Page 1

Positive

Displacement Pump

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412)-312-6320

Models PD3, 5, 7.5, 10, 15 and 25

IMB036/0898

Installation

Maintenance

Operation

Troubleshooting

Page 2

It’s a good idea to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Please keep this User Guide and all manuals, engineering

prints and parts lists together for documentation of your

equipment.

Date:

Manual Number: IMB036/0898

Serial number(s):

Model number(s):

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Please record your

equipment’s model and

serial number(s) and

the date you received it

Copyright 1998 All rights reserved

THE CONAIR GROUP, INC.

Page 3

IMB036/0898 Positive Displacement Pump

TABLE OF CONTENTS

I

NTRODUCTION

ATTENTION: Read this first so no one gets hurt . . . . . . . . .1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Optional Sound Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATIONS

Positive displacement pump . . . . . . . . . . . . . . . . . . . . . . . . .3

Pumps with sound enclosures . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION

Installing the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation and operation note . . . . . . . . . . . . . . . . . . . . . . .4

MAINTENANCE

Preventative maintenance schedule . . . . . . . . . . . . . . . . . . . .5

APPENDIX

Customer service information . . . . . . . . . . . . . . . . . . . . . .A-1

Warranty information . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

i

Page 4

Positive Displacement Pump IMB036/0898

1

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by

following the procedures outlined below and elsewhere in

the User Guide.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

WARNING: Voltage hazard

This equipment is powered by three-phase

alternating current, as specified on the machine

serial tag and data plate.

Always disconnect and lock out the incoming

main power source before performing

non-standard operating procedures, such as

routine maintenance. Only qualified personnel

should perform troubleshooting procedures that

require access to the electrical enclosure while

power is on.

WARNING: Improper installation,

operation or servicing may result in

equipment damage or personal injury.

This equipment should be installed, adjusted,

and serviced by qualified technical personnel

who are familiar with the construction, operation and potential hazards of this type of

machine.

All wiring, disconnects and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the the machine serial tag and

data plate.

Page 5

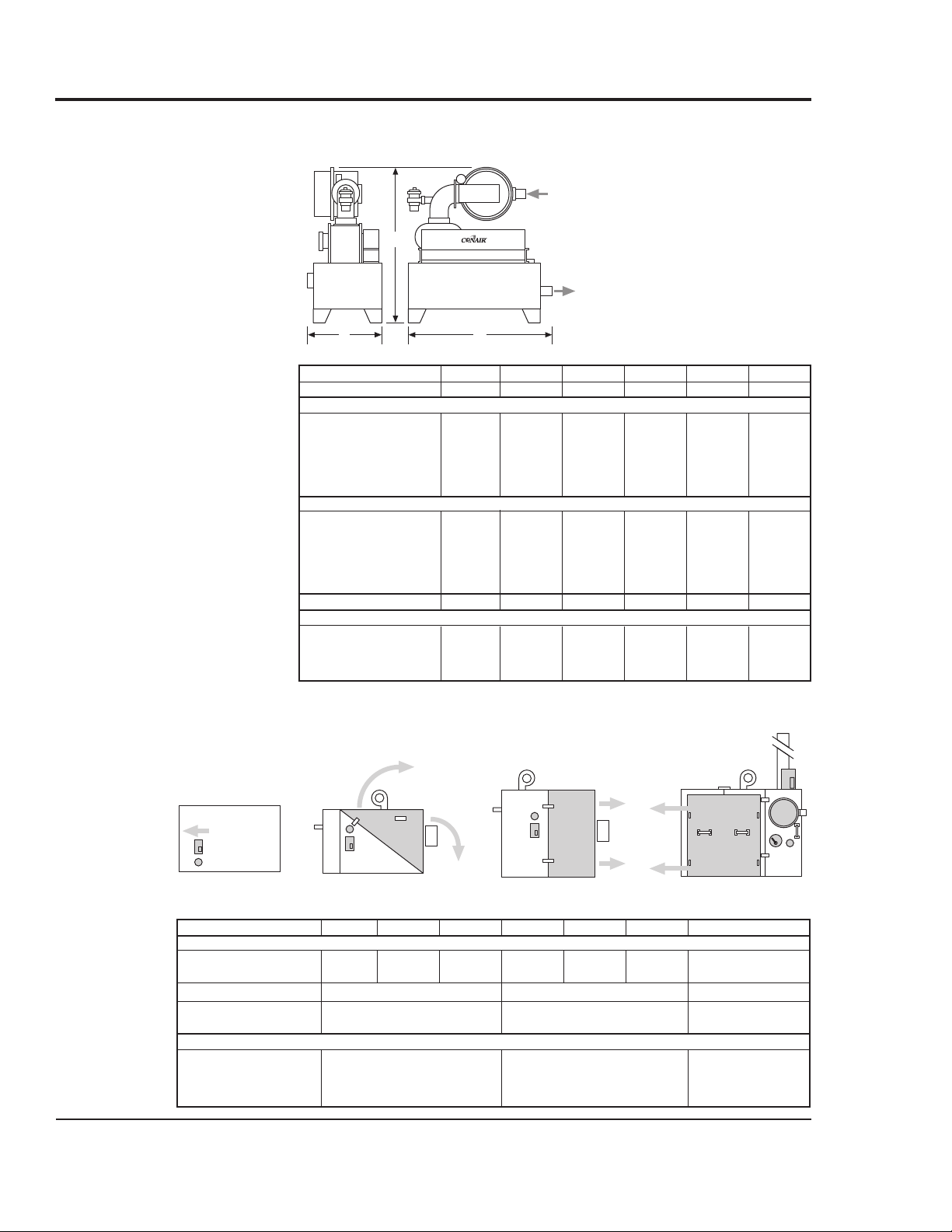

Conair positive displacement vacuum pumps are designed for

long distance, high-volume material conveying applications.

Each model employs a powerful, rotating lobe-type blower,

protected by a vacuum relief valve (factory-set to 12 in. Hg)

and belt driven by a three-phase motor with magnetic starter

and overload protection. An integrated pump protection filter

is included and all components are mounted on a rugged

frame, housing an integrated exhaust muffler.

An optional sound enclosure may be added to reduce noise

when installed near plant personnel.

Positive Displacement Pumps provide the strongest vacuum

power available, but when operated for long periods at high

performance levels, noise should be abated if the pump is

located near personnel. Sound Enclosures are available for all

pump models and provide maximum noise control with minimal space and easy access to pump maintenance areas.

Super Quiet Sound Enclosures include externally mounted

protection filter, vacuum gauge and filter gauge; 8 ft exhaust

stack (for noise); and easy access, tool-free front door.

2

IMB036/0898 Positive Displacement Pump

DESCRIPTION

OPTIONAL SOUND ENCLOSURES

5 HP Pumps in

Sound Enclosures

(with dust collectors)

Super Quiet Sound

Enclosure (with

Dust Collector)

Page 6

3

Positive Displacement Pump IMB036/0898

SPECIFICATIONS: POSITIVE DISPLACEMENT PUMP

MODEL PD3 PD5 PD7.5 PD10 PD15 PD25

Motor Type* TEFC TEFC TEFC ODP ODP ODP

Performance characteristics

Horsepower 3 5 7.5 10 15 25

Standard CFM at material

pickup point @ 10" Hg 52.6 76.6 121.2 154.5 201.1 346.2

Average sound level (dbA)

@ 8", 10" and 12" Hg 86 86.3 86 85.8 88.8 93

Dimensions / in. {mm}

Standard inlet line size (OD) 1.5 {38} 1.75 {44} 2.25 {57} 2.5 {64} 3.0 {76} 4.0 {102}

Exhaust line size (OD) 2.5 {64} 2.5 {64} 2.5 {64} 4.0 {102} 4.0 {102} 4.0 {102}

Height (H) 37 {940} 37 {940} 41 {1041} 51 {1295} 51 {1295} 52 {1321}

Width (W) 35 {889} 35 {889} 35 {889} 39.5 {1003} 39.5 {1003} 39.5 {1003}

Depth (D) 27 {686} 27 {686} 27 {686} 33 {838} 33 {838} 34 {864}

Installed Weight / lb {kg} 325 {147} 325 {147} 370 {168} 625 {283} 640 {290} 960 {435}

Voltage / Full Load Amps

240 V/3 phase/50-60 hz 7.6 12 18.8 28 39 59

480 V/3 phase/50-60 hz 3.8 6 9.4 14 19.5 29.5

575 V/3 phase/50 2.9 4.8 7.5 10.7 16 27

MODEL PD3 PD5 PD7.5 PD10 PD15 PD25 SUPER (ANY MODEL)

Performance characteristics

Average sound level (dbA)

@ 8", 10" and 12" Hg

61.9 69.8 76.2 79.3 86.0 90.0 Under 60 dbA

Enclosure Construction Painted Steel Natural Aluminum Painted Steel

Allowance Space for

service access / in

48 (Opposite Vacuum Inlet) 36 (Opposite Vacuum Inlet) 36 (Front, Next to Filter)

Dimensions / in. {mm}

Height (H) 49 {1245} 64 {1626} 96 {2438}

Width (W) 54 {1372} 55 {1397} 70 {1778}

Depth (D) 32 {813} 36 {914} 50 {1270}

D

H

W

Vacuum

Inlet

Exhaust

Specifications not listed below are the same as those listed above. All Sound Enclosures include a cooling fan 115 VAC @ 2 amps.

Starter

Service

Vacuum Inlet

Vacuum Gauge

V

10, 15, 25 HP

V

Super Quiet

V

SPECIFICATIONS: PUMPS WITH SOUND ENCLOSURES

3, 5, 7.5 HP

V

Page 7

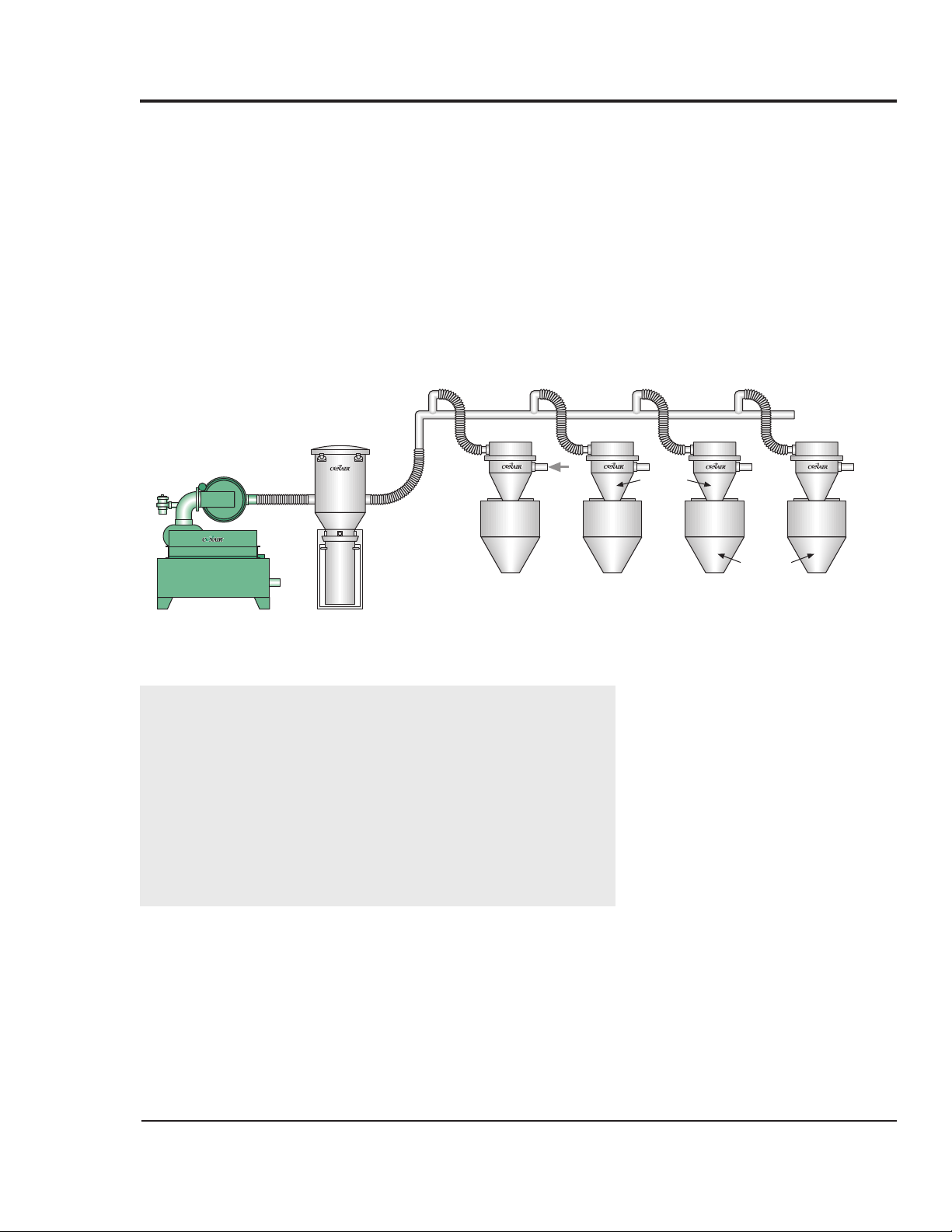

Set or mount the vacuum pump in any convenient location.

Refer to the accompanying wiring diagram for connection of

the main power supply and the conveying control circuit.You

must provide a wall-mounted disconnect for three-phase electrical connection. Incoming voltage and current must match

the electrical specifications on the pump data plate and serial

tag. Check for proper rotation of the pump after power has

been connected and before operation.

Install vacuum lines to loader stations and the dust collector.

Connect the dust collector vacuum outlet to the pump inlet.

Central

Vacuum Line

Positive

Displacement

Vacuum Pump

Material

Inlet

Material

Receivers

INSTALLING

THE

PUMP

Receiving

Hoppers

Central Dust Collector

INSTALLATION AND OPERATION NOTE:

The pump inlet is equipped with a vacuum relief

valve to prevent the vacuum from exceeding 12 in.

Hg. Excessive vacuum will reduce the life of the

pump and can destroy it.

For special applications requiring a higher vacuum

level, consult Conair service. If the vacuum relief

valve is adjusted by any person other than a factory service representative, the warranty is voided.

IMB036/0898 Positive Displacement Pump

4

Page 8

To maintain the best performance, you should follow the

maintenance recommendations outlined here and in any

included manuals from component manufacturers.

● Weekly, or as often as needed

❒

Check and clean the pump inlet filter.

An inlet filter has been provided to protect the pump

from solid material that can enter and damage the pump

impellers. material can enter the vacuum line if a loader

filter is improperly installed or if if has a hole in it.

Replace the pump inlet filter if it is torn or worn.

❒ Check all V/belts.

The V/belts have a tendency to stretch, so an adjustable

motor base is provided. Keep belts tight to prevent slippage and wear. Do not use belt dressings.

● Every 500 hours of operation

❒

Grease the pump.

Use No. 2 bearing grease or the equivalent. Refer to

manuals from the component manufacturer for

additional information and instructions.

● Every 1500 hours of operation

❒

Change the oil.

The vacuum pump has been filled with the proper oil

and tested by Conair before shipment. Even so, this oil

should be changed periodically. Use SAE 40 regular

or an equivalent oil.

● Every three months

❒

Check motor bearings and grease, if necessary.

The motor is equipped with double-shielded ball

bearings having sufficient grease to last indefinitely

under normal service. But if the motor is used

constantly in dirty, wet or corrosive atmospheres,

you should add 1/4 oz. of grease per bearing every three

months. Use a quality, rust-inhibiting, polyure-based

grease such as Chevron SRI. Refer to the motor manual

for additional instructions.

5

PREVENTATIVE MAINTENANCE SCHEDULE

Positive Displacement Pump IMB036/0898

Page 9

Conair has made the largest investment in customer support in

the plastics industry. Our service experts are available to help

with any problem you might have installing and operating

your equipment. Your Conair sales representative also can

help analyze the nature of your problem, assuring that it did

not result from misapplication or improper use.

WE’REHERE

TO

HELP

To contact Customer Service personnel, call:

From outside the United States, call:814-437-6861

You can commission Conair service personnel to provide onsite service by contacting the Customer Service Department.

Standard rates include an on-site hourly rate, with a one-day

minimum plus expenses.

If you do have a problem, please complete the

following checklist before calling Conair:

❒ Make sure you have all model, serial and parts list

numbers for your particular equipment. Service

personnel will need this information to assist you.

❒ Make sure power is supplied to the equipment.

❒ Make sure that all connectors and wires within

and between control systems and related

components have been installed correctly.

HOWTO

CONTACT

CUSTOMER

SERVICE

❒ Check the troubleshooting guide of this manual

for a solution.

❒ Thoroughly examine the instruction manual(s)

for associated equipment, especially controls.

Each manual may have its own troubleshooting

guide to help you.

❒ Check that the equipment has been operated as

described in this manual.

❒ Check accompanying schematic drawings for

information on special considerations.

Additional manuals and

prints for your Conair

equipment may be

ordered through the

Customer Service or

Parts Departments for a

nominal fee.

APPENDIXA-1

Page 10

APPENDIX A-2

EQUIPMENT

GUARANTEE

PERFORMANCE

WARRANTY

WARRANTY

LIMITATIONS

Conair guarantees the machinery and equipment on this order,

for a period as defined in the quotation from date of shipment,

against defects in material and workmanship under the normal

use and service for which it was recommended (except for

parts that are typically replaced after normal usage, such as

filters, liner plates, etc.). Conair’s guarantee is limited to

replacing, at our option, the part or parts determined by us to

be defective after examination. The customer assumes the cost

of transportation of the part or parts to and from the factory.

Conair warrants that this equipment will perform at or above

the ratings stated in specific quotations covering the equipment or as detailed in engineering specifications, provided the

equipment is applied, installed, operated and maintained in the

recommended manner as outlined in our quotation or specifications.

Should performance not meet warranted levels, Conair at its

discretion will exercise one of the following options:

● Inspect the equipment and perform alterations or adjust-

ments to satisfy performance claims. (Charges for such

inspections and corrections will be waived unless failure

to meet warranty is due to misapplication, improper

installation, poor maintenance practices or improper operation.)

● Replace the original equipment with other Conair equip-

ment that will meet original performance claims at no

extra cost to the customer.

● Refund the invoiced cost to the customer. Credit is sub-

ject to prior notice by the customer at which time a

Return Goods Authorization Number (RGA) will be

issued by Conair’s Service Department. Returned equipment must be well crated and in proper operating condition, including all parts. Returns must be prepaid.

Purchaser must notify Conair in writing of any claim and provide a customer receipt and other evidence that a claim is

being made.

Except for the Equipment Guarantee and Performance

Warranty stated above, Conair disclaims all other warranties

with respect to the equipment, express or implied, arising

by operation of law, course of dealing, usage of trade or

otherwise, including but not limited to the implied warranties of merchantability and fitness for a particular purpose.

Loading...

Loading...