Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

Approved by: Date:

(HRS)

Orion Energy Management

61 8003 011

HARDWARE REQUIREMENT

Valid from

Revision

P5

SPECIFICATION

HRS

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

TABLE OF CONTENTS

TABLE

1 DOCUMENT HISTORY..................... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .4

2 INTRODUCTION.....................................................................................................................5

2.1 PROJECT NAME....................................................................................................................5

2.2 PROJECT NUMBER................................................................................................................5

3 REFERENCES..........................................................................................................................5

4 DEFINITIONS...........................................................................................................................5

5 GENERAL REQUIREMENTS ...............................................................................................5

5.1 USER INTERFACE .................................................................................................................5

5.2 THERMOSTAT CONTROLLER..............................................................................................10

5.3 MOTION DETECTOR...........................................................................................................18

5.4 RF DEVICE......................................................................................................................... 21

OF CONTENTS.................................................................................................................2

5.1.1 Introduction.....................................................................................................................5

5.1.2 Housing............................................................................................................................6

5.1.3 Display.............................................................................................................................7

5.1.4 User Controls ..................................................................................................................7

5.1.5 Electrical interface levels........... ..... .... ..... ......... ..... ..... .... ..... ..... .... ..... .... ..... ..... .... ..... ..... .8

5.1.6 Module Communications Interface . .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .... ..... ..... .8

5.1.7 Service Interface......................... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .8

5.1.8 Power supply................................................. .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .9

5.1.9 Temperature sensor........... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .... ..... ..... .... ..... ..... .9

5.1.10 Firmware...................................................................................................................10

5.2.1 Introduction...................................................................................................................10

5.2.2 Housing..........................................................................................................................11

5.2.3 Electrical interfaces................................................ ..... .... ..... .... ..... ..... .... ..... ..... .... ..... .... 11

5.2.4 I/O Connector................................................................................................................11

5.2.5 Module Communications Interface . .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .... ..... ....12

5.2.6 Power supply................................................. .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ....14

5.2.7 Firmware.......................................................................................................................14

5.2.8 Parameters - CT The following parameters in NV memory is to control the TC. These

values are to be filled in by AAH and used by Computime. ......................................................14

5.2.9 Parameters - AAH .........................................................................................................16

5.2.10 Audit Trail ..................... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ....16

5.2.11 HVAC Control Chart – Standard Control........................ ..... .... ..... ..... .... ..... .... ..... .... 16

5.2.12 Real Time Clock (RTC) ..... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... ..... .... ..... ..... .... ..... .... 17

5.2.13 Counters ....................................................................................................................17

5.3.1 Introduction...................................................................................................................18

5.3.2 Housing..........................................................................................................................19

5.3.3 PIR Detector..................................................................................................................19

5.4.1 RF Device for User Interface (Phase 2)...................... .... ..... ..... .... ..... ..... .... ..... .... ..... .... 21

5.4.2 RF Device for Motion Detector.....................................................................................21

5.4.3 RF Device for Thermostat Controller ...........................................................................21

Valid from Revision

P7

Author(s): Jan Elfstrom Page 2/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

THERMOSTAT CONTROLLER EXPANDER ...........................................................................21

5.5

5.5.1 Introduction...................................................................................................................21

5.5.2 Housing..........................................................................................................................21

5.5.3 Connectors and interfaces.............................................................................................21

5.5.4 Housing..........................................................................................................................22

6 FIRMWARE REQUIREMENTS ..........................................................................................22

6.1 DESIGN...............................................................................................................................22

6.1.1 Firmware.......................................................................................................................22

7 ELECTRICAL REQUIREMENTS.......................................................................................22

8 MECHANICAL REQUIREMENTS.....................................................................................22

8.1 AESTHETIC DESIGN............................................................................................................22

8.2 FUNCTIONAL DESIGN .........................................................................................................23

9 SOFTWARE REQUIREMENTS ..........................................................................................23

10 ENVIRONMENTAL REQUIREMENTS.............................................................................23

10.1 TEMPERATURES.................................................................................................................23

10.1.1 Storage temperature......................................................... .... ..... ..... .... ..... ..... .... ..... .... 23

10.1.2 Operating temperature..............................................................................................23

10.2 HUMIDITY..........................................................................................................................23

10.2.1 Storage humidity................ ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... .... ..... .... 23

10.2.2 Operating humidity....................................................................................................23

10.3 PROTECTION ......................................................................................................................23

10.3.1 User Interface............................................................................................................24

10.3.2 Motion Detector.........................................................................................................24

10.3.3 Thermostat Controller...............................................................................................24

10.4 LIFE CYCLE REQUIREM E N T ................................................................................................24

10.4.1 User Interface............................................................................................................24

10.4.2 Motion Detector.........................................................................................................24

10.4.3 Thermostat controller................................................................................................24

10.5 WARRANTIES.....................................................................................................................24

11 SAFETY REQUIREMENTS ........................................................ ..... .... ..... ..... .... ..... .... ..... ....24

11.1 FCC ...................................................................................................................................25

11.2 CE......................................................................................................................................25

12 STANDARDS...........................................................................................................................25

12.1 WEEE................................................................................................................................ 25

12.2 ROHS.................................................................................................................................25

13 DOCUMENTATION ..............................................................................................................25

13.1 TECHNICAL DESCRIPTION..................................................................................................25

13.1.1 Mechanical design .... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... ..... ..... .... .... 25

13.1.2 Documentation ..........................................................................................................25

13.1.3 Firmware design........................................................................................................25

Valid from Revision

P7

Author(s): Jan Elfstrom Page 3/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

(HRS)

1 DOCUMENT HISTORY

Revision Date Description Author

P1

P2

P3

P4

P5

P6

P7

2009-01-26

2009-02-12

2009-03-05

2009-03-13

2009-04-28

2009-11-20

2010-07-28

Created Jan Elfström

Computime review Jan Elfström

Adjustments, Counters added Jan Elfström

Design Review Jan Elfström

Adjustments, Parameters Jan Elfström

Adjustments, parameters Gordon Qian

Adjustments, parameters Gordon Qian

Valid from Revision

P7

Author(s): Jan Elfstrom Page 4/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

(HRS)

Valid from Revision

2 INTRODUCTION

The purpose of this document is to describe the product requirements in the Orion Energy

Management project.

2.1 Project Name

Orion Energy Management

2.2 Project Number

8003

3 REFERENCES

The following documents are referenced in this document:

61 8003 001 – Orion Project Requirement Specification

61 1100 032-18 - D-032 KOMMUNIKATIONSPROTOKOLL English

Orion Requirement Spec

Aesthetic Design – Br es sler Group

P7

4 DEFINITIONS

The following abbreviations are used in this document:

PRS Product Requirement Specification (This document)

MK Market Requirement Specification

TBD To Be Decided

NA Not Applicable

AAH ASSA ABLOY Hospitality

MCU Micro Controller Unit

BDM Background Debug Module

5 GENERAL REQUIREMENTS

The assumption made for the rest of this document is that a third party will supply the actual

hardware and partly FW used for this project. The exception is the use of the RF device described

later where the device supplied by ASSA ABLOY Hospitality shall be used.

It is also assumed the reader is familiar with the document “Orion Project Requirement

Specification” and “Orion Requirement Spec”.

MCU:s shall be of the Freescale HCS08 family (other types/brands can be used after approval).

5.1 User Interface

5.1.1 Introduction

The User Interface (UI) is the device where a local (in-room) user can check status of the energy

management system (e.g. set temperature, fan-speed) and control certain functions (e.g. alter set

temperature).

Author(s): Jan Elfstrom Page 5/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

5

(HRS)

Orion Energy Management Doc.No: 61 8003 011

N.B. Shall not be

mounted together!

Optional

Battery +

Radio

Display +

Keys

TempSensor

UI MCU

Thermostat Controller (TC)

+ Radio

5.1.6 Module Communications Interface

Possible configuration of the UI

5.2.4 I/OConnector

5.1.2 Housing

5.1.2.1 The mechanical design shall be based on the information received from

Bressler.

(Computime to give best estimate of box size after receiving 3D-model)

Valid from Revision

P7

.1.7 Service-Connector

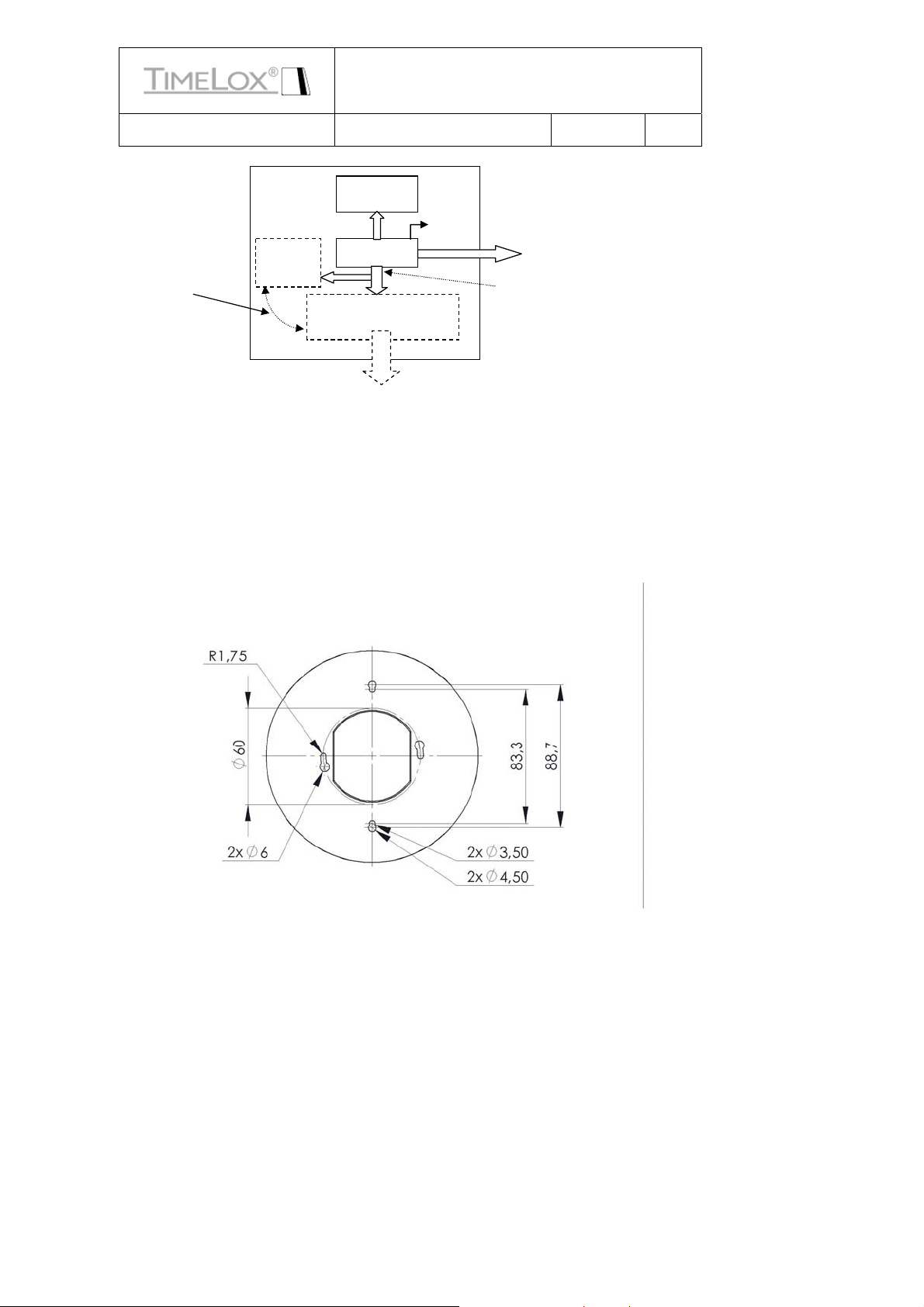

5.1.2.2 The mounting holes shall be such that t hey fit the following screw-patterns:

• Single gang junction box

• European single gang box

Example of hole pattern

Author(s): Jan Elfstrom Page 6/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.1.2.3 The mounting holes shall be of the key -hole type or similar to allow easy

mount/dismount and positi oning of the UI

5.1.2.4 The UI shall be designed to allow mounting of the TC or a battery pack

(3xAA) with a RF-device

5.1.2.5 The battery pack shall be easily accessed

5.1.2.6 The battery pack can be the standard AAH 3xAA cassette with cable (Art

No 4816065 + 4809763)

5.1.3 Display

5.1.3.1 The display shall have a visi b le size as defined by the indust rial design from

Bressler Group. (Computime to advice on the actual dimension)

5.1.3.2 The display graphics and sy m bols shall be designed accor ding to the

information received from Bressler.

Valid from Revision

P7

5.1.3.3 The following symbols shall be p o ss ible to control:

• Fan-speed indicator (Three steps)

• Service Indicator (Wrench)

• Error Indicator (E)

• Farenheit/Celsius Indica t or

• Locked Indicator (pad-lock symbol)

• Cooling/Heating Indicator (Snow-star/flame)

• Temperature read-out (two digits, seven segments)

• Battery indicator (Battery low only)

• Auto Indicator (AUTO) (This indicator can be an alpha numeric field)

5.1.3.4 The display technology shall be of the transflective LCD type.

5.1.3.5 Viewing angle

:

55o @12:00 clock direction

5.1.3.6 Backlighter shall be LED

5.1.3.7 Backlighter shall be possible to control (on/off)

5.1.3.8 Backlighter colour is to be white

5.1.4 User Controls

5.1.4.1 The following user controls shall be used

• On/Off button (Controls only EMS functions, not system power)

• Fan Control button (Switch steps through settings)

Author(s): Jan Elfstrom Page 7/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

• “Up” button

• “Down” button

• Celsius/Fahrenheit button (Toggle function)

5.1.5 Electrical interface levels

5.1.5.1 The UI I/O shall tolerate voltages in the range 3 – 5VDC

5.1.5.2 The UI output voltage-levels shall be in the range 0 - 5VDC

5.1.5.3 Logical high level shall be minimum 3.0V

5.1.5.4 Logical low level shall be maximum 0.5V

5.1.6 Module Communications Interface

5.1.6.1 The communication to/from the UI shall be wi t h asynchronous full duplex

communication (38400 8N1)

Valid from Revision

P7

5.1.6.2 The communication protocol shall be based on the specif ication D-032

5.1.6.3 The electrical interface betwe en the UI and other modules shall be over a 6pin JST PHR-6, tin plated or equivalent c onne ctor

5.1.6.4 The wire harness for the PHR-6 connector shall be 50 mm long

5.1.6.5 The following pin-out sh all be used:

1- VCC

2- GND

3- Activate (UI)

4- Wakeup (Module)

5- RxD (From UI)

6- TxD (To UI)

5.1.7 Service Interface

5.1.7.1 The UI shall have a service connect or o f the type 3.5mm stereo-jack

5.1.7.2 The Service connector shall be protected against ESD (8KV for air

discharge )

5.1.7.3 The following signals sh al l be used

1- Power input 3.5 – 10VDC (tip)

2- Serial communication (middle)

3- GND (inner)

Author(s): Jan Elfstrom Page 8/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.1.7.4 The serial communication to/from the service interface shall be with

asynchronous half duplex communication (38400 8N1)

5.1.7.5 The serial communication shall be initiated with an “ACK” (0x06) from the

UI when external power is detected at the service connector

5.1.7.6 The initiation shall be complete in the interval 50 - 200ms after external

power is detected

5.1.7.7 The service device shall answer with “ACK” in the interval 0 - 200ms after

the “ACK” is transmitted

5.1.7.8 The UI shall accept a command- set implemented by AAH

5.1.7.9 The UI shall handle communication through the service connector to the

thermostat or RF module over the module communications interface

5.1.7.10 The service-connector sh al l be placed at the bottom of the UI (Not visible

from front)

Valid from Revision

P7

5.1.7.11 The service-connector shall be placed such that it is easily accessible

5.1.7.12 The service-connector shall tolerate voltages in the range 3 – 10VDC

5.1.7.13 Logical high level shall be minimum 3.0V

5.1.7.14 Logical low level shall be maximum 0.5V

5.1.8 Power supply

5.1.8.1 The UI shall be possible to run off three AA 1.5V alkaline cells (3.2 – 4.5V)

5.1.8.2 The UI shall be possible to run on an external fixed +3.2 - +5V supply

(Supplied through the Module Communications Interface) from the TC

5.1.8.3 The UI shall have a maximum average current consumption of 4mA @4.5V

(not including other modules)

5.1.8.4 The UI shall have a maximum curren t consumption of 150mA @+4.5V (not

including other modules)

5.1.8.5 The supplied voltage shall be possible to read with a minimum resolution of

0.1V

5.1.9 Temperature sensor

Author(s): Jan Elfstrom Page 9/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

5

odule Communications

ace

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.1.9.1 The UI shall have the means of measuring temperature

5.1.9.2 The temperature value shall have a tolerance of +/-0.5°C including drift

5.1.9.3 The temperature sensor shal l have a calibrated value of +/-1°C @22°C

5.1.10 Firmware

5.1.10.1 The UI firmware (FW) shall be possible to upgrade through the service

connector using the AAH stan dard bootloader protocol

5.1.10.2 A callback function called when a key-press or other event occur shall be

implemented for AAH use.

5.1.10.3 A control structure shall be developed for accessing and controlling

resources in the UI (e.g. displayed symbols, temperature display etc)

5.1.10.4 A data structure with information of pressed keys, temperature reading etc

shall be developed

Valid from Revision

P7

5.2 Thermostat Controller

5.2.1 Introduction

The Thermostat Controller (TC) is the device where the actual logic for energy management is

implemented. It is also the device controlling the other in-room devices connected to the EMS

system and can be connected to a central control system.

Possible configuration of the TC

Author(s): Jan Elfstrom Page 10/25

CONFIDENTIAL ©TIMELOX AB

TC MCU

Signal

Conditioning

5.2.4 I/OConnector

.2.5 M

Interf

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.2.2 Housing

5.2.2.1 The TC shall be designed to fit the housing of the UI and the Thermo stat

Controller Expander device

5.2.3 Electrical interfaces

5.2.3.1 The electrical interface between the TC an d ot her modules shall be over a

6-pin, tin plated connector sui t able for a JST PHR-6 connector plug

5.2.3.2 The TC module I/O shall tolerate voltages in the range 3 – 5VDC

5.2.3.3 The TC module I/O output voltage-levels shall be in the range 0 - 5VDC

5.2.3.4 Logical high level shall be minimum 3.0V

5.2.3.5 Logical low level shall be maximum 0.3V

5.2.3.6 A connector for the MCU BDM shall be included in the desi gn

Valid from Revision

P7

5.2.4 I/O Connector

5.2.4.1 The TC shall have a I/O connector for contr ol li ng external systems, e.g. airhandlers

5.2.4.2 The TC module I/O shall tolerate voltages up to 30VDC

5.2.4.3 Logical high level shall be minimum 5.0V

5.2.4.4 Logical low level shall be maximum 0.5V

5.2.4.5 The I/O connector shall be of the type Molex KK 2695 2.54mm or

equivalent

5.2.4.6 The I/O connector shall have the following pin-out:

1- W/W2 – Heating (Output)

2- Y/W1 – Cooling / Compressor (Output)

3- G1 – Fan 1 (Output)

4- G2 – Fan 2 (Output)

5- G3 – Fan 3 (Output)

6- RV – Reversing valve (Output)

7- Emergency Heating - Outputs

8- Door Switch – Interior (Intput)

9- Door Switch – Exterior (Intput)

10- Extra Input1 (Intput)

11- Ground

Author(s): Jan Elfstrom Page 11/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management

12- Power out for External Switch

13- Power Supply Common for Thermostat

14- Power Supply for thermostat

Doc.No:

61 8003 011

5.2.4.7 The I/O connector shall control outputs through potential free switches (e.g.

relay)

5.2.4.8 The I/O connector shall have the same potential for all I/O

5.2.4.9 The TC shall be delivered with a wire-h a rn e ss fitting the I/O connector with

a wire length of 150mm +/-10mm. (Col o rs a s defined below)

1- W/W2 – White)

2- Y/W1 – Yellow

3- G1 – Green

4- G2 – Orange

5- G3 – Dark Blue

6- RV – Violet

7- Emergency Heating - Brown

8- Door Switch –Interior – Gray (not hard requirement)

9- Door Switch – Exter ior – Orange/Blue (not hard requirement)

10- Extra Input1 (Intput) – Pink (not hard requirement)

11- ground –Black

12- Power out for External Switch – White/Black

13- Power Supply Common for Thermostat – Light Blue

14- Power Supply for thermostat – Red

(HRS)

Valid from Revision

P7

5.2.4.10 The I/O Connector shall be secu red with a friction lock or similar

5.2.4.11 Wires with an area of AWG 22 shall be u sed

5.2.4.12 A visible label shall be incl uded indicating signals in I/O co nnector

5.2.5 Module Communications Interface

5.2.5.1 The communication to/from the TC shall be with asynchronous full duplex

communication (38400 8N1)

5.2.5.2 The TC shall accept a command-set implemented by AAH

5.2.5.3 The following pin-out sh all be used:

1- VCC (Power out to UI)

2- GND

3- Activate (UI)

4- Wakeup (TC)

5- RxD (To TC)

Author(s): Jan Elfstrom Page 12/25

CONFIDENTIAL

©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

6- TxD (From TC)

5.2.5.4 The TC firmware (FW) shall be possible to upgrade

(HRS)

Valid from Revision

P7

Author(s): Jan Elfstrom Page 13/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.2.5.5 There shall be a minimum of 32kByte Flash and 500 byte RAM availa bl e

for AAH use

5.2.6 Power supply

5.2.6.1 The TC shall be possible to run on a fixed 12 – 30VAC/DC supply

5.2.6.2 The TC shall have a maximum current consumption of 150mA @24VDC

TBD (not including other modules)

5.2.6.3 The power supply inputs shall be protected against reversed polarity

5.2.6.4 The power supply inputs shall have p r otection against short circui t (nonpermanent, no change of components)

5.2.7 Firmware

5.2.7.1 The TC firmware (FW) shall be possible to upgrade through the 6-pin

Module Communications Connector usi n g the AAH standard bootloader prot ocol

Valid from Revision

P7

5.2.7.2 Test-mode

When the TC is put in test-mode by the service-tool, all outputs shall be disabled. All

output and input-states shall be possible to observe on the te st-t ool.

5.2.7.3 A callback function called 1/ s shall be implemented for AAH use.

5.2.7.4 A control structure shall be dev eloped for accessing and co ntrolling

resources in the TC, including external inputs.

5.2.7.5 The responsibility for the actual implementation of different functionality is

AAH

5.2.8 Parameters - CT

The following parameters in NV memory is to control the TC. These values are to be

filled in by AAH and used by Computime.

5.2.8.1 ActualTemperature – The reported temperature (external sensor or UI

sensor)

5.2.8.2 ManualOverrideBitField – Controls for service purp oses

• Fan-on (bit7) – Turn on the fan

• Fan-speed (bit6-5) – Fan speed, 0 - 2

• Heat (bit4) – Turn on heating

• Cool (bit3) – Turn on cooling

• RFU (bit2-0)

Author(s): Jan Elfstrom Page 14/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

5.2.8.3 ControlBitfield1 – Controls for TC operation

• FanMan (bit7) – Manual Speed (1), Auto (0)

• FanSat (bit6) – Run when satisfied (1), Stop when satisfied (0)

• SetbackEnable (bit5) – Use setback set-point

• Thermostat enable (bit4) – 1: Turn on thermostat

• MaxFan (bit3-2) – Max allowed fan-speed (if less than three steps)

• Fan-speed (bit1-0) – Fan speed 0-2, valid if FanMan = 1

5.2.8.4 ControlBitfield2 – Controls for TC Service

• ServiceEnable (bit7) (Disables all outputs for manual control)

• BacklighterEnable (bit6) (For test of LED)

• REL6Enable (bit5)

• REL5Enable (bit4)

• REL4Enable (bit3)

• REL3Enable (bit2)

• REL2Enable (bit1)

• REL1Enable (bit0)

5.2.8.5 ActualSetpoint – The TC setpoint 0-99°F

(HRS)

Valid from Revision

P7

5.2.8.6 ActualDeadbands

• Heat/Cool switching (bit7,6,5,4) 2-4°F

• Thermostat deadband (bit3,2,1,0) 1-3°F

Author(s): Jan Elfstrom Page 15/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.2.8.7 ActualSetbackUpper - Setpoint in setback cooling 0-99°F

5.2.8.8 ActualSetbackLower - Setpoint in setback heating 0-99°F

5.2.9 Parameters - AAH

5.2.9.1 AAH Parameters – 84 bytes of NV memory st o ra ge shall be reserved for

AAH use

5.2.9.2 AAH RFU Parameters - 20bytes

5.2.10 Audit Trail

5.2.10.1 An audit trail of 100 entries shall be included

5.2.10.2 The audit trail shall be desi gned in a round-robin fashion such th at the

oldest event gets overwritten first

5.2.10.3 The audit trail shall be stored in a non volatile memory, e.g. ext ernal

E2PROM

Valid from Revision

P7

5.2.10.4 Each event shall be ten bytes long

5.2.10.5 Alarms e.g. battery-level shall set a flag that can be reset by EMS-system or

service terminal

5.2.11 HVAC Control Chart – Standard Control

Temperature difference from

Guest Setting

+4 Y, G3 (Cooling)

+3 Y, G2 (Cooling)

+2 Y, G1 (Cooling)

+1 None

0 None

-1 None

-2 W, G1 (Heating)

-3 W, G2 (Heating)

-4 W, G3 (Heating)

Active Outputs

Author(s): Jan Elfstrom Page 16/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.2.12 Real Time Clock (RTC)

5.2.12.1 A RTC shall be designed based on a standard low power 32kHz crys t al

5.2.12.2 The RTC function can be an internal MCU timer clocked by the low power

crystal

5.2.12.3 Maximum time deviation over a year sh a ll be + /-15 minutes

5.2.12.4 The minimum resolution shall be one minute

5.2.12.5 The real time shall be an incremental numb er with the length of four bytes

5.2.12.6 The start time for the real-time count (0) shall be 1996-07-20 00:00

5.2.12.7 No support for day-light savi ng shall exist

5.2.13 Counters

Valid from Revision

P7

5.2.13.1 Counter for total HVAC run time [32-bit value, minute resolution]

5.2.13.2 Counter for HVAC run time maintaining the guest set-point (starts when

guest set-point is first reached from set-back) [32- b it value, minute resolution]

5.2.13.3 Counter for total HVAC run time in unoccupied and unsold set-bac k

including recovery time from setback to set point [32-bit value, minute resolution]

5.2.13.4 Counter for total occupancy time [32 -bit v a lue, minute resolution]

5.2.13.5 Three maintenance run time parameters [32-bit value, minute resolution]

• tlmMaintenanceCounter1

• tlmMaintenanceCounter2

• tlmMaintenanceCounter3

Author(s): Jan Elfstrom Page 17/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.2.13.6 When one of the three maintenance parameter values match the total

HVAC run time counter, a notification shall be sent to the server indicating which of the

parameters that triggered the event.

5.2.13.7 The three maintenance run time parameters shall be possible to update

using the EMS GUI or the commissioning tool

5.2.13.8 The maintenance run time parameters shall be updated with an offset added

to the total HVAC run time counter

5.2.13.9 The counters and maintenance parameters shall be stored in non-volatile

memory

5.3 Motion Detector

5.3.1 Introduction

The Motion Detector (MD) is used to detect and report movement in the room. It can also be used

in suite configurations. It is a battery operated device.

Valid from Revision

P7

Author(s): Jan Elfstrom Page 18/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.3.2 Housing

5.3.2.1 The mechanical design shall be based on th e industrial design from

Bressler Group and modifie d when suitable lens design found)

5.3.2.2 The mounting holes shall be of the key -hole type or similar to allow easy

mount/dismount and positi oning of the MD

5.3.2.3 The MD shall be designed to allow mounting of a RF-device

5.3.2.4 The battery pack shall be easily accessed

5.3.2.5 The battery pack can be the standard AAH 3xAA cassette with cable (Art

No 4816065 + 4809763)

5.3.3 PIR Detector

5.3.3.1 The PIR Detector (PD) shall be powered by three AA alkaline batteries

Valid from Revision

P7

5.3.3.2 The PIR Detector (PD) Sense range and angle

Author(s): Jan Elfstrom Page 19/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.3.3.3 The PD shall have a maximum current consumption of 15mA @4.5VDC

TBD (not including other modules)

5.3.3.4 The PD shall have a maximum average current consumption of 150uA

@4.5V when PIR is on and 25uA @4.5V when PIR is OFF (not including other modules)

5.3.3.5 The PD shall have a service connector of the type 3.5mm stereo-jack

5.3.3.6 The Service connector shall be protected against ESD (8KVair discharge )

5.3.3.7 The following signals shal l be used (J2):

1- Power input 3.5 – 10VDC (tip)

2- Serial communication (middle)

3- GND (inner)

5.3.3.8 The electrical interface betwe en the PD and other modules shall be ove r a

6-pin JST PHR-6, tin plated or equivalent connector

5.3.3.9 The wire harness for the PHR-6 connector shall be 50 mm long

Valid from Revision

P7

5.3.3.10 The following pin-out shall be used (J1):

1- VCC (Battery voltage to RF-device)

2- GND

3- Activate

4- Wakeup

5- RxD (Serial connection to service connector)

6- TxD (Not used)

5.3.3.11 The following connection shall be used (including ESD protection etc):

1- Power (J1:1 – J2:1)

2- GND (J1:2 – J2:3)

3- Serial data (J1:5 – J2:2) (N.B. J1:1-2 might need to be externally connected)

Author(s): Jan Elfstrom Page 20/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

5.4 RF Device

5.4.1 RF Device for User Interface (Phase 2)

5.4.1.1 The RF device 68 3081 055 or similar supplied by AAH shall be used

5.4.1.2 The RF device firmware can be special for this application

5.4.2 RF Device for Motion Detector

5.4.2.1 The RF device 68 3081 055 or similar supplied by AAH shall be used

5.4.2.2 The RF device firmware can be special for this application

5.4.3 RF Device for Thermostat Controller

5.4.3.1 The RF device 68 3081 055 or similar supplied by AAH shall be used

5.4.3.2 The RF device firmware can be special for this application

Valid from Revision

P7

5.5 Thermostat Controller Expander

5.5.1 Introduction

The Thermostat Controller Expander (TCE) is accepting the TC as a piggy back device. This allows

the use of the TC+TCE as a standalone device with the possibility of e.g. external power and more

rugged connections. It will also form a more rugged housing for the TC.

(TCE will be designed for Phase 2 of this project)

5.5.2 Housing

5.5.2.1 TBD

5.5.3 Connectors and interfaces

5.5.3.1 The TCE shall have a service connect o r of the type 3.5mm stereo-jack

5.5.3.2 The Service connector shall be protected against ESD (8KV for air

discharge )

5.5.3.3 The following signals for the service connector shall be used

1- Power input 3.5 – 10VDC (tip)

2- Serial communication (middle)

3- GND (inner)

Author(s): Jan Elfstrom Page 21/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

5.5.3.4 The electrical interface between the TCE and the TC shall be over a 6-pin

JST PHR-6, tin plated or equivalent connector

5.5.3.5 The wire harness for the PHR-6 connector shall be TBD mm long

5.5.3.6 The following pin-out for the PHR- 6 shall be used:

1- VCC (Power to TCE logic)

2- GND

3- Activate (TBD)

4- Wakeup (TBD)

5- RxD (Serial connection to service connector)

6- TxD (Not used)

7-

5.5.4 Housing

5.5.4.1 TBD

(HRS)

Valid from Revision

P7

6 FIRMWARE REQUIREMENTS

6.1 Design

6.1.1 Firmware

6.1.1.1 The firmware shall be stored in a non-volat ile mem o ry

6.1.1.2 The firmware shall be possible to change in field

6.1.1.3 A boot-loader shall be used for ch ange of firmware through the serviceinterface

6.1.1.4 The bootloader shall function according to the AAH standard bootloader

protocol

7 ELECTRICAL REQUIREMENTS

NA

8 MECHANICAL REQUIREMENTS

8.1 Aesthetic design

The overall aesthetic design shall be according to the Bressler guidelines

Author(s): Jan Elfstrom Page 22/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

(HRS)

8.2 Functional design

The functional design is left open to best fit the production requirements and the aesthetic design

Valid from Revision

P7

9 SOFTWARE REQUIREMENTS

NA

10 ENVIRONMENTAL REQUIREMENTS

10.1 Temperatures

10.1.1 Storage temperature

10.1.1.1 The storage temperature for all devices shall be -20 - +85°C

10.1.2 Operating temperature

10.1.2.1 The operating temperature for all devices shall be 0 - + 45°C

10.2 Humidity

10.2.1 Storage humidity

10.2.1.1 The storage humidity for all devices shall be 10-98%RH non-condensing

10.2.2 Operating humidity

10.2.2.1 The operating humidity for all devices shall be 15-95%RH non-condensing

10.3 Protection

A general test shall be made with each device to find which components that is sensitive to

condensation. Those areas shall then be protected with conformal coating.

Author(s): Jan Elfstrom Page 23/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

(HRS)

Orion Energy Management Doc.No: 61 8003 011

10.3.1 User Interface

10.3.1.1 The device shall meet IP20 classification

10.3.2 Motion Detector

10.3.2.1 The device shall meet IP20 classification

10.3.3 Thermostat Controller

10.3.3.1 The device shall be part of the User Interface and is covered by that

housing

10.4 Life cycle requirement

10.4.1 User Interface

10.4.1.1 The LED backlighter intensity shall not degrade below 50%of the initial

value before 50000 h

Valid from Revision

P7

10.4.1.2 The switches shall not fail before 20000 cycles

10.4.1.3 The unit except the LED and switches shall have a life cycle of ten years of

normal use

10.4.2 Motion Detector

10.4.2.1 The unit shall have a life cycle of ten years of normal use

10.4.3 Thermostat controller

10.4.3.1 The r elays shall not fail before 100000 cycles

10.4.3.2 The unit shall have a life cycle of ten years of normal use

10.5 Warranties

11 SAFETY REQUIREMENTS

Normal safety precautions shall be made to prevent fire etc.

Author(s): Jan Elfstrom Page 24/25

CONFIDENTIAL ©TIMELOX AB

Hardware Requirement Specification

Orion Energy Management Doc.No: 61 8003 011

11.1 FCC

11.2 CE

12 STANDARDS

12.1 WEEE

12.2 RoHS

13 DOCUMENTATION

13.1 Technical Description

13.1.1 Mechanical design

(HRS)

Valid from Revision

P7

13.1.1.1 The mechanical design shall be fully documented

13.1.1.2 The IGS/STEP format shall be used for exchanging 3D models

13.1.1.3 The DXF format shall be used for exchanging 2D drawings

13.1.1.4 The native Solid Works format can be used for all documentation

13.1.2 Documentation

13.1.2.1 All final documentation shall be in the Timelox defined form an d shape

including document numbers

13.1.3 Firmware design

13.1.3.1 All open interfaces shall be fully documented

13.1.3.2 A general functional description shall be delivered

FCC STATEMENT

1. This device complies with Part 15 of the FCC Rules.Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

2. Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

RF warning statement:The device has been evaluated to meet general RF exposure requirement.

The device can be used in portable exposure condition without restriction.

Author(s): Jan Elfstrom Page 25/25

CONFIDENTIAL ©TIMELOX AB

Loading...

Loading...