace the

retaining screw.

15. Open the water supply to

circulate water to the

make-up system. Check the

solenoid valve for leakage.

Restart the unit as outlined

in section 3.

Figure 5.4F

Plunger

Spring

Top bonnet

Enclosure tube

Top bonnet

Figure 5.4C

Enclosure tube

Plunger

Diaphragm assembly

Figure 5.4D

O-Ring

Diaphragm assembly

Mesh screen

Figure 5.4E

O-Ring

Diaphragm and stem

Collar

Plate

Page 36

5.5 PUMP SEAL SERVICE

A. The VLA unit pump seal is a carbon/niresist shaft seal assembly

including a stationary member, rotating member and tension spring

(figure 5.5A).

B. The operator can

determine the pump

seal is leaking when

fluid is identified

leaking from the pump

case adapter. Generally,

a pump seal will leak

due to inadequate unit

pressure, excessive flow

and poor fluid quality.

C. The operator should

follow this procedure to

replace the pump seal:

1. Disengage process operations according to the procedure

outlined in section 3.4. The operator must be certain

process fluid temperature is under 100°F and water

make-up flow is shut off and all pressure relieved.

2. Disengage main power supply. The operator must verify the

POWER light on the display is “off”.

3. Access the pump motor by

opening or removing any

cover panels as necessary

(figure 5.5B).

4. Drain machine. Drain fluid

into a suitable container for

reuse or disposal according

to manufacturer’s

instructions (if a glycol

solution is used).

5. Locate and remove the

three motor wire leads

from the motor wiring

terminals. The operator

should “map” the wire

terminal locations to ensure

correct rewiring. The

power cord should be

removed from the motor

housing (figure 5.5C).

Page: 36

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

Stationary member

Rotating Member

Tension Spring

Figure 5.5A

Pump motor

Figure 5.5B

Pump motor power cord

Figure 5.5C

Page 37

6. Locate and remove the

pump casing bolts. These

bolts secure the motor and

motor adapter to the pump

casing (figure 5.5D).

7. Separate the motor and

motor adapter from the

pump casing to expose the

pump impeller (figure

5.5E). Remove the motor

and motor adapter from

the unit and place on a

workbench to continue the

procedure.

8. Locate and remove the

dust cap from motor end

to expose slotted motor

shaft. The motor shaft is

free to rotate, but must be

secured to remove the

impeller. To secure the

motor shaft, insert a flat

bladed screw driver in slot

to hold the shaft stationary

(Figure 5.5F).

9. Locate and remove the

impeller locking screw

(Figure 5.5G). Using a

socket and ratchet, the

impeller retaining screw

can be removed. Once the

retaining screw is removed,

the impeller can be

“unthreaded” from the

motor shaft to expose the

pump seal assembly.

10. Remove all seal parts

(Figure 5.5H). Note seal

component arrangement

to facilitate reassembly.

11. Clean motor shaft and

lubricate with a mild soap

solution.

12. Install new stationary seal

member in the pump

casing cavity (figure 5.5I).

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 37

Typical pump casing bolts

Figure 5.5D

Motor shaft

Figure 5.5F

Typical impeller

Figure 5.5G

Impeller

Figure 5.5E

Page 38

The operator must be

certain the stationary seal

member is fully squared

and seated in cavity.

13. Slide the rotating member

onto the lubricated pump

shaft (figure 5.5J). The

operator must be certain

not to damage or tear

rubber bellows assembly.

14. Place the spring onto the

rotating member.

15. Align the impeller, spring

and rotating member

before reinstalling the

impeller (figure 5.5K). The

operator must be certain

the spring and rotating

member are aligned before

the impeller is fully tighten

and the impeller retaining

screw is reinstalled.

16. Clean pump casing,

cavities, impeller and Oring before reassembly.

17. Mate the motor and motor

adapter to the pump

casing. Reinstall the pump

casing bolts.

18. Reconnect the motor

power cord and leads.

19. Restore all cover panels as

were removed.

E. When the pump seal replacement

procedure is complete, the

operator should check for leaks

before restarting the unit according

the section 3.

Page: 38

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

Stationary member

Figure 5.5I

Rotating member

Figure 5.5J

Seal members

Figure 5.5K

Seal components

Figure 5.5H

Page 39

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 39

5.6 CHECKING THE REFRIGERANT CHARGE

A. All standard Conair chillers are manufactured with thermostatic

expansion valves as the metering device to the evaporator.

B. All Conair chillers have a refrigerant sight glass with a moisture

indicator. To check the refrigerant charge under normal operating

conditions:

1. Remove the plastic cap covering the sight glass, if installed.

2. Start the chiller and allow system pressures and

temperatures to stabilize.

3. With the unit operating at 100% capacity (not in the “hot

gas bypass” mode) the sight glass should appear clear with

no foam or bubbles evident. If foam or bubbles are evident,

the chiller has suffered from a loss of refrigerant and should

be checked by a qualified refrigeration technician.

4. The “dot” in the middle of the sight glass is the moisture

indicator. It should appear green at all times. A white or

yellow color indicates moisture has invaded the

refrigeration system, which is detrimental to the life of the

compressor. The filter-drier should be replaced by a

qualified refrigeration technician.

Figure 5.6A

Typical refrigerant sight glass (cap removed)

Moisture

Indicator

Page 40

Page: 40

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

5.7 PROPER CLEANING PROCEDURE FOR BRAZED PLATE

EVAPORATORS

A. The brazed plate evaporator is

made of stamped stainless steel

plates, furnace brazed together

with copper based joints. The

complex geometry of the flow

passages promotes turbulent flow

which gives high efficiency and

reduces fouling by mineral

deposits. Large solids such as

plastic pellets or chunks of mineral

deposits will collect at the water

inlet port at the evaporator and

restrict flow through some of the

passages. If this possibility exists, Conair recommends filters or

strainers be added to the “from process” line. If the evaporator

becomes fouled there are a couple of methods for cleaning.

B. To begin, remove the piping to the “water in” port at the

evaporator. Remove any solids that have collected at this point.

Then backflush the evaporator to remove any solids that may be

trapped between the plates (see backflush procedure next page). If

there are mineral deposits adhered to the plates, the evaporator

must be backflushed with a mild acid solution (5% phosphoric or

5% oxalic acid is recommended.) After cleaning rinse with clear

water before returning to service. Continue with step C on next

page.

Typical evaporator installation

Figure 5.7A

RAZED PLATE HEAT EXCHANGER

(EVAPORATOR)

FREON OUT

FREON IN

ORIGINAL WATER IN PORT

BACKFLUSH WATER OUT PORT

(ROUTE WATER TO PROPER

SEWER OR DRAIN CONTAINER)

ORIGINAL WATER OUT PORT

BACKFLUSH WATER IN PORT

(SUPPLY BACKFLUSHING WATER

FLOW TO THIS PORT)

Page 41

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 41

C. Backflushing procedure:

1. Turn off all power to the machine. For chillers with a

reservoir tank, drain the tank to below the evaporator

outlet. For chillers without a reservoir tank, drain total unit.

2. Connect a water supply hose to the evaporator water

outlet. If acid cleaning, connect the discharge hose from

the acid pump to the evaporator outlet port.

3. Connect a hose to the evaporator water supply port and to

an appropriate containment vessel. If acid cleaning,

connect the evaporator water inlet port to an acid solution

reservoir tank. Dispose of all backflush fluid according to

local codes.

4. The cleaning fluid source should have at least 20 psi

available. If acid cleaning, follow the instructions supplied

with the acid solution carefully.

5. When the procedure is complete, reinstall all water lines to

original factory orientation. Restart the unit and check for

proper operation.

6. Note: this procedure is not normal maintenance.

Maintaining proper water quality and filtration will

minimize the need to backflush the evaporator.

Page 42

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

Page: 42

THIS PAGE INTENTIONALLY BLANK

Page 43

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 43

6.0 COMPONENTS

6.1 WATER SYSTEM

6.2 REFRIGERATION SYSTEM

Page 44

Page: 44

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

6.1 WATER SYSTEM

A. MOTOR/PUMP ASSEMBLY: the

motor/pump assembly circulates

chilled fluid to the process loop.

The pump assembly is built of total

stainless steel to maintain water

quality (figure 6.1A).

B. FREEZESTAT: the freezestat aids in

protecting the evaporator from

potential freezing. The freezestat is

factory adjusted to 40°F. The

freezestat must be field adjusted for

operating with setpoints below

48°F (figure 6.1B).

6.2 REFRIGERATION SYSTEM

A. COMPRESSOR: hermetic or semi-

hermetic compressors take low

pressure/low temperature

refrigerant gas and compress the

gas into high pressure/high

temperature gas (figure 6.2A).

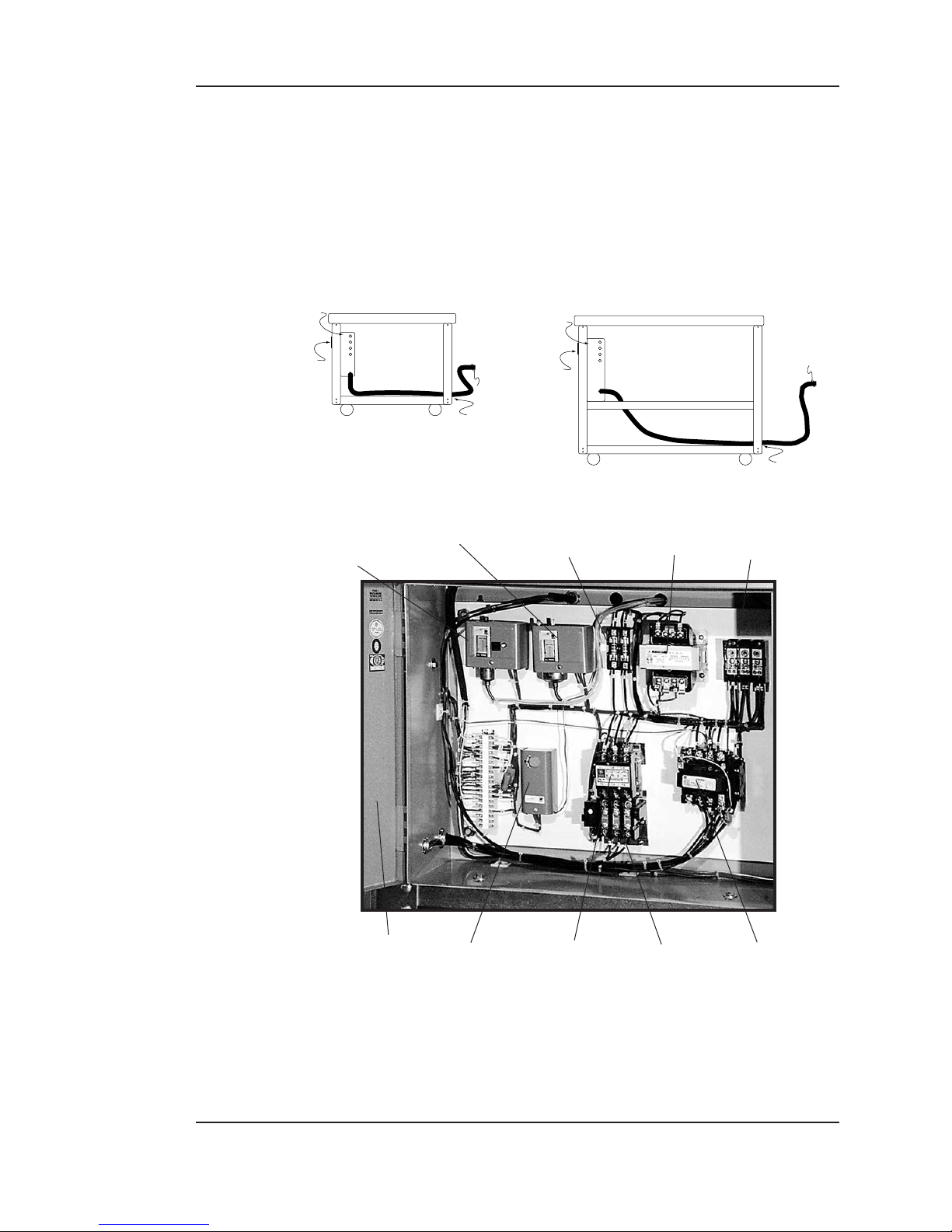

B1. WATER COOLED CONDENSER:

the water cooled condenser

removes BTU’s (heat) from the

compressed refrigerant gas. As the

heat is removed, the gas

“condenses” into a liquid state, still

under high pressure. Tube-in-shell

condensers are used on 15-30 ton

models. Tube-in-tube condensers

are used on 5-10 ton models.

Water regulator valves are used on

all models to control the refrigerant

head pressure by modulating the

condenser water flow (figure

6.2B1).

B2. AIR COOLED CONDENSER: the air

cooled condenser removes BTU’s

from the compressor refrigerant

gas. The action causes the gas to

“condense” into a liquid state still

under high pressure. Air flow across

the condenser is achieved via a

motor driven fan assembly or

centrifugal blower (figure 6.2B2).

Mechanical freezestat

Figure 6.1B

Hermetic compressor

Semi-hermetic compressor

Figure 6.2A

Pump

Figure 6.1A

Tube/shell

condenser

Regulator

valve

Tube/Tube condenser

Figure 6.2B1

Page 45

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 45

C. FILTER-DRIER: the filter-drier

removes contaminants and moisture

from the liquid refrigerant (figure

6.2C).

D. LIQUID LINE SOLENOID VALVE:

controlled by the instrument, this

valve closes when the compressor

cycles off to prevent refrigerant liquid

from migrating to the evaporator.

The valve opens when the

compressor cycles on (figure 6.2D).

E. REFRIGERANT SIGHT GLASS: the

refrigerant sight glass indicates

refrigerant charge and moisture

content. Refrigerant charge is

determined by a clear liquid flow.

Bubbles indicate low refrigerant.

Moisture content is indicated by the

color of the element. Element color is

normally green. If the color of the

element is chartreuse or yellow, the

system has been contaminated with

moisture. In such case, the filter-drier

must be replaced. The replacement

of the filter-drier must be completed

by a qualified refrigerant service

technician (figure 6.2E).

E. EXPANSION VALVE: the expansion

valve throttles flow of refrigerant

liquid into the evaporator and creates

a pressure drop in the refrigerant

system that allows the liquid

refrigerant to “boil off” inside the

evaporator (figure 6.2F).

F. EVAPORATOR: the evaporator is a

brazed plate heat exchanger where

the refrigerant liquid is allowed to

evaporate (boil off) to absorb heat

(BTU) from the process fluid. As the

heat is absorbed, the process fluid is

chilled (figure 6.2G).

G. HOT GAS BY-PASS SOLENOID: the

hot gas by-pass solenoid prevents

short cycling of the compressor by

reducing the capacity by 50% when

the process fluid temperature nears

the setpoint (figure 6.2H).

Typical filter-drier

Figure 6.2C

Typical liquid line

solenoid valve

Figure 6.2D

Typical refrigerant sight glass

Figure 6.2E

Fans

Blower

Figure 6.2B2

Page 46

H. HIGH/LOW PRESSURESTATS: the

high/low pressurestats protect the

refrigeration system from unsafe

operating levels. The high pressure

switch is factory set to open at 325

psi and protects the refrigeration

components and personnel from

potential damage of injury from

excessive high pressure. The high

pressure safety must not be altered

in the field for any reason. The low

pressure switch is factory set to

open at 58 psi and to close at 63

psi. The low pressure switch

protects the chillers from possible

damage due to low operating

pressure. The low pressure switch is

field adjustable for setpoints below

48°F (figure 6.2I).

I. Liquid receiver: located after the

condenser, this component receives

and stores liquid refrigerant leaving

the condenser.

J. Service valves: have been provided

throughout the system. Only a

qualified refrigeration service

technician shall operate these

valves.

K. Crankcase heater: insures that

freon and compressor crankcase oil

do not mix during the compressor’s

‘off ’ cycles. (Semi-hermetic only)

L. Oil pressure safety switch:

protects the compressor from

lubrication failure. (Semi-hermetic

only)

Typical evaporator

Figure 6.2G

Typical hot gas bypass valve

Figure 6.2H

High pressurestat

Low pressurestat

Figure 6.2I

Page: 46

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

Typical expansion valve

Figure 6.2F

Page 47

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 47

7.0 RELATED DRAWINGS

7.1 VLA-5/7.5/10 MECHANICAL SCHEMATIC

7.2 VLA-15/20/25/30 MECHANICAL SCHEMATIC

7.3 VLA-5A PHYSICAL

7.4 VLA-7.5/10 PHYSICAL

7.5 VLA-15/20/25/30 PHYSICAL

7.6 DUCT SCHEMATIC FOR AIR COOLED CHILLERS

7.7 VLA-5A/7.5/10 ELECTRICAL

7.8 VLA-15/20/25/30 ELECTRICAL

7.9 VLW-5/7.5/10 MECHANICAL SCHEMATIC

7.10 VLW-15/20/25/30 MECHANICAL SCHEMATIC

7.11 VLW-5/7.5/10 PHYSICAL

7.12 VLW-15/20/25/30/40 PHYSICAL

7.13 VLW-5/7.5/10 ELECTRICAL

7.14 VLW-15/20/25/30 ELECTRICAL

Page 48

Page: 48

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

7.1 VLA-5/7.5/10 MECHANICAL SCHEMATIC

FROM PROCESS

PORT CONNECTION

LEVEL SWITCH (optional)

SERVICE LID

(optional)

MAKE-UP PORT

CONNECTION

(optional)

MAKE-UP

SOLENOID VALVE

TO PROCESS

PORT CONNECTION

TO PROCESS

SENSOR PROBE

(5-ton model uses single fan)

AIR-COOLED CONDENSER w/FANS

LOW PRESSURE

SAFETY SWITCH

EVAPORATOR

RESERVOIR TANK

HOT GAS

BYPASS VALVE

RECEIVER

LIQUID LINE

COOLANT PUMP

EXPANSION VALVE

SIGHT GLASS

REFRIGERANT

LIQUID LINE

SOLENOID VALVE

FILTER-DRIER

COMPRESSOR

HIGH PRESSURE SAFETY SWITCH

(may be Scroll Hermetic or Recip)

Page 49

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 49

7.2 VLA-15/20/25/30 MECHANICAL SCHEMATIC

FROM PROCESS

PORT CONNECTION

LEVEL SWITCH (optional)

(optional)

MAKE-UP

SOLENOID VALVE

SERVICE LID

(optional)

MAKE-UP PORT

CONNECTION

TO PROCESS

PORT CONNECTION

TO PROCESS

SENSOR PROBE

LOW PRESSURE

AIR-COOLED CONDENSER w/blower

SAFETY SWITCH

EVAPORATOR

RESERVOIR TANK

HOT GAS

BYPASS VALVE

RECEIVER

LIQUID LINE

COOLANT PUMP

EXPANSION VALVE

SIGHT GLASS

REFRIGERANT

LIQUID LINE

SOLENOID VALVE

FILTER-DRIER

COMPRESSOR

HIGH PRESSURE SAFETY SWITCH

(may be Scroll Hermetic or Recip)

Page 50

Page: 50

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

7.3 VLA-5 PHYSICAL

3"

51"

PO

PUM

COMPRESSOR

HOT GAS BYPASS

WER

P

TEMPERATURE

TO PROCESS

SETPOINT

S

E

L

E

C

T

C

H

I

L

L

E

O

R

N

6"

34"

38"

Page 51

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 51

7.4 VLA-7.5/10 PHYSICAL

3"

51"

POWER

PUMP

COMPRESSOR

TEMPERATURE

HOT GAS BYPASS

TO PROCESS

SETPOINT

S

E

L

E

C

T

C

H

I

L

L

E

O

R

N

6"

54"

34"

Page 52

Page: 52

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

7.5 VLA-15/20/25/30 PHYSICAL

2"

94"

6"

P

O

W

P

U

M

C

O

M

H

O

T

58"

E

R

P

T

P

E

R

M

E

S

P

S

O

G

E

R

A

R

S

A

B

T

Y

P

U

A

R

S

S

E

T

O

P

R

O

C

E

S

S

S

E

T

P

O

I

N

S

E

T

L

E

C

T

C

H

IL

L

E

R

O

N

67 1/2"

Page 53

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 53

7.6 DUCT SCHEMATIC FOR AIR COOLED CHILLERS

1

2

3

6

NOTE: THIS DRAWING IS FOR

EXPLANATION PURPOSES ONLY,

NOT FOR CONSTRUCTION PURPOSES

4

5

7

8

9

10

Description

Item

Weather cap

1

Screen

2

Flashing to suit

3

Roof curb

4

Plant roof

12

11

13

5

Butterfly with counterbalance

6

Separate duct support from roof

7

Gate control for exhaust air flow

8

Manual chain control

9

Duct to plant heating system

10

Mating collar

11

Chiller air exhaust port

12

Air cooled chiller

13

Page 54

Page: 54

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

7.7 VLA-5/7.5/10 ELECTRICAL

This electrical drawing is presented for illustration purposes only.

For exact details, consult the electrical drawing supplied with your machine.

110VAC SEC.

TRANSFORMER

13

12

HEATER

CRANKCASE

11

F1

FAN MOTOR #2

REQUIRED ON 7.5 & 10 TON

F2

FAN MOTOR

M2

COMPRESSOR

19 19

19

GROUND

FU

3

3

1

3

12

1

POWER ENTRY

L4

L3

L2

L1

1

10

M2

FU 1 FU 2

97

9

7

97

9

7

3

2

M2

9

8

7

ANTI-DRAIN BACK SOLENOID

(OPTIONAL)

MOTOR COIL

50

Q

M1

22 50

22 22

22

1 MOL

21 22

21

OPTIONAL CUST. SUPPLIED CONTACTS

FOR REMOTE START/STOP.

HOT GAS BY-PASS SOLENOID

LIQUID LINE SOLENOID

50

5025

Q

262626

22

HIGH PRESSURESTAT

COMPRESSOR COIL

50

M2

26

FREEZESTAT

INSTRUMENT GROUND

50

Q

3

2

1

M1

1 MOL

6

M1

5

4

PROCESS PUMP

20

19

RED

BRN

21

LOW PRESSURESTAT

JUMPER

RED/YEL

GRN

22

22

RED/BRN

VL Chiller Control

RED/WHT

To Process

Setpoint

Temperature

Power

Pump

23

BLU

Compressor

Hot Gas Bypass

24 25

ORG

MOLEX

On

50

WHT

Off

PROBE

TO PROCESS

Page 55

UGH021/0301 VL Series Portable Chillers, 2 to 40 Tons

Page: 55

7.8 VLA-15/20/25/30 ELECTRICAL

This electrical drawing is presented for illustration purposes only.

For exact details, consult the electrical drawing supplied with your machine.

POWER ENTRY

L1L2L3

L4

110VAC SEC.

GROUND

GROUND

15

13

14

M3

FU 1 FU 2

M4

4 MOL

3

2

1

M3

TRANSFORMER

3

1

15

HEATER

CRANKCASE

14

12

M4

11

BLOWER

10

9

M3

8

7

COMPRESSOR

WATER MAKE-UP SOLENOID (OPTIONAL)

5020

3

Q

FU

19

20

TANK FLOAT

19 20

50

23 2322

2 MOL

1 MOL

21

MOTOR COIL

M1

OPTIONAL

(OPTIONAL)

ANTI DRAIN-BACK SOLENOID

Q

23 50

23

50

INSTRUMENT GROUND

HOT GAS BY-PASS SOLENOID

50

Q

27

LIQUID LINE SOLENOID

50

28

28 50

28

BLOWER COIL

COMPRESSOR COIL

50

M4

M3

28

OIL PRESSURE

SAFETY SWITCH

32A

COMPRESSOR

CONTROL MODULE

32

4 MOL

30

50

Q

50

50

19

HIGH PRESSURESTAT

6A

M2

5A

(OPTIONAL)

4A

2 MOL

3

2

1

M1

1 MOL

6

M1

5

19 19

4

PROCESS PUMP EVAPORATOR PUMP

RED

20

RED/BLU

FOR REMOTE START/STOP.

OPTIONAL CUST. SUPPLIED CONTACTS

212423

JUMPER

RED/YEL

RED/BRN

GRN

RED/WHT

To Process

Setpoint

MOLEX

On

50

WHT

27

28

RED/ORG

BLU

Off

Temperature

Power

Pump

Compressor

Hot Gas Bypass

29

29

29

FREEZESTAT

19

31

ORG

RED/BLK 29

TO PROCESS

35

LOW PRESSURESTAT

19

35

BRN

PROBE

VL Chiller Control

Page 56

Page: 56

VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

7.9 VLW-5/7.5/10 TON MECHANICAL SCHEMATIC

CONNECTION

MAKE-UP PORT