Compressed Air Advisors MH-US-15, MH-US-25, MH-US-35, MH-US-50, MH-US-75 Instruction Manual

...

COMPRESSED AIR DRYERS

INSTRUCTION

MANUAL

MH-US SERIES (MH-US-10 to MH-US-100)

WARRANTY NOTICE

Failure to follow the instructions and

procedures in this manual or misuse of this

equipment will VOID its warranty !

Page 2

TABLE OF CONTENTS

1. IMPORTANT SAFETY NOTES - Please read ........ 6

1.1. Transportation ............................................................. 6

1.2 Positioning ................................................................... 6

1.3 Installation .................................................................... 6

1.4 Before operating ........................................................ 6

1.5 Qualified service personnel .................................... 7

1.6 Maintenance by the user ......................................... 7

2.

INTRODUCTION TO THE MHUS DRYER ............ 7

3.

OPERATION .................................................................. 11

4.

ELECTRICAL CONTROLLER ................................... 13

4.1 Digi-Pro ......................................................................... 13

5. TECHNICAL SPECIFICATIONS.................................16

6. DIAGRAMS..................................................................... 17

6.1 Air Flow Diagrams....................................................... 18

6.2 Electrical Diagrams..................................................... 24

6.3 Electrical Diagrams..................................................... 26

7.

GENERAL ARRANGEMENTS..................................... 34

8. EXPLODED DIAGRAMS ............................................. 34

9.

COMPONENTS LOCATION..................................... 48

10. TROUBLESHOOTING ................................................ 49

11. WARRANTY .................................................................. 51

Page 3

Declaration of Conformity

PED 2014/68/EU

(NB No : 0408)

Manufacturer Mikropor Filters

I.OSB Büyük Selçuklu Caddesi, No:4 06935 Ankara/Turkey

Phone: 0312 267 0770

Fax: 0312 267 0552

Product Description

Serial No of Set (device)

Type of Product

Module

Assesment Modele

Confirmed By

TÜV Austria Service GMBH

Kind of inspection certification supplied standards

Certificate No:

Modules for compatibility assesment of pressure in-build elements;

Exchanger

Receiver

Separator

Compressor

Air Dryer

MH-US-15, MH-US-25, MH-US-35, MH-US-50, MH-US-75

MH-US-100

0118MA00001 to 5218MA99999

CAT II Air Dryer

Module A2

Module A2 type compatibility

Notified Body No 0408

Addres; Deutschstreasse 10 1230 Wien/Österreich

PED (2014/68/EU) Certification EN378-2

ZSTS / SWZE / 1790

CAT II MODUL A2

CAT I MODUL A2

CAT I MODUL A2

CAT I MODUL A2

Product Responsibility Mikropor Filter is responsible for product in conditions it

was delivered. Any modifications are forbidden.

Product be operated according to its application. In case

of breaking above conditions realized manufacturer from

responsibility for the product CE mark of the product will

be not valid.

Signature

Local Quality Manager, Pressure Vessel Ahmet Emin ÇAMLIBEL

Date; 29.03.2017

Page 4

EC DECLARATION OF CONFORMITY

MANUFACTURER

NAME : MİKROPOR MAK. SAN. VE TİC. A.Ş.

ADDRESS : Organize Sanayi Bölgesi Büyük Selçuklu Bulvarı No. 4, 06935, Ankara - Türkiye

TEL : +90 312 267 07 00 FAX: +90 312 267 05 52 WEB: www.mikropor.com.tr

Name and Address of the

Person authorised to compile the technical file

Organize Sanayi Bölgesi Büyük Selçuklu

Bulvarı No. 4, 06935, Ankara -Türkiye

The undersigned declares that the described products meet the essential requirements of the below

mentioned standards as based on Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/

EU, Electromagnetic Compatibility Directive 2014/30/EU

The item of equipments which identified below has been subject to internal manufacturing checks

with monitoring of the final assesment by Mikropor

MACHINE DESCRIPTION MODELS : Air Dryer

: Ahmet Emin ÇAMLIBEL

MH-US-15, MH-US-25, MH-US-35, MH-US-50, MH-US-75, MH-US-100

Serial No of Set (device): 0118MA00001 to 5218MA99999

APPLICABLE DIRECTIVES :

2006/42/EC MACHINE SAFETY DIRECTIVE

2014/35/EU LOW VOLTAGE DIRECTIVE

2014/30/EU ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

Certificate No: 16-PS-0279-TAT-16-MAD-1059

APPLICABLE REGULATIONS :

EN ISO 12100:2010; EN 60204-1:2006/AC:2010; EN 61000-6-2:2005; EN 61000-6-4:2007+A1:2011

EN 378-2

SIGNED ON BE HALF OF THE MANUFACTURER

NAME : Mustafa Uslu

POSITION : R&D Manager

PLACE/ DATE : ANKARA / 03.04.2017

SIGNATURE :

Page 5

I. IMPORTANT SAFETY NOTES Please READ

When operating the air dryer the operator must apply safe working methods and observe all local

safety instructions and relevant regulations.

A Prior to installation, the dryer and the compressed air system are to be depressurized and

disconnected from the electrical main supply.

B The user is responsible for safe operating conditions. Parts and accessories must be replaced if

inspection shows that safe operation cannot be assured.

C Installation, operation, maintenance and repair are only to be authorized, trained and skilled

engineers.

D The minimum and maximum values stated must be observed, as well as all of the safety precautions

described in this manual.

E If any statement in this manual does not comply with the local legislation, the strongest standard is to be

applied.

1.1. Transportation

A Use care and caution when transporting the dryer. Avoid dropping and other physical abuse.

B A forklift can be used to transport the dryers provided the forks are long enough to support its full width

or length and caution is used throughout the move.

1.2. Positioning

A The dryer must be installed horizontally. A minimum of 19.6 in. clearance around the dryer is necessary

to allow a good ventilation and easy access for servicing.

B The ambient temperature in the room should not exceed 113°F and should not be below 39.2°F, taking

the heat radiated by the dryer into account.

C (40 watt for each liter/sec under ISO 7183-A condition or 18 watts for each SCFM under ISO 7183-B

condition).

D There should be no chemicals in the atmosphere that will damage the copper source. (Ammonia gas

etc.)

1.3. Installation

In addition to the general mechanical construction procedures and local regulations, the following

instructions need to be emphasized:

1 Only authorized, trained and skilled engineers should install the compressed air dryer.

2 Safety devices, protecting covers or insulation in the dryers never to be dismantled or modified.

Each pressure vessel or accessory installed outside the dryer with air above atmospheric pressure must be

fitted with the required pressure relief safety valves.

1.4. Before Operating

The following points must be observed before operating the air dryer:

A Review all safety precautions.

B The dryer connection piping measurements must be selected correctly. (See Technical specifications)

C The dryer connection piping must be adapted to the operating pressure. (See Technical specifications)

D Never operate the dryer at pressure above the maximum specified on the dryer label (check the

technical specs too).

E The drains should be opened to atmosphere. If the drains are connected to a pipe / hose, the diameter

of the hose / pipe should be large enough to create no back pressure during drain. It is not recommended

to reduce the diameter of the hose / pipe less than port that is given at the drain outlet of the unit.

The hose / pipe should be at atmospheric pressure at all time. Back pressure in relevant pipe will result in

permanent damage on drain system and the aect function of the filters and / or dryers.

Page 6

1.5. Qualified service personnel

A Maintenance and repairs should only be performed when the air dryer is shut down and depressurized

and when the main power switch is turned o.

B Use only the appropriate tools for maintenance and repair.

C Before dismantling a part under pressure, disconnect the pressure sources and depressurize the

system.

D Proceed carefully during maintenance and repair. Prevent dirt from entering by covering parts and

orifices with a clean cloth, paper or tape. A receiver should never be welded or modified in any way.

E Never leave tools, loose parts or cleaning rags in or on the air dryer.

F Before returning the dryer into service, check the setting of the control and safety devices as well as the

pressure and the temperature of the compressed air circuit.

1.6. Maintenance by the user

A Keep the dryer clean.

B Regularly check the correct operation of the condensate drain trap.

C Every six months, check and clean the drain strainer by undoing the access screw and rinsing the filter

with tap water to remove the trapped dirt from the inside.

D For aircooled dryers, clean the air condenser as soon as it’s dirty or clogged.

E For optional water-cooled condensers, use only clean water andinstall a water filter if needed. Use

water counter flow to clean condenser if need.

F Check the trouble-shooting list in case of maintenance troubles.

G Check operating pressures, temperatures and time settings after maintenance. If operating and safety

devices function properly, the air dryer may be used.

2. INTRODUCTION TO THE DRYER

A) Manufacturer:

MiKROPOR / www.mikropor.com

B) Purpose of this dryer

1 This refrigerated compressed air dryer has been designed to remove water vapor from industrial

compressed air.

2 This dryer has been designed for indoor operation.

3 The minimum and maximum values stated must be observed, as well as the safety precautions

described in this manual.

Page 7

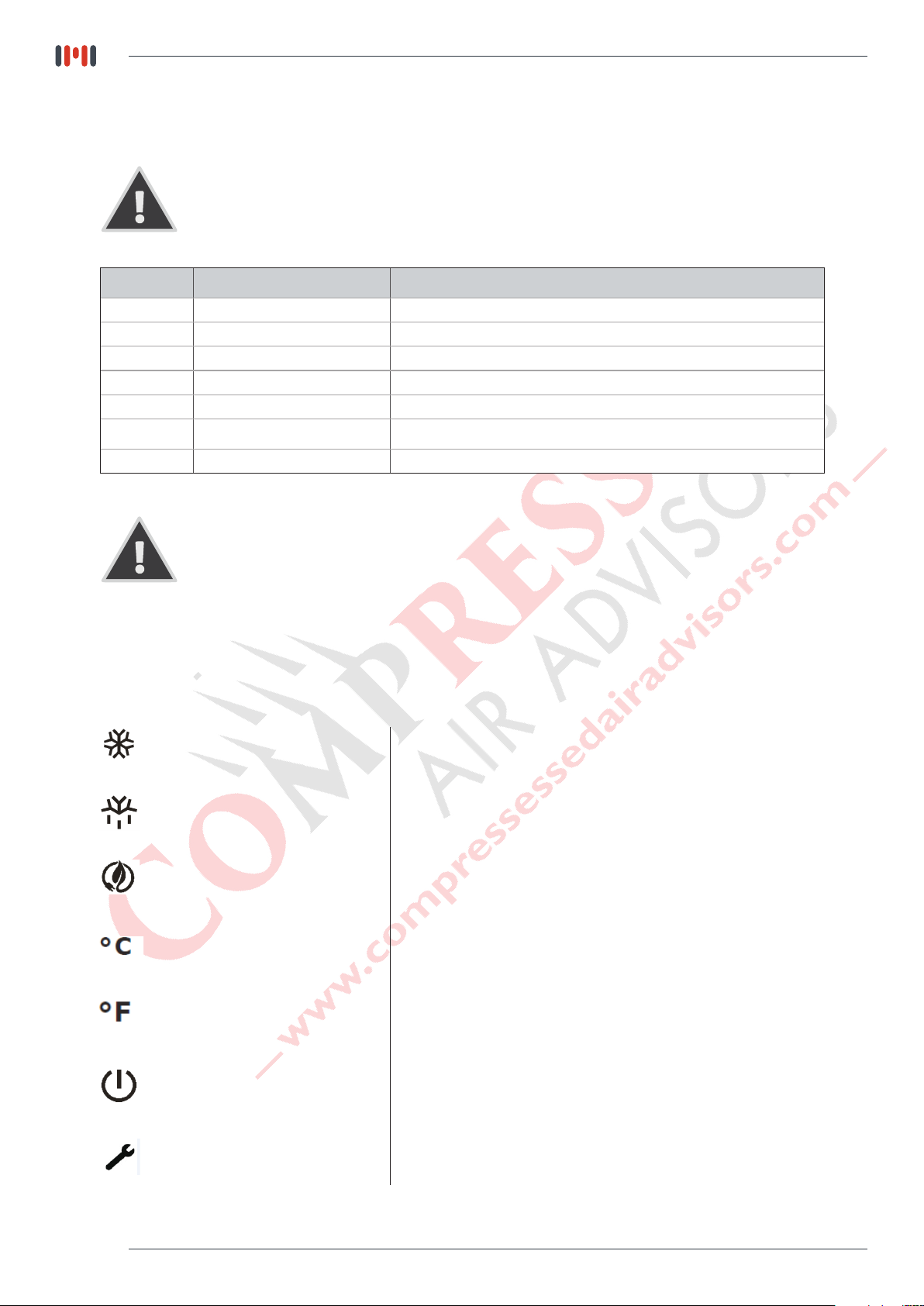

C) Dryer label

The following label is axed on the cabinet of the refrigerant compressed air dryer.

Dryer label describtions

Max. Refrigerant Pressure

Max. Air Pressure

Max. Air Inlet Temp.

Min. Ambient Temp.

Max. Ambient Temp.

Min. Circuit Ampacity

Max. Protective Device Rating

Mikropor America Inc.

251 N.Roeske Avenue Michigan City, IN 46360

www.mikroporamerica.com

Voltage

P Rating

Refrigerant R134a

Weight

Fan

Compressor

MODEL NO: MH-US

SERIAL NO:

MH-US

Model No: Dryer model no

Serial No: Dryer serial no

Max Refrigerant Pressure: Dryer maximum working pressure

Max. Air Pressure: Maximum air pressure

Max. Air Inlet Temp: Maximum air inlet temperature

Min. Ambient Temp. : Minimum ambient temperature

Max. Ambient Temp. : Maximum ambient temperature

Min. Circuit Ampacity : Maximum allowed amount of current

Max Protective Device Rating : Maximum protective device rating

Voltage :

IP Rating : Protection rating

Refrigerant 134a :

Weight : Dryer weight

Fan : Model of fan used

Compressor : Model of compressor used

D) Working details

1) Refrigerant circuit:

The refrigerant circuit can be divided in 3 parts:

Main supply voltage

Amount of refrigerant gas used

A Low pressure section with an evaporator (heat exchanger)

B High-pressure section including: Condenser, liquid receiver, (if installed) and the filter dryer.

C Control circuit including: Compressor, Expansion valve, by-pass valve (if installed),

Fan pressure switch (if installed)

2) The Refrigerant circuit operates as follows:

A The compressor compresses gaseous refrigerant to a high temperature.

B The hot refrigerant condenses in the condenser. Being liquefied it is stored in the liquid receiver (if installed).

C The liquid is taken out the storage vessel and injected in the evaporator (heat exchanger) by an expansion valve.

This expansion valve is protected by a filter, which removes particles and humidity that could be in the circuit.

D The injected liquid fills in the refrigerant section of the air / refrigerant heat exchanger and evaporates by taking

out the calories from the compressed air. The gaseous refrigerant is sucked in the compressor and the cycle carries

on.

E In order to keep the evaporation pressure steady, and thus the refrigerant temperature in the heat

exchanger, a by-pass valve is injecting hot gaseous refrigerant in the circuit. On certain dryers, an

automatic expansion valve regulates this.

3) Compressed air circuit:

A The saturated hot compressed air flows into the Economiserwhere it is pre-cooled by the out flowing dry chilled

air. In the cold zone of the air refrigerant section it continues to cool down to dew point and enters the separator

where condensates are collected. The outgoing chilled air is then warmed up in the economizer by the hot

incoming air.

Page 8

B The condensates are collected after centrifugal separation and drained out through the automatic trap.

C As long as the compressed air temperature does not drop below dew point, there will be no

condensation in the air circuit.

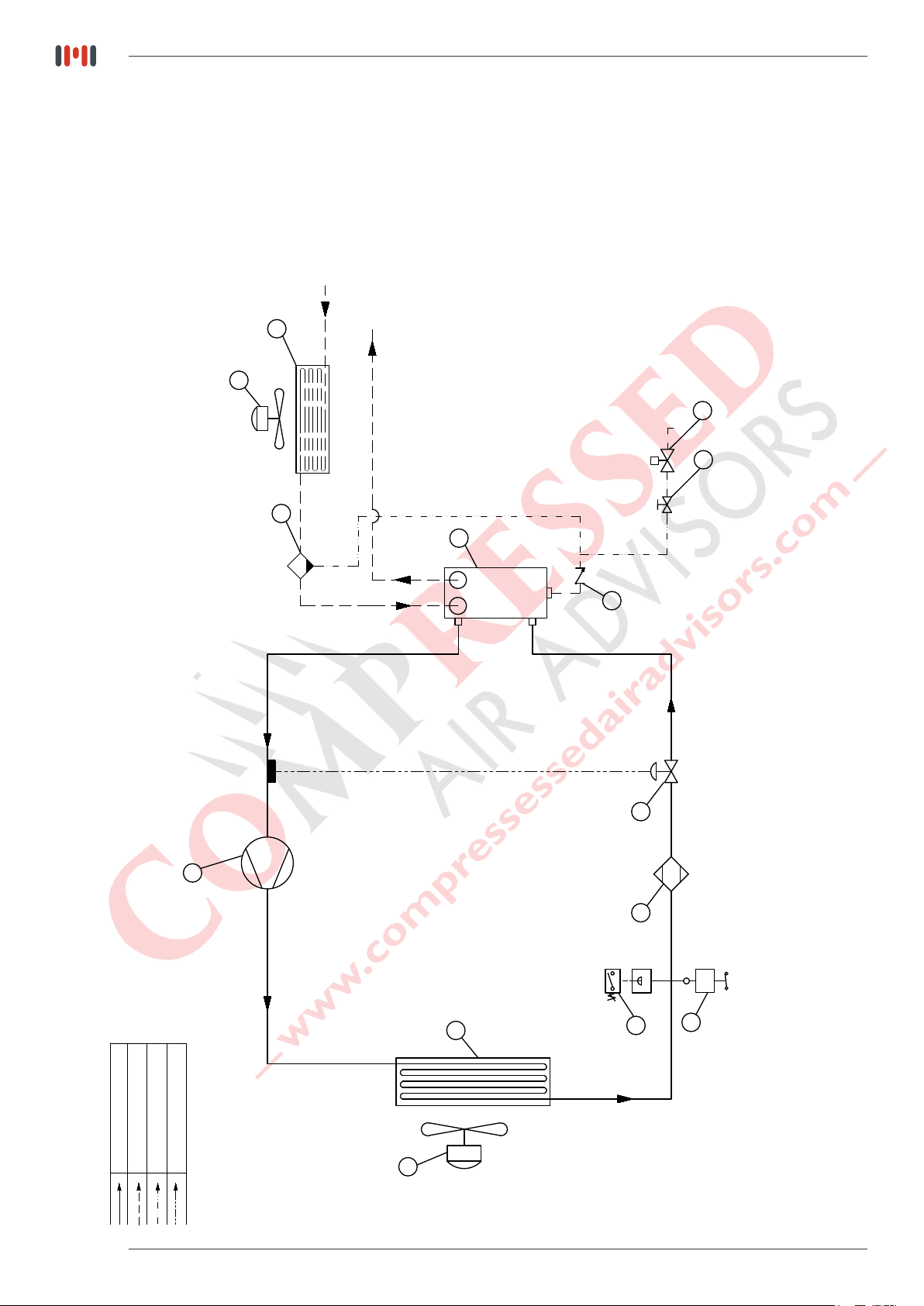

Compressed Air Dryer Working Principle

Compressed

A

B

L

J

B

C

D

H

F G

E

I

K

A-COMPRESSOR

B-FAN MOTOR

C-CONDENSER

D-HIGH PRESSURE SWITCH

E-FAN SWITCH

F-FILTER DRIER

G-EXPANSION VALVE

H-CHECK VALVE

I-SOLENOID VALVE

J-HEAT EXCHANGER

K-AFTERCOOLER

L-WATER SEPARATOR

Refrigerant Gas Flow Line

Compressed Air Flow Line

Drain Flow Line

Dry Air Outlet

Compressed

Dry Air Inlet

4) Refrigerant compressor

Increases the pressure and temperature of refrigerant. There is one type of compressor commonly used

according to refrigerant capacity on this application which is Piston Type.

5) Condenser

Dissipates the heat provided by evaporator and compressor.

There is one type of condenser used on the application:

- Air Cooled Type (standard)

These condensers are designed to dissipate the heat to the ambient air.

The fans are used to force the air flow through the fins to enhance the heat transfer.

6) Refrigerant circuit protection

A Klixon: The single phase compressors are equipped with a klixon which is a thermal sensitive switch

controlling the temperature of the compressor and possible overintensity.

In case of malfunction, the klixon trips but switches on again automatically as soon as the compressor has

cooled down.

B High Pressure Security Switch: Refrigerant line is considered as a pressure vessel. That is why it is

protected against bursts by the help of manually reset switch. It is set to 362 psi for dryers working with R134a

C Filter dryer: A refrigerant circuit is a closed circuit and total water removal in the refrigerant circuit is

paramount in order to obtain a correct functioning.

D To avoid problems, the refrigerant circuit must be vacuumed before loading the refrigerant.

It is equipped with a filter dryer, which also traps any solid particles, which may have migrated into the circuit during

assembly.

E Water-cooled dryers have a safety high-pressure switch.

In case of cooling water failure, the safety switch stops the dryer. When the safety switch has tripped out,

it has to be manually resettled before switching on the dryer.

Page 9

7) Refrigerant circuit controls

A Liquid refrigerant injection: The liquid refrigerant is into the evaporator by a control valve. This valve is a

thermostatic or pressostatic one maintaining a constant overheats of the refrigerant in the evaporator(s).

B Constant evaporating pressure: In the dryers equipped with a by-pass valve, the evaporating pressure is

kept constant by a controlled injection of hot gas from the high-pressure side into the low-pressure

section of the circuit.

8) Condensate drain - trap assembly

Dismantling the drain is easy because it can be isolated from the air circuit under pressure with a ball valve.

The drain has to be depressurized before being dismantled.

9) Heat Exchanger Modular design

AThe dryers are equipped with a compact

Mono Bloc Heat Exchanger module.

This assembly has been specially designed to

dry compressed air and is made of:

1 An Economiser which pre-cools the

entering hot air with the out flowing cold air.

2 An air/refrigerant exchanger cooling down

the compressed air.

3 A centrifugal separator concentrating all

condensates and requiring no maintenance.

10) Accessories

Temperature switch: Temperature switch: Located inside the dryer, this temperature switch is adjustable

from 32°F up to 95 °F.

Digital Controller –DigiPro: This device helps dryer save energy when there is not any compressed air flow

in the dryer. Those information can be reached; Dewpoint value, periodic maintenance interval display,

status report, run time meter, temperature unit selection (°F or °C)

Page 10

3. OPERATION

Control panels for MH-US Series

The control panel of the dryer includes the following elements:

Monophase Digital Controller

MH-US-15 - MH-US-100 Digi-Pro

IMPORTANT NOTE

The Dryer has two Compressed Air Filter inside.

It is better to change filter element for the best eciency when the alarm status is active.

It is recommended to keep replacement filter elements in your stock in order to replace them when needed.

ATTENTION

MH-US range dryers have low pressure drop according its competitors.

Do not use MH-US range dryers together with other dryers which have higher pressure drop

without getting the confirmation from our technical team.

Page 11

3.1. During Operation

Regularly check the digital temperature controller ESD3 or Digi-Pro on dryer.

3.2 Start up and shut-down

Warning: Avoid leaving the dryer o when compressed air is still flowing through it.

3.3 Starting for the first time or after a long stop

1 Set the rotary switch to “I” This preheats the dryer and turns the drain system on.

It is recommended to leave the dryer power on permanently so the crankcase heater runs continuously.

IMPORTANT NOTE!

2 After a long stop of the dryer it is MANDATORY to allow a preheating period of minimum 4 hours

before starting again, to avoid any compressed air flow during preheating.

3 Follow the daily starting and shut down preocedure.

3.4 Daily starting and shut-down

1 Push on the ON button to start the dryer.

2 The start light or Dryer Active will indicate that the dryer is running.

3 To stop the dryer, first stop the airflow (either shut-down the air compressor or close the inlet/outlet or

by-pass valve) When the air flow is stopped, set the rotary switch on “ 0 “ Set it again on “ I “ in order to keep the

preheating on.

IMPORTANT NOTE !

4 Avoid leaving the dryer stopped when compressed air is still flowing through it.

5 To switch the already preheated dryer on again, simply push the green start button.

Page 12

4) ELECTRICAL CONTROLLER

4.1 DIGI-PRO

4.1.1 Description

With the Digi-Pro series controllers, air dryers have outstanding technology for both functionality and

dynamism, as well as appearance. The multi-functional display provides an accurate digital dew point

display as well as coded alarm monitoring of the refrigerant dryer.

DIGITAL CONTROLLER ADVANTAGES;

• Digital dew point monitoring

• Energy-saving mode display

• Periodic maintenance interval display

• Status report

• Run time meter

• Fahrenheit and Centigrade selection

4.1.2 Operation

Using the Digi Pro controller as shown in the picture below:

4.1.3 Menu Buttons

PROGRAM

To modify the parameter, press and release button set. The menu

is used by service team. To disable the Key Lock: Press and hold

the SET for 4 sec.

POWER

MENU

MANUAL DRAİN

This button is used for starting and stopping the dryer. Press and

hold for 4 seconds to start or stop.

These buttons are used to navigate between screens and adjust

values.

This button is used for manual control of the drain output. Press

and hold for 4 seconds to drain manually.

Page 13

4.1.4 ALARM DISPLAY

Alarms / warnings are displayed on the digital screen. That means the dryer is not working

under normal operating conditions, which are outside the range of set values.

Alarm Code Alarm Description Reason for Alarm

tAL Low Temperature Alarm Refrigerant line temperature is lower than specified set values

tAH High Temperature Alarm Refrigerant line temperature is higher than specified set values

FIL Filter Change Alarm Filter element needs to be replaced

SEr General Service Alarm General service time of the dryer

HPr High Pressure Alarm Refrigerant high line pressure is higher than specified set values

Pr1 Temperature Probe Alarm Temperature sensor is faulty.

hFI Working Hours Alarm The dryer working hours allowed has been reached.

Please contact to the service when an alarm/warning occurs.

4.1.5 MODE DISPLAY

DRYER ACTIVE MODE

This mark indicates that the dryer is performed in active state

and drying.

Shows if the drain system is activated.AUTOMATIC DRAIN MODE

Shows if the energy saving mode is activatedENERGY SAVİNG MODE

Indicates that Celsius temperature unit is selected.CELSİUS UNİT MODE

Indicates that Fahrenheit temperature unit is selected.FAHRENHEİT UNİT MODE

This mode shows that the dryer is ready for drying operation.COMPRESSOR STANDBY MODE

Page 14

This mode shows that the dryer in the service time.SERVİCE MODE

4.2 Operation Principles

In order to start the dryer, the following conditions must be satisfied.

1. All the temperatures except the exchanger temperature and condenser outlet temperature must

be between their low and high limits. The low pressure line temperature can be ‘HIGH’.

2. Digital Input 3 (Compressor Fault) is not activated.

3. Digital Input 4 (Compressor Overload) is not activated.

4. Digital Input 5 (Fan Fault) is not activated.

5. Digital Input 6 (Fan Overload) is not activated.

6. Digital Input 7 (Phase Sequence Error) is not activated.

7. Digital Input 8 (Remote Disable) is not activated.

8. Digital Input 11 (High Pressure) is not activated.

9. Digital Input 12 (Low Pressure) is not activated.

If all the above conditions are satisfied, the dryer can be started.

Page 15

5. TECHNICAL SPECIFICATIONS

Model Capacity

(scfm)

MH-US-15 15 1/2" NPT 115/1/60 R134a 1,6

MH-US-25 25 1/2" NPT 115/1/60 R134a 2,5

MH-US-35 35 1/2" NPT 115/1/60 R134a 2,8

MH-US-50 50 3/4" NPT 115/1/60 R134a 1,7

MH-US-75 75 3/4" NPT 115/1/60 R134a 2,0

MH-US-100 100 3/4" NPT 115/1/60 R134a 2,4

FOR ALL MODELS

Nominal Working Pressure 100 psig

Maximum Working Pressure 230 psig

Maximum Ambient Temperature 120°F

Maximum Inlet Temperature 240°F

Connection

Size

Voltage Refrigerant

gas

Pressure

drop

(psig)

Page 16

6.1

MHUS

AIR FLOW DIAGRAMS

Page 17

6.DIAGRAMS

REFRIGERANT GAS FLOW LINE

COMPRESSED AIR FLOW LINE

6.1 AIR FLOW DIAGRAMS

MH-US-15 - MH-US-25

10

AIR INLET

AIR OUTLET

2

M

S

11

12

9

8

S

13

1

DRAIN FLOW LINE

PILOT FLOW LINE

7

6

3

M

4

5

2

Page 18

6.1 AIR FLOW DIAGRAMS

MH-US-15 - MH-US-25

13 CHECK VALVE

12

11

10

9

8

7

6

5

4

3

2

1

POS.

MANUEL VALVE

SOLENOID VALVE

AFTERCOOLER

WATER SEPERATOR

HEAT EXCHANGER

EXPANSION VALVE

FILTER DRIER

FAN SWITCH

HIGH PRESSURE SWITCH

CONDENSER

FAN MOTOR

COMPRESSOR

DESCRIPTION

1

1

1

1

1

1

1

1

1

1

1

2

1

QTY

Page 19

6.1 AIR FLOW DIAGRAMS

REFRIGERANT GAS FLOW LINE

COMPRESSED AIR FLOW LINE

MH-US-35

10

AIR INLET

AIR OUTLET

2

M

S

11

12

9

8

S

13

Page 20

1

DRAIN FLOW LINE

PILOT FLOW LINE

7

6

3

M

4

5

2

6.1 AIR FLOW DIAGRAMS

MH-US-35

13 CHECK VALVE

12

11

10

9

8

7

6

5

4

3

2

1

POS.

MANUEL VALVE

SOLENOID VALVE

AFTERCOOLER

WATER SEPERATOR

HEAT EXCHANGER

EXPANSION VALVE

FILTER DRIER

FAN SWITCH

HIGH PRESSURE SWITCH

CONDENSER

FAN MOTOR

COMPRESSOR

DESCRIPTION

1

1

1

1

1

1

1

1

1

1

1

2

1

QTY

Page 21

6.1 AIR FLOW DIAGRAMS

REFRIGERANT GAS FLOW LINE

COMPRESSED AIR FLOW LINE

MH-US-50 - MH-US-100

2

M

10

AIR INLET

11

AIR OUTLET

S

12

9

8

S

13

7

1

Page 22

DRAIN FLOW LINE

PILOT FLOW LINE

6

3

M

4

5

2

6.1 AIR FLOW DIAGRAMS

MH-US-50 - MH-US-100

13 CHECK VALVE

12

11

10

9

8

7

6

5

4

3

2

1

POS.

MANUEL VALVE

SOLENOID VALVE

AFTERCOOLER

WATER SEPERATOR

HEAT EXCHANGER

EXPANSION VALVE

FILTER DRIER

FAN SWITCH

HIGH PRESSURE SWITCH

CONDENSER

FAN MOTOR

COMPRESSOR

DESCRIPTION

1

1

1

1

1

1

1

1

1

1

1

2

1

QTY

Page 23

6.2

MHUS

ELECTRICAL DIAGRAMS

With Control & Power

“User must supply the protective earth conductor of the dryer. The conductor is to be connected to

the point on the conducting body of the dryer, specified by a sticker with the protective earth symbol

next to it. The size of the protective earth conductor should be minimum the size of the power

conductor, minimum 16 mm² for power conductor size between 16 and 35 mm², minimum half the

size of the conductor if it is larger than 35 mm².”

Page 24

6.2 ELECTRICAL DIAGRAMS

MH-US-15 to MH-US-100

MODEL

MH-US-15 115/1P/60 0,69 7,45 8,6 IP 54 26 8

MH-US-25 115/1P/60 0,69 7,57 8,8 IP 54 29 8

MH-US-35 115/1P/60 0,88 9,61 11,5 IP 54 36 12

MH-US-50 115/1P/60 0,5 10,75 13,4 IP 54 46 15

MH-US-75 115/1P/60 0,95 11 13,4 IP 54 46 15

MH-US-100 115/1P/60 1,16 13,18 15,8 IP 54 51 15

Voltage/Phase/

Hertz

INSTALLED

POWER

(kWatt)

Nominal

Ampacity

(Amp)

MCA A

ELECTRICAL

PROTECTION CLASS

ACCORDING IEC

TOTAL

LRA A

Fuse

(Amp)

Page 25

6.2 ELECTRICAL DIAGRAMS

MH-US-15 to MH-US-100

Page 26

6.3

MHUS

ID DIAGRAM DRAWINGS &

GENERAL ARRANGEMENTS

Page 27

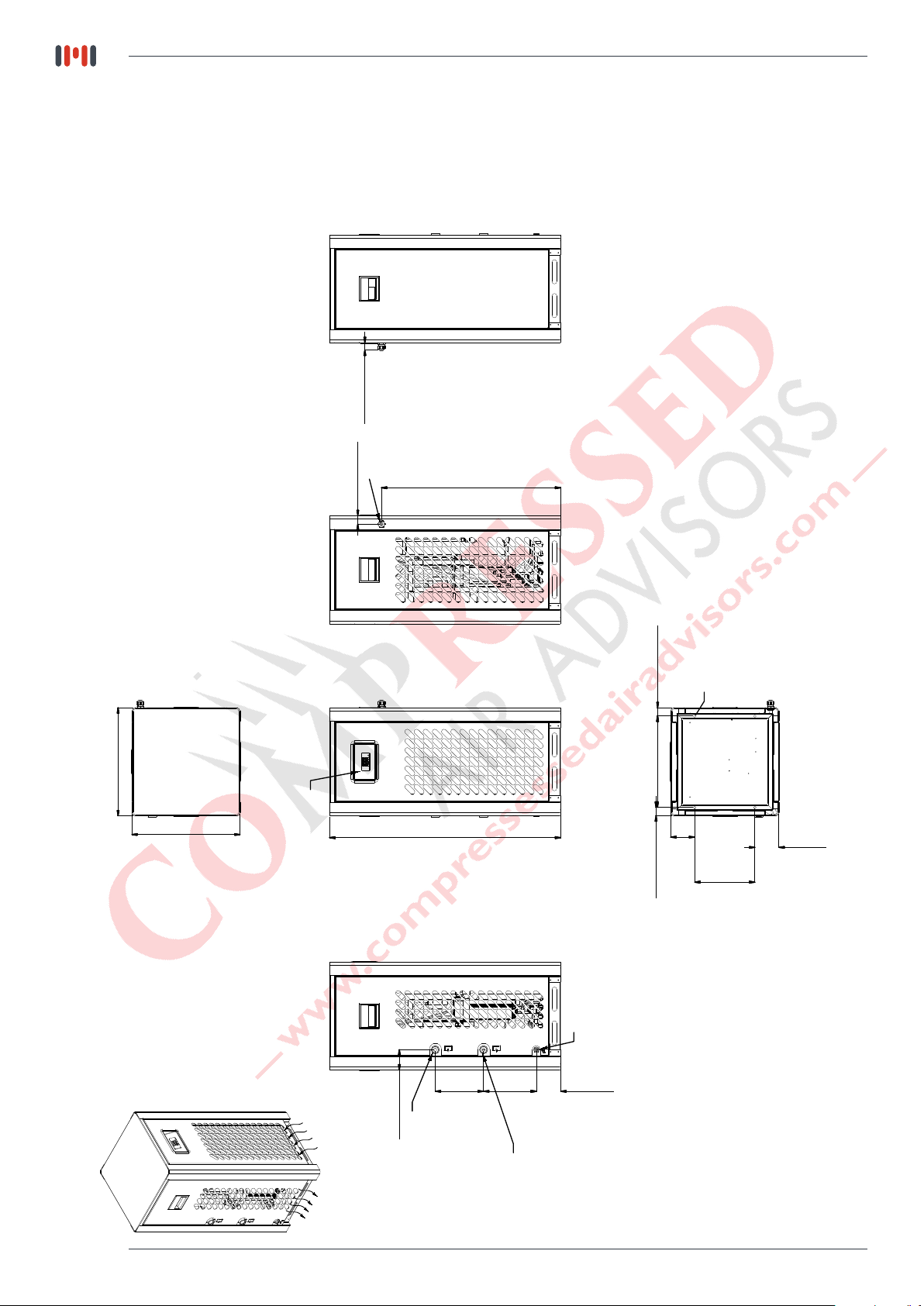

6.3 ID DIAGRAM DRAWINGS

3.89''

(99mm)

COOLING AIR OUTLET

MH-US-15

1.22'' (31mm)

1.37'' (35mm)

Cable

Connectıon

BACK VIEW

29.19'' (741,5mm)

17.61'' (447,5mm)

RIGHT VIEW

1.38'' (35,2mm)

(377,5mm)

14.86''

M8x4

TOP VIEW

FRONT VIEW

17.63'' (448mm)

Digital Controller

37.65'' (956,5mm)

Drain 3/8"

1.38'' (35,3mm)

NPT

(99mm)

3.89''

(250mm)

9.84''

BOTTOM VIEW

LEFT VIEW

Page 28

COOLING AIR INLET

3.30'' (84mm)

Air Outlet

1/2"

NPT

(200mm)

7.87''

(219mm)

8.62''

1/2"

Air Inlet

NPT

(100mm)

3.93''

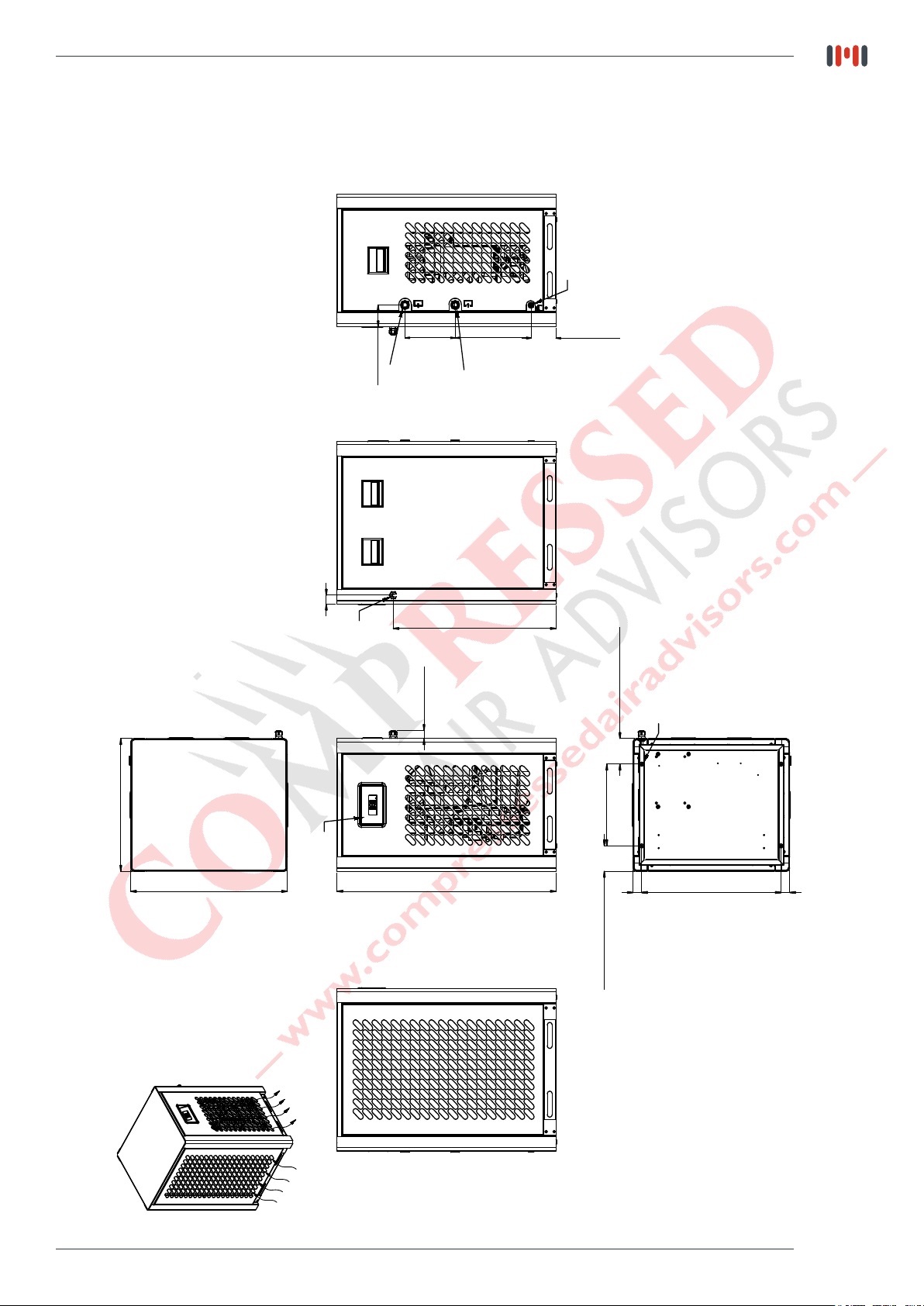

6.3 ID DIAGRAM DRAWINGS

3.89''

(99mm)

COOLING AIR OUTLET

MH-US 25

1.37'' (35mm)

1.22'' (31mm)

Cable

BACK VIEW

Connectıon

29.19'' (741,5mm)

RIGHT VIEW

17.61'' (447,5mm)

1.38'' (35,2mm)

(377,5mm)

14.86''

M8x4

TOP VIEW

FRONT VIEW

17.63'' (448mm)

Digital Controller

37.65'' (956,5mm)

Drain 3/8"

1.38'' (35,3mm)

NPT

(99mm)

3.89''

(250mm)

9.84''

BOTTOM VIEW

LEFT VIEW

(100mm)

3.93''

COOLING AIR INLET

3.30'' (84mm)

Air Outlet

1/2"

NPT

(200mm)

7.87''

(219mm)

8.62''

1/2"

Air Inlet

NPT

Page 29

6.3 ID DIAGRAM DRAWINGS

3.89''

(99mm)

COOLING AIR OUTLET

MH-US-35

1.37'' (35mm)

1.22'' (31mm)

Cable

BACK VIEW

Connectıon

29.19'' (741,5mm)

RIGHT VIEW

17.61'' (447,5mm)

1.38'' (35,2mm)

(377,5mm)

14.86''

M8x4

TOP VIEW

FRONT VIEW

17.63'' (448mm)

Digital Controller

37.65'' (956,5mm)

Drain 3/8"

1.38'' (35,3mm)

NPT

(99mm)

3.89''

(250mm)

9.84''

BOTTOM VIEW

LEFT VIEW

(100mm)

3.93''

COOLING AIR INLET

3.30'' (84mm)

Air Outlet

1/2"

NPT

(200mm)

7.87''

(219mm)

8.62''

1/2"

Air Inlet

NPT

Page 30

6.3 ID DIAGRAM DRAWINGS

24.68'' (627mm)

20.15'' (512mm)

34.50'' (876,5mm)

3.93''

(100,0mm)

11.94''

(303,5mm)

7.90''

(200,7mm)

3.34''

(85mm)

25.64'' (651,5mm)

13.54'' (34,4mm)

Air Outlet

3/4"

NPT

Air Inlet

3/4"

NPT

Drain 3/8"

NPT

12.20''

(31mm)

Digital Controller

Cable

Connection

21.94''

(557,5mm)

1.37''

(34,8mm)

1.37''

(34,8mm)

3.87'' (98,5mm)

12.40'' (315mm)

3.87'' (98,5mm)

M8x4

FRONT VIEW

TOP VIEW

BOTTOM VIEW

LEFT VIEW

RIGHT VIEW

BACK VIEW

COOLING AIR INLET

COOLING AIR OUTLET

MH-US-50

Page 31

6.3 ID DIAGRAM DRAWINGS

1.37''

(34,8mm)

COOLING AIR INLET

MH-US-75

Drain 3/8"

NPT

BACK VIEW

3.34''

Cable

13.54'' (34,4mm)

(85mm)

3/4"

Air Outlet

Connection

12.20''

NPT

(31mm)

(200,7mm)

7.90''

NPT

3/4"

Air Inlet

(303,5mm)

11.94''

25.64'' (651,5mm)

RIGHT VIEW

(100,0mm)

3.93''

3.87'' (98,5mm)

M8x4

Page 32

20.15'' (512mm)

TOP VIEW

24.68'' (627mm)

Digital Controller

34.50'' (876,5mm)

FRONT VIEW

12.40'' (315mm)

3.87'' (98,5mm)

(34,8mm)

1.37''

BOTTOM VIEW

(557,5mm)

21.94''

LEFT VIEW

COOLING AIR OUTLET

6.3 ID DIAGRAM DRAWINGS

1.37''

(34,8mm)

COOLING AIR INLET

MH-US-100

Drain 3/8"

NPT

BACK VIEW

3.34''

Cable

13.54'' (34,4mm)

(85mm)

3/4"

Air Outlet

Connection

12.20''

NPT

(31mm)

(200,7mm)

7.90''

NPT

3/4"

Air Inlet

(303,5mm)

11.94''

25.64'' (651,5mm)

RIGHT VIEW

(100,0mm)

3.93''

3.87'' (98,5mm)

M8x4

20.15'' (512mm)

TOP VIEW

24.68'' (627mm)

Digital Controller

34.50'' (876,5mm)

FRONT VIEW

12.40'' (315mm)

(34,8mm)

1.37''

BOTTOM VIEW

(557,5mm)

21.94''

3.87'' (98,5mm)

LEFT VIEW

COOLING AIR OUTLET

Page 33

7.GENERAL ARRANGEMENTS

Model Length

MH-US-15 17,60 17,65 37,65 137,8

MH-US-25 17,60 17,65 37,65 137,8

MH-US-35 17,60 17,65 37,65 141,1

MH-US-50 17,60 17,65 37,65 143,3

MH-US-75 20,15 24,70 34,50 189,6

MH-US-100 20,15 24,70 34,50 198,4

ALL

MODELS

Superheat of

thermostatic

expansion

valve

41.0 °F -50.0 °F 29.7 psi 130.5 - 174 psi 162,5 psi 23.2 psi 5 min. -5sec. 113 °F 159.5 psi

(inch)

Evaporating

pressure

Fan

pressure

switch

Width

(inch)

Security

high

pressure

switch

Height

(inch)

Security

low

pressure

switch

Drain

timer

Weight

(lbs)

Refrigerant

temperature

switch

Water flow

valve

(if water

condenser)

Page 34

8. MHUS

EXPLODED DIAGRAMS &

SPARE PART LISTS

Page 35

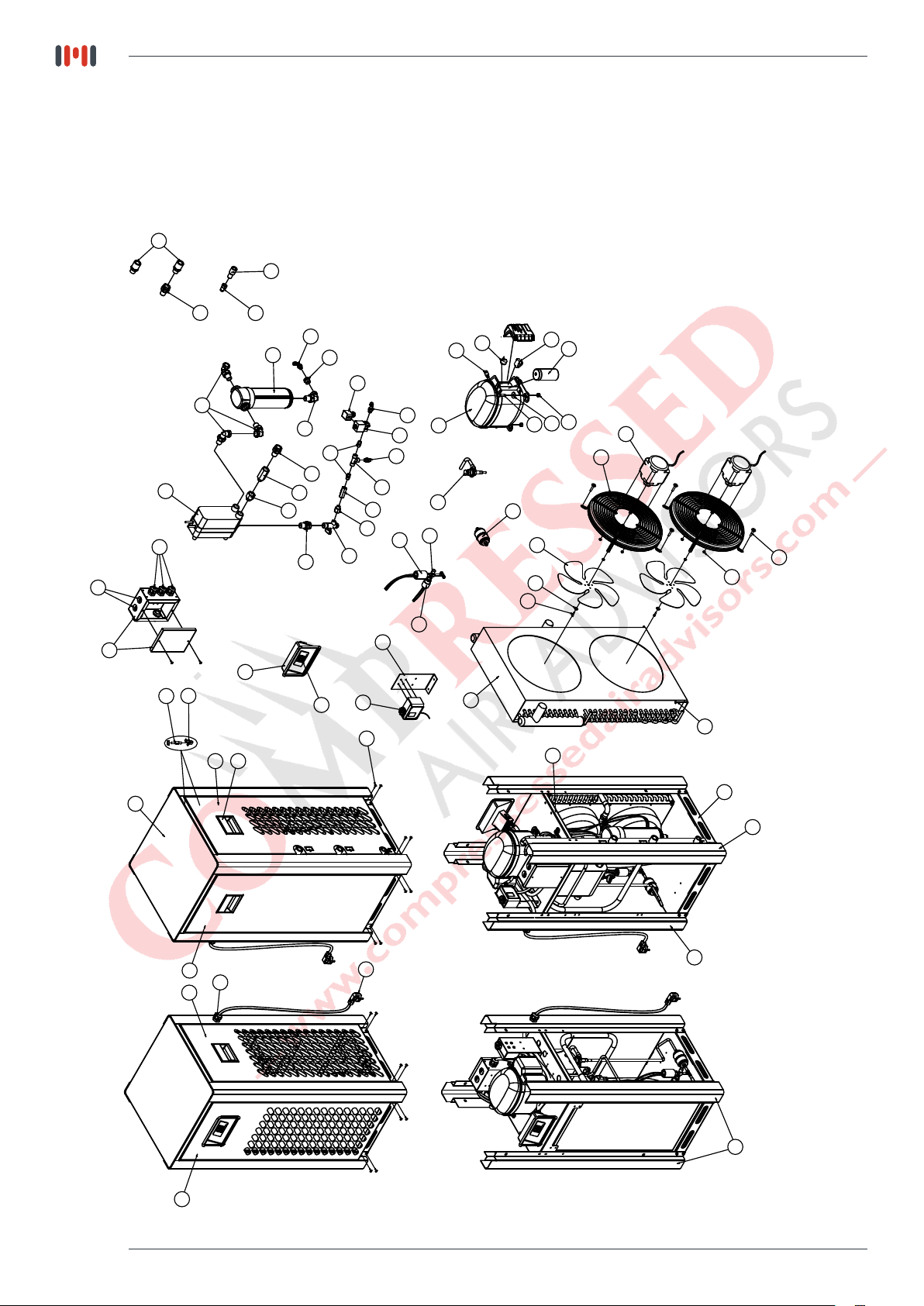

8.1 - ED & Spare Part List

MH-US-15

27

41

26

28

23

44

45

46

61

60

40

38

29

42

59

57

39

37

28

33

26

25

24

30

26

43

38

36

35

34

32

31

49

47

62

21

19

20

14

13

11

48

2

15

12

18

17

16

22

3

9

8

53

5

4

6

7

10

58

54

44

56

55

63

1

50

51

52

Page 36

DECAL CAPACITY

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

8.1 - ED & Spare Part List

MH-US-15

63

POWER CABLE

MK130E-PWC

43

DIGITAL

CONTROLLER

MK130E-DPI

41

M-DCF-0200-WTH

FITTING

DRAIN CONNECTION

36

M-SLV-0325-230

SOLENOID VALVE

27

AIR CONNECTION

FITTING

M-ACF-0050-WTH

15

COMPRESSOR

START RELAY

M-CSR-0035-220-1-50

14

COMPRESSOR

OVERLOAD PROTECTOR

M-COP-0035-220-1-50

12

COMPRESSOR

START CAPACITOR

M-CSC-0035-220-1-50

11

COMPRESSOR

M-CMP-0035-220-1-50

5

MK110E-FMT

AIR COOLED

220V/1Ph/50Hz

.........................

15 SCFM

MH-US-15

N/A

M-PWC-0100

MK130E-DPI

MK130E-DPI-115

M-DCF-0200

M-DCF-0200

M-SLV-0325-230

M-SLV-0150-115

M-ACF-0050

M-ACF-0050

M-CSR-0035-230-1-60

M-CSR-0035-115-1-60

M-COP-0035-230-1-60

M-COP-0035-115-1-60

M-CSC-0035-230-1-60

M-CSC-0035-115-1-60

M-CMP-0035-230-1-60

M-CMP-0035-115-1-60

M-FMT-0200

M-FMT-0150-115-1-60

AIR COOLED

AIR COOLED

230V/1Ph/60Hz

115V/1Ph/60Hz

.........................

.........................

15 SCFM

15 SCFM

MH-US-15

MH-US-15

DWG

SIZE

63

SEE.REF TABLE

62

MK90E-BLT412

61

M-FAS-6000

60

M-STU-6000

59

M-CHN-6000

58

MRH50-CTO

57

MRH50-CLE

56

MRH50-CRI

55

MRH50-CFR

54

MRH50-CRE

53

MRH50-CST

52

MRH050-LEG3

51

MRH050-LEG2

50

MRH050-LEG1

49

MRH50-TSS THERMOSTATIC SUPPORT SHEET

48

M-EXV-0075

47

M-THS-3000

46

MRH75-ECB

45

MK260E-CP11

44

MK260E-CG11

43

SEE.REF TABLE

42

MK260E-PCP

41

SEE.REF TABLE

40

MRH100-FTT

39

MRH100-RDC-1/2-1/4

38

MK170E-EWF

37

MK260E-SVC

36

SEE.REF TABLE

35

MK150E-FIT6 1 / 4" - 6mm FITTINGS

34

MK170E-T1/4 1 / 4" T CONNECTOR

33

MK170E-NIP1/4

32

MK170E-CHV

31

MK150E-RDC

30

M-DBV-0200

29

MRH-WSP-0100

28

MRH35-RKR*90

27

SEE.REF TABLE

26

MRH35-RKR

25

MRH50-MAS-1/2-50

24

MRH35-MAS-1/2-20

23

MRH35-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

MRH100-NT8

17

MK260E-WHR22

16

MK150E-BLT840

15

SEE.REF TABLE

14

SEE.REF TABLE

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR START CAPACITOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0150 FAN GRILL

3

M-FAN-0150 FAN BLADE

2

M-CON-0050-H

1

MRH50-CAD

ITEM

NO

PART NO

POWER CABLE

BOLT M4x12

CABINET FASTENER

CABINET STUD AND NUT

CABINET HANDLE (NEW)

CABINET TOP

CABINET SIDE-LEFT

CABINET SIDE-RIGHT

CABINET FRONT

CABINET REAR

CABINET SUPPORT SHEET

CABINET LEG3

CABINET LEG2

CABINET LEG1

EXPANSION VALVE

THERMOSTATIC SWITCH

ELECTICAL BOX

CABLE PLUG PG11

CABLE GLAND PG11

DIGITAL CONTROLLER

PLASTIC CONTROL PANEL

DRAIN CONNECTION FITTING

1/4 - 8mm FITTING

REDUCTION 1/2 - 1/4

ELBOW FITTINGS

SOLENOID VALVE COIL 1

SOLENOID VALVE

1 / 4" NIPPLE

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

WATER SEPARATOR

RECORD *90 1/2

AIR CONNECTION FITTING

RECORD 1/2

MANSON 1/2 - 50mm

MANSON 1/2 - 20mm

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

COMPRESSOR START RELAY

COMPRESSOR OVERLOAD PROTECTOR

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

1

24

15

15

3

1

1

1

1

1

1

1

1

1

1

1

1

1

2

6

1

1

1

1

1

2

1

1

1

2

1

1

1

1

4

2

3

1

1

1

1

1

1

1

4

4

4

1

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 37

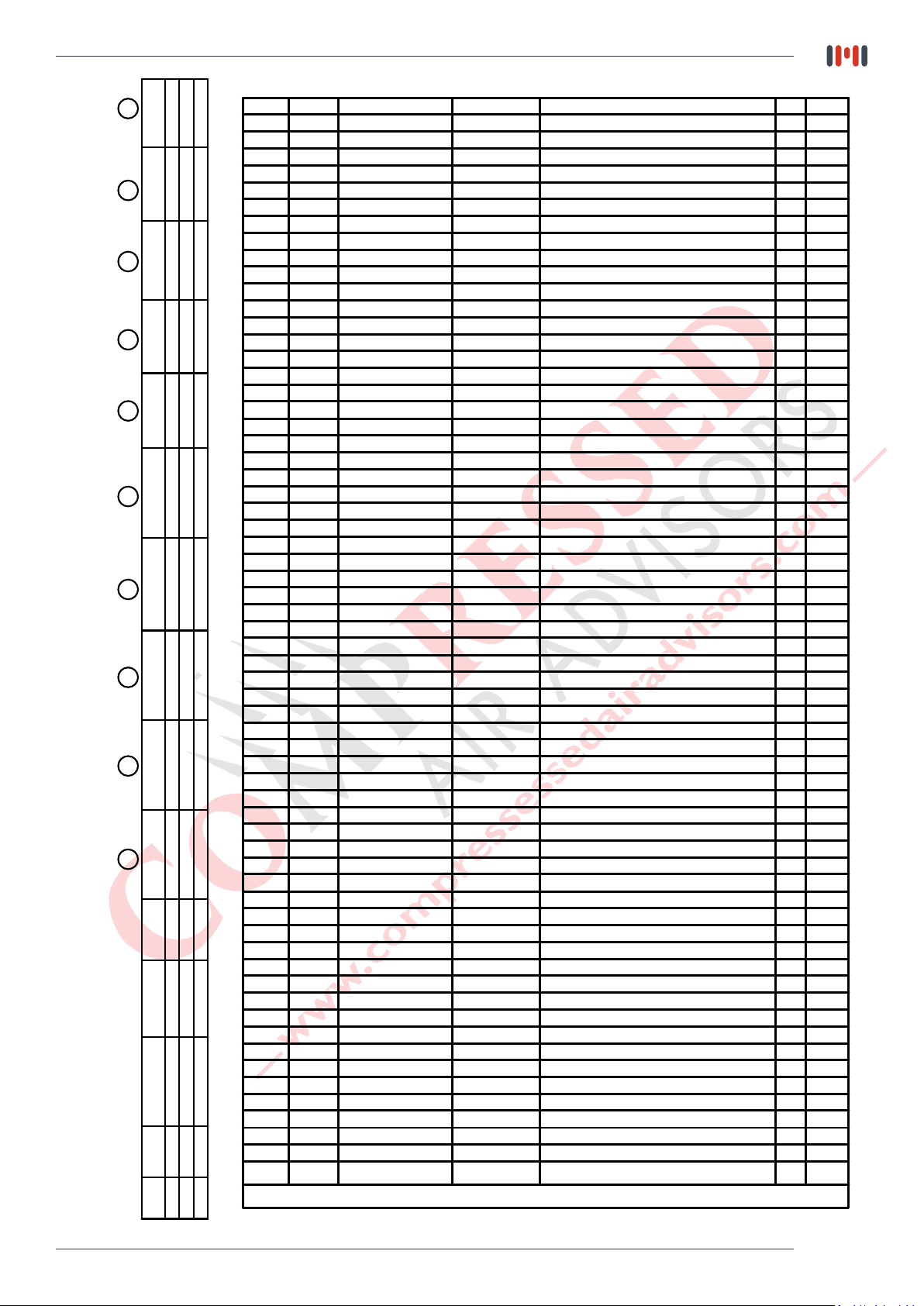

8.1 - ED & Spare Part List

MH-US-25

27

41

45

46

44

23

60

61

26

28

57

59

42

40

29

24

25

28

26

38

26

43

39

33

30

37

47

62

31

32

34

49

35

36

19

38

20

21

48

11

13

22

15

12

18

17

16

3

9

8

53

5

4

6

7

10

14

2

58

55

56

54

44

63

1

50

51

52

Page 38

DECAL CAPACITY

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

63

43

41

36

27

15

14

12

11

5

8.1 - ED & Spare Part List

MH-US-25

POWER CABLE

MK130E-PWC

N/A

M-PWC-0100

DIGITAL

CONTROLLER

MK130E-DPI

MK130E-DPI

MK130E-DPI-115

M-DCF-0200-WTH

M-DCF-0200

M-DCF-0200

FITTING

DRAIN CONNECTION

M-SLV-0325-230

M-SLV-0325-230

SOLENOID VALVE

AIR CONNECTION

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

M-SLV-0150-115

FITTING

M-ACF-0050-WTH

M-ACF-0050

M-ACF-0050

START RELAY

M-CSR-0050-220-1-50

M-CSR-0050-230-1-60

M-CSR-0050-115-1-60

OVERLOAD PROTECTOR

M-COP-0050-220-1-50

M-COP-0050-230-1-60

M-COP-0050-115-1-60

START CAPACITOR

M-CSC-0050-220-1-50

M-CSC-0050-230-1-60

M-CSC-0050-115-1-60

M-CMP-0050-220-1-50

M-CMP-0050-230-1-60

M-CMP-0050-115-1-60

MK110E-FMT

M-FMT-0200

M-FMT-0150-115-1-60

AIR COOLED

AIR COOLED

AIR COOLED

220V/1Ph/50Hz

230V/1Ph/60Hz

115V/1Ph/60Hz

.........................

.........................

.........................

25 SCFM

25 SCFM

25 SCFM

MH-US-25

MH-US-25

MH-US-25

DWG

SIZE

63

SEE.REF TABLE

62

MK90E-BLT412

61

M-FAS-6000

60

M-STU-6000

59

M-CHN-6000

58

MRH50-CTO

57

MRH50-CLE

56

MRH50-CRI

55

MRH50-CFR

54

MRH50-CRE

53

MRH50-CST

52

MRH050-LEG3

51

MRH050-LEG2

50

MRH050-LEG1

49

MRH50-TSS THERMOSTATIC SUPPORT SHEET

48

M-EXV-0075

47

M-THS-3000

46

MRH75-ECB

45

MK260E-CP11

44

MK260E-CG11

43

SEE.REF TABLE

42

MK260E-PCP

41

SEE.REF TABLE

40

MRH100-FTT

39

MRH100-RDC-1/2-1/4

38

MK170E-EWF

37

MK260E-SVC

36

SEE.REF TABLE

35

MK150E-FIT6 1 / 4" - 6mm FITTINGS

34

MK170E-T1/4 1 / 4" T CONNECTOR

33

MK170E-NIP1/4

32

MK170E-CHV

31

MK150E-RDC

30

M-DBV-0200

29

MRH-WSP-0100

28

MRH35-RKR*90

27

SEE.REF TABLE

26

MRH35-RKR

25

MRH50-MAS-1/2-50

24

MRH35-MAS-1/2-20

23

MRH35-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

MRH100-NT8

17

MK260E-WHR22

16

MK150E-BLT840

15

SEE.REF TABLE

14

SEE.REF TABLE

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR START CAPACITOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0150 FAN GRILL

3

M-FAN-0150 FAN BLADE

2

M-CON-0050-H

1

MRH50-CAD

ITEM

NO

PART NO

POWER CABLE

BOLT M4x12

CABINET FASTENER

CABINET STUD AND NUT

CABINET HANDLE (NEW)

CABINET TOP

CABINET SIDE-LEFT

CABINET SIDE-RIGHT

CABINET FRONT

CABINET REAR

CABINET SUPPORT SHEET

CABINET LEG3

CABINET LEG2

CABINET LEG1

EXPANSION VALVE

THERMOSTATIC SWITCH

ELECTICAL BOX

CABLE PLUG PG11

CABLE GLAND PG11

DIGITAL CONTROLLER

PLASTIC CONTROL PANEL

DRAIN CONNECTION FITTING

1/4 - 8mm FITTING

REDUCTION 1/2 - 1/4

ELBOW FITTINGS

SOLENOID VALVE COIL 1

SOLENOID VALVE

1 / 4" NIPPLE

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

WATER SEPARATOR

RECORD *90 1/2

AIR CONNECTION FITTING

RECORD 1/2

MANSON 1/2 - 50mm

MANSON 1/2 - 20mm

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

COMPRESSOR START RELAY

COMPRESSOR OVERLOAD PROTECTOR

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

1

24

15

15

3

1

1

1

1

1

1

1

1

1

1

1

1

1

2

6

1

1

1

1

1

2

1

1

1

2

1

1

1

1

4

2

3

1

1

1

1

1

1

1

4

4

4

1

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 39

8.1 - ED & Spare Part List

MH-US-35

27

41

45

46

44

23

60

61

26

28

57

59

42

40

29

24

25

28

26

38

26

43

39

33

30

37

47

62

31

32

34

49

35

36

19

38

20

21

11

48

13

22

15

12

18

17

16

3

9

8

53

5

4

6

7

10

14

2

58

55

54

56

44

63

1

50

51

52

Page 40

DECAL CAPACITY

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

63

43

41

36

27

15

14

12

11

5

8.1 - ED & Spare Part List

MH-US-35

POWER CABLE

MK130E-PWC

N/A

M-PWC-0100

DIGITAL

CONTROLLER

MK130E-DPI

MK130E-DPI

MK130E-DPI-115

M-DCF-0200-WTH

M-DCF-0200

M-DCF-0200

FITTING

DRAIN CONNECTION

M-SLV-0325-230

M-SLV-0325-230

SOLENOID VALVE

AIR CONNECTION

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

M-SLV-0150-115

FITTING

M-ACF-0050-WTH

M-ACF-0050

M-ACF-0050

START RELAY

M-CSR-0035-220-1-50

M-CSR-0035-230-1-60

M-CSR-0035-115-1-60

OVERLOAD PROTECTOR

M-COP-0035-220-1-50

M-COP-0035-230-1-60

M-COP-0035-115-1-60

START CAPACITOR

M-CSC-0035-220-1-50

M-CSC-0035-230-1-60

M-CSC-0035-115-1-60

M-CMP-0035-220-1-50

M-CMP-0035-230-1-60

M-CMP-0035-115-1-60

MK110E-FMT

M-FMT-0200

M-FMT-0150-115-1-60

AIR COOLED

AIR COOLED

AIR COOLED

220V/1Ph/50Hz

230V/1Ph/60Hz

115V/1Ph/60Hz

.........................

.........................

.........................

35 SCFM

35 SCFM

35 SCFM

MH-US-35

MH-US-35

MH-US-35

DWG

SIZE

63

SEE.REF TABLE

62

MK90E-BLT412

61

M-FAS-6000

60

M-STU-6000

59

M-CHN-6000

58

MRH50-CTO

57

MRH50-CLE

56

MRH50-CRI

55

MRH50-CFR

54

MRH50-CRE

53

MRH50-CST

52

MRH050-LEG3

51

MRH050-LEG2

50

MRH050-LEG1

49

MRH50-TSS THERMOSTATIC SUPPORT SHEET

48

M-EXV-0075

47

M-THS-3000

46

MRH75-ECB

45

MK260E-CP11

44

MK260E-CG11

43

SEE.REF TABLE

42

MK260E-PCP

41

SEE.REF TABLE

40

MRH100-FTT

39

MRH100-RDC-1/2-1/4

38

MK170E-EWF

37

MK260E-SVC

36

SEE.REF TABLE

35

MK150E-FIT6 1 / 4" - 6mm FITTINGS

34

MK170E-T1/4 1 / 4" T CONNECTOR

33

MK170E-NIP1/4

32

MK170E-CHV

31

MK150E-RDC

30

M-DBV-0200

29

MRH-WSP-0100

28

MRH35-RKR*90

27

SEE.REF TABLE

26

MRH35-RKR

25

MRH50-MAS-1/2-50

24

MRH35-MAS-1/2-20

23

MRH35-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

MRH100-NT8

17

MK260E-WHR22

16

MK150E-BLT840

15

SEE.REF TABLE

14

SEE.REF TABLE

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR START CAPACITOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0150 FAN GRILL

3

M-FAN-0150 FAN BLADE

2

M-CON-0050-H

1

MRH50-CAD

ITEM

NO

PART NO

POWER CABLE

BOLT M4x12

CABINET FASTENER

CABINET STUD AND NUT

CABINET HANDLE (NEW)

CABINET TOP

CABINET SIDE-LEFT

CABINET SIDE-RIGHT

CABINET FRONT

CABINET REAR

CABINET SUPPORT SHEET

CABINET LEG3

CABINET LEG2

CABINET LEG1

EXPANSION VALVE

THERMOSTATIC SWITCH

ELECTICAL BOX

CABLE PLUG PG11

CABLE GLAND PG11

DIGITAL CONTROLLER

PLASTIC CONTROL PANEL

DRAIN CONNECTION FITTING

1/4 - 8mm FITTING

REDUCTION 1/2 - 1/4

ELBOW FITTINGS

SOLENOID VALVE COIL 1

SOLENOID VALVE

1 / 4" NIPPLE

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

WATER SEPARATOR

RECORD *90 1/2

AIR CONNECTION FITTING

RECORD 1/2

MANSON 1/2 - 50mm

MANSON 1/2 - 20mm

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

COMPRESSOR START RELAY

COMPRESSOR OVERLOAD PROTECTOR

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

1

24

15

15

3

1

1

1

1

1

1

1

1

1

1

1

1

1

2

6

1

1

1

1

1

2

1

1

1

2

1

1

1

1

4

2

3

1

1

1

1

1

1

1

4

4

4

1

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 41

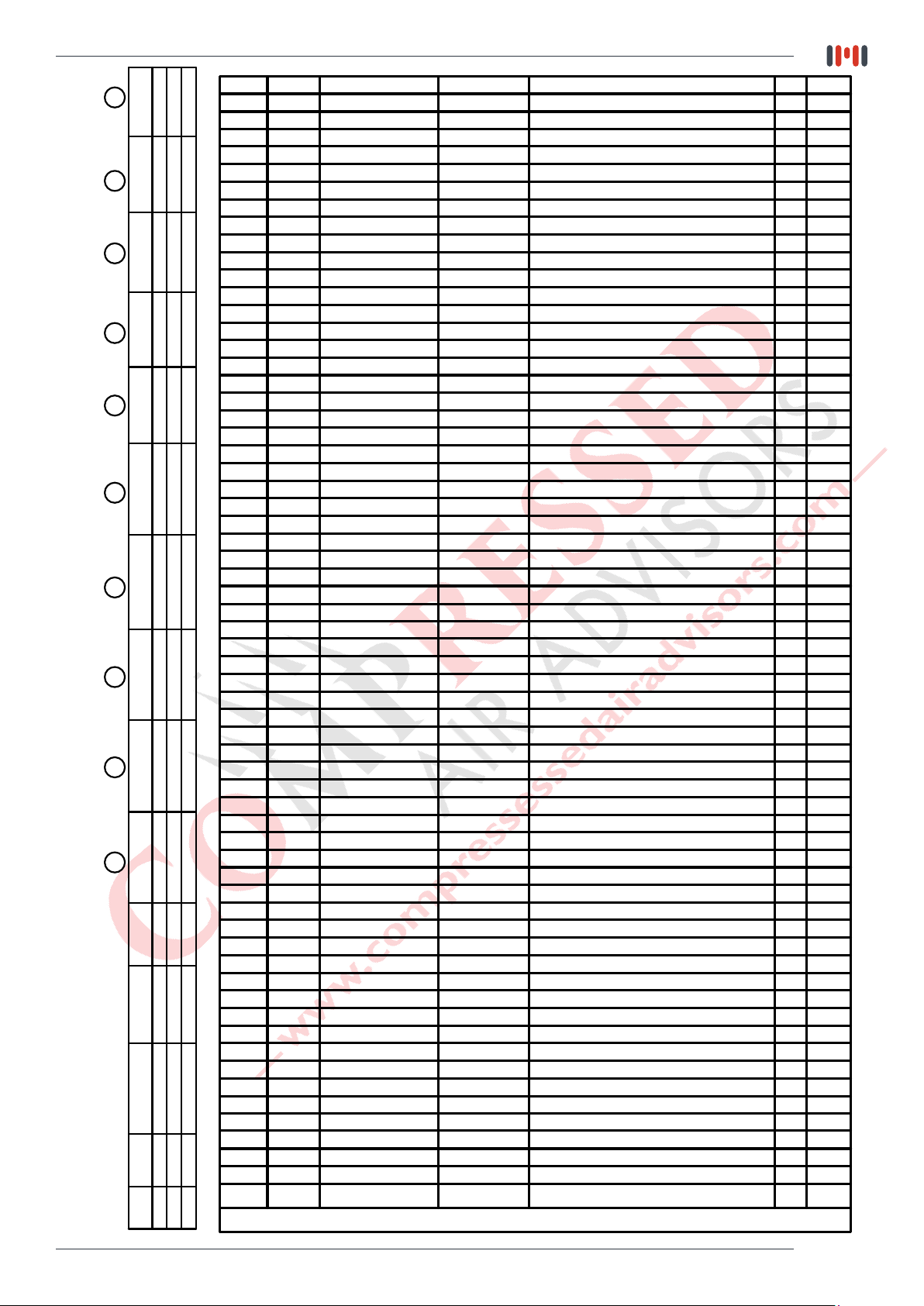

8.1 - ED & Spare Part List

MH-US-50

35

25

51

24

24

24

67

27

23

44

63

50

24

37

36

45

64

62

34

33

30

29

28

32

31

26

25

49

43

47

57

38

14

61

39

40

27

19

65

24

20

21

48

69

46

41

22

3

9

8

2

13

11

161718

5

4

42

15

12

6

7

10

53

1

Page 42

52

58

43

60

68

59

66

56

54

55

DECAL CAPACITY

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

66

POWER CABLE

MK130E-PWC

N/A

61

M-DCF-0200-WTH

M-DCF-0200

FITTING

DRAIN CONNECTION

48

DIGITAL

CONTROLLER

MK130E-DPI

MK130E-DPI

38

AIR CONNECTION

FITTING

M-ACF-0050-WTH

M-ACF-0050

33

M-SLV-0325-230

M-SLV-0325-230

SOLENOID VALVE

15

COMPRESSOR

START RELAY

M-CSR-0075-220-1-50

M-CSR-0075-230-1-60

14

COMPRESSOR

OVERLOAD PROTECTOR

M-COP-0075-220-1-50

M-COP-0075-230-1-60

12

COMPRESSOR

START CAPACITOR

M-CSC-0075-220-1-50

M-CSC-0075-230-1-60

11

COMPRESSOR

M-CMP-0075-220-1-50

M-CMP-0075-230-1-60

5

MK110E-FMT

M-FMT-0200

AIR COOLED

AIR COOLED

220V/1Ph/50Hz

230V/1Ph/60Hz

.........................

.........................

50 SCFM

50 SCFM

8.1 - ED & Spare Part List

MH-US-50

MH-US-50

MH-US-50

M-PWC-0100

M-DCF-0200

MK130E-DPI-115

M-ACF-0050

M-SLV-0150-115

M-CSR-0075-115-1-60

M-COP-0075-115-1-60

M-CSC-0075-115-1-60

M-CMP-0075-115-1-60

M-FMT-0150-115-1-60

AIR COOLED

115V/1Ph/60Hz

.........................

50 SCFM

MH-US-50

DWG

SIZE

69

MRH50-TSS

68

MRH50-CTO CABINET TOP

67

MRH50-MAS-1/2

66

SEE.REF TABLE POWER CABLE

65

MK90E-BLT412 BOLT M4x12

64

M-FAS-6000 CABINET FASTENER

63

M-STU-6000

62

M-CHN-6000

61

SEE.REF TABLE

60

MRH50-CRI

59

MRH50-CFR

58

MRH50-CRE

57

MRH50-CLE

56

MRH50-EXCD

55

MRH050-LEG4

54

MRH050-LEG3

53

MRH050-LEG2

52

MRH050-LEG1

51

MRH-WSP-0100

50

MK150E-FIT6

49

MK90E-BLT615

48

SEE.REF TABLE

47

MK260E-PCP

46

M-THS-3000

45

MRH75-ECB

44

MK260E-CP11

43

MK260E-CG11

42

MRH50-CST

41

M-EXV-0075

40

MRH100-MAS-3/4

39

MRH100-FTT

38

SEE.REF TABLE

37

MK110E-RTA2

36

MK70E-RTA3

35

MK170E-EWF

34

MK260E-SVC SOLENOID VALVE COIL

33

SEE.REF TABLE SOLENOID VALVE

32

MK170E-EWF

31

MK170E-T1/4

30

MK170E-NIP1/4 1 / 4" NIPPLE

29

MK170E-CHV

28

MK150E-RDC

27

M-DBV-0200

26

MRH100-RDC

25

MRH100-RKR

24

MRH100-RKR*90

23

MRH100-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

MRH100-NT8

17

MK260E-WHR22

16

MK150E-BLT840

15

SEE.REF TABLE

14

SEE.REF TABLE

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR START CAPACITOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0150 FAN GRILL

3

M-FAN-0150 FAN BLADE

2

M-CON-0050-H

1

MRH50-CAD

ITEM

NO

PART NO

THERMOSTATIC

MANSON 1/2

CABINET STUD AND NUT

CABINET HANDLE (NEW)

DRAIN CONNECTION FITTING

CABINET SIDE-RIGHT

CABINET FRONT

CABINET REAR

CABINET SIDE-LEFT

HEAT EXCHANGER SUPPORT SHEET

CABINET LEG4

CABINET LEG3

CABINET LEG2

CABINET LEG1

WATER SEPARATOR

1 / 4" - 6mm FITTINGS

BOLT M6x15

DIGITAL CONTROLLER 1

PLASTIC CONTROL PANEL

THERMOSTATIC SWITCH

ELECTICAL BOX

CABLE PLUG PG11

CABLE GLAND PG11

CABINET SUPPORT SHEET

EXPANSION VALVE

MANSON 3/4

1/4 - 8mm FITTING

AIR CONNECTION FITTING

ROTOLOCK ADAPTOR2

ROTOLOCK ADAPTOR3

ELBOW FITTINGS

90* 1 / 4" - 6mm ELBOW

1 / 4" T CONNECTOR

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

REDUCTION 3/4 - 1/2

RECORD 3/4

RECORD *90 3/4

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

COMPRESSOR START RELAY

COMPRESSOR OVERLOAD PROTECTOR

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

SUPPORT SHEET

1

1

1

1

24

15

15

3

1

1

1

1

1

2

1

1

1

1

1

1

4

1

1

1

2

6

1

1

2

1

2

1

1

1

1

1

2

1

2

1

1

1

2

2

6

1

1

1

1

1

4

4

4

1

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 43

8.1 - ED & Spare Part List

MH-US-75

38

35

25

25

23

63

64

14

24

24

67

36

43

37

58

59

34

33

30

29

32

31

26

25

49

42

37

62

40

24

28

22

27

62

47

46

41

19

21

48

61

28

39

18

20

2

3

9

8

11

13

151617

4

44

5

45

12

6

7

10

66

60

56

57

55

54

51

1

65

50

52

53

Page 44

DECAL CAPACITY

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

8.1 - ED & Spare Part List

MH-US-75

66

POWER CABLE

MK130E-PWC

61

M-DCF-0200-WTH

FITTING

DRAIN CONNECTION

48

DIGITAL

CONTROLLER

MK130E-DPI

45

COMPRESSOR

START RELAY

M-CSR-0075-220-1-50

44

M-COP-0075-220-1-50

COMPRESSOR

OVERLOAD PROTECTOR

38

AIR CONNECTION

FITTING

M-ACF-0100-WTH

33

M-SLV-0325-230

SOLENOID VALVE

12

COMPRESSOR

START CAPACITOR

M-CSC-0100-220-1-50

11

COMPRESSOR

M-CMP-0100-220-1-50

5

MK110E-FMT

AIR COOLED

220V/1Ph/50Hz

.........................

100 SCFM

MH-US-75

N/A

M-PWC-0100

M-DCF-0200

M-DCF-0200

MK130E-DPI

MK130E-DPI-115

M-CSR-0075-230-1-60

M-CSR-0075-115-1-60

M-COP-0075-230-1-60

M-COP-0075-115-1-60

M-ACF-0100

M-ACF-0100

M-SLV-0325-230

M-SLV-0150-115

M-CSC-0075-230-1-60

M-CSC-0075-115-1-60

M-CMP-0075-230-1-60

M-CMP-0075-115-1-60

M-FMT-0200

M-FMT-0150-115-1-60

AIR COOLED

AIR COOLED

230V/1Ph/60Hz

115V/1Ph/60Hz

.........................

.........................

100 SCFM

100 SCFM

MH-US-75

MH-US-75

DWG

SIZE

67

MK110E-RTA2 ROTOLOCK ADAPTOR2

66

SEE.REF TABLE POWER CABLE

65

MK260E-RNT8 RIVET NUT M8

64

M-FAS-6000 CABINET FASTENER

63

M-STU-6000

62

MK90E-BLT412

61

SEE.REF TABLE

60

MRH100-CTO

59

M-CHN-6000

58

MRH100-CRI

57

MRH100-CFR

56

MRH100-CLE

55

MRH100-CRE

54

MRH100-EXCD

53

MRH100-LEG4

52

MRH100-LEG3

51

MRH100-LEG2

50

MRH100-LEG1

49

MK90E-BLT615

48

SEE.REF TABLE

47

MK260E-PCP

46

M-THS-3000

45

SEE.REF TABLE

44

SEE.REF TABLE

43

MRH75-ECB

42

MRH75-SSH

41

M-EXV-0075

40

MRH100-MAS-3/4

39

MRH100-FTT

38

SEE.REF TABLE

37

MK260E-CG11 CABLE GLAND PG11

36

MK70E-RTA3

35

MK170E-EWF

34

MK260E-SVC SOLENOID VALVE COIL

33

SEE.REF TABLE SOLENOID VALVE

32

MK170E-EWF

31

MK170E-T1/4

30

MK170E-NIP1/4 1 / 4" NIPPLE

29

MK170E-CHV

28

MK150E-RDC

27

M-DBV-0200

26

MRH100-RDC

25

MRH100-RKR

24

MRH100-RKR*90

23

MRH100-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

M-BYV-0100

17

MRH100-NT8

16

MK260E-WHR22

15

MK150E-BLT840

14

MRH-WSP-0100

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR START CAPACITOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0200 FAN GRILL

3

M-FAN-0200 FAN BLADE

2

M-CON-0100-H

1

MRH100-CAD

ITEM

NO

PART NO

CABINET STUD AND NUT

BOLT M4x12

DRAIN CONNECTION FITTING

CABINET TOP

CABINET HANDLE (NEW)

CABINET SIDE-RIGHT

CABINET FRONT

CABINET SIDE-LEFT

CABINET REAR

HEAT EXCHANGER SUPPORT SHEET

CABINET LEG4

CABINET LEG3

CABINET LEG2

CABINET LEG1

BOLT M6x15

DIGITAL CONTROLLER 1

PLASTIC CONTROL PANEL

THERMOSTATIC SWITCH

COMPRESSOR START RELAY

COMPRESSOR OVERLOAD PROTECTOR

ELECTICAL BOX

SUPPORT SHEET

EXPANSION VALVE

MANSON 3/4

1/4 - 8mm FITTING

AIR CONNECTION FITTING

ROTOLOCK ADAPTOR2

ELBOW FITTINGS

90* 1 / 4" - 6mm ELBOW

1 / 4" T CONNECTOR

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

REDUCTION 3/4 - 1/2

RECORD 3/4

RECORD *90 3/4

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

BY-PASS VALVE

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

WATER SEPARATOR

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

1

1

4

15

15

16

1

1

3

1

1

1

1

2

1

1

1

1

4

1

1

1

1

1

1

1

1

1

2

3

1

1

1

1

2

1

2

1

1

1

1

3

4

1

1

1

1

1

1

4

4

4

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 45

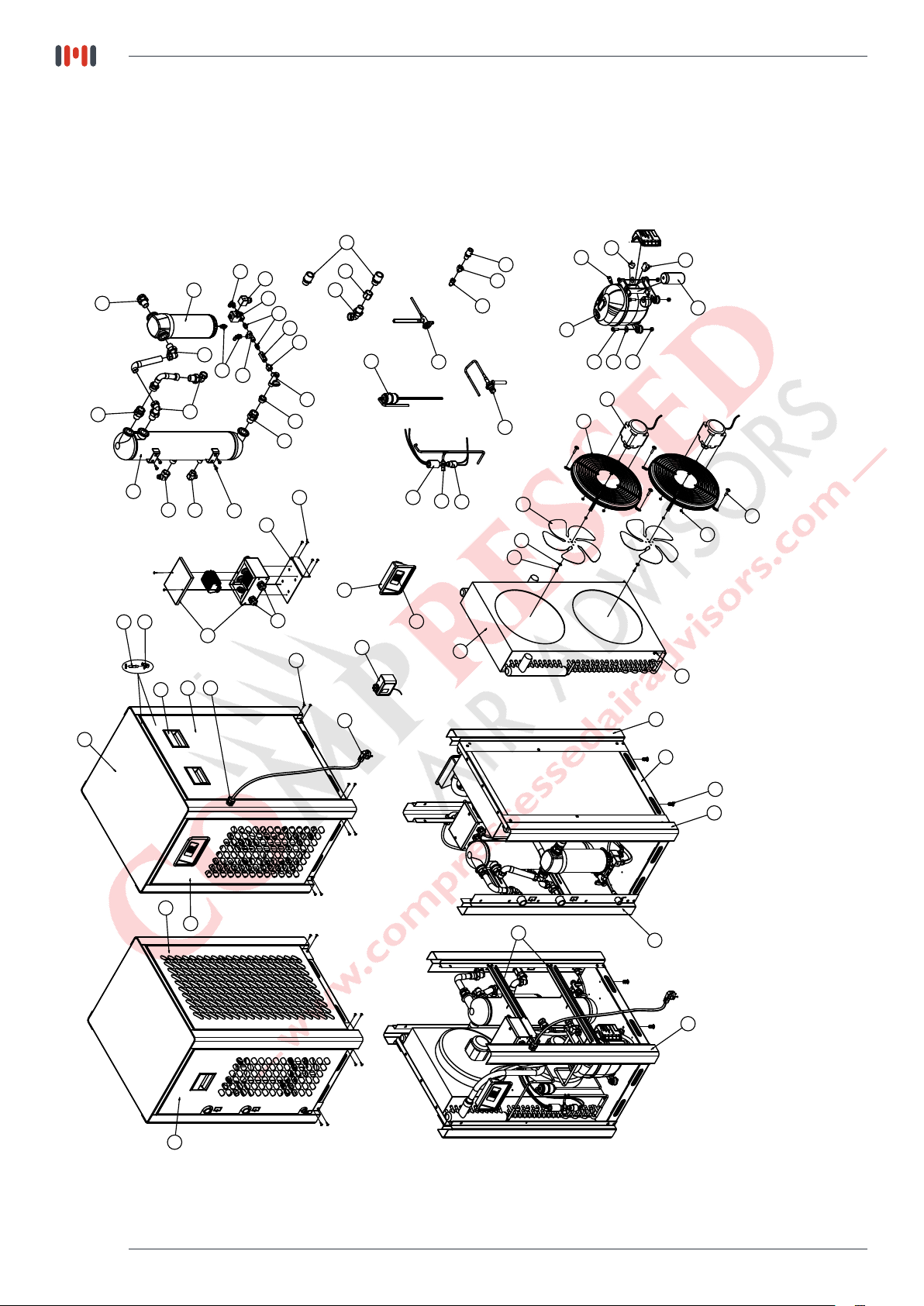

8.1 - ED & Spare Part List

MH-US-100

38

35

25

25

23

63

64

67

24

24

36

14

42

43

34

33

30

29

32

31

25

49

44

40

24

28

22

27

26

47

45

46

62

41

19

21

48

2

61

28

14

39

12

11

13

4

18

3

20

9

8

16

17

15

5

6

7

10

59

60

56

57

66

54

51

1

65

50

52

53

37

58

Page 46

55

DECAL

DRYER PART NUMBER POWER RATINGS COOLING FAN MOTOR

8.1 - ED & Spare Part List

MH-US-100

66

POWER CABLE

MK130E-PWC

61

M-DCF-0200-WTH

FITTING

DRAIN CONNECTION

48

DIGITAL

CONTROLLER

MK130E-DPI

45

COMPRESSOR

START CAPACITOR

M-CSC-0100-220-1-50

44

START RELAY

COMPRESSOR

M-CSR-0100-220-1-50

42

COMPRESSOR

ELECTRICAL BOX

M-CEB-0100-220-1-50

38

AIR CONNECTION

FITTING

M-ACF-0100-WTH

33

M-SLV-0325-230

SOLENOID VALVE

12

COMPRESSOR

M-COP-0100-220-1-50

OVERLOAD PROTECTOR

11

COMPRESSOR

M-CMP-0100-220-1-50

5

MK110E-FMT

AIR COOLED

220V/1Ph/50Hz

.........................

CAPACITY

100 SCFM

MH-US-100

N/A

M-PWC-0100

M-DCF-0200

M-DCF-0200

MK130E-DPI

MK130E-DPI-115

M-CSC-0100-230-1-60

M-CSC-0100-115-1-60

M-CSR-0100-230-1-60

M-CSR-0100-115-1-60

M-CEB-0100-230-1-60

M-CEB-0100-115-1-60

M-ACF-0100

M-ACF-0100

M-SLV-0325-230

M-SLV-0150-115

M-COP-0100-230-1-60

M-COP-0100-115-1-60

M-CMP-0100-230-1-60

M-CMP-0100-115-1-60

M-FMT-0200

M-FMT-0150-115-1-60

AIR COOLED

AIR COOLED

230V/1Ph/60Hz

115V/1Ph/60Hz

.........................

.........................

100 SCFM

100 SCFM

MH-US-100

MH-US-100

DWG

SIZE

67

MRH-WSP-0100 WATER SEPARATOR

66

SEE.REF TABLE POWER CABLE

65

MK260E-RNT8 RIVET NUT M8

64

M-FAS-6000 CABINET FASTENER

63

M-STU-6000

62

MK90E-BLT412

61

SEE.REF TABLE

60

MRH100-CTO

59

M-CHN-6000

58

MRH100-CRI

57

MRH100-CFR

56

MRH100-CLE

55

MRH100-CRE

54

MRH100-EXCD

53

MRH100-LEG4

52

MRH100-LEG3

51

MRH100-LEG2

50

MRH100-LEG1

49

MK90E-BLT615

48

SEE.REF TABLE

47

MK260E-PCP

46

M-THS-3000

45

SEE.REF TABLE

44

SEE.REF TABLE

43

MK110E-TRM

42

SEE.REF TABLE

41

M-EXV-0200

40

MRH100-MAS-3/4

39

MRH100-FTT

38

SEE.REF TABLE

37

MK260E-CG11 CABLE GLAND PG11

36

MK70E-RTA3

35

MK170E-EWF

34

MK260E-SVC SOLENOID VALVE COIL

33

SEE.REF TABLE SOLENOID VALVE

32

MK170E-EWF

31

MK170E-T1/4

30

MK170E-NIP1/4 1 / 4" NIPPLE

29

MK170E-CHV

28

MK150E-RDC

27

M-DBV-0200

26

MRH100-RDC

25

MRH100-RKR

24

MRH100-RKR*90

23

MRH100-EXC

22

M-DRI-0200

21

MK90E-TDP

20

M-HPS-0200

19

M-FNS-0200

18

M-BYV-0100

17

MRH100-NT8

16

MK260E-WHR22

15

MK150E-BLT840

14

MK110E-RTA2

13

MK260E-STC SETTING THE CONNECTION

12

SEE.REF TABLE COMPRESSOR OVERLOAD PROTECTOR

11

SEE.REF TABLE COMPRESSOR

10

MK90E-BLT412 BOLT M4x12

9

MK110E-WHR20 WASHER Ø20xØ4,3x1,5

8

MK110E-BLT414 BOLT M4x14mm

7

MK110E-NT4 NUT M4

6

MK260E-BLT630 BOLT M6x30

5

SEE.REF TABLE FAN MOTOR

4

M-GRL-0200 FAN GRILL

3

M-FAN-0200 FAN BLADE

2

M-CON-0100-H

1

MRH100-CAD

ITEM

NO

PART NO

CABINET STUD AND NUT

BOLT M4x12

DRAIN CONNECTION FITTING

CABINET TOP

CABINET HANDLE (NEW)

CABINET SIDE-RIGHT

CABINET FRONT

CABINET SIDE-LEFT

CABINET REAR

HEAT EXCHANGER SUPPORT SHEET

CABINET LEG4

CABINET LEG3

CABINET LEG2

CABINET LEG1

BOLT M6x15

DIGITAL CONTROLLER 1

PLASTIC CONTROL PANEL

THERMOSTATIC SWITCH

COMPRESSOR START CAPACITOR

COMPRESSOR START RELAY

THERMINAL BLOCK

COMPRESSOR ELECTRICAL BOX

EXPANSION VALVE

MANSON 3/4

1/4 - 8mm FITTING

AIR CONNECTION FITTING

ROTOLOCK ADAPTOR2

ELBOW FITTINGS

90* 1 / 4" - 6mm ELBOW

1 / 4" T CONNECTOR

CHECH VALVE

REDUCTION 3/8 - 1/4

DRAIN BALL VALVE

REDUCTION 3/4 - 1/2

RECORD 3/4

RECORD *90 3/4

HEAT EXCHANGER

DRYER-DEHYDRATOR

ADAPTOR T

HIGH PRESSURE SWITCH

FAN ON/OFF SWITCH

BY-PASS VALVE

NUT M8

WASHER Ø22xØ8,5x2,5

BOLT M8x40

ROTOLOCK ADAPTOR2

CONDANSER

CABINET BASE

DESCRIPTION REV QTY

PART LIST

1

1

4

15

15

16

1

1

3

1

1

1

1

2

1

1

1

1

4

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

2

1

1

1

1

3

4

1

1

1

1

1

1

4

4

4

1

1

1

1

6

2

2

8

8

2

2

2

1

1

Page 47

9. COMPONENTS LOCATION

All main components located into dryer identified with labels as listed here under.

CAUTION: Due to manufacture design, some components out of the list are not installed into the dryer.

Electrical components:

Accessories :

A01: Control circuit transformer

A02: Power circuit transformer

A10: ON warning light

A11: OFF warning light

A20: Drain solenoid valve

A30: Cranckase heater

A31: Electrical resistor

A40: Electrical capacity

EV3 Digital Controller (Digi-Pro)

A50-3: Energy saving device 3 (ESD3)

Relays :

K01: Compressor motor relay

K10: Fan motor relay

K20: Drain timer or Bekomat (optional)

K30: Temperature Controller

Switches :

S01: Main switch

S02: Start push button

S03: Stop push button

S10: Fan pressure control

S11: High-low pressure security control

S12: High pressure security control

S13: Low pressure security control

S20: Refrigerant temperature control

S21: Air temperature control

Motors :

M01: Refrigerant compressor motor

M10: Fan motor

Thermal protections :

P01: Refrigerant compressor thermal overload

P10: Fan motor thermal overload

Fuses protections :

See complete identification into electrical sketch included in dryer

F--: Transformer protection

F--: Fan protection

F--: Compressor relay protection

F--: Transformer protection

F--: Drain protection

F--: Fan relay protection

Refrigerant components:

G01: Liquid receiver

G02: Refrigerant drier

G03: Expansion valve

G04: Liquid separator

G05: Hot gas bypass valve

G06: Refrigerant solenoid valve

G10: Water cooled condenser

G11: Water control valve

G20: Refrigerant evaporating pressure gauge

G21: Refrigerant evaporating temperature gauge

Compressed air components :

H01: Air inlet prefilter

H11: Drain filter

H12: Pneumatic drain valve

Terminal boxes:

B01: Main terminal box

B11: Refrigeranbt unit termal box

B12: Free of potential terminal box

Page 48

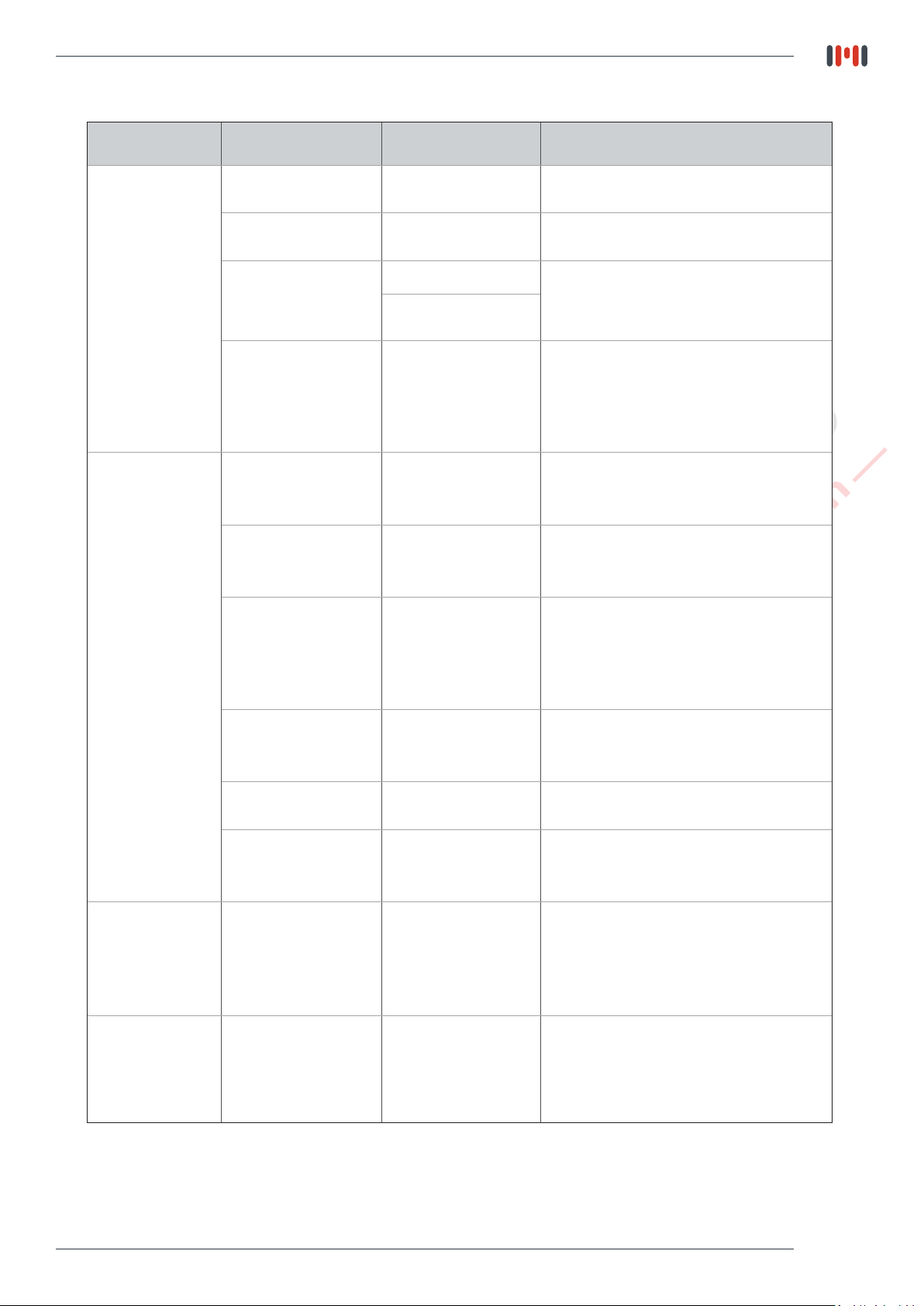

Problem Possible Cause Repair Comments

Dryer is

switched on,

indicator light

is lit but the

refrigerant

compressor

does not turn on.

Dryer is

switched on,

but the refrigerant

compressor

does not turn on.

Dryer is switched

on but fan is not

running.

The connection has

inverted phases

Refrigeration unit is not

functioning

The refrigerant highpressure

protection has tripped

Excessive ambient temperature

Excessive temperature on

crankcase of compressor.

Excessive compressed

air inlet temperature.

Clogged condenser fins or

clogged water condenser.

Possible high crankcase

temperature

Possible loss of phase

Possible low voltage causing

overload trip Possible failed

compressor

Too much compressed air

flow.

Faulty electrical wiring Inspect the circuit The compressor-on light should be wired into the

One electrical protection

has tripped.

Fan has to run if refrigerant

high

pressure reaches upper set

point.

Invert two phases 3-phase dryers are equipped with a phase controller

Check refrigeration compressor

The refrigerant safety high

pressure switch has tripped.

In case of water cooled condensers, check the water

control valve

Be sure that dryer is working

in temperatures lower than

the

design conditions.

Designed conditions and

correction factors are described

in this manual.

Allow time to compressor to

cool down. Reason may be a

possible incorrect adjustment

of hot gas bypass valve or

shortage of refrigerant

Be sure that dryer is working

in temperatures lower than

design conditions.

Clear fins or water condenser

of all obstructions.

Check actual flow

through the dryer.

Reset the protection or

replace the blown fuse.

Check that compressed air

flows through the dryer.

Check

that fan blades are free to

move.

Check the fan pressure

switch.

to avoid the fans from turning in the opposite

direction.

Several factors can cause compressor failure.

A qualified refrigeration technician needs to check

all the electrical and refrigerant circuit and controls.

The dryer is protected against excessively high

refrigerant pressure. If the condenser eciency has

reduced, the switch will trip. Manually reset the

switch.

A high ambient temperature may cause the

refrigerant system to operate at higher than normal

pressures. Results will be higher than normal

evaporator temperature.

lmportant: adequate air circulation around the dryer,

and proper ventilation in the equipment room should

guarantee a low enough ambient temperature.

Compressor is protected against overly high

temperatures of the crankcase by a thermal switch.

The dryer is designed for working in calculated

conditions (see description in this manual).

If conditions are exceeded, the dryer will be

overflowed, dew point will go up and protecting

devices can switch o.

The clogged fins in the condenser will restrict the

air passage and reduce the refrigeration capacity,

causing high temperature in the evaporator.

Same will occur if water condenser is clogged with

mud or dirt. Air condenser and water condenser

should be periodically checked and cleaned.

Protect water circuit by an adapted filter.

This dryer is designed for a maximum air flow at

design conditions. If too much air is pumped

into the dryer, water removal capacity may not be

sucient, resulting in liquid carryover down stream.

Check the rated output the air compressor.

refrigerant compressor circuit. See wiring diagrams

in this manual.

The dryer is protected against high amp draw by

fuse and/or overload relay that can trip in case of

need. Reset or replace fuse once, but do not persist

if it trips again, request assistance from a qualified

refrigeration contractor.

Fan operates automatically to keep refrigerant

pressure below the maximum value. The fan can

stop if pressure is under the recommended setting.

When compressor

starts, it vibrates

a lot and makes

mechanical noise.

Compressor is slugging

liquid refrigerant

at start up.

Be sure the pre-heating

period

of at least 2 hours is

respected

Refrigerant may move between receivers when

refrigerant compressor is stopped and not heated,

especially if stopped for a long time.

This migration may cause liquid shock (slugging) in

valves specially on large dryers containing more

refrigerant

Page 49

Problem Possible Cause Repair Comments

Water in system Compressed Air Inlet and

High

pressure

drop

The unit will not

run or cycles o

and on.

outlet connections are

reversed.

Drain system is clogged

or inoperative.