Page 1

Operation Manual

Compur Statox 4120

Page 2

Compur Statox 4120

This document is subject to changes without notice. Regular updates can be viewed on our web site

www.compur.com

You are welcome to communicate any proposal how to improve this document to Compur Monitors.

Copyright Compur Monitors GmbH & Co. KG

Published by: Compur Monitors GmbH & Co. KG

Weissenseestrasse 101

D-81539 München

Tel. 0049 (0) 89 62038 268

Fax. 0049 (0) 89 62038 184

2

Page 3

Compur Statox 4120

Contents

Seite

1. Important notice 4

2. The Statox 4120 System: Purpose of use and description 4

2.1 Statox 4120 sensor head 5

2.2 Statox 4120 rack 6

2.3 Statox 4120 control module 8

2.4 Diagnostic box 9

3. Installation and electrical connections 10

3.1 Statox 4120 sensor head 10

3.1.1 Mounting 10

3.1.2 Connecting the signal cable 11

3.2 Statox 4120 rack 13

3.3 Statox 4120 control module 14

3.4 Switch positions of the sensor head pcb 15

4. Compur Statox 4120 operation 18

4.1 Start - up 18

4.2 Alarm thresholds 18

4.3 Detection mode 18

4.4 Self test of the system 18

4.5 Manually triggered self test of the system 19

4.6 System failure 19

5. Trouble shooting 19

5.1 Using the diagnostic box 20

5.1.1 Operation and error codes of the diagnostic box 20

5.1.2 Status messages of the sensor head 21

6. Maintenance and calibration 22

6.1 Inspection Statox 4120 sensor head 22

6.2 Sensor head calibration 23

6.2.1 Using span gas 23

6.2.2 Use ex-works calibration 24

7. The maintenance request option 25

8. The option analog output inhibition 28

9. The option zero adjustment 29

10. Technical data 30

11. Accessories and spare parts 32

Addendum: Declaration of conformity 34

3

Page 4

Compur Statox 4120

1. Important notice

Statox 4120 is an explosion proof system for the detection of toxic gases. It can be operated in

hazardous areas classified division 1 and 2.

Before installing and putting Statox into operation read and observe this manual!

To operate the system safely, observe this manual carefully. It must be operated and maintained by

qualified and authorised personnel. No other application than ambient air monitoring of the gas

specified is authorised by the manufacturer.

Safety guidelines

Prior to connecting and installing the Statox 4120 system check if all any safety – relevant

parameters of the system and its environment are in accordance with specifications and

local regulations.

If the Statox sensor head is installed in a potentially hazardous atmosphere the safety

relevant parameters of the sensor head and the control module must be observed. Please

use cable specified as recommended in this operation manual.

Operating conditions must not exceed the specifications.

The alarm relays of Statox 4120 are only safe to operate 24 V DC. Do not connect to mains.

Maintenance work must be carried out by trained personnel only.

Use exclusively original spare parts, accessories and consumables.

If the safety guidelines are not observed, the Ex approval will be void!

The instrument has to be inspected and serviced in regular intervals by trained personnel. For service

or training contact your local Compur Monitors representative. The maximum maintenance interval

should be 6 months.

2. The Statox 4120 system: Purpose of use and description

Compur Statox 4120 is a stationary toxic gas detection system. It monitors continuously ambient

atmosphere indoor and outdoor. It`s integrated self test provides maximum safety of operation.

Two user - adjustable alarm thresholds A1 und A2 can be set to any value within the measuring range.

It consists of these components:

Statox 4120 sensor head

Statox 4120 rack

Statox 4120 control module

Diagnostic box

The Statox 4120 control module communicates a digital signal via a two-wire cable with the sensor

head. It operates as power supply, alarm device and signal display. The system permanently checks

itself for proper function and will alarm if any parameter is geting out of specifications. Sensor

calibration and system fault diagnosis is easily achieved using the Statox portable diagnostic box.

4

Page 5

Compur Statox 4120

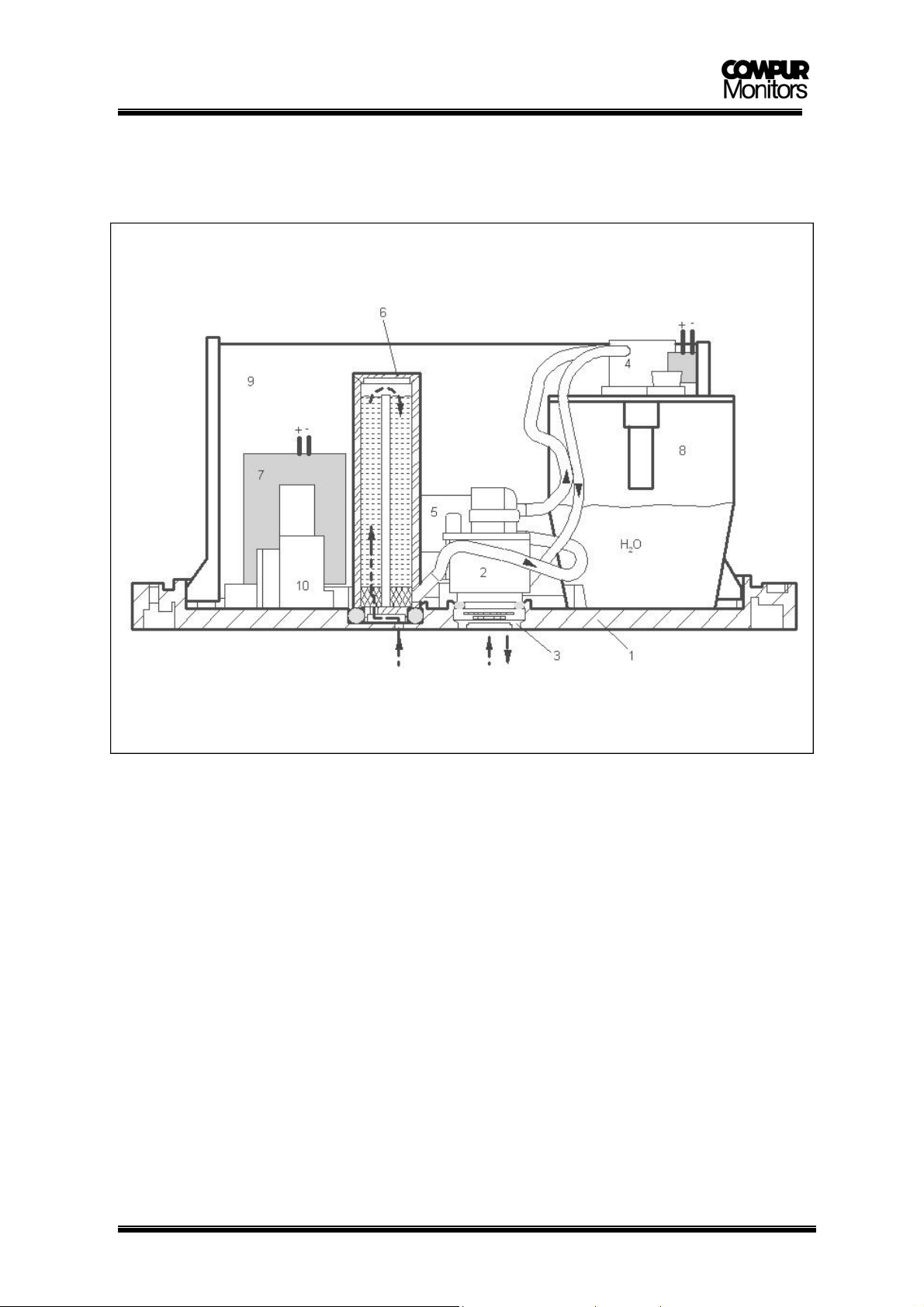

2.1 Statox 4120 sensor head

pic. 1: Statox 4120 sensor head

1 Bottom part

2 Statox 4120 sensor

3 Statox 4120 dust filter

4 Gas generator

5 Statox 4120 pump

6 Statox 4120 filter cartridge

7 Buffer battery for pump operation

8 Water container

9 Electronics

10 Opto - coupler for communication with the diagnostic box

5

Page 6

Compur Statox 4120

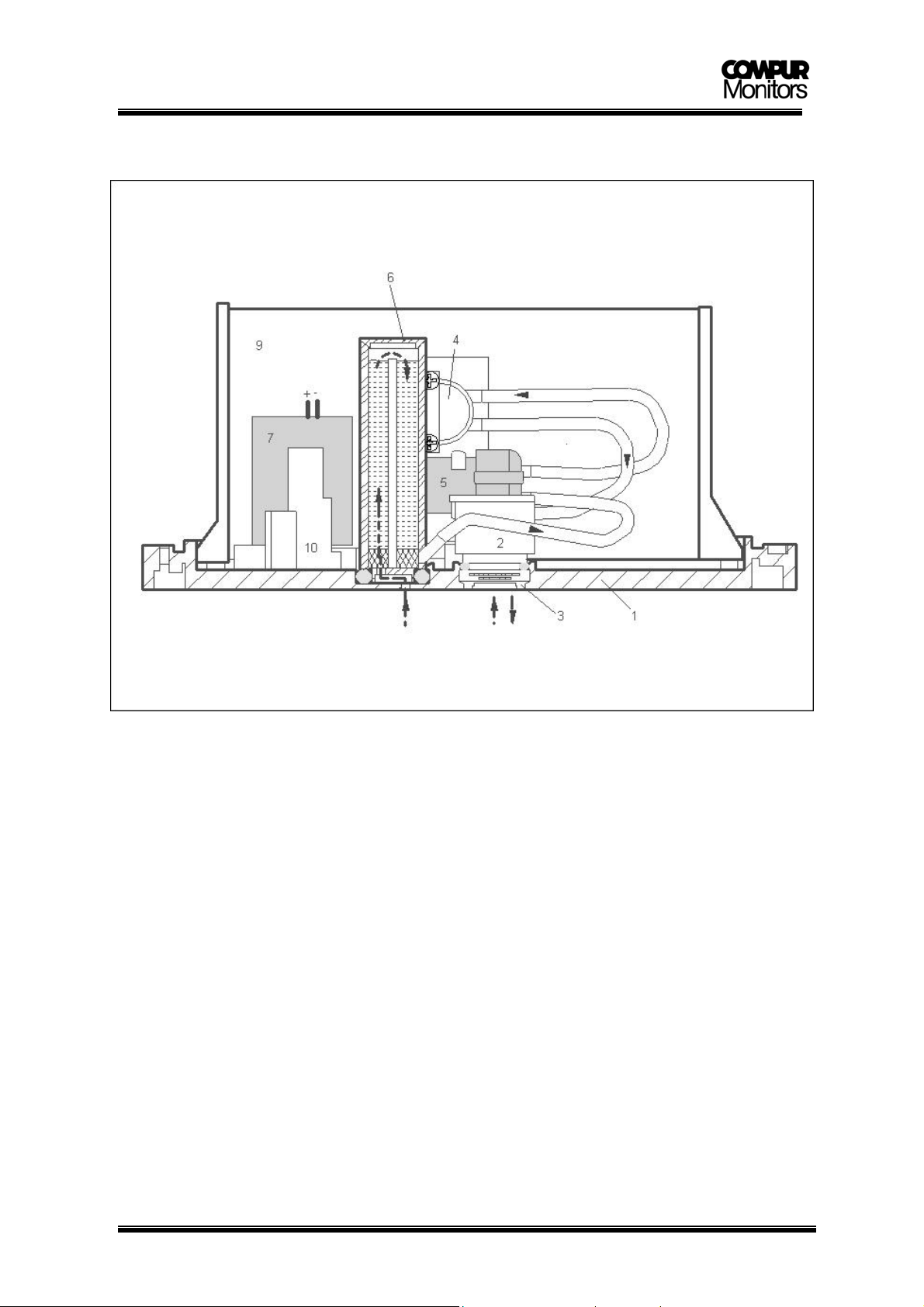

pic. 2: Statox 4120 sensor head for Cl

Operation principle

Ambient air enters the sensor (2) by diffusion through an opening at the bottom. The sensor creates a

current - signal proportional to the gas concentration. This signal is amplified, temperature

compensated and linearised. As a digital signal it is transmitted to the control module.

To protect the sensor from being poisoned by a high gas concentration, the Statox features a built – in

air purge. This is activated when the gas concentration exceeds 95 % of the measuring range and

stops when it has dropped below 80 %.

The battery pack (7) buffers the energy demand of the built – in pump (5). It is on permanent trickle

charge. The pump is activated in the protection mode and during the self test to purge the sensor and

provide test gas from the gas generator (4) to the sensor.

und ClO2

2

2.2 Statox 4120 rack

The Statox 4120 rack and the Statox 4120 control module provide the power supply for the sensor

head. They are certified explosion proof [EEx ib] IIC. The rack must not be installed in certified

areas!

6

Page 7

Compur Statox 4120

Construction:

The system consists of a 19“-4-HE rack with backplane and up to nine Statox 4120 control modules.

Each Statox 4120 sensor head is communicating with one control module. The Statox 4120 rack is

available in following designs:

STATOX 4120 Rack ½ x 19“ for 4 Control modules

STATOX 4120 Rack 19“ for 9 Control modules

STATOX 4120 Rack 19“ for 9 Control modules / RFI shielded

STATOX 4120 Desk case for 4 Control modules

STATOX 4120 Desk case for 19“ Rack with 9 Control modules

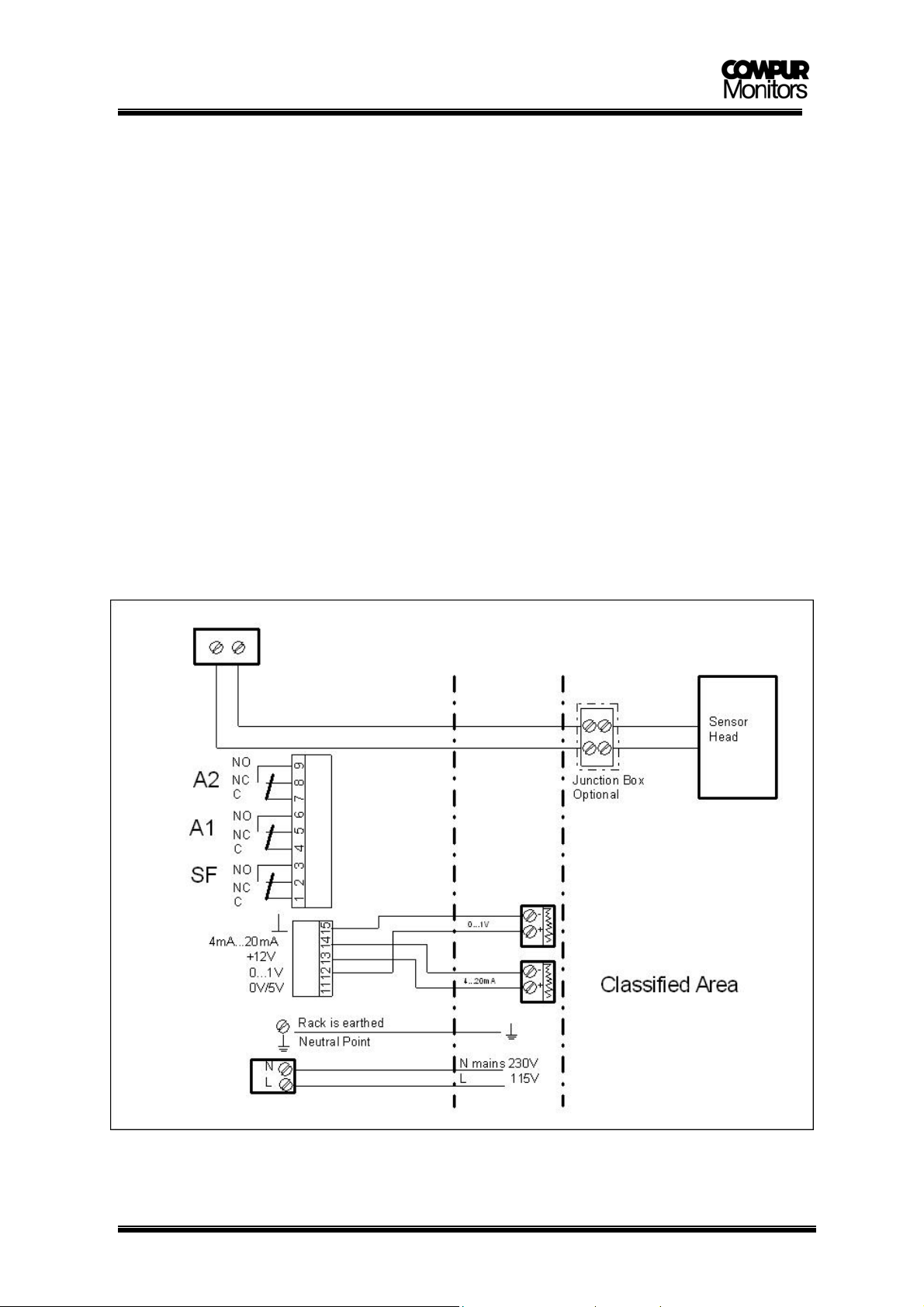

Connections:

On the backplane (pic. 3) you find the following terminals:

power supply 230 V/AC (115V/AC)

Intrinsically safe terminals (signal cable, 22V/DC, 50mA) for data transmission and sensor head

power supply.

Analog outputs: 0-1V

4-20 mA

Potential free relays: Pre-alarm A1

Main alarm A2

System alarm SF

The A1 and A2 relay signal of the Statox 4120 control module is programmable.

pic.3: Electrical connections

7

Page 8

Compur Statox 4120

2.3 Statox 4120 control module

Each Statox 4120 Control module has its own power supply. The intrinsically safe sensor head supply

circuit is supplied by a separate secondary winding.

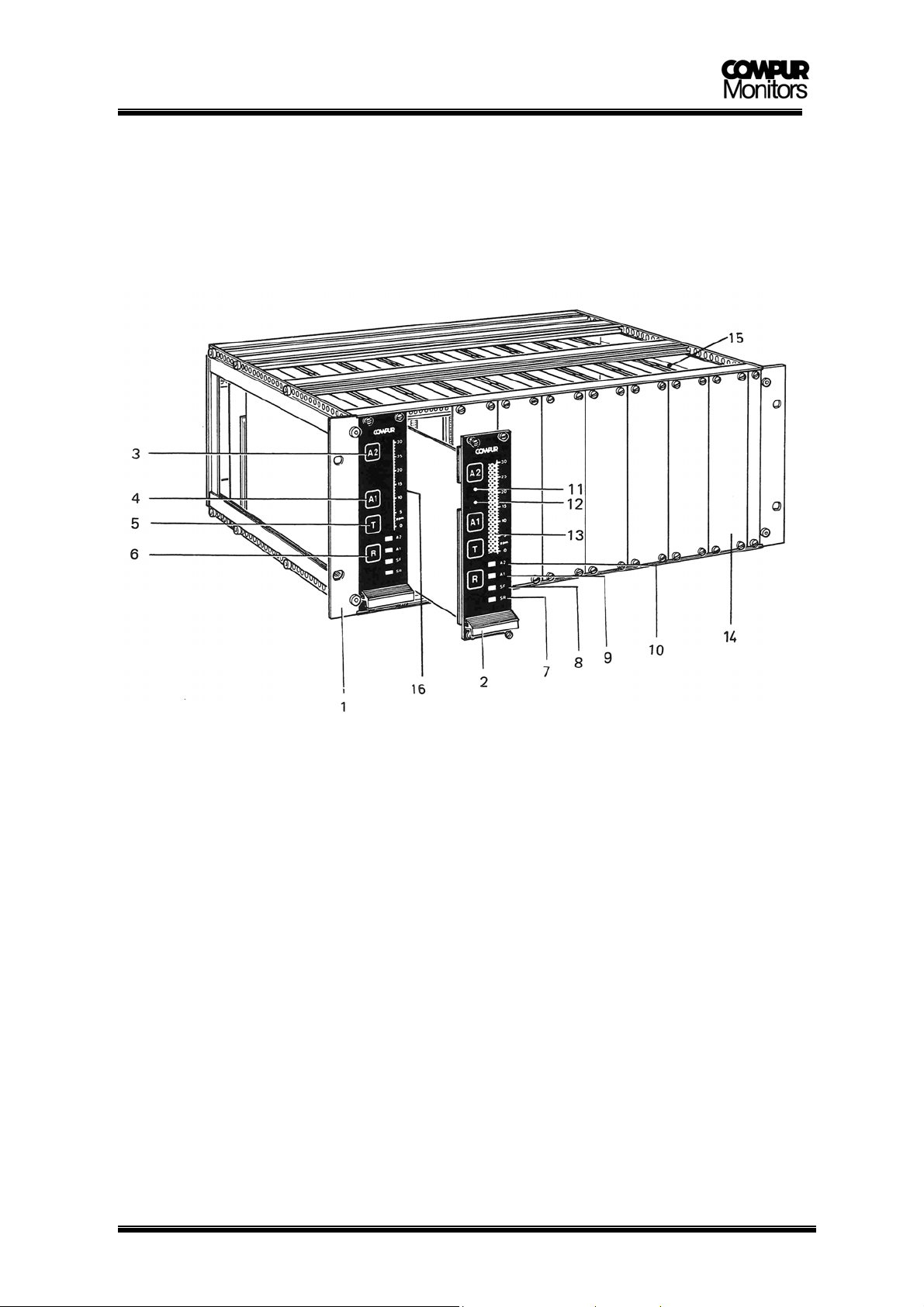

pic.4: Statox 4120 Rack

1 19“ Rack 9 LED A1

2 Statox 4120 control module 10 LED A2

3 Button A2 11 Potentiometer for A2

4 Button A1 12 Potentiometer A1

5 Button T 13 Bar graph display

6 Button R 14 Blind panel

7 LED SR 15 Rail

8 LED SF 16 ppm Scale

Bargraph display (13)

- Actual measured concentration value.

- Flashing when measuring range is exceeded and pump is on.

LED SR (7) „System ready“

- On if system is working properly.

- Flashing after power up until system is communicating fault - free.

- Flashing while diagnostic box is connected.

LED SF (8) „System Fail“

- On if a system failure has occurred. (Self test not passed, communication error, cable

interrupted).

8

Page 9

Compur Statox 4120

LED A1 (9)

- On if pre - alarm threshold is exceeded

Display A2 (10)

- On if main alarm threshold is exceeded

Button A1 (4)

- Press and hold button A1 to display A1 threshold. Adjust with Pot. (12). A1 must be < A2.

Button A2 (3)

- Press and hold button A2 to display A2 threshold. Adjust with Pot. (11).

Button T (5) „Test“

- Initiates self test.

Button R (6) „Reset“

- Rests Alarms A1, A2 und SF provided the reason for the alarm has disappeared. (If SF has

been triggered by a not passed self test, only a successful self test will reset it).

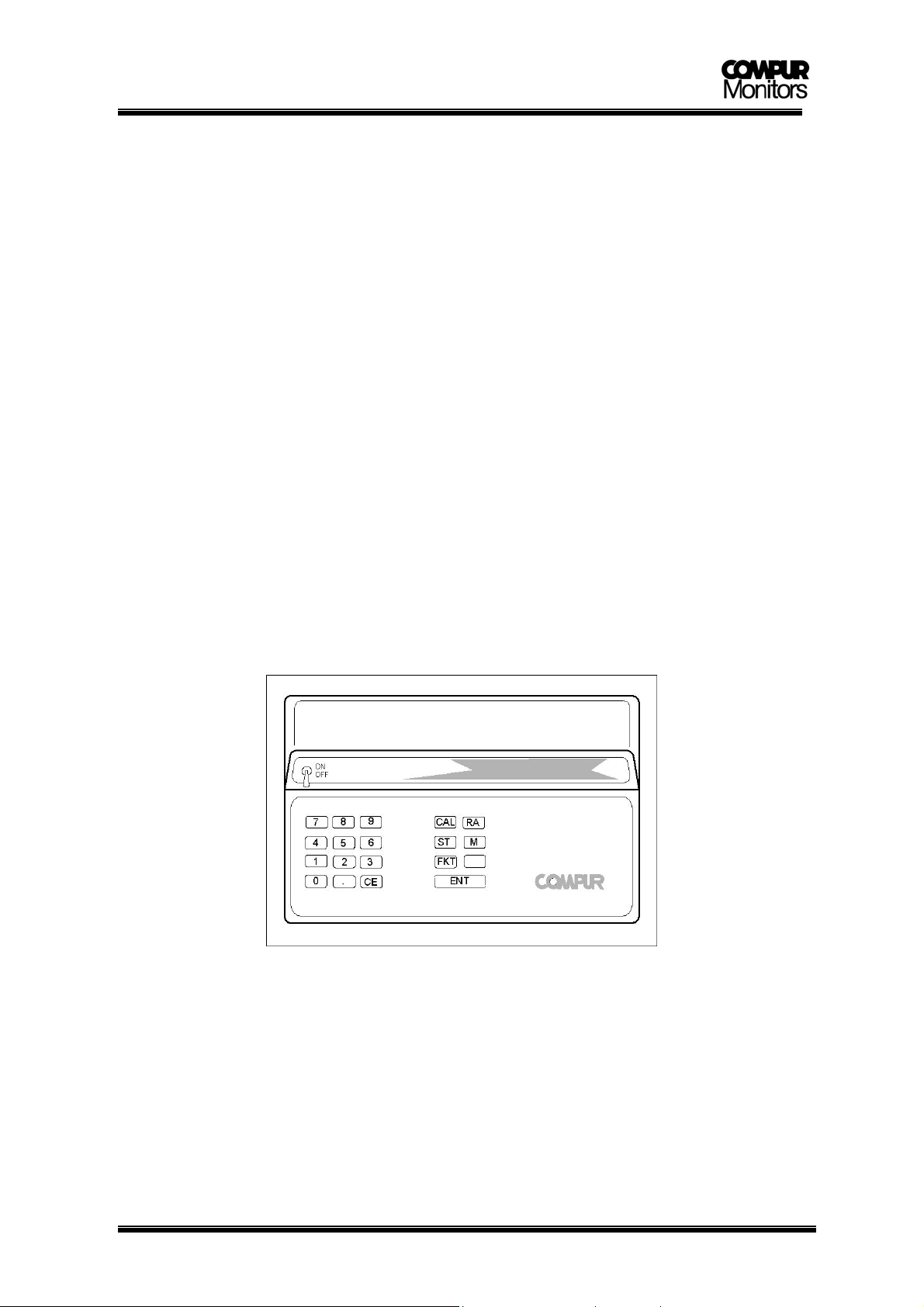

2.4 Diagnostic box

pic.5: Diagnostic box

The diagnostic box must not be charged in classified areas or with other than charger Art.# 518850.

It has the following purposes:

Calibration

Fault diagnosis

On site display

Function test

9

Page 10

Compur Statox 4120

3. Installation and electrical connections

3.1. Statox 4120 sensor head

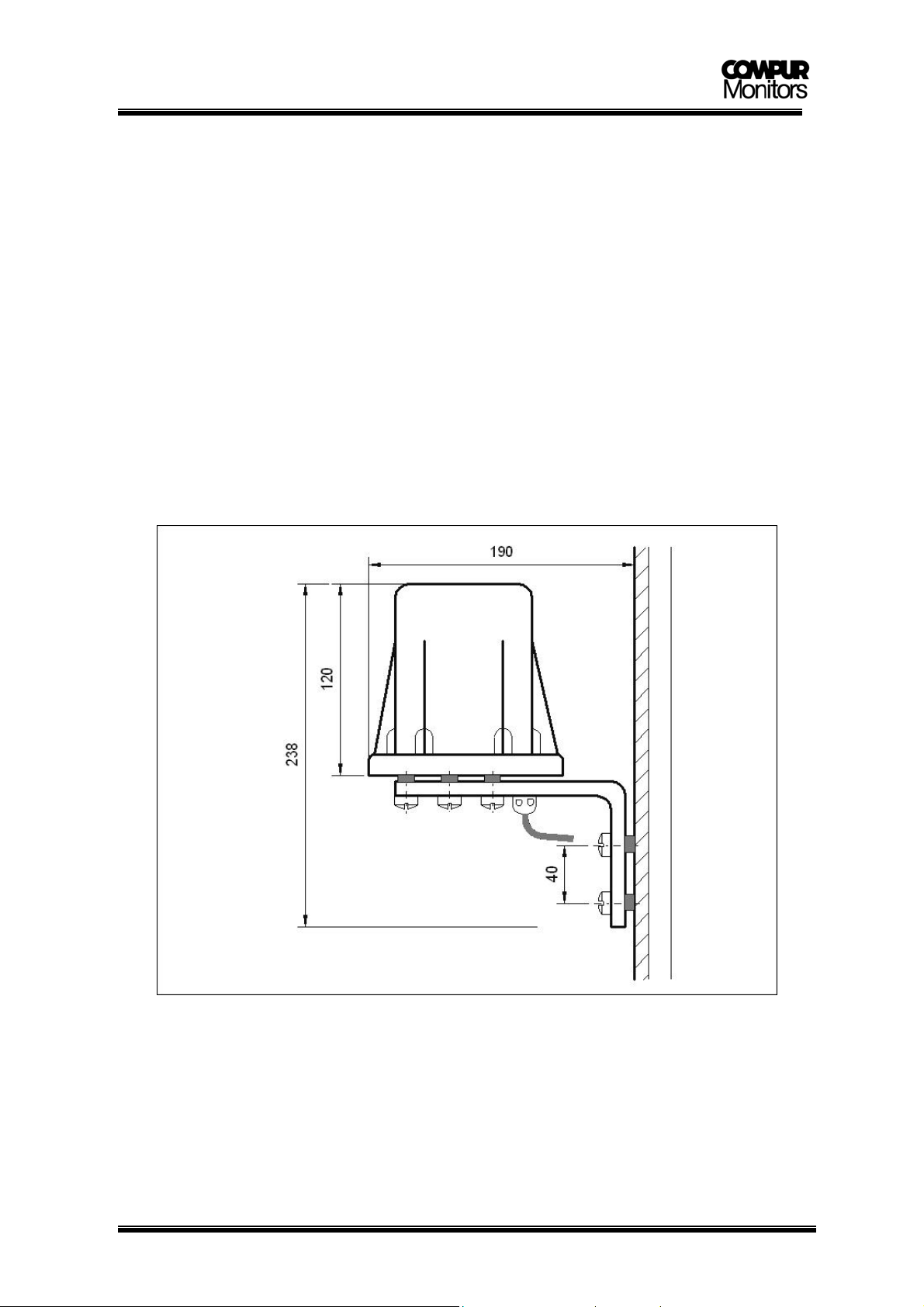

3.1.1. Mounting

The sensor head should be installed as close as possible to potential leaks. If it is used as industrial

hygiene device it should be located between a potential leak and personnel working in the area.

Parameters such as:

Air flow (wind, ventilation, thermal conditions)

Access from top (removing the cover) and bottom (loosening the screws)

Specifications of the gas to be detected (specific weight)

Protection from direct sunlight, splash water and dust must be taken care of.

Fasten the sensor head with three nylon screws on the mounting brackets using the rubber bearings

as electrical isolation (these accessories are included).

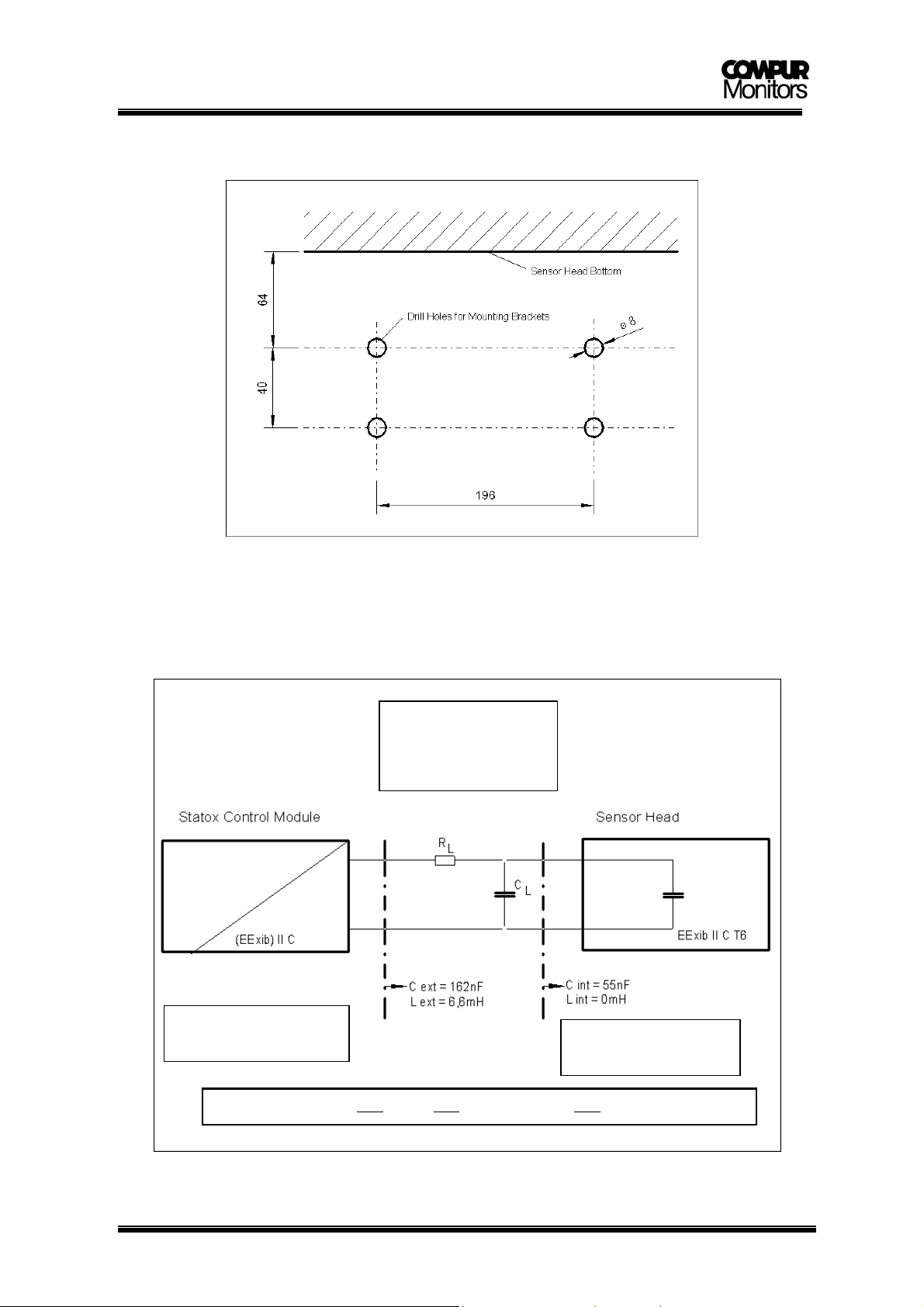

pic.6: Mounting the sensor head

Mount the sensor head in horizontal position +/ 15%. Assure there is free gas access to the sensor.

10

Page 11

Compur Statox 4120

A

pic.7: Drilling plan for the mounting brackets

3.1.2. Connecting the signal cable

The signal cable connects sensor head and control module. Use only shielded cable. The maximum

cable length depends on the cable specifications.

Cable:

Length l

Capacity CL [pF/m]

Inductivity LL [mH/m]

Approved parameters:

, IO, CO, LO

U

O

Conditions: UO < U

and IO < Ii and l x CL < CO - C

i

pproved parameters:

, Ii, Ci, Li

U

i

and l x LL < LO - Li

i

pic.8: Two wire signal cable

11

Page 12

Compur Statox 4120

Example of cable specifications:

Max. cable capacity: l x CL = Co - Ci = 107 nF

Max. cable inductivity: l x LL = L

- Li = 6,6 mH

o

Diameter: > 0,75 mm2

The Statox 4120 Systems will work reliably if the electrical resistance is : R

< 50 Ω.

L

Most commonly the maximum length is limited by the cable capacity.

Example: Cable diameter is 1,0 mm

2

(0,04 in), CL = 90 pF/m, LL = 0.7mH/km, RL / km = 19,5 Ω.

The maximum cable length results to be

CiCo

−

l =

R

= 2 x 1.189km (0,738 miles) x 19,5 Ω/km = 46,4Ω. So RL < 50Ω is OK.

L

= 1189 m (3900 ft), the electrical resistance is

mpF

/90

Sensor head connection procedure:

Open sensor head, remove cable gland.

Connect signal cable to terminals X3/1 und X3/2, polarity does not matter.

(DIN EN 60079-14 chapter 12 is applicable)

Fasten cable gland.

Connect battery pack: - Blue to terminal X4/1

- Orange to terminal X4/2

- Red to terminal X4/3

Connect signal cable to backplane of the rack. (See chapter 3.2)

pic.9: Sensor head pcb terminals

12

Page 13

Compur Statox 4120

3.2 Statox 4120 rack

Statox 4120 Rack must not be installed in hazardous areas. Observe local safety- and installation

regulations.

Protect any cable from tensile strain. The five - and the nine - contact terminals are plugged in. They

can be removed to ease wire connection.

pic.10: Backplane Statox 4120 Rack

Installation instructions:

The signal cable from sensor head to backplane must be shielded. The shield must make good

contact to the ground contact on the backplane as well as to the sensor head metal shield.

Do not remove the conductive silicon bearing of the sensor head housing.

The sensor head housing must be installed isolated from ground to avoid ground loops.

The entire system must only be grounded by the mains ground wire.

All control modules must be well connected and secured with the screws.

Connecting the mains cable initiates the system.

13

Page 14

Compur Statox 4120

Installation instructions for the RFI-shielded Statox 4120 rack:

Use well shielded signal cable. The shield must make good contact with the RFI resistant cable

glands. It must not be interrupted by connection boxes. If the signal cable is run through such,

these must also be equipped with RFI resistant cable glands. They must be installed isolated

from ground, and the shield must make good contact with the metal housing of the box.

Do not remove the conductive silicon bearing of the sensor head housing.

The sensor head housing must be installed isolated from ground to avoid ground loops.

The entire system must only be grounded by the mains ground wire.

All control modules must be well connected and secured with the screws.

Empty rack positions must be closed with blind panels.

3.3 Statox 4120 control module

Control module Circuit board includes power supply, fuses, relays, microprocessor control

electronics, DIP switches and a terminal connecting with the backplane.

Front pcb with bar graph display.

Foil keyboard.

pic.11: Control module Statox 4120

Each sensor head requires one control module. Before starting the system please check the DIP

switch position. The following list comprises all possible DIP switch positions:

14

Page 15

Compur Statox 4120

Slide switch S1:

S1 ON OFF

1 Relay active during alarm A2 Relay inactive at alarm A2

2 Relay active during alarm A1 Relay inactive at alarm A1

Toggle switch S3:

S3 ON OFF

1 Detection mode 2 Rest Alarm by resetbutton R auto - reset

3 Detection mode 4 Detection mode 5 Measured value accepted if logic

signal is 0V

6 Detection mode 7 Detection mode Modem - and analog signal

8 Detection mode Delete EPROM for service only!

Ex works settings

-

adjustment for service only!

3.4 Switch positions of the sensor head pcb

DIP switch S2 (see pic. 9) programs the following parameters:

S2 ON OFF

1 - Detection mode

2 Measured value in ppm Measured value in TLV

3 No self test after “power on“ Self test after “power on“

4 Cal. Factor =1 Factor information from control

module

5 No self test Self test in a 24 h interval

6 - 7 Detection mode 8 Detection mode Modem “On” for service

Ex works setting

15

Page 16

Compur Statox 4120

DIP switch S1 (see pic. 8) programs gas and measuring range. If you change your Statox to another

gas or measuring range, a hardware modification may be required and the electronics must be re adjusted. This must be done by authorised personnel.

Table 1: Switch position for H

S

2

Measuring range: 0-30 ppm 0-50 ppm 0-100 ppm

S1/1 ON OFF OFF

S1/2 ON ON ON

S1/3 ON ON ON

S1/4 ON ON OFF

S1/5 ON ON OFF

S1/6 ON OFF ON

S1/7 ON ON OFF

S1/8 ON ON ON

E-PROM Index sensor head 12, 13, 14 12, 13, 14 12, 13, 14

E-PROM Index control module ≥ 02 ≥ 02 ≥ 02

Table 2: Switch position for HCN

Measuring range: 0-15 ppm 0-30 ppm 0-50 ppm 0-100 ppm

S1/1 ON ON OFF OFF

S1/2 ON ON ON ON

S1/3 ON ON ON ON

S1/4 OFF OFF OFF ON

S1/5 OFF ON ON ON

S1/6 OFF ON OFF ON

S1/7 OFF ON ON ON

S1/8 ON ON ON ON

E-PROM Index sensor head 13 12, 13, 14 12, 13, 14 15

E-PROM Index control module ≥ 02 ≥ 02 ≥ 02 ≥ 02

Table 3: Switch position for COCl

2

Measuring range: 0-0,1 ppm 0-0,3 ppm 0-0,3 ppm 0-0,5 ppm 0-1,5 ppm 0-15 ppm 0-100 ppm

S1/1 OFF ON ON OFF OFF OFF OFF

S1/2 ON ON ON ON ON ON ON

S1/3 ON ON ON ON ON ON ON

S1/4 OFF ON ON ON OFF ON ON

S1/5 ON OFF ON OFF ON OFF OFF

S1/6 ON ON ON OFF OFF OFF ON

S1/7 ON ON ON ON OFF OFF ON

S1/8 ON ON ON ON ON ON ON

E-PROM Index

sensor head

E-PROM Index

control module

20 12, 13, 14 18 12, 13, 14 12, 13, 14 12, 13, 14 17

04

≥ 02 ≥ 02 ≥ 02 ≥ 02 ≥ 02 ≥ 02

16

Page 17

Compur Statox 4120

Table 4: Switch position for Cl

2

Measuring range: 0-1,5 ppm 0-3 ppm 0-10 ppm

S1/1 ON ON OFF

S1/2 ON ON ON

S1/3 ON ON ON

S1/4 ON OFF ON

S1/5 ON ON OFF

S1/6 ON ON ON

S1/7 OFF OFF OFF

S1/8 ON ON ON

E-PROM Index sensor head 12, 13, 14 12, 13, 14 12, 13, 14

E-PROM Index control module 02, 03 ≥ 02 02, 03

Table 5: Switch position for CO

Measuring range: 0-150 ppm

S1/1 ON

S1/2 ON

S1/3 ON

S1/4 ON

S1/5 ON

S1/6 OFF

S1/7 OFF

S1/8 ON

E-PROM Index sensor head 12, 13, 14

E-PROM Index control module ≥ 02

Table 6: Switch position for HCl Table 7: Switch position for ClO

2

Measuring range: 0-100 ppm Measuring range: 0-0,5 ppm

S1/1 OFF S1/1 OFF

S1/2 ON S1/2 ON

S1/3 ON S1/3 ON

S1/4 ON S1/4 OFF

S1/5 ON S1/5 ON

S1/6 ON S1/6 ON

S1/7 ON S1/7 ON

S1/8 ON S1/8 ON

E-PROM Index sensor head 19 E-PROM Index sensor head 17

E-PROM Index control module

≥ 02

E-PROM Index control module

≥ 02

17

Page 18

Compur Statox 4120

Table 8: Switch position for SO

Measuring range: 0-0,5 ppm Measuring range: 0-15 ppm

S1/1 OFF S1/1 ON

S1/2 ON S1/2 ON

S1/3 ON S1/3 ON

S1/4 OFF S1/4 ON

S1/5 ON S1/5 ON

S1/6 ON S1/6 ON

S1/7 ON S1/7 ON

S1/8 ON S1/8 ON

E-PROM Index sensor head 21 E-PROM Index sensor head 21

E-PROM Index control module 04 E-PROM Index control module 04

2

Table 9: Switch position for NO2

4. Compur Statox 4120 operation

4.1 Start - up

Connecting the Statox 4120 rack to mains (230 V/ 50 Hz or 115 V 60 Hz) activates the system.

The green LED will be flashing until the initial data exchange with the sensor head has been

finalised. It flashes also if the calibration box is connected.

The green LED stays on as soon as the system is in the detection mode.

4.2 Alarm thresholds

A1: Push and hold button A1 for 5 s to obtain a display of the alarm threshold on the bar graph.

A2: Push and hold button A2 for 5 s to obtain a display of the alarm threshold on the bar graph.

4.3 Detection mode

The green SR LED is on and the actual measured value is displayed on the bar graph.

4.4 Self test of the system

Every 24 hours the entire system tests itself. During the test all LED`s are on and the bar graph

dispays full scale. The analog output goes to full scale. (How to avoid this see chapter 7 and 8).

If an error is detected, the red LED SF goes on.

At temperatures below –20°C (-4°F) the self test can not be activated.

18

Page 19

Compur Statox 4120

4.5 Manually triggered self test of the system

Push and hold button T for 2 s to initiate a self test.

The next self test will start automatically after 24 h.

4.6 System failure

As soon as the Statox detects a faulty system condition the LED SF goes on and relay SF is activated.

This will be the case if:

Self test not passed

Data transmission faulty

No signal

5. Trouble shooting

As soon as the Statox detects a faulty system condition the LED SF goes on and relay SF is activated.

To locate the problem follow this procedure:

Push the reset button R on the control module.

If the green LED starts flashing now, there is a data transmission problem.

If there is no reaction, there is a hardware problem in the sensor head (f. i. pump, sensor, gas

generator, battery).

Now push button T to initiate a new self test. If SF goes off, the system is now ready again. If SF

stays on, the sensor head must be checked with the diagnostic box.

SF ON

Connect diagnostic box to sensor

head. Potential errors:

Sensor defective

Pump defective

Battery defective

Amplifier defective

R

Push button R

SF flashing

Data transmission problem.

Potential errors:

Signal cable interrupted

Wrong connection(SF goes on again

after 4 min)

Data transmission faulty

Duty cycle needs adjustment

19

Page 20

Compur Statox 4120

5.1 Using the diagnostic box

Switch the diagnostic box on. Then connect it to the opto- coupler receptacle on sensor head bottom.

Keep the LED`s and the phototransistors of the opto- coupler clean for proper data transmission.

5.1.1 Operation and error codes of the diagnostic box

Note: If a combination of push button operations is requested ( f. i. ST + ENT), the buttons must be

operated in a short time distance.

Example: ST + ENT initiates a self test. The display says „WAIT-TEST RUN“ until the self test is

finished.

Diagnostic box queries:

Button Display

M Measured value in ppm

M + ENT WAIT; after a while reading of actual measured value in ppm

RA Sensor head measuring range

RA + ENT Gas

ST Status passed (System OK) or error message (see 5.1.2)

ST + ENT (initiates self test), TEST Run

FKT Calibration factor

ZERO + ENT * ZERO RUN (start zero adjustment)

* only available with systems with zero adjustment

Diagnostic box error messages:

ERR INPU

ERR KONZ

ERR FACT

DS.W.POS

WARN TIM

WARN DTE

WARN CHE

TEMP.OU

TEMP.IN

CH.BATT

(audible alarm)

NO ZERO

PUMP RUN

CAL END

NO CALIB

Faulty or too slow input. Repeat.

Calibration gas concentration out of range.

Calibration factor is out of range.

Measuring range or gas not correctly programmed.

Time error during data transmission.

Faulty data transmission.

No self test due to too low temperature.

Temperature out of the admissible range.

Temperature is back in the admissible range.

Charge calibration box battery.

Zero adjustment not possible. Wrong EPROM in sensor

head and control module.

Sensor is flushed with air because the gas concentration is

too high.

Calibration routine has been cancelled with CE button.

Calibration not possible within the time limit.

20

Page 21

Compur Statox 4120

5.1.2 Status messages of the sensor head

Button ST scans the system status:

Code

Passed

Error A1

Error B1

Error B2

Error PU

Error T2

Error C1

Error C2

Error C3

Error C4

Caution:

Disconnect the diagnostic box first and then switch it off. Don not forget to protect the opto - coupler

with the plug. To preserve battery power, the diagnostic box display goes off after 2 minutes. Operate

any key to switch it on again.

Status and action required

System OK.

Amplifier defective: Repeat adjustment or replace pcb.

Check battery pack connection. Battery pack discharged or defective, replace.

If battery pack discharges frequently, check charging circuit.

Battery pack voltage drops under load.

Pump energy consumption too high. Replace.

Temperature is out of compensation range. Measured values are corrected

with the end of range - value.

Zero not found at start of self test (or sensor signal is too high for zero

adjustment).

- check filter cartridge: Fresh? Tight?

- Filter cartridge gas intake at the bottom of the sensor head dirty

- Filter cartridge exhausted

- Dust filter dirty

- Sensor too slow

Zero not found at end of self test:

Sensor too slow, replace.

Test peak not achieved:

- Sensor too slow

- Sensor lost sensitivity

- Gas generator expired

- Sensor too slow

- Pump defective

- Filter cartridge polluted

Zero not found at end of self test:

- Sensor too slow, replace.

- Filter cartridge polluted

- Pump defective

21

Page 22

Compur Statox 4120

6. Maintenance and calibration

6.1 Inspection Statox 4120 Sensor head

The following maintenance intervals are general recommendations. Specific applications may request

different intervals.

Splash guard, visual inspection every 4 weeks

Dust filter, visual inspection every 4 weeks

Statox 4120 sensor, replace after expiration of the „best before“ – date (calendar week / year)

Statox 4120 generator, replace after expiration of the „best before“ – date (calendar week / year)

Filter cartridge replace after 6 months

Water container visual inspection of liquid level every 6 months

Battery pack, replace after 18 months

Information on sensor and generator labels:

Serial No.

Gas

Current output at test gas concentration (sensor only)

Test gas concentration (sensor only)

Calibration factor (sensor only)

Best before (week / year)

Initial quality control personnel

Water container

Remove container. Fill level up to the marking. Non - foaming anti - freeze agents are OK to be used.

Statox 4120 dust filter

This filter protects the sensor from dirt. It must be in proper condition to allow the target gas to enter

the sensor. It must be replaced whenever it is dirty.

Splash guard

The splash guard at the sensor head bottom protects the dust filter from particles and water. It is

fastened with two screws.

Caution! The type plate must be next to the dust filter to allow gas access to the filter cartridge.

Sensor replacement

Disconnect old sensor

Remove tube and sensor by turning it sideward

Replace dust filter

Replace bearing

Replace sensor

Connect new tube

Connect cable

Proceed factor calibration, see 6.2.2

22

Page 23

Compur Statox 4120

Filter cartridge replacement

Remove tube

Remove filter cartridge and bearing

Clean air access opening

Replace filter cartridge and bearing

Replace tube

Generator cell replacement

Disconnect generator cell, remove tube to pump

Remove generator cell

Replace generator cell

Replace tube

Connect generator cell

6.2 Sensor head calibration

6.2.1 Using span gas

What you need: -Span gas

-Regulator

-Flow meter

-Gas calibration adapter

-Gas tube (clean, dry, chemical resistant)

-Diagnostic box

Caution:

The test gas adapter is not part of the ex-certified sensor head.

The gas flow should be adjusted to 500 ml/min (30 l/h).

Statox sensor heads working in the flow mode can be calibrated with the mounted flow adapter.

Keep the working mode gas flow.

Calibration adapter

23

Flow adapter

Page 24

Compur Statox 4120

Procedure:

Remove splash guard and replace it by test gas adapter.

Connect span gas cylinder. Do not open regulator yet!

Connect diagnostic box to sensor head.

Reading diagnostic box: Red LED flashing; - “ready” – “x.xxx ppm”

Push CAL button Reading diagnostic box: “CALIBR”

Push ENT button Reading diagnostic box: “ppm = ?”

Enter span gas concentration in ppm. Reading diagnostic box: ppm = „value“.

If you have entered a wrong value push button CE and repeat.

If you have entered an invalid concentration, the reading is “ERR KONZ”: Push button CAL

again and repeat.

Now push button ENT Reading diagnostic box: “GAS ON!”

This is the last opportunity to abort the procedure!

Open span gas regulator

Push button ENT Reading diagnostic box: “WAIT”

Reading of a measured value after 2 minutes. Display diagnostic box: “x.xx ppm” (this not a

calibration value yet).

Wait 1 minute to obtain second measured value from sensor head. Reading diagnostic box:

“x.xx ppm“ (this not a calibration value yet).

Wait 1 minute

This procedure will repeat until the difference between two measured values is within the specified

range. Then the new calibration factor will be displayed for 10 seconds.

Reading diagnostic box: “FKT = x.xx”; “GAS OFF!”

Close span gas regulator

Confirm gas is off by pushing ENT Display diagnostic box: “READY”

Disconnect diagnostic box and switch it off. Close receptacle for opto coupler with the plug. Mount

splash guard.

6.2.2 Use ex – works calibration

Each sensor carries a calibration factor. This factor indicates how far its individual sensitivity differs

from a theoretical value (=1). Values between 0.60 and 2.00 will be accepted by the system. The lower

the factor, the higher its sensitivity. The sensor head microprocessor corrects the sensor signal with

this factor to obtain the correct measured value.

Programming the calibration factor:

Action Reading Diagnostic box

Switch diagnostic box on

Connect diagnostic box to sensor head Red LED flashing;

READY-x.xxx ppm

Push FKT FCT x.xx

Push FKT + ENT (no long break!) FCT = ?

ERR INPU

Enter factor If you have entered a wrong factor, push CE and

repeat.

Now push ENT twice immediately Red LED flashing READY

Switch diagnostic box off, Factor will be transmitted.

Disconnect diagnostic box

24

FCT = 1.20 (example

FCT = ?

Page 25

Compur Statox 4120

7. The maintenace request option

Purpose:

This option can differentiate between fatal errors in the sensor head and maintenance requirements. It

requires a Statox 4120 control module equipped with EPROM Index ≥ 03. It also sets the analog

output to 4 mA during the self test, if required.

Operation modes:

The Statox 4120 can operate in 9 different modes. The relevant mode can be seen by the control

module LED`s and relays.

Operation mode Statox Analog output SR-LED

Control

module

O Self test 0mA / 4mA / 0V „on“ „on“ active passive active

SF-LED

Control

module

SF-Relay MR-

Relay

PCS-*

Relay

O Diagnostic box connected: 0mA / 4mA / 0V flashing „off“ active passive active

O Alarm threshold adjustment: 0mA / 4mA / 0V „on“ „off“ active passive active

O Start-mode 4mA / 0V flashing „off“ active passive passive

O Detection mode: Analog signal „on“ „off“ active passive passive

O Maintenance request:

B1 Battery Low

B2 Battery low under load

C1 Purge before test

C2 Purge between test peaks

C3 Sensitivity

(programmable by S3)

C4 Purge

PU Pump current too high

T2 Temperature out of specs

O System failure:

A1 Amplifier

C3 Sensitivity

(programmable by S3)

O Data transmission error 4mA/0V „off“ „on“ open passive passive

O Power failure 0mA/0V „off“ „off“ open passive passive

Analog signal

4mA / 0V

flashing

„off“

„off“

„on“

active

open

active

passive

passive

passive

*(PCS=Process control system)

25

Page 26

Compur Statox 4120

Error C3 (Too low sensitivity during self test):

S3/3 on the control module offers the option to choose if C3 shall be a maintenance request (position

ON) or system failure (position OFF).

The system failure messages A1 and C3 (both defined as SF):

The sensor head still transmits measured values to the control module, but these measured values will

not be displayed on the bar graph display nor be transmitted to the analog output. For safety reasons

they will still be compared to the alarm thresholds and an alarm will be activated if they are exceeded.

Also the sensor protection feature will be activated if the measuring range is exceeded.

Mounting the maintenance request pcb

Connect the the pcb to the 5 contact terminal on the Statox 4120 rack backplane. (see pic. 10).

Shorting plugs program the analog output to 4-20 mA or 0-1V (see pic.12). Ex works setting is

4-20 mA.

As an option the 4-20 mA output can be set to 0 mA during the self test, the alarm threshold

programming and when the diagnostic box is connected (measured value not valid).

On the terminals 1 to 8 the relays MR and PCS as well as the analog signal can be accessed. The

maximum load of the relays is 24V/100mA.

Service mode control module

Set the service switch on the control module (S3/7) to „OFF“ to simulate the mode „normal“, „WB“ and

„PCS”. Select by the following keys:

Key mode Relay PCS Relay WB Analog signal Reading

T Detection mode passive passive 4 mA / 0V 0%

A1 Self test/Maintenance,

active passive 4 mA / 0V 50%

Adjusting A1 und A2

A2 Maintenance request passive active 20 mA / 0V 100%

26

Page 27

Compur Statox 4120

pic.12: Electrical connections and short circuit contacts

Short circuit contacts on the maintenance request pcb:

Bridge Analog

0-1V

1 ●

2 ● ●

3 ●

4 ● ●

5 ●

6 ● ●

7 ●

* Analog output 0 mA, if PCS-relay active, f. i. during self test, alarm threshold adjustment and if the

diagnostic box is connected. In any other case 4-20 mA.

Analog

4-20 mA

Analog

4(0)-20mA*

27

Page 28

Compur Statox 4120

N

8. The option analog output inhibition

This option inhibits the analog output if the logic signal of the control module (see pic. 3, terminal 11) is

set to 5 V instead of 0 V. This is the case if the system is unable to provide a valid measured value, for

instance if:

- Alarm thresholds are adjusted or displayed

- During self test

- During the diagnostic box is connected

- During system start.

As soon as the sensor head provides the next valid data telegram, the analog output is activated

again. This option will work with control module equipped with EPROM 02!

The analog output is programmed by solder straps. The terminals 23 and 24 provide an additional

relay, closing when the analog signal is switched off.

Abb. 13: Solder straps on the pcb analog output inhibitor

Analog Terminal Solder straps Analog

4-20 mA + - 1-2 1-2

0 – 1 V Gnd + 2-3 2-3

13 14 JP1 JP2 23 24

O

28

Page 29

Compur Statox 4120

9. The option zero adjustment

This option is available for COCl

adjustment of the sensor is started via diagnostic box.

System requirements:

Sensor head EPROM index 18c, control module EPROM index 03a, diagnostic box EPROM index 02.

A zero adjustment must only be done in clean air. It is started with the buttons ZERO + ENT. It

should be done before starting a calibration.

The set zero value is not visible.

If no zero adjustment has been done ever, the default value is 0.

After replacing a control module, a new zero setting has to be carried out. The zero value is

stored in the control module and is transmitted to the sensor head.

An error message C1 caused by a too high sensor zero current will only be cancelled after a

successful self test.

sensor heads with measuring range 0.3 ppm only. The zero

2

29

Page 30

Compur Statox 4120

10. Technical data

General:

Gas Measuring range

Cl2 0-1.5 ppm, 0-3 ppm, 0-10 ppm

CO 0-150 ppm

COCl2 0-0.1 ppm, 0-0.3 ppm, 0-0.5 ppm, 0-1.5 ppm, 0-15 ppm, 0-100 ppm

HCN 0-15 ppm, 0-30 ppm, 0-50 ppm, 0-100 ppm

HCl 0-100 ppm

H2S 0-30 ppm, 0-50 ppm, 0-100 ppm

ClO2 0-0.5 ppm

NO2 0-15 ppm

SO2 0-5 ppm

Accuracy at TLV: +/- 10 %

Alarms: 2 adjustable alarm thresholds, system alarm

RFI: CE conform

Manufacturer: Compur Monitors, Munich

Sensor head:

Type: 5330 xxx (xxx: measuring range / gas)

Weight: 1.9 kg

Dimensions (mm, HxBxT): 180x300x180

Operating temperature: -20 to +40 oC

Storage temperature: -30 to +50

Humidity: 20-95 % r.H. (not condensing)

Pressure: 800-1200 hPa

Protection class: IP53

Approvals (div.countries): Cl

, COCl2, H2S

2

Explosion protection: EEx ib IIC T6

Operating environment : II 2 G

Operating voltage Ui: max. 22 VDC

Operating current Ii: max. 50 mADC

Internal capacity C

Internal inductivity L

: 55 nF

i

: 0 mH

i

o

C

30

Page 31

Compur Statox 4120

Control module:

Type: 5331 0x0 (115 / 230 VAC)

Operating temperature: -20 to +40 oC

Storage temperature: -30 to +60

Explosion protection : [EEx ib] IIC

Operating environment: II 2 G

power: 15 W per control module

Supply voltage: 115 / 230 VAC

Max. operating voltage Uo: 22 V DC

Max. operating current Io: 50 mA DC

Max. external capacity Co: 162 nF

Max. external inductivity Lo: 6.6 mH

Display: Bargraph

Analog output: 4-20 mA / 400 Ω max.

0-1 V / Ri = 1k Ω

Relays: 24 V 100 mA

o

C

Rack:

Type: 5332 xxx (xxx: ½ 19” and 19” , 115 / 230 V AC)

Explosion protection: [EEx ib] IIC

Operating environment: II 2 G

Dimensions (HxBxT) ½ x 19“: 180x270x420 mm

19“: 180x485x420 mm

RFI : 180x485x505 mm

Diagnostic box:

Temperature range: -20 to +40 oC

Weight: 0,9 kg

Dimensions (HxBxT) 50x190x160 mm

Explosion protection: EEx ib IIC T6

Protection class: IP30

Operation time: max. 3 h

Charging time: max. 14 h

31

Page 32

Compur Statox 4120

11. Accessories and spare parts

Art. Nr. STATOX 4120 ACCESSORIES

508885 STATOX Diagnostic box

518876 STATOX Diagnostic box charger 115 V

518850 STATOX Diagnostic box charger 230 V

509115 STATOX Control module service adapter

508588 STATOX Sensor head flow adapter

500223 STATOX Head Splash guard plug

500224 STATOX Head Calibration gas adapter plug

500225 STATOX Head plug adapter

508638 STATOX Sensor head rain shield

508539 STATOX Sensor head splash guard stainless

507283 STATOX Sensor head Splash guard PTFE

551869 STATOX Analog output inhibitor (for EPROM 02)

551703 STATOX Maintenance request (for EPROM ≥ 03)

561165 STATOX Upgrade COCl2 0,1 ppm

Art.Nr. STATOX 4120 SPARE PARTS

508950 STATOX Diagnostic box battery

508778 STATOX Diagnostic box Lpcb inkl.LED

508836 STATOX Diagnostic box opto- coupler

509000 STATOX Diagnostic box mould

508415 STATOX Diagnostic box EPROM “02”

553030 STATOX Control module EPROM "02"

551711 STATOX Control module EPROM "03"

508410 STATOX Control module EPROM "03a"

561207 STATOX Control module EPROM "04"

505550 STATOX Control module front plate incl.LED

505543 STATOX Control module pcb

821155 STATOX Control module quartz 1,0 MHZ

508075 STATOX Control module scale 3 PPM

508083 STATOX Control module scale 5 PPM

508067 STATOX Control module scale 10 PPM

507994 STATOX Control module scale 15 PPM

508000 STATOX Control module scale 30 PPM

508018 STATOX Control module scale 50 PPM

507978 STATOX Control module scale 0,3 PPM

508042 STATOX Control module scale 0,5 PPM

507986 STATOX Control module scale 1,5 PPM

508059 STATOX Control module scale 100 PPM

508091 STATOX Control module scale 150 PPM

561215 STATOX Control module scale 0,1 PPM

507820 STATOX Control module T1 power supply

507804 STATOX Control module T2 transducer

505931 STATOX Control module alarm relay

534295 STATOX Manual -D-

32

Page 33

Compur Statox 4120

558435 STATOX Manual -E518330 STATOX Sensor head battery

506947 STATOX Sensor head bearing 236 mm

557874 STATOX Sensor head EPROM "12"

562197 STATOX Sensor head EPROM "13"

502052 STATOX Sensor head EPROM "14"

550700 STATOX Sensor head EPROM "15"

551695 STATOX Sensor head EPROM "17"

554483 STATOX Sensor head EPROM "18"

508413 STATOX Sensor head EPROM "18c"

558856 STATOX Sensor head EPROM "19"

561199 STATOX Sensor head EPROM "20"

562544 STATOX Sensor head EPROM "21"

506921 STATOX Sensor head mould upper part

506897 STATOX Sensor head mould bottom

551976 STATOX Sensor head hybrid A 525 -ICL 8022503845 STATOX Sensor head hybrid A 526 -ICL 8023577849 STATOX Sensor head pcb

505311 STATOX Sensor head plug opto coupler opening

507036 STATOX Sensor head water container

532828 STATOX TRITOX M pump

Art. Nr. SENSORS & GENERATOR CELLS

507770 STATOX Generator cell ClO2

517084 STATOX Generator cell Cl2

532570 STATOX Generator cell COCl2

516961 STATOX Generator cell H2S/HCN/CO/HCl/SO2

562379 STATOX Generator cell NO2

538791 STATOX Sensor Cl2 10 PPM

516201 STATOX Sensor Cl2 1,5/3 PPM

507630 STATOX Sensor ClO2 0,5 PPM

516128 STATOX Sensor CO 150 PPM

533719 STATOX Sensor COCl2 15 PPM

531200 STATOX Sensor COCl2 1,5 PPM

516060 STATOX Sensor COCl2 0,3/0,5 PPM

551687 STATOX Sensor COCl2 100 PPM

560845 STATOX Sensor COCl2 0,1 PPM

516003 STATOX Sensor H2S 30/50/100 PPM

558849 STATOX Sensor HCl 100 PPM

562106 STATOX Sensor HCN 15 PPM

504918 STATOX Sensor HCN 100 PPM

516086 STATOX Sensor HCN 30/50 PPM

562361 STATOX Sensor NO2 15 PPM

562411 STATOX Sensor SO2 5 PPM

33

Page 34

Compur Statox 4120

Specifications are subject to change without notice, and are provided only for comparison of products. The

conditions under which our products are used, are beyond our control. Therefore, the user must fully test

our products and/or information to determine suitability for any intended use, application, condition or

situation. All information is given without warranty or guarantee. Compur Monitors disclaims any liability,

negligence or otherwise, incurred in connection with the use of the products and information. Any

statement or recommendation not contained herein is unauthorized and shall not bind Compur Monitors.

Nothing herein shall be construed as a recommendation to use any product in conflict with patents

covering any material or device or its use. No licence is implied or in fact granted under the claims of any

patent. Instruments are manufactured by Compur Monitors GmbH & Co. KG, Munich.

The General Conditions of Supply and Service of Compur Monitors GmbH & Co. KG are applicable.

5330 000 999 07 12 / 07.04 558435

36

Loading...

Loading...