Page 1

Temperature Monitoring

CompX eLock® unit CompX eLock® temperature display keypad

A

C D

B

A

B

C

A

D

E

E

F

H

CompX eLock® unit

A: Green LED indicator of successful open cycle

B: Red LED indictor of unsuccessful attempt

C: Asterisk button used to clear entry or remove user /

supervisors

D: Pound button used to insert PIN or program new users /

supervisors

G

Note: not actual size; shown at 150%

I

J

CompX eLock® temperature

display keypad

A: Minimum and maximum temperature limits

B: Unit is unlatched. This icon is not visible when latching

mechanism is in the locked position.

C: Programming mode

D: Bell icon indicates alarm is enabled. Flashing bell sound waves

means the alarm is sounding. Flashing bell means the alarm

has been muted. Does not indicate alarm volume setting:

soft-medium-loud.

E: Degree sign and unit of temperature measure. Will either show

˚C or ˚F.

F: Display of time or temperature or setting.

G: Back button

H: Scroll up button

I: Enter button

J: Scroll down button

***IMPORTANT INFORMATION***

This unit comes with factory reset codes/cards. Please save the attached stickers/cards and place in a secure location. This unit can

be reset to original Factory Set-up Mode by entering the factory reset code or presenting the factory reset card. CAUTION: ENTERING

THE FACTORY RESET MODE WILL ERASE ALL USERS/SUPERVISORS THAT ARE CURRENTLY PROGRAMMED IN THE LOCK.

Basic unit Features:

k Records 8,000 temperature events

k Accuracy within +/- 1˚C

k Single probe, mounted in non-toxic glycol bottle

k Easy to read LCD display

k Operating range of from -40˚F to 122˚F (-40˚C to 50˚C)

k Requires 6 AA batteries (9V) not included

General functionality:

k Pressing the scroll up arrow will display the maximum

temperature that the monitor has recorded

k Pressing the scroll down arrow will display the minimum

temperature that the monitor has recorded

k Pressing the key will display the current date

k Pressing the key twice will display the day of the week

1

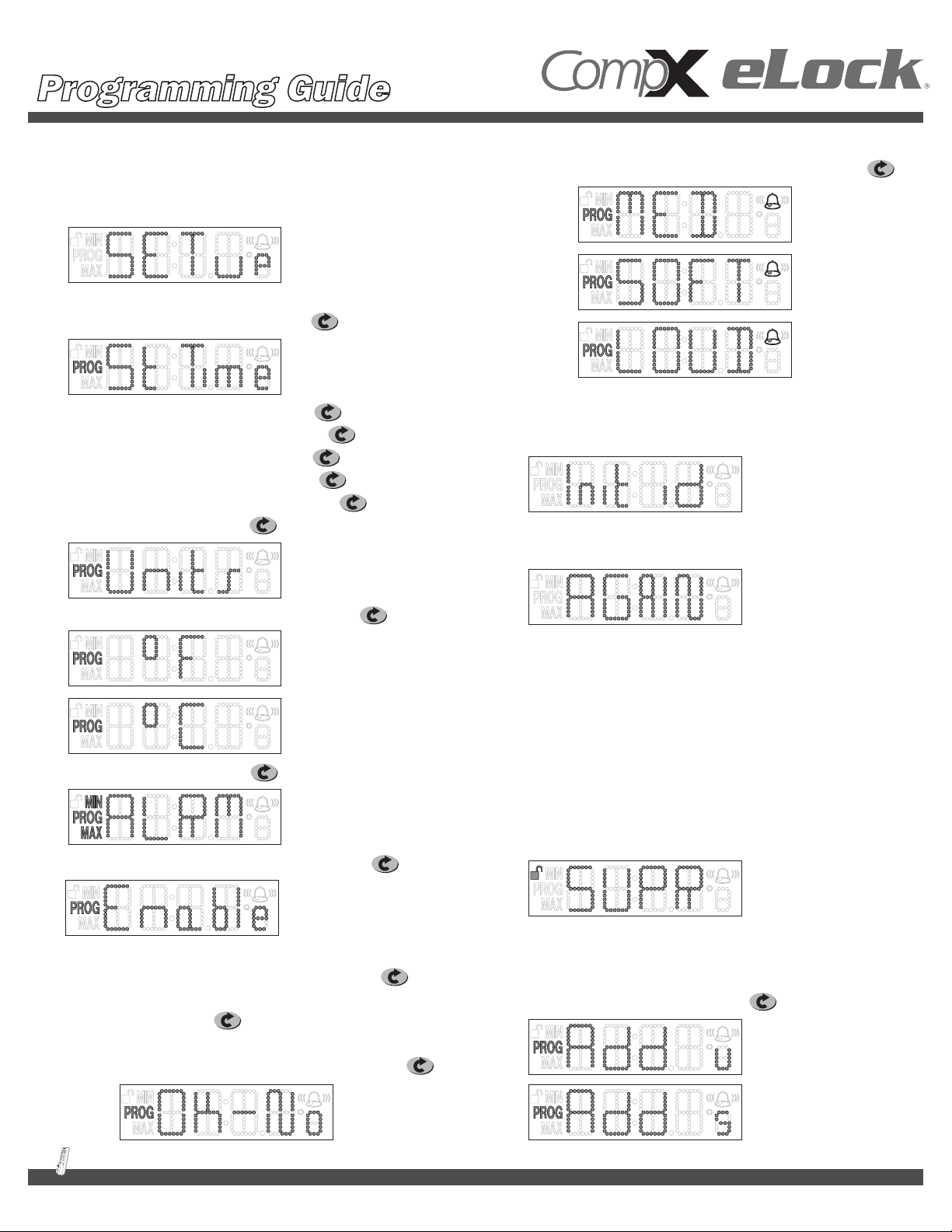

Page 2

Temperature Monitoring

Getting Started

1. Unit is shipped in “Set-up” mode. Once 6AA batteries

(not included) are installed, the LCD will say “SET up."

2. Press and hold # (about three seconds) to get started.

3. LCD will display ST Time (set time). Hit .

4. Set Year using up and down arrows. Hit .

5. Set Month using up and down arrows. Hit .

6. Set Day using up and down arrows. Hit .

7. Set Hour using up and down arrows. Hit .

8. Set Minutes using up and down arrows. Hit .

9. Display will show “Units." Hit .

d. Adjust speaker volume, 3 possible settings, LOUD,

MED, SOFT, by using up and down keys and hit .

13. The unit will display “Init ID” which is prompting you to program

the initial credential. Remember, the first credential is always

a Supervisor and goes into Slot 001.

14. Enter PIN or present card followed by #.

15. Unit will display “AGAIN” for confirmation of the code / card.

10. Choose ˚F or ˚C with up and down arrows. Hit .

11. Display will show “ALRM." Hit .

12. Enable or disable alarm with up or down key. Hit .

a. If enabled, minimum degrees will appear.

Adjust using up and down arrows and hit .

b. Adjust Maximum degrees using up and down

arrows and hit .

c. If you want to disable the alarm, press the up or down

arrow until it says “Enable – Okay No” and hit .

16. Enter PIN or present card followed by # again.

17. The unit is now successfully initialized. The LCD display will

alternate time and temp.

How to Change Modes

After Initial Set-up

ADDING USERS OR ADDITIONAL SUPERVISORS:

1. Enter supervisor code/card and press #. Display will show “Supr.”

2. Press and hold # (again) for about three seconds.

3. Display will show “Add u” which means add user. If you use

the up or down arrow, the display will show “Add s” which

means add supervisor.

4. Pick either “Add u” or “Add s” and hit .

2

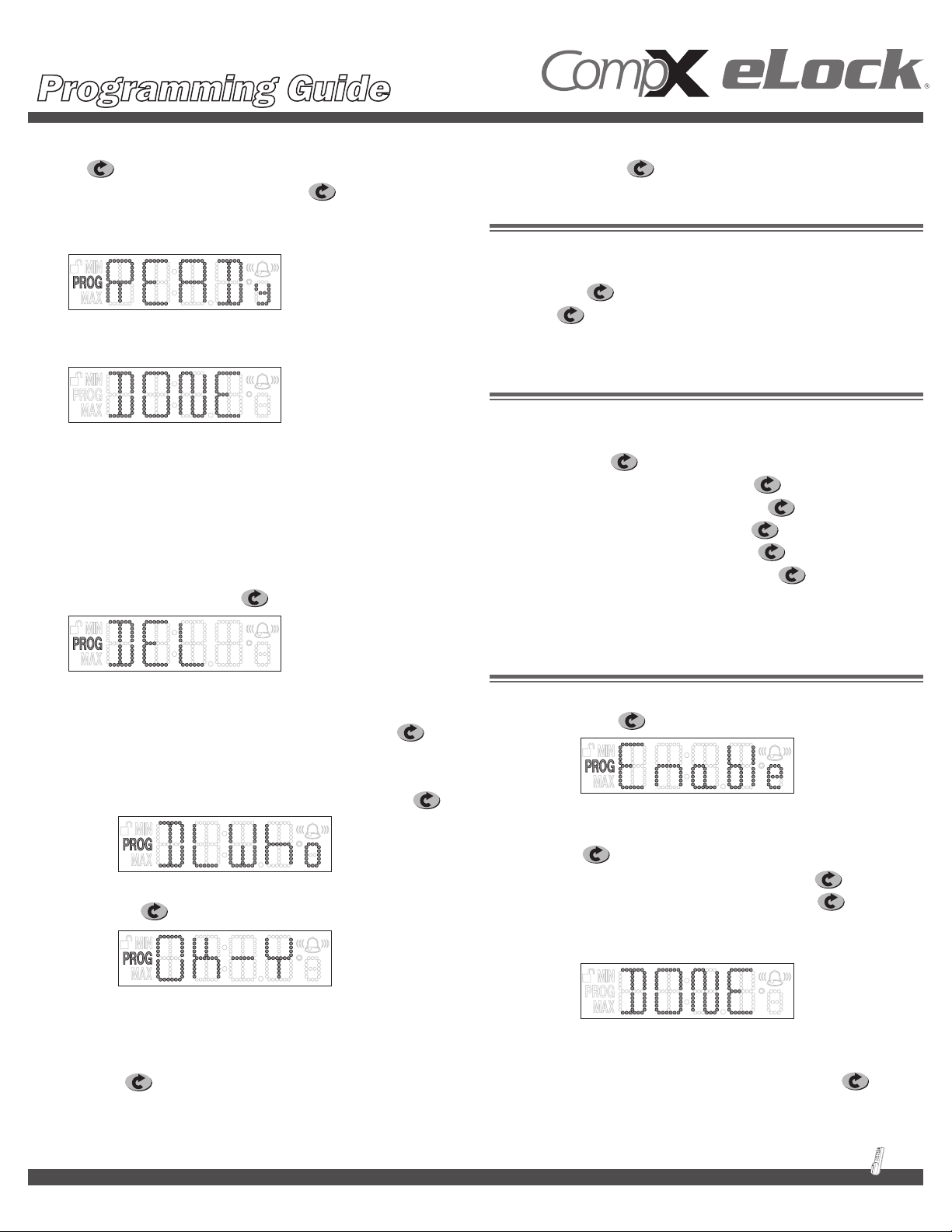

Page 3

Temperature Monitoring

5. The display will show the next available slot to program into.

Hit (All entries done by slots will need to be logged.)

Take the next available slot by pushing or program

by specific slot by scrolling with the up and down buttons.

6. The unit will display “READy."

7. Enter PIN followed by # or present card.

8. Unit will say “DONE.”

9. Unit will return to normal operating mode, showing alternating

time and temp.

DELETING USERS OR SUPERVISORS:

1. Enter supervisor code / card and press #. Display will

show “Supr.”

2. Press and hold * for about three seconds.

3. Display will show “DEL." Hit .

“ALRM” – use the up or down arrows to toggle between Units, St Time

and ALRM modes. Hit on desired mode.

UNITS

If Units is chosen, the eLock will allow you to select either F˚ or

C.˚ Scroll using the up or down arrows until “Units” appears on the

display and hit . Using the up or down key, select either F˚ or C˚

and press . The display will show “DONE” momentarily and then

revert back to time and temperature.

SET TIME (ST TIME)

If St Time is chosen, the eLock will allow you to adjust the time and

date. Scroll using the up or down arrows until “St Time” appears on

the display and hit .

Set Year using up and down arrows. Press .

Set Month using up and down arrows. Press .

Set Day using up and down arrows. Press .

Set Hour using up and down arrows. Press .

Set Minutes using up and down arrows. Press .

The display will show “DONE” momentarily and then revert back to

time and temperature.

4. At this point you can enter the PIN followed by # or present

the card for the credential you want to remove.

a. If you want to delete by slot assignment, hit

after you see “DEL” in the display.

b. The units will display “DL-Who." Use the up or down

key to select the slot you want to clear and hit .

c. Unit will display “ok-y” and alternate “slot.”

d. Hit to confirm. Unit will show “Done.”

Changing Lock settings

Enter supervisor code / card and press #. Display will show “Supr.”

Press and hold for about three seconds. Display will show

ALARM (ALRM)

If ALRM is chosen and the alarm is Disabled, the LCD screen will

read “Enable.” Press to confirm ALRM enabling.

a. Next screen will display “Limits” which allows you set

the upper and lower limits of the alarm mode. Press

to begin Limits programming

b. Set minimum temperature and press

c. Set maximum temperature and press

d. The display will show “DONE” momentarily and then

revert back to time and temperature

If ALRM is chosen and ALRM is Enabled, the LCD screen will display

Limits. Use the up or down arrows to toggle between Limits, disable,

A-Vol, MUTE, and R-SET. Select desired mode and press .

3

Page 4

Temperature Monitoring

LIMITS (ALARM MUST BE ENABLED TO CHANGE THIS SETTING)

Use this screen to set the upper and lower limits of the alarm mode.

1. If you choose Limits, the next screen will show you the

minimum temperature. Press up or down buttons or enter via

keypad until the desired minimum temperature is reached

and press .

2. The next screen is your maximum temperature screen. Again,

use the up or down buttons or enter via keypad until the

desired maximum temperature is displayed and hit .

RESET

1. This function will reset the upper and lower temperatures

the unit has recorded since the last time it was reset.

It will not reset the upper and lower limits for alarming.

If the alarm limits need to be changed, see previous section

on “LIMITS.”

2. Hit on the R’set screen. The screen will prompt you

“OK-y.” Press to confirm.

3. The unit will momentarily say “Done” and then revert back

to time and temp.

DISABLE (ALARM MUST BE ENABLED TO CHANGE THIS SETTING)

If you choose Disable, the screen will allow you to turn the alarm

off. Choose the desired setting and press . Press again

to confirm.

A-VOL: (Alarm must be enabled to change this setting)

1. If you select Adjust Volume, you can pick the alarm volume

level from three preset settings: LOUD, MED, Soft. Select

desired setting and hit . DONE will appear momentarily

and then the screen will revert back to Time and Temp. Factory

default setting is MED.

TO CHANGE ANY SETTING AFTER INITIAL SET-UP,

A SUPERVISOR CODE WILL BE NEEDED.

TEMPERATURE-BUFFERED SENSOR

The temperature probe (green bottle) provides and maintains

accurate readings when refrigerator doors are opened.

Probe is sealed in a miniature bottle that simulates vials, and is filled

with non-toxic glycol (recognized by the FDA as safe), eliminating

concerns about incidental contact with food or medicines.

Self adhesive wire routing clips provided for your convenience.

Bring wire over door, keeping the wire taut. Use wire routing clips to

keep the wire in place. Wire is 10 feet long, allowing it to be used

anywhere within the refrigerator.

It is highly recommended that this probe is placed on a shelf along

with other medications and not on the inside of the refrigerator door.

MUTE: (Alarm must be enabled to change this setting)

1. Selecting the Mute setting will silence the alarm. Select desired

setting and hit . The bell icon on the LCD will flash

indicating the alarm was muted.

4

Page 5

Temperature Monitoring

Step

Install the strike

1:

Note: The end of the metal

strike needs to curve up.

Foam Tape Installation

Please note that if foam tape installation

of the strike is used, the strike will not

be adjustable once it's put in place.

a. Clean top of both the refrigerator

and the strike with rubbing alcohol.

Wait for the alcohol to dry.

b. With a pencil, mark refrigerator 7-1 ⁄16"

from the front of the door and at least

3.5" from the non-hinged edge.

There are two main parts of this installation: installing the strike and installing the

eLock assembly. The strike and the eLock assembly can be mounted either with foam

tape or by drilling holes and using screws. It is important to note that mounting the

strike and the eLock assembly are independent of each other. One can be foam

tape mounted, and one can be drill mounted if desired. The two do not need

to be mounted using the same method.

Mount the strike

at least 3.5" from

NoN-hiNged edge

of the refrigerator.

Measure from this line to the front

of the cabinet (dim. “A”); cut a piece

of tape this length.

c. Remove tape backer and affix to end

of strike. The upward curve should be

on top. Apply tape to the opposite

side. Remove backer. Line up strike

with line on refrigerator; apply

pressure to seal it on.

Drilling Installation

a. Before drilling, verify that there are

no refrigerant lines inside the top

of the refrigerator.

b. Drill a 9/64" hole, 6-1 ⁄ 16" from

the edge of the front of the refrigerator

and at least 3.5" from the non-hinged

edge of the refrigerator.

Step

2:

Secure the strike and attach the strike cover (if strike was mounted using foam tape, ONLY do b.)

a. Screw one tamper resistant sheet

metal screw into the center of the strike's

slotted area. Note: The end of the metal

strike needs to curve up.

b. Place the plastic strike cover over the

metal strike. If strike was mounted using

foam tape, please proceed to Step 3.

c. Attach with one tamper resistant

machine screw.

5

Page 6

Temperature Monitoring

Step

Mount the main CompX eLock® body to the refrigerator door

3:

The CompX eLock® assembly (body) can be mounted to the front of the refrigerator

either by using foam tape or by drilling holes.

Foam Tape Installation

Please note that if foam tape installation of the strike is used,

the main CompX eLock® will not be adjustable once it's put in place.

a. Install one piece of double-sided tape on each side

of the CompX refrigerator eLock assembly.

b. Remove liner from double-sided tape.

c. Carefully press CompX eLock® onto the center of the strike.

Drilling Installation

a. Click CompX eLock® onto strike.

b. Push assembly up and center it on the strike.

c. Drill six 9/64" holes through the housing into the refrigerator door

for the mounting screws. Secure with screws. Note: Top two screws may

be omitted if they interfere with door handle access.

Note: If foam tape was used to mount the strike, the CompX eLock

installation is COMPLETE. The CompX eLock® may now be used.

Step

Finish installation of the strike (ONLY if drilled installation of strike was used)

®

refrigerator kit

4:

a. Remove the plastic cover from the strike plate. Drill 9/64" hole

in second opening of strike.

b. If adjustment of strike is needed, loosen up the first strike

screw and adjust the strike. Tighten up the screw.

c. Drill hole for second screw and install second screw.

d. Reattach the plastic strike cover and attach with two

tamper resistant machine screws.

6

Page 7

Temperature Monitoring

sample

sample

sample

sample

sample

These stickers are included with each CompX eLock® unit. Please review the information and keep the stickers in a safe

location as they may be needed to reset or identify a specific eLock unit. The codes shown here are not real codes. They

are representations of what the stickers will look like.

Sticker #1

Sticker #2

Sticker #3

2d bar code. Provides the same information as sticker

number three, but a 2d laser scanner is needed to

decode the information.

1d bar code. Place this sticker on or around the CompX

eLock® unit to help identify which codes to use if

resetting the lock is necessary.

Keep this sticker in a safe location.

Serial #: Needed to identify CompX eLock® units

Passcode: Unique to lock. Needed for LockView.

Prevents unauthorized LockView use

User Rst: Allows administrator or owner to erase

all user codes from eLock unit but keep

supervisor codes

Fact Rst: Erases all codes from eLock, including

settings. eLock unit will need to be set

up again after a Factory Reset (see page 2)

(SAMPLE) CompX eLock® Registration card

Company Phone# ( ) -

Address

Authorized Contact

Position

Serial #

Pass Code

User Reset Code

Factory Reset Code

Sticker #3

NoTe:

Don't forget

to fill out and

return your

warraNTy

card!

Affix one copy of sticker #3 to

the CompX eLock® registration

card and return to CompX Fort

at address shown on the other

side of the registration card.

7

Page 8

Temperature Monitoring

Accessories

®

HID

PROX USER,

SUPERVISOR CARD

MAGSTRIPE USER,

SUPERVISOR CARD

Part Number:

SUPERVISOR

EL-2004-PC (no logo)

EL-2004-PC-S (CSP logo)

LOCKVIEW

®

3.0

SOFTWARE KIT

(provided with 7 ft., 6-pin RJ11 cable,

1-USB dongle, 1 LockView® CD)

Part Number:

EL-LOCKVIEW-3

SCREWDRIVER

Part Number:

EL-DRV-15

HID is a trademark of HID Corporation. * These items are offered as Ser vice / Replacement Parts only.

Part Number:

EL-2004-MSC (no logo)

EL-2004-MSC-S (CSP logo)

®

HID

PROX TAG

Part Number:

EL-2004-PT

BIT

Part Number:

EL-BIT-15

LockView® 3.0 Software

q Add, edit, view and delete users / supervisors

and their credentials

q Add, edit and delete CompX eLocks

®

q Assign access rights between users / supervisors

and CompX eLocks® in the database

q USB connection required

q Download, view, save, print, archive and delete

audit trails

LockView is a Registered Trademark of CompX International. Windows is a trademark of the Microsoft Cor poration. Specifications may vary based on user application.

8

Reorder #: 331856000000

Copyright 2009 © CompX Security Products. CompX eLock and Lockview are Registered Trademarks of CompX International

q Dual credential access available

q Set real time clock

q Time based access restrictions

q Create user groups

q WindowsTM based

q View Temperature Logs

q View Temperature Graphs

q Edit Temperature Settings

864.297.6655

elock@compx.com

Mauldin, SC 29662

compxelock.com

PO Box 200

Page 9

Temperature Monitoring

Below are the factory default settings for eLocks equipped with temperature monitoring.

NOTE:

k User Permissions can only be changed using

the optional LockView® software.

k The User Permissions checked in gray scale,

and the User box (Set the time/date), in gray

scale are fixed.

Provided no User Permission changes

have been made in LockView®, the following

Temperature/Alarm Settings can be modified

using manual programming:

Low Limit and High Limit

Default: Only Supervisor(s) can modify

Fahrenheit and Celsius

Default: Both User(s) and Supervisor(s) can modify

Enable/disable the alarm

Default: Only Supervisor(s) can modify

Alarm Volume

Default: Only Supervisor(s) can modify

k LockView® is required to modify the following

default Temperature/Alarm Settings:

Alarm Delay*

Alarm Time

Logging Frequency

* Alarm Delay default time is .33 which equals 20

seconds. All times on this form are expressed

in minutes. This is the amount of time the

temperature reading has to be out of range

before the alarm starts sounding. After an alarm

starts sounding, and the Alarm Time has expired,

the alarm will “chirp” once per minute until the

alarm is either muted or disabled.

Reorder #: 331907000000

864.297.6655

compxelock.com

elock@compx.com

PO Box 200

Mauldin, SC 29662

Copyright 2009 © CompX Security Products. CompX eLock and Lockview are Registered Trademarks of CompX International

Page 10

Hit enter.

Hit enter.* Hit enter.*

Hit enter.*

Hit enter.*

selection and pressing

enter, the user will see

the “DONE” screen,

* After making this

as shown above.

Hit enter.

Hit enter.

Hit enter.

Hit enter.

Hit enter.*

Hit enter.

Hit enter.

Hit enter.*

Hit enter.*

Hit enter.

Hit enter.

Hit enter.*

Hit enter.

Temperature Monitoring

Alarm is ENablEd Alarm is OFF

Hit enter.

Hit enter.*

Hit enter.

Hit

enter.*

Hit enter.

Hit enter.*

Hit enter.

Hit enter.*

Follow steps to set

Hit enter.

date and time.

Loading...

Loading...