Portable

Model

Field

2100M

Dental

Unit

Operation

And

Maintenance

Manual

Compressor

7002

South

Englewood

Technologies,

Revere

(303)

Parkway,

Colorado

799-8177

80112

1-800-847-0694

USA

LTD.

Unit

90

TABLE

OF

CONTENTS

age

hg

U

WU

LI)

A

UU

DIA

Section

General

Customer

Description

Principals

Performance

Equipment

Service

Of

Of

Characteristics

Not

Specification,

Limited

Safety

Delivery

Waste

Water

Compressor

Preparation

System

Waste

Fresh

System

Cleaning

Warranty

Precautions

Unit

Container

Container

Unit

For

Shut

Down

Container

Water

Flush

Purging

Procedures

Repacking

Storage

Equipment

General

Testing

Care

Service

Equipment

Maintenance

Water

Air

Air/Water

Three

Daily

Basic

Maintenance

Parts

Filter

Intake

Filter

Regulators

way

Syringe

Functional

Troubleshooting

And

Lists

Diagrams

System

Operation

Provided

Capacities

Setup

Connections

Setup

Use

And

Inspection

Information

And

Tools

Checklist

Guide

Storage

And

Technical

Required

and

Maintenance

Inspection

Data

Schedule

Record

SECTION

1

INTRODUCTION

1.1

The

set-up,

repair

All

maintain

review

and

12

In

please

speak

Representatives.

am.

Monday

13

The

contained

unit

system

provides

driven

a

handpiece,

three

evacuator.

water

irrigation

liquids

The

standard

GENERAL.

information

operation,

of

the

authorized

or

this

manual.

maintained

CUSTOMER

the

event

you require

call

1(800)

with

to

5:00

through

DESCRIPTION

Model

Midwest

2100M

portable

designed

includes

power

vacuum

Tradition L fiber

Midwest

way

syringe,

The

supply

and a waste

and

debris

system

electrical

contained

Model

service

by

one

p.m.,

Friday

for

to

system.

system

for

contains

in

this

maintenance,

2100M

personnel

the

The

trained

445-8765

of

Our

Field

dental

field

an

the

Rhino

saliva

handpiece

from

connections

Field

who

Field

Unit

system should

personnel

SERVICE.

assistance

or

our

service

Mountain

oilless

dental

all

hours

excluding

OF

SYSTEM.

Unit

is a light-weight,

operating

or

operatory

air

instruments

The

delivery

low

ejector

contains a self-contained

container

the

evacuation

necessary

manual

troubleshooting

(303)

Customer

Standard

compressor

optic

speed

and

coolant and

for

covers

Unit.

either

should

with

carefully

be

operated

only.

this

operate,

system,

790-2000

Service

are

from

holidays.

and

treatment

use.

and

unit

supports

high

handpiece,

high

volume

collection

and

and

8:00

Time,

self-

The

that

air-

speed

oral

system.

tubings

for

operation.

and

the

of

13.1

Module

system

The

cylinder

wall

The

115V/60Hz

system

to

compressed

Features:

*

+

*

+

-

*

+

+

*

132

contains a fold

instrumentation

instrument

Bandpieees,

reservoir

system

contains

the

Ejector.

waste

Compressor

consists

that

provides > 3.8

compressor

piston

and

teflon

1%

HP

or

is

air-cooled

reduce

Fan

1%

horsepower

Aluminum,

coated

Coiled

Pressure

(1)

10

cord

(1) 10

Grounding

Rotationally

storage

removable

for

High

the

air.

induced

oilless

cylinder

compressed

switch

foot

hospital

(115Vac/60Hz)

foot

CEE-7

cable

case

end

Delivery

tray.

control

with

high

the

an

air

Volume

The

Vacuum

container

Module:

of

1%

HP

consists

that

utilizes a teflon

ring

piston

electrical

230V/50Hz

and

incorporates

operating

air

cooled

system

electric

compressor

wall

and

air

aftercooler

and

unloader

grade

cord

molded,

with

out

and

regulators

operated

with

polyethylene

recessed

caps

Unit

Module:

control

provides a work

The

delivery

blocks,

and-afiber~eptictighting

handpiece,

speed

vacuum

Evacuator

system

automatic

The

Compressor

oilless

air

compressor

scfm

of

free

air

at

40

of a reciprocating,

coated

for

lube-free

motor

motor

(230Vac/50Hz)

unit

operates

electrical

temperature

pump

teflon

piston

system

NEMA

hardware

The

for

placement

unit

water

supply,

system

(HVE)

includes a removable

overflow

cylinder

operation.

from

supply.

an

after-cooler

of

with

teflon

ring

5-15

electrical

carrying,

and

delivery

of

surface

for

contains

and

an

unit

The

to

power

and

Saliva

protection.

psi.

one

a

The

the

unit

the

the

the

air

also

The

entire

repacked

for

only

structural

into

safe

transportation

act

to

housing

unit

can

two

rotationally

protect

the

for

be

quickly

and

system

the

unit.

disassembled

molded

storage.

but

carrying

The

also

and

cases

cases

not

provide

the

Features:

+

Autoclavable

*

Two

handpiece

+

Fwo

straight

Midwest

+

Aseptic

*

Variable

coolant

Three-way

removable,

+

Pressurized

water

+

Water

*

Water

*

Individual

each

*

Individual

air,

-

Repair

*

High

with

*

Saliva

straight

+

Air

- 6 foot

*

Waste

shutoff

+

(1) 10

cord (115

*

(1)

-

Rotationally

storage

14

141

connectors

non-retraction

speed

water

filter

coolant

flush

drive

handpiece

pressure

water,

kit

volume

straight

ejector

tubing

driven

vacuum

suction

container

foot

10

foot

CEE-7

case

PRINCIPALS

AIR

COMPRESSOR

stainless

control

ascpsis

syringe

autoclavable

water

system

vacuum

evacuator

tubing

control

disc

switch

with

container

flow

control

air

pressure

gauges

and

pump

handpiece

type

exhaust

with

automatic

hospital

Vac/60

grade

Hz)

cord

molded,

with

polyethylene

recessed

OF

steel,

instrument

system

tubings

water

coolant

foot

control

coiled

tubing

tip

with

35

Micron

for

eaelf

handpieces,

adjustment

for

handpiece

air

tank

control

(autoclavable)

vent

(230

(autoclavable)

with

tubing

overflow

NEMA-S15

Vac/50Hz)

carrying,

hardware

OPERATION.

MODULE.

tray

with

with

and

for

drive

electrical

142

A

dissipation

thermodynamics

energy

the

extreme

gas.

The

systems

a)

module

the

electric

b)

coiled

exhaust

cooling

lower

level

removal

acceptable

143

The

switch

off

pressure.

air

turns

again

COOLING

special

operating

of

dictates

energy

Fan

case

Aftercooler - The

and

air

as

pressure

will

rise

in

compressor

for

dissipation

Induced

employs

housing

motor.

tubing

the

that

needed

off

under

that

valve

to

air.

The

temperature

to

assist

of

moisture

dry

PRESSURE

UNLOADER.

compressor

automatically

to

An

unloader

against

to

prevent

load.

SYSTEMS.

problem

heat

generated. A basic

and

that

if a

be

concentrated

the

temperature

system

Cooling - The

fans

to

cool

compressed

is

dissipate

aftercooler

in

the

operating

maintain

the

the

with

the

law

fluid

employs

of

heat.

that

blow

the

compressor

placed

immediately

heat

serves

of

the

condensing

from

the

air.

SWITCH

module

turns

the

is

placed

piston

motor

compressors

of

conservation

(air)

is

resulting

of

the

two

air

ambient

air

is

cooled

to

the

to

substantially

air

to

an

and

air

to

includes a pressure

the

system

required

to

eliminate

whenever

from

having

is

the

law

of

of

compressed,

in

an

compressed

cooling

compressor

air

through

pump

and

using

after the

surrounding

operating

subsequent

achieve

an

AND

on

and

operating

back

the

unit

to

start

Air

Compressor

is

powered

reciprocating

moves

downstroke,

muffler.

upstroke

intake valves

through

hose

The

teflon

for

an

by a 1%

piston.

up

and

air

The

exhaust

of

the

close

the

exhaust

to

the

delivery

compressor

coated

cylinder

external

Pump:

down

is

pump

lubricant.

The

HP

electric

To

in

drawn

valve

piston,

and

compressed

valve

unit.

uses a teflon

sleeve

in

air

and

air

compressor

motor

compress

the

cylinder.

through

remains

is

compressed.

then

to

eliminate

that

drives

air,

the

On

the

air

closed.

air

is

forced

through

ring

piston

the

pump

piston

the

intake

On

the

The

out

the

air

and

need

a

144

Compressor

stored

used.

through

air

filters

compressed

1.4.4.1

used

of

DELIVE

in

an

Air

the

pressure

out

any

Handpiece

by

the

the

handpiece

is

handpieces

Compressed

handpiece

while

to

drilling.

air

is

taken

air

tank

at a pressure

taken

from

Air/Filter

desired

the

to

remaining

air.

Operation:

to

that

rapidly

air

is

also

provide

additional

IT

MOD

in

by

the

delivery

the

air

tank

Regulators

operating

moisture

drive

released

droplets

Compressed

turbines

spin

by

cooling

o

of

100

that

the

cutting

the

of

unit

psi

and

routed

reduce

levels

from

air

in

the

head

of

tooth

the

and

until

the

and

the

is

head

bur.

the

1.4.42

pressurized

water

syringe,

the

Water

by

pressure

water

handpiece

System - The

the

compressed

necessary

coolant

flush

for

spray

system.

fresh

water

air

to

operation

for

the

handpieces

system

provide

of

three

is

the

way

and

1.443

evacuation

powered

is

used

which

surrounding

The

debris

collection

the

1.4.4.4

an

automatic

automatic

a

second

15

The

with

1500

The

Evacuation

system

by

compressed

to

accelerate

creates a negative

it.

vacuum

created

through

container

liquid

and

Drain

drain

system

when

PERFORMANCE

system

the

operates

maximum

Watts.

system

is

environmental

System - Suction

is

created

air.

the

is

used

the

HVE

and

which

solids.

System - The

as

well

will

drain

the

compressor

on

115/230

power

able

to

perform

conditions.

for

using a (venturi)

The

venturi

speed

of

pressure

to

pull

Saliva

Ejector

separates

delivery

as a manual

the

air

tank

cycle

the

air

or

air,

liquids

the

air

module

drain.

for

starts.

principle

stream

vacuum

into

1/10

CHARACTERISTICS.

Vac/50/60

requirement

under

less

the

following

the

pump

and

the

from

has

The

of

Hz

than

a

Temperature:

Altitude:

Humidity:

1.6

1)

2)

3)

EQUIPMENT

Electrical

Consumables

a)

Oral

b)

Saliva

Handpieces

30°

to

120°

©)

0

to

8,500

Feet

above

sea

level

0

to

95%

relative

NOT

Power

Evacuation

Source

which

Ejector

Mouthpiece

Fahrenheit

(0 to

(-2°

2,591

humidity

PROVIDED.

include:

Tip

to

49°

meters)

17

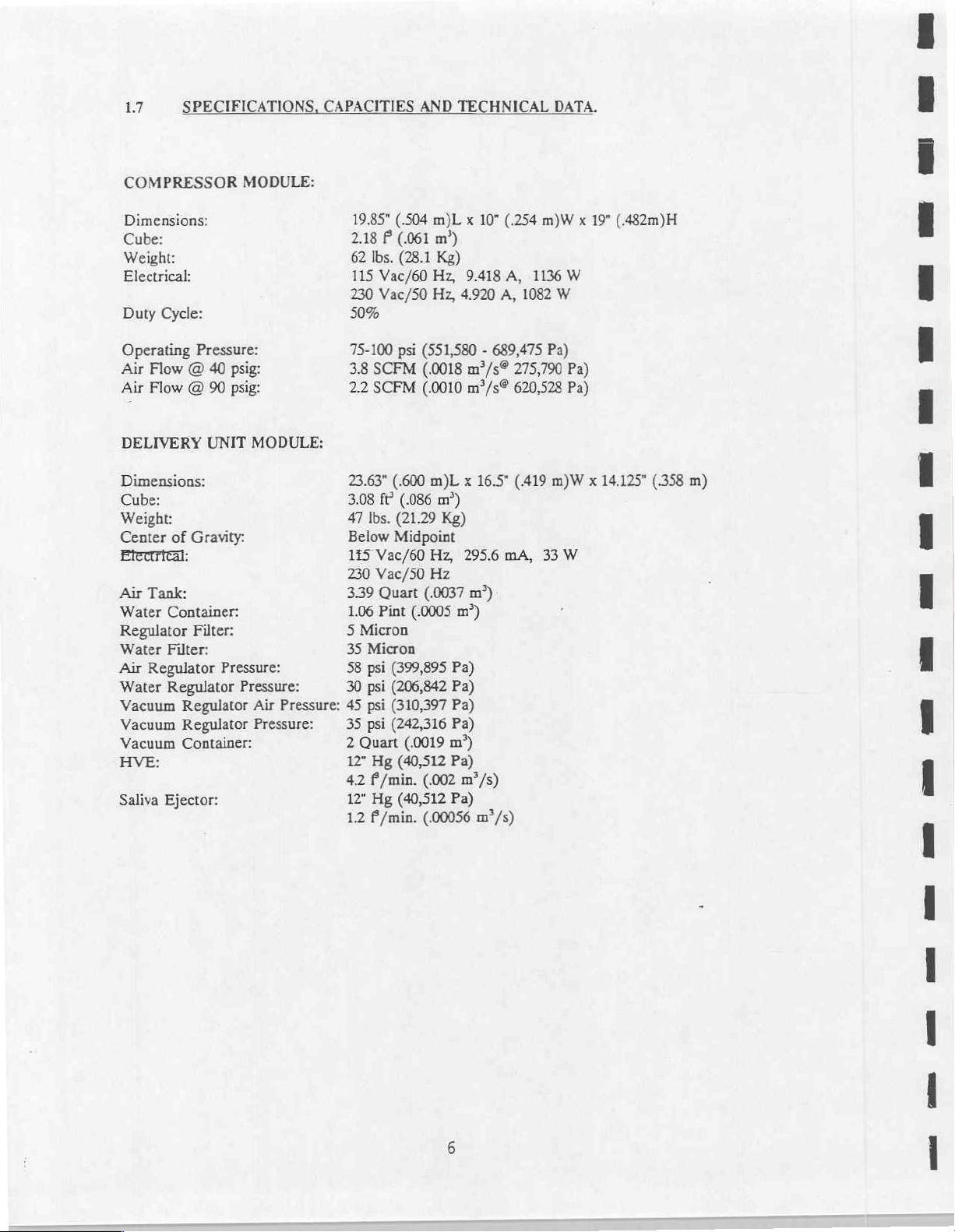

SPECIFICATIONS,

CAPACITIES

AND

TECHNICAL

DATA.

COMPRESSOR

Dimensions:

Cube:

Weight:

Electrical:

Duty

Cycle:

Operating

Air

Air

DELIVERY

Dimensions:

Cube:

Weight:

Center

Electrical:

Air

Tank:

Water

Regulator

Water

Air

Regulator

Water

Vacuum

Vacuum

Vacuum

HVE:

Saliva

Pressure:

Flow @ 40

Flow @ 90

of

Gravity:

Container:

Filter:

Filter:

Regulator

Regulator

Regulator

Container:

Ejector:

MODULE:

psig:

psig:

UNIT

MODULE:

Pressure:

Pressure:

Air

Pressure:

Pressure:

19.85"

(.504

2.18 P (061

62

lbs.

(28.1

115

Vac/60

230

Vac/50

50%

75-100

3.8

2.2

23.63"

3.08

47

Below

145

230

3.39

1.06

5

35

58

30

45

35

2

12"

4.2

12"

1.2

psi

SCFM

SCFM

(.600

fé

(.086

Ibs.

(21.29

Midpoint

Vac/60

Vac/50

Quart

Pint

Micron

Micron

psi

(399,895

psi

(206,842

psi

(310,397

psi

(242,316

Quart

(.0019

Hg

(40,512

£/min.

Hg

(40,512

£/min.

(.0005

m)L x 10"

πι)

(.254

m)W x 19"

Kg)

Hz,

9.418

A,

1136

Hz,

4.920

A,

1082

W

(551,580 - 689,475

(.0018

m°/s®

(.0010

m°/s®

m)L x 16.5"

m?)

Pa)

275,790

620,528

(.419

m)W x 14.125"

Kg)

Hz,

295.6

mA,

33

Hz

(.0037

m°)

m?)

Pa)

Pa)

Pa)

Pa)

m?)

Pa)

(.002

m*/s)

Pa)

(.00056

m*/s)

W

Pa)

Pa)

W

(.482m)H

(358

m)

18

DNTL

LIMITED

WARRANTY.

DNTL

of

freight

consumable

DNTL

The

The

improper

products

DNTL

Corporation

delivery

(except

costs

Corporation’s

buyer

shall

warranty

installation

resulting

shall

for

warranty

type

shall be

in

no

consent.

This

warranty

warranties

person

herein,

any

Notwithstanding

is

DNTL

liability,

customer

is

of

merchantability

authorized

shall

loss

or

others

warrants

for

items

sole

have

no

or

from

event

made

to

have

or

the

above

shall

this

product

handpieces

service

including

obligation

other

voided

which

for a period

light

under

remedy.

by

alterations

maintenance,

careless

expressly

give

no

damage

not

or

be

responsible

in

or

fitness

any

warranties

liability

caused

limitations

exceed

neglectful

lieu of

or

the

against

have a warranty

bulbs.

All

accident

for

for

responsibility

or

and

amount

defects

of

90

days

said

warranty

special,

of

equipment

or

misuse.

transportation.

any

warranty

all

other

particular

of

any

nature

alleged

warranties,

paid

in

material

of

six

from

the

is

to

repair,

incidental

warranties,

purpose.

to

to

by

and

except

This

warranty

work

on

behalf

customer

be

caused

DNTL’s

customer

or

workmanship

months).

time

of

delivery.

or

at

its

consequential

by

DNTL

expressly

done

without

expressed

No

employee,

of

DNTL

or

any

other

directly

liability

for

hereunder

the

particular

for

DNTL

will

This

warranty

option,

Corporation,

replace

damages

excludes

first

obtaining

or

implied,

agent,

franchise,

Corporation.

person

or

or

indirectly

for

“equipment”

one

year

pay

labor

the

are

excluded.

or

tampering

all

damage

DNTL's

including

dealer

Except

entity

with

by

damages

from

the

time

and

standard

does

not

cover

defective

any

"equipment".

part.

with,

to

these

written

implied

or

other

as

provided

respect

incurred

involved.

to

by

19

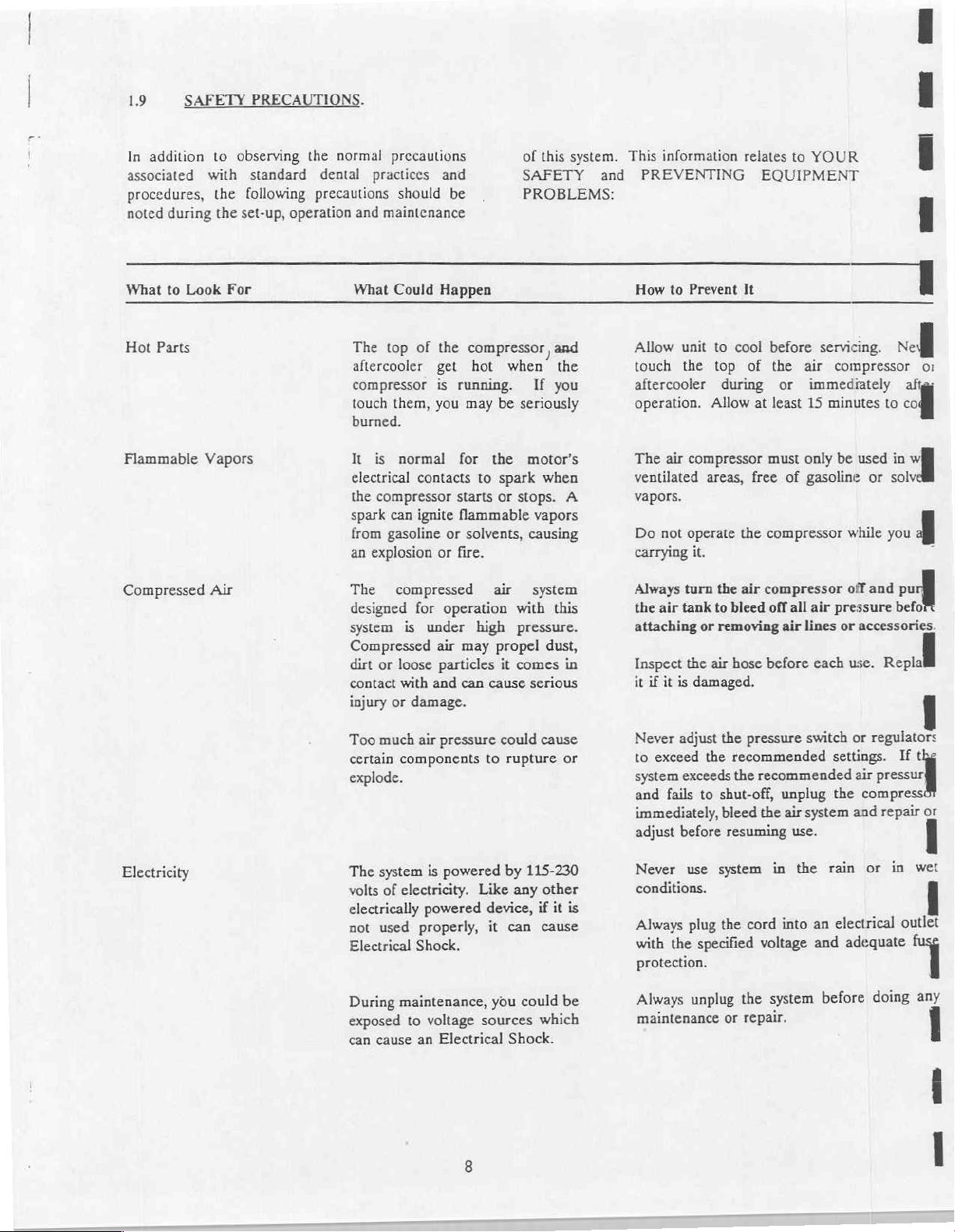

SAFETY

PRECAUTIONS.

을 mm

In

addition

associated

procedures,

noted

during

What

to

Look

Parts

Hot

Flammable

Compressed

to

observing

with

the

following

the

set-up,

For

Vapors

Air

the

standard

operation

normal

dental

precautions

precautions

practices

and

maintenance

What

Could

The

top

aftercooler

compressor

touch

them,

burned.

It is

electrical

the

compressor

spark

can

from

gasoline

an

explosion

The

compressed

designed

system

Compressed

dirt

or

contact

injury

or

should

Happen

of

the

get

is

you

normal

contacts

ignite

or fire.

for

is

under

air

loose

particles

with

and

damage.

and

be

compressor

hot

running.

may

be

for

the

to

spark

starts

or

flammable

or

solvents,

air

operation

high

may

propel

it

can

cause

of

this

SAFETY

PROBLEMS:

and

when

the

If

you

seriously

motor's

when

stops.

vapors

causing

system

with

this

pressure.

dust,

comes

in

serious

system.

and

A

This

information

PREVENTING

How

to

Prevent

Allow

touch

aftercooler

operation.

The

ventilated

unit

the top

air

compressor

vapors.

Do

not

operate

carrying

Always

the air

attaching

Inspect

it

if

it

turn

tank

the

is

it.

or

damaged.

relates

It

to

cool

of

during

Allow

areas,

free

the

the

air

to

bleed

removing

air

hose

to

YOUR

EQUIPMENT

before

the

air

or

immediately

at

least

15

must

only

of

gasoline

compressor

compressor

off

all

air

air

lines

before each

servicing.

compressor

minutes

be

pressure

or

vel]

to

used

in

or

solv

while

you

off

and

accessories.

use.

Replal

을

mě

mil

Οἱ

абы

해

개

3

1

vu]

befoi

Electricity

Too

much

air

certain

explode.

The

volts

electrically

not

Electrical

During

exposed

can

components

system

used

cause

is

of

electricity.

powered

properly,

Shock.

maintenance,

to

voltage

an

pressure

powered

could cause

to

rupture

by

Like

device,

it

can

you could

sources

Electrical

Shock.

115-230

any

other

if

it

cause

which

or

is

be

Never

adjust

the

to

exceed

system

and

immediately,

adjust

Never

conditions.

Always

with

protection.

Always

maintenance

exceeds

fails

to

before

use

plug

the

specified

unplug

the

shut-off,

bleed

resuming

system

the

or

pressure

recommended

the

recommended

cord

the

repair.

switch

unplug

the

air

system

use.

in

the

into

voltage

system

an

and

or

regulators

settings.

air

pressur,

the

compress:

and

rain

or

electrical

adequate

before

doing

If

repair

or

in

wet

outlet

any

the

What

to

Look

For

What

Could

Happen

How

to

Prevent

It

Electricity (cont.)

Improper

a

risk

event

reduces

providing

electric

grounding

of

electrical

of a short

the

an

current.

shock.

circuit,

risk of

escape

can

result

In

grounding

shock

wire

for

in

the

by

the

Ensure

properly

and

that

grounded.

repair

the

should

electrician.

system

All

be

performed

and

electrical

electrical

source

arc

maintenance

by a qualifiec

SECTION

II

2.1

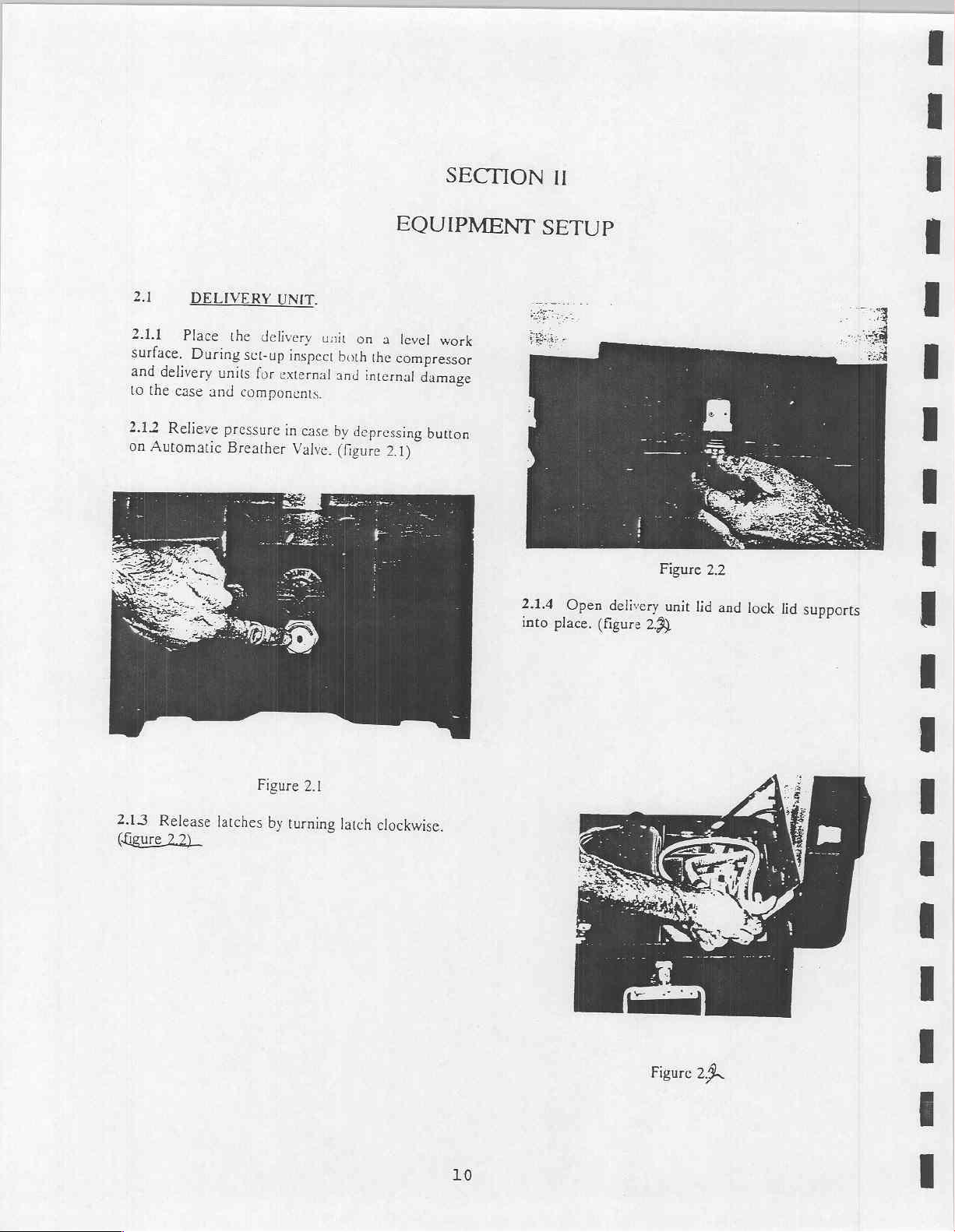

2.1.1

surface.

and

to

2.12

on

Place

delivery

the

case

Relieve

Automatic

DELIVERY

the

During

sct-up

units

and

components.

pressure

Breather

UNIT.

delivery

inspect

for

external

in

c:

ase

Valve.

unit on

both

and

internal

by

depressing

(figure

EQUIPMENT

a

level

work

the

compressor

damage

button

2.1)

SETUP

2.1.4

Open

into

place.

Figure

delivery

(figure

unit

2.3)

2.2

lid

and

lock

lid

supports

2.13

Release

(Ggure

22)

Figure

latches

by

2.1

turning

latch

clockwise.

10

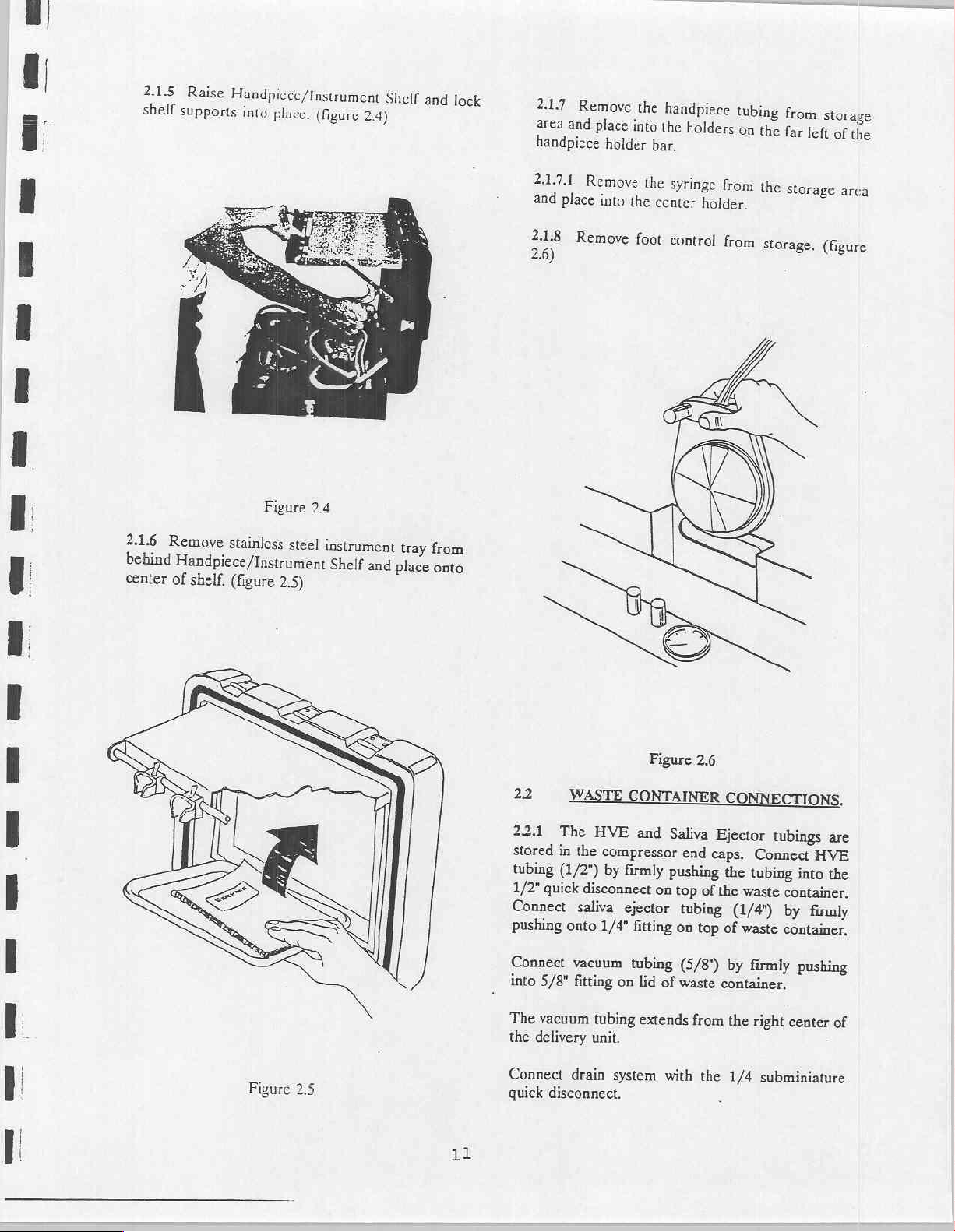

Figure

24

2.1.5

Raise

shell

supports

Handpivec/Instrument

into

place.

(figure

Shelf

2.4)

and

lock

2.1.7

Remove

area

and

place

handpiece

holder

the

handpiece

into

the

bar.

holders

tubing

on

the

from

far

left

storage

of

the

2.1.6

behind

center

Figure

Remoye

Handpiece/Instrument

of

stainless

shelf.

(figure

2.4

steel

2.5)

instrument

Shelf

and

place

tray

from

onto

2.1.7.1

and

place

2.1.8

2.6)

Remove

into

Remove

the

the

foot

syringe

center

control

from

holder.

from

the

storage

storage.

arca

(figure

Figure

2.5

11

22

22.1

stored

tubing

1/2"

quick

Connect

pushing

Connect

into

5/8"

The

vacuum

the

delivery

Connect

disconnect.

guick

WASTE

The

HVE

in

the

compressor

(1/2")

by

disconnect

saliva

onto

1/4"

vacuum

fitting

tubing

unit,

drain

Figure

CONTAINER

and

firmly

on

ejector

fitting

tubing

on

lid

of

extends

system

2.6

Saliva

end

pushing

top

of

tubing

on

top

(5/8")

waste

from

with

the

CONNECTIONS.

Ejector

caps.

the

the

of

container.

tubings

Connect

tubing

waste

container,

(1/4)

by

the

1/4

by

waste

container.

firmly

right

subminiature

are

HVE

into

the

firmly

pushing

center

of

222

Place

the

handpiece

the

HVE

holders

and

(on

the

Saliva

Ejector

right),

valves

(figure

2.7)

in

2.42

Place

feet

ten

to

2.43

Remove

latches

bottom

on

of

the

away

cach

the

both

case.

compressor

delivery

the

from

end

caps

side

and

(figure

on

a

by

latch

2.8)

level

surface

unit.

releasing

on

the

the

top

eight

two

and

23

23.1

center

water

relieve

water

Remove

the

the

lines.

232

to

recommended

unnecessary

control

of

24

2.4.1

cool

muffler

could

The

allow

dirt

filter

should

changed. A clean

provides

The

of

pressure

all

and

top

edge

cap,

Place

Ifthe

high

level

panel

the

entire

COMPRESSOR

Operate

and

must

reduce

air

compressor

for

that

is

be

WATER

water

the

delivery

relief

air

pressure

air

the

cap

and

with

tighten

and

the

container

water

of

mineralization

to

only

failure

components,

system.

the

well

ventilated

be

kept

air

proper

collects

located

cooling.

on

inside

changed

longer

service.

CONTAINER.

container

lines

in

delivery

when

air

Figure

either

your

of

air

pump

the

2.7

case.

toggle

then

(male

fill

to

approximately

distilled

reconnect

back

area

use

distilled

handpieces

thus

SET-UP.

compressor

area.

clear

of

and

Clean

air

compressor

the

the

piston

compressor

is

located

To

into

disconnect

quick

into

contains a moderate

(hard

prolonging

of

obstructions

the

case

or

compressor

in

open

the

the

off

disconnects)

water.

the

water

its

holder.

water),

water

or

damage

in a dry,

The

air

compressor.

are

designed

blow

filter.

and

cylinder

runs

cooler

the

lid,

position

both

1"

below

Replace

and

to

prevent

to

the

clean,

air

intake

which

off

dust

case

back

turn-

ta

the>

air

it

is

the

life

to

or

The

and

are

and

244

The

compressor

operating

other

2.45

and

end

from

Attach

quick

located

control

2.4.6

compressor

2.4.7

source,

cord

motor.

temperature.

obstructions

Remove

saliva

ejector

caps

and

the

work

air

connect

in

panetjust

Connect

If

extra

use

to

avoid

Figure

ventilation

are

necessary

on

electrical

tubings

place

area.

line

from

on

end

on

the

right

behind

the

and

delivery

distance

extra

air

voltage

2.8

openings

to

Do

not

or

near

these

cord

sets,

and

exhaust

end

caps

in

compressor

of

air

line

side

of

the

pressure

power

hose

drop

supply

modules.

is

reguired

instead

and

on

maintain

place

openings.

air

hose,

line

an

area

by

pushing

onto

male

the

delivery

gauges.

cord

to

the

of

an

power

loss

your

air

proper

objects

or

HVE

from

the

separate

female

coupler

unit

to

the

electrical

extension

to

the

12

If

you

a)

A

grounding

will

b)

In

50

c)

d)

10

increases

AWG

use

must

use

3-wire

accept

good

feet

or

gauge

and

AWG

12

and

extension

extension

plug,

and

the

plug

condition.

shorter.

(AWG)

as

8

gauge

AWG,

or

thinner.

or

number

may

cord,

cord

that

a

3-slot

on

the

larger.

also

be

sure

has

a

3-blade

receptacle

compressor.

(Wire

size

decreases.)

be

used.

10

Do

it

is:

that

not

13

SECTION

III

OPERATION

3.1

3.1.1

ejector

3.12

the

3.13

on

3.1.4

on

several

and

automatically

required

3.1.5

PREPARATION

Install a sterilized

mouthpiece.

Install

the

handpieces.

Turn

the

the

compressor

Turn

the

the

compressor

minutes

system.

pressure.

Check

the

Water

Air

Pressure:

Vacuum

Air

Tank

syringe

desired

power

power

to

The

when

System

Pressure:

Pressure(1):

cutting

switch

unit.

switch

unit.

build

up

compressor

the

Pressure

Pressure:

FOR

USE.

tip,

instrument

to

to

Allow

the

pressure

system

HVE

the

"ON"

the

"ON"

air

compressor

to

the

will

has

reached

Gauges

30

psi

58

psi

45

psi

75-100

and

saliva

bits

into

position

position

air

tank

shut

psi

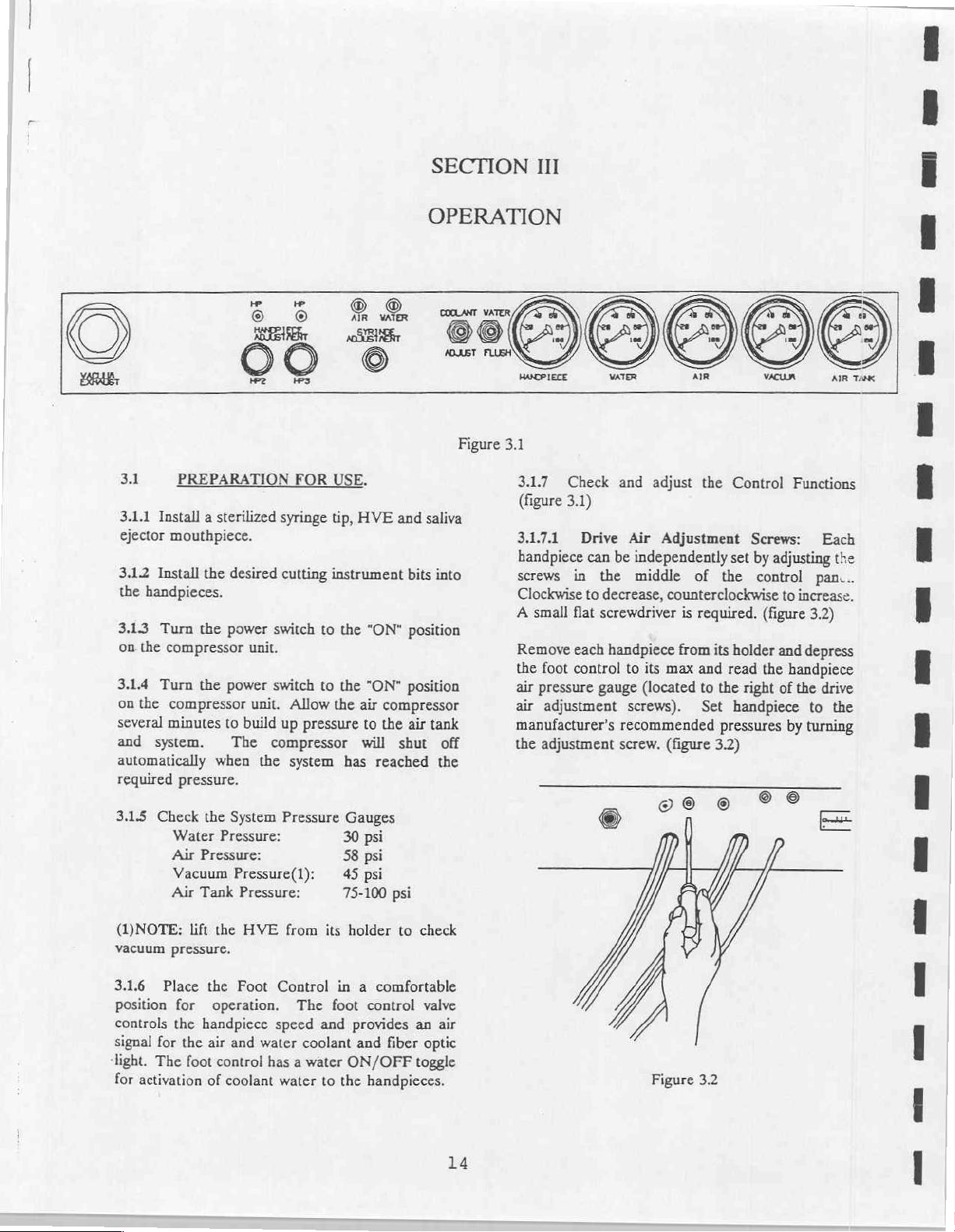

Figure

off

the

3.1

3.1.7

(figure

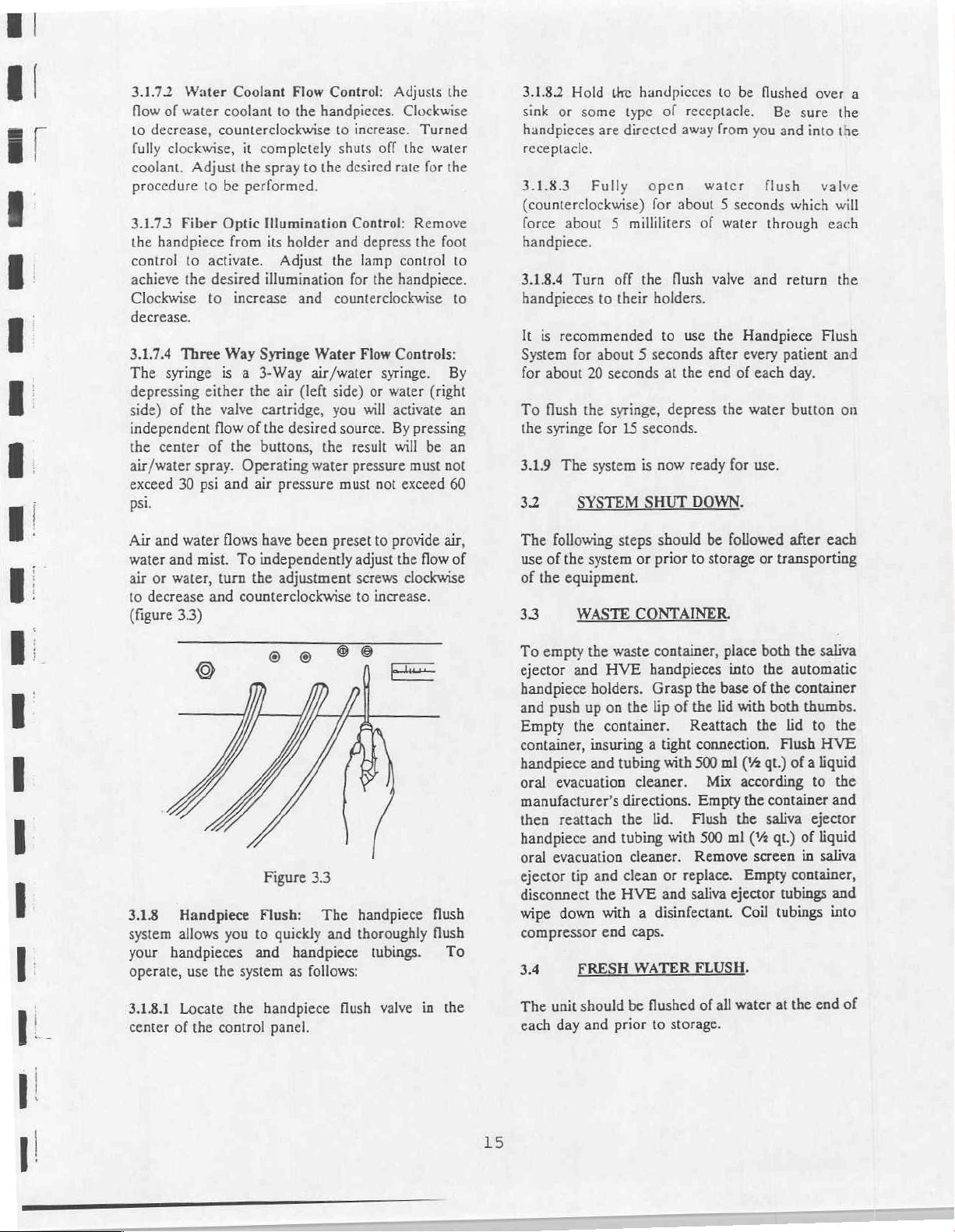

3.1.7.1

handpiece

screws

Clockwise

A

Remove

the

air

air

manufacturer’s

the

Check

3.1)

Drive

can

in

to

small

flat

each

foot

control

pressure

adjustment

adjustment

and

adjust

Air

Adjustment

be

independently

the

middle

decrease,

screwdriver

handpiece

gauge

counterclockwise

is

from

to

its

max

(located

screws).

recommended

screw.

(figure

voo

©

the

Control

Screws:

set

by

of

the

control

required.

its

and

to

Set

(figure

holder

read

the

the

right

handpiece

pressures

3.2)

20

Functions

Each

adjusting

to

the

pan...

increase.

3.2)

and

depress

handpiece

of

the

drive

to

the

by

turning

EE

(NOTE:

vacuum

3.16

position

pressure.

Place

controls

signal

for

«light.

The

for

activation

lift

the

the

for

operation.

the

handpiece

the

air

foot

control

of

HVE

Foot

and

water

has a water

coolant

from

its

Control

The

speed

and

coolant and

water

to

holder

to

check

in a comfortable

foot

control

provides

ON/OFF

the

handpieces.

valve

an

fiber

optic

toggle

air

14

Figure 3.2

3.1.72

flow

to

fully

coolant.

procedure

3.1.73

the

control

achieve

Clockwise

decrease.

3.1.7.4

The

depressing

side)

independent

the

air/water

exceed

Water

of

water

decrease,

clockwise,

Adjust

to

Fiber

handpiece

to

activate.

the

to

Three

syringe

either

of

the

center

spray.

30

psi

of

psi.

Air and

water

air

to

(figure

water

and

mist.

or

water,

decrease

33)

Coolant

coolant

counterclockwise

it

the

be

Optic

from

desired

increase

Way

is a 3-Way

valve

flow

the

Operating

and

flows

To

turn

and

counterclockwise

Flow

to

the

completely

spray

to

performed.

Illumination

its

holder

Adjust

illumination

and

Syringe

the

air

(left

cartridge,

of

the

desired

buttons,

air

pressure

have

been

independently

the

adjustment

Control:

handpieces.

to

shuts

the

desired

and

the

counterclockwise

Water

air/water

side)

you

source.

the

water

must

preset

Adjusts

Clockwise

increase.

off

the

rate

Control:

depress

lamp

control

for

the

handpiece.

Flow

Controls:

syringe.

or

water

will

activate

By

result

will

pressure

not

exceed

to

provide

adjust

the

screws

to

clockwise

increase.

the

Turned

water

for

the

Remove

the

foot

to

to

By

(right

an

pressing

be an

must

not

60

air,

flow

of

3.1.8.2

sink

handpicces

receptacle.

3.1.8.3

(counterclockwise)

force

handpiece.

3.1.8.4

handpieces

It

System

for

To

the

3.1.9

32

The

use

of

33

Hold

tre

handpicces

or

some

type

are

directed

Fully

about 5 milliliters

Turn

to

is

recommended

for

about 5 seconds

about

20

flush the

syringe

of

the

for

The

system

SYSTEM

following

the

system

equipment.

WASTE

open

for

off

the flush

their

seconds

syringe,

15

seconds.

is

steps

or

CONTAINER.

to

of

receptacle.

away

from

water

about 5 seconds

of

water

valve

holders.

to

use

the

after

at

the

end

depress

now

should

prior

the

ready

DOWN.

be

to

storage

for

followed

be

flushed

Be

you

and

flush

which

through

and

return

Handpiece

every

patient

of

each

day.

water

button

use.

after

or

transporting

over

sure

into

valve

Flush

a

the

the

will

each

the

and

on

each

3.1.8

system

your

handpieces

operate,

3.1.8.1

center

of

©

Handpiece

allows

you

use

the

system

Locate

the

the

control

e

©

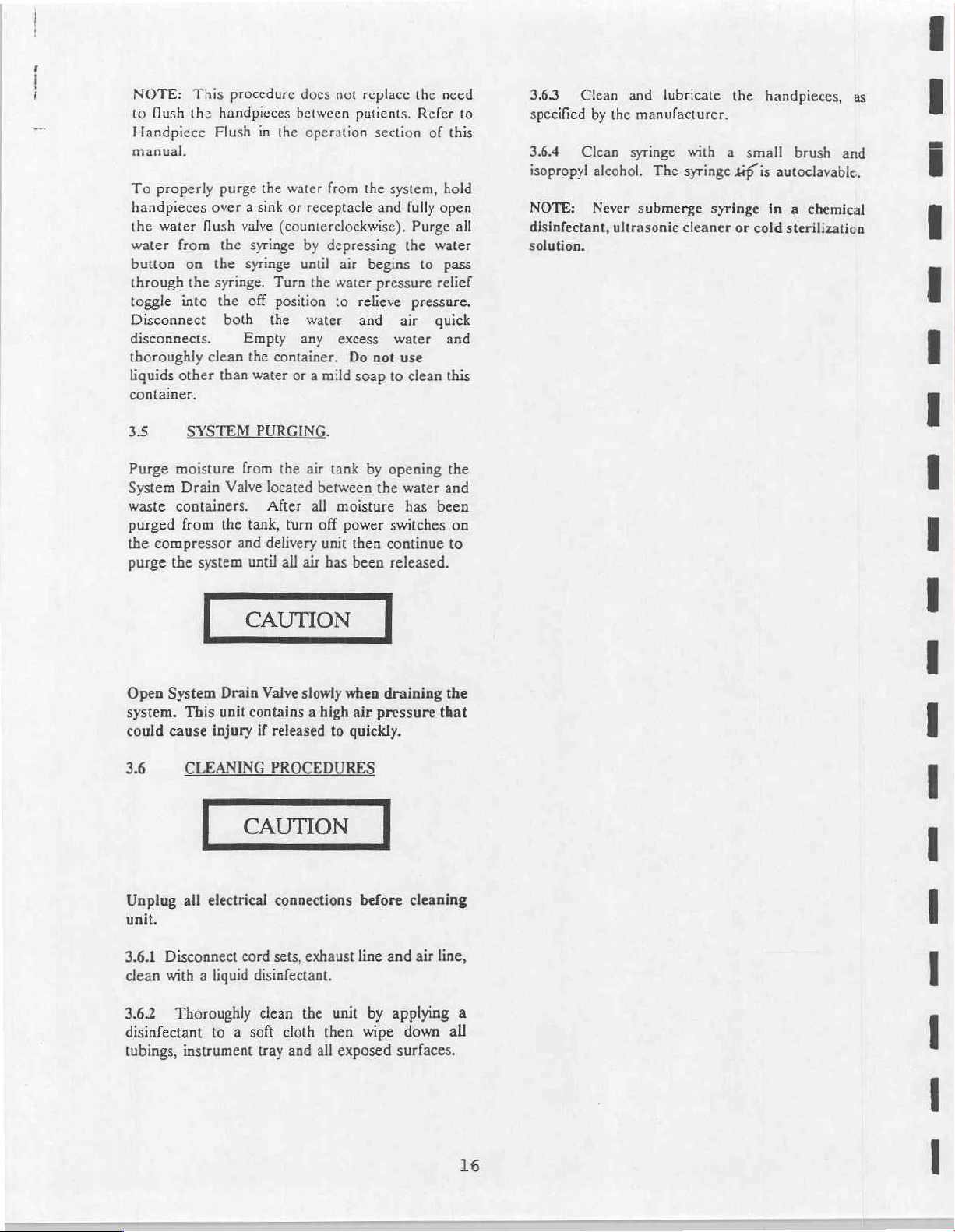

Figure

Flush:

to

quickly and

and

handpiece

as

follows:

handpiece

panel.

3.3

The

00

handpiece

thoroughly

tubings.

flush

valve

==

flush

flush

in

To

the

To

empty

the

waste

ejector

handpiece

and

Empty

container,

handpiece

oral

manufacturer's

then

handpiece

oral

ejector

disconnect

wipe

compressor

3.4

The

each

and

HVE

holders.

push

up

on

the

container.

insuring a tight

and

tubing

evacuation

reattach

and

evacuation

tip

and

the

down

with a disinfectant.

end

FRESH

unit

should

day

and

prior

directions.

the

tubing

clean

HVE

container,

handpieces

Grasp

the

lip

of

with

cleaner.

lid.

with

cleaner.

or

and

caps.

WATER

be

flushed

to

storage.

place

into

the

base

the

lid

with

Reattach

connection.

500

ml

(Y

Mix

according

Empty

the

Flush

the

500

ml

(Y

Remove

replace.

saliva

Empty

ejector

Coil

FLUSH.

of

all

water

both

the

the

automatic

of

the

container

both

thumbs.

the

lid

Flush

qt.)

of a liquid

container

saliva

qt.)

of

screen

in

container,

tubings

tubings

at

the

saliva

to

the

HVE

to

the

and

ejector

liquid

saliva

and

into

end

of

NOTE:

to

Handpiece

flush

the

This

manual.

To

properly

handpieces

the

water

water

button

through

toggle

over a sink

flush

from

on

the

into

Disconnect

disconnects.

thoroughly

liquids

container,

clean

other

procedure

handpieces

Flush

in

the

purge

the

water

or

valve

(counterclockwise).

the

syringe

the

syringe

syringe.

the

both

than

Turn

off

position

the

Empty

the

container.

water

does

not

between

operation

from

receptacle

by

depressing

until

air

the

water

to

water

any

excess

Do

or a mild

replace

patients.

the

the

Refer

section

system,

and

fully

Purge

the

begins

to

pressure

relieve

and

pressure.

air

water

not use

soap

to

clean

need

to

of

this

hold

open

all

water

pass

relief

quick

and

this

3.63

specified

3.6.4

isopropyl

NOTE:

disinfectant,

Clean

by

the

Clean

alcohol.

Never

ultrasonic

solution.

and lubricate

manufacturer.

syringe

submerge

with a small

The

syringe

syringe

cleaner

the

handpieces,

tiff

is

autoclavable.

in a chemical

or

cold

sterilization

brush

as

and

3:5

Purge

System

waste

purged

the

purge

Open

system.

could cause

3.6

SYSTEM

moisture

Drain

containers.

from

compressor

the

System

This

CLEANING

from

Valve

the

and

system

Drain

unit

injury

PURGING.

the

air

tank

located

After

tank,

delivery

until

Valve

turn

all

air

slowly

between

all

moisture

off

power

unit

has

when

contains a high

if

released

to

PROCEDURES

by

opening

the

switches

then

continue

been

released.

draining

air

pressure

quickly.

water

has

the

and

been

on

to

the

that

Unplug

unit.

3.6.1

clean

3.62

all

electrical

Disconnect

with a liquid

Thoroughly

disinfectant

tubings,

instrument

connections

cord

sets,

disinfectant.

clean

to a soft

tray

exhaust

the

cloth

and

all

before

line

unit

then

exposed

and

by

applying

wipe

surfaces.

cleaning

air

line,

down

all

a

16

SECTION

IV

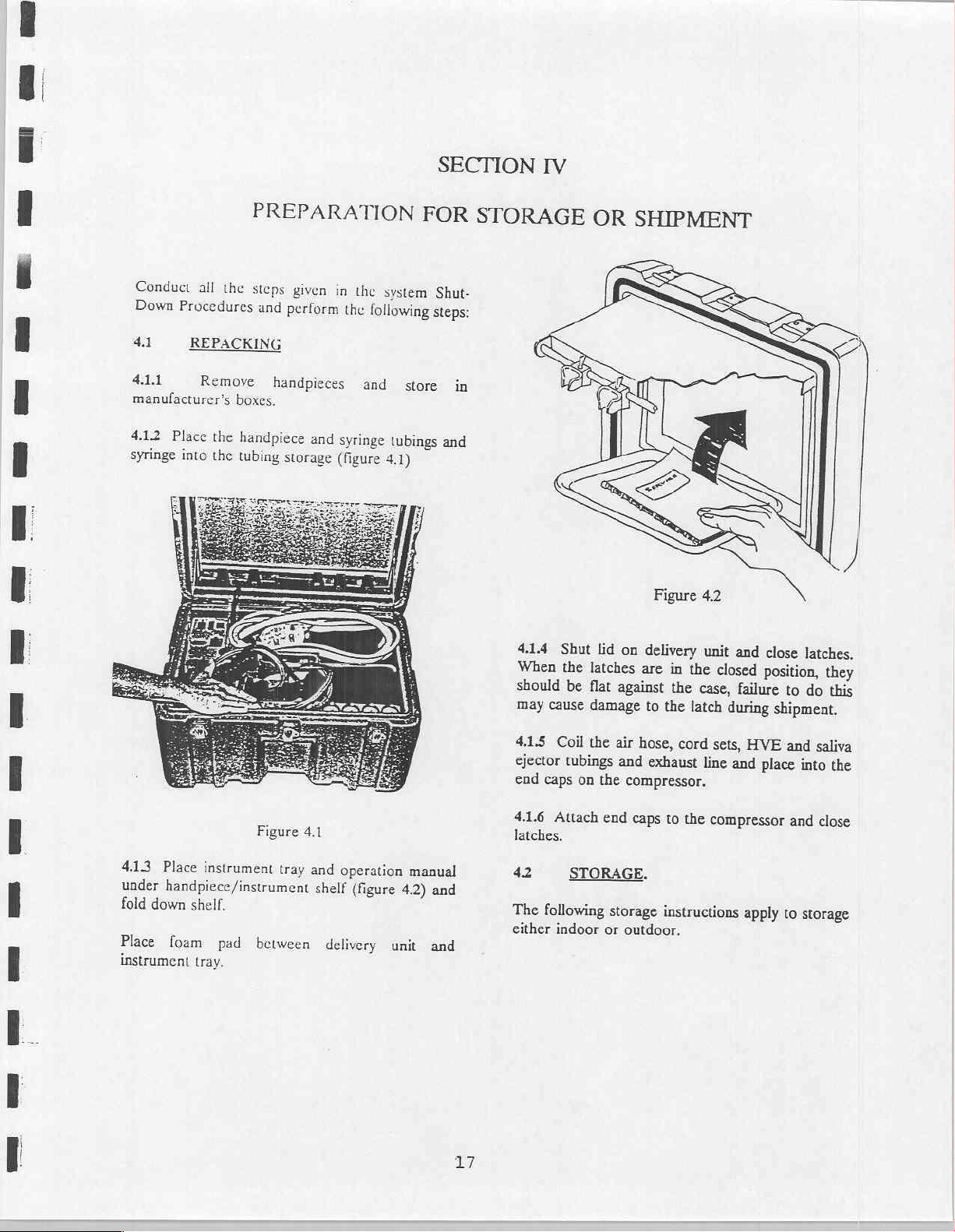

Conduct

Down

41

411

manufacturer’s

4.12

syringe

all

the

Procedures

REPACKING

Remove

Place

the

into

the

PREPARATION

steps

given

and

perform

handpieces

boxes.

handpiece

tubing

and

storage

in

the

system

the

following

and

syringe

(figure

tubings

4.1)

FOR

Shut-

steps:

store

STORAGE

in

and

4.1.4

When

should

may

cause

Shut

the

be

OR

SHIPMENT

lid

on

latches

flat

against

damage

delivery

are

in

the

the

to

the

latch

unit

closed

case,

during

and

close

position,

failure

shipment.

latches,

they

to

do

this

4.13

Place

instrument

under

handpiece/instrument

fold

down

shelf.

Place

instrument

foam

tray,

pad

Figure

between

4.1

tray

and

operation

shelf

(figure

delivery

manual

4.2)

unit

and

and

17

4.1.5

Coil

ejector

end

4.1.6

latches.

42

The

either

tubings

caps

Attach

following

indoor

the

air

and

on

the

compressor,

end

STORAGE.

storage

or

outdoor.

hose,

cord

exhaust

caps

to

the

instructions

sets,

HVE

line

and

place

compressor

apply

and

saliva

into

and

to

storage

the

close

The

ideal

(0°C)

and

be

stored

40°C)

to

Storage

cause

permanent

storage

100°F

(37°C);

in

temperatures

140°F

in

(60°C)

temperatures

damage

temperature

however

is

the

ranging

if

no

other

out

of

these

to

the

unit.

Part

O-RINGS:

Water

Air/Filter

Water

Water

Air/Water

Foot

Needle

Handpieces

Quick

Automatic

Suction

Syringe

Water/Air

Push

Quick

System

Compressor,

Solenoid

Waste

Waste

between

field

unit

from

-40°F

options

ranges

Description

Regulator

Container

Relay

Control

Valves

Low

Speed

High

Speed

Disconnects

1/4"

Water

1/4"

Water

3/8"

Air

Handpieces

Block

Lock

Coupler

Drain

Container

Container

32°F

can

(-

exist.

could

Regulator

Syringe

In/Out

In/Out

In

Brass

Quick

Handpiece

Coolant

Fittings

Block

Fittings

Valve

Pump

Automatic

Quick

Prior

to

instructions

storage.

need

to

storage.

Once

following

or

Female

Male

Holder

(HVE & LVE)

removed

replaced.

Disconnect

Valves

Shut-off

Disconnects

storage,

Once

be

items

follow

for

the

in

inspected

will

Qty.

the

field

storage,

until

from

long

need

to

m

NUS

Om

ANDO

PARA

cleaning

unit

to

the

field

it's

removed

term

be

inspected,

and

repacking

insure

unit

proper

will

storage,

lubricated

not

from

the

GASKETS

Compressor,

Delivery

Compressor

Automatic

Automatic

Venturi

GROMMETS

Compressor,

Delivery

Case,

Breather

Dual

Suction

Unit

Pump

Neoprene

Case,

Neoprene

Handpiece

Air

Hose 1 1/16

Wire

18

Seal

Seal

Valves

Block

HENNE

Grommets

SECTION

MAINTENANCE

V

5.1

5.1.1

and

optimal

The

be

+

+

+

Should

would

system

replacements,

52

52.1

gaskets

install

If

carefully

EQUIPMENT

INSPECTION.

The

equipment

disinfected

performance.

following

performed

Look

for

mechanical

safe

operation.

Insure

wear

Inspect

and

mechanical

affect

should

GENERAL

When

or

new

the old

check

there

components

frayed

servicing

diaphragms,

ones

gasket

should

after

use

visual

checks

before

the

correcting

operating

are

no

missing

electrical

or

other

safety

not

be

SERVICE

components

when

reassembling

or

diaphragm

for

pin

holes

damage

for

it

be

thoroughly

each

and

the

parts

tightness,

cords.

damage

of

use

used

the

defects

INFORMATION.

is

generally

or

cracks.

ARE

cleaned

day

to

maintain

inspections

unit:

that

or

rust,

be

or

operation,

until

are

that

the

is

to

should

could

affect

accessories

cracks,

evident

repair

made.

bave

rubber

advisable

components.

be

reused,

AND

that

the

or

to

When

servicing

component

cleaned

Any

cloth.

rinse

Periodic

consequent

trained

inspection

warranty.

$3

and

wiping should

Flush

them

service

TESTING

REQUIRED.

dental

disassembled

inspected

all

in

isopropyl

maintenance

service

nor

for

be

done

parts

with

should

personnel

service

EQUIPMENT

(figure

alcohol.

systems,

the

should

defects

is

before

with a soft,

clear,

inspections

be

accomplished

only.

part

of

5.1)

parts

be

thoroughly

reassembly.

lint

hot

water,

and

Neither

the

equipment

TOOLS

of

any

free

ther

any

by

the

Before

coating

easier,

damaged.

lubricated

When

that

nevertheless

flow.

too

connection.

to

becomes

installing

of

silicone

and

The

before

trouble

although

Crimps

short,

so

allow

adequate

crimped)

will

can

Remember

O-rings,

grease.

prevent

seal

inserting

shooting

this

tubing

become

are

often

that

it

the

bores

the

is

crimped

caused

is

stretched

when

length.

always

This

should

the

system,

resistant

(slack

apply a light

makes

O-rings

also

stems

bear

to

and

by

the

at

the

installing

installation

from

being

be

lightly

or

pistons.

in

mind

crimping,

obstruct

tubing

barb

any

tubing

it

the

being

tubing

rarely

19

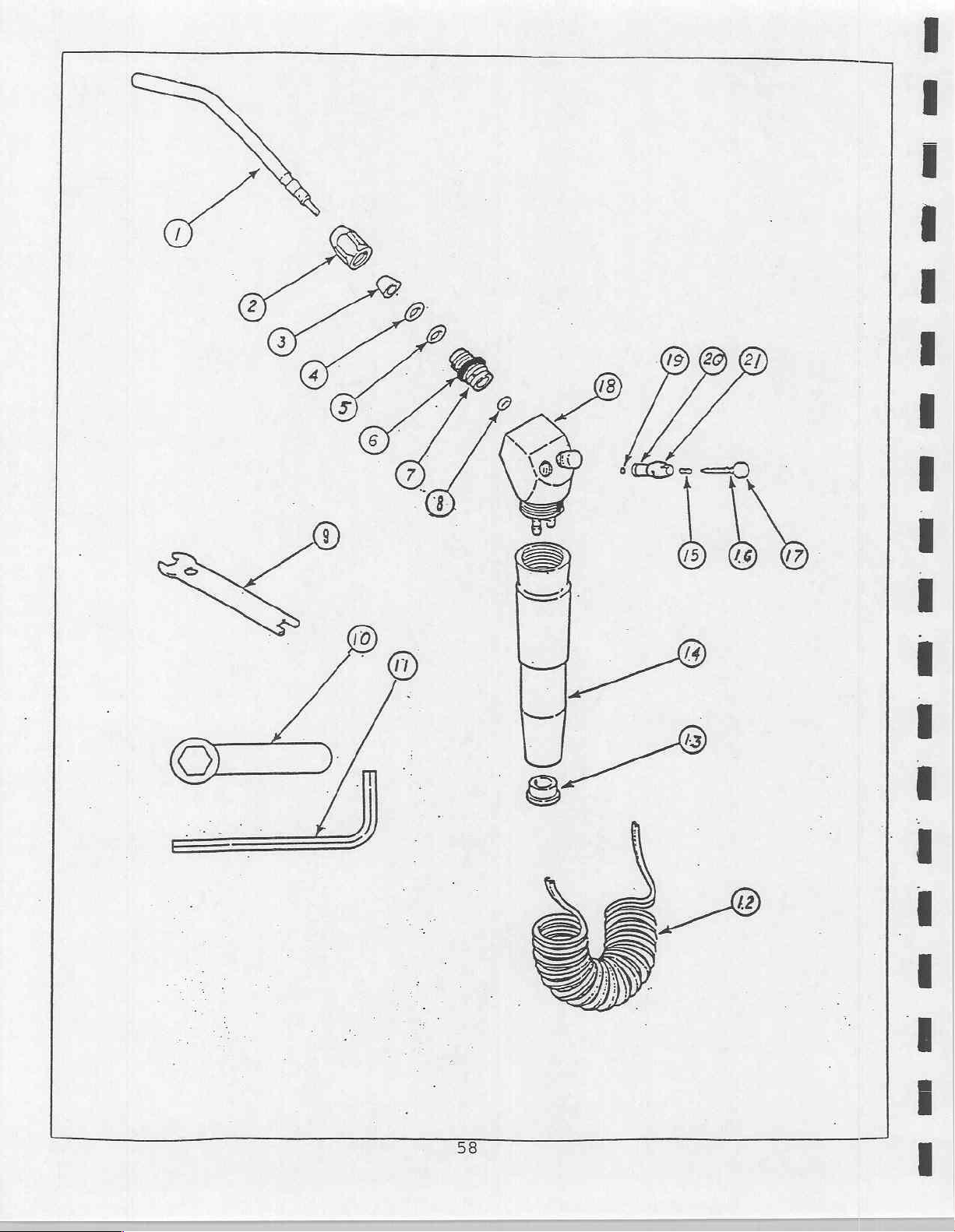

Figure

5.1

Flat

Jewelers

kit)

Used

handpieces

Flat

Screwdriver:

panels

of

frame.

Hemostats:

or

water

flow

or

repairing

Nut

Driver

from

fan

and

Ratchet

removing

Allen

5/64"

3/32"

8:

Wrenches:

Used

the

Used

holder

1/8"

Used

motor

5/32"

Used

eccentric

Screwdriver:

for

adjusting

and

three-way

Used

compressor

Useful

the

5/16":

Socket

bolts

automatic

for

through

delivery

motor

7/16"

from

(Set

for

accessing

for

adhering

to

the

for

tightening

shaft

for

tightening

shaft

(provided

air

and

syringe.

to

remove

module

tubing

For

shaft.

compressor

of

handpiece

support

and

temporarily

while

unit.

removing

or

Nutdriver

4,

provided

the

switch

the

automatic

bar

the

the

in

the

repair

water

pressure

screws from

the

delivery

stopping

troubleshooting

hex

pump

with

mechanism

holder

eccentric

Piston

the

head

7/16":

head.

repair

handpiece

to

rod

to

to

end

unit

air

bolt

For

kit)

in

the

the

drops

below

the

syringe,

serviced.

5.43

Servicing:

from

the

external

delivery

from

The

which

bottom

moisture

bowl

valve

To

main

delivery

opening

mini

bowls.

Unscrew

unscrew

5.5

unit

external

air

filter

is

housed

of

separator.

can

be

or

with

replace a clogged

power

modules

the

quick

the

the

WATER

the

numbers

the

clement

Remove

case.

(cut

out

case.

consists

in a bowl,

the

regulator.

Any

released

automatic

switches

and

system

coupler

bowl from

filter

element

FILTER

indicated

is

the

Pull

for

hand)

of a replaceable

liquid

by

opening

drain

air

filter

on

beth

relieve

drain

valve.

located

the

and

while

clogged

delivery

up on

until

and

attached

It

also

accumulations

the

system.

element,

the

compressor

all

air

Disconnect

below

the

regulator

replace.

operating

and

must

unit

frame

center

unit

is

filter

element

to

serves

in

system

turn

off

pressure

regulator

and

be

of

(rez

the

as

a

the

drain

the

ane-

by

the

then

Syringe

removal

the

main

servicing

Air

Pressure

gauge

with a 0-100

pressure

unit.

5.4

5.4.1

Regulator

pass

through

Filter

elements

become

the

regulators.

5.42

Checking

air

supply,

that

the

external

While

pressing

pressure

air

is

15

Tools:

of

air

the

at

MAINTENANCE.

sufficiently

water

water

gauges.

psi;

(Provided)

threaded

and

water

syringe.

Test

psi

various

Filters:

filters

should

the

Be

sure

supply

source.

the

The

for

water

points

syringe

barrel

Gauge:

range,

before

clogged

Filters:

there

maximum

it

This

assembly.

supply

Use

for

while

The

air

entering

be

serviced

to

Connect

is

water

tube

button,

is

10

tool

is

used

Be

sure

is

turned

use

troubleshooting

and

impede

is

psi.

off

an

air

pressure

in

checking

water

supplies

the

regulators.

when

the

the

unit

in

the

tank,

connected

check

the

pressure

If

the

drop

pressure

prior

flow

to

to

system

for

that

to

air

the

they

to

its

or

an

for

The

water

is

filtered

with a reusable

5.51

Servicing:

tubes

from

the

water

filter.

Relieve

button

on

housing,

the

disc

dry

it

with

HVE.

when

assembling

5.6

Air

is

drawn

keep

dust

system.

filter

removed

components

all

the

water

separate

with

isopropyl

the

Be

sure

IR

INTAKE

into

and

Do

not

to

in

by an

porous

disc

Disconnect

container

air

pressure

container.

and

remove

alcohol and

air

from

the

O-ring

the

filter

FILTER.

the

compressor

other

debris

operate

prevent

the

compressor

in-line

filter

the

before

by

depressing

Unscrew

the

the

syringe

is

properly

housing.

from

the

compressor

undue

wear

pump.

35

micron

element.

air/water

servicing

the

filter

disc.

then

thoroughly

or

with

positioned

and

filtered

entering

with

on

the

filter

supply

the

the

red

filter

Clean

the

to

the

air

the

teflon

20

2)

3)

External

Internal

Leakage

Leakage

Make

sure

down

for

15

5.6.1

Servicing:

all

times. A dirty

compressor

filter

becomes

To

replace

the

filter

is

dirty,

it

with a mild

5.7

The

instruments

through

delivery

the

in

simply

AIR/WATER

operating

air

unit

pressure.

5.7.1

Checking

should

5.72

regulators,

between

air

Be

Check

before

be

as

Water

Pressure:

Air

Pressure:

Vacuum

Servicing:

verify

70-100

regulator

sure

there

the

filters

adjusting

the

compressor

minutes.

Keep

air

intake

to

operate

dirty,

it

must

filter,

pull

place

and

replace

pull

it

out

detergent

REGULATORS.

air

and

and

vacuum

regulators.

indicate

follows:

Pressure:

the

the

Regulators:

Before

that

psi.

Do

if

supply

pressure

is

water

as

explained

the

regulators.

has

the

air

intake

filter

at

full

capacity.

be

cleaned

out

the

with a new

and

clean;

and

warm

water

devices

The

gauges

regulated

30

psi

(- 5 psi)

58

psi

(+/- 5 psi)

45

psi

(+/- 5 psi)

adjusting

the

air

not

attempt

is

in

the

in

the

at

least

filter

clean

will

not

allow

When

or

replaced.

tow

pins

one.

you

may

water.

pressures

are

controlled

inside

air

and

The

pressures

the

air

or

tank

pressure

to

adjust

less

than

water

container.

Filters

cooled

at

the

the

holding

If

it

wash

to

the

the

water

water

is

the

70

psi.

section

5.73.1

is

5.73.2.

leakage

following

1)

the

valve

leaking

2)

from

regulator

tightening

new

3)

from a loose

assembly.

leak,

5.733

indicates

unit

inlet

replacing

the

material

5.7.4

leakage

by

ting.

water

Install a new

Filter

covered

Leakage

Leakage

in

External

from

action

filter

bowl

core.

persists,

the

bowl

or

the

O-ring.

around

Leakage

If

replace

Internal

that

is

not

being

seal.

or

new

poppet,

on

Servicing

around

replacing

Leakage

pressure

the

from

Try

from a defective

around

tightening

the

the

This

cleaning

the

the

regulator.

Element:

Filter

Leakage:

the

air

according

the

purge

results

tightening

replace

the

not

being

bowl.

If

the

the

cover

or a defective

diaphragm.

Leakage:

pressure

used,

there

can

the

be

certain

sealing

the

Water

the

inlet

sleeve

around

the

are

indications

Service

section.

from a loose

the

top

top

the

normally

surfaces

or

of

the

filter

In

the

event

of

filter-regulator,

to

the

point

of

valve

at

the

bottom

or

the

valve

core.

valve core.

of

the

filter

bowl

screwed

leaking

cover

If

creeps

poppet.

that

or

replacing

adjusting

tightly

O-ring

persists,

of

the

regulator

does

the

air

pressure

upward

is

air

leaking

be

When

there

in

the

Regulator:

outlet

can

the

knob

of

internal

seal.

diaphragm

not stop

when

corrected

is

no

valve

be

corrected

internal

or

clement

external

take

the

leakage:

of

defective

If

the

results

onto

the

Try

install

a

results

the

gauge

the

past

the

by

installing

foreign

body.

External

o-

erratic

leakage.

If

adjustment

required,

increase

pressure.

necessary

before

water

5.73

Regulators

problems:

1)

pressure

reading

syringe

Servicing

Clogged

of

turn

When

to

relieve

button.

used

either

the

air

or

the

regulator

or

counter-clockwise

decreasing

the

gauge.

the

Air

are

Filter

the

the

pressure

Do

this

Regulator:

subject

Element

water

knob

water

in

by

The

to

three

pressure

clockwise

to

decrease

pressure,

the

pressing

system

Air

types

it

the

Filter-

is

to

is

of

21

58

The

easily

the

5.8.1.1

approximately

straight

not

is

only).

HREE

way

three

serviced

repair

kit.

Changing

out.

visible.

syringe

with

three

Push

Retighten

WAY

the

the

turns.

sterile

SYRINGE.

designed

is

and

tools

Loosen

Tip:

Pull

in

tip

retaining

can

it

that

so

contained

parts

retaining

contaminated

reminder

until

(hand-tight

nut

be

in

nut

tip

ring

5.9

The

piston

be

drops

operation

simultaneously

5.9.1

unplug

the

AIR

air

compressor

and

teflon

replaced

below

of

Servicing:

the

delivery

COMPRESSOR

whenever

the

the

or

unit

unit

pump

coated

and

to

sleeve.

the

level

handpieces

after

500

Before

servicing

disconnect

relieve

PUMP.

contains a teflon

These

parts

air

compressor

required

and

hours

of

the air

any

pressure.

efficiency

to

vacuum

operation.

the

compressor,

hose

ring

should

maintain

system

from

apply a small

the

o-ring

into

into

place

for

to

the

O-ring.

worn.

plate,

entire

the

screws

Place

tighten

Ensure

gasket

head

7/16"

and

the fan

the

assembly

socket

tighten.

hex

amount

proper

proper

and head,

onto

of

place.

seating and

Inspect

alignment

onto

and

the

motor

head

screw.

Be sure

o-ring

lubrication

to

to

the

gasket

of

then

carelully

the

pump

ratchet,

shaft

guide

the

prevent

and

the

o-ring

lower

frame.

replace

and

replace

to

hold

O-ring

damage

replace

valve

the

Using

the

four

and

if

5.9.1.1

the

remove

(air

a

and

Using

screw

motor

Using

on

rod

assembly.

Using a ratchet

driver,

top

head

access

the

assembly.

through

Removing

compressor

the

hose)

flat

screwdriver

carefully

the

from

shaft

the

the

piston

forward

remove

of

the

assembly

to

the

O-ring

the

end

of

the

remove

5/16"

the

and

5/32"

rod

from

pump

and

piston

from

Pull

pump

the

Piston

pump,

plate

compressor

and

Nut

inside

pull

allen

assembly

and

the

head assembly.

the

the

frame

it

oppesite

remove

the

end

Driver,

of

the

the fan

wrench,

the

bearing

deep

7/16"

four

machine

valve

plate

and

cylinder

bottom

cylinder

and

will

from

and

Assembly:

be

necessary

of

the

exhaust

module

plate.

remove

sleeve

housing.

the

retaining

the

fan

mounted

the

shaft.

loosen

the

pull

the

on

the

socket

or

screws

Carefully

assembly

sleeve.

of

the

and

discard.

To

access

to