Page 1

Traveling Sa w

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax:(412)-312-6227

CTS Models 5, 7 and 9

UGE058/0803

Installation

Operation

Maintenance

Troubleshooting

Page 2

It is important to record the model and serial number(s) of

your equipment and the date you received it in the User

Guide. Our service department uses this information, along

with the manual number, to provide help for the specific

equipment you installed.

Keep this User Guide and all manuals, engineering prints and

parts lists together for documentation of your equipment.

Date:

Document Number: UGE058/0803

Serial number(s):

Model number(s):

Power Specifications:

Amps

Volts

Phase

Cycle

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors

contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this

information. Conair makes no warranty of any kind with regard to

this information, including, but not limited to the implied warranties

of merchantability and fitness for a particular purpose.

Record your equipment’s

model and serial number(s) and the date you

received it in the spaces

provided.

Copyright 2003

All rights reserved

THE CONAIR GR OUP, INC.

Page 3

UGE058/0803 CTS Saw

TABLE OF

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . .1-1

Purpose of the User Guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2

How the Guide is Organized . . . . . . . . . . . . . . . . . . . . . . .1-2

Your Responsibilities as a User . . . . . . . . . . . . . . . . . . . . .1-2

ATTENTION: Read this so no one gets hurt . . . . . . . . . . .1-3

How to Use the Lockout Device . . . . . . . . . . . . . . . . . . . .1-5

DESCRIPTION . . . . . . . . . . . . . . . . . . . .2-1

What is the CTS Saw? . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

How the CTS Saw Works . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

CTS Saw Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

I

NSTALLATION . . . . . . . . . . . . . . . . . . . .3-1

Unpacking the Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Positioning the CTS Saw . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Connecting the Main Power Source . . . . . . . . . . . . . . . . . .3-6

Installing the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Installing the Saw Blades . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Preparing for Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

OPERATION . . . . . . . . . . . . . . . . . . . . . .4-1

The Saw Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Machine Frame and Support System . . . . . . . . . . . . . . . . .4-4

Blade Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Upper Clamp Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Pneumatic Cylinder Operation . . . . . . . . . . . . . . . . . . . . .4-6

Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Machine Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

System Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Chip Collection Shrouds and Blower Connection . . . . . . .4-10

MAINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Maintenance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Maintenance Overview . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Preventative Maintenance Schedule . . . . . . . . . . . . . . . . . .5-4

i

Page 4

CTS Saw UGE058/0803

MAINTENANCE CONTINUED . . . . . . . . . . .5-1

Checking the Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Checking Electrical Connections . . . . . . . . . . . . . . . . . . . .5-7

TROUBLESHOOTING . . . . . . . . . . . . . . . .6-1

Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

A Few Words of Caution . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Identify the Cause of a Problem . . . . . . . . . . . . . . . . . . . . .6-3

Electrical Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Product Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Checking the Servo Amplifier . . . . . . . . . . . . . . . . . . . . . .6-7

Checking the Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Service Information . . . . . . . . . . . . . . . . . . . . . .A-1

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Servo Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

PARTS/DIAGRAMS

This section has been provided for you to

store spare parts lists and diagrams.

ii

Page 5

1-1

UGE058/0803 CTS Saw

●●

Purpose of the User Guide . . . .1-2

●●

How the User Guide

is organized . . . . . . . . . . . . . . .1-2

●●

Your Responsibilities

as a User . . . . . . . . . . . . . . . .1-2

●●

ATTENTION: Read this so

no one gets hurt . . . . . . . . . . .1-3

●●

How to Use the

Lockout Device . . . . . . . . . . . .1-5

INTRODUCTION

Page 6

CTS Saw UGE058/0803

1-2 INTRODUCTION

This User Guide describes the Conair CTS Saw and explains

step-by-step how to install, operate, maintain and repair this

equipment.

Before installing this product, please take a few moments to

read the User Guide and review the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This

review won’t take long, and it could save you valuable installation and operating time later.

Symbols have been used to help organize the User Guide and

call your attention to important information regarding safe

installation and operation.

Symbols within triangles warn of conditions that could

be hazardous to users or could damage equipment.

Read and take precautions before proceeding.

Numbers within shaded squares indicate tasks or steps

to be performed by the user.

A diamond indicates the equipment’s response to an

action performed by the user.

An open box marks items in a checklist.

A shaded circle marks items in a list.

You must be familiar with all safety procedures concerning

installation, operation and maintenance of this equipment.

Responsible safety procedures include:

● Thorough review of this User Guide, paying particular

attention to hazard warnings, appendices and related diagrams.

● Thorough review of the equipment itself, with careful

attention to voltage sources, intended use and warning

labels.

● Thorough review of instruction manuals for associated

equipment.

● Step-by-step adherence to instructions outlined in this

User Guide.

PURPOSE OF

THE USER

GUIDE

HOW THE USER

GUIDE IS

O

RGANIZED

1

◆

❒

●

YOUR

RESPONSIBILITY

ASAUSER

Page 7

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should only be installed,

adjusted, and serviced by qualified technical

personnel who are familiar with the construction, operation, and potential hazards of this

type of machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your

region. Always maintain a safe ground. Do not

operate the equipment at power levels other

than what is specified on the machine serial

plate.

INTRODUCTION 1-3

We design equipment with the user’s safety in mind. You can

avoid the potential hazards identified on this machine by following the procedures outlined below and elsewhere in the

User Guide.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

UGE058/0803 CTS Saw

DANGER: Sharp blades!

Most injuries caused by knife blades occur

when the saw has been turned off. Handle

blades with care at all times.

● Always wear cut-resistant gloves when the

blade guard is open and when handling

blades.

● Always lock out the saw before opening any

guards.

● Always wait until the saw blade has stopped

completely before opening the saw guard.

(approximately five minutes)

CTS Saw are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

● The STOP button activates a circuit that

stops the saw.

Page 8

CTS Saw UGE058/0803

1-4 INTRODUCTION

WARNING:Voltage Hazard

This equipment is powered by three-phase

alternating current, as specified on the machine

serial tag and data plate.

A properly-sized conductive ground wire from

the incoming power supply must be connected

to the chassis ground terminal inside the electrical enclosure. Improper grounding can result in

severe personal injury and erratic machine

operation.

Always disconnect and lockout power before

opening the electrical enclosure or performing

non-routine procedures such as maintenance.

ATTENTION:

READ THIS SO NO

ONE GETS HURT

Page 9

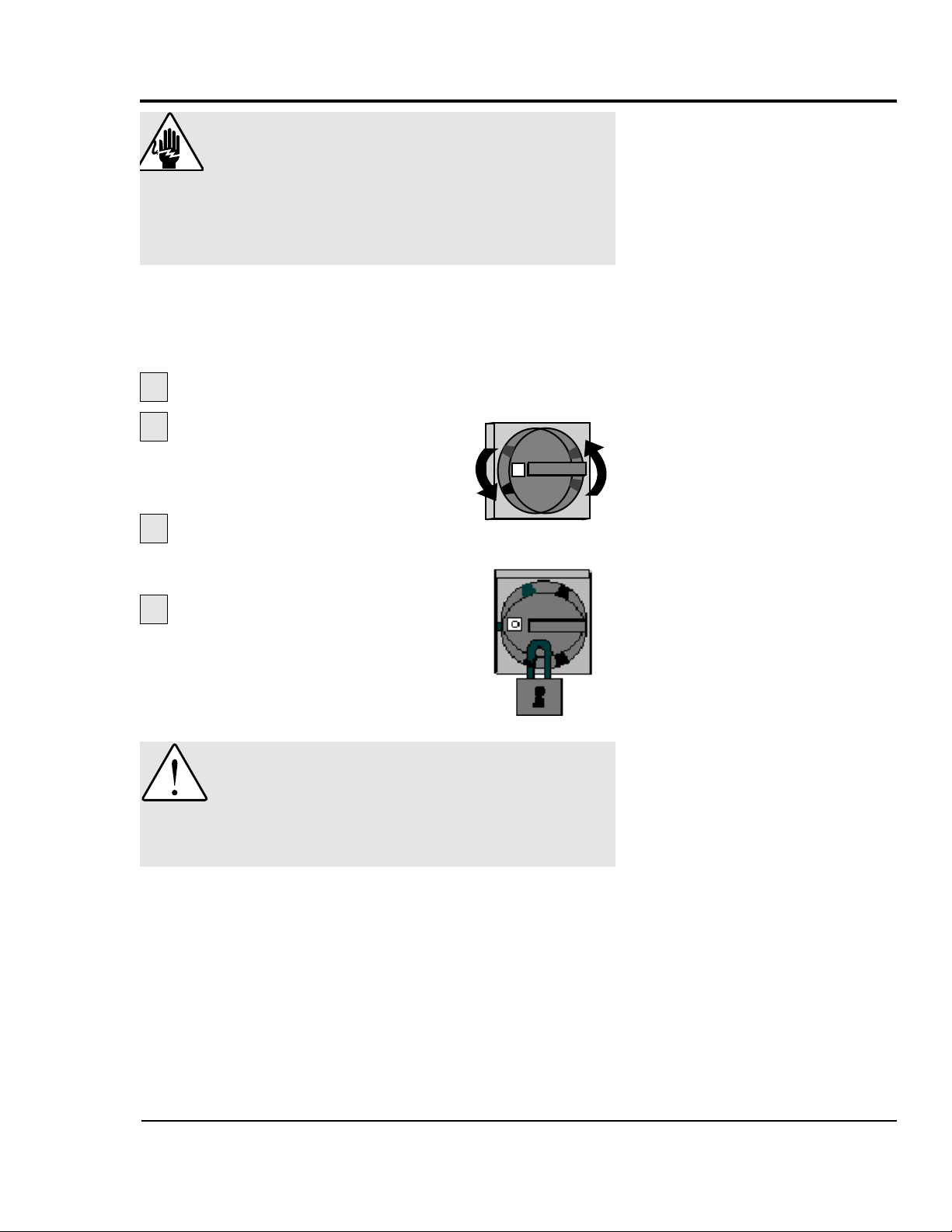

HOW TO USE

THE

LOCKOUT

DEVICE

UGE058/0803 CTS Saw

INTRODUCTION 1-5

WARNING: Electrical hazard

Before performing maintenance or repairs on

this product, disconnect and lock out electrical

power sources to prevent injur y from unexpected energization or start-up. A lockable device

has been provided to isolate this product from

potentially hazardous electricity.

Lockout is the preferred method of isolating machines or

equipment from energy sources. Your Conair product is

equipped with the lockout device pictured below. To use the

lockout device:

Stop or turn off the equipment.

Isolate the equipment from

electrical power.

Turn the rotary disconnect switch to

OFF or O position.

Secure the device with an

assigned lock or tag.

The equipment is now locked

out.

CAUTION: Moving parts

Before removing lockout devices and returning

switches to the ON position, make sure that all

personnel are clear of the machine, tools have

been removed and all safety guards are reinstalled.

3

4

1

2

O

Page 10

Page 11

2-1

UGE058/0803 CTS Saw

●●

What is the CTS Saw? . . . . . . . .2-2

●●

Typical Applications . . . . . . . . . .2-2

●●

How the CTS Saw Works . . . . . .2-3

●●

CTS Saw Features . . . . . . . . . . .2-5

●●

Specifications . . . . . . . . . . . . . .2-6

●●

Optional Equipment . . . . . . . . . .2-7

DESCRIPTION

Page 12

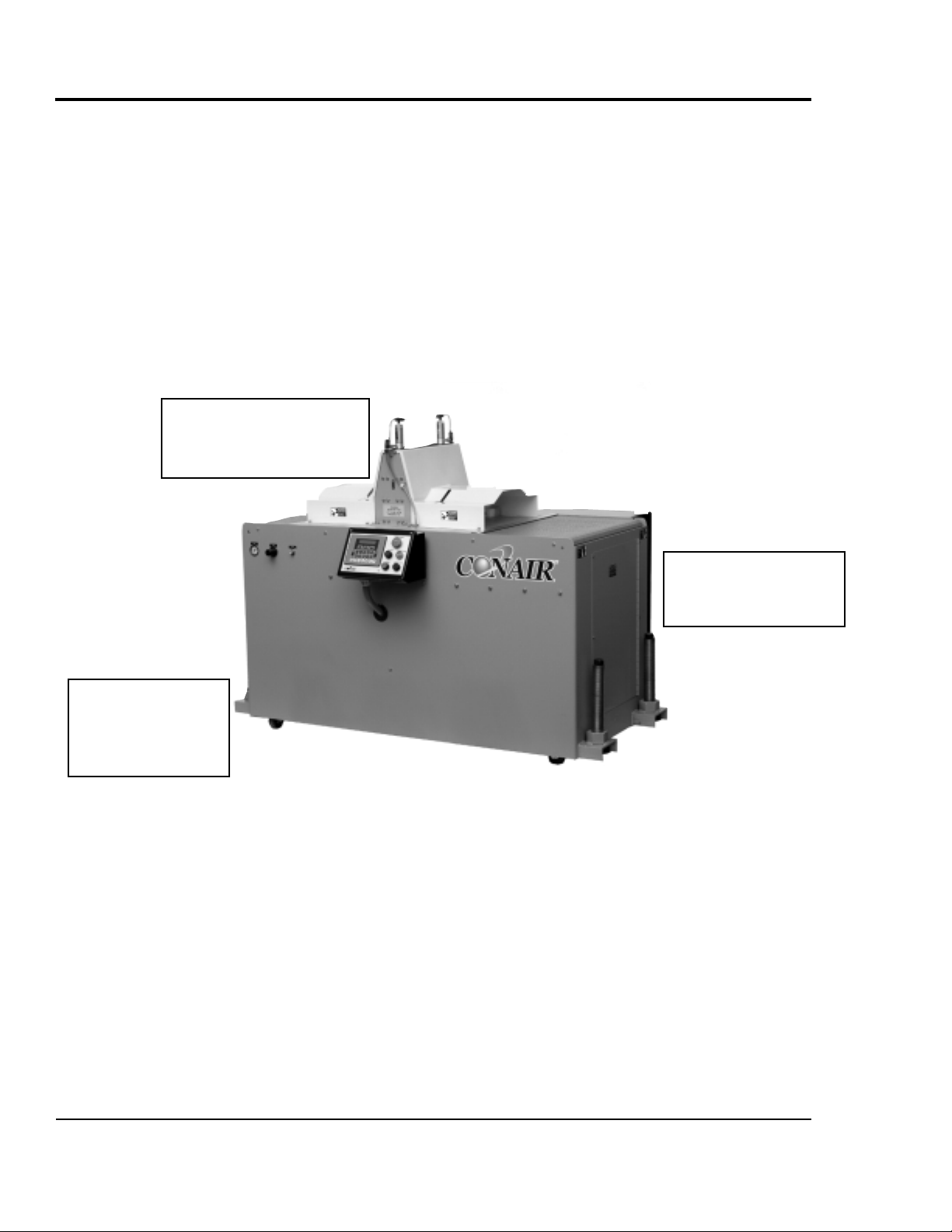

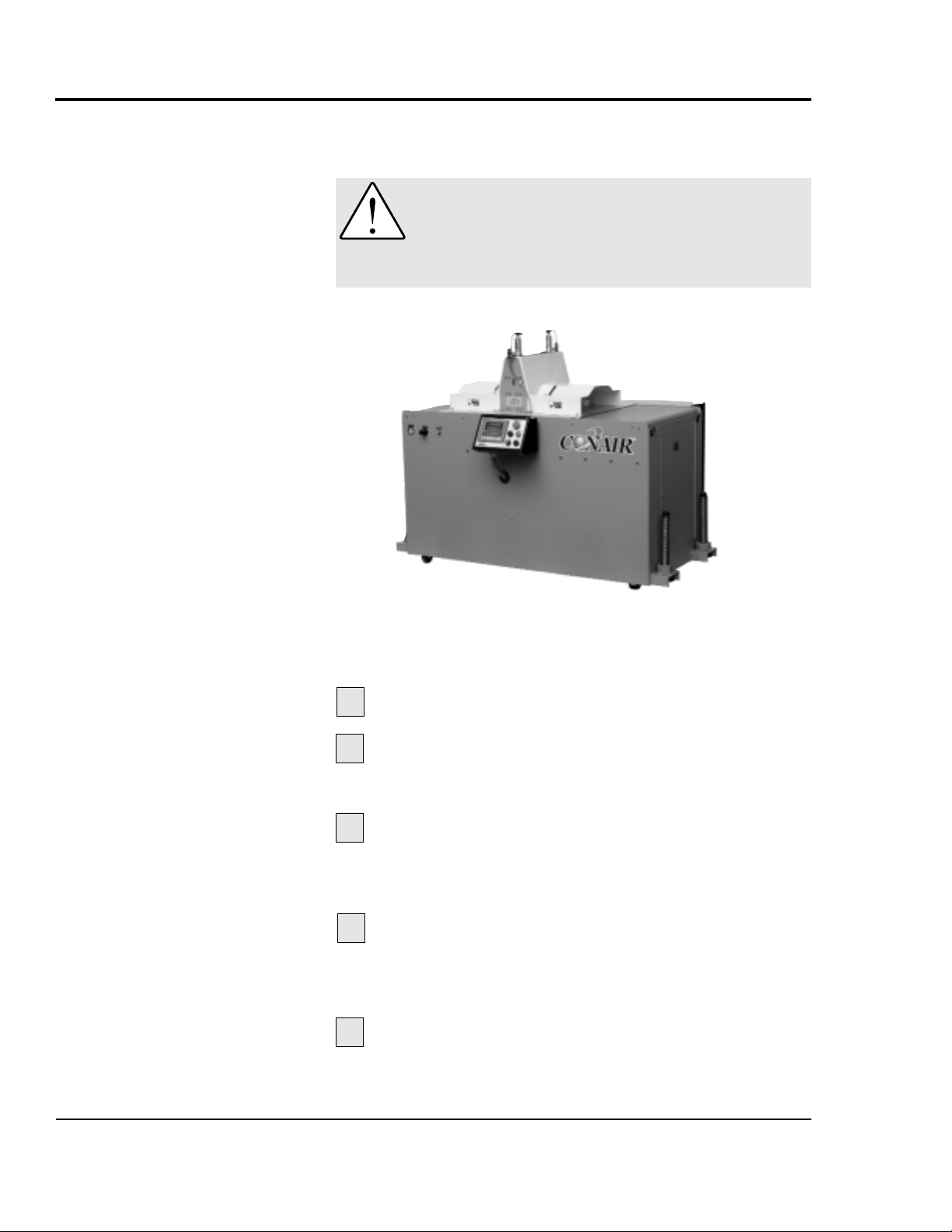

The Conair CTS Saw is an on- or off-line sawing device capable of both on-demand and continuous cutting.

Conair CTS Saws can cut extrudable plastics and rubber both

on- and off-line. Other extrudable materials-foods, ceramics,

magnets, soaps, etc.-may also be cut depending on specific

application requirements.

CTS Saws are available with different cutting capacities (5, 7,

and 9 inches) to suit your specific needs. The standard saw

orientation is right-to-left, saws can also be made with a leftto-right orientation (see Specifications in this section). (The

illustrations in this User Guide represent the standard right-to

left configuration.)

CTS saws are limited to a specific range of product sizes

based on each unit's cutting capacity.

Different materials, line speeds, temperatures and material

cross-sections can result in different cutting torques. If you are

changing any of these parameters, consult your Conair service

personnel to be sure your equipment can handle the changes.

WHAT IS THE

CTS SAW?

CTS Saw UGE058/0803

2-2 DESCRIPTION

TYPICAL

A

PPLICATIONS

Page 13

UGE058/0803 CTS Saw

DESCRIPTION 2-3

The Conair CTS saws are designed for the inline cutting of

profiles, pipe and tubing of a wide variety of sizes.

Located as part of the extrusion line downstream of the

extruder, the CTS performs five sequential functions in the cut

operation as follows:

1. The saw table begins to travel with the product in a linear

motion then the clamps lock the product to the table.

2. The saw blade travels up and through the product

3. The saw blade returns to its down (home) position

4. The clamp releases the product

5. The saw table returns to its starting (home) position and

readies for the next cycle

These functions are preformed automatically with contact closure by means of either depressing the manual cut pushbutton

or by activating a flag switch mounted downstream of the unit

as standard.

There are available options that also initiate the cut cycle

including an internal timer, electronic length counter, or any

other device that has a N.O. (normally open) contact.

H

OW THE CTS

S

AW WORKS

Page 14

CTS Saw UGE058/0803

2-4 DESCRIPTION

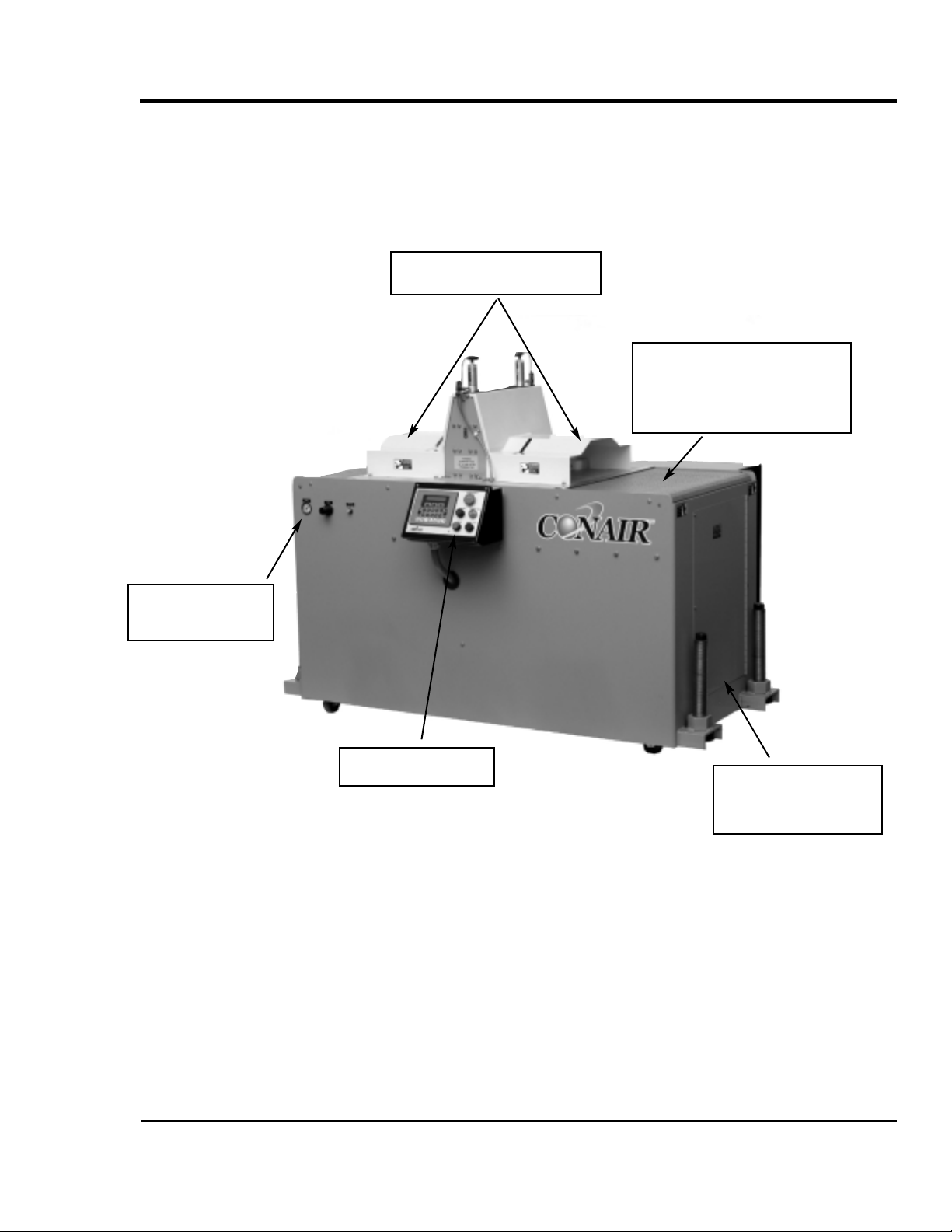

The CTS Saw models have these features:

H

OW THE CTS

S

AW WORKS

C

ONTINUED

Saw clamps hold the product in place while the

blades passes through it

during the cutting cycle.

Cut pieces are collected on a dump

table or carried away

on a conveyor

Extruded material

enters the saw from the

upstream side.

(right-to-left operation)

Page 15

UGE058/0803 CTS Saw

DESCRIPTION 2-5

Access doors on

both ends of the saw

for easy maintenance.

Self-contained table to

reduce machine footprint

and enhance safety with no

moving parts extending past

the base

Front mounted

pneumatic flow

controls

Front mounted electrical controls

CTS SAW

FEATURES

Hinged table guards for

easy access to the clamps

Page 16

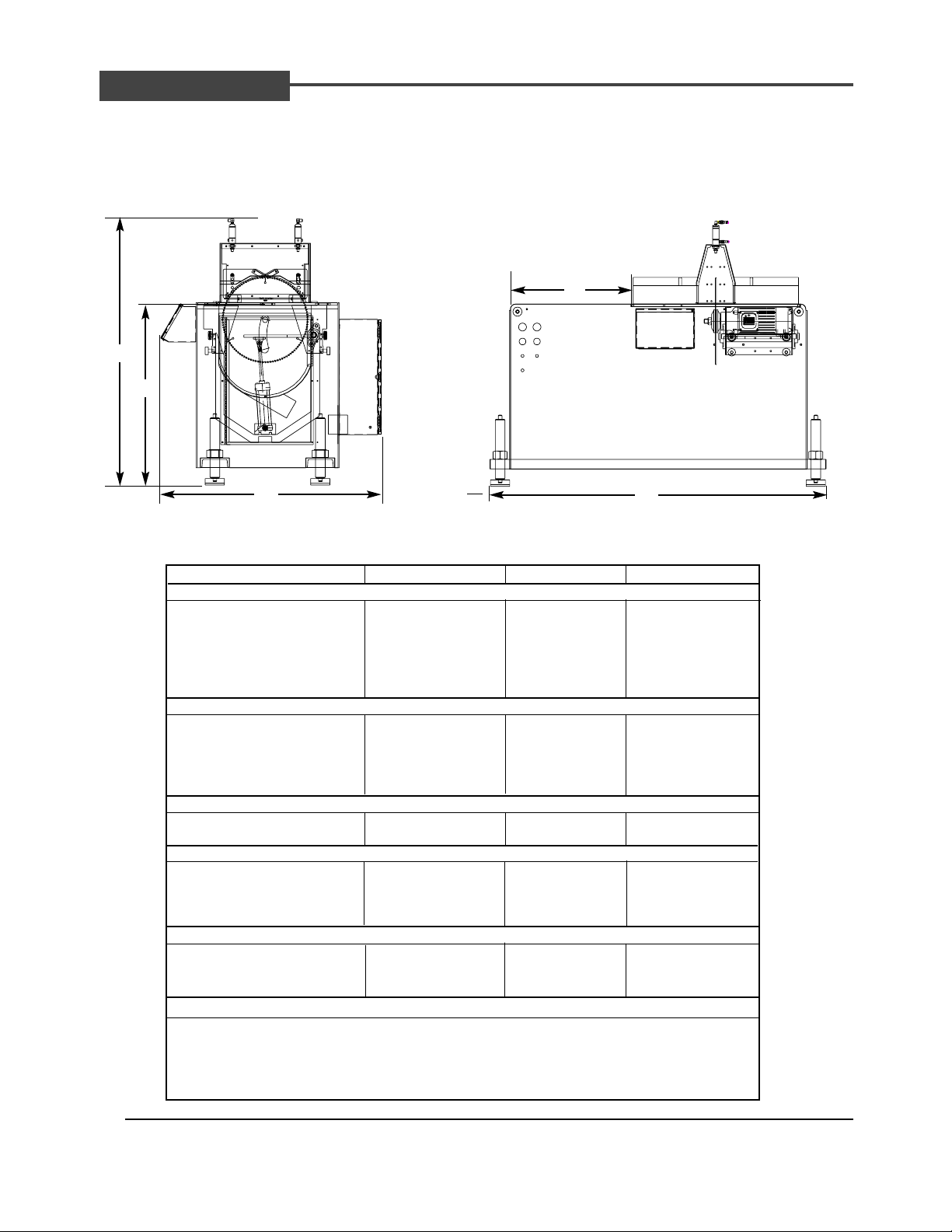

TRAVELING CUT-OFF SAW

CTS Series

TPES014/0603

SPECIFICATIONS

UGE058/0803 CTS Saw

DESCRIPTION 2-6

MODELS CTS-5 CTS-7 CTS-9

Performance characteristics

Pipe capacity in. {mm} OD 5 {127} 7 {178} 9 {229}

Profile capacity in. {mm} HxW* 4 x 8 {102 X 203} 5x13 {127 X 330} 6X17 {152 X 432}

Blade size in. {mm} 18 {457} 23 {584} 27 {686}

Blade type carbide tipped carbide tipped carbide tipped

Blade drive motor Hp {kW} 3 {2.2} 5 {3.7} 5 {3.7}

Feed direction

†

Right to left Right to left Right to left

Dimensions in. {mm}

A - Height 57 {1448} 60 {1524} 63 {1600}

B - Height to centerline 40 {1016} 40 {1016} 40.4 {1026}

C - Width 46.5 {1181} 57 {1448} 61 {1549}

D - Length 70 {1778} 88 {2235} 88 {2235}

E - Table Travel 24 {609} 24 {609} 24 {609}

Weight lbs. {kg}

‡

Installed 575 {261} 825 {374} 1700 {771}

Shipping 675 {306} 925 {420} 1800 {817}

Voltage Total Amps

§

230V/3 phase/60 Hz 9.7 A 15.1 A 15.1 A

460V/3 phase/60 Hz 4.9 A 7.6 A 7.6 A

230V/3 phase/60 Hz (servo) 26.2 A 30.6 A 30.6 A

460V/3 phase/60 Hz (servo) 13.1 A 15.3 A 15.3 A

Compressed air requirement

Pressure psi {bars} 80 {5.52} 80 {5.52} 80 {5.52}

Consumption ft3/m {liter/sec} 5 {2.4} 7 {3.3} 8 {3.8}

NPT fitting size 3/8 in. 3/8 in. 3/8 in.

SPECIFICATION NOTES:

* The HxW dimension is provided for guidance only. The actual capacity can vary depending on the profile you are

trying to produce.

† Left to right feed direction is available as an option.

‡ If the optional chip collection system is ordered, add 50 lbs. {22.7 kg} to to the installed and shipping weights.

§ The optional chip collection system adds 6 A on 230V models; 3 A on 460V models.

CTS-5, CTS-7 AND CTS-9

Front View

Side View

A

B

C

D

E

Page 17

UGE058/0803 CTS Saw

DESCRIPTION 2-7

Flag switch for cut length activation

Programmable length counter for cut length acti-

vation

Servo control for optimal cut length and repeat-

able length accuracy

Dust collector system for material particulates

retention

(highly recommended for proper operation)

Left to right machine operation

This options changes the machine direction from the standard

right to left extrusion flow.

Finer tooth blade for thin material and materials

that are easy to fracture.

OPTIONAL

EQUIPMENT

Page 18

Page 19

3-1

UGE058/0803 CTS Saw

●●

Unpacking the Boxes . . . . . . . . .3-2

●●

Preparing for Installation . . . . . .3-3

●●

Positioning the CTS Saw . . . . . .3-4

●●

Connecting the Main

Power Source . . . . . . . . . . . . .3-6

●●

Installing the Encoder . . . . . . . .3-7

●●

Installing the Saw

Blades . . . . . . . . . . . . . . . . . . .3-8

●●

Preparing for Testing . . . . . . . . .3-9

●●

Testing the Installation . . . . . . . .3-9

INSTALLATION

Page 20

The CTS Saw comes fully assembled in a single crate.

UNPACKING THE

BOXES

CTS Saw UGE058/0803

3-2 INSTALLATION

CAUTION: Lifting

To avoid personal injury or damage to the saw

lift the saw using a forklift or hoist with straps

that have been positioned at the saw's center of

gravity.

Carefully uncrate the saw and its components.

Remove all packing material

, protective paper,

tape, and plastic. Compare contents to the shipping papers

to ensure that you have all the parts.

Carefully inspect all components to make sure

no damage occurred during shipping. Check all wire terminal connections, bolts, and any other electrical connections, which may have come loose during shipping.

Record serial numbers and specifications in the

blanks provided on the back of the User Guide's title

page. This information will be helpful if you ever need

service or parts.

You are now ready to begin installation.

Complete the preparation steps on page 3-3.

1

2

3

4

5

Page 21

You need these tools for installation:

❒ wire strain relief

❒ 16- or 18-inch adjustable wrench

❒ set of Allen wrenches

❒ ½ inch open or box end wrench

❒ flashlight

Plan the location. Make sure the area where the saw

is installed has the following:

● A grounded power source. Check the saw’s serial-

al tag for the correct amps, voltage, phase and

cycles. All wiring should be completed by qualified

personnel and should comply with your region’s

electrical codes.

● Clearance for safe operation and maintenance.

Make sure there is enough clearance around the saw

for maintenance and servicing.

PREPARING FOR

INSTALLATION

UGE058/0803 CTS Saw

INSTALLATION 3-3

1

2

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial tag and data

plate.

Page 22

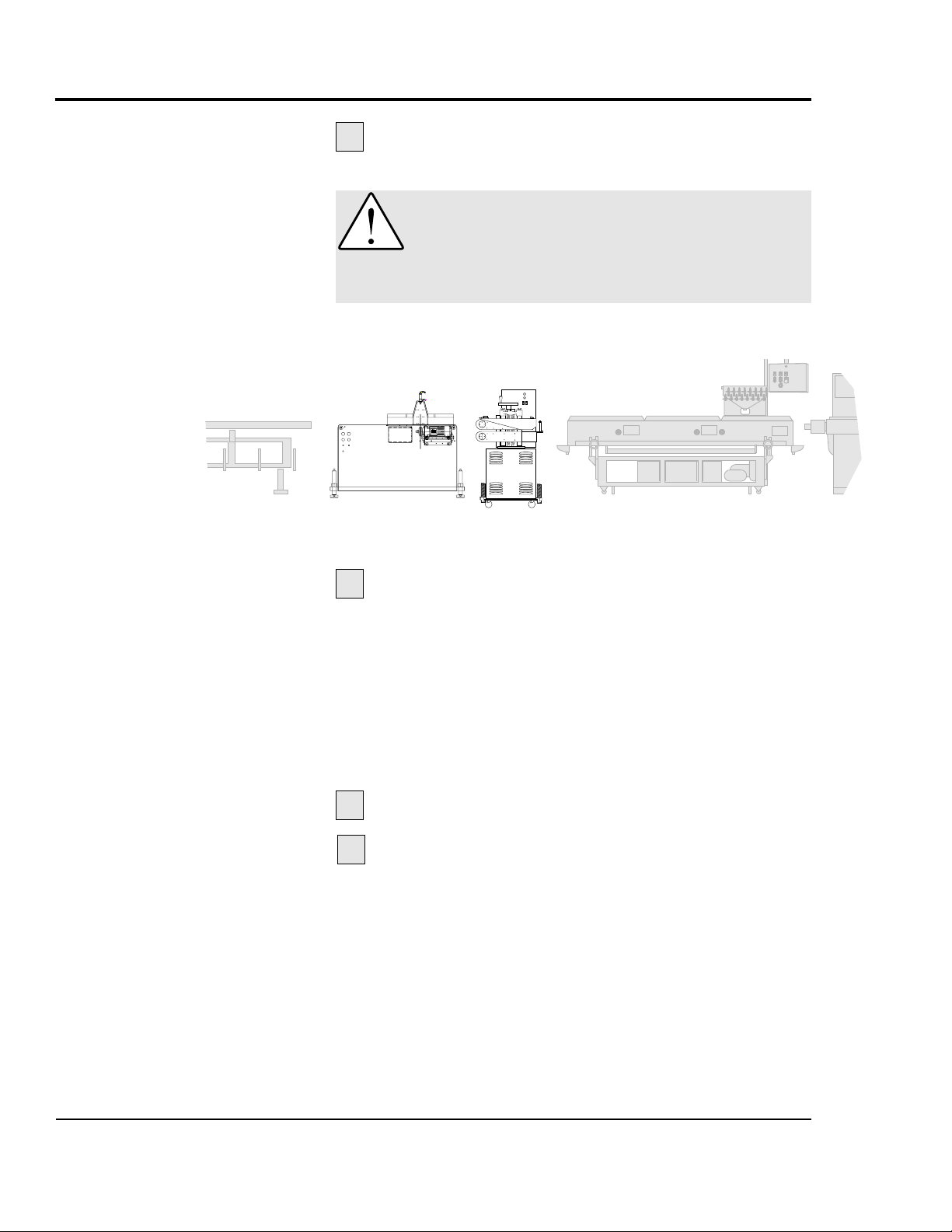

Move the saw into position. Place the saw in posi-

tion downstream of the belt puller.

Determine the best distance from the belt puller to

the CTS Saw.

● For flexible products, the saw should be as close as

possible to the puller.

● For rigid products, leave enough space to allow

the product to flex during the cutting cycle. In some

cases, it may be necessary to allow 6-8 feet between

the puller and saw.

Align the saw with the extrusion line.

Measure the centerline height

of the extrudate as

it exits the extrusion die. Adjust all equipment on the

extrusion line (sizing tank, cooling tanks, belt puller, and

saw) to this height.

CTS Saw UGE058/0803

3-4 INSTALLATION

1

P

OSITIONING

THE

CTS SAW

CAUTION: Lifting

To avoid personal injury or damage to the saw,

lift the saw using a forklift or hoist with straps

that have been positioned at the saw's center of

gravity.

2

3

Saw

4

continued on the next page

Page 23

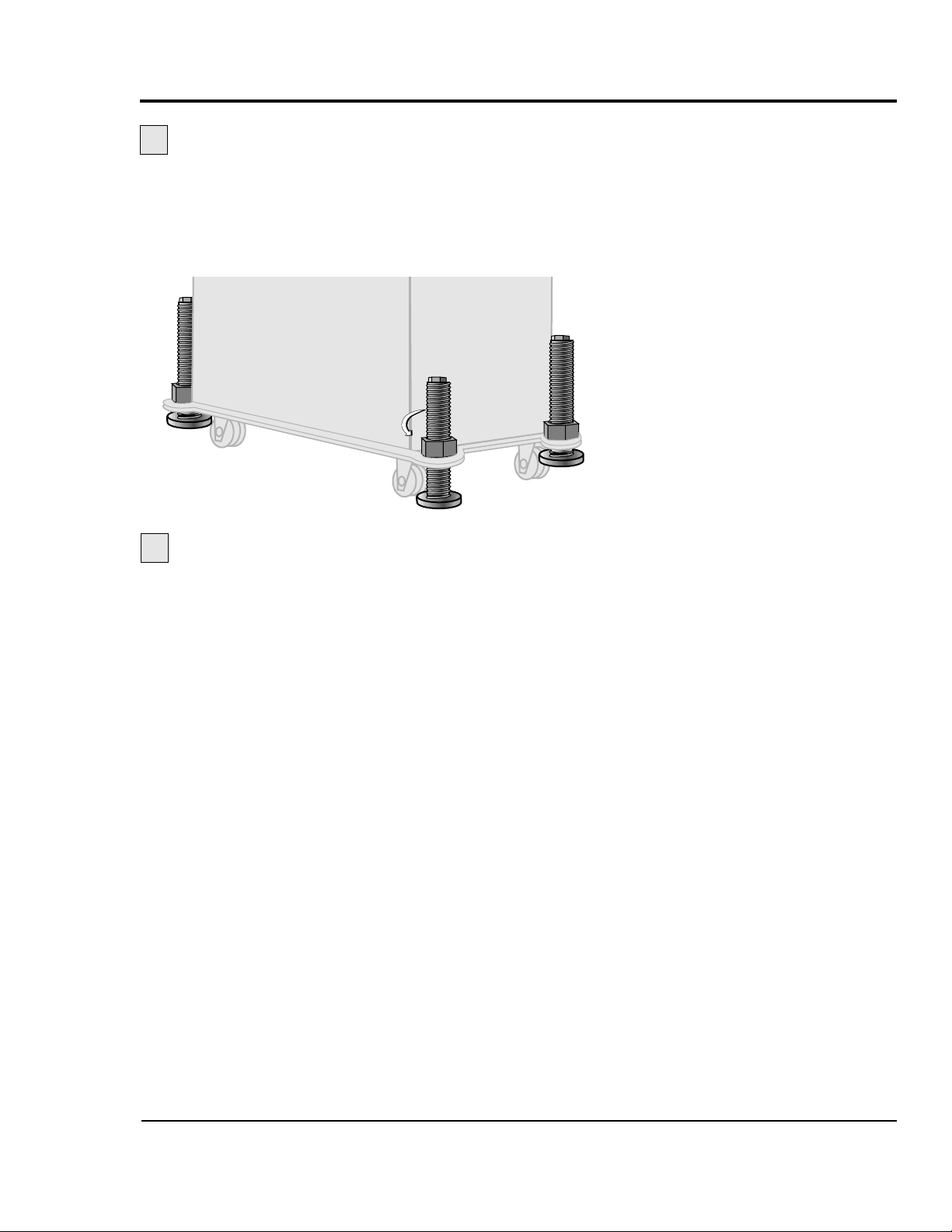

Adjust the saw's floorlock/caster assembly to

the center height of the extrusion line using a 16- or 18inch adjustable wrench. Once the correct height is

reached, adjust the pad assembly to remove the weight

from the casters for operation. This minimizes machine

vibration during the cutting cycle.

Use a plumb line or laser to check for a

straight line

from the extrusion die through each line

component to the saw center line of the table. Adjust as

necessary.

POSITION THE

SAW

CONTINUED

UGE058/0803 CTS Saw

INSTALLATION 3-5

5

6

Page 24

3-6 INSTALLATION

Open the servo saw’s electrical

enclosure.

Turn the disconnect dial on

the door to the OFF or O position and

open the door.

Insert the main power wire through the knockout

in the side of the enclosure. Secure the wire with a rubber

compression fitting or strain relief.

Connect the power wires to the terminals indicated

on the wiring diagram that came with your machine.

Check every terminal screw to make

sure wires are secure. Gently tug each

wire. If a wire is loose, use a screwdriver

to tighten the terminal.

Connect the ground

wire

to either grounding

point shown in the diagram.

1

2

IMPORTANT: Always refer to

the wiring diagrams that

came with your saw before

making electrical connections.The diagrams show the

minimum size main power

cable required for your saw,

and the most accurate electrical component information.

CONNECTING

THE

MAIN

POWER SOURCE

3

WARNING: Electrical hazard

Before performing any work on this product, disconnect and lock out electrical power sources

to prevent injury from unexpected energization

or start-up. A lockable device has been provided to isolate this product from potentially hazardous electricity.

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial tag and data

plate.

4

5

CTS Saw UGE058/0803

Page 25

UGE058/0803 CTS Saw

INSTALLATION 3-7

Conair uses bi-directional encoders to ensure that only product

that moves forward is counted.

Installing the encoder consists of several parts:

● the encoder

● the measuring wheel

● the connecting cable

The encoder is fitted with a 1 foot circumference wheel which rides on

either the upper belt of the belt puller or (for

rigid profiles and pipe) on the extrudate itself upstream of the

puller.

The encoder is supplied with an integral mounting bracket.

How and where you attach the encoder to the puller depends

on your particular puller and application.

● If the wheel rides on the puller belt, make sure that its lin-

ear alignment is the same as the belt. Place the wheel near

the center of the belt to minimize bouncing. Try to avoid

cracks and other belt features that may affect accuracy.

● Make sure the location allows you to keep the wheel

clean. Any small buildup on the wheel will affect its circumference and change the cut length.

After the encoder is installed, attach it to the saw control using

the supplied cable. The cable has been hard-wired to the control at the factory.

INSTALLING THE

ENCODER

CAUTION: Handle with care.

The encoder is a delicate piece of equipment

and must be handled gently.

Wheels

Connecting

Cable

Encoder

Page 26

CTS Saw UGE058/0803

3-8 INSTALLATION

I

NSTALLING THE

SAW BLADES

DANGER: Sharp blades!

Most injuries caused by saw blades occur when

the saw has been turned off. Handle blades

with care at all times.

● Always wear cut-resistant gloves when the

blade guard is open and when handling

blades.

● Always lock out power to the saw before

opening any guards.

● Always wait until the saw blade has completely stopped before opening the saw

guard. (approximately five minutes)

CTS saws are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

Open the rear access door of the machine.

Remove the screws that retain the blade door

to the blade shroud and hinge open the door.

Remove the hex nut.

The blade is held on with a hex nut tightened on the motor

arbor shaft. Based on either right to left or left to right saw

operation, the hex nut will be either a left hand or right

hand thread. A right to left saw operation means that the

product is entering the saw from the right side. A right to

left operating saw will use a left-handed threaded arbor.

This is done to insure that the arbor nut will want to continually tighten during blade rotation. The motor has an

arrow on the housing to indicate the arbor rotation.

Remove the hex nut using the spanner wrench provided to

hold the blade shaft. The saw blades will be removable at

this time.

IMPORTANT: Always note the blade tooth direction

when removing blade to insure that the replacement

blade is installed the same.Rotating a carbide blade in

the wrong direction will usually damage the blade.As

standard, the blade rotation should have the top of the

blade rotating away from the front or operator side of the

unit.

1

2

3

Page 27

UGE058/0803 CTS Saw

INSTALLATION 3-9

Make sure all components are installed according

to assembly drawings. Make sure that all bolts on the saw

have been tightened.

Check that saw is firmly locked into position with

the anchoring screws.

Check that all wiring conforms to electrical

codes

, and all wiring covers are in place.

Plug in the air supply

Turn on the main disconnect.

Plug in the main

power cord and turn on the main disconnect.

Check that the E-Stop button is in the out,

extended position.

Press the vacuum start button.

Check the rotation of the vacuum motor for correct phasing. (The phase in your plant may be different from the

Conair factory.)

Press the saw start button.

Turn off the saw and vacuum.

Check the saw blade rotation.

The top of the saw blade should turn towards the front or

operator side. If the top of the blade is spinning away

from you or the operator side switch one of the 3-phase

plug wires. Then recheck the blade rotation.

Make a sample cut. Restart the vacuum and the saw

motor and press the manual cut button. The saw should

make one sample cut.

If the saw is not working properly at any time, turn it off

immediately and refer to the Troubleshooting section of this

User Guide.

If you do not encounter any problems, proceed to the

Operation section.

1

2

PREPARING FOR

TESTING

1

3

TESTING THE

INSTALLATION

2

3

4

5

6

4

Page 28

Page 29

4-1

UGE058/0803 CTS Saw

●●

The Saw Control . . . . . . . . . . . . .4-2

●●

Machine Frame and Support

System . . . . . . . . . . . . . . . . . . . .4-4

●●

Blade Height Adjustment . . . . . .4-4

●●

Upper Clamp Adjustment . . . . .4-5

●●

Power Supply . . . . . . . . . . . . . . .4-5

●●

Control Panels . . . . . . . . . . . . . .4-5

●●

Pneumatic Cylinder

Operation . . . . . . . . . . . . . . . .4-6

●●

Electrical Operation . . . . . . . . . .4-7

●●

Machine Lubrication . . . . . . . . .4-8

●●

System Inspection . . . . . . . . . .4-8

●●

Blade Replacement . . . . . . . . . .4-9

●●

Chip Collection Shrouds

and Blower Connection . . . .4-10

OPERATION

Page 30

CTS Saw UGE058/0803

4-2 OPERATION

THE SAW

CONTROL

Connect the electrical line cord to a source of power compatible with the nameplate on the saw cut-off saw.

Connect the air supply to the FRL (filter-regulator-lubricator)

on the saw.

If the optional dust collector was purchased, install and con-

nect the dust collector

Turn the main disconnect switch to the ON position; the

POWER ON light will illuminate.

Press Start or (if equipped with Dust Collector) turn Dust

Collector power “ON” first and then press saw motor “START”

Check the motor rotation. If the motor rotation is incorrect:

Reverse the connections at the AC plug end.

Once the rotation is correct, disconnect the power, and

install the blade on the cut-off saw.

Make sure that the FRL is set for 6--65 PSI

Press MANUAL CUT

Adjust the TABLE FORWARD speed control to match the

approximate line speed.

Adjust the SAW BLADE UP speed control to the desired

blade travel speed.

Set the blade height limit by adjusting the collar on the lifting

rod (located on the table surface)

1

2

3

4

5

6

7

8

9

10

11

12

IMPORTANT: Before applying power, ensure that the

SAW BLADE UP and TABLE FORWARD valves are

closed (fully clockwise), and that the saw blade is not

installed on the cut-off saw.

NOTE: Setting the FRL to higher level will only release

air from the system.The CTS is equipped with a relief

valve that is preset for approximately 70 PSI. The CTS

is equipped with a relief valve that is preset for approximately 70 PSI.The relief valve is in place to protect the

air components from damage due to excessive air pressure.

continued on the next page

Page 31

UGE058/0803 CTS Saw

OPERATION 4-3

Adjust the TABLE RETURN speed control to the

suitable travel return speed.

Adjust the clamp pressure regulator to grasp the profile firmly.

THE CONTROL

FEATURES

CONTINUED

13

14

NOTE: The TABLE RETURN pressure must be set high

enough to return the table to the start position and tr igger the TABLE START micro-switch.

NOTE: Both the clamp pads and pressure can be

adjusted so that the profile is not crushed.

Page 32

The machine frame is constructed of welded steel that has

been primed and painted to resist corrosion and provide a

maintenance free finish. The frame is supported by, four leveling screws, that both permanently fix the position of the unit

and also help accommodate any uneven flooring. These

screws have a welded hex nut to allow adjustment with a

wrench.

The motors and machine components are mounted inside the

frame and completely guarded for operator safety.

These and all guards should always remain securely in place

when machine is running and should be re-installed after any

maintenance procedures that have required their removal.

The saw blades are mounted to and driven by a 3500 RPM

arbor motor. This motor is mounted on a pivot assembly,

which guides and secures the saw blade through the cutting

process.

There is adjustment for how high the saw blade will extend

through the table depending on the product being cut. For

maximum cut cycles, the saw blade should be adjusted so that

the blade just passes through the product before returning

home. Too much blade extension will waste valuable time and

limit the amount of cuts that will be available per minute. This

adjustment is made externally with the hand knob positioned

at the rear of the cutting table. Turning the knob counterclockwise will allow the blade to extend farther up through the

table and turning the knob clockwise will reduce the amount

that the blade will come up.

CTS Saw UGE058/0803

4-4 OPERATION

MACHINE

FRAME AND

SUPPORT

SYSTEM

BLADE

HEIGHT

ADJUSTMENT

Page 33

As with the blade height adjustment, there is also a requirement to adjust the product clamps to adequately clamp different size products. The clamps are reversible and can be used

for clamping round or flat items. If you are running a round

product such as pipe or tubing, the side of the clamp that has a

"V" notch should be used and for flat surfaced products, the

straight side of the clamp should be used.

To remove and/or adjust each clamp assembly:

Lock out and tag out the power to the saw.

See

Section 1: Introduction, How to use the Lockout Device.

Wait at least five minutes for the blade to stop

completely.

Pull the hitch pin from the clamp keeper pin

and remove both pins.

Slide the clamps to the desired position.

Re-insert the keeper pins.

Re-install the hitch pins.

This equipment is powered by either 230 or 460 VAC , Three

Phase, as specified on the machine nameplate.

Connect the machine power through a fused discon-

nect of proper rating. Make sure the power is grounded

through the power cable to the plant electrical ground.

The operator control panels are located on the front of the saw

frame. The pneumatic control panel is located to the left of the

operator controls platform. It consists of a pressure regulator,

pressure gauge, and flow controls. All items are labeled, easily

accessible and lockable.

The electrical control panel is located just to the right of the

pneumatic control. It consists of start and stop pushbuttons, a

power on light, a manual cut pushbutton and an emergency

stop extended pushbutton. All items are labeled and easily

accessible.

POWER SUPPLY

UGE058/0803 CTS Saw Manual

OPERATION 4-5

CONTROL

PANELS

U

PPER CLAMP

A

DJUSTMENT

1

2

3

4

IMPORTANT: The clamps should be set approximately

1/8"-1/4" above the product in the "up" position to allow

for positive clamping. Always check to see if setting is

correct before operating in line.

1

5

6

Page 34

The carriage travel, blade pivot and clamp assemblies are

moved with air cylinders. The speed of the movement of the

carriage assembly is controlled by flow controls located on

the operator panel. Clockwise rotation will slow the table

speed and counterclockwise rotation will increase the table

speed.

The blade pivot assembly is moved up and down with an air

cylinder located below the table. It is controlled by flow controls mounted on the operator panel. These are labeled table

up speed and table down speed. Clockwise rotation will slow

the table movement speed and counterclockwise rotation will

increase the table movement speed.

The clamp assembly is moved up and down by air cylinders

mounted above the clamp. They are controlled by flow controls mounted on the Cylinders. Clockwise rotation will slow

the clamp movement speed and counterclockwise rotation will

increase the clamp movement speed.

The table and clamp pressure setting is adjusted with a pressure regulator located on the operator panel. The pressure

level setting is displayed on the gauge located above the regulator. The table and clamp pressure should never exceed 60

PSI.

The main filter/regulator/lubricator is mounted on the side of

the machine near the electrical enclosure and should be maintained as described in the manufacturers documentation.

This unit should always be supplied with clean dry air.

Incoming pressure should be set at approximately 65 PSI.

Maximum pressure is 70 PSI.

PNEUMATIC

CYLINDER

OPERATION

CTS Saw Manual UGE058/0803

4-6 OPERATION

IMPORTANT: This unit should always be supplied with

clean dry air. Incoming pressure should be set at

approximately 65 PSI. Maximum pressure is 70 PSI.

Page 35

The operation of the saw consists of an automatic sequence of

events.

To start the saw the main power must be on and the appropriate air supply to the machine. With the power on, the

control panel will have the power on light illuminated.

To start the saw motor, push the start button.

Once the saw motor is started, push the yellow manual cut

button and the machine will start its automatic cycle. The

clamps will come down and the table will begin to travel

away from its home position. Immediately after this happens, the saw pivot assembly will raise the blade up

through the table slot until it reaches its up limit switch.

Upon reaching this switch, the saw pivot will immediately

return down through the table, the clamps will raise and the

table will return to its home position, completing one

cycle.

UGE058/0803 CTS Saw

OPERATION 4-7

ELECTRICAL

OPERATION

IMPORTANT: An important reminder is that the speed

settings of the pneumatic flow controls will affect the

cycle time of the machine.The flow controls must be set

properly to a compromise between cycle time and cut

quality. Flow control settings should be adjusted at this

time and fine-tuned during the initial phase of the saw

operation.

1

2

Page 36

The machine is supplied to you completely lubricated. After

running the unit for long periods of time, this lubrication will

break down and become useless.

Follow this lubrication chart for optimum performance.

Component Type of Lubricant Duration

Table Pivot Bearings Chassis Lube 6-9 months

Clamp Post Slides Chassis Lube 5-6 months

Although this unit was designed to require a minimum amount

of maintenance, it should be inspected periodically to insure

that it remains in top operating condition.

Items to inspect are as follows:

- Saw Tracks- The steel tracks that the saw motor carriages

travel on, will after time, begin to wear from the constant contact with the cam rollers. They should be visually inspected

for wear and replaced as necessary.

- Saw Track Rollers- The steel cam rollers that the saw motor

carriages travel on, will after time, begin to wear from the

constant contact with the saw tracks. They should be visually

inspected for wear and replaced as necessary.

- Pneumatic System- Approximately once every 12 months or

sooner if able, all system pneumatic components should be

visually inspected. All hoses should be checked for wear or

damage. All regulators and flow controls should be adjusted

through their usable ranges to insure proper operation.

MACHINE

LUBRICATION

CTS Saw UGE058/0803

4-8 OPERATION

SYSTEM

INSPECTION

Page 37

Lock out and tag out the power to the saw. See

Section 1: Introduction, How to use the Lockout Device.

Wait at least five minutes for the blade to stop

completely.

Open the rear access door of the machine.

Remove the screws that retain the blade door

to the blade shroud and hinge open the door.

Remove the hex nut.

The blade is held on with a hex nut tightened on the motor

arbor shaft. Based on either right to left or left to right saw

operation, the hex nut will be either a left hand or right

hand thread. A right to left saw operation means that the

product is entering the saw from the right side. A right to

left operating saw will use a left-handed threaded arbor.

This is done to insure that the arbor nut will want to continually tighten during blade rotation. The motor has an

arrow on the housing to indicate the arbor rotation.

Remove the hex nut using the spanner wrench provided to

hold the blade shaft. The saw blades will be removable at

this time.

BLADE

REPLACEMENT

UGE058/0803 CTS Saw

OPERATION 4-9

IMPORTANT:

Always note the blade tooth direction

when removing blade to insure that the replacement

blade is installed the same. Rotating a carbide blade in

the wrong direction will usually damage the blade.As

standard, the blade rotation should have the top of the

blade rotating away from the front or operator side of the

unit.

1

2

3

WARNING:

Electrical hazard

Before performing maintenance or repairs on

this product, disconnect

and lock out electrical

power sources to prevent injury from unexpected energization or

start-up. A lockable

device has been provided to isolate this product from potentially hazardous electricity.

CAUTION:

Moving parts

Before removing lockout

devices and returning

switches to the ON position, make sure that all

personnel are clear of

the machine, tools have

been removed and all

safety guards are reinstalled.

4

5

Page 38

The CTS Saw has been equipped with a chip collection

shroud that is connected to the outside of the base to aid in

removing chips and debris from the blade area.

The success rate of chip removal is dependent on the type and

ability of the customer supplied removal system or Conair’s

optional vacuum system.

CHIP

COLLECTION

SHROUDS AND

BLOWER

CONNECTION

CTS Saw UGE058/0803

4-10 OPERATION

WARNING: If you did not purchase a Conair dust collec-

tion system you must connect a customer supplied dust

collector.Failure to do so may result in a fire hazard!

Page 39

5-1

UGE058/0803 CTS Saw

●●

Maintenance Features . . . . . . . .5-2

●●

Warnings and Cautions . . . . . . .5-2

●●

Maintenance Overview . . . . . . .5-4

●●

Preventative Maintenance

Schedule . . . . . . . . . . . . . . . . .5-4

●●

Checking the Blades . . . . . . . . .5-6

●●

Checking Electrical

Connections . . . . . . . . . . . . . .5-7

MAINTENANCE

Page 40

W

ARNINGS AND

CAUTIONS

The CTS Saw models need regular, scheduled maintenance

for peak performance. Among the features that require maintenance are:

● Saw blades

● Blade mounting hardware

● Product guides

● The saw guard hardware

● Saw alignment

● Floor locks

● Shafts of optional slide rail system

● Electrical cables

● Control panel lights

MAINTENANCE

FEATURES

CTS Saw UGE058/0803

5-2 MAINTENANCE

To maintain the best performance of the saw it must be

cleaned and inspected regularly. Maintenance includes a daily,

weekly, quarterly, and semi-annual (every 6 months) schedule.

Use this maintenance schedule as a guide. You may need to

shorten the time of the maintenance schedule, depending on

how often you use the saw, and the types of material flowing

through it.

Follow all precautions and warnings when working on the

equipment.

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Page 41

UGE058/0803 CTS Saw

MAINTENANCE 5-3

WARNING:Voltage Hazard

This equipment is powered by alternating current, as specified on the machine serial tag and

data plate. Do not operate the equipment at

power levels other than what is specified on the

machine serial tag and data plate.

A properly-sized conductive ground wire from

the incoming power supply must be connected

to the chassis ground terminal inside the electrical enclosure. Improper grounding can result in

severe personal injury and erratic machine

operation.

Before performing maintenance or repairs on

this product, disconnect and lock out electrical

power sources to prevent injur y from unexpected energization or start-up. A lockable device

has been provided to isolate this product from

potentially hazardous electricity.

DANGER: Sharp blades!

Most injuries caused by saw blades occur when

the saw has been turned off. Handle blades

with care at all times.

● Always wear cut-resistant gloves when the

blade guard is open and when handling

blades.

● Always lock out power to the saw before

opening any guards.

● Always wait until the saw blade has completely stopped before opening the saw

guards. (approximately five minutes.)

CTS saws are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

WARNINGS AND

CAUTIONS

CONTINUED

Page 42

This section describes the daily, weekly, monthly and semiannual maintenance schedules that should be performed when

changing materials or lines, or when changing equipment, as

well as the maintenance procedures to follow.

Cutting either flexible or rigid materials generates tremendous

shock and vibration to the entire unit. Anything that can

loosen, will over time.

To maintain the best performance, follow this maintenance

schedule and develop an effective preventative maintenance

program.

●

Daily

❒❒

Checking saw blade(s)

Clean, sharpen or replace as needed (see Section 4,

Blade Replacement.)

❒❒

Inspecting the blade mounting hardware

The blade securing bolt should use both a lock washer

and flat washer, and be tightened enough to fully compress the lock washer. Replace the holding pins if they

appear worn.

❒❒

Inspecting the the saw product guides for wear and

alignment.

❒❒

Inspecting saw alignment

Proper saw alignment is critical for optimum performance. Use a plumb line or laser to check for a

straight line from the extrusion die to the saw bushings.

❒❒

Check floor locks

It is always recommended that the weight be removed

from the casters for optimum stability during cutting

cycles. Check to see if the floor locking mechanism is

properly adjusted.

CTS Saw UGE058/0803

5-4 MAINTENANCE

MAINTENANCE

OVERVIEW

PREVENTATIVE

M

AINTENANCE

SCHEDULE

Page 43

● Weekly

❒❒

Blow or vacuum, dust and chips from all surfaces of

the saw. Open pneumatic and electrical enclosures

and remove the dust and chips from all components.

❒❒

Check that the FRL (filter-regulator-lubricator) for

the air input is filled with oil and that the oilier is

working. Pressure should be set for around 60 PSI.

This unit also has an automatic drain for any moisture that may develop. The bowl should be kept

clean to ensure it will operate properly.

●

Quarterly

❒❒

Blow or vacuum, dust and chips from the inside

the saw. Remove all dust and chips from inside all

control cabinets. Remove any excess oil from the

pneumatic enclosure.

❒❒

Verify that all electrical terminals are tight.

❒❒

Check that all air lines are in order (free of cuts or

abrasions). Check the saw travel rails and rollers

for debris and wear.

❒❒

Check that the adjustable mufflers on the SAW

BLADE UP cylinder is set for a smooth downward

return.

❒❒

Check that the adjustable mufflers on the clamp

cylinder are set so that the clamp operates quickly a slow cycle on the clamp-down will cause inaccurate cuts in length.

❒❒

Check the condition of the clamp pads. If worn or

damages, replace with a new set of pads.

❒❒

Check the condition of the clamp pads. If worn or

damages, replace with a new set of pads.

❒❒

Check the condition of the blade. If the blade is

dull, have the unit sharpened; if it is damaged, have

the blade replaced.

PREVENTATIVE

MAINTENANCE

SCHEDULE

C

ONTINUED

UGE058/0803 CTS Saw

MAINTENANCE 5-5

WARNING:

Electrical hazard

Before performing maintenance or repairs on

this product, disconnect

and lock out electrical

power sources to prevent injury from unexpected energization or

start-up. A lockable

device has been provided to isolate this product

from potentially hazardous electricity.

CAUTION: Moving

parts

Before removing lockout devices and

returning switches to

the ON position, make

sure that all personnel

are clear of the

machine, tools have

been removed and all

safety guards are reinstalled.

Page 44

DANGER: Sharp blades!

Most injuries caused by knife blades occur

when the saw has been turned off. Handle

blades with care at all times.

● Always wear cut-resistant gloves when the

blade guard is open and when handling

blades.

● Always lock out the saw before opening any

guards.

● Always wait until the saw blade has stopped

completely before opening the saw guard.

(approximately five minutes)

CTS Saw are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

● The STOP button activates a circuit that

stops the saw.

Blades become dull over time depending on the material being

cut, cut rate, blade speed, and blade material and thickness.

Check blades regularly for sharpness as well as scratches,

nicks, burrs, and material buildup. Clean, sharpen or replace

as needed (see Installing Saw Blades).

CHECKING

BLADES

CTS Saw UGE058/0803

5-6 MAINTENANCE

WARNING: Improper installation,

operation, or servicing may result in

equipment damage or personal

injury.

This equipment should only be installed,

adjusted, and serviced by qualified technical

personnel who are familiar with the construction, operation, and potential hazards of this

type of machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your

region. Always maintain a safe ground. Do not

operate the equipment at power levels other

than what is specified on the machine serial

plate.

Page 45

UGE058/0803 CTS Saw

MAINTENANCE 5-7

Be sure the main power is disconnected and

the saw is locked out

. Always disconnect and

lock out the main power source before opening the unit or

servicing.

Turn the main power disconnect to the off

position

before opening the electrical enclosure on the

back of the saw or the back of the control. This is a safety

device to prevent you from opening the doors if the power

is still on.

CHECKING

ELECTRICAL

CONNECTIONS

WARNING: Electrical hazard

Before performing any work on this product,

disconnect and lock out electrical power

sources to prevent injury from unexpected energization or start-up. A lockable device has been

provided to isolate this product from potentially

hazardous electricity.

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed by qualified electrical technicians in

accordance with electrical codes in your region.

Always maintain a safe ground. Do not operate

the equipment at power levels other than what

is specified on the machine serial tag and data

plate.

1

2

Main power

safety

disconnect

continued on the next page

Page 46

CHECKING

ELECTRICAL

CONNECTIONS

CONTINUED

CTS Saw UGE058/0803

5-8 MAINTENANCE

Open the electrical enclosure.

Inspect all wires and connections

. Look for loose

wires, burned contacts, and signs of over-heated wires.

Have a qualified electrician make any necessary repairs or

replacements.

Close the electrical enclosure door.

Inspect the exterior power cords.

Cords should

not be crimped, exposed, or rubbing against the frame. If

the main power cord runs along the floor, make sure it is

not positioned where it could rest in pooling water or

could be run over and cut by wheels or casters.

3

4

5

6

Page 47

6-1

UGE058/0803 CTS Saw

●●

Before Beginning . . . . . . . . . . . .6-2

●●

A Few Words of Caution . . . . . .6-2

●●

Identifying the

Cause of a Problem . . . . . . . . .6-3

●●

Electrical Problems . . . . . . . . . .6-4

●●

Product Quality Problems . . . . .6-5

●●

Checking the Servo Amplifiers .6-7

●●

Checking the Encoder . . . . . . . .6-8

TROUBLESHOOTING

Page 48

You can avoid most problems by following the recommended

installation, operation and maintenance procedures outlined in

this User Guide. If you have a problem, this section will help

you determine the cause and tell you how to fix it.

Find any wiring, parts, and assembly diagrams that were

shipped with your equipment. These are the best reference for

correcting a problem. The diagrams will note any custom features or options not covered in this User Guide.

Verify that you have all instructional materials related to the

saw. Additional details about troubleshooting and repairing

specific components are found in these materials.

Check that you have manual for other equipment connected in

the system. Troubleshooting may require investigating other

equipment attached to, or connected with the saw.

BEFORE

BEGINNING

CTS Saw UGE058/0803

6-2 TROUBLESHOOTING

A F

EW WORDS

OF

CAUTION

WARNING: Improper installation, operation, or servicing may result in

equipment damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential hazards of this type of

machine.

All wiring, disconnects, and fuses should be

installed and adjusted by qualified electrical

technicians in accordance with electrical codes

in your region. Always maintain a safe ground.

Do not operate the equipment at power levels

other than what is specified on the machine

serial tag and data plate.

WARNING: Electrical hazard

Before performing maintenance or repairs on

this product, disconnect and lock out electrical

power sources to prevent injur y from unexpected energization or start-up. A lockable device

has been provided to isolate this product from

potentially hazardous electricity.

Page 49

The Troubleshooting section covers problems directly related

to the operation and maintenance of the saw. This section does

not provide solutions to problems that originate with other

equipment. Additional troubleshooting help can be found in

manuals supplied with the other equipment.

The main problems you will see with the saw are:

● Saw operation problems, which focus on problems that

are clearly related to the operation of the saw’s electrical

control systems.

● Plastic product quality concerns, which deal with prod-

uct characteristics that may be related to saw operation.

Of course, other sections of the extrusion line also influence the quality of the extruded product. This section

does not provide solutions to problems originating with

other equipment on the extrusion line.

Additional troubleshooting help can be found in the manufacturer’s manuals included with this User Guide.

IDENTIFYING THE

CAUSE OF A

PROBLEM

UGE058/0803 CTS Saw

TROUBLESHOOTING 6-3

DANGER: Sharp blades!

Most injuries caused by saw blades occur when

the saw has been turned off. Handle blades

with care at all times.

● Always wear cut-resistant gloves when the

cutting chamber is open and when handling

blades.

● Always lock out power to the saw before

opening the cutting chamber.

● Always wait until the saw has completely

stopped before opening the cabinet door.

CTS saws are equipped with several safety

devices to ensure safe operation. Never remove

or disable these devices to sustain production.

Operating without these devices can cause

severe injury.

Page 50

CTS Saw UGE058/0803

6-4 TROUBLESHOOTING

ELECTRICAL

PROBLEMS

Look in this section when you have problems such as lights on

the control that are working improperly, buttons that do not

execute the function properly, and when information input is

not executed properly.

Symptom

◆ Saw will not

start

◆ Saw blade runs

backwards

Possible cause

The E-stop button is

depressed.

Motor overload tripped

Disconnect in the off position.

AC Power is phased

incorrectly for your plant

Solution

Make sure the E-stop is

extended.

Reset motor overload.

Turn disconnect to the on position.

Change the wire on the plug to

match your plants AC phasing.

Page 51

UGE058/0803 CTS Saw

TROUBLESHOOTING 6-5

Symptom

◆ Cut not square

◆ Crack or frac-

tures in cut surfaces

◆ General poor

cut quality

◆ Product melting

at cut

Possible cause

Product guides not

aligned square to the

blade face

Blade speed too fast

Incorrect blade design

Incorrect cooling of

extrudate

Incorrect blade design

Blade running backwards

Blade speed too slow

Incorrect blade design

Solution

Re-align the product guides.

Insure that the rear guide is

square with the saw blade and

tighten. Adjust the front guide

accordingly allowing enough

clearance for smooth product

passage.

Adjust speed control for blade

feed into part (slower)

Investigate blade choice for the

application.

Improve the molecular structure with variation of cooling

time or temperature.

Investigate blade choice for the

application.

Check motor rotation

Check blade installation

Adjust speed control for blade

feed into part (faster)

Investigate blade choice for the

application.

PRODUCT

QUALITY

PROBLEMS

Page 52

PRODUCT

QUALITY

PROBLEMS

C

ONTINUED

CTS Saw UGE058/0803

6-6 TROUBLESHOOTING

Symptom

◆ Incorrect cut

length

◆ Table motion

inconsistent

Possible cause

Encoder or input device

problem

Puller problem

Counter problem

Saw clamps not holding

Roller ways dirty

Rodless cylinder problem

Solenoid problem

Low air pressure

Solution

Check encode or input device

Check puller for drive consistencies or any belt to product

slippage.

Check cut length counter

Check rubber saw clamps for

wear and replace as necessary

Clean roller ways

Check and clean rodless cylinder

Check table actuation solenoid

for proper operation

Check main system regulator

for incoming air pressure settings

Page 53

UGE058/0803 CTS Saw

TROUBLESHOOTING 6-7

The servo amplifier is equipped with a digital readout that

can be seen through the viewing window on the electrical

enclosure. This display shows amplifier status and error messages. Refer to the supplier's documentation included with

this User Guide.

NOTE: Make sure you look for servo amplifier messages

before you shut off the power.

CHECKING THE

SERVO

AMPLIFIER

Page 54

When the encoder is working properly, the encoder LEDs on

the control panel light or flicker as the encoder wheel moves

and generates signals. If the LEDs do not light when the

encoder wheel moves:

Check all connections.

Check the encoder cable for damage.

If neces-

sary, replace.

Check the connector that attaches the cable to

the encoder.

Internal wiring may be shorted out if this

connector is not handled properly.

Check the encoder itself. There should be no play

in the shaft.

If all else fails, contact Conair Customer Service. See

Appendix page A-1.

CHECKING THE

ENCODER

CTS Saw UGE058/0803

6-8 TROUBLESHOOTING

WARNING: Delicate equipment

The encoder is a delicate piece of equipment.

Any rough handling can damage fragile parts.

3

1

2

4

5

Page 55

SERVICE INFORMATION

APPENDIX A-1

Conair has made the largest investment in customer support in

the plastics industry. Our service experts are available to help

with any problem you might have installing and operating

your equipment. Your Conair sales representative also can help

analyze the nature of your problem, assuring that it did not

result from misapplication or improper use.

To contact Customer Service personnel, call:

From outside the United States, call: 814-437-6861

You can commission Conair service personnel to provide onsite service by contacting the Customer Service Department.

Standard rates include an on-site hourly rate, with a one-day

minimum plus expenses.

If you do have a problem, please complete the

following checklist before calling Conair:

❒ Make sure you have all model, serial and parts list

numbers for your particular equipment. Service

personnel will need this information to assist you.

❒ Make sure power is supplied to the equipment.

❒ Make sure that all connectors and wires within

and between the saw and related components have

been installed correctly.

❒ Check the troubleshooting guide of this manual

for a solution.

❒ Thoroughly examine the instruction manual(s)

for associated equipment, especially controls.

Each manual may have its own troubleshooting

guide to help you.

❒ Check that the equipment has been operated as

described in this manual.

❒ Check accompanying schematic drawings for

information on special considerations.

BEFORE

YOU

C

ALL ...

HOW TO

CONTACT

CUST OMER

SERVICE

Additional manuals and

prints for your Conair

equipment may be

ordered through the

Customer Service or

Parts Departments for

a nominal fee.

WE’RE HERE

TO

H

ELP

Page 56

A

PPENDIX A-2

WARRANTY INFORMATION UGE058/0803

EQUIPMENT

GUARANTEE

PERFORMANCE

WARRANTY

WARRANTY

LIMITATIONS

Conair guarantees the machinery and equipment on this

order, for a period as defined in the quotation from date of

shipment, against defects in material and workmanship under

the normal use and service for which it was recommended

(except for parts that are typically replaced after normal

usage, such as filters, liner plates, etc.). Conair’s guarantee is

limited to replacing, at our option, the part or parts determined by us to be defective after examination. The customer

assumes the cost of transportation of the part or parts to and

from the factory.

Conair warrants that this equipment will perform at or above

the ratings stated in specific quotations covering the equipment or as detailed in engineering specifications, provided

the equipment is applied, installed, operated and maintained

in the recommended manner as outlined in our quotation or

specifications.

Should performance not meet warranted levels, Conair at its

discretion will exercise one of the following options:

● Inspect the equipment and perform alterations or adjust-

ments to satisfy performance claims. (Charges for such

inspections and corrections will be waived unless failure

to meet warranty is due to misapplication, improper

installation, poor maintenance practices or improper

operation.)

● Replace the original equipment with other Conair equip-

ment that will meet original performance claims at no

extra cost to the customer.

● Refund the invoiced cost to the customer. Credit is sub-

ject to prior notice by the customer at which time a

Return Goods Authorization Number (RGA) will be

issued by Conair’s Service Department. Returned equipment must be well crated and in proper operating condition, including all parts. Returns must be prepaid.

Purchaser must notify Conair in writing of any claim and

provide a customer receipt and other evidence that a claim is

being made.

Except for the Equipment Guarantee and Performance

Warranty stated above, Conair disclaims all other warranties

with respect to the equipment, express or implied, arising by

operation of law, course of dealing, usage of trade or otherwise, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

Page 57

Conair Servo

Traveling Saw

Operator Control

Instructions

The Operator Control provides an intuitive user-friendly

method to interface with the Conair Servo Traveling Saw.

Information is viewed and entered at the Operator Control

and is communicated to the servo positional amplifier via

the RS-232 serial communication link.

The Operator Control is a flat membrane panel consisting

of 22-keys and a large 2 line x 20 back lit LCD screen.

CONAIR SERVO SAW

Version 1.1

Soft Keys

Soft keys - these are the three keys directly under the

display. All three have a triangle on them. Occasionally,

pages will appear that allow the operator to use one of the

soft keys. On those occasions, text would typically appear

directly above the key and the key will have a function.

Think of the text as the soft key function indicator or title.

Appendix B-1 (1)

Page 58

Conair Servo

Traveling Saw

Operator Control

Instructions

Numeric keys

These are the black keys containing numbers 0 to 9.

Numbers permit data entry of parameters. See Raise and

Lower for value trim.

Fixed Function Keys (at Bottom)

Underneath the numeric keys are fixed function keys. They

contain universal symbols and text. The fixed function keys

are Raise, Lower, Next, Prev (previous), Enter, Delete,

Exit, Menu and Mute. These functions are described in the

“Function keys - Fixed Functions” section of this manual.

LCD Screen

The screen shows various pages depending on operator

actions. In addition, it is used to indicate warnings.

Mostly, it is used for viewing status and for setting

parameters.

Appendix B-1 (2)

Page 59

Conair Servo

Contents

Traveling Saw

Operator Control

Instructions

Page 4 ...........Power up Sequence

Page 5 ...........Main Screen – Length Counter

...........Count On/Off

Page 6 ...........Total

...........Total Reset

...........Total On/Off

Page 7 ...........Length Preset

...........Total Reset

Page 8 ...........Homing

Page 9 ...........Home Already

Page 10 ...........Menu Area

...........Password Access

Page 11 ...........Maintenance Area

...........Encoder Direction

Page 12 ...........Preventive Maintenance Area

...........Power On Time

Page 13 ...........Machine Cycles

...........Table Speeds

Page 14 ...........Table Return Speed

Page 15 ...........Table Advance Speed

Page 16 ...........Factory Area

...........Error Message

Appendix B-1 (3)

Page 60

Conair Servo

**STARTING COMMS**

Traveling Saw

Operator Control

Instructions

Power Up Sequence

At power up a series of system screens briefly appear. The

software is Red Lion’s Edict-97. This screen or similar

shows first.

Edict-97 Runtime

Ver. 5.05.117

Next, the Communications message appears

If there are any problems with communications, this screen

will remain on longer than a couple of seconds.

If there are no communication problems the Conair Servo

Traveling Saw program will begin to run. The following

CONAIR SERVO SAW

Version 1.1

message or similar shows for 5-seconds.

After the 5 second delay the Main Screen will appear.

Appendix B-1 (4)

Page 61

Conair Servo

Traveling Saw

Operator Control

Instructions

Main Screen

The Main Screen has three features. The top line displays

the Length Counter. The bottom line contains the two soft

key functions, Total and Length.

0000.000 in.

Total Off Length

Length Counter

The Length Counter displays counts only when the

machine is started and soft key On/Off is on. If the machine

is stopped or soft key On/Off is off, this counter will be

forced to zero.

The length counter resides in the servo drive. The main

screen shows snapshots of the count value that is read over

the communications channel. A slight delay in updates will

be noticed.

If a negative symbol is shown to the left of the count value,

the encoder signal is reversed, i.e. rotating in the wrong

direction. The Saw will not function while the encoder is

going negative. It is possible to correct this by using the

Direction function on the Maintenance Area page found in

the Menu area. This will be shown later in the Menu

section of this manual.

On/Off Softkey

Under the count in the center of the bottom line of the

display is a soft key labeled On or Off. Pressing this key

while On is displayed will disable the counter. Likewise

pressing this key while Off is displayed enables the

counter. Pressing the stop button forces the counter off.

Appendix B-1 (5)

Page 62

Conair Servo

Traveling Saw

Operator Control

Instructions

Total Softkey

By pressing the soft key located under the word Total on

the Main Screen, a six-decade total counter is available.

TOTAL 000,000 pcs.

Off Exit Reset

Total Screen

This is typically used to count cut pieces during the day or

days that the product is being produced.

Sample or aborted cuts are not counted. It is also possible

to turn this counter off or on.

Reset Softkey

Under the counter, on the right is a soft key labeled Reset.

Pressing this key will zero the counter.

Exit Softkey

Under the counter, in the center is a soft key labeled Exit.

Pressing this key will return the display to the Main screen.

On/Off Softkey

Under the counter on the left is a soft key labeled On or

Off. Pressing this key while On is displayed will disable the

counter. Likewise pressing this key while Off is displayed

enables the counter.

EXIT or PREV, fixed function keys return the display

to the Main screen.

Appendix B-1 (6)

Page 63

Conair Servo

Traveling Saw

Operator Control

Instructions

Length Softkey

By pressing the soft key located under the word Length on

the Main Screen, the preset for the Length counter is

available.

LENGTH 0000.000 in.

Exit

The number shown is the current length preset value, i.e.

the length to cut the product. A cursor will appear in the

least significant digit. The user has a choice of ways to

adjust this number.

Exit or Prev- if no change is required press Exit or Prev to

return to the Main screen.

Raise will increase the preset by 0.01”. The key can be

pressed once for each 0.01” increment required or held

down to scroll up. Releasing the key will freeze the preset

at the last value.

Lower will decrease the preset by 0.01”. The key can be

pressed once for each 0.01” decrement required or held

down to scroll down. Releasing the key will freeze the

preset at the last value.

Numeric keys

Key in the length required and press enter. The decimal

place is fixed so remember this when entering the preset. If

you require 24 inches you must key in 24000 and then

press enter. Keying only 24 will set the length to 0.024

inches.

Enter or Delete?

If the keyed in number is correct press the enter key for it

to be accepted and return to the Main screen. If it is wrong

press the delete key and the previous preset will reappear.