Page 1

SMS-458B

Modem Protection Switch

Installation and Operation Manual

Part Number MN/SMS458B. IOM Revision 2

Page 2

Page 3

Comtech EF Data is an ISO 9001

Registered Company.

SMS-458B

Modem Protection Switch

Installation and Operation Manual

Part Number MN/SMS458B.IOM

Revision 2

August 4, 2003

Page 4

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

Customer Support

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480 333.2200 (Main Comtech EF Data Number)

480 333.4357 (Customer Support Desk)

480 333.2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the Comtech EF

Data Customer Support Department.

Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

2. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

3. Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xiii

.

ii

Page 5

Table of Contents

CHAPTER 1. INTRODUCTION.................................................................................. 1–1

1.1 Overview.......................................................................................................................................................1–1

1.2 Purpose and Function..................................................................................................................................1–2

1.3 Description....................................................................................................................................................1–4

1.4 Major Assemblies.........................................................................................................................................1–8

1.5 System Requirements...................................................................................................................................1–8

1.6 Specification..................................................................................................................................................1–9

CHAPTER 2. INSTALLATION................................................................................... 2–1

2.1 Unpacking.....................................................................................................................................................2–1

2.2 Rack Installation..........................................................................................................................................2–2

2.3 External Connections...................................................................................................................................2–4

2.3.1 Data I/O ..................................................................................................................................................2–6

2.3.2 Remote Interface (J1, J2, J3) ..................................................................................................................2–7

2.3.3 Online Status (J4, J5)..............................................................................................................................2–7

2.3.4 Relay-Remote/Fault (J6).........................................................................................................................2–8

2.3.5 Downlink Inputs (J7 to J10, J12 to J15).................................................................................................2–9

2.3.6 Back-Up Demods (J11, J16)...................................................................................................................2–9

2.3.7 Prime Mod Inputs (J18 to J25) ...............................................................................................................2–9

2.3.8 Back-Up Mod Inputs (J26, J36)..............................................................................................................2–9

2.3.9 Offline IF Outputs (J17, J27) ................................................................................................................2–10

2.3.10 IF Outputs (J28 to J35).......................................................................................................................2–10

2.3.11 AC Power (J37, J38)...........................................................................................................................2–10

2.3.12 Ground................................................................................................................................................2–10

iii

Page 6

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

CHAPTER 3. FRONT PANEL OPERATION ............................................................. 3–1

3.1 Overview.......................................................................................................................................................3–1

3.2 LED Indicators.............................................................................................................................................3–2

3.3 Keypad and LCD Display............................................................................................................................3–3

3.4 System and Modem Setup...........................................................................................................................3–7

3.4.1 Prime Uplink and Downlink Ports..........................................................................................................3–7

3.4.2 System Setup ..........................................................................................................................................3–7

3.4.2.1 Time and Date Menu.......................................................................................................................3–8

3.4.2.2 Active Downlink Option Menu....................................................................................................... 3–8

3.4.2.3 Active Prime Modulators Menu......................................................................................................3–9

3.4.2.4 Active Prime Demodulators Menu..................................................................................................3–9

3.4.2.5 Active Backup Modulators Menu ...................................................................................................3–9

3.4.2.6 Active Backup Demodulators Menu...............................................................................................3–9

3.4.2.7 Modem Addresses Menu.................................................................................................................3–9

3.4.2.8 Prime Channel Unit Menu.............................................................................................................3–10

3.4.2.9 Backup Channel Unit Menu..........................................................................................................3–10

3.4.3 Modem Setup........................................................................................................................................3–10

3.4.3.1 Downlink Selection Menu.............................................................................................................3–11

3.4.3.2 Demodulator Priorities Menus ......................................................................................................3–11

3.4.3.3 Modulator Priorities Menus...........................................................................................................3–11

3.4.3.4 Demodulator Delay .......................................................................................................................3–12

3.4.3.5 Modulator Delay............................................................................................................................3–12

3.4.3.6 Channel Unit Selection..................................................................................................................3–13

3.4.4 Modem Configuration...........................................................................................................................3–13

3.4.4.1 Prime and Backup Modem Configuration.....................................................................................3–13

3.4.4.2 Modem Configuration Menu.........................................................................................................3–14

3.4.5 Operation Modes ..................................................................................................................................3–15

3.4.5.1 Bypass Mode.................................................................................................................................3–15

3.4.5.2 Auto Mode.....................................................................................................................................3–15

3.4.5.3 Local Mode....................................................................................................................................3–18

3.4.5.4 Remote Mode................................................................................................................................3–18

3.4.6 Faults ....................................................................................................................................................3–19

3.4.6.1 Modulator Operation Fault............................................................................................................3–22

3.4.6.2 Demodulator Operation Fault........................................................................................................3–22

3.4.6.3 M:N Faults.....................................................................................................................................3–22

3.4.6.4 Battery Faults ................................................................................................................................3–23

3.4.7 Front Panel Theory of Operation..........................................................................................................3–23

iv

Page 7

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

CHAPTER 4. THEORY OF OPERATION.................................................................. 4–1

4.1 Monitor and Control....................................................................................................................................4–1

4.1.1 General....................................................................................................................................................4–1

4.1.2 Description of Options............................................................................................................................4–2

4.1.2.1 M&C Serial Interface......................................................................................................................4–2

4.1.2.2 Remote Baud Rate...........................................................................................................................4–3

4.1.2.3 Remote Address ..............................................................................................................................4–3

4.1.2.4 External Remote Serial Interface Selection.....................................................................................4–4

4.1.2.5 Battery.............................................................................................................................................4–4

4.1.2.6 Error Response Switch....................................................................................................................4–5

4.1.2.7 External I/O Interrupt Arbitration ...................................................................................................4–5

4.1.3 Modem Control Interface Specification..................................................................................................4–5

4.1.4 Relay-Remote Interface Specification....................................................................................................4–6

4.1.4.1 Scope...............................................................................................................................................4–6

4.1.4.2 General............................................................................................................................................4–6

4.1.4.3 Command Structure.........................................................................................................................4–6

4.1.5 Fault Interface Specification...................................................................................................................4–9

4.1.5.1 Controller Fault .............................................................................................................................4–10

4.1.5.2 M:N Fault......................................................................................................................................4–10

4.1.5.3 Demodulator Signal Fault..............................................................................................................4–10

4.1.6 Online Status Specification...................................................................................................................4–10

4.1.7 Monitor and Control Theory of Operation ...........................................................................................4–11

4.2 Interface Switches ......................................................................................................................................4–11

4.2.1 IDR/G.703 Interface Switch.................................................................................................................4–11

4.2.1.1 General Description.......................................................................................................................4–11

4.2.1.2 Specification (IDR/G.703) ............................................................................................................4–12

4.2.1.3 Connector Pinout...........................................................................................................................4–13

4.3 Address Decoder/Driver............................................................................................................................4–15

4.3.1 General..................................................................................................................................................4–15

4.3.2 Specifications........................................................................................................................................4–16

4.3.3 Address Decoder/Driver Theory of Operation .....................................................................................4–17

4.4 IF Switch Driver.........................................................................................................................................4–18

4.5 Data Switch Controller Card....................................................................................................................4–19

4.6 IF Switch.....................................................................................................................................................4–20

4.6.1 General..................................................................................................................................................4–20

4.6.2 Specifications........................................................................................................................................4–20

4.6.3 IF Switch Theory of Operation.............................................................................................................4–20

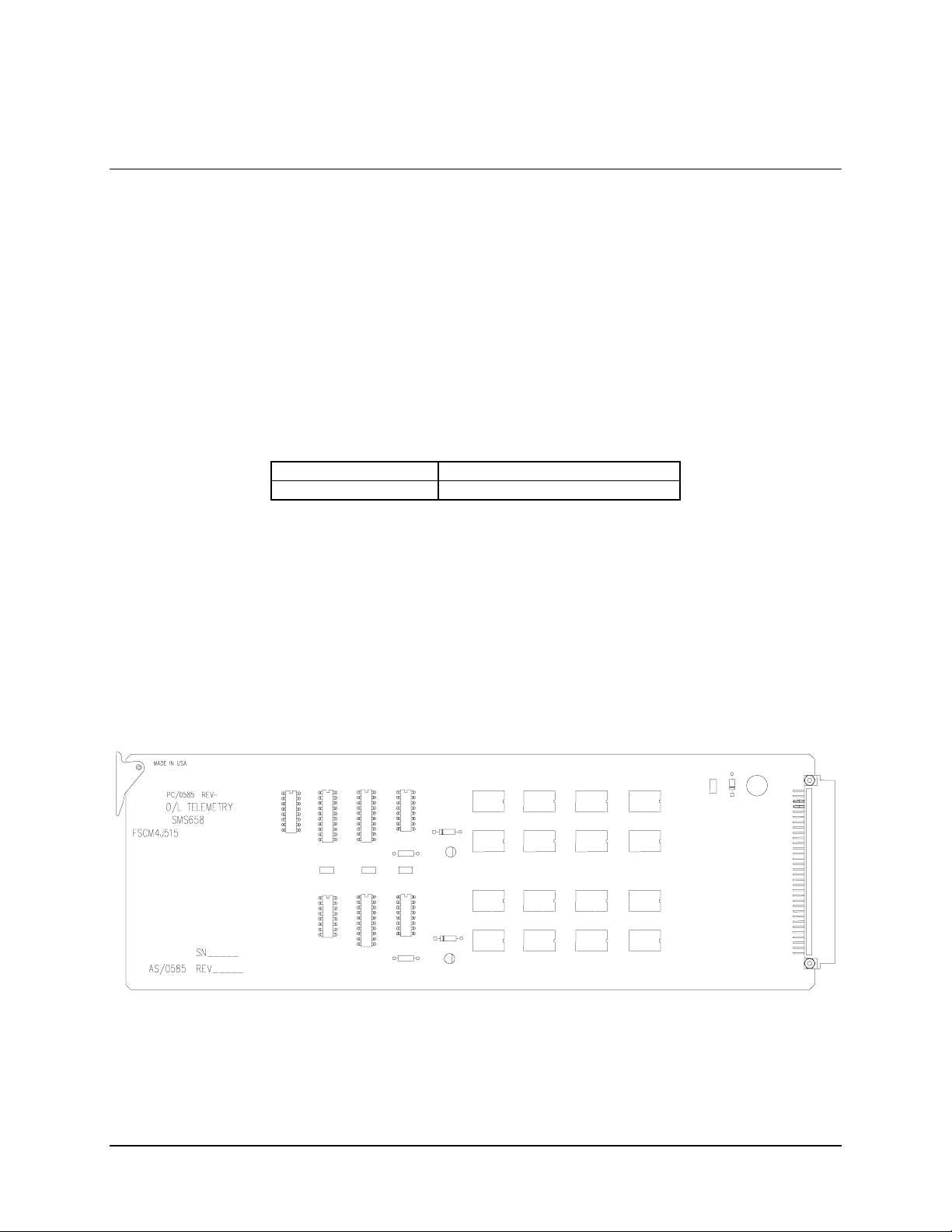

4.7 Online Telemetry........................................................................................................................................4–22

4.7.1 General..................................................................................................................................................4–22

4.7.2 Specifications........................................................................................................................................4–22

4.7.3 Online Telemetry Theory of Operation ................................................................................................4–22

v

Page 8

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

4.8 Power Supply..............................................................................................................................................4–24

4.8.1 General..................................................................................................................................................4–24

4.8.2 Specifications........................................................................................................................................4–24

CHAPTER 5. MAINTENANCE................................................................................... 5–1

5.1 Fault Descriptions ........................................................................................................................................5–1

5.1.1 General....................................................................................................................................................5–1

5.1.2 Modulator Operation Fault .....................................................................................................................5–1

5.1.3 Demodulator Operation Fault.................................................................................................................5–2

5.1.4 M:N Faults..............................................................................................................................................5–2

5.1.5 Battery Faults..........................................................................................................................................5–3

5.2 Fault Isolation...............................................................................................................................................5–3

5.2.1 Modulator Operation ..............................................................................................................................5–3

5.2.2 Demodulator Operation ..........................................................................................................................5–4

5.2.3 M:N Operation ........................................................................................................... .............................5–5

5.2.4 Battery.....................................................................................................................................................5–6

5.3 Module Replacement ...................................................................................................................................5–7

5.3.1 General....................................................................................................................................................5–7

5.3.2 Power Supply..........................................................................................................................................5–7

5.3.3 IF Switch.................................................................................................................................................5–8

5.3.4 Switch Driver..........................................................................................................................................5–8

5.3.5 Address Decoder/Driver.........................................................................................................................5–8

5.3.6 Monitor and Control...............................................................................................................................5–8

5.3.7 Online Telemetry....................................................................................................................................5–8

5.3.8 Interface Switches...................................................................................................................................5–8

5.3.9 Data Switch Controller ...........................................................................................................................5–9

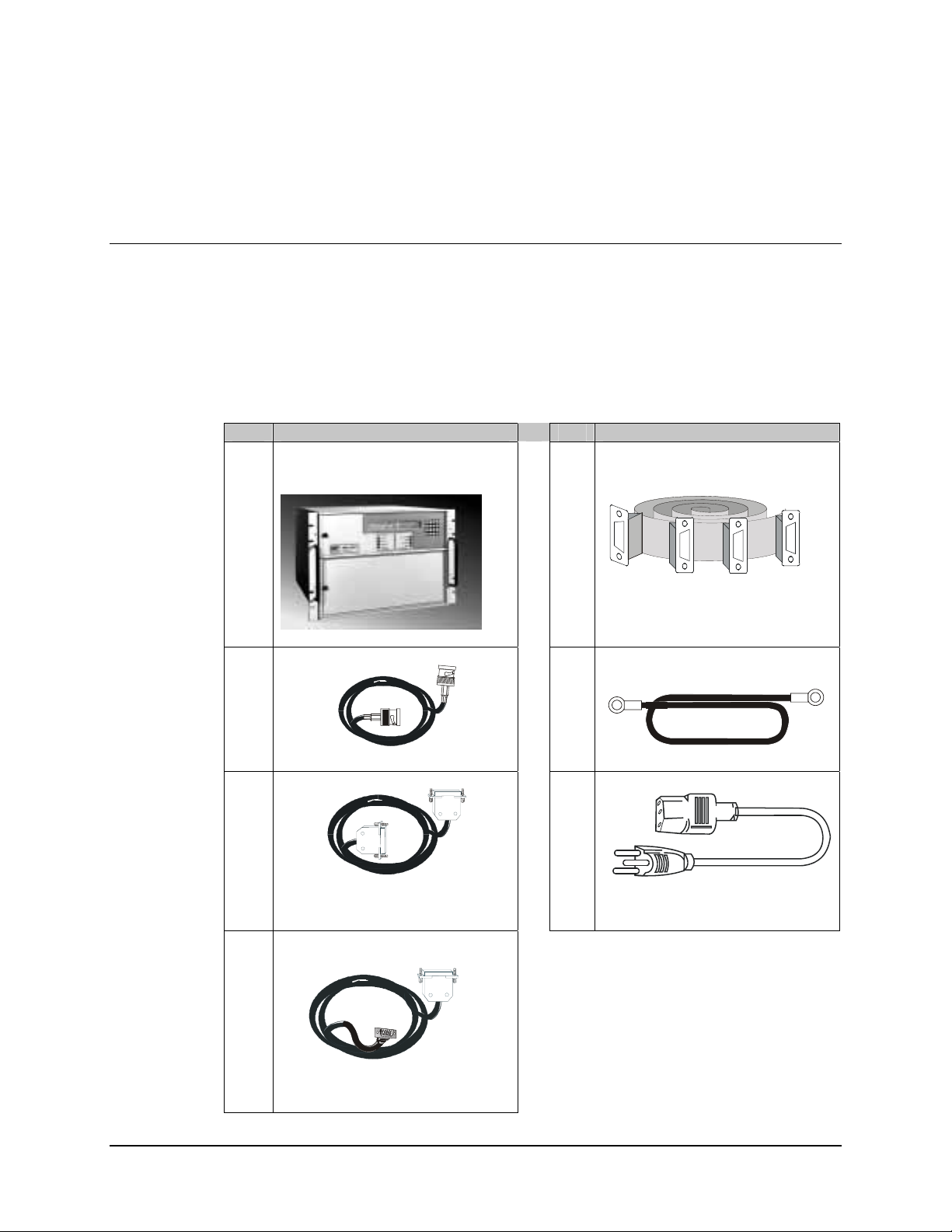

APPENDIX A. CABLING CONFGIURATIONS..........................................................A–1

A.1 General........................................................................................................................................................A–1

A.2 SDM-2020 Modulator (TX only) with ECL/HSSI Data Interface.........................................................A–3

A.3 SDM-2020 Modulator (TX only) with G.703 Data Interface .................................................................A–6

A.4 SDM-9000 Satellite Modem with 50-Pin Data Interface .......................................................................A–9

vi

Page 9

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

APPENDIX B. REMOTE CONTROL OPERATION: INDEPENDENT MOD/DEMOD B–1

B.1 General........................................................................................................................................................B–1

B.2 Message Structure...................................................................................................................................... B–1

B.3 Start Character...........................................................................................................................................B–2

B.4 Device Address............................................................................................................................................ B–2

B.5 Command/Responses ................................................................................................................................. B–2

B.6 End of Message Character......................................................................................................................... B–3

B.7 Modulator Configuration Commands/Responses ................................................................................... B–3

B.8 Backup Modulator Configuration Commands/Responses .....................................................................B–4

B.9 Demodulator Configuration Commands/Responses............................................................................... B–5

B.10 Backup Demodulator Configuration Commands/Responses............................................................... B–5

B.11 Modem Configuration Commands/Responses....................................................................................... B–7

B.12 Status Commands/Responses..................................................................................................................B–7

B.13 Operational Commands...........................................................................................................................B–9

B.14 Load Modem Configurations ................................................................................................................ B–10

B.15 Verify Modem Configuration(s)............................................................................................................. B–10

B.16 Operational Status Commands (Faults)...............................................................................................B–11

GLOSSARY ............................................................................................................. g–1

INDEX ........................................................................................................................ i–1

vii

Page 10

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

Figures

Figure 1-1. SMS-458B.....................................................................................................................................1–1

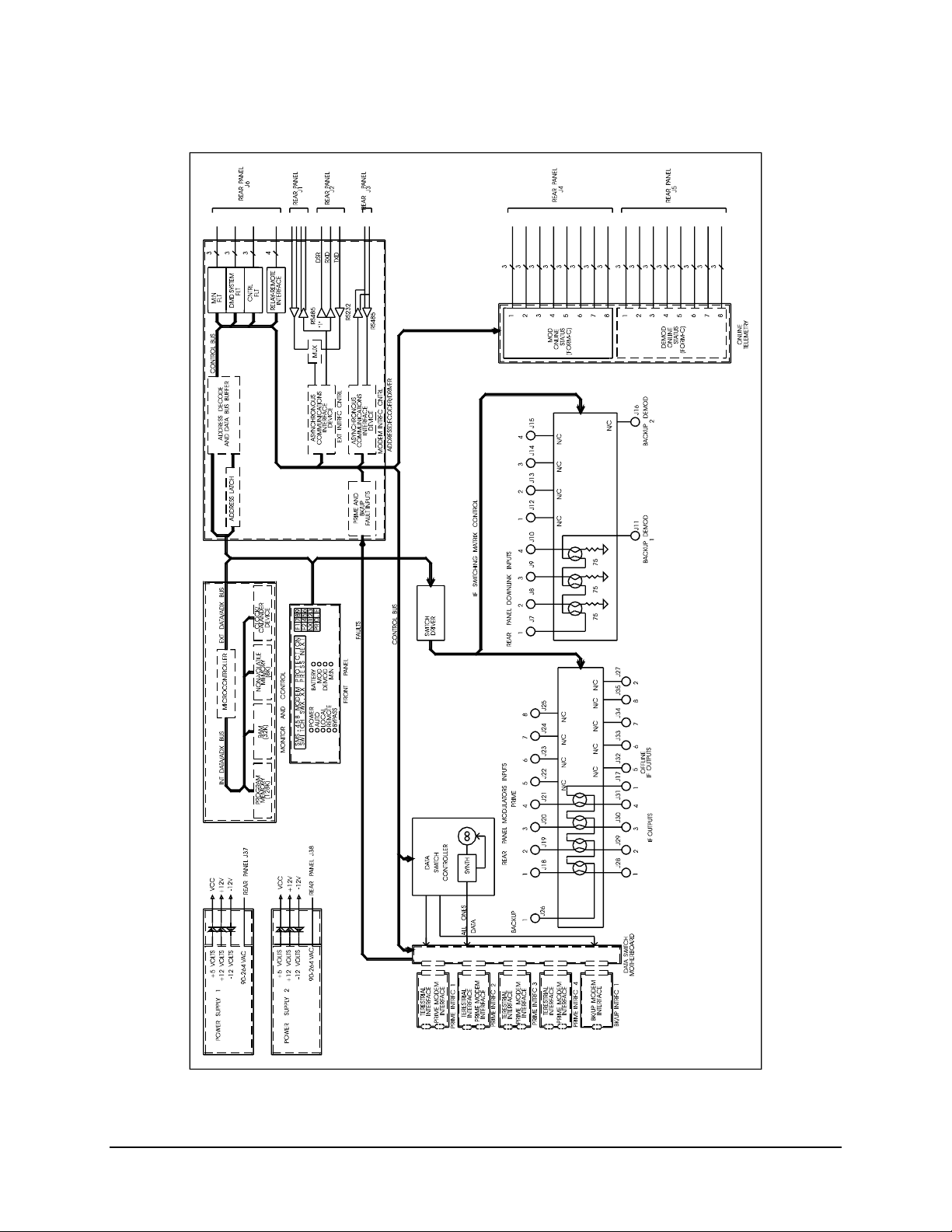

Figure 1-2. System Block Diagram .................................................................................................................1–3

Figure 1-3. SMS-458B Upper-front Section Interior.......................................................................................1–5

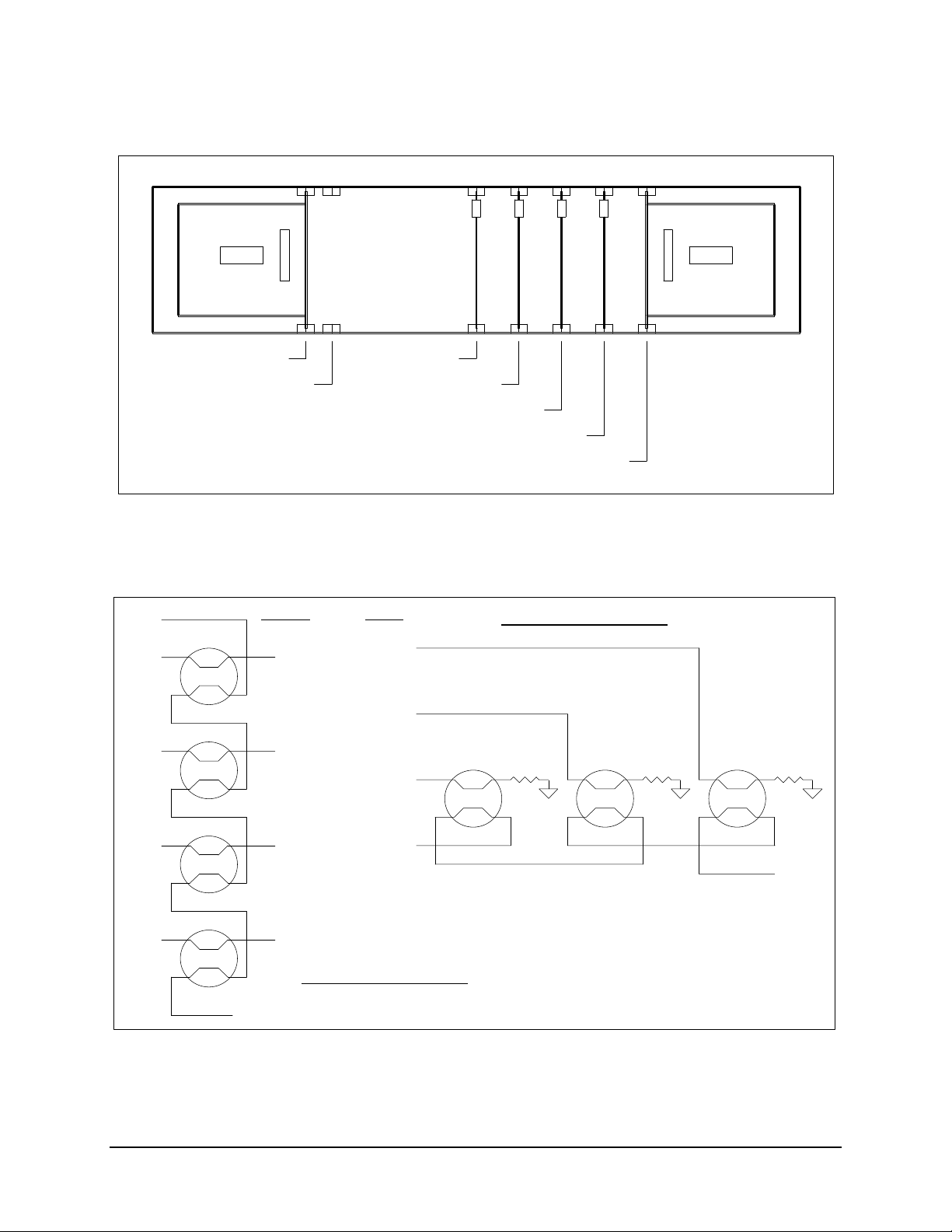

Figure 1-4. SMS-458B IF Switching Matrix...................................................................................................1–5

Figure 1-5. Lower Section Interconnect Diagram ...........................................................................................1–6

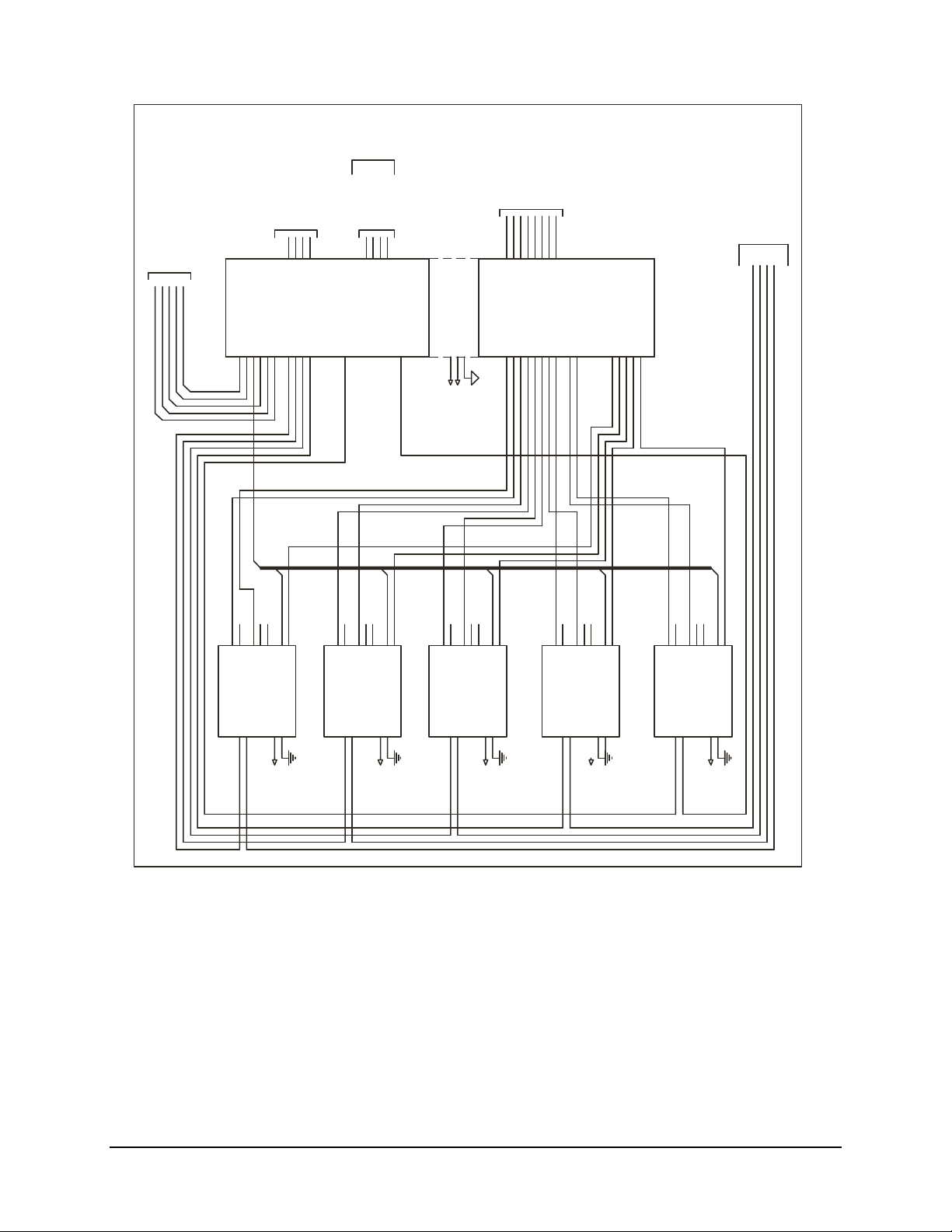

Figure 1-6. SMS-458B Block Diagram...........................................................................................................1–7

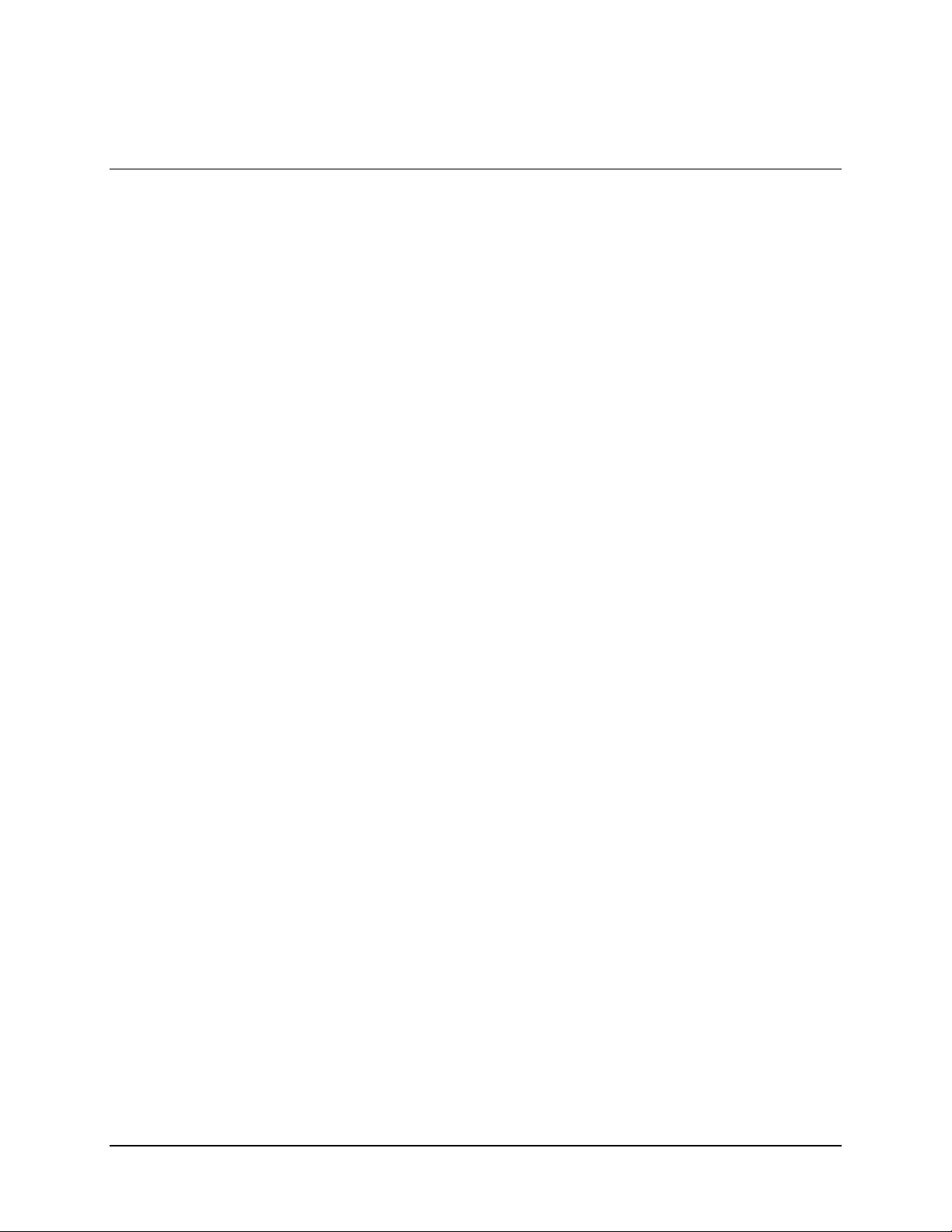

Figure 2-1. Typical Switch Rack Installation ..................................................................................................2–3

Figure 2-2. SMS-458B Rear Panel View.........................................................................................................2–5

Figure 3-1. SMS-458B Front Panel View .......................................................................................................3–2

Figure 3-2. Display Map..................................................................................................................................3–5

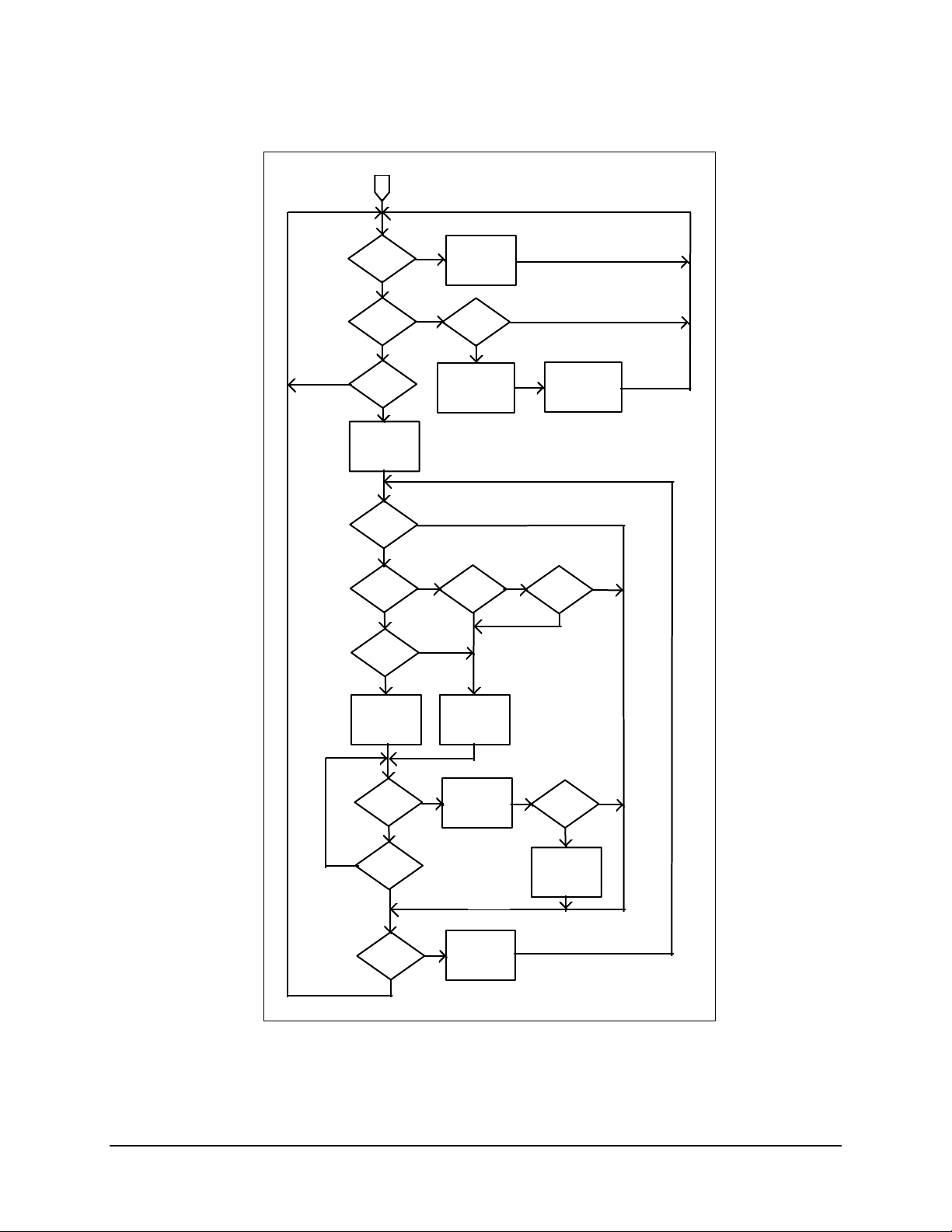

Figure 3-3. SMS-458B Switching Algorithm Flow Chart Demodulator/Modem .........................................3–20

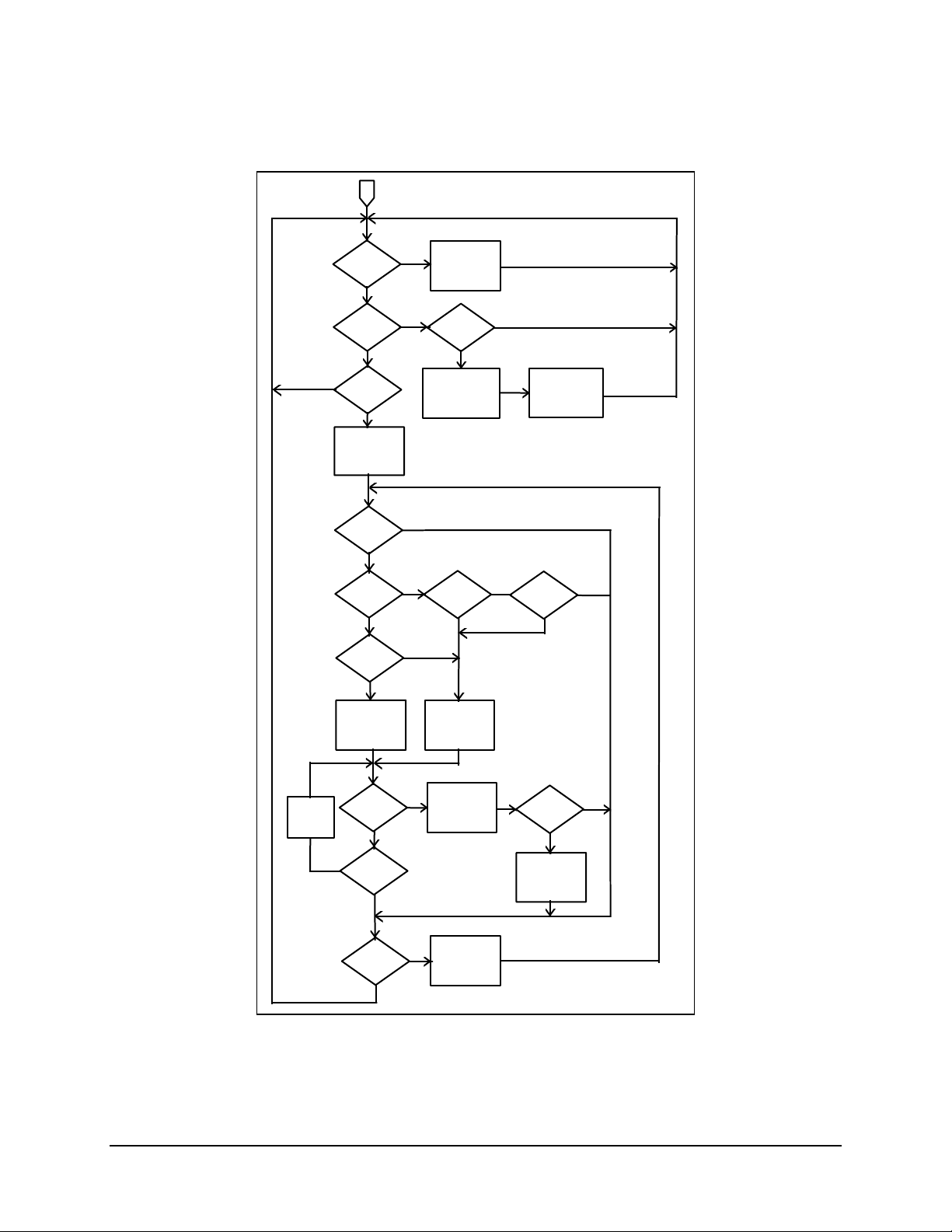

Figure 3-4. SMS-458B Switching Algorithm Flow Chart Modulator...........................................................3–21

Figure 4-1. Monitor and Control .....................................................................................................................4–2

Figure 4-2. Prime IDR/G.703 Interface Switch.............................................................................................4–14

Figure 4-3. Backup IDR/G.703 Interface Switch ..........................................................................................4–14

Figure 4-4. Address Decoder/Driver..............................................................................................................4–15

Figure 4-5. Address Decoder/Driver .............................................................................................................4–16

Figure 4-6. Switch Driver..............................................................................................................................4–18

Figure 4-7. IF Switch Driver Block Diagram................................................................................................4–18

Figure 4-8. Data Switch Controller Card.......................................................................................................4–19

Figure 4-9. IF Switch.....................................................................................................................................4–21

Figure 4-10. Online Telemetry ......................................................................................................................4–22

Figure 4-11. Online Telemetry Block Diagram.............................................................................................4–23

Figure A-1. SMS-458B for SDM-2020 Modulator (TX only) with ECL/HSSI Data Interface ....................A–4

Figure A-2. SMS-458B for SDM-2020 Modulator (TX only) with ECL/HSSI Data Interface.....................A–5

Figure A-3. SMS-458B for SDM-2020 Modulator (TX only) with G.703 Data Interface.............................A–7

Figure A-4. SMS-458B for SDM-2020 Modulator (TX only) with G.703 Data Interface.............................A–8

Figure A-5. SMS-458B for SDM-9000 Satellite Modem with 50-Pin Data Interface .................................A–10

Figure A-6. SMS-458B for SDM-9000 Satellite Modem with 50-Pin Data Interface .................................A–11

Tables

Table 1-1. SMS-458B Specification................................................................................................................1–9

Table 2-1. Rear Panel Connections..................................................................................................................2–4

Table 4-1. Relay-Remote Command Words....................................................................................................4–7

Table 4-2. Modem Target Words ....................................................................................................................4–7

Table 4-3. Relay-Remote Command Functions...............................................................................................4–8

Table 4-4. Relay-Remote Command Examples...............................................................................................4–9

Table A-1. Equipment List .............................................................................................................................A–2

Table A-2. Cable Assembly............................................................................................................................A–3

Table A-3. Cable Connection .........................................................................................................................A–3

Table A-4. Cable Assembly............................................................................................................................A–6

Table A-5. Cable Connection .........................................................................................................................A–6

Table A-6. Cable Assembly............................................................................................................................A–9

Table A-7. Cable Connection .........................................................................................................................A–9

viii

Page 11

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

About this Manual

This manual provides installation and operation information for the Comtech EF Data

SMS-458B Modem Protection Switch. This a technical document intended for earth

station engineers, technicians, and operators responsible for the operation and

maintenance of the SMS-458B..

Related Documents

The following documents are referenced in this manual:

• Department of Defense (DOD) MIL-188-114A, “Electrical Characteristics of

Digital Interface Circuits”

• Comtech EF Data, SDM2020 Modulator, Rev. 4 dated, September 15, 1999

Installation and Operation Manual

• Comtech EF Data, SDM-9000, Rev. 4, dated, May 5, 1997 Installation and

Operation Manual

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARNING

IMPORTANT indicates a statement that is associated with the task

IMPORTANT

being performed.

ix

Page 12

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

Trademarks

Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Customer

Support Department.

Overview of Changes Made to Revision 1

x

Page 13

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

ELECTRICAL SAFETY

The SMS-458B Modem Protecrtion Switch has been shown to comply with the following safety

standard:

• EN 60950: Safety of Information Technology Equipment, including electrical business

machines.

The equipment is rated for operation over the range 90 to 264 volts AC. It has a maximum

power consumption of 160 watts.

FUSES

The SMS-458B Modem Protecrtion Switch is fitted with two fuses, one each for line and neutral

connections. These are contained within the body of the IEC power connector, behind a small

plastic flap.

• For 230 volt AC operation, use T0.75A, 20mm fuses.

• For 115 volt AC operation, use T1.25A fuses, 20mm fuses.

IMPORTANT

Environmental

The SMS-458B Modem Protecrtion Switch must not be operated in an environment

where the unit is exposed to extremes of temperature outside the ambient range 0 to 50°C

(32 to 122°F), precipitation, condensation, or humid atmospheres above 95% RH,

altitudes (un-pressurized) greater than 2000 meters, excessive dust or vibration,

flammable gases, corrosive or explosive atmospheres.

Operation in vehicles or other transportable installations that are equipped to provide a

stable environment is permitted. If such vehicles do not provide a stable environment,

safety of the equipment to EN60950 may not be guaranteed.

For continued operator safety, always replace the fuses with the

correct type and rating.

xi

Page 14

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

Installation

The installation and connection to the line supply must be made in compliance to local or

national wiring codes and regulations.

The SMS-458B Modem Protecrtion Switch is designed for connection to a power system

that has separate ground, line and neutral conductors. The equipment is not designed for

connection to power system that has no direct connection to ground.

The SMS-458B Modem Protecrtion Switch is shipped with a line inlet cable suitable for

use in the country of operation. If it is necessary to replace this cable, ensure the

replacement has an equivalent specification. Examples of acceptable ratings for the cable

include HAR, BASEC and HOXXX-X. Examples of acceptable connector ratings include

VDE, NF-USE, UL, CSA, OVE, CEBEC, NEMKO, DEMKO, BS1636A, BSI, SETI,

IMQ, KEMA-KEUR and SEV.

International Symbols:

Symbol Definition Symbol Definition

~

Alternating Current

Fuse

Telecommunications Terminal Equipment Directive

In accordance with the Telecommunications Terminal Equipment Directive 91/263/EEC,

this equipment should not be directly connected to the Public Telecommunications

Network.

Protective Earth

Chassis Ground

xii

Page 15

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

EMC (Electromagnetic Compatibility)

In accordance with European Directive 89/336/EEC, the SMS-458B Modem Protecrtion

Switch has been shown, by independent testing, to comply with the following standards:

Emissions: EN 55022 Class B - Limits and methods of measurement of radio

interference characteristics of Information Technology Equipment.

(Also tested to FCC Part 15 Class B)

Immunity: EN 50082 Part 1 - Generic immunity standard, Part 1: Domestic,

commercial and light industrial environment.

Additionally, the SDM-2020D has been shown to comply with the following standards:

EN 61000-3-2 Harmonic Currents Emission

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2 ESD Immunity

EN 61000-4-4 EFT Burst Immunity

EN 61000-4-5 Surge Immunity

EN 61000-4-6 RF Conducted Immunity

EN 61000-4-8 Power frequency Magnetic Field Immunity

EN 61000-4-9 Pulse Magnetic Field Immunity

EN 61000-4-11 Voltage Dips, Interruptions, and Variations Immunity

EN 61000-4-13 Immunity to Harmonics

In order that the Modem continues to comply with these standards,

observe the following instructions:

IMPORTANT

• Connections to the transmit and receive IF ports (Type N and Type F, female,

connectors) should be made using a good quality coaxial cable - for example

RG58/U (50Ω) or RG59/U (75Ω).

• All 'D' type connectors attached to the rear panel must have back-shells that

provide continuous metallic shielding. Cable with a continuous outer shield

(either foil or braid, or both) must be used, and the shield must be bonded to the

back shell.

• The equipment must be operated with its cover on at all times. If it becomes

necessary to remove the cover, the user should ensure that the cover is correctly

re-fitted before normal operation commences.

xiii

Page 16

SMS-458B Modem Protection Switch Revision 2

Preface MN/SMS458B.IOM

Warranty Policy

This Comtech EF Data product is warranted against defects in material and workmanship

for a period of one year from the date of shipment. During the warranty period, Comtech

EF Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF

Data and all related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible

for the freight charges only for return of the equipment from the factory to the customer.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and recommendations

in this manual and in any guides or related documents are believed reliable, but the

accuracy and completeness thereof are not guaranteed or warranted, and they are not

intended to be, nor should they be understood to be, representations or warranties

concerning the products described. Further, Comtech EF Data reserves the right to make

changes in the specifications of the products described in this manual at any time without

notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EF Data Customer Support Department.

xiv

Page 17

Chapter 1. INTRODUCTION

This chapter describes the SMS-458B Modem Protection Switch (Figure 1-1), referred to

in this manual as “the switch,”.

1.1 Overview

The SMS-458B Modem Protection Switch is a rack-mounted unit that provides

independent backup control for modulators and demodulators, or simultaneous modulator

and demodulator (modem) switching. The switch limits the loss of communication if a

primary modem element failure occurs.

Figure 1-1. SMS-458B

1–1

Page 18

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

1.2 Purpose and Function

The switch is a fully-automated, self-contained, switching unit for the following

equipment:

• SDM-2020 (Modulator) Satellite Modem

• SDM-2020 (Demodulator) Satellite Modem

• SDM-9000 Satellite Modem

The switch is designed to interface with ASI, G.703, or compatible data streams.

One backup modem provides redundancy for up to four prime modems. The switch will

automatically or manually switch one backup modem to take the place of any of four

prime modems.

In normal operation, each prime modem input is fed through to its corresponding IF

output, and the backup modems are fed to the offline IF outputs. When a modem fault is

detected, the faulted modem is switched offline and re-routed to one of the offline IF

outputs. The backup modem is configured identically to the failed modem and is

switched in its place, unless the backup modem is already backing up a prime of equal or

greater priority.

The switch does not contain an IF signal combining/dividing section, so that the user may

externally tailor the combiner/divider loss for a minimum configuration per application.

Figure 1-2 shows the switch interface between the prime and backup modems, the

terminal equipment, and IF converter equipment. The switch provides:

• All data and IF switching circuitry

• Complete status and fault reporting

1–2

Page 19

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

FROM

DOWNLINK

TO

UPLINK

AND

STATUS REPORTING

REMOTE CONTROL

INTF

RS-485 EXT INTF

RS-232 EXT INTF

MODEM CNTL

J1J2J3J4J5

J10

J11

J9

RX CLK

RX DATA

EQUIPMENT

J29

J30

J31

MOD PRIME 2

MOD PRIME 3

MOD OL STATUS

J12

TX DATA

MOD PRIME 4

DEMOD OL STATUS

REMOTE/FAULT

J6

J18 MOD PRIME 1 J28

J19

J20

J21

J13

J8

J7

SCT

FAULT

TX CLK

REMOTE

INPUTS

DEMOD

DOWNLINK

FOR BACKUP EQUIPMENT

J7

J8

J9

J10

DOWNLINK 1

DOWNLINK 2

DOWNLINK 3

DOWNLINK 4

MOD BACKUP

J26

J10

J9

RX CLK

RX DATA

DEMOD BACKUP

J11

J11

J12

J13

J7

J8

SCT

FAULT

TX CLK

TX DATA

REMOTE

ALL UNUSED

NOTE:

CONNECTIONS MUST BE

IF SECTION

SMS-458B

AC1

AC2

CGND TERMINATED INTO 75 OHMS.

AC1

AC2

GND

90-264 VAC

90-264 VAC

J10

J9

J12

J13

J11

RX CLK

TX CLK

TX DATA

RX DATA

EQUIPMENTTOTERMINAL

FROM

DOWNLINK

EQUIPMENT

A5,J2

A7,J1

A1,J2

A3,J1

A3,J2

123

123

A1,J4

A3,J3

A3,J4

A5,J1

A5,J3

RXTXRX

A5,J4

A7,J3

A7,J2

4

BK/UP

MODEM

4

A7,J4

A10,J1

A10,J2

J11

J12

J13

J9

J10

SCT

TX CLK

RX CLK

TX DATA

RX DATA

SMS-458B

DATA SECTION

DEMOD PRIME 1

DEMOD PRIME2DEMOD PRIME3DEMOD PRIME 4

A2,J6

A4,J6

A6,J6

A8,J6

A10,J3

J7

J8

FAULT

REMOTE

J9

RX DATA

J7

J8

J11

J10

J12

J13

SCT

FAULT

TX CLK

RX CLK

REMOTE

TX DATA

A1,J1

TERR

INTRFC

TXRXTXRXTX

PRIME

MODEMS

A1,J3

J7

J8

SCT

FAULT

REMOTE

PRIME 1

IF

AC1ACGRND

TX

RX IF

CP1

CP2

120 VAC

PRIME 2

TX IF

SDM-XXXX

GND

RX IF

AC

CP1

CP2

PRIME 3

AC1

GRND

GND

120 VAC

TX IF

RX IF

SDM-XXXX

AC1

AC

GND

CP1

CP2

120 VAC

PRIME 4

TX IF

RX IF

GRND

SDM-XXXX

AC1

AC

GND

CP1

CP2

120 VAC

BACKUP 1

TX IF

RX IF

AC1

GRND

SDM-XXXX

GRND

SDM-XXXX

AC

GND

CP1

CP2

120 VAC

Figure 1-2. System Block Diagram

1–3

Page 20

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

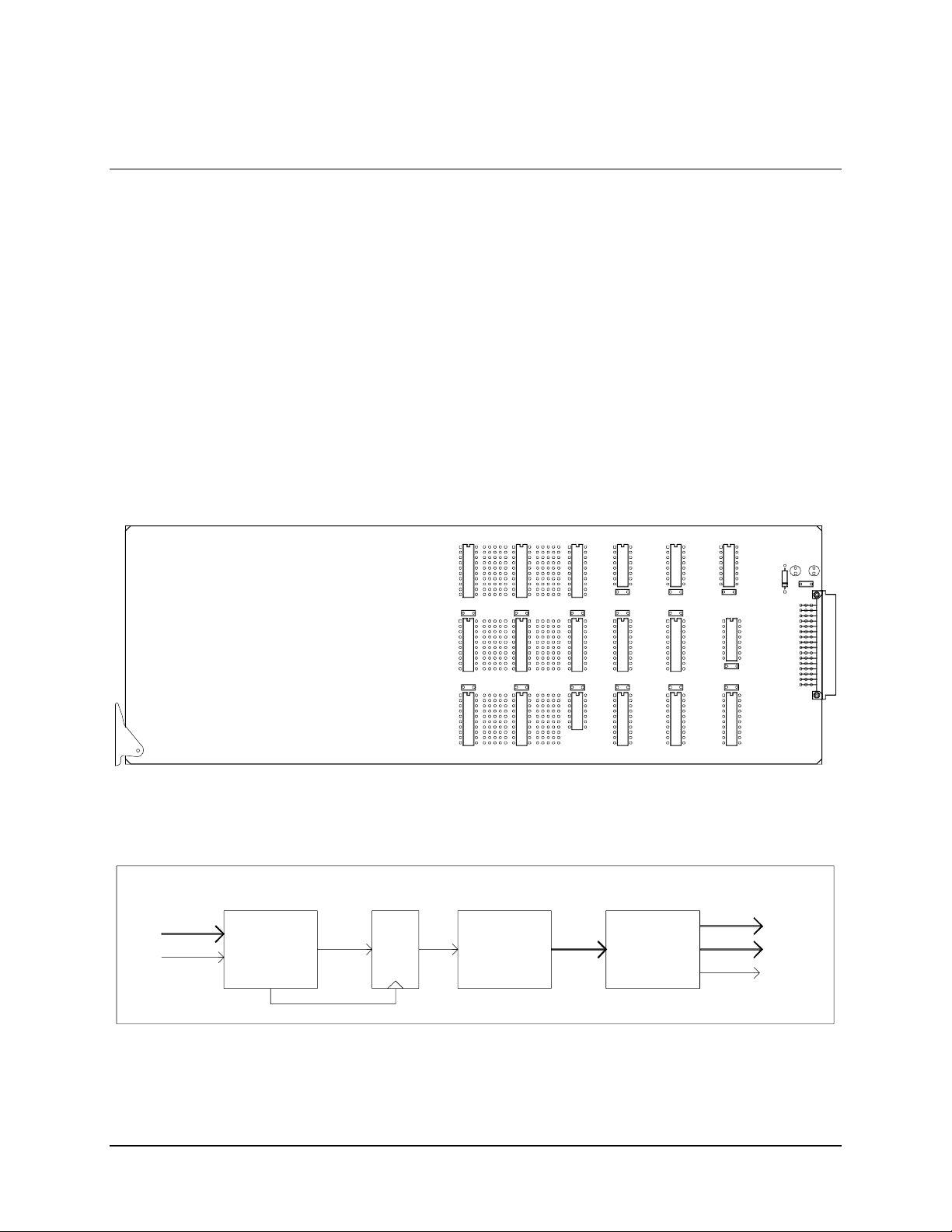

1.3 Description

The switch is complete and self-contained in a standard 19-inch (48 cm) rack-mounted

enclosure weighing approximately 50 lbs (22.68 kg). Modular construction methods were

used for ease in replacing modules.

The chassis assembly is segmented with upper and lower chassis-mounted backplanes.

The top section (Figure 1-3) contains:

• Two power supplies and four printed circuit board (PCB) assemblies, providing:

! Front panel keypad and display accessible from the front panel.

! Serial remote interfaces, relay-remote/fault, status, and IF connections

accessible from the rear panel. Refer to Figure 1-4 for a block diagram of the

IF switching matrix.

The lower section (Figure 1-5) contains:

• High-speed data switching matrix and matrix driver.

• Data switch interface modules accessible from the rear.

Refer to Figure 1-6 for the interconnect diagram of the lower section.

The switch contains a microcontroller system. This system controls all switching

functions and maintains communication with the modems. It also communicates with an

optional external controller. A remote operator can control the switching by using a

terminal or computer and the remote serial interface.

Redundant power supplies maintain switch operation even if one power supply fails. The

switch and modem configurations are stored in battery-backed memory devices for

protection against power loss.

1–4

Page 21

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

BU MOD 1

MOD 1

MOD 2

SLOT 1

POWER SUPPLY

SLOT 3

SWITCH DRIVER

SLOT 2

SLOT 4

ADDRESS DEC/DRVNOT USED

MONITOR AND CONTROL

SLOT 5

ONLINE TELEMETRY

SLOT 6

POWER SUPPLY 2

SLOT 7

Figure 1-3. SMS-458B Upper-Front Section Interior

IF 1

IF 2

INPUTSOUTPUTS

DOWNLINK 4

DOWNLINK 3

DOWNLINK 2

DEMODULATOR SWITCH

MOD 3

MOD 4

IF 3

IF 4

DOWNLINK 1

BACKUP DEMOD 1

DEMODULATOR SWITCH

BACK-UP 1 IF OUTPUT

Figure 1-4. SMS-458B IF Switching Matrix

1–5

Page 22

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

TX DATA

J1

RX DATA

J2

J3

BACKUP

MODEM

J27

J18

J17

TERR

J28

J26

J25

J5

J6

PRIME 4

TX

TERR

RX

TX

MODEM

RX

PRIME 3

J1

J5

J2

J3

J6

J4

JP1

TX

TERR

RX

TX

MODEM

RX

JP2

J1

J2

J3

J4

PRIME 2

J5

J6

TX

TERR

RX

TX

MODEM

RX

J1

J2

J3

J4

J30 J31

J19

J20

J5

J6

J11

J12

PRIME 1

TX

TERR

RX

TX

MODEM

RX

J1

J2

J3

J4

J16

J15

AS/1314-1

RX DATA

SWITCH

J24

J23

JP3

DATA SWITCH

CONTROLLER

AS/2031

J2

J1

Figure 1-5. Lower Section Interconnect Diagram

J21

J22

AS/1314-1

TX DATA

SWITCH

J13

J14

J27J28

1–6

Page 23

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

Figure 1-6. SMS-458B Block Diagram

1–7

Page 24

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

1.4 Major Assemblies

The switch consists of the following assemblies:

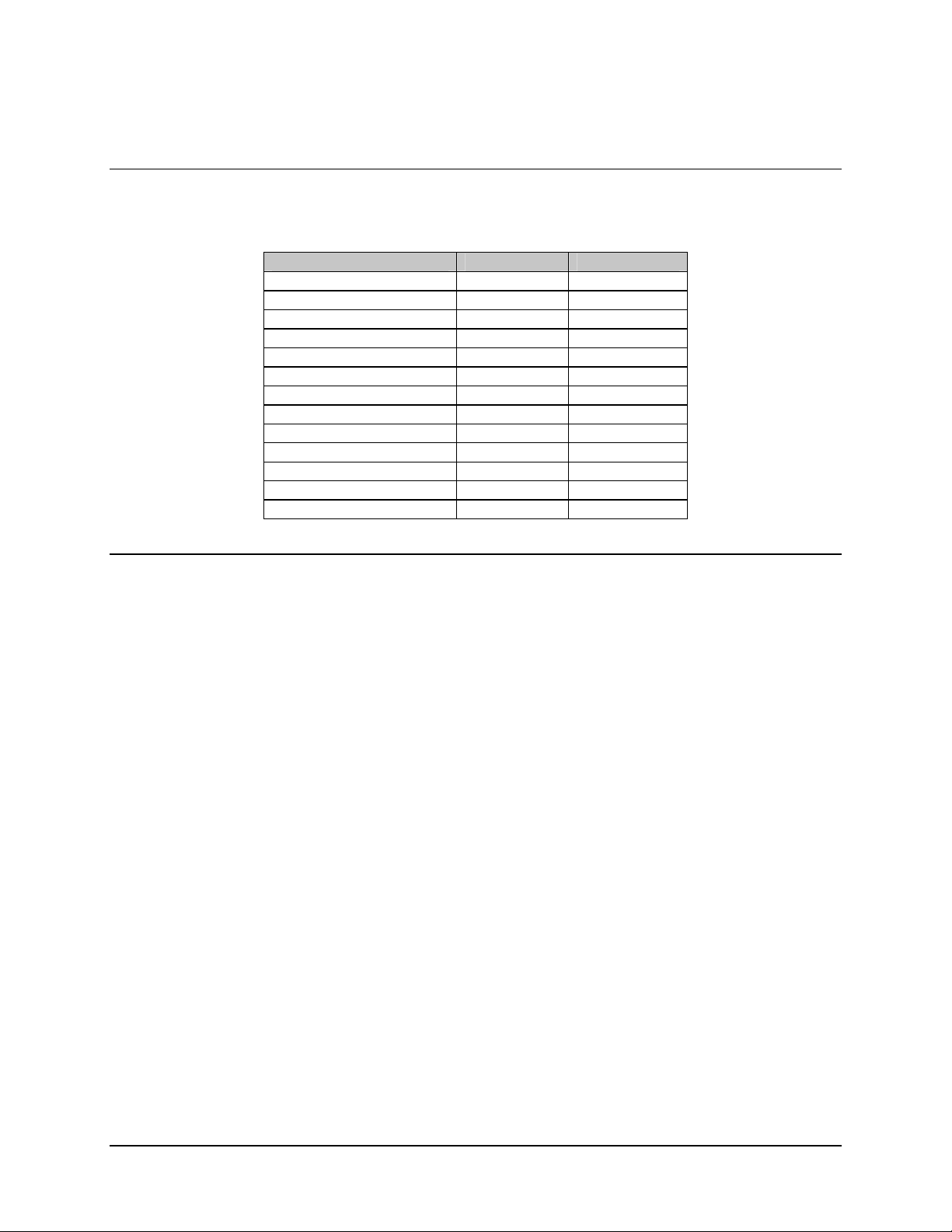

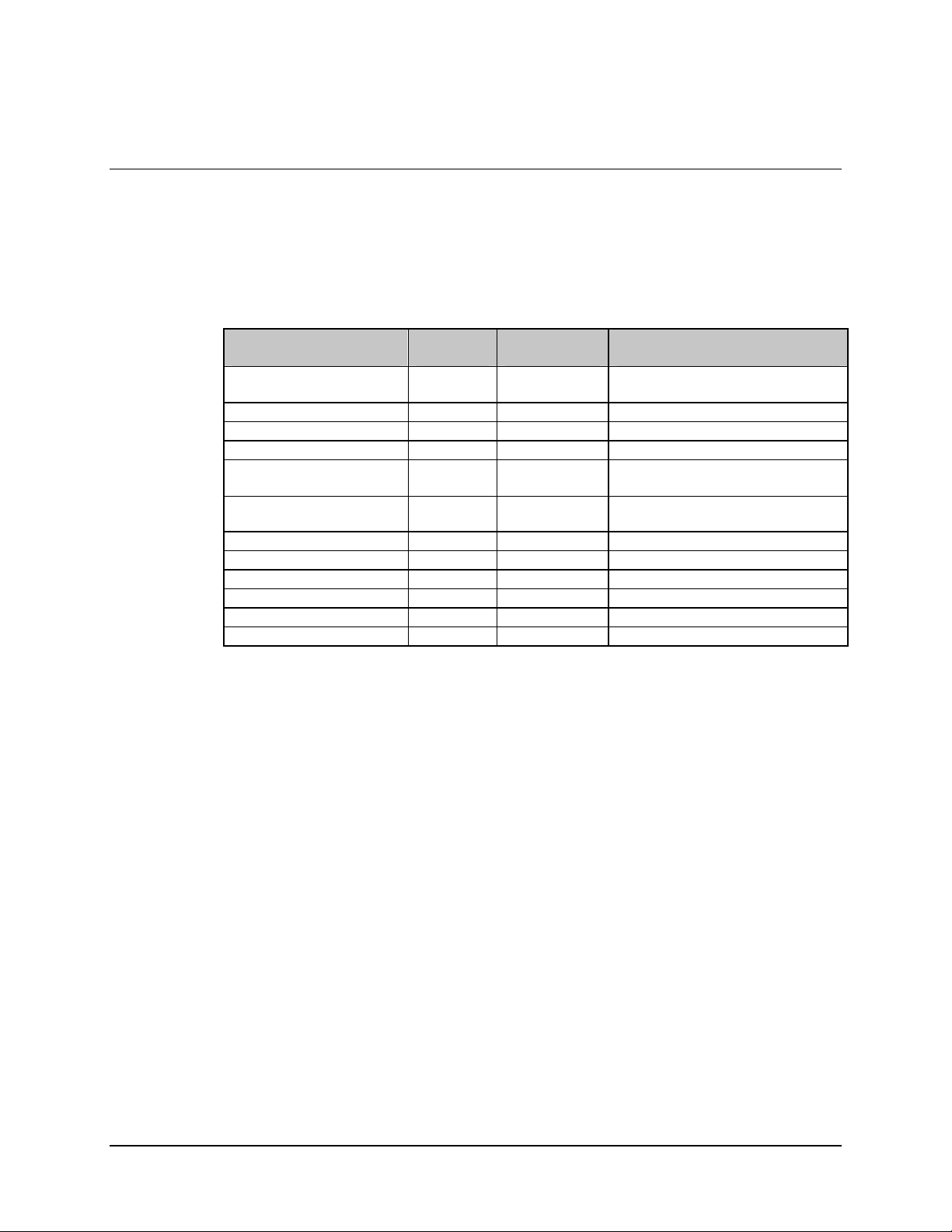

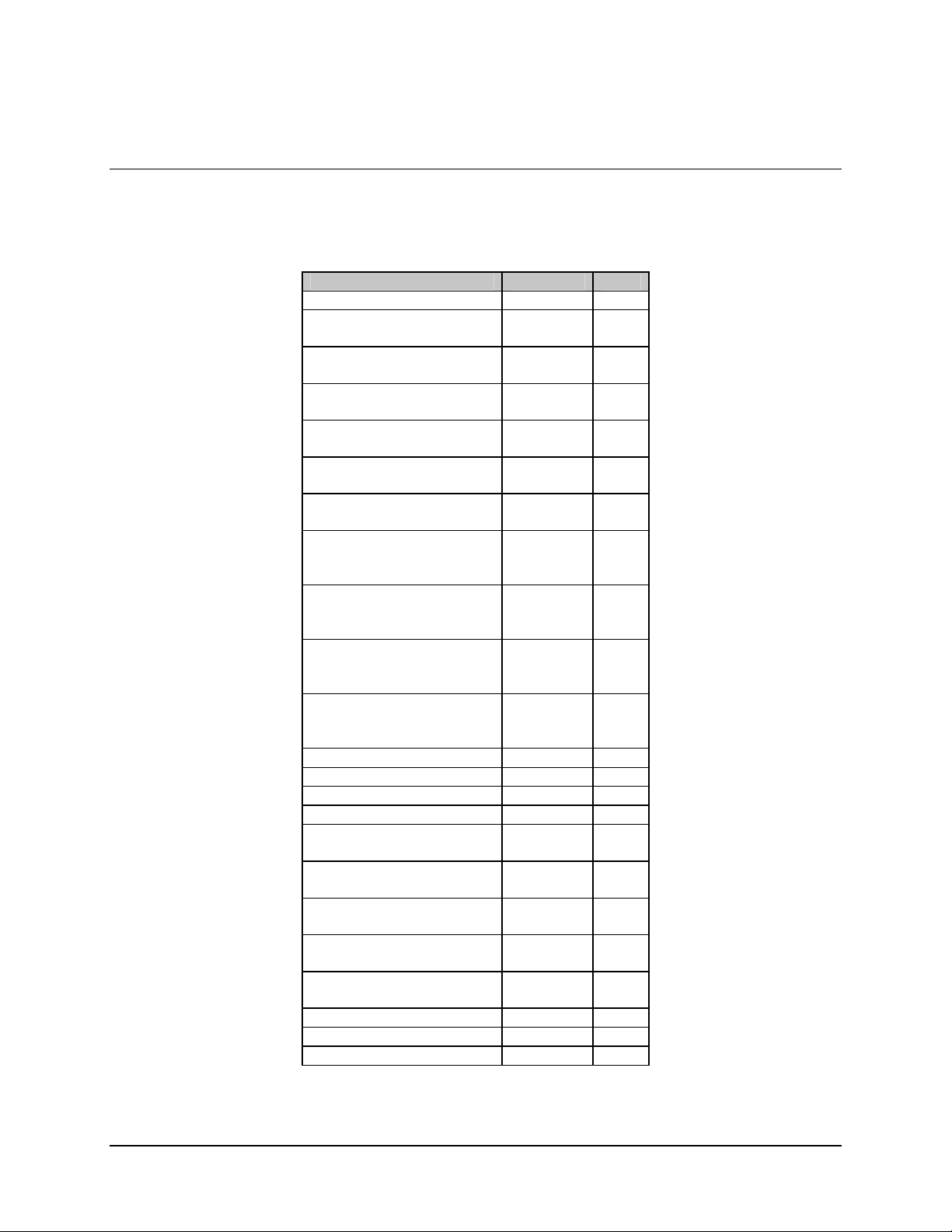

Assembly Description Part No. QTY

Chassis AS/2040-1

Controller Motherboard AS/1317

Data Switch Motherboard AS/2034

Data Switch Controller AS/2031 2 each

Monitor and Control AS/0356

Address Decoder/Driver AS/1048

IF Switch Driver AS/1316

IF Switch AS/1314

O/L Telemetry AS/0585

Display/Keypad AS/0540

Power Supply AS/1508-1 2 each

Prime Interface Switch AS/2068 up to 4

Backup Interface Switch AS/2069 1 each

1.5 System Requirements

With all interface switch modules installed, the switch is capable of operation as a 1:4

protection switch (i.e., one full-duplex standby modem can back up four full-duplex

primary modems).

The switch can be configured in any combination including:

• TX only modems

• RX only modems

• Multiple downlinks (limited to 4)

Refer to Section 3.1 for a complete explanation of the configuration function.

1–8

Page 25

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

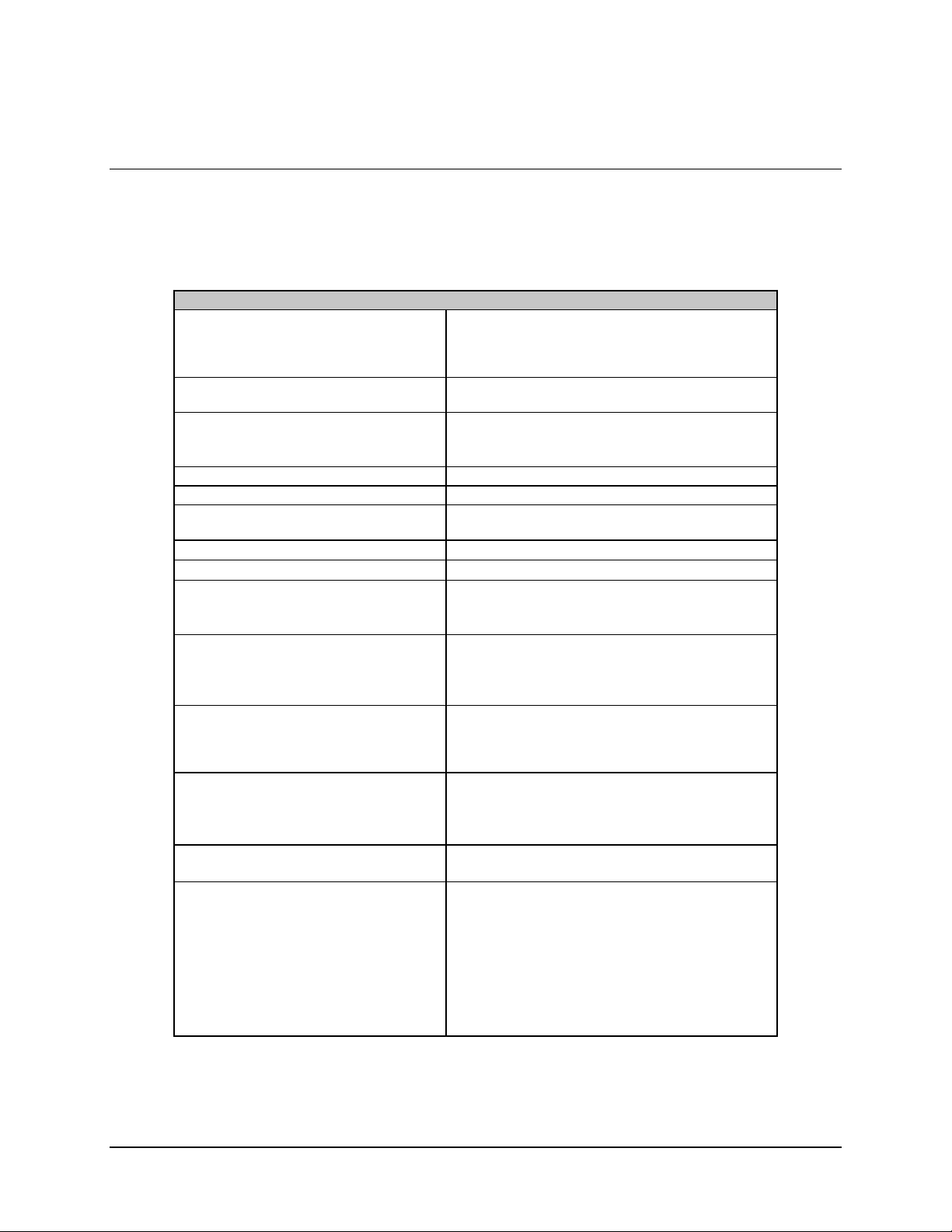

1.6 Specification

The operating specifications for the switch are described in Table 1-1.

Table 1-1. SMS-458B Specification

Operation

Number of Online Modems Expandable from 1 to 4 with plug-in prime

interface switch modules (the modems can be of

different data rates as long as the backup modems

are compatible).

Number of Backup Modems 1 backup modem with a plug-in backup interface

switch module.

Data Interfaces ASI

ECL

G.703

Return Loss > 15 dB.

IF Frequency Response 50 to 180 MHz.

Downlinks Each demodulator is configurable for 1 of 4

downlink connections.

Prime Modulator to Output Loss

Backup Modulator to Prime Output Loss

Manual Delay Switch-Over Time Modulator: 0 to 127.0 sec., in 0.5 sec. steps

Auto Delay Switch-Over Time Modulator: < 1 sec

Switch-over Priority 1 of 3 priority levels independent for each

Remote Control Interfaces External control: EIA-485 or EIA-232

Batteries M&C: NiCad, 30-day memory retention.

Alarm Reporting Controller Fault Alarm: Form-C relay contact to

≤ 1 dB

≤ 1 dB

Demodulator: 0 to 127.0 sec., in 0.5 sec. steps

Demodulator: < 3 sweep periods of the back-up

demodulator.

modulator and demodulator (modulators and

demodulators may switch simultaneously in certain

applications).

Baud rates from 110 to 9600.

Parity: Even or Odd.

Addresses from 1 to 255.

48 hr. charge time.

indicate controller or power supply failure.

System Fault Alarm: Form-C relay contact to

indicate any non-catastrophic failure.

Demodulator Fault Alarm: Form-C relay contact to

indicate all demodulators faulted and a probable IF

loss.

1–9

Page 26

SMS-458B Modem Protection Switch Revision 2

Introduction MN/SMS458B.IOM

Table 1-1. SMS-458B Specification (Continued)

Indicators Front panel LEDs:

• Power supply on

• Auto mode

• Local mode

• Remote mode

• Bypass mode

• Battery fault

• Modulator system failure

• Demodulator system failure

• Controller and power supply fault

48 character display of:

• Prime modulator status

• Prime demodulator status

• Backup demodulator status

• Backup modulator status

• Active modulators (prime and backup)

• Active demodulators (prime and backup)

• Modem address

• Modem interface

• Modem downlink

• Modem priority

• Modem delay

• Modem configuration

• Fault menus

Operation Modes Auto

Local

Remote

Bypass

Controls Complete control of all M:N functions from the

front panel or through the remote interface.

General

Input Voltage 90 to 264 VAC (-48 Vdc optional).

Line Power 160 W max. with both power supplies operating.

Line Frequency 47 to 63 Hz

Size 19 W x 22D x 12.20H inches

(48.2 6W x 55.88 D x 31H cm)

Weight 50 lbs (22.68 kg)

1–10

Page 27

Chapter 2. INSTALLATION

This chapter provides the information reflecting unpacking, external connections, and

installation.

2.1 Unpacking

The switch and manual are packaged in preformed reusable foam inside a cardboard

carton.

To remove the switch, proceed as follows:

Do not use any cutting tool that will extend more than 1 inch into the

container and cause damage to the switch.

CAUTION

CAUTION

1. Cut the tape at the top of the carton and open the flaps.

The switch weights 50 lbs. (22.68 kg). Use caution when lifting the switch

out of the carton to avoid bodily injury.

2. Lift off the preformed foam packing and remove the manual and the unit.

3. Save the packing material for reshipment either back to the factory or to another

site.

4. Inspect the equipment for damage incurred during shipment.

5. Check the equipment against the packing list shipped with the equipment to

ensure that the shipment is complete.

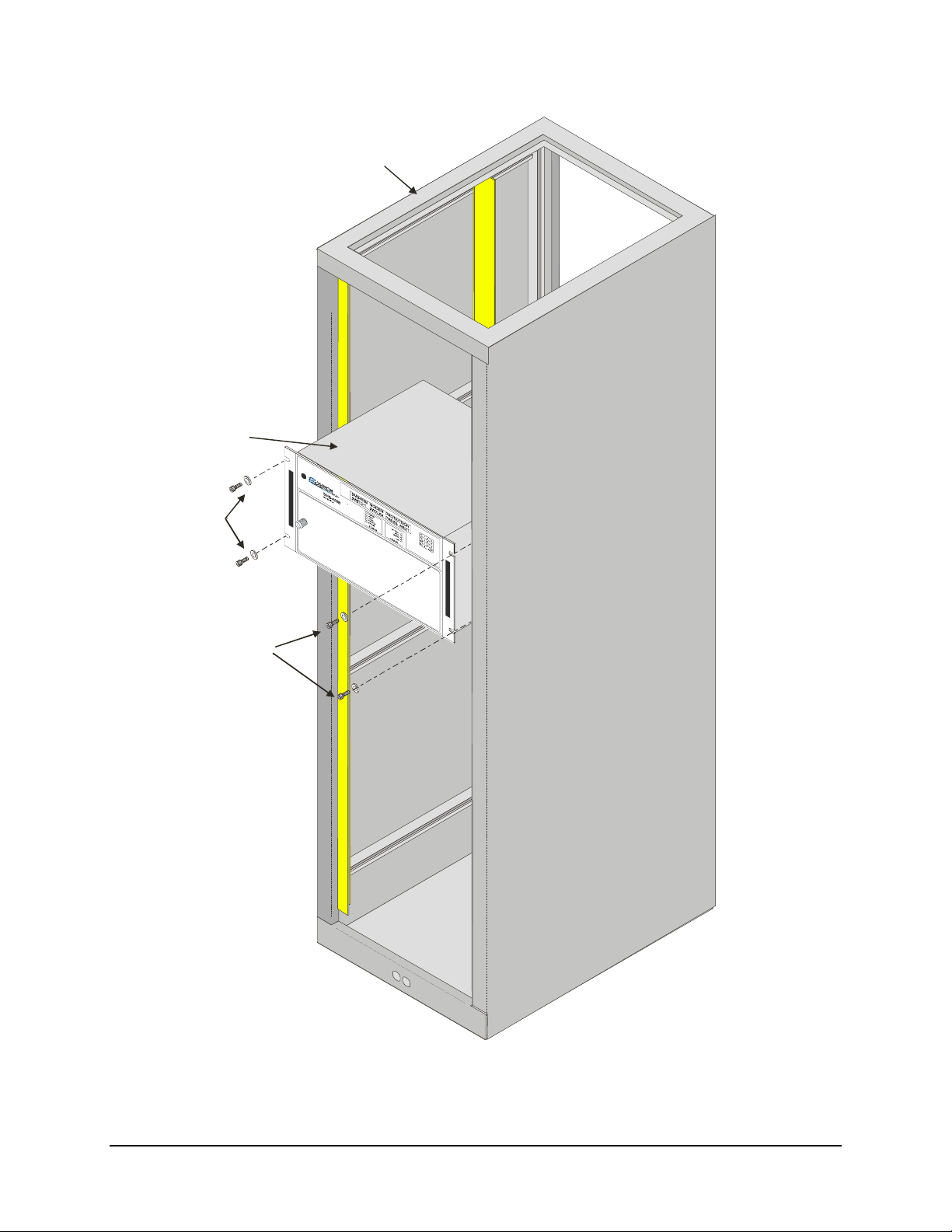

2.2 Rack Installation

2–1

Page 28

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

Install the switch in the rack (Figure 2-1) as follows:

1. Be sure that all interface switch modules are in their proper positions and are

fully seated in the rear backplane.

2. Mount the switch in the customer-selected position in the equipment rack. Secure

using eight mounting bolts and washers.

3. Turn front panel knob and open the front panel. Verify that the two power

supplies and four circuit modules are properly seated in the upper backplane.

4. Prior to turning on the power switches, read and become familiar with Chapter 3,

Front Panel Operation.

5. Turn on each power supply POWER switch located inside the front panel. The

power switch is on when the switch is depressed toward the “1” symbol or when

the red-side of the switch is exposed.

6. Close the front panel by securing the front panel knob. Configure the switch as

described in Chapter 3. Place the switch in the proper mode for operation.

7. Connect all appropriate connectors to the switch rear panel connectors as

specified in Appendix A.

8. If any problems occur during installation or operation, refer to Chapter 5 for

troubleshooting information.

2–2

Page 29

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

EQUIPMENT RACK

SMS-458 SWITCH

MOUNTING

BOLTS AND

WASHERS

MOUNTING

BOLTS AND

WASHERS

Figure 2-1. Typical Switch Rack Installation

2–3

Page 30

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

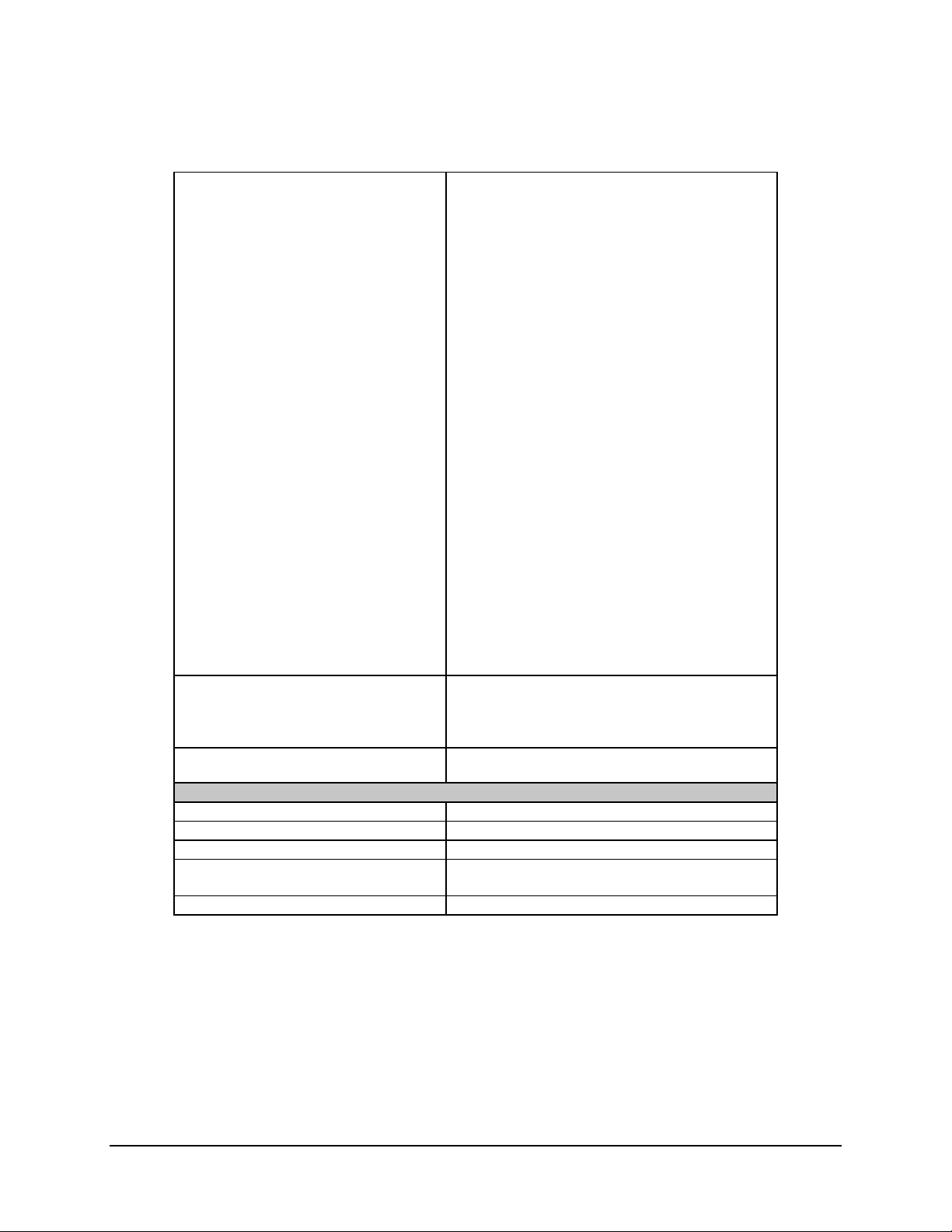

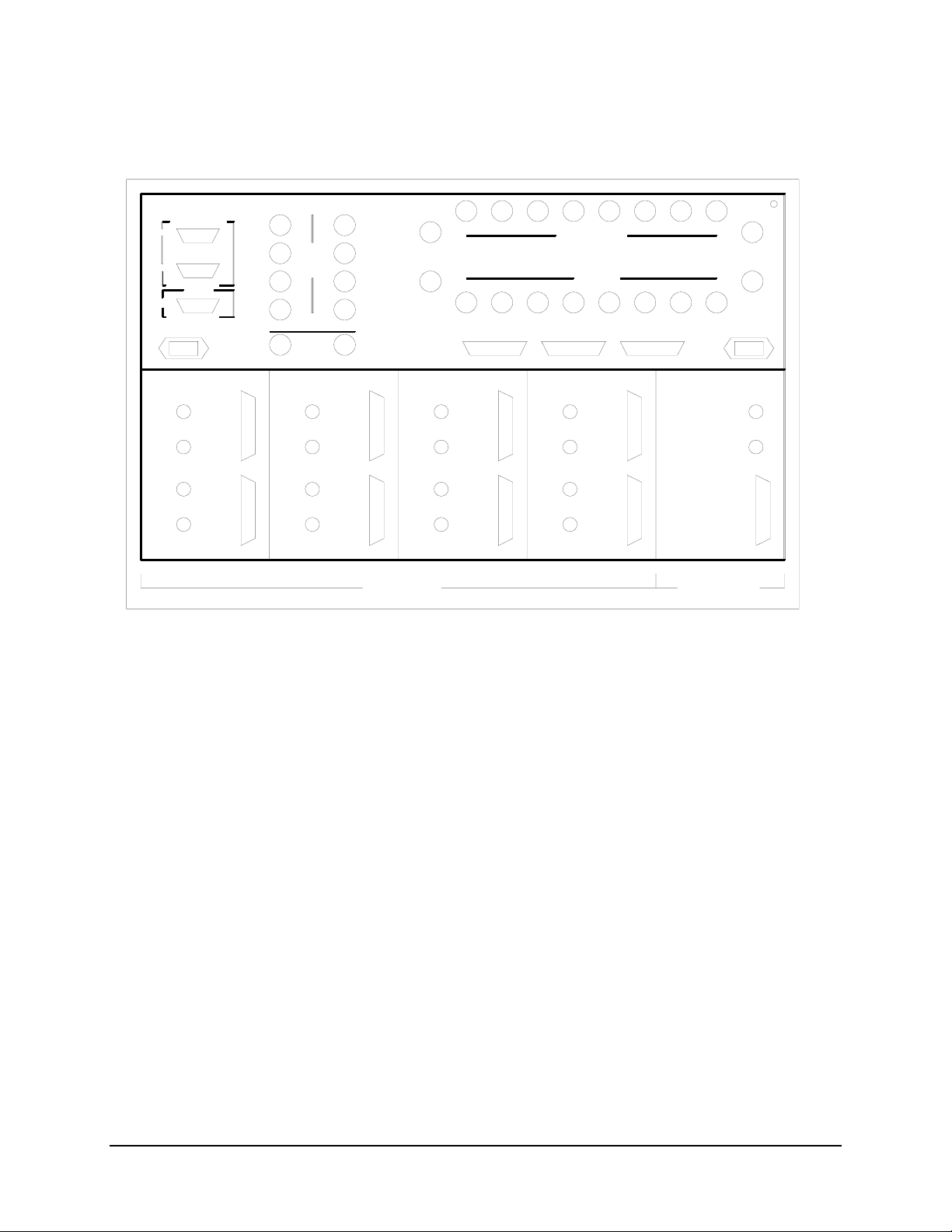

2.3 External Connections

All connections between the switch and other equipment are made through rear panel

connections. Table 2-1 lists these connectors, and Figure 2-2 shows their locations. The

uses of these connectors are described in the following sections.

Table 2-1. Rear Panel Connections

Name

DATA I/O MODULES J5, J6

REMOTE J1, J2, J3 9-pin D Remote Interface

ON-LINE STATUS J4, J5 25-pin D Online Status Reporting

RELAY/REMOTE FAULTS J6 25-pin D Relay/Remote and Faults

DOWNLINK INPUTS J7 to J10,

BACK-UP DEMODS J11, J16 BNC Downlink Outputs to Backup

PRIME MOD INPUTS J18 to J25 BNC Modulator IF Inputs

BACK-UP MOD INPUTS J26, J36 BNC Backup Mod IF Inputs

OFF-LINE IF OUTPUTS J17, J27 BNC Offline Mod IF Outputs

IF OUTPUTS J28 to J35 BNC IF Outputs to Uplinks

AC POWER J37, J38 CEE22 AC Power Input

GROUND J39 #10-32 stud Chassis Ground

Ref Desig

J1 – J4

J12 to J15

Connector

Type

50-pin D BNC

BNC

BNC Downlink IF Inputs

Function

Mod, Demod Faults

G.703, ECL/HSSI, I/O

Demods

Note: All unused BNC connectors must have a 75 Ω termination.

2–4

Page 31

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

RS485

RS232

RS485

TX

DATA

RX

DATA

J2

TX

DATA

J3

RX

DATA

J4

EXTERNAL

CONTROL

90-264 VAC

A1

J1

J2

MODEM

J3

AS/2068

J37

A2 A3

TERR

DATAJ1

J5

PRIME

MODEM

J6

J7

J8

J9

J10

J11

TX

DATA

J1

RX

DATA

J2

TX

DATA

J3

RX

DATA

J4

1 1 N/C

22

DOWN

LINK

INPUTS

33

4 4 N/C

BACK-UP

1 2 N/C

DEMODS

AS/2068

J12

N/C

J13

N/C

J14

J15

J16

DATA

J5

PRIME

MODEM

J6

A4

PRIME INTERFACE

SWITCH MODULES

1

J17

OFF-LINE

IF OUTPUTS

N/C

J27

2

A5

TX

DATATERR

J1

RX

DATA

J2

TX

DATA

J3

RX

DATA

J4

123

J28 J29 J30

MOD

ON-LINE STATUS

J4

A6

TERR

DATA

J5

PRIME

MODEM

J6

AS/2068

321

TX

DATA

J1

RX

DATA

J2

TX

DATA

J3

RX

DATA

J4

J20J19J18

Figure 2-2. SMS-458B Rear Panel View

N/C

J22J21

J23

54

PRIME MOD INPUTS

IF OUTPUTS

45

J31 J32

DEMOD

ON-LINE STATUS REMOTE/FAULT

J5

A7 A8

TERR

DATA

J5

PRIME

MODEM

J6

AS/2068

N/C

67

N/C N/C N/C

J33 J34

J6 J38

N/CN/CN/C

J25

J24

8

76

BACK-UP

MOD INPUTS

8

J35

90-264 VAC

A9 A10

TX

DATA

J1

RX

DATA

J2

BACK-UP

MODEM

J3

AS/2069

BACKUP INTERFACE

SWITCH MODULE

1

J26

N/C

J36

2

2–5

Page 32

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

2.3.1 Data I/O

Connect the Modem and Terrestrial Data I/O to the plug-in interface switch modules in

the lower-rear section of the switch. The interface switch module slots are designated A1

through A10 (left to right, viewed from the rear):

• A1 through A8 are slots for prime interface switch modules 1 through 4

(1 module for every 2 slots).

• A9 and A10 are the backup module slots (1 module for every 2 slots).

Prime interface switch modules have two sets of connectors:

• Connectors J1, J2, and J5 on the top connect to terrestrial equipment.

• J3, J4, and J6 on the bottom connect to the prime modem.

The backup interface switch module has three connectors designated J1, J2, and J3 for

backup modem connection.

Refer to Section 4.2 for electrical specifications and pinouts of the data connectors.

2–6

Page 33

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

2.3.2 Remote Interface (J1, J2, J3)

The remote interface connectors provide serial remote interface to the switch.

For external control of the switch, an external controller can connect through J1

(EIA-485) or J2 (EIA-232).

The prime and backup modems connect to the switch through J3 (EIA-485), the modem

control interface connector. This connector provides a bus-type control interface,

required for system operation.

The remote interfaces connectors are 9-pin female D connectors, with screw locks for

mechanical security. The remote connector is a DCE interface.

EIA-485 EIA-232

Pin # Name Pin # Name

1 GND 1 N/C

2 N/C 2 RD (RX)

3 N/C 3 TD (TX)

4 +RX/TX 4 N/C

5 -RX/TX 5 GND

6 N/C 6 N/C

7 N/C 7 N/C

8 +RX/TX 8 N/C

9 -RX/TX 9 N/C

2.3.3 Online Status (J4, J5)

Connectors J4 and J5 provide the output for the modulator and demodulator backup

online status in form-C format.

J4 is for the modulator online status and J5 the demodulator online status.

2–7

Page 34

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

Two 25-pin female D connectors provide the online status interfaces. Screw locks

provide mechanical security for the mating connector.

J4 J5

Pin # Name Name

1 Mod 1 COM Demod 1 COM

2 Mod 1 NC Demod 1 NC

3 Mod 1 NO Demod 1 NO

4 Mod 2 COM Demod 2 COM

5 Mod 2 NC Demod 2 NC

6 Mod 2 NO Demod 2 NO

7 Mod 3 COM Demod 3 COM

8 Mod 3 NC Demod 3 NC

9 Mod 3 NO Demod 3 NO

10 Mod 4 COM Demod 4 COM

11 Mod 4 NC Demod 4 NC

12 Mod 4 NO Demod 4 NO

13 to 24 No Connection No Connection

25 GND GROUND

2.3.4 Relay-Remote/Fault (J6)

This multi-pin connector provides both input and output signals. The inputs are contact

closures or logic level remote control inputs. The outputs are form-C relay contact

closure alarms for controller fault, M:N fault, and demodulator system fault.

The relay-remote input and fault status interface connects through a 25-pin female D

connector. Screw locks provide mechanical security for the mating connector.

Pin # Name

1 Controller Fault COM

2 Controller Fault NC

3 Controller Fault NO

4 Relay-Remote Input 0

5 Relay-Remote Input 1

6 Relay-Remote Input 2

7 Relay-Remote Input 3

8 Demodulator Fault COM

9 Demodulator Fault NC

10 Demodulator Fault NO

11 M:N Fault COM

12 M:N Fault NC

13 M:N Fault NO

14 to 24 No Connection

25 Ground

2–8

Page 35

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

2.3.5 Downlink Inputs (J7 to J10, J12 to J15)

These are the downlink-input connectors. These connections provide the inputs to the

downlink-switching matrix.

J7, J8, J9, and J10 Inputs to backup modem 1

Note: J12, J13, J14, and J15are not used with this switch.

Up to four downlinks can be connected to the switch. Downlink inputs that are not being

used must be terminated into 75 Ω.

2.3.6 Back-Up Demods (J11, J16)

J11 and J16 Outputs from the downlink switching matrix

J11 Backup demod 1 output. It connects to the backup modem RX IF input.

Note: J16 is not used in this switch

Any of the 4 downlinks can be directed to J11. The default setting is downlink 1. The

input frequency range is 50 to 180 MHz, with input impedance of 75Ω. Terminate any

back-up demod port into 75Ω when not being used.

2.3.7 Prime Mod Inputs (J18 to J25)

J18 through J25 Prime modulator IF input connections to the modulator IF switching matrix.

They connect to the prime modem IF outputs.

Note: J22 through J25 are not used with this switch.

The input frequency range is 50 to 180 MHz, with input impedance of 75 Ω.

Prime mod inputs that are not being used must be terminated into 75 Ω.

2.3.8 Back-Up Mod Inputs (J26, J36)

J26 and

J36

The input frequency range is 50 to 180 MHz, with input impedance of 75 Ω.

Back-up modulator IF input connectors. They connect to the back-up modem IF

outputs.

Note: J36 is not used in this switch.

2–9

Page 36

SMS-458B Modem Protection Switch Revision 2

Installation MN/SMS458B.IOM

2.3.9 Offline IF Outputs (J17, J27)

J17 and J27 Offline IF output connectors, used as monitor and test points.

Note: J27 is not used in this switch.

The outputs of the backup modulators are routed here when not in use.

When backups are online, the offline primes are routed here.

2.3.10 IF Outputs (J28 through J35)

J28 through J35 Modulator IF switching matrix output connections. They connect to the

external uplink power combiners.

Note: J32 through J35 are not used in this switch.

Notes: Observe the following parameters:

1. During normal operation, the prime modulator IF outputs are switched at this

location.

2. During a fault condition, the backup modulators IF output will be switched at this

location.

3. The frequency range is 50 to 180 MHz, with output impedance of 75Ω.

4. The typical output power level is equal to the modem TX output level, which is

from -5 dBm to -20 dBm.

5. Any IF outputs that are not being used must be terminated into 75Ω.

2.3.11 AC Power (J37 and J38)

Applying incorrect input voltage to these connectors can cause severe

damage to the switch and will void the product warranty. Verify that

CAUTION

the source voltage is correct before connecting the switch.

J37 and J38 Two independent, nonlocking, 3-prong power cords connect AC power to the two

power supplies.

Normal input voltage is 90 to 264 VAC, at 47 to 63 Hz (-48 ± 4.8 Vdc are optional).

Maximum power consumption is 80 W for each power supply.

2.3.12 Ground

A #10-32 stud is available on the rear panel for connecting the chassis to ground.

2–10

Page 37

Chapter 3. FRONT PANEL

This chapter describes the front panel operation of the switch.

3.1 Overview

The switch front panel (Figure 3-1) provides the local interface to configure, operate, and

monitor the switch. Proper operation of the switch depends on its proper configuration

and setup. The following sections describe the front panel and its operation in detail.

A 48-character, 2-line LCD display in the upper-front panel displays options, and status

for the user.

The nine LEDs grouped under the LCD display provide mode and fault status at a glance,

and a 16-key keypad to the right allows the user to perform setup, configuration, and

operation functions.

OPERATION

3–1

Page 38

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

Figure 3-1. SMS-458B Front Panel View

All switch functions are accessible to the user from the front panel through the function

keys, [F1] or [F2], the [PREV] key, and the [NEXT] key.

3.2 LED Indicators

Nine LEDs on the front panel indicate the general switch status and summary fault

information, as follows:

Faults

M:N (Red LED) Lights if M:N fault condition occurs.

MOD (Red LED) Lights if a modulator operation fault occurs.

DEMOD (Red LED) Lights if demodulator operation fault occurs.

BATTERY (Red LED) Lights if one of the battery voltages is low.

STATUS

POWER ON (Green LED) Lights when power is applied to the switch.

AUTO (Green LED) Lights when the switch is in the automatic operating mode.

LOCAL (Green LED) Lights when the switch is in the local operating mode.

REMOTE (Green LED) Lights when the switch is in the remote operating mode.

BYPASS (Green LED) Lights when the switch is in the bypass-operating mode.

3–2

Page 39

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

3.3 Keypad and LCD Display

The keypad and LCD display provide an interface for the local user to access the menus

that configure and operate the switch. The keypad includes:

• Numbers 0 through 9

• Decimal

• [ENT]

• [F1] and [F2]

• [NEXT]

• [PREV]

The last four keys specified control the hierarchical menu structure. Menus provide for

local setup, configuration, and operation. Each menu contains a portion of the switch

control or setup algorithm. Only a limited knowledge of the switch is required, as the

menus are self-prompting and all options are displayed.

The base levels of this tree-structured front panel menu are as follows:

• ID menu displayed at power-on

• SYSTEM and MODEM SETUP menu

• MODEM CONFIGURATION menu

• FAULT menu

• MODE menu

• STATUS display

3–3

Page 40

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

The ID menu displays the version of firmware implemented in the switch.

The [NEXT], [PREV], [F1], [F2], and [ENT] keys control the menus and allow menu

selections.

Some display messages have menu options on the right side aligned with the [F1] and

[F2] keys. Pressing either of these keys directs the display to the selected menu.

The user can also move forward or backward through the selected menu by pressing the

[NEXT] or [PREV] keys.

The switch beeps in response to keypad inputs:

• One beep acknowledges a valid entry with the appropriate action being taken.

• Two beeps indicate that the entry was invalid and no action was taken.

Once the correct menu is selected, the user can press the [ENT] key to enter, change, or

view the functions within that menu.

The STATUS display follows the MODE menu. It includes the following:

• Identifies the active modulator and demodulator, both prime and backup.

• Shows backup online status.

• Shows the fault status of both prime and backup modulators and demodulators.

The STATUS menu displays only the active modulators and demodulators. If any

modulator or demodulator is faulted, an “F” alternates with the modem number on the

display. The display shows online backup modulators and demodulators, with an arrow

pointing to the number of the prime being backed-up.

“Hot Standby” mode is identified by a dash between the backup modulator/demodulator

and the prime modulator/demodulator.

An asterisk is displayed while the backup modulator/demodulator is in process of backing

up a prime modulator/demodulator.

In all modes except BYPASS, the switch returns to the STATUS display returns after

approximately three minutes.

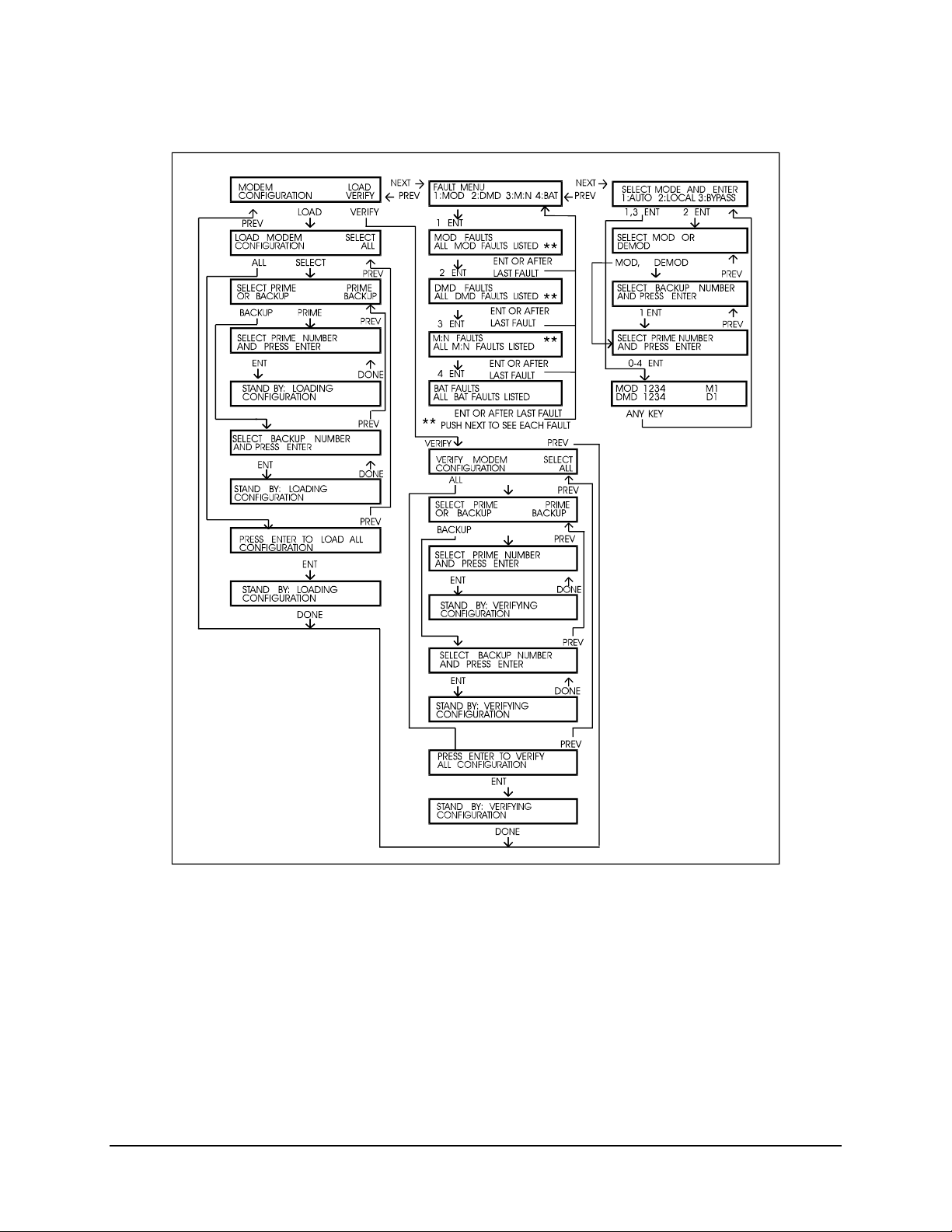

Refer to Figure 3-2 for a detailed description of the front panel menu. This figure

describes the independent mod/demod switch with support for use with an external

buffer/channel unit.

3–4

Page 41

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

Figure 3-2. Display Map

3–5

Page 42

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

Figure 3-2. Display Map (Continued)

3–6

Page 43

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

3.4 System and Modem Setup

3.4.1 Prime Uplink and Downlink Ports

J28 through J35 Eight IF outputs available to connect to customer-supplied uplink power

combiners.

Note: Only J28 through J31 are used for this switch.

J7, J8, J9, J10 J7 through J10 are used when four downlink transponders are specified in the

system.

The following steps describe the uplink and downlink connections:

1. Connect the IF output cables 1 to 4 to the appropriate customer-furnished uplink

signal combiner inputs.

2. Connect the Downlink input cables 1 to 4 to the appropriate customer-furnished

downlink splitters.

Note: Be sure to terminate all unused IF outputs and downlink inputs with one of the

supplied 75Ω BNC terminations.

3.4.2 System Setup

Enter the SYSTEM SETUP menu to enter, change, or view the system setup

configuration. The definitions of the system setup functions are as follows:

Function Description

TIME AND DATE Time and date are entered and displayed.

DOWNLINK OPTIONS Prime and backup downlinks are selected and

displayed.

PRIME MODS Active prime modulators are selected and displayed.

PRIME DEMODS Active prime demodulators are selected and displayed.

BACKUP MODS Active backup modulators are selected and displayed.

BACKUP DEMODS Active backup demodulators are selected and

displayed.

MODEM ADDRESSES Prime and backup modem addresses are selected and

displayed.

*PRIME C/U Active prime channel unit addresses are selected and

displayed.

*BACKUP C/U Active backup channel unit addresses are selected and

displayed.

* Note: These functions are applicable only for Version 2.02.

3–7

Page 44

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

In the SYSTEM SETUP menu, view system configuration parameters by using the

[NEXT] and [PREV] keys. The user also can enter data or change a parameter through

keypad entries.

• When all data or changes for that parameter are entered correctly,

press [ENT] to load the information into memory.

• If an incorrect entry is made, press [PREV] to return to that menu and re-enter

the data.

3.4.2.1 Time and Date Menu

This menu displays the current time and date. Enter and reset time and/or date as follows:

Time Press: F1

Type: HH MM (Use this format)

Press: ENT (Seconds reset to “0” and the new time loads into the clock

device)

Date Press: F2

Type: MM DD YY (Use this format)

Press: ENT (Loads the new date into the clock device)

3.4.2.2 Active Downlink Option Menu

Note: This switch uses only the 4-downlink/2 backup option. There are only four prime

modems and backup 2 is ignored.

This menu displays the current downlink and backup options that are active in the

system.

1. Press one of the [1] through [9] keys toggles the active status between:

• 4 downlinks — 2 backups

• 7 downlinks — 1 backup

2. Press [ENT] to load information into memory.

3.4.2.3 Active Prime Modulators Menu

3–8

Page 45

SMS-458B Modem Protection Switch Revision 2

Operation MN/SMS458B.IOM

This menu displays the current prime modulators that are active in the system.

1. Press one of the [1] through [4] keys toggles the active status (ON/OFF)

of the corresponding modulator only.

2. Press [ENT] to load information into memory.

3.4.2.4 Active Prime Demodulators Menu

This menu displays the current prime demodulators that are active in the system.

1. Press one of the [1] through [4] keys toggles the active status of the

corresponding demodulator only.

2. Press [ENT] to load information into memory.

3.4.2.5 Active Backup Modulators Menu

This menu displays the current backup modulators that are active in the system.

1. Press the [1] key to toggle the active status of the backup modulator only.

2. Press [ENT] to load information into memory.

3.4.2.6 Active Backup Demodulators Menu

Note: The switch does not support the use of a second backup modem. When selecting

the active backup for mod, demod, and downlink, the active backup can only be number

1. Selecting backup number 2 to be active will have no effect on the system, except

causing backup faults to occur.

This menu displays the current backup demodulators that are active in the system.

1. Press the [1] key to toggle the active status of the backup demodulator only.

2. Press [ENT] to load information into memory.

3.4.2.7 Modem Addresses Menu

This menu displays the current addresses of the prime and backup modems.

Addresses of 1 through 255 are valid.

1. Enter a new address and press [ENT] to load the address into memory.

2. If no address is entered for an active modem, an M:N fault results.

3–9

Page 46