Page 1

SYSTEM CONFIGURATION

for S900II robots

Software Version 1.0

Corporate Office: 412.312.6000 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

USERGUIDE

www.conairnet.com

WARNING - Reliance on this Manual Could Result in Severe Bodily Injury or Death!

This manual is out-of-date and is provided only for its technical information, data and capacities. Portions of this manual

detailing procedures or precautions in the operation, inspection, maintenance and repair of the product forming the subject

matter of this manual may be inadequate, inaccurate, and/or incomplete and cannot be used, followed, or relied upon.

Contact Conair at info@conairgroup.com or 1-800-654-6661 for more current information, warnings, and materials about

more recent product manuals containing warnings, information, precautions, and procedures that may be more adequate

than those contained in this out-of-date manual.

Page 2

Page 3

System

Configuration

S900II

I – Memory

I – MEMOR

Y

I – 1. Accessing the memory

After

accessing ”Memory Management” by pressing [Memo_M] (programming menu), pressing the

[M_Read] key gives access to the read (or modification) function of the user and system RAM or

EEPROM memory (at the address of the memory box by default if necessary).

The

address of the

keypad and the first row of alphanumerical keys of the keyboard.

Certain areas are directly accessible from the keyboard :

: beginning of the PRG editing area (0 x 006 430).

: beginning of the PLC editing area (0 x 009 430).

: beginning of the program storage in RAM area (0 x 00B 300).

: beginning of the MODULE where the programs are stored (0 x 800 000).

: transfer buffer PRG E17.

area at which reading is to begin is given in hexadecimal (0 to F) using the numerical

: robot serial number in RAM.

: RAM access password.

: beginning of parameters in RAM.

: beginning of the faults 200 to 204 message table in RAM.

For example

: to access the beginning of the program storage area, the procedure is as follows :

[Memo_M] –> [M_Read] –> [Address] –>

*

The keys

:

[ + ] or [ – ] to change addresses 2 by 2.

[ ]

[PG DN] or [PG UP] to change addresses 100 by 100 (hexadecimal).

or

[ ]

to change addresses 10 by 10 (hexadecimal).

Page 4

I – Memory

* The function keys F1 to F5 :

[Address] to change the address.

[Modif] to change the contents of the memory area displayed (word).

[Search] to search for a particular word (e.g. : FA1B)

System

Configuration

S900II

[Print] to

print the memory contents from the displayed address (in order to search

for the incorrect instructions which will be printed as ????).

[StopPr] to stop sending the memory contents to the printer.

Note

: To access the modification function, a password is necessary which remains valid as long as the

user

does not exit the “M_Read” procedure. Certain critical system areas cannot be read

and all requests

to modify them will be rejected.

By default, the value given after modification request is 0 x FFFF (useful to delete words in the

memory).

As for the other functions, the EXIT key is used to abandon a request or to exit the procedure.

Page 5

System

Configuration

S900II

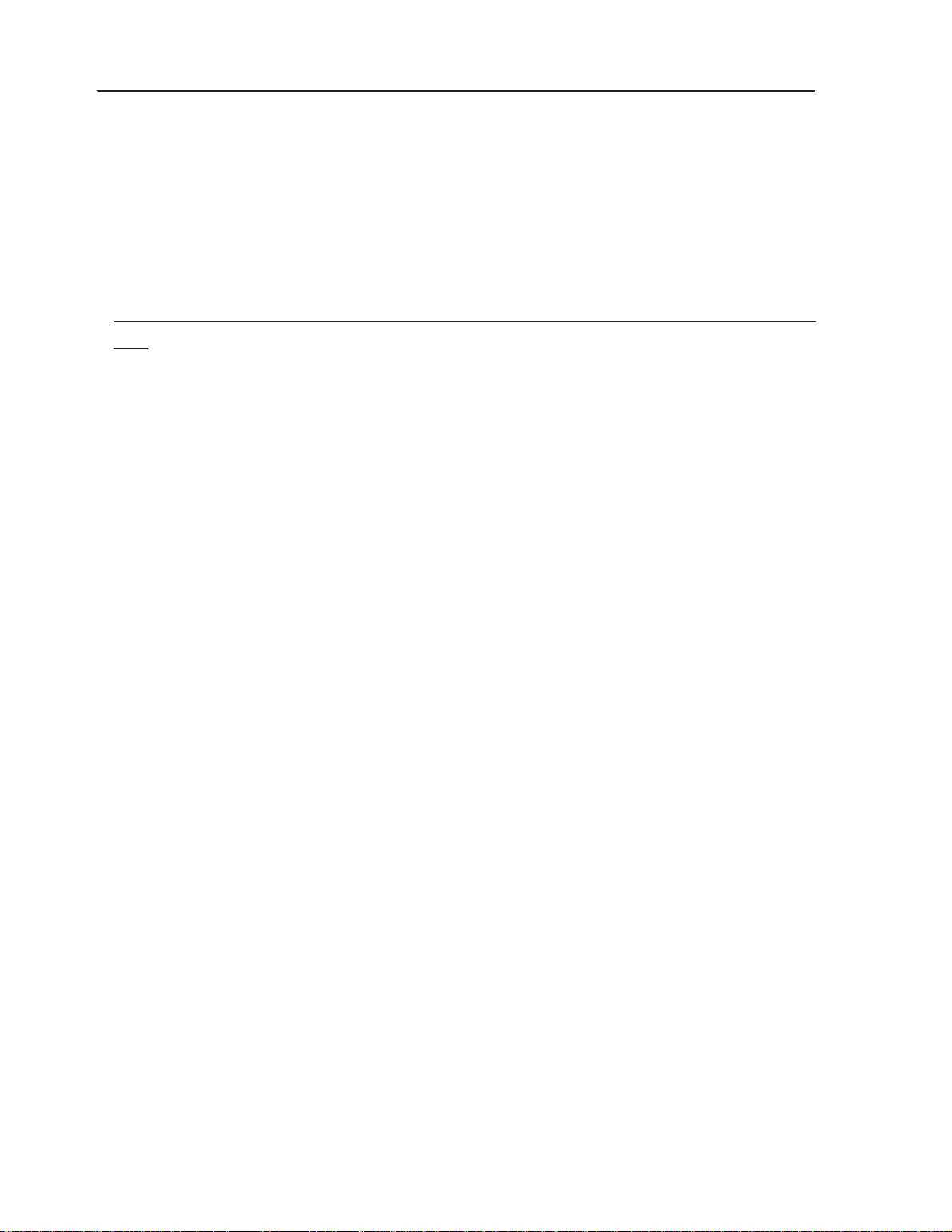

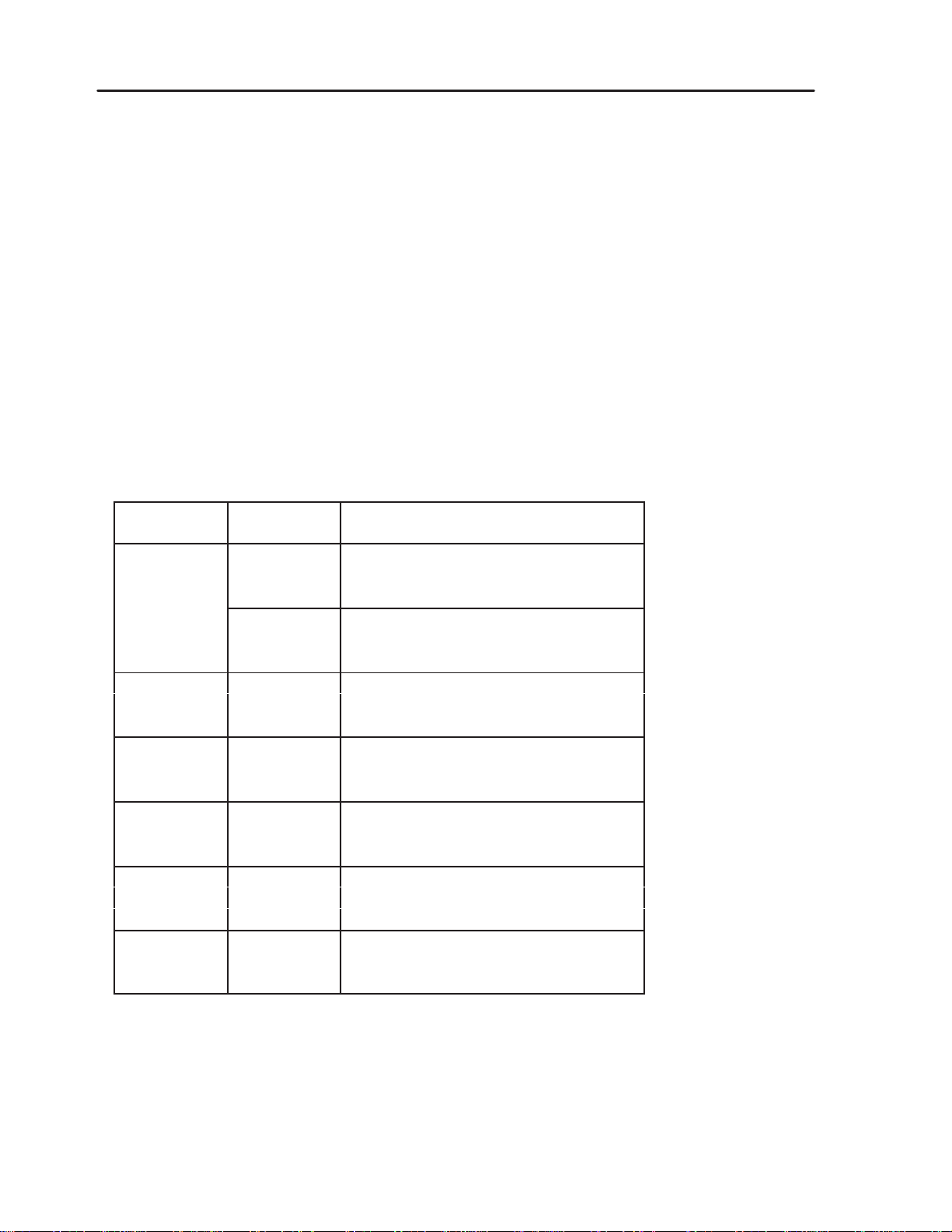

I – 2. Memory areas

I – 2. 1.Data saved in RAM (512 K x 8) 0 to 7 FFFF

ess in

Addr

Hexadecimal

00000

Variables used by Philips (BOOT)

027FF

02800

“Fixed” SEPRO variables, see table below for

details of the variables

0A4FF

0A500

SEPRO parameters in RAM

0B2FF

0B300

PRG storage area (128 K × 8)

2A6FF

2A700

SEPRO variables / work tables

37FFF

38000

Temporary transfer area (128 K x 8)

57FFF

58000

Piles and heaps used by the ERM kernel

7FFFF

Contents

I – Memory

02800 En Ordre = RAM contents correct indicator (GIRLAFRIDOU).

02810 Bit_U_S = System and user bits table.

02890 Bit_Tpo = PLC timer bits table.

028A0 Imag_S = Images of the 255 ON/OFF outputs.

029A0 Imag_E = Image of the 255 ON/OFF inputs.

02AA0 Word_U = User words table (16–bit WORD).

02AE0 Word_S

= System words table (see Programming Level 2 manual for description).

02B20 Tpo_Aut = PLC timers table.

02B40 Compt = Counters table (standard and stacking).

04AA0 Pile_Def = Pile of historic faults.

04BC0 Comptime = Times basic counter.

04BC4 Dir_RAM = PRG / PLC directory in editing area.

04C04 Dir_PP = PRG directory in save area.

05254 Dir_PLC = PLC directory in save area.

05710 Mod_PP = PRG directory in the module.

05D60 Mod_PLC = PLC directory in the module.

0621C Tab_temps = Robot times table.

06230 WWord_U = Double words table (32 bits).

06430 Ram_PP = PRG editing area.

09430 Ram_PLC = PLC editing area.

Page 6

I – Memory

System

Configuration

S900II

I – 2. 2.Program addressing in memory

The PRG and PLC programs are stored in the RAM memory, starting from the address 0xB300.

The maximum length of a PRG is 12286 bytes ; 4096 bytes for a PLC.

This area reserved for the permanent storage varies depending on the option 32 to 128 Kbytes.

that it remains compatible with previous software versions, the RAM if formatted with 0xFFFF like

So

an

EEPROM.

This formatting is carried out when the robot is first started up (for the 128 Kbytes) or

when the memory is totally set to 0 [ RsMEM ] (on the size provided for in the options)

parameters are stored in FLASHPROM at the address

The

0xF10E0000. An image of this address is

stored in RAM at the address 0xA500. The length of the parameters is fixed at 2800 bytes.

“SAP message” file is stored in FLASHPROM at the address 0xF10E1200.

The

Its length is fixed at

4590 bytes.

The programs, parameters and SAP messages are transferred via a temporary buffer of 12286 bytes

at the address 0x38000. (This buffer can be extended to 128 Kbytes).

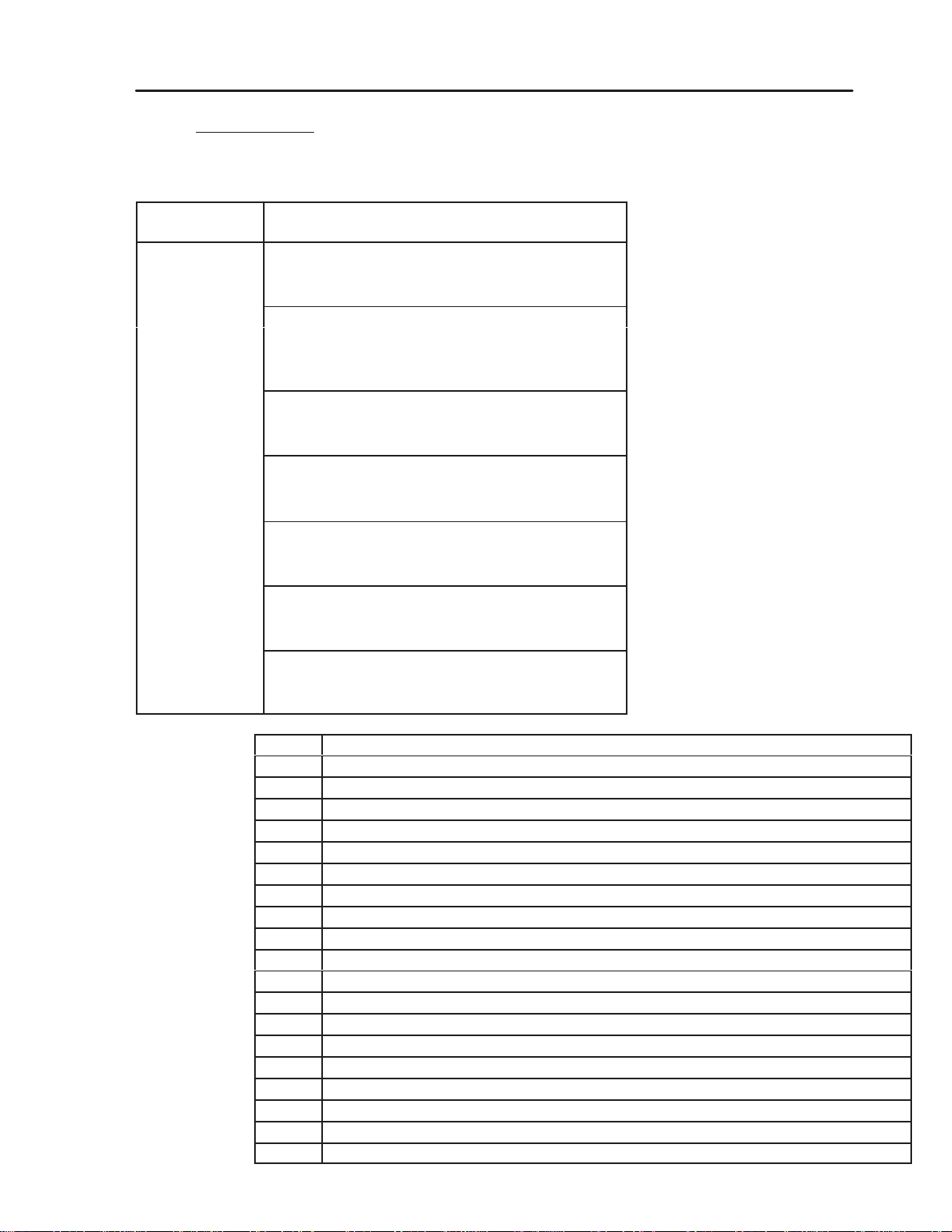

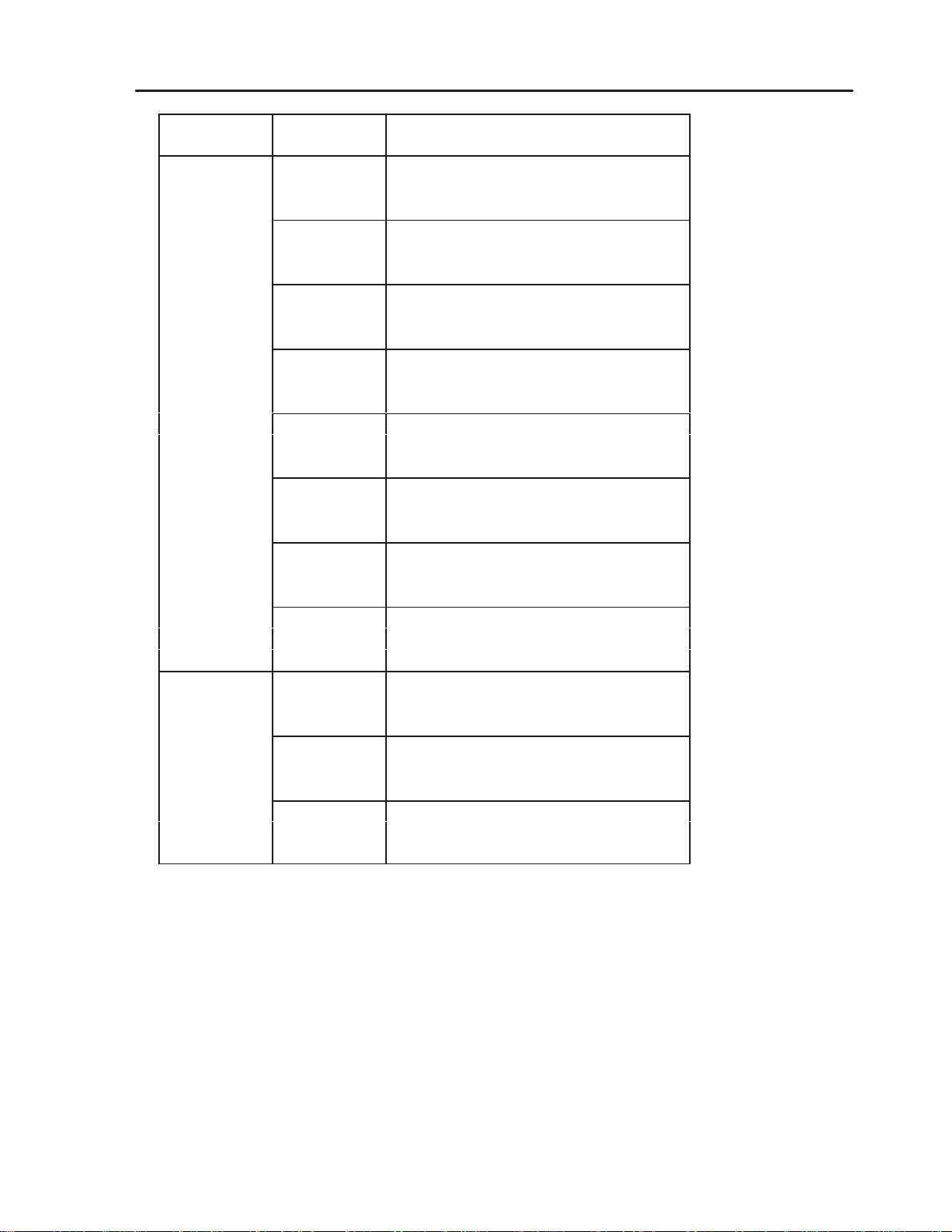

I – 2. 3.Data in Flashprom (1 M x 8) F10 00000 to F10 FFFFF

Block

number

Addr

ess in

Hexadecimal

Contents

F10 00000

ERM kernel + SEPRO program

1st block F10 0FFFF

F10 10000

SEPRO code (1)

F10 1FFFF

F10 20000

2nd block SEPRO code (2)

F10 3FFFF

F10 40000

3rd block SEPRO code (3)

F10 5FFFF

F10 60000

4th block SEPRO code (4)

F10 7FFFF

F10 80000

5th block SEPRO code (5)

F10 9FFFF

F10 A0000

6th block Reserved for extension of SEPRO code

F10 BFFFF

Page 7

System

Configuration

S900II

I – Memory

Block

number

Addr

ess in

Hexadecimal

Contents

F10 C0000

Messages in language 1

F10 CEBEF

F10 CEBF0

Messages in language 2

F10 DD7DF

F10 DD7E0

Font robot 1

F10 DE7EF

F10 DE7F0

Font robot 2

7th block F10 DF7FF

F10 DF800

Messages Code converter table IMM 1

F10 DF9FF

F10 DFA00

Code converter table IMM 2

F10 DFBFF

F10 DFC00

Code converter table Printer 1

F10 DFDFF

F10 DFE00

Code converter table Printer 2

F10 DFFFF

F10 E0000

SEPRO parameters

8th block F10 E0DFF

F10 E1200

Parameters

SAP messages

and SAP F10 E2256

F10 E2400

Reserved for SEPRO

F10 FFFFF

Page 8

I – Memory

System

Configuration

S900II

I – 3. Specific information

These are directly accessed using the Memory Read function followed by the request [Address] and

a letter :

to access the memory area containing the passwords.

–

to access the memory area containing the serial number and the type of robot.

–

15 0

B2A0

B2A2

B2A4

B2A6

B2A8

B2AA

B2AC

B2AE

B2B0

B2B4

B2E0

B2E2

B2E4

B2E6

B2E8

B2EA

B2EC

B2EE

00 00

00 00

00 00

04 D2

00 00

00 00

00 00

00 00

00 00

00 00

000400

00

007335

98

Password to access edition (....)

Password to access parameters (....)

Password to access maintenance (....)

Password to block the modes (....)

Password to block the selection of the PRG N° to be

executed (....)

Operating time.

Operating time in automatic.

Robot serial number :

E.g. 1024

Robot type :

E.g. 350 BB (000) –> 3503000–D –> 357398–H

Model Type Specific

0 BX

1 BY

2 BZ

3 BB

4 BC

5 AX

6 AY

7 AZ

Page 9

System

Configuration

S900II

II – Instruction codes

II – INSTRUCTION

CODES

II – 1. Part programs

Type

Display Codop (hexadecimal) Examples

of Instruction

ACTION ACT 00 (to 99) * A000 [oper. 16 bits] A000000C = ACT12

Action

No.

OUTPUT OUT 000 (to 255) * A001 [oper. 16 bits] A0010050 = OUT080

Output No.

INPUT IN 000 (to 255) A002 [oper. 16 bits] A002000A = IN010

Normal

Input No.

INPUT IN/000 (to 255) A003 [oper. 16 bits] A0030020 = IN/032

Reverse

TIMER TIME 001 to 999

A004[oper.4bits]0[oper.11bits] A004000A = TIME010

Input No.

SAP marker

No.

V

alue

in 1/10s

A004300A = TIME010

Marker P03

TIME W_00 à 15 A004 0000 1 [oper.11bits] A004080A = TIMEW10

A004080F = TIMEW15

Word

No.

BIT BIT 000 (to 127) A005 [oper. 16 bits] A0050063 = BIT 99

Bit No.

/ BIT 000 (to 127) A006 [oper. 16 bits] A006007D = BIT 127

* The actions and outputs replaced by text (e.g.: part grip 1) keep the same CODOP

Page 10

II – Instruction codes

System

Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

FUNCTIONS (FUNC)

SPEED VEL.X 001 to 100 B000[oper.4bits][oper.12bits] B0000062 = VEL.X 098

in % of the VEL.Y 001 to 100

parametered speed VEL.Z 001 to 100

VEL.B 001 to 100

VEL.C 001 to 100

B001[oper.4bits][oper.12bits] B001000A = VEL.Y 010

B002[oper.4bits][oper.12bits] B0020012 = VEL.Z 018

B003[oper.4bits][oper.12bits] B0030064 = VEL.B 100

B004[oper.4bits][oper.12bits] B004A032 = VEL.C 050

SAP marker

N°

V

alue in

1/10s

Marker P10

VEL.X WW_*nn B050 0000 [oper.12bits] B0500042 = VEL.X WW066

VEL.Y WW_*nn B051 0000 [oper.12bits] B0510043 = VEL.Y WW067

VEL.Z WW_*nn B052 0000 [oper.12bits] B0520042 = VEL.Z WW066

VEL.B WW_*nn B053 0000 [oper.12bits] B0530042 = VEL.B WW066

VEL.C WW_*nn B054 0000 [oper.12bits] B0540043 = VEL.C WW067

*(nn

= 00 to 55

Word

and 66 to 67)

No.

ACCELERATION ACC.X 001 to 100 B010 [oper. 16 bits] B010000F = ACC.X 015

in % of the parametered ACC.Y 001 to 100 B011 [oper. 16 bits] B0110064 = ACC.Y 100

acceleration ACC.Z 001 to 100 B012 [oper. 16 bits] B0120044 = ACC.Z 068

ACC.B 001 to 100 B013 [oper. 16 bits] B0130005 = ACC.B 005

ACC.C 001 to 100 B014 [oper. 16 bits] B0140032 = ACC.C 050

Value

in %

Master MOVEMENT MASTER.X B030

MASTER.Y B031

MASTER.Z B032

MASTER.B B033

MASTER.C B034

IMPRECISION IMP.X B040

IMP.Y B041

IMP.Z B042

IMP.B B043

IMP.C B044

Page 11

System Configuration

S900II

II – Instruction codes

Type

of Instruction

Display Codop (hexadecimal) Examples

MOTORIZED

MOTIONS

SLOW APPROACH SLA.X 001 to 100 B020 [oper. 16 bits] B0200026 = SLA.X 026

in % of the maximum SLA.Y 001 to 100 B021 [oper. 16 bits] B0210034 = SLA.Y 034

parametered speed SLA.Z 001 to 100 B022 [oper. 16 bits] B0220090 = SLA.Z 090

SLA.B 001 to 100 B023 [oper. 16 bits] B0230100 = SLA.B 100

SLA.C 001 to 100 B024 [oper. 16 bits] B0240010 = SLA.C 010

Value

in %

LINEAR

ABSOLUTE X.ABS_L distance C000[oper.8bits][oper.24bits] C00000000664=X.ABS.L00163.6

(Numerical operands) Y.ABS_L distance C001[oper.8bits][oper.24bits] C001000F423F=Y.ABS.L99999.9

Z.ABS_L distance C002[oper.8bits][oper.24bits] C00200000320=Z.ABS.L00080.0

B.ABS_L distance C003[oper.8bits][oper.24bits] C0030000003F=B.ABS.L00006.3

C.ABS_L distance C004[oper.8bits][oper.24bits] C0040000050C=C.ABS.L00150.0

STACKING X.STK_L distance C010[oper.8bits][oper.24bits] C01000008ACF=X.STK.L03453.5

Y.STK_L distance C011[oper.8bits][oper.24bits] C01100030DE3=Y.STK.L20016.3

Z.STK_L distance C012[oper.8bits][oper.24bits] C01200000159=Z.STK.L00034.5

B.STK_L distance C053 Reserved for general STKs

C.STK_L distance C054 Absolute distances from the header

RELATIVE X.REL_L distance C020[oper.8bits][oper.24bits] C020800000A0=X.REL.L–0016.0

Y.REL_L distance C021[oper.8bits][oper.24bits] C021000000A0=Y.REL.L–0016.0

Z.REL_L distance C022[oper.8bits][oper.24bits] C0228001869F=Z.REL.L–9999.9

B.REL_L distance C023[oper.8bits][oper.24bits] C02300002706=B.REL.L+0999.9

C.REL_L distance C024[oper.8bits][oper.24bits] C0240000000A=C.REL.L+0001.0

CHECKING X.CTL_L distance C030[oper.8bits][oper.24bits] C03000000664=X.CTL.L00163.6

Y.CTL_L distance C031[oper.8bits][oper.24bits] C031000F423F=Y.CTL.L9999.9

Z.CTL_L distance C032[oper.8bits][oper.24bits] C03200000320=Z.CTL.L00080.0

B.CTL_L distance C033[oper.8bits][oper.24bits] C0330000003F=B.CTL.L00006.3

C.CTL_L distance C034[oper.8bits][oper.24bits] C0340500050C=C.CTL.L00150.0

Marker

Distance in 1/10 mmSAP marker No.

P05

ROTATING

ABSOLUTE X.ABS_R Angle C100[oper.8bits][oper.24bits] C10000000664=X.ABS.R00163.6

(Numerical operands) Y.ABS_R Angle C101[oper.8bits][oper.24bits] C101000005DC=Y.ABS.R00150.0

Z.ABS_R Angle C102[oper.8bits][oper.24bits] C10200000320=Z.ABS.R00080.0

B.ABS_R Angle C103[oper.8bits][oper.24bits] C1030000003F=B.ABS.R00006.3

C.ABS_R Angle C104[oper.8bits][oper.24bits] C10400000159=C.ABS.R00034.5

STACKING X.STK_R Angle C110[oper.8bits][oper.24bits] C11000008ACF=X.STK.R03453.5

Y.STK_R Angle C111[oper.8bits][oper.24bits] C11100030DE3=Y.STK.R20016.3

Z.STK_R Angle C112[oper.8bits][oper.24bits] C11200000159=Z.STK.R00034.5

RELATIVE X.REL_R Angle C120[oper.8bits][oper.24bits] C12000000384=X.REL.R+90.0

Y.REL_R Angle C121[oper.8bits][oper.24bits] C12180000320=Y.REL.R–90.0

Z.REL_R Angle C122[oper.8bits][oper.24bits] C12200000320=Z.REL.R+80.0

B.REL_R Angle C123[oper.8bits][oper.24bits] C12380000159=B.REL.R–34.5

C.REL_R Angle C124[oper.8bits][oper.24bits] C1240000003F=C.REL.R+06.3

Page 12

II – Instruction codes

System Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

CHECKING X.CTL_R Angle C130[oper.8bits][oper.24bits] C13000000664=X.CTL.R00163.6

Y.CTL_R Angle C131[oper.8bits][oper.24bits] C131000F423F=Y.CTL.R9999.9

Z.CTL_R Angle C132[oper.8bits][oper.24bits] C13200000320=Z.CTL.R00080.0

B.CTL_R Angle C133[oper.8bits][oper.24bits] C1330000003F=B.CTL.R00006.3

C.CTL_R Angle C134[oper.8bits][oper.24bits] C1340000050C=C.CTL.R00150.0

Angle

in

1/10 deg.

C10200AAAAAA=Z.ABS.RTeach

TEACHING Teach C

Previous

instruction

Instruction code

SAP Marker No.

[oper.8bits]AAAAAA C01000AAAAAA=X.STK.LTeach

SAP marker No.

MOTORIZED

MOTIONS (cont’d)

LINEAR

ABSOLUTE X.ABS_L WW *nn C200 [oper. 16 bits] C200000A = X.ABS.L WW10

(Words) Y.ABS_L WW *nn C201 [oper. 16 bits]

Z.ABS_L WW *nn C202 [oper. 16 bits]

B.ABS_L WW *nn C203 [oper. 16 bits]

C.ABS_L WW *nn C204 [oper. 16 bits]

STACKING X.STK_L WW *nn C210 [oper. 16 bits]

C210000B = X.STK.L WW11

Y.STK_L WW *nn C211 [oper. 16 bits]

Z.STK_L WW *nn C212 [oper. 16 bits]

RELATIVE X.REL_L WW *nn C220 [oper. 16 bits]

C2200041 = X.REL.L WW65

Y.REL_L WW *nn C221 [oper. 16 bits]

Z.REL_L WW *nn C222 [oper. 16 bits]

B.REL_L WW *nn C223 [oper. 16 bits]

C.REL_L WW *nn C224 [oper. 16 bits]

CHECKING X.CTL_L WW *nn C230 [oper. 16 bits]

C2300010 = X.CTL.L WW16

Y.CTL_L WW *nn C231 [oper. 16 bits]

Z.CTL_L WW *nn C232 [oper. 16 bits]

B.CTL_L WW *nn C233 [oper. 16 bits]

C.CTL_L WW *nn C234 [oper. 16 bits]

ROTATING

ABSOLUTE X.ABS_R WW *nn C300 [oper. 16 bits] C300000A = X.ABS.R WW10

(Words) Y.ABS_R WW *nn C301 [oper. 16 bits]

Z.ABS_R WW *nn C302 [oper. 16 bits]

B.ABS_R WW *nn C303 [oper. 16 bits]

C.ABS_R WW *nn C304 [oper. 16 bits]

STACKING X.STK_R WW *nn C310 [oper. 16 bits]

C3100020 = X.STK.R WW32

Y.STK_R WW *nn C311 [oper. 16 bits]

Z.STK_R WW *nn C312 [oper. 16 bits]

*(nn

= 00 to 55 and 64 to 65)

Page 13

System

Configuration

S900II

II – Instruction codes

Type

Display Codop (hexadecimal) Examples

of Instruction

RELATIVE X.REL_R WW *nn C320 [oper. 16 bits] C3200001 = X.REL.R WW01

Y.REL_R WW *nn C321 [oper. 16 bits]

Z.REL_R WW *nn C322 [oper. 16 bits]

B.REL_R WW *nn C323 [oper. 16 bits]

C.REL_R WW *nn C324 [oper. 16 bits]

CHECKING X.CTL_R WW *nn C330 [oper. 16 bits]

C3300041 = X.CTL.R WW65

Y.CTL_R WW *nn C331 [oper. 16 bits]

Z.CTL_R WW *nn C332 [oper. 16 bits]

B.CTL_R WW *nn C333 [oper. 16 bits]

C.CTL_R WW *nn C334 [oper. 16 bits]

*(nn

= 00 to 55 and 64 to 65)

WWORD

No.

FREE X. FREE C040

Y. FREE C041

Z. FREE C042

B. FREE C043

C. FREE C044

LINE LIN. B046

Page 14

II – Instruction codes

System Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

LINEAR

POS_ANA X = POS ANA + distance C060 [oper. 32 bits]

Y = POS ANA + distance C061 [oper. 32 bits]

Z = POS ANA + distance C062 [oper. 32 bits]

B = POS ANA + distance C063 [oper. 32 bits]

C = POS ANA + distance C064 [oper. 32 bits]

POS_NUM X = POS NUM + distance C070 [oper. 32 bits]

Y = POS NUM + distance C071 [oper. 32 bits]

Z = POS NUM + distance C072 [oper. 32 bits]

B = POS NUM + distance C073 [oper. 32 bits]

C = POS NUM + distance C074 [oper. 32 bits]

VEL ANA NORMAL X = VEL ANA_N + distance C080 [oper. 32 bits]

Y = VEL ANA_N + distance C081 [oper. 32 bits]

Z = VEL ANA_N + distance C082 [oper. 32 bits]

B = VEL ANA_N + distance C083 [oper. 32 bits]

C = VEL ANA_N + distance C084 [oper. 32 bits]

VEL ANA INTEGRAL X = VEL ANA_I + distance C090 [oper. 32 bits]

Y = VEL ANA_I + distance C091 [oper. 32 bits]

Z = VEL ANA_I + distance C092 [oper. 32 bits]

B = VEL ANA_I + distance C093 [oper. 32 bits]

C = VEL ANA_I + distance C094 [oper. 32 bits]

VEL NUM NORMAL X = VEL NUM_N + distance C0A0[oper. 32 bits]

Y = VEL NUM_N + distance C0A1 [oper. 32 bits]

Z = VEL NUM_N + distance C0A2 [oper. 32 bits]

B = VEL NUM_N + distance C0A3 [oper. 32 bits]

C = VEL NUM_N + distance C0A4 [oper. 32 bits]

VEL NUM INTEGRAL X = VEL NUM_I + distance C0B0[oper. 32 bits]

Y = VEL NUM_I + distance C0B1 [oper. 32 bits]

Z = VEL NUM_I + distance C0B2 [oper. 32 bits]

B = VEL NUM_I + distance C0B3 [oper. 32 bits]

C = VEL NUM_I + distance C0B4 [oper. 32 bits]

Page 15

System

Configuration

S900II

II – Instruction codes

Type

Display Codop (hexadecimal) Examples

of Instruction

ROTATING

POS_ANA X = POS ANA + angle C160 [oper. 32 bits]

Y = POS ANA + angle C161 [oper. 32 bits]

Z = POS ANA + angle C162 [oper. 32 bits]

B = POS ANA + angle C163 [oper. 32 bits]

C = POS ANA + angle C164 [oper. 32 bits]

POS_NUM X = POS NUM + angle C170 [oper. 32 bits]

Y = POS NUM + angle C171 [oper. 32 bits]

Z = POS NUM + angle C172 [oper. 32 bits]

B = POS NUM + angle C173 [oper. 32 bits]

C = POS NUM + angle C174 [oper. 32 bits]

VEL ANA NORMAL X = VEL ANA_N + angle C180 [oper. 32 bits]

Y = VEL ANA_N + angle C181 [oper. 32 bits]

Z = VEL ANA_N + angle C182 [oper. 32 bits]

B = VEL ANA_N + angle C183 [oper. 32 bits]

C = VEL ANA_N + angle C184 [oper. 32 bits]

VEL ANA INTEGRAL X = VEL ANA_I + angle C190 [oper. 32 bits]

Y = VEL ANA_I + angle C191 [oper. 32 bits]

Z = VEL ANA_I + angle C192 [oper. 32 bits]

B = VEL ANA_I + angle C193 [oper. 32 bits]

C = VEL ANA_I + angle C194 [oper. 32 bits]

VEL NUM NORMAL X = VEL NUM_N + angle C1A0[oper. 32 bits]

Y = VEL NUM_N + angle C1A1 [oper. 32 bits]

Z = VEL NUM_N + angle C1A2 [oper. 32 bits]

B = VEL NUM_N + angle C1A3 [oper. 32 bits]

C = VEL NUM_N + angle C1A4 [oper. 32 bits]

VEL NUM INTEGRAL X = VEL NUM_I + angle C1B0[oper. 32 bits]

Y = VEL NUM_I + angle C1B1 [oper. 32 bits]

Z = VEL NUM_I + angle C1B2 [oper. 32 bits]

B = VEL NUM_I + angle C1B3 [oper. 32 bits]

C = VEL NUM_I + angle C1B4 [oper. 32 bits]

Page 16

II – Instruction codes

System

Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

TEST, CONDITIONS

. 1 Operand

on Bit IF BIT 000 (to 127) D000 [oper. 16 bits]

IF/BIT 000 (to 127) D010 [oper. 16 bits]

on Output IF OUT 000 (to 255) D001 [oper. 16 bits]

IF/OUT 000 (to 255) D011 [oper. 16 bits]

on Input IF IN/000 (to 255) D002 [oper. 16 bits]

IF IN 000 (to 255) D003 [oper. 16 bits]

IF/IN 000 (to 255) D013 [oper. 16 bits]

on Timer IF TIM 00 (to 15) D004 [oper. 16 bits]

IF/TIM 00 (to 15) D014 [oper. 16 bits]

Operand

No.

. 2 Operands

* on Word (16 bits) IF WRD 000 (to 4095) D300 [oper. 16 bits]

–> 1st Operand IF/WRD 000 (to 4095) D310 [oper. 16 bits]

with decimal value = 0000 (to 9999) D400 [oper. 16 bits]

> = 0000 (to 9999) D401 [oper. 16 bits]

< = 0000 (to 9999) D402 [oper. 16 bits]

AND 0000 (to 9999) D403 [oper. 16 bits]

with hexadecimal value = 0000 (to FFFF) D410 [oper. 16 bits]

> = 0000 (to FFFF) D411 [oper. 16 bits]

< = 0000 (to FFFF) D412 [oper. 16 bits]

AND 0000 (to FFFF) D413 [oper. 16 bits]

Note : If the decimal

value cannot exceed

9,999, the hexadecimal

value

goes up to

65,535.

with Counter = CNT 00 (to 15) D420 [oper. 16 bits]

> = CNT 00 (to 15) D421 [oper. 16 bits]

< =CNT 00 (to 15) D422 [oper. 16 bits]

AND CNT 00 (to 15) D423 [oper. 16 bits]

with Inputs (modulo 16) =IN 000 (to 112) D430 [oper. 16 bits]

> =IN 000 (to 112) D431 [oper. 16 bits]

< =IN 000 (to 112) D432 [oper. 16 bits]

AND IN 000 (to 112) D433 [oper. 16 bits]

with Word (16 bits) = WRD 0000 (to 4095) D440 [oper. 16 bits]

> = WRD 0000 (to 4095) D441 [oper. 16 bits]

< = WRD 0000 (to 4095) D442 [oper. 16 bits]

AND WRD 0000(to 4095) D443 [oper. 16 bits]

Page 17

System

Configuration

S900II

II – Instruction codes

Type

Display Codop (hexadecimal) Examples

of Instruction

* on WWord (32 bits) IF WWRD 000 (to 127) D320 [oper. 16 bits]

–> 1st Operand IF/WWRD 000 (to 127) D330 [oper. 16 bits]

with decimal value =

> =

< =

AND

with hexadecimal value =

> =

< =

AND

00000000

00000000 (to FFFFFFFF)

(to 09999999)

00000000

00000000

00000000

00000000

00000000

00000000

(to 09999999)

(to 09999999)

(to 09999999)

(to FFFFFFFF)

(to FFFFFFFF)

(to FFFFFFFF)

D500 [oper. 32 bits]

D501 [oper. 32 bits]

D502 [oper. 32 bits]

D503 [oper. 32 bits]

D510 [oper. 32 bits]

D511 [oper. 32 bits]

D512 [oper. 32 bits]

D513 [oper. 32 bits]

with Counter = CNT 00 (to 15) D520 [oper. 16 bits]

> = CNT 00 (to 15) D521 [oper. 16 bits]

< = CNT 00 (to 15) D522 [oper. 16 bits]

AND CNT 00 (to 15) D523 [oper. 16 bits]

with Inputs (modulo 16) = IN 000 (to 112) D530 [oper. 16 bits]

> = IN 000 (to 112) D531 [oper. 16 bits]

< = IN 000 (to 112) D532 [oper. 16 bits]

AND IN 000 (to 112) D533 [oper. 16 bits]

Note

: If the decimal

value cannot exceed

9,999,999,

the

hexadeci

mal value goes up to

4,294,967,295.

-

with Word (16 bits) = WRD 0000 (to 4095) D540 [oper. 16 bits]

> = WRD 0000 (to 4095) D541 [oper. 16 bits]

< = WRD 0000 (to 4095) D542 [oper. 16 bits]

AND WRD 0000(to 4095) D543 [oper. 16 bits]

with WWord (32 bits) = WWRD 000 (to 127) D550 [oper. 16 bits]

> = WWRD 000 (to 127) D551 [oper. 16 bits]

< = WWRD 000 (to 127) D552 [oper. 16 bits]

AND WWRD 000(to 127) D553 [oper. 16 bits]

* on Counter IF CNT 00 (to 15) D340 [oper. 16 bits]

–> 1st Operand IF/CNT 00 (to 15) D350 [oper. 16 bits]

with decimal value = 0000 (to 9999) D900 [oper. 16 bits]

> = 0000 (to 9999) D901 [oper. 16 bits]

< = 0000 (to 9999) D902 [oper. 16 bits]

AND 0000 (to 9999) D903 [oper. 16 bits]

with hexadecimal value =

0000 (to FFFF) D910 [oper. 16 bits]

> = 0000 (to FFFF) D911 [oper. 16 bits]

< = 0000 (to FFFF) D912 [oper. 16 bits]

AND 0000 (to FFFF) D913 [oper. 16 bits]

with Counter = CNT 00 (to 15) D920 [oper. 16 bits]

> = CNT 00 (to 15) D921 [oper. 16 bits]

< = CNT 00 (to 15) D922 [oper. 16 bits]

AND CNT 00 (to 15) D923 [oper. 16 bits]

Page 18

II – Instruction codes

System

Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

with Inputs (modulo 16) = IN 000 (to 112) D930 [oper. 16 bits]

> = IN 000 (to 112) D931 [oper. 16 bits]

< = IN 000 (to 112) D932 [oper. 16 bits]

AND IN 000 (to 112) D933 [oper. 16 bits]

with Word (16 bits) = WRD 0000 (to 4095) D940 [oper. 16 bits]

> = WRD 0000 (to 4095) D941 [oper. 16 bits]

< = WRD 0000 (to 4095) D942 [oper. 16 bits]

AND WRD 0000(to 4095) D943 [oper. 16 bits]

INITIALIZATION

. 1 Operand

* on Bit –> 1 SET.BIT 032 (to 127) D015 [oper. 16 bits]

on Bit –> 0 RST.BIT 032 (to 127) D017 [oper. 16 bits]

* on Output –> 1 SET.OUT 000 (to 127) D016 [oper. 16 bits]

on Output –> 0 RST.OUT 000 (to 127) D018 [oper. 16 bits]

* on Word –> 0 RST.WRD 0000 (to 4095) D019 [oper. 16 bits]

V

ariable number

* on WWord –> 0 RST.WWRD 00 (to 63) D01D [oper. 16 bits]

Variable

number

* on Counter –> 0 RST.CNT 0000 (to 0015) D01A 00 [oper. 8 bits]

Counter number

RST.CNT 0041 (to 9980)

D01A[oper. 8 bits] [oper. 8 bits]

PRG No.

SP No.

. 2 Operands

* on Word (16 bits) SET.WRD 0000 (to 4095) D600 [oper. 16 bits]

–> 1st Operand

with decimal value = 0000 (to 9999) D700 [oper. 16 bits]

+ 0000 (to 9999) D701 [oper. 16 bits]

– 0000 (to 9999) D702 [oper. 16 bits]

x 0000 (to 9999) D703 [oper. 16 bits]

/ 0000 (to 9999) D704 [oper. 16 bits]

AND 0000 (to 9999) D705 [oper. 16 bits]

OR 0000 (to 9999) D706 [oper. 16 bits]

with hexadecimal value = 0000 (to FFFF) D710 [oper. 16 bits]

+ 0000 (to FFFF) D711 [oper. 16 bits]

– 0000 (to FFFF) D712 [oper. 16 bits]

x 0000 (to FFFF) D713 [oper. 16 bits]

/ 0000 (to FFFF) D714 [oper. 16 bits]

AND 0000 (to FFFF) D715 [oper. 16 bits]

OR 0000 (to FFFF) D716 [oper. 16 bits]

Page 19

System Configuration

S900II

II – Instruction codes

Type

Display Codop (hexadecimal) Examples

of Instruction

with Counter = CNT 00 (to 15) D720 [oper. 16 bits]

+ CNT 00 (to 15) D721 [oper. 16 bits]

– CNT 00 (to 15) D722 [oper. 16 bits]

x CNT 00 (to 15) D723 [oper. 16 bits]

/ CNT00 (to 15) D724 [oper. 16 bits]

AND CNT 00 (to 15) D725 [oper. 16 bits]

OR CNT 00 (to 15) D726 [oper. 16 bits]

with Inputs (modulo 16) = IN 000 (to 112) D730 [oper. 16 bits]

+ IN 000 (to 112) D731 [oper. 16 bits]

– IN 000 (to 112) D732 [oper. 16 bits]

x IN 000 (to 112) D733 [oper. 16 bits]

/ IN 000 (to 112) D734 [oper. 16 bits]

AND IN 000 (to 112) D735 [oper. 16 bits]

OR IN 000 (to 112) D736 [oper. 16 bits]

with Word (16 bits) = WRD 0000 (to 4095) D740 [oper. 16 bits]

+ WRD 0000 (to 4095) D741 [oper. 16 bits]

– WRD 0000 (to 4095) D742 [oper. 16 bits]

x WRD 0000 (to 4095) D743 [oper. 16 bits]

/ WRD 0000 (to 4095) D744 [oper. 16 bits]

AND WRD 0000 (to 4095)D745 [oper. 16 bits]

OR WRD 0000 (to 4095) D746 [oper. 16 bits]

* on WWord (32 bits) SET.WWRD 000 (to 127) D620 [oper. 16 bits]

–> 1st Operand

with decimal value =

with hexadecimal value =

with Counter = CNT 00 (to 15

00000000

00000000

+

–

00000000

x

00000000

/

00000000

AND

OR

00000000

+

00000000

00000000

–

x

00000000

/

00000000

AND

OR

+ CNT 00 (to 15

– CNT 00 (to 15

x CNT 00 (to 15

/ CNT 00 (to 15

(to 09999999)

(to 09999999)

(to 09999999)

(to 09999999)

(to 09999999)

00000000

00000000

(to FFFFFFFF)

(to FFFFFFFF)

(to FFFFFFFF)

(to FFFFFFFF)

(to FFFFFFFF)

00000000

00000000

(to 09999999)

(to 09999999)

(to FFFFFFFF)

(to FFFFFFFF)

) D820 [oper. 16 bits]

) D821 [oper. 16 bits]

) D822 [oper. 16 bits]

) D823 [oper. 16 bits]

) D824 [oper. 16 bits]

AND CNT 00 (to 15

OR CNT 00 (to 15

) D826 [oper. 16 bits]

D800 [oper. 32 bits]

D801 [oper. 32 bits]

D802 [oper. 32 bits]

D803 [oper. 32 bits]

D804 [oper. 32 bits]

D805 [oper. 32 bits]

D806 [oper. 32 bits]

D810 [oper. 32 bits]

D811 [oper. 32 bits]

D812 [oper. 32 bits]

D813 [oper. 32 bits]

D814 [oper. 32 bits]

D815 [oper. 32 bits]

D816 [oper. 32 bits]

) D825 [oper. 16 bits]

Page 20

II – Instruction codes

System

Configuration

S900II

Type

Display Codop (hexadecimal) Examples

of Instruction

with Inputs (modulo 16) = IN *nn D830 [oper. 16 bits]

+ IN *nn D831 [oper. 16 bits]

– IN *nn D832 [oper. 16 bits]

*nn = 00 to 112 x IN *nn D833 [oper. 16 bits]

and 136 to 240 / IN *nn D834 [oper. 16 bits]

AND IN *nn D835 [oper. 16 bits]

OR IN *nn D836 [oper. 16 bits]

with Word (16 bits) = WRD 0000 (to 4095) D840 [oper. 16 bits]

+ WRD 0000 (to 4095) D841 [oper. 16 bits]

– WRD 0000 (to 4095) D842 [oper. 16 bits]

x WRD 0000 (to 4095) D843 [oper. 16 bits]

/ WRD 0000 (to 4095) D844 [oper. 16 bits]

AND WRD 0000 (to 4095) D845 [oper. 16 bits]

OR WRD 0000 (to 4095) D846 [oper. 16 bits]

with WWord (32 bits) =

WWRD *nn and 200–202 D850 [oper. 16 bits]

+ WWRD *nn D851 [oper. 16 bits]

– WWRD *nn D852 [oper. 16 bits]

*nn = 0 to 127 x WWRD *nn D853 [oper. 16 bits]

/ WWRD *nn D854 [oper. 16 bits]

AND WWRD*nn D855 [oper. 16 bits]

OR WWRD *nn D856 [oper. 16 bits]

* on Counter SET.CNT 0000 (to 0015) D640 [oper. 8 bits] Standard counter

–> 1st Operand SET.CNT 0041 (to 9980)

D640[oper. 8 bits] [oper. 8 bits] Stacking counter

PRG

No.

SP No.

with decimal value = 0000 (to 9999) DA00 [oper. 16 bits]

+ 0000 (to 9999) DA01 [oper. 16 bits]

– 0000 (to 9999) DA02 [oper. 16 bits]

x 0000 (to 9999) DA03 [oper. 16 bits]

/ 0000 (to 9999) DA04 [oper. 16 bits]

AND 0000 (to 9999) DA05 [oper. 16 bits]

OR 0000 (to 9999) DA06 [oper. 16 bits]

with hexadecimal value =

0000 (to FFFF) DA10 [oper. 16 bits]

+ 0000 (to FFFF) DA11 [oper. 16 bits]

– 0000 (to FFFF) DA12 [oper. 16 bits]

x 0000 (to FFFF) DA13 [oper. 16 bits]

/ 0000 (to FFFF) DA14 [oper. 16 bits]

AND 0000 (to FFFF) DA15 [oper. 16 bits]

OR 0000 (to FFFF) DA16 [oper. 16 bits]

with Counter = CNT 00 (to 15) D920 [oper. 16 bits]

+ CNT 00 (to 15) D921 [oper. 16 bits]

– CNT 00 (to 15) D922 [oper. 16 bits]

x CNT 00 (to 15) D922 [oper. 16 bits]

/ CNT 00 (to 15) D922 [oper. 16 bits]

AND CNT 00 (to 15) D923 [oper. 16 bits]

OR CNT 00 (to 15) D923 [oper. 16 bits]

Page 21

System Configuration

S900II

II – Instruction codes

Type

Display Codop (hexadecimal) Examples

of Instruction

with Inputs (modulo 16) = IN 000 (to 112) DA30 [oper. 16 bits]

+ IN 000 (to 112) DA31 [oper. 16 bits]

– IN 000 (to 112) DA32 [oper. 16 bits]

x IN 000 (to 112) DA33 [oper. 16 bits]

/ IN 000 (to 112) DA34 [oper. 16 bits]

AND IN 000 (to 112) DA35 [oper. 16 bits]

OR IN 000 (to 112) DA36 [oper. 16 bits]

with Word (16 bits) = WRD 0000 (to 4095) DA40 [oper. 16 bits]

+ WRD 0000 (to 4095) DA41 [oper. 16 bits]

– WRD0000 (to 4095) DA42 [oper. 16 bits]

x WRD 0000 (to 4095) DA43 [oper. 16 bits]

/ WRD 0000 (to 4095) DA44 [oper. 16 bits]

AND WRD 0000 (to 4095)DA45 [oper. 16 bits]

OR WRD 0000 (to 4095) DA46 [oper. 16 bits]

–> + 1 INC.CNT 0000 (to 0015) D01B 00 [oper. 8 bits]

Standard No.

INC.CNT 0041 (to 9980)

D01B[oper. 8 bits] [oper. 8 bits]

PRG

No.

SP No.

–> – 1 DEC.CNT 0000 (to 0015) D01C 00 [oper. 8 bits]

Standard No.

DEC.CNT 0041 (to 9980)

D01C[oper. 8 bits] [oper. 8 bits]

PRG No.

SP No.

Page 22

II – Instruction codes

II – 2. PLC programs

System Configuration

S900II

Type

Display Codop (hexadecimal)

of Instruction

PROG.PLC xx header (num) PLC xx FC [oper. 16 bits]

PLC

No.

TEST CONDITION IF ... See part programs

INITIALISATION SET ... See part programs

RST ...

INC ...

DEC ...

COMPARISON xxxx > = xxxx

CMP 0000 (to 0015) V

0000 (to 0015)

AL 0000 (to FFFF)

D020 [oper. 16 bits] [oper. 16 bits]

Counter No.

Value

TIMER xx VALUE xxxx TIMER 00 (to 15) VAL 0000 (to 9999) D021 [oper. 16 bits] [oper. 16 bits]

Timer No.

Pre–selection No.

AND FUNCTION on BIT AND BIT 000 (to 127) D022 [oper. 16 bits]

AND FUNCTION on OUTPUT AND OUT 000 (to 127) D023 [oper. 16 bits]

AND FUNCTION on BIT OR BIT 000 (to 127) D024 [oper. 16 bits]

OR FUNCTION on OUTPUT OR OUT 000 (to 127) D025 [oper. 16 bits]

Variables

No.

END OF PROGRAM END F5 [oper. 16 bits]

PLC No.

Page 23

System Configuration

S900II

III – Pr

ogram codes

III – PROGRAM

III – 1.

Declaration of programs, subroutines and PLCs

"

Header codes of PRG, SP,..., SR, PLC

G F9b xn = Main program

G b = 0, standard PRG (encoded on 15 bits)

b = 1 , SAP PRG (encoded on 15 bits)

G FAnn = STD, STK.. // subroutine (see stacking header)

G FBnn = Return subroutine (see home return header)

G FCnn = PLC program

G FEnn = FREE

"

STEP TRANSITION codes

G EC00 + Step number 0 to 999

G E.g. : EC12 => Step number 18 (decimal)

G E.g. : ED00 => Step number 256 (decimal)

CODES

"

END of PRG, SP..., SR, PLC codes

G F0nn = End of ”standard” SP nn.

G F1nn = End of ”standard” stacking SP nn.

G F2nn = End of ”general” stacking SP nn.

G F3nn = End of SP // nn.

G F4nn = End of simple or total SR nn.

G F8nn = End of simple or total SR with return to step 0 of PRG 00.

G F5nn = End of PLC nn.

G F7nn = End of main program (PRG) nn.

"

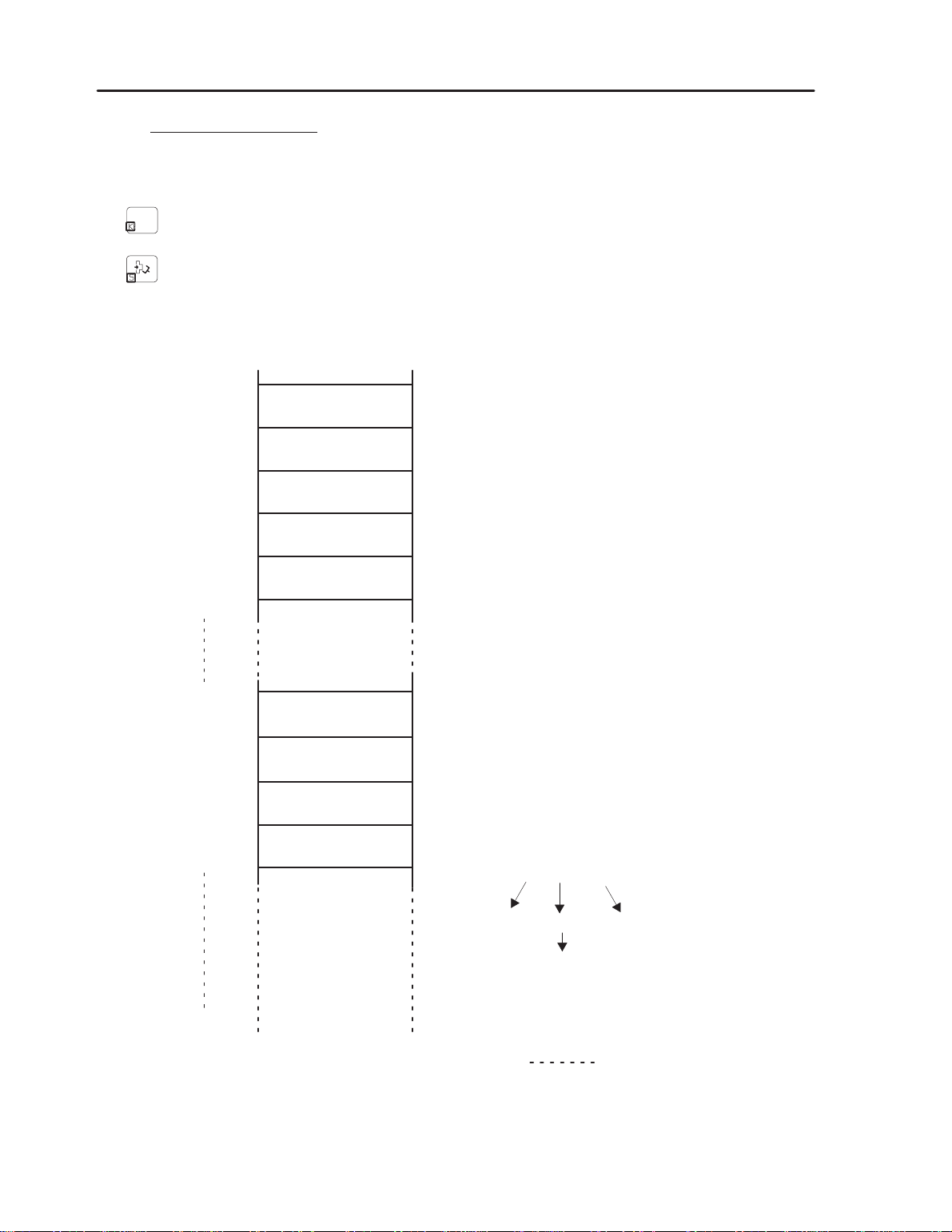

PRG architecture in the memory area

pr

evious pr

ogram

F9 nn

PRG (text)

F7 nn

FA xx

SP

PRG nn

F1 xx

FB pp

F4 pp

F9 mm

SR

following PRG

Page 24

III – Pr

ogram codes

System

Configuration

S900II

III – 2.

Subroutine and program calls

"

SPECIFIC codes for SP, SR, PLC as an instruction

G E000 [oper. 16 bits] :

Standard SP SP nn Lmm (nn = 01 to 40) (mm = 00 to 99)

Regular Stacking SP SP nn D Lmm (or I Lmm) (nn = 41 to 60) (mm = 00 to 99)

General Stacking SP SP nn D Lmm (or I Lmm) (nn = 61 to 80) (mm = 00 to 99)

Parallel SP SP nn L00 (nn = 81 to 99)

The operand contains :

. high order word –> the LABEL number

–> bit 0 x 8000 at 0 indicates DIRECT

–> bit 0 x 8000 at 1 indicates REVERSE

. low order word –> the SP number.

E.g. : E000 0103 –> SP 03 L01

E.g. : E000 8229 –> SP 41 I L02

G E100 [oper. 16 bits] : PLC prog. – Display : PLC 00 (to 99)

G E500 [oper. 16 bits] : Home Return – Display : SR 01 (to 99)

"

Return label

G E600 [oper. 16 bits] : Labels ”L” for SP – Display : L00 to L99

G E700 [oper. 16 bits] : Labels ”R” for SR – Display : R00 to R99

Page 25

System

Configuration

S900II

IV – V

ariable addr

essing

IV – V

ARIABLE

IV – 1. Output – OUT –

Accessible in read and write.

Number

(logical address)

OUT 000

OUT 255

IV – 2. Input – IN –

Accessible in read.

ADDRESSING

Physical

address

28A0

299F

Structures / Functions

2 A1D

Forcing

(Extended monitor)

not used

Continuous status

(See Param. No 14)

OUT

125

Number

(logical address)

IN 000

Physical

address

29A0

2 9AB

IN 255

2A9F

IV – 3. User and system bits – BIT –

Each address corresponds to an 8 bit structure in memory.

not used

0281x

Forcing

(Extended monitor)

x = bit number in hexadecimal (e.g.: Bit 31, address = 0282F).

Only the low order word is used.

– System bits accessible in Read – No. 0 to 30.

Structures / Functions

not used

BIT 0

IN

01

1

– System bits accessible in Read and Write – No. 31 to 33.

– User bits accessible in Read and Write – No. 34 to 127.

For the definition of these bits, see the Programming Level 2 manual, paragraph I3.

Page 26

IV – V

ariable addr

essing

IV – 4. 16 bits user and system words – WRD –

System

Configuration

S900II

Number

(logical address)

WRD 0000 2AA0

WRD 0031 2ADF

WRD 0032 2AE0

WRD 0063 2B1E

WRD 0064 2B20

WRD 0079 2B3F

WRD 0080 2B40

WRD 0095 2B5F

WRD 0096 2B60

WRD 4096 3A9F

Physical

address

Structures / Functions

32 user Words (read/write) with no predefined functions.

B15 0

16 bit structure available

32 system Words (read only). For the definition of these

words, see the Programming Level 2 manual, paragraph

I4

16 user Words (read/write) supporting the PLC timers

(TIM 00 to TIM 15).

16 user Words (read/write) supporting the standard

counters (CNT 00 to CNT 15).

4000 user Words (read/write) supporting the stacking

subroutine counters (CNT 0041 to CNT 9980).

IV – 5. 32 bit user and system words – WWRD –

Number

(logical address)

WWRD 000 6230

WWRD 063 6327

WWRD 064 6328

Physical

address

Structures / Functions

64 user Words (read/write) with no predefined functions.

b31 0

32 bit structure available

64 system Words (read only). For the definition of these

words, see the Programming Level 2 manual, paragraph

I5

WWRD 127 642C

Specific words

WWRD 0116 6400 Values for calculating the automatic anticipated restart.

WWRD 0117 6404 Values for calculating the automatic anticipated restart.

See chapter VI – page 28.

Page 27

System

Configuration

S900II

IV – 6. Counters

Each address corresponds to a 16 bit structure in the memory.

WRD0088

b15 b0

2 B4x

CNT0008

. values from 0000 to 9999 in decimal

. values from 0000 to FFFF in hexadecimal

x = bit number in hexadecimal (e.g.: CNT 0008, address = 2 B50).

– Standard counters – No. 0000 to 0015 (0x2B40 to 0x2B5E).

– Regular stacking counters – No. 0041 to 9960 (as from 0x2 B60).

– General stacking counters – No 0061 to 9980.

IV – V

ariable addr

essing

For the definition of these counters, see the Programming Level 2 manual, paragraph I6.

IV – 7. Timers

IV – 7. 1.End of timer for part program

Accessible in read and write.

Number

(logical address)

Physical

address

Structures / Functions

TIM00 2 890

TIM01 2 891

TIM02 2 892

TIM03 2 893

TIM04 2 894

TIM05 2 895

TIM06 2 896

2 897

TIM07 2 897

TIM08 2 898

not used

TIM09 2 899

TIM10 2 89A

Only the low order word is used

TIM11 2 89B

TIM12 2 89C

TIM13 2 89D

TIM14 2 89E

TIM15 2 89F

TIM07

IV – 7. 2.PLC timer

TIM00 to 15 = WRD 0064 to 0079 see chapter IV – 4.

Accessible in read and write.

Page 28

V – CPU fault signalling

System

Configuration

S900II

V – CPU FAUL

V – 1. Flashing

These signal a CAN network fault by displaying the problem number in binary on the LEDs at the

bottom of the CPU, and the node number (if concerned) on the LEDs at the top if the pendant is not

functioning.

30

Leds

T SIGNALLING

1 = CAN driver initialization fault

2 = Write problem in Flashprom

5 = A double (or more) node on the network (code + node)

6 = Problem during the CONNECTION phase (code + node)

7 = Problem during the PREPARATION phase (code + node)

8 = Problem during the START phase (code + node)

= The network does not correspond to the parametered configuration (code + node)

9

10 = “Node–guarding” problem (code + node). Communication fault with the pendant ;

this

may be due to the CAN speed being too great for the length of the cable used,

line adaptation, or interference, etc.

11 = CPU emission problem

12 = CPU reception problem

13 = Topology fault of the remote I/O

15

= EMERGENCY message received (code + node). Problem on the pendant or with

communication between the pendant and the CPU (see 10)

or a bad

Note : In the event of a NODE GUARDING fault, fault 15 may appear alternately with fault 10.

Page 29

System

Configuration

S900II

V – CPU fault signalling

V – 2. Fixed

Leds

These signal a fault when powering up by giving the problem number in binary on the LEDs at the

bottom of the CPU, and the node number (if concerned) on the LEDs at the top if the pendant is not

functioning.

1 = Problem with recovering the parameters in Flashprom

2 = Problem during the opening of the PC link

3 = Problem during the opening of the EUROMAP 17 link

4 = Problem during the opening of the printer 2 link

5 = Problem during the opening of the CAN link

6 = Message not present in Flashprom

7 = Problem with the CPU’

8 = Problem with the Flashprom’

s RAM

s checksum

9 = Problem with the axes declared and the axes’ boards present

10 = The configuration has changed

11 = Problem during the initialization of the axes’ boards by the CPU

15

= Communication problem with the

pendant during powering up. The CAN speed

may be changed by transfering the parameters with the PC at 2400 Bds, slave = 1.

Page 30

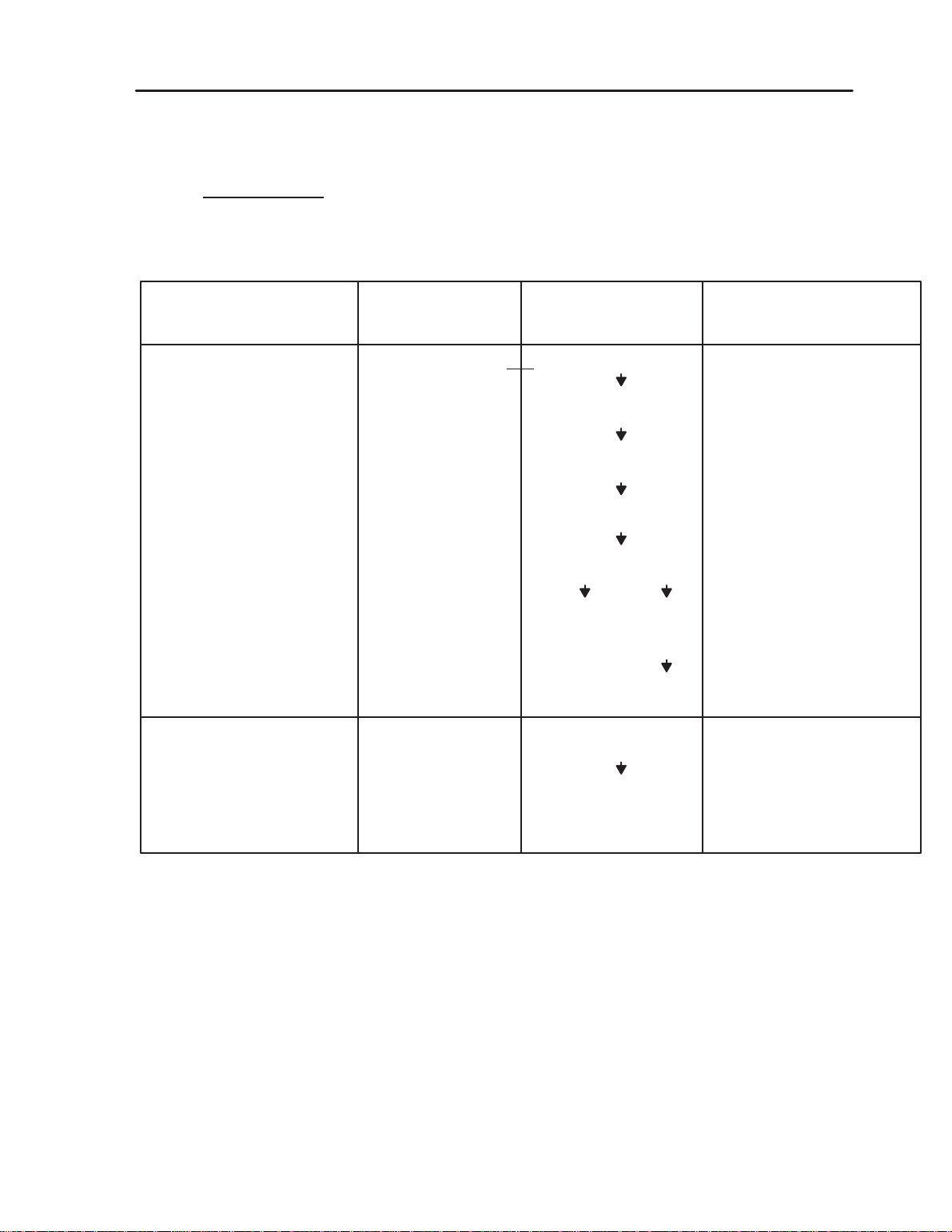

VI – IMM Anticipated Restart

System Configuration

S900II

VI – IMM

"

ANTICIPATED REST

Parameter 174 : type of IMM anticipated restart

ART

G 0 : no anticipated restart

G 1 : anticipated restart

G 2 : programmed delay anticipated restart –> WWRD 63 programmed in step 0.

"

Parameter

175 : basic value of the auto–adaptative delay and

the programmed delay

"

Parameter 176 : minimum value of the auto–adaptative delay (safety margin)

Anticipated restart effective if :

G offset wait is not valid (parameter 451)

G and if the robot is in automatic

G and if Kv equals 100 %

G and if there is a SET WWRD63 in step 0 of the program

G and if the value of WWRD63 is greater than or equal to

VCM

programmed

VCM

Tr = WWRD 116

double the minimum value of

in

the case of

restart with

parameter 175

2

programmed

delay

BHM

P176

Tm = WWRD 117

MO

Tr = robot disengaging time in 1/10 s (WWRD 116)

Tm = IMM motion start time in 1/10 s (WWRD 117)

Rt = theoretical delay = Tr – Tm + P176 or 0 if the result is negative

Rapp = Applied delay

Rapp > Rt

yes

no

Rapp = Rt

Rapp = 66% of (Rt – Rapp)

There is a fault if mould open (or OPA) goes to 0 and BHM = 0

D_5

: MOVEMENT OUTSIDE CAMS

D_32:

PREMATURE MACHINE RESTART

(if there is no anticipated restart running)

(if there is an anticipated restart running)

Page 31

System

Configuration

S900II

Safety circuit principle.

VI – IMM Anticipated Restart

A hard–wired circuit controls the respective positions of the moving mould (“MO” = Mould Open

signal) and of the robot (“ZBD” = Arm Free Area / “ZHM” = Outside Mould Area signal).

output of this

The

hard–wired circuit (”MO” + ”ZBD” + ”ZHM” = ”KA301”) activates a power relay

(KA301 contactor).

During normal operation, the KA301 relay is activated. The KA301 contacts are used in series with

the SBD relay contact from the interface board, which therefore means that the software safety that

manages the SBD relay with a hard–wired safety device is doubled.

When

there

is a fault (robot position not conform compared to the moving mould position), the KA301

relay falls, which

in turn activates the control relay KA16A, which is self–powered and which stops

the KA301 relay becoming active (the blocking of KA301 prohibits the IMM cycle).

You must power down the robot cabinet to cancel this fault.

FOR 32 OUTPUT BOARDS : as OUTxx active at power up

ANCILLARY “ARM

FREE” SAFETY

“KA301” relay

CONTROL

ANCILLARY “ARM

FREE” SAFETY

“KA301” relay

CONTROL

Page 32

VI – IMM Anticipated Restart

System

Configuration

S900II

IF IN XX

SET WORD 62 = 200

Until a parameter for the control input for the anticipated restart safety circuit is integrated into the

software, this input must be monitored and a fault must be generated using the monitoring PLC.

RELANCE ANTICIPEE NON CONFORME : in French

ANTICIPATED RESTART NOT CONFORM : in English

REARME ANTICIPADO NO CONFORME : in Spanish

VORAUSB. NEUSTART FEHLERHAFT : in German

Loading...

Loading...