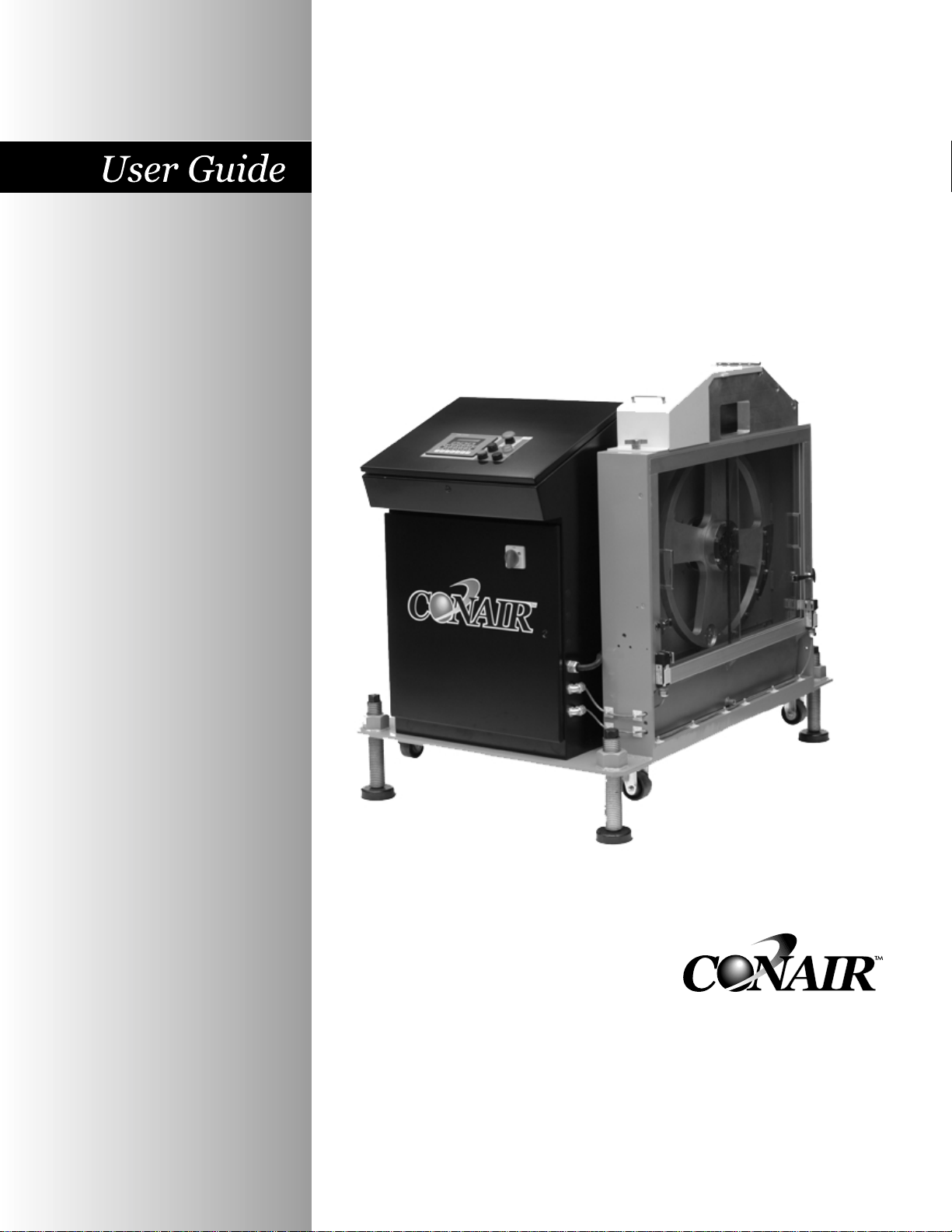

Page 1

Sure Cut Rotary Knife Cutter

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax:(412)-312-6227

SC-5 Servo Model

UGE059/1003

Installation

Operation

Maintenance

Troubleshooting

Page 2

It is important to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Keep this User Guide and all manuals, engineering prints and

parts lists together for documentation of your equipment.

Date:

Document Number: UGE059/1003

Serial number(s):

Model number(s):

Power Specifications:

Amps

Volts

Phase

Cycle

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Record your equipment’s

model and serial number(s) and the date you

received it in the spaces

provided.

Copyright 2003

All rights reserved

THE CONAIR GR OUP, INC.

Page 3

UGE059/1003 SC-5 SURE CUT Servo Knife Cutters

TABLE OF

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . .1-1

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2

How the Guide is Organized . . . . . . . . . . . . . . . . . . . . . . .1-2

Your Responsibilities as a User . . . . . . . . . . . . . . . . . . . . .1-2

ATTENTION: Read this so no one gets hurt . . . . . . . . . . .1-3

How to Use the Lockout Device . . . . . . . . . . . . . . . . . . . .1-5

DESCRIPTION . . . . . . . . . . . . . . . . . . . .2-1

What is the SC-5 Sure Cut? . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

How the SC-5 Sure Cut Works . . . . . . . . . . . . . . . . . . . . . .2-5

SC-5 Sure Cut Features . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

INSTALLATION . . . . . . . . . . . . . . . . . . . .3-1

Unpacking the Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Positioning the SC-5 Sure Cut . . . . . . . . . . . . . . . . . . . . . .3-4

Connecting the Main Power Source . . . . . . . . . . . . . . . . . .3-6

Installing the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Installing the Cutter Blades . . . . . . . . . . . . . . . . . . . . . . . .3-8

Mounting the Cutter Bushings . . . . . . . . . . . . . . . . . . . .3-10

Checking Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Preparing for Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

OPERATION . . . . . . . . . . . . . . . . . . . . . .4-1

The Cutter Control Feature . . . . . . . . . . . . . . . . . . . . . . . .4-2

Before Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Preset to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Time Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Cut Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Maintenance Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Encoder Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Unit of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Scale Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Offset Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Power On Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

Checking Cut Quality . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Starting the SC-5 Sure Cut . . . . . . . . . . . . . . . . . . . . . . . .4-29

Making Adjustments During Operation . . . . . . . . . . . . . .4-30

Stopping the SC-5 Sure Cut . . . . . . . . . . . . . . . . . . . . . . .4-31

i

Page 4

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

MAINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Maintenance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Maintenance Overview . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Preventative Maintenance Schedule . . . . . . . . . . . . . . . . . .5-4

Checking the Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Inspecting Cutter Bushing Screws . . . . . . . . . . . . . . . . . . .5-7

Checking the Closure Latch . . . . . . . . . . . . . . . . . . . . . . . .5-7

Cleaning the Blade Tray . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Lubricating the Slide Rail System . . . . . . . . . . . . . . . . . . .5-8

Adjusting the Proximity Switches . . . . . . . . . . . . . . . . . . .5-9

Checking Electrical Connections . . . . . . . . . . . . . . . . . . .5-10

B-Loc Installation and Removal . . . . . . . . . . . . . . . . . . . .5-12

TROUBLESHOOTING . . . . . . . . . . . . . . . .6-1

Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

A Few Words of Caution . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Identify the Cause of a Problem . . . . . . . . . . . . . . . . . . . . .6-3

Electrical Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Product Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Replacing Safety and Proximity Switches . . . . . . . . . . . .6-12

Checking the Servo Amplifier . . . . . . . . . . . . . . . . . . . . .6-12

Adjusting the Proximity Switches . . . . . . . . . . . . . . . . . .6-14

Checking the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Checking the Motor/Reducer Assembly . . . . . . . . . . . . . .6-17

Checking Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Service Information . . . . . . . . . . . . . . . . . . . . . .A-1

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Cutter Blade Selection and Use . . . . . . . . . . . . . . . . . . . . .B-1

Cutting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Calculating Blade Interruption . . . . . . . . . . . . . . . . . . . . . .B-4

Conair Cutter Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

All About Cutter Bushings . . . . . . . . . . . . . . . . . . . . . . . .C-1

Blade and Bushing Lubrication . . . . . . . . . . . . . . . . . . . . .D-1

Operator Display Overview . . . . . . . . . . . . . . . . . . . . . . . . E-1

P

ARTS/DIAGRAMS

This section has been provided for you to

store spare parts lists and diagrams.

ii

Page 5

1-1

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

●●

Purpose of the User Guide . . . .1-2

●●

How the User Guide

is organized . . . . . . . . . . . . . . .1-2

●●

Your Responsibilities

as a User . . . . . . . . . . . . . . . .1-2

●●

ATTENTION: Read this so

no one gets hurt . . . . . . . . . . .1-3

●●

How to Use the

Lockout Device . . . . . . . . . . . .1-5

INTRODUCTION

Page 6

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

1-2 INTRODUCTION

This User Guide describes the Conair SC-5 Sure Cut Servo

Knife Cutter and explains step-by-step how to install, operate,

maintain and repair this equipment.

Before installing this product, please take a few moments to

read the User Guide and review the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This

review won’t take long, and it could save you valuable installation and operating time later.

Symbols have been used to help organize the User Guide and

call your attention to important information regarding safe

installation and operation.

Symbols within triangles warn of conditions that could

be hazardous to users or could damage equipment.

Read and take precautions before proceeding.

Numbers within shaded squares indicate tasks or steps

to be performed by the user.

A diamond indicates the equipment’s response to an

action performed by the user.

An open box marks items in a checklist.

A shaded circle marks items in a list.

You must be familiar with all safety procedures concerning

installation, operation and maintenance of this equipment.

Responsible safety procedures include:

● Thorough review of this User Guide, paying particular

attention to hazard warnings, appendices and related diagrams.

● Thorough review of the equipment itself, with careful

attention to voltage sources, intended use and warning

labels.

● Thorough review of instruction manuals for associated

equipment.

● Step-by-step adherence to instructions outlined in this

User Guide.

PURPOSE OF

THE USER

GUIDE

HOW THE USER

GUIDE IS

O

RGANIZED

1

◆

❒

●

YOUR

RESPONSIBILITY

ASAUSER

Page 7

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial plate.

INTRODUCTION 1-3

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by following the procedures outlined below and elsewhere in the

User Guide.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

DANGER: Sharp blades!

Most injuries caused by knife blades occur

when the cutter has been turned off. Handle

blades with care at all times.

● Always lock out the cutter before opening the

cutting chamber.

● Always wear cut-resistant gloves when the

cutting chamber is open and when handling

blades.

SC-5 cutters are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

● When the knife guard is opened, the knife

guard switch stops the cutter.

● Two proximity-type safety switches prevent

operation unless the cutter bushings are in

place.

● The STOP button activates a circuit that

stops the knife.(Do not attempt to change a

blade or work in the cutting chamber with out

locking out the power.

Page 8

In order to protect the operator from possible harm from the

rotating blade wheel, several safety features are built into this

cutter. They include:

Two electric switches make a contact between the side

and the clear polycarbonate sliding blade observation

windows such that the windows MUST BE CLOSED

in order to enable the blade wheel to spin.

●●

This prevents someone from opening the windows and

having the blade wheel spin which can cause serious

injury. Tampering with this safety feature will VOID

ANY responsibility for safety.

A proximity switch is positioned on both the upstream

and downstream side of the bushing holder. If there

are no bushings in either side, the blade will not spin.

●●

This prevents someone from inserting their hands or

fingers in the cutting mechanism while the blade wheel

is spinning. Tampering with this feature will also

VOID ANY responsibility for safety.

A safety switch is positioned on the bushing holder flip

up guard to prevent operation unless fully closed.

●●

This prevents someone from inserting their hands or

fingers in the cutting mechanism while the blade wheel

is spinning. Tampering with this feature will also

VOID ANY responsibility for safety.

A lockable main power disconnect is provided to pre-

vent the possibility of hazardous electrical shock while

servicing the main electrical enclosure. (See How to

use the Lockout Device, in Section 1)

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

1-4 INTRODUCTION

WARNING:Voltage Hazard

This equipment is powered by three-phase

alternating current, as specified on the machine

serial tag and data plate.

A properly-sized conductive ground wire from

the incoming power supply must be connected

to the chassis ground terminal inside the electrical enclosure. Improper grounding can result in

severe personal injury and erratic machine

operation.

Always disconnect and lockout power before

opening the electrical enclosure or performing

non-routine procedures such as maintenance

and service.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

CAUTION:It is always recommend

that the main power cord be disconnected and placed in clear view

of the operator or service personnel while changing blades or servicing the cutter in any capacity.

Page 9

HOW TO USE

THE

LOCKOUT

DEVICE

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INTRODUCTION 1-5

WARNING: Electrical hazard

Before performing maintenance or repairs on

this product, disconnect and lock out electrical

power sources to prevent injur y from unexpected energization or start-up. A lockable device

has been provided to isolate this product from

potentially hazardous electricity.

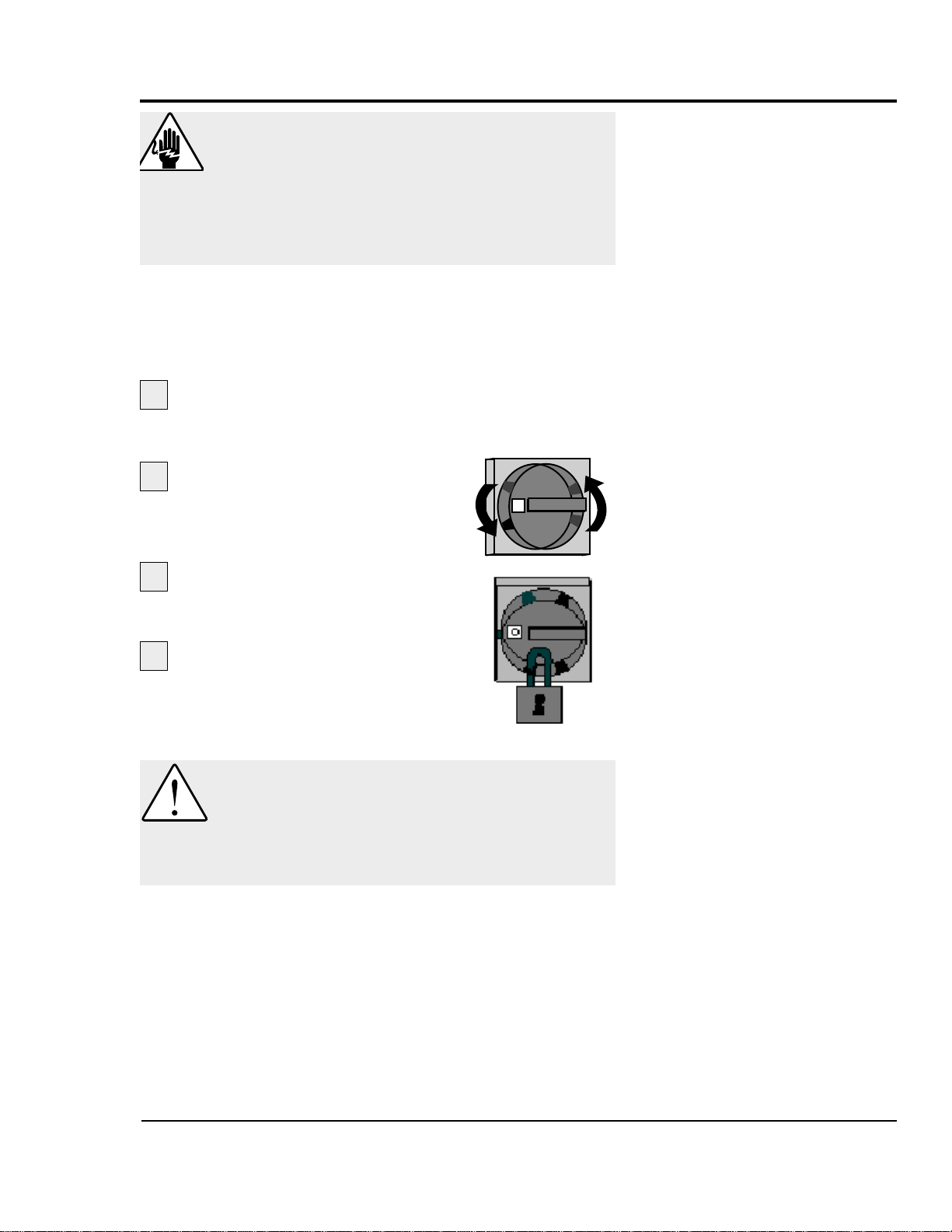

Lockout is the preferred method of isolating machines or

equipment from energy sources. Your Conair product is

equipped with the lockout device pictured below. To use the

lockout device:

Stop or turn off the equipment. Do not stop the

cutter by turning off the disconnect. Always touch the off

soft key on the interface first.

Isolate the equipment from

electrical power.

Turn the rotary disconnect switch to

OFF or O position.

Secure the device with an

assigned lock or tag.

The equipment is now locked

out.

CAUTION: Moving parts

Before removing lockout devices and returning

switches to the ON position, make sure that all

personnel are clear of the machine, tools have

been removed and all safety guards are reinstalled.

3

4

1

2

O

Page 10

Page 11

2-1

●●

What is the SC-5 Sure Cut

Knife Cutter . . .............2-2

●●

Typical Applications . . . .......2-4

●●

How the SC-5Works ...........2-5

●●

SC-5 Features . ...............2-7

●●

Specifications . ...............2-7

●●

Optional Equipment . . . . .......2-8

DESCRIPTION

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

Page 12

The Conair SC-5 Sure Cut Series rotary knife cutter has been

designed to be “The most versatile cutter of the industry”.

With both capacity to cut small parts at high speeds or large

tubes or profiles at low speeds this cutter can eliminate the

need for moving cutters in and out of a line per application.

Today with custom profile houses potentially running 2-3 different profiles on one line in a given day, time is at a premium. Having to move different cutters in and out of line is no

longer acceptable when time is money.

Mechanical Features

This series of servo rotary knife cutters use a 24 inch diameter

flywheel optimizing surface speed and power. This is in fact

the largest diameter wheel which could be used while still

allowing it’s mounting under the bushing holder.

Flywheel

With a 24 inch diameter flywheel which is 1inch thick, many

benefits become available.

Planetary Gear Reducer

A 10:1 in-line servo motor rated planetary gear reducer with 7

arc-minutes maximum backlash is mounted directly to a 3000

rpm brushless servomotor. A top flywheel speed of 300 rpm is

realized. Even though the flywheel appears to be moving

slowly, the actual surface speed at the blade at only 300

RPM’s is over 0.438 inch per millisecond. That’s twice the

surface speed of a typical clutch brake cutter.

Instead of mounting the cutter head directly to the servo motor

shaft, which is generally not designed for high radial load or

axial load due to small shaft diameters, the 24 inch flywheel is

mounted to the planetary gear reducer shaft which is designed

for just this type of application. At the gear ratio and output

speeds which this cutter was designed, radial load on the output shaft of the reducer is in excess of 1000 lbs where the

servo motor shaft may only be 100 lbs or less. Potential wear

on the servo motor shaft bearings is minimized.

The high speed\low torque power of the servo motor is efficiently converted into a low RPM\high surface speed\high

torque power more suitable for cutting applications.

WHAT IS THE

SC-5 SURE

CUT?

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

2-2 DESCRIPTION

Continued

Page 13

W

HAT IS THE

SC-5 S

URE

CUT?

CONTINUED

DESCRIPTION 2-3

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

The larger diameter flywheel used on the servo cutter offers

the potential of higher surface speeds at dramatically lower

blade rpm’s with high cutting torque. The typical grey area

between on-demand cutting and flywheel cutting (150 cpm

on-demand up to 300 cpm flywheel), typically seen in DC driven clutch\brake cutter is eliminated.

It should not be necessary to cut in on demand mode in excess

of 150 cuts per minute which will greatly save on premature

wear to the system. Not only does this cutter offer optimum

blade surface speed throughout an extremely wide cuts per

minute range, but extreme accuracy throughout.

The added benefit of the 24 inch diameter by one inch thick

aluminum wheel is the stored inertia which adds power for

cutting larger profiles and tubes. The size of the wheel actually adds horsepower to the system. Due to the use of 10:1 gear

reduction, the servomotor is made extremely efficient and easily able to handle this weight with out detrimental effects.

Page 14

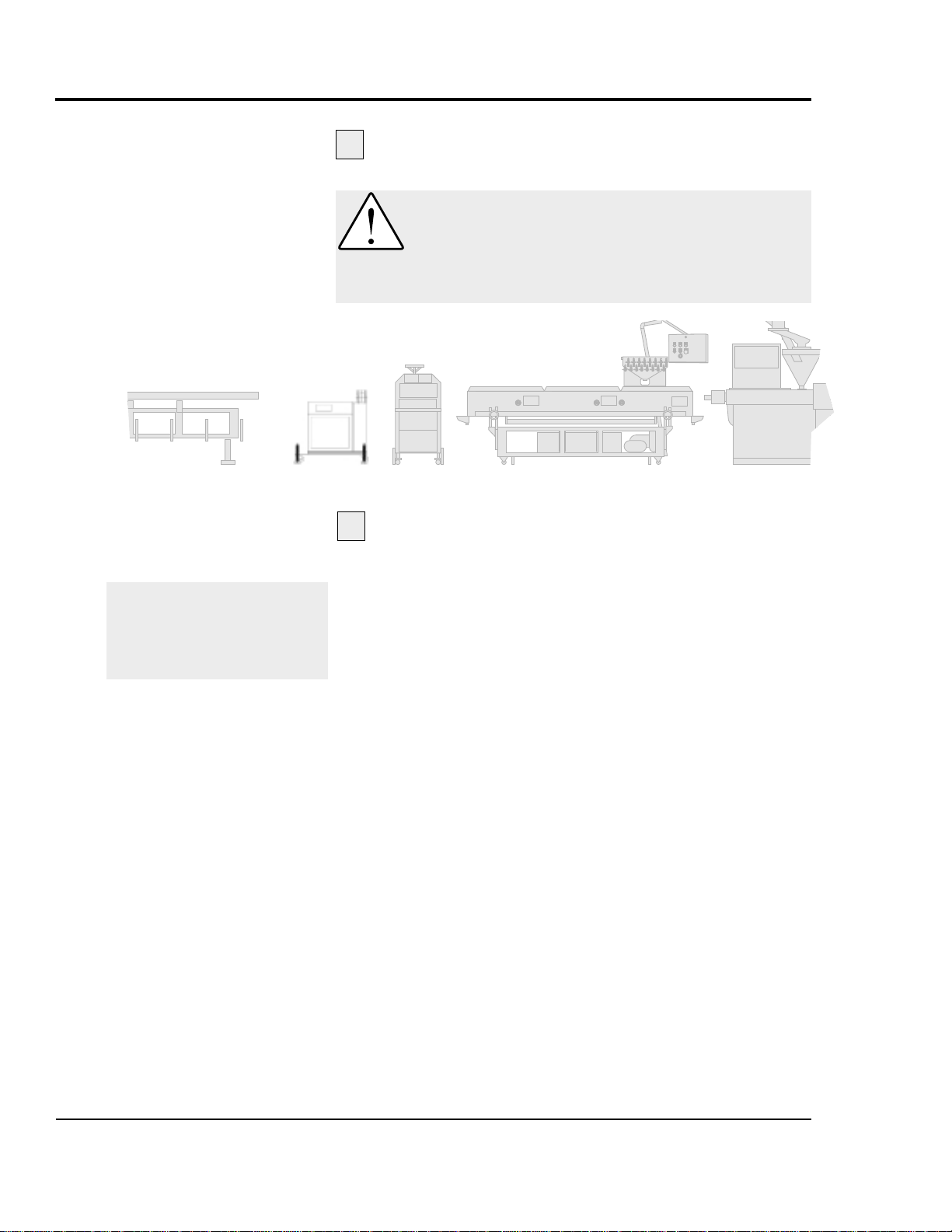

Cutting from Below the Bushing Holder

The SC-5 Sure Cut Servo Cutter housing maximizes versatility and operational ease. Due to the size of the flywheel it was

determined best to mount it directly below the bushing holder

keeping the center of gravity low and offering the following

benefits:

● Accessibility of the flywheel for ease of blade changes.

● Built in blade lubrication tray can be integral to the design

of the cutting chamber.

● An optional blade heating system can be added to give

optimum versatility to this cutter.

● With the bushing holder above the flywheel tremendous

cutting capacity is available without extreme blade length.

● Ease of discharge conveyor interface for part support and

automatic ejection systems is made simple with this layout.

● The optional slide system can enable the use of rigids and

flexibles.

To get the full benefit from the servo cutter Conair has provided several cutting modes, see Cutter Control, Section 4. The

Conair SC-5 Sure Cut servo rotary knife cutter is a truly innovative cutter. Loaded with features and backed up by the most

extensive service support system in the industry.

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

2-4 DESCRIPTION

TYPICAL

APPLICATIONS

Page 15

Extruded material that has been sized and cooled enters the

cutter from the upstream side (See How the SC-5 Sure Cut

Works, Section 2, step 1). Typically, a puller is placed just

before the cutter; the puller pulls the extrudate through the

sizing and/or cooling tanks and feeds it into the cutter.

The positional servo motor, is direct coupled to the cutter

head, or an in-line planetary gear reducer that drives the cutter head. The planetary gear reducer arrangement increases

cutting torque, improves servo motor efficiency, and offers

improved bearing load ratings.

The cutting knife, attached to the cutter head, is driven by

the servo motor (See How the SC-5 Sure Cut Works, Section

2, step 2). Two cutter bushings guide and support both the

extrudate and the cutting knife. The cutter head is mounted

directly to the in-line planetary gear reducer shaft using a BLoc coupling device, and may have as many as four optional

blade positions. See Installation and Removal of B-Loc,

Section 5.

Two types of cutting modes are available. On-demand cutting modes (Timer, Encoder, Auto and Product) provide a

single rotation cut cycle. However, in continuous cutting

modes (Flywheel and Optional Follower) the cutting mechanism rotates continuously.

The knife guard includes a stainless steel lower tray, which

can be used for blade lubrication. The upper knife guard

includes a clear polycarbonate window. This allows you to

watch the cutting blade during operation.

Cut pieces are collected or carried on to further processing

by an optional conveyor (See How the SC-5 Sure Cut Works,

Section 2, step 3).

Continued on next page.

H

OW THE SC-5

S

URE CUT

WORKS

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

DESCRIPTION 2-5

Page 16

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

2-6 DESCRIPTION

The cutter head holds the

blade(s) as they rotate

and pass between the

bushings, cutting the

extrudate.

Extruded material enters the

cutter from the upstream side.

1

Cut pieces are collected or

carried away on a conveyor.

2

3

HOW THE SC-5

S

URE CUT

WORKS

C

ONTINUED

Page 17

The SC-5 Sure Cut Servo Cutter features:

SC-5

F

EATURES

DESCRIPTION 2-7

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

Swivel Casters

Parts discharge chute or

optional discharge conveyor

Optional slide base

assembly with position

locking mechanism

Wide Range of Cutter

Bushing Capacities

24-inch diameter flywheel with multiple

blade mounting system

Polycarbonate blade

observation window

Optional blade

lubrication system

Heavy-duty leveling

screws and pads

The standard control:

● Large easy-to-read display.

● Soft keys allows the opera-

tor to select different functions.

● Numeric keys permits data

entry for the operator.

● Fixed function keys contain

universal symbols and text.

MODELS SC-5

Performance characteristics

Extruder capacity in. {mm}

Tube diameters 2.25 - 5.25 {57 - 133}

Profile dimensions 2x4 - 2x10, 4x7 {51x102 - 51x254, 102x178}

Blade drive motor Hp {kW} 4.6 {3.4}

Feed direction right>left

Dimensions in. {mm}

A - Height 47 {1194}

B - Height to centerline 40±2 {1016±50.8}

C - Length 44 {1118}

D - Width 52 {1321}

Voltage/phase/frequency 230 V/3/60 Hz 0r 460 V/3/60 Hz

Cutter control Red Lion {CL01/FM4}

A

B

C D

● 24-inch flywheel

● Up to 150 cuts/minute on

demand with one blade

● Up to 300 cuts/minute with one

blade on Flywheel mode

● Blade speeds adjustable to

300 RPM

● Surface speeds to 0.438 inches

per millisecond

● Heavy-duty positional AC

brushless servo drive

● 10:1 planetar y gear head

reducer

● 3,000 pulse bi-directional

encoder

S

PECIFICATIONS

CONAIR SERVO CUTTER

Version 1.0

Page 18

OPTIONAL

EQUIPMENT

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

2-8 DESCRIPTION

Slide Base

This option is highly recommended for cutting flexible extrudates. While the cutter base is fixed and aligned with the

puller, the cutter itself is mounted on a set of linear slides that

allow as much as 12 inches of movement. The cutter can be

moved away from the puller for startup, then moved close to

the puller to enhance delivery to the cutter bushings.

Blade Wipe

The blade wipe system keeps the cutting blade clean by

removing lubricant and particles from the blade. A felt pad

sandwiched between two pieces of stainless steel and mounted

next to the bushing wipes the knife before each cut.

Custom Bushing Holder Sizes Available:

Heavy Duty Blade Positions

●●

One blade position standard

●●

Optional 2 or 4 blade positions available

●●

Optional simitare blade available (see parts list for optional

blades.)

Round Profile

2.25 inch (standard) 2x4 inch

3.25 inch 2x6 inch

4.25 inch 2x8 inch

5.25 inch 2x10 inch

3x6 inch

4x7 inch

Page 19

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

DESCRIPTION 2-9

TIP: Conair strongly recom-

mends the use of an isolation

transformer.Ensuring clean

and proper power can help

avoid the need for costly service calls.

Discharge Conveyor

A discharge conveyor facilitates the removal of cut parts.

Discharge conveyors are available in the following sizes:

● 6 inches wide by 6 feet long

● 6 inches wide by 10 feet long

● 6 inches wide by 16 feet long

Isolation Transformer

The isolation transformer protects sensitive electronics from

incoming power, which helps prevent errors caused by electrical noise. It also protects equipment from electrical noise generated by the servo motor and associated amplifier.

NOTE: An isolation transformer will not compensate for a

ground that does not meet code requirements.

Left to Right Machine Operation

This option changes the machine direction from the standard

right to left extrusion flow.

Special Paint Type or Color

This option covers any change from the standard Conair

paint.

Your Conair sales representative can analyze your needs and

recommend the options that are right for your system.

OPTIONAL

EQUIPMENT

Page 20

Page 21

3-1

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

●●

Unpacking the Boxes . . . . . . . . .3-2

●●

Preparing for Installation . . . . . .3-3

●●

Positioning the SC-5

Sure Cut . . . . . . . . . . . . . . . . .3-4

●●

Connecting the Main

Power Source . . . . . . . . . . . . .3-6

●●

Installing the Encoder . . . . . . . .3-7

●●

Installing the Cutter

Blades . . . . . . . . . . . . . . . . . . .3-8

●●

Mounting the Cutter

Bushings . . . . . . . . . . . . . . . .3-10

●●

Checking Repeatability . . . . . .3-12

●●

Preparing for Testing . . . . . . . .3-13

●●

Testing the Installation . . . . . . .3-13

INSTALLATION

Page 22

The SC-5 Sure Cut Series Servo Knife Cutter comes fully

assembled in a single crate.

UNPACKING THE

BOXES

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

3-2 INSTALLATION

CAUTION: Lifting

To avoid personal injury or damage to the cutter, lift the cutter using a for klift or hoist with

straps that have been positioned at the cutter's

center of gravity.

Carefully uncrate the cutter and its components.

Remove all packing material

, protective paper,

tape, and plastic. Compare contents to the shipping papers

to ensure that you have all the parts.

Carefully inspect all components to make sure

no damage occurred during shipping. Check all wire terminal connections, bolts, and any other electrical connections, which may have come loose during shipping.

Record serial numbers and specifications in the

blanks provided on the back of the User Guide's title

page. This information will be helpful if you ever need

service or parts.

You are now ready to begin installation.

Complete the preparation steps in Preparing for

Installation, Section 3.

1

2

3

4

5

Page 23

You need these tools for installation:

❒ wire strain relief

❒ 16- or 18-inch adjustable wrench

❒ set of Allen wrenches

❒ set of feeler gauges

❒ ½ inch open or box end wrench

❒ flashlight

Plan the location. Make sure the area where the

servo cutter is installed has the following:

● A grounded power source. Check the cutter’s seri-

al tag for the correct amps, voltage, phase and

cycles. All wiring should be completed by qualified

personnel and should comply with your region’s

electrical codes.

● Clearance for safe operation and maintenance.

Make sure there is enough clearance around the

servo cutter for maintenance and servicing. If the

servo cutter has the optional slide base, be sure to

check for clearance by extending the slide system in

both directions.

PREPARING FOR

INSTALLATION

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INSTALLATION 3-3

1

2

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial tag and data

plate.

Page 24

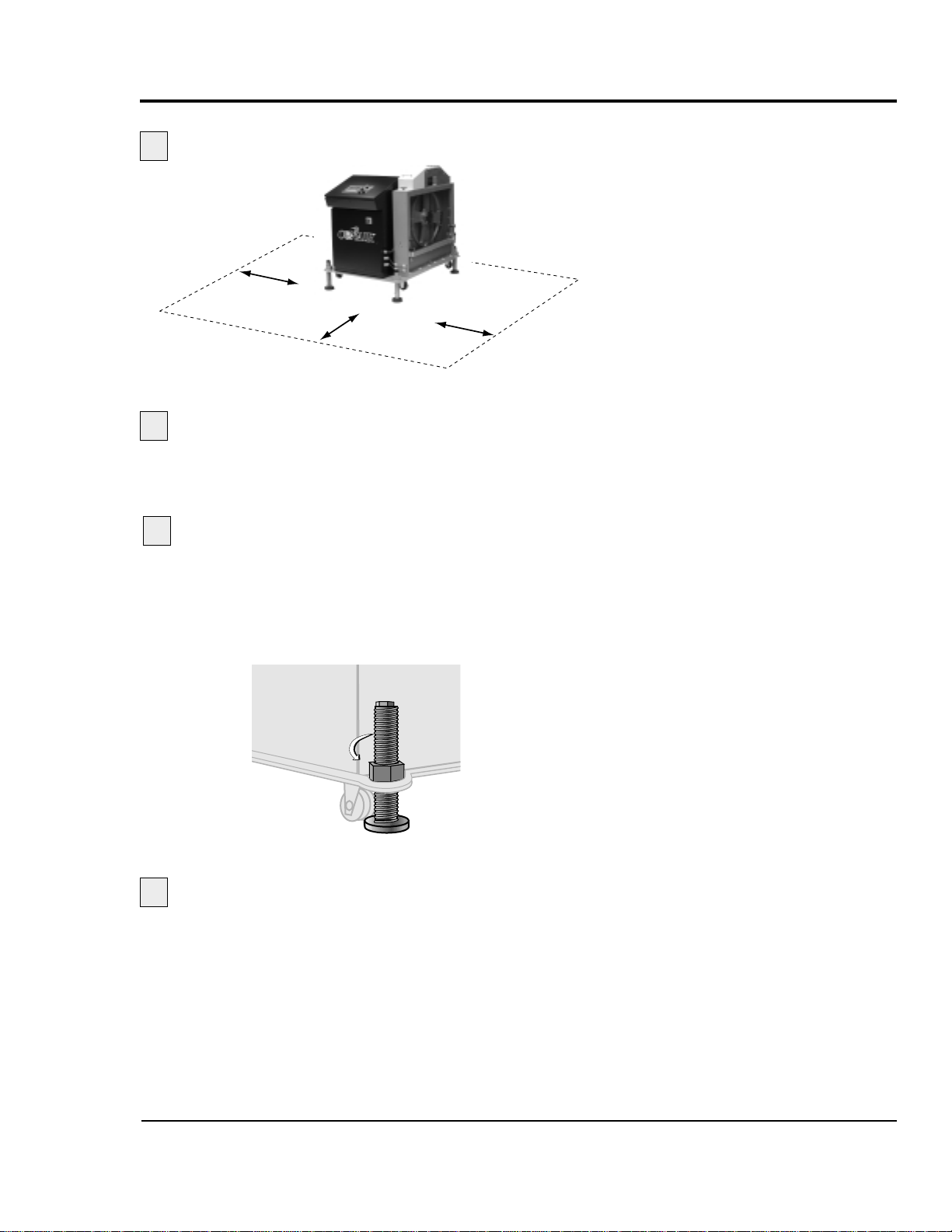

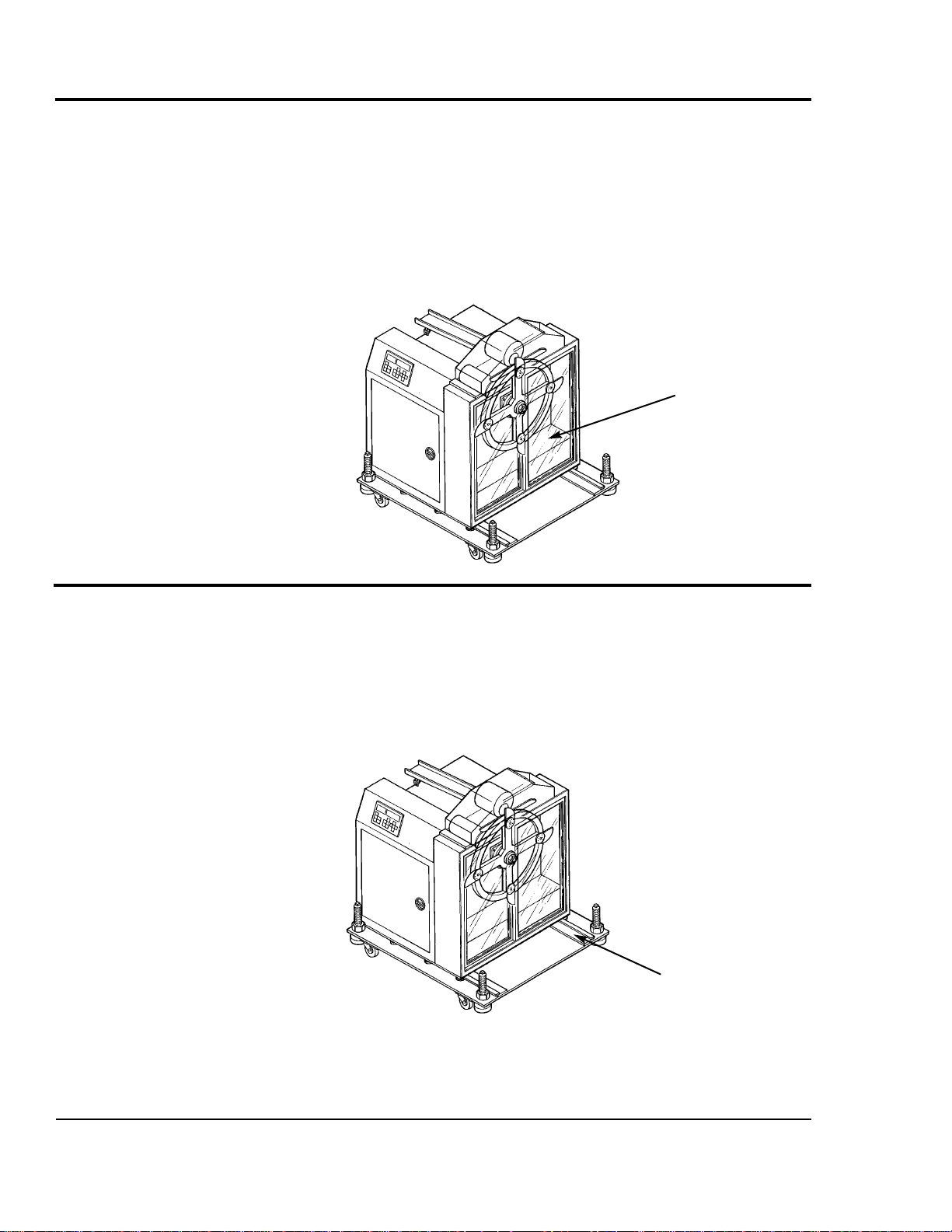

Move the servo cutter into position. Place the

servo cutter in position downstream of the belt puller.

Determine the best distance from the belt puller to

the SC-5 Sure Cut cutter.

● For flexible products, the cutter should be located

as close to the puller as possible to insure a minimum amount of space for the product between the

point of exit of the puller and the inlet to the cutter

bushing for most flexible products.

● For rigid products, allow some deflection space

between the puller and cutter. This will minimize

product sag or excessive deflection during cutting

which could affect the cut length accuracy.

As a general rule, place the cutter such that you feel

no shock from the cut with your fingernail placed

on the extrudate on the entrance of the puller. If you

feel shock form the cut, simply allow more space

between the cutter and puller.

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

3-4 INSTALLATION

1

P

OSITIONING

THE

SERVO

CUTTER

CAUTION: Lifting

To avoid personal injury or damage to the cutter, lift the cutter using a for klift or hoist with

straps that have been positioned at the cutter's

center of gravity.

2

NOTE: If the slide base option

was purchased, the cutting

chamber can be slid back from

the frame to allow ease of the

string up procedure.

SC-5 Cutter

Continued

Page 25

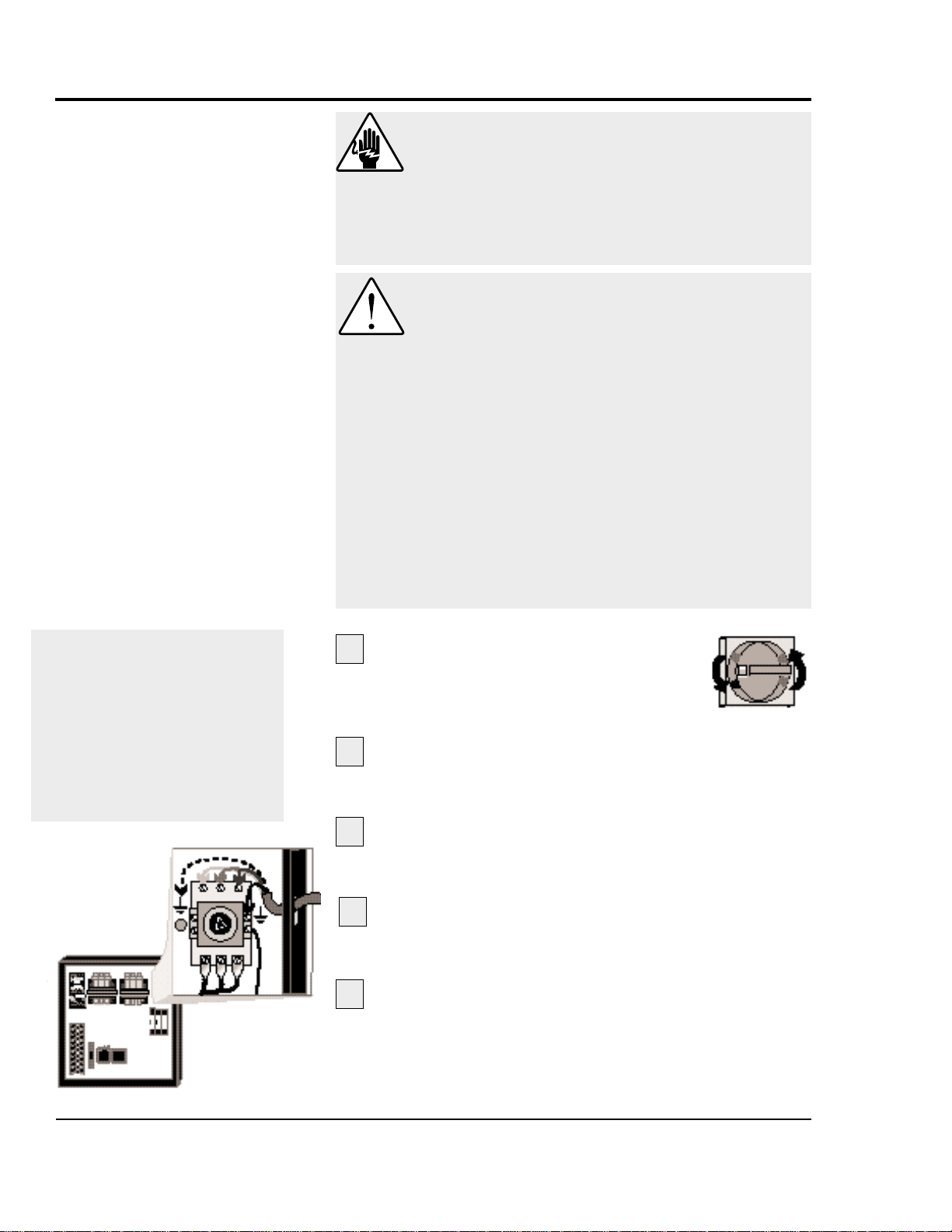

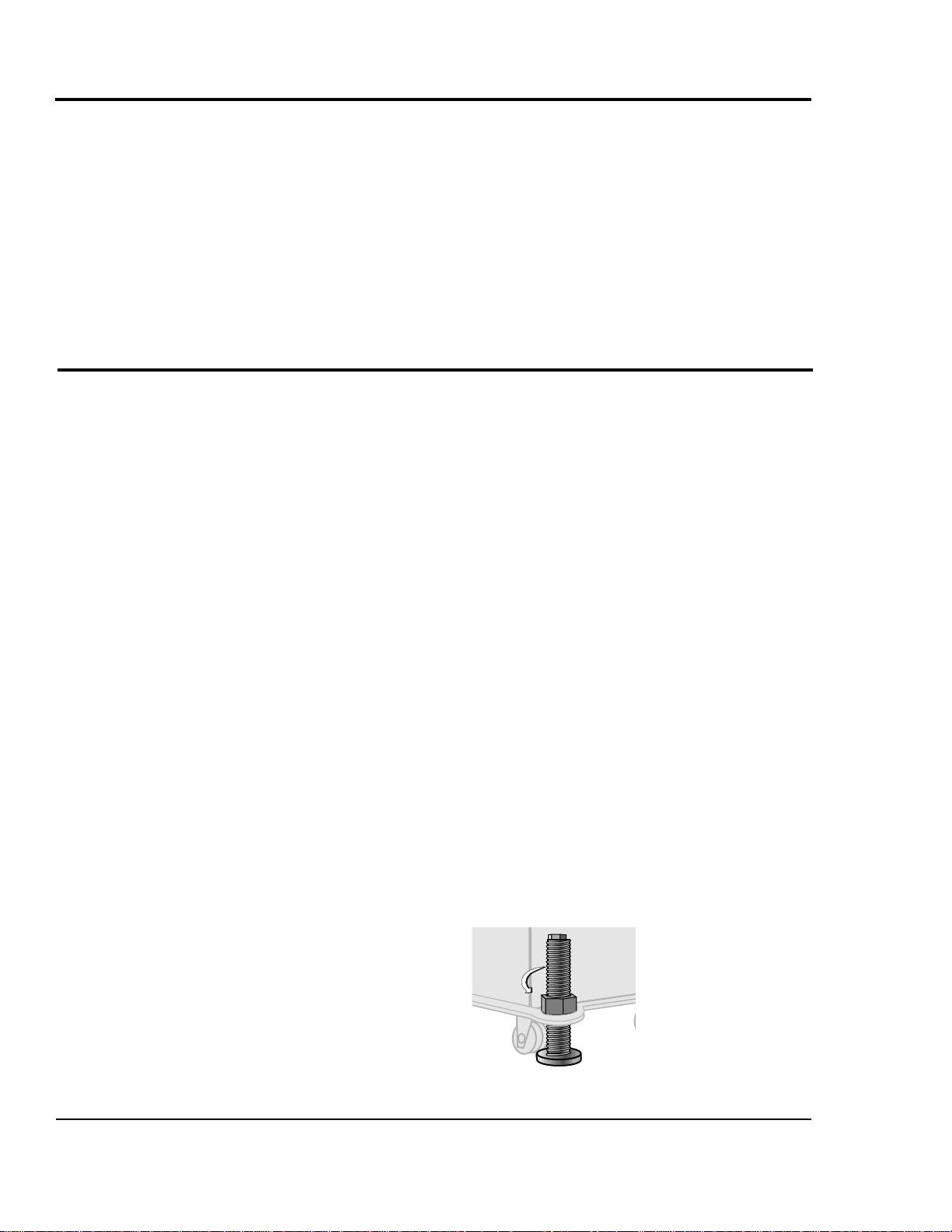

Align the cutter with the extrusion line.

Measure the centerline height of the extrudate as

it exits the extrusion die. Adjust all equipment on the extrusion

line (sizing tank, cooling tanks, belt puller, and cutter) to this

height.

Adjust the cutter's floorlock/caster assembly

to the center height of the extrusion line using a 16- or

18-inch adjustable wrench. Once the correct height is

reached, adjust the pad assembly to remove the weight

from the casters for operation. This minimizes machine

vibration during the cutting cycle.

Use a plumb line or laser to check for a

straight line

from the extrusion die through each line

component to the cutter bushings. Adjust as necessary.

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INSTALLATION 3-5

4

5

6

3

POSITIONING

THE

SERVO

CUTTER

CONTINUED

Page 26

3-6 INSTALLATION

Open the servo cutter’s electrical

enclosure.

Turn the disconnect dial on

the door to the OFF or O position and

open the door.

Insert the main power wire through the knockout

in the side of the enclosure. Secure the wire with a rubber

compression fitting or strain relief.

Connect the power wires to the terminals indicated

on the wiring diagram that came with your machine.

1

2

IMPORTANT: Always refer to

the wiring diagrams that

came with your servo cutter

before making electrical connections.The diagrams show

the minimum size main power

cable required for your cutter,

and the most accurate electrical component information.

CONNECTING

THE

MAIN

POWER SOURCE

3

WARNING: Electrical hazard

Before performing any work on this product, disconnect and lock out electrical power sources

to prevent injury from unexpected energization

or start-up. A lockable device has been provided to isolate this product from potentially hazardous electricity.

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial tag and data

plate.

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

Check every terminal screw to make sure wires are

secure. Gently tug each wire. If a wire is loose, use a

screwdriver to tighten the terminal.

Connect the ground wire to either grounding point

shown in the diagram.

4

5

Page 27

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INSTALLATION 3-7

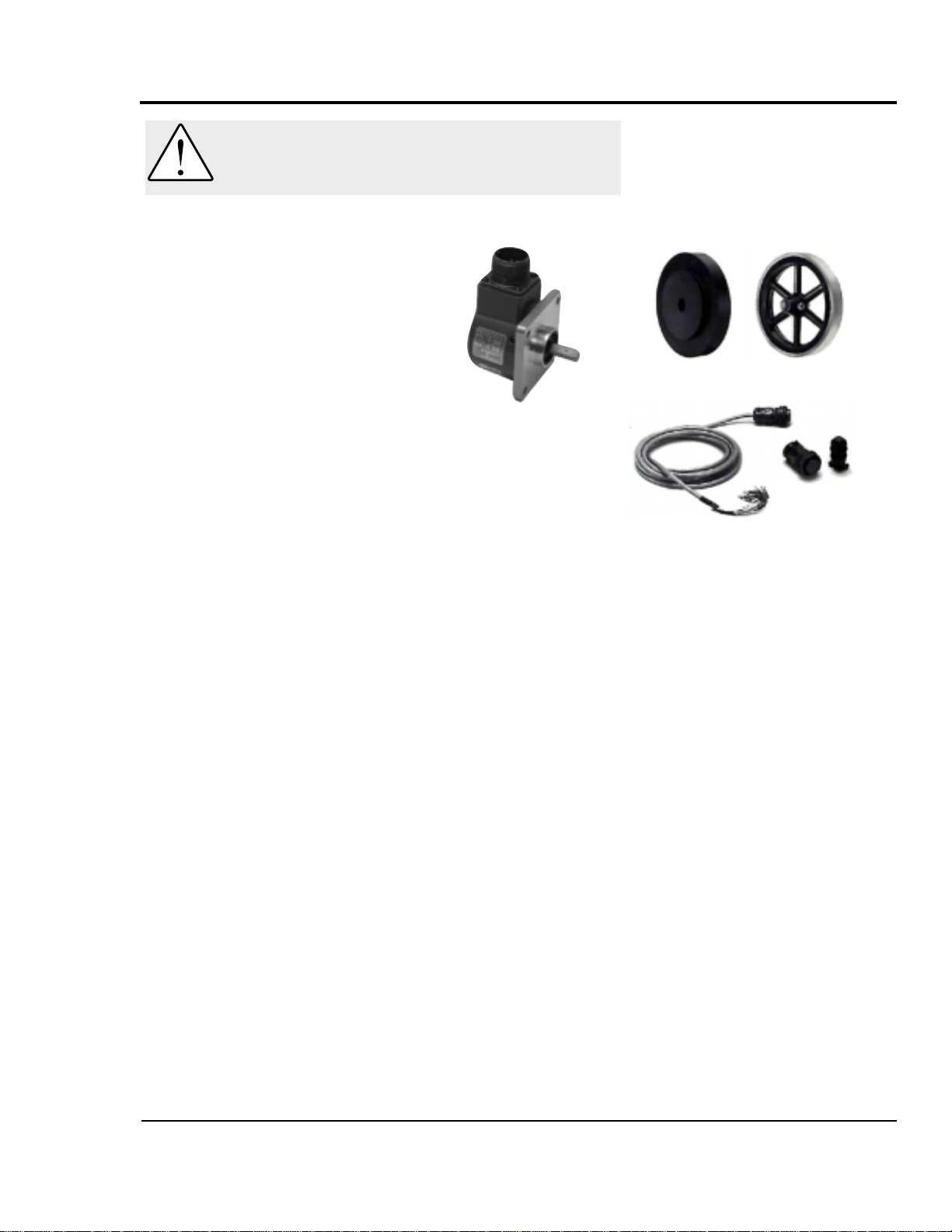

Conair uses bi-directional encoders to ensure that only product

that moves forward is counted.

Installing the encoder consists of several parts:

● the encoder

● the measuring wheel

● the connecting cable

The encoder is fitted with a one foot

circumference wheel which rides on

either the upper belt of the belt puller or (for rigid profiles and

pipe) on the extrudate itself upstream of the puller.

The encoder is supplied with an integral mounting bracket.

How and where you attach the encoder to the puller depends

on your particular puller and application.

● If the wheel rides on the puller belt, make sure that its lin-

ear alignment is the same as the belt. Place the wheel near

the center of the belt to minimize bouncing. Try to avoid

cracks and other belt features that may effect accuracy.

● Make sure the location allows you to keep the wheel

clean. Any small buildup on the wheel will effect its circumference and change the cut length.

After the encoder is installed, attach it to the cutter control

using the supplied cable. The cable has been hard-wired to the

control at the factory.

INSTALLING THE

ENCODER

CAUTION: Handle with care.

The encoder is a delicate piece of equipment

and must be handled gently.

Wheels

Connecting

Cable

Encoder

Page 28

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

3-8 INSTALLATION

I

NSTALLING THE

CUTTER

BLADES

DANGER: Sharp blades!

Most injuries caused by knife blades occur

when the cutter has been turned off. Handle

blades with care at all times.

● Always lock out power to the cutter before

opening the cutting chamber.

● Always wear cut-resistant gloves when the

cutting chamber is open and when handling

blades.

● Always wait until the cutter head has completely stopped before opening the knife

guard.

SC-5 Sure Cut cutters are equipped with several safety devices to ensure safe operation.

Never remove or disable these devices to sustain production. Operating without these devices

can cause severe injury.

Never attempt to change or work on Blades

without first locking out power to the machine.

● When the knife guard is opened, the

knife guard switch stops the cutter.

● Two proximity-type safety switches prevent

operation unless the cutter bushings

are in place.

● The STOP button activates a circuit that

stops the cutter head.

Installing the Cutter Blades

Shut off the main power disconnect and

unplug the main power cord

when entering the

cutter housing. There is a safety interlock on the cutter

blade housing that will deactivate the servo amplifier and

control system.

Remove the screws holding the blades,

remove the old blades and insert the new

blades.

The blade, or blades as the case may be, will fit

onto a roll pin or in a machined slot with a blade

clamp to squeeze or tighten. Secure the blade.

For more information about choosing the appropriate blade for

your material, see the Appendix B.

1

2

Continued

Page 29

INSTALLATION 3-9

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

TIP: We recommend that you:

● Apply some protective cover on the portion of

the blade you are handling, such as masking tape

to help prevent getting cut during installation and to

leave it on until such time that you will start and

check the cutting operation.

● Check the length that the blade extends out of

the cutter blade wheel. The blade needs to be

carefully checked to insure that the entire blade will

pass completely through the product.

This is especially important with the very first insta-

llation and can be accomplished by rotating the

wheel with the blade installed manually though the

bushing and visually check to see that it will completely cover the entire bore of the bushing.

INSTALLING THE

CUTTER

BLADES

C

ONTINUED

CAUTION:Never attempt to change or work on

blades without first locking out power to the

machine.

CAUTION: Use extreme caution as the blades

will be very sharp.With the power off, the blade

wheel can spin freely.

Page 30

DANGER: Sharp blades!

Always wear cut-resistant gloves when the cutting chamber is open and when handling

blades.Never open cutting chamber without

locking out the cutter power and waiting until

the cutter head stops spinning.

3-10

INSTALLATION

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

MOUNTING THE

CUTTER

BUSHINGS

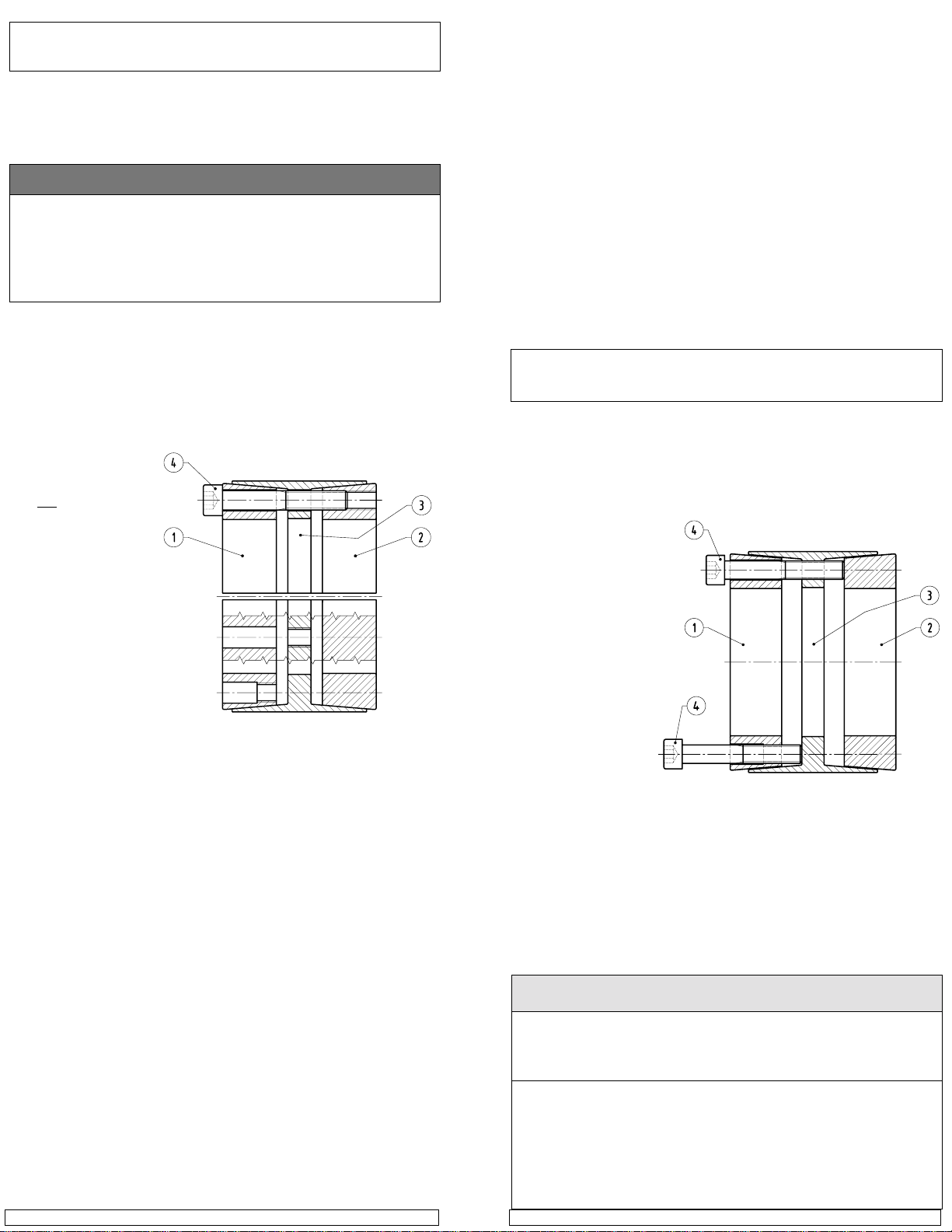

The Bushings

Generally, the bushing will be in two parts, an inlet and an

outlet with the inlet bushing being tapered or otherwise contoured to assist in guiding the product into the cutter mechanism. It is extremely crucial to the success of the cutting

process that bushing bores be exact and in perfect alignment

with each half. They should be polished smoothed, burr free

and generally several thousands oversized for optimum performance.

Installation of the bushing

Open the top hinged cover (yellow) to expose

the top of the bushing holder.

Use the two set screws positioned on top of the

bushing holder and turn them counterclock

wise to loosen and remove the bushings.

Replace the desired bushings and tighten up

the two set screws just enough to barely be

able to move the bushings.

Rotate the blade wheel until the blade enters

the space between the two bushings.

Move the outlet bushing in until you can bare-

ly feel the blade scrape along the inside of the

bushing.

Move the inlet bushing inward until there is

about 0.001 to 0.003 inch clearance between

the blade and the outlet bushing.

Tighten the two screws in the housing to lock

in the bushings.

Rotate the blade wheel

by hand so that the blade

passes through the space between the two bushings to

insure that it will clear without hitting either bushing and

passes through the space with little effort.

1

2

3

4

5

6

7

8

Page 31

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INSTALLATION 3-11

CHECKING THE

ALIGNMENT OF

THE

BUSHINGS

For more information about

setting and adjusting the gap

for the bushings, see About

Cutter Bushings in the

Appendix C.

Checking the Alignment of bushing to blade

Once you are sure that the blade will easily clear the bushings as it goes through the space you should then make

some test cuts to insure quality.

Close the safety cover.

Turn on the Power (Rotary main disconnect).

Press the Green start button.

Do several test cuts by pressing the manual

cut button.

Check the quality of the cuts. Adjust the bushing if necessary.

1

2

3

4

5

Page 32

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

3-12 INSTALLATION

CHECKING

REPEATABILITY

Before any Conair SC-5’s are shipped, they are tested for cut

time repeatability to be sure they are within performance specifications. The repeatability test checks the performance of the

rotary knife cutter to return to the home park position after a

complete cut. Acceptable repeatability times allowed for each

cutter model prior to shipping are:

Type of Cutter Repeatability Time

AC Pneumatic Cutter Less than 1 millisecond

DC Pneumatic Cutter Less than 1.5 millisecond

Positional Servo Less than 0.1 millisecond

Note: 1-millisecond at 60 feet per minute is equal to 0.012 inches.

The repeatability mode is built into the Conair cutter controls

and allows you to perform similar tests, without any external

test equipment. It is recommended that you check repeatability

on a regular basis. Refer to Operation Section 4, Control

Instructions Test to run repeatability tests. Acceleration/deceleration delays of the servo do not contribute to repeatability

error; any error is attributed solely to motor stability, couplings, assembly, power, and proximity sensor alignment.

Use any blade speed and line speed. The line speed is only

seen while in the Encoder or Product modes. It is recommended that the tests be performed at cut intervals between 0.5 and

5-seconds. Do not change the blade speed or the line speed

after starting the test.

Page 33

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

INSTALLATION 3-13

Make sure all components are installed according

to assembly drawings. Make sure that all bolts on the cutter have been tightened.

Check that cutter is firmly locked into position

with the anchoring screws.

Check that all wiring conforms to electrical

codes

, and all wiring covers are in place.

Locate the main disconnect switch on the front

of the control cabinet.

Turn it on. You should see the

Redlion interface illuminate and start communications

and the yellow power light should now be on.

Make sure the bushings and the blade doors

are in place and secure.

Check that the bushing

access door is closed and the threaded knob is tight and

the E-stop is in the out position.

Press the green start button. If the guard circuit is

ready the green start button will now be illuminated.

Do a test cut, by pressing the black manual cut

button.

You should have caused the flywheel to com-

plete on test cut.

To enable the cutter, push the center arrow

key .

If for any reason any of these steps could not be achieved

please refer to the troubleshooting section of the manual.

1

2

PREPARING FOR

TESTING

1

3

TESTING THE

INSTALLATION

2

3

4

5

Page 34

Page 35

4-1

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

●●

The Cutter Control . . . . . . . . . . .4-2

●●

Before Starting . . . . . . . . . . . . . .4-3

●●

Powering Up . . . . . . . . . . . . . . . .4-3

●●

Main Screen . . . . . . . . . . . . . . . .4-5

●●

Total Screen . . . . . . . . . . . . . . . .4-6

●●

Batch Screen . . . . . . . . . . . . . . .4-7

●●

Length Screen . . . . . . . . . . . . . .4-9

●●

Preset to Run . . . . . . . . . . . . . .4-10

●●

Time Preset . . . . . . . . . . . . . . .4-11

●●

Blade Speed . . . . . . . . . . . . . . .4-13

●●

Function Areas . . . . . . . . . . . . .4-15

●●

Test Screen . . . . . . . . . . . . . . . .4-16

●●

Cut Mode . . . . . . . . . . . . . . . . .4-18

●●

Min. Measurement . . . . . . . . . .4-19

●●

Maintenance Area . . . . . . . . . .4-19

●●

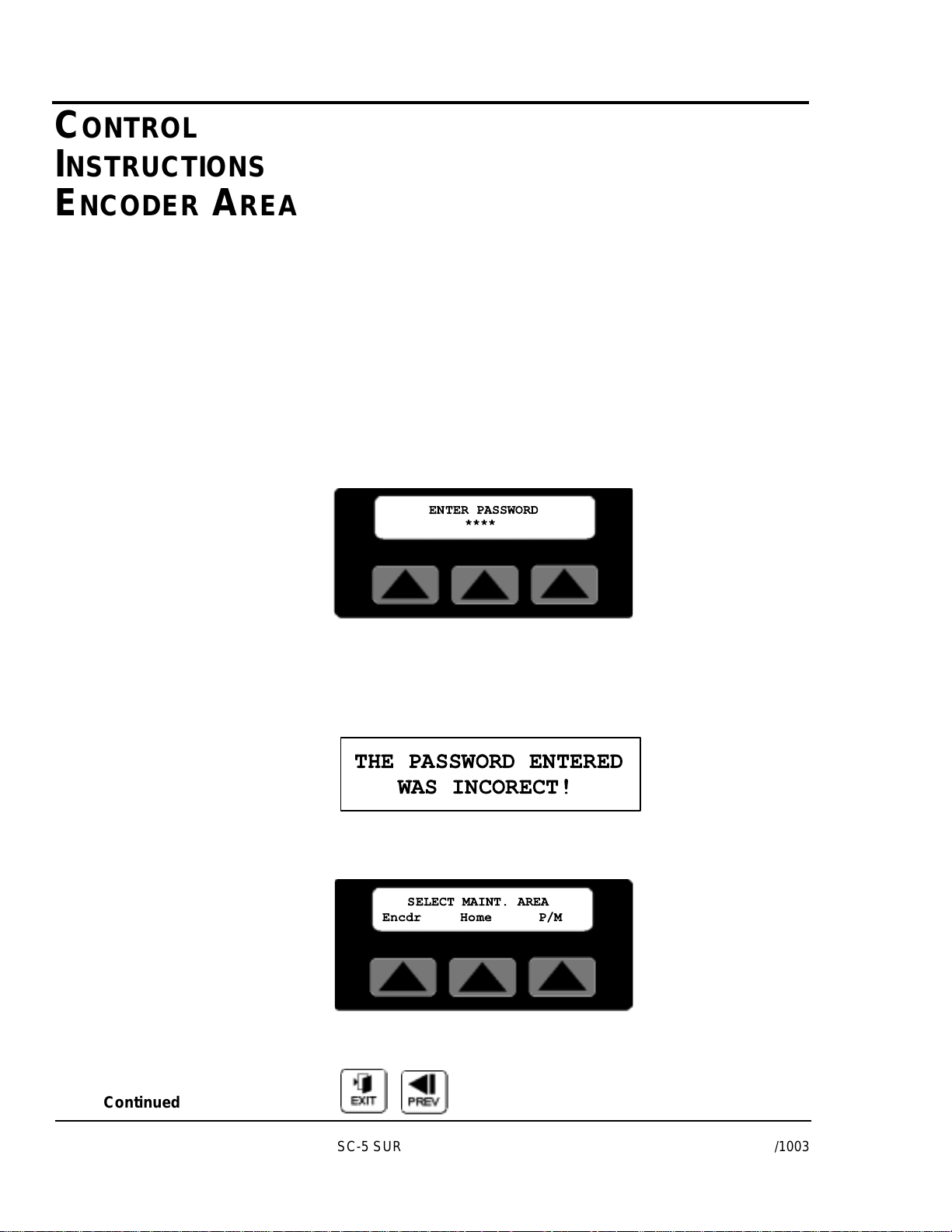

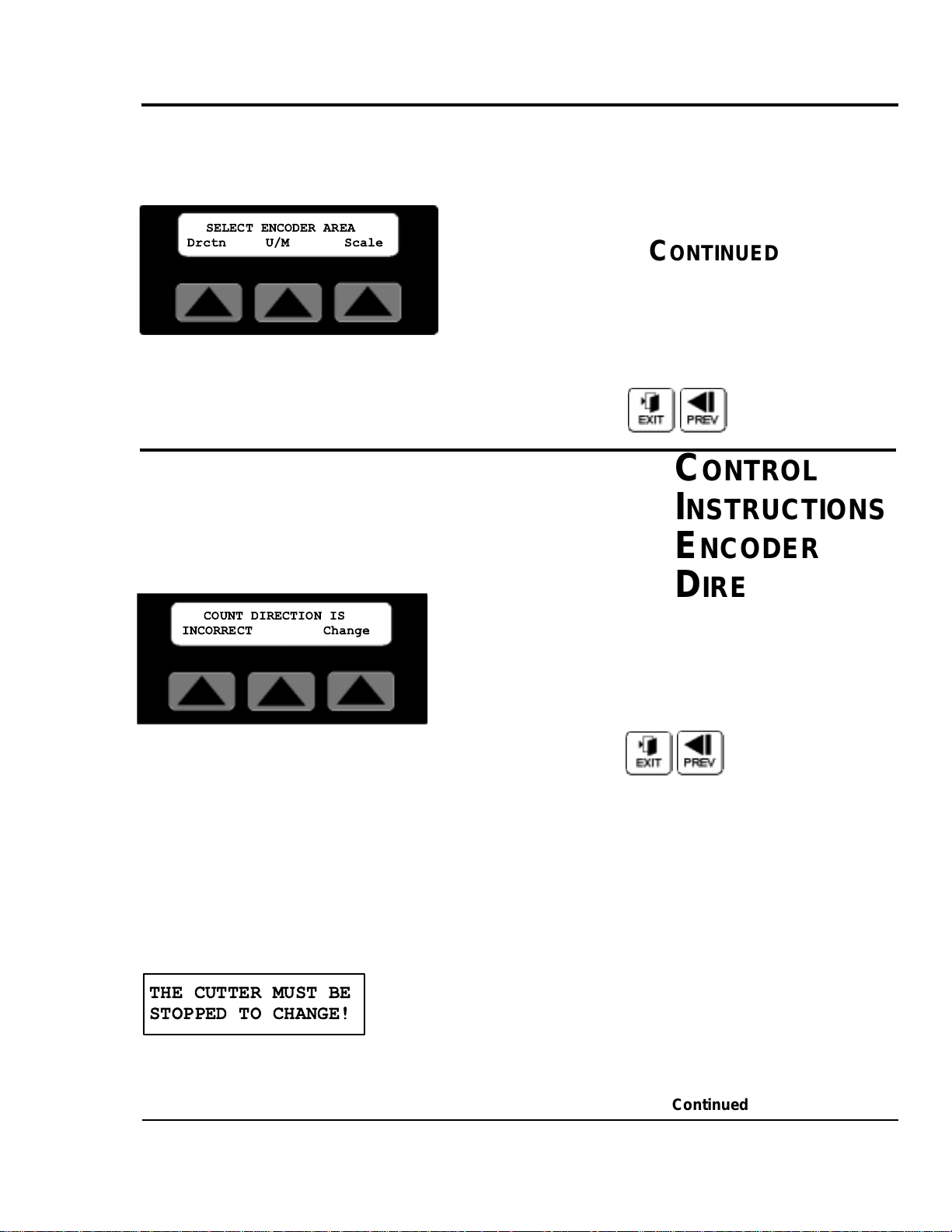

Encoder Area . . . . . . . . . . . . . .4-20

●●

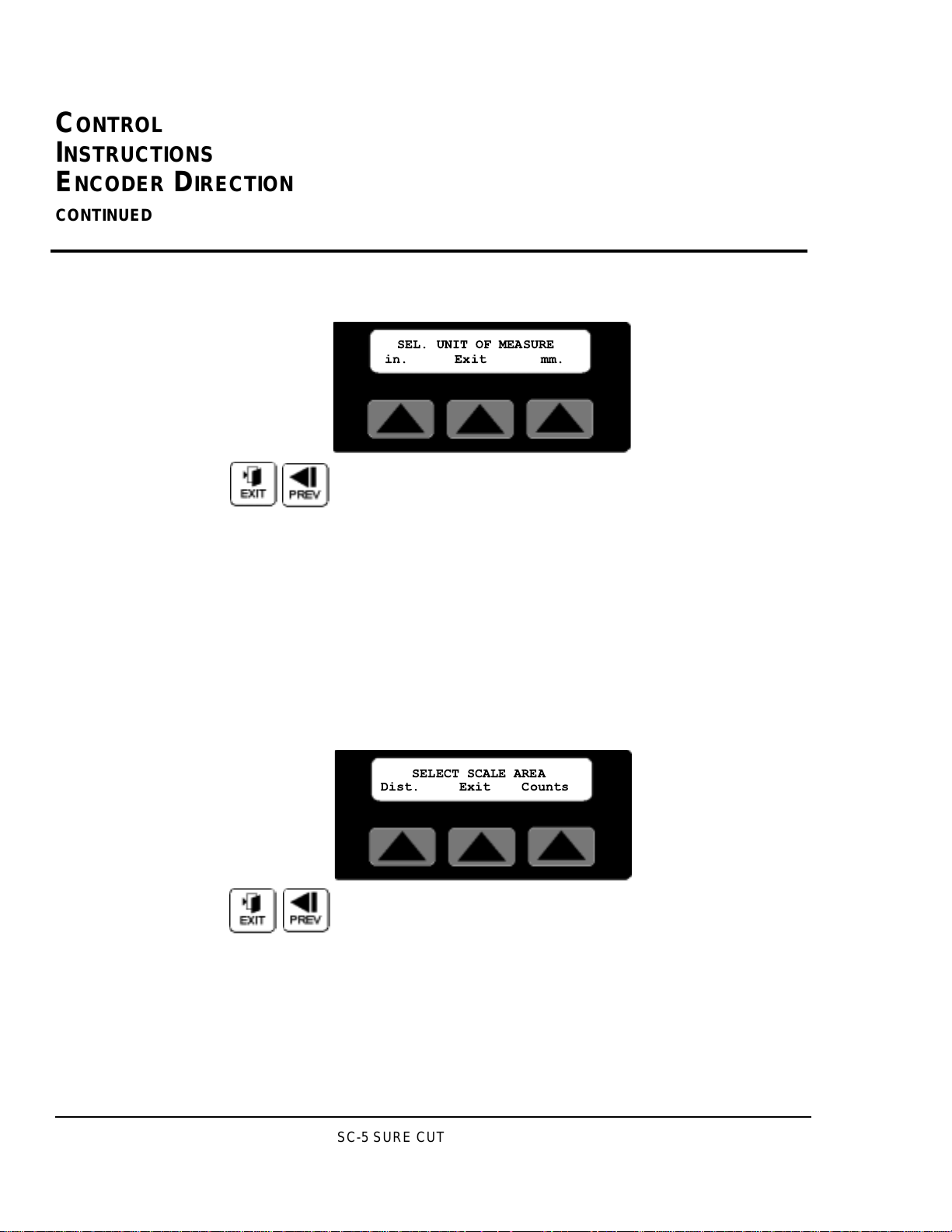

Unit of Measure . . . . . . . . . . . .4-22

●●

Scale Distance . . . . . . . . . . . . .4-23

●●

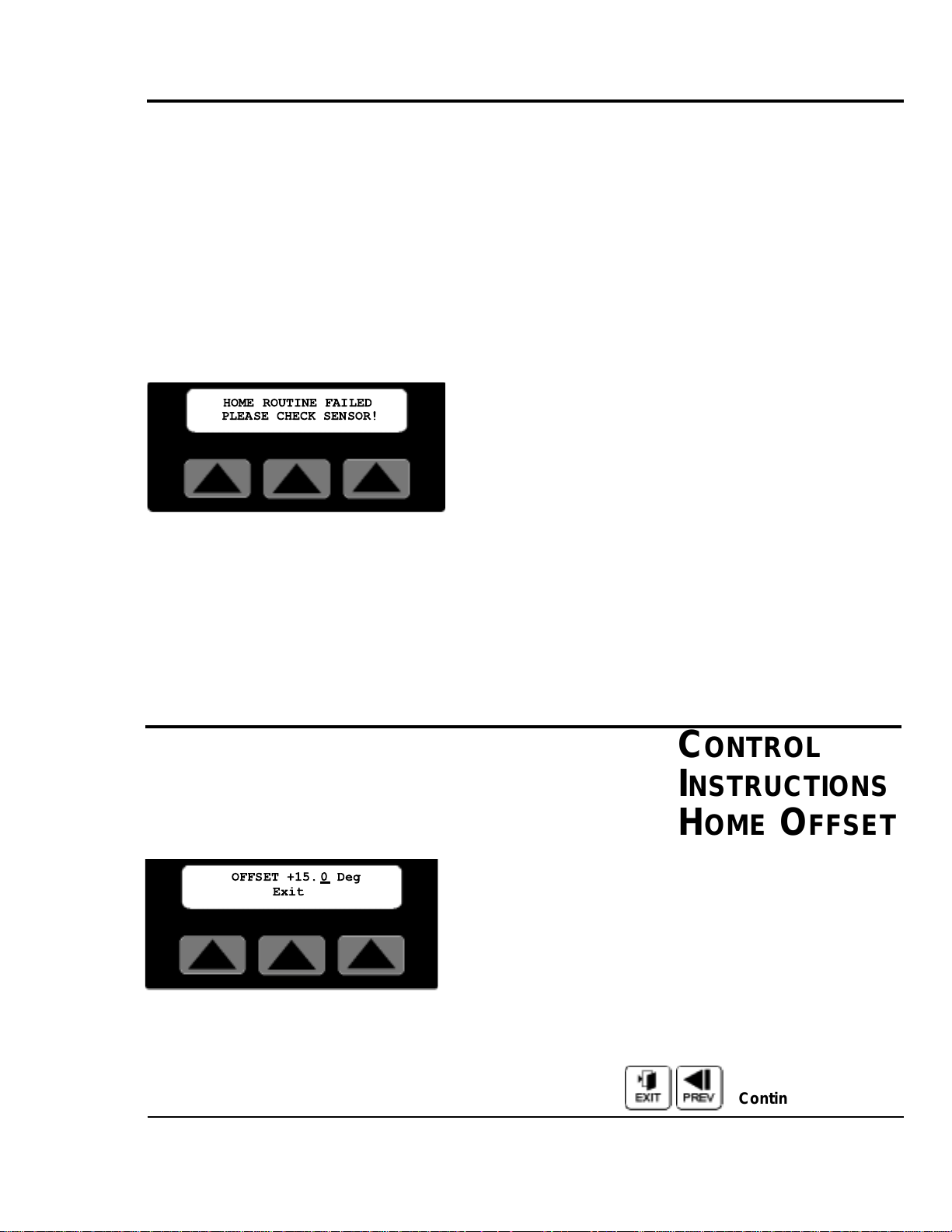

Homing . . . . . . . . . . . . . . . . . . .4-25

●●

Offset Example . . . . . . . . . . . . .4-26

●●

Preventative Maintenance . . . .4-27

●●

Power On Time . . . . . . . . . . . . .4-28

●●

Checking Cut Quality . . . . . . . .4-29

●●

Starting the SC-5 Sure Cut . . .4-29

●●

Making Adjustments

During the Operation . . . .4-30

●●

Stopping the SC-5 Sure Cut . .4-31

OPERATION

Page 36

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

4-2 OPERATION

OPERATOR

CONTROL

FEATURES

The Operator Control provides an intuitive user-friendly

method to interface with the Conair Servo Cutter. Information

is viewed and entered at the Operator Control and is communicated to the servo positional amplifier via the RS-232 serial

communication link.

The Operator Control is a flat membrane panel consisting of

22-keys and a large 2 line x 20 back lit LCD screen.

Soft Keys-allows

the operator to

select different

functions.

Numeric KeysPermits data entry

for the operator

Fixed Function

Keys-Contain uni-

versal symbols &

text

Soft Keys

Soft keys - these are the three keys directly under the display.

All three have a triangle on them. Occasionally, pages will

appear that allow the operator to use one of the soft keys. On

those occasions, text would typically appear directly above

the key and the key will have a function. Think of the text as

the soft key function indicator or title. These keys will be

referred to in this manual from left to right as soft keys 1, 2

and 3 respectively.

Numeric keys

These are the black keys containing numbers 0 to 9. Numbers

permit data entry of parameters. See Raise and Lower for

value trim.

Fixed Function Keys (at Bottom)

Underneath the numeric keys are fixed function keys. They

contain universal symbols and text. The fixed function keys

are Raise, Lower, Next, Prev (previous), Enter, Delete, Exit,

Menu and Mute. These functions are described in the

"Function keys - Fixed Functions" section of this manual.

LCD Screen

The screen shows various pages depending on operator

actions. In addition, it is used to indicate warnings.

Mostly, it is used for viewing status and for setting parameters.

CONAIR SERVO CUTTER

Version 1.0

Page 37

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

OPERATION 4-3

Before you start daily operation of the servo cutter, you need

to perform preventative maintenance. Necessary maintenance

is described in the Maintenance section of this Users Guide,

see preventative maintenance, Section 5.

Daily maintenance includes:

● Inspecting the cutter blades

● Inspecting the blade mounting hardware

● Making sure the cutter bushings are properly secured

● Inspecting the closure latch on the knife guard

● Checking cutter alignment with extrusion line

● Performing any floor lock adjustments as needed

These items and weekly, monthly, and semi-annual maintenance procedures are detailed in the Maintenance section of

this User Guide.

Plug in the power cord to restore power after any

required maintenance.

Turn on the main power. The cutter control will

bootup. The amber power on light illuminates.

While the cutter is booting up, perform the next three steps:

Make sure the E-Stop button is in the out,

extended position.

Make sure that the Cut Enable is Off.

If necessary, press button to display off.

Press Start Cutter button.The light in the button

should light. On SC-5 cutters, the cutter head will make

one revolution until it finds its home offset position.

BEFORE

STARTING

WARNING: Be sure that power to the SC-5

cutter is OFF when doing any maintenance on

the servo cutter.Follow all safety rules when

performing any maintenance on this equipment.

P

OWERING U

P

NOTE:You can watch the servo motor amplifier's

status screen during bootup through the

window on the back of the electrical enclosure.This display gives information that may

be useful if you have a problem. See the

Troubleshooting section.

1

2

3

4

5

Continued

Page 38

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

4-4 OPERATION

POWERING UP

C

ONTINUED

Open the knife guard. The machine start push

button should go out.

If the cutter is not working properly at any time, turn it off

immediately and refer to the Troubleshooting section of this

User Guide.

If you do not encounter any problems, proceed to the

Operation section.

Power Up Sequence

At power up a series of system screens briefly appear. The

software is Red Lion's Edict-97. This screen or similar shows

first.

Next, the Communications message appears

If there are any problems with communications, this screen

will remain on longer than a couple of seconds.

If there are no communication problems the Conair SC-5

Cutter program will begin to run. The following message or

similar shows for 5-seconds.

After the 5 second delay the Main Screen will appear.

Note: If “Home Runtime Failed” message is dis

played.Check for malfunctions of misadjusted

sensor.

6

Edict-97 Runtime

Ver. 5.05.134

**STARTING COMMS**

CONAIR SERVO CUTTER

Version 1.0

Page 39

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

OPERATION 4-5

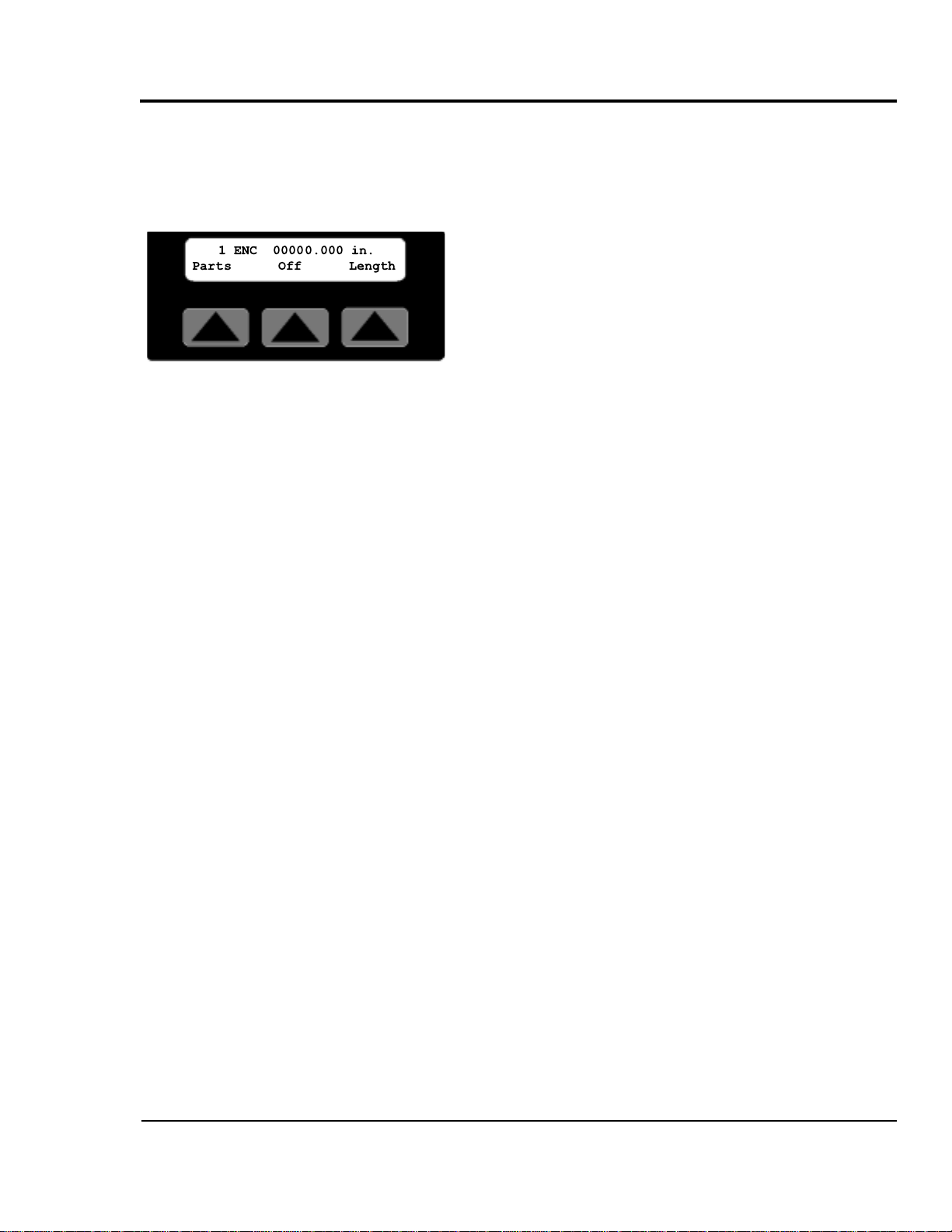

MAIN SCREEN

There are two types of main screens, length or time measurement and cuts per minute measurement. The type displayed

varies depending on the current cut mode setting.

See the mode operator display overviews.

The Main Screen has seven features. The top line displays the

active preset (only with multi preset option), cut mode, active

measurement and the unit of measure. The bottom line contains three soft key functions, softkey1/Parts, softkey2/cut

On/Off and softkey3, which varies depending on the current

cut mode setting.

Active Preset

With the multi preset option in on-demand modes the active

preset value changes upon batch completion. As the cutter

sequences through multiple presets, the operator always

knows which preset is being processed.

Active Measurement

The measurement value displayed will be the active length or

time preset or cuts per minute depending on the active cut

mode. It displays the value only when the machine is started

and softkey2 On/Off is on. If the machine is stopped or softkey2 On/Off is off, this counter will be forced to zero.

If a negative symbol is shown to the left of the measurement

value, the encoder signal is reversed, i.e. rotating in the wrong

direction. The Cutter will not function while the encoder is

going negative. It is possible to correct this by using the

encoder direction function located in the encoder area of the

maintenance area. See the maintenance area display overview.

Length, Time or Blade Softkey

This key is mode dependent see the mode operator display

overview for the current cut mode.

On/Off Softkey

Under the active measurement in the center of the bottom line

of the display is a soft key labeled On or Off. Pressing this

key while On is displayed will disable the cutter. Likewise

pressing this key while Off is displayed enables the cutter.

Pressing the stop button forces the cut enable off.

Manual cuts can still be made while the cut enable is off.

OPERATOR

CONTROL

INSTRUCTIONS

MAIN SCREEN

1 ENC 00000.000 in.

Parts Off Length

Page 40

4-6 OPERATION

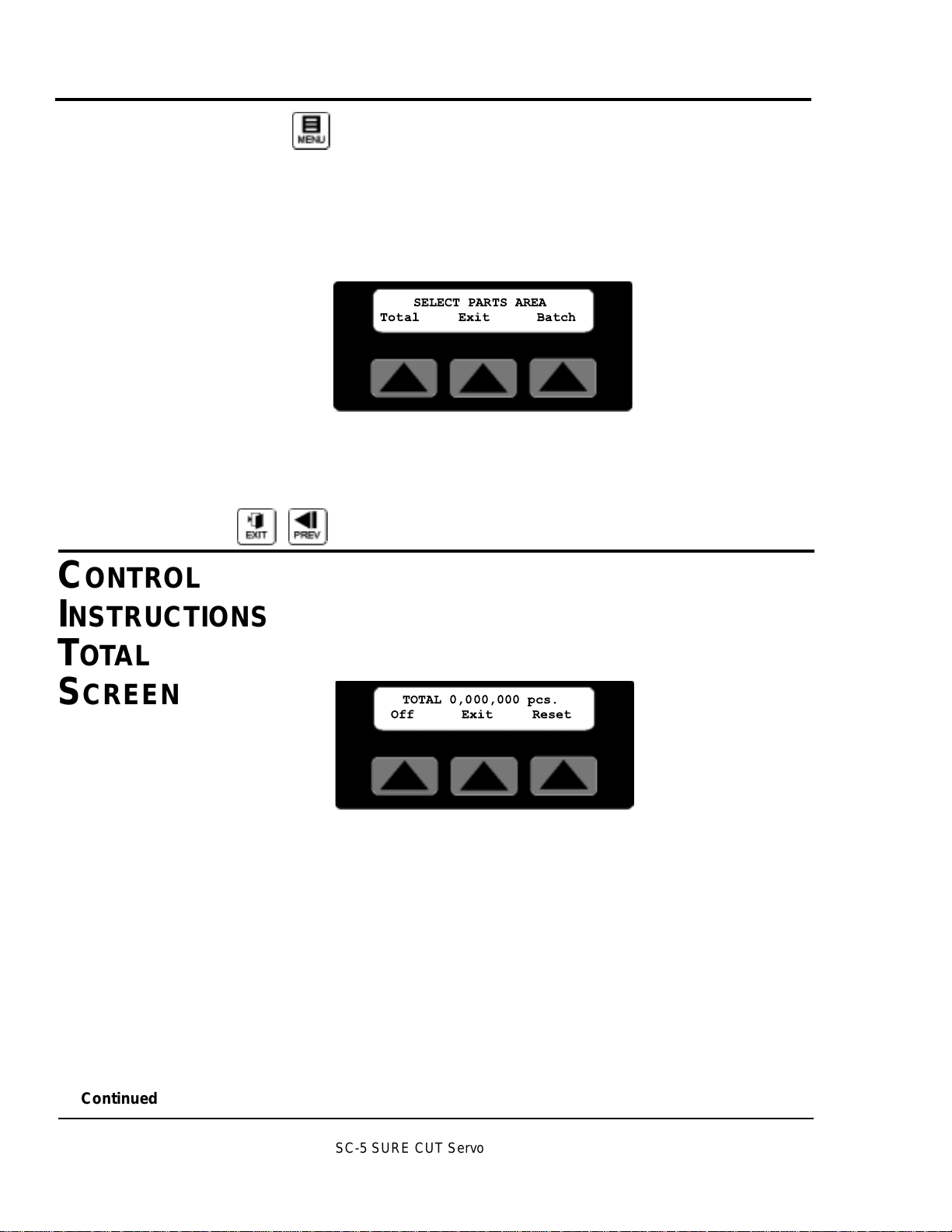

Menu function key is used to access the Menu Area.

This area can only be accessed from the main display

screen for each mode. See the Menu Area section for more

information.

Parts Select Area Screen

Under the current mode on the left side of the bottom line of

the display is a soft key labeled Parts. Pressing this key

accesses the Parts Select Screen.

This screen provides access to the parts Total/softkey1 or

Batch/softkey3 areas. Pressing Exit/softkey2 returns the display to the active main screen. If no selection is made within

30 seconds the display returns to the active main screen.

EXIT or PREV, fixed function keys return the display to the

previous screen.

TOTAL SCREEN

By pressing softkey1 located under the word Total on the Parts

Select Screen, a seven-decade total counter is available.

Additional information on how to access this screen can be

found in the operator display overview in Appendix E of this

manual.

This is typically used to count cut pieces during the day or

days that the product is being produced. Sample or manual

cuts are not counted. When enabled the count continues to

accumulate even if the total display is not being viewed. It is

also possible to turn this counter off or on.

On/Off Softkey1

Under the counter on the left is a soft key labeled On or Off.

Pressing this key while On is displayed will disable the

counter. Likewise pressing this key while Off is displayed

enables the counter.

Exit Softkey2

Under the counter, in the center is a soft key labeled Exit.

Pressing this key will return the display to the Parts Select

screen.

CONTROL

INSTRUCTIONS

C

ONTROL

INSTRUCTIONS

TOT AL

S

CREEN

Continued

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

SELECT PARTS AREA

Total Exit Batch

TOTAL 0,000,000 pcs.

Off Exit Reset

Page 41

OPERATION 4-7

Reset Softkey3

Under the counter, on the right is a soft key labeled Reset.

Pressing this key will zero the counter.

EXIT or PREV, fixed function keys return the display to the

Parts Select screen.

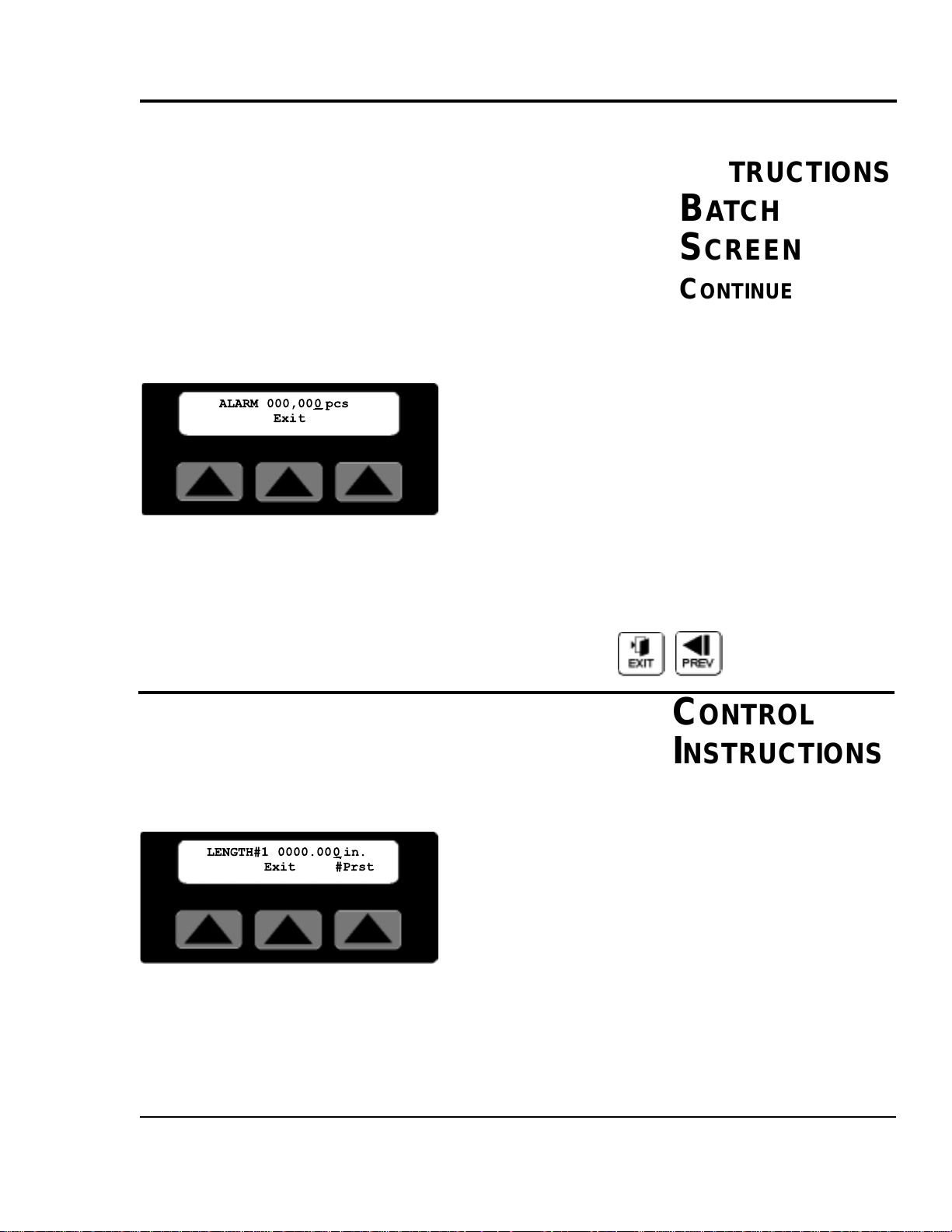

BATCH SCREEN

By pressing softkey3 located under the word Batch on the

Parts Select Screen, a six-decade Batch counter is available.

Additional information on how to access this screen can be

found in the operator display overview in Appendix E of this

manual.

This is typically used to count the pieces required to fill a carton, with the product being cut. The batch counter counts up

to the batch preset and resets to zero. As the accumulated

count reaches the alarm preset the batch pre-warn output-3

energizes then when the batch preset is reached the batch

complete output-2 briefly energizes and both outputs turn

back off. Sample/Manual cuts are not counted. When enabled

the count continues to accumulate even if the batch display is

not being viewed. It is also possible to turn this counter off or

on.

Change Softkey1

Under the counter, on the left is a soft key labeled Change.

Pressing this key displays the Select Batch Area screen. The

operator can then choose to set the batch or alarm preset.

On/Off Softkey2

Under the counter near the center is a soft key labeled On or

Off. Pressing this key while On is displayed will disable the

counter. Likewise pressing this key while Off is displayed

enables the counter.

Reset Softkey3

Under the counter, on the right is a soft key labeled Reset.

Pressing this key will zero the batch counter.

EXIT or PREV, fixed function keys return the display to the

Parts Select screen.

CONTROL

INSTRUCTIONS

BATCH

SCREEN

CONTROL

INSTRUCTIONS

TOTAL SCREEN

CONTINUED

Continued

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

BATCH 000,000 pcs.

Change Off Reset

Page 42

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

4-8 OPERATION

Batch Select Area Screen

Under the batch counter, on the left is a soft key labeled

Change. Pressing this key displays the Select Batch Area

screen. Additional information on how to access this screen

can be found in the operator display overview in Appendix E

of this manual.

This screen provides access to the batch Preset/softkey1 or

batch Alarm/softkey3 areas. Pressing Exit/softkey2 returns the

display to the batch counter screen. If no selection is made

within 30 seconds the display returns to batch counter screen.

Batch Preset Screen

By pressing the soft key located under the word Batch on the

Batch Area Screen, the preset for the Batch counter is available.

The number shown is the current batch preset. A cursor will

appear in the least significant digit. The user has a choice of

ways to adjust this number.

Exit or Prev, If no change is required press Exit or Prev to

return to the Main screen.

Raise will increase the preset by 1. The key can be pressed

once for each increment required or held down to scroll up.

Releasing the key will freeze the preset at the last value.

Lower will decrease the preset by 1. The key can be pressed

once for each decrement required or held down to scroll

down. Releasing the key will freeze the preset at the last

value.

CONTROL

INSTRUCTIONS

BATCH

SCREEN

C

ONTINUED

Continued

SELECT BATCH AREA

Preset Exit Alarm

PRESET 000,000

Exit

pcs

Page 43

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

OPERATION 4-9

Numeric keys

Key in the batch required and press enter. If you require a

batch of 50 parts you must key in 50 and then press enter.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Main screen. If it is wrong press

the delete key and the previous preset will reappear.

Batch Pre-Alarm Preset Screen

By pressing the soft key located under the word Alarm on the

Batch Area Screen, the preset for the Batch pre-warn Alarm is

available.

The number shown is the current alarm preset. A cursor will

appear in the least significant digit. The user has a choice of

ways to adjust this number. See entering the batch preset

above. Please note: This value must be less than the batch

preset.

Exit or Prev, if no change is required press Exit or Prev to

return to the Main screen.

LENGTH SCREEN

By pressing the soft key located under the word Length on

the Encoder, Follower or Auto Mode Main Screen, the preset

for the Length counter is available. Additional information on

how to access this screen can be found in the operator display overview in Appendix E of this manual.

The number shown is the current length preset value, i.e. the

length to cut the product. A cursor will appear in the least

significant digit. The user has a choice of ways to adjust this

number. Pressing the #Prst/Softkey3 accesses the number of

presets to run screen. This feature is only available with the

multiple preset/batch option.

CONTROL

INSTRUCTIONS

LENGTH

SCREEN

Continued

CONTROL

INSTRUCTIONS

BATCH

SCREEN

C

ONTINUED

ALARM 000,00

Exit

pcs

0

LENGTH#1 0000.00

Exit #Prst

0 in.

Page 44

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

4-10 OPERATION

Exit or Prev, if no change is required press Exit or

Prev to return to the Main screen.

Raise will increase the preset by 0.010 inch. The key can be

pressed once for each 0.010 inches increment required or held

down to scroll up. Releasing the key will freeze the preset at

the last value then press enter.

Lower will decrease the preset by 0.010 inch. The key can be

pressed once for each 0.010 inch decrement required or held

down to scroll down. Releasing the key will freeze the preset

at the last value then press enter.

Numeric keys

Key in the length required and press enter. The decimal place

is fixed so remember this when entering the preset. If you

require 24 inches you must key in 24000 and then press enter.

Keying only 24 will set the length to 0.024 inches.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Main screen. If it is wrong press

the delete key and the previous preset will reappear.

PRESETS TO RUN SCREEN

By pressing the soft key located under the word #Prst on any

Length Screen, the value for the number of presets to run is

available. Additional information on how to access this screen

can be found on the multiple preset example in the operator

display overview in Appendix E of this manual.

The number shown is the current number of presets to run

value, i.e. how many measurement presets and batches to run.

The acceptable range for this value is 1 to 4. The cutter will

process preset#1/batch#1 then #2 then #3 then #4 and back to

#1 continuously. If a 2 is entered only preset/batch 1 and 2 are

processed. A cursor will appear in the least significant digit.

The user has a choice of ways to adjust this number.

CONTROL

I

NSTRUCTIONS

PRESET TO

RUN SCREEN

Continued

CONTROL

INSTRUCTIONS

LENGTH

SCREEN

C

ONTINUED

RUN 4 PRESETS

Exit

Page 45

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

OPERATION 4-11

Exit or Prev, If no change is required press Exit or Prev to

return to the previous Length Screen.

Raise will increase the number by 1. The key can be pressed

once for each increment of 1 required or held down to scroll

up. Releasing the key will freeze the preset at the last value

then press enter.

Lower will decrease the preset by 1. The key can be pressed

once for each decrement of 1 required or held down to scroll

down. Releasing the key will freeze the preset at the last

value then press enter.

Numeric keys

Key in the number required and press enter. If you require 4

presets key in 4 and then press enter.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Main Timer Mode screen. If it

is wrong press the delete key and the previous preset will

reappear.

TIME SCREEN

By pressing the soft key located under the word Time on the

Main Timer Mode Screen, the preset for the timer is available. Additional information on how to access this screen can

be found in the operator display overview in Appendix E of

this manual.

The number shown is the current time preset value, i.e. the

time interval to cut the product. A cursor will appear in the

least significant digit. The user has a choice of ways to adjust

this number.

Exit or Prev, If no change is required press Exit or Prev to

return to the Main Timer Mode Screen.

C

ONTROL

INSTRUCTIONS

TIME SCREEN

CONTROL

INSTRUCTIONS

PRESET TO

RUN SCREEN

CONTINUED

Continued

TIME 00000.00 0

Exit

sec

Page 46

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

4-12 OPERATION

Raise will increase the preset by 0.010 second. The key can

be pressed once for each 0.010 second increment required or

held down to scroll up. Releasing the key will freeze the preset at the last value then press enter.

Lower will decrease the preset by 0.010 second. The key can

be pressed once for each 0.010 second decrement required or

held down to scroll down. Releasing the key will freeze the

preset at the last value then press enter.

Numeric keys

Key in the time required and press enter. The decimal place is

fixed so remember this when entering the preset. If you

require 1.5 seconds you must key in 1500 and then press enter.

Keying only 15 will set the time to 0.015 seconds.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Main Timer Mode screen. If it is

wrong press the delete key and the previous preset will reappear.

HOLD-OFF TIME SCREEN

By pressing the soft key located under the word Time on the

Main End Sense Mode Screen, the preset for the hold-off

timer is available. Additional information on how to access

this screen can be found in the operator display overview in

Appendix E of this manual.

The number shown is the current hold-off time preset, i.e. the

time interval to ignore the photo eye and avoid false cuts. A

cursor will appear in the least significant digit. The user has a

choice of ways to adjust this number.

Exit or Prev, If no change is required press Exit or Prev to

return to the Main End Sense Mode Screen.

C

ONTROL

INSTRUCTIONS

HOLD-OFF

S

CREEN

CONTROL

INSTRUCTIONS

TIME SCREEN

C

ONTINUED

Continued

Holdoff 00000.500

Exit

sec

Page 47

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

OPERATION 4-13

Raise will increase the preset by 0.010 second. The key can

be pressed once for each 0.010 second increment required or

held down to scroll up. Releasing the key will freeze the preset at the last value then press enter.

Lower will decrease the preset by 0.010 second. The key can

be pressed once for each 0.010 seconds decrement required or

held down to scroll down. Releasing the key will freeze the

preset at the last value then press enter.

Numeric keys

Key in the time required and press enter. The decimal place is

fixed so remember this when entering the preset. If you

require 1.000 seconds you must key in 1000 and then press

enter. Keying only 1 will set the time to 0.001 seconds and an

error message will be displayed.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Main End Sense Mode screen. If

it is wrong press the delete key and the previous preset will

reappear.

BLADE SPEED SCREEN

By pressing the soft key located under the word Blade or

Speed depending on the current mode, the preset for that

modes blade speed is available. Additional information on

how to access this screen can be found in the operator display

overview in Appendix E of this manual.

The number shown is the active modes current blade speed

preset, i.e. the speed the blade will pass through the part. A

cursor will appear in the least significant digit. The user has a

choice of ways to adjust this number.

Exit or Prev, if no change is required press Exit or Prev to

return to the Blade Select or Main Mode Screen.

C

ONTROL

I

NSTRUCTIONS

BLADE SPEED

S

CREEN

CONTROL

INSTRUCTIONS

HOLD-OFF

SCREEN

CONTINUED

Continued

SPEED 0750.0 rpm

Exit

Page 48

Raise will increase the preset by 1.0. The key can be pressed

once for each 1.0 increment required or held down to scroll

up. Releasing the key will freeze the preset at the last value

then press enter.

Lower will decrease the preset by 1.0. The key can be pressed

once for each 1.0 decrement required or held down to scroll

down. Releasing the key will freeze the preset at the last value

then press enter.

Numeric keys

Key in the time required and press enter. The decimal place is

fixed so remember this when entering the preset. If you

require 750.0 rpm you must key in 7500 and then press enter.

Keying only 750 will set the speed to 075.0 rpm and an error

message with the valid range will be displayed.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Blade Select or Main Mode

Screen. If it is wrong press the delete key and the previous

preset will reappear.

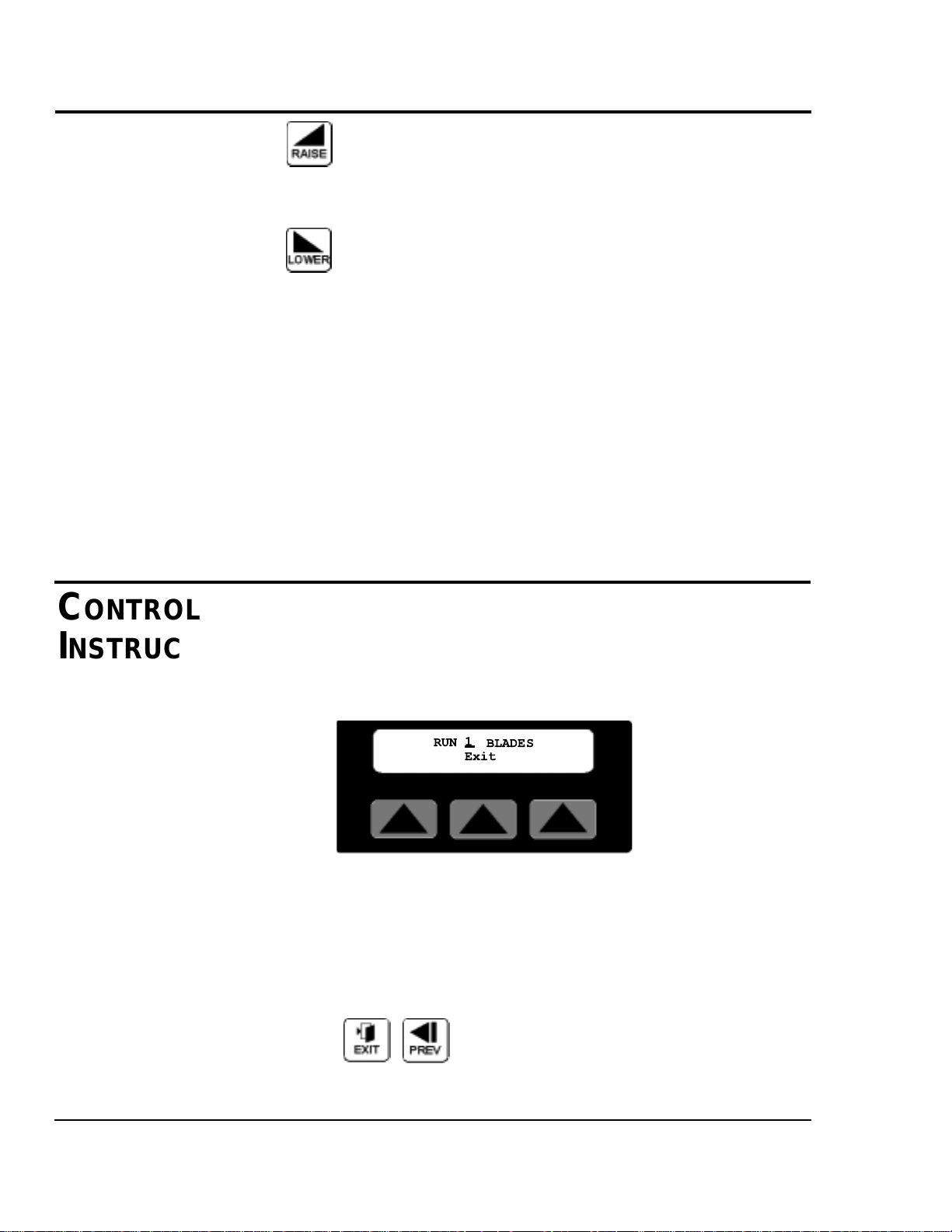

BLADE COUNT SCREEN

By pressing the soft key located under the word Blade or

Count depending on the current mode, the preset for the blade

count is available. Additional information on how to access

this screen can be found in the operator display overview in

Appendix E of this manual.

The number shown is the current blade count preset, i.e. the

number of blades mounted to the cutter head. A cursor will

appear in the least significant digit. The user has a choice of

ways to adjust this number.

Exit or Prev, if no change is required press Exit or Prev to

return to the Blade Select or Main Mode Screen.

CONTROL

INSTRUCTIONS

BLADE COUNT

SCREEN

Continued

CONTROL

INSTRUCTIONS

BLADE SPEED

SCREEN

CONTINUED

4-14 OPERATION

SC-5 SURE CUT Servo Knife Cutter UGE059/1003

1

RUN

BLADES

Exit

Page 49

Raise will increase the preset by 1. The key can be pressed

once for each 1 increment required or held down to scroll up.

Releasing the key will freeze the preset at the last value then

press enter.

Lower will decrease the preset by 1. The key can be pressed

once for each 1 decrement required or held down to scroll

down. Releasing the key will freeze the preset at the last value

then press enter.

Numeric keys

Key in the number of blades mounted and press enter. If the

value entered is out of range an error message with the valid

range will be displayed.

Enter or Delete?

If the keyed in number is correct press the enter key for it to

be accepted and return to the Blade Select or Main Mode

Screen. If it is wrong press the delete key and the previous

preset will reappear.

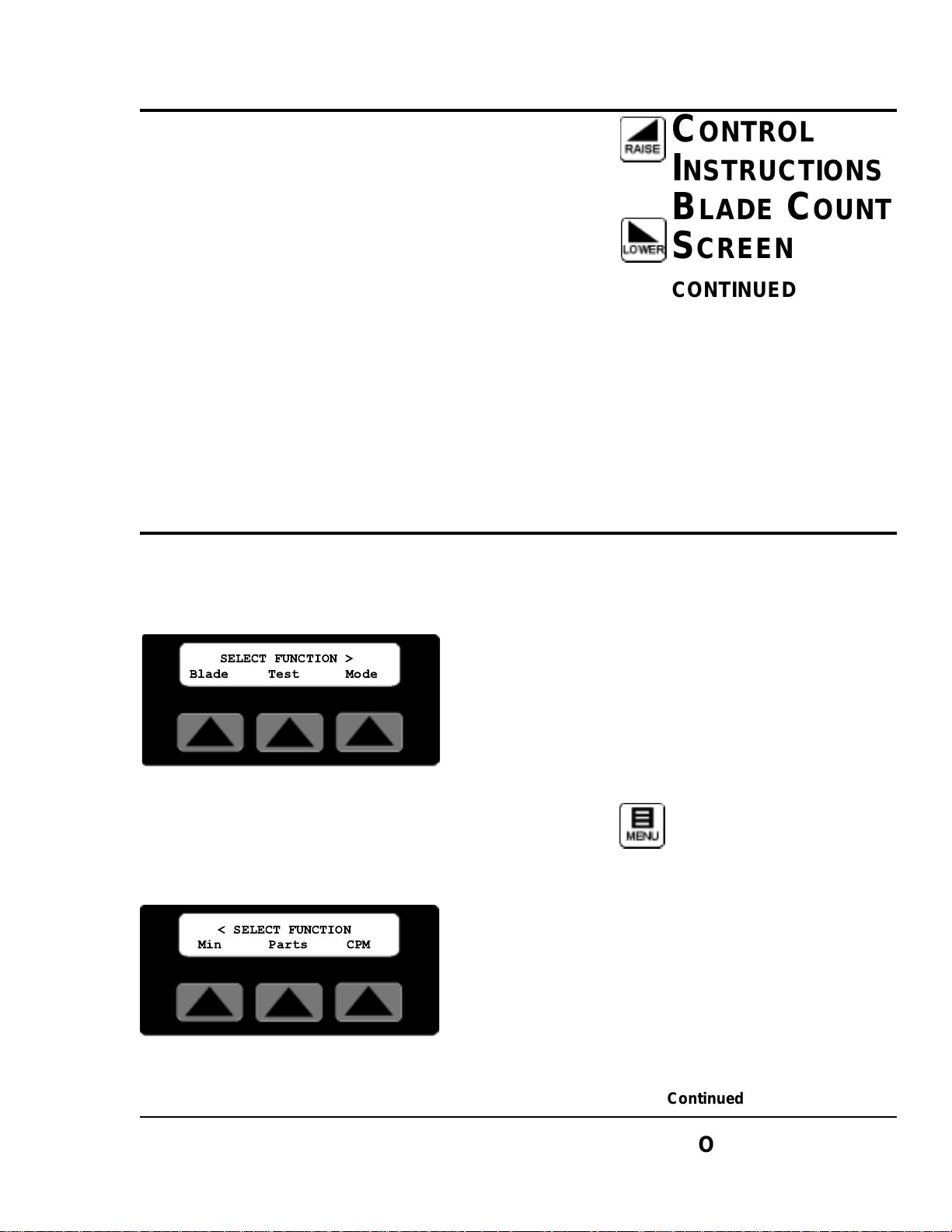

FUNCTION AREAS

Additional information on how to access and navigate these

screens can be found in the operator display overview section

of this manual.

Menu fixed function key is used to access the Function Areas

from any main mode screen. There are two Function Area

screens. The user can toggle between the two screens with the

Next and Prev fixed function keys.

CONTROL

I

NSTRUCTIONS

FUNCTION

AREAS

C

ONTROL

INSTRUCTIONS

BLADE COUNT

SCREEN

CONTINUED

Continued

O

PERATION 4-15

UGE059/1003 SC-5 SURE CUT Servo Knife Cutter

SELECT FUNCTION >

Blade Test Mode

< SELECT FUNCTION

Min Parts CPM

Page 50

Next or Prev, Pressing Next selects the second Function Area.

Pressing Prev returns the display to the first Function Area

screen. Pressing Prev from the first Function Area screen

returns the display to the active main mode screen.

Menus are a convenient way to access and monitor parameters

that do not need to be altered often, i.e. blade speed, blade

count, cut mode, repeatability test, min. allowable measurement and cuts per minute.

The most frequently used functions for a certain cutting mode

are directly available from the main screen for the active

mode. For a guide to screen navigation for any active mode

see the operator display overview section of this manual for

that mode. For information on the Blade and Parts Softkeys

see their respective sections covered earlier in this manual.

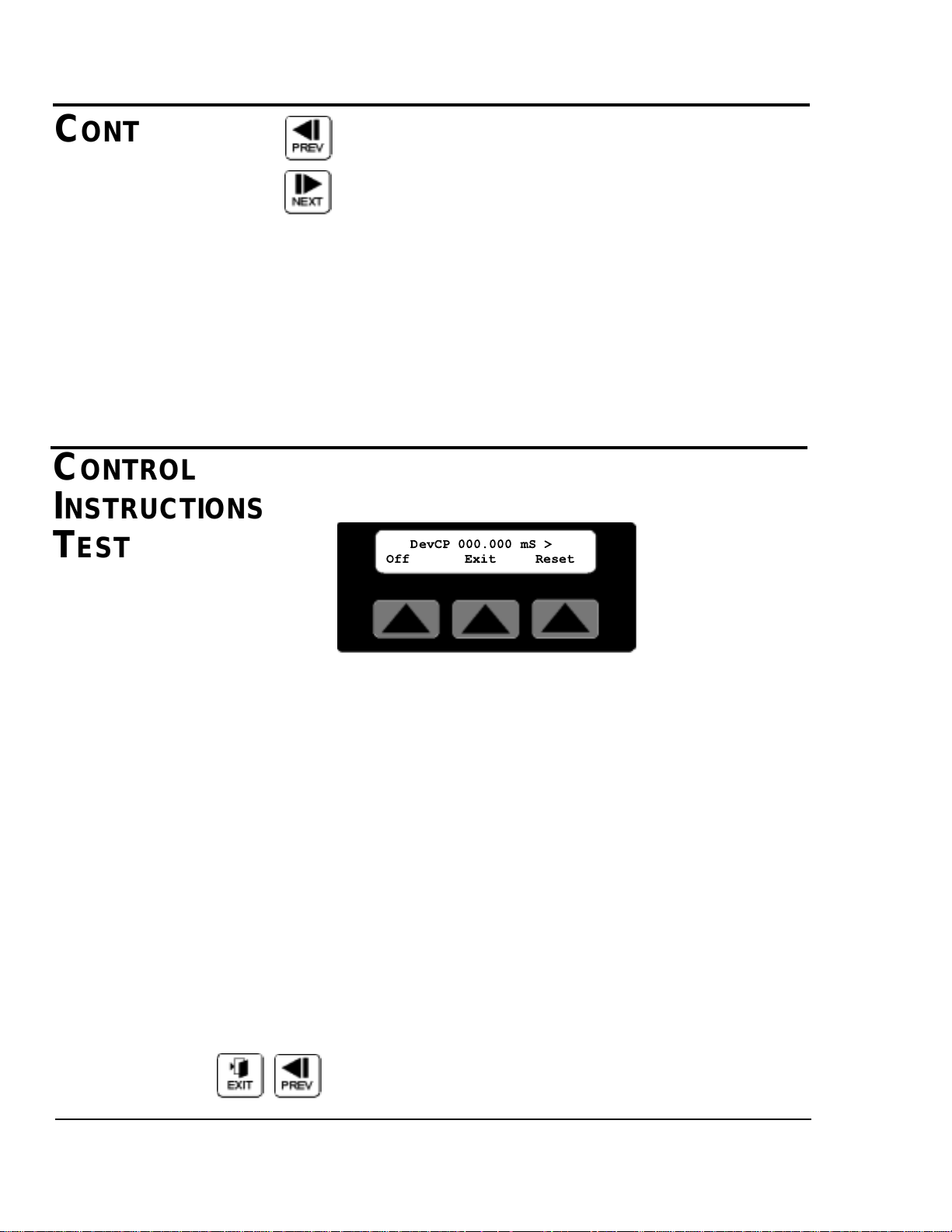

TEST SOFTKEY

Pressing soft key two located under the word Test on the first

Function area screen, selects the repeatability tester.

The DevCP repeatability tester displays total deviation time in

milliseconds. This time is from a cut being requested until the

blade reaches the part. The smallest measured value is subtracted from the largest measured value and the resulting deviation is displayed on the screen. New data is sampled every

consecutive cut. The DevCP repeatability test is available in

all on-demand modes. This test is used as a tool for verifying

the accuracy of the cutter.

On/Off Softkey1

On the display, on the lower left side is a soft key labeled On

or Off. Pressing this key while On is displayed will reset all

values and disable testing. Likewise pressing this key while

Off is displayed starts the test.

Reset Softkey3

On the display, on the lower right side is a soft key labeled

Reset. Pressing this key will reset all test values and start a

new test.

Exit or Prev, Pressing Exit, Prev or the Softkey under the

word Exit resets all values and disables testing then returns the

display to the Function area screen.

CONTROL

INSTRUCTIONS

T

EST

CONTROL

INSTRUCTIONS

FUNCTION

AREAS

C

ONTINUED

Continued

4-16 OPERATION