Page 1

CONAIR

MNL-00102

WARNING - Reliance on this Manual Could Result in Severe Bodily Injury or Death!

This manual is out-of-date and is provided only for its technical information, data and capacities. Portions of this manual

detailing procedures or precautions in the operation, inspection, maintenance and repair of the product forming the subject

matter of this manual may be inadequate, inaccurate, and/or incomplete and cannot be used, followed, or relied upon.

Contact Conair at info@conairgroup.com or 1-800-654-6661 for more current information, warnings, and materials about

more recent product manuals containing warnings, information, precautions, and procedures that may be more adequate

than those contained in this out-of-date manual.

MANUAL

CL-79

05-15-96 79 1

Page 2

CONAIR

Contents

1. Introduction.....................................................................................................3

2. Technical specifications ............................................................................ 4

2.1 Dimensions ......................................................................................................... 4

2.2 Data ....................................................................................................................4

3. Functional description ............................................................................ 5-6

3.1 Overview.............................................................................................................5

3.2 Safety system..................................................................................................... 6

4. Safety regulations ...................................................................................... 7

4.1 Overview ............................................................................................................. 7

4.2 Sound level ......................................................................................................... 7

5. Installation ................................................................................................ 8-9

5.1 Pre-start checks .................................................................................................. 8

5.2 Opening and closing the hopper and screenbox ................................................ 8

5.3 Electrical connection........................................................................................... 9

6. Operation and daily maintenance..........................................................10-11

6.1 Starting and stopping........................................................................................ 10

6.2 Inspection ......................................................................................................... 10

6.3 Cleaning............................................................................................................ 11

6.4 Trouble-shooting............................................................................................... 11

7. Servicing ................................................................................................. 12-17

7.1 Changing the knives ....................................................................................12-13

7.2 Sharpening the knives .................................................................................14-15

7.3 Inspecting and adjusting the belts .................................................................... 16

7.4 Lubrication ........................................................................................................ 1 6

7.5 Assembling/disassembling the rotor pulley.......................................................17

8. Spare parts list .................................................................................... 18-26

8.1 Overview........................................................................................................... 18

8.2 Ordering spare parts......................................................................................... 18

8.1.1 79, Cutter housing, all models.............................................................................. 19

8.1.1 79, Cutter housing,all models .......................................................................... 20-21

8.1.2 79, table ................................................................................................................ 22

8.1.2 79, diagram ........................................................................................................... 22

8.1.3 79, table ................................................................................................................ 23

8.1.3 79,diagram ............................................................................................................ 23

8.1.4 79, Hopper ............................................................................................................ 24

8.1.5 79, Blower F3 with cyclone AX-5.......................................................................... 25

8.1.6 Pause/pulse relay when emptying with air veyor ................................................. 26

9. Electrical scheme......................................................................................... 27

10. Layout .................................................................................................... 28-31

10.1 Dimensions ..................................................................................................28-31

11. Options .................................................................................................... 32-35

11.1 Overview ........................................................................................................... 32

11.1.1 79, all models: Third fixed knife, disassembling/assembling ............................. 33

11.1.2 79, all models: Third fixed knife, sharpening...................................................... 34

05-15-96 79 2

Page 3

1. Introduction

This manual is for CONAIR MAR TIN's 79 series granulators. The

abbreviations mean:

-B = Band conveyor -U = Suction blower

-L = Low level -V = Ejector (Air V eyor).

The manual should be studied carefully before installing and using the

equipment, in order to prevent personal injury and damage to the machinery .

Always take great care when the knives are within reach,

since they are very sharp and can cause personal injury.

CONAIR MAR TIN granulators are built for granulation of injection moulded,

blow moulded or extruded plastic waste where the granulator’s size and

performance corresponds to the type of waste. For any other products or

materials, approval must be obtained from the dealer or head-office in order for

the conditions of the guarantee to remain valid.

CONAIR

The different types of granulator are designed so that maintenance and cleaning

can be carried out quickly and simply , both during routine maintenance as well

as when changing colour or material.

All servicing work should be carried out by a person with technical training or

corresponding professional experience. The manual contains instructions for

both handling and servicing the granulator . Chapter 7, which contains servicing

instructions, is intended for service engineers. Other chapters contain

instructions for the daily operator .

Delivered with the granulator are a manual, tool kit and touch-up paint.

Any modifications, changes, or rebuilding of the granulator must be approved

by CONAIR MAR TIN in order to avoid personal injury and damage to

machinery and to ensure that the documentation remains correct.

If you have any questions, please contact your local dealer or our head-office.

05-15-96 79 3

Page 4

CONAIR

2. Technical specifications

2.1 Dimensions

See chapter 10, Layout.

2.2 Data

Serial Number

Motor power......................................................................

Capacity ......................................................................

V-belts ......................................................................

Voltage ......................................................................

Blower type (optional) .......................................................

Rotating knives .................................................................

Fixed knives ......................................................................

Screen ......................................................................

Weight:.............................................................................. -L= 185 kg

.................................................................................. -LB = 220 kg

.................................................................................. -LBU = 250 kg

.................................................................................. -LBV= 240 kg

05-15-96 79 4

Page 5

CONAIR

3. Functional description

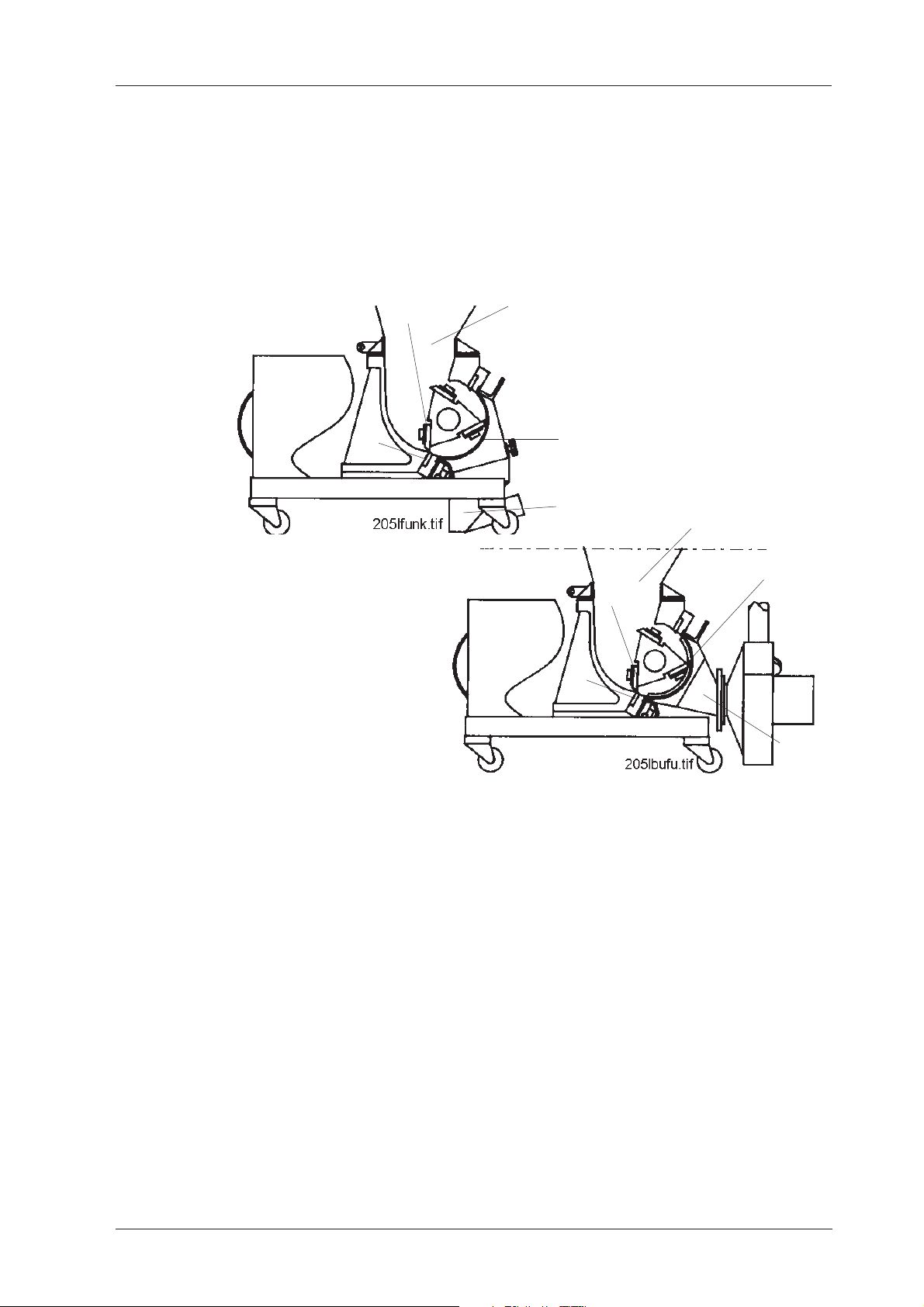

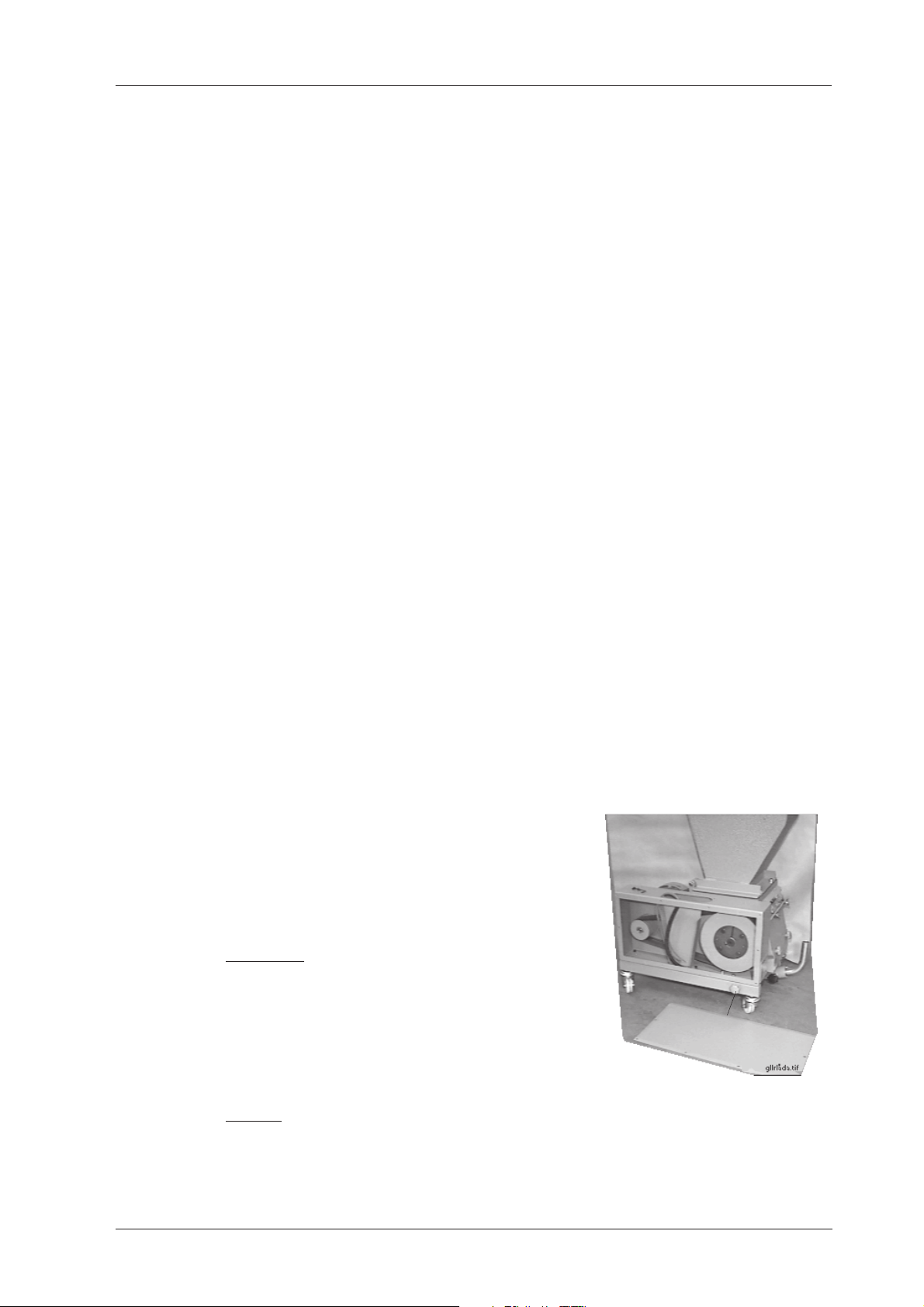

3.1 Overview

79 granulators are designed for grinding different types of plastic waste.

79

79

C

B

A

E

D

A

D

B

C

E

The granulator is controlled from an electrical cabinet with a start/stop function

and an emergency stop button.

The material is fed into the hopper (A) and falls down to the rotor. The rotor’s

knives (B) grind the material against the fixed knives (C) in the cutter housing.

Both the fixed and rotating knives can be changed or re-sharpened when

necessary . The sharpening is carried out in a special fixture outside of the

granulator .

Under the rotor is a screen (D) through which the granulate passes before it

comes down into the granule bin. The screen is available with various hole sizes

depending on the required degree of coarseness of the granulate.

The granulated material is then collected in the granule bin (E). The standard -L

model is fitted with a suction pipe. The -LBU is fitted with a suction blower

which sucks the granulate out of the granule bin. The -LBV is fitted with an

ejector (air veyor).

The granule bin, screen and screen box are designed to be removed so that the

rotor can easily be cleaned. The hopper is constructed so that it can be opened

up to allow improved access for cleaning and maintenance.

05-15-96 79 5

Page 6

CONAIR

3.2 Safety system

Since there are rotating knives inside the granulator, there is a built-in safety

system to prevent personal injury .

Emergency stop: The equipment is fitted with an emergency stop switch on the

electrical cabinet. The emergency stop is activated by pushing the button. It is

reset by turning the button in the direction of the arrow (anti-clockwise).

Safety switches: The safety system includes 2 safety switches. The switches are

located as follows:

• 1 by the hopper

• 1 by the screenbox

The system is designed so that you have to unscrew the break screw by the

screenbox to be able to open it. The break screw actuates the safety switch,

which cuts off the power so that the rotor stops before the screenbox can be

opened.

The hopper must be lowered and locked before the granulator can be operated.

The safety switch has been installed so that it is not possible to start the

granulator when the hopper is open.

05-15-96 79 6

Page 7

CONAIR

4. Safety regulations

4.1 Overview

The granulator is equipped with safety switches to prevent the front door and

the hopper from being opened during operation.

The following safety measures should always be observed when handling the

granulator:

• Always switch off the power supply using the main circuit-breaker (on

top of the electrical cabinet) before opening the granulator.

• Never put any part of your body into any openings on the granulator

unless the main circuit-breaker is in the "OFF" (=0) position.

• Always be careful when the knives are in reach since they are very

sharp. When the rotor has to be rotated manually, this must be done

with the greatest care!

• Be careful when the hopper and screenbox are opened and closed so

that no part of your body gets caught.

• The granulator cannot be started until the doors and the hopper are

locked.

4.2 Sound level

• Equivalent continuous A-weighted acoustic pressure level 79 = 83.6 dBA

Value measured 1 m from the surface of the machine and 1.6 m above the

surface of the floor during grinding of 5 litres of PE bottles (polyethylene).

05-15-96 79 7

Page 8

CONAIR

5. Installation

All instructions must be carried out in the order described, to prevent personal

injury or damage to machinery .

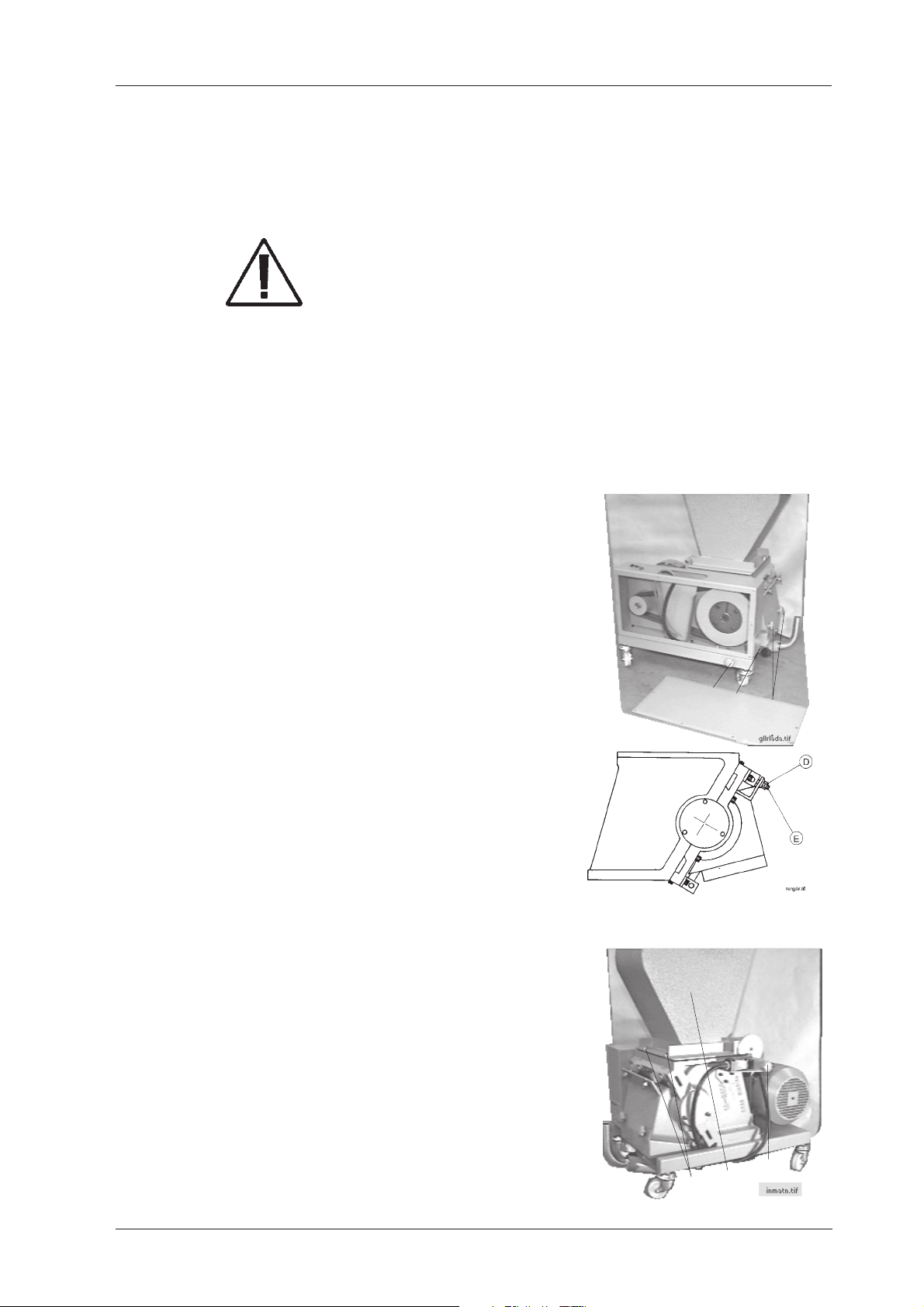

Always take great care when handling the knives since they ar e

very sharp and can cause personal injury.

The granulator should be connected to the mains supply by an

authorised electrician.

5.1 Pre-start checks

• Before the granulator is installed, the rust preventive should be carefully

cleaned from the parts which are not painted or rustproof.

5.2 Opening and closing the hopper and screenbox

Screenbox:

1. Unscrew the star knob (A) and pull out the

granule bin (B).

2. Unscrew the breakscrew (C) until the door's

stop plate is released. A safety switch is then

activated, which cuts off the current to

prevent the machine from being started when

the screenbox is open.

3. Loosen the nuts (D).

4. Raise the link screws (E).

5. Lower the screenbox and lift out the screen.

NOTE: When mounting the screenbox the link

screws' nuts (D) must be tightened quite

hard to avoid only one of the link screws

taking the whole load. Tighten them quite

hard so that the break screw turns easily.

Hopper:

C

B

A

1. Unscrew the break screw (F) on the

right side of the hopper.

2. Loosen the nuts (G).

3. Raise the hopper (I).

F

I

G

05-15-96 79 8

Page 9

CONAIR

5.3 Electrical connection

The granulator should be connected up by an authorised electrician.

• Connect the granulator to the mains supply. See Electrical scheme, chapter

9, connecting (Q1).

Check the granulator motor’s rotation direction as follows:

• Set the main circuit-breaker on the control box to position (1) = “On”.

• Check that the emergency stop switch is not activated. It can be reset by

turning the knob in the direction of the arrow (anti-clockwise).

• Check that the break screws to the

screenbox's and hopper's safety switches

are completely tightened.

• Press in the “START” push-button.

• Check that the granulator motor’s

rotation direction is consistent with the

arrow on the hood.

If a blower is connected, check that its

rotation direction is consistent with the

arrow on the blower hood.

If the rotation direction is not correct:

• Change the incoming phases.

05-15-96 79 9

Page 10

CONAIR

6. Operation and daily maintenance

6.1 Starting and stopping

The start and stop functions are controlled by a change-over button on the

electrical cabinet.

NOTE: The granulator should not be stopped until it has finished grinding all

the material in the hopper and cutter housing. Any remaining material can slow

down the rotor when it is re-started which can overload the motor and trigger

the overload protector. (See 6.4)

6.2 Inspection

There should not be any material in the granulator when the inspection is to be

carried out.

6.2.1 Daily inspection

• Flaps in the hopper. Check that the flaps are not damaged. Damaged parts

should be replaced immediately to prevent bits of the flaps from falling into

the cutter housing and damaging the knives. There is also a risk that

damaged flaps can be thrown back by the machine.

• Emergency stop. Check the emergency stop function by starting the

granulator and then stopping it using the emergency stop button. The

emergency stop is reset by turning the emergency stop button in the

direction of the arrow. The machine can then be re-started by pressing

“START”.

6.2.2 Weekly inspection

• Cables. Inspect all cabling in the machine to see that there is no wear or

other damage. For reasons of personal

protection, damaged parts should be replaced

immediately.

• Safety switches. There are two safety

switches, one for the screen box and one for

the hopper:

Screenbox: Check the safety switch by starting

the granulator and then unscrewing the break

screw (A) on the bottom of the belt guard, as

described in chapter 5.2. The granulator should

have stopped before you are able to open the

screenbox.

A

Hopper: Open the hopper as described in chapter 5.2, but close and lock the

screenbox. Check the safety switch to the hopper by starting the granulator . It

should not be possible to start the granulator until the hopper is lowered and the

break screws are screwed in.

05-15-96 79 10

Page 11

CONAIR

6.3 Cleaning

Always take great care when handling the knives since they ar e

very sharp and can cause personal injury.

1. Open the hopper and screenbox as

described in chapter 5.2.

2. Clean the hopper, flaps, screen and

screenbox and granule bin.

3. Clean the cutter-housing and inside the

stand.

4. Replace all parts in reverse order.

NOTE: When mounting the screenbox the

link screws' nuts (A) must be tightened quite

hard to avoid only one of the link screws

taking the whole load.

A

Note: Steps 2 - 4 should be carried out every time the machine is cleaned,

or at least once every 300 hours.

6.4 T rouble-shooting

6.4.1 If the granulator does not start

• Check that the saftey switches’ break screws are turned fully clockwise. It is

not possible to start the granulator unless the break screws are screwed in.

• Check that the emergency stop is not activated. It can be reset by turning the

button in the direction of the arrow.

• The bimetal relay F1 in the electrical cabinet,

according to the diagram opposite, is

released if you press stop or overload the

granulator. This is indicated by the small

green rectangular pin (P), which sticks up

above the surface of the bimetal relay. When

you reset by pressing the "Reset" button, the

pin (P) is pushed back in so that it is level

with the surface of the bimetal relay.

P

NOTE: Set the main circuit-breaker to position "0" when cleaning the

granulator. Empty the granulator of all material before restarting it.

05-15-96 79 11

Page 12

7. Servicing

All servicing work should be carried out by a qualified service engineer and in

the order described, to prevent personal injury or damage to machinery .

7.1 Changing the knives

When changing the knives, also check for any wear to the screen. For safety

reasons, this should be replaced when the holes in the screen become dropshaped.

Always take great care when handling the knives since they are

very sharp and can cause personal injury. Use protective gloves!

7.1.1 Changing the fixed and rotating knives

For safety reasons, damaged screws must be replaced.

• Open the screenbox as described in chapter 5.2.

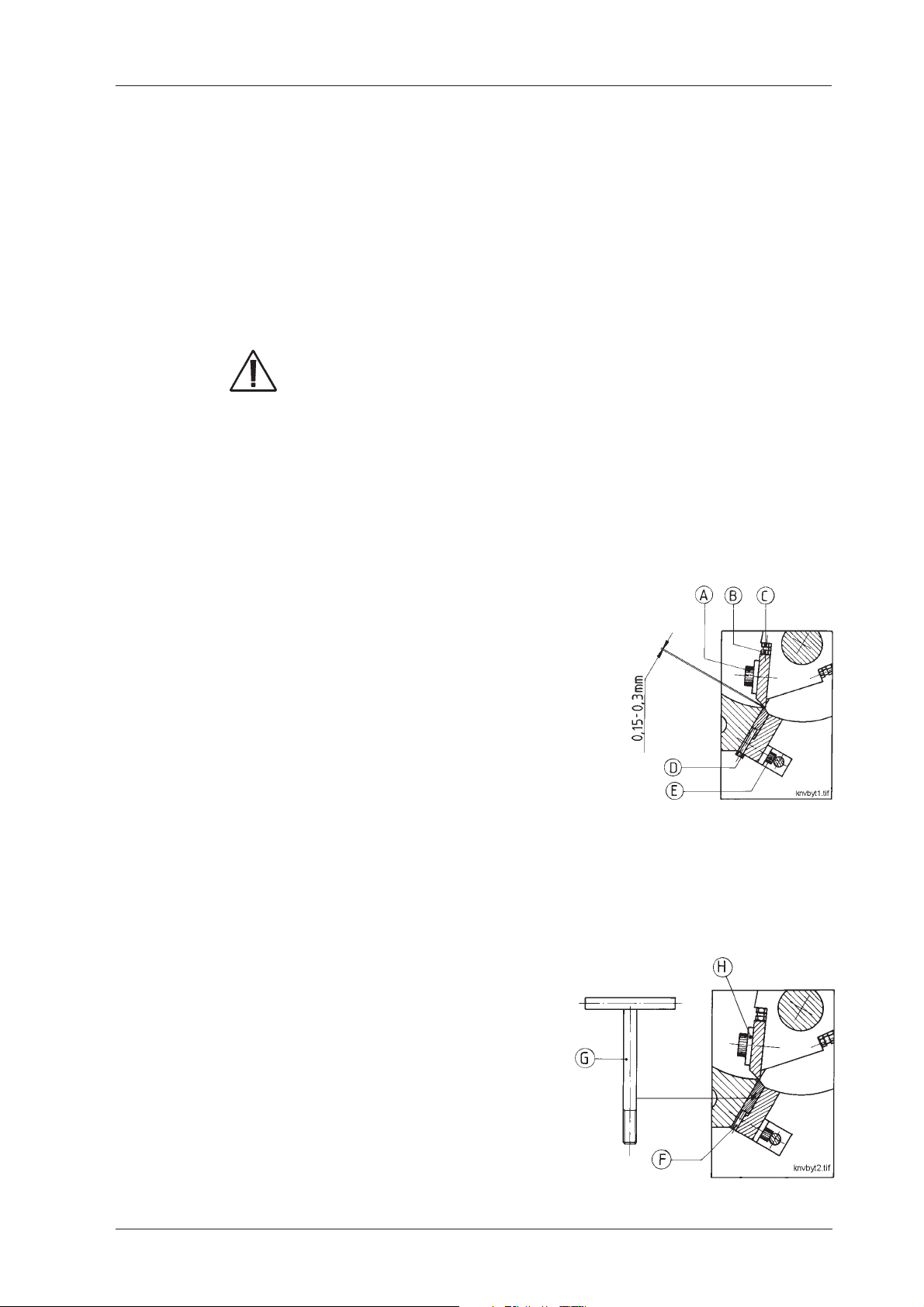

Disassembling the rotating knives (C):

CONAIR

1. Remove the fastening screws (A) and washers (H).

Disassembling the fixed knives:

1. Loosen screws (E), 5 on each long side and 2

on the short side opposite the belt guard, total

12 pieces.

2. Remove the screws (D), 2 on each fixed knife.

3. Loosen the stop screws (F), 2 on each fixed

knife.

4. Screw the special extractor (G) (in the tool kit)

into the threaded hole on the knife end and pull

out the knife.

Assembling the lower fixed knife:

1. Check that the knives and the grooves for the knives are free from plastic

waste, grease, etc.

2. Place the lower fixed knife in position.

3. Adjust the lower fixed knife to its

forward position using the adjusting

screws (F). NOTE: These screws should

only support the rear edge of the knife

and should not be tightened so much that

the knife bends.

4. Tighten the 5 screws (E) (in the diagram

above) along the lower long side with a

torque of 20 Nm.

5. Screw in and tighten the screws (D).

05-15-96 79 12

Page 13

CONAIR

Assembling the rotating knives

1. Clean the cutter's knife location and place a rotating knife in the knife

location.

2. Fasten the screws (A) together with the washers (H) and tighten gently.

3. Adjust the knife using the setting

screws (B) to give the correct

amount of play, 0.15-0.30 mm

between the fixed and rotating

knives. Check using the feeler

gauge included in the tool kit.

4. When the correct amount of play

has been obtained, tighten the

screws (A) with a torque of 200

Nm.

5. Tighten the counter nut.

6. Re-check the amount of play.

Assembling the upper fixed knife

7. Push the upper fixed knife into its

groove.

8. Turn the cutter so that the rotating

knife's cutting edge comes exactly

in front of the upper fixed knife's

cutting edge.

9. Adjust the fixed knife using the

setting screws (D) and (F). By

tightening screws (F) the knife is

moved towards the cutter's centre.

By tightening screws (D) the knife

is moved away from the cutter's

centre.

10.Tighten the 5 screws (E) along the

upper long side, and the two that were loosened on one short side.

11.Check that screws (D) and (F) by the upper fixed knife are not loose.

However, they should not be tightened too much.

12.Rotate the rotor and replace the other rotating knives according to steps 1 5 above.

13.Using a feeler gauge, check that the distance between the fixed and rotating

knives is correct. The distance should not be less than 0.15 mm.

Granulator fitted with a third fixed knife:

See instructions in chapter 11.

05-15-96 79 13

Page 14

CONAIR

7.2 Sharpening the knives

Always take great care when sharpening the knives since they

are very sharp and can cause personal injury.

7.2.1 Overview

NOTE: Use the services of a skilled person when re-sharpening the knives

and only sharpen the edges marked with the special sign! (see diagram

under 7.2.2 and 7.2.3)

The knives must be sharpened so that the correct grinding angles are obtained,

otherwise the granulator will not operate effectively with lightly cutting knives.

During sharpening, the knife must be cooled the whole time with plenty of

water and must definitely not burn or start blueing on the edge since this means

that the knife lacks durability and stability . If this occurs, the knife cannot be

repaired by further grinding down or grinding away of the blued or burnt

colour. The tempered knife may have deep deformations with possible cracking

as a consequence.

The following instructions apply only if you are using CONAIR MARTIN's

sharpening fixture 79. The sharpening fixture is intended for use in a surface

grinding machine and should be fixed on a magnetic board.

7.2.2 Sharpening the fixed and rotating knives

Fixed knives:

Regarding the third fixed knife, see chapter 11.

NOTE: Only the surfaces marked with the special sign should be sharpened.

The specified measurements apply when sharpening the knives.

• The fixed knives are fastened as shown

in the adjacent figure, left part, and the

cutting angle is sharpened at 200.

• The knives can be sharpened only as much as is

shown in the adjacent figure. After that, they are

worn out and should be replaced by new ones in

order for the granulation to be effective.

05-15-96 79 14

Page 15

CONAIR

Rotating knives:

NOTE: All rotating knives should be sharpened equally so that the cutter does

not become unbalanced.

• The rotating knife is fastened

with the stirrup (A) under the

lower part of the knife, as shown

in the adjacent figure, right part.

Ball washers should be used

when tightening. In this position

the relief angle is sharpened.

• Loosen the screws and remove

the stirrup (A), fasten the knife

again. In this position the cutting

angle is sharpened.

• The knives can be sharpened only as

much as is shown in the adjacent

figure. After that, they are worn out

and should be replaced by new ones

in order for the granulation to be

effective.

05-15-96 79 15

Page 16

CONAIR

7.3 Inspecting and adjusting the belts

The V-belts must be inspected after 30 hours’ operation.

• Loosen and remove the outer plate

on the belt guard.

• Load one of the V-belts between the

rotor pulley and the motor pulley

with 25 N in the middle of and at a

right angle to the belt. Measure the

deflection and adjust the distance

between the pulleys as necessary until the tension is correct. The V-belt

should stretch 6 mm.

Adjusting:

• Tension the belt by screwing on the flange nuts (A).

F = 25 N

l = 6 mm

A

7.4 Lubrication

The bearing is delivered filled with grease. The bearing is maintenance-free and

needs no further lubrication.

05-15-96 79 16

Page 17

CONAIR

7.5 Rotor pulley , assembling/disassembling

7.5.1 Rotor pulley

Disassembling

1. Loosen all screws a few turns.

2. Unscrew two of the screws.

3. Lubricate both screws and screw them into the disassembling holes (A).

4. Tighten both disassembling screws alternately until the flange bushing comes

loose from the hub and the unit sits freely on the axle.

5. Lift the whole unit from the axle.

Assembling

1. Clean and degrease the contact surfaces carefully.

2. Place the "flange bushing" in the hub so that the bolt holes line up with each

other.

3. Lubricate the screws. Mount all screws without tightening them completely.

4. If a key is used, it should be

placed in the key way

before the "flange bushing"

is fitted in. Check that there

is sufficient play over the

key.

5. Fit the hub with the "flange

bushing" on the axle.

6. Tighten the screws

alternately until

approximately half the torque has been reached (49/2=24.5Nm).

7. Tap lightly between the axle and the bolts on the "flange bushing". Use a

block of wood or plastic to protect against damage.

8. Continue to alternately bolt and tighten the screws once or twice until the

correct torque has been reached, i.e. 49 Nm.

05-15-96 79 17

Page 18

8. Spare parts list

8.1 Overview

8.1.1 79, Cutter housing .......................................................... 19-21

8.1.2 79 ...................................................................................... 22

8.1.3 79, ...................................................................................... 23

8.1.4 79, Hopper ........................................................................... 24

8.1.5 79, Blower F3 with cyclone AX-5 ....................................... 25

8.1.6 Pause/pulse relay when emptying with air veyor ................. 26

8.2 Ordering spare parts

Only use spare parts from CONAIR MAR TIN when replacing machine parts.

Orders should go to the representative in the country where the machine was

purchased.

CONAIR

Page

When ordering, the following should be specified:

• machine designation, as specified on the machine plate

• serial number, as specified on the machine plate

• article number, as specified in the spare parts list

• quantity, as specified in this spare parts list.

05-15-96 79 18

Page 19

CONAIR

8.1.1 79, Cutter housing, all models

1 1 9-30172 10 1 9-50082 19 2 4-02411

2 3 9-30075 11 1 2-14198 20 2 9-50066

3 1 9-90017 12 3 3-08107 21 2 4-08108

4 6 9-40054 13 1 4-02406 22 1 2-02534

5 1 4-02403 14 1 4-02408 23 2 4-02409

6 2 9-60034 15 1 9-40139 24 1 3-02414

7 1 4-02405 16 1 4-02404 25 1 2-07660

8 2 4-02407 17 2 9-40158 (25 1 2-15797

Pos Qty. Part no. Pos Qty. Part no. Pos Qty. Part no.

05-15-96 79 19

9 1 2-02534 18 2 4-02412 for 79)

Page 20

CONAIR

8.1.1 79, Cutter housing, all models

05-15-96 79 20

Page 21

CONAIR

8.1.1 Cutter housing, all models, continued

Pos Qty. Part no.

A 6 9-40165

B 6 9-40150

C 6 9-40203

D 4 9-40161

E 6 9-40140

E 8 9-40054

F 4 9-40160

G 1 4-02531

H 6 4-11835

05-15-96 79 21

Page 22

8.1.2 79

CONAIR

1 1 2-12112 13 2 9-91255

2 1 9-50353 14 2 4-13022

Pos. Qty. Part no. Pos. Qty. Part no.

3 1 2-11756 15 1 3-13561

4 4 9-50071 16 1 4-16677

5 1 4-12109 17 1 4-04229

6 1 4-12890 23 2 4-02292

7 1 4-13129 24 1 4-14226

8 1 4-13128 25 1 3-17241

9 1 9-10651 26 1 4-17242

11 1 2-12888 28 1 3-09076

10 1 9-11034 27 2 4-01016

12 1 4-12891 32* 1 3-11733

*only for 79

05-15-96 79 22

Page 23

8.1.3 79

CONAIR

3 1 2-11756 13 2 9-91255

4 4 9-50071 14 2 4-13022

Pos. Qty. Part no. Pos. Qty. Part no.

5 1 4-12109 15 1 3-13561

6 1 4-12890 16 1 4-16677

7 1 4-13129 17 1 4-04229

8 1 4-13128 23 2 4-02292

9 1 9-10651 24 1 4-14226

10 1 9-11034 25 1 3-17241

11 1 2-12888 26 1 4-17242

12 1 4-12891 27 2 4-01016

05-15-96 79 23

Page 24

CONAIR

8.1.4 79, Hopper

79

Pos. Qty. Part no.

29 1 9-11034

30 1 2-13737

31 1 3-13742

79

Pos. Qty. Part no.

29 1 9-11036-10

30 1 2-15799

31 1 9-10789

79

Pos. Qty. Part no.

29 1 9-11038

30 1 2-15799

31 1 9-10789

79

Pos. Qty. Part no.

29 1 9-11036-11

30 1 2-15799

31 1 9-10789

05-15-96 79 24

Page 25

CONAIR

8.1.5 79, Blower F3 with cyclone AX-5

Pos. Qty. Part no.

1 1 2-10593

2 1 9-20480

3 1 3-17772

4 1 2-15838

5 1 2-15831

6 1 9-20485

7 1 4-15930

8 1 3-15795

05-15-96 79 25

Page 26

CONAIR

8.1.6 Pause/pulse relay when emptying with air veyor

In those cases when emptying of the granule bin with an air veyor has been

chosen, the pause/pulse relay should be cancelled to prevent a glut in the

granule bin.

When delivered, the relay is preset

as follows:

T1 = range 1 - 10 m

T2 = range 6 - 60 s

where

Pause time T1 (the time the air

veyor is idle) is selected using

switches (A) and (B). Then the

time is set using the handwheel

T

= T1.

off

Delay time interval T2 (the time

the air veyor is working) is

selected using switches (C) and

(D). Then the time is set using the handwheel Ton = T2.

05-15-96 79 26

Page 27

CONAIR

9. Electrical scheme

05-15-96 79 27

Page 28

10. Layout

10.1 Dimensions

10.1.1 79 ...................................................28

10.1.2 79 ....................................................29

10.1.3 79 ....................................................30

10.1.4 79 ....................................................31

10.1.1 79

CONAIR

Page

05-15-96 79 28

Page 29

10.1.2 79

CONAIR

05-15-96 79 29

Page 30

10.1.3 79

CONAIR

05-15-96 79 30

Page 31

10.1.4 79

CONAIR

05-15-96 79 31

Page 32

11. Options

11.1 Overview

11.1 Overview ..................................................................................................32

11.1.1 79, all models: Third fixed knife,

11.1.2 79, all models: Third fixed knife, sharpening ....................... 34

11.1.3 79, Hopper with band conveyor........................................... 35

Ordering spare parts

Only use spare parts from CONAIR MAR TIN when replacing machine parts.

Orders should go to the representative in the country where the machine was

purchased.

CONAIR

Page

disassembling/assembling ..................................................... 33

When ordering, the following should be specified:

• machine designation, as specified on the machine plate

• serial number, as specified on the machine plate

• article number, as specified in the spare parts list

• quantity, as specified in this spare parts list.

05-15-96 79 32

Page 33

CONAIR

11.1.1 79, all models: Third fixed knife, disassembling/

assembling

Pos. Qty. Part no.

1 1 1-19022

2 1 2-17732

3 1 2-17733

4 2 9-40106

5 2 9-40302

6 1 3-19021

7 2 9-40075

8a 2 9-50086

8b 2 9-50214

9 2 9-40050

Disassembling

1. Unscrew the screws (4) and release the ruler (3).

2. Lift out the knife (6).

Assembling

1. Clean any grease or plastic waste from the knife location.

2. Position the fixed knife (6) with the adjusting screw (5) and press against the

rear edge.

3. Adjust to obtain the correct amount of play between the fixed and rotating

knife using the adjusting screws (5).

4. Using a feeler gauge, check that the correct amount of play, 0.15 - 0.30 mm,

has been obtained.

5. When the amount of play is correct, place the ruler (3) with the screws (4)

on the knife and tighten with a torque of 100 Nm.

05-15-96 79 33

Page 34

CONAIR

11.1.2 79, all models: Third fixed knife, sharpening

0

20

The third fixed knife is fastened in the left

position in the 79 fixture and sharpened to

its correct relief angle, 200. See next

diagram.

Then the knife is fastened in the 79 fixture and

is sharpened to its correct cutting angle, 150.

NOTE: Turn the knife so that the correct

surface is sharpened.

15

0

05-15-96 79 34

Page 35

CONAIR

11.1.3 79, Hopper with band conveyor

Disassembling/Assembling the band conveyor

Disassembling

1. Release the fastening screw (A). This

is done most easily by unscrewing the

nut on the under side. The vibration

absorber is then released.

2. Release the hood over the screw (B)

and remove the screw.

3. Pull the worm-gear unit motor off the

shaft.

4. Release the shaft gears by unscrewing

the two screws (C) on each side of the hopper funnel.

5. Loosen the band conveyor's height

setting by unscrewing the screw which

fastens the height setting by the guide

pin (D).

6. Release the shaft gears and move the

band conveyor to the right so that the

left shaft goes free from the hub. Turn

the band conveyor to the right until the

shaft end goes free from the hopper

funnel.

Move the band conveyor to the left

until the motor shaft end goes free

from the hopper funnel. The band

conveyor can then be released.

B

A

D

C

05-15-96 79 35

Page 36

CONAIR

12. Transporting and storing

12.1 Overview

Handling and transporting of the machinery should be carried out by specially

trained personnel.

The machine is packed in weather-proof and partly shock-proof plastic sheeting.

It is fixed with straps to a pallet for transportation.

12.1.1 Unpacking and checking

• Check that the machine has not been damaged in transit. Report any damage

to the forwarder.

• Do not unpack the machine until it has been moved to its installation

location.

• After unpacking, check that the delivery is complete by checking against the

delivery note.

12.1.2 Lift and transport to installation location

For information about the machine's weight, refer to chapter 2, Technical data.

For information about the space required, refer to chapter 10, Layout.

The machine can be lifted and handled using a fork-lift truck.

12.1.3 Placing at the installation location

See chapter 5, Installation.

12.2 Storing

Normally , the machine is pre-packed for transport to the installation location

where it is to be put into operation immediately . Therefore, it is only protected

with rust-preventive oil.

12.2.1 Long-term storage

• The machine should be kept in a storage area with constant temperature and

humidity.

• Before storing for a long time, the machine should be given a coating of

long-term rust preventive, for example Castrol DWX 160 with durability 24

- 36 months in a suitable storage area.

12.2.3 Preservation

The machine is protected with rust-preventive oil Castrol DWX 22 on all

surfaces which are not painted or rust-free.

12.2.4 Durability

The rust protection from the rust-preventive oil Castrol DWX 22 is effective for

up to 12 months if the conditions described in 12.2.1 are fulfilled.

05-15-96 79 36

Page 37

Loading...

Loading...