Conair Carousel Plus W Series, Carousel Plus W300, Carousel Plus W200, Carousel Plus W150, Carousel Plus W400 User Manual

Page 1

U S E R G U I D E

UG D 05 1-0 4 14

Carousel Plus Dryer

W Series Models 150, 200, 300 and 400 with DC-T Controls

www.conairgroup.com

Corporate Office: 724.584.5500 l Instant Access 24/7 (Parts and Service): 800.458.1960 l Parts and Service: 814.437.6861

Page 2

Please record your equipment’s

model and serial number(s) and

the date you received it in the

spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and the date

you received it in the User Guide. Our service department uses this information, along with

the manual number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists together for

documentation of your equipment.

Date:

Manual Number: UGD051-0414

Serial Number(s):

Model Number(s):

*Display firmware Version:

*Display Menu Version:

* Control Firmware Version:

✐

NOTE: Displayed upon initialization, during power up, or on a data tag inside the door.

DISCLAIMER: Conair shall not be liable for errors contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this information. Conair makes no

warranty of any kind with regard to this information, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

C o p y ri g ht 20 14 l Co n ai r l A l l ri gh t s re se rv ed

Page 3

Ta b l e o f C o ntents

1-1 I ntr o d uct i o n

Purpose of the User Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the Guide Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the Carousel Plus W Series as a Central Dryer. . . . . . . . . . . . . . . . . . . 1-2

Your Responsibility as a User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

How to Use the Lockout Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 D esc r i pti o n

What is the Carousel Plus W Series Dryer?. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

How the Carousel Plus W Series Dryer Works . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Specifications: Carousel Plus W Series Dryer . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Carousel Plus W Series Dryer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3-1 I nst a l lat i o n

Unpacking the Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Positioning the Dryer on the Floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the Cable Tie from the Desiccant Wheel . . . . . . . . . . . . . . . . . . . . 3-3

Connecting the Main Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connecting the RTD probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Connecting the Setback RTD Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Checking for Proper Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting the Air Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting the Dryer to the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting Air Hose Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connecting the Aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Mounting a Loader on the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Using Communications (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4-1 O per a t ion

The Dryer System control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

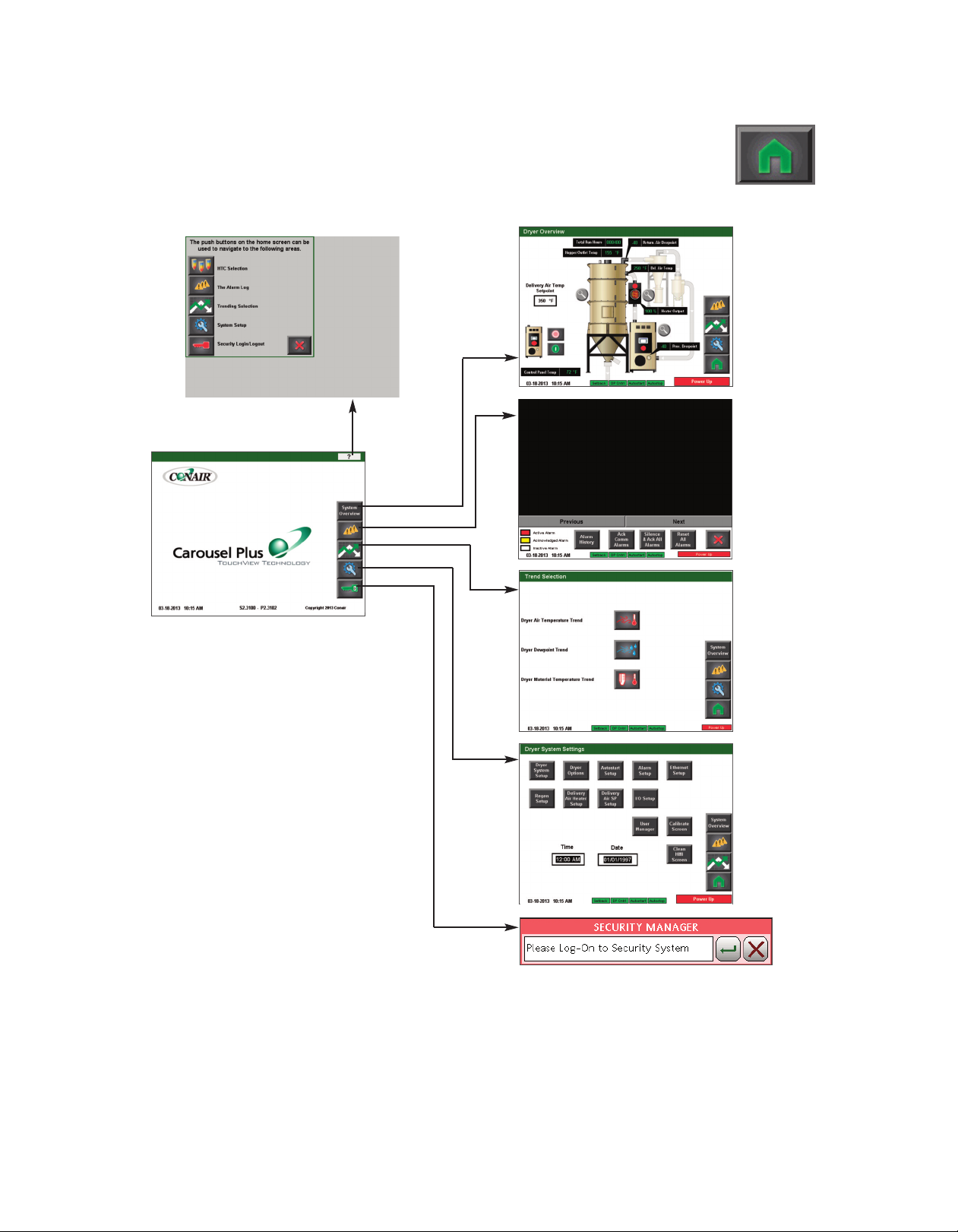

How to navigate the control screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

DC-T Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Ta b le o f Co nt en ts l i

Page 4

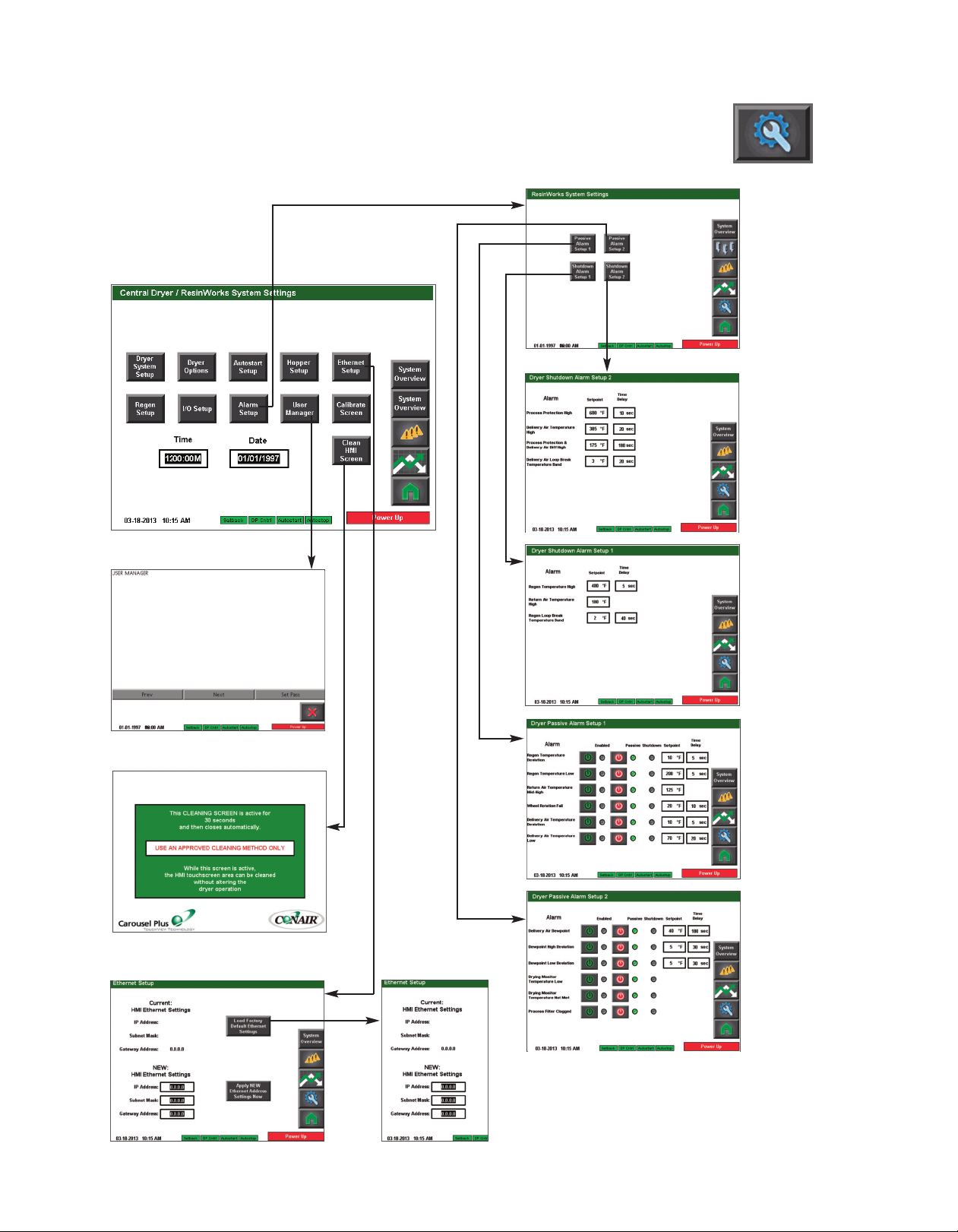

Operation - ResinWorks Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

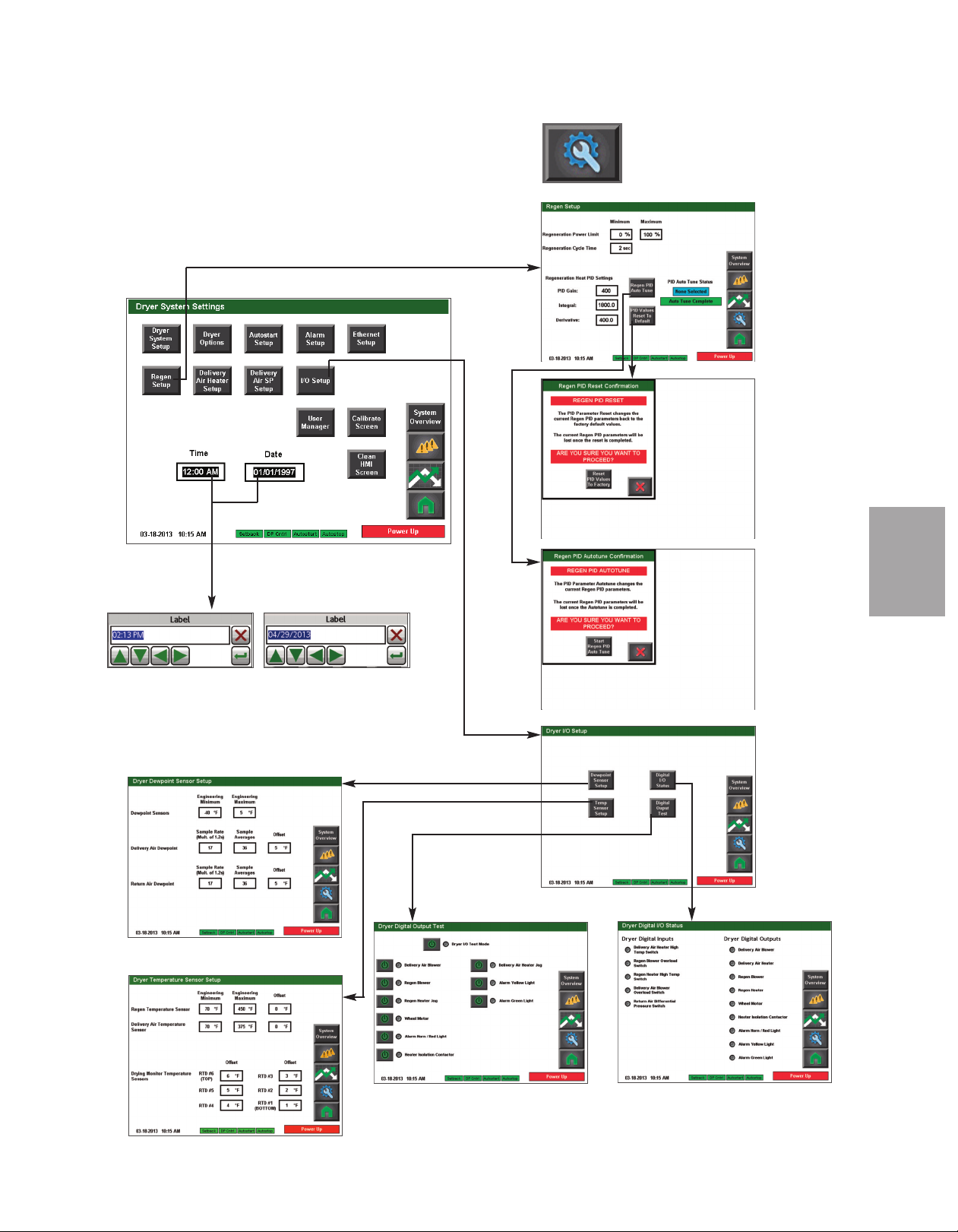

Control Function Flow Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Control Function Descriptions - ResinWorks Configuration. . . . . . . . . 4-16

Operation - Stand Alone Dryer Configuration . . . . . . . . . . . . . . . . . . . . . 4-45

Control Functions Flow Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Control Function Descriptions - Stand Alone Configuration . . . . . . . . 4-56

General Operation - Stand Alone and

ResinWorks Dryer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-81

DC-T Security Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

Starting the Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Adjusting the temperature setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

Stopping the Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Stopping the Dryer in an emergency . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Understanding the Control LED Lights . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Alarm Email and Text Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Ethernet TCP/IP Adress Setup to Enable Email/Text Notification . . . . . 4-87

Email Alarm Activation and Address Setup. . . . . . . . . . . . . . . . . . . . . 4-88

Configuring the Email and Text Addresses . . . . . . . . . . . . . . . . . . . . . 4-89

Text Messaging Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

Enabling and Disabling Notification for Individual Alarms . . . . . . . . . . 4-90

DC-T Web Access Logon and Security . . . . . . . . . . . . . . . . . . . . . . . . 4-94

Web Server Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-95

5-1 Ma inten an ce

Preventative Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Checking Dewpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Cleaning the Process Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Cleaning the Regeneration Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Cleaning the Aftercooler Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Cleaning the Precooler Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Cleaning the Volatile Trap on the Demister. . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Inspecting Hoses and Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Cleaning the DC-T HMI Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

i i

l Tab l e of C on te nt s

Page 5

6-1 Tr ou bl eshoo ti ng

Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A Few Words of Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Diagnostics

How to Identify the Cause of a Problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Shutdown Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Passive Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Additional Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Dewpoint Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Poor Material Drying Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Repair

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Checking Heater Solid State Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Checking or Replacing Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . 6-32

Replacing the Heaters

Regeneration Heater Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Process Heater Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Replacing the Desiccant Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Replacing the Desiccant Wheel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

A A ppe n d ix

We’re Here to Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to Contact Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Before You Call... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equipment Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Warranty Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

B A ppe n d ix

Installing a Precooler (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C A d den d u m

DC-T Modbus TCP/IP Read Only Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Ta b le o f Co nt en ts l ii i

Page 6

i v l Ta b l e of C on te nt s

Page 7

I n troduc t i o n

P u r p o s e of t he U se r Gui de . . . . . . . . . . . . . . . . . 1 - 2

H o w t he Gu id e Is Or ga ni ze d . . . . . . . . . . . . . . . . 1 - 2

U s i n g the Ca ro us el P l u s W S er ie s

a s a C e n t r a l Dr ye r . . . . . . . . . . . . . . . . . . . . 1- 2

S E C T I O N

1

I n tro d uc ti o n

1

Yo ur Re sp on si bi li ti es a s a U se r . . . . . . . . . . . . . . 1 -3

A t t e n t i o n : R ea d Th is s o No One Ge ts H ur t . . . . . . . 1- 4

H o w t o U se t he Lo ck ou t De vi ce . . . . . . . . . . . . . . 1- 6

I n t r od u ct i on l 1 - 1

Page 8

P u r p o s e o f t h e U ser Gu i d e

This User Guide describes the Conair Carousel Plus W Series Dryers and explains step-bystep how to install and operate, maintain, and repair this equipment.

Before installing this product, please take a few moments to read the User Guide and review

the diagrams and safety information in the instruction packet. You also should review manuals covering associated equipment in your system. This review won’t take long, and it could

save you valuable installation and operating time later.

H o w t h e G u i d e i s O r g an i z e d

Symbols have been used to help organize the User Guide and call your attention to important

information regarding safe installation and operation.

Symbols within triangles warn of conditions that could be hazardous to users or could damage equipment. Read and take precautions before proceeding.

Numbers indicate tasks or steps to be performed by the user.

1

A diamond indicates the equipment’s response to an action performed by the user.

◆

An open box marks items in a checklist.

❒

A circle marks items in a list.

•

Indicates a tip. A tip is used to provide you with a suggestion that will help you with the maintenance and

✒

the operation of this equipment.

✐

Indicates a note. A note is used to provide additional information about the steps you are following

throughout the manual.

U s i n g t h e C a r ou s e l P l u s W S e r i es a s a

C e n t r a l D r y e r

This manual incorporates the information necessary to use the Conair Carousel Plus W

Series dryer as a central dryer. Throughout this manual, information particular to central

dyer application of the W Series dryer is called out by the following treatment.

This box will contain information or highlight system differences particular to the application of the W series dryer as a central dryer.

1 - 2 l In tr o du ct i on

Page 9

Yo

u r

R e

s

p o

n s

i b i l i t

r

e

U s

a

s

a

y

Yo

m

• T

• T

• T

• S

ai

ap

i

d

, an

n

o

i

at

er

p

, o

n

o

i

at

l

al

st

n

i

g

n

i

n

er

c

n

co

es

r

u

d

ce

o

r

p

y

et

saf

l

al

h

t

i

w

r

a

i

l

i

am

f

e

b

st

u

m

u

:

e

d

u

cl

n

i

es

r

u

d

ce

o

r

p

y

et

saf

e

l

b

si

n

o

sp

. Re

t

en

m

p

i

u

eq

s

i

h

t

f

ce o

an

n

e

t

n

s,

g

n

i

n

war

d

zar

a

h

o

t

n

o

i

t

en

t

at

r

a

l

cu

i

t

r

a

p

g

n

i

ay

e, p

d

i

Gu

User

s

i

h

t

f

o

ew

i

ev

r

h

g

u

o

r

o

h

s.

am

r

ag

i

d

ed

at

el

r

d

an

ces,

i

d

en

p

ces,

r

u

e so

ag

t

l

vo

o

t

n

o

i

t

en

t

t

a

l

u

ef

ar

c

h

t

, wi

f

sel

t

i

t

en

m

p

i

u

eq

e

h

t

f

o

ew

i

ev

r

h

g

u

o

r

o

h

s.

el

b

a

l

g

n

i

n

war

d

n

se a

u

ed

d

n

e

t

n

.

t

en

m

p

i

u

eq

ed

t

a

i

c

sso

a

r

o

f

s

al

u

an

m

n

o

i

ct

u

r

t

s

n

i

f

o

ew

i

ev

r

h

g

u

o

r

o

h

e.

d

i

Gu

s User

i

h

t

n

i

d

e

n

i

l

t

u

o

s

n

o

i

t

c

u

r

st

n

i

o

t

e

c

n

e

r

e

h

ad

ep

st

-

y

b

-

ep

t

I n tro d uc ti o n

1

I n t r od u ct i on l 1 - 3

Page 10

AT T E N TI O N :

R e a d T h i s S o N o O n e G e t s H urt

We design equipment with the user’s safety in mind. You can avoid the potential hazards

identified on this machine by following the procedures outlined below and elsewhere in the

User Guide.

WA RN IN G: I mp ro pe r i ns ta ll at io n, o p e r a t i o n , o r s er vi c i n g may re su lt i n equ ip me nt da ma ge o r per so na l

i n j u r y.

This equipment should be installed, adjusted, and serviced by qualified technical personnel who are familiar with the construction, operation, and potential

hazards of this type of machine.

All wiring, disconnects, and fuses should be installed by qualified electrical

technicians in accordance with electrical codes in your region. Always maintain

a safe ground. Do not operate the equipment at power levels other than what is

specified on the machine serial tag and data plate.

WA RN IN G: V ol ta ge h az ar d

This equipment is powered by three-phase alternating current, as specified on

the machine serial tag and data plate.

A properly sized conductive ground wire from the incoming power supply must

be connected to the chassis ground terminal inside the electrical enclosure.

Improper grounding can result in severe personal injury and erratic machine

operation.

Always disconnect and lock out the incoming main power source before opening the electrical enclosure or performing non-standard operating procedures,

such as routine maintenance. Only qualified personnel should perform troubleshooting procedures that require access to the electrical enclosure while

power is on.

1 - 4 l In tr o du ct i on

Page 11

AT T E N TI O N :

R e a d T h i s S o N o O n e G e t s H urt

We design equipment with the user’s safety in mind. You can avoid the potential hazards

identified on this machine by following the procedures outlined below and elsewhere in the

User Guide.

( c o nt i nu ed )

CA UT IO N: H ot Su rfa ce s.

Always protect yourself from hot surfaces inside the dryer and hopper. Also

exercise caution around exterior surfaces that may become hot during use.

These include the hopper door frame, the exterior of an uninsulated hopper, the

return air hose and the dryer’s process filter housing and moisture exhaust outlet.

WA RN IN G: D o n ot p la ce ae ro so l, c o m p r e s s e d ga s o r

f l a m m a b l e mat er ia l s on o r nea r t hi s eq u i p m e n t .

The hot temperatures associated with the drying process may cause aerosols or

other flammable materials placed on the dryer or hopper to explode.

I n tro d uc ti o n

1

I n t r od u ct i on l 1 - 5

Page 12

H o w t o U s e t h e L o c k o ut De v i c e

CAUTION: Before performing maintenance or repairs on this product, you should discon-

nect and lockout electrical power sources to prevent injury from unexpected energization or

start-up. A lockable device has been provided to isolate this product from potentially hazardous electricity.

Lockout is the preferred method of isolating machines or equipment from energy sources.

Your Conair product is equipped with the lockout device pictured below. To use the lockout

device:

1

Stop or turn off the equipment.

2

Isolate the equipment from the electric power. Turn the rotary

disconnect switch to the OFF, or “O” position.

3

Secure the device with an assigned lock or tag. Insert a lock or tag

in the holes to prevent movement.

4

The equipment is now locked out.

WARNING: Before removing lockout devices and returning switches to the ON position, make sure that all personnel are clear of the machine, tools have been

removed, and all safety guards reinstalled.

To restore power to the dryer, turn the rotary disconnect back to the ON position:

1

Remove the lock or tag.

2

Turn the rotary disconnect switch to the ON or “I” position.

1 - 6 l In tr o du ct i on

Page 13

S E C T I O N

2

D e script i o n

W h a t is th e Ca ro us el Pl us W Ser i e s Dr ye r? . . . . . . . 2- 2

Typ ic al A pp li ca t i o n s . . . . . . . . . . . . . . . . . . . . . . 2- 2

H o w I t Wo r k s . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -4

S p e c i f i c a ti on s: C a r o u s e l Pl us W S er ie s

D r y er . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 6

C a r o u s e l Pl us W S er ie s D ry er Op ti on s . . . . . . . . . . 2- 7

D e scr i pt io n

2

D e s c ri p ti o n l 2 - 1

Page 14

W h a t i s t h e C a r o use l P l u s W S e r i e s

D r y er?

The Carousel Plus W Series dehumidifying dryer produces hot, low-dewpoint air that

removes moisture from hygroscopic plastics. The dryer pulls warm, moist air from a drying

hopper and circulates it through a dehumidifying desiccant wheel. The dryer then heats the

air to the drying temperature you selected and circulates it through the material in the hopper.

The dryer’s closed-loop design ensures a continuous supply of hot, dehumidified air while

preventing contamination from moisture in the plant.

Ty p i c al Ap p l i c a ti o n s

1 Dryer on the floor; hopper on the throat.

2 Hopper on a floor stand; the dryer next to it.

3 Dryer on the floor, multiple hoppers in central configuration (ResinWorks) with separate

heat source for each hopper.

When supplied for central drying applications,

the W series dryer is not equipped with a

process heater. Therefore, as a central dryer,

the W dryer will only supply dry air to the

hoppers.

2 - 2 l De sc r ip ti o n

( C o nt i nu ed )

Page 15

Ty p i c al Ap p l i c a ti o n s ( co n ti nu ed )

The W Series Dryer can be used successfully in applications that require:

• A contamination-free drying environment.

• Drying temperatures within the ranges shown in the following table:

Model Drying Temperature Range

Low temperature (with precooler)* 100° - 150°F {38° - 66°C}

Standard 150° - 240°F {66° - 116°C}

High heat (with aftercooler)* 150° - 375°F {66° - 191°C}

Low-high (with aftercooler & precooler)* 100° - 375°F {38° - 191°C}

* See page 3-13 and Appendix B and C.

• Throughput rates of 150 to 400 lbs {68.1 to 149.2 kg} per hour (some materials can be -

run at a higher rate).

• Dewpoints of -40°F {-40°C}.

Use the aftercooler when:

• You are drying at temperatures over 240°F {116°C}.

• Throughput rates are less than 50% of the dryer’s rated capacity.

• You are pre-drying material at temperatures over 150°F {66°C}

Standard Dryer Features

• Dewpoint monitor / dewpoint control

• Audible and visual alarm

• Temperature setback

D e scr i pt io n

2

D e s c ri p ti o n l 2 - 3

Page 16

H o w I t Work s

The W dryer achieves continuous, closed loop drying by passing air simultaneously through

two heaters and a continuously rotating desiccant wheel.

THE PROCESS (DRYING) CYCLE

The process blower pulls moist air from the top of the drying hopper. The air passes

through the process filter and aftercooler into the desiccant wheel, where moisture is

removed. The now dry air moves through the optional precooler (if installed) and process

heater, where it is heated to the drying temperature selected by the operator. The hot, dry air

is delivered to the hopper where a spreader cone evenly distributes the air through the material.

THE PROCESS (DRYING) CYCLE

The process blower pulls moist air from the top of the drying hopper. The air

passes through the process filter and aftercooler, then into the desiccant

wheel, where moisture is removed. The dry air is delivered to the hopper

(after it passes through the optional precooler, if installed) where a spreader

cone evenly distributes the air through the material.

The Regeneration Cycle

The regeneration blower pulls air through the regeneration filter into the dryer’s regeneration

heater. The air is heated to 350° F {177° C} before it is pushed into the “wet” section of the

wheel. The hot air purges moisture from the desiccant. The moist air is blown out the

exhaust at the back of the dryer.

The Cooling Cycle

Regenerated desiccant must be cooled before it rotates back into the process cycle. The

process blower pushes a small amount of air through the cooling section of the desiccant

wheel. The cooling air then passes through the aftercooler and repeats the circuit.

2 - 4 l De sc r ip ti o n

Page 17

R

EGENERATION

AIR FILTER

DESICCANT

WHEEL

REGENERATION

BLOWER

REGENERATION

H

EATER

HIGH TEMP

SHUTOFF

REGENERATION

RTD

HOPPER

PROCESS

BLOWER

RETURN

AIR

FILTER

4 PROCESS FILTER STATUS

RETURN

AIR

RTD

P

ROCESS

R

TD

2 SETBACK TEMPERATURE

H

IGH TEMP

SHUTOFF

PROCESS

HEATER BOX

7 PRECOOLER

7

DRYER OPTIONS

3 DEWPOINT MONITOR / CONTROL

PROCESS

COOLING

REGENERATION

2

3

4

P

ROCESS

P

ROTECTION

R

TD

REGENERATION

OUTLET

RTD

6

6 PHASE ROTATION PROTECTION

AFTERCOOLER

A

LARM LIGHT

A

LARM BELL

5 CURRENT METER

5

5

1 PROCESS CFM MONITOR

1

H o w I t Work s ( c o nt i nu ed )

D e scr i pt io n

2

The components identified by this type of box in the drawing are not supplied with the

W series dryer when it is configured as a central dryer.

D e s c ri p ti o n l 2 - 5

Page 18

S p e c i f ic a t i o n s: C ar o u s e l P l us W S e ri e s

D r y ers

A

B

C

MODEL W150 W200 W300 W400

Performance characteristics (with full hopper)

Drying temperature

†

All models 100°- 375°F {38°- 191°C} with options

Dew point All models -40°F {-40°C}

Dimensions inches {cm}

A - Height 64.3 {163.3}

B - Overall width 29 {73.7}

C - Depth 51.5 {130.8}

Outlet/inlet tube size OD 2.5 {63.5} 5.0 {127.0} 5.0 {127.0} 5.0 {127.0}

Weight lbs {kg}

Standard dryer installed 600 {272} 660 {300} 710 {322} 760 {345}

Voltage - Full load amps Standard/Central drying

230 V/3 phase/60 Hz 47.1 / 16.7 57.6 / 19.9 67.7 / 30.0 N/A

400 V/3 phase/50 Hz

*

23.4 / 8.9 32.1 / 10.4 37.9 / 16.2 64.5 / 21.1

460 V/3 phase/60 Hz 21.0 / 8.4 28.9 / 10.0 34.0 / 15.1 56.3 / 18.6

575 V/3 phase/60 Hz 16.8 / 6.7 23.7 / 8.6 27.3 / 12.2 43.2 / 13.0

Water requirements {for aftercooler or optional precooler}

Recommended temperature

Water flow

Water connections NPT 3/4 inch NPT

SPECIFICATION NOTES:

gal./min.{liters/min.}

‡

45°- 85°F

3 {11.4}

†

* Dryers running at 50 Hz will have 17% less airflow, and a 17% reduction in material throughput.

†

When drying below 150°F {66°C} a precooler is required.

‡

Temperatures above or below the recommended levels may affect dryer performance.

Tower, chiller or municipal water sources can be used.

Specifications may change without notice. Consult a Conair representative for the most current information.

APPLICATION NOTES:

All dryers are supplied with an aftercooler

as standard. The aftercooler reduces the

temperature of the return air from the drying hopper, improving the efficiency of the

desiccant. The aftercooler must be connected with the proper water flow rate and temperature to attain the rated throughput.

When to use central models

Central dryers do not have process

heaters. These models should be used

when drying multiple materials that

require different drying temperatures.

Central models dehumidify the process

air, which is then heated to the correct

setpoint by a Heater Pack mounted on the

hopper and controlled from the dryer.

When to use additional filtration

The standard return air cartridge filter is

sized for the airflow of each dryer model

and is suited for most applications. You

should consider adding an optional dust

collector and/or volatile trap if:

●

The material contains excessive fines. An

additional dust collector or cyclone will

extend time between filter cleaning.

●

The material produces volatiles during

drying which condense into a waxy or

oily residue. A volatile trap will help to

protect the desiccant.

2 - 6 l De sc r ip ti o n

TPDX018-0113

Page 19

C a r o u s el P lu s W Ser i e s D r y e r O p t i o n s

• Volatile trap (only in conjunction with aftercooler) - The volatile trap is recommended if

drying materials that produce volatile that condense into a waxy or oily residue and/or if

the material contains excessive fines.

• Precooler - The precooler reduces the temperature of air flow after the desiccant wheel

and before the process heater.

• Filter check - The Filter check sensor will activate a passive alarm when the process

filter is clogged or needs to be replaced.

• Heater current monitor - The heater current monitor measures the total amperage

across both the process and regeneration heaters and the pre-determined power consumption values for the blowers and the control.

• CFM monitor - The CFM monitor measures the cubic feet per minute of airflow across

the inlet/outlet of the process blower.

• DeviceNet or SPI communications - Allows the dryer to be networked to industrial con-

trol systems. DeviceNet communications are standard. Alternate communications are

available.

D e scr i pt io n

2

( C o nt i nu ed )

D e s c ri p ti o n l 2 - 7

Page 20

2 - 8 l De sc r ip ti o n

Page 21

I n stalla t i o n

U n p a c k i n g the Bo xe s . . . . . . . . . . . . . . . . . . . . . 3- 2

P r e p a r i n g for In st al la ti on . . . . . . . . . . . . . . . . . . 3- 3

Po si ti on in g t he D r y e r on t h e Fl oo r . . . . . . . . . . . . 3 -3

R e m o v i n g th e C a b l e Ti e fr om th e D e s i c c a n t Wh ee l . . 3 - 3

S E C T I O N

3

I n sta l la ti on

3

C o n n e c t i n g th e M a i n Po we r . . . . . . . . . . . . . . . . . 3- 4

C o n n e c t i n g th e P r o c e s s RT D Pro be . . . . . . . . . . . . 3 -5

C o n n e c t i n g th e S e t b a c k RT D Pro be . . . . . . . . . . . . 3 -5

C h e c k i n g fo r P r o p e r A ir Fl ow . . . . . . . . . . . . . . . . 3 -6

C o n n e c t i n g th e Ai r Ho se s . . . . . . . . . . . . . . . . . . 3 - 9

C o n n e c t i n g th e D r y er t o the Ho pp er . . . . . . . . . . . 3 -9

C o n n e c t i n g A ir Ho se A d a pt er s . . . . . . . . . . . . . . 3 -1 0

C o n n e c t i n g th e Af te rc oo le r . . . . . . . . . . . . . . . . 3- 11

M o u n t i n g a L o a d e r on t h e Ho pp er . . . . . . . . . . . . 3- 12

Te st in g t he I ns ta ll a t i o n . . . . . . . . . . . . . . . . . . . 3 -1 2

U s i n g Com mu ni ca t io ns ( Op ti on al ) . . . . . . . . . . . . 3 - 1 3

I n s t al l at io n l 3 - 1

Page 22

U n p a c k in g th e B o x e s

The Carousel Plus W series dryer comes in one to four boxes, depending on the model and

options ordered. The boxes could include (depending on the options selected):

• Carousel Plus W series dryer

• Delivery air hose - 10 ft {3.05 m} - Insulated with High Heat option.

• Return air hose - 10 ft {3.05 m}

• Process RTD

• Setback RTD

• User manual

1 Carefully remove the dryer and components from their shipping containers. Note that

the dryer is secured to its shipping container with straps that pass through the bottom of

the dryer frame.

2 Remove all packing material, protective paper, tape, and plastic.

3 Open the side panel and remove the cable tie securing the desiccant wheel. See

Installation section entitled, Removing the cable tie from the desiccant wheel.

4 Carefully inspect all components to make sure no damage occurred during shipping,

and that you have all the necessary hardware.

5 Take a moment to record serial numbers and electrical power specifications in the

blanks provided on the back of the User Guide’s title page. The information will be helpful if you ever need service or parts.

6 You are now ready to begin installation.

Follow the preparation steps on the next page, then choose one of the four mounting

options:

• Dryer on the floor; hopper on a floor stand (see page 3-5).

• Dryer on the floor; hopper machine mounted

• Central dryer, with ResinWorks system.

3 - 2 l In st a ll at io n

Page 23

P r e p a r in g fo r I n s t a l la t i o n

The Carousel Plus W Series Dryer is easy to install if you plan the location and prepare the

mounting area properly.

1 Make sure the mounting area provides:

❒

A grounded power source supplying the voltage and correct current for your

dryer model. Check the dryer’s serial tag for the correct amps, voltage, phase, and

cycles. Field wiring should be completed by qualified personnel to the planned location for the dryer. All electrical wiring should comply with your region’s electrical

codes.

❒

A source of water, if you have an aftercooler and/or optional precooler.

The W dryer’s aftercooler and optional precooler require 3 gals./min. {11.4 liters/min.}

tower, city, or chiller water at temperatures of 45° to 85°F {7° to 29°C}. Pipe should

be run to the planned dryer location. Use flexible hose to connect the water pipes to

the aftercooler and/or optional precooler.

❒

Minimum clearance for safe operation and maintenance.

You should maintain 24 in. {61 cm} clearance on all sides of the dryer.

Posit i o n i n g t he Dr y e r o n t h e F l oo r

Material and conveying

✒

lines installed. If you

plan to use vacuum or

compressed air loaders

to fill the hopper, install

conveying lines to the

drying hopper location.

I n sta l la ti on

3

1 Lift the dryer from the shipping container using a fork truck.

2 Position the dryer on the floor near the processing machine. Make sure the

location allows for the connection of all hoses.

R e m o v in g t h e C a b l e T i e f r o m t h e

D e s i c c an t Wh e e l

1 Open the dryer side panels and remove the cable tie securing the desiccant wheel, if

it was not done while unpacking the dryer.

Desiccant cable tie

I n s t al l at io n l 3 - 3

Page 24

C o n n e c ti n g t h e M a i n Po w e r

CAUTION: Always disconnect and lock out the main power sources before making electrical con-

nections. Electrical connections should be made only by qualified personnel.

1 Open the dryer’s electrical enclosure. Turn the discon-

nect dial on the dryer door to the Off or “O” position.

Lock out the main power (see Page 1-6 for complete

lock out information). Turn the captive screw, and swing

the door open.

2

Insert the main power

side of the enclosure or the rear of the dryer. ( The

dryer’s electrical wire connection location was a factory

option and may be connected through the front or the

rear of the dryer.) Secure the wire with an appropriate

strain relief.

wire through the knockout in the

IMPORTANT: Always refer to the

wiring diagrams that came with

your dryer before making electrical

connections.

3 - 4 l In st al la ti on

Connect the power wires

3

to the three terminals at the top of the power disconnect.

4 Connect the ground wire to the ground lug as shown in the photo.

Page 25

C o n n e c ti n g t h e P r o c e ss RTD P r obe

The process RTD probe monitors the temperature of the drying air as it enters the hopper. If

the probe is not installed correctly, temperature readings will be inaccurate.

1 Insert the probe at the inlet to the

hopper. The end of the probe must not touch the

walls of the inlet. The tip of the probe should be

approximately in the center of the tube. Tighten the

compression fitting to lock the probe in place.

Setback RTD

Process RTD

2 Plug the probe’s cable

into the receptacle

labeled process on the left

side of the electrical

enclosure. Hand tighten

the connector. Coil any

excess cable and secure it

with a wire tie.

C o n n e c ti n g t h e S e t b a ck RTD

1 Insert the probe in the hopper outlet at the top of the hopper. The end of the probe

must not touch the walls of the inlet. The tip of the probe should be approximately in the

center of the tube. Tighten the compression fitting to lock the probe in place.

2 Plug the probe’s cable into the receptacle labeled setback on the left side of the elec-

trical enclosure. Hand tighten the connector. Coil any excess cable and secure it with a

wire tie.

I n sta l la ti on

3

When configured as

a central dryer, monitoring the drying air

temperature is not

necessary since there

is no process heater

in the system.

Therefore, installation and connection

of the RTD probe

and/or setback probe

is not applicable.

I n s t al l at io n l 3 - 5

Page 26

O

FF

O

O

N

I

✐

NOTE: Users must be

logged in as Maint 1

(user level 3) in order to

perform this operational

test.

C h e c k i ng for Pr o p e r A i r F l o w

IMPORTANT: This procedure must be performed before loading material into the hopper.

CAUTION: If the airflow direction is incorrect due to improper phase connection, material from

the hopper can be pulled back into the dryer, causing permanent damage to this equipment.

1 Turn on the main power to the dryer. Make sure the dryer’s disconnect dial is in the ON

position. This powers up the control and the display will illuminate.

When configured as a

central dryer, the drying temperature can

not be set since there

is no process heater in

the system.

2 From the Home Screen , press the “Setup” button.

WARNING: All wiring, disconnects, and fuses should be installed by qualified electrical technicians in accordance with electrical codes in your region. Always maintain a safe ground. Do not operate the equipment at power levels other than what

is specified on the machine serial tag and data plate.

3 - 6 l In st a ll at io n

Page 27

C h e

e

3 Pr

e

4 Pr

e

5 Pr

powe

e

Pr

one

n

k i

c

O S

/

I

“

e

h

t

s

s

we

o

p

e

h

t

s

s

“De

ss the

button to star

r

button agai

ss the

ond to stop the

c

se

d )

i n u e

n t

o

c

(

w

l o

F

r

i

A

r

e

p

o

r

P

r

o

f

g

.

n

o

t

t

u

b

”

t

s

Te

O

/

I

“

e

h

t

n

e

h

t

d

n

a

n

o

t

t

u

b

”

p

u

t

e

.

e

d

o

m

t

s

e

t

e

l

b

a

n

e

o

t

”

e

d

o

M

t

s

Te

O

/

I

r

e

y

Dr

“

e

d

i

s

e

b

n

o

t

t

u

b

r

I n sta l la ti on

3

”

r

owe

l

B

r

Ai

y

r

ve

i

l

.

r

owe

bl

t the

about

r

n afte

.

r

owe

bl

✐

NOTE: On initial test (first time

in Dryer I/O Test Mode) the

process blower will automati-

cally start. Press the button

beside “Delivery Air Blower” to

stop the blower.

ear the

n

d

n

a

h

your

ld

6 Ho

feel

ld

u

sho

u

o

Y

tlet.

u

o

ir

a

tlet.

u

e o

th

of

t

u

o

CAUTION: Hot surface Do not place

your hand directly on the delivery air

outlet. The outlet and the air can get

hot enough to burn your hand.

If air flow is incorrect disconnect

7

power, follow proper lockout proce

dures and swap any 2 of the 3 main

power wires.

delivery

lowin

air b

Return

g

-

Air Inlet

Dry Delivery

Air

Moisture

Exhaust

( C o nt i nu ed )

I n s t al l at io n l 3 - 7

Page 28

C h e c k i ng for Pr o p e r A i r F l o w ( co nt i nu ed )

✐

INSTALLATION NOTE: Models 150, 200, 300, and 400

These models use a three-phase process blower. If the dryer shuts down and a Process Loop

Break shutdown alarm is indicated within the first few minutes of operation, check for proper air

flow or check the Process RTD for proper installation.

If the air flow is reversed, the process blo wer is turning in the wrong direction. Turn

off and lock out the main power source. Open the electrical enclosure and reverse

any two leads connecting the main power supply to the dryer.

LEADS

3 - 8 l In st a ll at io n

WARNING: All wiring, disconnects, and fuses should be installed by qualified

electrical technicians in accordance with electrical codes in your region. Always

maintain a safe ground. Do not operate the equipment at power levels other

than what is specified on the machine serial tag and data plate.

Page 29

C o n n e c ti n g t h e A i r H o s e s

Using the two flexible hoses provided, connect the inlets and outlets of the drying hopper to the dryer. If you have positioned the dryer on the floor or mounted it to an optional floor stand, make sure the dryer is located as close as possible to the hopper to reduce

heat loss. (10 ft {3.05 m} of hose supplied)

✐

NOTE: If you have ordered an insulated hose, it should be installed between the dr yer outlet and

the hopper inlet, see step 2.

1 Attach one hose from the return air

inlet of the dryer to the return air

outlet from the top of the hopper.

Return

Air Inlet

Dry

2 Attach one hose from the delivery

air outlet of the dryer to the delivery

air inlet of the hopper.

Delivery

Air

I n sta l la ti on

3

3 Secure hoses with clamps.

The hose clamp should be secured at

least 1/4 in. {0.64 cm} from the end of

the inlet or outlet tube.

C o n n e c ti n g t h e D r ye r to th e Ho p p e r

W 150 has a 2 1/2 inch {63.5 mm} inlet and outlet hose connections.

W 200, W 300 and W 400 have a 5 inch {127 mm} inlet and outlet hose connections.

If your dryer hose connection and your hopper hose connection are not the same

size, you will need a hose adapter. Contact Conair Parts 1-800-458-1960.

✐

NOTE: Do not allow the

flexible hoses to kink or

crimp.

✐

NOTE: Water to cooler

should be turned off

when the dryer is not

running to prevent

condensation

.

I n s t al l at io n l 3 - 9

Page 30

C o n n e c ti n g A i r H o s e A d a pte r s

Depending on the hopper you purchased you may need to install an air hose adapter to connect the hopper to your dryer.

To connect the air hose adapter:

1 Place high temperature gasket half way down over the dryer outlet to the

hopper.

2 Place hose adapter inside high temperature gasket flush to the dryer outlet, secure

with pressure clamp.

Pressure clamp

3 Attach the hopper inlet hose over the adapter, secure with clamp.

3 - 1 0 l In st al la ti o n

( C o nt i nu ed )

Page 31

C o n n e c ti n g t h e A f t e r co o l e r ( O pt io n al )

The aftercooler and optional precooler require a source of city, tower, or chiller water and a

discharge or return line. You can use water at temperatures of 45 to 85°F {7 to 29°C}. But

the water flow should be at least 3 gal/min {11.4 liters/min}. See Appendix B for installation and water connection instructions for the optional precooler.

1 Secure the aftercooler assembly in the after-

cooler housing using the six screws.

Aftercooler

2 Connect the water supply line to the aftercool-

er inlet. If a manual shut off valve is used, it

should be mounted on

the inlet line.

TIP: Make the water supply and dis-

✒

charge / return connections with

flexible hoses at least 24 in.

{61 cm} long. This allows you to

easily remove the aftercooler

assembly for cleaning.

I n sta l la ti on

3

3 Connect the water discharge or return line to

the aftercooler outlet.

IMPORTANT: Turn the water off when the dryer is not in use to preventcondensation.

TIP: If an optional flow control is also

✒

being installed with the aftercooler,

the manual shut off valve should be

installed on the inlet line for the flow

control.

I n s t al l at io n l 3 - 1 1

Page 32

M o u n t i ng a L o ad e r o n t h e H o p p e r

If you have a Conair loader or vacuum receiver, you can use the

flange and mounting clips provided on the top of the hopper.

Refer to the manuals that came with your receiver or loader for

detailed installation instructions.

Tes t i n g t h e I n sta l l a t ion

You have completed the installation. Now it’s time to make sure

everything works.

1 Make sure there is no material in the hopper. If you have

mounted a loader or vacuum receiver on the hopper, disconnect

the material inlet hose at the source or turn the loader off.

2 Turn on the main power to the dryer. Make sure the dryer’s

disconnect dial is in the ON position. This powers up the control and the display lights will illuminate.

3 From the Home Screen, press the

“System Overview” button.

When configured

as a central dryer,

the drying temperature can not be

set since there is

no process heater

in the system.

3 - 1 2 l In st al la ti o n

4 From the Overview Screen, press the

magnifying glass button beside the

dryer. (Also referred to as the “Dryer

Zoom” button.)

5 From the Dryer Screen, verify that set-

points are correct, and press the dryer

start button.

125

-40

350

( C o nt i nu ed )

Page 33

Tes t i n g t h e I n sta l l a t ion (c o n ti nu ed )

If everything is installed correctly:

• The regeneration and process blowers turn on

• The regeneration heater turns on

• The process heater will energize (if configured as a stand alone dryer)

• The dryer’s desiccant wheel starts turning. (If the desiccant wheel does

not turn, turn off the dryer, disconnect from power, and verify that the desiccant

wheel tie has been removed

6 From the Dryer Detail screen, press the dryer stop button.

If everything is installed correctly:

• The blowers will continue running as needed to cool the

heaters. (Until regeneration heaters are less than 150°F

{66°C}.)

7 The test is over. If the dryer performed the normal operating

sequences as outlined, reconnect the material source to the

optional hopper receiver and begin normal operation. If it did

not, refer to the Troubleshooting section of the User Guide.

125

-40

IMPORTANT: Be sure the cable tie

has been removed from the desic-

cant wheel.

I n sta l la ti on

3

U s i n g C o m m un i c a t i on s ( O p ti o na l)

To use the optional Modbus, Ethernet, SPI or standard DeviceNet communications, see

the Addendum for hardware installation and configuration.

SPI connection

Ethernet connection

DeviceNet connection

✐

NOTE: These communications can be left disconnected, if not in use.

I n s t al l at io n l 3 - 1 3

Page 34

3 - 1 4 l In st al la ti o n

Page 35

O p eratio n

The Dryer System Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

How to navigate the Control Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

DC-T Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Operation - ResinWorks Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Control Function Flow Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Control Function Descriptions - ResinWorks Configuration . . . . . . . . 4-16

Operation - Stand Alone Dryer Configuration . . . . . . . . . . . . . . . . . . . . 4-45

Control Functions Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

S E C T I O N

4

O p era tio n

4

Control Function Descriptions - Standard Configuration . . . . . . . . . . 4-56

General Operation - Stand Alone and

ResinWorks Dryer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-81

DC-T Security Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

Starting the Dryer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Adjusting the Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

Stopping the Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

Stopping the Dryer in An Emergency . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Understanding the Control LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

Alarm Email and Text Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

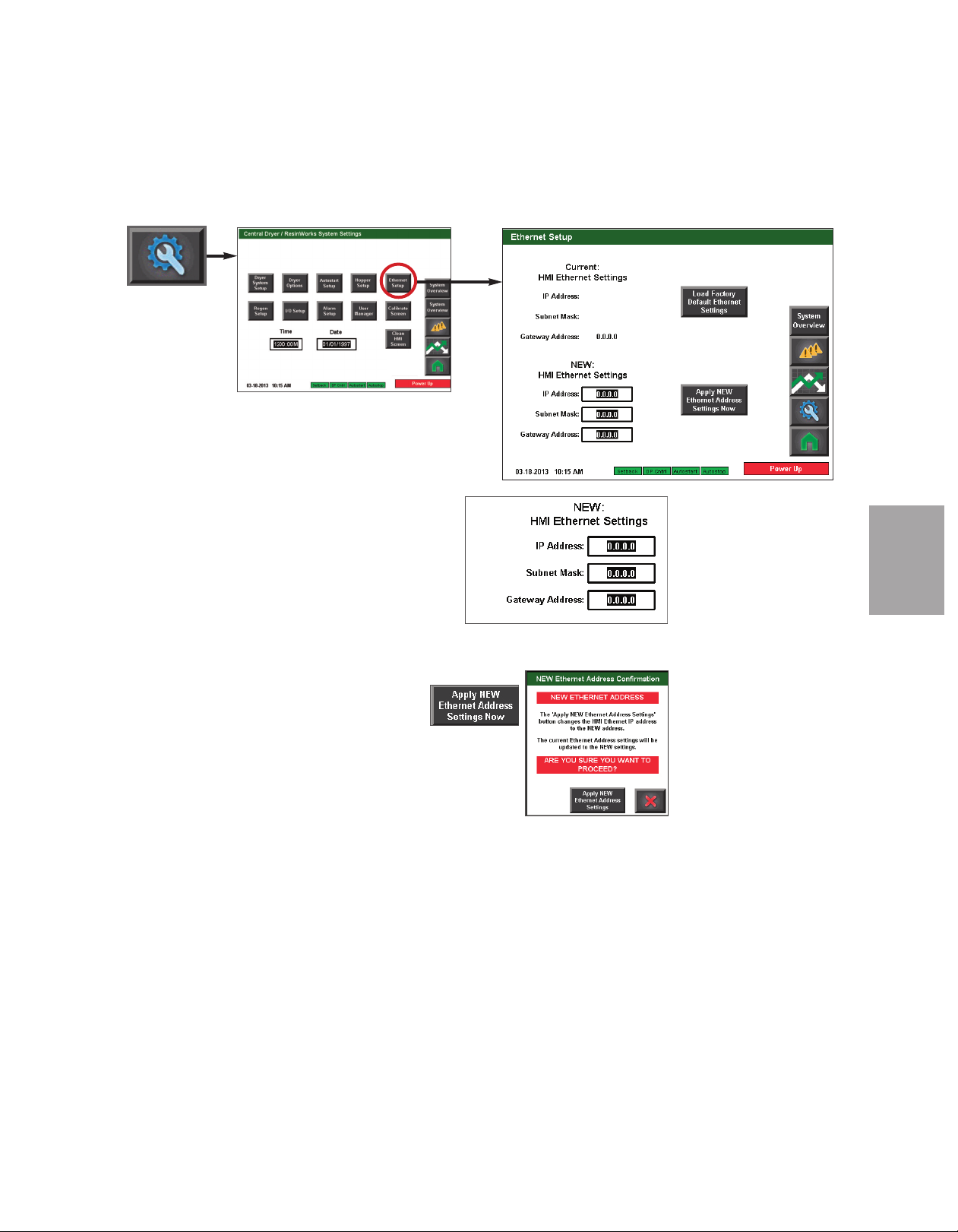

Ethernet TCP/IP Address Setup to Enable Email/Text Notification . . . 4-87

Email Alarm Activation and Address Setup . . . . . . . . . . . . . . . . . . . . 4-88

Configuring the Email and Text Addresses . . . . . . . . . . . . . . . . . . . . 4-89

Text Messaging Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

Enabling and Disabling Notification for Individual Alarms . . . . . . . . . 4-90

DC-T Web Access Logon and Security . . . . . . . . . . . . . . . . . . . . . . . 4-94

Web Server Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-95

O p e r at io n l 4 - 1

Page 36

D r y er S ys t e m C o n t rol Panel

✐

NOTE: The bottom of the Home

screen displays valuable infor-

mation, including the current

date and time, the HMI software

version, the dryer board ver-

sion, and Conair’s copyright.

The software version and board

version will be helpful for serv-

ice and troubleshooting purpos-

es.

Dryer board version

HMI software version

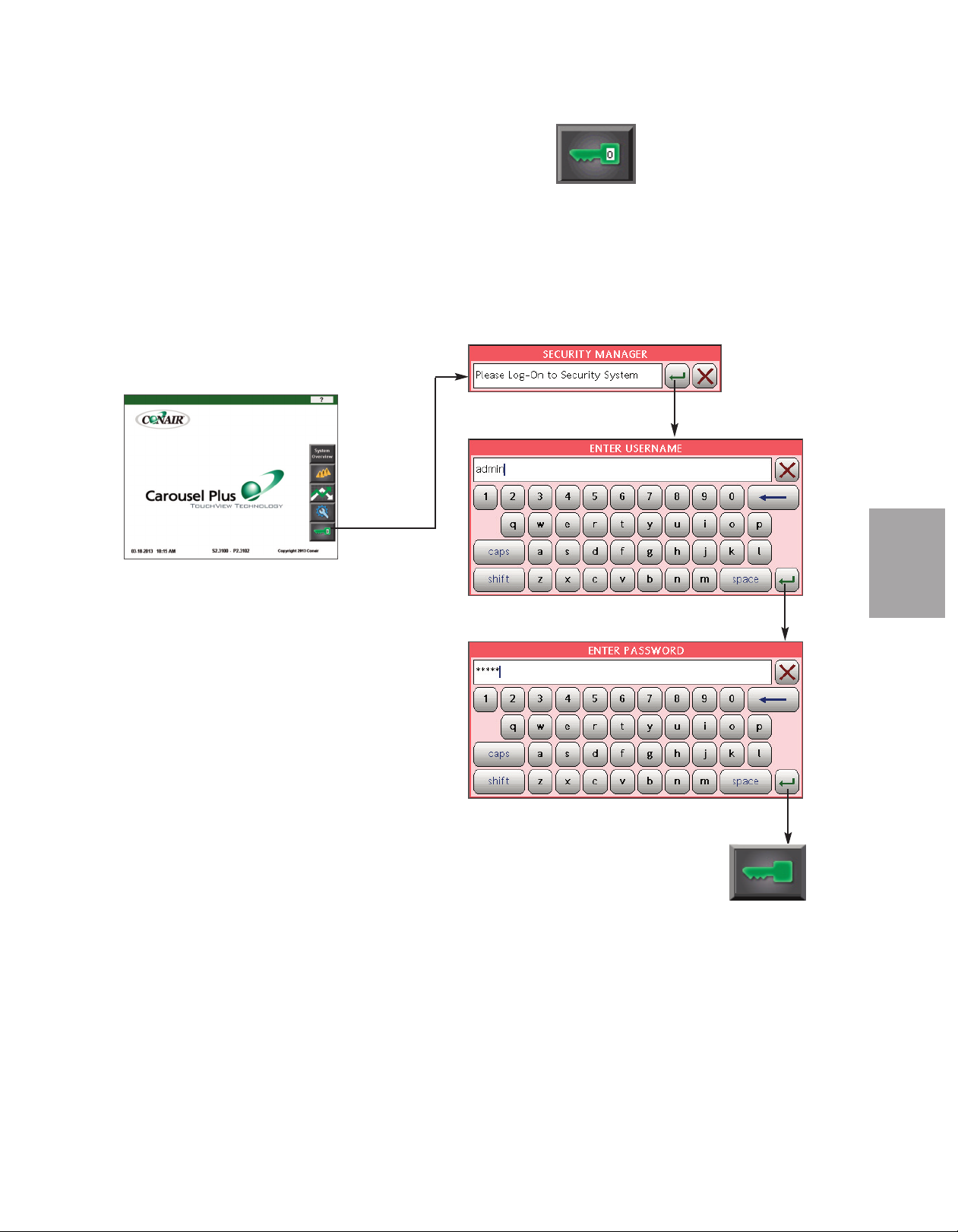

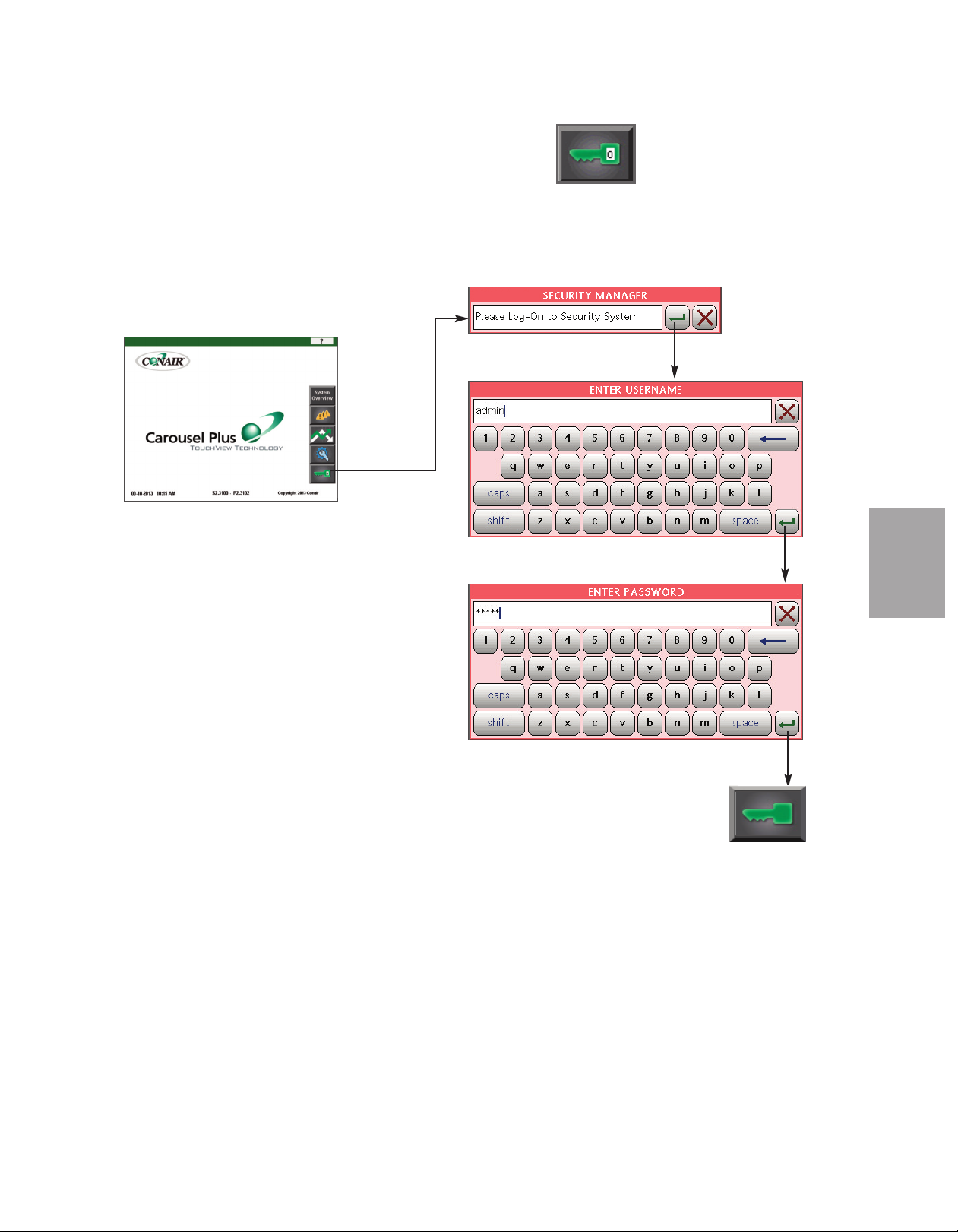

On power-up, the Carousel Plus Dryer control displays the initial system Home screen.

At start-up, the system security level is "Default". Once the operator clicks the Login button and enters the user name and password, access is permitted to various areas of the control. The user, depending on security access level, can access the various system and setup

screens for the entire Carousel Plus Dryer system.

4 - 2 l O pe ra ti on

Stand alone dryer

Central or ResinWorks dryer

Your DC-T Carousel Plus Dryer Control has been configured at the factory based on the

configuration you chose when placing the order. The DC-T can be configured for use with

a ResinWorks dryer with multiple hoppers, a central dryer with separate heat source to

multiple hoppers, or as a stand alone dryer with a single hopper. Once this factory configuration is set (based upon your order) a customer can not change this configuration. The

screens, the screen flow, and operation will differ greatly depending on which configuration

you are using. The Operation section of this user guide covers each of the three configurations individually.

Page 37

H o w t o N a v i g a te th e Co n t r o l S c re e n s

Navigate through the DC-T control screens by touching any navigation "buttons" and/or

magnifying glass icons.

Navigation Buttons

Touching the navigation

buttons will take the

user to the control

screen selected.

O p era tio n

4

Magnifying Glass Icons

Touching the magnifying glass icons will

take the user to screens that contain

detailed information about the system component selected.

(continued)

O p e r at io n l 4 - 3

Page 38

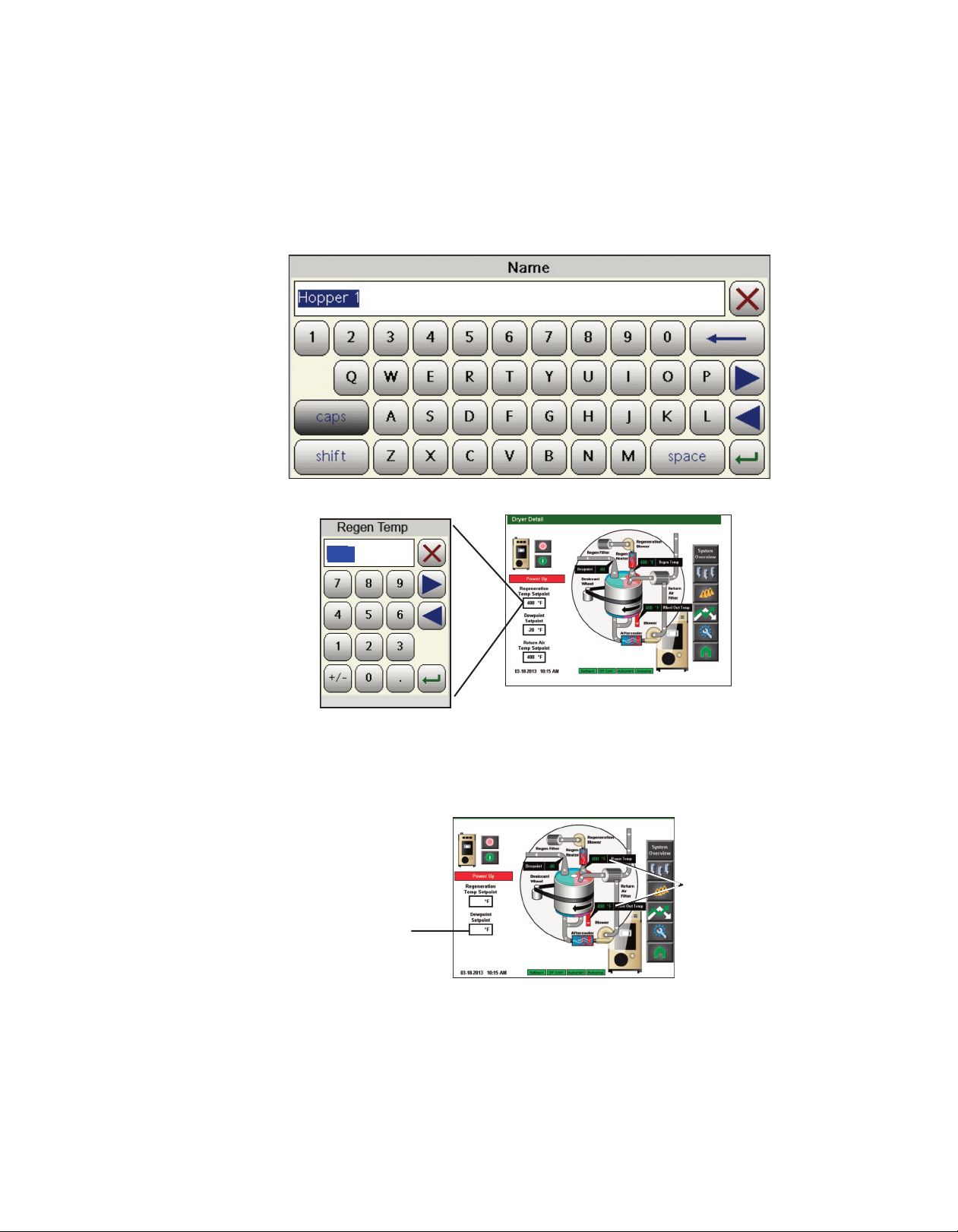

H o w t o N a v i g a te th e Co n t r o l S c re e n s

( c o nt i nu ed )

The user name, password and other information can be entered using the pop-up keyboard

window that appears when an appropriate field is touched.

✐

NOTE: Changing most parame-

ters will require a user login at

the proper security level.

the Operation section of this

User Guide entitled DC-T

System Security Levels for

more information about user

login levels and access.

See

350

Set points can be entered within fields with a heavy black boundaries. Values shown within

colored boxes are “actual” values and can not be changed.

Actual Values

(NonChangeable)

Set point Field

(User Changeable)

350

-40

4 - 4 l O pe ra ti on

(continued)

Page 39

H o w t o N a v i g a te th e Co n t r o l

S c r e e n s ( c on t in ue d)

All beveled grey buttons on the DC-T control screen are selectable and will direct you to

another screen. At any point, pressing the Home button will return you to the home screen.

O p era tio n

4

O p e r at io n l 4 - 5

Page 40

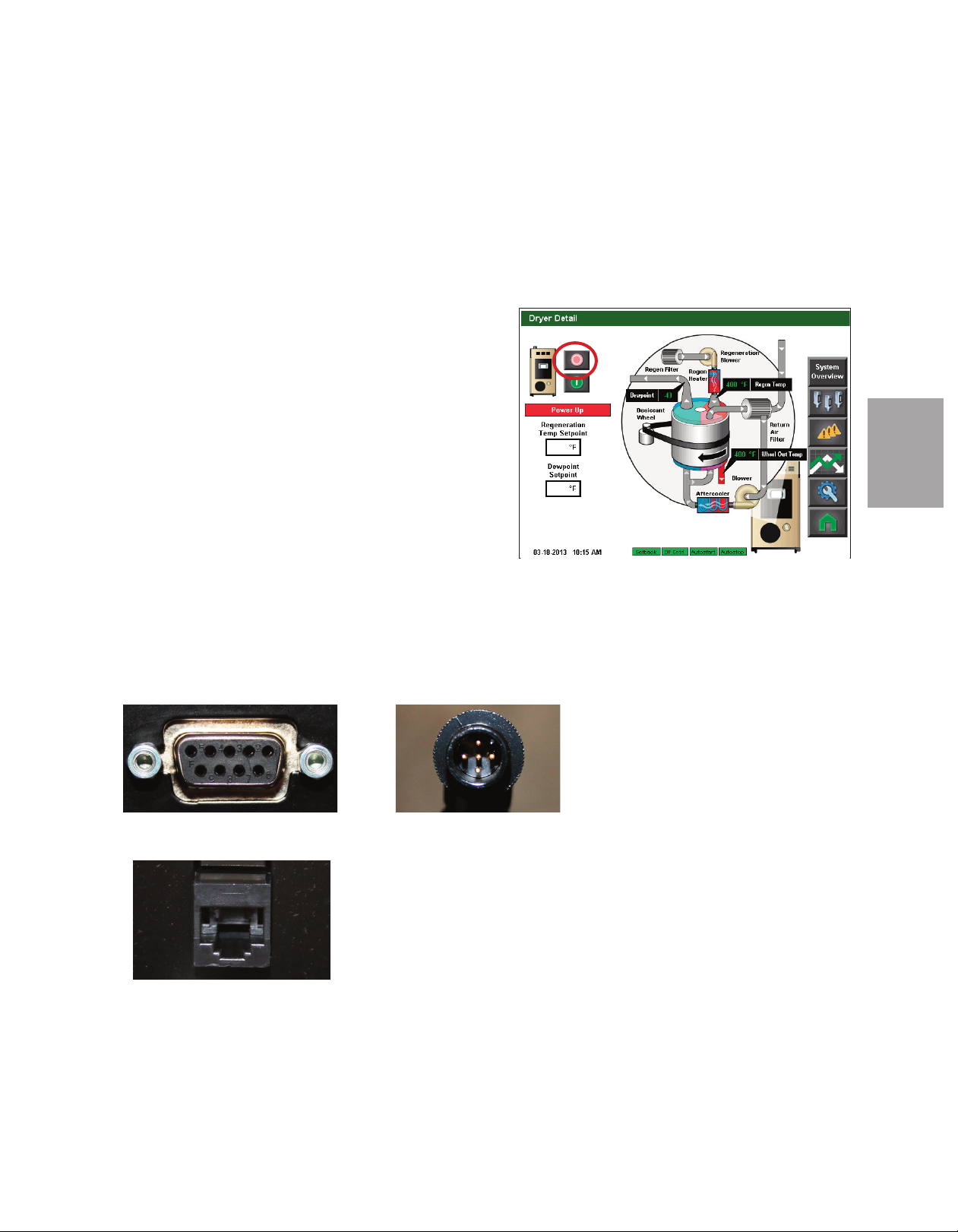

Screen name

Indicates what screen

you are currently

l

ooking at.

T h e D C - T C o n t ro l Panel

Below is a screen from the DC-T while in operation. This screen is shown as a sample of

functionality of a typical DC-T screen. See the functional descriptions below. The following pages are helpful in understanding how to use the DC-T Control.

Displayed data

D

isplays the current

live data for the piece

o

f equipment. If this

data displays as all

dashes or blanks,

t

here is a communi-

cation error.

Magnifying glass /

“Zoom button”

Use these buttons to

zoom to more information about the equipment. In this example,

this Dryer Zoom button

takes you to the

ResinWorks Dryer

screen.

Date and Time

This area displays the

current date and time.

Enabled Options

This area displays icons to let you

see what options are currently

being used. For example, this dryer

is using the Temperature Setback

feature, the Dewpoint Control, and

Autostart and Autostop.

✐

NOTE: Depending upon which options were

ordered or are enabled, different icons may

appear as available or una vailable.

System status

This area displays messages to let you know the

current status of the

dryer.

Help Overview button

Help for the current screen.

Previous button

Returns to the previous list of items.

Next button

Moves to the next list of items.

Hopper Selection button

Go to the Hopper Selection

s

creen.

Alarms button

Go to the Alarms area.

Trending buttons

Go to the Trend Selection

screen.

Setup button

Go to the Setup screen.

Home button

Go to the Home screen.

4 - 6 l O pe ra ti on

System Overview button

Go to the System Overview screen.

Login/Logout button

This button is used to login or log

out as a user.

Page 41

O p eratio n - R e s i n W orks C o n f i g u r a t i o n

The following pages (screen flow charts, screen descriptions, and basic operation) describe

the operation of the dryer when factory configured as a ResinWorks dryer attached to multiple hoppers, or as a central dryer attached to one or multiple hoppers with delivery air heat

at each hopper.

O p era tio n

4

O p e r at io n l 4 - 7

Page 42

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Hom e sc r ee n

Home

Help

Overview

ResinWorks

Overview

Active

Alarms

Trend

Selection

4 - 8 l O pe ra ti on

Setup

Login/

Logout

Page 43

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Ove r vie w sc r ee n

System Overview

Dryer Detail

Hopper

Selection

O p era tio n

4

In

eq

In

d

iv

id

u

al h

op

p

er

s

creen

Ready to Run

d

iv

id

u

al h

op

p

er DM3-e (if

u

ip

p

ed

) s

et

t

in

g

s

s

creen

In

d

iv

id

u

al h

op

p

er

settings screen

O p e r at io n l 4 - 9

Page 44

Home

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Ala r m s c re e n

Alarms

4 - 1 0 l O pe ra ti on

Page 45

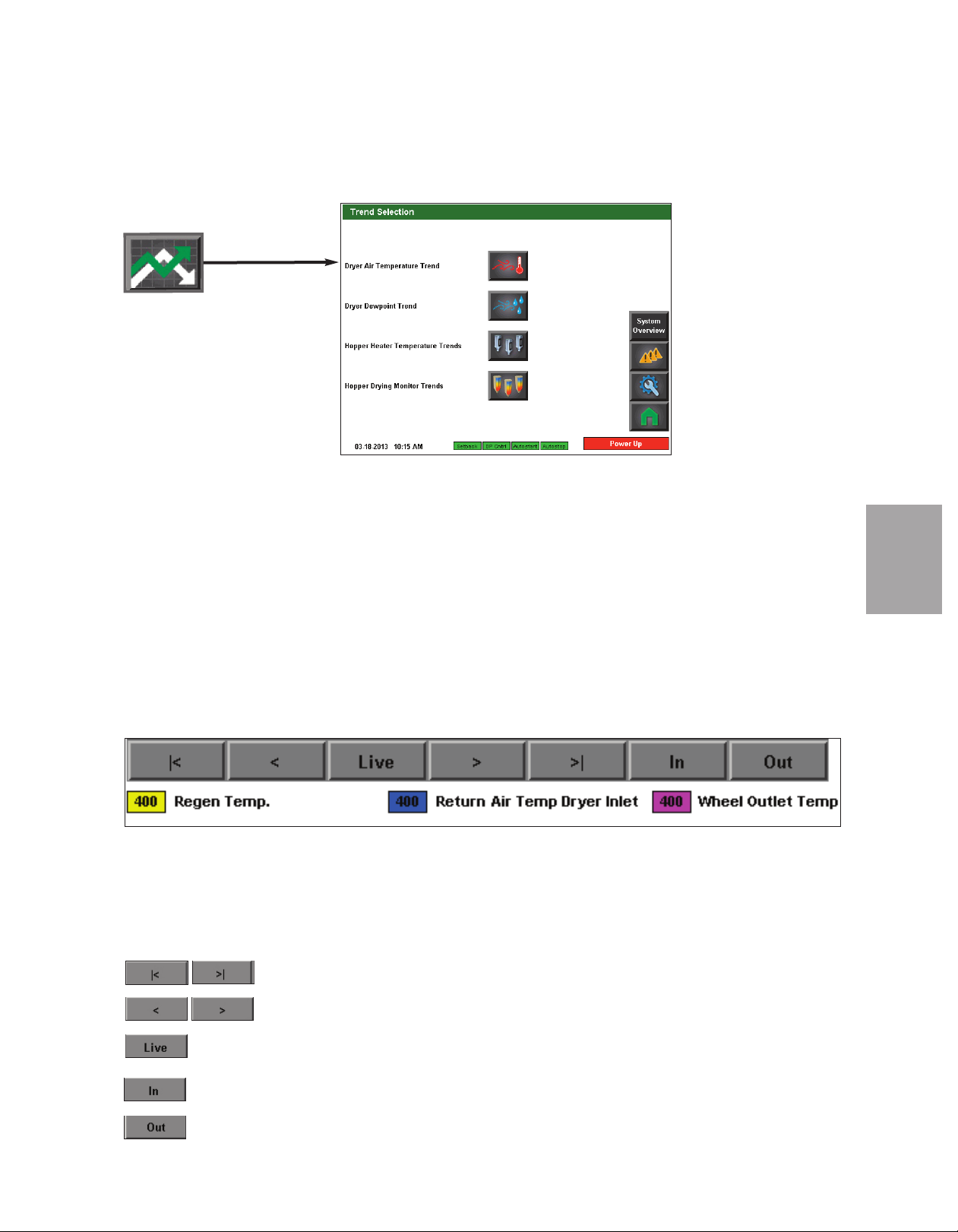

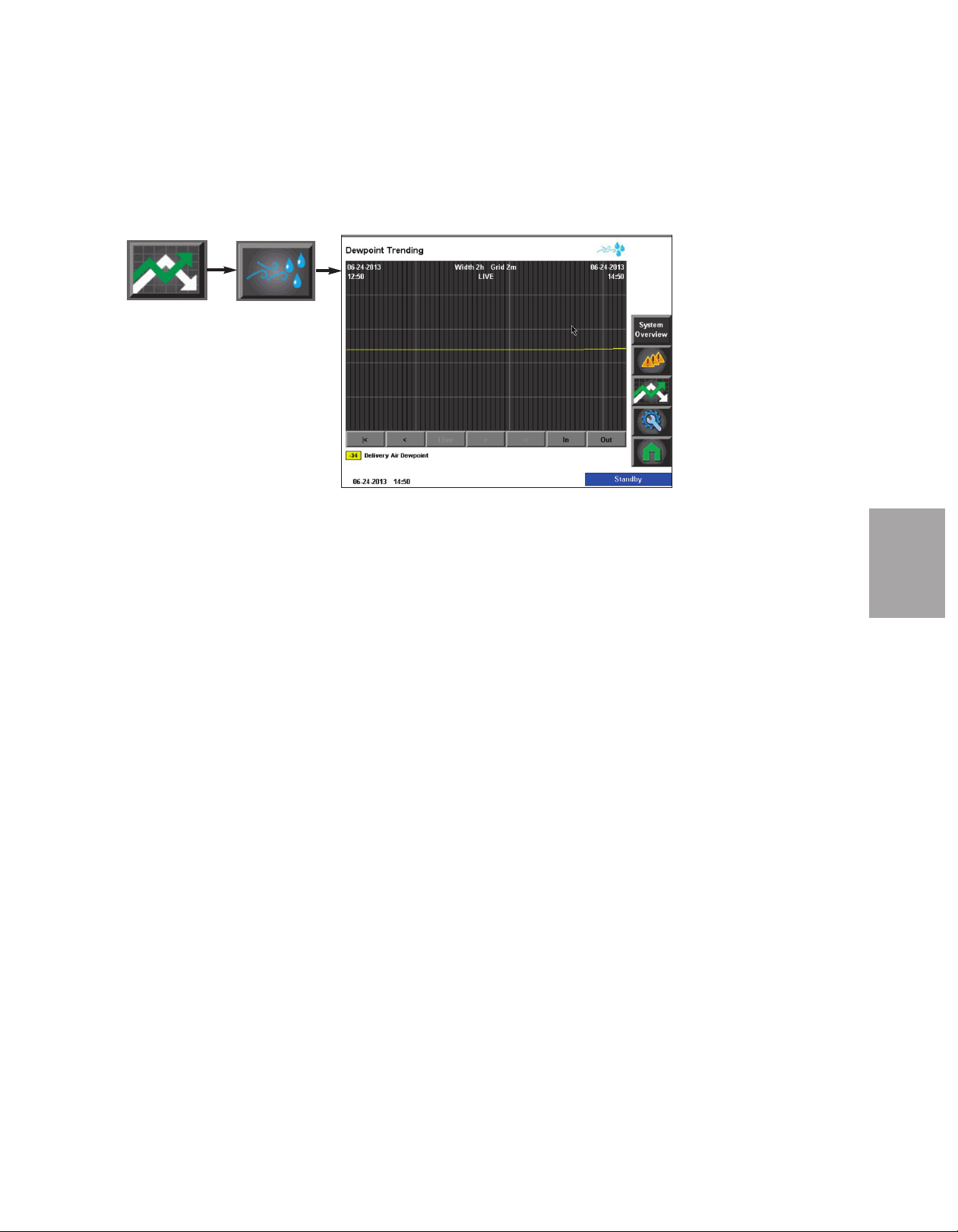

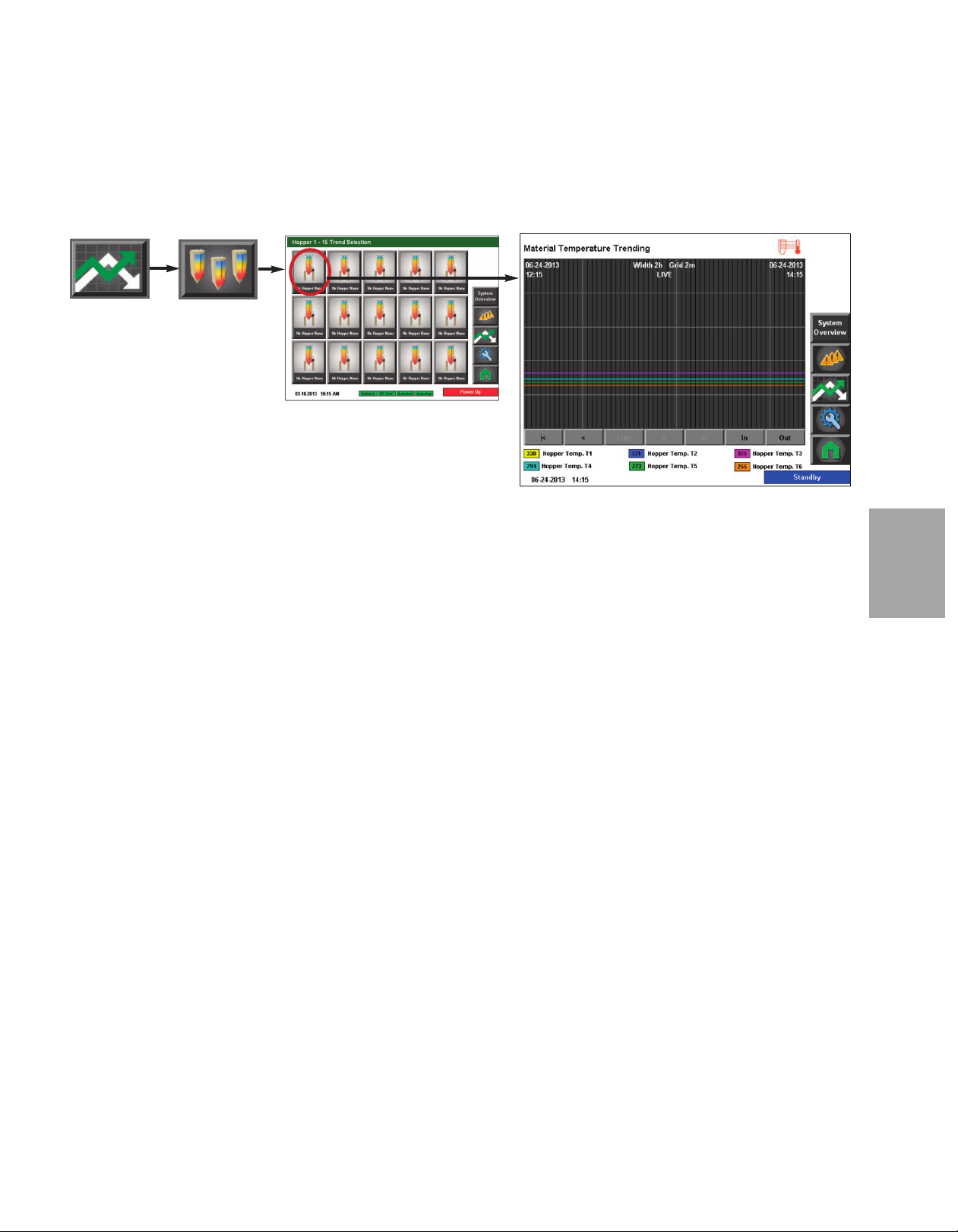

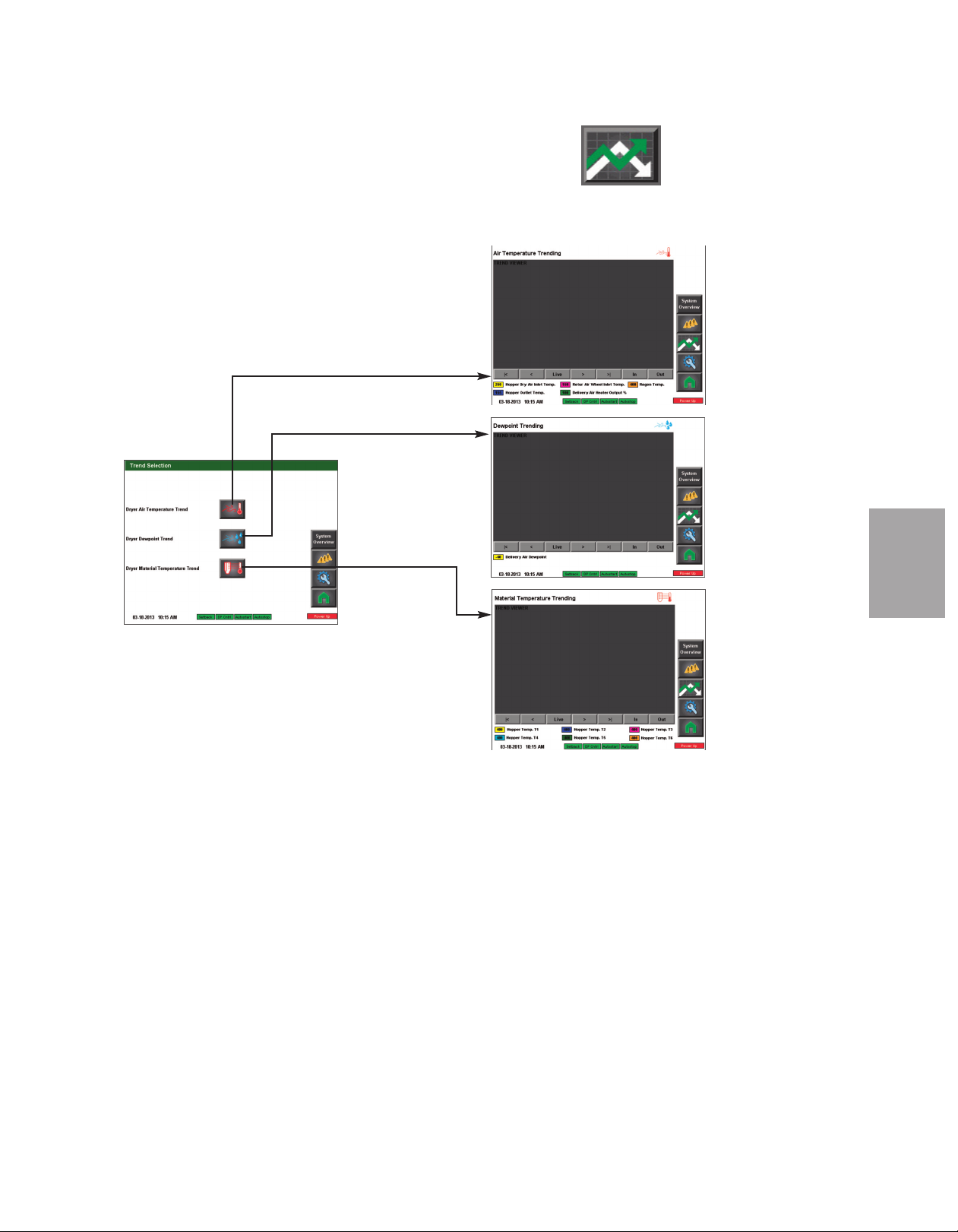

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Tr e nd S ele c ti o n s c ree n

Air Temp.

Trending

DM3-e

Hopper

Trend

Selection

DM3-e

Individual

Hopper

Trend

Trend

Selection

Dewpoint

Trending

O p era tio n

4

Hopper

Heater

Trend

Selection

Individual

Hopper Air

Temp.

Trend

( C o nt i nu ed )

O p e r at io n l 4 - 1 1

Page 46

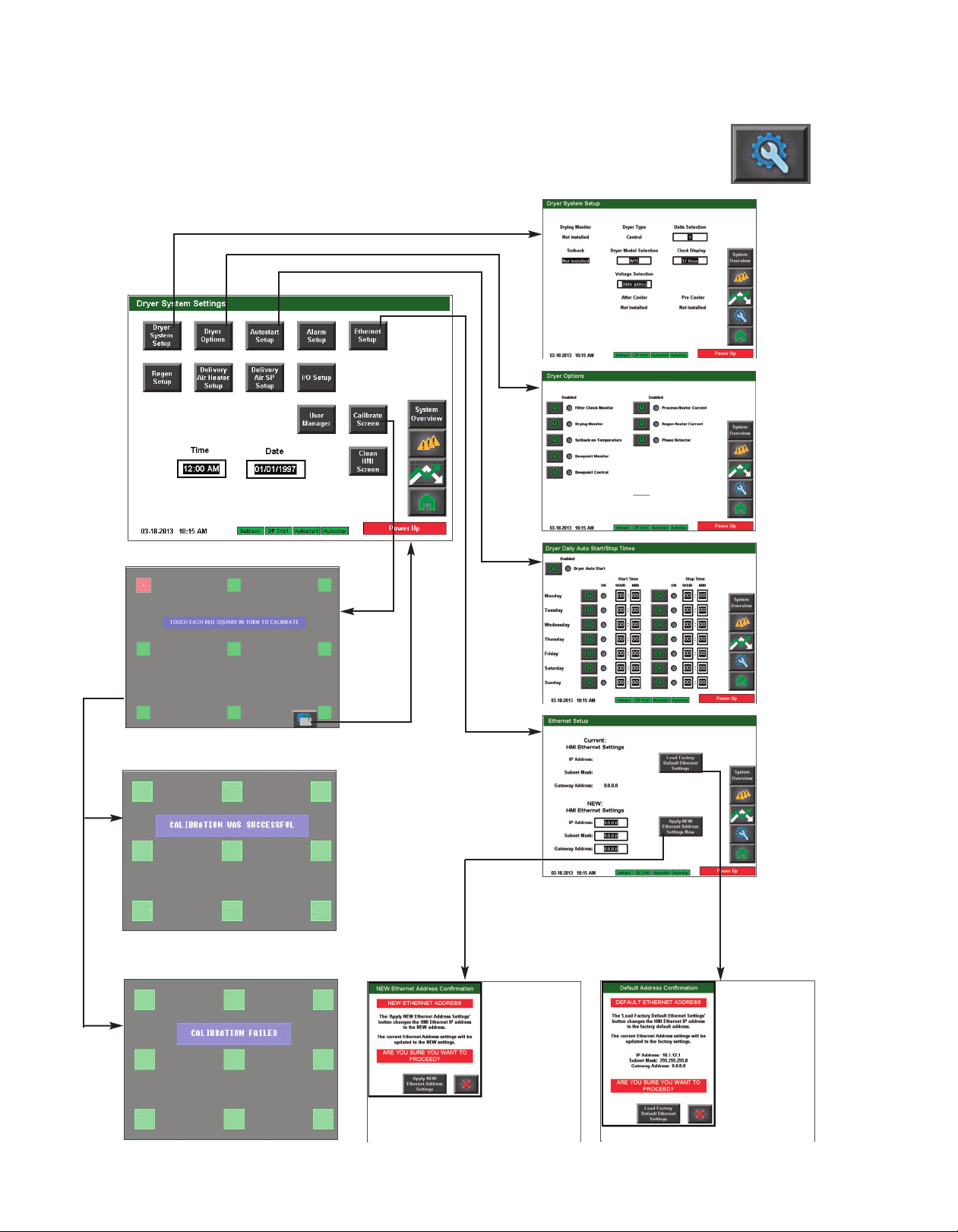

Setup

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Set u p s c re e n

ResinWorks

Setup

RW Dryer

Options

Autostart

Setup

or

4 - 1 2 l O pe ra ti on

Hopper

Names

Hopper

Setup

Hopper

Comms

( C o nt i nu ed )

Page 47

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Set u p s c re e n (c on ti n ue d)

Setup

Set Time

and Date

Regen

Setup

Regen PID

Auto Tune

O p era tio n

4

PID Values

Reset To

Default

Dewpoint Setup

Temp Sensor Setup

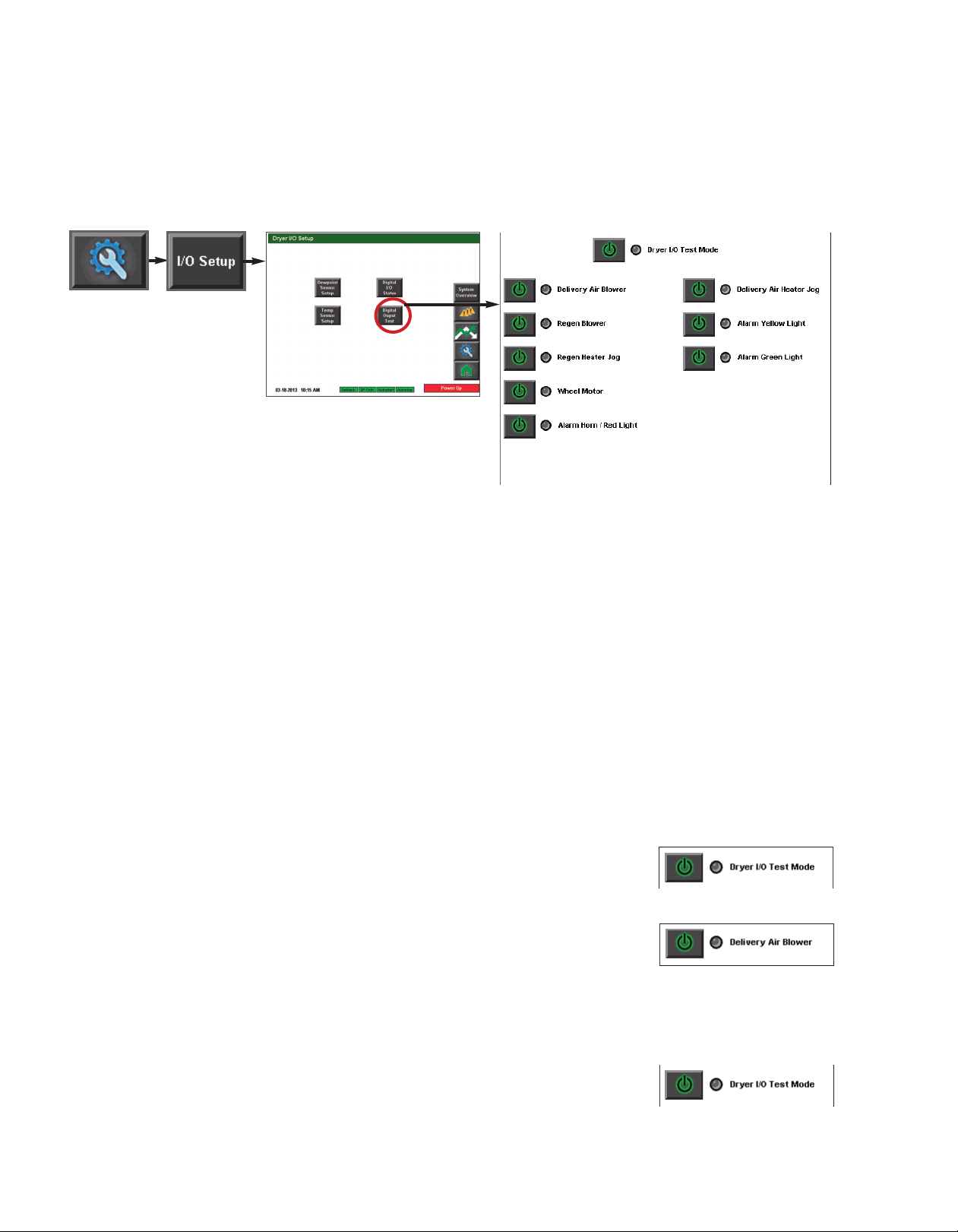

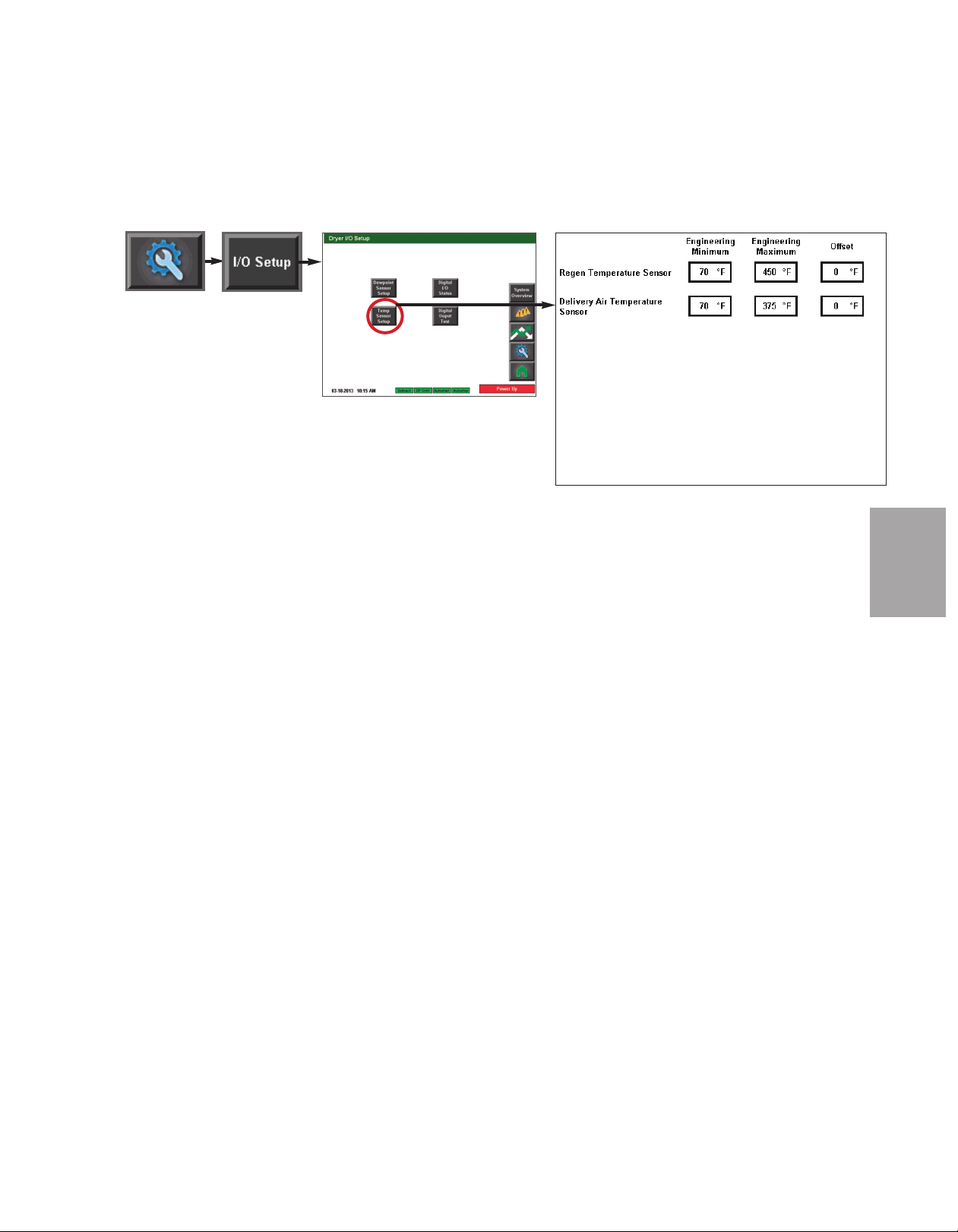

Digital Output Test

(continued)

I/O Setup

Digital

I/O

Status

O p e r at io n l 4 - 1 3

Page 48

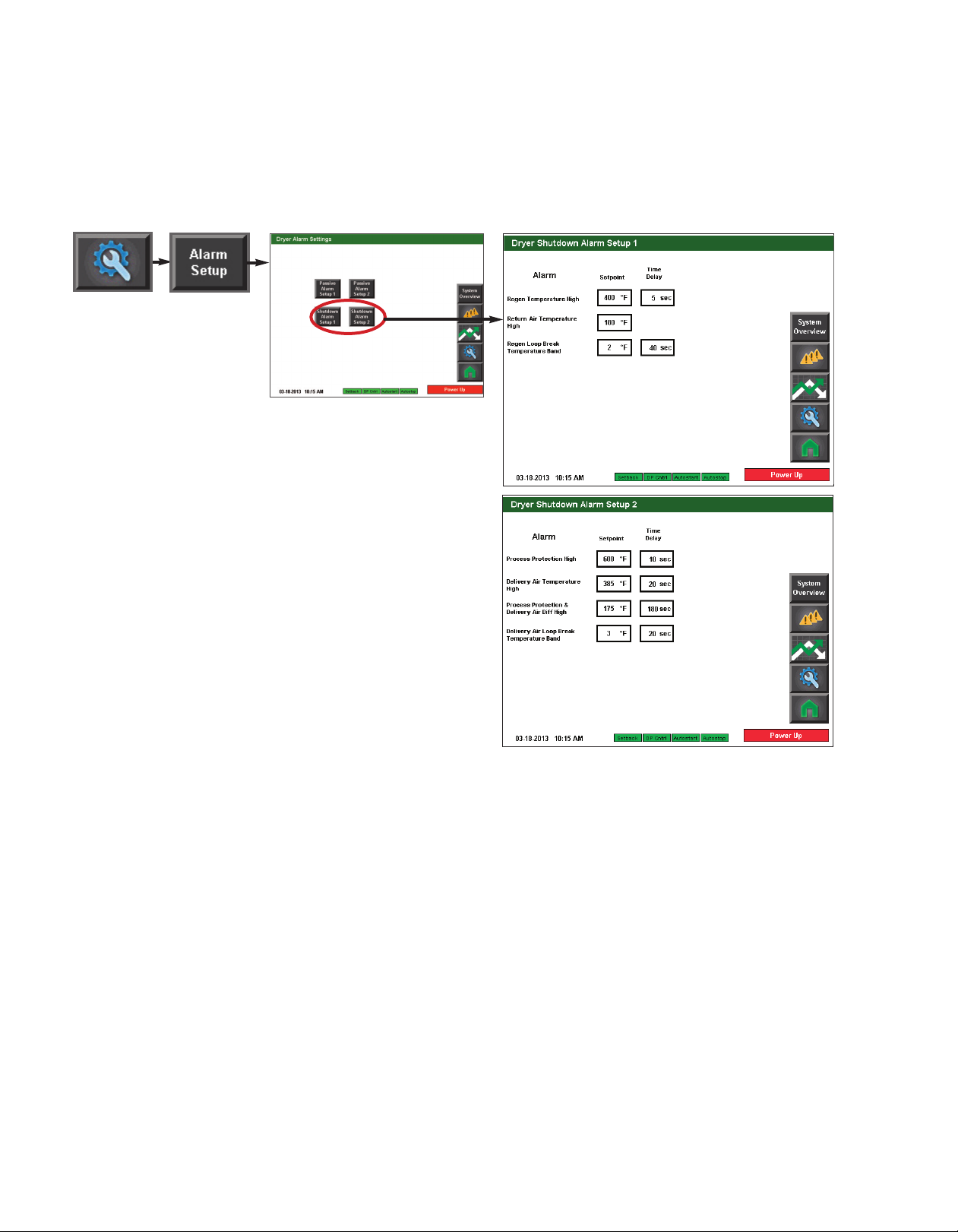

Setup

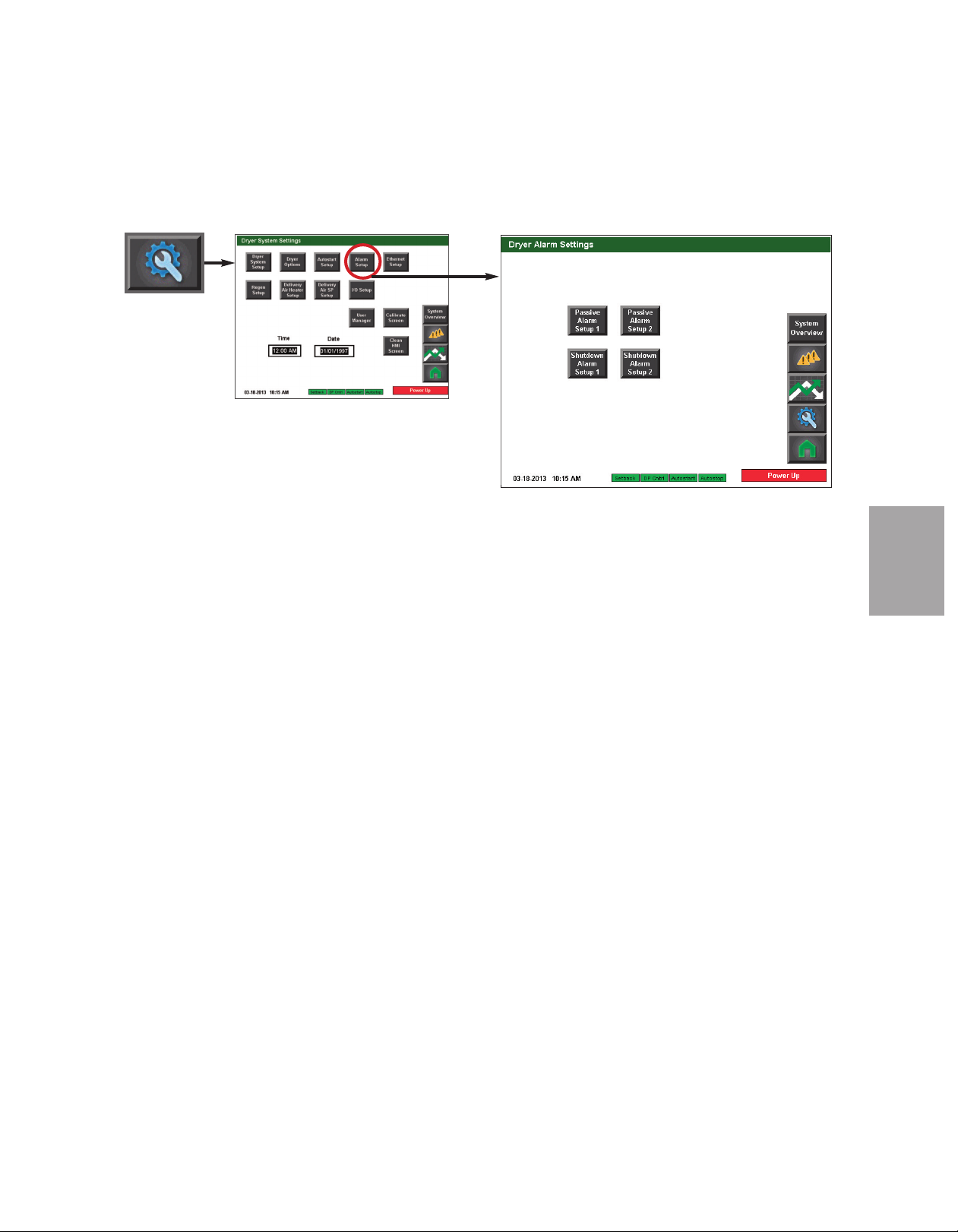

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Set u p s c re e n (c on ti n ue d)

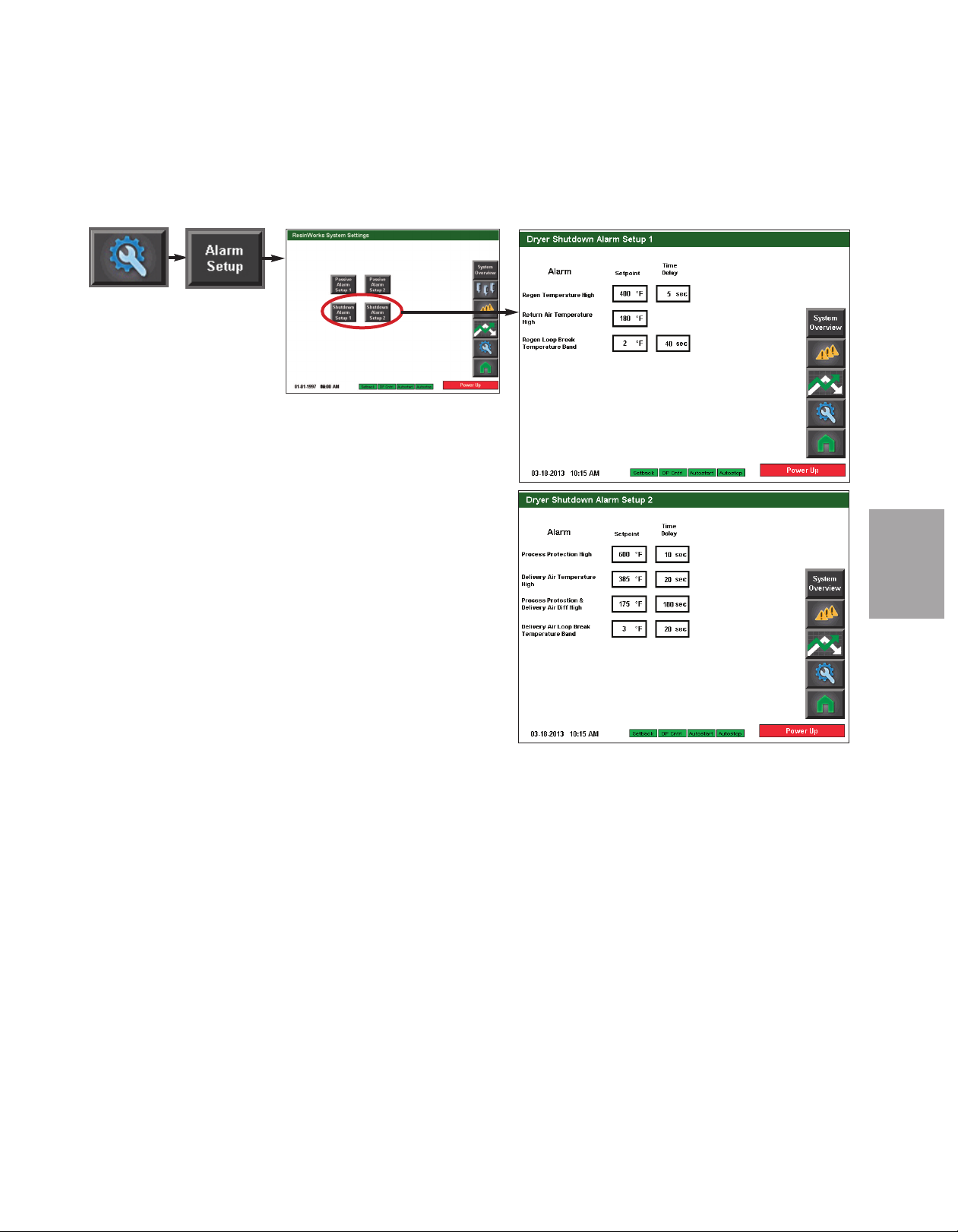

Alarm

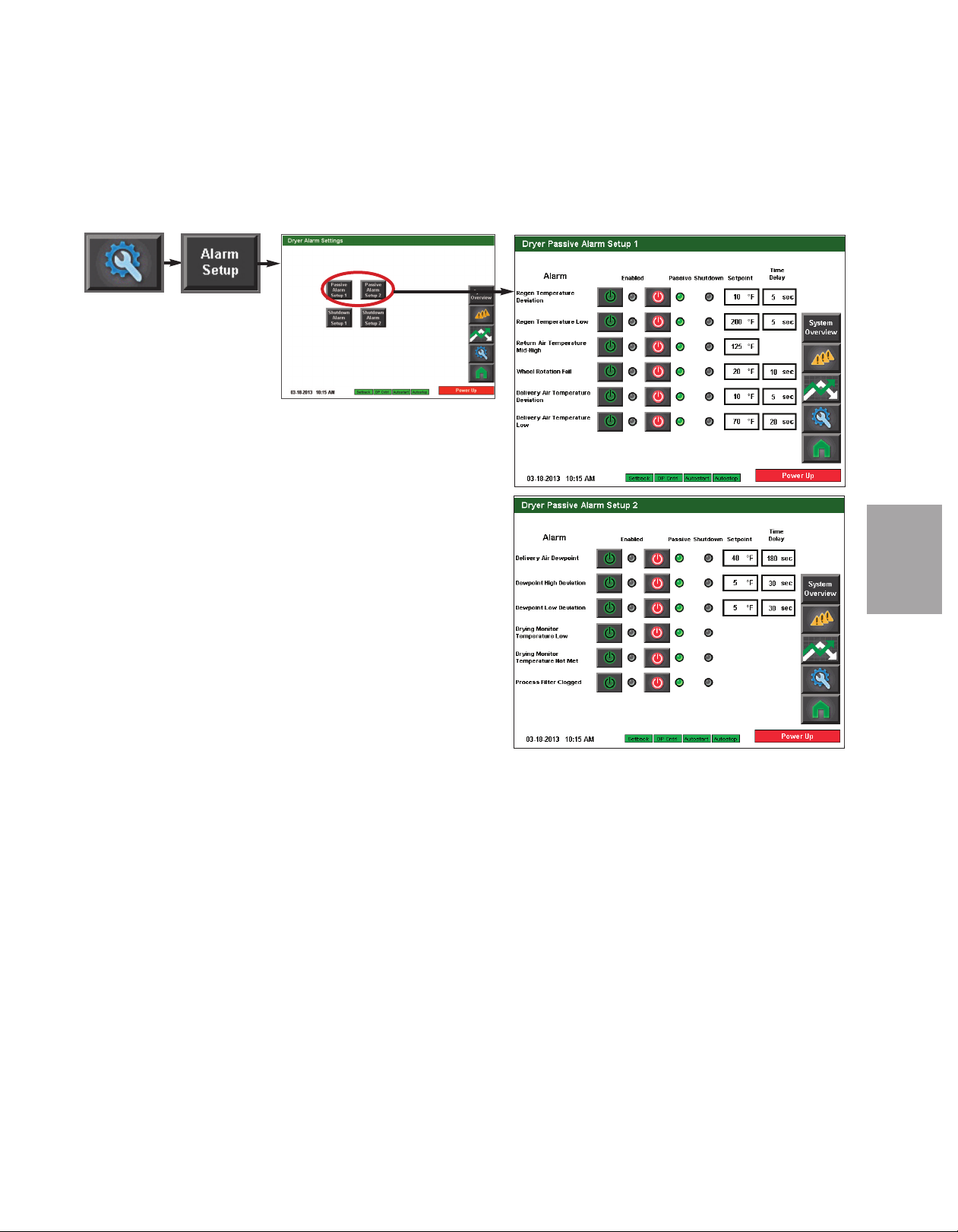

Setup

Shutdown

Alarm

Setup 2

User Manager

Clean Screen

Ethernet Setup

Shutdown

Alarm

Setup 1

Passive

Alarm

Setup 1

Passive

Alarm

Setup 2

4 - 1 4 l Op er at io n

Page 49

C o n t r o l F u nc t i o n F l o w C ha r t s

F ro m th e Log i n/ L og o ut s c re e n

Security Manager

Home

O p era tio n

4

3

O p e r at io n l 4 - 1 5

Page 50

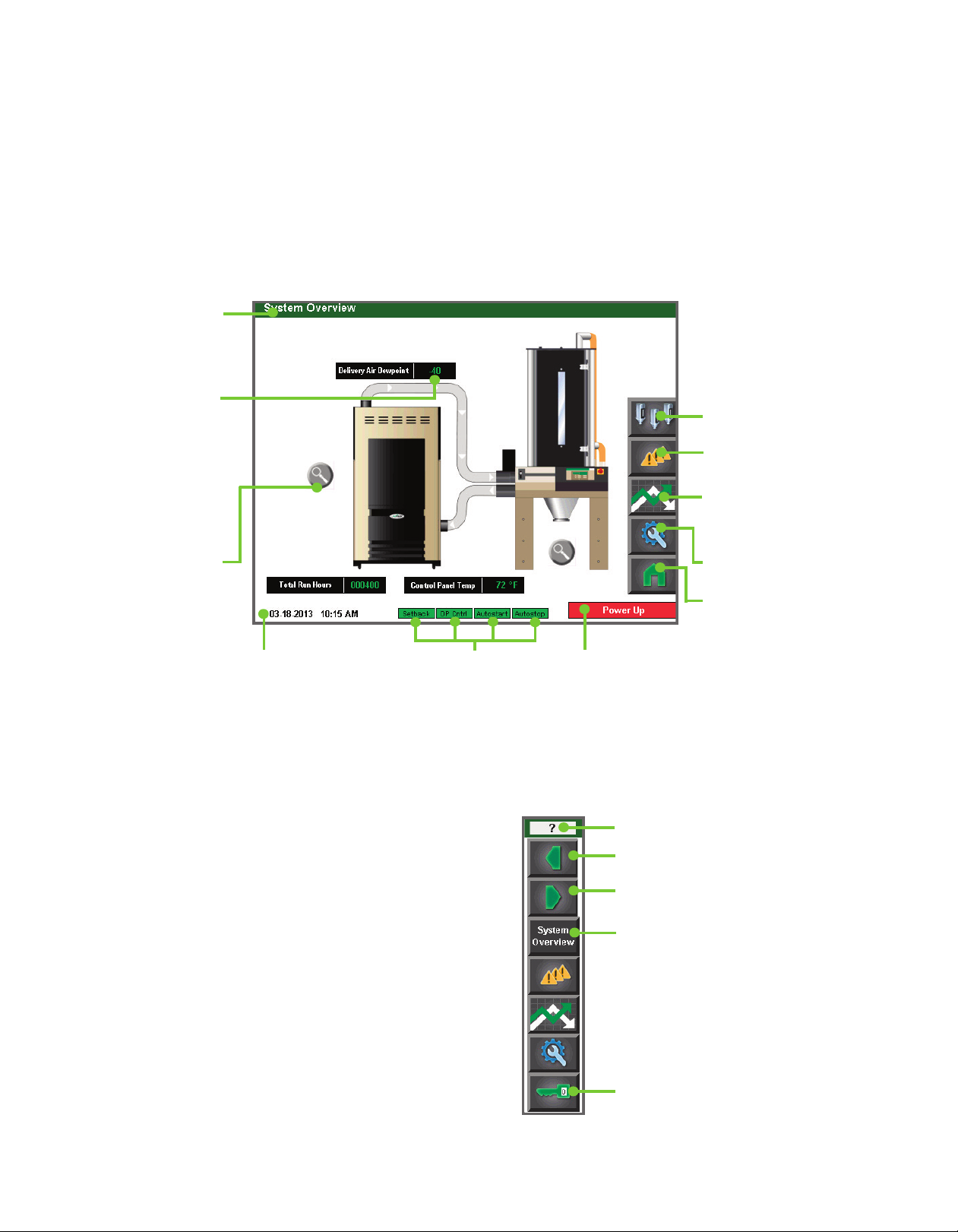

✐

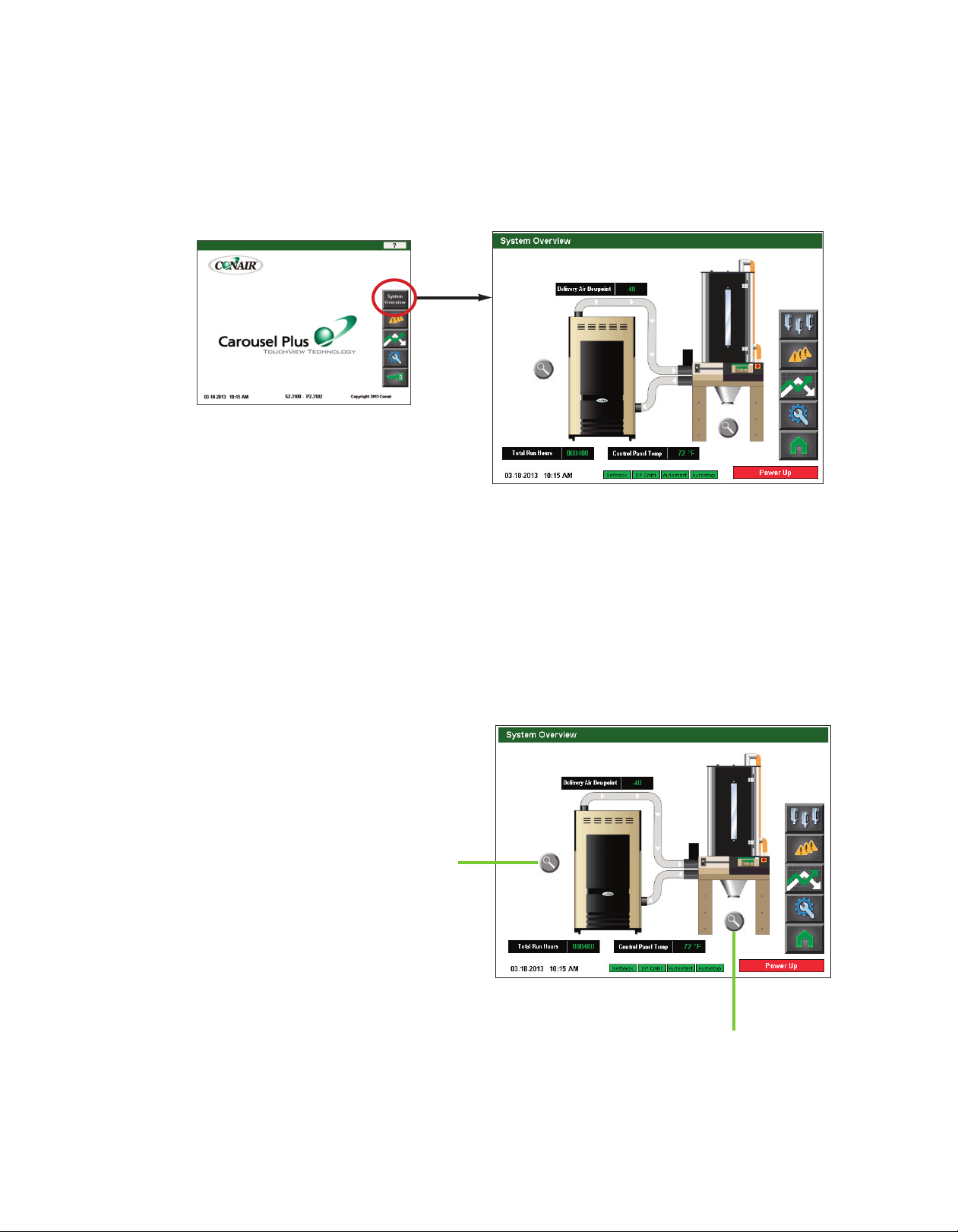

NOTE: On this Overview screen,

live data is displayed. Data is

displayed as colored text inside a

solid black box. Set points boxes

are white with heavy black borders. Set points can be changed,

if the user has logged in at the

proper security level, by pressing

the set point boxes. This will

launch a pop-up keypad window

that can be used to change the

See Operation section

set point.

entitled, How to Navigate the

Control Screens.

set point value has been entered,

press the "Enter" key to lock in

the new set point.

After the new

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n

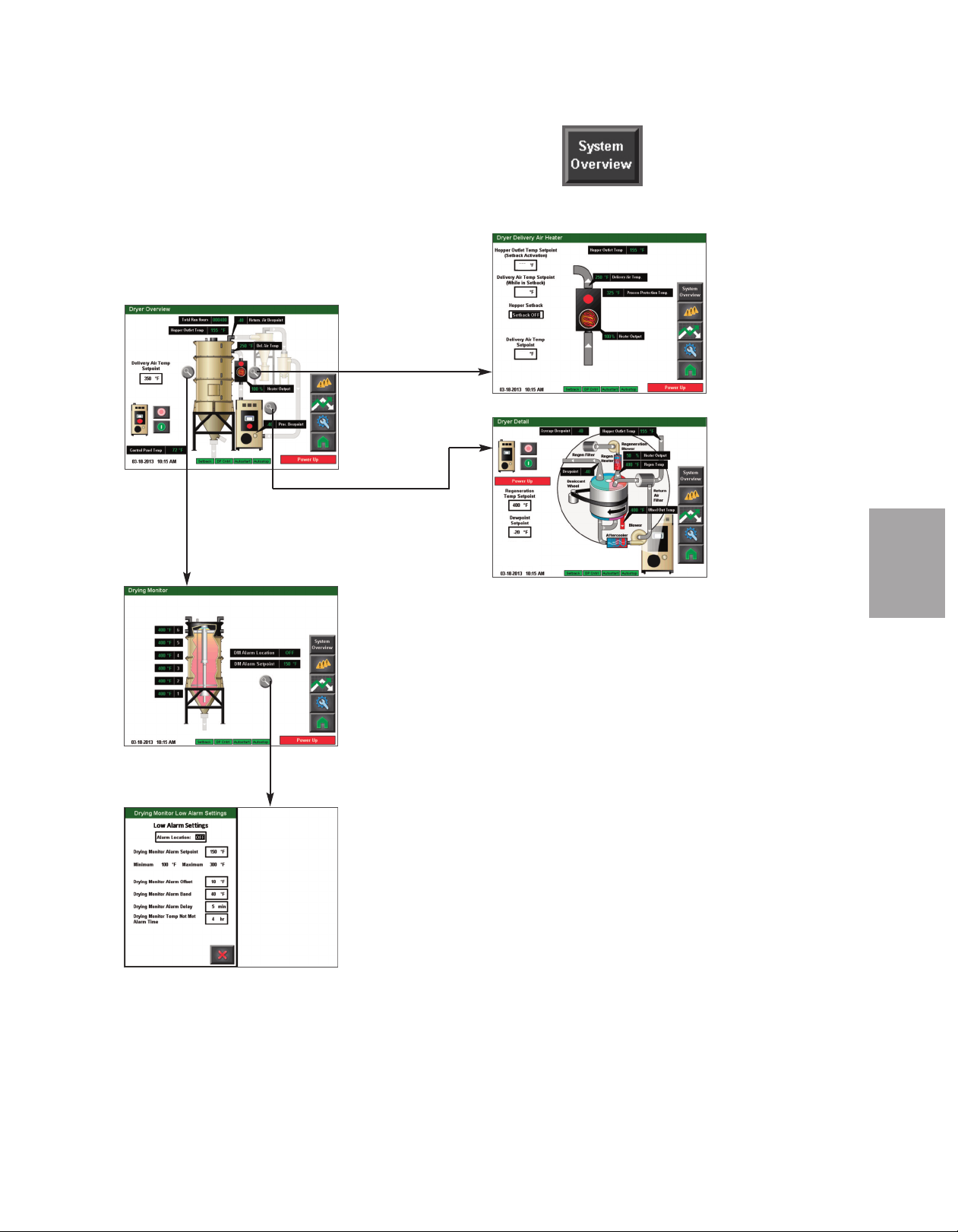

System Overview Screen

To access the System Overview Screen:

1 Press the System Overview button located on the home screen.

The System Overview screen provides the user with the current live information concerning

the delivery air dewpoint, the total run hours, and the control panel temperature.

This screen also allows the user to use the zoom buttons and select the dryer detail information or the hopper(s) detail information.

4 - 1 6 l O pe ra ti on

Dryer zoom

Hopper zoom

(continued)

Page 51

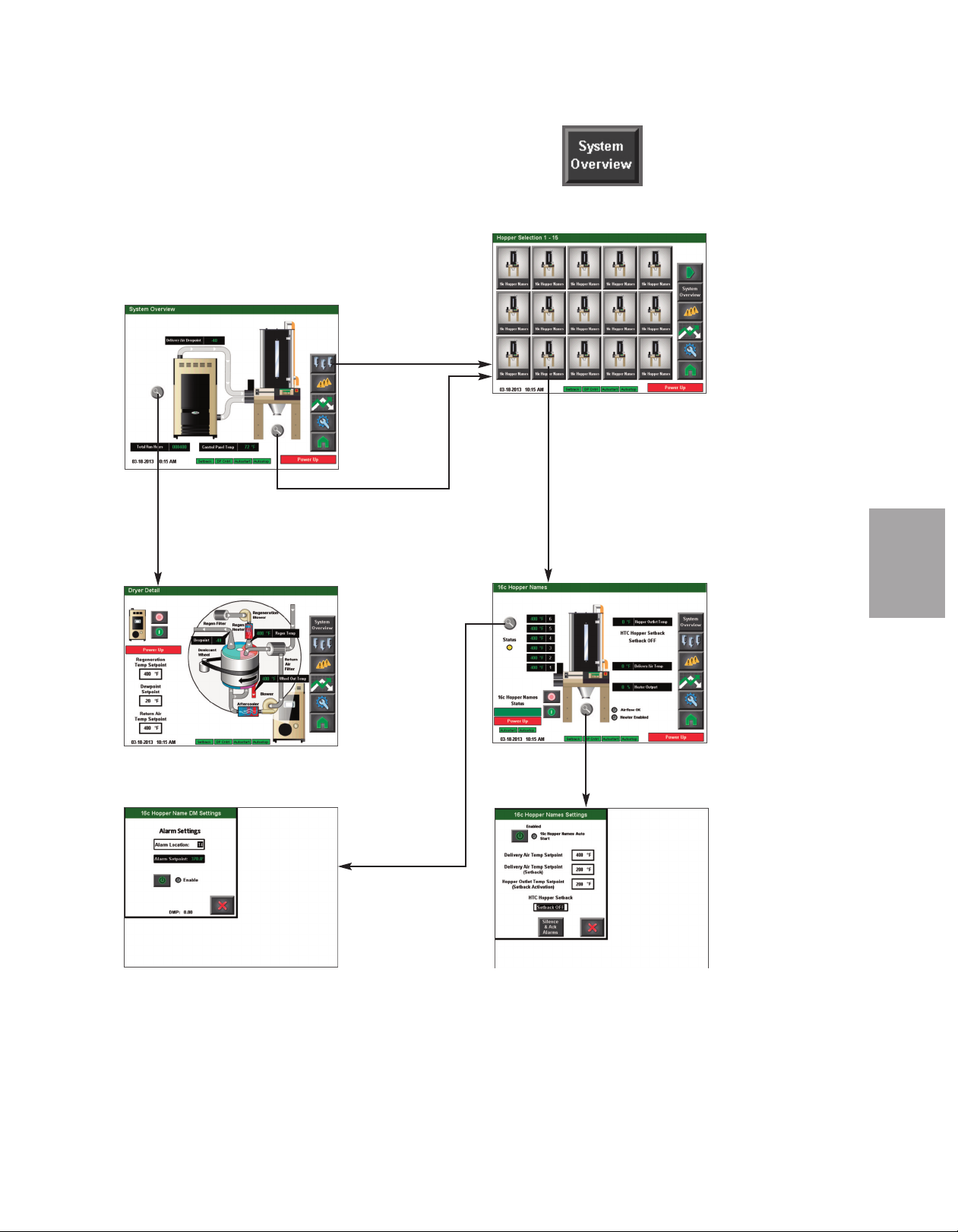

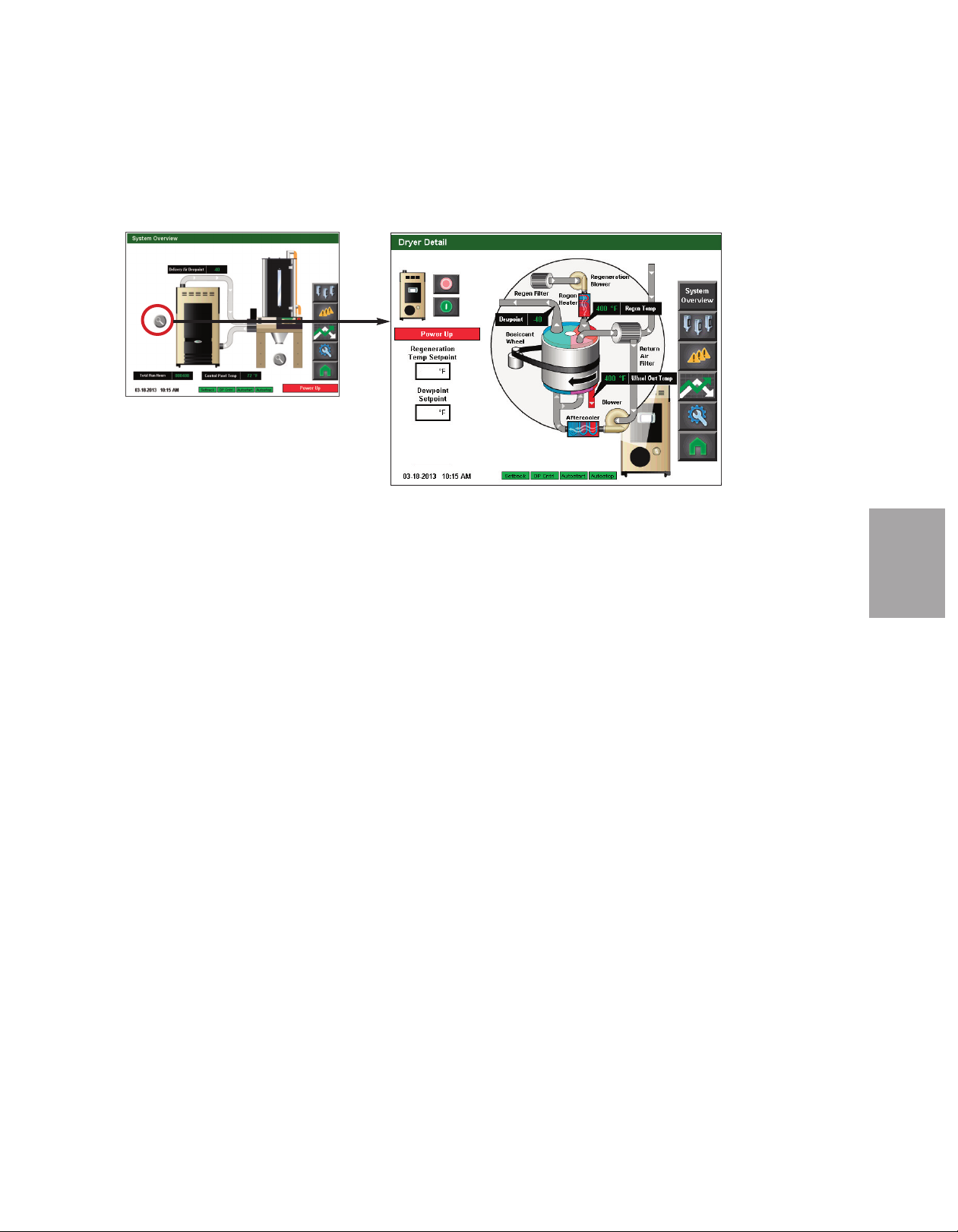

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n

System Overview Screen

To access the System Overview screen:

( c o nt i nu ed )

350

-40

1 Press the Magnifying Glass (zoom) button associated with the dryer on the System

Overview screen.

O p era tio n

4

The System Overview screen provides the user with the current live information concerning

the processes within the dehumidifying dryer including:

• Regeneration Temperature (Regen. Temp)

• Return Air Temperature (Temp)

• Dewpoint

• Wheel Out Temperature (Temp)

It also tells the user the current status of the dryer blower (running or idle), as well as which

features (Autostart, Autostop, Setback, Dewpoint Control) are enabled.

If the user is logged-in at the proper security level, setpoint changes can be made to:

• Regeneration Temperature Setpoint - Conair recommends not changing this setting.

• Dewpoint Setpoint (optional)

This screen also allows the user to start or stop the dryer. The user can also view the other

system parameters, view alarms, view trending, view hopper settings, return to the System

Overview screen, or return to the Home screen by pressing the applicable buttons on the

right of the screen.

✐

NOTE: Live data is displayed as

colored text inside a solid black

box. Set points boxes are white

with heavy black borders. Set

points can be changed, if the user

has logged in at the proper security level, by pressing the set

point boxes. This will launch a

pop-up keypad window that can

be used to change the set point.

See Operation section entitled,

How to Navigate Control Screens.

After the new set point value has

been entered, press the "Enter"

key to lock in the new set point.

(continued)

O p e r at io n l 4 - 1 7

Page 52

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n ( c on ti nu e d)

Hopper Selection Screen

To access the Hopper Selection screen:

1 Press the Magnifying Glass (zoom) button associated with the hopper on the System

Overview screen.

The Hopper Selection screen provides the user with the list of enabled hoppers. If the list is

empty, or does not show the proper number of hoppers, Setup has not been completed yet.

See Operation section entitled: Hopper Setup.

✐

NOTE: Depending on which options

your dryer has been configured

with, and whether or not you have

the DM3-e Drying Monitor enabled,

your screens and icons may appear

different. For example, if your

ResinWorks system is DM3-e

equipped, your hoppers will display

as Drying Monitor hoppers.

4 - 1 8 l O pe ra ti on

(continued)

Page 53

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n ( c on ti nu e d)

Individual Hopper Screen

Ready to Run

✐

NOTE: Depending on

which options your dryer

has been configured with,

and whether or not you

have the DM3-e Drying

Monitor enabled, your

screens and icons may be

different from what is

shown here. For example,

if your ResinWorks system

is DM3-e equipped, your

hoppers will display as

Drying Monitor hoppers (as

shown in these graphics).

To access the Individual Hopper screen:

1 Press the hopper button of the hopper you would like to view.

The Individual Hopper screen provides the user with the current live information concerning the processes within the hopper including:

• Current temperature in each of the six DM3-e sensor zones (if equipped).

• DM3-e status (if equipped).

• Hopper process heater status (if equipped).

• Hopper Outlet Temperature (Temp)

• Setback status (if equipped)

• Process Temperature

• Process Heater Output %

• Dryer Status

• Dryer features active (Setback, Dewpoint Control, Autostart, Autostop)

This screen allows the user to start or stop the hopper heater.

It also tells the user the current status of the dryer (running or idle), as well as which features (Autostart, Autostop, Setback, Dewpoint Control) are active.

If the user is logged-in at the proper security level, they can use the Magnifying Glass

(zoom) button near the tempeature zones to access DM3-e Settings, and the Magnifying

Glass (zoom) button near the bottom of the hopper to access the hopper setpoint settings.

The user can also view the other system parameters, view alarms, view trending, view hopper settings, return to the System Overview screen, or return to the Home screen by pressing

the applicable buttons on the right of the screen.

O p era tio n

4

✐

NOTE: See the Appendix of this

User Guide for more information

about using the DM3-e Drying

Monitor.

✐

NOTE: In addition to starting

and stopping the dryer, the Start

and Stop buttons indicate

whether the dryer can currently

be started or stopped. A faded

or not vibrant button indicates

that the dryer is not

ready/able to complete that function.

For example, a faded

Stop button indicates

the dryer is not ready

to stop.

(continued)

O p e r at io n l 4 - 1 9

Page 54

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

✐

NOTE: Depending on which options

your dryer has been configured

with, and whether or not you have

the DM3-e Drying Monitor enabled,

your screens and icons may appear

different. For example, if your

ResinWorks system is DM3-e

equipped, your hoppers will display

as Drying Monitor hoppers.

✐

NOTE: Set points boxes are white

with heavy black borders. Set

points can be changed, if the user

has logged in at the proper security

level, by pressing the set point

boxes. This will launch a pop-up

keypad window that can be used to

change the set point.

section entitled, How to Navigate

the Control Screens.

set point value has been entered,

press the "Enter" key to lock in the

new set point.

See Operation

After the new

C o n f i g ur a t i o n

( c o nt i nu ed )

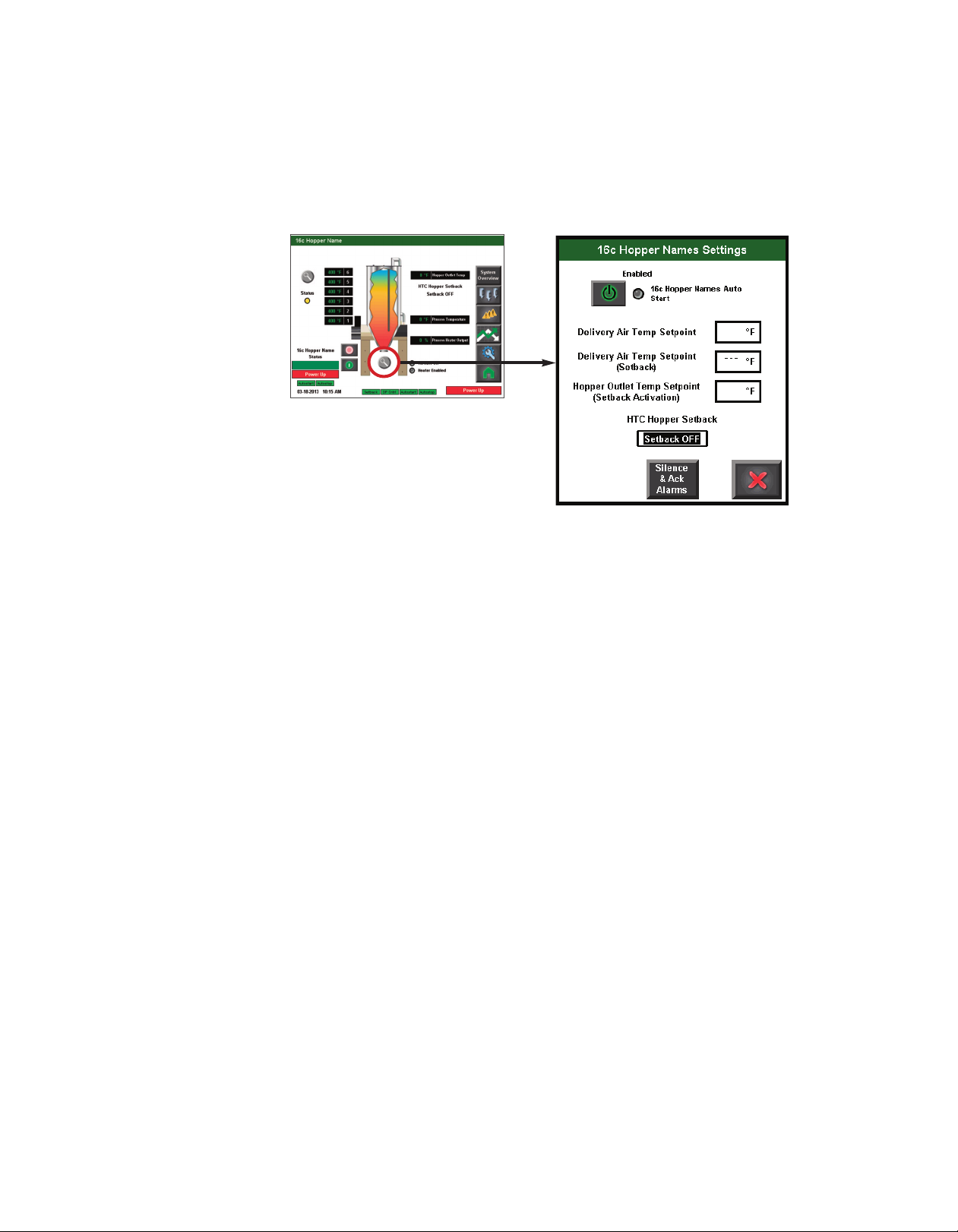

Hopper Setpoint Settings screen

350

Ready to Run

280

2

00

To access the Hopper Setpoint Settings screen:

1 Press the Magnifying Glass (zoom) button associated with the hopper on the

Individual Hopper screen.

The Hopper Settings Screen allows the user to establish the setpoints for the Delivery Air,

the Setback, the Hopper Outlet Temperature, and to enable/disable the Setback feature.

These setpoints can be adjusted for each hopper in your drying system (if equipped with

setback).

✐

NOTE: Setback must be inistalled and enabled at each HTC in a central drying system.

✐

NOTE: See the Appendix of this

User Guide for more information

about using the DM3-e Drying

Monitor.

4 - 2 0 l O pe ra ti on

Temperature Setback explained:

The purpose of Temperature Setback is to save on delilvery air heat (energy) and to minimize resin degradation due to overheating the material.

Temperature Setback works by monitoring the air temperature at the top of the hopper. The

setback features drops the delivery air temperature if the air temperature at the top of the

hopper gets too high. This saves energy and keeps the material from overheating.

✐

NOTE: High temperature at the top of the hopper could be the result of dried resin not leaving the hopper as it

should, or fresh resin not entering the hopper as it should. Check the conveying system to make sure that

material is entering and exiting the hopper when it should be.

(continued)

Page 55

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n

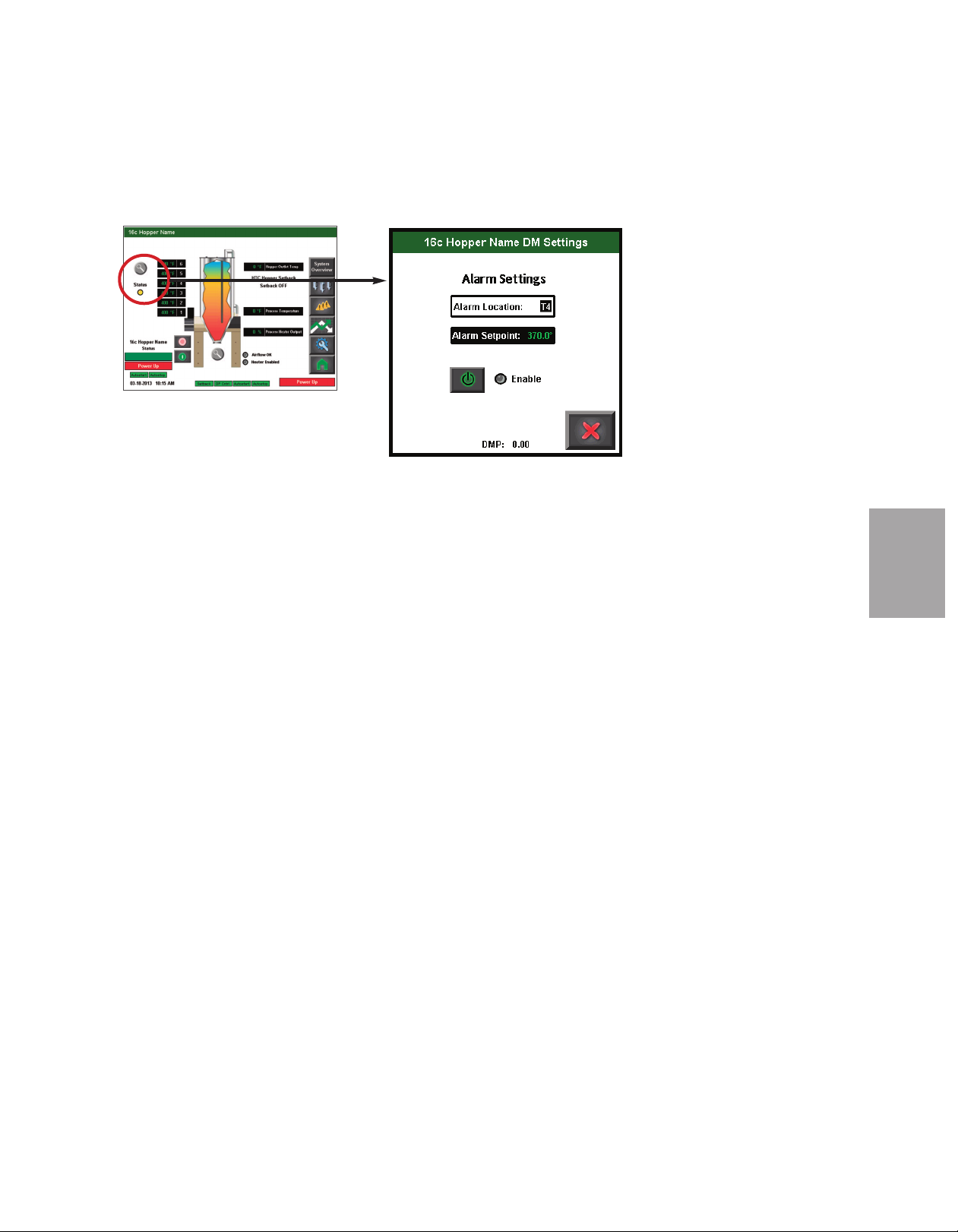

DM3-e Hopper Settings Screen (if equipped)

Ready to Run

To access the DM3-e Hopper Settings screen:

( c o nt i nu ed )

1 Press the Magnifying Glass (zoom) button associated with the Drying Monitor (beside

the temperature zones).

✐

NOTE: See the Appendix of this

User Guide for more information

about using the DM3-e Drying

Monitor.

✐

NOTE: The Drying Monitor

board version number is listed

on the bottom of this p op up

window. This information is

helpful for service and troubleshooting.

O p era tio n

4

The DM3-e Hopper Settings Screen provides the user with the current alarm location zone,

and the Alarm Setpoint, as well as a button to enable or disable DM3-e for this hopper.

These settings can be adjusted for each hopper in your DM3-e system.

(continued)

O p e r at io n l 4 - 2 1

Page 56

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

✐

NOTE: Your DC-T control should

have been configured at the factory

for your ResinWorks system. These

settings should not need changed

unless your system changed, or the

control was replaced. Proper login

is required to change these settings.

C o n f i g ur a t i o n

ResinWorks System Setup screen

To access the ResinWorks Setup screen:

( c o nt i nu ed )

1 Press the Settings button from the Home screen.

2 Press the ResinWorks Setup button.

✐

NOTE: See the Appendix of this

User Guide for more information

about using the DM3-e Drying

Monitor.

The ResinWorks System Setup screen provides the user with the ability to change the system settings of this ResinWorks system.

This screen allows you to change:

• Hopper and hopper heater count

• Units selection (Fahrenheit and Celsius)

• Drying Monitor (DM3-e) enabling

• Dryer model

• Clock display (12 hour and 24 hour)

• Voltage selection

4 - 2 2 l O pe ra ti on

(continued)

Page 57

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n

ResinWorks Dryer Options screen

To access the ResinWorks Dryer Options screen:

( c o nt i nu ed )

1 Press the Settings button from the Home screen.

2 Press the ResinWorks Dryer Options button.

The ResinWorks Dryer Options screen provides the user with the ability to enable or disable options.

O p era tio n

4

This screen allows you to change:

• Filter Check Monitor

• Dewpoint Monitor

• Dewpoint Control

• Regen Heater Current

✐

NOTE: Proper login is

required to change these

settings.

(continued)

O p e r at io n l 4 - 2 3

Page 58

✐

NOTE: Proper login is required to

change these settings.

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n ( c on ti nu e d)

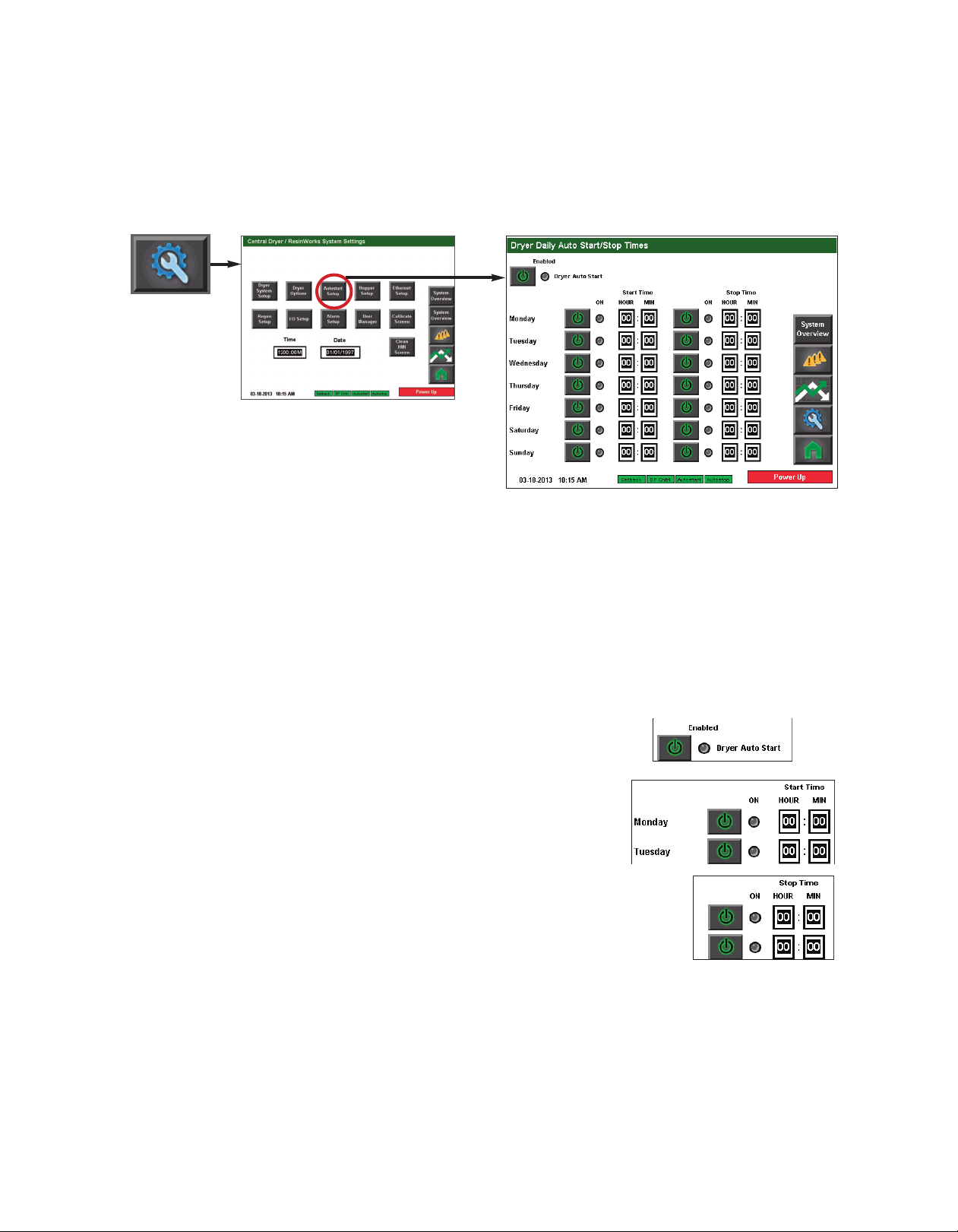

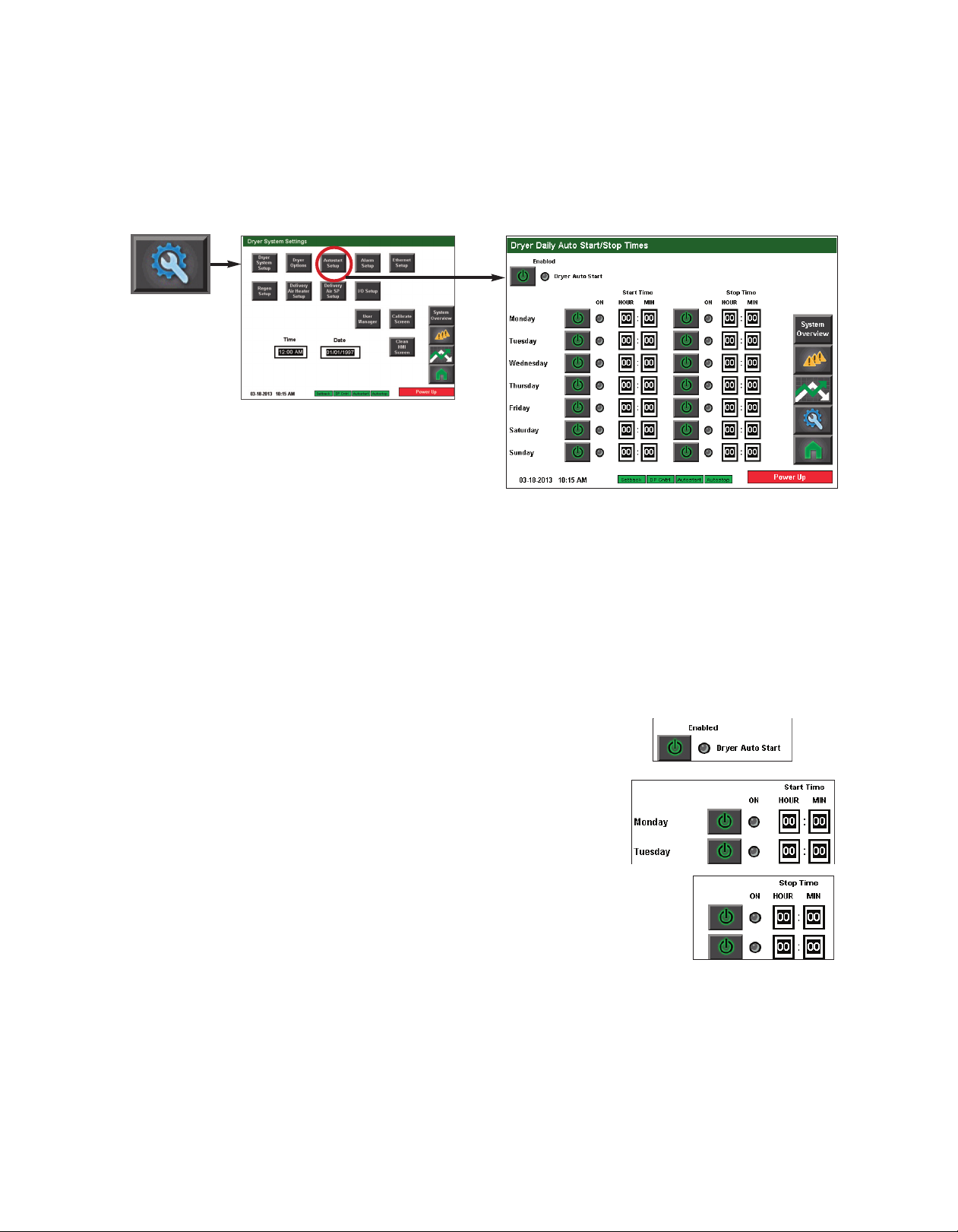

Autostart Setup screen

To access the ResinWorks Autostart screen:

1 Press the Settings button from the Home screen.

✐

NOTE: Autostart timer uses 24

hour time format. 00:00 is midnight. Note that this is a seven (7)

day repeating calendar, and not real

time.

2 Press the Autostart Setup button.

The ResinWorks Autostart Setup screen provides the user with the ability to enable or disable and set the start and stop time for dryer for each day of the week.

To setup Auto Start and Auto Stop:

1 Press the Enable button to enable Dryer Auto Start.

2 Press the Enable button next to each day of the

week you would like to set the Auto Start time.

3 Set the Auto Start time for each day you have

enabled.

4 Press the Enable button next to each day of the week you

would like to set the Auto Stop time.

5 Set the Auto Stop time for each day that you have enabled.

4 - 2 4 l Op er at io n

(continued)

Page 59

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

C o n f i g ur a t i o n ( c on ti nu e d)

ResinWorks Hopper Setup screen

To access the ResinWorks Hopper Setup screen:

1 Press the Settings button from the Home screen.

2 Press the Hopper Setup button.

O p era tio n

4

The ResinWorks Hopper Setup screen provides the user with the ability to move to a screen

where you can:

• Customize hopper names

• Enable hopper heater communication

• Enable DM3-e communication (if equipped)

• Enable DM3-e alarms (if equipped)

✐

NOTE: Proper login is required to change these settings.

✐

NOTE: See the Appendix of this

User Guide for more information

about using the DM3-e Drying

Monitor.

(continued)

O p e r at io n l 4 - 2 5

Page 60

C o n t r o l F u nc t i o n D e s cr i p t i o ns - R W

✐

NOTE: Proper login is required to

change these settings.

C o n f i g ur a t i o n

Hopper Names screen

To access the Hopper Names screen:

( c o nt i nu ed )

1 Press the Settings button from the Home screen.

2 Press the Hopper Setup button.

✐

NOTE: Changing the hopper display

name does not change the order of

the hoppers. This order is based on

the hopper communications settings

and can not be changed.

✐

NOTE: Hopper names can be

changed multipe times as necessary. Conair recommends naming

the hopper using whatever system

works for your application. Some

users may choose to name hoppers

by material type or color; others

may choose to name hoppers

based on physical characteristics,

such as CH-54 Hopper.

3 Press the Hopper Names button.

The Hopper Names screen provides the user with the ability to customize the name of any

hopper in the system. This name will be displayed as the hopper name on all future

screens.

To customize a hopper name:

1 Press the text inside the box of the hopper you would like to rename. All hoppers

are factory named “16c Hopper Name”. (This is simply a space holder for a user

entered hopper name up to 16 characters.)

2 Use the keypad to

enter your new hopper name. Hopper

names can be up to 16

characters in total

length.

3 Press the enter button

when complete.

4 Use steps 1 through 3

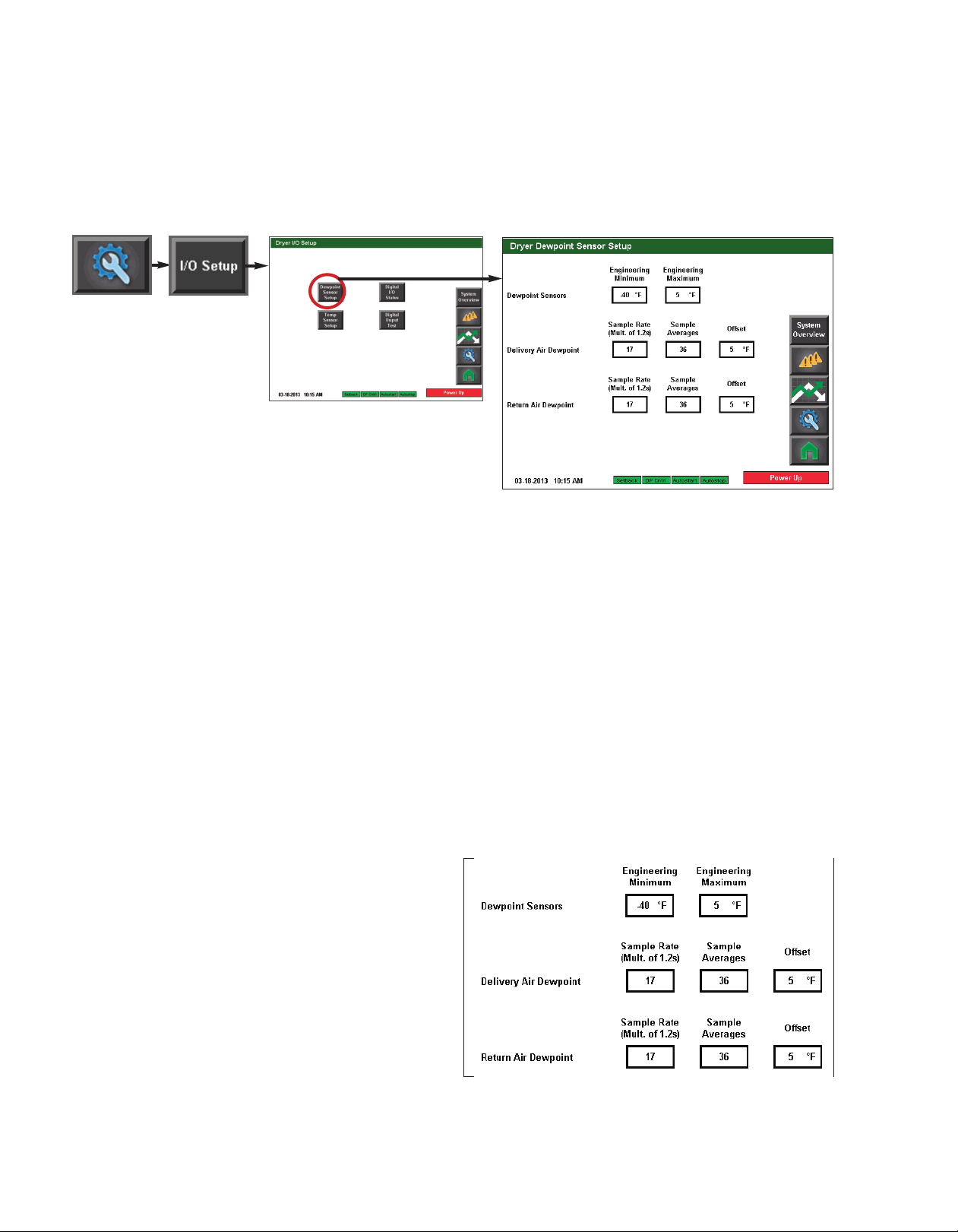

to change the name of