Page 1

Qualifier X-Ray

Non-Intrusive

Dwelling Ingress Integrity

Measurement System

USER GUIDE

CSI Doc. 101399-001

Page 2

Qualifier X-Ray

Limited Warranty

Hardware: ComSonics, Inc. (ComSonics) warrants to the original end user

(Customer) that the new ComSonics branded products will be free from defects in

workmanship and materials, under normal use, for one (1) year from the date of

original shipment. ComSonics warrants repaired and refurbished ComSonics

products for ninety (90) days from date of shipment.

Agency Notice

Hand Held Device Vehicle Mounted Device

FCC ID: PYN2007HHD FCC ID: PYN2007VMD

IC: 4261A-2007HHD IC: 4261A-2007VMD

Complete Limited Warranty and Agency Notice documentation is printed in the

back section of this user guide.

(brief)

(brief)

Technical Support

ComSonics maintains a Technical Support Service for customer convenience.

Contact a Support Representative at 1-800-336-9681 or 1-540-434-5965;

Fax 1-540-432-9794; or Email tech-support@comsonics.com.

Copyright

All material in this manual is the property of ComSonics, Inc. and protected under

the United States copyright law. No material shall be reproduced or used in any

form or by any means (graphic, electronic, or mechanical, including photocopying,

recording, taping, or information storage and retrieval systems) without the written

permission of:

Harrisonburg, Virginia 22801 USA

Phone: (540) 434-5965 USA Toll Free: (800) 336-9681

Email: marketing@comsonics.com

Qualifier is a trademark of ComSonics, Inc.

2007 ComSonics, Inc. All Rights Reserved

ComSonics, Inc.

1350 Port Republic Road

Post Office Box 1106

Fax: (540) 434-9847

Internet: www.comsonics.com

CSI Doc. 101399-001 Rev. 1.05

sh

i

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 3

Table of Contents

Introduction.......................................................................................................1

FCC License Requirement ...........................................................................1

Unpacking ....................................................................................................1

Qualifier X-Ray System Overview ................................................................2

General Information..........................................................................................3

Hand Held Device (HHD) .............................................................................3

Battery Installation .................................................................................3

Single Button Control.............................................................................3

Auto Power Off ......................................................................................3

Display Screen.......................................................................................4

Threshold Value Setup ..........................................................................4

Hardware Installation ...................................................................................6

Dual Band Antenna................................................................................7

Vehicle Mount Device (VMD).................................................................7

Check / Select Transmit Frequency.......................................................8

Test the VMD Installation.......................................................................8

Qualifier System Installation Verification......................................................9

Troubleshooting Notes .................................................................................9

Using the Qualifier X-Ray System.................................................................10

Dwelling Shielding Integrity Measurement Procedure ...............................10

Specifications .................................................................................................11

Accessories / Parts.........................................................................................12

Warranty Statement........................................................................................13

Agency Notice.................................................................................................15

w w w . c o m s o n i c s . c o m

ii

Page 4

Qualifier X-Ray

Major Components

Display

Screen

Power / Test

Button

Test Button

Power Button

Status Indicators

Antenna Connector

Power Harness Connector

Input

Connector

Battery

Compartment

Fuse

iii

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 5

Introduction

FCC License Requirement

A FCC license is required to operate the Qualifier X-Ray System, specifically the

vehicle mount transmitter component (VMD).

Refer to the Qualifier Transmitter Licensing section on our website at

www.comsonics.com/downloads.html for application instructions and templates.

If you need assistance, please call our Customer Service Department at 1-800336-9681.

Unpacking

The Qualifier X-Ray System and accessories are shipped in a single container

designed to provide maximum protection during transit. Immediately upon receipt,

inspect the container and contents for signs of physical damage. Notify the freight

forwarder of any damage detected.

Installation Caution!

The Qualifier X-Ray System is designed only for vehicles equipped with a 12-volt

negative ground electrical system.

w w w . c o m s o n i c s . c o m

1

Page 6

Qualifier X-Ray

Qualifier X-Ray System Overview

The ComSonics Qualifier X-Ray System provides a method for identifying the

internal shielding integrity of the CATV network in a subscriber’s residence without

the need to enter the premises.

A test activation transmitter is located within the Qualifier hand held device (HHD).

The transmitter provides an activation signal to the Qualifier Vehicle Mounted

Device (VMD) and sets up the HHD to measure levels of ingress from the VMD

signal appearing in the return upstream path.

With the HHD connected to either the residential ground block or the drop tap, a

press of the HHD button activates the VMD to generate a brief 5-watt signal pulse

at a frequency, just above the CB radio band, within the upstream frequency spectrum.

The VMD test signal envelopes the residence with a level of about +58 dBmV

(assuming the service vehicle is about 75 feet from the residence). Shielding

flaws, within the residential cabling, allow the VMD signal to enter the return upstream path. The HHD detects the VMD test signal and displays a shielding integrity value based on the ingress level measured.

The threshold setup function in the HHD determines the indication of PASS or

FAIL with the integrity measurement.

Shielding Integrity Measurement

The Qualifier X-Ray System utilizes a unique measurement method to determine

the relative shielding integrity of a customer premise without a need to enter the

structure. This method provides the user with a numeric display representing a

calculated shielding factor, in dB, of the premise under test.

The type of flexible coaxial cable used for drops and house wiring typically has a

shielding integrity factor in the range of 60 to 80 dB. But with the addition of connectors, splitters, VCRs, televisions, PC modems, and other devices along with

improper installation techniques; the total overall shielding integrity can degrade

appreciably. The possibility of noise ingress (undesirable signals) increases

greatly if the shielding integrity is not sufficient. Noise ingress causes interference

with the return path signals and reduces the reliability of two-way signal communications.

The Qualifier X-Ray System enables the user to obtain a shielding integrity reading in the range of 80 dB (very good) to 25 dB (very poor). Each measurement

reading includes a PASS or FAIL indication, based on a user selectable threshold

value, for easy measurement status determination. The threshold function can be

turned off.

Formula for calculating the shielding integrity reading:

D2I = Pmax [+85] - (antenna gain [2.5] + free space loss [25]) - measured value

*D2I is the acronym for Dwelling Ingress Integrity

2

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 7

General Information

Hand Held Device

The Hand Held Device (HHD) is a small pocket size unit containing the test activation transmitter and the ingress test signal

receiver.

Battery Installation

The HHD is powered by three standard AAA alkaline batteries.

To install the batteries, loosen the battery compartment screw

and remove the cover. Install the batteries, all three with the

positive end in the same direction, as indicated. Replace the

cover and tighten the screw. Use care not to over tighten the

screw.

Be sure to recycle or properly dispose of old batteries.

The HHD automatically powers off when the battery condition

is low to protect the batteries from excessive discharge and

possible leakage. Periodically remove the battery cover and

inspect the batteries for signs of leakage.

Caution: Do not store the HHD for extended periods of time

with the batteries installed. Failures due to battery leakage are

not covered under warranty.

Single Button Control

The HHD is controlled by one multi-function button.

To power the HHD on:

Press and hold the Button for one second.

To activate an integrity measurement cycle:

Press the Button once.

This also resets the back light and power auto-off timers.

To access the PASS/FALL threshold setup mode:

Press the Button twice within one second.

Press the Button to set the threshold level.

To power the HHD off:

Press and hold the Button for one second.

Auto Power Off

The HHD automatically powers off sixteen seconds after the last Button press.

The back light turns off in six seconds and the HHD powers off ten seconds later.

Cover

Screw

w w w . c o m s o n i c s . c o m

3

Page 8

Qualifier X-Ray

Display Screen

The Display screen provides information on the

battery condition, units of measure, shielding

integrity value, and if enabled, the PASS/FAIL

status of the measurement. A back light illuminates the display.

Battery Level

A fresh set of batteries is indicated by four bars.

Each bar represents approximately 25% runtime

capacity. A low battery condition is indicated by

no bars showing. The HHD automatically powers off when the battery state is low.

Note: The accuracy of the battery level indicator is relative and will vary with the

battery type and manufacturer.

Shielding Integrity Measurement Value

When a measurement is made, by a single press of the Button, the level of the

ingress signal is displayed as a shielding integrity value in dB units-of-measure.

The value range is 80 dB (very good shielding) to 25 dB (very poor shielding).

PASS / FAIL Function

The HHD can be setup with a measurement threshold value to determine if the

integrity reading is acceptable. PASS is displayed if the measured integrity value

is higher (better) than the threshold value. FAIL is displayed if the measured integrity value is lower (worse) than the threshold value. The PASS/FAIL threshold

value is user selectable. This function can be disabled as described on the next

page.

Threshold Value Setup

To access the threshold value setup mode, press the Button twice within one

second when the HHD is on. The PASSFAIL readout activates and two digits

display the current threshold value. Press and hold the Button to scroll to the desired threshold value. Release the Button to stop rapid scrolling and then use

single presses of the Button to the desired value. If a lesser value is desired, continue to hold the Button as the value wraps around from 80 and then back down to

25 dB. Release the Button and allow the HHD to auto power off (six seconds). At

the next power up, the newly set threshold value is enabled and the PASS or the

FAIL indicator will display accordingly. See the next sections for the procedure to

disable or enable the PASS / FAIL function.

4

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 9

Disable the PASS / FAIL Function

The HHD PASS / FAIL function can be disabled by setting the threshold value to

80 dB. In this mode, neither the PASS nor the FAIL indicator appears.

Enable the PASS / FAIL Function

To enable the HHD PASS / FAIL function, set the threshold value to a setting

other than 80 dB.

Test Signal Verification

The combined PASSFAIL label is displayed along with the integrity reading if the

HHD is unable to clearly receive the VMD test signal. The HHD performs a pretest

signal level measurement prior to triggering the VMD and then compares that

level with the measurement made during the VMD transmit interval. If the VMD

signal level is no greater than the pretest level, then the combined PASSFAIL

label is shown. The test signal verification function is not affected by disabling the

Threshold function.

w w w . c o m s o n i c s . c o m

5

Page 10

Qualifier X-Ray

Vehicle Hardware Installation

Vehicle Mount Device (VMD)

The Qualifier X-Ray system requires installation of the Qualifier Vehicle Mounted

Device (VMD) and a Dual Band Antenna.

Installation Precautions

Please observe the following during installation.

Wear eye protection when installing the system.

The vehicle must have a 12-volt negative ground electrical system.

Insure that no mounting hardware makes contact with any wiring, fuel/brake

lines or other components.

Insure the mounting position of the VMD is clear of obstacles.

Protect the system from metal debris.

Do not route cabling or wiring through sharp edged openings or potential

pinch points to prevent future failures and safety hazards.

Maintain at least one inch of clearance around the VMD for proper cooling.

6

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 11

Install the Antenna

Install the Vehicle Mounted Device (VMD)

Check the hardware in your Qualifier

VMD Installation Kit (part number

101488-001) to the illustration.

Four screws

Power cable

Use the hardware contained in the kit to install the VMD as follows:

Place the VMD over the selected mounting location. Allow at least a two inch

clearance beyond the rear panel for installation of cables. Mark the location of the

four mounting holes using a center punch. Alternate mounting methods may be

required in certain installations.

Protect the VMD from debris and use a 1/4-inch nut driver attached to a power

screwdriver or variable speed drill to install four (4) one-inch self-drilling screws.

DO NOT OVER TIGHTEN THE SCREWS! Remove any debris remaining from the

drilling operation.

Connect the antenna cable to the VMD.

Place the Magnetic Mount Dual Band Antenna on a

flat roof surface of the vehicle. Position it near as

possible to the center of the roof away from nearby

metallic objects; such as other antennas, booms, or

ladders. Route the cable, perpendicular to the centerline of the roof, to the point where the antenna cable

enters the vehicle. Use caution to prevent damage to

the cable. Coil any excess cable in a loose loop inside

the vehicle. Secure the cable as needed.

Note: Periodically remove the antenna and clean dust

and grit from the vehicle surface and bottom of the

antenna to reduce abrasion to the vehicle finish.

Route the

antenna

cable to

side of

vehicle.

w w w . c o m s o n i c s . c o m

7

Page 12

Qualifier X-Ray

Install the VMD Power Harness

Connect the RED lead to the vehicle (+12V) ignition or accessory fuse block circuit. Connect the BLACK lead to the vehicle ground. A 2-ampere safety fuse is

used in the red lead.

Connect the power harness to the VMD.

The red Standby indicator is on with power applied and the VMD Power Switch

set to OFF.

Check / Select the VMD Transmit Frequency

Push the VMD power switch to the ON position; wait a few seconds for the VMD

to initialize, and the green Power indicator to illuminate. Then, press and hold the

Test button for 2 seconds. The orange Receive indicator flashes showing the

operating frequency by the following patterns:

One flash and a pause frequency 1 = 27.45 MHz

Two flashes and a pause frequency 2 = 27.47 MHz (factory default)

Three flashes and a pause frequency 3 = 27.49 MHz

To select a different transmit frequency while a code is flashing; press the Test

button to step to the next frequency. The frequency select sequence wraps

around from frequency 3 back to frequency 1.

The VMD returns to normal operating mode after the indicator flashes the code

sequence for 10 seconds. The selected operating frequency is retained regardless

of powering conditions.

In accordance with FCC License requirements, the operating frequency may need

to be changed. Refer to the Qualifier Transmitter Licensing section on our website at ‘www.comsonics.com/downloads.html’ for application instructions and templates.

Test the VMD Installation

Push the VMD power switch to the ON position and wait a few seconds for the

VMD to initialize. Momentarily press the Test button and the yellow Transmit indicator comes on for a few seconds as the VMD generates the output power signal

to the antenna.

Warning: The Dual Band Antenna must be properly mounted on the vehicle and

connected to the VMD before performing this test or operating the Qualifier system. Improper operation of the system may result in permanent damage to the

VMD and is not covered under warranty.

8

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 13

Qualifier System Installation Verification

1. Power-on the VMD and wait a few seconds for it to initialize.

2. On the HHD, connect a ≈ 2 inch stub antenna to the BNC connector.

(Example: Use a straightened paperclip inserted into a BNC-to-F adapter.)

Make sure the HHD batteries are fresh.

3. Stand about 10 feet from the vehicle and hold the

HHD with a vertical orientation of the stub antenna.

4. Power on the HHD and then press the Button.

5. The VMD orange Receive indicator flashes once

and then the yellow Transmit indicator comes on for

a moment.

6. The HHD displays ‘ - - dB’ briefly and then shows a

reading between 25 and 80 dB.

Note: If the HHD shows ‘> 80 dB’ and the

‘PASSFAIL’ label, check the Dual Band Antenna

connection and repeat the ‘Test the VMD Installation’ procedure.

7. Set the HHD Threshold to a value less than the

displayed reading.

8. Repeat the test and note that PASS is displayed.

9. Set the HHD Threshold to a value greater than the

displayed reading.

10. Repeat the test and note that FAIL is displayed.

11. Set the HHD Threshold Level to 80 dB.

12. Repeat the test and note that neither PASS nor FAIL is displayed.

13. Reset the HHD Threshold to a value for system test operation.

Troubleshooting Notes:

If the trigger signal from the HHD is marginal, the VMD orange Receive indicator

flashes several times and the yellow Transmit indicator does not come on.

If the VMD is triggered by the HHD and the orange Receive indicator flashes once

(as normal) but the yellow Transmit indicator does not come on, there is a problem with the antenna or the internal transmitter section of the VMD.

If the TEST button on the VMD is pressed momentarily and the yellow Transmit

indicator does not come on, there is a problem with the antenna or the internal

transmitter section of the VMD.

The reliability of the HHD triggering the VMD may be reduced in these test location scenarios:

The elevation of the HHD test location is significantly lower than the VMD

vehicle antenna.

The residence under test, located between the HHD and the VMD vehicle,

significantly blocks or absorbs the HHD trigger signal.

Initial Power On

Measurement in Process

w w w . c o m s o n i c s . c o m

9

Page 14

Qualifier X-Ray

Using the Qualifier X-Ray System

Residential Shielding Integrity Measurement Procedure:

1. Locate the Qualifier VMD equipped vehicle about 50 to 75 feet from the test

residence.

2. Set the VMD power switch to ON.

3. Disconnect the CATV drop cable from the residence ground block or splitter.

As an alternative method, disconnect and test at the tap or pedestal.

4. Use a BNC-to-F adapter and a short jumper cable to connect the Qualifier

HHD to the open residential terminal. If using the tap or pedestal method, connect the HHD to the free end of the drop cable. If needed, use a quality extension cable and a F-81 barrel. Tighten connections as needed.

5. Power on the HHD.

6. Press the HHD Button to activate the measurement

sequence.

7. The HHD displays ‘- - dB’ briefly and then shows the

shielding integrity reading. PASS or FAIL may also be

displayed, based on the Threshold value setting.

8. Repeat the measurement sequence a second time to

insure the reading.

For a low integrity reading from a tap or pedestal

location, retest from the residence ground block or

splitter location.

For a low integrity reading when connected to the

input of the residential splitter, disconnect each cable from the splitter output (one at a time) and retest

to determine the path of ingress.

If the PASSFAIL label appears, the indication of not

clearly receiving the VMD test signal, check the HHD

connection and the VMD operation. Integrity readings in the range of 25 to 80 with the PASSFAIL

label showing may indicate excessive noise signals.

9. Disconnect the HHD jumper cable and reconnect the drop cable.

10.Weather-proof the connection as needed.

Initial Power On

Measurement in Process

10

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 15

Specifications

Hand Held Device (HHD)

Operational Control

Input Frequency Range

Input Level Range

Integrity Measurement Range 25 to 80 dB (shielding effectiveness)

Accuracy

Threshold Function Range

Power Source

Custom Display

Auto Power Off

Size

Weight

Operating Temperature

Storage Temperature

Humidity

Vehicle Mount Device (VMD) (FCC license required)

Output Frequency

Output Power

User Controls

Indicators

Power Source

Size

Mounting

Operating Temperature

Storage Temperature

Humidity

(User Selectable)

Single Button

27.45 to 27.49 MHz

-30 to +30 dBmV

± 2.0 dB (input level to converted reading)

25 to 79 dB (user selectable, 80 disable)

AAA Alkaline x 3 cells

1.2” x 1.5”

16 seconds

5.5” x 2.5” x 1.75”

0.5 lbs

0ºF to 120ºF

-20ºF to 150ºF

Moderate Rainfall

(30 mm x 39 mm),

(0.23 kg)

(-18ºC to 49ºC)

(-29ºC to 66ºC)

with backlight

(140mm x 64mm x 44 mm)

27.45 MHz, 27.47 MHz*, or 27.49 MHz

5 Watts, EIRP

Power On/Off and Test/Output Frequency

Standby, Power, Receive, and Transmit

12 VDC negative ground, < 12 Watts

6” x 3.5” x 1” (150 mm x 90 mm x 26 mm),

Fixed

0ºF to 140ºF (-18ºC to 60ºC)

-20ºF to 150ºF (-29ºC to 66ºC)

0 ~ 95% non-condensing

* Factory Default Setting

w w w . c o m s o n i c s . c o m

11

Page 16

Qualifier X-Ray

Accessories / Parts

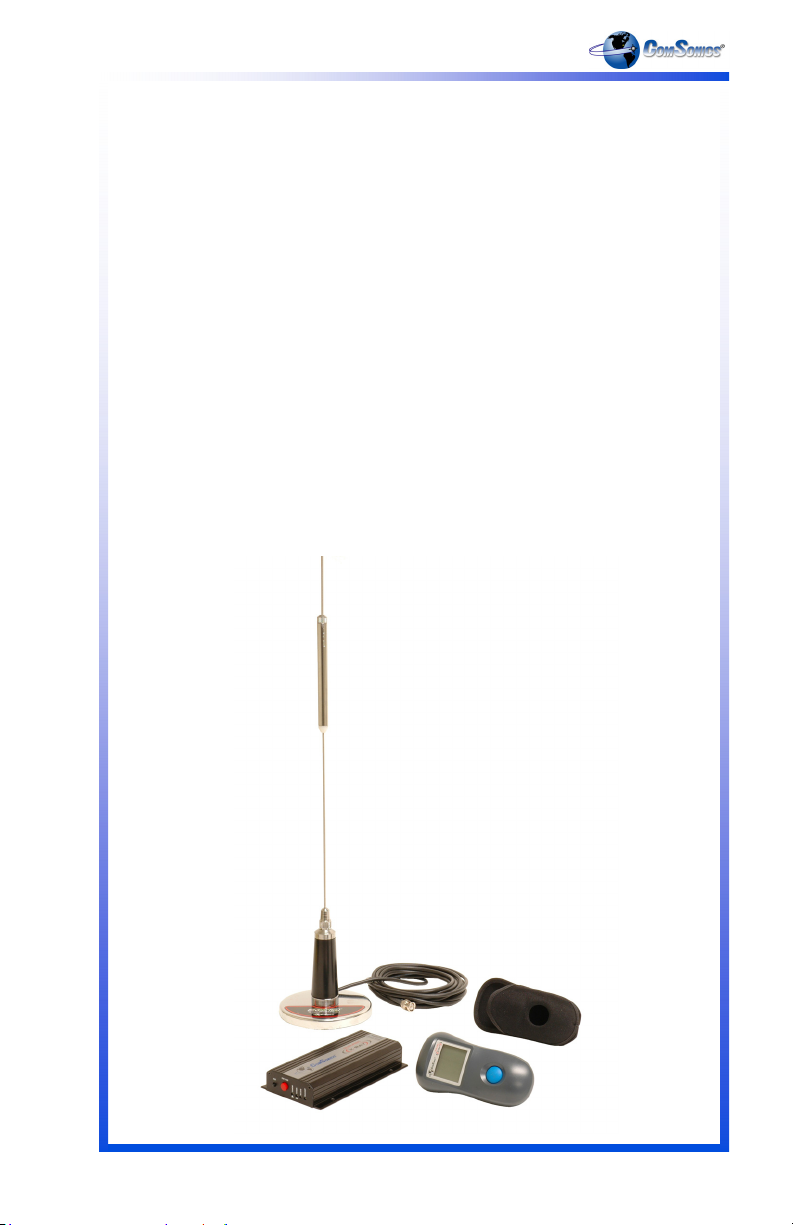

System Package - Qualifier X-Ray Hand Held Device, Holster,

Vehicle Mounted Device, Power Harness, Dual Band Antenna,

and User Guide

Qualifier Hand Held Device (HHD)

Qualifier Vehicle Mounted Device (VMD)

Qualifier Dual Band Vehicle Magnetic Antenna

Holster for Qualifier Hand Held Device (belt clip type)

Power Harness for Qualifier Vehicle Mounted Device

Battery for Qualifier Hand Held Device (3 required)

Qualifier X-Ray User Guide

101396-001SC

101393-001

101396-001

101272-001

101240-001

101488-001

BB-542

101399-001

12

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 17

Limited Warranty

Hardware: ComSonics, Inc. (ComSonics) warrants to the original end user

(Customer) that the new ComSonics branded products will be free from defects in

workmanship and materials, under normal use, for one (1) year from the date of

original shipment. ComSonics warrants repaired and refurbished ComSonics

products for ninety (90) days from date of shipment.

Exclusions

This warranty excludes:

Damage to the physical surface of the product, including cracks or

scratches to any part.

Damage caused by misuse, neglect, improper installation or testing, un-

authorized attempts to open, repair, or modify the product, or any other

cause beyond the range of the intended use.

Damage caused by accident, fire, power changes, other hazards, or acts

of nature.

Use of the product with any non-recommended device or service if such

device or service causes the problem.

Any third party products, including software, included with ComSonics products

are not covered by this ComSonics warranty and ComSonics makes no representations or warranties on behalf of such third parties. Any warranty on such products is from the supplier or licensor of the product.

Exclusive Remedies

Should a covered defect occur during the warranty period and you notify ComSonics, your sole and exclusive remedy shall be, at ComSonics sole option and

expense, to repair or replace the product. If ComSonics cannot reasonably repair

or replace then ComSonics may, in its sole discretion, refund the purchase price

paid for the product. Replacement products or parts may be new or reconditioned

or comparable versions of the defective item. ComSonics warrants any replaced

or repaired product, or part for a period of ninety (90) days from shipment, or

through the end of the original warranty, whichever is longer.

Obtaining Warranty Service: Customer must contact ComSonics Technical

Support or Customer Service within the applicable warranty period. Products or

parts shipped by Customer to ComSonics must be sent postage-paid and packaged appropriately for safe shipment. ComSonics is not responsible for damage

occurring in transit from Customer to ComSonics. Repaired or replacement products will be shipped to Customer at ComSonics’ expense. All products or parts

that are replaced become the property of ComSonics. ComSonics shall not be

responsible for Customer’s software, firmware, information, or memory data contained in, stored on, or integrated with any products returned to ComSonics for

repair, whether under warranty or not.

w w w . c o m s o n i c s . c o m

13

Page 18

Qualifier X-Ray

WARRANTIES EXCLUSIVE: THE FOREGOING WARRANTIES AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, CORRESPONDENCE WITH DESCRIPTION, AND NON-INFRINGEMENT, ALL OF WHICH ARE EXPRESSLY

DISCLAIMED BY COMSONICS AND ITS SUPPLIERS.

LIMITATION OF LIABILITY: NEITHER COMSONICS NOR ITS SUPPLIERS

SHALL BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF ANY KIND, LOSS OF INFORMATION OR

DATA, OR OTHER FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION

WITH THE SALE OR USE OF THIS PRODUCT, WHETHER BASED IN CONTRACT, TORT (INCLUDING NEGLIGENCE) OR ANY OTHER THEORY, EVEN

IF COMSONICS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. COMSONICS ENTIRE LIABILITY SHALL BE LIMITED TO REPLACEMENT, REPAIR, OR REFUND OF THE PURCHASE PRICE PAID, AT CONSONICS’ OPTION.

Disclaimer: Some countries, states, or provinces do not allow the exclusion or

limitation of implied warranties or the limitation of incidental or consequential damages so the above limitations and exclusions may be limited in their application to

you. When implied warranties may not be excluded their entirety, they will be

limited to the duration of the applicable written warranty. This warranty gives you

specific legal rights; you may have other rights that may vary depending on local

law. Your statutory rights are not affected.

Governing Law: This Limited Warranty shall be governed by the laws of the State

of Virginia, U.S.A., and by the laws of the United States, excluding their conflicts

of laws principles. The United Nations Convention on Contracts for the International Sale of Goods is hereby excluded in its entirety from application to this Limited Warranty.

ComSonics, Inc.

1350 Port Republic Road

Post Office Box 1106

Harrisonburg, Virginia 22801

United States of America

www.comsonics.com

June 1, 2007

14

1 - 8 0 0 - 3 3 6 - 9 6 8 1

Page 19

Agency Notice

FCC Part 15

Qualifier X-Ray, Hand Held Device

FCC ID: PYN2007HHD

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

FCC Part 15 for Handheld Devices

To comply with FCC RF exposure requirements, this device must be operated in

the hand with a minimum separation distance of 23 cm or more from a person's

body. Other operating configurations should be avoided.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy. If not installed and used in accordance with the

instructions, the equipment may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

own expense.

Qualifier X-Ray, Vehicle Mounted Device

FCC ID: PYN2007VMD

FCC Compliance and RF Exposure Information

This product is certified by the FCC as compliant with CFR.47 Part 90.

Changes or modifications not expressly approved by the manufacturer could void

the user's authority to operate the equipment.

Industry Canada

Qualifier X-Ray, Hand Held Device

IC: 4261A-2007HHD

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil

numérique de la Classe A est conforme à la norme NMB-003 du Canada.

Qualifier X-Ray, Vehicle Mounted Device

IC: 4261A-2007VMD

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil

numérique de la Classe A est conforme à la norme NMB-003 du Canada.

The installer of this radio equipment must ensure that the antenna is located or

pointed such that it does not emit RF field in excess of Health Canada limits for

the general population; consult Safety Code 6, obtainable from Health Canada's

website www.hc-sc.gc.ca/rpb.

w w w . c o m s o n i c s . c o m

15

Page 20

Qualifier X-Ray

ComSonics, Inc.

1350 Port Republic Road

Post Office Box 1106

Harrisonburg, Virginia 22801 USA

Phone: (540) 434-5965 USA Toll Free: (800) 336-9681

Fax: (540) 434-9847

Email: marketing@comsonics.com

Internet: www.comsonics.com

2007 ComSonics, Inc. All Rights Reserved

Document No. 101399-001 Rev. 1.05

sh

Loading...

Loading...