Comstock Castle F-3 Service Manual

INSTALLATION • OPERATION MANUAL for

COMSTOCK-CASTLE FOOD SERVICE EQUIPMENT

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service, operation or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing, operating or servicing this equipment.

NOTICE

Instructions must be posted in a prominent location that will provide the user

of this equipment with procedures, in the event he/she smells and/or detects

gas. This information must be obtained by consulting the local gas utility.

READ CAREFULLY AND KEEP FOR FUTURE REFERENCE!

NOTE: The equipment for which this Installation • Operation Manual is provided may be certified,

have certification pending or not be certified under the standards of one or more of the following

organizations: Intertek Testing Services (ETL). Please ref er to the chart on page 3 for the status

of each specific unit.

CONTENTS: PAGE NO:

Definitions and Shipping Damage ...................................................3

General Information......................................................................3-4

Installation ....................................................................................4-5

Gas Connection & Conversion Procedure....................................5-6

Lighting Instructions. ....................................................................6-7

Calibration and Adjustments ........................................................7-8

Thermostat Calibration.................................................................8-9

Manual Pilot and Thermocouple.................................................9-10

Preparation.....................................................................................10

Griddle Plate/Broiler Option .....................................................10-11

Lava or Radiant Broiler Option.......................................................11

Maintenance and Service Instructions. ..........................................11

Drawings...................................................................................12-18

Troubleshooting Chart....................................................................19

Comstock-Castle Warranty............................................................20

Comstock-Castle Stove Co. suggests that the user

read this Installation/Operation Manual in its

entirety before installing this equipment.

COMSTOCK-CASTLE STOVE COMPANY

119 WEST WASHINGTON

QUINCY IL 62301

217-223-5070 (Voice)

217-223-0007 (Fax)

www.castlestove.com

2

IN THE EVENT YOU SMELL GAS: Open Windows, Do Not

Touch Electrical Switches, Extinguish All Open Flame, and

IMMEDIATELY CALL Your Gas Utility.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED

OPERATING PERSONNEL

Qualified or authorized operating personnel are those

who have carefully read this manual and are familiar with

the functions of the equipment. Those who have had

previous experience with the functions and operations of

similar equipment should also read this manual to

acquaint themselves with the unique characteristics of

this equipment.

QUALIFIED INSTALLATION OR

SERVICE PERSONNEL

Qualified Installation and/or Service Personnel are

defined as those who, either in person or through a

representative, are engaged in and are responsible for:

The installation or replacement of gas piping from the

outlet side of the meter, (or the service regulator when a

meter is not provided), and the connection, installation,

repair, or servicing of the equipment. Qualified personnel

must be experienced in such work, be familiar with all

precautions required, and be able to comply with all

requirements of state or local authorities having

jurisdiction. Reference:

National Fuel Gas Code ANSI Z223.1-latest edition

(NFPA Code 54).

SHIPPING DAMAGE CLAIM

PROCEDURE

UNPACKING:

Inspect the crating for possible damage. Carefully

remove the gas appliance from the crate, and inspect the

unit for concealed damage. (Perform applicable steps.)

1. Remove top grates, and the range griddle plate if

applicable.

2. Open Oven door, remove rack(s), and Oven bottom.

3. All packing material and burner tie down wire, if applicable, must be removed.

4. If stainless steel, remove the protective covering.

5. Properly install the legs or casters on the range.

NOTE: For proper operation and combustion, the legs or

casters MUST be installed. STDHP counter units do not

have legs.

6. Locate the Oven door handle and associated screws.

Before mounting handle clear the insulation around

the mounting holes on the Oven door. Using the two

screws, mount handle to Oven door.

Upon receipt and during installation of your new

Comstock-Castle equipment, inspect it thoroughly for

damage that may have been incurred during shipment. If

damage is evident, contact the carrier immediately.

FOR YOUR PROTECTION, IF SHIPMENT

ARRIVES DAMAGED:

NOTE: FILE CLAIM FOR DAMAGES IMMEDIATELY,

regardless of the extent of the damage. Time limits are

in effect.

VISIBLE LOSS OR DAMAGE – Be certain this is noted

on the freight bill or express receipt, and signed by

the person making the delivery.

9 2. CONCEALED LOSS OR DAMAGE – If damage

is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and

file a “concealed damage” claim with them. This

should be done within 15 days of the date delivery is

made to you. Be sure to retain container for

inspection.

Comstock-Castle cannot assume responsibility for damage or loss incurred in transit. Comstock-Castle will,

however, be glad to assist you and furnish you with any

necessary documentation to support your claim.

GENERAL INFORMATION

TO AVOID POSSIBLE INJURY, FIRE, and/or

EXPLOSION, the following precautions must be read,

understood, and followed explicitly.

CERTIFICATION STATUS • MINIMUM CLEARANCE

Combustible Non-combustible

Model Back Side Back Side

OVENS &

RANGES

F3 Series 2” 2” 0” 0”

(ETL)

FK4 Series 6” 6” 0” 0”

(ETL)

P Series 6” 6” 0” 0”

(ET L)

B Series 6” 6” 0” 0”

(ETL)

HOT PLATES

FHP Series 5” 4” 0” 0”

(ETL)

STFHP Series 6” 6” 2” 2”

(ETL)

HPK4 Series 6” 6” 2” 2”

(ETL)

CSP Series 6” 6” 4” 0”

(ETL)

SP Series 6” 6” 4” 0”

(ETL)

GRIDDLES

FHP Series 5” 4” 0” 0”

(ETL)

10 Series 6” 6” 0” 0”

(ETL)

9 Series 6” 6” 0” 0”

(ETL)

3

BROILERS

Do not obstruct the flow of combustion gases or ventilation

FHP Series 5" 4" 0" 0"

(ETL)

9 Series 6" 6" 0" 0"

(ETL)

FRYERS

2932SF 6" 6" 6" 2"

(ETL)

J01HG 6" 6" 6" 2"

(ETL)

2616HG 6" 6" 6" 2"

(ETL)

H Series 6" 6" 6" 2"

(ETL)

All F3 and FCK4 Series Ranges of this series are suitable

for installation on combustible floors. Counter equipment is

for use on non-combustible counters.

NOTE: The Model No. HPK4 Series Hot Plates are not

AGA Certified Designs.

All FHP Series, STFHP Series and HPK4 Series Hot

Plates are for use in combustible and non-combustible

locations when installed on a non-combustible counter.

The BTU input rating on all equipment is calibrated for elevations up to 2,000 feet above sea level. All orifice drill

sizes are referenced for operation at or below this altitude.

For operation at elevations above 2,000 feet, the BTU rating must be reduced 4% for each 1,000 feet of elevation or

the orifice drill size must be changed appropriately. For

high altitude drill sizes, call your local gas company, or

Factory Authorized Service Center.

All units are equipped with fixed orifices and cannot be

adjusted. If converting the gas appliance from natural to

propane, or vice versa, all orifices and the regulator must

be changed. The correct type of gas, for which the unit is

configured, is noted on the name plate. The type of gas

specified MUST be used. For proper conversion, contact a

qualified service technician or your Factory Authorized

Service Center.

When installed with casters, adequate means of restraint

must be provided to limit the movement of the appliance

without depending on the connector and the quick disconnect device or its associated piping to limit the units

movement. The restraint should be securely fastened to

the back of the unit. If disconnection of the restraint is nec essary, the restraint must be reconnected after the appliance has been returned to its original installation position.

For a gas appliance that is equipped with casters, the

installation shall be made with a connector that complies

with the Standard for Connectors for Movable Gas

Appliances, ANSI Z21.69 - 1987, and addenda Z21.69a 1989, and a Quick Disconnect Device that complies with

the Standards for Quick Disconnect Devices for Use With

Gas Fuel, Z21.69 - latest edition, and Z21.41- latest

edition.

Provisions shall be made in the design of the kitchen, to

ensure an adequate fresh air supply for proper ventilation

and combustion.

air.

Never enclose the bottom of the unit with a raised curb

and/or any other construction that would obstruct the air

flow into the unit.

One of the most important considerations in the installation

of this unit is ventilation. A commercial gas appliance must

be installed so that the products of combustion are efficiently removed. However, the kitchen ventilation system

must not produce a draft that would interfere with the proper operation of the burners.

The area around this and any other appliance mus t always

be kept free and clear of combustibles such as: grease,

food particles, fuel, solvents, cleaning fluids, gasoline,

mops, rags, etc.

During installation, use thread compound sparingly.

Always use a compound that is impervious to chemical

reaction with propane gases. NEVER put any of the

compound on the first two outer threads. This will minimize

the possibility of the compound breaking free and clogging

the pilots, burner orifices, and controls.

When a commercial gas appliance is first installed, the gas

pressure must be checked with a manometer by a

qualified service technician. This will ensure that the

existing gas facilities will deliver the BTU's of gas required

on the rating plate. WARNING - If the appliance is

configured for LP Gas, never connect the equipment

directly to the pressure tank. Damage will result to the

appliance if the tank pressure is not properly regulated.

The regulator supplied with your unit is a low pressure (1/ 2

PSI max.) appliance regulator. For proper pressure

regulation specifications, consult your local Factory

Authorized Service Agency or an LP Gas Distributor.

INSTALLATION

THIS APPLIANCE IS INTENDED FOR OTHER THAN

HOUSEHOLD USE

All Comstock-Castle commercial gas appliances are

manufactured by skilled craftsman using the finest quality

materials. PROPER installation by qualified personnel is

essential for safe, efficient, and trouble-free operation of

the unit. Any alteration and/or tampering, without proper

knowledge, tools, and test equipment, is DANGEROUS

and will void all warranties.

The installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1-latest edition.

PRESSURE TESTING:

FAILURE TO INSTALL PRESSURE REGULATOR WILL

VOID WARRANTY. (Most units have a convertible

regulator.)

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in excess

of 1/2 psig (3.45 kPa).

4

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.45 kPa).

NOTICE

The proper installation of this gas appliance is the

total responsibility of the end user.

It is the responsibility of the purchaser to determine that

the installer is qualified in installation procedures.

Conversion, connecting gas lines, calibrating thermostats,

burners, lighters, setting gas pressure with manometer,

etc., is all part of normal installation and will not be paid for

under warranty. If a warranty technician is called out and

finds the unit improperly installed, the end user may be

subject to billing.

FOR MAINTENANCE, SERVICE, REPAIRS, OR INSTALLATION - Contact your dealer or the factory, for your local

Factory Authorized Service Agency.

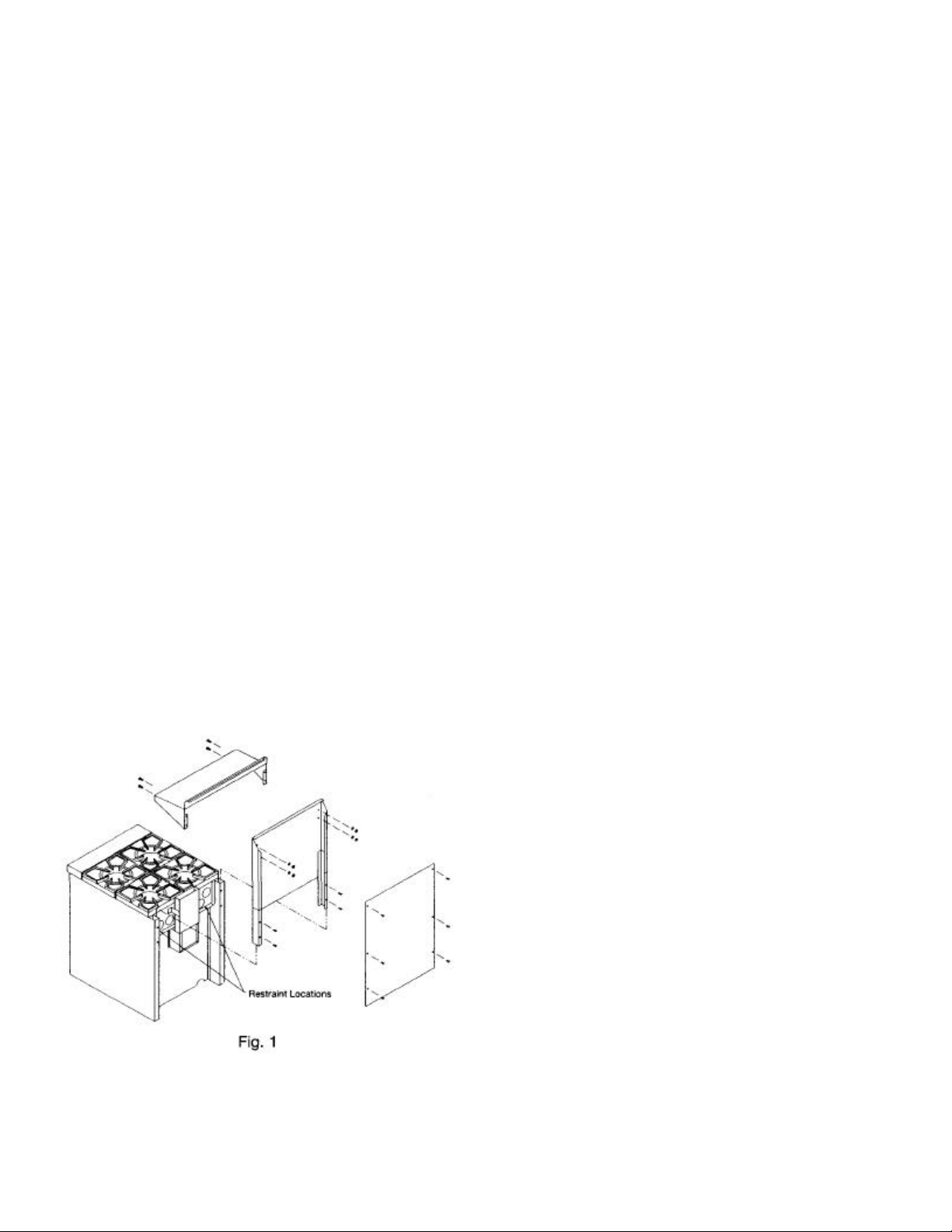

INSTALLING THE BACKSPLASH OR HIGH SHELF:

To install a backsplash or high shelf on a Castle Range,

proceed as follows:

1. Ensure back of unit is easily accessible.

2. If mounting low back (backsplash), slide into supports

on back of unit, and secure with #10 x 5/8 sheet metal

screws.

3. If mounting high shelf, mount shelf to high back using

#24 x 3/4" machine screws with nut and washer.

4. Slide backsplash into the side supports on back of unit,

and secure with #10 x 5/8" sheet metal screws. (Fig. 1)

GRIDDLE PLATE INSTALLATION:

Griddle Plate front trim must be placed under the plate rest

to prevent plate from moving. Rear of plate must be lifted

to allow front edge under the plate rest. If unit is equipped

with thermostat, sensing bulbs need to be installed under

the plate prior to placing front trim under plate rest.

GAS CONNECTION &

CON VERSION PROCEDURE

GAS CONNECTION:

The size of the gas line is extremely important. If the

line is too small, the gas flow in the manifold will be

low. This inadequate flow will cause slow recovery and

delayed ignition. If in doubt about the proper size of your

service line, consult your local gas utility company.

DO NOT connect appliance before testing the pressure of

the gas service supply piping system.

FOR NATURAL GAS - Fixed orifices are set at 4" W.C.

(water column). If a pressure regulator is supplied, it must

be installed when the unit is connected to the gas supply.

FOR PROPANE GAS - Fixed orifices are set at 10" W.C.

(water column). If a pressure regulator is supplied, it must

be installed when the unit is connected to the gas supply.

Pressure regulator must be tested in a full flow condition

(all valves "ON"). A condensation/particulate trap must be

provided in the supply line, with a separate shut-off valve

upstream of the regulator. These items are customer

installation responsibilities.

Your Comstock-Castle appliance is equipped with a 3/4"

NPT entrance pipe. Level the appliance under station

exhaust hood, and connect the gas line from the service

gas shut-off valve to the inlet side of the gas pressure

regulator using 3/4" pipe. DO NOT use a domestic type

gas flexible connector. If a flexible or semi-flexible

connector is used, an AGA Certified Flexible Connector

with an I.D. equal to 3/4" must be used. Always avoid

sharp bends that could restrict the gas flow to the

appliance. All piping must be installed in accordance with

local codes, or in the absence of local codes, with the

National Fuel Gas Codes: ANSI Z223.1-latest edition NFPA No. 54.

IMMEDIATELY CHECK the plumbing with a concentrated

soap solution or an approved gas detector. Coat all joints

associated with the gas distribution system. Bubbles

indicate leaks, and the appliance MUST NOT be operated

until the leak is corrected. NEVER use an open flame to

test for leaks. Be sure to check all gas connections with

the main burner "ON" and "OFF". Check and, if necessary,

adjust the manifold pressure.

HOOK-UP PROCEDURE FOR COMBINATION UNITS:

Units prefixed with a 2 may be shipped separately. For

connection, set the units side by side. Install backsplash.

Install hook-up strip in the front center of the two units.

Ensure that everything is aligned properly. Install and

tighten all screws.

GAS CONVERSION:

A qualified service technician must be used to safely

convert the appliance from natural gas to propane

gas, or vice versa. The regulator, burner orifices, pilot

orifice, and possibly the pilot lighter bar orifice, if

applicable, must be converted. The appliance must be

retested for proper alignment, calibration and gas

pressure.

Caution: Never attempt conversion when the unit is

hot!

For All Manually and Thermostatically Controlled

Equipment:

If a regulator has been shipped with the unit, it MUST be

installed properly. If not factory installed, connect

regulator with arrow pointing in the direction of gas flow.

Use thread compound sparingly. NOTE: DO NOT APPLY

thread compound to the female threads of any part.

Some larger models may have two gas inputs for the

manifold system. If this is the case, all gas inputs to the

unit MUST have a factory approved regulator.

IMPORTANT NOTICE FOR UNITS WITH

CONVERTABLE PRESSURE REGULATORS

PROPANE GAS CONVERSION INSTRUCTIONS

A griddle is equipped with fixed orifice hoods and shipped

from the factory for use on natural gas. To convert to

propane gas, install the propane burner orifice hoods

supplied as follows:

1. Remove the griddle plate by lifting with 2 people and

set it aside.

2. Slide the burners back off of the valve orifice hoods a

couple of inches and let it rest.

3. Remove the natural gas orifice hoods with a 1/2"

wrench.

4. Apply a very little bit of pipe dope on the treads of the

valve. DO NOT APPLY PIPE DOPE INTO ORIFICE

HOOD.

5. Attach the supplied propane burner orifice hoods with

a 1/2" wrench.

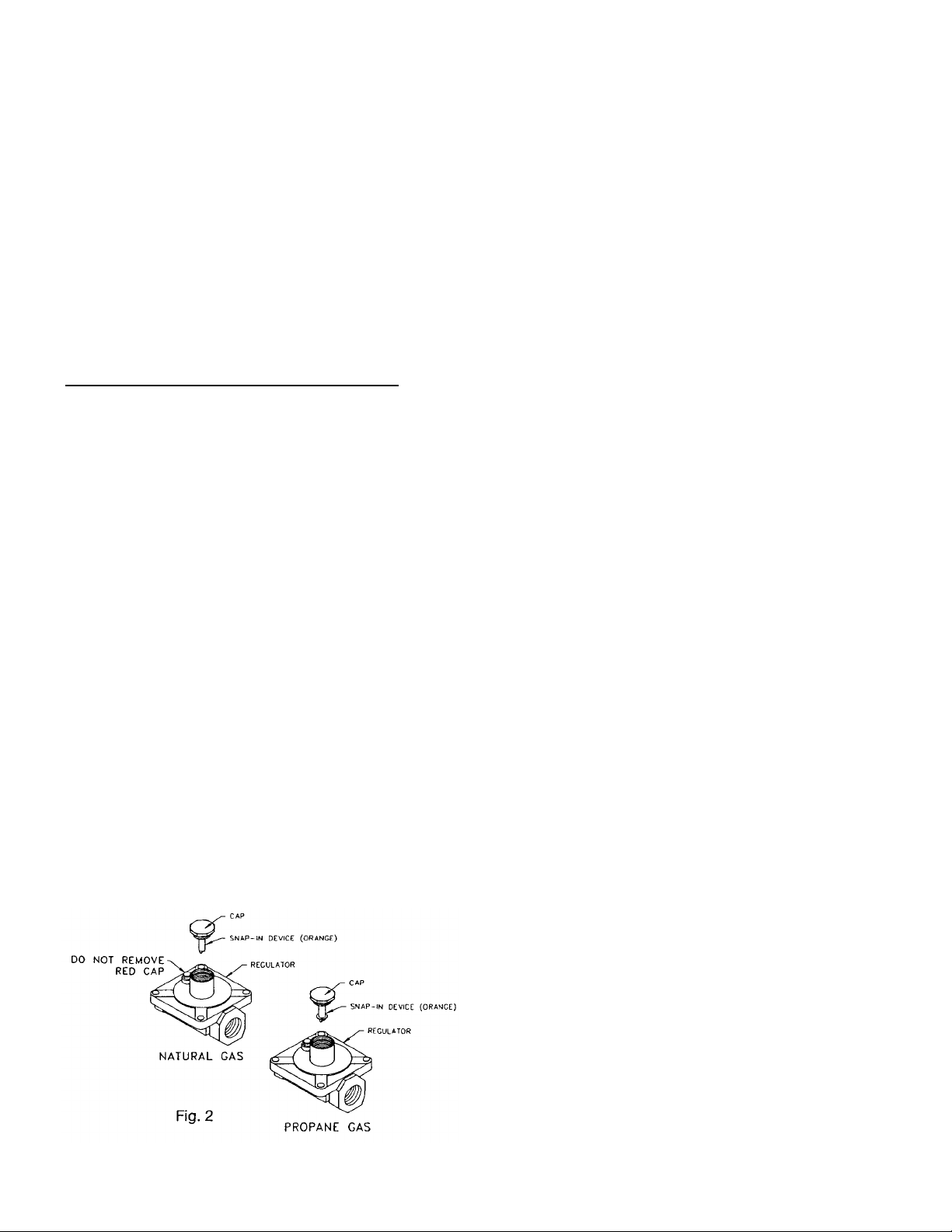

6. Convert the pressure regulator from Natural to

Propane gas by inverting the snap-in device beneath

the cap on the regulator. This will require a fair

amount of pressure. Do not remove the spring. When

replacing the cap make sure the snap-in insert goes

down on top of the middle of the spring.

7. Test for proper pressure; 10" W.C. (Water Column)

using a Manometer.

8. Slide burners back onto orifice hoods.

9. Apply the Propane "Notice" sticker to the front of the

unit for future reference.

LIGHTING INSTRUCTIONS

NOTE: While lighting a manual pilot system, sufficient

time must be allowed for the proper pilot flame to heat

the thermocouple that will hold the safety valve open. If

lighting for the first time, allow some time for air to be

purged from the gas distribution system.

TO LIGHT THE CHINA HAT PILOTS: (OPEN TOP

BURNERS)

1. The main gas valve should be "OFF" for at least five

minutes to allow any accumulated gas to escape the

combustion chamber.

2. Remove spider rings, open top grates, and locate the

Pilots.

3. Turn supply gas "ON", and hold match close to the

pilot head. The pilot should light.

4. Turn the manual gas control to the "ON" position. The

main burners should light.

TO TURN THE CHINA HAT PILOTS OFF:

1. Turn the supply gas control to the "OFF" position and

ensure all burners are off.

NOTE: Pilots cannot be shut off unless the main gas

supply to the appliance is shut off.

TO LIGHT THE OVEN PILOT:

Remove the lower kick panel below the oven door. Open

oven door and remove the oven rack. Remove oven

bottom.

1. The Robertshaw Grayson TS11J safety valve should

be closed for at least five minutes to allow any

accumulated gas to escape the combustion chamber.

2. Turn the thermostat to the lowest possible setting.

3. Depress and hold down the red button while lighting

the pilot. Hold the button down for about 45 seconds.

4. Release the reset button. The pilot should stay lit.

5. Set the thermostat to the desired temperature. The

main burners should light.

TO TURN OFF THE OVEN PILOT: (See Fig. 3)

1. Turn the thermostat to the lowest possible setting.

2. Blow out pilot. The safety valve will automatically shut

off the gas supply system.

TO LIGHT THE GRIDDLE:

(Thermostatically Controlled Griddles)(0ptional)

For units that are equipped with a thermostatically controlled Griddle, proceed as follows:

1. The Robertshaw Grayson TS11J safety valve should

be closed for at least five minutes to allow any

accumulated gas to escape the combustion chamber.

2. Turn the thermostat to the lowest possible setting.

6

Loading...

Loading...