Page 1

0

r

XPA-20

Solid-State High Power Amplifie

Installation and Operation Manual

Part Number MN/XPA200.IOM Revision 2

Page 2

Page 3

Errata A

Comtech EFData Documentation Update

Subject:

Date:

Document:

Part Number:

Collating

Instructions:

Comments:

The following changes provide updated information. This information

will be incorporated into the next revision.

Various Changes

February 28, 2003

XPA200-7984-I-OPT1, X-Band SSPA Installation and

Operation Manual, Rev. 2

Attach these pages at the beginning of the

manual.

Change Specifics:

1. Section 3.3.2.1 should be amended to include (amendments or

changes in bold):

. . .

EXT mute on from external J4 control (see section 1)

ON muted by M&C control or via remote control

2. Section 5.8.2.2 should be amended to include (amendments or

changes in bold):

. . .

Confirmation: >DEV/MUT_xxx’cr’lf’]

Note: On Status queries, the ‘MUT’ command may also return EXT

(mute on from external J4 control) or INH (mute on or inhibited by

Mitec 2723B via J5).

3. Section 5.8.3.1 should be amended to include (amendments or

changes in bold):

. . .

TX_nnn’cr’ Transmit – ON/OFF/EXT/INH

. . .

Filename: XPA200-7984-I-OPT1_Errata_a.doc 1

Page 4

4. Section 5.8.3.5 should be amended to include (amendments or

changes in bold):

. . .

+10_2_xx’cr’ +10 PS#2 Fault

SHTD_xx’cr’ Thermal Shutdown

. . .

Note: A temperature fault is indicated if the unit is less than 20C or more than 85 degrees C. This creates a summary fault and

will cause the unit to mute itself and switchover to the back-up

unit. However, the 10V supply to the FET transistors will remain

on until the unit reaches the thermal shutdown temperature of 90

degrees C or above. For protection reasons, the unit will

shutdown the 10V supply to the power transistors at temperatures

at or above 90 degrees C.

5. Section 5.8.3.8 should be amended to include (amendments or

changes in bold):

. . .

Confirmation: >DEV/PACRCS_aabcde'cr''lf']

where: aa = # of 0.25 dB steps in HEX above 0dB (0to120)

b = 1 if Amplifier ON, 0 if OFF

c = 1 if Tx ON, 0 if OFF, 2 if external mute

command, 3 if external inhibit command

d = 1 if unit ONLINE, 0 if OFFLINE

e = 1 if Auto Recovery enabled, else 0

6. Section 5.8.3.9 should be amended to include (amendments or

changes in bold):

. . .

iii = RF forward pwr, .1 dBm steps above 26.0 dBm in Hex

jjj = RF reverse pwr, .1 dBm steps above 19.0 dBm in Hex

7. Section 5.8.3.12 should be amended to include (amendments or

changes in bold):

. . .

Confirmation: >DEV/PACRAS_abcdefghijkl'cr''lf']

. . .

. . .

g = 1 if +10 PS#2 Fault, else 0

h = 1 if TEMP Fault, else 0

i = 1 if Thermal Shutdown, else 0

j = 1 if FAN 1 Fault, else 0

k = 1 if FAN 2 Fault, else 0

l = 1 if PROC Fault, else 0

Filename: XPA200-7984-I-OPT1_Errata_a.doc 2

Page 5

Note: A temperature fault is indicated if the unit is less than 20C or more than 85 degrees C. This creates a summary fault and

will cause the unit to mute itself and switchover to the back-up

unit. However, the 10V supply to the FET transistors will remain

on until the unit reaches the thermal shutdown temperature of 90

degrees C or above. For protection reasons, the unit will

shutdown the 10V supply to the power transistors at temperatures

at or above 90 degrees C.

Filename: XPA200-7984-I-OPT1_Errata_a.doc 3

Page 6

Page 7

XPA200-7984-I-OPT1, X-Band SSPA Policy

POLICY

WARRANTY

This COMTECH Product is warranted against defects in material and

workmanship for a period of one year from the date of shipment.

During the warranty period, COMTECH will, at it's option, repair

or replace products which prove to be defective. For warranty

service, the product must be returned to COMTECH, all shipping

charges prepaid by the buyer. COMTECH will pay shipping charges

to return repaired, or replaced, products shipped by normal

surface delivery within the continental U.S..

The information within this document is subject to change without

notice. Contact the COMTECH Customer Service Representative,

1-(480)333-4357, for information updates that apply to this

product.

LIMITATIONS of WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper installation or maintenance, abuse, unauthorized

modification, or operation outside of the environmental

specifications for this product, or, for damages that occur as a

result of improper repackaging of equipment for return to

COMTECH.

No other warranty is expressed or implied. COMTECH specifically

disclaims the implied warranties of Merchantability and Fitness

for Particular Purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the buyer's sole and exclusive

remedies. COMTECH shall not be liable for any direct, indirect,

special incidental, or consequential damages, whether based on

contract, tort, or any other legal theory.

XPA200-7984-I-OPT1, Rev.2

Page 8

Page 9

XPA200-7984-I-OPT1, X-Band SSPA Preface

Preface

Manual

This manual describes the installation, operation and

maintenance for the XPA200-7984-I 200 watt X-Band Solid State

High Power Amplifier (SSPA).

Intended Users

This is a technical document intended for satellite earth

station engineers, technicians and operators responsible for the

installation, operation and maintenance of the XPA200-7984-I XBand SSPA.

Organization of Manual

This manual includes the following chapters:

! Section 1 - describes the purpose, function,

description, options and systems specifications of this

product.

! Section 2 - describes the unpacking, installation and

and brief operating instructions for use with the Mitec

2723B Variable Phase Combiner and Redundancy Switching

System.

! Section 3 - describes the system operation.

! Section 4 - describes the redundant system operation.

! Section 5 - describes the remote control operation.

! Section 6 - describes the maintenance and

troubleshooting procedures.

XPA200-7984-I-OPT1, Rev.2 i

Page 10

XPA200-7984-I-OPT1, X-Band SSPA Preface

Manual Revision Numbering Scheme

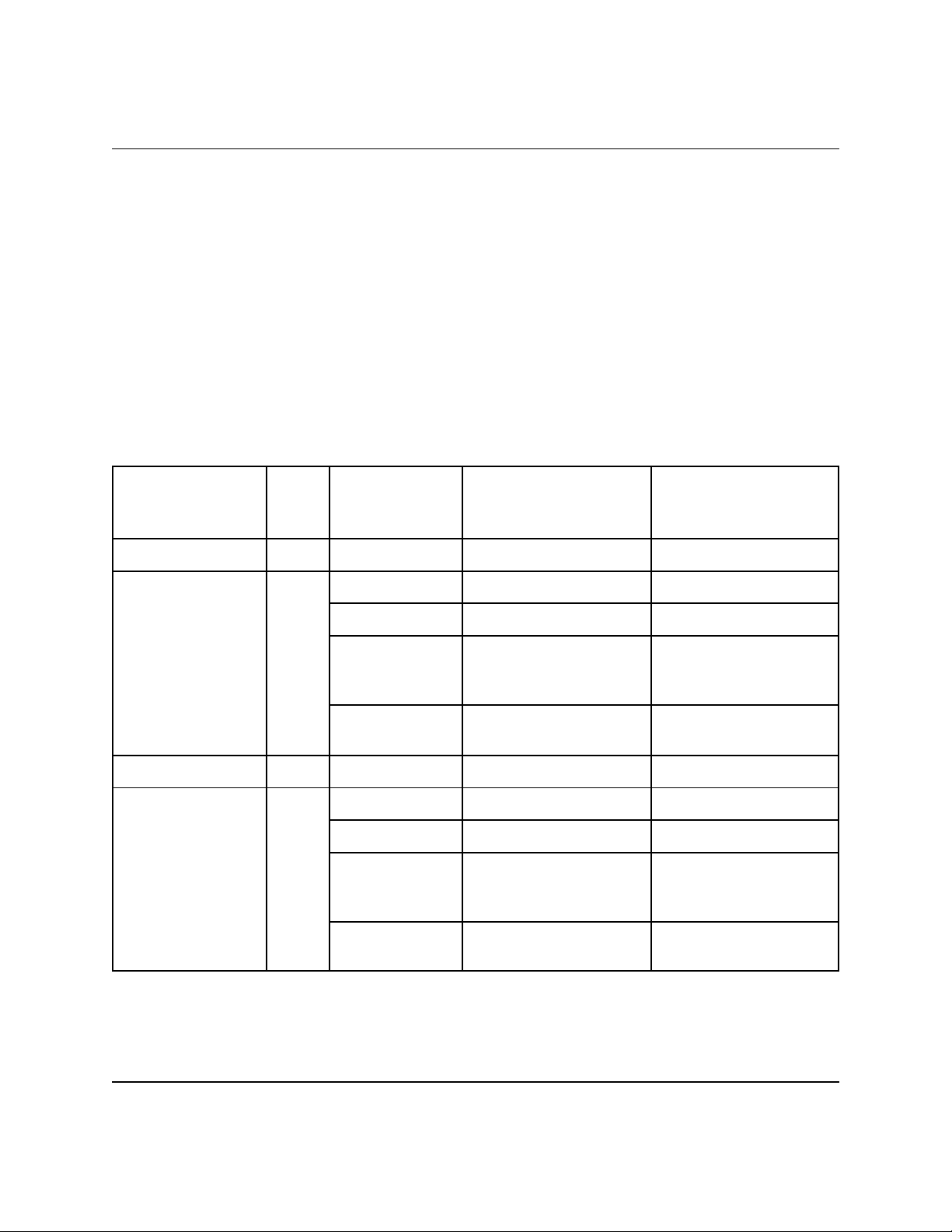

The following table identifies the revision numbering

scheme utilized for the COMTECH Operation and Maintenance

Manuals, Addenda and Supplements:

Part Number Description

XPA200-7984-I-

2nd edition of the Manual.

OPT1, REV.2

Reporting Comments or Suggestions Concerning This Manual

Comments and suggestions regarding the contents and

design of this manual will be appreciated. To submit your

Comments, please contact the COMTECH Customer Service

Representative, 1-(480)333-4357.

Safety Notice

This equipment has been designed to minimize exposure of

personnel to hazards. The operators and technicians must:

! NEVER TURN ON THE UNIT WITHOUT PROPER RF TERMINATIONS.

! Know how to work around, with and on high voltage and

high RF power level equipment.

! Exercise every precaution to ensure personnel safety.

! Exercise extreme care when working near high

voltages/high RF power level equipment.

! Be familiar with the warning presented in this manual.

! CAUTION - Disconnect the power supply cord before

servicing the SSPA.

! Lithium Battery Replacement - CAUTION: There is a

danger that the Lithium battery on the M&C assembly

XPA200-7984-I-OPT1, Rev.2 ii

Page 11

XPA200-7984-I-OPT1, X-Band SSPA Preface

will explode if the battery is incorrectly replaced.

Replace only with the same or equivalent type battery

recommended by the manufacturer. Dispose of used

batteries according to the Lithium battery

manufacturer’s instructions.

Returning a Product

The following information applies to a COMTECH equipment

product being returned for repair or replacement service:

NOTE: An item is considered “out-of-Warranty” if the warranty

period (as determined by the original purchase) has

expired; or the equipment has been damaged or otherwise

made unusable as a result of an accident or

unreasonable use, neglect, improper or unauthorized

service, repairs or modifications, or other causes not

arising out of defects in design, material, or

workmanship.

To return a COMTECH product for repair or replacement:

1. Request a Return Material Authorization (RMA)number

from the COMTECH Customer Service Representative, 1-(480)

333-4357, FAX 1-(480)333-2500.

2. Provide the Customer Service Representative with the

following information:

a. Model number.

b. Serial number.

c. Description of the problem.

d. Description of action taken to identify the

problem.

e. Name and telephone number of the company

contact.

3. The product being shipped should be packed in it's

original shipping container with proper packing material to

prevent possible shipping damage.

XPA200-7984-I-OPT1, Rev.2 iii

Page 12

XPA200-7984-I-OPT1, X-Band SSPA Preface

4. Ship the product, prepaid, to COMTECH. Provide the

following address on the shipping label, with the RMA number

clearly marked on the label and the shipping container:

COMTECH EF Data Corp.

2114 W. 7th Street

Tempe, Arizona 85281 U.S.A.

Attention: Customer Service Department, RMA Number:

For more information regarding the COMTECH warranty policy,

please refer to the policy page located on the back of the title

page.

Product Application, Upgrading or Training Information

To obtain product application, upgrade or training

information, Please contact theCustomer Service Representative at

the numbers above.

XPA200-7984-I-OPT1, Rev.2 iv

Page 13

XPA200-7984-I-OPT1, X-Band SSPA Table of Contents

Table of Contents

Section Description Page No.

1 Introduction 1-1

1.1 Scope 1-1

1.2 Functional Description 1-1

1.3 Specifications 1-3

1.4 Prime Power Input 1-4

1.5 Physical Dimensions 1-4

1.6 Environmental specifications 1-4

1.7 Front Panel Controls 1-4

1.8 Front Panel Indicators 1-5

1.9 Front Panel Display 1-7

1.10 Front Panel Test Point Samples 1-7

1.11 Rear Panel Connections 1-7

1.12 Prime Power Switch 1-11

2 Installation/Operation with Mitec 2723B

2.1 Unpacking and Inspection 2-1

2.2 Rack Mount Installation 2-1

2.3 Combined/Redundant System Operation 2-4

and Setup

3 System Operation 3-1

3.1 General 3-1

3.2 Switching Power On 3-1

3.3 Operation 3-3

3.3.1 SSPA Commands 3-9

3.3.2 Configuration Menu 3-10

3.3.3 Monitor Status Menu 3-11

3.3.4 Current Faults Menu 3-11

3.3.5 Stored Faults Menu 3-12

3.3.6 Utility Menu 3-13

XPA200-7984-I, Rev.1 i

Page 14

XPA200-7984-I-OPT1, X-Band SSPA Table of Contents

Section Description Page No.

4 Redundant System Operation

4.1 General 4-1

5 Remote Control 5-1

5.1 General 5-1

5.2 Electrical Interface 5-1

5.2.1 RS-232C 5-1

5.2.2 RS-485 5-1

5.3 Physical Interface 5-1

5.3.1 Connector 5-2

5.3.2 Pin-Out 5-2

5.3.3 Cables 5-3

5.4 Protocol 5-4

5.4.1 Transmission Mode 5-4

5.4.2 Baud Rate 5-4

5.4.3 Format 5-4

5.4.4 Character Set 5-4

5.4.5 Response Timeout 5-5

5.4.6 Bus Inactivity Requirement 5-5

5.5 Access Methods 5-5

5.6 Addresses 5-5

5.6.1 Physical Address 5-5

5.7 Message Structure 5-6

5.7.1 Start Character 5-6

5.7.2 Device Address 5-6

5.7.3 Command 5-6

5.7.4 Confirmation Response 5-7

5.7.5 Error Response 5-7

5.7.6 End of Message 5-7

5.8 Command/Response Pairs 5-8

5.8.1 Utility Commands 5-8

5.8.2 Configuration Commands 5-11

5.8.4 Status Commands 5-12

5.8.5 Stored Alarm 5-17

XPA200-7984-I, Rev.1 ii

Page 15

XPA200-7984-I-OPT1, X-Band SSPA Table of Contents

Section Description Page No.

5.9 Error Processing 5-18

5.9.1 General Errors 5-18

5.9.2 Configuration Errors 5-18

5.9.3 Time Outs 5-18

Remote Command Summary Sheet 5-19

6 Maintenance and Troubleshooting 6-1

6.1 General 6-1

6.2 Maintenance Testing 6-2

6.2.1 Test Point Samples 6-2

6.3 Troubleshooting 6-2

6.3.1 SSPA Faults 6-2

6.3.1.2 DC Power Supply Module 6-3

6.3.1.3 Temperature Fault 6-4

6.3.1.4 Monitor & Control Board 6-4

6.4 Returning the SSPA to COMTECH 6-5

6.4.1 Return Material Authorization (RMA) 6-5

6.4.2 Shipment to COMTECH 6-5

6.5 Product Application, Upgrading or Training

Information 6-6

7 Addendum 7-1

7.1 General 7-1

7.2 Additional Troubleshooting Helps 7-1

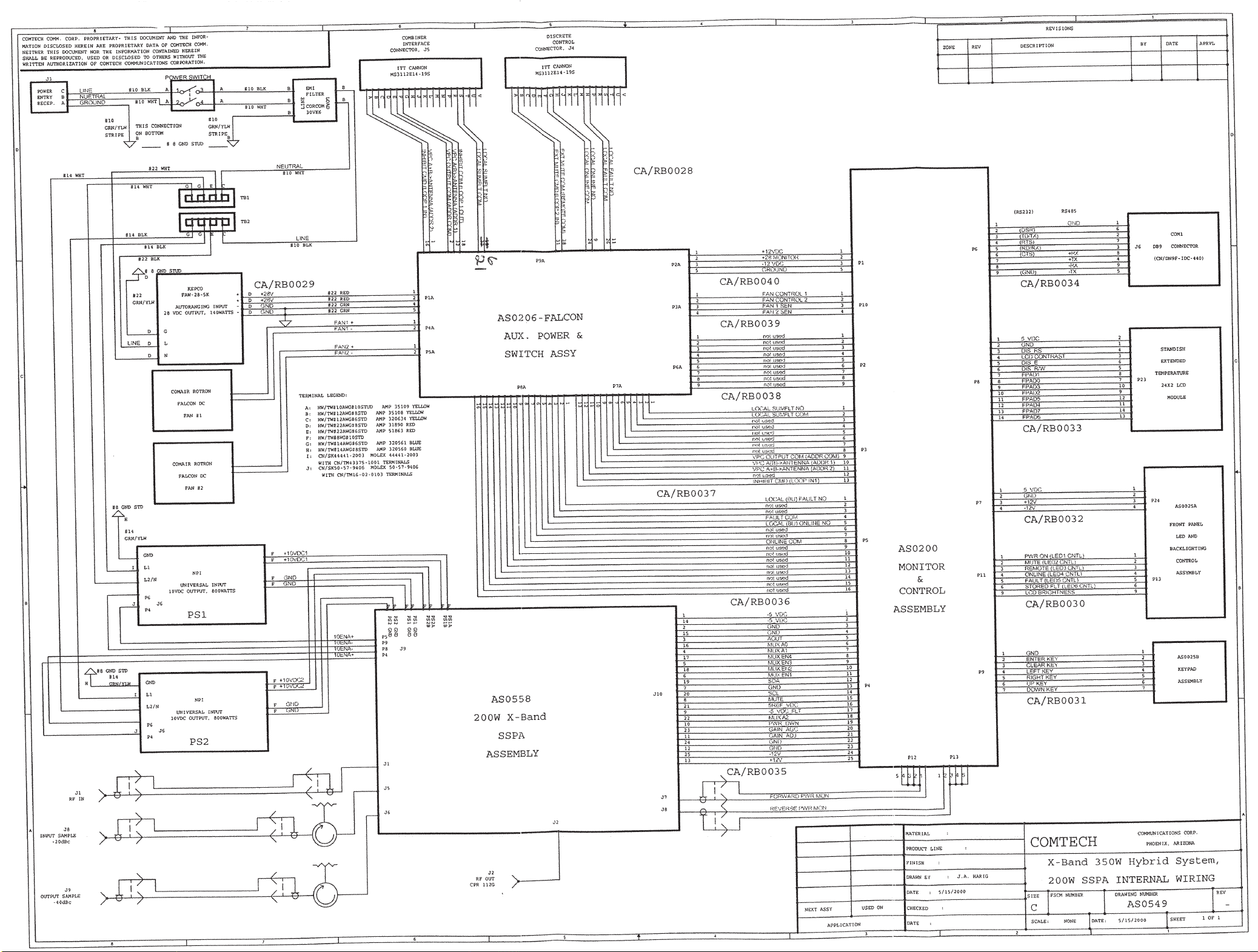

7.3 Wiring Diagram 7-5

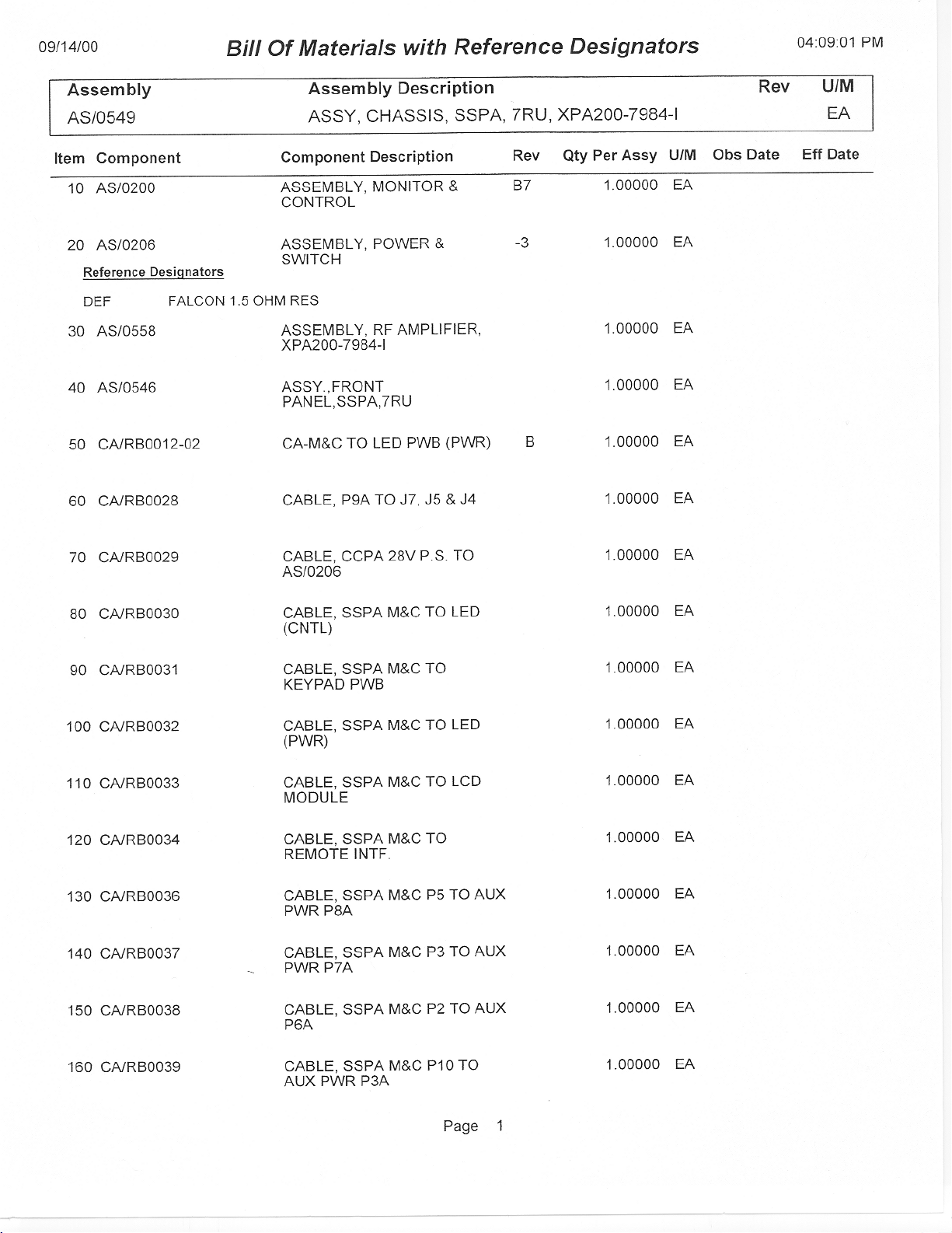

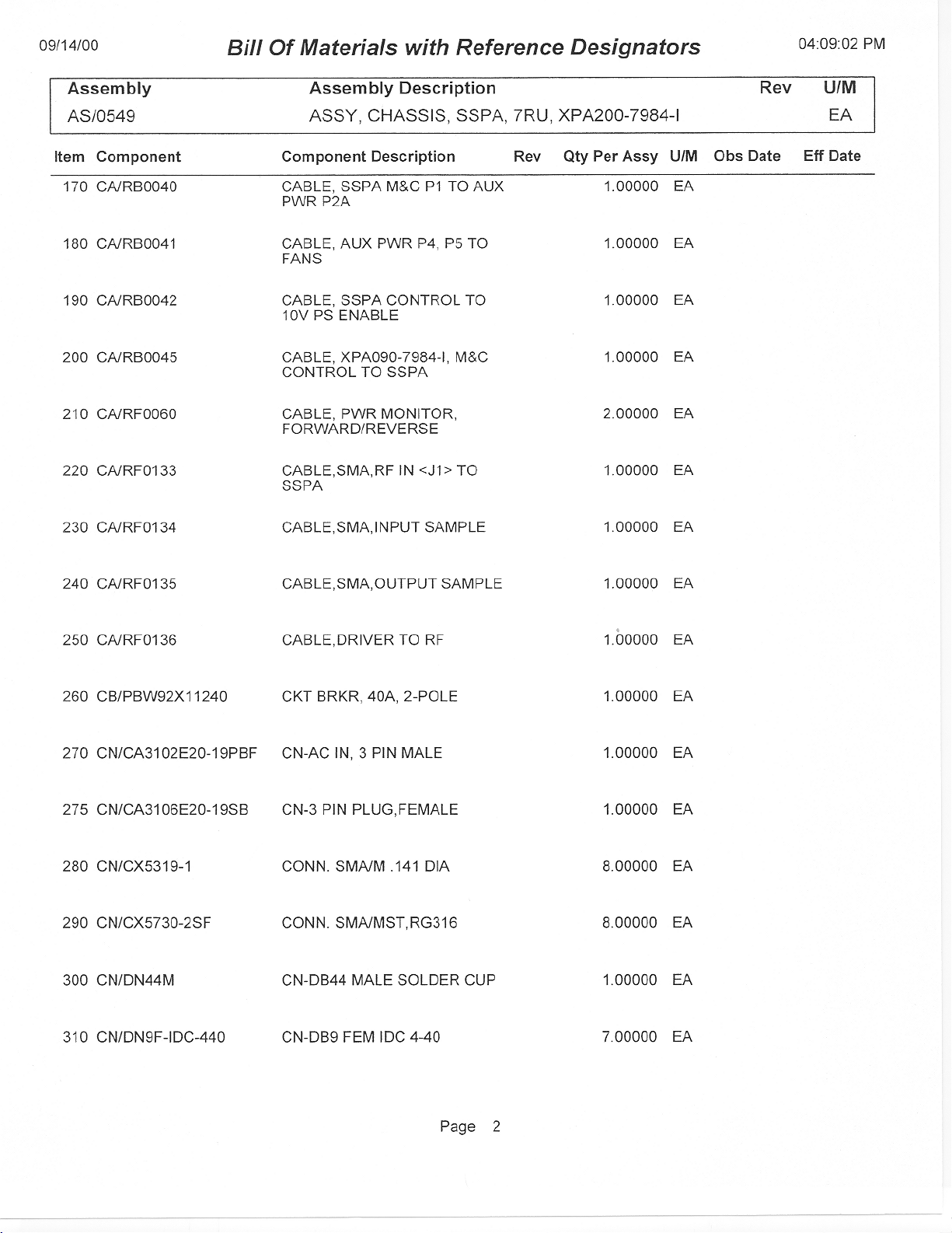

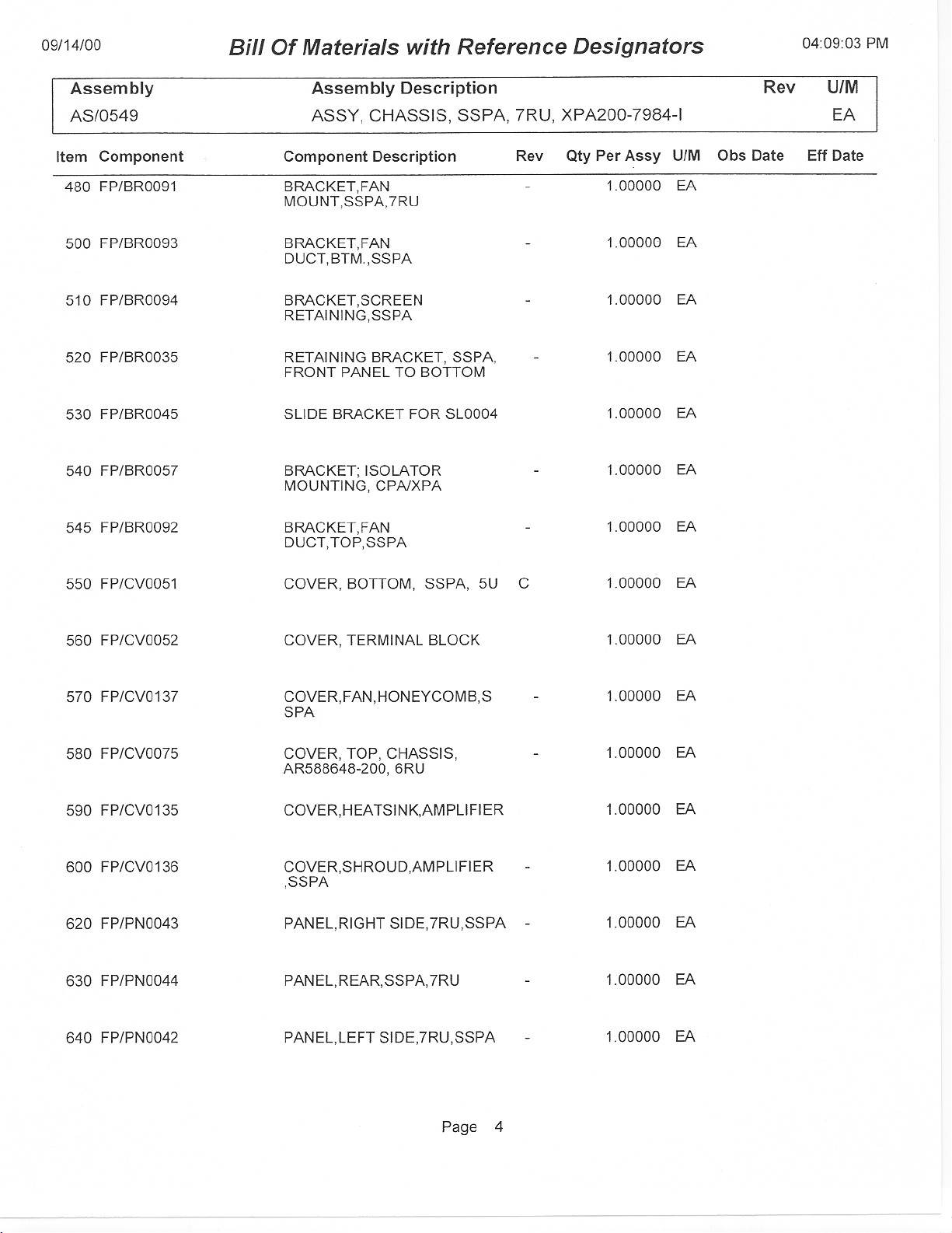

7.4 Parts List 7-6

XPA200-7984-I, Rev.1 iii

Page 16

Page 17

XPA200-7984-I-OPT1, X-Band SSPA Introduction

Section 1

Introduction

1.1 Scope

This manual provides instructions on the installation,

operation and maintenance of the XPA200-7984-I X-Band Solid State

High Power Amplifier manufactured by COMTECH COMMUNICATIONS Corp.

1.2 Functional Description

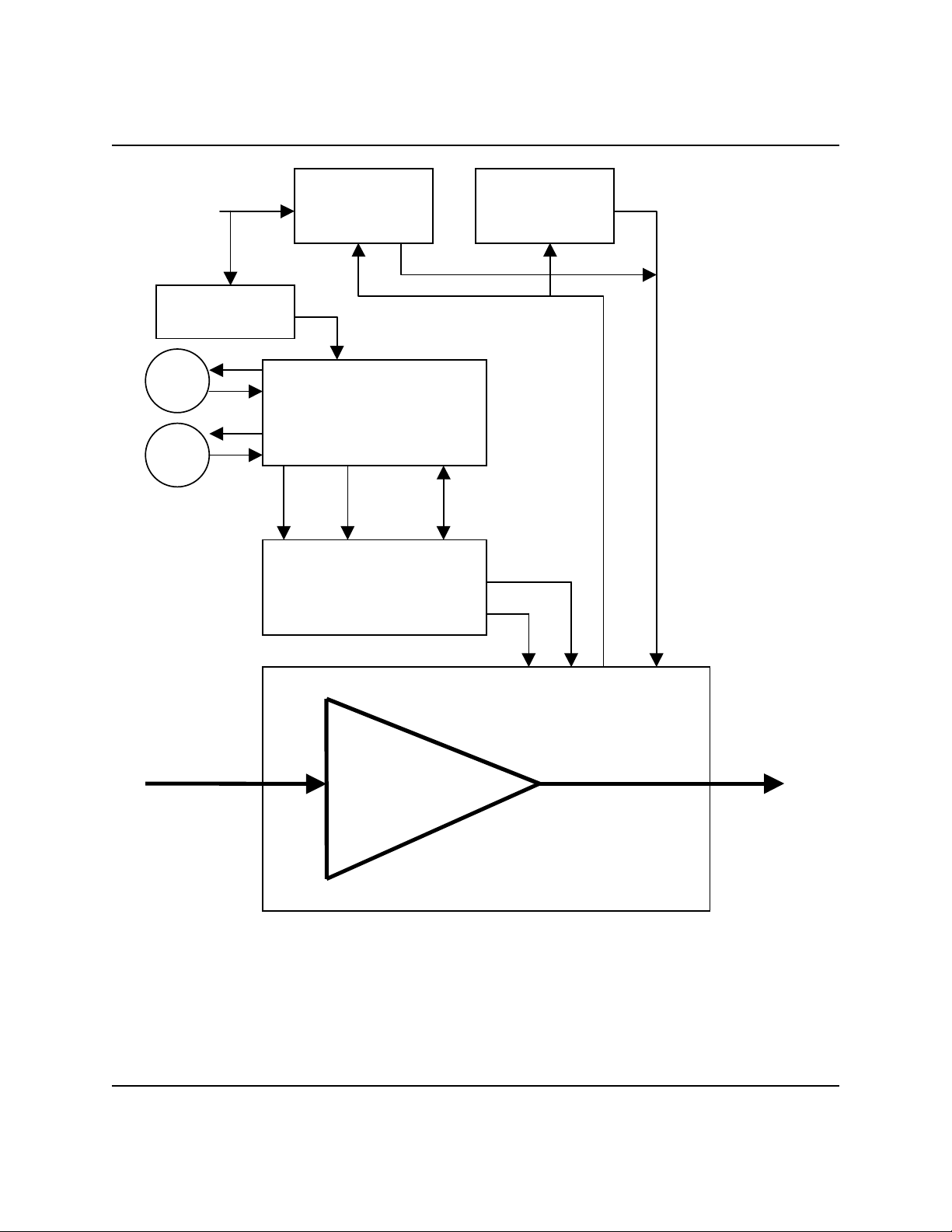

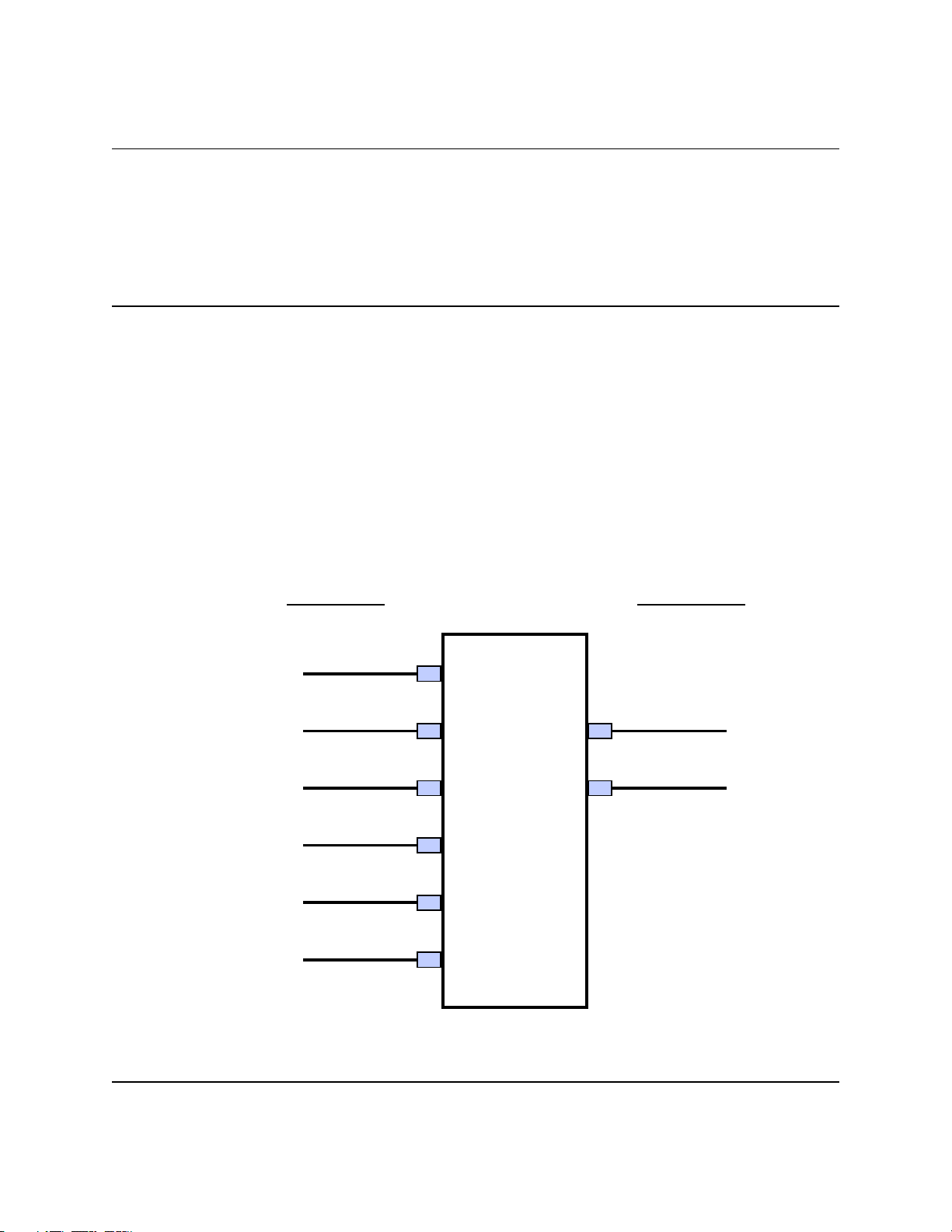

The XPA200-7984-I X-Band High Power Amplifier (SSPA) is

designed for use in communication systems, or in satellite uplink data systems. The SSPA operates over the RF input frequency

range of 7900 to 8400 MHZ. The RF power output is 53.0 dBm

minimum at 1 dB compression. A functional block diagram is shown

in Figure 1-1.

The SSPA is designed to be hard mounted in a standard 19inch rack or cabinet, or to be rack mounted using COMTECH slide

mechanisms provided with the SSPA to allow it to be serviced

without its removal from the rack. Two internally mounted

exhaust fans are mounted on the chassis for cooling. An AC power

connector, with an on/off switch, is located on the rear on the

chassis.

All operator controls, indicators and displays for local and

remote operation as well as the RF Input and Output sample test

ports are located on the front panel of the SSPA. Connectors for

the external interface connections are located on the rear of the

SSPA chassis.

XPA200-7984-I-OPT1, REV.3 1-1

Page 18

XPA200-7984-I-OPT1, X-Band SSPA Introduction

Prime

Power

Input

PS # 2 28Vdc

FAN1

FAN2

PS #1 10Vdc

PS #2 10Vdc

-5Vdc Interlock

AUX. PS & SWITCH

CONTROL

AS/0206

+12V -12V CONTROL

& MONITOR

MONITOR & CONTROL

-5V

AS/0200

+5V

+10Vdc

RF INPUT RF OUTPUT

POWER

AMPLIFIER

AS/0558

Figure 1.1 FUNCTIONAL BLOCK DIAGRAM

XPA200-7984-I-OPT1, REV.3 1-2

Page 19

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.3 Specifications

The following are the design, operating and environmental specifications

for the XPA200-7984-I X-Band Solid State High Power Amplifier (SSPA).

Output Front Panel

Frequency 7.900-8.400 GHz Display 24 x 2 LCD

Power 53.0dBm min. @ 1dB Comp. Data Entry Cursor Control Keypad

Mute -80dB Input Sample Type N,50 Ohms,-20dBc

VSWR 1.25:1 Max.

Connector CPR-112G Waveguide Flange

Gain Remote Control

Linear 62dB min, 67dB typ. Comm Port RS-485 or RS-232C

Adjust 20dB in 0.25dB Steps Protocol Comtech ASCII or Emul.

Per 500MHz +

Per 40 MHz +

+0 - +50C +

Third Order Intermod. Tx ON Yellow

Intercept +60.5dBm Min.,+62.0dBm Typ. Online Yellow

Products -30dBc typ., -25dBc max @ Remote Yellow

AM to PM Conversion Height 12.25 inches

2.0 degrees typ., 3.0 max @ rated output Width 19 inches

(see Note 1) Output Sample Type N,50 Ohms,-40dBc

.75dB

.25dB Alarms

0.50dB @ center Freq. Summary Fault Form C

±1.00dB @ full band

3 dB total back off

(two tones,

ªf= 1MHz)

LED

Power Green

Fault Red

Stored Fault Red

Mechanical

Depth 24 inches

Weight 100 lbs.

Group Delay

Linear +

Parabolic +

Ripple 1.0ns Peak-to-Peak (See Note 1)

Spurious 0-100% Noncond. Stor.

Carrier Related -65dBc Shock Normal Commercial

Line Related -50dBc Shipping & Handling

Input

Impedance 50 Ohms Power Requirements

Noise Figure 10dB Typ.,15dB Max. 115 VAC, 47-63 Hz, 2600 VA

VSWR 1.25:1 Max.

Connector Type N

Note 1: P1dB only guaranteed 0 to 40C. Operation above 40C not recommended.

0.03ns/MHZ Environmental

0.003ns/MHz

2

Temperature 0 to +50C Operation

Humidity 10-95% Noncond. Oper.

-40 to +70C Storage

XPA200-7984-I-OPT1, REV.3 1-3

Page 20

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.4 Prime Power Input

The power input requirements for the XPA200-7984-I X-Band SSPA

are as follows:

! 115 volts AC.

! 47 to 63 Hz.

! 2600 VA (approx. 1800W) nominal

1.5 Physical Dimensions

! Width: 19 inches.

! Height: 12.25 inches.

! Depth: 24 inches.

! Weight: 100 lbs.

1.6 Environmental Specifications

! Temperature: 0 to +50 degrees C operating.

(Note: P1dB guaranteed only 0 to 40C.

Operation above 40C not recommended).

! Humidity: 10 to 95% noncondensing operation.

1.7 Front Panel Controls

The front panel contains a User Interface Key-Pad which is used

by a local operator to input commands to the SSPA. The key-pad

is used to select the configuration for operating and monitoring

the status of the SSPA. In conjunction with the front panel two

line, twenty four character, LCD display, the key-pad allows the

operator to select one of five configurations. The configuration

functions are "Configuration Menu", "Monitor Status Menu",

"Currents Faults Menu", "Stored Faults Menu" and "Utility

Functions Menu".

XPA200-7984-I-OPT1, REV.3 1-4

Page 21

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.7 Front Panel Controls (Continued)

The key-pad has six keys: Enter, Clear, Right Arrow, Left

Arrow, Up Arrow and Down Arrow. Each key has a logical function:

! Enter Key: (ENT)

Used to select a display function, or to execute a

command to change the configuration of the SSPA.

! Clear Key: (CLR)

Used to cancel a selection, or to cancel a

configuration change which has not been executed

using the "Enter" key. After pressing the "Clear"

key the display will return to the previous

selection.

! Right and Left Arrow Keys:

/

These keys are used to select or change an operating

mode within a function, or to input or change the

configuration input data (numbers).

! Up and Down Arrow Key:

/

These keys are used to move to the next operation

mode, or to move the cursor to select a specific

parameter or digit within an operating mode

selected.

1.8 Front Panel Indicators

There are six LED indicator lights on the front panel which

indicate the status of the SSPA and provide summary fault

information. The indicators are defined as follows:

XPA200-7984-I-OPT1, REV.3 1-5

Page 22

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.8 Front Panel Indicators (continued)

Faults:

C Fault (Red):

Indicates that a fault condition exists

when the LED light is on.

C Stored Fault (Red):

Indicates that the fault has been logged and

stored When the LED light is on. The fault

may, or may not, be active.

Status:

C Power (Green):

Indicates that power is applied to the

SSPA when the LED light is on.

C Tx ON (Yellow):

Indicates that the transmit function of the

SSPA is on when the LED light is on.

The indicator light reflects the actual

condition of the transmit function.

C On Line (Yellow):

Indicates that the SSPA is operating

on-line to transmit data.

C Remote (Yellow):

Indicates that the SSPA is being

operated in the remote control mode where

commands and data are transferred via an

RS-485 (RS-232C is optional) serial

communications link.

XPA200-7984-I-OPT1, REV.3 1-6

Page 23

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.9 Front Panel Display

The front panel display is a two line by twenty-four

character, LCD display. Each configuration function, or

operating mode, is shown on the display when the operator enters

a command into the key-pad on the front panel.

1.10 Front Panel Test Point Samples

Two test point connections are located on the front panel

for monitoring the RF input and the RF output. A type N female

connector is provided for the RF sample test points.

1.11 Rear Panel Connections

The following is a list of the connectors on the rear panel:

! Connector J1: SSPA RF Input (RF in).

! Connector J2: SSPA RF Output (RF output).

! Connector J3: AC Prime Power Input (AC in).

! Connector J4: Cust. Discrete Control (Discrete Control).

! Connector J5: Combiner Interface.

! Connector J6: COM1 Port (RS-232C/RS-485) (COM1).

! AC Power On / Off Switch.

XPA200-7984-I-OPT1, REV.3 1-7

Page 24

XPA200-7984-I-OPT1, X-Band SSPA Introduction

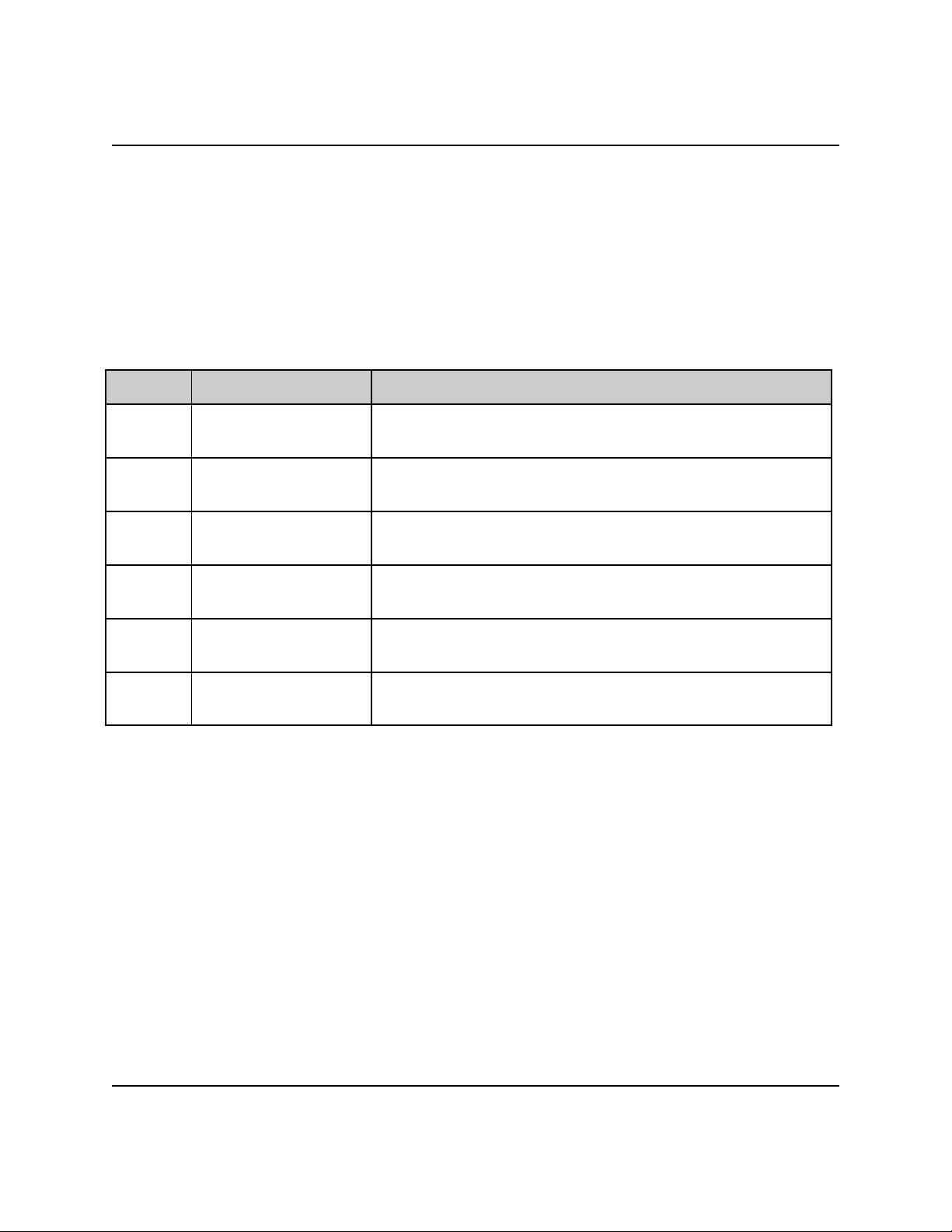

1.11.1 RS-485/RS-232C Interface (COM1), Connector J6

The RS-485/RS-232C Interface connector, J6, is a 9 pin "D"

type DB9F connector socket. The pin-out specifications are

contained in Table 1-1. The mating connector is a DB9M.

Table 1-1.

J6, COM1 connector Pin-Out

Pin # RS-232C RS-485 4-Wire RS-485 2-Wire

1 no connect GND; Ground GND; Ground

2 TD; Transmit Data no connect no connect

3 RD; Receive Data no connect no connect

4 no connect +TX; Signal +RX/TX; Signal

5 GND; Ground -TX; Signal

Complement

6 DSR; Unit Ready -

no connect no connect

always high.

7 RTS; Request to

no connect no connect

Send. Looped to

CTS

8 CTS; Clear to

+RX; Signal +RX/TX; Signal

Send

9 no connect -RX; Signal

Complement

-RX/TX; Signal

Complement

-RX/TX; Signal

Complement

XPA200-7984-I-OPT1, REV.3 1-8

Page 25

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.11.2 Customer Discrete Control, Connector J4

The Customer Discrete Control connector, J4, is a 19 pin

circular connector, type MS3112E14-19S. The pin-out

specifications is contained in Table 1-2. The mating connector

is a MS3116F14-19P.

Table 1-2.

J4, Customer Discrete Control Connector Pin-Out

Pin Signal Name Description

A External Mute

Cmd

B External Mute

External Mute Command. TTL input “high”

mutes the unit.

External Mute Common.

Common

G Local Online

Local Online Status Common.

Common

H Local Online

Tied to pin G when Online, else open.

NO

N Summary Fault

Summary Fault Status Common.

Common

P Summary fault

Open when Faulted, else tied to Pin N.

NO

Note: All other pins are unused.

XPA200-7984-I-OPT1, REV.3 1-9

Page 26

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.11.3 Combiner Interface, Connector J5

The Redundant Loop interface connector, J5, is a 19 pin

circular connector, type MS3112E14-19S. The pin-out

specifications is contained in Table 1-3 The mating connector is

a MS3116F14-19P.

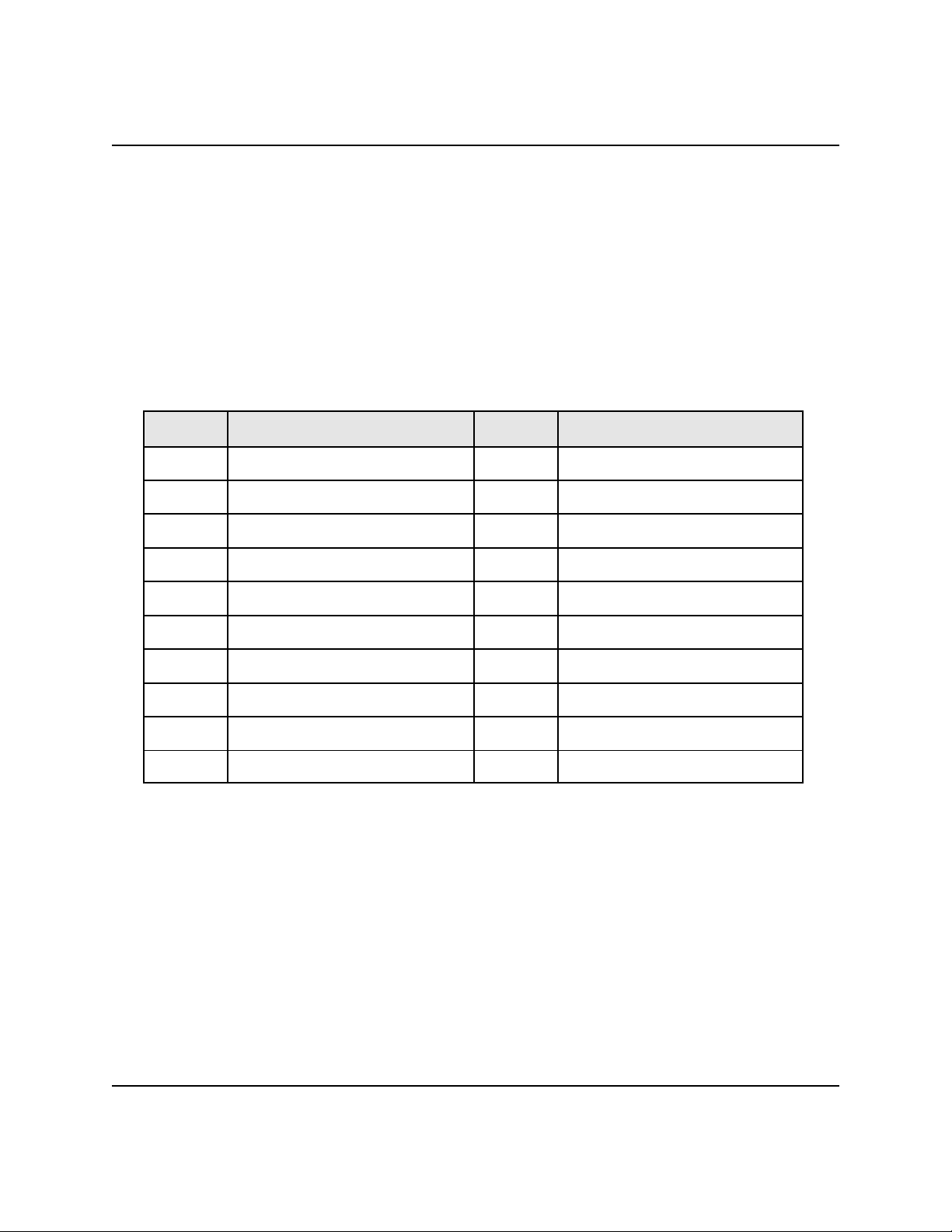

Table 1-3.

J5, Combiner Interface Connector Pin-Out

Pin # Description Pin # Description

A Inhibit Command L not used

B VPC A+B->Antenna M not used

C not used N not used

D not used P not used

E VPC Output Common R not used

F VPC A(B)->Antenna S Local SumFlt Common

G not used T Local SumFlt NO

H Inhibit Common U not used

J not used V not used

K not used

XPA200-7984-I-OPT1, REV.3 1-10

Page 27

XPA200-7984-I-OPT1, X-Band SSPA Introduction

1.11.4 AC Prime Power Input Connector, J3

The AC prime power input connector, J3, is a 3 pin circular

connector, type CA3102E20-19PB FMLB A. The ground connector, pin

A, is of the first make, last break type. The pin-out

specifications are contained in Table 1-4. A mating connector of

type CA3106E20-19SB is included for the customer.

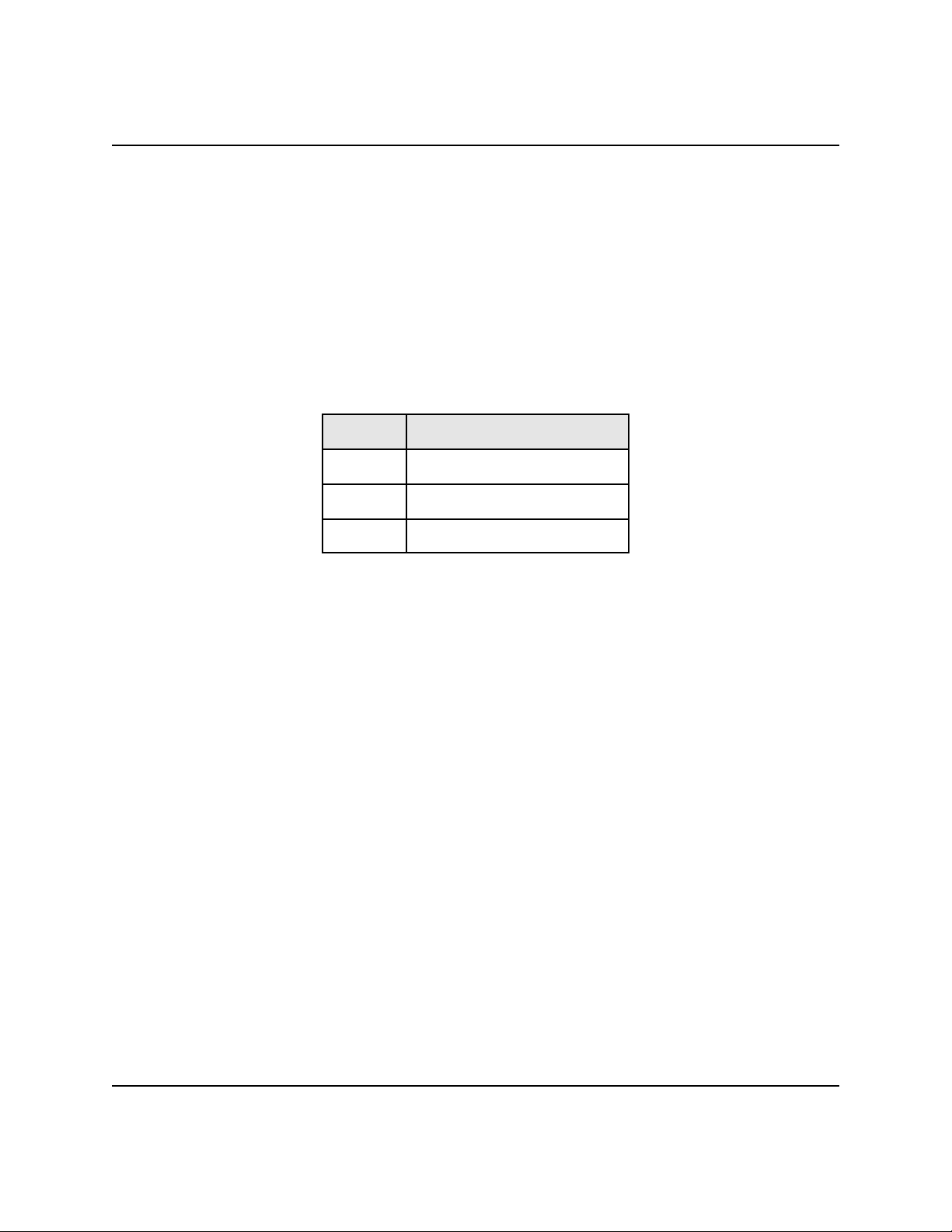

Table 1-4.

J3, AC Prime Power Input Connector

Pin # Description

A Ground

B Neutral

C Line

1.12 Prime Power Switch

The on/off prime power switch is located on the rear of the

chassis adjacent to the prime power input connector. The circuit

breaker is rated for 40 Amps.

XPA200-7984-I-OPT1, REV.3 1-11

Page 28

Page 29

XPA200-7984-I-OPT1, X-Band SSPA Installation

Section 2

Installation/Operation with

Mitec 2723B

Variable Phase Combiner and

Redundant Switching System

2.1 Unpacking and Inspection

This section is intended to give a brief explanation on how to

setup and operate two Comtech XPA200 SSPAs with the Mitec 2723B

Variable Phase Combiner and Redundant Switching System. More detailed

explanations on operation of the SSPA are contained in later sections

of this manual. More detailed operating instructions for the Mitec

Combiner and redundant switching system can be found in it’s

associated manual.

Inspect the shipping container for damage. The shipping

container and packing materials should be retained for possible reshipment. Check to determine that all parts, materials and

documentation have been shipped with the SSPA. The SSPA should be

inspected for possible damage, and then tested for proper operation.

If the shipment is incomplete, or there is mechanical damage, or

the SSPA does not operate properly, notify the COMTECH Customer

Service representative immediately. If there is damage to the

shipping container, notify the carrier, and retain all shipping

materials for inspection by the carrier.

2.2 Rack Mount Installation

2.2.1 XPA200 Installation

The XPA200-7984-I X-Band SSPA is designed for installation to

mount in a standard 19 inch rack cabinet or enclosure. The SSPA

chassis requires 12.25 (7RU) inches of panel height space.

Adequate air ventilation should be provided to the rack

mounted equipment. Cool air is taken in through the front panel and

XPA200-7984-I-OPT1, Rev.2 2-1

Page 30

XPA200-7984-I-OPT1, X-Band SSPA Installation

exhausted out the rear panel. Locate the unit so the input and

output airflow paths are not obstructed or restricted. This will

minimize the amplifier operating temperature, and provide years of

reliable operation.

If the SSPA is to be mounted on slides, the slides must be the

COMTECH rack slides provided with the SSPA. Mount the slides on the

sides of the SSPA chassis with the mounting hardware provided.

Then, install the slide rails in the rack cabinet enclosure.

Secure the SSPA to the rack cabinet with four screws inserted

through the SSPA front panel slotted holes.

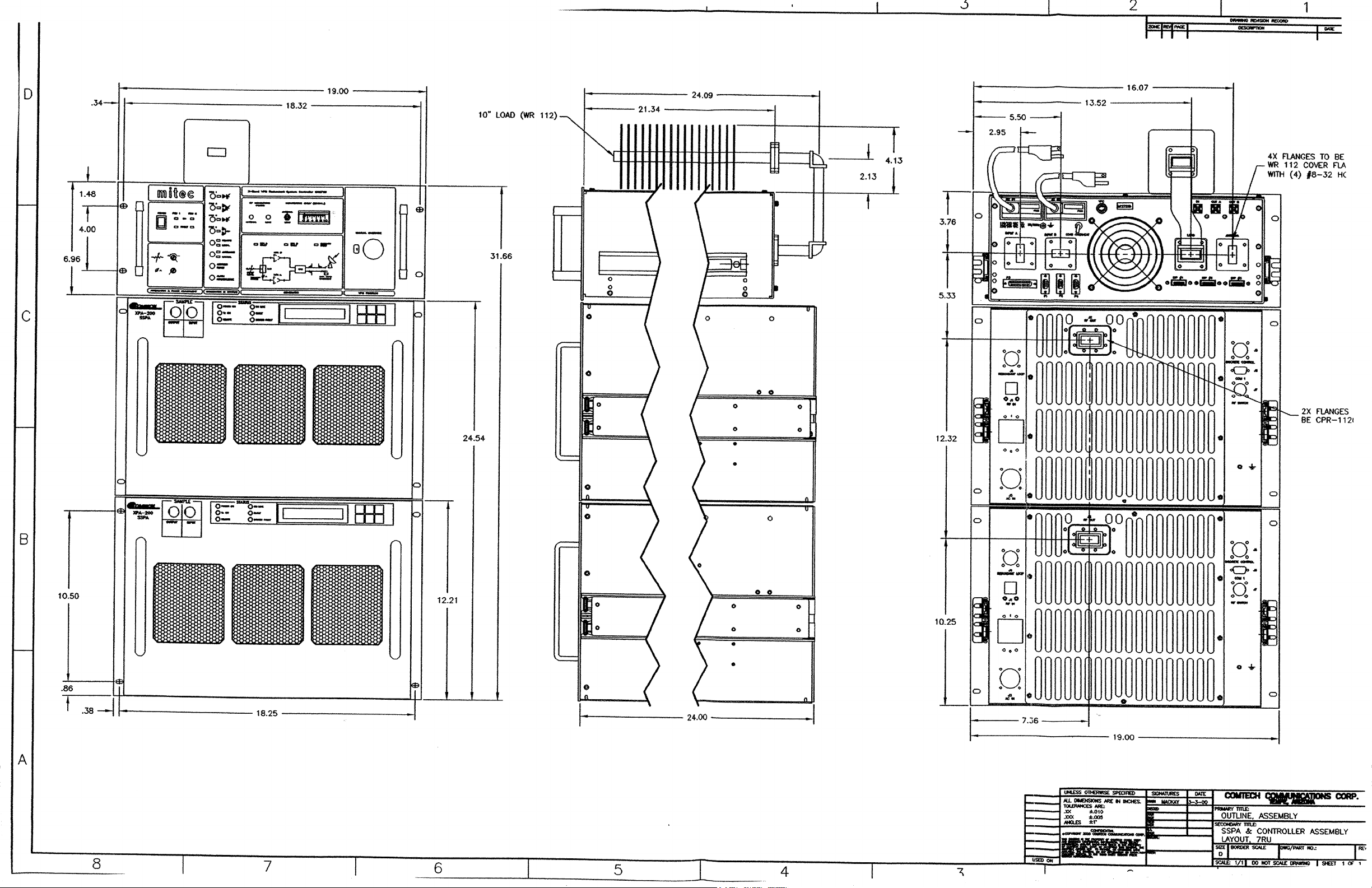

2.2.2 Combined/Redundant Amplifier Installation and Cabling

For the complete combined/redundant amplifier system, it is

most common to install the Mitec 2723B combiner in the top position

of the rack, followed by SSPA B, with SSPA A in the bottom position.

(See the outline drawing at the end of this section.)

Connect the Comtech supplied inter-unit control cable,

CA/8981, between the Mitec Combiner ports P1,P2,P3 and to each J5 of

SSPA A and SSPA B as indicated by the labels on the cable. (Note

that this cable is setup for the bottom SSPA be SSPA A.)

Attach the supplied waveguide termination to the load port of

the Mitec 2723B such that the termination resides above the unit.

(See outline drawing.)

Attach user supplied coaxial cables and waveguide between the

Mitec 2723B and each XPA200. Refer to Figure 2.3 of the Mitec

manual. A waveguide pressure window has also been supplied and can

be attached according to customer preference.

(Note that CA/8981 has been constructed for SSPA A to be in the

bottom position. The coaxial cables and waveguides should be

connected accordingly. In case of conflict, it will be necessary to

modify either CA/8981 or the coaxial cables and waveguides.)

CAUTION!

Before applying AC power to the units, make sure the waveguide

output of the amplifiers and the antenna and load ports of the

combiner are properly terminated. Failure to do so could lead to

equipment damage and excessive RF radiation levels.

Attach power cords to the units. Two standard power cords are

supplied with the Mitec 2723B. Each XPA200 is supplied with a

mating connector to enable the user to fabricate a power cord. See

sections 1.4 and 1.11.4.

XPA200-7984-I-OPT1, Rev.2 2-2

Page 31

XPA200-7984-I-OPT1, X-Band SSPA Installation

2.2.3 Some Notes on Establishing Remote Communications

1. The Mitec 2723B combiner was set at the Comtech factory to

RS-232 operation per customer request, on address 00 (30H)

through P4. However, the Mitec 2723B has a non-standard pin-

out on this I/O connector. Connections should be made as

shown below:

Common PC 9-Pin Serial Port

Mitec 2723B Remote Serial Access

Port, P4 (9-pin)

Pin 2 (Rd) Pin 3

Pin 3 (Td) Pin 4

Pin 5 (Gnd) Pin 5

Table 2.1 Typical RS-232 Connection to Mitec P4

2. Physical remote cabling information for each Comtech SSPA

is described in section 5.3 of this manual. It is recommended to

set SSPA A to address 001 and SSPA B to address 002. These and

other communication parameters can be set via the front panel of

each SSPA, as described in section 3 and section 5.

3. A special Windows-compatible program has been included on

a floppy disk in this manual to assist in communicating with the

Combined/Redundant Amplifier system. Refer to the file “Notes.txt”

for operating instructions.

XPA200-7984-I-OPT1, Rev.2 2-3

Page 32

XPA200-7984-I-OPT1, X-Band SSPA Installation

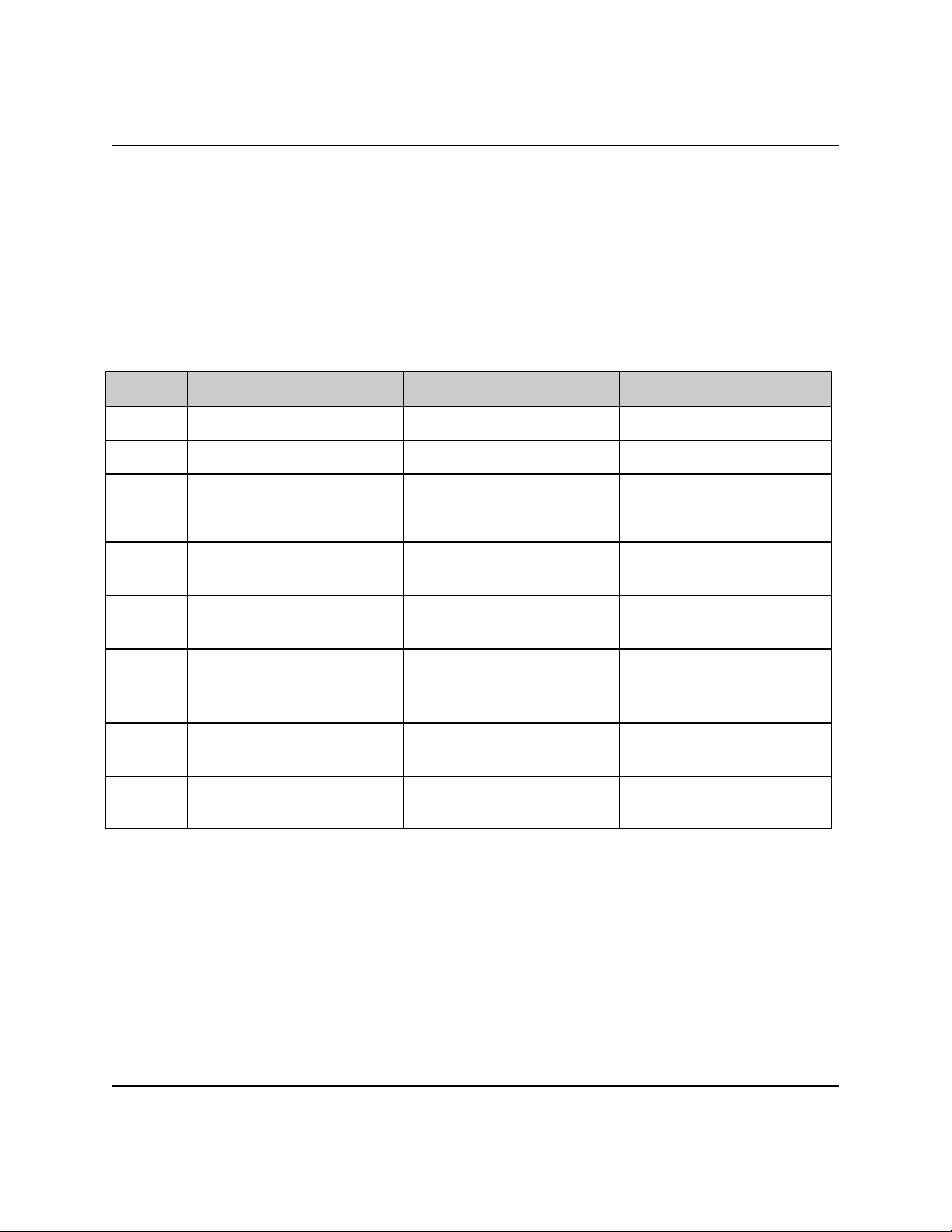

2.3 Notes on Combined/Redundant System Operation and Setup

The following paragraphs are intended to give a brief explanation

of system operation of the Comtech XPA200 SSPAs with the Mitec 2723

Variable Phase Combining and Redundant Switching System. More

detailed information can be found in each unit’s respective operating

manual. A review of the operation of a Variable Phase Combiner is

shown in Table 2.2 below.

(Note: The Load Overheat function mentioned in the Mitec 2723B manual

is not operational. The Mitec factory explained that this was an

option for another project that is not available to Comtech. However,

this should not cause any concern because the load is rated for 1000W

(convection cooling) and the maximum power possible into the load is

approximately 525W.)

VPC

Function

VPC

Pos.

Applied

Power

Power Observed

at Load

(less I.L.)

Power Observed

at Antenna

(less I.L.)

A to Antenna 1 A and B Full Power of B Full Power of A

A only Half Power of A Half Power of A

B only Half Power of B Half Power of B

A + B to

Antenna

2

A & B not

phase

adjusted

A & B phase

adjusted*

Partial Power of

A & B

Negligible Power

Partial Power

of A & B

Full Combined

Power of A & B

B to Antenna 3 A and B Full Power of A Full Power of B

A only Half Power of A Half Power of A

B only Half Power of B Half Power of B

A + B to

Load

4

A & B not

phase

adjusted

Partial Power of

A & B

Partial Power

of A & B

A & B phase

adjusted*

Full Combined

Power of A & B

Negligible Power

* A & B must have equal carrier magnitude and frequency.

Table 2.2 Variable Phase Combiner Operation

XPA200-7984-I-OPT1, Rev.2 2-4

Page 33

XPA200-7984-I-OPT1, X-Band SSPA Installation

2.3.1 Redundant Operation and Setup

The system can operate in a standard 1:1 redundant

configuration by choosing VPC position 1 (SSPA A to antenna) or 3

(SSPA B to antenna) on the Mitec 2723B. For example, if the Mitec

2723B was set to run in Automatic mode and SSPA A was normally

operating to the antenna (VPC position 1), a fault on SSPA A would

cause the system to immediately switch to postion 3, or SSPA B to

antenna.

Each SSPA may have slightly different gain values. A

procedure to equalize gain and output power between SSPA A and SSPA

B for redundancy operation is described below. The output powers

from SSPAs A and B are first equalized by measurements at the load

port before switching power to the antenna port.

A. To set the output power of SSPA A:

1. Mute SSPA B via remote or front panel controls.(To

prevent unwanted power from SSPA B going to antenna.)

2. Set VPC to position 3 (B to antenna, A to load).

3. Connect a power meter to the Mitec calibrated load

measuring port (see 2723B test data for exact calibration

data). Adjust output power of SSPA A to desired level by

adjusting input RF power or by using the SSPA A attenuation

setting.

B. To set the output power of SSPA B:

1. Mute SSPA A via remote or front panel controls.(To

prevent unwanted power from SSPA A going to antenna.)

2. Set VPC to position 1 (A to antenna, B to load).

3. Connect a power meter to the Mitec calibrated load

measuring port (see 2723B test data for exact calibration

data). Adjust output power of SSPA B to desired level

(usually the same as A) by adjusting input RF power or by

using the SSPA B attenuation setting.

C. Choose the unit desired to be on-line.

1. Mute both units to prevent unwanted power from going to

the antenna.

2. Choose SSPA A (position 1) or SSPA B (position 3) for

operation to the antenna. The other unit will be sent to

the load.

3. Set the Mitec unit in Automatic mode and un-mute the

SSPAs.

4. Verify proper output power going to antenna by

connecting a power meter to the Mitec Antenna Forward

power

measuring port (see Mitec test data for calibration factor).

XPA200-7984-I-OPT1, Rev.2 2-5

Page 34

XPA200-7984-I-OPT1, X-Band SSPA Installation

2.3.2 Combined (SSPA A and SSPA B) Operation and Setup

The full powers of SSPAs A and B can be phase combined for

increased system power output. Maximum output is obtained only if

the signals of SSPA A and B have equal or close carrier magnitude

and frequency, and the relative phase between them is adjusted.

Phase adjustment of the input signals for maximum output power is

accomplished via the screw adjustment on the front panel of the

Mitec 2723B.

A procedure to maximize output power by phase combining the

outputs of SSPA A and B is given below. The procedure first

optimizes the power off-line by using the load port, and then

switches the maximized power on-line through the antenna port.

(Note of Caution: During the phase adjustment period, it is possible

to send a significant signal level to the antenna port even though

the combiner is directed to the load. Therefore, it is recommended

to perform the phase combining adjustment at low power levels or

activate any maintenance switches which may keep unwanted signal

from the actual antenna.)

1. Connect a power meter to the Mitec calibrated load measuring

port (see 2723B test data for exact calibration data).

2. Select VPC position 1, (A to Antenna, B to Load). Adjust

SSPA B input signal level and attenuation to achieve desired

output power level from SSPA B. For example, 40.0 dBm.

3. Select VPC position 3, (B to Antenna, A to Load). Adjust

SSPA A input signal level and attenuation to achieve an output

power level within +/- .3 dB of that obtained from SSPA B in step

2 above. (It may be necessary to repeat step 2 and increase

attenuation level of SSPA B if SSPA B has more gain than SSPA A.)

4. Select VPC position 4, A&B to load. Adjust the phase trimmer

on the Mitec 2723B front panel until maximum power is reached,

typically 2.7-2.95 dB above the single unit output power level.

For this example, 42.7-42.95.

5. Select VPC position 2, A&B to load, to go on-line and route

power to the antenna port.

6. Monitor the output power through the Antenna Forward

measuring port on the Mitec unit (see 2723B test data for exact

calibration data). Perform any minor trimming of the phase

shifter to maximize output power.

7. Note: Whenever a significant change in signal frequency

occurs, it will be necessary to re-adjust the phase shifter.

XPA200-7984-I-OPT1, Rev.2 2-6

Page 35

Page 36

Page 37

XPA200-7984-I-OPT1, X-Band SSPA System Operation

Section 3

System Operation

3.1 General

This section contains instructions for operating the solid state

high power amplifier (SSPA). The front panel of the SSPA has a keypad for operator input commands, an LCD Display, LED status

indicators, and connector test sample ports to monitor the RF input

and output signals. Table 3-1 is provided to show the control and

operating functions of the SSPA.

3.2 Switching Power On

Before turning the Prime Power Switch to the "on" position, check

to ensure that the installation is complete, and verify that the SSPA

is connected to the proper prime power source, RF input and RF output.

Switch the ON/OFF Prime Power Switch on the rear panel to ON.

Verify that the cooling fans are operating, and that the POWER ON LED

STATUS indicator light is on.

After the prime power is switched on, the STATUS indicators

should be as follows:

! POWER ON: Indicator ON.

! TRANSMIT: Indicator OFF.

! REMOTE: Indicator ON.

! ON LINE: Indicator ON.

! FAULT: Indicator OFF.

! STORED FAULT: Indicator OFF.

After the AC power is switched on and before pressing the buttons

on the key-pad, the LCD display message should be similar to:

XPA200-7984-I

SW VER X.XX SN7984XXXX

XPA200-7984-I-OPT1, Rev.2 3-1

Page 38

XPA200-7984-I-OPT1, X-Band SSPA System Operation

Table 3-1. Operating Functions - Front Panel

Item Functional Description Reference

Designation

Key-Pad;

ENT key

Key-Pad;

CLR key

Key-Pad;

Right Arrow key

Key-Pad;

Left Arrow key

Key-Pad;

Up Arrow key

Key-Pad;

Down Arrow key

LCD Display Displays commands and data entered

STATUS Indicator,

Green

STATUS Indicator,

yellow

STATUS Indicator,

yellow

Enters commands into the

converter.

Clears commands and data selected

and not entered.

Selects functions and the menu

operating data.

Selects functions and the menu

operating data.

Selects the operating menu and

data values.

Selects the operating menu and

data values.

into the key-pad.

Prime power is applied when the

light is on.

Transmit function operating when

the light is on.

In Remote Control Mode when the

light is on.

ENT

CLR

Right Arrow

Left Arrow

Up Arrow

Down Arrow

POWER ON

TRANSMIT ON

REMOTE

STATUS Indicator,

yellow

STATUS Indicator,

Red

STATUS Indicator,

Red

INPUT SAMPLE Type N connector test point

OUTPUT SAMPLE Type N connector test point to

XPA200-7984-I-OPT1, Rev.2 3-2

Operating on-line to receive

data when the light is on.

Fault condition exists when the

light is on.

Faults stored and logged

when the light is on.

to sample RF input.

sample RF output.

ON LINE

FAULT

STORED

FAULT

SAMPLE INPUT

SAMPLE OUTPUT

Page 39

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3 Operation

Local operation of the 200 watt, X-Band SSPA is controlled by

operator input commands initiated through the six button key-pad on

the front panel. The key-pad is the local operator's interface to

control, configure and monitor the status of the SSPA. Operator

inputs and commands entered into the key-pad are displayed by the

front panel twenty-four character, two line, LCD display. See Section

5.0 for Remote Control Operation.

There are five operating command functions: Configuration,

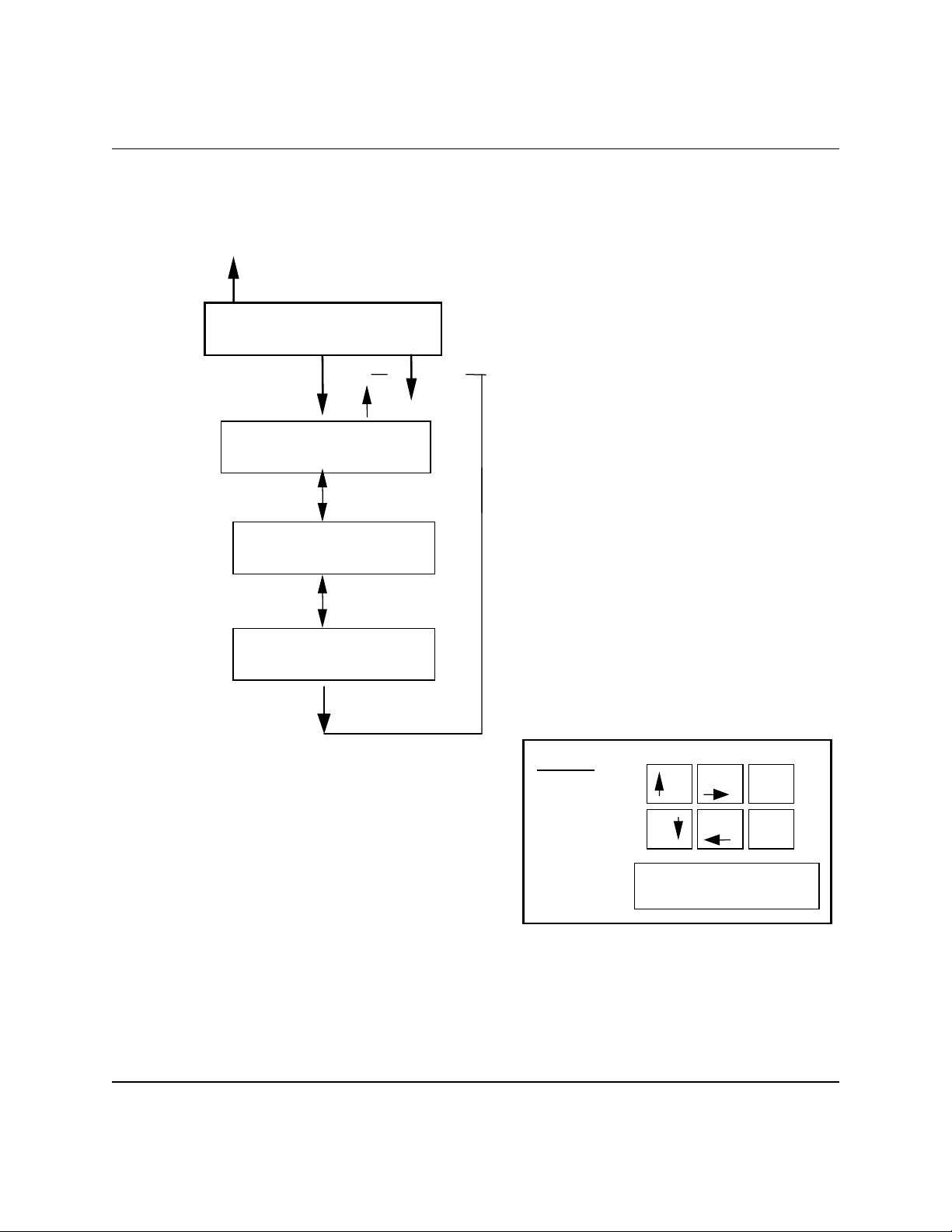

Monitor Status, Currents Faults, Stored Faults and Utility Functions.

A flow chart for selecting the commands, operating menus, and data

inputs is shown in Figures 3-1 through 3-6.

---------

CONFIGURATION-MENU

----

(See Figure 3-2)

---------

MONITOR-STATUS-MENU

--

(See Figure 3-3)

---------

CURRENT-FAULTS-MENU

--

(See Figure 3-4)

ENTER

SELECT

SELECT

SELECT

---------

--

---------

---------

XPA200-7984-I

----

SW VER 1.02 SNXXX

---

---

-----

LEGEND

KEY-PAD

DISPLAY

---------

---

---------

UTILITY-FUNCTIONS-MENU

-

SELECT

STORED-FAULTS-MENU

---------

(See Figure 3-5)

SELECT

---------

(See Figure 3-6)

UP

DOWN

------------------------

------------------------

-

RIGHT

LEFT

ENTER

CLR

Figure 3-1. SSPA Operating Command Functions

XPA200-7984-I-OPT1, Rev.2 3-3

Page 40

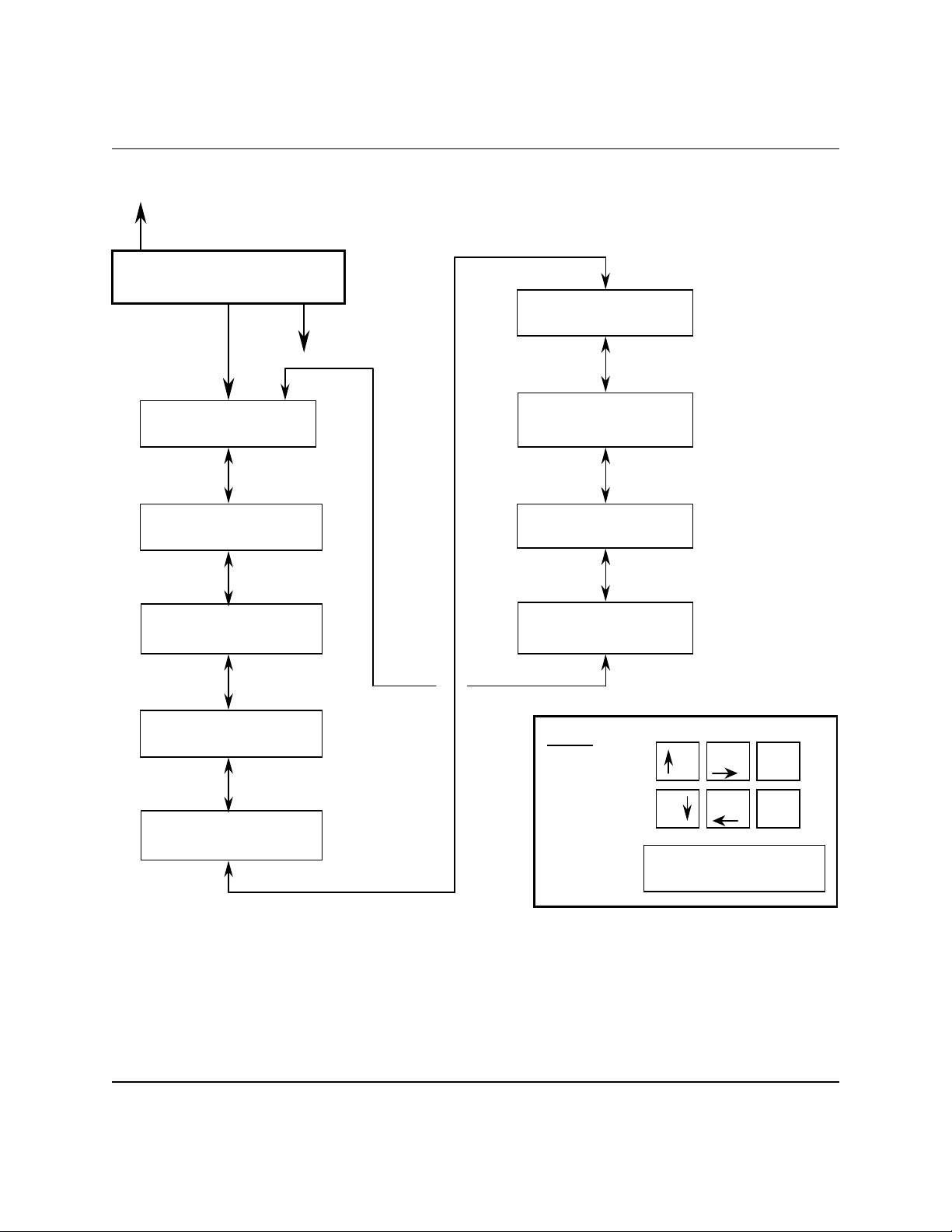

XPA200-7984-I-OPT1, X-Band SSPA System Operation

UP

------ SELECT ------

-- CONFIGURATION MENU

ATTENUATION-=-10.00-dB

AMPLIFIER=-ON--MUTE=-OFF

(See Para. 3.3.2.1)

-

------------------------

(See Para. 3.3.2.2)

FAULT RECOVERY:MANUAL

---------------------

(See Para. 3.3.2.3)

(See Para. 3.3.2)

ENTER

ENTRY MODE -= REMOTE

DOWN

--

-

LEGEND

RIGHT

UP

ENTER

KEY-PAD

DISPLAY

DOWN

---------------------

---------------------

LEFT

CLR

Figure 3-2. Configuration Menu Commands.

XPA200-7984-I-OPT1, Rev.2 3-4

Page 41

XPA200-7984-I-OPT1, X-Band SSPA System Operation

UP

---------SELECT---------

--MONITOR-STATUS-MENU---

ENTER

+12V=+12.2-----12V=-12.0

--VCC=4.9------5V=-4.9--

----28-VDC-PS-=-27.9----

10VPS1=10.3 10VPS2=10.3

--AMPLIFIER-TEMP=+44C---

------------------------

(See Para. 3.3.3)

DOWN

-RF-FET----Q3-=-X.X-AMPS

-RF-FET----Q4-=-X.X-AMPS

-RF-FET----Q5-=-X.X-AMPS

-RF-FET----Q6-=-X.X-AMPS

-RF-FET----QX-=-X.X-AMPS

-RF-FET----QX-=-X.X-AMPS

-RF-FET----Q18=-X.X-AMPS

-RF-FET----Q19=-X.X-AMPS

FORWARD-RF-PWR:- 53.0-DBM

REVERSE-RF-PWR:-<26.2-DBM

LEGEND

RIGHT

UP

ENTER

KEY-PAD

--RF-FET----Q1-=-XXXmA--

--RF-FET----Q2-=-XXXmA--

DISPLAY

DOWN

------------------------

------------------------

LEFT

CLR

Figure 3-3. Monitor Status Menu Commands

XPA200-7984-I-OPT1, Rev.2 3-5

Page 42

XPA200-7984-I-OPT1, X-Band SSPA System Operation

UP

---------SELECT---------

--CURRENT-FAULTS-MENU---

ENTER

POWER-FAULTS:----+12V=OK

-12V=OK--VCC=OK---5V=OK-

(See Para. 3.3.4.1)

-----28-VDC-PS-=-OK-----

--10VPS1=OK--10VPS2=OK--

(See Para. 3.3.4.1)

(See Para. 3.3.4)

DOWN

---AMPLIFIER-TEMP-=-OK--

-FAN-1-=-OK--FAN-2-=-OK-

(See Para. 3.3.4.2,

Para. 3.3.4.3)

--M&C-PROCESSORS-=-OK---

------------------------

(See Para. 3.3.4.3)

LEGEND

KEY-PAD

DISPLAY

RIGHT

UP

DOWN

------------------------

------------------------

LEFT

ENTER

CLR

Figure 3-4. Currents Faults Menu Commands

XPA200-7984-I-OPT1, Rev.2 3-6

Page 43

XPA200-7984-I-OPT1, X-Band SSPA System Operation

UP

---------SELECT---------

---STORED-FAULTS-MENU---

ENTER

TOTAL-FAULTS-STORED:--XX

LAST-19:20:05---02/15/95

(See Para. 3.3.5.1)

----CLEAR-ALL-STORED----

------FAULTS?-NO--------

(See Para. 3.3.5)

DOWN

(See Para. 3.3.5.2)

LEGEND

RIGHT

UP

ST-FAULT-XX-----19:20:05

KEY-PAD

DOWN

LEFT

OK-FINE-LOCK----02/15/95

------------------------

(See Para. 3.3.5.3)

DISPLAY

------------------------

Figure 3-5. Stored Faults Menu Command

XPA200-7984-I-OPT1, Rev.2 3-7

ENTER

CLR

Page 44

XPA200-7984-I-OPT1, X-Band SSPA System Operation

UP

---------SELECT---------

--UTILITY-FUNCTIONS-MENU---

ENTER

----TIME:- 10:20:05AM----

-----DATE--09/15/94------

---SERIAL-MODE=RS232C--ADDR=XXX-BAUD=YYYY-P=ZZ-

SERIAL-PORT-DATA-FORMAT=

-7-DATA,-2-STOP,-PARITY-

(See Para. 3.3.6)

DOWN

FORWARD -RF-POWER-MONITOR

----OFFSET-=-+0.0dBm----

REVERSE-RF-POWER-MONITOR

----OFFSET-=-+0.0dBm----

--------LAMP-TEST-------

----------OFF-----------

LEGEND

KEY-PAD

DOWN

UP

RIGHT

LEFT

ENTER

CLR

-DISPLAY-CONTRAST-=XX-DISPLAY-BRIGHTNESS-=-XX-

DISPLAY

------------------------

------------------------

Figure 3-6. Utility Functions Menu Commands

XPA200-7984-I-OPT1, Rev.2 3-8

Page 45

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3.1 SSPA commands

The SSPA commands are in a tree structured menu format

designed for access and execution of all control functions, and

to prevent the execution of an invalid entry by the operator.

When the prime power is turned on, the LCD display will contain a

message indicating the SSPA model number and the version number

of the firmware installed in the SSPA.

To select a Command Function press the "ENT" button on the

key-pad. The LCD display will indicate:

SELECT

CONFIGURATION MENU

This will provide the local operator access to the Command

Function Menus, which is the top level structure to start the

selection of Command Function Menus to input into the SSPA. To

sequence to the next Command Function Menu press a "DOWN" or "UP"

arrow button on the key-pad. The SSPA will step to the next

Command Function Menu each time a "DOWN" or "UP" arrow button is

pressed. The current Command Function Menu will be displayed on

the LCD display. The Command Function Menus are shown in Figure

3-1.

To select a specific Command Function Menu press the "ENT"

key-pad button. If a function is selected in error, press the

clear ("CLR") button which will return the SSPA to the main

command menus to allow the selection of another function. Any

one of the five Command Function Menus can be selected using this

procedure.

Once a Command Function has been selected, use the "RIGHT"

or "LEFT" arrow key-pad buttons to sequence through the Operating

Mode Commands. Each of the modes will be displayed on the LCD

display. A specific operating mode is selected by pressing the

"ENT" button. If an mode is selected in error, press the clear

("CLR") button which will return the SSPA to the operating menus

to allow the selection of another mode.

XPA200-7984-I-OPT1, Rev.2 3-9

Page 46

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3.1 SSPA Commands (cont.)

When an operating mode is selected, a parameter or a digit

within the parameter will be flashing on the LCD display. Use

the "RIGHT" and "LEFT" arrows buttons to sequence through the

parameters or digits to select the next parameter or digit. A

specific parameter or value is selected by pressing the "ENT"

button. If a parameter or value is selected in error, press the

clear ("CLR") button which will return the SSPA to the original

parameter or value to allow another selection.

After selecting a parameter or digit, use the "UP" or "DOWN"

arrow buttons to select the next parameter, or to increment or

decrement the value of a digit. A specific new parameter or new

value is selected by pressing the "ENT" button. If a parameter

or value is selected in error, press the clear ("CLR") button

which will return the SSPA to the original parameter or value to

allow another selection.

Each time the clear ("CLR") button is pressed, the SSPA will

return to the menu level prior to the last "ENT" command.

3.3.2 Configuration Menu

The Configuration Functions are as follows:

3.3.2.1 Frequency Operating Mode

Attenuation (ATTN):

Input and displays the SSPA attenuation setting which

is selected between 0.00 to 20.00 in 0.25 dB steps.

The default setting is 10.00 dB.

Amplifier: Control supply voltage to RF FETS. The

default mode is ON.

Mute: Provide SSPA mute control. The default is OFF.

Other possible modes are:

INH inhibited or muted by the Mitec 2723B

EXT mute on from external J4 control (see

section 1).

XPA200-7984-I-OPT1, Rev.2 3-10

Page 47

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3.2.2 Entry Mode

Mode: The entry mode is Local or Remote. The default

is Local.

3.3.2.3 Fault Recovery: Fault Recovery is Manual or Auto. The

default is Auto.

3.3.3 Monitor Status Menu

Monitors and displays the status of:

! All SSPA power supplies.

! SSPA internal temperature.

! RF output power level.

! RF FET currents (Q1 through Q19).

3.3.4 Current Faults Menu

Displays the status of the current fault conditions. The

LCD display will indicate "FT" when a fault condition exists.

The display will indicate "OK" when a fault has not occurred.

3.3.4.1 Power Faults

Displays the DC voltage power supply faults. The DC

voltages displayed are:

! +12 VDC.

! -12 VDC.

! VCC.

! -5 VDC.

! +28 VDC

! +10 VDC, PS1 and PS2

XPA200-7984-I-OPT1, Rev.2 3-11

Page 48

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3.4.2 SSPA Over Temperature Fault

Displays a SSPA temperature fault condition.

3.3.4.3 Fan Faults

Displays status of both FAN #1 and FAN #2.

3.3.5 Stored Faults Menu

The SSPA displays a total of one hundred (100) faults which

a date and time stamped and stored in memory as they occur. The

stored faults remain in memory until a clear command is entered.

3.3.5.1 Total Stored Faults

Displayed the total number of faults stored. The most

recent fault stored is displayed on the LCD display.

3.3.5.2 Clear All Stored Faults

Input command to clear all faults. The command is

"YES" or “NO” which is displayed on the LCD display.

3.3.5.3 Display Stored Fault

The local operator can sequence through the stored

faults starting with the most recent fault. The Fault

number, time, description and date is displayed on the

LCD display.

XPA200-7984-I-OPT1, Rev.2 3-12

Page 49

XPA200-7984-I-OPT1, X-Band SSPA System Operation

3.3.6 Utility Menu

The local operator can input commands to the following

Utility Functions which are displayed on the LCD display:

! TIME. Military time is used in hours, minutes and

seconds.

! DATE. The date is displayed in month, day and year.

! Serial MODE (communications link).

C RS-232C, RS-485-2, RS-485-4.

C Physical Address. The default address starts from

one (001).

C BAUD (Rate). The default baud rate is 9600.

! SERIAL PORT DATA FORMAT. The default is 7 Data, 2 Stop

Bits, with Parity. An optional format is 8 Data, 1 Stop

Bit, with No Parity. This can only be changed via the

front panel menu system.

! DISPLAY CONTRAST. The default is 15, with values from

zero (0) to thirty (30).

! DISPLAY BRIGHTNESS. The default is 15, with values

from zero (0) to thirty (30).

! FORWARD RF POWER MONITOR OFFSET. This function allows

the operator to calibrate (fine tune) the RF Power

Monitor for a specific carrier frequency. The RF Power

Monitor is calibrated in the factory at the SSPA center

frequency. The operator can adjust (offset) the

display level using this function. The range equals

-6.0 to +6.0 dBm in 0.1 dBm steps.

! REVERSE RF POWER MONITOR OFFSET. This function allows

the operator to calibrate (fine tune) the RF Power

Monitor for a specific carrier frequency. The RF Power

Monitor is calibrated in the factory at the SSPA center

frequency. The operator can adjust (offset) the

display level using this function. The range equals

-6.0 to +6.0 dBm in 0.1 dBm steps.

! LAMP TEST. The default is OFF

XPA200-7984-I-OPT1, Rev.2 3-13

Page 50

Page 51

XPA200-7984-I-OPT1, X-Band SSPA Redundant System Operation

Section 4

Redundant System Operation

4.1 GENERAL

This option or application uses a Mitec variable phase

combiner for redundany use which is totally different than the

standard Comtech Communications redundancy operating features.

Section 2 contains the specialized redundancy system

features for this option. Also see the Mitec 2723B manual for

more detailed information.

XPA200-7984-I-OPT1, Rev.2 4-1

Page 52

Page 53

XPA200-7984-I-OPT1, X-Band SSPA Remote Control

Chapter 5

Remote Control

5.1 GENERAL

Each COMTECH X-Band SSPA can be remotely controlled through a

serial port. COMTECH’s simplified Command/Response protocol is

easily invoked by either a monitor and control computer, a nonintelligent ASCII terminal or a laptop computer operating in

terminal emulation mode. All SSPA configuration parameters as well

as all monitor and status information is available via the remote

port.

5.2 ELECTRICAL INTERFACE

The remote control interface supports either 2-wire RS-485,

4-wire RS-485 or RS-232C. The default port is 2-wire RS-485.

Selection of the interface type is made via front panel menu

selection.

5.2.1 RS-232C

Levels, pulse shapes and impedances conform to EIA standards

for asynchronous operation.

5.2.2 RS-485

Levels, pulse shapes and impedances conform to EIA

standards.

5.3 PHYSICAL INTERFACE

All three interface types (2-wire RS-485, 4-wire RS-485 and

RS-232C) are implemented alternately through the same 9-pin

connector.

XPA200-7984-I-OPT1, Rev.2 5-1

Page 54

XPA200-7984-I-OPT1, X-Band SSPA Remote Control

5.3.1 Connector

The remote control port is a female DB-9 connector located

on the rear of the SSPA.

5.3.2 Pin-out

5.3.2.1 RS-232C

PIN NAME FUNCTION

2 TD SSPA Transmit Data

3 RD SSPA Receive Data

5 GND Ground

6 DSR Unit Ready. Always high.

7 RTS Request to Send. Looped to CTS.

8 CTS Clear to Send

It should be noted that Comtech SSPA’s do not require the

hardware handshaking provided by the DSR, RTS and CTS signals.

These signals are provided for customers who are using interface

terminals that require this handshaking. Most of today’s PC’s

are provided with RS-232C serial ports that do not require the

hardware handshaking. In these instances, the interface can be

reduced to three (3) signals; TD, RD and GND.

5.3.2.2 RS-485

Both 2-wire and 4-wire applications are supported. The 4-wire

interface provides independent signal wires for each of the receive

(+RX) signal and its complement (-RX) as well as the transmit (+TX)

signal and its complement (-TX). In the 2-wire interface, the

receive signal and the transmit signal (+RX/TX) share one wire and

likewise the complement signals (-RX/TX) share one wire. Choice of

2-wire versus 4-wire is based on the customers interface equipment

and the cabling between this equipment and the SSPA(s).

XPA200-7984-I-OPT1, Rev.2 5-2

Page 55

XPA200-7984-I-OPT1, X-Band SSPA Remote Control

5.3.2.2.1 RS-485 2-wire

The pinout for the 2-wire interface is provided below. Note

that each signal pair (+RX/TX and -RX/TX) is provided on two

pins. This is done to provide customers who are using ‘soldercup’ type DB-9 connector the ability to more easily daisy chain

the signals to multiple devices while maintaining one wire per

‘solder-cup’. Customers who use ‘IDC Mass Terminated’ style DB-9

connectors (Ribbon cable types) need only use three (3) signals.

PIN NAME FUNCTION

1 GND Ground

4 +RX/TX Signal Loop In

5 -RX/TX Signal Complement Loop In

8 +RX/TX Signal Loop Out

9 -RX/TX Signal Complement Loop Out

5.3.2.2.2 RS-485 4-wire

The pinout for the 2-wire interface is provided below. Note

that all five (5) signals are required.

PIN NAME FUNCTION

1 GND Ground

4 +TX Transmit Signal

5 -TX Transmit Signal Complement

8 +RX Receive Signal

9 -RX Receive Signal Complement

5.3.3 Cables

5.3.3.1 RS-232

The remote control port is configured with pin 2 as the

transmit data signal (TD) and pin 3 as the receive data signal.

This arrangement allows straight connection (pin 2 to pin 2 and

pin 3 to pin 3) between the SSPA and most standard serial ports

using any standard RS-232C cable (i.e. no need to swap pins 2 and

3).

XPA200-7984-I-OPT1, Rev.2 5-3

Page 56

XPA200-7984-I-OPT1, X-Band SSPA Remote Control

5.3.3.2 RS-485

RS-485 cabling can be implemented with a single ribbon cable

using ‘IDC Mass Terminated’ style connectors or with discrete

wires using ‘solder-cup’ style connectors. A sufficient length

of ribbon cable must be allowed to reach the system monitor and

control computer.

5.4 PROTOCOL

5.4.1 Transmission Mode

The transmission mode is half duplex implemented in

Command/Response convention. This method requires the external

system monitor and control unit to initiate all communications by

command and the SSPA to respond with either confirmation or an

error message. The confirmation may contain status information.

5.4.2 Baud Rate

The default serial port Baud Rate is 9600. Baud rates of

4800, 2400, and 1200 and 300 are also supported.

5.4.3 Format

The following parameters are the default character format.

1 Start Bit

7 Data Bits

2 Stop Bits

1 Parity Bit

An optional character format that can be selected is:

This can only be selected from the Front Panel Menu.

1 Start Bit

8 Data Bits

1 Stop Bit

0 Parity Bits

5.4.4 Character Set

The character set implemented is ASCII.

XPA200-7984-I-OPT1, Rev.2 5-4

Page 57

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.4.5 Response Timeout

A minimum of 500 milliseconds should be provided before

declaring a ‘no reponse’ instance, at which time the command

should be re-transmitted.

5.4.6 Bus Inactivity Requirement

COMTECH recommends that a minimum of 50 milliseconds bus

inactivity be provided by the user between the receipt of a

response from an addressed SSPA and issuing the next command on

the serial bus.

5.5. ACCESS METHODS

SSPAs may be directly accessed by the RS-232C interface or

by the RS-485 interface in a buss configuration.

5.5.1 RS-485

In this control network, the SSPA is paralleled on a common

RS-485 cable, and has a unique physical address. Only one RS-485

port is required on the system's monitor and control computer.

5.5.2 RS-232C

For RS-232C control, a direct RS-232C cable connection is

made to each SSPA to be accessed. If an external Monitor and

Control Computer is used, one RS-232 port per SSPA is required.

5.6 ADDRESSES

All SSPAs are addressed in a command by the Device Address.

The Device Address consists of a physical address or a physical

address plus a virtual address.

5.6.1 Physical Address

Each SSPA in the system must have a unique physical address.

The physical address consists of a string of 1, 2 or 3 numbers

from 1 to 256. The physical address is entered into a SSPA via

the front panel.

Example: 10 Addresses SSPA whose physical

XPA200-7984-I-OPT1, Rev.2

address is 10.

5-5

Page 58

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.7 Message Structure

The structure of either a Command , Response or Error

Message is as follows:

Start Character

Device Address

Command or Response

End of Message String

5.7.1 Start Character

The Start Character begins each message:

Example: < Start of a user Command.

> Start of a SSPA response.

5.7.2 Device Address

The Device Address consists of a Physical Address. For this

document DEV is used for the generic case examples.

Example: <10 direct addressing

5.7.3 Command

A Command is a variable length character string beginning

with a / and containing either an instruction or an instruction

and data for a SSPA to act upon. If data is passed by command it

is appended to the instruction by an underscore( _ ). If data is

retrieved by command underscore follows the instruction flagging

the SSPA to supply data in a response. In this document /COM is

used for the generic case examples.

Example: <DEV/COM_xxx'cr' Sends data to a SSPA.

Example: <DEV/COM_'cr' Requests information from

a SSPA.

5.7.4 Confirmation Response

A confirmation will change the start character, and echo the

Device Address and Command. Any requested data will be appended

XPA200-7984-I-OPT1, Rev.2

5-6

Page 59

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

to the Command.

Example: >DEV/COM_xxx'cr''lf']

5.7.5 Error Response

If a SSPA cannot execute a Command or detects a protocol

violation, an error response is generated. An error is flagged

by changing the "/" command designator in the response to a "?".

Following the "?" error symbol are two characters which are

unique error symbols useful for computer analysis. The two error

symbols are followed by a text string explaining the error for

the convenience of a human operator. For this document ER is

used for the generic case examples response.

Example: >DEV?COM ER Error Message 'cr''lf']

5.7.6 End Of Message

End of message strings were devised in such a way that an

orderly screen presentation would result when SSPAs are

controlled by simple ASCII terminals.

5.7.6.1 Command Ending

The end of message for a command is a carriage return. For

this document 'cr' is used for the carriage return.

Example: <DEV/COM'cr'

5.7.6.2 Response Ending

End of message for a response is a carriage return, line

feed and a bracket: 'cr''lf'].

Example: >DEV/COM'cr''lf']

XPA200-7984-I-OPT1, Rev.2

5-7

Page 60

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8 COMMAND/RESPONSE PAIRS

5.8.1 Utility Commands

5.8.1.1 Time

Set Time: <DEV/TIM_hh:mm:ss'cr' hh = Hour*

Confirmation: >DEV/TIM_hh:mm:ss'cr''lf'] mm = Minutes

ss = Seconds

Retrieve Time: <DEV/TIM_'cr'

Confirmation: >DEV/TIM_hh:mm:ss'cr''lf']

* Note: 24 hour military time is used.

5.8.1.2 Date

Set Date: <DEV/DAT_mm/dd/yy'cr' mm = Month

Confirmation: >DEV/DAT_mm/dd/yy'cr'lf'] dd = Day

yy = Year

Retrieve Date: <DEV/DAT_'cr'

Confirmation: >DEV/DAT_mm/dd/yy'cr''lf']

5.8.1.3 Physical Address

The default Physical Address from is 1.

Set Physical Address: <DEV/SPA_xxx'cr' xxx = 1 to 255

Confirmation: >DEV/SPA_xxx'cr''lf']

Retrieve Phys. Addr: <DEV/SPA_'cr'

Confirmation: >DEV/SPA_xxx'cr''lf']

5.8.1.4 Baud Rate

The default baud rate is 9600.

Set Baud Rate: <DEV/SBR_xxxx'cr' xxxx = 300,

Confirmation: >DEV/SBR_xxxx'cr''lf'] 1200, 2400,

Retrieve Baud Rate: <DEV/SBR_xxxx'cr'

Confirmation: >DEV/SBR_xxxx'cr''lf']

4800 or 9600

XPA200-7984-I-OPT1, Rev.2

5-8

Page 61

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.1.5 Parity Bit

The default parity is even.

Set Parity Bit: <DEV/SPB_xxxx'cr' xxxx = ODD

Confirmation: >DEV/SPB_xxxx'cr''lf'] or EVEN

Retrieve Parity Bit: <DEV/SPB_'cr'

Confirmation: >DEV/SPB_xxxx'cr''lf']

5.8.1.6 LCD Contrast

The default is 15.

Set Contrast: <DEV/CON_xx'cr' xx = 0 to 30

Confirmation: >DEV/CON_xx'cr''lf']

Retrieve Contrast: <DEV/CON_'cr'

Confirmation: >DEV/CON_xx'cr''lf']

5.8.1.7 LCD Brightness

The default is 15.

Set Brightness: <DEV/LCD_xx'cr' xx = 0 to 30

Confirmation: >DEV/LCD_xx'cr''lf']

Retrieve Brightness: <DEV/LCD_'cr'

Confirmation: >DEV/LCD_xx'cr''lf']

5.8.1.8 Lamp Test

The default is off.

Test Lamps: <DEV/LAM_xxx'cr' xxx = ON or OFF

Confirmation: >DEV/LAM_xxx'cr''lf']

Lamp Test Status: <DEV/LAM_'cr'

Confirmation: >DEV/LAM_xxx'cr''lf']

XPA200-7984-I-OPT1, Rev.2

5-9

Page 62

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.1.9 Equipment Type

Equipment Type is a command that retrieves the model number

and software version of the equipment. The information

cannot be changed by command.

Retrieve Equipment Type: <DEV/RET_'cr'

Confirmation: >DEV/RET_xxxxxxx yyyyy'cr''lf']

xxxxxxx = Model Number yyyyy = Software Version

Example: >DEV/RET_XPA200-7984-I SW_1.07

5.8.1.10 Application Identification

The Application Identification (AID) command allows a free

form message to be created. It is intended to identify either

the satellite, transponder, beam, destination or other aspects of

the application that may be significant to operations. The

message length corresponds to capability of the LCD and is 48

characters in total. The second line begins at character 25,

therefore, blanks must be used after line 1 information in order

to space to line 2. A carriage return ends the command.

Trailing blanks will be generated to fill the LCD field. The AID

display will alternate with the Equipment type display by use of

the clear function key on the front panel. The default is "AID

MESSAGE".

Application ID: <DEV/AID_xxxxxxx ... xxxxx'cr'

Confirmation: >DEV/AID_'cr'

xxxxxxxxxxxxxxxxxxxxxxxx'cr'

xxxxxxxxxxxxxxxxxxxxxxxx'cr''lf']

Retrieve ID: <DEV/AID_'cr'

Confirmation: >DEV/AID_'cr'

xxxxxxxxxxxxxxxxxxxxxxxx'cr'

xxxxxxxxxxxxxxxxxxxxxxxx'cr''lf']

Note: xxxxxxx ... xxxxx = Your message, maximum 48

characters.

XPA200-7984-I-OPT1, Rev.2

5-10

Page 63

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.2 Configuration Commands

5.8.2.1 Amplifier ON/OFF

The XPA200-7984-I provides the user direct control of the 10

VDC supply voltage to the solid state RF power FETs. This

feature provides the ability to put the SSPA into a low power

consumption mode when the unit is offline. The default is on.

Amplifier control: <DEV/AMP_xxx'cr' xxx = ON or OFF

Confirmation: >DEV/AMP_xxx'cr''lf']

Retrieve AMP Status: <DEV/AMP_'cr'

Confirmation: >DEV/AMP_xxx'cr''lf']

5.8.2.2 Mute Output

The user is provided output mute control via the remote

interface using this command. The default is on.

Mute Output: <DEV/MUT_xxx'cr' xxx = ON or OFF

Confirmation: >DEV/MUT_xxx'cr''lf']

Retrieve Mute Status: <DEV/MUT_'cr'

Confirmation: >DEV/MUT_xxx'cr''lf']

5.8.2.3 Attenuator

The default is 10 dB.

Set Attenuator: <DEV/ATT_ yy.yy'cr'

Confirmation: >DEV/ATT_yy.yy'cr'lf']

Retrieve Attenuator:: <DEV/ATT_'cr'

Confirmation: >DEV/ATT_ yy.yy'cr''lf']

Note: yy.yy = 0.0 to 20.00 dB in 0.25 steps.

5.8.2.4 Auto Fault Recovery

The SSPA output is automatically muted in the event of a

detected fault. Auto Fault Recovery, if enabled, will cause the

output signal to go active (unmuted) if all faults clear. If

disabled, the output will remain muted even after all faults

clear until a MUT_OFF command is received (see 5.8.2.2). The

default is off.

XPA200-7984-I-OPT1, Rev.2

5-11

Page 64

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

Set Fault Recovery: <DEV/AFR_xxx'cr' xxx = ON or 0FF

Confirmation: >DEV/AFR_xxx'cr''lf']

Retrieve Status: <DEV/AFR_'cr'

Confirmation: >DEV/AFR_xxx'cr''lf']

5.8.3 Status Commands

Status commands retrieve configuration, maintenance and

alarm status in summary form.

5.8.3.1 Configuration Status

Configuration Status: <DEV/RCS_'cr'

Confirmation: >DEV/RCS_'cr'

ATT_yy.yy'cr' Attenuator

AMP_nnn’cr’ Amplifier - ON/OFF

TX_nnn'cr' Transmit - ON/OFF

ONL_nnn'cr' Online - ON/OFF

AFR_nnn'cr' Auto Flt Recovery-ON/OFF

5.8.3.2 Maintenance Status

Maintenance Status: <DEV/RMS_'cr'

Confirmation: >DEV/RMS_'cr'

V+28_xx.x'cr' +28 VDC Supply

V+12_xx.x'cr' +12 VDC Supply

V-12_xx.x'cr' -12 VDC Supply

V +5_x.x'cr' +5 VDC Supply

V -5_x.x'cr' -5 VDC Supply

V+10_1_xx.x'cr' 10 VDC Supply #1

V+10_2_xx.x'cr' 10 VDC Supply #2

TEMP_xx'cr' Temperature

FPWR_xx.x'cr’ RF Forward Power (dBm)

RPWR_xx.x'cr''lf'] RF Reflected Power (dBm)

XPA200-7984-I-OPT1, Rev.2

5-12

Page 65

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.3.3 FET Status

FET Status: <DEV/RFS_'cr'

Confirmation: >DEV/RFS_'cr'

FET1_xxx'cr' FET1 current in milliamps

FET2_x.x'cr' FET2 current in amps

FET3_x.x'cr' FET3 current in amps

FET4_x.x'cr' FET4 current in amps

FET5_x.x'cr' FET5 current in amps

FET6_x.x'cr' FET6 current in amps

FET7_x.x'cr' FET7 current in amps

FET8_x.x'cr' FET8 current in amps

FET9_x.x'cr' FET9 current in amps

FET10_x.x'cr' FET10 current in amps

FET11_x.x'cr' FET11 current in amps

FET12_x.x'cr' FET12 current in amps

FET13_x.x'cr' FET13 current in amps

FET14_x.x'cr' FET14 current in amps

FET15_x.x'cr' FET15 current in amps

FET16_x.x'cr' FET16 current in amps

FET17_x.x'cr' FET17 current in amps

FET18_x.x'cr' FET18 current in amps

FET19_x.x'cr''lf'] FET19 current in amps

5.8.3.4 Utility Status

Utility Status: <DEV/RUS_'cr'

Confirmation: >DEV/RUS_'cr'

COMM_aaaaaa'cr' RS-232 or RS-485

ADD_xxx'cr' Address (001 to 255)

BR_nnnn'cr' Baud Rate (300 to 9600)

PAR_nn'cr' Parity (OD or EV)

CON_xx'cr' LCD Contrast (0 to 30)

LCD_xx'cr''lf'] LCD Brightness (0 to 30)

XPA200-7984-I-OPT1, Rev.2

5-13

Page 66

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.3.5 Alarm Status

Alarm Status: <DEV/RAS_'cr'

Confirmation: >DEV/RAS_'cr'

+28_xx'cr' +28 VDC Fault

+12_xx'cr' +12 VDC Fault

-12_xx'cr' -12 VDC Fault

+5_xx'cr' +5 VDC Fault

-5_xx'cr' -5 VDC Fault

+10_1_xx'cr' +10 PS#1 Fault

+10_2_xx'cr' +10 PS#2 Fault

TEMP_xx'cr' Temperature Fault

FAN1_xx’cr’ Fan 1 Fault

FAN2_xx’cr’’lf’] Fan 2 Fault

xx = OK or FT

5.8.3.6 Summary Alarm Status

Summary alarm is set to Fault (FT) if any of the items in

paragraph 5.8.4.5 are faulted.

Summary Alarm: <DEV/SAS_'cr' xx = OK or FT

Confirmation: >DEV/SAS_xx'cr''lf']

5.8.3.7 Terminal Status Change

The TSC_ command can be used to determine if the status of

the terminal has changed since it was last polled. If any of the

parameters listed in the RCS or RUS commands have changed as a

result of user operations or if any new fault condition occur the

TSC_ command will return YES. The TSC_ command will then

continue to return YES until any of the following commands are

received: RCS_, RUS_, RAS_, PACRCS_, PACRUS_, or PACRAS.

Configuration Status: <DEV/TSC_'cr'

Confirmation: >DEV/TSC_nnn'cr''lf'] nnn = YES/NO

XPA200-7984-I-OPT1, Rev.2

5-14

Page 67

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

5.8.3.8 Packed Configuration Status

Configuration Status: <DEV/PACRCS_'cr'

Confirmation: >DEV/PACRCS_aabcdeefg'cr''lf']

where: aa = # of 0.25 dB steps in HEX above 0dB (0to120)

b = 1 if Amplifier ON, 0 if OFF

c = 1 if Tx ON, 0 if OFF

d = 1 if unit ONLINE, 0 if OFFLINE

ee = SSPA number = BU,01 or 02 (if e = 0, ff = 00)

f = A if Auto Mode, M if Manual Mode

g = 1 if Auto Recovery enabled, else 0

5.8.3.9 Packed Maintenance Status

Packed Maitenance Status: <DEV/PACRMS_'cr'

Confirmation: >DEV/PACRMS_

aabbccddeeffgghhhiiijjj'cr''lf']

where:

aa = +28 supply, 100mV per count above 10.0V in Hex

bb = +12 supply scaled 100mV per count in Hex

cc = -12 supply scaled 100mV per count in Hex

dd = +5 supply scaled 100mV per count in Hex

ee = -5 supply scaled -100mV per count in Hex

ff = +10 supply #1 scaled 100mV per count in Hex

gg = +10 supply #2 scaled 100mV per count in Hex

hhh = Signed temperature in degrees C (-10 to +95)

iii = RF forward pwr, .1 dBm steps above 32.0 dBm in

Hex

jjj = RF reverse pwr, .1 dBm steps above 25.0 dBm in

Hex

5.8.3.10 Packed FET Status

Packed FET Status: <DEV/PACRFS_'cr'

Confirmation: >DEV/PACRFS_

where:

aa = FET1 current in Hex, formula: FET1 = (aa * 3)mAmps

bb = FET2 current in Hex, scaled 100mA per count

cc = FET3 current in Hex, scaled 100mA per count

dd = FET4 current in Hex, scaled 100mA per count

ee = FET5 current in Hex, scaled 100mA per count

ff = FET6 current in Hex, scaled 100mA per count

gg = FET7 current in Hex, scaled 100mA per count

XPA200-7984-I-OPT1, Rev.2

aabbccddeeff. . rrss'cr''lf']

5-15

Page 68

XPA200-7984-I-OPT1, X-Band SSPA Remote Control Remote Control

hh = FET8 current in Hex, scaled 100mA per count

ii = FET9 current in Hex, scaled 100mA per count

jj = FET10 current in Hex, scaled 100mA per count

kk = FET11 current in Hex, scaled 100mA per count

ll = FET12 current in Hex, scaled 100mA per count

mm = FET13 current in Hex, scaled 100mA per count

nn = FET14 current in Hex, scaled 100mA per count

oo = FET15 current in Hex, scaled 100mA per count

pp = FET16 current in Hex, scaled 100mA per count

qq = FET17 current in Hex, scaled 100mA per count

rr = FET18 current in Hex, scaled 100mA per count

ss = FET19 current in Hex, scaled 100mA per count

5.8.3.11 Packed Utility Status

Packed Utility Status: <DEV/PACRUS_'cr'

Confirmation: >DEV/PACRUS_abbcdeeff'cr''lf']

where: a = com1 mode; 0=RS-232, 1=RS-485-2, 2-RS-485-4

bb = Address in hex (01 to FF)

c = 0 if Baud Rate 9600

= 1 if Baud rate 4800

= 2 if Baud rate 2400

= 3 if Baud rate 1200

= 4 if Baud rate 300

d = 0 if Parity Even, 1 if Parity Odd

ee = LCD Contrast (0 to 30)

ff = LCD Brightness (0 to 30)

5.8.3.12 Packed Alarm Status

Packed Alarm Status: <DEV/PACRAS_'cr'

Confirmation: >DEV/PACRAS_abcdefghijk'cr''lf']

where: a = 1 if +28 Fault, else 0

b = 1 if +12 Fault, else 0