Page 1

D

A

XPA-200-O

Outdoor SSP

Installation and Operation Manual

Part Number MN/XPA200OD.IOM

Revision 1

Page 2

Page 3

XPA-200-OD

Comtech EF Data is an ISO 9001

Registered Company.

Outdoor SSPA

Installation and Operation Manual

Part Number MN/XPA200OD.IOM

REVISION 1

February 9, 2005

Copyright © Comtech EF Data, 2005. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, .480.333.2200, FAX: 480.333.2161.

Page 4

CUSTOMER SUPPORT

Contact the Comtech EF Data Customer Support Department for:

Product support or training

Information on upgrading or returning a product

Reporting comments or suggestions concerning manuals

Contact Customer Support using any of the following methods:

Mail: Comtech EF Data

Email: service@comtechefdata.com

Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

Phone: 480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

Fax: 480.333.2161

Internet: www.comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the Comtech

EF Data Customer Support Department.

2. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

3. To ensure that the product is not damaged during shipping, pack the product

in its original shipping carton/packaging.

4. Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. v.

Page 5

Table of Contents

Customer Support......................................................................................................................... ii

This page left intentionally blank.About this Manual..............................................................iii

About this Manual ....................................................................................................................... iv

Conventions and References ....................................................................................................... iv

Cautions and Warnings.............................................................................................................. iv

Metric Conversion ....................................................................................................................... iv

Trademarks .................................................................................................................................. iv

Reporting Comments or Suggestions Concerning this Manual................................................. iv

Warranty Policy............................................................................................................................ v

Limitations of Warranty.............................................................................................................. v

Exclusive Remedies.................................................................................................................... v

Disclaimer................................................................................................................................... v

CHAPTER 1. SYSTEM OPERATION .......................................................................... 6

1.1 Connector J3: AC Power, Mains, 205 to 240 VAC.......................................................... 6

1.2 Connector J6: COMM, Remote communications port. ................................................... 6

1.3 Turning On the SSPA............................................................................................................. 7

1.4 Configuring the SSPA ............................................................................................................ 7

1.4.1 Attenuation......................................................................................................................... 7

1.4.2 Mute ................................................................................................................................... 7

1.4.3 TX Amplifier ..................................................................................................................... 7

CHAPTER 2. CUSTOMER COMMANDS ..................................................................10

2.1 Introduction........................................................................................................................... 10

2.2 RS-485 .................................................................................................................................... 10

i

Page 6

XPA-200-OD Revision 1

Introduction MN/XPA200OD.IOM

This page left intentionally blank.

iii

Page 7

XPA-200-OD Revision 1

Introduction MN/XPA200OD.IOM

ABOUT THIS MANUAL

This manual provides installation and operation information for the Comtech EF Data

Outdoor SSPA. This is a technical document intended for earth station engineers,

technicians, and operators responsible for the operation and maintenance of the Outdoor

SSPA.

CONVENTIONS AND REFERENCES

CAUTIONS AND WARNINGS

Indicates information critical for proper equipment function.

IMPORTANT

CAUTION

Indicates a hazardous situation that, if not avoided, may result in minor or moderate

injury. CAUTION may also be used to indicate other unsafe practices or risks of

property damage.

Indicates a potentially hazardous situation that, if not avoided, could result in

WARN ING

death or serious injury.

METRIC CONVERSION

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing non-metric to metric

conversions.

TRADEMARKS

All product names mentioned in this manual may be trademarks or registered trademarks

of their respective companies and are hereby acknowledged.

REPORTING COMMENTS OR SUGGESTIONS CONCERNING THIS MANUAL

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Technical

Publications Department: tpubs@comtechefdata.com

iv

Page 8

Page 9

Chapter 1. SYSTEM OPERATION

This section contains instructions for operating the XPA-200-OD outdoor SSPA. The

primary customer interface to the XPA is via the Remote Communications port. This

section defines in detail the customer interface.

1.1 CONNECTOR J3: AC POWER, MAINS, 205 TO 240 VAC.

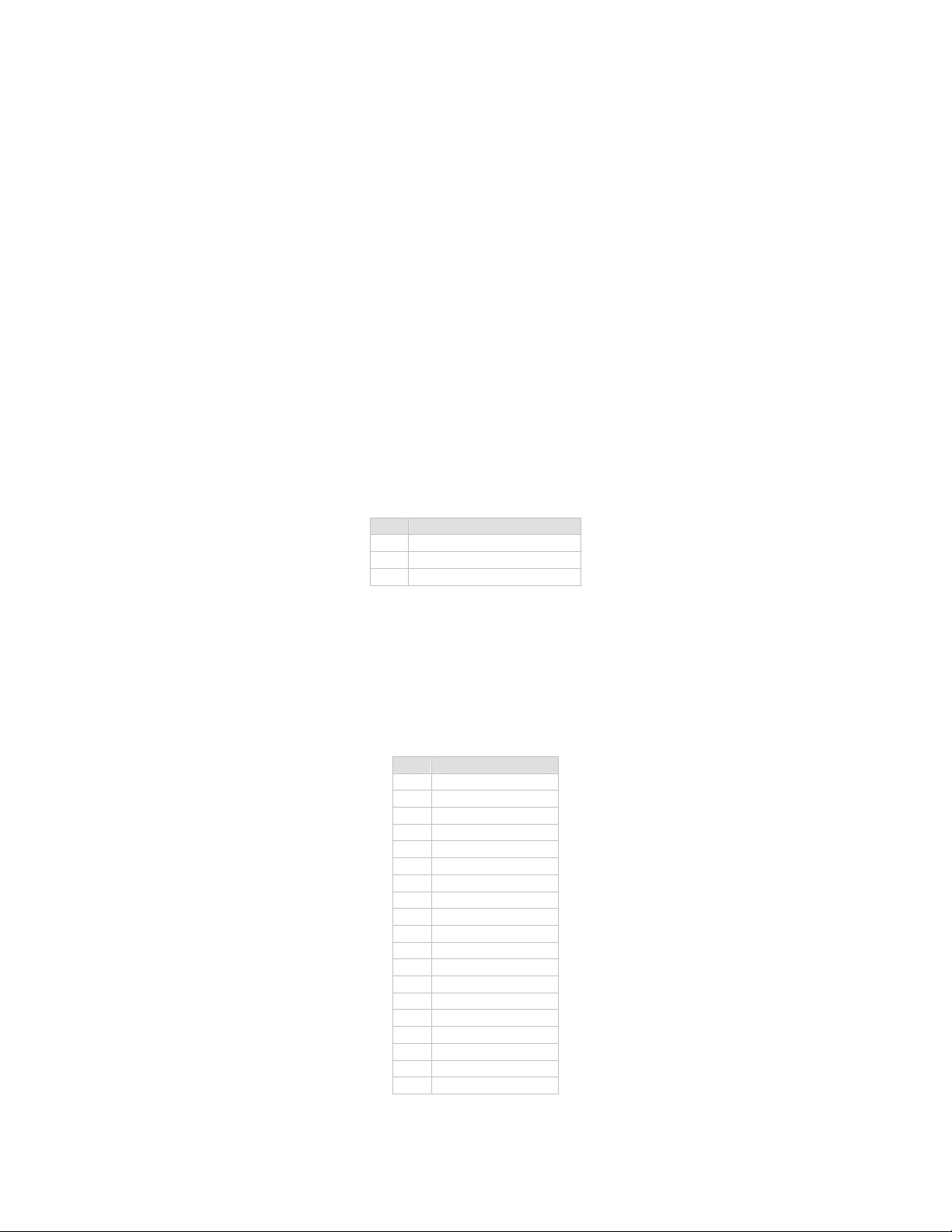

Table 1. Connector J3 Pinout

Pin Mating Connector Type

A Ground

B L2

C L1

1.2 CONNECTOR J6: COMM, REMOTE COMMUNICATIONS PORT.

Mating connector: ITT: KPT06J14-19P or MS3116J14-19P connections, see Table 2.

Table 2. Connector J6 Pinout

Pin Outdoor SSPA

A RS485_+RX

B RS485_-RX

C RS485_+TX

D RS485_-TX

E RS232_RD

F Analog_Pwr_Mon

G RS232_TD

H Aux_In

J Aux_Out

K SumFLT_COM

L SumFLT_NO

M SumFLT_NC

N GND

P ONLINE_Status

R +24V

S Mute Control

T Minor_FLT_COM

U Minor_FLT_NO

V Minor_FLT_NC

6

Page 10

XPA-200-OD Revision 1

System Operation MN/XPA200OD.IOM

1.3 TURNING ON THE SSPA

The SSPA does not contain a ‘Power On/Off’ switch. The SSPA is powered ON by

connecting the J3 AC Power connector to the appropriate prime power source.

Never turn the unit ON without proper waveguide termination on the

J2 “RF OUTPUT” port. Individuals can be exposed to dangerously

WARN ING

high electromagnetic levels.

1.4 CONFIGURING THE SSPA

The following paragraphs provide a quick start guide to the most commonly used

commands. Full coverage of all user remote commands is contained in Chapter 2.

1.4.1 ATTENUATION

The SSPA’s attenuation is user configurable. The SSPA’s attenuation can be selected

between 00.00 and 25.00 dB in 0.25 dB increments.

Associated Remote Command(s): ATT=

1.4.2 MUTE

The transmitter output state (the ‘RF OUT’ port, J2) will be ON only if the following

three requirements are met:

(1) The SSPA hardware must be fault free (i.e., No faults).

(2) The SSPA must be unmuted (i.e., MUT=0).

(3) The Amplifier must be ON (i.e., AMP=1).

Associated Remote Command(s): MUT=

1.4.3 TX AMPLIFIER

The amplifier ON/OFF state is user controllable. Turning the TX amplifier OFF removes

the 10Vdc supply to the RF Power FETs. The TX Amplifier must be ON in order for the

SSPA to transmit a RF signal.

Associated Remote Command(s): AMP=

7

Page 11

XPA-200-OD Revision 1

System Operation MN/XPA200OD.IOM

Figure 1. Outdoor Unit

8

Page 12

XPA-200-OD Revision 1

System Operation MN/XPA200OD.IOM

NOTES:

9

Page 13

Chapter 2. CUSTOMER COMMANDS

2.1 INTRODUCTION

This section describes the protocol and message command set for remote monitor and

control of the SSPA product.

The electrical interface is either an RS-485 multi-drop bus (for the control of many

devices) or an RS-232 connection (for the control of a single device), and data is

transmitted in asynchronous serial form, using ASCII characters. Control and status

information is transmitted in packets of variable length in accordance with the structure

and protocol defined in later sections.

2.2 RS-485

For applications where multiple devices are to be monitored and controlled, a full-duplex

(4-wire) RS-485 is preferred. Half-duplex (2-wire) RS-485 is possible, but is not

preferred.

In full-duplex RS-485 communication there are two separate, isolated, independent,

differential-mode twisted pairs, each handling serial data in different directions. It is

assumed that there is a ‘controller’ device (a PC or dumb terminal), which transmits data,

in a broadcast mode, via one of the pairs. Many ‘target’ devices are connected to this pair

which all simultaneously receive data from the controller. The controller is the only

device with a line-driver connected to this pair; the target devices only have linereceivers connected.

In the other direction, on the other pair, each target has a tri-stateable line driver

connected, and the controller has a line-receiver connected. All the line drivers are held in

high-impedance mode until one (and only one) target transmits back to the controller.

Each target has a unique address, and each time the controller transmits, in a framed

‘packet’ of data, the address of the intended recipient target is included. All of the targets

receive the packet, but only one (the intended) will reply. The target enables its output

line driver, and transmits its return data packet back to the controller in the other direction

on the physically separate pair.

10

Page 14

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

2.3 RS-485 (FULL DUPLEX) SUMMARY:

Two differential pairs - one pair for controller to target, one pair for target to

controller.

Controller-to-target pair has one line driver (controller), and all targets have line-

receivers.

Target-to-controller pair has one line receiver (controller), and all targets have tri-

state drivers.

2.4 RS-232

This is a much simpler configuration in which the controller device is connected directly

to the target via a two-wire-plus-ground connection. Controller-to-target data is carried,

via RS-232 electrical levels on one conductor, and target-to-controller data is carried in

the other direction on the other conductor.

2.5 BASIC PROTOCOL

Whether in RS-232 or RS-485 mode, all data is transmitted as asynchronous serial

characters, suitable for transmission and reception by a UART. The asynchronous

character format is fixed at 8 data bits, no parity, and 1 stop bit. Only two (2) baud rates

are supported: 9600 baud and 19200 baud.

All data is transmitted in framed packets. The host controller is assumed to be a PC or

ASCII dumb terminal, which is in charge of the process of monitor and control. The

controller is the only device that is permitted to initiate, at will, the transmission of data.

Targets are only permitted to transmit when they have been specifically instructed to do

so by the controller.

All bytes within a packet are printable ASCII characters, less than ASCII code 127. In

this context, the Carriage Return and Line Feed characters are considered printable.

All messages from controller to target require a response (with one exception). This will

be either to return data that has been requested by the controller, or to acknowledge

reception of an instruction to change the configuration of the target. The exception to this

is when the controller broadcasts a message (such as Set time/date) using Address 0,

when the target is set to RS-485 mode.

11

Page 15

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

2.6 PACKET STRUCTURE

Controller-to-target:

Start of Packet Target

Address

<

ASCII code 60

(1 character)

(4 characters)

Example: <0412/MUT=1{CR}

Target-to-controller:

Start of Packet Target

Address

>

ASCII

code 62

(1 character)

(4 characters)

Example: >0412/MUT=1{CR}{LF}

Each of the components of the packet is now explained.

2.6.1 START OF PACKET

Controller to Target: This is the character ‘<’ (ASCII code 60)

Address

De-limiter

/

ASCII code 47

(1 character)

Address

De-limiter

/

ASCII

code 47

(1 character)

Instruction

Code

(3 characters)

Instruction

Code

(3 characters)

Code

Qualifier

= or ?

ASCII code

61 or 63

(1 character)

Code Qualifier Optional

=, ?, !, or *

ASCII code 61,

63, 33 or 42

(1 character)

Optional

Arguments

(n characters)

Arguments

(From 0 to n

characters)

End of Packet

Carriage

Return

ASCII code 13

(1 character)

End of Packet

Carriage Return,

Line Feed

ASCII code 13,10

(2 characters)

Target to Controller: This is the character ‘>’ (ASCII code 62)

Because this is used to provide a reliable indication of the start of packet, these two

characters may not appear anywhere else within the body of the message.

2.6.2 ADDRESS

Up to 9,999 devices can be uniquely addressed. In both RS-232 and RS-485 applications,

the permissible range of values is 1 to 9999. It is programmed into a target unit using the

remote control port.

IMPORTANT

The controller sends a packet with the address of a target - the destination of

the packet. When the target responds, the address used is the same

address, to indicate to the controller the source of the packet. The controller

does not have its own address.

12

Page 16

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

2.6.3 INSTRUCTION CODE

This is a three-character alphabetic sequence that identifies the subject of the message.

Wherever possible, the instruction codes have been chosen to have some significance.

This aids in the readability of the message, should it be displayed in its raw ASCII form.

Upper case and lower case alphabetic characters may be used (A-Z, and a-z).

2.6.4 INSTRUCTION CODE QUALIFIER

This is a single character that further qualifies the preceding instruction code.

Code Qualifiers obey the following rules:

1. From Controller to Target, the only permitted values are:

= (ASCII code 61)

? (ASCII code 63)

They have these meanings:

The ‘=’ code (controller to target) is used as the assignment operator, and is used to

indicate that the parameter defined by the preceding byte should be set to the value of the

argument(s) which follow it.

For example, in a message from controller to target, MUT=1 would mean ‘enable the

mute function’.

The ‘?’ code (controller to target) is used as the query operator, and is used to indicate

that the target should return the current value of the parameter defined by the preceding

byte.

For example, in a message from controller to target, MUT? would mean ‘return the

current state of the mute function’.

2. From Target to Controller, the only permitted values are:

= (ASCII code 61)

? (ASCII code 63)

! (ASCII code 33)

* (ASCII code 42)

# (ASCII code 35)

They have these meanings:

The ‘=’ code (target to controller) is used in two ways:

13

Page 17

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

First, if the controller has sent a query code to a target (for example MUT?, meaning ‘is

mute enabled or disabled?’), the target would respond with MUT=x, where x represents

the state in question, 1 being ‘enable’ and 0 being disable.

Second, if the controller sends an instruction to set a parameter to a particular value, and,

providing the value sent in the argument is valid, then the target will acknowledge the

message by replying with MUT= (with no message arguments).

The ‘?’ code (target to controller) is only used as follows:

If the controller sends an instruction to set a parameter to a particular value, and, if the

value sent in the argument is not valid, then the target will acknowledge the message by

replying (for example) with MUT? (with no message arguments). This indicates that

there was an error in the message sent by the controller.

The ‘*’ code (target to controller) is only used as follows:

If the controller sends an instruction to set a parameter to a particular value, and, if the

value sent in the argument is valid, however the target is in the wrong mode (e.g., standby

mode in redundancy configuration) that it will not permit that particular parameter to be

changed at that time, then the target will acknowledge the message by replying (for

example) with MUT* (with no message arguments).

The ‘!’ code (target to controller) is only used as follows:

If the controller sends an instruction code which the target does not recognize, then the

target will acknowledge the message by echoing the invalid instruction, followed by the !

character with. Example: XYZ!

The ‘#’ code (target to controller) is only used as follows:

If the controller sends an instruction code which the target cannot currently perform

because of hardware resource issues, then the target will acknowledge the message by

echoing the invalid instruction, followed by the # character. This response can only

occur if the operator sends two or more ‘hardware configuration’ type commands without

allowing adequate time between commands for the hardware to be configured. For

example, if the operator issued commands to change both the frequency and the

attenuation with less than 100 milliseconds between commands, and if this response is

returned, then the command has not been excepted and the operator must resend the

command.

14

Page 18

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

2.6.5 MESSAGE ARGUMENTS

Arguments are not required for all messages. Arguments are ASCII codes for the

characters 0 to 9 (ASCII 48 to 57), period (ASCII 46) and comma (ASCII 44).

2.6.6 END OF PACKET

Controller to Target: This is the ‘Carriage Return’ character (ASCII code 13)

Target to Controller: This is the two-character sequence ‘Carriage Return’, ‘Line Feed’.

(ASCII code 13, and code 10.)

Both indicate the valid termination of a packet.

15

Page 19

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Command

Attenuation ATT= 5 bytes,

RF Power

Amplifier State

Mute State MUT= 1 byte,

Online Status N/A 1 byte,

Redundancy

Sate

Redundancy

Mode: Auto or

Manual

(Instruction

Code and

qualifier)

AMP= 1 byte,

RED= 1 byte,

RAM= 1 byte,

Arguments for

Command or

Response to

Query

numerical

value of 0, 1

value of 0,1

value of 0,1

value of 0, 1

value of 0, 1

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Command or Query.

Valid attenuation level, in dB, at 0.25-dB step size

as factory default.

Example: ATT=12.25

Command or Query

Turns ON or OFF the RF power amplifiers.

0 = Off

1 = On

Command or Query.

Mute the unit, where:

0 = Disabled

1 = Enabled

Example: MUT=1

Command or Query.

Online status (applies only to redundancy), where:

0 = Disabled

1 = Enabled

Example: ONL=1

Command or Query

Turns ON or OFF the redundancy state.

0 = OFF, 1 = ON

Command or Query.

Sets Auto or Manual mode for redundancy.

0 = Manual, 1 = Auto

Response to

Command

(target to controller)

ATT= (message ok)

ATT? (received ok, but

invalid arguments

found)

ATT* (message ok, but

not permitted in current

mode)

AMP= (message ok)

AMP? (received ok, but

invalid arguments

found)

AMP* (message ok, but

not permitted in current

mode)

MUT= (message ok)

MUT? (received ok, but

invalid arguments

found)

MUT* (message ok, but

not permitted in current

mode)

ONL= (message ok)

ONL? (received ok, but

invalid arguments

found)

RED= (message ok)

RED? (received ok, but

invalid arguments

found)

RAM= (message ok)

RAM? (received ok, but

invalid arguments

found)

Query

(Instruction

Code and

qualifier)

ATT? ATT=xx.xx

AMP? AMP=x

MUT? MUT=x

ONL? ONL=x

RED? RED=x

RAM? RAM=x

Response to

query

(target to

controller)

(same format as

command

arguments)

(same format as

command

arguments)

(same format as

command

arguments)

(same format as

command

arguments)

(same format as

command

arguments)

(same format as

command

arguments)

16

Page 20

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Command

Force Back-Up

State

Remote Address SPA= 4 bytes,

Remote Baud

Rate

Set RTC(Real-

Time-Clock) Date

Set RTC Time TIM= 6 bytes,

Clear All Stored

Alarms

Serial Number N/A 9 bytes, numeric

Retrieve

Equipment Type

(Instruction

Code and

qualifier)

FBU= 1 byte,

SBR= 4 bytes Command or Query.

DAT= 6 bytes,

CAA= None Command only

N/A 22 bytes,

Arguments for

Command or

Response to

Query

value of 0, 1, 2

numeric

numeric

numeric

000000000 to

999999999

alpha-numeric

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Command or Query

Force one of the online units to be a back-up for

maintenance and test purposes.

0 = Removed force back-up situation

1 = SSPA #1 is forced to be a back-up

2 = SSPA #2 is forced to be a back-up

Command or Query.

Set Physical Address-between 0001 to 9999.

Resolution 0001

Example: SPA=0412

Set remote baud rate as follows:

9600 = 9600 baud

19K2 = 19200 baud

Command or Query.

A command in the form mmddyy, where; dd = day

of the month, between 01 and 31, mm = month of

the year, between 01 and 12 and yy = year,

between 00 and 96 (2000 to 2096)

Example: DAT=042503 would be April 24, 2003

Command or Query.

A command in the form hhmmss, indicating the

time from midnight, where hh = hours, between 00

and 23; mm = minutes, between 00 and 59, and ss

= seconds, between 00 and 59

Example: TIM=231259 would be 23 hours, 12

minutes and 59 seconds from midnight.

Instructs the slave to clear all Stored Events

This command takes no arguments.

Query only.

Used to Query the units 9 digit serial number.

Slave returns its S/N, in the form xxxxxxxxx.

Example: RSN=000000165

Query only.

The unit returns a string indicating the Model

Number and the the value of internal software

revision installed

Example: RET=CPA-300 VER: 1.0.3

Response to

Command

(target to controller)

FBU= (message ok)

FBU? (received ok, but

invalid arguments

found)

SPA= (message ok)

SPA? (received ok, but

invalid arguments

found)

SBR= (message ok)

SBR? (received ok, but

invalid arguments

found)

DAT= (message ok)

DAT? (received ok, but

invalid arguments

found)

DAT* (message ok, but

not permitted in current

mode)

TIM = (message ok)

TIM? (received ok, but

invalid arguments

found)

TIM * (message ok, but

not permitted in current

mode)

CAA= (message ok)

N/A RSN?

N/A RET?

Query

(Instruction

Code and

qualifier)

FBU? FBU=x

SPA?

SBR?

DAT?

TIM?

N/A

Response to

controller)

(same format as

command

arguments)

SPA=x

(same format as

command

arguments)

SBR=xx

(same format as

command

arguments)

DAT=xx

(same format as

command

arguments)

TIM=xx

(same format as

command

arguments)

N/A

RSN=xxxxxxxxx

(see description

for details of

arguments)

RET=x….x

(see description

for details of

arguments)

query

(target to

17

Page 21

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Auto Fault

Recovery

Retrieve next 5

unread Stored

Alarms

Retrieve Number

of unread

Stored Alarms

Summary Fault

Status

Terminal Status

change

Command

(Instruction

Code and

qualifier)

AFR= 1 byte,

N/A 145 bytes Query only

N/A 2 bytes, numeric Query only.

N/A 1 byte,

N/A 1 byte,

Arguments for

Command or

Response to

Query

value of 0, 1

value of 0,1

value of 0,1

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Command or Query.

The SSPA output will automatically be muted in

the event of detected fault. If auto fault recovery is

enabled, it will cause the output to go active

(unmute) if all faults are cleared. If disabled, the

output will remain muted even if all faults are

cleared.

The unit returns the oldest 5 Stored Events which

have not yet been read over the remote control.

Reply format: Sub-body{CR}Sub-body{CR}Sub-

body{CR}Sub-body{CR}Sub-body, where Subbody=

YYYYYYYYYY ZZ mmddyy hhmmss,

YYYYYYYYYY being the fault description.

ZZ being the alarm type.

FT = Fault

OK = Clear

IF = Information

If there are no new events, the unit will reply with

LNA*

Returns the number of Stored Events which

remain unread, in the form xx. Example reply:

TNA=18

Query only.

Used to Query the status of the Summary Fault

Relay.

Example: SFS=0

where: 0 = OK 1 = FT

Query only.

Used to Query the status of the Terminal Status.

Example: TSC=0

Where: 0 = no change in status, 1 = change in

status

Response to

Command

(target to controller)

AFR = (message ok)

AFR? (received ok, but

invalid arguments

found)

AFR* (message ok, but

not permitted in current

mode)

N/A LNA?

N/A TNA?

N/A SFS?

N/A TSC?

Query

(Instruction

Code and

qualifier)

AFR? AFR=x

Response to

(target to

controller)

(same format as

command

arguments)

LNA=YY..ss

(see description

for details of

arguments)

TNA=xx

(see description

for details of

arguments)

SFS=x

(see description

for details of

arguments)

TSC=x

(see description

for details of

arguments)

query

18

Page 22

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Circuit

Identification

Retreive

Firmware

Number

Retrieve

Maintenance

Status

Command

(Instruction

Code and

qualifier)

CID= 24 bytes,

N/A Query only

N/A 168 bytes,

Arguments for

Command or

Response to

Query

alpha-numeric

alpha- numeric

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Command or Query

Used to identify or name the unit or station. First

line is limited to 12 characters. Second line is also

limited to 12 characters. No carriage return

between first line and second line.

Example: CID=’cr’

--Earth Station 1—

---SSPA #1----

Gets the Firmware Number of the unit.

Example: <1/FRW=

>0001/FRW/10786’cr’

BULK=FW/10786’cr’

MnC=FW/10787’cr’

FPGA=FW/10788’cr’’lf’

Query only.

Used to Query the maintenance status of the unit

P24VT=024.1’cr’

P15VT=015.2’cr’

P10V1=010.4’cr’

P10V2=010.4’cr’

P7V5T=007.8’cr’

P5VLT=005.8’cr’

N5VLT=-05.7’cr’

FANR1=100.0’cr’

FANR2=100.0’cr’

ATEMP=+40.0’cr’

A10V1=010.2’cr’

A10V2=010.2’cr’

FWPWR=+37.6’cr’

RVPWR=02.0’cr’’If’

*Note: REFV will appear if REF OSC module is

installed.

Response to

Command

(target to controller)

CID= (message ok)

CID? (received ok, but

invalid arguments

found)

N/A FRW? FRW=FWxxxxx

N/A RMS?

Query

(Instruction

Code and

qualifier)

CID? CID=x…x

Response to

query

(target to

controller)

(see description

for details of

arguments)

RMS=x….x

(see description

for details of

arguments)

19

Page 23

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Concise

Maintenance

Status

Retrieve

Utility Status

Concise

Utility Status

Command

(Instruction

Code and

qualifier)

N/A 84 bytes numeric Query only.

N/A 27 bytes, alpha-

N/A

Arguments for

Command or

Response to

Query

numeric

11 bytes, alpha-

numeric

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Used to Query the Maintenance status of the unit

in concise format. Response is comma delimited.

Example: CMS=aaa.a,bbb.b,ccc.c,ddd.d,eee.e,

fff.f,ggg.g,hhh.h,iii.i,jjj.j,kkk.k,lll.l,mmm.m,nnn.n,

’cr’’lf’

where:

aaa.a = +24V Power Supply

bbb.b = +15V Power Supply

ccc.c = +10V-1 Power Supply

ddd.d = +10V-2 Power Supply

eee.e = +7.5V Power Supply

fff.f = +5V Power Supply

ggg.g = -5V Power Supply

hhh.h = Fan #1 speed (in percent)

iii.i = Fan #2 speed (in percent)

jjj.j = Amplifier temperature in deg. C

kkk.k = Ampifier 10V1

lll.l = Amplifier 10V2

mmm.m=Forward RF output power, in dBm

Note: nnn.n will appear for Ref Voltage if

Reference Osc Module is installed.

Query only.

Used to Query the utility status of the unit

Example: RUS=’cr’

ADR=0001’cr’

BDR=9600’cr’

Query only.

Used to Query the Maintenance status of the unit,

response is comma delimited.

Example: CUS=aaaa,bbbb,ccc,’cr’’lf’

where:

aaaa = Remote Unit Address

bbbb = Remote Baud Rate

Response to

Command

(target to controller)

N/A CMS?

N/A RUS?

N/A

Query

(Instruction

Code and

qualifier)

CUS?

Response to

query

(target to

controller)

CMS=x….x

(see description

for details of

arguments)

RUS=x….x

(see description

for details of

arguments)

CUS=x….x

(see description

for details of

arguments)

20

Page 24

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Retrieve

Alarm Status

Concise

Alarm Status

Command

(Instruction

Code and

qualifier)

N/A

N/A

Arguments for

Command or

Response to

Query

117 bytes,

alpha-numeric

25 bytes,

numeric with

commas

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Query only.

Used to Query the Alarm status of the unit

Example: RAS=’cr’

P24VT=OK’cr’

P15VT=OK’cr’

P10V1=OK’cr’

P10V2=OK’cr’

P7V5T=OK’cr’

P5VLT=OK’cr’

N5VLT=OK’cr’

FAN#1=OK’cr’

FAN#2=OK’cr’

HSTMP=OK’cr’

SHTDN=OK’cr’

IICST=OK’cr’

FPOUT=OK’cr’’IF’

Query only.

Used to Query the Alarm status of the unit,

response is comma delimited.

Example: CMS=a,b,c,d,e,f,g,h,I,j,k,I,m’cr’’lf’

where: a thru k = 0 or 1, 0 = OK 1 = FT

a = +24V Power Supply

b = +15V Power Supply

c = +10V-A Power Supply

d = +10V-B Power Supply

e = +7.5V Power Supply

f = +5V Power Supply

g = -5V Power Supply

h = Fan#1 State

i = Fan#2 State

j = Heatsink Temp

k = Shutdown

l = llC Status

m=Forward Power Alarm

Response to

Command

(target to controller)

N/A

N/A

Query

(Instruction

Code and

qualifier)

RAS?

CAS?

Response to

query

(target to

controller)

RAS=x….x

(see description

for details of

arguments)

CAS=x….x

(see description

for details of

arguments)

21

Page 25

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

Retrieve

Configuration

Status

Concise

Configuration

Status

Command

(Instruction

Code and

qualifier)

N/A

N/A 24 bytes,

Arguments for

Command or

Response to

Query

45 bytes, alpha-

numeric

numeric

Description of arguments

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Query only.

Used to Query the configuration status of the unit

Example: RCS=’cr’

ATT=12.75’cr’

AMP=1’cr’

MUT=1’cr’

ONL=1’cr’

RED=1-1’cr’

GOF=00.00’cr’

AFR=1’cr’’lf’

where:

ATT= attenuation in dB

AMP= RF power amplifier state, 0=OFF, 1=ON

MUT=RF mute state, 0=unmuted, 1=muted

ONL=Online status for redundancy

RED=Redundancy state and mode,

states: 0=OFF, 1=ON,

modes: 0 = auto, 1 = manual

GOF=Gain Offset in dB

AFR= auto fault recovery, 0=manual, 1=auto

Query only.

Used to query the summarized version of RCS.

Example: CCS=aaaaa,b,c,d,e-e,fffff,g,‘cr’

Where:

aaaaa = attenuation in dB

b = RF power amplifier state

c = mute state, 0 = unmuted, 1 = muted

d = online status

e-e = redundancy state and mode

fffff = gain offset in dB

g = AFR

Response to

Command

(target to controller)

N/A

N/A CCS? CCS=x….x

Query

(Instruction

Code and

qualifier)

RCS?

Response to

query

(target to

controller)

RCS=x….x

(see description

for details of

arguments)

(see description

for details of

arguments)

22

Page 26

XPA-200-OD Revision 1

Customer Commands MN/XPA200OD.IOM

RF Power FET

Current status

Concise RF

Power FET

Current Status

Command

(Instruction

Code and

qualifier)

N/A

N/A

Arguments for

Command or

Response to

Query

variable length

(Note: the

number of FETs

is determined on

the information

string [INF])

variable length Query only

(note that all arguments are ASCII numeric

codes, that is, ASCII codes between 48 and 57)

Query only

Used to display all the FET currents.

Example: RFS?

Q01=xx’cr’

Q02=xx’cr’

Q03=xx.x’cr’

Q04=xx.x’cr’

Q05=xx.x’cr’

Q06=xx.x’cr’

Q07=xx.x’cr’

Q08=xx.x’cr’

Q09=xx.x’cr’

Q10=xx.x’cr’

Q11=xx.x’cr’

Q12=xx.x’cr’

Q13=xx.x’cr’

Q14=xx.x’cr’

Q15=xx.x’cr’

Q16=xx.x’cr’’lf’

Concise version of RFS.

Example: CFS=xxx,xxx,x.x,x.x,……….,x.x,

Description of arguments

Response to

Command

(target to controller)

N/A

N/A

Query

(Instruction

Code and

qualifier)

RFS?

CFS?

Response to

(target to

controller)

RFS=x….x

(see description

of arguments)

CFS=x…..x

(see description

of RFS. Note

that each

argument is

separated by a

comma)

query

23

Page 27

XPA-200-OD Revision 1

Power Supply Replacement MN/XPA200OD.IOM

Chapter 3. POWER SUPPLY

REPLACEMENT

Loosen 4 captive screws to

replace power supply

Figure 2. Power Supply Replacement

24

Page 28

XPA-200-OD Revision 1

Power Supply Replacement MN/XPA200OD.IOM

NOTES:

25

Page 29

METRIC CONVERSIONS

Units of Length

Unit

1 centimeter — 0.3937 0.03281 0.01094

1 inch 2.540 — 0.08333 0.2778

1 foot 30.480 12.0 — 0.3333

1 yard 91.44 36.0 3.0 —

Centimeter

Inch

Foot

Yard

Mile

6.214 x 10

1.578 x 10

1.893 x 10

5.679 x 10

Meter

-6

0.01 — —

-5

0.254 — 25.4

-4

0.3048 — —

-4

0.9144 — —

Kilometer Millimeter

1 meter 100.0 39.37 3.281 1.094

1 mile

1 mm — 0.03937 — — — — — —

1 kilometer — — — — 0.621 — — —

1.609 x 10

5

6.336 x 104 5.280 x 103 1.760 x 103

6.214 x 10

-4

—

— — —

1.609 x 103

1.609 —

Temperature Conversions

Unit

32° Fahrenheit

212° Fahrenheit

-459.6° Fahrenheit

° Fahrenheit

—

—

—

° Centigrade

0

(water freezes)

100

(water boils)

273.1

(absolute 0)

Formulas

C = (F - 32) * 0.555

F = (C * 1.8) + 32

Units of Weight

Unit

1 gram — 0.03527 0.03215 0.002205 0.002679 0.001

Gram

Ounce

Avoirdupois

Ounce

Troy

Pound

Avoir.

Pound

Troy

Kilogram

1 oz. avoir. 28.35 — 0.9115 0.0625 0.07595 0.02835

1 oz. troy 31.10 1.097 — 0.06857 0.08333 0.03110

1 lb. avoir. 453.6 16.0 14.58 — 1.215 0.4536

1 lb. Troy 373.2 13.17 12.0 0.8229 — 0.3732

1 kilogram

1.0 x 10

3

35.27 32.15 2.205 2.679 —

Page 30

2114 WEST 7TH STREET TEMPE ARIZONA 85281 USA

480 • 333 • 2200 PHONE

480 • 333 • 2161

FAX

Loading...

Loading...