Page 1

EarthSmart

TM

ECM Series, 0.50 to 0.75 ton models

Corporate Office: 724-584-5500 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

USER GUIDE

UGH031-0209

www.conairgroup.com

Page 2

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and

the date you received it in the User Guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment

you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists

together for documentation of your equipment.

Date:

Manual Number: UGH031-0209

Serial Number(s):

Model Number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors contained in this User Guide or

for incidental, consequential damages in connection with the furnishing, performance or use of

this information. Conair makes no warranty of any kind with regard to this information, including,

but not limited to the implied warranties of merchantability and fitness for a particular purpose.

Copyright 2009 l The Conair Group l All rights reserved

Page 3

Table of Contents

1-1 Introduction

Purpose of the user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Your responsibilities as a user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . . 1-4

2-1 Description

What is the EarthSmart ECM Series Chiller?. . . . . . . . . . . . . . . . . . .2-2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

How it works: Process circulation. . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Refrigeration circulation . . . . . . . . . . . . . . . . . . . . . . 2-5

Component listing . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Specifications: EarthSmart ECM Series Chiller. . . . . . . . . . . . . . . . . 2-8

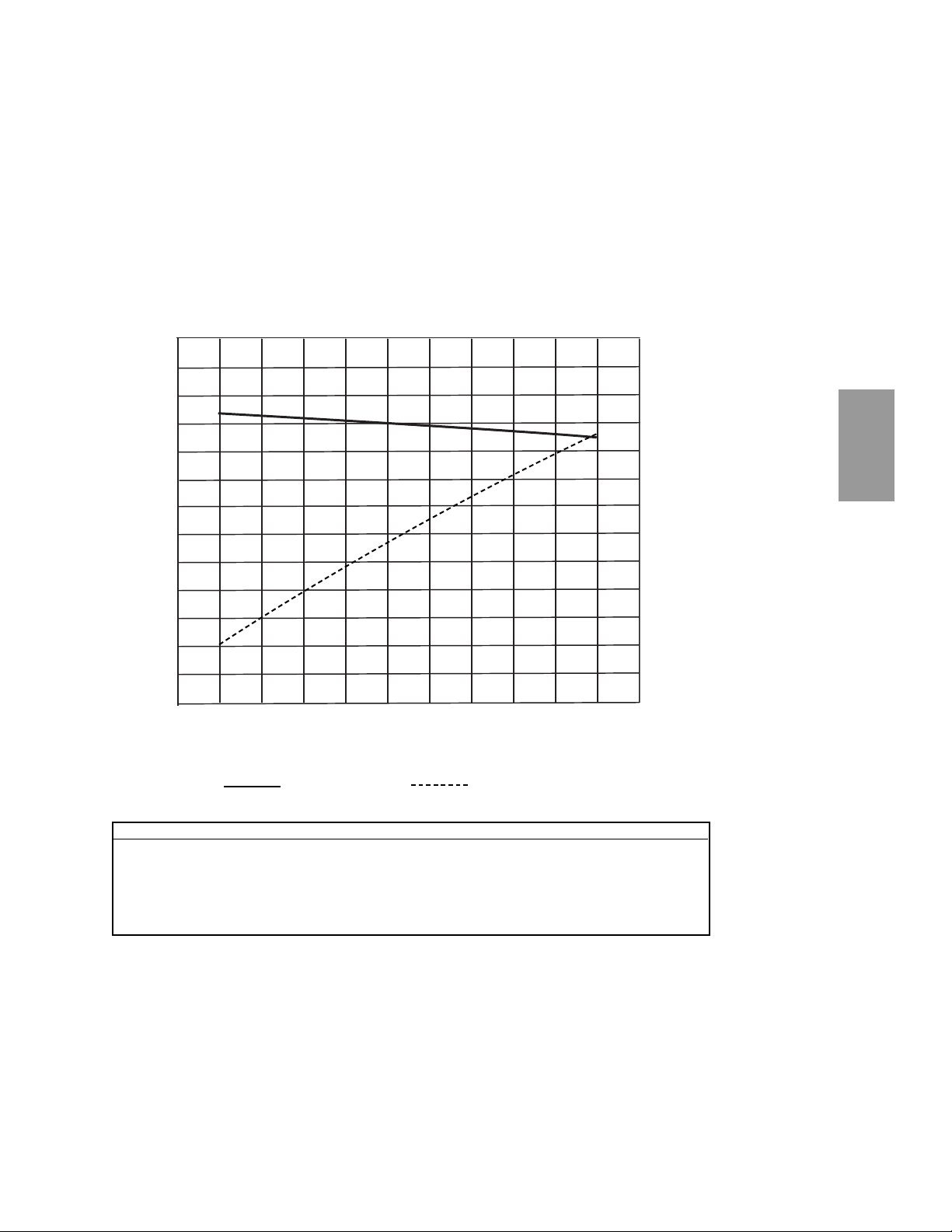

Pump curve: EarthSmart ECM Series Chiller . . . . . . . . . . . . . . . . . . 2-9

3-1 Installation

Unpacking the boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Warning and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Making process plumbing connections . . . . . . . . . . . . . . . . . . . . . . 3-5

Filling the chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Drain connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Checking the refrigerant charge . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Connecting the main power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4-1 Operation

EarthSmart ECM Series Chiller: Control descriptions . . . . . . . . . . . . 4-2

Starting the chiller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table of Contents l i

Page 4

Stopping the chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Changing temperature units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chiller operation sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Resetting the high pressure switch of the compressor . . . . . . . . . . 4-8

5-1 Maintenance

Preventative maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Checking electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cleaning the brazed plate adapter . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Cleaning the air-cooled condenser . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Checking the reservoir level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Cleaning the pump strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Checking the refrigerant charge and quality . . . . . . . . . . . . . . . . . 5-12

6-1 Troubleshooting

Before beginning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A few words of caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

DIAGNOSTICS

How to identify the cause of a problem . . . . . . . . . . . . . . . . . . . . . 6-3

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Checking or replacing the temperature sensor . . . . . . . . . . . . . . . . 6-8

Checking or resetting the circuit breakers . . . . . . . . . . . . . . . . . . . . 6-9

A Appendix

We’re here to help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to contact customer service . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Before you call... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equipment guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Warranty limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

ii l Table of Contents

Page 5

B Appendix

Safety adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C Appendix

Water quality control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

D Appendix

Chiller capacity and derate chart . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

E Appendix

Pressure-temperature chart for R-134A refrigerant . . . . . . . . . . . . . E-1

F Appendix

RTD resistance chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

G Appendix

Overhead plumbing details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

H Appendix

Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

I Appendix

Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

J Appendix

Plumbing schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-1

Table of Contents l iii

Page 6

iv l Table of Contents

Page 7

Introduction

Purpose of the user guide. . . . . . . . . . . . . . 1-2

How the guide is organized . . . . . . . . . . . . . 1-2

Your responsibilities as a user. . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . 1-4

SECTION

1

Introduction l 1-1

1

Introduction

Page 8

✐

Purpose of the User Guide

This User Guide describes the EarthSmart ECM Series Chiller and

explains step-by-step how to install, operate, maintain and repair this

equipment.

Before installing this product, please take a few moments to read the User

Guide and review the diagrams and safety information in the instruction

packet. You also should review manuals covering associated equipment in

your system. This review won’t take long, and it could save you valuable

installation and operating time later.

How the Guide is Organized

Symbols have been used to help organize the User Guide and call your

attention to important information regarding safe installation and operation.

Symbols within triangles warn of conditions that could be hazardous to users or

could damage equipment. Read and take precautions before proceeding.

Numbers indicate tasks or steps to be performed by the user.

A diamond indicates the equipment’s response to an action performed by the user.

An open box marks items in a checklist.

A circle marks items in a list.

Indicates a tip. A tip is used to provide you with a suggestion that will help you with

the maintenance and the operation of this equipment.

Indicates a note. A note is used to provide additional information about the steps

you are following throughout the manual.

1

◆

❒

•

✒

1-2 l Introduction

Page 9

Introduction l 1-3

Your Responsibility as a User

You must be familiar with all safety procedures concerning installation, operation and maintenance of this equipment. Responsible safety procedures include:

• Thorough review of this User Guide, paying particular attention

to hazard warnings, appendices and related diagrams.

• Thorough review of the equipment itself, with careful attention

to voltage sources, intended use and warning labels.

• Thorough review of instruction manuals for associated equipment.

• Step-by-step adherence to instructions outlined in this User Guide.

1

Introduction

Page 10

ATTENTION:

Read this so no one gets hurt

We design equipment with the user’s safety in mind. You can avoid the potential

hazards identified on this machine by following the procedures outlined below and

elsewhere in the User Guide.

WARNING: Improper installation, operation or

servicing may result in equipment damage or

personal injury.

This equipment should be installed, adjusted and serviced by a qualified technician who is familiar with the construction, operation and

potential hazards of this type of machine.

All wiring, disconnects and fuses should be installed by a qualified

electrical technician in accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate the equipment at power

levels other than what is specified on the machine serial tag and data

plate.

WARNING: Voltage hazard

This equipment is powered by single-phase alternating current,

as specified on the machine serial tag and data plate.

A properly-sized conductive ground wire from the incoming power

supply must be provided. Improper grounding can result in severe

personal injury and erratic machine operation. (Units are supplied with

a grounded plug that must be plugged into a grounded out.)

Always disconnect and lock out the incoming main power source before

opening the electrical enclosure or performing non-standard operating

procedures, such as routine maintenance. Only a qualified technician

should perform troubleshooting procedures that require access to the

electrical enclosure while power is on.

1-4 l Introduction

(continued)

Page 11

1

Introduction

Introduction l 1-5

CAUTION: Hot Surfaces

Always protect yourself from hot surfaces when working on the

chiller, especially when working on or around the compressor and

condenser. These devices can be over 160°F {71°C}. Allow these

devices to cool before performing any maintenance or

troubleshooting.

WARNING: Refrigerant hazard

Only certified refrigerant technicians should examine and correct

problems involving the refrigerant circuit.

ATTENTION:

Read this so no one gets hurt

(continued)

Page 12

1-6 l Introduction

Page 13

Description l 2-1

Description

What is the EarthSmart ECM Series Chiller?. . 2-2

Typical applications. . . . . . . . . . . . . . . . . . 2-2

Limitations. . . . . . . . . . . . . . . . . . . . . . . . 2-3

How it works: Process circulation . . . . . . . . 2-4

Refrigeration circulation . . . . . 2-5

Component listing . . . . . . . . . 2-6

Specifications: EarthSmart ECM

Series Chillers . . . . . . . . . . . . . . . . . . 2-8

Pump curve: EarthSmart ECM

Series Chillers . . . . . . . . . . . . . . . . . . 2-9

SECTION

2

2

Description

Page 14

What is the EarthSmart ECM Series

Chiller?

The Conair EarthSmart ECM Series Chillers provide self-contained sources of

chilled water and are available with compressor ranges of 0.5 Hp or 0.75 Hp

(nominal capacities of 0.41 tons or 0.70 tons of refrigeration).

IMPORTANT: Nominal chilling capacities are based on 95°F {35°C} ambient air conditions and

processing 50°F {10°C} leaving water.

ECM Series Chillers are designed to provide chilled fluid for industrial applications requiring 24-hour-a-day performance. Units are totally self-contained for

easy, economical installation. All parts wetted by the process are non-ferrous.

Typical Applications

ECM Series Chillers can be used anywhere a reliable source of process cooling

water at temperatures ranging from 45° to 65°F {7.2°C to 18.3°C} is required.

These chillers at full load, will discharge approximately 7,500 or 12,500

BTU/hr of heat into the atmosphere (depending on model).

Chillers are available for:

● Injection molding ● Dryer intercoolers/aftercoolers

● Blow molding ● Heatset/web offset printing presses

● Thermoforming ● Degreasing

● Extrusion ● Laser

● Air compressors ● Anodizing

● Metal plating

2-2 l Description

NOTE: Chiller’s environment

and cooling temperatures

below the default cooling

ranges will affect cooling

capacities.

✐

Page 15

Description l 2-3

2

Description

Limitations

Conair EarthSmart ECM Series Chillers are chosen based on the cooling load,

ambient temperature and cooling temperature.

● Cooling load - Choose a chiller that has 0 - 10% more cooling capacity than

the process load to be chilled.

● Ambient temperature - The chiller’s air-cooled condenser requires an

ambient air temperature between 40° to 95°F {4.4° to 35°C} for efficient

operation. Operation above 95°F {35°C} may result in elevated condensing

pressures and will eventually cause the chiller to shut down due to a high

pressure safety switch. Contact Conair Service for information for operating

within ambient air temperatures above 95°F {35°C} or below 40°F {4.4.°C}.

● Temperature - As standard, ECM Series Chillers can provide cooling

temperature ranges of 45°F to 65°F {7.2°C to 18.3°C}. For cooling

temperatures below 45°F {7.2°C}, contact Conair Service.

Use this information as a general guide. Consult your Conair representative for

assistance when choosing a Conair EarthSmart ECM Series Chiller.

Page 16

2-4 l Description

How it Works: Process Circulation

Hot fluid from the process enters the chiller

through the “From Process” inlet into the

chiller’s reservoir.

Pump moves fluid from the reservoir through

evaporator where it is chilled.

Fluid is chilled in the evaporator and exits

through the “To Process” outlet, returning to

the process.

1

2

3

1

2

3

(Left-side as viewed from the control)

Page 17

2

Description

Description l 2-5

How it Works: Refrigerant Circulation

The evaporator extracts heat from the process fluid,

causing the refrigerant to vaporize (evaporate) into a gas.

Vaporized refrigerant travels to the compressor, where the

low-pressure vapor is compressed into a high-pressure,

high-temperature vapor.

The high-pressure, high-temperature vapor travels from the

compressor through the condenser, where the fan cools

and condenses the vapor into a high-pressure, hightemperature liquid.

High-pressure, high-temperature liquid is metered back to

the evaporator by the expansion valve (TXV), changing it

to a low-pressure, low-temperature vapor.

1

3

3

To Process outlet

From Process inlet

Drain/Fill

Pump

(Left-side as viewed from the control)

(Right-side as viewed from the control)

1

2

4

2

4

Page 18

How it Works: Component Listing

Water system

• Motor/Pump assembly - The motor/pump assembly circulates chilled

coolant through the process loop. The pump assembly is built with brass to

maintain water quality.

Refrigeration system

• Compressor - Hermetic compressor takes low-pressure, low-temperature

refrigerant gas and compresses the gas into high-pressure, high-temperature

vapor.

•

Air-cooled condenser - The air-cooled condenser removes heat BTUs from

the compressor refrigerant gas. The action causes the gas to “condense” into a

liquid state still under high pressure. Air flow across the condenser is

achieved by a motor driven fan.

•

Fan cycling switch - The fan cycling switch is adjustable when the chiller is

in an environment cooler than 95°F {35°C}. See Appendix J entitled,

Plumbing Schematic.

• Filter-dryer - The filter-drier removes contaminants and moisture from the

liquid refrigerant.

• Liquid receiver - Serves as a collection tank for high-pressure liquid

refrigerant to ensure total charge at all times.

• Refrigerant sight glass - The refrigerant sight glass indicates refrigerant

charge and moisture content. Refrigerant charge is determined by a clear

liquid flow. Bubbles indicate low refrigerant. Moisture content is indicated by

the color of the sight glass view port element. The element’s color is normally

green. If the color of the element is dark brown or yellow, the system has

been contaminated with moisture and the refrigerant circuit needs to be

serviced by a qualified refrigerant service technician. See Maintenance

section entitled, Checking the Refrigerant Charge and Quality.

• Expansion valve - The expansion valve meters flow of liquid refrigerant

into the evaporator and creates a pressure drop in the refrigerant system that

allows the liquid refrigerant to “boil off” inside the evaporator.

2-6 l Description

(continued)

Page 19

• Evaporator - The evaporator is a brazed plate heat exchanger where the

liquid refrigerant is allowed to evaporate (boil off) to absorb the heat (BTU)

from the process fluid. As the heat is absorbed, the process fluid is chilled.

• High/Low Pressure Switches: The high/low pressure switches protect the

refrigeration system from unsafe operating levels. The high pressure switch

is factory set to open at 230 PSI and protects the refrigeration components

and personnel from potential damage or injury from excessively high

pressure. The high pressure safety must not be altered in the field for any

reason. The low pressure switch is factory set to open at 25 PSI and to close

at 35 PSI. The low pressure switch protects the chillers from possible damage

due to low operating pressure. The low pressure switch is field adjustable for

setpoints below 45°F {7.2°C}, contact a Conair representative for more

information.

How it Works: Component Listing

(continued)

Description l 2-7

2

Description

IMPORTANT: Altering the High Pressure Switch setting will void any chiller warranty.

NOTE: The fan cycling switch

is adjustable when the chiller

is in an environment cooler

than 95°F {35°C}.

See

Appendix J entitled, Plumbing

Schematic.

✐

Page 20

2-8 l Description

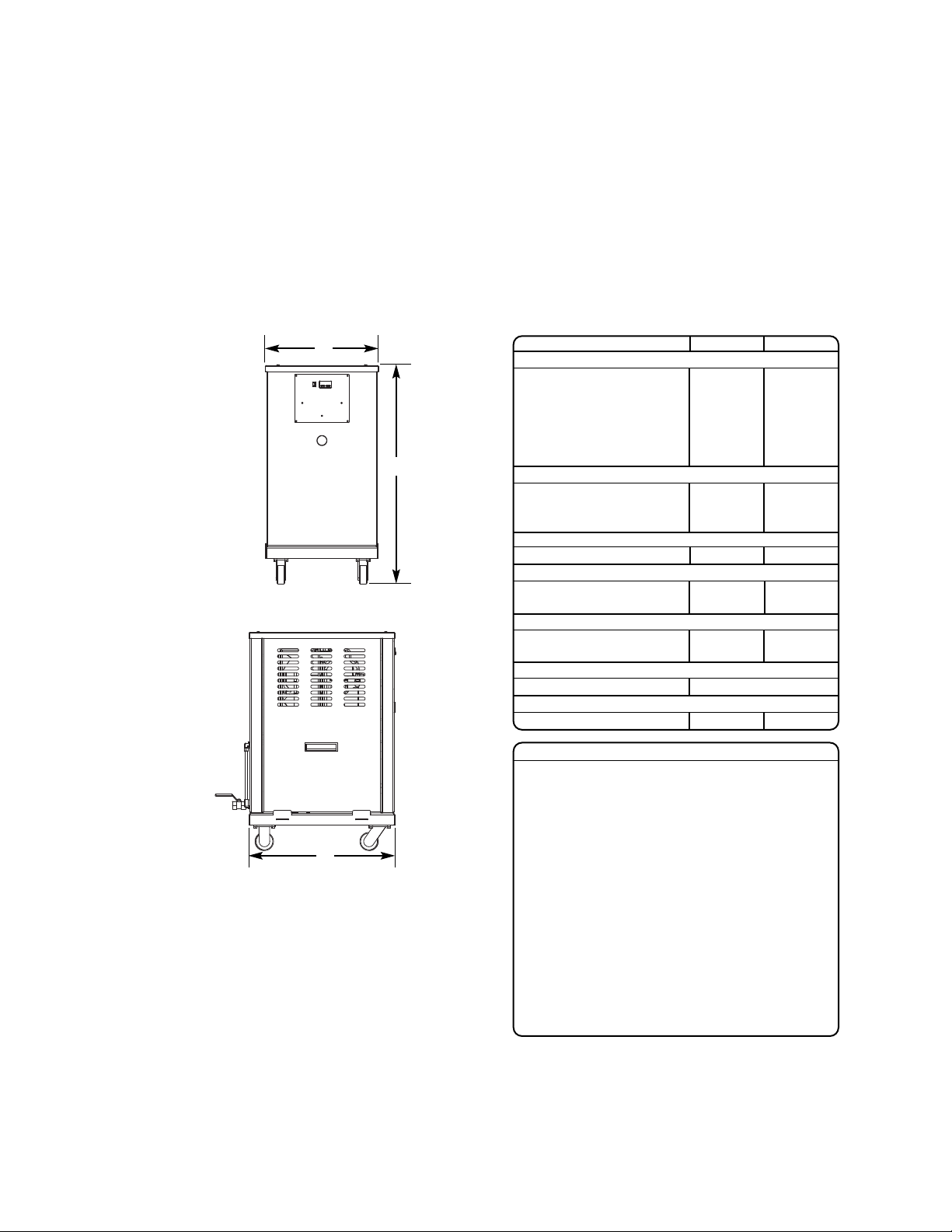

Specifications: EarthSmartTMECM

Series Chillers

A

B

C

TPHS039-1208

MODEL ECM-0.5 ECM-0.75

Performance characteristics

Capacity* tons 0.41 0.70

Compressor Hp {kW}

✝

0.5 {0.37} 0.75 {0.56}

Pump Hp {kW} 0.25 {0.19} 0.5 {0.37}

Chilled water flow‡gpm {lpm} 0.9 {3.4} 1.7 {6.4}

Chilled water pressure‡psi {bar} 60 {4.1} 60 {4.1}

Reservoir capacity gal {liters} 10 {37.8} 10 {37.8}

Dimensions inches {mm}

A - Height 39.7 {1008} 39.7 {1008}

B - Width 18.7 {475} 18.7 {475}

C - Depth 24.2 {615} 24.2 {615}

Process connections inches {mm}

Process (to and from) 0.5 0.5

Weight lb {kg}

§

Installed 223 {101} 233 {106}

Shipping 170 {77} 180 {82}

Voltages full load amps

**

115V/1 phase/60Hz 14 NA

220V/1 phase/60Hz NA 11

Refrigerant

R-134A

Refrigerant charge lb {kg}

1.3 {0.6} 1.3 {0.6}

SPECIFICATION NOTES:

* Ton capacity at 12,000 BTU/ton @ 50°F {10°C} leaving

water temperature @ 115°F {46°C} condensing temperature. Capacities may be ± 5% as reserved by the

compressor manufacturer. Capacity multipliers are: 50°F

{10°C} - 1.00; 40°F {4.4°C} - 0.80.

✝

The ECM Series Chiller uses a hermetic reciprocating

compressor.

‡

Consult pump curve for exact characteristics relating to

pump performances.

§

Chiller installed weight includes a completely filled

reservoir.

**

No allowance for inrush current. Ground fault interruption

to be supplied by the customer. Full load amps must be

used to size supply conductors. Consult a Conair representative for 50 Hz operation.

Specifications can change at any time. Contact your Conair

representative for the most current information.

Page 21

Description l 2-9

2

Description

Pump Curve: EarthSmartTMECM

Series Chillers

25

50 75 100 125 150 175 200 225 25025

20

30

40

50

60

70

80

90

100

110

120

130

140

10

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

Outlet Pressure* (PSI)

Horsepower

Flow Rate (GPH at 1725 RPM)

SPECIFICATION NOTES

* Pump curves do not reflect pressure drops due to internal piping.

This pump curve is non-overloading using the service factor of the motors.

Specifications may change without notice. Check with your Conair representative for the most current information.

100 GPH

100 GPH

Horsepower Flow rate

Page 22

2-10 l Description

Page 23

Installation l 3-1

Installation

Unpacking the boxes . . . . . . . . . . . . . . . . . 3-2

Warnings and cautions . . . . . . . . . . . . . . . . 3-3

Preparing for installation . . . . . . . . . . . . . . 3-4

Making process plumbing connections . . . . . 3-5

Filling the chiller . . . . . . . . . . . . . . . . . . . 3-6

Drain connection . . . . . . . . . . . . . . . . . . . . 3-7

Checking the refrigerant charge . . . . . . . . . 3-8

Connecting the main power . . . . . . . . . . . . . 3-9

SECTION

3

3

Installation

Page 24

3-2 l Installation

Unpacking the Boxes

The EarthSmart ECM Series Chiller comes fully assembled in a single crate.

Units are shipped with the casters attached.

1 Carefully uncrate the chiller and its components.

2 Remove all packing material, protective paper, tape and plastic. Compare

contents to the shipping papers to ensure that you have all the parts.

3 Carefully inspect all components to ensure no damage occurred during ship-

ping. If any damage is found, notify the shipping agent immediately to file a

claim. Check all wire terminal connections, bolts and any other electrical connections, which may have come loose during shipping. Check for pinched

wires and kinked hoses.

4 Cut the bands holding the chiller onto the pallet.

5 Record serial numbers and specifications for the chiller in the blanks

provided on the back of this User Guide’s title page. This information will be

helpful if you ever need service or parts.

CAUTION: Lifting

Conair EarthSmart ECM Series Chillers are designed to easily roll on casters. If, for

some reason you need to lift the chiller, take all precautions to avoid personal

injury or damage to the chiller. Lift the chiller using a forklift or hoist with straps

that have been positioned at the chiller’s center of gravity. Do not try to lift the

chiller manually.

Page 25

Installation l 3-3

3

Installation

Warnings and Cautions

WARNING: Improper installation, operation, or

servicing may result in equipment damage or

personal injury.

This equipment should only be installed, adjusted and serviced by a qualified

technician who is familiar with the construction, operation and potential

hazards of this type of machine.

All wiring, disconnects and fuses should be installed by a qualified electrical

technician in accordance with electrical codes in your region. Always maintain

a safe ground. Do not operate this equipment at power levels other than what

is specified on the machine data plate.

CAUTION: Hot Surfaces

Always protect yourself from hot surfaces when working on the chiller,

especially when working on or around the compressor and condenser. These

devices can over 160°F {71°C}. Allow these devices to cool before performing

any maintenance or troubleshooting.

CAUTION: Ventilation

The unit requires a clean and well ventilated operating environment. Do not

place anything on top of the unit while operating.

Units require enough clearance around the perimeter for access panels to be

removed completely. Units require a minimum of 2 ft {0.6 m} clearance around

the perimeter for proper air flow.

WARNING: Refrigerant hazard

Only certified refrigerant technicians should examine and correct problems

involving the refrigerant circuit.

Page 26

Preparing for Installation

Plan the location for the chiller and prepare the area properly.

Position the chiller as close to the process machine as possible. Place the chiller in

position near the process machine so that coolant lines can be connected from the

process machine to the chiller and back.

Make sure the area where the chiller is installed has:

❒❒

A grounded power source.

Check the chiller’s serial tag for the correct amps, voltage, phase and

cycle. All wiring should be completed by a qualified technician and

comply with your region’s electrical codes.

❒❒

Clearance for safe operation and maintenance.

Ensure there is 2 ft {0.6 m} of clearance at the air intake and 2 ft

{0.6 m} of clearance at the exhaust discharge for proper operation. Air

flow is generated by the motor driven fan. Air flow is from the outside

of the chiller, through the condenser and exhausted through the unit.

Exhaust air can not be ducted on motor driven fan models.

Position the locking casters to prevent the chiller from moving. For

maintenance and servicing, be sure there is enough clearance to

remove all access panels completely.

❒❒

Available water source.

Ensure water make-up source is plumbed to the chiller’s installation

location. High points in the plumbing require vent valves; low points

require drain valves.

3-4 l Installation

NOTE: Models must be posi-

tioned so that the condenser

air inlet is no warmer than

95°F {35°C} and the condenser

air outlet is not blocked or

restricted in any way.

✐

Chiller

Process machine

Alternate

locations

NOTE: Locate models away

from heat producing equip-

ment. These items will affect

ambient air conditions and the

performance of the chiller.

✐

Page 27

Installation l 3-5

3

Installation

Making Process Plumbing

Connections

All process piping materials (such as hoses, rigid piping, valves or filters) used

with process water piping circuitry must be rated for 100°F {37.8°C} minimum

temperature and 150 PSI {10.3 bar} minimum pressure.

All such materials must have the equivalent or larger diameter of the particular

process connection that the length of process water piping is connected to.

Process water piping circuitry should be designed to avoid an excessive use of

elbows and/or lengths of pipe or hose. If hose is the material of choice, avoid

tight twists or curls and excessive lengths.

Valves and filters may be installed in the process water piping circuitry to

facilitate service and maintenance provided that these devices maintain the full

inside diameter of the process connection. If installed, all devices must be open

and clean during unit operation.

Warm coolant from process equipment enters the chiller at the “From Process”

inlet and chilled coolant returns to the process equipment through the “To

Process” outlet.

To connect process plumbing:

1 Remove the shipping plastic pipe plugs from the female “To Process” and

“From Process” connections on the back of the portable chiller.

2 Make sure the male pipe threads are clean and new.

3 Wrap the male pipe threads with Teflon tape or pipe dope.

4 Connect the “From Process” valve (factory optional) on the back of the

chiller to the “From Process” tubing that is from the “Water Out” manifold on the mold or process. Start by hand until the threads engage and then

tighten with an appropriately-sized pipe wrench. Tighten only enough to prevent leaks; do not over-tighten.

5 Connect the “To Process” valve (factory optional) on the back of the chiller

to “To Process” tubing that is from the “Water In” manifold on the mold

or process. Start by hand until the threads engage and then tighten with an

appropriately-sized pipe wrench. Tighten only enough to prevent leaks; do not

over-tighten. If process lines are higher than the chiller, see Appendix G, entitled

Overhead Plumbing Details.

From Process

inlet

To Process

outlet

Fill/drain port

NOTE: The ability of the unit to

maintain process temperature

control depends on the method

of installation.

✐

NOTE: Assure the piping

installation has continuous

flow at all times. If using a

mechanical valve to regulate

process flow you MUST install

a bypass in the process

piping.”

✐

Page 28

3-6 l Installation

Filling the Chiller

The chiller is shipped without coolant. The chiller is manually filled during installation using water as its coolant.

For atypical process temperatures below 45°F {7.2°C}, use the table below to

determine the percentage (by volume) of glycol needed for the process temperature that is required. Mix the proper percentage of glycol with water.

To fill with water:

1 Attach the water supply to the Fill/Drain valve, located on the back of the

chiller.

2 Open the “To Process” and “From Process” valves (factory optional).

3 Open the Fill/Drain valve or water supply and fill the chiller to the 7/8 full

level on the water level gauge. If the chiller is overfilled, the excess water

spills out the vent tube. DO NOT OVERFILL.

4 Close the Fill/Drain valve.

5 Check the coolant level. When the chiller is turned on the coolant level drops

as it begins to circulate, filling the connected plumbing. Check the

coolant level on the back of the chiller. Make sure the coolant level is filled to

the 7/8 full level on the water level gauge. Shut down the chiller and add more

coolant, if needed.

6 Disconnect water hose from Fill/Drain valve, if the chiller is to be used

elsewhere.

Recommended Percentages of Glycol for

Chilled Water Freeze Protection (by volume)

Discharge water % Propylene % Water

Temperature Glycol

40°F 20 80

30°F 30 70

25°F 40 60

IMPORTANT: The chiller’s control does not monitor the percentage mixture of glycol.

IMPORTANT: Evaporator freeze-ups

are not

covered under warranty.

Page 29

Installation l 3-7

3

Installation

Drain Connection

To drain the chiller for storage or transport:

1 Rotate the chiller’s drain valve counterclockwise. If using chemicals or

additives with your process coolant, observe local disposal laws and regulations.

2 Close the chiller’s drain valve by turning it clockwise once final

evacuation of all process coolant is complete.

IMPORTANT: Drainage procedures must be done prior to shipment or outdoor storage of

the unit. If not, freezing damage can occur.

From Process inlet

To Process outlet

Fill/drain port

Water level gauge

IMPORTANT: Ensure long-term storage environments are above freezing temperatures. If

not, allow the chiller to thaw for several hours before returning it to operation or fill the

chiller’s internal piping with a high mixture of glycol to water during storage.

Page 30

3-8 l Installation

Checking the Refrigerant Charge

WARNING: Refrigerant hazard

Only certified refrigerant technicians should examine and correct problems

involving the refrigerant circuit.

All chillers are fully charged with R-134A refrigerant from Conair. Your chiller’s

model nameplate identifies the type and amount of total refrigerant charge

required.

Check the refrigerant charge while the chiller is running through the sight glass.

Locate the sight glass by removing the left-side panel and using a flashlight, if

necessary to check the sight glass:

❒❒

Under full load conditions, the refrigerant should be clear (no bubbles).

❒❒

Under low load conditions, when the Hot-gas Bypass valve is energized,

bubbles may be visible in the sight glass. This is normal.

If the charge is low and the unit is under warranty, contact Conair service.

Otherwise have a local, certified refrigeration technician add R-134A refrigerant to

the system.

Sight glass

NOTE: In this diagram, the

chiller’s panels are removed

for clarity.

✐

CAUTION: Always disconnect and lock out the main power sources before making

electrical connections. Electrical connections should be made only by a qualified

electrical technician.

Page 31

Connecting the Main Power

The Conair EarthSmart ECM Chiller uses standard 115 Volt, 60 Hz or 220 Volt,

60Hz single-phase power, depending on model.

To connect the the main power to the chiller:

1 Connect the chiller’s plug into a properly-sized and rated electrical outlet.

IMPORTANT: Always refer

to the wiring diagrams that

came with your chiller to

locate specific electrical

components. Illustrations in

the User Guide are intended

to be representative only.

CAUTION: Always disconnect and lock out the main power sources before making

electrical connections. Electrical connections should be made only by a qualified

electrical technician.

Installation l 3-9

3

Installation

220 Volt/60 Hz,

20 amp plug

IMPORTANT: Depending on the state of the refrigeration system the compressor may turn on

momentarily upon connecting power. The compressor will stop when the refrigerant is

pumped into the condenser and a low pressure condition exists in the evaporator.

Page 32

3-10 l Installation

Page 33

SECTION

4

4

Operation

Operation

EarthSmart ECM Series Chiller:

Control descriptions . . . . . . . . . . . . . . . 4-2

Starting the chiller . . . . . . . . . . . . . . . . . . 4-3

Stopping the chiller . . . . . . . . . . . . . . . . . . 4-4

Changing temperature units . . . . . . . . . . . . 4-5

Chiller operation sequence . . . . . . . . . . . . . 4-6

Resetting the high pressure switch

of the compressor . . . . . . . . . . . . . . . . 4-8

Operation l 4-1

Page 34

12 %

SD

EarthSmart ECM Chiller: Control Descriptions

Hot-Gas

Bypass Status

Indicates the status

of the Hot-Gas

Bypass valve.

Actual Chiller

Temperature

Shows the (process) actual

temperature value.

On/Off Toggle

Switch

Used to turn the

power to the chiller

on or off.

Alarm Indication

Indicates the alarm status. (High Temperature

Alarm only.)

Setpoint

Temperature

Shows the userentered setpoint

temperature value.

4-2 l Operation

Control Codes

See See Trouble-

shooting section for

a list of possible

causes and solutions

for alarm conditions.

Infinity Button

Pressing the

“Infinity” button

will acknowledge

alarms and return

the user to the Main

screen.

Return Button

Pressing the “Return” button will

scroll through the chiller’s menu

screens.

Increment/

Decrement

Buttons

Used to increase or

decrease the userentered process

temperature setpoint.

Page 35

4

Operation

Operation l 4-3

Starting the Chiller

To start the chiller:

1 Toggle the power switch to the On or “I” position. The control display will

illuminate. Facing the chiller’s control, the “To Process” actual temperature

will be on the left, the setpoint temperature is on the right. See Operation

section entitled, Chiller Sequence of Operation.

2 Set the cooling temperature setpoint. Use the up arrow button ▲ on the

control, to raise the setpoint. Use the down arrow button ▼ to lower the setpoint. The temperature will ramp up at approximately 1 (one) degree per

second. After 2 (two) seconds of inactivity the setpoint entered will become

the targeted setpoint temperature.

On Position

NOTE: If the setpoint displays “OFF”

in the display, raise the setpoint

with the up arrow button

▲ to see

the actual setpoint.

✐

12 %

SD

Infinity Button

Pressing the “Infinity” button will acknowledge alarms

and return the user to the Main screen.

Page 36

4-4 l Operation

Stopping the Chiller

To stop the chiller:

1 Toggle the power switch to the Off or “O” position.

Off Position

12 %

SD

IMPORTANT: Do NOT rapidly cycle the chiller’s power on and off (short cycle). Once the

power has been turned off, wait at least three (3) minutes before cycling the chiller’s

power back on.

Page 37

4

Operation

Operation l 4-5

Changing Temperature Unit

To stop the chiller:

1 Press the green “Return” button once to access the Temperature Units

Selection screen. Press the ▲ or ▼ buttons to toggle between fahrenheit and

celsius temperature units.

2 Press the “Infinity” button to lock in the selection and return to the

Main screen. The control will default back to the Main screen if no buttons are

pressed after 1 minute.

12 %

SD

Return

Button

12 %

SD

Infinity

Button

NOTE: The temperature display will

not indicate Fahrenheit or Celsius

temperature units. The chiller’s

control is set for Fahrenheit temperature units as standard from

Conair.

✐

Page 38

4-6 l Operation

Chiller Operation Sequence

The EarthSmart ECM Series Chiller has a unique user interface that controls the

process temperature and prevents refrigeration migration during compressor off

times.

When the main power is connected:

1 Depending on the state of the refrigeration system, the compressor may

turn on momentarily upon connecting power. The compressor will stop when

the refrigerant is pumped into the condenser and a low pressure condition exists

in the evaporator.

When the power toggle switch is turned to the “On”or “I” position:

2 Turning the toggle switch on immediately starts the process pump and

illuminates the control. When flow is established and the unit is not in a low

temperature alarm, the Liquid Line Solenoid valve (LLSV) will open. This

allows the refrigerant to migrate to the evaporator and increase the pressure.

When the low refrigerant pressure switch is satisfied the compressor will turn on

and process coolant will begin cooling.

3 When the process temperature is above setpoint the compressor will run

and the Hot-Gas Bypass valve (HGBP) will not open. If the process

temperature falls below the setpoint, the HGBP valve will energize, raising the

actual process temperature to maintain the user-entered setpoint temperature.

The HGBP valve can energize up to 9 out of 10 seconds. If there is less load

on the chiller and the temperature continues to fall to 4°F {2.2°C} below the

user-entered setpoint the controller will alarm (A2.lo) and close the LLSV. The

compressor will pump the refrigerant out of the evaporator and the low pressure

switch will shut off the compressor. This is a normal function of the chiller and

will not require troubleshooting.

4 The controller stays in this alarm condition (A2.lo) until the temperature is

2°F {1.1°C} above the user-entered setpoint, at which point the controller

allows the LLSV to re-open and the compressor to restart.

(continued)

Page 39

Operation l 4-7

4

Operation

Chiller Operation Sequence (continued)

5 The condenser fan can energize anytime the toggle switch is in the “On”

or “I” position. The fan is controlled by the fan cycling (high refrigeration)

pressure switch. This switch maintains the high side refrigeration pressure

under cooler ambient temperatures and lower loads. The fan will turn on when

the high refrigeration pressure reaches 200 PSI {13.8 bar}. It will turn off

when the pressure drops below 125 PSI {8.6 bar}.

6 The high refrigeration safety pressure switch shuts off the compressor

immediately when the high refrigeration pressure reaches 230 PSI

{15.9 bar} without going through pump down during a low pressure cycle.

If the high pressure switch trips, it must be manually reset by pressing the

“Reset” button on the switch. The compressor can start immediately when

this is reset so caution should be exercised. See Operation section entitled,

Resetting the Compressor’s High Pressure Switch.

CAUTION: The compressor can start immediately when the High Pressure “Reset”

button is pressed.

Page 40

4-8 l Operation

Resetting the High Pressure Switch

of the Compressor

The high refrigeration safety pressure switch shuts off the compressor

immediately when the high refrigeration pressure reaches 230 PSI {15.9 bar}

without going through pump down during a low pressure cycle. If the high

pressure switch trips, it must be manually reset by pressing the “Reset” button

on the switch. The compressor can start immediately when this is reset so

caution should be exercised.

To reset the high refrigeration safety switch:

1 Be sure the main power is disconnected and the chiller is locked out. Always

disconnect/unplug and/or lockout the main power source before opening the unit

for servicing.

2 Remove the chiller’s right-side panel, as viewed from the control.

3 Locate the high refrigeration safety switch within the top portion of the

chiller’s cabinet.

4 Push the “Reset” button, until there is a “click”.

5 Replace the chiller’s right-side panel, as viewed from the control.

6 Reapply main power.

Reset

Button

NOTE: The High Pressure

Safety switch may not reset

due to the chiller’s refrigerant

state. Allow the refrigerant to

cool before attempting to

reset.

✐

CAUTION: The compressor can

start immediately when the

High Pressure “Reset” button

is pressed.

Page 41

Maintenance

Preventative maintenance schedule . . . . . . . 5-2

Checking electrical connections. . . . . . . . . . 5-4

Cleaning the brazed plate adapter . . . . . . . . 5-5

Cleaning the air-cooled condenser . . . . . . . . 5-7

Checking the reservoir level . . . . . . . . . . . . 5-9

Cleaning the pump strainer . . . . . . . . . . . . 5-10

Checking the refrigerant charge

and quality . . . . . . . . . . . . . . . . . . . . 5-12

SECTION

5

Maintenance

5

Maintenance l 5-1

Page 42

5-2 l Maintenance

Preventative Maintenance Schedule

Daily, or as often as needed

❒

Checking process fluid level in the pump tank

Check the process fluid level in the water level gauge on the back of the

chiller. If low, see Maintenance section entitled, Checking the Reservoir

Level.

❒

Verifying pump discharge pressure

While the pump is running, check to ensure that the pump pressure gauge

(located on the front of the chiller) is within range. To change the pressure,

open or close the “To Process” valve (factory optional).

❒

Inspecting piping for leaks

Check to see that pipes are not leaking. Look for standing water on the floor

or inside the chiller cabinet.

❒

Inspecting the condenser coil for debris

Check the condenser for adequate air flow. Check the condenser face for

dirt and clogging. If dirt or clogs are present, clean the condenser, see

Maintenance section entitled, Cleaning the Air-cooled Condenser. Check,

clean, and/or replace the filter at the air inlet of the air-cooled condenser coil,

as needed.

Weekly, or as often as needed

❒

Checking temperature and pressure readings

Check that the temperature displays on the control screen and the reading on

the pressure gauge (located on the front of the chiller) indicates normal

operation. See Description section entitled, Pump Curve: EarthSmart ECM

Series Chillers.

❒

Inspecting the filter

Check, clean and/or replace the filter at the air inlet of the air-cooled condenser coil, as needed. see Maintenance section entitled, Cleaning the Air-

cooled Condenser.

❒

Checking refrigerant site glass

There should not be any bubbles. See Maintenance section entitled,

Checking the Refrigerant Charge and Quality.

❒

Checking reservoir level

Check the water level gauge on the back of the chiller. If fluid level is low,

fill, see Maintenance section entitled, Checking Reservoir Level.

(continued)

Page 43

Maintenance l 5-3

Preventative Maintenance Schedule

(continued)

Monthly

❒

Inspecting cooling water treatment system

If your chiller uses a cooling water treatment system, maintain proper chemical levels and follow the recommendations of your water treatment specialist.

Change water in the reservoir tank monthly to reduce water hardness.

❒

Checking electrical connections, amps and volts

Check to ensure the electrical connections are properly seated and that the

chiller is operating at its rated amps and voltage. See Description section

entitled, Specifications: EarthSmart ECM Series Chillers.

❒

Cleaning

Wipe all external surfaces to maintain performance.

❒

Inspecting condenser

Check the air-cooled condenser for adequate air flow. Check the condenser

face for dirt and clogging. If dirt or clogs are present, clean the condenser.

Check, clean and/or replace the filter at the air inlet of the air-cooled condenser coil, as needed. See Maintenance section entitled, Cleaning the Air-

cooled Condenser.

❒

Inspecting the control panel

Check for loose wires, burned contacts and signs of overheated wires.

Check that all panel lights illuminate. See Maintenance section entitled,

Checking Electrical Connections.

❒

Checking refrigerant charge and quality

With the compressor running, check the sight glass between the receiver and

evaporator for proper refrigerant condition. See Maintenance section entitled,

Checking Refrigerant Charge and Quality.

❒

Checking the pump strainer.

Check to ensure the pump strainer is not clogged or damaged, replace as

needed. See Maintenance section entitled, Cleaning the Pump Strainer.

Annually

❒

Cleaning the evaporator

See Maintenance section entitled, Cleaning the Brazed Plate Evaporator.

❒

Check refrigerant piping

Verify that no oil is present on fittings or cabinet. Wipe clean and check

charge/operation of circuit.

5

Maintenance

Page 44

5-4 l Maintenance

Checking Electrical Connections

WARNING: Electrical Hazard

Before performing any work on this item, disconnect and lock out electrical power

sources to prevent injury from unexpected energization or startup. Be sure that

power to the chiller is OFF when doing any maintenance on the chiller. Follow all

safety rules when performing any maintenance on this equipment.

WARNING: Improper installation, operation or

servicing may result in equipment damage or

personal injury.

This equipment should only be installed, adjusted and serviced by a qualified

technician who is familiar with the construction, operation and potential hazards

of this type of machine.

All wiring, disconnects and fuses should be installed by a qualified electrical

technician in accordance with electrical codes in your region.

To check electrical connections:

1 Be sure the main power is disconnected and/or the chiller is locked out. Always

disconnect/unplug and lockout the main power source before opening the unit for

servicing.

2 Remove the chiller’s top lid, by first removing both side panels and then the four

(4) retaining bolts that secure the chiller’s top lid.

3 Inspect all wires and connections.

Look for loose wires, burned contacts and signs of over-heated wires. Compare

the wiring to the wiring diagrams you received with your chiller. Have a qualified

electrician make any necessary repairs or replacements.

4 Replace the chiller’s side panels and then the top lid by replacing the four (4)

retaining bolts.

5 Inspect the exterior power cords.

Cords should not be crimped, exposed or rubbing against the frame. If the main

power cord runs along the floor, make sure it is positioned where it could not rest

in pooling water or could not be ran over and cut by wheels or casters.

NOTE: Always refer

to the wiring diagrams you received

with your chiller to

locate specific electrical components.

✐

NOTE: Also inspect

the chiller’s plug

wiring terminations.

✐

Page 45

Cleaning the Brazed Plate Evaporator

Minerals and other contaminants produce deposits, scales, slime or algae on the heat

transfer surfaces exposed to water. Fouled surfaces could result in decreased cooling

capacity. Implement a water treatment program to slow the fouling.

CAUTION: Hot Surfaces

Always protect yourself from hot surfaces when working on the chiller, especially when working on or around the compressor and condenser. These

devices can reach over 160°F {71°C}. Allow these devices to cool before

performing any maintenance or troubleshooting.

Water quality should be maintained at a pH level of 7.4, but not less than 6.0 for

proper heat exchanger life.

To clean the brazed plate adapter:

1 Prepare a 5% solution of Phosphoric acid or Oxalic acid and water. Do not

heat the acid solution.

2 Disconnect and/or lockout main power to the chiller.

3 Shut the “To” and “From Process” valves (factory optional) and the drain

reservoir. See Installation section entitled, Drain Connection.

4 Remove the chiller’s side panels.

5 Disconnect the pump from the heat exchanger. Install a cap in the opening of

the heat exchanger where the pump was connected.

Maintenance l 5-5

NOTE: These connections

may vary depending on the

model you have purchased.

Be sure to see the labeling on

your particular unit.

✐

5

Maintenance

From Process inlet

To Process outlet

Fill/drain port

Water level gauge

(continued)

Page 46

5-6 l Maintenance

Cleaning the Brazed Plate Evaporator

(continued)

5 Remove RTD from bottom of evaporator.

6 Connect 3/8-inch tubing to the 3/8-inch connections of the heat exchanger.

SEE below to install customer-supplied chemical pump and solution fitted to the

heat exchanger.

7 Back-flush the solution through the heat exchanger and the chiller.

8 Flush the heat exchanger and the chiller piping with fresh water after

cleaning.

9 Reconnect the chiller pump to the heat exchanger. Remove the cap in the heat

exchanger and reconnect the hose to the pump.

NOTE: These connections

may vary depending on the

model you have purchased.

Be sure to see the labeling on

your particular unit.

✐

Acid

solution

Fluid circuit

Heat

Exchanger

To pump

To Process

connection

Valve

Pump

CAUTION: Hot Surfaces

Always protect yourself from hot surfaces when working on the chiller,

especially when working on or around the compressor and condenser. These

devices can reach over 160°F {71°C}. Allow these devices to cool before

performing any maintenance or troubleshooting.

Page 47

5

Maintenance

Cleaning the Air-Cooled Condenser

WARNING: Electrical Hazard

Before performing any work on this item, disconnect and lock out electrical

power sources to prevent injury from unexpected energization or startup. Be

sure that power to the chiller is OFF when doing any maintenance on the

chiller. Follow all safety rules when performing any maintenance on this

equipment.

CAUTION: Hot Surfaces

Always protect yourself from hot surfaces when working on the chiller,

especially when working on or around the compressor and condenser. These

devices can reach over 160°F {71°C}. Allow these devices to cool before

performing any maintenance or troubleshooting.

The air-cooled condenser and condenser filter can accumulate dirt and clog quickly if

it is ran in a dusty or dirty environment. A clogged condenser or condenser filter

increases refrigerant discharge pressure, lowers performance, and may cause the fan

motors and compressor to overheat.

To clean the air-cooled condenser:

1 Disconnect and/or lockout main power to the chiller.

2 Remove the chiller’s top lid, by first removing both side panels and then the four

(4) retaining bolts that secure the chiller’s top lid.

3 Remove the filter, that is located towards the back of the chiller, by lifting it

straight up and out of the chiller.

4 Inspect the condenser coils. Use a flashlight to check between coil surfaces.

5 Clean the dirty coils with a soft brush.

6 Flush with cool water or a commercial coil cleaner that is compatible with

aluminum alloys. It is recommended that the coil cleaner is sprayed from inside

the cabinet.

Maintenance l 5-7

(continued)

Page 48

Cleaning the Air-Cooled Condenser

(continued)

7 Check the air filter. If the filter is blinded or torn, replace the filter.

8 Replace the chiller’s side panels and then the top lid by replacing the four (4)

retaining bolts.

9 Reapply main power.

CAUTION: Wear eye protection.

If you use compressed air to clean the equipment, you must wear eye protection and observe all OSHA and other safety regulations pertaining to the

use of compressed air.

Replacement air filters are

available from Conair.

Contact Conair Parts

(800) 458 1960

From outside of the

United States, call:

(814) 437 6861

5-8 l Maintenance

Page 49

Maintenance l 5-9

Checking Reservoir Level

WARNING: Electrical Hazard

Before performing any work on the chiller, disconnect and lock out electrical

power sources to prevent injury from unexpected energization or startup. Be

sure that power to the chiller is OFF when doing any maintenance on the

chiller. Follow all safety rules when performing any maintenance on this

equipment.

Check the coolant level in the reservoir. The coolant level in the sight glass on the

back of the chiller should be 7/8 full.

To manually fill the reservoir:

1 Disconnect and lockout power to the chiller.

2 Locate the Fill/Drain valve on the back of the chiller. Open the Fill/Drain valve

or coolant supply and fill the chiller to the 7/8 full level on the water level gauge.

If the chiller is overfilled, the excess water spills out the vent tube. DO NOT

OVERFILL.

3 Refill the reservoir. Monitor the level using the water level indicator on the back

of the chiller, ensuring you are adding the correct fluid for your application.

4 Close the Fill/Drain valve.

5 Check the coolant level. When the chiller is turned on the coolant level drops

as it begins to circulate, filling the connected plumbing. Check the

coolant level on the back of the chiller. Make sure the coolant level is filled to

the 7/8 full level on the water level gauge. Shut down the chiller and add more

coolant, if needed.

6 Disconnect water hose from Fill/Drain valve, if the chiller is to be used

elsewhere.

Fill/drain port

Water level gauge

5

Maintenance

Page 50

Cleaning the Pump Strainer

EarthSmart Chillers use a rotary pump to flow process coolant through their internal

piping and to the process. A strainer on the pump may periodically need cleaning,

depending upon the quality of the process coolant.

WARNING: Electrical Hazard

Before performing any work on the chiller, disconnect and lock out electrical

power sources to prevent injury from unexpected energization or startup. Be

sure that power to the chiller is OFF when doing any maintenance on the

chiller. Follow all safety rules when performing any maintenance on this

equipment.

To clean the pump’s strainer:

1 Be sure the main power is disconnected and/or the chiller is locked out. Always

disconnect/unplug and lockout the main power source before opening the unit for

servicing.

2 Drain all process coolant from the chiller, see Installation section entitled, Drain

Connection.

3 Remove the chiller’s right-side panel. (As viewed from the control)

4 Locate the chiller’s pump. It is located in the lower portion of the chiller’ cabinet

and towards the front of the chiller.

5 Locate the pump strainer’s end cap, remove the cap by unscrewing it counter-

clockwise with an appropriately-sized wrench.

5-10 l Maintenance

Strainer end cap

NOTE: The front panel of the

chiller has been removed in

this image for clarity.

✐

(continued)

Page 51

Cleaning the Pump Strainer (continued)

6 Remove the strainer from its housing.

7 Inspect the strainer for holes or blinding, clean or replace as necessary.

8 Re-install the strainer and strainer cap. Properly seal all piping with approved

Teflon tape or pipe dope.

9 Check to ensure no leaking has occurred before returning the chiller to normal

operation.

Replacement strainers are

available from Conair.

Contact Conair Parts

(800) 458 1960

From outside of the

United States, call:

(814) 437 6861

IMPORTANT: Check to ensure the strainer is properly seated before applying the strainer

cap. Crushing of the strainer can occur if it is not fully inserted back into the strainer

housing.

5

Maintenance

Maintenance l 5-11

Page 52

5-12 l Maintenance

Checking the Refrigerant Charge and

Quality

WARNING: Refrigerant Hazard

Only certified refrigerant technicians should examine and correct problems

involving the refrigerant circuit.

All chillers are fully charged with R-134A refrigerant from Conair. Your chiller’s

model nameplate identifies the type and amount of total refrigerant charge required.

See Description section entitled, Specifications: EarthSmart ECM Series Chillers.

Check refrigerant charge while the chiller is running under normal load. Check the

refrigerant charge through the sight glass. Use a flashlight, if necessary, and check the

liquid-line sight glass:

• Under full load conditions, the refrigerant should be clear (no bubbles).

• Under low load conditions, when the Hot-Gas Bypass valve (HGBP) is

operating, bubbles may be visible in the sight glass. This is normal.

A refrigerant quality label is located within the sight glass. A green label is normal. A

yellow or dark brown label indicates that the refrigerant is contaminated and must be

replaced.

If the charge is low or contaminated and the chiller is under warranty, contact Conair

service; or have a local, certified refrigeration technician service the system.

Sight glass

CAUTION: Always disconnect and lock out the main power sources before making

electrical connections. Electrical connections should be made only by a qualified

electrical technician.

NOTE: In this diagram, the

chiller’s panels are removed

for clarity.

✐

Page 53

Troubleshooting

Before beginning . . . . . . . . . . . . . . . . . . . . 6-2

A few words of caution . . . . . . . . . . . . . . 6-3

DIAGNOSTICS

How to identify the cause of a problem . . . . 6-3

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . 6-5

Checking or replacing the

temperature sensor . . . . . . . . . . . . . . . 6-8

Checking or resetting the circuit breakers. . . 6-9

SECTION

6

6

Troubleshooting

Maintenance l 6-1

Page 54

Before Beginning

You can avoid most problems by following the recommended installation and

maintenance procedures outlined in this User Guide. If you do have a problem,

this section will help you determine what caused it and how to fix it.

❏ Diagnose causes from the control panel.

1 Note the alarm and press the “Infinity” button once to acknowledge

the alarm and resume control if required.

2 Address the alarm message and fix the problem. See Troubleshooting

section for descriptions of possible alarm conditions.

3 If the alarm reappears the problem was not fixed.

❏ Find the wiring and equipment diagrams that were shipped with your

chiller. These diagrams are the best reference for correcting a problem. The

diagrams also will note any custom features, such as special wiring or alarm

capabilities, not covered in this User Guide.

12 %

SD

This red light

indicates a

High

Temperature

alarm condition

The “Infinity”

button should be

pressed once to

acknowledge a

High Temperature

alarm.

6-2 l Troubleshooting

Page 55

6

Troubleshooting

A Few Words of Caution

Improper corrective actions can lead to hazardous conditions and should

never be attempted to sustain production.

WARNING: Only a qualified electrical technician should examine and

correct problems that require opening the chiller’s electrical enclosure

or using electrical wires to diagnose the cause.

WARNING: High voltage. Always stop the chiller, disconnect and lock out

the main power source before troubleshooting or performing repairs.

CAUTION: Hot surfaces. Always protect yourself from hot surfaces inside

and outside of the chiller.

How to Identify the Cause of a

Problem

The High Temperature Alarm is indicated by an illuminated alarm light on

the EarthSmart ECM control panel and an alarm code, (A2.hi) is displayed in

the control display.

When an alarm code is displayed in the control:

1 Find the error message in the diagnostics table of this

Troubleshooting section and reference the control labeling in the upper

right-hand side of the control face.

2 Note that, after correcting the problem, pressing the “Infinity”

button will clear the alarm. The alarm will only clear if the

condition causing the alarm has been corrected.

Troubleshooting l 6-3

Page 56

6-4 l Troubleshooting

Alarms

If the red alarm LED is illuminated, an alarm is activated. The chiller has automatically pumped down because it has detected a serious problem that could damage

your process or chiller. Note that the alarm must be acknowledged before the control will resume operation by pressing the “Infinity” button.

Problem

A2.hi (Alarm light illuminated) – If the “To Process”

temperature exceeds the

process high temperature deviation setpoint, it shuts down

the chiller. Default is set to

20°F {11.1°C}.

Er.in (Input error)

A2.lo – (Alarm light illumi-

nated) – If the “To Process”

temperature exceeds the

process low temperature deviation setpoint, it closes the liquid line solenoid valve and the

compressor pumps down and

shuts down. Default is set to

4°F {2.2°C}.

Possible cause

The Hot-gas Bypass valve is not

operating properly (stuck open).

Load is too high for the chiller.

Process coolant is not flowing between

the supply outlet and return inlet.

Dirty condenser coil.

Ambient temperature is above 95°F

{35°C}.

Warm process coolant.

Failed RTD.

Loose RTD connection to the control.

Reversed RTD input.

Load is too low for the chiller.

Solution

Have a certified refrigeration technician

replace the solenoid valve.

Remove some load from the process.

Check for plugged pipes, closed valves,

or failed flow switch(es).

Clean condenser coil. See Maintenance

section entitled, Cleaning the Aircooled Condenser.

Lower ambient temperature or move

the chiller to a lower temperature environment.

Lower the temperature of the process

coolant.

Replace the RTD. See Troubleshooting

section entitled, Checking or Replacing

the Temperature Sensor and Appendix F

entitled, RTD Resistance Chart.

Check RTD connection to the controller.

Resecure as necessary.

Check RTD wiring.

The chiller’s compressor will automatically restart once the “To Process”

temperature exceeds the user-entered

setpoint on the control by 2°F {1.1°C}.

Page 57

Troubleshooting l 6-5

6

Troubleshooting

Troubleshooting

Problem

The chiller will not start.

(Control not illuminated)

Pump will not start.

Possible cause

Tripped circuit breaker.

Incorrect incoming voltage.

The power toggle switch is not turned

to the “On” or “I” position.

Open motor winding.

Internal overload has tripped.

Loose wire connection or defective

start capacitor.

CB2 circuit breaker has been tripped.

Solution

Verify resistance to ground. Reset

breaker. See Troubleshooting section

entitled, Checking or Resetting the

Circuit Breakers.

Check incoming power source for

correct voltage and amperage as

detailed on the chiller nameplate. See

Description section entitled,

Specifications: EarthSmart ECM Series

Chillers.

Turn the power toggle switch on the

control to the “On” or “I” position.

Contact Conair Service.

Auto-resetting. Allow the chiller’s

motor to cool and restart the chiller.

Check wiring diagrams, see Appendix

H entitled, Electrical Schematic,

replace connections or capacitor.

Verify resistance to ground. Reset

breaker. See Troubleshooting section

entitled, Checking or Resetting the

Circuit Breakers.

Page 58

Troubleshooting (continued)

Problem

Compressor will not start.

Possible cause

High pressure switch has been tripped.

Circuit breaker has been tripped.

Loose wire connection or defective

start capacitor.

The actual “To Process” temperature is

below the setpoint.

Damaged or defective start capacitor.

Poor water flow.

Damaged or defective compressor.

Solution

Reset the High Pressure switch. See

Operation section entitled, Resetting

the High Pressure Switch.

Verify resistance to ground. Reset

breaker. See Troubleshooting section

entitled, Checking or Resetting the

Circuit Breakers.

Check wiring diagrams, see Appendix

H entitled, Electrical Schematic,

replace connections or capacitor.

Lower setpoint temperature value. See

Operation section entitled, Starting the

Chiller.

Contact Conair Service.

Check pump rotation.

Clean the pump strainer. See

Maintenance section entitled, Cleaning

the Pump Strainer.

Have a certified refrigeration

technician replace the compressor.

6-6 l Troubleshooting

NOTE:

Also, see

Troubleshooting section,

entitled, Troubleshooting,

“Chiller shuts down due

to a High Pressure switch

alarm” and “Chiller shuts

down due to a Low

Pressure switch”.

✐

Page 59

Troubleshooting (continued)

Problem

Chiller shuts down due to a

High Pressure switch alarm.

Chiller shuts down due to a

Low Pressure switch.

Possible cause

Low air flow across the condenser.

Fan not operating.

High ambient temperature.

Insufficient clear space around unit.

Clogged air filter.

Attempting to operate the chiller with

process coolant below 45°F {7.2°C}.

Low refrigerant charge.

Poor heat transfer in the evaporator

tank due to a high percentage of glycol

to water.

Low flow through the evaporator due

to glycol foaming.

Low flow through the evaporator.

Faulty pump motor.

Clogged pump strainer.

Solution

Check for dirty condenser fins. Clean

as necessary. See Maintenance section

entitled, Cleaning the Air-cooled

Condenser.

Reset High Pressure switch. See

Operation section entitled, Resetting the

High Pressure Safety Switch.

Check for loose fan blade or

open/grounded motor winding.

Move the chiller to a lower ambient

temperature location.

Increase clearance around the chiller.

Replace filter. See Maintenance section

entitled, Cleaning the Air-cooled

Condenser.

Increase temperature setpoint above

45°F {7.2°C}. See Operation section

entitled, Starting the Chiller.

See Installation section entitled,

Checking the Refrigerant Charge.

Reduce the glycol mixture of the

process coolant. See Installation

section entitled, Filling the Chiller.

Replace the process coolant. See

Installation section entitled, Filling the

Chiller.

See Maintenance section entitled,

Cleaning the Brazed Plate Evaporator.

Contact Conair Service.

Clean or replace the strainer. See

Maintenance section entitled, Cleaning

the Pump Strainer.

6

Troubleshooting

Troubleshooting l 6-7

NOTE: The is a normal

shutdown for other

alarm conditions when

the chiller’s main power

has been switch off.

✐

Page 60

Checking or Replacing the

Temperature Sensor

The EarthSmart ECM Series Chiller uses a RTD sensor to monitor the temperature

of the process coolant.

To check or replace an RTD sensor:

1 Disconnect and/or lockout the main power supply.

2 Locate the RTD sensor.

3 Check the sensor’s position and condition. Temperature readings will be

incorrect if the sensor is touching the wall of a pipe or if the sensor or wiring is

damaged. Sensor wires should be attached to the appropriate connection points

on the chiller’s control center.

4 To check with ohm meter, measure the resistance across the RTDs. The

resistance should be approximately 110 ohm at room temperature. See

Appendix F entitled, RTD Resistance Chart.

5 Remove the sensor from its housing using an appropriately-sized wrench.

6 Inspect the sensor for cleanliness. Replace if necessary with another sensor of

the same rating.

7 Replace the RTD, by wrapping the its threads with Teflon tape or pipe dope.

8 Re-insert the RTD into its housing, start by hand until its threads engage.

Tighten with an appropriately-sized wrench, do not over tighten.

Typical location of

the RTD at the

chiller’s evaporator.

IMPORTANT

: Always refer

to the wiring diagrams

that came with your

chiller to locate specific

electrical components.

Illustrations in the User

Guide are intended to be

representative only.

Replacement RTDs are

available from Conair.

Contact Conair Parts

(800) 458 1960

From outside of the

United States, call:

(814) 437 6861

6-8 l Troubleshooting

Page 61

Troubleshooting l 6-9

Checking or Resetting the Circuit

Breakers

The EarthSmart ECM Series Chiller uses electrical circuit breaker to protect the

chiller from overloads or improper operating conditions.

To check or reset the chiller’s circuit breakers:

1 Disconnect and lockout the main power supply.

2 Remove the chiller’s top lid, by first removing both side panels and then the

four (4) retaining bolts that secure the chiller’s top lid.

3 Locate the appropriate circuit breaker(s), located behind the chiller’s

control panel. See the wiring diagrams that came with your chiller.

4 Check the circuit breaker(s) position and condition. The chiller will not

operate correctly if one or more circuit breakers have been tripped (facing

down).

5 Reset the circuit breaker(s), if necessary.

6 Replace the chiller’s side panels and then the top lid by replacing the four

(4) retaining bolts.

7 Reapply main power.

IMPORTANT

: Always refer

to the wiring diagrams

that came with your

chiller to locate specific

electrical components.

Illustrations in the User

Guide are intended to be

representative only.

Circuit Breakers

Page 62

A-1 l Appendix

We’re Here to Help

Conair has made the largest investment in customer support in the plastics industry. Our service experts are available to help with any problem you might have

installing and operating your equipment. Your Conair sales representative also

can help analyze the nature of your problem, assuring that it did not result from

misapplication or improper use.

How to Contact Customer Service

To contact Customer Service personnel, call:

You can commission Conair service personnel to provide on-site service by

contacting the Customer Service Department.

Before You Call...

If you do have a problem, please complete the following checklist before

calling Conair:

❒

Make sure you have all model, control type and serial numbers from the serial

tag, and parts list numbers for your particular equipment. Service personnel will

need this information to assist you..

❒

Make sure power is supplied to the equipment.

❒

Make sure that all connectors and wires within and between control systems

and related components have been installed correctly.

❒

Check the troubleshooting guide of this manual for a solution.

❒

Thoroughly examine the instruction manual(s) for associated equipment, especially controls. Each manual may have its own troubleshooting guide to help you.

❒

Check that the equipment has been operated as described in this manual.

❒

Check accompanying schematic drawings for information on special considerations.

PARTS & SERVICE

U

S

8

0

0

4