Page 1

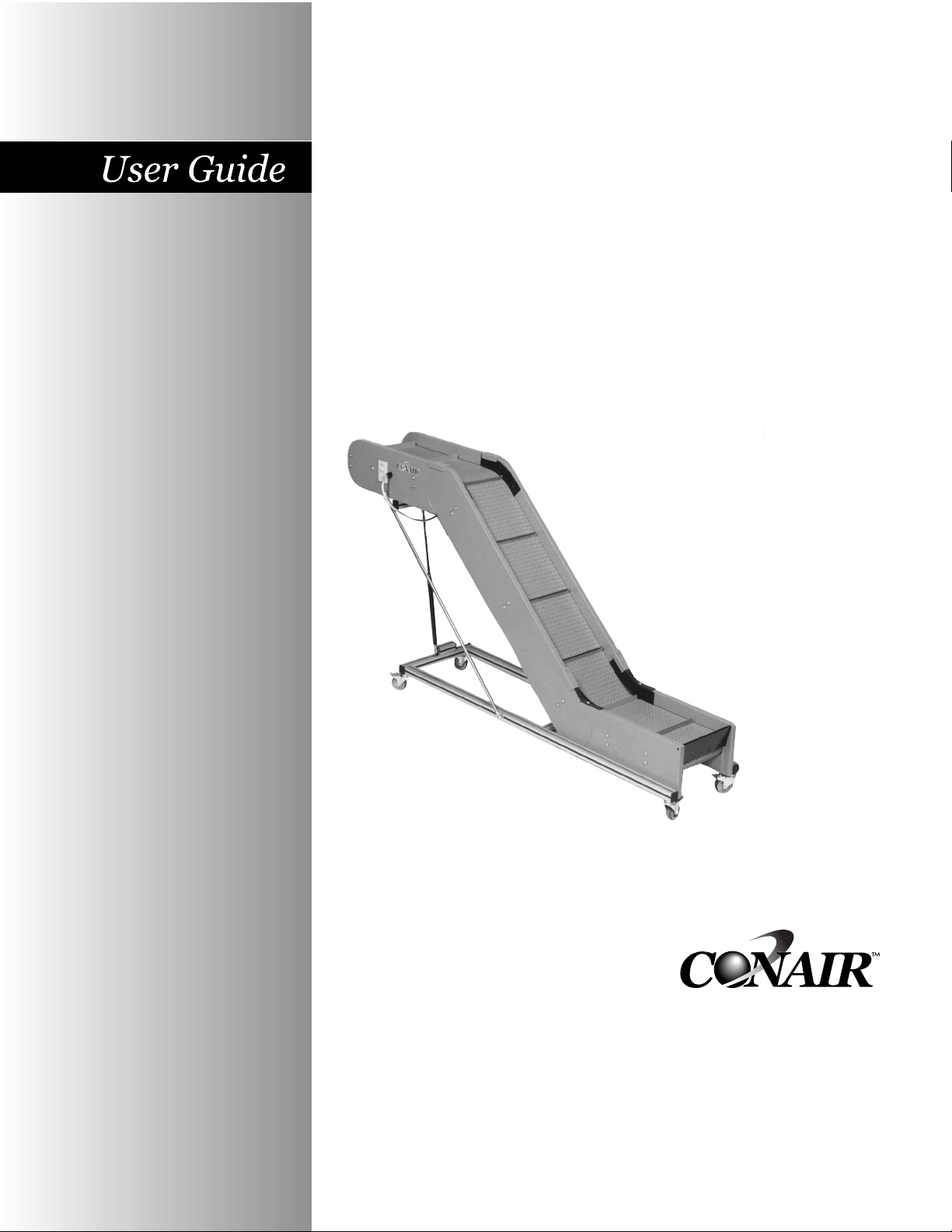

Belt Conveyor

Moducon series

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412)-312-6227

UGR004/1200

Installation

Operation

Maintenance

Troubleshooting

Page 2

It is important to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Keep this User Guide and all manuals, engineering prints and

parts lists together for documentation of your equipment.

Date:

Document Number: UGR004/1200

Serial number(s):

Model number(s):

Power Specifications:

Amps

Volts

Phase

Cycle

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Record your equipment’s

model and serial number(s) and the date you

received it in the spaces

provided.

Copyright 2000

All rights reserved

THE CONAIR GROUP, INC.

Page 3

UGR004/1200 Moducon Belt Conveyor

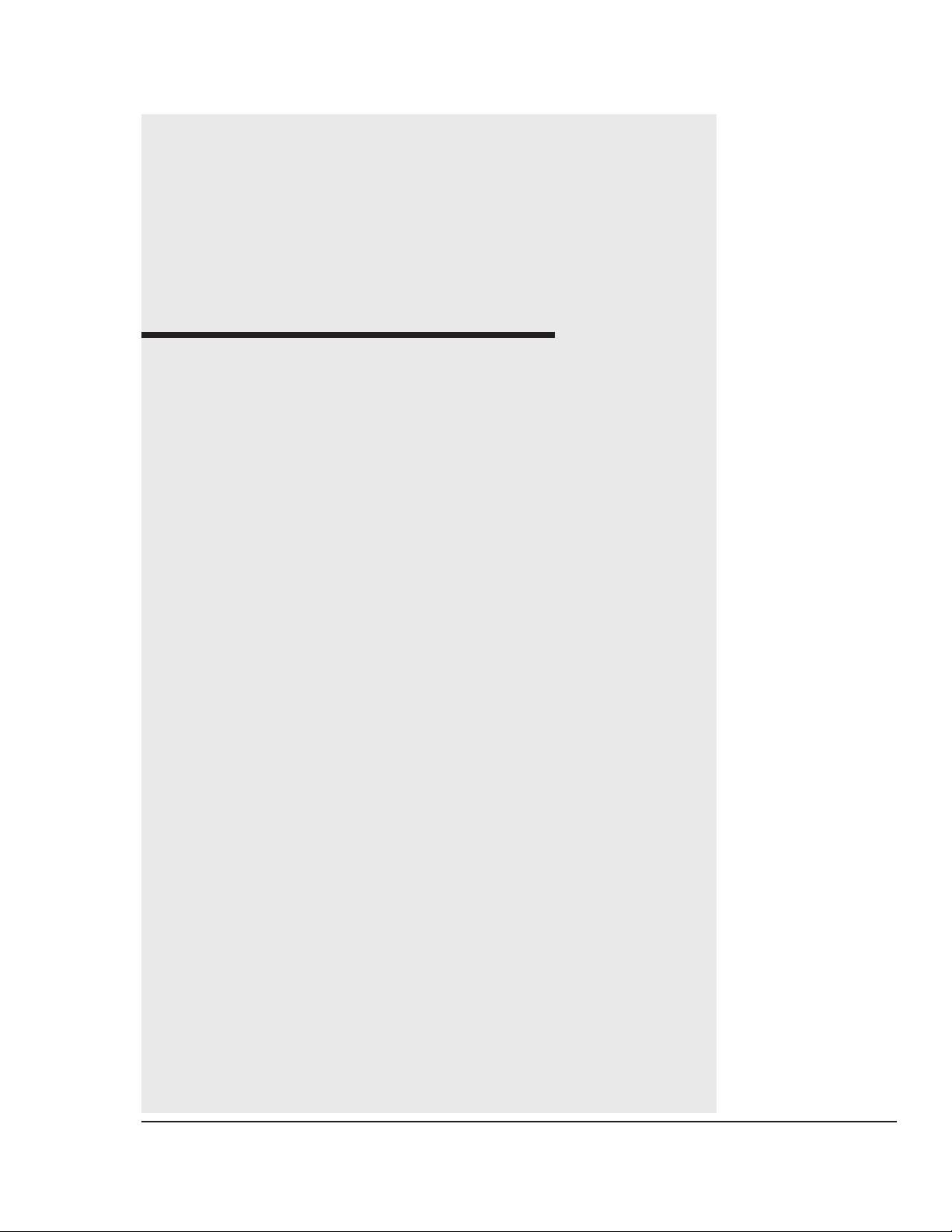

INTRODUCTION . . . . . . . . . . . . . . . . . . .1-1

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2

How the Guide is Organized . . . . . . . . . . . . . . . . . . . . . . .1-2

Your Responsibility as a User . . . . . . . . . . . . . . . . . . . . . .1-2

ATTENTION: Read this so no one gets hurt . . . . . . . . . . .1-3

DESCRIPTION . . . . . . . . . . . . . . . . . . . .2-1

What is the Belt Conveyor? . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Belt Conveyor Features . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

INSTALLATION . . . . . . . . . . . . . . . . . . . .3-1

Unpacking the Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Positioning the Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Setting the Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Connecting the Main Power . . . . . . . . . . . . . . . . . . . . . . . .3-5

Adjusting the Conveyor Speed . . . . . . . . . . . . . . . . . . . . . .3-6

O

PERATION . . . . . . . . . . . . . . . . . . . . . .4-1

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Starting the Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Stopping the Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

M

AINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Preventive Maintenance Schedule . . . . . . . . . . . . . . . . . . .5-3

Checking Electrical Connections . . . . . . . . . . . . . . . . . . . .5-4

TROUBLESHOOTING

. . . . . . . . . . . . . . . .6-1

Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

A Few Words of Caution . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Identifying the Cause of a Problem . . . . . . . . . . . . . . . . . .6-3

The Conveyor Does Not Move . . . . . . . . . . . . . . . . . . . . . .6-4

Movement is Wrong . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

APPENDIX

Appendix A: Customer Service . . . . . . . . . . . . . . . . . . . . .A-1

Appendix A: Guarantee/Warranty . . . . . . . . . . . . . . . . . . .A-2

Appendix B: AXU Series Control . . . . . . . . . . . . . . . . . . .B-1

PARTS/DIAGRAMS

i

TABLE OF

CONTENTS

Page 4

Page 5

1-1

UGR004/1200 Moducon Belt Conveyor

●●

Purpose of the User Guide . . . .1-2

●●

How the User Guide

is organized . . . . . . . . . . . . . . .1-2

●●

Your Responsibilities

as a User . . . . . . . . . . . . . . . .1-2

●●

ATTENTION: Read this so

no one gets hurt . . . . . . . . . . .1-3

INTRODUCTION

Page 6

Moducon Belt Conveyor UGR004/1200

1-2 INTRODUCTION

This User Guide describes the Conair Moducon Series Belt

Conveyors and explains step-by-step how to install, operate,

maintain and repair this equipment.

Before installing this product, please take a few moments to

read the User Guide and review the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This

review won’t take long, and it could save you valuable installation and operating time later.

Symbols have been used to help organize the User Guide and

call your attention to important information regarding safe

installation and operation.

Symbols within triangles warn of conditions that could

be hazardous to users or could damage equipment.

Read and take precautions before proceeding.

Numbers within shaded squares indicate tasks or steps

to be performed by the user.

A diamond indicates the equipment’s response to an

action performed by the user.

An open box marks items in a checklist.

A shaded circle marks items in a list.

You must be familiar with all safety procedures concerning

installation, operation and maintenance of this equipment.

Responsible safety procedures include:

● Thorough review of this User Guide, paying particular

attention to hazard warnings, appendices and related diagrams.

● Thorough review of the equipment itself, with careful

attention to voltage sources, intended use and warning

labels.

● Thorough review of instruction manuals for associated

equipment.

● Step-by-step adherence to instructions outlined in this

User Guide.

PURPOSE OF

THE USER

GUIDE

HOW THE USER

GUIDE IS

O

RGANIZED

1

◆

❒

●

YOUR

RESPONSIBILITY

A

SAUSER

Page 7

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should only be installed,

adjusted, and serviced by qualified technical

personnel who are familiar with the construction, operation, and potential hazards of this

type of machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your

region. Always maintain a safe ground. Do not

operate the equipment at power levels other

than what is specified on the machine serial

plate.

INTRODUCTION 1-3

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by following the procedures outlined below and elsewhere in the

User Guide.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

UGR004/1200 Moducon Belt Conveyor

WARNING: Disconnect power

sources to prevent injury from

unexpected energization or startup.

This product has a moving belt. To prevent

possible injury from unexpected startup, always

disconnect and lockout the main power source

before performing maintenance or troubleshooting procedures on this product.

WARNING: Electrical Shock Hazard

This device must be properly grounded.

Improper grounding can result in severe

personal injury and erratic machine operation.

Do not operate the equipment at power levels

other than what is specified on the machine

serial plate.

Page 8

Page 9

2-1

UGR004/1200 Moducon Belt Conveyor

●●

What is the belt conveyor? . . . .2-2

●●

Typical applications . . . . . . . . . .2-2

●●

Conveyor features . . . . . . . . . . .2-3

●●

Specifications . . . . . . . . . . . . . .2-4

●●

Conveyor options . . . . . . . . . . . .2-5

DESCRIPTION

Page 10

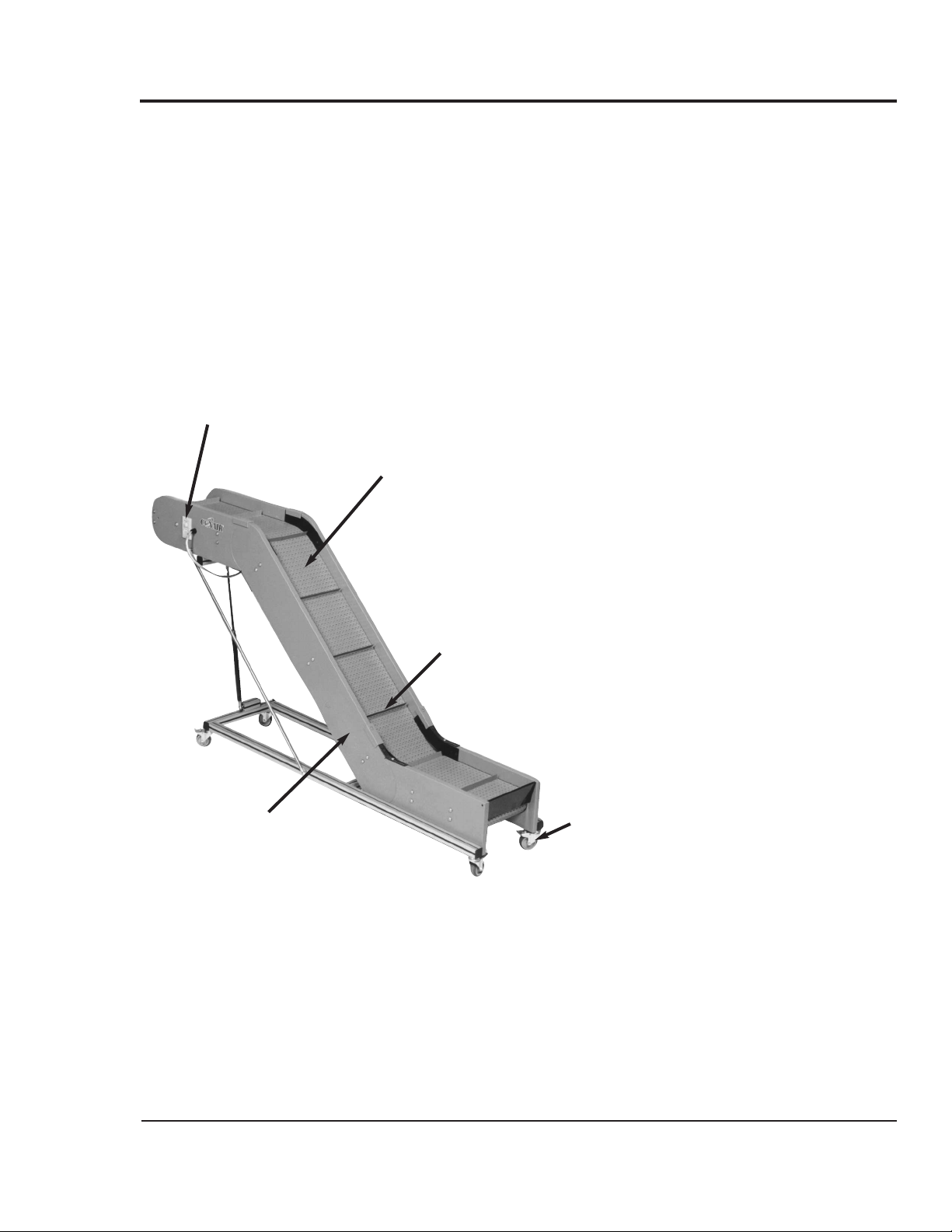

The Moducon Belt Conveyor is a lightweight, mobile conveyor that can be rolled into place and used to move parts or

materials to or from your process.

Because of its modular construction, the conveyor can be built

in virtually any shape, length and width to fit your

application.

Standard belt design is durable modular link polypropylene.

The patented design compensates for belt stretch that causes

slack, a common problem in other conveyor designs.

Permanent belt tracking ensures no wear on belt edges. The

belt system is easy to modify or repair by simply replacing

individual links or flights in the belt.

The Conair Belt Conveyor Moducon series is simple to operate. Just move it into position, adjust the height and plug it in.

The variable speed control lets you set the belt speed to the

desired rate. The optional flights move parts along the inclined

belt.

Moducon Belt Conveyors are ideal for:

● Conveying parts removed from a mold by a robot or

sprue picker.

● Carrying scrap or sprues to a granulator for recovery

● Conveying parts from the processing machine to an

assembly area.

As the application changes, the conveying length can be easily

modified by adding or subtracting side panels, belt links and

belt flights.

WHAT IS THE

BELT CONVEYOR?

Moducon Belt Conveyor UGR004/1200

2-2 DESCRIPTION

TYPICAL

APPLICATIONS

Page 11

UGR004/1200 Moducon Belt Conveyor

DESCRIPTION 2-3

BELT

CONVEYOR

FEATURES

Variable speed control

Allows you to operate at

variable speeds or indexing

to time the belt conveyor

with other auxiliary equipment.

Side walls

Low friction, replaceable

walls are available with optional

extensions that can be fitted to

either side of the conveyor.

Belt

Choose from the standard modular link

design or optional open or side-flexing

designs. The belts are available in:

● Polypropylene (standard)

● Acetal or polyamide (optional)

● Lengths from 3 to 15 feet in 1-foot

increments

● widths from 3 to 36 inches in 3-inch

increments

Steel casters

For easy mobility

(optional).

Flights

Set at regular intervals

move parts along the incline

at 1-, 2- and 3-inch intervals.

Modular construction allows the Moducon series conveyors to

be configured for almost any application. Conveyor types are:

● Flat

● Fixed angle

(30°, 45

°, and 60°)

● Adjustable angle

(0° to 45°), shown below

● Stepped

● 90° radius bend

Page 12

Moducon Belt Conveyor UGR004/1200

2-4 DESCRIPTION

SPECIFICATIONS

ADJUSTABLE ANGLE CONVEYOR

FLAT CONVEYOR

FIXED ANGLE CONVEYOR

STEPPED CONVEYOR

Conveyor length

Floor to belt height

Angle is

adjustable

from

5

° to 45°

Incline length 60 in.

{1500 mm} maximum

Horizontal length

Plastic side panel

Aluminum support frame

Plastic belt

Overall

width

Belt

width

Belt length

Height

above

belt

Height

below

belt

Support frame length

Plastic side panel

Aluminum support frame

Plastic belt

Overall

width

Belt

width

Conveyor length

Floor

to belt

height

Support frame length

Height

above

belt

Height

below

belt

Conveyor length

Floor

to belt

height

Incline length

Horizontal length

Plastic side panel

Aluminum support frame

Plastic belt

Overall

width

Belt

width

Height

above

belt

Height

below

belt

Support frame length

Conveyor length

Floor

to belt

height

Discharge

length

Incline

length

Horizontal

length

Plastic side panel

Aluminum support frame

Plastic belt

Overall

width

Belt

width

Height

above

belt

Height

below

belt

Support frame length

BELT CHARACTERISTICS Temperature Range Strength Hardness Wear Resistance Impact Resistance

BELT MATERIAL

Polypropylene (Standard) 34° - 218° F relatively low relatively low average low below 45° F

Acetal 40° -190° F very good very good average very good

Polyamide (Nylon) - 40° to 284° F excellent relatively high excellent low below -40° F

CONVEYOR TYPE FLAT STEPPED FIXED ANGLE ADJUSTABLE ANGLE

Performance characteristics

Inclines available — Fixed 30°, 45° or 60° Fixed 30°, 45° or 60° Adjustable 5° to 45°

Construction Aluminum frame; plastic sidewalls; plastic belt connector pins, standard; Stainless steel pins, optional

Belt materials Polypropylene, standard; Acetal or Polyamide (Nylon), optional

Belt type, 1-inch pitch Modular link designs, standard; Open or Side flexing designs, optional

Dimensions

Side wall height 2.4 in. {60 mm} above the belt; 4 in. {102 mm} or 8 inch {203 mm} with optional extensions

Belt width Specify desired width from 3 inches {76 mm} to 36 inches {915 mm} in 3-inch {76 mm} increments

Belt length Specify desired length from 3 feet {0.92 M} to 15 feet {5 M} in 12-inch {305 mm} increments

Floor to belt height Specify desired distance from floor to belt surface

Conveyor length Specify horizontal, incline and discharge lengths where applicable

Page 13

UGR004/1200 Moducon Belt Conveyor

DESCRIPTION 2-5

CONVEYOR

OPTIONS

Available options include:

● Belt types

Open belt - This belt has a 1-inch pitch

with an open design that allows faster

parts cooling. You can increase the cooling rate with optional fans mounted

beneath the belt. Belt widths start at 3

inches (76 mm) and increase in 3-inch increments to 36

inches (914 mm). All belt designs can be fitted with 1-, 2or 3-inch flights. The open belt is available in polypropylene, polyamide (nylon) and acetal. Choose color: blue,

gray, red, black or white.

Side flexing belt - this 1-inch pitch

side flexing belt has a turning inside

radius of 2.3 times the belt width. This

belt can be fitted with flights and rubber gripper sections. The side flexing belt material is

available in polypropylene, polyamide (nylon) and acetal.

Choose color: blue, gray, red, black or white.

●

Flights

Flights set at regular intervals in the belt

help hold the part in place on an incline or

decline of the conveyor. Optional flights

are available in heights of 1, 2 or 3 inches.

The application determines the distance between flights.

●

Side flexing units

Optional side flexing modules with a

90

°

bend can be added to flat or inclined

conveyors.

● Gripper sections

Optional grippers help hold the part in

place as it moves along the conveyor. The

rubber grip face is available on the side

flexing belt.

●

Bed plates

When conveying heavy products — weighing 11 lb

(5 kg) or more — bed plates can be added to provide

more support.

●

Stainless steel belt connector pins

When conveying heavy products, the optional stainless

steel connector pins provide better support than standard

plastic pins. Choose when the conveyor may be exposed

to moisture or water.

Page 14

Page 15

3-1

UGR004/1200 Moducon Belt Conveyor

●●

Unpacking the boxes . . . . . . . . .3-2

●●

Cautions and warnings . . . . . . .3-2

●●

Preparing for Installation . . . . . .3-3

●●

Positioning the Conveyor . . . . .3-4

●●

Setting the Height . . . . . . . . . . .3-4

●●

Connecting the Conveyor . . . . .3-5

●●

Adjusting the Conveyor . . . . . . .3-6

INSTALLATION

Page 16

The Moducon Belt Conveyor is shipped already assembled.

Carefully unpack the conveyor and its

components.

Remove all packing material, protective paper,

tape, and plastic. Compare contents to the shipping papers

to ensure that you have all the parts.

Carefully inspect all components to make sure

no damage occurred during shipping. If any damage is

found, notify the shipping agent immediately. Check all

wire terminal connections, bolts, and any other electrical

connections, which may have come loose during shipping.

Record serial numbers and specifications

in the blanks provided on the back of the User Guide's

title page. This information will be helpful if you ever

need service or parts.

Proceed to

P

REPARING FORINSTALLATION

.

UNPACKING

THE

BOXES

Moducon Belt Conveyor UGR004/1200

3-2 INSTALLATION

1

2

3

4

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should only be installed,

adjusted, and serviced by qualified technical

personnel who are familiar with the construction, operation, and potential hazards of this

type of machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your

region. Always maintain a safe ground. Do not

operate the equipment at power levels other

than what is specified on the machine serial

tag and data plate.

Page 17

UGR004/1200 Moducon Belt Conveyor

INSTALLATION 3-3

PREPARING FOR

INSTALLATION

Plan the location. Make sure the area where the belt conveyor

is installed has the following:

● A grounded power source. The belt conveyor

requires single phase, 100-115V, 50/60 Hz. All wiring

should be completed by qualified electrical technicians

and should comply with your region’s electrical codes.

● Clearance for safe operation and maintenance.

Make sure there is enough clearance around the conveyor for safe operation, maintenance and servicing.

We recommend maintaining at least 24 inches

(510mm) around all sides of the conveyor.

Perform the installation in the following order:

❒ Move the conveyor into position and adjust the level-

ing devices on the legs (or lock the optional casters).

❒ Adjust the height of the legs so that the conveyor belt

is at the proper height for your needs.

❒ Connect the conveyor to the power source.

❒ Adjust the belt speed.

24 inches

(610 mm)

24 inches

(610 mm)

24 inches

(610 mm)

24 inches

(610 mm)

Page 18

Moducon Belt Conveyor UGR004/1200

3-4 INSTALLATION

S

ETTING THE

H

EIGHT

POSITIONING

THE

CONVEYOR

Place the conveyor where it is needed, then verify that the

conveyor is level. If the conveyor is not level, adjust the

leveling devices on the legs. If your conveyor has the optional

casters, lock the casters in position.

Measure from the floor to the top of the conveyor belt. Adjust

the height of the belt by loosening the bolts on the legs and

sliding the conveyor up or down. Be sure to support the

conveyor while adjusting the bolts. Do not move the height

above the height of the leg frame.

Leg frame

Bolts

Belt

Leg frame

Side wall

Leg frame

Height adjustment

bolt above the belt

Belt

Leveling device

Height adjustment,

bolt below the belt

Page 19

UGR004/1200 Moducon Belt Conveyor

INSTALLATION 3-5

CONNECTING

MAIN POWER

WARNING: Disconnect power

sources to prevent injury from

unexpected energization or startup.

This product has a moving belt. To prevent

possible injury from unexpected startup, always

disconnect and lockout the main power source

before performing maintenance or troubleshooting procedures on this product.

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should only be installed,

adjusted, and serviced by qualified technical

personnel who are familiar with the construction, operation, and potential hazards of this

type of machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your

region. Always maintain a safe ground. Do not

operate the equipment at power levels other

than what is specified on the machine serial

tag and data plate.

Verify that the control button is set to Standby.

Plug the conveyor belt power cord into the

main power source supplying 100-115C/1 phase/50-60Hz.

1

2

Control button

Page 20

Moducon Belt Conveyor UGR004/1200

3-6 INSTALLATION

If the conveyor is not working properly at any time, slide the

control button to the Standby position immediately and unplug

the conveyor from the main power source. Refer to the

T

ROUBLESHOOTING

section of this User Guide.

If you do not encounter any problems during testing, proceed

to the

O

PERATION

section.

ADJUSTING THE

CONVEYOR

To adjust the speed of the conveyor belt:

Turn the speed control dial to Low.

If the speed is not set on Low, turn the dial counterclockwise as far as possible to the Low position. The belt

should not be moving.

Slide the control button to the Run position.

The conveyor belt begins to move.

Adjust the speed of the belt by turning the dial

clockwise until the belt is moving at the speed you want.

2

3

1

Dial

Turn clockwise to increase

belt speed. Turn counterclockwise to slow belt speed.

Control button

Page 21

4-1

UGR004/1200 Moducon Belt Conveyor

●●

Control features . . . . . . . . . . . . .4-2

●●

Before starting . . . . . . . . . . . . . .4-2

●●

Starting the belt conveyor . . . . .4-3

●●

Stopping the belt conveyor . . . .4-3

●●

Emergency stopping . . . . . . . . .4-3

OPERATION

Page 22

The belt conveyor control allows you to start, stop and control

the speed of the belt. Lights indicate when power is being

supplied to the unit and when an alarm condition exists.

CONTROL

FEATURES

Moducon Belt Conveyor UGR004/1200

4-2 OPERATION

S

TARTING THE

CONVEYOR

Make sure the conveyor is level and locked.

Adjust leveling feet as needed. Lock the optional casters.

Inspect the belt and mounting hardware.

Tighten any loose fittings or hardware. Replace any belt

links or flights that are worn, cracked or fractured.

Make sure the control button

in the Standby position.

Turn the speed control dial to Low.

Apply power to the conveyor.

Plug the power cord into the power source.

Slide the control button to the

Run position.

Adjust the belt speed as needed.

Turn the speed control dial clockwise to increase speed.

Turn the dial counterclockwise to decrease speed.

Indicator lights

display power on and

alarm conditions.

Dial

Turn clockwise to increase

belt speed. Turn counterclockwise to slow belt speed.

Control button

Slide left to Run position to

start belt movement.

Slide right to Standby to stop

the belt.

NOTE: The belt does not

move, but power to the the

conveyor is still on when the

unit is in Standby.

2

3

1

5

6

4

7

Page 23

UGR004/1200 Moducon Belt Conveyor

OPERATION 4-3

STOPPING THE

CONVEYOR

To stop the conveyor during operation:

Slide the control button to

the Standby position.

IMPORTANT: The Standby position is not a Power

OFF switch. When you want to stop the conveyor

motor for a long time, disconnect the conveyor from

the main power source.

To stop the conveyor for maintenance or repair:

Slide the control button to

the Standby position.

Disconnect the unit from the power source.

Remove the power plug from the electrical outlet. Follow

the lockout/tagout procedures developed in your facility to

ensure that power cannot be restored to the unit until the

maintenance or repair has been completed.

NOTE: Alarm conditions may stop the conveyor.

The conveyor will stop automatically under the following

alarm conditions:

● The load on the belt exceeds the rated torque

applied to the motor for more than 5 seconds.

The LED indicator light flashes and the motor stops.

● The motor cable or connector is disconnected.

The LED indicator light turns on and the motor stops.

● The motor speed exceeds 2800 rpm.

The LED indicator light turns on and the motor stops.

● Voltage applied to the control is 30% or more

below the the voltage setting.

The LED indicator light turns on and the motor stops.

2

1

1

Page 24

Page 25

5-1

UGR004/1200 Moducon Belt Conveyor

●●

Preventive Maintenance

Schedule . . . . . . . . . . . . . . . . .5-3

●●

Checking Electrical

Connections . . . . . . . . . . . . . .5-4

MAINTENANCE

Page 26

The Belt Conveyor Moducon series models need regular,

scheduled maintenance for peak performance.

Use the maintenance schedule on the following page as a

guide. You may need to shorten the time of the maintenance

schedule, depending on how often you use the conveyor.

Follow all safety procedures when working on the equipment.

PREVENTIVE

MAINTENANCE

SCHEDULE

Moducon Belt Conveyor UGR004/1200

5-2 MAINTENANCE

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should be installed, adjusted,

and serviced only by qualified technical personnel who are familiar with the construction,

operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed and maintained by qualified electrical

technicians in accordance with electrical codes

in your region.

WARNING: Disconnect power

sources to prevent injury from

unexpected energization or startup.

This product has a moving belt. To prevent

possible injury from unexpected startup, always

disconnect and lockout the main power source

before performing maintenance or troubleshooting procedures on this product.

WARNING: Electrical Shock Hazard

This device must be properly grounded.

Improper grounding can result in severe

personal injury and erratic machine operation.

Do not operate the equipment at power levels

other than what is specified on the machine

serial plate.

Page 27

UGR004/1200 Moducon Belt Conveyor

MAINTENANCE 5-3

PREVENTIVE

MAINTENANCE

SCHEDULE

To maintain the best performance, follow this maintenance

schedule.

●●

Daily, or as needed

❒❒

Inspect leveling feet or casters.

Verify that conveyor is level. Adjust leveling feet as

needed. If the conveyor has optional casters, verify that

they are properly locked in position before operation.

●●

Monthly, or as needed

❒❒

Inspect the conveyor belt.

Check the belt links, pins and flights for wear, cracks

or fractures. Replace sections as needed.

❒❒

Inspect fittings and mounting hardware.

Make sure all fittings, screws, and component mounting hardware are tight. Tighten as needed.

❒❒

Inspect electrical connections.

Make sure all electrical terminals are tight. Adjust as

needed. See

C

HECKINGELECTRICAL

C

ONNECTIONS

, in

this section.

❒❒

Check all electrical cables.

Inspect all electrical cables for cuts and abrasions.

Replace as needed.

Page 28

Moducon Belt Conveyor UGR004/1200

5-4 MAINTENANCE

Be sure the main power is disconnected.

Always disconnect and lock out the main power source

before servicing the unit.

Inspect all wires and connections.

Look for loose wires, burned contacts, and signs of overheated wires. Have a qualified electrician make any necessary repairs or replacements.

Inspect the exterior power cord.

The cord should not be crimped, exposed, or rubbing

against the frame. If the cable runs along the floor, make

sure it is not positioned where it could rest in pooling

water or could be run over and cut by wheels or casters.

CHECKING

ELECTRICAL

CONNECTIONS

1

2

3

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should be installed, adjusted,

and serviced only by qualified technical personnel who are familiar with the construction,

operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed and maintained by qualified electrical

technicians in accordance with electrical codes

in your region.

WARNING: Disconnect power

sources to prevent injury from

unexpected energization or startup.

To prevent possible injury from unexpected

startup, always disconnect and lock out the

main power source before performing maintenance or troubleshooting on this product.

WARNING: Electrical Shock Hazard

This device must be properly grounded.

Improper grounding can result in severe

personal injury and erratic machine operation.

Do not operate the equipment at power levels

other than what is specified on the machine

serial plate.

Page 29

6-1

UGR004/1200 Moducon Belt Conveyor

●●

Before Beginning . . . . . . . . . . . .6-2

●●

A Few Words of Caution . . . . . .6-2

●●

Identifying the

Cause of a Problem . . . . . . . . .6-3

●●

Answering an Alarm . . . . . . . . .6-3

●●

The Conveyor Does

Not Move . . . . . . . . . . . . . . . . .6-4

●●

Movement is Wrong . . . . . . . . . .6-5

TROUBLESHOOTING

Page 30

You can avoid most problems by following the recommended

installation, operation and maintenance procedures outlined in

this User Guide. If a problem should occur:

❒ Find any wiring, parts, and assembly diagrams that

were shipped with your equipment. These are the best

reference for correcting a problem. The diagrams will note

any custom features or options not covered in this User

Guide.

❒ Verify that you have all instructional materials related

to the conveyor and to any other equipment connected

to the system. Additional details about troubleshooting and

repairing specific components are found in these materials.

BEFORE

BEGINNING

Moducon Belt Conveyor UGR004/1200

6-2 TROUBLESHOOTING

A FEW WORDS

OF

CAUTION

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should be installed, adjusted,

and serviced only by qualified technical personnel who are familiar with the construction,

operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed and maintained by qualified electrical

technicians in accordance with electrical codes

in your region.

WARNING: Disconnect power

sources to prevent injury from

unexpected energization or startup.

This product has a moving belt. To prevent

possible injury from unexpected startup, always

disconnect and lockout the main power source

before performing maintenance or troubleshooting procedures on this product.

WARNING: Electrical Shock Hazard

This device must be properly grounded.

Improper grounding can result in severe

personal injury and erratic machine operation.

Do not operate the equipment at power levels

other than what is specified on the machine

serial plate.

Page 31

IDENTIFYING THE

CAUSE OF A

PROBLEM

UGR004/1200 Moducon Belt Conveyor

TROUBLESHOOTING 6-3

The Troubleshooting section covers problems directly related

to the operation and maintenance of the belt conveyor.

This section does not provide solutions to problems that originate with other equipment. Additional troubleshooting help

can be found in manuals supplied with the other equipment.

The following alarm conditions will stop the belt conveyor

automatically:

● The load on the belt exceeds the rated torque applied

to the motor for more than 5 seconds.

The LED indicator light flashes and the motor stops.

● The motor cable or connector is disconnected.

The LED indicator light turns on and the motor stops.

● Motor speed exceeds 2800 rpm.

The LED indicator light turns on and the motor stops.

● Voltage applied to the control is 30% or more below the

the voltage setting.

The LED indicator light turns on and the motor stops.

When an alarm occurs during operation, the belt conveyor

stops. The belt will not move and the alarm light will continue

to flash or stay lit until the error is corrected.

Page 32

Moducon Belt Conveyor UGR004/1200

6-4 TROUBLESHOOTING

THE CONVEYOR

DOES NOT

MOVE

For additional information on problems that may have been

caused by the speed control unit, see

A

PPENDIX

B: AXU

S

ERIES

C

ONTROL

.

Symptom

The conveyor does

not move.

Possible cause

Electrical connections

are not correct.

The control button is in the

Standby position.

Both the clockwise and the

counterclockwise inputs are

turned on.

The speed setting potentiometer is not adjusted.

Load on belt exceeds rated

torque applied to the motor

for more than 5 seconds.

Motor speed exceeds

2800 rpm.

Voltage applied to the

control is 30% or more

below the voltage setting.

Solution

Check that:

❒ The conveyor is plugged into a

power source.

❒ The main power source is on.

❒ The interface cables are

connected.

❒ The fuses are good.

❒ The power to the conveyor is on.

Slide the control button to Run.

Turn off either the CW or the CCW

input. See

A

PPENDIX

B: AXU

S

ERIESCONTROL

.

Turn the speed setting potentiometer

slightly clockwise See

A

PPENDIX

B:

AXU S

ERIESCONTROL

.

Remove the excess load from the

belt.

Check voltage to motor. If incoming

voltage is wrong, connect to the

proper power source. If voltage is

correct, contact Conair Service.

Check voltage to motor. If incoming

voltage is wrong, connect to the

proper power source. If voltage is

correct, contact Conair Service.

Page 33

UGR004/1200 Moducon Belt Conveyor

TROUBLESHOOTING 6-5

Symptom

The motor turns

in the wrong

direction.

Motor operation is

unstable and

vibrating.

Possible cause

The clockwise input and

the counterclockwise input

are incorrect or electrical

connection is wrong.

The motor rotates in the

opposite direction depending on gearhead speed

reduction ratio.

The centerline is not

aligned between the motor

(gearhead) output shaft and

load shaft.

The motor and gearhead

are not assembled correctly.

Solution

Set the inputs to the correct

positions: when CW input is at

level L the motor shaft rotates

clockwise; when the CCW input

is at level L it rotates counterclockwise. See

A

PPENDIX

B:

AXU S

ERIESCONTROL

.

Reverse the CW and CCW input

operations. See

A

PPENDIX

B:

AXU S

ERIESCONTROL

.

Check the connection between

the motor (gearhead) output

shaft and the load shaft. See

A

PPENDIX

B: AXU S

ERIES

C

ONTROL

.

Check how the motor and gearhead are assembled. Check the

pinion shaft type. See

A

PPENDIX

B: AXU S

ERIESCONTROL

.

For additional information on problems that may have been

caused by the speed control unit, see

A

PPENDIX

B: AXU

S

ERIES

C

ONTROL

.

BELT MOTOR

MOVEMENT IS

WRONG

Page 34

Page 35

UGR004/1200 CUSTOMER SERVICE

APPENDIX A-1

Conair has made the largest investment in customer support in

the plastics industry. Our service experts are available to help

with any problem you might have installing and operating

your equipment. Your Conair sales representative also can help

analyze the nature of your problem, assuring that it did not

result from misapplication or improper use.

To contact Customer Service personnel, call:

From outside the United States, call: 814-437-6861

You can commission Conair service personnel to provide onsite service by contacting the Customer Service Department.

Standard rates include an on-site hourly rate, with a one-day

minimum plus expenses.

If you do have a problem, please complete the

following checklist before calling Conair:

❒ Make sure you have all model, serial and parts list numbers

for your particular equipment. Service personnel will need

this information to assist you.

❒ Make sure power is supplied to the equipment.

❒ Make sure that all connectors and wires within and between

the conveyor and related components have been installed

correctly.

❒ Check the troubleshooting guide of this manual for a solu-

tion.

❒ Thoroughly examine the instruction manual(s) for associat-

ed equipment, especially controls. Each manual may have

its own troubleshooting guide to help you.

❒ Check that the equipment has been operated as described in

this manual.

❒ Check accompanying schematic drawings for information

on special considerations.

BEFORE YOU

C

ALL ...

H

OW TO

C

ONTACT

C

USTOMER

SERVICE

Additional manuals and

prints for your Conair

equipment may be

ordered through the

Customer Service or

Parts Department for a

nominal fee.

WE’RE HERE

TO

HELP

Page 36

GUARANTEE/WARRANTY UGR004/1200

A-2

APPENDIX

EQUIPMENT

GUARANTEE

PERFORMANCE

WARRANTY

WARRANTY

LIMITATIONS

Conair guarantees the machinery and equipment on this order,

for a period as defined in the quotation from date of shipment,

against defects in material and workmanship under the normal

use and service for which it was recommended (except for

parts that are typically replaced after normal usage, such as

filters, liner plates, etc.). Conair’s guarantee is limited to

repairing or replacing, at our option, the part or parts determined by us to be defective after examination. The customer

assumes the cost of transportation of the part or parts to and

from the factory.

Conair warrants that this equipment will perform at or above

the ratings stated in specific quotations covering the equipment or as detailed in engineering specifications, provided the

equipment is applied, installed, operated and maintained in the

recommended manner as outlined in our quotation or specifications.

Should performance not meet warranted levels, Conair at its

discretion will exercise one of the following options:

● Inspect the equipment and perform alterations or adjust-

ments to satisfy performance claims. (Charges for such

inspections and corrections will be waived unless failure to

meet warranty is due to misapplication, improper installation, poor maintenance practices or improper operation.)

● Replace the original equipment with other Conair equip-

ment that will meet original performance claims at no extra

cost to the customer.

● Refund the invoiced cost to the customer. Credit is subject

to prior notice by the customer at which time a Return

Goods Authorization Number (RGA) will be issued by

Conair’s Service Department. Returned equipment must be

well crated and in proper operating condition, including all

parts. Returns must be prepaid.

Purchaser must notify Conair in writing of any claim and provide a customer receipt and other evidence that a claim is

being made.

Except for the Equipment Guarantee and Performance

Warranty stated above, Conair disclaims all other warranties with respect to the equipment, express or

implied, arising by operation of law, course of dealing,

usage of trade or otherwise, including but not limited to

the implied warranties of merchantability and fitness for

a particular purpose.

Loading...

Loading...