Page 1

M

-

2

p

SN

O

eration and Maintenance Manual

100

LinkSync Modem

Part Number MN/SNM1002.OM Revision 2

Page 2

Page 3

SNM-1002

LinkSync™ Modem

Operation and Maintenance Manual

Part Number MN/SNM1002.OM

Comtech EFData is an ISO 9001

Registered Company.

Revision 2

May 15, 2002

Comtech EFData, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161.

Copyright © Comtech EFData, 2000. All rights reserved. Printed in the USA.

Page 4

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

Network Customer Support

The Network Customer Support Plan identifies the steps to be followed in resolving the

Customer’s concern.

The resolution efforts will follow these levels of contact:

• Level One Contact – Factory Authorized Service Center.

• Level Two Contact – Comtech EF Data Customer Support.

• Level Three Contact – Network Test and Field Support

Procedural Steps

Step Procedure

1

2

3

4

5

The Customer raises a concern with the Level One Contact.

The Level One Contact will perform Hardware repairs and Network Operations

troubleshooting in accordance with the Comtech EF Data Service Center

agreement.

If the Level One Contact is unable to resolve the concern, then the Level One

Contact will inform the Level Two Contact of the concern in accordance with the

instructions found within the attached Comtech EF Data Customer Support

Department’s document.

The Level Two Contact will enter the concern into the Comtech EF Data database

and determine whether the concern is a Hardware concern or a Network

Operations concern

The Level Two Contact will interface with the Level One Contact and provide

the appropriate hardware support and enter all correspondence into the Comtech EF

Data database.

6

7

8

If the Level Two Contact determines that the concern is a Network Operations

concern, then the Level Two Contact will inform the Level Three Contact.

The Level Three Contact will interface with the Level One Contact and provide

the appropriate support and enter all correspondence into the Comtech EF Data

database.

If the Level Three Contact determines that there is a Hardware failure then the

Level Three Contact will inform the Level Two Contact. Go to Step 5.

ii

Page 5

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.om

Network Customer Support Plan

Customer

Yes

Midas Network is functioning

properly?

No

Level One Contact is notified

Authorized Factory Service

Center

Resolved by Hardware repair

or Network Operations

troubleshooting?

No

Level Two Contact is notified

CEFD Customer Support

Hardware or Network

Operations issue?

*Note: If equipment was purchased

directly from Comtech EFData (not

through a Factory Authorized

Service Center), then CEFD

Customer Support will be the initial

point of contact.

Yes

CEFD Customer Support

provides HW support

Hardware

Hardware

Network

Operations

Level Three Contact is notified

CEFD Network Test and Field

Support

Hardware or Network

Operations issue?

CEFD Network Test and Field

Support

provides Network Operations

support

iii

Page 6

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

See the Comtech EF Data website at http://www.comtechefdata.com

Service Center. Contact the Factory Authorized Service Center for:

for contact information for a Factory Authorized

• Product support

• Information on upgrading or returning a product

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

480.333.2500 FAX

or, E-Mail can be sent to the Systems Support Engineering at:

midasfss@comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or replacement:

1. Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support Department.

2. Be prepared to supply the Customer Support representative with the model number, serial

number, and a description of the problem.

3. To ensure that the product is not damaged during shipping, pack the product in its

original shipping carton/packaging.

4. Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

iv

Page 7

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.om

Contact the Comtech EF Data Network Test and Field Support for:

• System level Network Operations support

• Information on upgrading Network Operation software

• Reporting comments or suggestions concerning manuals

A Network Test and Field Support representative may be reached at:

Comtech EF Data

Attention: Network Test and Field Support

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.3693 (Network Test and Field Support)

480.333.2161 (FAX)

or, E-Mail can be sent to the Network Test and Field Support Department at:

mailto:midasfss@comtechefdata.com

Contact us via the web at www.comtechefdata.com

.

v

Page 8

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

This page is intentionally left blank.

vi

Page 9

Table of Contents

CHAPTER 1. INTRODUCTION......................................................................................................1–1

Overview......................................................................................................................................1–1

1.1

1.2 Mode of Operation......................................................................................................................1–2

1.3 Options.........................................................................................................................................1–5

1.4 Specifications...............................................................................................................................1–6

1.4.1 Summary Specifications........................................................................................................................ 1–6

1.4.2 Environmental and Physical.................................................................................................................. 1–8

1.5 Bit Error Rate Performance ......................................................................................................1–8

1.6 Typical Spectral Occupancy ....................................................................................................1–10

1.7 Dimensional Envelope ..............................................................................................................1–11

CHAPTER 2. INSTALLATION................................................................................... 2–1

2.1 Unpacking....................................................................................................................................2–1

2.2 Installation...................................................................................................................................2–2

2.2.1 Typical Single-Thread Cable Installation.............................................................................................. 2–4

2.2.2 Typical Redundant Cable Installation................................................................................................... 2–5

2.3 Rear Panel Connections..............................................................................................................2–7

2.3.1 Remote Connector and Pinouts (J6)...................................................................................................... 2–8

2.3.2 Data I/O Interface Connector (J8)......................................................................................................... 2–8

2.3.3 RF Output Connector (CP1).................................................................................................................. 2–8

2.3.4 RF Input Connector (CP2) .................................................................................................................... 2–8

2.3.5 External Reference (CP3)...................................................................................................................... 2–9

2.3.6 AC Power Connector ............................................................................................................................ 2–9

2.3.7 DC Power - Optional............................................................................................................................. 2–9

2.3.8 Ground Connector (GND)..................................................................................................................... 2–9

vii

Page 10

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

CHAPTER 3. OPERATION........................................................................................3–1

3.1 Front Panel..................................................................................................................................3–1

3.1.1 LED Indicators...................................................................................................................................... 3–2

3.1.2 Front Panel Keypad............................................................................................................................... 3–3

3.2 Menu System ...............................................................................................................................3–4

3.3 Front Panel Menu.......................................................................................................................3–5

3.4 OPENING SCREEN...................................................................................................................3–6

3.4.1 FUNCTION SELECT:CONFIGURATION......................................................................................... 3–6

3.4.1.1 CONFIGURATION:MODULATOR..............................................................................................3–7

3.4.1.2 CONFIGURATION:DEMODULATOR......................................................................................3–11

3.4.1.3 CONFIGURATION:INTERFACE...............................................................................................3–15

3.4.1.4 CONFIGURATION:SAVE...........................................................................................................3–20

3.4.1.5 CONFIGURATION:RECALL......................................................................................................3–20

3.4.2 FUNCTION SELECT:MONITOR ....................................................................................................... 3–21

3.4.2.1 MONITOR:RAW BER.................................................................................................................3–21

3.4.2.2 MONITOR:CORRECTED BER...................................................................................................3–21

3.4.2.3 MONITOR:EB/NO.......................................................................................................................3–21

3.4.2.4 MONITOR:RECEIVE SIGNAL...................................................................................................3–22

3.4.2.5 MONITOR:SWEEP FREQUENCY.............................................................................................3–22

3.4.2.6 MONITOR:BUFFER FILL...........................................................................................................3–22

3.4.3 FUNCTION SELECT:FAULTS/ALARMS......................................................................................... 3–23

3.4.3.1 FAULTS AND ALARMS:MODULATOR..................................................................................3–24

3.4.3.2 FAULTS AND ALARMS:DEMODULATOR............................................................................. 3–24

3.4.3.3 FAULTS AND ALARMS:TX INTERFACE...............................................................................3–25

3.4.3.4 FAULTS AND ALARMS:RX INTERFACE...............................................................................3–26

3.4.3.5 FAULTS AND ALARMS:COMMON.........................................................................................3–27

3.4.4 FUNCTION SELECT:STORED FLTS/ALMS.................................................................................... 3–28

3.4.4.1 STORED FLTS/ALMS:MODULATOR ......................................................................................3–29

3.4.4.2 STORED FLTS/ALMS:DEMODULATOR.................................................................................3–29

3.4.4.3 STORED FLTS/ALMS:TX INTERFACE....................................................................................3–30

3.4.4.4 STORED FLTS/ALMS:RX INTERFACE....................................................................................3–31

3.4.4.5 STORED FLTS/ALMS:COMMON..............................................................................................3–32

3.4.4.6 STORED FLTS/ALMS:CLEAR...................................................................................................3–32

3.4.5 FUNCTION SELECT:UTILITY.......................................................................................................... 3–33

3.4.5.1 UTILITY:MODULATOR.............................................................................................................3–34

3.4.5.2 UTILITY:DEMODULATOR.......................................................................................................3–37

3.4.5.3 UTILITY:INTERFACE................................................................................................................3–39

3.4.5.4 UTILITY:SYSTEM......................................................................................................................3–43

3.4.5.5 UTILITY:MODEM TYPE............................................................................................................3–48

3.4.5.6 UTILITY:FACTORY SETUP (NOT APPLICABLE)..................................................................3–53

viii

Page 11

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

CHAPTER 4. THEORY OF OPERATION................................................................. 4–1

4.1 Monitor and Control (M&C).....................................................................................................4–1

4.2 Modulator....................................................................................................................................4–3

4.2.1 Modulator Specifications ...................................................................................................................... 4–5

4.2.2 Theory of Operation.............................................................................................................................. 4–6

4.2.3 Theory of Modulation Types................................................................................................................. 4–7

4.3 Demodulator................................................................................................................................4–9

4.3.1 Demodulator Specifications.................................................................................................................. 4–10

4.3.2 Theory of Operation.............................................................................................................................. 4–11

CHAPTER 5. MAINTENANCE.................................................................................. 5–1

5.1 System Checkout.........................................................................................................................5–1

5.1.1 Interface Checkout ................................................................................................................................ 5–2

5.1.2 Modulator Checkout.............................................................................................................................. 5–3

5.1.3 Demodulator Checkout ......................................................................................................................... 5–6

5.2 Fault Isolation..............................................................................................................................5–8

5.2.1 System Faults/Alarms ........................................................................................................................... 5–8

5.2.2 Faults/Alarms Display........................................................................................................................... 5–12

5.2.3 Faults/Alarms Analysis......................................................................................................................... 5–12

APPENDIX A. REMOTE CONTROL OPERATION..................................................A–1

APPENDIX B. REDUNDANT WIRING SCHEMATIC...............................................B–1

ix

Page 12

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

Figures

Figure 1-1. SNM-1002 .............................................................................................................................................1–1

Figure 1-2. Typical NMS Configuration..................................................................................................................1–2

Figure 1-3. Typical Redundancy for the Network and LinkSync Modems..............................................................1–3

Figure 1-4. Modular Design .....................................................................................................................................1–3

Figure 1-5. Block Diagram.......................................................................................................................................1–5

Figure 1-6. Viterbi BER Performance Curves..........................................................................................................1–9

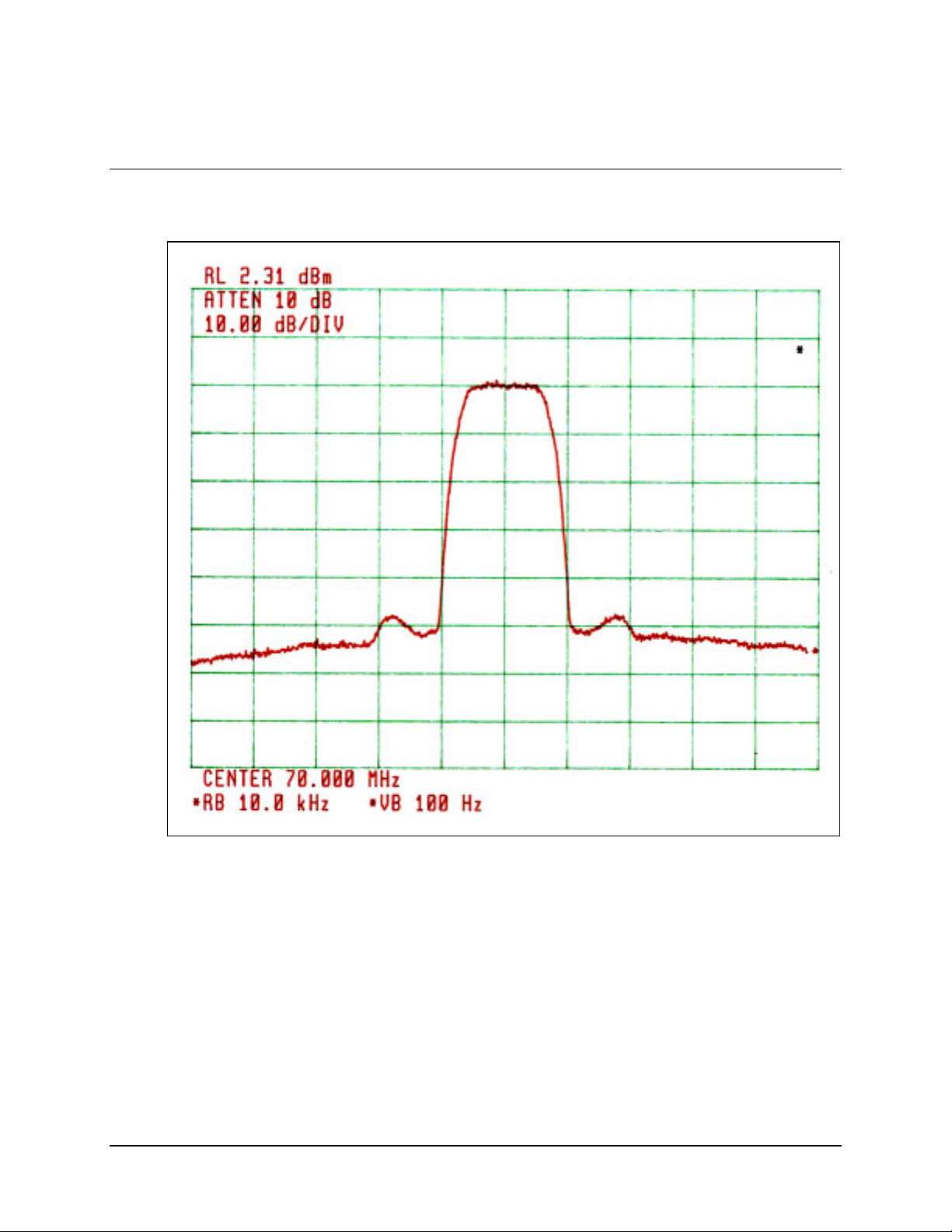

Figure 1-7. Typical Spectral Occupancy................................................................................................................1–10

Figure 1-8. SNM-1002 Dimensional Envelope......................................................................................................1–11

Figure 2-1. Installation of the Mounting Bracket.....................................................................................................2–3

Figure 2-2. Typical Single-Thread Installation.........................................................................................................2–4

Figure 2-3. Typical Redundant Wiring Schmetic.....................................................................................................2–6

Figure 2-2. View of Rear Panel................................................................................................................................2–7

Figure 3-1. Front Panel View...................................................................................................................................3–1

Figure 3-2. Keypad...................................................................................................................................................3–3

Figure 3-3. Main Menu.............................................................................................................................................3–5

Figure 3-4. Baseband Loopback.............................................................................................................................3–18

Figure 4-1. M&C Block Diagram.............................................................................................................................4–2

Figure 4-2. Modulator Block Diagram.....................................................................................................................4–4

Figure 4-3. Demodulator Block Diagram.................................................................................................................4–9

Figure 5-1. Fault Isolation Test Setup ......................................................................................................................5–2

Figure 5-2. Typical Output Spectrum (with Noise)..................................................................................................5–5

Figure 5-3. Typical Output Spectrum (without Noise).............................................................................................5–5

Figure 5-4. Typical Eye Constellations....................................................................................................................5–7

Tables

Table 1-1. Summary Specifications..........................................................................................................................1–6

Table 1-2. Environmental and Physical....................................................................................................................1–8

Table 2-1. Rear Panel Connectors............................................................................................................................2–4

Table 2-2. Remote Connector and Pinouts (J6)........................................................................................................2–5

Table 3-1. LED Indicators........................................................................................................................................3–2

Table 4-1. Modulator Specifications ........................................................................................................................4–5

Table 4-2. Demodulator Specification....................................................................................................................4–10

Table 5-1. Conversion to S/N and Eb/N0 Chart.........................................................................................................5–4

Table 5-2. SNM-1002 Fault Tree .............................................................................................................................5–9

x

Page 13

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

About this Manual

This manual provides installation and operation information for the Comtech EF Data

SNM-1002 LinkSync™ Modem. This is a technical document intended for earth station

engineers, technicians, and operators responsible for the operation and maintenance of

the SNM-1002 LinkSync™ Modem.

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

WARNING

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

IMPORTANT indicates a statement that is associated with the task

IMPORTANT

being performed. .

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only. For more information, refer to the Department of Defense

(DOD) MIL-STD-188-114A, “Electrical Characteristics of Digital Interface Circuits.”

xi

Page 14

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

Trademarks

Products names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Technical

Publications department: techpub@comtechefdata.com

Electrical Safety

The SNM-1002 LinkSync Modem has been shown to comply with the following safety

standard:

• EN 60950: Safety of Information Technology Equipment, including electrical business

machines.

The equipment is rated for operation over the range 85 to 264 volts AC. It has a maximum

power consumption of 60 watts.

Fuses

The SNM-1002 LinkSync Modem is fitted with two fuses, one each for line and neutral

connections. These are contained within the body of the IEC power connector, behind a small

plastic flap.

• For 230 volt AC operation, use T0.75A, 20mm fuses.

• For 115 volt AC operation, use T1.25A fuses, 20mm fuses.

IMPORTANT

Environmental

The SNM-1002 must not be operated in an environment where the unit is exposed to extremes of

temperature outside the ambient range 0 to 50°C (32 to 122°F), precipitation, condensation, or

humid atmospheres above 95% RH, altitudes (un-pressurised) greater than 2000 metres,

excessive dust or vibration, flammable gases, corrosive or explosive atmospheres.

Operation in vehicles or other transportable installations that are equipped to provide a stable

environment is permitted. If such vehicles do not provide a stable environment, safety of the

equipment to EN60950 may not be guaranteed.

For continued operator safety, always replace the fuses with the

correct type and rating.

xii

Page 15

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

Installation

The installation and connection to the line supply must be made in compliance to local or national

wiring codes and regulations.

The SNM-1002 is designed for connection to a power system that has separate ground, line and

neutral conductors. The equipment is not designed for connection to power system that has no

direct connection to ground.

The SNM-1002 is shipped with a line inlet cable suitable for use in the country of operation. If it

is necessary to replace this cable, ensure the replacement has an equivalent specification.

Examples of acceptable ratings for the cable include HAR, BASEC and HOXXX-X. Examples of

acceptable connector ratings include VDE, NF-USE, UL, CSA, OVE, CEBEC, NEMKO,

DEMKO, BS1636A, BSI, SETI, IMQ, KEMA-KEUR and SEV.

International Symbols:

Symbol Definition Symbol Definition

~

Alternating Current

Fuse

Telecommunications Terminal Equipment Directive

In accordance with the Telecommunications Terminal Equipment Directive 91/263/EEC, this

equipment should not be directly connected to the Public Telecommunications Network.

Protective Earth

Chassis Ground

xiii

Page 16

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

EMC (Electromagnetic Compatibility)

In accordance with European Directive 89/336/EEC, the SNM-1001 Network Modem has been

shown, by independent testing, to comply with the following standards:

Emissions: EN 55022 Class B - Limits and methods of measurement of radio interference

characteristics of Information Technology Equipment.

(Also tested to FCC Part 15 Class B)

Immunity: EN 50082 Part 1 - Generic immunity standard, Part 1: Domestic, commercial and light

industrial environment. Additionally, the SNM-1001-has been shown to comply with the

following standards:

EN 61000-3-2 Harmonic Currents Emission

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2 ESD Immunity

EN 61000-4-4 EFT Burst Immunity

EN 61000-4-5 Surge Immunity

EN 61000-4-6 RF Conducted Immunity

EN 61000-4-8 Power frequency Magnetic Field Immunity

EN 61000-4-9 Pulse Magnetic Field Immunity

EN 61000-4-11 Voltage Dips, Interruptions, and Variations Immunity

EN 61000-4-13 Immunity to Harmonics

In order that the Modem continues to comply with these standards,

observe the following instructions:

IMPORTANT

• Connections to the transmit and receive IF ports (BNC female connectors) should

be made using a good quality coaxial cable - for example RG58/U (50 Ω or

RG59/U (75 Ω).

• All 'D' type connectors attached to the rear panel must have back-shells that

provide continuous metallic shielding. Cable with a continuous outer shield

(either foil or braid, or both) must be used, and the shield must be bonded to the

back-shell.

• The equipment must be operated with its cover on at all times. If it becomes

necessary to remove the cover, the user should ensure that the cover is correctly

re-fitted before normal operation commences.

xiv

Page 17

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

Warranty Policy

This Comtech EF Data product is warranted against defects in material and workmanship for a

period of two years from the date of shipment. During the warranty period, Comtech EF Data

will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF Data and all

related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for the freight

charges only for return of the equipment from the factory to the customer. Comtech EF Data will

return the equipment by the same method (i.e., Air, Express, Surface) as the equipment was sent

to Comtech EF Data.

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the implied

warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF Data shall

not be liable for any direct, indirect, special, incidental, or consequential damages, whether based

on contract, tort, or any other legal theory.

Disclaimer

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-to-use

guide to your equipment. All statements, technical information, and recommendations in this

manual and in any guides or related documents are believed reliable, but the accuracy and

completeness thereof are not guaranteed or warranted, and they are not intended to be, nor should

they be understood to be, representations or warranties concerning the products described.

Further, Comtech EF Data reserves the right to make changes in the specifications of the products

described in this manual at any time without notice and without obligation to notify any person of

such changes.

If you have any questions regarding your equipment or the information in this manual, please

contact the Comtech EF Data Network Customer Support Department.

xv

Page 18

SNM-1002 LinkSync™ Modem Revision 2

Preface MN/SNM1002.OM

This page is intentionally left blank.

xvi

Page 19

Chapter 1. INTRODUCTION

This chapter provides an overview of the SNM-1002 LinkSync Modem, referred to in

this manual as “the modem” (Figure 1-1).

Figure 1-1.

SNM-1002

LinkSync

Modem

1.1 Overview

The SNM-1002 LinkSync™ modem is a high performance, digital modem designed to

provide LinkSync™ functionality for Comtech EF Data ' s Bandwidth-on-demand (BOD)

Multimedia Integrated Digital Access System (MIDAS).

Features of the SNM-1002 include:

• 19.2 kbit/s, QPSK, 1/2 rate continuous demodulator.

• 2.4 kbit/s to 4.375 mbit/s continuous modulator.

• 50/180 MHz operation.

• Extensive online monitoring.

• Built in Self-test.

1–1

Page 20

SNM-1002 LinkSync™ Modem Revision 2

V

A

V

A

A

ALA

A

A

A

Introduction MN/SNM1002.OM

1.2 Mode of Operation

The SNM-1002 is an integral component of the MIDAS Network Management System

(NMS), providing the LinkSync™ monitor and control communication between the NMS

and the MIDAS network.

LinkSync™ provides three key functions for the MIDAS network.

• Automatic Frequency Control (AFC) for all modems within the network.

• Power Management for all active traffic circuits within the network.

• Circuit Disruption capability which allows the NMS to terminate circuits

between any two internal traffic nodes (SNM-1010/1010L)in the network.

The SNM-1002 performs a critical roll for each of these three LinkSync™ capabilities

under the direct control of the MIDAS NMS. Refer to Chapter 4. Theory of Operation.

OPERATOR

WORKSTATION

OPTIONAL PRINTER

(USER SUPPLIED)

ETHERNET

NETWOR K C ONTROL M O D EM

NMS

CONTROLLER

EIA-422

EIA-232

EIA-232

(SNM-1001)

SNM -1001 Network Control Modem

TR

TRANSMIT

NSMIT

F

E

E

RECEI

RECEI

SDT-1200

U

L

R

COMMON

SATELLITE TERMINAL

T

M

S

S

STORED

LinkSync MODEM

(SNM-1002)

ENTER

R

CLE

POWERON

ENTER

TR

NSMITTERON

RRIERDETECT

C

R

CLE

TESTMODE

TM

Figure 1-2. Typical NMS Configuration

IF

(50-180 MHz)

RFT

1–2

Page 21

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

Figure 1-3. Typical LinkSync Redundancy

1.2.1 Description

The modem contains:

Built-in scramblers/descramblers TX and RX frequency synthesizers

Differential encoder/decoder Multi-rate FEC convolutional Viterbi Decoder

The modem is a complete, self-contained unit in a standard, one-rack unit (1 RU), 19inch (48 cm), rack-mountable enclosure weighing approximately 9 lbs. (4 kg). The unit

was constructed using modular design (Figure 1-4), and consists of from two to five

Printed Circuit Boards (PCBs), depending on the configuration. The modem consists of

two, major, replaceable assemblies as follows:

• Rear panel, main PCB, and power supply

• Upper and lower enclosures (chassis) and the front panel

1–3

Page 22

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

Figure 1-4. Modular Design

The front panel of the modem contains all Monitor and Control (M&C) function

indicators used for operating the modem. The modem can be operated remotely via the

M&C connection on the rear panel. Refer to Chapter 2 for connector information and

Appendix A for remote control operation information.

1–4

Page 23

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

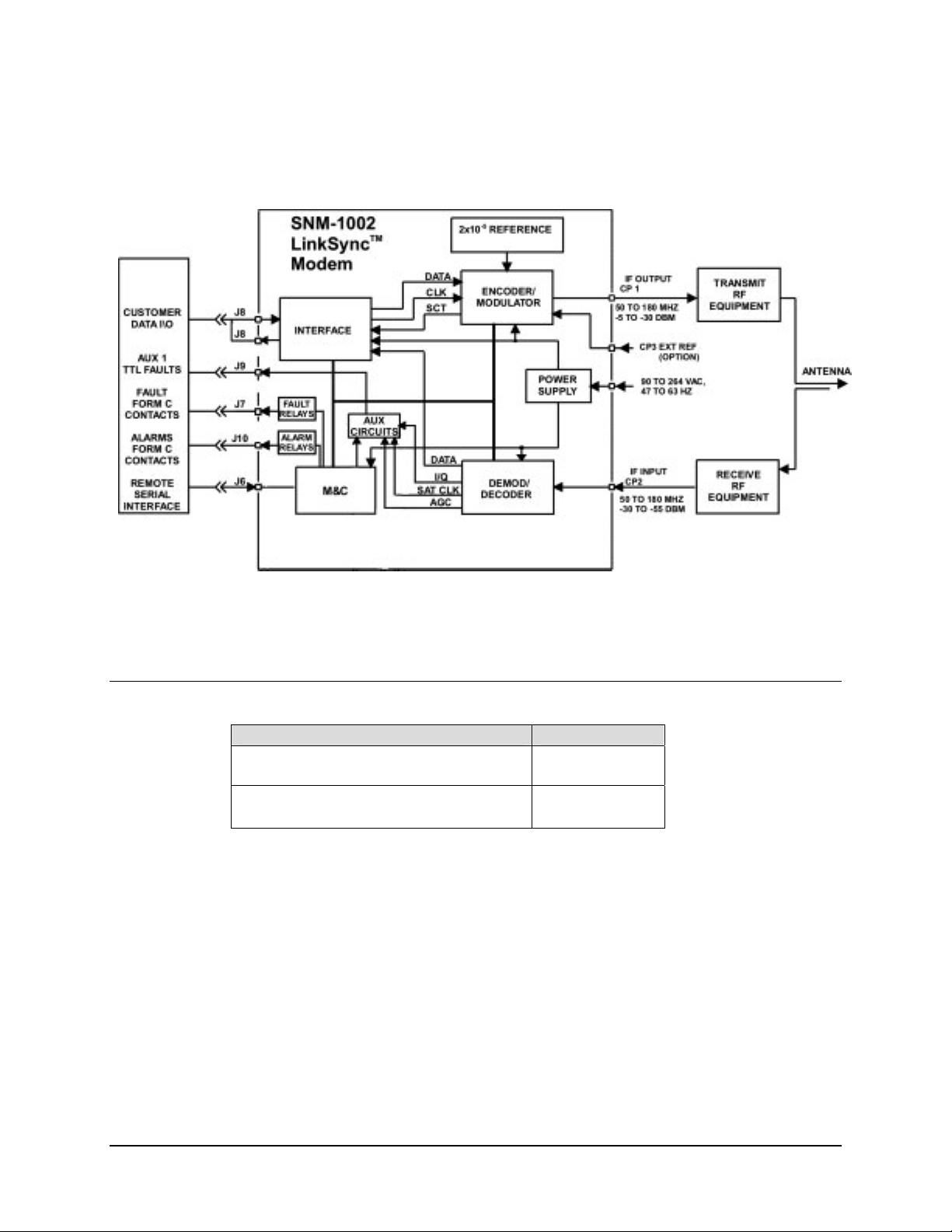

Refer to Figure 1-5 for a system block diagram.

1.3 Options

Option Remarks

Primary Input Power: 90-264 VAC KT/8000-3

-48 VDC KT/8000-4

IF Impedance : 75Ω

50Ω

Figure 1-5. Block Diagram

PL/6093-1

PL/6093-3

1–5

Page 24

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

1.4 Specifications

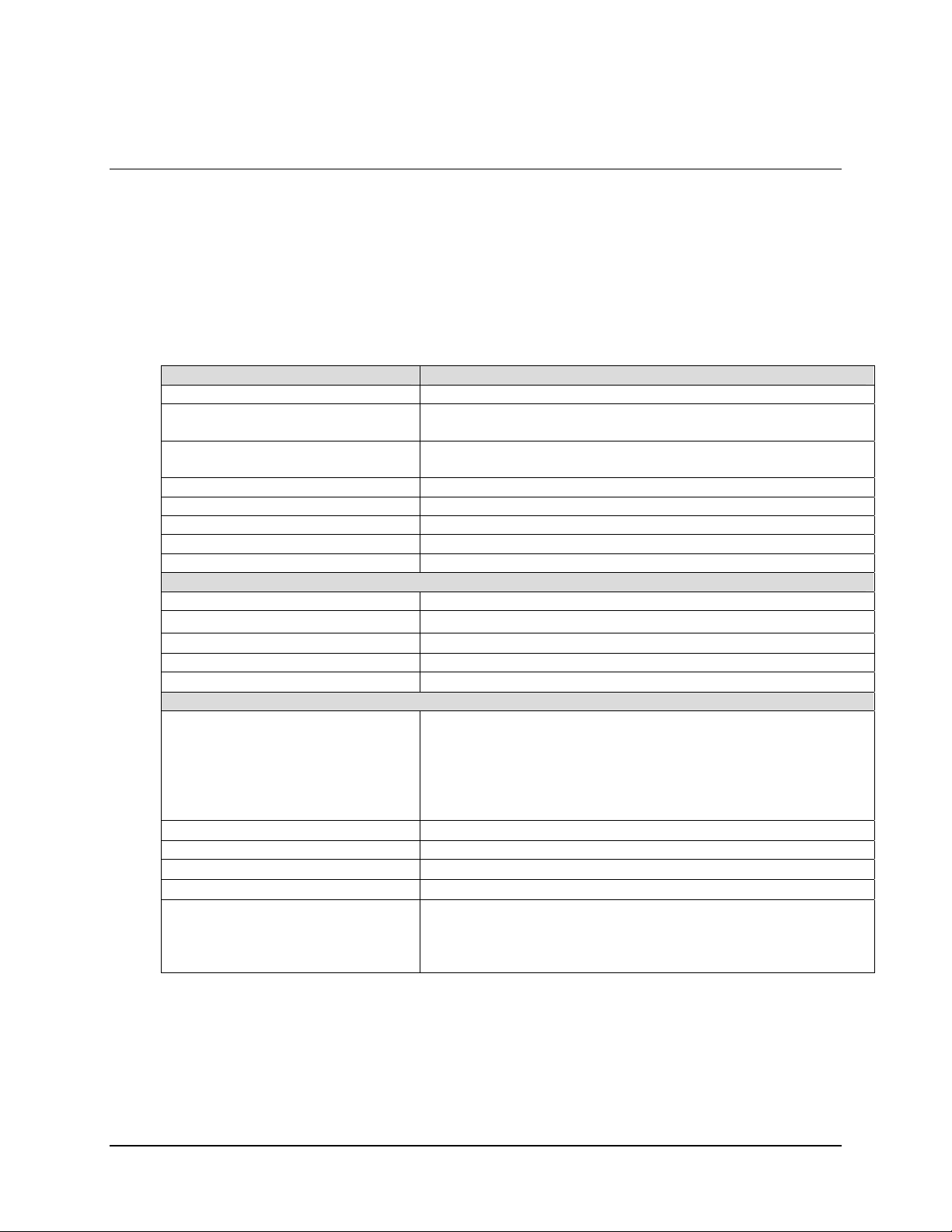

1.4.1 Summary Specifications

Table 1-1 lists a summary of the specifications.

Table 1-1. Summary Specifications

Parameter Specification

Operating Frequency Range 50 to 180 MHz, in 1 Hz steps

Modulation Type QPSK

BPSK

Operating Channel Spacing Less than 0.5 dB degradation operating with 2 adjacent-like channels,

each 10 dB higher at 1.3 times the symbol rate.

Digital Interface EIA-422/449 on 37-pin D

Digital Data Rate QPSK, R=1/2, 2.4 kbps to 4.375 Mbps

Scrambling/Descrambling CCIT INTELSAT V.35

Forward Error Correction Viterbi, K=7, Rate 1/2, 3/4, 7/8

Filter Mask Types Closed net (Comtech EF Data)

Modulator

Output Power -5 to –30 dBm, adjustable in 0.1 dB steps

Output Spurious < -55 dBc, 0 to 500 MHz

Output Impedance

Output Return Loss 20 dB

Data Clock Source

Demodulator

Input Power:

Desired Carrier

Adjacent Carriers

Maximum Total

Input Impedance

Input Return Loss 20 dB

Carrier Acquisition Range

Clock Acquisition Range

AGC Output 0 to 10V at 10 mA maximum

75Ω (Optional: 50Ω)

-5

Internal , ± 1 x 10

-30 to –55 dBm

+30 dBc total power within 10 MHz from desired carrier

+40 dBc in-band (0 to 500 MHz)

-5 dBm

75Ω (Optional: 50Ω)

± 35 kHz maximum

± 100 PPM

Default Levels: 0V for –60 dBm

10V for –25 dBm

Levels can be programmed in 0.5V increments.

stability

1–6

Page 25

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

Table 1-1. Summary Specifications (Continued)

Remote Control Specification

Signal Interface EIA-232

Baud Rate 19.2 kbps

Signals Controlled/Monitored Acquisition Sweep Parameters

Baseband Loopback

Buffer Clock TX/RX/INT

Buffer Size

Code and decode Rate

Data Rate Select

Descrambler On/Off

Descrambler Type

Differential Encoding and Decoding

IF Loopback

Interface Loopback

MOD/DEMOD Spectrum Normal/Invert

Rev Emulation Current/Function

RF Loopback

RX Clock Normal/Invert

RX Frequency

Scrambler On/Off

Scrambler Type

Self Test

Transmitter On/Off

TX Frequency

TX Power

TX/RX Filter Mask

Signals Monitored Corrected BER

Fault Status

Power Supply Voltage

Raw Error Rate

RX Carrier Detect

RX Eb/No

RX Signal Level

Stored Fault Status

Configuration Retention Will maintain current configuration for at least 1 year without power.

Addressing Programmable from 1 to 255 possibilities

Address 0 is reserved for global addressing.

Diagnostic

Diagnostic Features BER Monitoring

Buffer Fill Status Monitoring

Fault Monitoring (include current and stored faults)

IF Loopback

Input IF Power Monitoring

Remote Control via Serial Port

RF Loopback

1–7

Page 26

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

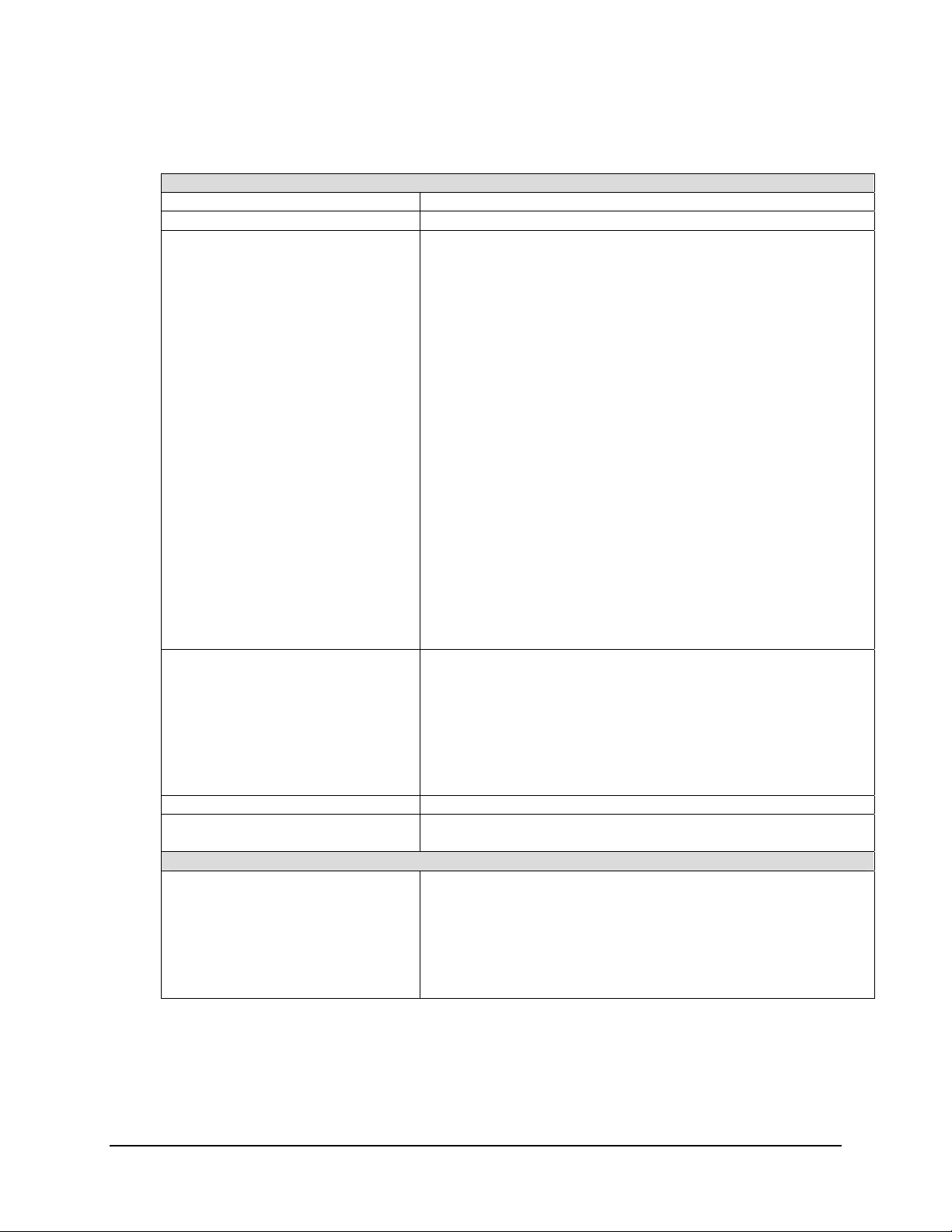

1.4.2 Environmental and Physical

Table 1-2. Environmental and Physical

Parameter Specifications

Size 1 rack unit (1RU)

1.75" H x 19.0" W x 14" D (4.4 H x 48 W x 36 D cm)

Power Prime power 90 to 264 VAC, 47 to 63 Hz,

40W maximum, fused at 2A

Optional: 38 to 64 VDC

Operating Temperature

Storage Temperature

Humidity 0 to 95% non-condensing

Mounting Standard 19-inch (48.3 cm) rack mounts

Operational Shock When any one corner of the modem is dropped from 1 cm

Survivability Shock and Vibration MIL-STD-810D Method 514.4, Procedure 8, 1 hour/axis

Weight 9 lbs. Maximum

Shipping:

Weight

Size

0 to 50°C (32 to 122° F)

-55 to +70° C (-67 to 158° F)

Note: Front and rear accepts standard rack mount slides

onto a hard surface, the modem will not take any errors or

faults

MIL-STD-167-1

(4 kg Maximum)

15 lbs. (7 kg)

20 x 21 x 9 inch (51 x 53 x 23 cm)

1.5 Bit Error Rate Performance

The following specifications for the Eb/N0 required to achieve 10-3 to 10

different coding configurations. All values are for operating in QPSK mode. Without

coding, the modem provides QPSK operation within 0.8 dB of theoretical for BER in the

range 10

connected back-to-back through an additive white Gaussian noise channel. Refer to

Figure 1-6 for the performance BER curves.

-1

to 10-6. Performance measurements were recorded with transmit and receive IF

Eb/N0 (dB) Specification

BER 1/2 Rate 3/4 Rate 7/8 Rate

10-3 4.2 5.2 6.4

10-4 4.8 6.0 7.2

10-5 5.5 6.7 7.9

10-6 6.1 7.5 8.6

10-7 6.7 8.2 9.2

10-8 7.2 8.8 9.9

-8

BER for

1–8

Page 27

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

1.5.1 BER Threshold

The modem will have a programmable BER threshold function. This will allow the

operator to set the threshold from 1.0 E-3 to 1.0 E-8.

10-2

-3

10

10-4

10

10

BER

10-7

10

10

-10

10

-5

-6

-8

-9

1/2 Rate 3/4 Rate 7/8 Rate

SPECIFICATIONS

3.0 4.0 5.0 6.0

7.0 8.0 9.0 10.0 11.0

E

(dB)

b/N0

Figure 1-6. Viterbi BER Performance Curves

1–9

Page 28

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

1.6 Typical Spectral Occupancy

Figure 1-7. Typical Spectral Occupancy

1–10

Page 29

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

1.7 Dimensional Envelope

Note: All dimensions are in English units (centermeters are in parenthesis).

Figure 1-8. SNM-1002 Dimensional Envelope

1–11

Page 30

SNM-1002 LinkSync™ Modem Revision 2

Introduction MN/SNM1002.OM

This page is intentionally left blank.

1–12

Page 31

Chapter 2. INSTALLATION

This chapter provides unpacking and installation instructions, and a description of

external connections information.

The equipment contains parts and assemblies sensitive to damage by

Electrostatic Discharge (ESD). Use ESD precautionary procedures when

CAUTION

touching, removing, or inserting PCBs.

2.1 Unpacking

The modem and manual are packaged in pre-formed, reusable, cardboard cartons

containing foam spacing for maximum shipping protection.

Do not use any cutting tool that will extend more than 1 inch into the

container. This can cause damage to the modem.

CAUTION

Unpack the modem as follows:

1. Cut the tape at the top of the carton indicated by OPEN THIS END.

2. Remove the cardboard/foam space covering the modem.

3. Remove the modem, manual, and power cord from the carton.

4. Save the packing material for storage or reshipment purposes.

5. Inspect the equipment for any possible damage incurred during shipment.

6. Check the equipment against the packing list to ensure the shipment is correct.

7. Refer to Section 2.2 for installation instructions.

2–1

Page 32

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

2.2 Installation

The modem arrives fully assembled from the factory. After unpacking the modem, install

the modem as follows:

1. If required, install the mounting bracket in equipment rack (Figure 2-1). Install

and tighten the bracket bolts.

2. Loosen the screw with flat washer located on the left side of modem chassis.

Mount the modem chassis into the equipment rack and slide the screw with flat

washer through the slot of the mounting bracket. Tighten the screw sufficiently to

allow the modem chassis to slide in the bracket.

3. Connect the cables to the proper locations on the rear panel. Refer to Section 2.3

for connector pinouts, placement, and function.

4. Connect the primary power cable to the power source. Before turning on the

power switch, become familiar with the front panel operation in Chapter 3.

5. If problems exist with the installation, refer to Chapter 5 for troubleshooting

information.

2–2

Page 33

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

Figure 2-1. Installation of the Mounting Bracket

2–3

Page 34

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

2.2.1 Typical Single-Thread Cable Installation

Note: Cables may be procured from Comtech EF Data by contacting Comtech EF Data

Network Customer Support department for information.

1. Connect supplied Y-Cable (Figure 2-2) as follows:

a. Connect the supplied-cable base connector to the FASTCOM card.

b. Connect supplied-cable Port 1 connector to the Comtech EF Data

supplied EIA-422 cable from SNM-1001 Modem.

c. Cable Port 2 connector is not connected.

2. Connect 9-pin EIA-232 cable from Controller Server COM 1 port to SNM-1001

Remote port (J6).

a. If non-redundant SNM-1001, the following remote settings are required:

• EIA-232

• 19.2 Baud rate

• 8N1

3. Connect 9-pin EIA-232 cable from Controller Server COM 2 port to SNM-1002

Remote port (J6).

4. Connect 25-pin pre-programmed dongle (security key) to Controller Server

25-pin I/O port.

Figure 2-2. Typical Single-Thread Installation

2–4

Page 35

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

Item No. Cable Description From To

1 Comtech EF Data

Supplied

2 CA/5684 Supplied Y-Cable Port 1 of the SNM-1001

3 EIA-232 MIDAS Controller COM 2 SNM-1002 Remote port (J6)

4

EIA-232 MIDAS Controller COM 1 SNM-1001Remote port (J6)

FASTCOM Card CA/5684

2.2.2 Redundant LinkSync (Network Control) Modem Installation

A typical redundant wiring schematic is included to assist the user in establishing a

redundant configuration. The following table can assist the user in cable selection and

location. One or both of the 1:1 redundant configurations can be installed in a MIDAS

System. Figure 2-3 shows both Network Control Modem and LinkSync Modem

Redundancy.

Item No. Cable Description From To

1 CA/5684 MIDAS Controller SMS-301 J1 COM

2 EIA-422 37-pin SMS-301 (J2) SNM-1001(A) (J8)

3 EIA-422 37-pin SMS-301 (J3) SNM-1001 (B) (J8)

4 BNC SMS-301 (J4) (TX-IF) Combiner

5 BNC SMS-301 (J8) (RX-IF) Combiner

6 BNC SMS-301 (J9) A SNM-1001(A) CP2 TX/IF

7 BNC SMS-301 (J6) B SNM-1001(B) CP1 TX/IF

8 BNC SMS-301 (J7) B SNM-1001(B) CP2 RX/IF

9 BNC SMS-301 (J5) A SNM-1001(A) CP1 TX/IF

10 EIA-232 9-pin

Network Control Modem

11 EIA-232 SMS-301 (J10)

12 EIA-422 37-pin SMS-301 (J2) SNM-1002 (A) Data I/O

13 EIA-422 37-pin SMS-301 (J3) SNM-1002 (B) Data I/O

14 EIA-232 9-pin

15 BNC SMS-301 (J9) A SNM-1002 A) CP2 RX-IF

16 BNC SMS-301 (J8) RX-IF Combiner

17 BNC SMS-301 (J4) TX-IF Combiner

18 BNC SMS-301 (J5) A SNM-1002(A) CP1 TX-IF

19 BNC SMS-301 (J7) B SNM-1002(B) CP2 RX-IF

LinkSync Modem

20 BNC SMS-301 (J6) B SNM-1002(B) CP1 TX-IF

21 EIA-232 SMS-301 (J10)

Ribbon Cable

Ribbon Cable

SMS-301 (J13)

Modem COM

Remote Control

SMS-301 (J13)

Modem COM

Remote Control

SNM-1001(A) (J6) Remote

SNM-1001(B) (J6) Remote

MIDAS Controller COM1

SNM-1002(A) (J6) Remote

SNM-1002(B) (J6) Remote

MIDAS Controller COM2

2–5

Page 36

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

Figure 2-3. Typical Redundant Wiring Schematic

2–6

Page 37

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

2.3 Rear Panel Connections

The rear panel connectors provide all necessary external connections between the modem

and other equipment.

Table 0-1 lists these connectors, and Figure 2-4 shows their locations.

Figure 2-4. View of Rear Panel

Table 0-1. Rear Panel Connectors

Name

REMOTE J6 9-pin D Remote Interface

FAULT

Connector is not used.

DATA I/O J8 37-pin D EIA-422

AUX 1

Connector is not used.

ALARMS

Connector is not used.

TX/IF OUTPUT CP1 BNC RF Output

RX/IF INPUT CP2 BNC RF Input

EXTERNAL REF CP3 BNC Input

AC INPUT NONE IEC

GROUND NONE 10-32 Stud

REF DES Connector Type

J7 9-pin D FORM C Fault Relay Contacts

J9 9-pin D (TTL) Faults

Satellite Clock

Demod I/Q

Automatic Gain Control (AGC) Out

J10 9-pin D FORM C Alarm

Relay Contacts

Function

Note: The European EMC Directive (EN55022, EN50082-1) requires using properly shielded

cables for DATA I/O. These cables must be double-shielded, ensuring a continuous ground

shield.

2–7

Page 38

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

2.3.1 Remote Connector and Pinouts (J6)

The remote connector is a 9-pin female D connector (J6) located on the rear panel of the

modem. Screw locks are provided for mechanical security of the mating connector.

The remote connector interfaces the M&C functions to the MIDAS Controller. This is an

EIA-232 DCE interface. Refer to Appendix A for a description of the remote interface.

Refer to Table 0-2 for pinout information.

Table 0-2. Remote Connector and Pinouts (J6)

EIA-232

Pin # Name

1

2 RD (RX)

3 TD (TX)

4

5 GND

6 DSR

7 RTS

8 CTS

9

2.3.2 Data I/O Interface Connector (J8)

This connector is only utilized when the modem is operating in a Redundant LinkSync

Configuration. In a Redundant LinkSync Configuration, the Data I/O cable connects

between an SNM-301 1:1 Switch and J8 of the LinkSync modem. Refer to Chapter 1,

Figure 1-3.

2.3.3 RF Output Connector (CP1)

CP1 is a BNC connector for the transmit IF signal. The standard output impedance is 75Ω,

and the output power level is -5 to -30 dBm. In normal operation, the output will be a

QPSK- or BPSK-modulated signal between 50 and 180 MHz, in 1 Hz steps.

2.3.4 RF Input Connector (CP2)

CP2 is a BNC connector for the receive IF signal. The standard input impedance is 75. For

normal operation, the desired carrier signal level should be between -30 and -55 dBm.

Signals between 50 and 180 MHz are selected and demodulated to produce clock and data

at the Data I/O connector.

2–8

Page 39

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

2.3.5 External Reference (CP3)

CP3 is a BNC connector for an external reference. The input impedance is 75Ω. For

normal operation, the reference signal is

≥ 0 dBm.

2.3.6 AC Power Connector

The AC power is supplied to the SNM-1002 by a standard, d etachab le, non-locking,

3-prong power cord. Refer to the following listing for AC power specifications.

Input power

Input voltage

Connector type

Fuse protection

50W max.

90 to 264 VAC, 47 to 63Hz.

Note: Unit switches ranges automatically.

IEC

1A slo-blo line and neutral fusing 5 mm type fuses.

2.3.7 DC Power - Optional

For DC supplied units, the DC Power is supplied by terminal lugs installed on the back

panel. Refer to the following table for specifications

Input power

Input voltage

Connector type

Fuse protection

50W max.

38 to 64 VDC.

Terminal Lug

1A slo-blo 5 mm type fuses.

2.3.8 Ground Connector (GND)

A #10-32 stud on the rear panel of the modem is used for connecting a common chassis

ground among all equipment.

Note: The AC power connector provides the safety ground.

2–9

Page 40

SNM-1002 LinkSync Modem Revision 2

Installation MN/SNM1002.OM

This page is intentionally left blank.

2–10

Page 41

Chapter 3. OPERATION

3.1 Front Panel

Note: Front panel operation of the LinkSync modem is only required for initial

installation for setting the remote communication parameters. Under normal operation,

the MIDAS NMS configures and controls the LinkSync for all of the functions it

provides. A complete menu tree is shown for navigational purposes only.

The modem front panel (Figure 3-1) enables control of modem configurations parameters

and displays the modem status.

Figure 3-1. Front Panel View

The front panel features include:

• 32-character, 2-line LCD display

• 6-button keypad for local control

• 10 LEDs to provide overall status at a glance

3–1

Page 42

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.1.1 LED Indicators

The 10 LEDs on the front panel indicate:

• General modem summary faults

• Status

• Alarms

The indicators are defined in Table 3-1 as follows:

Table 3-1. LED Indicators

Name LED Meaning

Faults

Transmit Red A fault condition exists in the transmit chain.

Receive Red A fault condition exists in the receive chain.

Common Red A common equipment fault condition exists.

Stored Yellow A fault has been logged and stored.

The fault may or may not be active.

Status

Power On Green Power is applied to the modem.

Transmitter On Green Transmitter is currently on.

This indicator reflects the actual condition of the transmitter, as

opposed to the programmed condition.

Carrier Detect Green Decoder is locked.

Test Mode Yellow Flashes when the modem is in a test configuration.

Alarms

Transmit Yellow A transmit function is in an alarm condition.

Receive Yellow A receive function is in an alarm condition.

3–2

Page 43

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.1.2 Front Panel Keypad

The front panel keypad permits local operation of the modem. The keypad consists of six

keys (Figure 3-2). It is locked out for normal use.

ENTER

CLEAR

Figure 3-2. Keypad

Each key provides one or more logical functions. These functions are defined in the

following table.

ENTER This key is used to select a displayed function or to execute a modem

configuration change.

CLEAR This key is used to back out of a selection or to cancel a configuration change

which has not been executed using [ENTER]. Pressing [CLEAR] generally

returns the display to the previous selection.

Left and Right

Diamond Keys

Top and Bottom

Diamond Keys

These keys are used to move to the next selection or to move the cursor for

certain functions.

Note: Throughout this chapter, [

diamond keys.

These keys are used primarily to change configuration data (numbers). At times,

they are also used to move from one section to another.

Note: Throughout this chapter, [

diamond keys.

←] and [→] are used to indicate left and right

↑] and [↓] are used to indicate top and bottom

The modem responds by beeping whenever a key is pressed:

• A single beep indicates a valid entry and the appropriate action was taken.

• A double beep indicates an invalid entry or a parameter is not available for

operation.

3–3

Page 44

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.2 Menu System

Use the Main menu in Figure 3-3 as a quick reference for accessing the modem functions.

When the modem power is applied, the base level of the menu system displays the

sign-on message:

• Line 1 of the sign-on message is the modem type.

• Line 2 is the node address.

The main level of the menu system is Function Select. To access this level from the

sign-on message, press the [←] or [→] keys. From the Function Select menu, select one

of the functional categories:

• Configuration

• Monitor

• Faults/Alarms

• Stored Faults/Alarms

• Utility

Press [←] or [→] to move from one selection to another. When line 2 displays the desired

function, select that level by pressing [ENTER]. After entering the appropriate functional

level, press [←] or [→] to move to the desired function.

To view the modem’s configuration, enter the Configuration level from the Function

Select menu. Once in the Configuration menu, press [←] or [→] to scroll through the

Configuration menu selection:

• Modulator

• Demodulator

• Interface

• Save

• Recall

Press [ENTER] to select the desired Configuration menu option. To view the options for

the selected configuration parameters, press [←] or [→].

Notes:

1. Menus or commands that are specific to certain modem configurations are only

accessible after selecting the appropriate modem configuration. This prevents

incompatible parameters from accidentally being selected.

3. All of the windows are accessible in the Custom mode. Take caution not to select

incompatible parameters, as the modem does not shut out incompatible command

choices in the Custom mode.

3–4

Page 45

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.3 Front Panel Menu

SELECT

CONFIGURATION

MONITOR

FAULTS/ALARMS

STORED FLTS/ALMS

UTILITY

FACTORY SETUP (NOT APPL ICABLE

MODULATOR

DEMODULATOR

INTERFACE

SAVE

RECALL

RAW BER

CORRECTED BER

EB/NO

RECEIVE SIGNAL

SWEEP FREQUENCY

BUFFER FILL

MODULATOR

DEMODULATOR

TX INTERFACE

RX INTERFACE

COMMON

MODULATOR

DEMODULATOR

TX INTERFACE

RX INTERFACE

COMMON

CLEAR

MODULATOR

DEMODULATOR

INTERFACE

SYSTEM

MODEM TYPE

CODE/DATA RATE

TX-IF FREQUENCY

TX-IF OUTPUT

TX POWER LEVEL

SCRAMBLER

DIFF ENCODER

CARRIER MODE

MODEM REFERENCE

CODE/DATA RATE

RX-IF FREQUENCY

DESCRAMBLER

DIFF DECODER

RF LOOP BACK

IF LOOP BACK

BER THRESHOLD

SWEEP CENTER

SWEEP RANGE

REACQUISITION

TX CLOCK SOURCE

TX CLOCK PHASE

EXT-CLK FREQ

BUFFER CLOCK

RX CLOCK PHASE

B-BAND LOOP BACK

BUFFER SIZE

BUFFER CENTER

LOOP TIMING

ASSIGNED FILTERS

MOD POWER OFFSET

MODULATOR TYPE

ENCODER TYPE

TX BPSK OREDERING

MOD SPECTRUM

TX SYMBOL RATE

ASSIGNED FILTERS

DEMODULATOR TYPE

DECODER TYPE

RX BPSK ORDERING

DEMOD SPECTRUM

RX SYMBOL RATE

TX OVERHEAD TYPE

RX OVERHEAD TYPE

TX TERR INTERFACE

RX TERR INTERFACE

BUFFER PROGRAM

FRAMING STRUCTURE

RTS TX-IF CNTRL

TX DATA PHASE

RX DATA PHASE

CTS DELAY

TIME/DATE

REMOTE BAUD RATE

REMOTE ADDRESS

REMOTE TYPE

OPERATION MODE

YEAR DISPLAY

TEST MODE STATUS

LAMP TEST

SELF TEST

DISPLAY CONTRAST

M&C FIRMWARE

BOOT FIRMWARE

FPGA FIRMWARE

DEMO MODE

EXT AGC: MAX PWR

EXT AGC: MIN PWR

MASTER RESET

MODEM TYPE

MODEM EMULATION

REV EMULATION

MODEM OPTIONS

LOCAL MODEM AUPC

MODEM SERIAL

CONFIGURATION CODE

Figure 3-3. Main Menu

3–5

Page 46

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

Note: The following menus tree shows the modem functions available for an SNM-1002

LinkSync Modem. The defaulkt settings used when deployed in a MIDAS Network are

underlined.

3.4 OPENING SCREEN

SNM 1002

Ver:X.X.X

3.4.1 FUNCTION SELECT:CONFIGURATION

FUNCTION SELECT

CONFIGURATION

The main level of the menu system is Function Select. To access this level from the

sign-on message, press the [←] or [→] keys. From the Function Select menu, select one

of the functional categories:

• Configuration

• Monitor

• Faults/Alarms

• Stored Faults/Alarms

• Utility

Press [←] or [→] to move from one selection to another. When line 2 displays the desired

function, select that level by pressing [ENTER]. After entering the appropriate functional

level, press [←] or [→] to move to the desired function.

3–6

Page 47

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.1 CONFIGURATION:MODULATOR

CONFIGURATION

MODULATOR

To view the modem’s configuration, enter the Configuration level from the Function

Select menu. Once in the Configuration menu, press [←] or [→] to scroll through the

Configuration menu selection:

• Modulator

• Demodulator

• Interface

• Save

• Recall

Press [ENTER] to select the desired Configuration menu option. To view the options for

the selected configuration parameters, press [←] or [→].

3.4.1.1.1 MODULATOR: CODE RATE/TYPE

TX-X QPSK 1/2

19.200 kbps

Transmit code rate/type as follows:

TX-A QPSK 1/2 19.200 kbps

TX-B QPSK 1/2 19.200 kbps

TX-C QPSK 1/2 19.200 kbps

TX-D QPSK 1/2 19.200 kbps

TX-V QPSK 1/2 19.200 kbps

Upon entry, the current transmitter rate is displayed.

3–7

Page 48

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.1.2 MODULATOR:TX-IF FREQENCY

TX-IF FREQUENCY

70.000000 MHz

Displays the modulator TX IF frequency between 50 and 180 MHz, in 1 Hz steps.

Upon entry, the current transmitter frequency is displayed with the flashing cursor on the

first character. Press [← ] or [→] to move the flashing cursor, and [↑ ] or [↓ ] to increase

or decrease the digit at the flashing cursor. Press <ENTER> to execute the change.

3.4.1.1.3 MODULATOR:TX-IF OUTPUT

TX-IF OUTPUT

ON

Displays the modulator output status, either On

Upon entry, the current TX-IF output is displayed with the flashing cursor on the first

character. Press [↑ ] or [↓ ] to On or Off. Press <ENTER> to execute the change.

or Off.

3.4.1.1.4 MODULATOR:TX POWER LEVEL

TX POWER LEVEL

-10.0 dBm

Displays the modulator output level from:

• -5.0 to –30.0 dBm (Normal Range)

Upon entry, the current TX power level is displayed with the flashing cursor on the first

character. Press [← ] or [→] to move the flashing cursor, and [↑ ] or [↓ ] to increase or

decrease the digit at the flashing cursor. Press <ENTER> to execute the change.

3–8

Page 49

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.1.5 MODULATOR:SCRAMBLER

SCRAMBLER

ON

Displays the scrambler status, either On

Upon entry, the current scrambler is displayed with the flashing cursor on the first

character. Press [↑ ] or [↓ ] to change the carrier mode. Press <ENTER> to execute the

change

or Off.

3.4.1.1.6 MODULATOR:DIFF. ENCODER

DIFF. ENCODER

ON

Displays the differential encoder status, either On

Upon entry, the current differential decoder is displayed with the flashing cursor on the

first character. Press [↑ ] or [↓ ] to change the carrier mode. Press <ENTER> to execute

the change.

or Off.

3–9

Page 50

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.1.7 MODULATOR:CARRIER MODE

CARRIER MODE

NORMAL-MODULATED

Displays the carrier mode of operation as follows:

Normal-Modulated

Center-CW

Offset-CW

Dual-CW

Upon entry, the current carrier mode is displayed with the flashing cursor on the first

character. Press [↑ ] or [↓ ] to change the carrier mode. Press <ENTER> to execute the

change.

The carrier mode in normally in this Modulated position.

Generates a carrier at the current modulator frequency. This can be used to

measure the output frequency.

Generates a single, upper, side-band-suppressed carrier signal. The upper sideband is at one-quarter of the symbol rate from the carrier. When inverted

spectrum is selected, this generates a single, lower, side-band-suppressed

carrier.

Generates a dual side-band suppressed carrier signal. Side-bands are at one-half

of the symbol rate from the carrier. This is used to check the channel balance and

carrier null.

3.4.1.1.8 MODULATOR:MODEM REFERENCE

MODEM REFERENCE

INTERNAL

Displays the following references to the modulator:

• INTERNAL

• EXT1, EXT5, EXT10, and EXT20 MHz

Note: If any EXT REF is selected for the modem reference and there is no input to CP3,

the modem will detect an alarm and switch to the INTERNAL clock.

Upon entry, the current modem reference is displayed with the flashing cursor on the first

character. Press [↑ ] or [↓ ] change the modem reference. Press <ENTER> to execute the

change.

3–10

Page 51

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.2 CONFIGURATION:DEMODULATOR

CONFIGURATION

DEMODULATOR

3.4.1.2.1 DEMODULATOR:CODE RATE/TYPE

RX-X QPSK 1/2

19.200 kbps

Receive code rate/type as follows:

RX-A QPSK 1/2 19.200 kbps

RX-B QPSK 1/2 19.200 kbps

RX-C QPSK 1/2 19.200 kbps

RX-D QPSK 1/2 19.200 kbps

RX-V QPSK 1/2 19.200 kbps

Upon entry, the current transmitter rate is displayed. Press [↑ ] or [↓ ] change the

assigned filter. Press <ENTER> to execute the change.

3.4.1.2.2 DEMODULATOR:RX-IF FREQUENCY

RX-IF FREQUENCY

70.000000 MHZ

Displays the demodulator receive frequency, between 50 and 180 MHz, in 1 Hz steps.

Upon entry, the current RF-IF frequency is displayed. Press [↑ ] or [↓ ] change the

assigned filter. Press <ENTER> to execute the change.

3–11

Page 52

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.2.3 DEMODULATOR:DESCRAMBLER

DESCRAMBLER

ON

Displays the descrambler status, either On

Upon entry, the current descrambler is displayed. Press [↑ ] or [↓ ] change the assigned

filter. Press <ENTER> to execute the change.

or Off.

3.4.1.2.4 DEMODULATOR:DIFF.DECODER

DIFF. DECODER

ON

Displays the differential decoder status, either On

Upon entry, the current differential decoder is displayed. Press [↑ ] or [↓ ] change the

assigned filter. Press <ENTER> to execute the change.

or Off.

3.4.1.2.5 DEMODULATOR:RF LOOP BACK

RF LOOP BACK

OFF

Displays the RF loop back status, either On or Off

Upon entry, the current RF loop back is displayed. Press [↑ ] or [↓ ]. Press <ENTER> to

execute the change.

.

3–12

Page 53

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.2.6 DEMODULATOR:IF LOOP BACK

IF LOOP BACK

OFF

Displays the IF loop back status, either On or Off

Upon entry, the current IF loop back is displayed. Press [↑ ] or [↓ ]. Press <ENTER> to

execute the change.

.

3.4.1.2.7 DEMODULATOR:BER THRESHOLD

BER THRESHOLD

NONE

Displays the BER threshold .

If the BER threshold set is exceeded, a receive fault will be indicated by the modem

status indicators. BER threshold may be set from 1.0 E-3 to 1.0 E-8, or may be disabled

by specifying NONE

Upon entry, the current BER threshold is displayed. Press [↑ ] or [↓ ]. Press <ENTER> to

execute the change.

.

3.4.1.2.8 DEMODULATOR:SWEEP CENTER

SWEEP CENTER

+ 0 HZ

Displays the sweep center frequency for the directed sweep function. When in directed

sweep, the value from the sweep monitor screen (when the modem was last locked)

should be entered for the sweep center frequency. The sweep center frequency can be set

in the range from –35000 to +35000 Hz. Default: 0 Hz

Upon entry, the current sweep center frequency is displayed with the flashing cursor on

the first character. Press [← ] or [→] to move the flashing cursor, and [↑ ] or [↓ ] to

increase or decrease the digit at the flashing cursor. Press <ENTER> to execute the

change.

3.4.1.2.9 DEMODULATOR:SWEEP RANGE

3–13

.

Page 54

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

SWEEP RANGE

60000 HZ

Displays the overall travel of the sweep width range during acquisition in the directed

sweep mode. The sweep width may be set from 0 to 70000 Hz. Default: 60000 Hz

When set at 70000 Hz, the modem is in Normal acquisition mode. The smaller the range,

the faster the modem will lock, provided the receive carrier center frequency is within the

RX-IF frequency sweep range.

.

3.4.1.2.10 DEMODULATOR:REACQUISITION

REACQUISITION

0 SECONDS

Displays the sweep reacquisition mode time duration. This is the time that the modem

will remain in a narrow sweep after loss of acquisition. After this timer runs out, the

modem will return to the normal acquisition sweep. The reacquisition time is 0 to 999

seconds. Default: 0 seconds

.

3–14

Page 55

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.3 CONFIGURATION:INTERFACE

CONFIGURATION

INTERFACE

3.4.1.3.1 INTERFACE:TX CLOCK SOURCE

TX CLOCK SOURCE

SCT (INTERNAL)

Programs the clock source for the modem transmitter clock to the following

configurations:

TX TERRESTRIAL

SCT (INTERNAL)

RX (SATELLITE)

EXT CLOCK

Upon entry, the current TX clock source is displayed. Press [↑ ] or [↓ ] to make the

selection. Press <ENTER> to execute the change.

Sets the TX clock to recover timing from the incoming clock/data.

Sets the TX clock to operate from the modem internal clock (this also is the

fallback clock).

Note: When loop timing is enabled, SCT (LOOP) is displayed instead of SCT

(INTERNAL).

Sets the RX clock to recover timing from the output clock/data.

Sets the TX clock to operate from the EXT-CLK clock. Transmit clock source

must be phase/frequency locked to the data that is being transmitted. The

correct frequency must be programmed into EXT-CLK FREQ.

3–15

Page 56

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.3.2 INTERFACE:TX CLOCK PHASE

TX CLOCK PHASE

INVERT

Programs the TX clock phase to AUTO, NORMAL, INVERT

Upon entry, the current TX clock phase is displayed. Press [↑ ] or [↓ ] to make the

selection. When AUTO is s elected, the modem will automatically select NORMAL or

INVERT to properly phase the TX clock with the TX data. Press <ENTER> to execute

the change.

.

3.4.1.3.3 INTERFACE:EXT-CLK FREQ

EXT-CLK FREQ

1544.000 KHZ

Programs the external reference clock input frequency between 8.0 kHz and 10.0 MHz.

Default: 1544 kHz

Note: The clock rate must be equal to the data rate unless the asymmetrical loop timing

option is present.

This clock frequency can be any multiple of 600 Hz from 2.4 to 64 kHz, and can be any

multiple of 8 kHz from 64 kHz to 4.376 MHz.

This can be used for the Doppler/plesiochronous buffer reference. It can be a reference to

SCT. Use the master clock input on J8 for the external master reference. The EXT REF

on CP3 only allows for 1, 5, 10, and 20 MHz external reference input.

Upon entry, the current setting for the external reference is displayed. Press [←] or [→]

to increment or decrement the digit at the flashing cursor. Press [ENTER] to execute the

change.

.

3–16

Page 57

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.3.4 INTERFACE:BUFFER CLOCK

BUFFER CLOCK

RX (SATELLITE)

Programs the interface buffer output clock to one of the following modes:

RX (SATELLITE)

SCT (INTERNAL)

EXT. CLOCK

TX TERRESTRIAL

INSERT CLOCK

Upon entry, the current setting of the plesiochronous buffer clock is displayed. Press [↑] or

[↓] to make the selection. Press [ENTER] to execute the change.

Sets the output buffer clock to the satellite clock. (This is a Bypass.)

Sets the buffer clock to operate from the modem internal clock. This is

also the fallback clock.

Sets this clock source to the external clock.

Sets the buffer output clock to recover timing from the incoming TX data

clock.

Selects the recovered clock from the insert send data input received from

the terrestrial equipment.

3.4.1.3.5 INTERFACE:RX CLOCK PHASE

RX CLOCK PHASE

NORMAL

Programs the RX clock phase to Normal

Upon entry, the status of the RX Clock is displayed. Press [↑] or [↓] to make the selection.

Press [ENTER] to execute the change.

or Inverted.

3–17

Page 58

SNM-1002 LinkSync Modem Revision 2

/

Operation MN/SNM1002.OM

3.4.1.3.6 INTERFACE:B-BAND LOOP BACK

B-BAND LOOP BACK

OFF

Programs the modem for baseband loopback operation, On or Off

When baseband loopback is turned on, the data and timing signals are switched from the

demodulator to the modulator on the modem side of the interface. The DTE baseband

signals are also looped back from the transmitter data and clock to receiver data and clock

on the customer side of the interface. This is a bi-directional loopback of the baseband data.

Refer to figure 3-4 for a block diagram of baseband loopback operation.

Upon entry, the status is displayed. Press [↑] or [↓] to make the selection. Press [ENTER] to

execute the change.

.

CUSTOMER

DATA

REMOTE SERIAL

INTERFACE

FAULT INDICATORS

IBS OR IDR

INTERFACE

SATELLITE MODEM

ENCODER/

MODULATOR

MICRO-

COMPUTER

DEMODULATOR

DECODER

POWER SUPPLY

TRANSMIT RF

EQUIPMENT

AC POWER

RECEIVE RF

EQUIPMENT

Figure 3-4. Baseband Loopback

Note: When baseband loopback is turned on, data is looped back on the customer side of the

interface. This is a bi-directional loopback of the baseband data. This test mode will verify the

customer equipment and cabling between the modem and the customer equipment. The baseband

loopback is not bi-directional in D&I.

ANTENNA

3–18

Page 59

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

3.4.1.3.7 INTERFACE:BUFFER SIZE

BUFFER SIZE

0 (BYPASS)

Sets the size of the buffer, 32 to 262144 bits, 1 to 99 mS , or 0 (Bypass)

Upon entry, the current buffer length is displayed. Press [↑] or [↓] to select the desired

buffer size. The buffer size is displayed in seconds or bits. Enter the Utility Interface menu

to change the buffer units to seconds or bits.

• If selecting seconds, choose from 1 to 99 ms, in increments of 1 ms,

or 0 (Bypass).

• If selecting bits, choose from 32 to 262144 bits, in increments of 16 bits.

• Press [ENTER] to execute the change.

Note: To have the modem calculate the plesiochronous shift, set the buffer units to ms.

When a specific buffer depth is desired, set the buffer units to bits. Select bits or ms from

the Utility Interface menu.

3.4.1.3.8 INTERFACE:BUFFER CENTER

BUFFER CENTER

YES/NO

This configuration function is used to center the buffer. Choosing YES centers the buffer.

Press <ENTER> twice to center the buffer.

3.4.1.3.9 INTERFACE:LOOP TIMING

3–19

Page 60

SNM-1002 LinkSync Modem Revision 2

Operation MN/SNM1002.OM

LOOP TIMING

OFF

The SCT output will become phase-locked to the RX satellite clock.

TX and RX data rates must be equal unless the asymmetrical loop timing option is On or

.

Off

Upon entry, the status is displayed. Press [↑] or [↓] to make the selection. Press [ENTER]

to execute the change.

3.4.1.4 CONFIGURATION:SAVE

CONFIGURATION

SAVE

The Configuration Save menu allows programming of configuration parameters into

memory on the M&C. There are five memory locations that may be used to store specific