Page 1

DeviceMaster® EIP-MOD

EtherNet®/IP - Modbus®

User Guide

Page 2

Trademark Notices

Document Number: 2000664 Rev A

Comtrol, DeviceMaster, and PortVision are trademarks owned by Pepperl + Fuchs, GmbH and are used

under license by Pepperl + Fuchs Comtrol, Inc.

Concept is a trademark of Schneider Electric.

Modbus is a registered trademark of Schneider Electric.

ControlLogix, PLC-5 and Rockwell Automation are registered trademarks of Rockwell Automation.

MicroLogix, RSLinx, RSLogix 5, RSLogix 500, RSLogix 5000 and SLC are trademarks of Rockwell

Automation.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

Portions of the web interface are copyrighted by GoAhead Software, Inc. Copyright © 2001. GoAhead

Software, Inc. All Rights Reserved.

Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries.

Other product names mentioned herein may be trademarks and/or registered trademarks of their respective

owners.

First Edition, April 3, 2019

Copyright © 2019. Pepperl + Fuchs Comtrol, Inc.

All Rights Reserved.

Pepperl + Fuchs Comtrol, Inc. makes no representations or warranties with regard to the contents of this

document or to the suitability of the Pepperl + Fuchs Comtrol, Inc. product for any particular purpose.

Specifications subject to change without notice. Some software or features may not be available at the time of

publication. Contact your reseller for current product information.

Page 3

Table of Contents

Chapter 1. Introduction........................................................................................................7

1.1. EtherNet/IP-Modbus Gateway Overview.......................................................................................... 7

1.2. System Architecture .............................................................................................................................. 9

1.3. EtherNet/IP to Modbus Translation Layer Architecture............................................................ 10

1.4. Translation Layer Connections ........................................................................................................ 11

1.4.1. Connection Methods Table............................................................................................................. 11

1.4.2. EtherNet/IP Controllers Class1 to/from Shared Memory ............................................................ 12

1.4.3. EtherNet/IP Controllers via Data Mapping to/from Tag/File ...................................................... 12

1.4.4. EtherNet/IP Controllers CIP Modbus Object via MSG Instructions........................................... 13

1.5. Data Type Definitions ......................................................................................................................... 13

1.5.1. Terms and Definitions .................................................................................................................... 14

1.6. What is Modbus? ................................................................................................................................... 16

1.6.1. Modbus/RTU ................................................................................................................................... 16

1.6.2. Modbus/ASCII................................................................................................................................. 17

1.6.3. Modbus/TCP.................................................................................................................................... 18

1.7. Locating the Latest Software and Documentation ...................................................................... 19

Chapter 2. EtherNet/IP Interface Profile (ControlLogix)...........................................21

2.1. Modbus Object (44 Hex, 1 Instance) ................................................................................................. 21

2.1.1. Class Attributes .............................................................................................................................. 21

2.1.2. Instance Attributes......................................................................................................................... 21

2.1.3. Common Services............................................................................................................................ 21

2.1.4. Object Specific Services (Instance Specific) .................................................................................. 22

2.1.4.0.1. Read Discrete Inputs Service (4B Hex)..................................................................................................22

2.1.4.0.2. Read Coils Service (4C Hex)....................................................................................................................22

2.1.4.0.3. Read Input Registers Service (4D Hex)..................................................................................................22

2.1.4.0.4. Read Holding Registers Service (4E Hex)..............................................................................................23

2.1.4.0.5. Write Coils Service (4F Hex)...................................................................................................................23

2.1.4.0.6. Write Holding Registers Service (50 Hex)..............................................................................................23

2.1.4.0.7. Modbus Passthrough Service (51 Hex)...................................................................................................23

2.1.4.0.8. Vendor Specific Write Single Coil Service (70 Hex)...............................................................................23

2.1.4.0.9. Vendor Specific Write Single Register Service (71 Hex) .......................................................................23

2.1.4.0.10. Vendor Specific Write Mask Register (72 Hex)....................................................................................23

2.1.4.0.11. Vendor Specific Read/Write Holding Registers (73 Hex) ....................................................................24

2.2. Informational Objects ......................................................................................................................... 24

2.2.1. Identity Object (01 Hex, 1 Instance).............................................................................................. 24

2.2.1.1. Class Attributes .................................................................................................................... 24

2.2.1.2. Instance Attributes ............................................................................................................... 24

2.2.1.3. Status Word........................................................................................................................... 25

2.2.1.4. Common Services .................................................................................................................. 26

2.2.2. Message Router Object (02 Hex).................................................................................................... 27

2.2.2.1. Class Attributes .................................................................................................................... 27

2.2.2.2. Instance Attributes ............................................................................................................... 27

2.2.2.3. Common Services .................................................................................................................. 27

2.2.3. Connection Manager Object (06 Hex) ............................................................................................ 28

2.2.3.1. Class Attributes Object (06 hex) .......................................................................................... 28

2.2.3.2. Instance Attributes (06 hex)................................................................................................. 28

2.2.3.3. Common Services Object (06 hex) ........................................................................................28

2.2.4. Port Object (F4 Hex - 1 Instance) .................................................................................................. 29

2.2.4.1. Class Attributes .................................................................................................................... 29

2.2.4.2. Instance Attributes (F4 Hex, Instance 1) ............................................................................ 29

2.2.4.3. Instance Attributes (F4 Hex, Instance 2) ............................................................................ 30

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Table of Contents - 3

Page 4

2.2.4.4. Common Services .................................................................................................................. 31

2.2.5. TCP Object (F5 Hex - 1 Instance) .................................................................................................. 31

2.2.5.1. Class Attributes .................................................................................................................... 31

2.2.5.2. Instance Attributes ............................................................................................................... 31

2.2.5.3. Common Services .................................................................................................................. 33

2.2.6. Ethernet Link Object (F6 Hex) ...................................................................................................... 33

2.2.6.1. Class Attributes .................................................................................................................... 33

2.2.6.2. Instance Attributes ............................................................................................................... 34

2.2.6.3. Common Services .................................................................................................................. 35

2.2.7. Assembly Object (For Class 1 Interface) ....................................................................................... 35

2.2.7.1. Class Attributes .................................................................................................................... 35

2.2.7.2. Instance Attributes ............................................................................................................... 35

2.2.7.2.1. Instance Attribute Definitions: Attribute 3-Request/Write Data.........................................................36

2.2.7.2.2. Instance Attribute Definitions: Attribute 4-Data Length.....................................................................36

2.2.7.3. Common Services .................................................................................................................. 36

2.2.7.4. Instance Definitions .............................................................................................................. 36

2.2.7.4.1. Instance Definitions (Default).................................................................................................................36

2.2.7.4.2. All Available Instance Definitions..........................................................................................................37

Chapter 3. Configuration Overview ................................................................................41

3.1. Home Page ............................................................................................................................................. 41

3.2. Serial Port - Configuration Overview ............................................................................................. 43

3.3. Modbus Over TCP Overview - Configuration Overview............................................................. 45

Chapter 4. Serial Menus .....................................................................................................47

4.1. Serial Port Overview Page................................................................................................................. 47

4.2. Serial Port Configuration Page ........................................................................................................ 48

Chapter 5. Modbus Menus..................................................................................................53

5.1. Modbus over TCP (not Modbus/TCP) Overview ........................................................................... 53

5.2. Modbus over TCP (not Modbus/TCP) Socket Configuration Page ........................................... 54

5.3. Modbus/TCP Configuration Page ..................................................................................................... 56

5.4. Remote Modbus/TCP Device Configuration .................................................................................. 57

5.5. Modbus Alias Configuration .............................................................................................................. 59

Chapter 6. Network Menus ................................................................................................61

6.1. Network Configuration Page............................................................................................................. 61

6.2. Password Page ...................................................................................................................................... 63

6.3. Security Settings Page ........................................................................................................................ 64

6.4. Key and Certificate Management Page........................................................................................... 65

6.5. EtherNet/IP Stack Configuration ..................................................................................................... 67

Chapter 7. Data Mapping Menus ......................................................................................69

7.1. Modbus to EtherNet/IP Tag/File Configuration Page ................................................................. 69

7.2. EtherNet/IP Tag/File to Modbus Configuration Page ................................................................. 72

7.3. Modbus to Modbus Configuration Page.......................................................................................... 75

7.4. Shared Memory Configuration Page ............................................................................................... 78

7.5. EtherNet/IP Class 1 Page.................................................................................................................... 83

7.5.1. Active Class1 Interface Page ......................................................................................................... 83

7.5.2. All Shared Memory Class1 Interface Page ................................................................................... 84

7.6. Data Mapping Verification Page ...................................................................................................... 85

7.7. Shared Memory Map Page ................................................................................................................. 87

4 - Table of Contents DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 5

Chapter 8. Diagnostic Menus ............................................................................................91

8.1. Serial Communication Statistics Page ............................................................................................ 92

8.2. Modbus RTU/ASCII over Ethernet TCP Statistics Page ............................................................. 94

8.3. Serial Interface Logs ........................................................................................................................... 96

8.4. Known Modbus Slave Device List .................................................................................................... 97

8.5. Modbus/TCP and Serial Modbus Master Statistics Page .......................................................... 100

8.6. Modbus/TCP Connections Page ...................................................................................................... 104

8.7. Modbus Alias Device ID Statistics Page ....................................................................................... 106

8.8. Shared Memory Contents ................................................................................................................. 107

8.8.1. Shared Holding Block Register Blocks ........................................................................................ 107

8.8.2. Shared Coil Blocks........................................................................................................................ 109

8.9. Ethernet/IP Interface Statistics Page ........................................................................................... 111

8.10. Modbus to EtherNet/IP Tag/File Diagnostics Page.................................................................. 113

8.11. EtherNet/IP Tag/File to Modbus Diagnostics Page.................................................................. 115

8.12. Modbus to Modbus Diagnostics Page .......................................................................................... 116

8.13. System Log ......................................................................................................................................... 118

Chapter 9. System Menus .................................................................................................119

9.1. Update Firmware ............................................................................................................................... 119

9.2. Configuration File Page.................................................................................................................... 121

9.2.1. Saving a Configuration File ......................................................................................................... 121

9.2.2. Loading a Configuration File ....................................................................................................... 122

9.3. System Snapshot Page ...................................................................................................................... 123

9.4. Restore Defaults Page ....................................................................................................................... 124

9.5. Reboot ................................................................................................................................................... 125

Chapter 10. PLC Programming for Modbus Object (44 Hex)...................................127

10.1. Read Discrete Inputs Service (4B Hex)....................................................................................... 127

10.2. Read Coils Service (4C Hex) .......................................................................................................... 129

10.3. Read Input Registers Service (4D Hex) ...................................................................................... 131

10.4. Read Holding Registers Service (4E Hex) .................................................................................. 133

10.5. Write Coils Service (4F Hex).......................................................................................................... 135

10.6. Write Holding Registers Service (50 Hex) ..................................................................................137

10.7. Vendor Specific Write Single Coil Service (70 Hex)................................................................. 141

10.8. Vendor Specific Write Single Register Service (71 Hex) ........................................................ 143

10.9. Vendor Specific Write Mask Register (72 Hex) ......................................................................... 145

10.10. Vendor Specific Read/Write Holding Registers (73 Hex)...................................................... 148

Chapter 11. Class 1 Interface Definition.......................................................................151

11.1. Configuring an I/O Ethernet Module on a ControlLogix PLC............................................... 151

Chapter 12. Troubleshooting and Technical Support ...............................................155

12.1. Troubleshooting Checklist ............................................................................................................ 155

12.2. General Troubleshooting ............................................................................................................... 156

12.3. Daisy-Chaining DeviceMaster EIP-MOD Units With Two Ethernet Ports ......................... 157

12.4. Technical Support............................................................................................................................ 158

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Table of Contents - 5

Page 6

6 - Table of Contents DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 7

Chapter 1. Introduction

This document describes how to configure the DeviceMaster EIP-MOD for the EtherNet/IP-Modbus after

basic DeviceMaster EIP-MOD installation and configuration procedures.

• EtherNet/IP Interface Profile (ControlLogix)

• Configuration Overview

• Serial Menus

• Modbus Menus

• Network Menus

• Diagnostic Menus

• System Menu

See Locating the Latest Software and Documentation

and tools.

on Page 47

on Page 53

on Page 61

s on Page 119

on Page 41

on Page 91

1.1. EtherNet/IP-Modbus Gateway Overview

The DeviceMaster EtherNet/IP-Modbus gateway provides the following functionality.

EtherNet/IP interface support:

• Supports all fully CIP compliant controllers including Rockwell ControlLogix, CompactLogix, SoftLogix,

Schneider Electric, Omron, and GE PLCs, OPC Servers, SCADA systems, HMIs and many more.

• Supports PCCC based PLCs such as MicroLogix, SLC 5/05 and PLC-5.

• EtherNet/IP Interface specifics:

- Maximum CIP sessions = 128

- Maximum CIP input (to PLC) connections = 128

- Maximum CIP output (from PLC) connections = 16

- Write-to-Tag/File and Read-from-Tag/File support

- CIP Modbus Object support. Custom service codes support additional Modbus function codes.

• EtherNet/IP controllers can communicate to:

• Shared Memory

• A wide variety of Modbus slave devices:

- Local serial Modbus/RTU and Modbus/ASCII slave devices

- Modbus/TCP slaves

- Remote serial Modbus/RTU and Modbus/ASCII devices connected to other gateways

• A wide variety of Modbus masters via Shared Memory:

- Modbus/TCP masters

- Modbus/RTU and Modbus/ASCII masters over Ethernet TCP connections

- Serial Modbus/RTU and Modbus/ASCII masters

• Other EtherNet/IP controllers via Shared Memory

- Via Class1 connections to Shared memory

- CIP Modbus Object messages

on Page 21

on Page 19 to locate the latest firmware, documentation,

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 7

Page 8

EtherNet/IP-Modbus Gateway Overview

- Via Read-from-Tag/File and Write-to-File/Tag configurations

The most extensive Modbus functionality in the industry:

• Up to 96 Modbus/TCP connections

• Support up to eight unique Modbus TCP socket port numbers. (i.e. 502, 503, 505, etc.)

• Multiple Modbus/RTU and/or Modbus/ASCII over Ethernet TCP connections

• Local serial Modbus/RTU and Modbus/ASCII slave devices

• Maximum sized Modbus messages

• Serial Modbus/RTU and Modbus/ASCII masters

• Shared Memory that can be configured to provide communication interfaces between a vast array of

Modbus slaves, Modbus masters and EtherNet/IP controllers.

• Modbus Alias functionality

• Remote Modbus device connectivity

• Modbus slave to Modbus slave communication

• Private Modbus serial bus connectivity – A serial port connected to a serial master and one or more serial

slave devices

A Data Mapping process that provides:

• EtherNet/IP Tag/File to Modbus connectivity - to either Modbus device(s) or Shared memory

• Modbus to EtherNet/IP Tag/File connectivity - from either Modbus device(s) or Shared memory

• Modbus to Modbus connectivity

- Can read from multiple Modbus devices into Shared Memory.

- Can write from Shared memory to multiple Modbus devices.

- Can read directly from one Modbus slave device to another Modbus slave device anywhere on the

Modbus network. These devices can be of any supported type, local or remote.

- Can convert from Modbus register type to another automatically.

• A Data Mapping verification web page that checks for possible Modbus write conflicts, incorrect

configuration and write violations.

• A Shared Memory map web page that displays the Shared Memory read and write memory blocks as

defined utilized by the Data Mapping.

8 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 9

1.2. System Architecture

The DeviceMaster EtherNet/IP-Modbus firmware utilizes the following architecture.

System Architecture

The firmware architecture is designed to take full advantage of a broad range of EtherNet/IP and Modbus

routing functionality supported by the DeviceMaster EtherNet/IP-Modbus gateway.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 9

Page 10

EtherNet/IP to Modbus Translation Layer Architecture

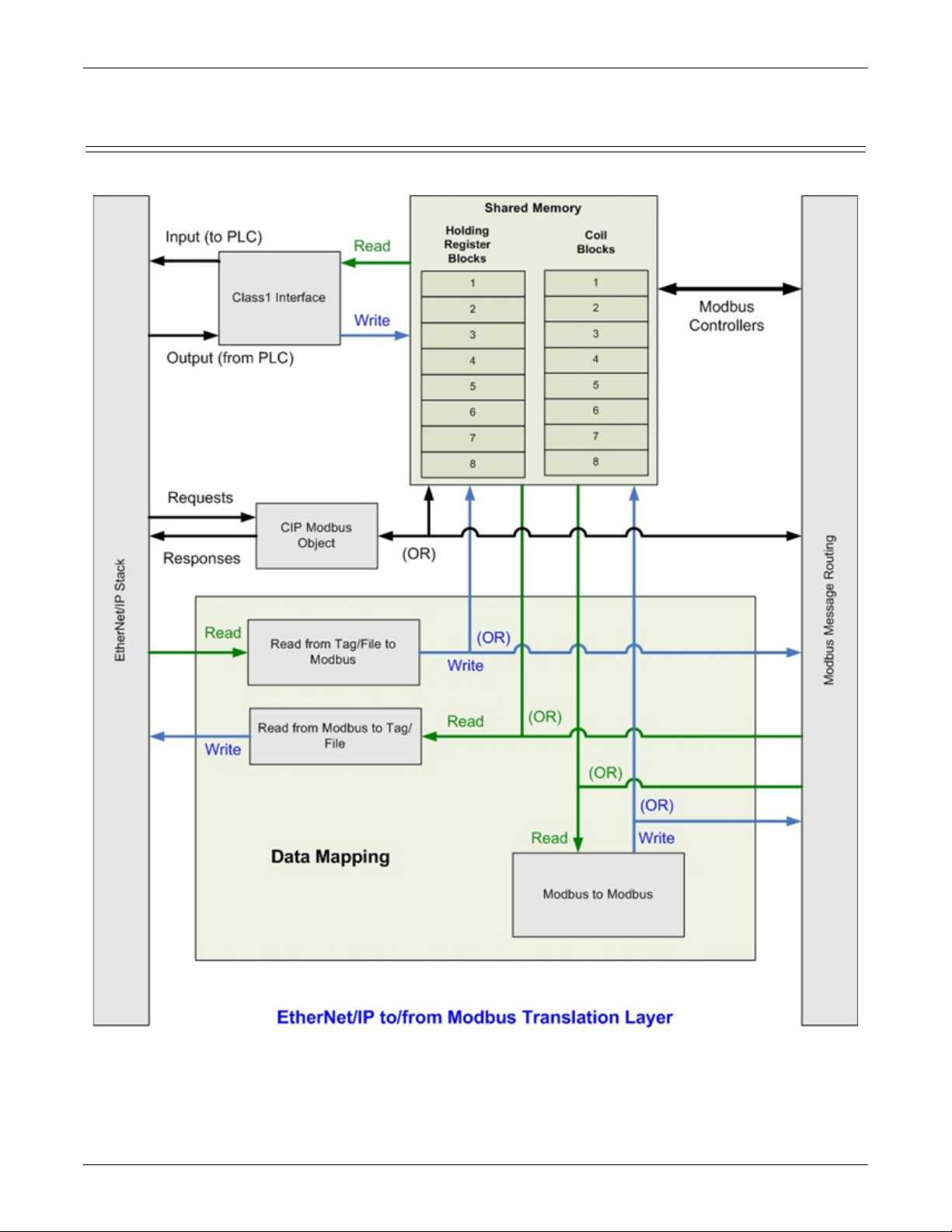

1.3. EtherNet/IP to Modbus Translation Layer Architecture

The following image illustrates the EtherNet/IP to/from Modbus translation layer.

10 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 11

Translation Layer Connections

1.4. Translation Layer Connections

The following connections are possible through the translation layer.

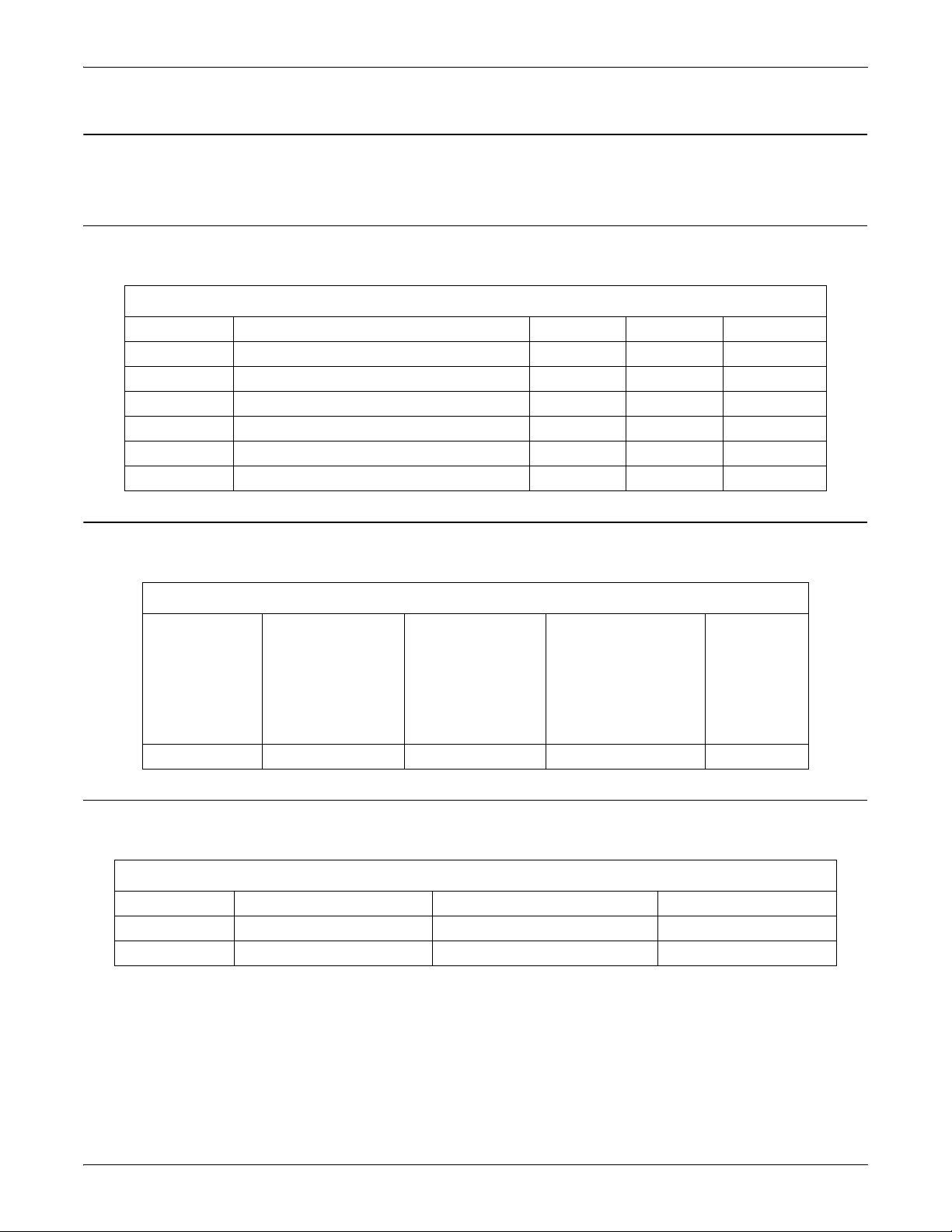

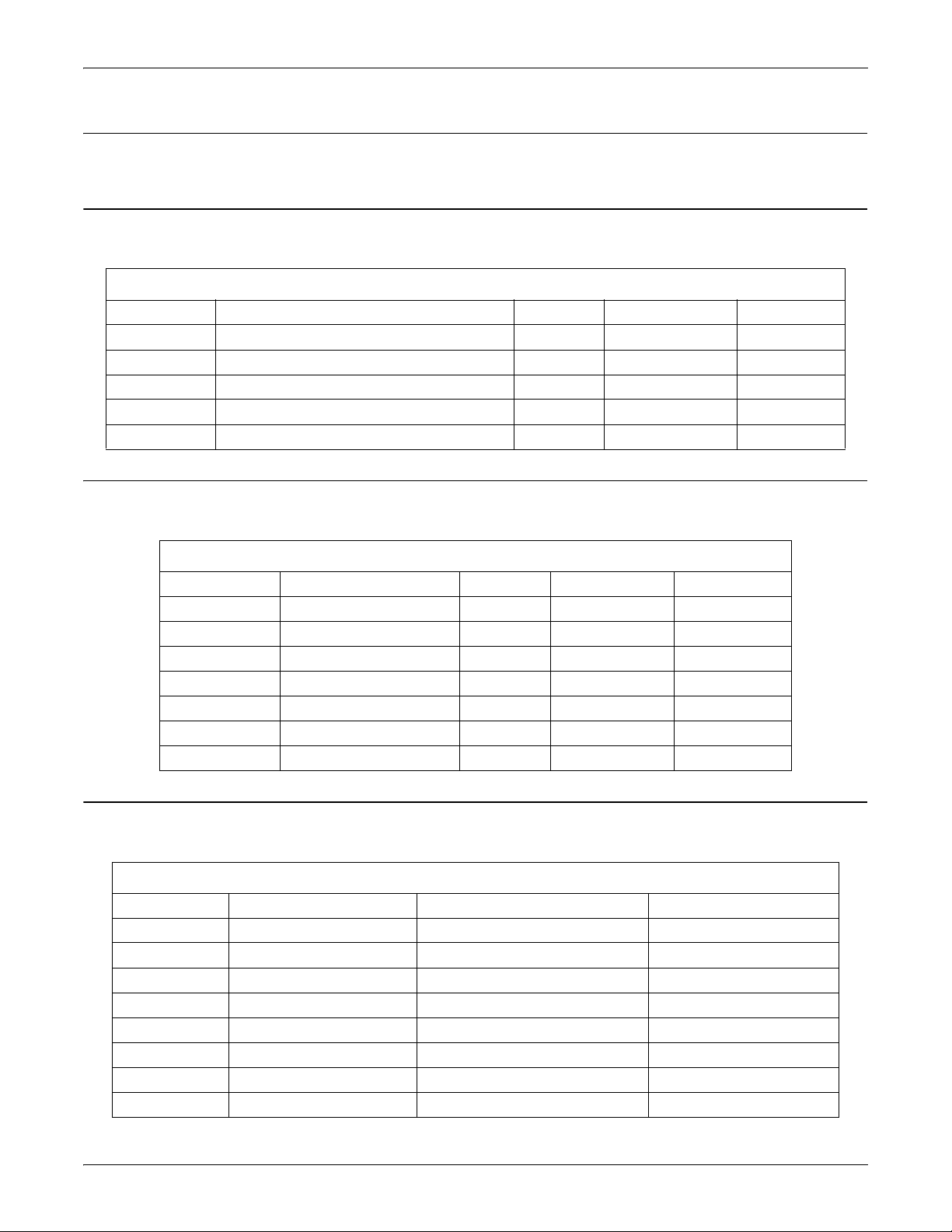

1.4.1. Connection Methods Table

This table lists the possible connections and the methods available for a wide variety of EtherNet/IP and

Modbus interfaces.

Write (To)

via Tag/File

Class1 Connection

EtherNet/IP PLC(s) via

EtherNet/IP PLC(s) via

Class1 Connection

EtherNet/IP PLC(s) via Tag/

File

EtherNet/IP PLC(s) via

Modbus Object

Modbus/TCP Master(s)2322221,31,31,3

Modbus RTU/ASCII Serial

Master(s)

Modbus RTU/ASCII Over

Ethernet TCP Master(s)

Read (From)

Modbus RTU/ASCII Serial

Slave(s)

Modbus/TCP Slave(s) 3 3,4 1,3 1,3 1,3 1,3 3,4 3,4 3,4

Remote Modbus RTU/ASCII

Serial Slave(s)

Where the method is:

1 = via direct message to Modbus slave device

2 = via Shared Memory

3 = via Shared Memory and use of Data Mapping

4 = via use of only Data Mapping

232222333

3333333,43,43,4

2322221,31,31,3

2322221,31,31,3

2322221,31,31,3

3 3,4 1,3 1,3 1,3 1,3 3,4 3,4 3,4

3 3,4 1,3 1,3 1,3 1,3 3,4 3,4 3,4

EtherNet/IP PLC(s)

via Modbus Object

EtherNet/IP PLC(s)

Modbus/TCP Master(s)

Serial Master(s)

Modbus RTU/ASCII

Modbus RTU/ASCII

Over Ethernet TCP Master(s)

Serial Slave(s)

Modbus RTU/ASCII

Serial Slave(s)

Modbus/TCP Slave(s)

Remote Modbus RTU/ASCII

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 11

Page 12

EtherNet/IP Controllers Class1 to/from Shared Memory

1.4.2. EtherNet/IP Controllers Class1 to/from Shared Memory

The following provides information about EtherNet/IP controllers Class1 to and from shared memory.

• Combined with the Data Mapping Modbus to Modbus functionality:

- Local serial Modbus/RTU and Modbus/ASCII slave devices.

- Remote serial Modbus/RTU and Modbus/ASCII slave devices (via additional gateways).

- Remote Modbus/TCP slaves.

• Modbus Controllers:

- Modbus/TCP masters

- Modbus/RTU and Modbus/ASCII over Ethernet TCP masters

- Serial Modbus/RTU and Modbus/ASCII masters

• Other EtherNet/IP controllers:

- Utilizing Class1 connections

- Combined with the Data Mapping Read Tag/File Write Modbus functionality

- Combined with the Data Mapping Read Modbus Write Tag/File functionality

1.4.3. EtherNet/IP Controllers via Data Mapping to/from Tag/File

The following provides information about EtherNet/IP controllers via data mapping to and from Tag/File.

• Directly to/from Modbus slave devices:

- Local serial Modbus/RTU and Modbus/ASCII slave devices.

- Remote serial Modbus/RTU and Modbus/ASCII slave devices (via additional gateways).

- Modbus/TCP slaves.

• Through Shared Memory:

- Combined with the Data Mapping Modbus to Modbus functionality:

- Local serial Modbus/RTU and Modbus/ASCII slave devices.

- Remote serial Modbus/RTU and Modbus/ASCII slave devices (via additional gateways).

- Remote Modbus/TCP slaves.

- Modbus Masters:

- Modbus/TCP masters

- Modbus/RTU and Modbus/ASCII over Ethernet TCP masters

- Serial Modbus/RTU and Modbus/ASCII masters

- Other EtherNet/IP controllers:

- Utilizing Class1 connection(s)

- Combined with the Data Mapping Read Tag/File Write Modbus functionality

- Combined with the Data Mapping Read Modbus Write Tag/File functionality

12 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 13

EtherNet/IP Controllers CIP Modbus Object via MSG Instructions

1.4.4. EtherNet/IP Controllers CIP Modbus Object via MSG Instructions

The following provides information about EtherNet/IP controller CIP Modbus object via MSG instructions.

• Directly to/from Modbus slave devices:

- Local serial Modbus/RTU and Modbus/ASCII slave devices.

- Remote serial Modbus/RTU and Modbus/ASCII slave devices (via additional gateways).

- Modbus/TCP slaves.

• Through Shared Memory:

- Combined with the Data Mapping Modbus to Modbus functionality:

- Local serial Modbus/RTU and Modbus/ASCII slave devices.

- Remote serial Modbus/RTU and Modbus/ASCII slave devices (via additional gateways).

- Remote Modbus/TCP slaves.

- Modbus Masters:

- Modbus/TCP masters

- Modbus/RTU and Modbus/ASCII over Ethernet TCP masters

- Serial Modbus/RTU and Modbus/ASCII masters

- Other EtherNet/IP controllers:

- Utilizing Class1 connection(s)

- Combined with the Data Mapping Read Tag/File Write Modbus functionality

- Combined with the Data Mapping Read Modbus Write Tag/File functionality

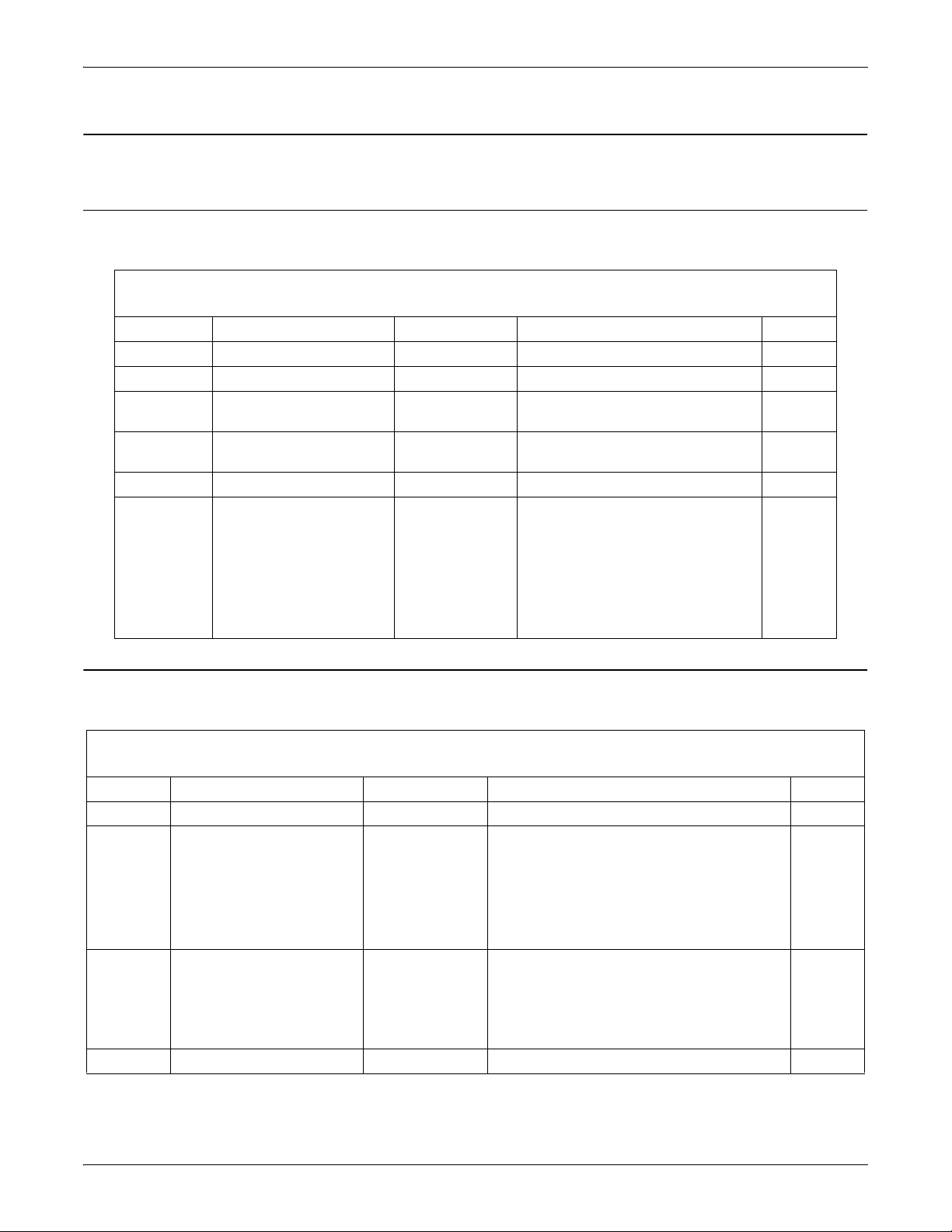

1.5. Data Type Definitions

The following list defines the available data types.

Data Type Definition

USINT Unsigned short integer (8-bits)

UINT Unsigned integer (16-bit)

UDINT Unsigned double integer (32-bits)

INT Signed integer (16-bits)

DINT Signed double integer (32-bits)

BYTE Bit string (8-bits)

WORD Bit string (16-bits)

DWORD Bit string (32-bits)

STRING Character string (1-byte per character)

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 13

Page 14

Terms and Definitions

1.5.1. Terms and Definitions

This section uses the following terms and definitions.

Term Definition

Otherwise called implicit messaging, is a method of communication between

EtherNet/IP controllers and devices that:

Class 1

Class 3

EtherNet/IP

Ethernet TCP/IP

Ethernet UDP/IP

Multicast

Point-to-Point

Master (or Client)

Mode

Slave (or Server)

Mode

Device ID

Device ID Offset

Received Device ID The original device ID received in the Modbus message from a Modbus master.

Alias Device ID

Local Slave Device

Remote Slave

Device

• Uses Ethernet UDP messages.

• Is cyclic in nature. Input and/or output data is exchanged between the

controllers and devices at regular time intervals.

Otherwise called explicit messaging, is a method of communication between

EtherNet/IP controllers and devices that:

• Uses Ethernet TCP/IP messages.

• By itself is not cyclic in nature. The controller and devices must send

individual messages to each other.

An Ethernet based industrial communication protocol utilized to communicate

between controllers, often times PLCS, and devices.

Standard Ethernet communications protocol utilizing socket communication

interfaces that guarantees delivery to the intended device.

Standard Ethernet communications protocol utilizing socket communication

interfaces that does not guarantee delivery. The data may or may get to the

intended device.

Multicast addressing involves Ethernet devices sending messages to each other

using a multicast address. Multicast addressing:

• Uses a specified IP address range designated for multicast communication.

• Allows either one or multiple devices to receive the same messages.

Point-to-Point, otherwise called unicast, addressing involves Ethernet devices

sending messages directly to each other using their own IP addresses. Messages

are sent to only one device.

The method of operation when a PLC, a gateway, or an application is operating

as a Master or the message originator.

The method of operation when a PLC, a gateway, or an application is operating

as a Slave or the message receiver.

The Modbus device identification number. Device IDs include:

• 0 = Broadcast

• 1-247 = Standard device IDs

• 248-255 = Reserved device IDs (generally used for vendor specific gateway

functions)

An offset applied at the slave serial port interface that changes the message

device ID range to match the serial device(s) device ID range.

The device ID that the original received ID is changed to when an Alias Device

ID is configured.

A local slave device is one that is connected directly to a serial port on the

gateway.

A remote slave device is either a slave Modbus/TCP device or a serial slave

device attached to another gateway and accessed as a remote Modbus/TCP

device.

14 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 15

Terms and Definitions

Term Definition (Continued)

The standard Modbus messages, in hexadecimal format, that are typically

transmitted over serial lines but can also be transmitted over other

Modbus/RTU

communication methods such as wireless or Ethernet TCP/IP socket

connections.

Note: Modbus/RTU over Ethernet TCP/IP is not the same as Modbus TCP.

Modbus/ASCII

An ASCII, or character based, form of Modbus. The base message is the same as

Modbus/RTU, but the format is somewhat different.

An Ethernet based form of Modbus communication. The base message is the

Modbus/TCP

same as Modbus/RTU, but a special Modbus header is included for packet

identification and routing purposes.

The process where a PLC or Application requests data on a continual basis. In

Polling

this operation the Master sends the request messages while the Slave responds

to the messages.

Ethernet TCP/IP A form of Ethernet connectivity that provides a level of guaranteed delivery and

data verification. This is used for many upper layer protocols such as Modbus/

TCP and can be also used for transferring Modbus/RTU and Modbus/ASCII.

messages.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 15

Page 16

What is Modbus?

1.6. What is Modbus?

This subsection discusses:

•

Modbus/RTU

• Modbus/ASCII on Page 17

• Modbus/TCP

1.6.1. Modbus/RTU

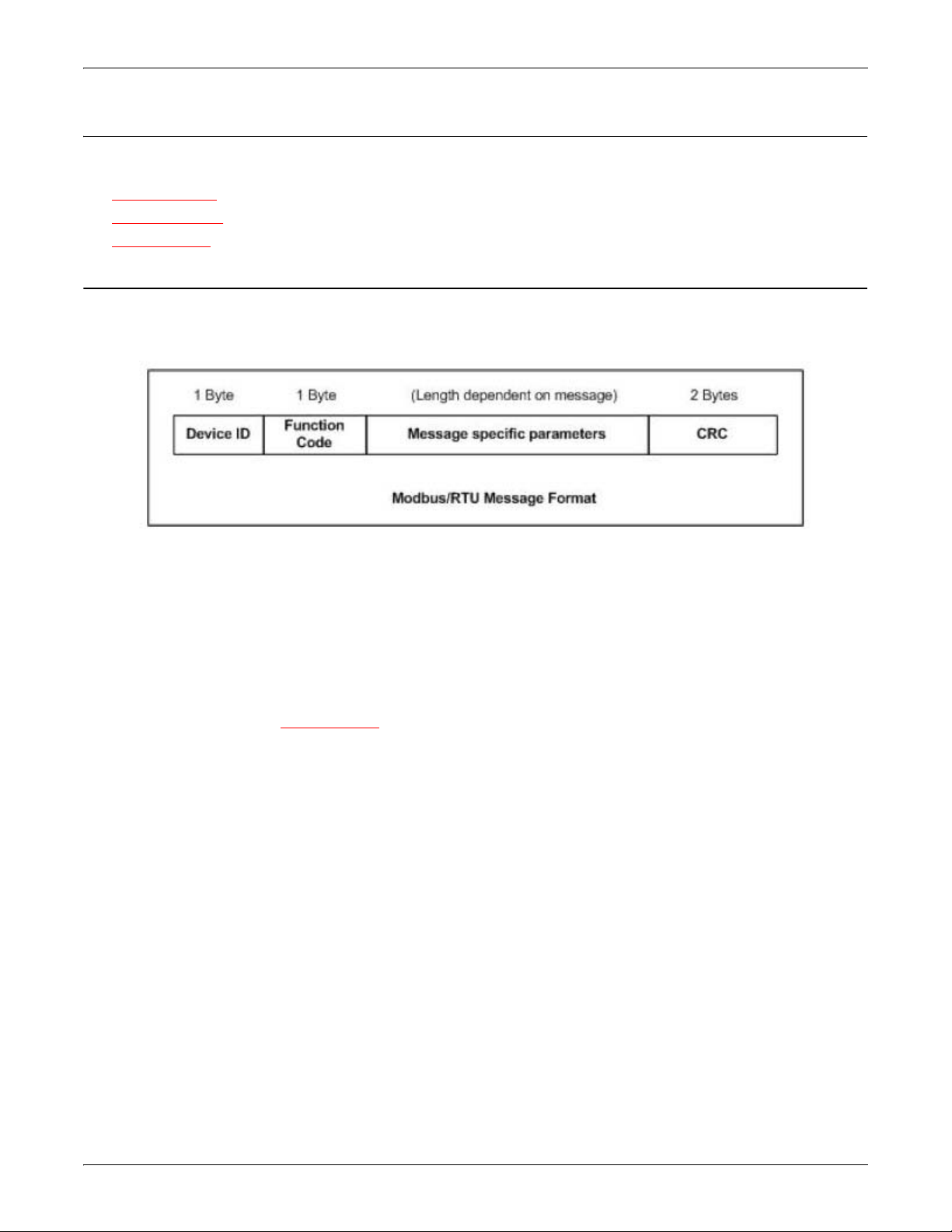

Modbus/RTU is native Modbus in hexadecimal format. These are the base Modbus messages that contain

simple read and write requests. The format is as follows:

on Page 18

Where:

•The terms Master or Client are used to identify the sender of the message.

•The terms Slave or Server are used to identify the devices responding to the message.

Modbus/RTU is used primarily for:

• Serial port connectivity

RS-485 is the most common serial mode, but RS-232 and RS-422 are also widely used. Commonly used by

both Master and Slave devices.

• Ethernet TCP/IP socket connections

This is not the same as Modbus/TCP

remote devices. It is used by many applications and some OPC servers.

Note: This communication method typically is not supported by PLCs.

on Page 18, but does provide a very simple method of interfacing to

16 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 17

Modbus/ASCII

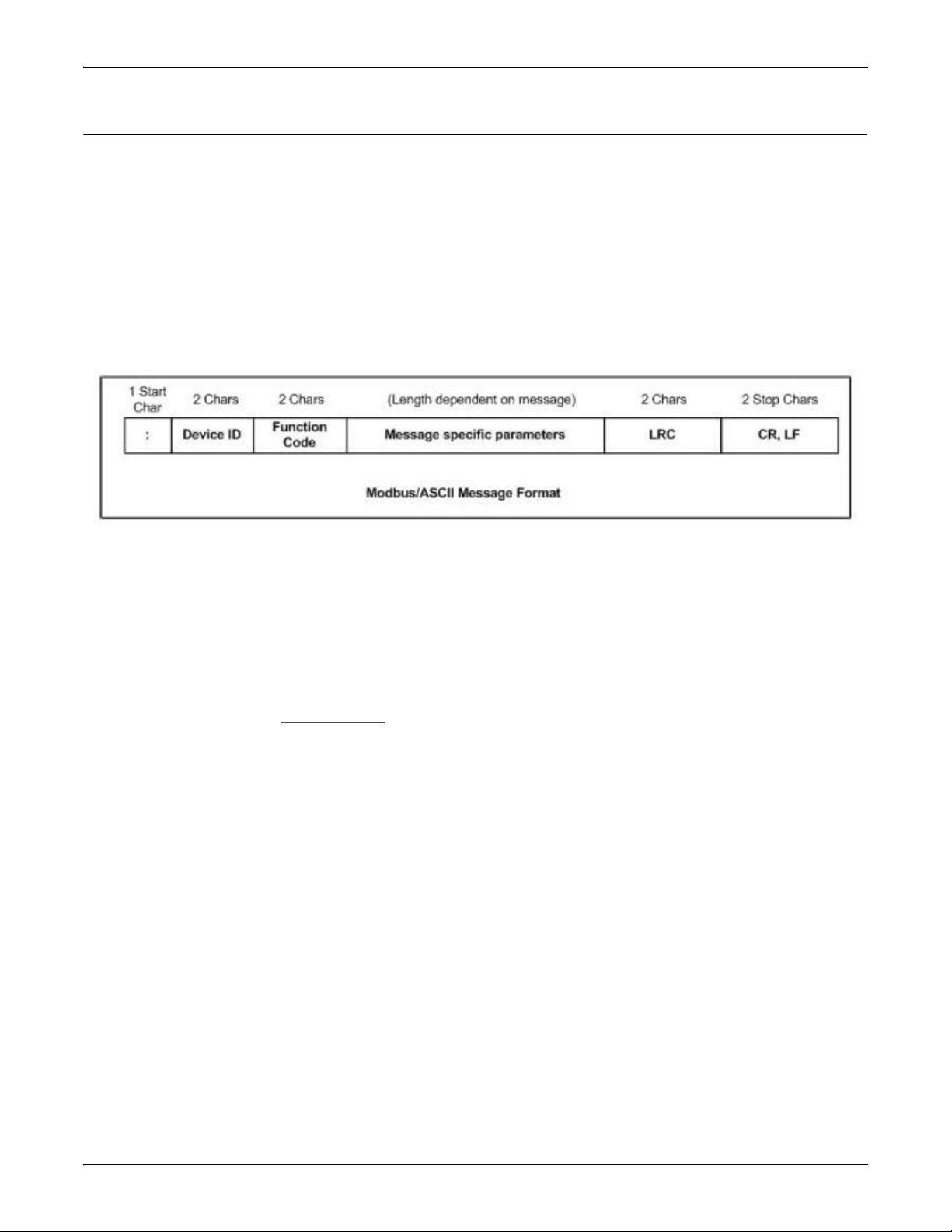

1.6.2. Modbus/ASCII

Modbus/ASCII is native Modbus in ASCII format. This protocol is used primarily by legacy devices and is no

longer supported as widely as Modbus/RTU.

Like Modbus/RTU, Modbus/ASCII contains the base Modbus messages that contain simple read and write

requests. The differences between Modbus/ASCII and Modbus/RTU are:

1. The message data is sent in ASCII format, so the message length is twice as long. It requires two ASCII

characters for each byte of data.

2. An 8-bit LRC is attached to verify the message instead of a 16-bit CRC. The LRC is also transmitted in

ASCII format.

3. There are defined starting and ending characters to determine a Modbus/ASCII messages.

The format is as follows:

Where:

•The terms Master or Client are used to identify the sender of the message.

•The terms Slave or Server are used to identify the devices responding to the message.

Modbus/ASCII is used primarily for:

• Serial port connectivity

RS-485 is the most common serial mode, but RS-232 and RS-422 are also used. Used primarily by legacy

Slave devices.

• Ethernet TCP/IP socket connections

This is not the same as

Modbus/TCP, but does provide a very simple method of interfacing to remote

devices. It is used by some applications and some OPC servers.

Note: This communication method typically is not supported by PLCs.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 17

Page 18

Modbus/TCP

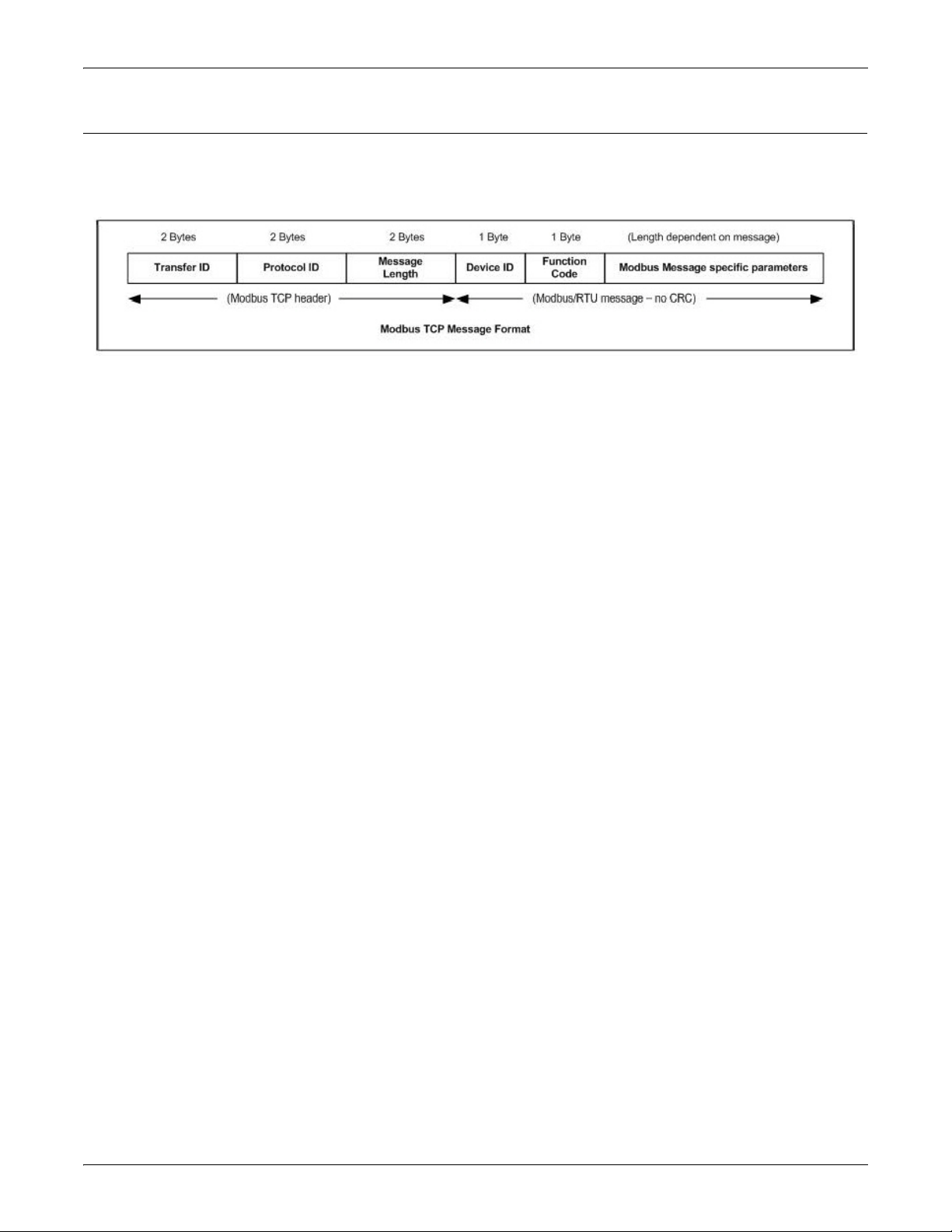

1.6.3. Modbus/TCP

Modbus/TCP is an Ethernet network based protocol that contains a Modbus/RTU message, with the exception

of the 2-byte CRC. The Modbus/TCP message contains a header with information designed to provide

message identification and routing information. The format is as follows:

Where:

•The terms Master or Client are used to identify the sender of the message.

•The terms Slave or Server are used to identify the devices responding to the message.

• Modbus/TCP messages are typically sent to and received on a defined Ethernet TCP/IP socket of 502.

• Modbus/TCP implementations provide more capability, but also require more processing than simpler

Modbus/RTU implementations.

Modbus/TCP is used for connecting advanced Ethernet based devices, such as PLCs, HMIs, SCADA Systems,

and most OPC Servers to:

• Other Ethernet devices supporting Modbus/TCP.

• Remote serial Modbus/RTU and/or Modbus/ASCII devices through gateways (such as the DeviceMaster

EIP-MOD running the EtherNet/IP-Modbus or Modbus/TCP applications).

• Remote serial or Ethernet TCP/IP ASCII devices (barcode scanners, printers, RFID readers, visions

systems, etc) through a gateway (such as the DeviceMaster EIP-MOD running the Modbus/TCP

application).

18 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 19

Locating the Latest Software and Documentation

1.7. Locating the Latest Software and Documentation

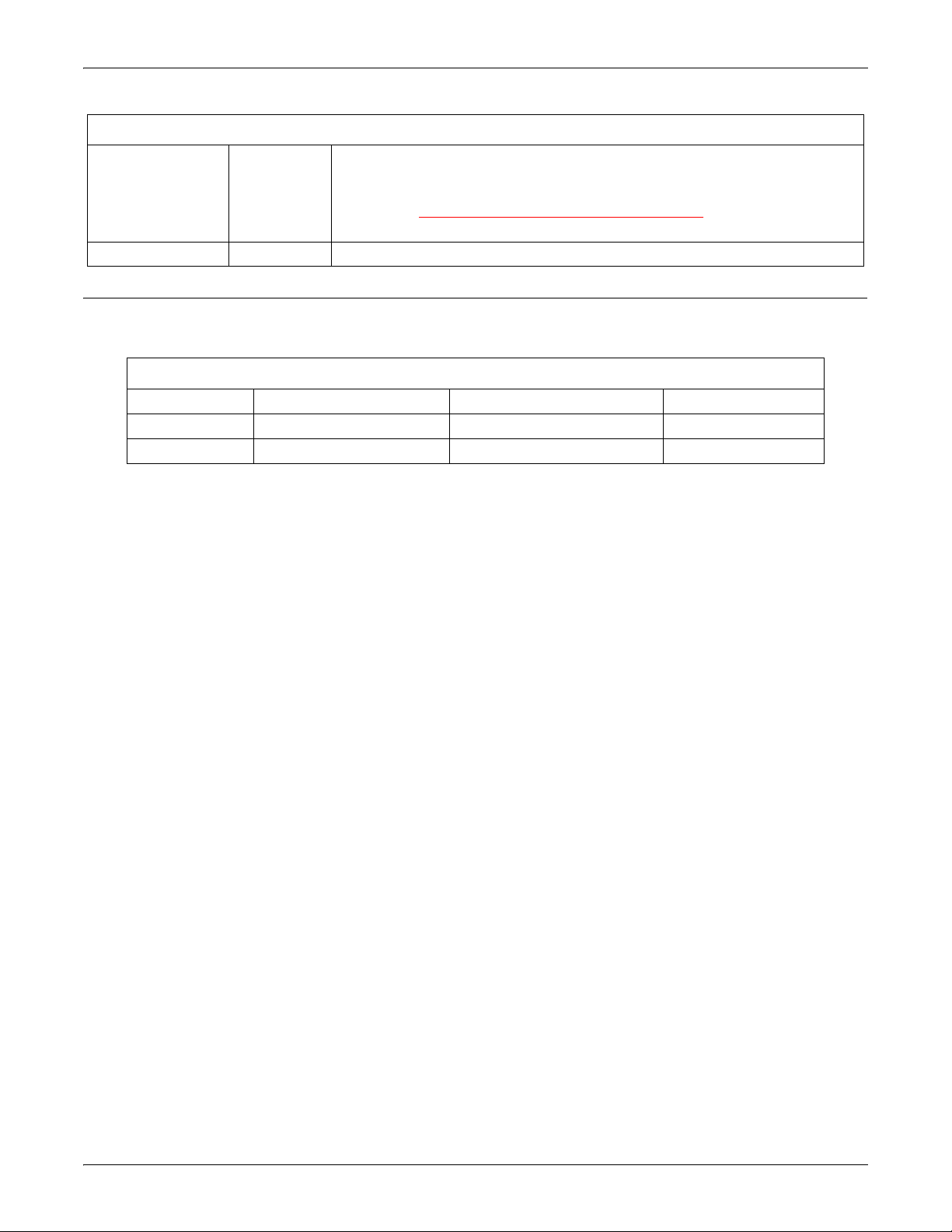

You can use the links in this table to check for updated software or documentation.

Software and Documentation FTP

Use PortVision DX to manage Pepperl+Fuchs Comtrol, Inc. Ethernetattached devices to:

• Scan the network for attached devices

• View networked devices in real-time

• Access product-specific network settings configurations

• Assign IP addresses and network settings to one or multiple

devices

PortVision DX

(Windows)

EtherNet/IP-Modbus

Firmware

EtherNet/IP-Modbus

Hardware Installation and

Configuration Guide

EtherNet/IP-Modbus User

Guide

(this guide)

• Upload the latest firmware or Bootloader

• Save and load configuration files

• Access DeviceMaster EIP-MOD configuration web pages

• Access Telnet/SSH sessions

• Remotely reboot devices

• Download technical documentation

• Enable event logging to assist in monitoring and troubleshooting

• Create shortcuts to quickly access your favorite applications

• Organize devices into folders and create multiple views

• Enter notes about a folder or device

This is the application that may or may not have been loaded on the

DeviceMaster EIP-MOD depending on the model that was ordered.

You may need to use PortVision DX to load this firmware.

This contains hardware installation, configuration information, and

connector information.

This includes using PortVision DX to configure the IP address and if

necessary, how to update the firmware.

This User Guide contains detailed information about the EtherNet/IPModbus (application) firmware, which includes additional information

about the web configuration interface.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 1. Introduction - 19

Page 20

Locating the Latest Software and Documentation

20 - Chapter 1. Introduction DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 21

Chapter 2. EtherNet/IP Interface Profile (ControlLogix)

This section describes the EtherNet/IP objects included in the ControlLogix EtherNet/IP interface and

supported by the DeviceMaster EIP-MOD.

2.1. Modbus Object (44 Hex, 1 Instance)

The Modbus Object provides an interface to the data and functions within a Modbus device or the Shared

memory on the DeviceMaster EtherNet/IP-Modbus gateway. It utilizes CIP object specific services to

implement Modbus functions through an explicit CIP message.

Note: The instance number is used to define the device or unit Id of the Modbus device or Shared memory.

2.1.1. Class Attributes

The following table displays the Class Attributes for Modbus Object (44 hex, 1 Instance).

There is no support for broadcast Modbus messages, which have a device Id of zero.

Attribute

ID

1 Revision UINT 1 Get

2 Max Instance UINT 255 (maximum Modbus device Id) Get

3 Num Instances UINT 255 (maximum Modbus device Id) Get

6

7

Name

Maximum

Number Class

Attribute

Maximum

Number Instance

Attribute

Data

Type

UINT 7 Get

UINT 0 Get

Data Value(s)

2.1.2. Instance Attributes

There are no Instance Attributes.

2.1.3. Common Services

This table provides the Common Services for Modbus Object (44 hex, 1 instance).

Service Code Implemented in Class Implemented in Instance Service Name

Access

Rule

0E hex Yes Yes Get_Attribute_Single

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 21

Page 22

| Modbus Object (44 Hex, 1 Instance) | Object Specific Services (Instance Specific) | |

2.1.4. Object Specific Services (Instance Specific)

These services are provided to implement the supported Modbus functions. All Modbus Object services, as

specified in Volume 7: Integration of Modbus Devices into the CIP Architecture, are supported as well as

several additional services.

Service Code Service Name Service Description

4B hex Read Discrete Inputs Reads one or more contiguous discrete input(s).

4C hex Read Coils Reads one or more contiguous coil(s).

4D hex Read Input Registers Reads one or more contiguous input register(s).

4E hex Read Holding Registers Reads one or more contiguous holding register(s).

4F hex Write Coils Writes one or more contiguous coil(s).

50 hex Write Holding Registers Writes one or more contiguous holding register(s).

51 hex Modbus Pass through

70 hex ** Write Single Coil Writes a single coil.

71 hex ** Write Single Register Writes a single holding register.

72 hex ** Mask Write Register

73 hex ** Read/Write Holding Registers

** = Vendor specific services provided to support additional Modbus functions.

Provides encapsulation of any public or private

Modbus function.

Perform a mask write operation on a single holding

register.

Writes one or more holding register(s) and reads one

or more holding register(s).

Note: In order to use these services, the Enable Vendor Specific Modbus Object Services option on the

EtherNet/IP Stack Configuration web page must be selected.

2.1.4.0.1. Read Discrete Inputs Service (4B Hex)

This service reads one or more discrete inputs from the Modbus Discrete Inputs table. This service results in

the DeviceMaster EIP-MOD issuing a Read Discrete Inputs function (function code 0x02) to either the Shared

Memory or the Modbus Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3 and/or

MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

2.1.4.0.2. Read Coils Service (4C Hex)

This service reads one or more coils from the Modbus Coils table. This service results in the DeviceMaster

EIP-MOD issuing a Read Coils function (function code 0x01) to either the Shared Memory or the Modbus

Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3 and/or MODBUS Application

Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

2.1.4.0.3. Read Input Registers Service (4D Hex)

This service reads one or more input registers from the Modbus Input Register table. This service results in

the DeviceMaster EIP-MOD issuing a Read Input Registers function (function code 0x04) to either the Shared

Memory or the Modbus Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3 and/or

MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

22 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 23

| Modbus Object (44 Hex, 1 Instance) | Object Specific Services (Instance Specific) | |

2.1.4.0.4. Read Holding Registers Service (4E Hex)

This service reads one or more holding registers from the Modbus Holding Register table. This service results

in the DeviceMaster EIP-MOD issuing a Read Holding Registers function (function code 0x03) to either the

Shared Memory or the Modbus Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3

and/or MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

2.1.4.0.5. Write Coils Service (4F Hex)

This service writes one or more coils to the Modbus Coils table. This service results in the DeviceMaster EIPMOD issuing a Write Multiple Coils function (function code 0x0F) to either the Shared Memory or the

Modbus Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3 and/or MODBUS

Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

2.1.4.0.6. Write Holding Registers Service (50 Hex)

This service writes one or more holding registers to the Modbus Holding Registers table. This service results

in the DeviceMaster EIP-MOD issuing a Write Multiple Registers function (function code 0x10) to either the

Shared Memory or the Modbus Message Routing subsystem. Refer to CIP Standard Vol1_3.22 Section 5B-3

and/or MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

2.1.4.0.7. Modbus Passthrough Service (51 Hex)

The Modbus Passthrough service provides a way for a client to initiate a specific Modbus function to a target

Modbus device. The Modbus request and response are encapsulated in the CIP request and response service

data fields with no modification. The DeviceMaster EIP-MOD does not attempt to perform any byte endian

conversion on the bytes in the data stream (either request or response). Refer to CIP Standard Vol1_3.22

Section 5B-3 and/or MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more

details.

2.1.4.0.8. Vendor Specific Write Single Coil Service (70 Hex)

This service writes one coil to the Modbus Coils table. This service results in the DEVICEMASTER

ETHERNET/IP- DeviceMaster EIP-MOD issuing a Write Single Coil function (function code 0x05) to either

the Shared Memory or the Modbus Message Routing subsystem. Refer to MODBUS Application Protocol

Specification V1.1b3.pdf at www.modbus.org

for more details.

Note: In order to use this service, the Enable Vendor Specific Modbus Object Services option on the EtherNet/

IP Stack Configuration web page must be selected.

2.1.4.0.9. Vendor Specific Write Single Register Service (71 Hex)

This service writes one holding register to the Modbus Holding Registers table. This service results in the

DeviceMaster EIP-MOD issuing a Write Single Registers function (function code 0x06) to either the Shared

Memory or the Modbus Message Routing subsystem. Refer to MODBUS Application Protocol Specification

V1.1b3.pdf at www.modbus.org

for more details.

Note: In order to use this service, the Enable Vendor Specific Modbus Object Services option on the EtherNet/

IP Stack Configuration web page must be selected.

2.1.4.0.10. Vendor Specific Write Mask Register (72 Hex)

This service performs a write mask operation on one holding register in the Modbus Holding Registers table.

This service results in the DeviceMaster EtherNet/IP-Modbus gateway issuing a Write Mask Register

function (function code 0x16) to either the Shared Memory or the Modbus Message Routing subsystem. Refer

to MODBUS Application Protocol Specification V1.1b3.pdf at www.modbus.org

for more details.

Note: In order to use this service, the Enable Vendor Specific Modbus Object Services option on the EtherNet/

IP Stack Configuration web page must be selected.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 23

Page 24

| Informational Objects | Identity Object (01 Hex, 1 Instance) | Class Attributes |

2.1.4.0.11. Vendor Specific Read/Write Holding Registers (73 Hex)

This service performs first write and then read operations on multiple holding registers in the Modbus

Holding Registers table. This service results in the DeviceMaster EtherNet/IP-Modbus gateway issuing a

Read/Write Holding Registers function (function code 0x17) to either the Shared Memory or the Modbus

Message Routing subsystem. Refer to MODBUS Application Protocol Specification V1.1b3.pdf at

www.modbus.org

Note: In order to use this service, the Enable Vendor Specific Modbus Object Services option on the EtherNet/

IP Stack Configuration web page must be selected.

for more details.

2.2. Informational Objects

The following object definitions are included for informational purposes only. While some software packages,

such as RSLinx make use of these objects, few PLC programmers will have a need to directly access them.

2.2.1. Identity Object (01 Hex, 1 Instance)

The Identity Object provides identification of and general information about the DeviceMaster EIP-MOD.

2.2.1.1. Class Attributes

The following table provides information about the Identity Object (01 hex, 1 Instance) Class Attributes.

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2 Max Class UINT 1 Get

3 Max Instance UINT 1 Get

6 Maximum Number Class Attribute UINT 7 Get

7 Maximum Number Instance Attribute UINT 7 Get

2.2.1.2. Instance Attributes

The following table provides information about the Identity Object (01 hex, 1 Instance) Instance Attributes.

Attribute ID Name Data Type Data Value(s) Access Rule

1 Vendor ID UINT 909 (Pepperl+Fuchs Comtrol, Inc.) Get

2 Device Type UINT 43 (Generic product device) Get

3 Product Code UINT

Revision (product or software release)

Structure of:

4

Minor Revision USINT 1 to 999

5 Status WORD See below. Get

6 Serial Number UDINT 1-FFFFFFFF hex Get

As defined by Pepperl+Fuchs

Comtrol, Inc.

Get

GetMajor Revision USINT 1 to 127

24 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 25

| Informational Objects | Identity Object (01 Hex, 1 Instance) | Status Word |

Attribute ID Name Data Type Data Value(s) Access Rule

Product Name

Structure of:

7

Name Length USINT Length of string

Get

Name String STRING See below

2.2.1.3. Status Word

Refer to Page 52 of Volume 3.5 of the CIP Common Specification. The following applies to the Identity Object

status word for the DeviceMaster EtherNet/IP-Modbus gateway.

Status Word Bit Setting Description

00

Ownership Flag. Does not apply to the DeviceMaster EtherNet/IPModbus gateway.

1 0 Reserved.

0

2

1

DeviceMaster EtherNet/IP-Modbus gateway is operating on the default

configuration.

The DeviceMaster EtherNet/IP-Modbus gateway has a configuration

other than the default configuration.

30Reserved

0101 (0x50) Indicates that there is a major fault (either Bit 10 or Bit 11 is set).

0100 (0x40) Indicates the stored configuration is invalid.

0011 (0x30)

0110 (0x60)

4-7

Indicates the system is operational and there are no I/O (Class 1)

connections.

Indicates the system is operational and there is at least one active I/O

(Class 1) connection.

Indicates the system is not operational. It may be in any of the following

states:

• System startup.

0000

• Configuration in process.

•Idle.

• Critical (major) fault.

0

8

1

No recoverable minor fault. No error history entry reported within the

last ten seconds.

Recoverable minor fault. The DeviceMaster EtherNet/IP-Modbus

gateway has reported an error within the last ten seconds and a major

fault has not been detected.

91

Unrecoverable minor fault. Does not apply to the DeviceMaster

EtherNet/IP-Modbus gateway.

0 No recoverable major fault.

10

1

A major recoverable fault exists. This is a fault that the DeviceMaster

EIP-MOD may be able to recover from by a system reset. If the system

does not recover automatically, a system reset message or a power cycle of

the DeviceMaster EtherNet/IP-Modbus gateway may be required.

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 25

Page 26

| Informational Objects | Identity Object (01 Hex, 1 Instance) | Common Services |

Status Word Bit Setting Description (Continued)

0 No major unrecoverable fault.

11

1

A major unrecoverable fault has occurred in the DeviceMaster EIP-MOD.

If the major fault is not corrected with a system reset or a power cycle,

refer to the Troubleshooting and Technical Support

on Page 155 or call

Pepperl+Fuchs Comtrol, Inc. support.

12-15 0 Reserved.

2.2.1.4. Common Services

This table displays Common Services for Identity Object (01 hex, 1 Instance).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

05 hex No Yes Reset

0E hex Yes Yes Get_Attribute_Single

26 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 27

| Informational Objects | Message Router Object (02 Hex) | Class Attributes |

2.2.2. Message Router Object (02 Hex)

The Message Router Object provides a messaging connection point through which a client may address a

service to any object or instance residing in the physical device.

2.2.2.1. Class Attributes

This table displays the Class Attributes for Message Router Object (02 hex).

Attribute ID Name Data Type Data Value Access Rule

1 Revision UINT 1 Get

2 Max Class UINT 1 Get

3 Max Instance UINT 1 Get

4 Optional Attribute List UINT 2 Get

5 Option Service List UINT 1 Get

6 Maximum Number Class Attribute UINT 7 Get

7 Maximum Number Instance Attribute UINT 2 Get

2.2.2.2. Instance Attributes

This table displays Instance Attributes for Message Router Object (02 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

Object List

Structure of:

1

Number

Classes

UINT

Array of UINT List of supported

Number of supported

class codes

class codes

Get

2 Max Connections UINT 128 Get

2.2.2.3. Common Services

This table displays Common Services for Message Router Object (02 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes No Get_Attribute_All

0E hex Yes Yes Get_Attribute_Single

0A hex No Yes Multiple_Service_Req

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 27

Page 28

| Informational Objects | Connection Manager Object (06 Hex) | Class Attributes Object (06 hex) |

2.2.3. Connection Manager Object (06 Hex)

The Connection Manager Object provides services for connection and connection-less communications.

2.2.3.1. Class Attributes Object (06 hex)

The following table displays the Class Attributes for the Connection Manager Object (06 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 1 Get

2 Max Class UINT 1 Get

3 Max Instance UINT 1 Get

4 Optional Attribute List UINT 8 Get

6 Maximum number Class Attribute UINT 7 Get

7 Maximum Number Instance Attributes UINT 8 Get

2.2.3.2. Instance Attributes (06 hex)

This table displays the Instance Attributes for the Connection Manager Object (06 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Open Requests UINT 0-0xffffffff Set/Get

2 Open Format Rejects UINT 0-0xffffffff Set/Get

3 Open Resource Rejects UINT 0-0xffffffff Set/Get

4 Open Other Rejects UINT 0-0xffffffff Set/Get

5 Close Requests UINT 0-0xffffffff Set/Get

6 Close Format Requests UINT 0-0xffffffff Set/Get

7 Close Other Requests UINT 0-0xffffffff Set/Get

8 Connection Time Outs UINT 0-0xffffffff Set/Get

2.2.3.3. Common Services Object (06 hex)

This table displays the Common Services for the Connection Manager Object (06 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

02 hex No Yes Set_Attribute_ALL

0E hex Yes Yes Get_Attribute_Single

10 hex No Yes Set_Attribute_Single

4E hex N/A N/A Forward_Close

52 hex N/A N/A Unconnected_Send

54 hex N/A N/A Forward_Open

5A hex N/A N/A Get_Connection_Owner

5B hex N/A N/A Large_Forward_Open

28 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 29

| Informational Objects | Port Object (F4 Hex - 1 Instance) | Class Attributes |

2.2.4. Port Object (F4 Hex - 1 Instance)

The Port Object enumerates the CIP ports on the DeviceMaster EIP-MOD.

2.2.4.1. Class Attributes

This table displays Class Attributes for Port Object (F4 hex - 1 Instance).

Attribute

ID

Name Data Type Data Value(s)

1 Revision UINT 2 Get

2 Max Instance UINT 2 Get

3 Num Instances UINT 2 Get

6

7

Maximum Number

Class Attributes

Maximum Number

Instance Attributes

UINT 9 Get

UINT 10 Get

8 Entry Port UINT 1 Get

[0]=0

[1]=0

9 All Ports Array of UINT

[2] = 1 (Vendor Specific)

[3] = 1 (Backplane)

[4]=TCP_IP_PORT_TYPE (4)

[5]=TCP_IP_PORT_NUMBER(2)

2.2.4.2. Instance Attributes (F4 Hex, Instance 1)

This table illustrates the Instance Attributes for the Port Object (F4 hex – Instance 1).

Access

Rule

Get

Attribute

ID

Name Data Type Data Value(s)

Access

Rule

1 Port Type UINT 1 Get

2 Port Number UINT 1 Get

Port Object

Structure of:

3

16-bit word count in path UINT 2

Get

Path Array of UINT [0]=6420 hex

[1]=0124

Port Name

4

Structure of:

Get

String Length USINT 10

Port Name Array of USINT “Backplane”

7 Node Address USINT[2] 10 hex, 0 hex Get

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 29

Page 30

| Informational Objects | Port Object (F4 Hex - 1 Instance) | Instance Attributes (F4 Hex, Instance 2) |

Attribute

ID

Name Data Type Data Value(s)

17 hex:

• Bit 0: Routing of incoming

Unconnected Messaging supported

• Bit 1: Routing of outgoing

10 Port Routing Capabilities UDINT

Unconnected Messaging supported

• Bit 2: Routing of incoming Transport

Class 0/1 Connections supported

• Bit 4: Routing of incoming Transport

Class 2/3 Connections supported

2.2.4.3. Instance Attributes (F4 Hex, Instance 2)

This table illustrates the Instance Attributes for the Port Object (F4 hex – Instance 2).

Attribute

ID

Name Data Type Data Value(s)

1 Port Type UINT 4 (TCP/IP) Get

2 Port Number UINT 2 (TCP/IP) Get

Port Object

Structure of:

3

16-bit word count in path UINT 2

Path Array of UINT [0]=F520 hex

[1]=0124 hex

Port Name

Structure of:

4

String Length USINT 17

Port Name Array of USINT “Ethernet/IP Port”

7 Node Address USINT[2] 10 hex, 0 hex Get

17 hex:

Bit 0: Routing of incoming

Unconnected Messaging supported

Bit 1: Routing of outgoing

10 Port Routing Capabilities UDINT

Unconnected Messaging supported

Bit 2: Routing of incoming Transport

Class 0/1 Connections supported

Bit 4: Routing of incoming Transport

Class 2/3 Connections supported

Access

Rule

Get

Access

Rule

Get

Get

Get

30 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 31

| Informational Objects | TCP Object (F5 Hex - 1 Instance) | Common Services |

2.2.4.4. Common Services

This table displays Common Services for Port Object (F4 hex, Instance 2).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

0E hex Yes Yes Get Attribute Single

2.2.5. TCP Object (F5 Hex - 1 Instance)

The TCP/IP Interface Object provides the mechanism to retrieve the TCP/IP attributes for the DeviceMaster

EIP-MOD.

2.2.5.1. Class Attributes

This table displays the Class Attributes for TCP Object (F5 hex - 1 instance).

Attribute ID Name Data Type Data Value Access Rule

1Revision UINT 4Get

2 Max Instance UINT 1 Get

3 Num Instances UINT 1 Get

4 Optional Attribute List UINT 4 Get

6 Maximum Number Class Attribute UINT 7 Get

7 Maximum Number Instance Attribute UINT 13 Get

2.2.5.2. Instance Attributes

This table displays Instance Attributes for TCP Object (F5 hex - 1 instance).

Attribute

ID

Name Data Type Data Value(s)

Access

0 = The Interface Configuration

attribute has not been configured.

1 Status DWORD

1 = The Interface Configuration

attribute contains configuration

Get

obtained from DHCP or nonvolatile

storage.

2 Configuration Capability DWORD 14 hex (DHCP and SETTABLE) Get

0=Use stored IP address (static IP

3 Configuration Control DWORD

address)

Get

2=DHCP

Rule

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 31

Page 32

| Informational Objects | TCP Object (F5 Hex - 1 Instance) | Instance Attributes |

Attribute

ID

4

5

6

8

9

13

Name Data Type Data Value(s)

Physical Link Object

Structure of:

Path Size UINT 2

Path Array of USINT [0]=20 hex

[1]=F6 hex

[2]=24 hex

[3]=01 hex

Interface Configuration

Structure of:

IP Address UDINT <IP address>

Network Mask UDINT <Network mask>

Gateway Address UDINT <Gateway Addr>

Name Server UDINT <Name server>

Name Server 2 UDINT <Name server 2>

Domain Name UINT <Length of name>

Length Domain Name STRING <Domain name>

Host Name

Structure of:

Host Name Length UINT 0 to 15

Host Name STRING <Default = IP address>

TTL (Time-to-Live) value

for IP multicast packets

USINT

1 to 255

<Default = 1>

Struct of:

USINT –Allocation Allocation Control

0=Default Algorithm

1 = Configuration

Num Multicast Addresses:

1-32

IP Multicast Address

Configuration

Control

USINT – Reserved

UINT – Num Mcast

Start Multicast Address:

UDINT – Start

Multicast Address

239.192.1.0 to

239.255.255.255

Encapsulation Inactivity

Timeout USINT

Number of seconds of inactivity

before TCP connection or DTLS

session is closed

Access

Rule

Get

Set

Set

Set

Set

Set

32 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 33

| Informational Objects | Ethernet Link Object (F6 Hex) | Common Services |

2.2.5.3. Common Services

This table shows the Common Services for the TCP Object (F5 hex - I Instance).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

02 hex No Yes Set_Attribute_All

0E hex Yes Yes Get_Attribute_Single

10 hex No Yes Set_Attribute_Single

2.2.6. Ethernet Link Object (F6 Hex)

The Ethernet Link object maintains link-specific counters and status information for the Ethernet

communications on the DeviceMaster EIP-MOD.

2.2.6.1. Class Attributes

This table displays the Class Attributes for the Ethernet Link Object (F6 hex).

Attribute ID Name Data Type Data Value(s) Access Rule

1 Revision UINT 4 Get

2 Max Instance UINT

3 Num Instances UINT

4

Optional Attribute

List

UINT 4 Get

1 = One Ethernet Port Models

3 = Two Ethernet Port Models

1 = One Ethernet Port Models

3 = Two Ethernet Port Models

Get

Get

Maximum

6

Number Class

UINT 7 Get

Attributes

Maximum

7

Number Instance

UINT 11 Get

Attributes

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 33

Page 34

| Informational Objects | Ethernet Link Object (F6 Hex) | Instance Attributes |

2.2.6.2. Instance Attributes

This table displays the Instance Attributes for the Ethernet Link Object (F6 hex).

Attribute

ID

1

Interface speed (Current

operational speed)

Name Data Type Data Value(s) Access Rule

UDINT

10=10 Mbit

100=100 Mbit

Get

Bit 0 =link status

(0=inactive)

(1=active)

Bit 1=Half/Full Duplex

(0=half duplex)

2

Interface Flags (Current

operational status)

DWORD

(2=full duplex)

Get

Bits 2-4:

00 = negotiation in progress

01 = negotiation failed

02 = negotiation failed speed OK

03 = negotiation success

3 Physical Address Array of 6 USINT MAC Address Get

7 Interface Type USINT 2 = Twisted Pair Get

8 Interface State USINT

1 = Interface is enabled and

operational

Get

9 Admin State USINT 1 = Interface enabled Get

USINT16 Length = 1 to 64 ASCII characters

10 Interface Label

Array of USINT <Default = IP address in

Get

“xxx.xxx.xxx.xxx” format>

Capability bits - Interface

capabilities, other than speed/

duplex

UDINT

Value = 6

Bit 1: Auto-negotiate

Bit 2: Auto-MDIX

11 Interface Capability

Struct of:

Get6

USINT Speed/Duplex Array Count = 1

Array of:

UINT Interface Speed - 10 or 100

Interface Duplex Mode

USINT

0=half duplex

1=full duplex

34 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Page 35

| Informational Objects | Assembly Object (For Class 1 Interface) | Common Services |

2.2.6.3. Common Services

This table displays the Common Services for Ethernet Link Object (F6 hex).

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes Yes Get_Attribute_All

0E hex Yes Yes Get_Attribute_Single

2.2.7. Assembly Object (For Class 1 Interface)

The EtherNet/IP specification requires that all Class 1 interfaces be provided through the Assembly Object

interface. The Assembly Object interface is used to directly tie Vendor Specific objects to a standard interface,

which the EtherNet/IP controller, or PLC, uses to communicate to the device.

For the DeviceMaster EtherNet/IP-Modbus gateway, the Assembly Object corresponds to the Serial and

Socket Data Transfer objects. Each instance of the Assembly Object corresponds to one or more of the Serial

and/or Socket Data Transfer Object attributes.

The Assembly object defines the interface by which a Class 1 PLC or controller can:

• Request the receive data packets from the DeviceMaster EtherNet/IP-Modbus gateway.

• Write the transmit data to the DeviceMaster EtherNet/IP-Modbus gateway.

2.2.7.1. Class Attributes

This table shows the Class Attributes for the Assembly Object for a Class 1 Interface.

Attribute ID Name Data Type

Data

Value(s)

Access Rule

1Revision UINT 2Get

2 Max Instance UINT 132 Get

3 Num Instances UINT 32 Get

4 Optional Attribute List UINT 4 Get

6 Maximum Number Class Attribute UINT 7 Get

7 Maximum Number Instance Attribute UINT 4 Get

2.2.7.2. Instance Attributes

This table shows the Instance Attributes for the Assembly Object for a Class 1 Interface.

Attribute ID Name Data Type Data Value(s) Access Rule

3 Data Array of BYTE 0-255 Get/Set

4 Data Length UINT

Maximum number of bytes

in Attribute 3

Get

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 35

Page 36

| Informational Objects | Assembly Object (For Class 1 Interface) | Common Services |

2.2.7.2.1. Instance Attribute Definitions: Attribute 3-Request/Write Data

Dependent on the instance number, this is either the PDI data block and/or the PDO data block.

2.2.7.2.2. Instance Attribute Definitions: Attribute 4-Data Length

This is the maximum data length for each Assembly instance.

2.2.7.3. Common Services

This table shows the Common Services for the Assembly Object for a Class 1 Interface.

Service Code Implemented in Class Implemented in Instance Service Name

01 hex Yes No Get_Attributes_All

0E hex Yes Yes Get_Attribute_Single

10 hex No Yes Set_Attribute_Single

02 hex No No Set_Attribute_All

2.2.7.4. Instance Definitions

Each Assembly instance is tied directly to a Shared Memory block of Holding Registers or Coils. Each input

instance is enabled only if the corresponding block’s Read Class1 Enable has been selected in the Shared

Memory configuration. Each output instance is enabled only if the corresponding block’s Write Master(s)

option has been set to EIP Class1.

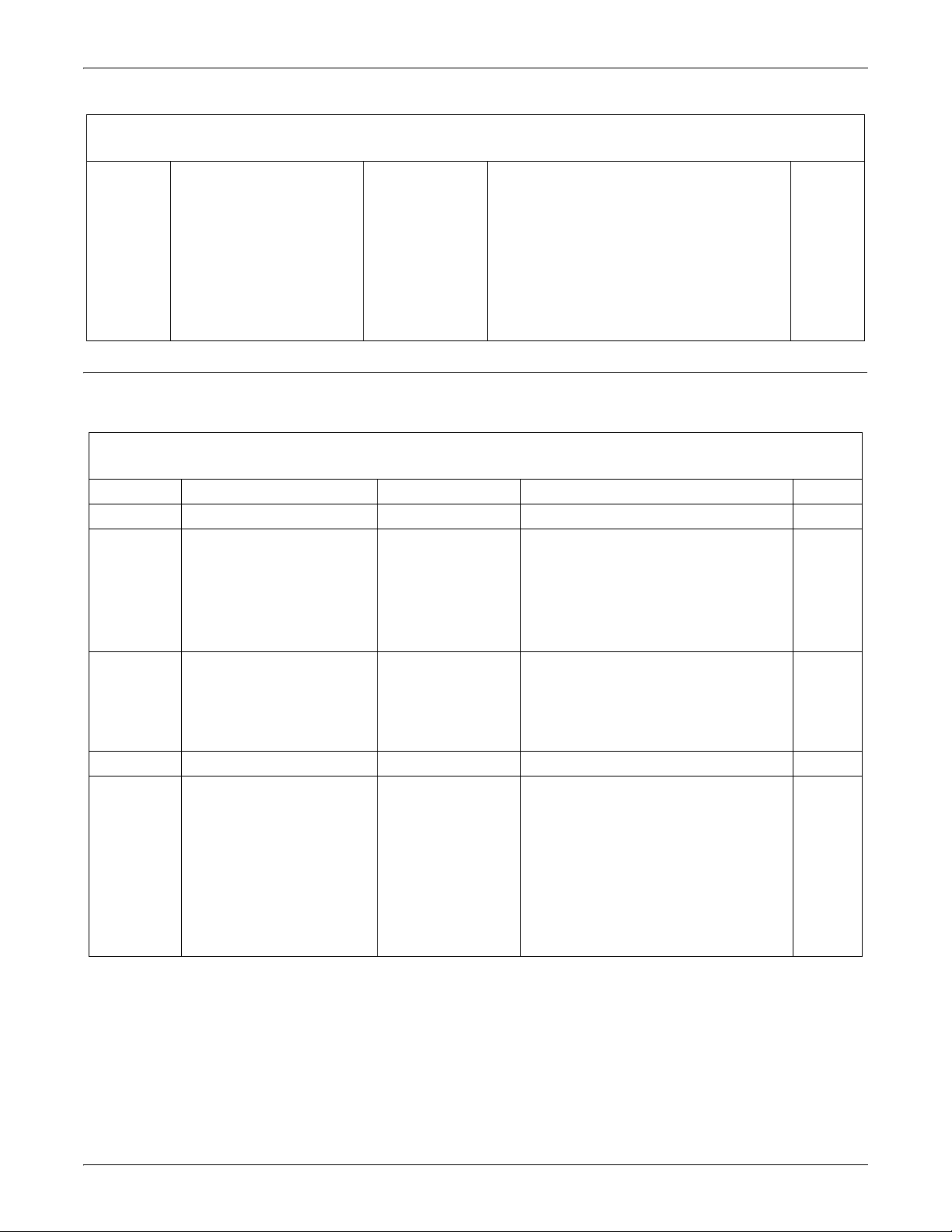

2.2.7.4.1. Instance Definitions (Default)

This table shows the Assembly Object instance definitions for the default Shared Memory configuration.

Default Configuration Shared Memory Configuration

Holding Register Block 1 Read Class1 Enable selected

Coils Block 1 Read Class1 Enable selected

Holding Register Block 2 Write Master(s) set to EIP Class1

Coils Block 2 Write Master(s) set to EIP Class1

For all other Shared Memory blocks:

• Read Class1 Enable not selected

• Write Master(s) not set to EIP Class1

Assembly Input Instances

Assembly

Instance

Number

Description Data Type Data Values

Access

Rule

101

109

36 - Chapter 2. EtherNet/IP Interface Profile (ControlLogix) DeviceMaster EIP-MOD User Guide: 2000664 Rev. A

Read data from Shared Memory

Holding Registers Block 1

Read data from Shared Memory

Coils Block 1

WORD Array

Length = 200

WORD Array

Length = 20 Words (320 coils)

0-FFFF (hex) Get

0-FFFF (hex) Get

Page 37

| Informational Objects | Assembly Object (For Class 1 Interface) | Instance Definitions |

Assembly Output Instances

Assembly

Instance

Description Data Type Data Values

Number

118

126

Write data to Shared Memory

Holding Registers Block 2

Write data to Shared Memory

Coils Block 2

WORD Array

Length = 200

WORD Array

Length = 20 Words (320 coils)

2.2.7.4.2. All Available Instance Definitions

This table displays all available Instance Definitions.

Assembly Input Instances

Assembly

Instance

Description Data Type Data Values

Number

101

102

103

104

105

106

107

108

109

110

111

Read data from Shared

Memory Holding Registers

Block 1

Read data from Shared

Memory Holding Registers

Block 2

Read data from Shared

Memory Holding Registers

Block 3

Read data from Shared

Memory Holding Registers

Block 4

Read data from Shared

Memory Holding Registers

Block 5

Read data from Shared

Memory Holding Registers

Block 6

Read data from Shared

Memory Holding Registers

Block 7

Read data from Shared

Memory Holding Registers

Block 8

Read data from Shared

Memory Coils Block 1

Read data from Shared

Memory Coils Block 2

Read data from Shared

Memory Coils Block 3

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 200

WORD Array

Length = 20 Words (320 coils)

WORD Array

Length = 20 Words (320 coils)

WORD Array

Length = 20 Words (320 coils)

Access

0-FFFF (hex) Set

0-FFFF (hex) Set

Access

Rule

0-FFFF (hex)

Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

0-FFFF (hex) Get

Rule

DeviceMaster EIP-MOD User Guide: 2000664 Rev. A Chapter 2. EtherNet/IP Interface Profile (ControlLogix) - 37

Page 38

| Informational Objects | Assembly Object (For Class 1 Interface) | Instance Definitions |

Assembly Input Instances (Continued)

Assembly

Instance

Number

112

113

114

115

116

Assembly

Instance

Number

117

118

119

120

121

122

123

124

125

126

127

Description Data Type Data Values

Read data from Shared

Memory Coils Block 4

Read data from Shared

Memory Coils Block 5

Read data from Shared

Memory Coils Block 6

Read data from Shared