Page 1

ALL INFORMATION CONTAINED IN THIS DOCUMENT IS PROVIDED AS IS WITHOUT WARRANTY OF ANY KIND.

THE CREATOR OF THIS DOCUMENT , HEREINAFTER REFERRED TO AS THE 'WRITER' HEREBY DISCLAIMS ALL

WARRANTIES, EXPRESSED, IMPLIED OR OTHERWISE, INCLUDING WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS. THE

WRITER DOES NOT ASSUME OR AUTHORIZE ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN

CONNECTION WITH THIS CONTENT. IN NO EVENT SHALL THE WRITER BE LIABLE TO THE READER OF THE

CONTENT OF THIS DOCUMENT, OR ANY SUBSEQUENT USER, INCLUDING THE ULTIMATE END-USER, IN

CONTRACT, TORT, WARRANTY, STRICT LIABILITY, OR OTHERWISE FOR ANY SPECIAL, INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO, THE COST OF LABOR, REQUALIFICATION,

DELAY, LOSS OF PROFITS OR GOODWILL, EVEN IF THE WRITER IS ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. BY LOOKING AT THE CONTENT OF THIS DOCUMENT THE READER AGREES THAT THEY HAVE READ

AND AGREE TO THE ABOVE CONDITIONS ENTIRELY.

USER GUIDE

REV. 1.00

COMPRESS-IUV600S--1.00

COMPRESS IUV600S SERIES PRINTER

Page 2

Compress iUV600s Series User Guide

This page has been intentionally left blank

2

Page 3

Compress iUV600s Series User Guide

No part of this product or publication may be stored, reproduced, copied, or transmitted in any form or

by any means without the express permission of IMPRESSION TECHNOLOGY.

The product and the contents of this publication may be changed at any time without prior notification.

IMPRESSION TECHNOLOGY has made the best efforts to keep this publication free from error, but if you

find any uncertainties or misprints, please call us or the dealer from where you bought this equipment.

IMPRESSION TECHNOLOGY shall not be liable for any damages or troubles resulting from the use or misuse of this equipment or this manual either directly or indirectly.

Important

For Users in Europe

IMPORTANT:

This is a Class A product approved for industrial environments. In some

environments this product may cause radio interference in which case you may

be required to take measures to re-locate this product.

For Users in the United States

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Notice

Trademarks Mentioned in this Manual

• COMPRESS, iUV600s, WIMS, AOD, ACCULOK AND BMS are registered trademarks or product

names of IMPRESSION TECHNOLOGY.

• Centronics and BiCentronics are registered trademarks or product names of Centronics Data

Computer Corporation.

• Windows XP, Windows Vista, Windows 7 or greater and MS- DOS are registered trademarks or

product names of Microsoft Corporation.

• Intel and Pentium are trademarks or registered trademarks of Intel Corporation.

• Other company and product names may be registered trademarks or product names.

•

i

Page 4

Compress iUV600s Series User Guide

Warranty

IMPRESSION TECHNOLOGY warrants part repair or replacement as a sole measure only if a failure

is found in the system or in the materials and workmanship of the product the seller produced.

However, if the cause of failure is uncertain or cannot be conclusively proved to be directly related

to defect in workmanship any part repair or replacement shall be solely at the discretion of

Impression Technology.

The warranty shall not apply to any direct or indirect loss, or compensation for the loss due to the

product that has been subject to misuse, neglect, or improper alternation whether directly or

indirectly.

ALL INFORMATION CONTAINED IN THIS DOCUMENT IS PROVIDED AS IS WITHOUT WARRANTY OF

ANY KIND. THE CREATOR OF THIS DOCUMENT , HEREINAFTER REFERRED TO AS THE 'WRITER'

HEREBY DISCLAIMS ALL WARRANTIES, EXPRESSED, IMPLIED OR OTHERWISE, INCLUDING

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS. THE WRITER DOES NOT ASSUME OR

AUTHORIZE ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION

WITH THIS DOCUMENT CONTENT. IN NO EVENT SHALL THE WRITER BE LIABLE TO THE READER

OF THE CONTENT OF THIS DOCUMENT, OR ANY SUBSEQUENT USER, INCLUDING THE ULTIMATE

END-USER, IN CONTRACT, TORT, WARRANTY, STRICT LIABILITY, OR OTHERWISE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED

TO, THE COST OF LABOR, REQUALIFICATION, DELAY, LOSS OF PROFITS OR GOODWILL, EVEN IF

THE WRITER IS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BY LOOKING AT THE CONTENT

OF THIS DOCUMENT THE READER AGREES THAT THEY HAVE READ AND AGREE TO THE ABOVE

CONDITIONS ENTIRELY.

Limitations

ii

Page 5

Compress iUV600s Series User Guide

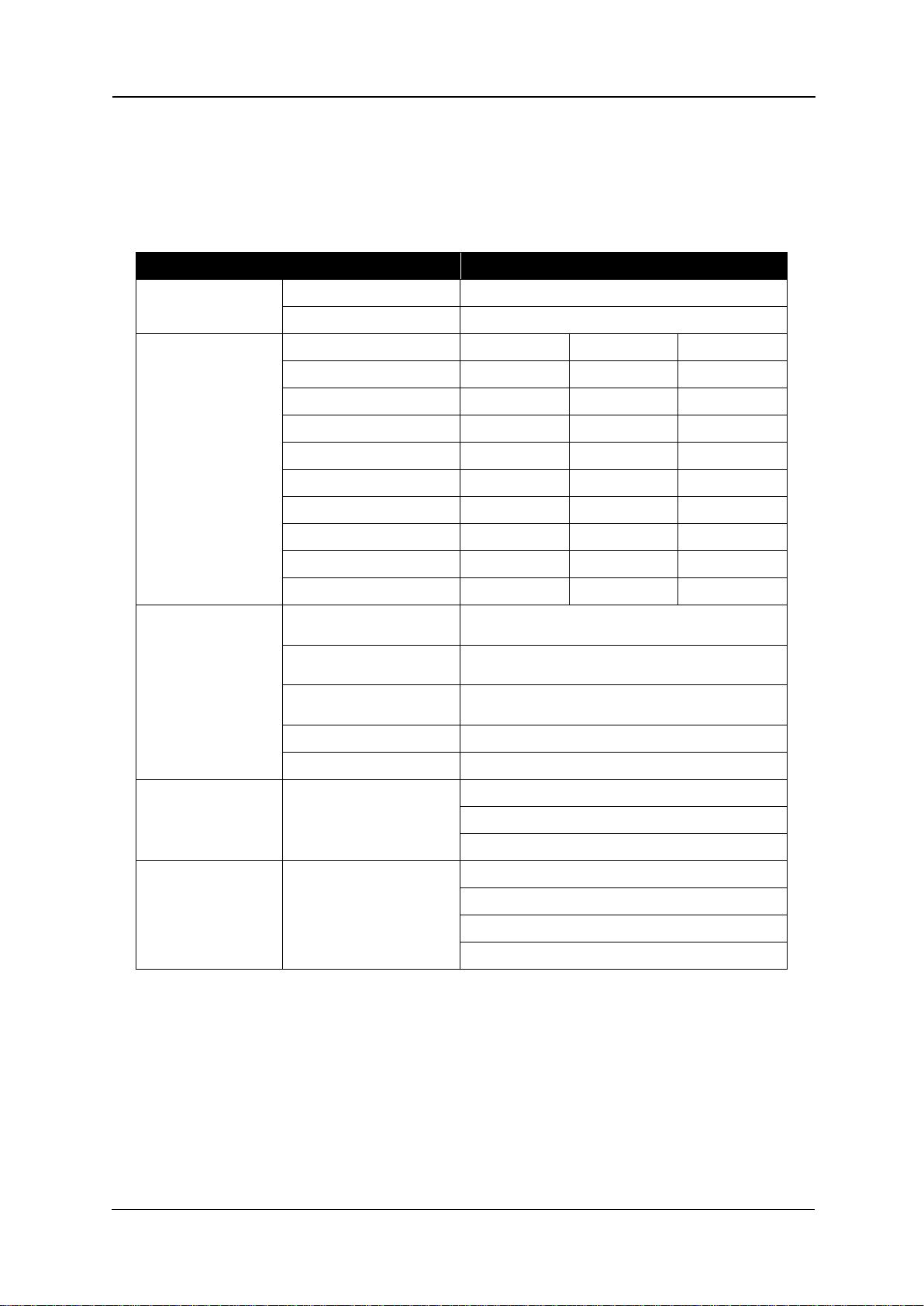

Section

Contents

1 Safety Instructions

Explains types of warnings, cautions and warnings labeled on the

printer

2 Product Overview

Explains the features, part names, and functions of the printer.

3 Initial Setup and Basic

Operations

Explains the procedures for the initial setup & basic operations

of the printer.

4 Printing on substrates

Explains the procedures of preparation for & printing to

substrates with the printer.

5 Maintenance

Explains daily and other periodical maintenance of the printer.

9 Troubleshooting

Explains troubles that may occur when using the printer and

how to solve them.

10 Appendix

Printer specifications

About this

Manua

l

A. Purpose and Target Readers

This manual explains the preparations and procedures for operating the Compress iUV600s series

printer.

This is a common User Guide for the Compress series of printers. Unless specifically mentioned to

the contrary, the descriptions in this manual are common for all Compress series models.

This manual is designed to assist the end user in the use, maintenance and general troubleshooting

of the Compress series printers. Before using the Compress series printer you are required to read

and fully understand the contents and directions in this manual.

B. Manual Configuration

iii

Page 6

Compress iUV600s Series User Guide

Revision Date

Summary of Changes

15th October 2015

Initial release

C. Document Change History

This version of the document replaces and obsoletes all previous versions. The following table

describes the most recent changes:

iv

Page 7

Compress iUV600s Series User Guide

Symbol

Meaning

Must be followed carefully to avoid death or serious bodily

injury or catastrophic damage to your equipment.

Must be observed to avoid slight or moderate bodily injury or

damage to your equipment.

Contains important information and useful tips on the operation

of the product

Indicates useful tips for operating or understanding the

equipment or getting the best performance from your

equipment.

Indicates reference pages in this manual

WARNING

CAUTION

NOTE

TIP

D. Manual Notation

The following symbols are used in this manual for easier understanding of the information.

v

Page 8

Page 9

Compress iUV600s Series User Guide

GENERAL TABLE OF CONTENTS

1. Safety Instructions .................................... 7

1.1 Introduction .......................................................................... 7

1.2 Warnings, Cautions and Notes .............................................. 7

1.3 Important Safety Instructions ............................................... 8

1.4 Warning Label types and meanings .................................... 11

1.4.1 Handling the Warning Labels .............................................. 11

1.4.2 Locations of Warning Labels ............................................... 12

2. Product Overview ................................... 13

2.1 Introduction ........................... Error! Bookmark not defined.

2.2 Features .............................................................................. 13

2.2.1 High Resolution Image Quality ........................................... 13

2.2.2 Ink Supply System .............................................................. 13

2.2.3 Operation Efficiency Improvement ..................................... 13

2.2.4 Operability Improvement ................................................... 13

2.3 Part Names and Functions .................................................. 14

2.3.1 Front Section ..................................................................... 15

2.3.2 Rear Section ....................................................................... 17

2.3.3 WIMS ................................................................................. 18

2.3.4 Operation Panel ................................................................. 20

2.4 Printer Status ...................................................................... 23

2.4.1 Normal .............................................................................. 23

1

Page 10

Compress iUV600s Series User Guide

2.4.2 Setup Menu ....................................................................... 23

2.4.3 Changing Printer status ...................................................... 23

3. Initial Setup & Basic Operations .............. 24

3.1 Introduction ........................................................................ 25

3.2 Before you Get Started ....................................................... 25

3.2.1 Commit to Maintenance .................................................... 25

3.2.2 Get to Know your iUV600s ................................................. 25

3.3 Choosing a Place for the Printer .......................................... 28

3.3.1 Installation Environment Requirements ............................. 28

3.3.2 Required Space .................................................................. 29

3.4 Minimum Computer Requirements .................................... 31

3.5 Basic Operations ................................................................. 32

3.5.1 Switching the Printer ON .................................................... 32

3.5.2 Switching the Printer OFF. .................................................. 34

3.5.3 Connecting the Printer to the PC ........................................ 35

3.5.4 Confirming Default Settings ............................................... 37

3.5.5 Performing a Head Clean from the Operation Panel ........... 42

3.6 Initial Setup ......................................................................... 44

3.6.1 Removal of Shipping Tape .................................................. 44

3.6.2 Remove Carriage Lock Bracket ........................................... 45

3.6.3 Initial Ink Fill Process - Colours ........................................... 46

3.6.4 Initial Ink Fill Process – White ............................................. 50

3.6.5 Loading Media for Printing ................................................. 52

3.6.6 Checking media height ....................................................... 53

3.6.7 Performing a Nozzle Check Test Print ................................. 55

3.6.8 Examining a Nozzle Check Test Print .................................. 57

2

Page 11

Compress iUV600s Series User Guide

3.6.9 Bi-Directional (Bi-D) Adjustment ........................................ 58

3.6.10 Installing & Using Printer Drivers........................................ 68

4. Printing to Substrates ............................. 85

4.1 Introduction ........................................................................ 86

4.2 Prepare Your Image ............................................................. 86

4.3 Substrate Preparation ......................................................... 89

4.4 Load substrate/template to the printer .............................. 90

4.4.1 Put the template onto the Platen ....................................... 90

4.4.2 Adjust Printing Bed Height / Move Platen to the Top of Page

position 91

4.5 Print Your Image .................................................................. 91

4.6 Post-Printing ........................................................................ 92

4.7 Cancelling a Print Job .......................................................... 93

4.7.1 Introduction ....................................................................... 93

4.7.2 Cancelling the Print Job ...................................................... 93

4.7.3 Re-starting the Printer after Cancelling a Print Job ............. 93

5. General Care & Maintenance .................. 94

5.1 Introduction ........................................................................ 95

5.2 Execute a Print Head Clean at the end of production ......... 95

5.3 Run the Nozzle Check test print each day before starting

production ................................................................................... 95

5.4 Maintaining the Ink System ................................................. 95

5.4.1 Accessing the Capping Station ............................................ 95

3

Page 12

Compress iUV600s Series User Guide

5.4.2 Cleaning the Flushing Tray ................................................. 97

5.4.3 Cleaning the Wiper and Head Cap ...................................... 98

5.4.4 Manual Print Head Guards Clean ........................................ 99

5.4.5 Parking the Print Head ..................................................... 100

5.4.6 Emptying the waste ink container ....................................... 101

5.5 Other Maintenance Items ................................................. 102

5.5.1 Powerful Head Cleaning ................................................... 102

5.5.2 Ink Charge ....................................................................... 104

5.5.3 Clean the CR Encoder Strip ............................................... 110

5.5.4 Clean the CR Guide (X Rail) ............................................... 113

5.5.5 Clean the CR Drive Belt, Roller and Pulley ........................ 114

5.6 General Care ..................................................................... 114

5.6.1 Environment .................................................................... 114

5.6.2 Clean your Compress iUV600s™ ....................................... 115

5.6.3 Avoid White Ink Separation .............................................. 115

5.6.4 Replace WIMS filter ......................................................... 115

5.6.5 Empty & Wash White Ink Container ................................. 116

5.6.6 Ink Levels ......................................................................... 116

5.6.8 Flushing the printer ......................................................... 116

5.7 Transportation of Printer .................................................. 118

6. Troubleshooting .................................... 119

6.1 Introduction ...................................................................... 120

6.2 Troubleshooting with Error Messages .............................. 120

6.2.1 Operation Status .............................................................. 121

6.2.2 Errors with Message ......................................................... 122

6.2.3 Data Errors ....................................................................... 124

4

Page 13

Compress iUV600s Series User Guide

6.2.4 Command Errors .............................................................. 125

6.2.5 Errors Requiring Reboot ................................................... 126

6.3 Troubleshooting Without Error Messages ........................ 134

6.3.1 Initial Operation Problems ................................................ 134

6.3.2 Printing Problems ............................................................ 137

6.3.3 Noise Problems ................................................................ 152

6.3.4 Problems with Curing / Washing ........... Error! Bookmark not

defined.

6.3.5 Other Problems................................................................ 153

7. Appendix .............................................. 154

7.1 Product Specifications ....................................................... 155

7.1.1 Main Unit Specifications .................................................. 155

7.1.2 Print Operation Specifications .......................................... 155

7.1.3 Printer physical specifications .......................................... 156

7.2 Interface Specifications ..................................................... 158

7.2.1 USB Interface Specifications ............................................. 158

7.2.2 Network Interface Specifications ...................................... 159

7.3 Options/Supplies List ......................................................... 159

7.3.1 Options ............................................................................ 159

7.3.2 Supplies ........................................................................... 160

5

Page 14

Compress iUV600s Series User Guide

6

Page 15

Safety Instructions Compress iUV600s Series User Guide

Safety Terms

Details

Must be followed carefully to avoid death or serious bodily injury

Must be observed to avoid slight or moderate bodily injury or damage

to whole or part of the product

Contains important information and useful tips on the operation of the

product

TABLE 0-1 SAFETY TERMS

WARNING

CAUTION

WARNING

NOTE

Safety Instructions

1.0 Introduction

This chapter explains the meaning of safety terms for personnel who install, operate, or maintain this

equipment, important safety instructions, and the warning labels attached to the equipment.

Make sure to follow all instructions and warnings on this manual when installing, operating, or maintaining

the equipment.

1.1 Warnings, Cautions and Notes

Safety terms in this manual and the contents of warning labels attached to the printer are categorized into

the following three types depending on the degree of risk (or the scale of accident).

Read the following explanations carefully, and follow the instructions in this manual.

7

Page 16

Compress iUV600s Series User Guide Safety Instructions

WARNING

1.2 Important Safety Instructions

General safety instructions that must be observed to use the equipment safely are explained below.

ALWAYS CONSULT YOUR PRODUCT REPRESENTATIVE PRIOR TO SWITCHING ON YOUR MACHINE

Do not place the printer in the following areas. Doing so may result in the printer tipping or falling

over and causing serious injury.

Unstable or loose surfaces

Angled surfaces

Areas subject to vibration by other equipment

Do not stand on or place heavy objects on your printer. Doing so may result in the printer tipping or

falling over and causing injury.

Do not look directly at the LED UV lamp whilst the machine is in operation, this can be damaging to

human eyes. The use of UV proof sunglasses is strongly recommended

Do not cover the ventilation hole of your printer with cloth, such as a blanket or table cloth. Doing so

could obstruct ventilation and cause fire.

Do not place the printer in humid and dusty areas. Doing so may result in electrical shock or fire.

Make sure to use the power cable packed with the printer you purchased. Not doing so may result in

electrical shock or fire.

Do not use the power cable if it is damaged in any way. Doing so may result in electrical shock or fire.

Do not insert or drop metal or objects which are easily combustible through the openings such as the

ventilation hole of your printer. Doing so may result in electrical shock or fire.

Do not operate the printer if it has been contaminated by foreign substances or liquid spills as doing

so may result in electrical shock or fire. Immediately turn off the power switch, disconnect the power

plug from the electric socket, and contact your authorized DTG Dealer.

Make sure to use only the specified power supply (AC 100 V - 120 V or AC 220 V - 240 V). If the power

supply other than the specified voltage is used, it could cause an electric shock and fire.

Make sure to double check LED curing lamp voltages are set for your specific countries voltage rating.

Take power for the printer directly from the power socket (AC 100 V - 120 V or AC 220 V - 240 V). Do

not use complex multiple plugs on the same socket. This could generate heat and might cause fire.

Make sure that the following is performed before parts replacement.

Turn off the power to the printer.

Remove the power cable from the power outlet. Not doing so may cause electric shock or

damage to the electric circuit.

Unplug the cables connected to the printer. Failure to do so could result in damage to the

printer.

8

Page 17

Safety Instructions Compress iUV600s Series User Guide

CAUTION

Pay attention to the following when handling the power cable:

Do not do anything forcefully (e.g. pull, bend, twist) to the power cable

Do not place heavy objects on the power cable

Do not route the power cable near heat sources

Pay attention to the following points while handling the power supply plug. Not going so may result

in electrical shock or fire:

Make sure that the power cable / plug is not contaminated by any foreign substances such as

dust etc.

Make sure that the power plug is correctly connected to the power socket.

Pay attention when handling inks so that ink does not get into the eyes or spill on your skin. If the ink

does get into eyes or onto skin, immediately wash the affected area with water. The inks may cause

mild skin irritation and/or inflammation of the eyes. Consult with medical personnel in the case of

any adverse reaction.

Be careful to ensure that fingers are not caught in the opening when lifting and closing the top cover

of the printer.

Do not use strong solvents such as thinners, benzene or alcohol on the printer. These products may

damage the paint on the printer.

Take care that moisture does not enter the printer. There is a risk of a short circuit of the electrical

circuit(s) within the printer if this occurs.

Ensure that the printer is always kept in a horizontal position, even whilst it is being lifted or moved.

Do not leave the printer on a slanted surface. Do not leave the printer upside down. Doing so may

cause ink leakage and / or trouble that cannot be restored, as the printer is originally assembled in the

factory with a high accuracy of 1/100 mm.

Ensure all packing materials are removed from the printer before lifting from it’s crate. If the printer

is lifted with materials attached, it may slip from the hands and be damaged.

Assembling and disassembling of the printer are possible only for the parts that disassembling

procedures are shown in this manual, and should be undertaken only by DTG authorized and trained

professionals. Do not disassemble any frame parts or parts that disassembling procedures are not

shown in this manual. Doing so may cause trouble that cannot be restored, as the printer is originally

assembled in the factory with a high accuracy of 1/100 mm.

Do not touch the elements on the circuit board with bare hands. Doing so may cause static

electricity and cause catastrophic invisible damage.

Do not press the transparent film on the damper assembly with your hands. Doing so may discharge the

ink filled inside the damper assembly or damage the pressure valve.

Be careful not to damage the transparent film on the damper assembly.

Do not touch the nozzle plate of the print head, keep free from dust.

There is ink in the tubes throughout the printer. Be careful that the ink is not spilled from any tube

outlet onto the printer or items close to the printer.

9

Page 18

Compress iUV600s Series User Guide Safety Instructions

If you need to operate the printer with the cover removed for maintenance or repair, be careful not to

get injured by any moving parts.

Never lubricate the printer mechanism with anything other than that designated by Impression

Technology. Doing so may damage the parts or shorten the lifetime of the parts and / or printer.

If the power board assembly needs to be removed, remove the power cable and wait for 5 minutes or

more before taking it out; this will discharge the residual electrical charge of the electrolytic capacitor.

Touching the board before the capacitor discharges may cause electric shock or death.

When connecting or removing an FFC type cable on a main board assembly connector, make sure to

connect or remove the cable perpendicular to the connector. Connecting or removing at a slant may

damage, break or short-circuit the inner terminal of the connector and may damage the components

on the board.

When connecting or removing an FFC type cable on the CR board assembly connector, make sure to

connect or remove the cable perpendicular to the connector. Connecting or removing at a slant

angle may damage, break or short-circuit the inner terminal of the connector. That may damage the

components on the board.

Make sure there is sufficient space around the printer when performing maintenance work.

Maintenance must be done by more than two person for the following work.

When disassembling or reassembling the product

When packing the printer for transportation

10

Page 19

Safety Instructions Compress iUV600s Series User Guide

Ref

Warning Label Type

A

Using this area as a lift point will cause damage to the printer.

B

Do not touch anything in this area unless instructed.

C

Dangerous voltages present in this area.

D

Fingers may be trapped and ripped off in this area.

TABLE 0-2 WARNING LABEL TYPE

A

B

C

D

NOTE

1.3 Warning Label types and meanings

The handling, attachment locations, and types of warning labels are explained below.

Warning labels are attached to areas where care should be taken. Read and understand the positions and

contents thoroughly before maintenance operation.

1.3.1 Handling the Warning Labels

Make sure to note the following when handling the warning labels.

Make sure that all warning labels can be recognized. If text or illustrations cannot be seen clearly,

clean or replace the label.

When cleaning warning labels, use a cloth with water or neutral detergent. Do not use any solvent or

gasoline products.

If a warning label is damaged, lost, or cannot be recognized, replace the label.

11

Page 20

Compress iUV600s Series User Guide Safety Instructions

Ref

Warning Label Type

A

Using this area as a lift point will cause damage to the printer.

B

Do not touch anything in this area unless instructed.

C

Dangerous voltages present in this area.

D

Fingers may be trapped and ripped off in this area.

B

C

D

B

A

D

A

1.3.2 Locations of Warning Labels

The locations of warning labels are shown below.

12

Page 21

Product Overview Compress iUV600s Series User Guide

Product Overview

1.4 Features

The features of the printer are explained below.

1.4.1 High Resolution Image Quality

This model uses the drop on-demand piezo head with a high performance coated nozzle plate.

The ability to eject >40pl droplet size enables excellent white ink delivery.

1.4.2 Ink Supply System

This model uses a microprocessor controlled pressurised color ink supply system and a patented White

Ink Management System (WIMS) utilising high performance brushless motors designed to provide trouble

free, accurate white ink delivery at all times.

1.4.3 Operation Efficiency Improvement

Loading media onto the media platens is done away from the printer and then slipped into the ACCULOK

platen locating and holding system.

1.4.4 Operability Improvement

The simple and intuitive GO/NO GO system uses two high brightness LED’s to indicate to the user

whether or not the printer is ready to receive a print job.

Sending a print when either LED is not green will result in a failed print job.

13

Page 22

Compress iUV600s Series User Guide Product Overview

Left

Upper

Rear

Front

Right

Lower

FIGURE 0-1 PRINTER ORIENTATION

1.5 Part Names and Functions

Part names and functions are explained in this section.

For the directions described in this document, refer to the following orientation figure:

14

Page 23

Product Overview Compress iUV600s Series User Guide

FIGURE 0-2 PRINTER FRONT

SECTION PARTS

Emergency stop

LCD and keypad

Bed up/down

buttons &

status light

Bed Load/eject

status light

Waste ink

access

Pressure reset

and status light

WIMS &

Bulk ink

system

Media

tray

1.5.1 Front Section

access and

cooling system

buttons &

15

Page 24

Compress iUV600s Series User Guide Product Overview

Name

Function

Emergency stop

This button removes mains power from the printer in an emergency.

Bed UP button

This button causes the motorised bed to move upwards and decrease the gap

between the print head and media.

Bed DOWN button

This button causes the motorised bed to move downwards and increase the gap

between the print head and media.

Bed STATUS light

This solid state lamp indicates the status of the bed height and it’s relation to

the head safety beam.

GREEN indicates that the media is at, or lower than, the optimum print height.

RED indicates that the media is at, or higher than, the recommended safe print

height.

AMBER indicates that the media height/head protection system has been

disabled and only the bed down button can be used. This mode is accessed by

depressing the bed UP button and the bed DOWN button at the same time

Bed LOAD button

This button causes the printer to move the bed into the start of print position in

which the top most area of the bed will be aligned with the top of the selected

print position.

Bed EJECT button

This button causes the printer to move the bed into the end of print position in

which the bottom most area of the bed will be situated in the entry point of the

printer.

Bed STATUS light

GREEN indicates that the bed is loaded in to the printer and the printer is ready

to print.

RED indicates that the bed is NOT loaded in to the printer and the printer will

not be able to print correctly, an error will occur if a print is sent to the printer

when the bed status light is red.

RED FLASH – the Bed STATUS light will flash red 1 times immediately when the

printer is powered on. This is an indicator that the printer is an X series printer.

Pressure Reset

Button & Status

Light

The CMYK pressure system comprises a pressure control board, DC motor driven

diaphragm pump and pressure limit switch. There is also a reset switch, warning

beeper and a status indicator light. The system will pump for a limited time to

build the correct CMYK ink pressure level, if this is not achieved the indicator

lamp will flash red, the beeper will sound and the pump will stop. This is to alert

the user to a pressure loss. This can be reset by pressing & holding the reset

switch for 1-2 seconds which will cause the pump to start again and the light will

go yellow. When the correct pressure is reached and all is well the indicator

lamp will pulse green.

TABLE 0-1 PRINTER FRONT SECTION PART FUNCTION

16

Page 25

Product Overview Compress iUV600s Series User Guide

Name

Function

AC mains power inlet

For inserting the mains power cable plug.

Network interface connector

Connector to connect a network interface cable.

USB cable connector

Connector to connect a USB cable.

FIGURE 0-3 PRINTER REAR

SECTION PARTS

Media tray

Mains

inlet

Ethernet and

USB

WIMS unit

WIMSPump

and stirrer

Colour ink

bottles

Optical

sensor

Waste ink

access

Pressure reset

and status light

1.5.2 Rear Section

access and

cooling system

TABLE 0-2 PRINTER REAR SECTION PARTS FUNCTION

17

Page 26

Compress iUV600s Series User Guide Product Overview

FIGURE 0-4 WIMS PARTS

Magnetic

Motor

WIMS Pump

WIMS mode

button

WIMS

Status Light

WIMS Rest

Setting

WIMS Stir

Setting

WIMS Filter

Provision for clear

Ink bottle

WIMS Pump

WIMS power

connector/status light

1.5.3 WIMS

Stirrer

18

Page 27

Product Overview Compress iUV600s Series User Guide

Name

Function

WIMS stirrer power

This indicator is BLUE during standby and RED when the printer is active. This

indicator is an integral part of the WIMS power plug.

WIMS stirrer

This assembly stirs the white ink by rotating the stirrer paddle clockwise for

approximately 10 seconds and then anti-clockwise for approximately 10

seconds. This is repeated while the unit is active

WIMS pump

This assembly circulates the white ink by peristaltic action to prevent the heavy

white pigment from settling in the pipes and bulk container.

WIMS Mode button

This button has two functions. In normal operating mode it will over-ride all

settings and force the pump and stirrer to operate continuously.

This mode is entered into, and cancelled, by pressing and holding the button for

more than three seconds. Diagnostic mode is entered by pressing the button

whilst power is being applied to the WIMS.

WIMS status light

GREEN indicates that WIMS has operated for a total of less than 1500

hours.

AMBER indicates that WIMS has operated for more than 1500 but less than

1700 hours

RED indicates that WIMS has operated for more than 1900 hours and that the

peristaltic pump tube should be replaced as soon as possible.

WIMS rest setting

This selects the length of time in segments of one hour for which the WIMS will

be at rest between stirring and circulating the ink.

WIMS stir setting

This selects the length of time in two minute segments for which the WIMS will

be actively stirring and circulating the ink.

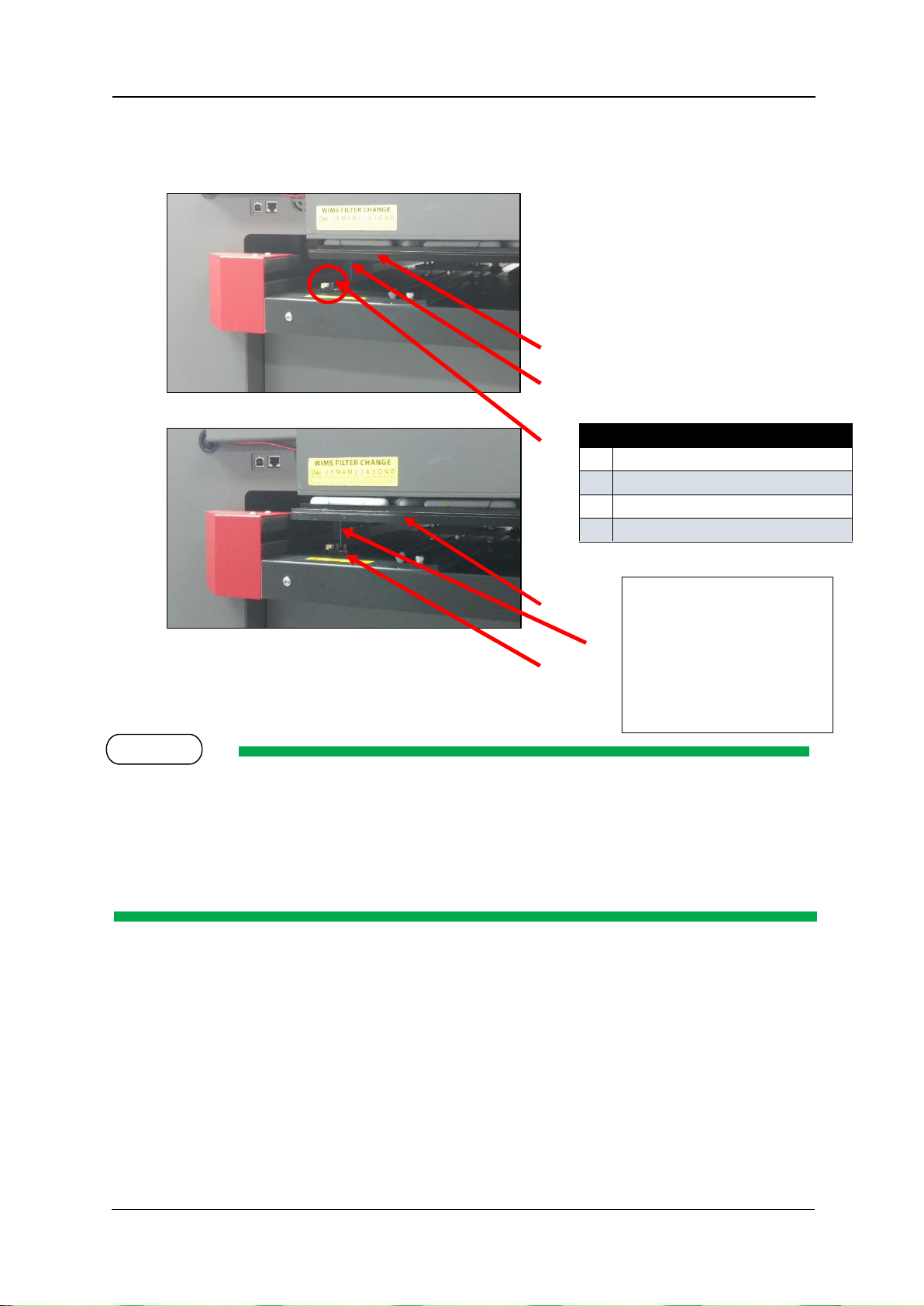

WIMS Filter

The WIMS filter is a 20µm in-line filter capsule and is used as a protection

measure for the print head and dampers. Particles or other contaminants

which may be present in or ingress into the white ink should be trapped by the

WIMS filter and therefore not progress through to the dampers and print head.

The WIMS filter should be replaced at least monthly, and more frequently

during high volume consumption of white ink.

TABLE 0-3 WIMS PARTS FUNCTION

19

Page 28

Compress iUV600s Series User Guide Product Overview

NOTE

1

2

3

4

5

6

7

8

9

10

11

FIGURE 0-5 OPERATION PANEL

1.5.4 Operation Panel

The operation panel (LCD & Keypad) is used to set operational conditions, display the status of the

printer, and set other functions.

explained below.

The names and functions of the operation keys and status lamps are

1.5.4.1 Operation Keys

Some keys have multiple functions and names depending on the printer status (normal or setup menu

display). See 1.6 "Printer Status" p.23 for more details.

20

Page 29

Product Overview Compress iUV600s Series User Guide

No.

Name

Normal Operation Function

Setup Menu Display Function

1

[Menu] key

Changes the LCD monitor display to

setup menu status.

Changes the setup menu display

status to normal status.

2

[Enter] key

- Selects the menu to be set and

shifts to the next hierarchy.

- Determines and saves the

parameter value.

[Cleaning] key

If held down for 2 seconds or more,

starts cleaning the printer

head.(note: platen should be loaded

and hood should be lifted to switch

of the UV lamps)

-

3

[Cancel] key

- During printing: Terminates printing

forcibly and deletes 1 file of

remaining data.

- During reception/analysis: Deletes

the data that has been already

received/analysed and ignores 1 file

of data received after that.

- Returns to the previous menu

hierarchy. Changed parameter

values are disabled.

- Changes the setup menu display

status to normal status.

[Cut] key

DO NOT USE

-

4

[Back] key

DO NOT USE except to toggle Roll

Lamp (below) to Green

Changes the menu in reverse order.

5

[Next] key

DO NOT USE

Changes the menu in forward order.

6

[Reverse feed] key

DO NOT USE

-

[ ˄ ] key

DO NOT USE

- Changes the setting value in the

forward direction.

- Increases the value when inputting

values.

7

[Forward feed] key

DO NOT USE

-

[ ˅ ] key

-

- Changes the setting value in the

reverse direction.

- Decreases the value when

inputting values.

8

[Power] key

Turns the printer on and off.

Turns the printer on and off.

TABLE 0-4 OPERATION KEYS FUNCTIONS

21

Page 30

Compress iUV600s Series User Guide Product Overview

No. Name Color Status Function

1

Power lamp

Green

On

The printer is switched on.

Blinking

An error has occurred. Error content will be displayed on

the LCD monitor.

Off

The printer is switched off.

2

Data lamp

Red

On

- The printer is analyzing received data.

- The printer is printing data.

Blinking

The printer is receiving data.

Off

The printer is not receiving, analyzing or printing data.

3

Roll lamp

Green

On

The printer is set to roll media.

Off

The printer is set to cut media. INCORRECT SETTING

Off

The printer is set to roll sheet. INCORRECT SETTING

Off

The plot mode is set to High speed. INCORRECT SETTING

4

LCD monitor

- - This monitor displays the operation status and error

messages of the printer.

1.5.4.2 LCD Monitor and Status Lamps

TABLE 0-5 LCD MONITOR & STATUS LAMPS

22

Page 31

Product Overview Compress iUV600s Series User Guide

NOTE

1.6 Printer Status

The status of the printer is explained below.

1.6.1 Normal

Indicates that the printer can print when the platen is loaded.

Both indicator LED’s (Power lamp & Roll Lamp) are green.

1.6.2 Setup Menu

The settings required for normal printing are usually made via the printer driver or RIP, but can also be

made using the operation panel.

1.6.3 Changing Printer status

(1) Normal → Setup Menu Display

When the printer is in “normal” mode, press the [Menu] key

The operation panel will shift to the setup menu display and show "*Me nu * T es tP lo t >".

(2) Setup Menu Display → Normal

While the printer is in setup menu display, if either of the following operation is done, the operation

panel shifts to Normal display.

[Menu] key on operation panel is pressed.

In the Setup menu, leave the keys untouched for three minutes.

For details on Status message, refer to 5.2.1 "Operation Status" p.121

23

Page 32

Compress iUV600s Series User Guide Initial Setup & Basic Operations

2. Initial Setup & Basic Operations

24

Page 33

Initial Setup & Basic Operations Compress iUV600s Series User Guide

2.1 Introduction

This chapter provides information on the initial setup and basic operation of the iUV600s Printer.

It is highly recommended that the initial setup of the printer be performed by a Compress trained &

authorized technician. Damage caused by incorrect setup will not be warrantied.

Initial setup should be undertaken in the following order:

1. Position the printer 2.3 "Choosing a Place for the Printer" p.28

2. Remove packaging materials 2.6.1 "Removal of Shipping Tape" p.44

3. Load colour inks (before power is applied to the printer) 2.6.3 “Priming the cooling

system.

4. Before the LED UV lamps can be operational you must first prime the entire lamp cooling

system. The reservoir for the pump is located in the waste tank bay via the small grey door.

The Pump unit and reservoir are located to the right as shown below

Reach in and lift the reservoir bottle from its location, you may need to angle the bottle to aid in the

removal. Bring bottle out as shown below.

25

Page 34

Compress iUV600s Series User Guide Initial Setup & Basic Operations

You will notice a green solution in the bottle, this is anti freeze, simply fill the bottle ¾ full with

distilled water, reattach the lid and then return bottle to the original location.

To Prime the LED lamp cooling system;

1- Release the E stop only, do not power up printer.

2- Raise the machine lid. You should see 2x blue LED’s illuminated.

3- Release and move carriage away from the capping station as per picture below. At this point

you will hear the pump running, this means that the system will be starting to prime, look at

the cooling tubes connecting to the lamps, once the air has been flushed from the tubing,

the system is primed, at the same time checking for leaks, allow the pump to continue

running for the entire 4 minutes (cooling down period) after which the pump will

automatically stop. Tubes should be solid and NO air visible.

4- Check the reservoir bottle and ensure that fluid is visible

26

Page 35

Initial Setup & Basic Operations Compress iUV600s Series User Guide

5. Initial Ink Fill Process - Colours" p.45

6. Load white ink 0 "3 .6. 5 Initial Ink Fill Process – White" p.50

7. Load media for printing 5.6.6 "Loading Media for Printing" p.52

2.2 Before you Get Started

2.2.1 Commit to Maintenance

Your Compress iUV600s™ represents a significant investment, not only of your money but also of your

commitment to your new business opportunity with the Compress iUV600s™.

Whilst the mechanics of the printing unit of the iUV600s are similar to that of a normal inkjet printer,

printing on rigid substrates is not the same as printing on paper. Various substrates can generate

more dust, it may require a much greater volume of ink, and the application of primers can become

airborne if applied by spraying and can ingress into the iUV600s. Each of these factors individually can

cause problems with your Compress iUV600s™, and in combination can be critical to the ongoing

27

Page 36

Compress iUV600s Series User Guide Initial Setup & Basic Operations

Left

Upper

Rear

Front

Right

Lower

FIGURE 2-1 PRINTER ORIENTATION

Top Cover (Lid)

LCD and keypad

Bulk ink

system

operation of the printer. All is not lost, however! A few minutes of your time each day spent

undertaking some basic maintenance tasks on the printer will ensure it’s continued optimal

performance. Please refer to the sections within this User’s Guide on Preventative Maintenance for

further information.

2.2.2 Get to Know your iUV600s

Starting a new business or adding to your existing product line with the Compress iUV600s™ is a very

exciting, and potentially very profitable time. Don’t get too carried away though and start accepting

orders before you even have your printer. Allow plenty of time to become familiar with your printer

and to learn not only the basics, but also the variables that can impact on your finished product.

These variables include image types, substrate types, your operating environment, and substrate

preparation. Thoroughly read this manual, ask questions of your Compress Technician or Distributor,

talk to other users. Be prepared for a learning curve. Be realistic about deadlines when accepting

orders and allow yourself sufficient time (and perhaps a couple of extra blank products) to complete

the order.

28

Page 37

Initial Setup & Basic Operations Compress iUV600s Series User Guide

Media tray

Mains

inlet

Ethernet

and USB

WIMS unit

Pump and

stirrer

Colour ink

bottles

Optical

sensor

Waste ink

cooling system

access

Pressure reset

and status light

FIGURE 2-3 PRINTER REAR

SECTION PARTS

FIGURE 2-2 PRINTER FRONT SECTION

PARTS

access and

29

Page 38

Compress iUV600s Series User Guide Initial Setup & Basic Operations

30

Page 39

Initial Setup & Basic Operations Compress iUV600s Series User Guide

Installation space

5m

2

or more, 2.6m or more is required for the width

Floor loading capability

Up to 3000Pa (450kgf/m2) or more

Electrical

specifications

Voltage

AC 100 V - 120 V ± 10% or AC 200 V - 240 V ± 10% (LED lamps not

auto switching and must be configured prior to switching on the

machine, contact your product representative for more details)

Frequency

50/60Hz ± 1Hz

Capacity

Up to 4A or more

Environmental conditions

Temperature

Humidity

Operation environment

18º C (64F) to 30ºC (86F)

20% to 80%, with no

condensation

Printing accuracy warranty range

18ºC (64F) to 28ºC

(82.4F)

40% to 60%, with no

condensation

Rate of change

2ºC per hour or less

5% per hour or less

WARNING

2.3 Choosing a Place for the Printer

Do not place the printer in a location under the following conditions. Doing so may cause the

product to fall over, become damaged, or cause serious injury:

o Unstable or shaky surfaces.

o Slippery, slanted or angled surfaces.

o Locations that are subject to vibration from other products.

Do not stand, or lean, on the printer or place any objects on it. Doing so may cause it to fall

over, become damaged, or cause injury.

Do not cover any ventilation holes or slots of the printer with anything at all. Doing so could

prevent the printer from ventilating and cause fire.

Keep the printer away from damp, humid or dusty areas. Failure to do so may result in electrical

shock or fire.

2.3.1 Installation Environment Requirements

Choose a place for printer installation following the requirements of the table below.

TABLE 2-1 INSTALLATION ENVIRONMENT REQUIREMENTS

31

Page 40

Compress iUV600s Series User Guide Initial Setup & Basic Operations

NOTE

NOTE

Avoid the following temperature and humidity conditions. Otherwise, printed images may appear

differently from what you expect and machine operation may be erratic or incorrect.

Places where sudden changes in temperature or humidity are expected, even if the condition is

within the range specified within this document.

Places where direct sunlight or excessive lighting conditions are expected

Places where air conditioners blow directly.

Impression Technology strongly recommends that the printer should be installed where air

conditioning airflow, humidity and temperature can be adjusted easily.

2.3.2 Required Space

Install the printer on a flat surface that meets the following conditions:

The load bearing surface will fully support the full weight of the printer (and/or stand) plus

100%.

The load bearing surface has an angular difference from level by no more than 2 degrees.

The load bearing surface is textured and firm enough to be considered a non-slip, hard

surface.

The load bearing surface will fully support lateral forces in all directions in excess of 100kg.

For printer options Section 6.3 Options/Supplies List p.159

Do not use the Compress iUV600s series on unstable surfaces.

32

Page 41

Initial Setup & Basic Operations Compress iUV600s Series User Guide

FIGURE 2-4 IUV600S DIMENSIONS

Compress iUV600s Printer dimensions are illustrated below

Machine weight +/- 148kg uncrated.

33

Page 42

Compress iUV600s Series User Guide Initial Setup & Basic Operations

Processor

Requires a PC based on Quad Core (2.2 GHz) technology or higher

processor.

Operating System

Microsoft® Windows® XP or later.

Hard Disk

Hard Drive with SATA interface and 100 GB free disk space.

RAM

2GB DDR2 or more.

Monitor

SVGA or better with resolution of 800 x 600 or better. 16 Bits or more

color support recommended.

CAUTION

2.4 Minimum Computer Requirements

Ensure that your computer has the minimum specifications as recommended here to ensure

optimum performance of your printer and the RIP:

34

Page 43

Initial Setup & Basic Operations Compress iUV600s Series User Guide

WARNING

CAUTION

2.5 Basic Operations

Some basic printer operations are described here as they are referred to in the Initial Setup

instructions.

2.5.1 Switching the Printer ON

Be sure to use the power cable supplied with the printer. If incorrect power cables are used,

electric shock or fire may result

Do not use a power cable that is damaged. To do so could result in electric shock or fire.

1. Ensure that the emergency stop is engaged by pressing hard on the red cap.

2. Plug the supplied mains cord into the socket at the rear of the printer.

Pay attention to the following when handling the power cable:

Do not do anything forcefully (e.g. pull, bend, twist) on the power cable

Do not place heavy objects on the power cable

Do not route the power cable near heat sources

3. Failure to remove the shipping tape before powering up the printer may result in catastrophic

damage to the printer drive mechanism.

4. Plug the other end of the power cord into the wall socket and turn ON.

5. Rotate the red cap of the emergency stop to allow the printer to receive power.

35

Page 44

Compress iUV600s Series User Guide Initial Setup & Basic Operations

5 seconds

Initializing

NOTE

CAUTION

NOTE

6. Press the Power button on the operation panel.

7. After a short delay the screen will display Initializing

The printer is likely to perform a short head cleaning operation shortly after turning on.

Do not attempt to operate the printer during this period.

8. After a short delay the screen will display No Waste Tank for approximately 15 seconds, after

which Cover Open will be displayed, indicating that the printer is ready to begin normal

operations.

9.

To bring printer to a “print ready” state, the platen must be loaded. After Platen is loaded, the

screen display will change from Cover Open to (briefly) Print Ready and then to MediaWidth 610mm.

Press the [Menu], [Enter], [Back] or [Cancel] buttons from the Control Panel to change display to

Print Ready.

36

Page 45

Initial Setup & Basic Operations Compress iUV600s Series User Guide

NOTE

CAUTION

Cover Open

15+seconds

2.5.2 Switching the Printer OFF.

1. Press the Power button on the operation panel. After about 15 seconds or so the Operation

panel display will be blank.

2. Ensure that the emergency stop is engaged by pressing hard on the red cap.

3. Unplug the power cord from the rear of the printer.

During normal non-operational periods such as overnight and during weekends it is recommended

that the printer is NOT switched off.

Do not attempt to operate the printer during this period.

37

Page 46

Compress iUV600s Series User Guide Initial Setup & Basic Operations

No. Part name

1

USB interface connector port

2

Network interface connector port

TIP

NOTE

2.5.3 Connecting the Printer to the PC

The Compress iUV600s has both Ethernet and USB interface ports for connection to the PC. You will

require either a USB or Ethernet interface cable for connecting to the PC, depending upon your

objectives.

2.5.3.1 Connecting Ethernet (network) interface cable

Turn off both your PC and the printer 2.5.2 "Switching the Printer OFF." p.34

Insert the network interface cable connector into the network interface connector port located at

the rear of the printer:

Connect the other network interface connector to your PC.

Refer to the Operation Manual of your PC for connection to your PC

2.5.3.2 Connecting USB interface cable

Install the printer driver Section 2.6.9 "Installing & Using Printer Drivers" p.68 before connecting

the USB cable

Insert the USB cable into the USB connector on the back of the printer.

Connect the other USB cable connector to your PC.

38

Page 47

Initial Setup & Basic Operations Compress iUV600s Series User Guide

TIP

Refer to the Operation Manual of your PC for the connection to your PC

USB connection supports Windows 98 and higher

This printer supports USB 2.0. If the connection is made under the following conditions,

the speed may decrease to the level measure ins USB1.1

o When the USB connection is used in Windows 98

o When your PC does not support USB 2.0

o When a USB hub of not USB 2.0 type is used

When using the printer with USB connection, install the printer driver into your PC using

the printer driver provided with the plotter

39

Page 48

Compress iUV600s Series User Guide Initial Setup & Basic Operations

CAUTION

2.5.4 Confirming Default Settings

This section gives an overview of the Setup Menu and the iUV600s series default settings.

There are some critical iUV600s series default settings that ensure that the printer operates in

accordance with the iUV600s series specifications. If these settings are not set at the correct value,

the printer will not behave correctly. Table 2-2 Setup Menu Structure page 41

Take care not to alter the default settings of the printer. If it is necessary to enter the Setup Menu for

any reason, follow the instructions below carefully and ensure that settings are maintained as

described in 2.5.4.4 "Setup Menu Structure" p.41

2.5.4.1 Enter the Setup Menu

When the printer is in “normal” mode, press the [Menu] key

The operation panel will shift to the setup menu display and show "*Me nu * T es tP r i n t > ".

2.5.4.2 Return to Normal Display

While the plotter is in setup menu display, if either of the following operation is done, the operation

panel shifts to Normal display.

[Menu] key on operation panel is pressed.

In the Setup menu, leave the keys untouched for three minutes.

40

Page 49

Initial Setup & Basic Operations Compress iUV600s Series User Guide

2.5.4.3 Menu Setup Procedure

Follow the following procedure to configure various setup menus.

1. Check that the operation panel is Normal, and is in ready to print status (Display will read

Re a dy t o P r i n t).

2. Press the [Menu] key on the operation panel.

"* Me n u* T e s t P r i nt >" will be displayed on the operation panel.

The setup menu display will be displayed.

3. Press the [Back] key or [Next] key on the operation panel to select a setup item and press the

[Enter] key.

The settings will be confirmed.

When setup item has a submenu, the submenu will be displayed.

41

Page 50

Compress iUV600s Series User Guide Initial Setup & Basic Operations

NOTE

NOTE

When a setup item has a submenu, [>] is displayed on the right end of the LCD monitor of the

operation panel.

If a submenu item displayed on the LCD monitor of the operation panel is blinking, it’s setting can be

changed.

Press the [Forward] key or [Reverse] key to change the setting.

5. To save the changed setting, press the [Enter] key on the operation panel.

1. The setting will be saved and the next setup item will be displayed.

If the [Cancel] key, [Forward] or [Reverse] key is pressed after changing a setting, without pressing

[Enter] key, that setting will not be saved.

42

Page 51

Initial Setup & Basic Operations Compress iUV600s Series User Guide

6. Press the [Menu] key or [Cancel] key on the operation panel to exit from the setup.

The previous setup menu will be displayed.

3. When the main menu is displayed, the screen turns to Normal.

43

Page 52

Compress iUV600s Series User Guide Initial Setup & Basic Operations

Setup Menu Item

Setup Menu Sub Menu Item

Setup Menu Sub Menu Item / Setting Value

Test Print Menu

Setup

NozzleCheck

MediaSet Menu

Media

[Plain]

Effect

[None]

Fine&Fog

Fine&Fuzz

Fog

Wave

PF

ConfirmPrint

InitialChange

<InitialPrint>

MicroChange

MicroPrint

Network Menu

IPaddress

000.000.000.000 to <192.168.001.253> to

255.255.255.225

SubnetMask

000.000.000.000 to <255.255.255.225> to

255.255.255.225

Gateway

000.000.000.000 to <192.168.001.254> to

255.255.255.225

BiDir Port

10610

MACAddress

xx:xx:xx:xx:xx:xx

Utility Menu

Menu Mask

<Normal>

OFF

AlwaysOFF

Cleaning Menu

Time

Short

Longer

Long

Normal

2.5.4.4 Setup Menu Structure

The setup menu has the following items.

< > parts in each list are initial settings

[ ] parts in each list are iUV600s series default settings (if different from initial settings).

TABLE 2-2 SETUP MENU STRUCTURE

44

Page 53

Initial Setup & Basic Operations Compress iUV600s Series User Guide

*** Press 2sec. ***

2 seconds

Cleaning 2min

Cleaning 1min

2 minutes

Print Ready

2.5.5 Performing a Head Clean from the Operation Panel

1. Ensure the printer is in Print Ready mode

2. Press the load button and ensure platen is loaded, this will allow the WIMS motor to operate

during the cleaning cycle

3. Open the top hood of the machine in order to deactivate the LED lamps, cleaning cycles with

LED lamps active are strongly discouraged.

4. Press and hold the ‘ENTER’ key.

5. The operation panel will display *** Press 2sec. *** . After about 2 seconds the printer

will begin head cleaning.

6. The operation panel will display the remaining time until the clean is finished. After about

two minutes or so the clean operation will complete.

45

Page 54

Compress iUV600s Series User Guide Initial Setup & Basic Operations

TIP

TIP

Head cleaning will consume some ink during operation, this is normal with all printers.

Executing a 2nd Head Cleaning from the operation panel within one print of the 1st Head Cleaning will

trigger a longer than Normal clean.

Ensure that the waste ink tank is placed in the correct position and that it will not overflow during the

head clean cycle.

46

Page 55

Initial Setup & Basic Operations Compress iUV600s Series User Guide

NOTE

CAUTION

2.6 Initial Setup

Once your printer has been removed from the crate and positioned as per Section 2.3 “ Choosing a

Place for the Printer” p.28 , use the following directions to prepare the printer for printing.

2.6.1 Removal of Shipping Tape

No tools are required for this procedure.

1. Remove any tape from the printer top cover (lid) then open the top cover (lid).

2. Locate the shipping tape near the centre part of the carriage belt as shown.

3. Carefully remove this tape, do not use any form of cutting instrument.

4. Locate the shipping tape on the media tray drive belt.

5. Carefully remove this tape, do not use any form of cutting instrument.

Failure to remove the shipping tape before powering up the printer may result in catastrophic

damage to the printer drive mechanism.

47

Page 56

Compress iUV600s Series User Guide Initial Setup & Basic Operations

CAUTION

NOTE

TIP

2.6.2 Remove Carriage Lock Bracket

1 x Philips Head screwdriver required for this procedure.

1. Remove the two screws securing the red carriage lock bracket (located at rear of print head

carriage), remove the carriage lock bracket.

Failure to remove the carriage lock bracket before powering up the printer may result in catastrophic

damage to the print head drive mechanism.

Be sure to put aside the carriage lock clamp and screws – these will be required should you need to

transport or store your printer in future.

48

Page 57

Initial Setup & Basic Operations Compress iUV600s Series User Guide

2.6.3 Priming the cooling system.

Before the LED UV lamps can be operational you must first prime the entire lamp

cooling system. The reservoir for the pump is located in the waste tank bay via the small

grey door.

The Pump unit and reservoir are located to the right as shown below

Reach in and lift the reservoir bottle from its location, you may need to angle the bottle to aid in the

removal. Bring bottle out as shown below.

49

Page 58

Compress iUV600s Series User Guide Initial Setup & Basic Operations

Press down carriage lock

mechanism and slide entire

head carriage towards the left

to release

You will notice a green solution in the bottle, this is anti freeze, simply fill the bottle ¾ full with

distilled water, reattach the lid and then return bottle to the original location.

To Prime the LED lamp cooling system;

5- Release the E stop only, do not power up printer.

6- Raise the machine lid. You should see 2x blue LED’s illuminated.

7- Release and move carriage away from the capping station as per picture below. At this point

you will hear the pump running, this means that the system will be starting to prime, look at

the cooling tubes connecting to the lamps, once the air has been flushed from the tubing,

the system is primed, at the same time checking for leaks, allow the pump to continue

running for the entire 4 minutes (cooling down period) after which the pump will

automatically stop. Tubes should be solid and NO air visible.

8- Check the reservoir bottle and ensure that fluid is visible

50

Page 59

Initial Setup & Basic Operations Compress iUV600s Series User Guide

NOTE

CAUTION

2.6.4 Initial Ink Fill Process - Colours

Observe all recommended ink handling procedures as prescribed in the relevant MSDS for inks.

Use protective gloves to avoid stained fingers.

The below instructions assume a generic machine configuration of CMYK+WWWW, if however your

printer is configured with clear ink please consult your technical advisor for any updated ink charge

procedures.

1. Unscrew the lids on each of the four colour ink containers and ensure they are empty. There

may be a small quantity of shipping fluid inside which will need to be poured out.

2. Fill each container with UV ink to just below the curve at the top of each container as shown.

The UV ink containers are of a dark colour to enhance UV ink stability, each bottle is clearly

marked as C-Y-M-K, be sure to fill the right colour in the right bottle. The below pictures

showing clear bottles are for illustrative purposes only

3- Take note of the coloured band on each of the colour ink lines, and match this to the ink in

each of the containers when screwing the containers back in to the lids. To screw the

containers to the lids, simply hold the lid firmly and screw the container up into the lid.

51

Page 60

Compress iUV600s Series User Guide Initial Setup & Basic Operations

No. Part name

1

LED lamps indicator lights

2

Coolant pipes

3

CR board assembly cover

LED lamp limit switch located

behind machine control

panel, visible only with the

machine hood in the up

position

3. Open the top cover of the printer to ensure LED lamp limit switch is switched off

4.

52

Page 61

Initial Setup & Basic Operations Compress iUV600s Series User Guide

NOTE

3 .6. 5 Initial Ink Fill Process – White

No tools are required for this procedure. Use protective gloves to avoid stained fingers.

1. Ensure that the printer is switched off on both the control panel and the red emergency off

switch and very gently insert the metal glass coated stirrer bar inside the white ink bottle. The

stirrer bar will be found inside the white ink bottle when first unpacking the machine.

2. Unscrew the white ink container lid by holding the lid and rotating the container. There will

be a small quantity of shipping fluid inside which will need to be poured out. Ensure the

container is empty & clean.

3. Fill the container with P70i UV white ink to just below the curve at the top of the container as

shown.

4. Now screw the container back up to the lid. To do this simply hold the lid firmly and screw the

container up into the lid. Double check that all tube clamps are in the open position and all

connectors are firmly joined.

5.

53

Page 62

Compress iUV600s Series User Guide Initial Setup & Basic Operations

5. Switch the printer on in accordance with the instructions in Section 2.5.1 "Switching the Printer

ON" p.32

Please note, for illustrative purposes clear white ink containers and ink lines are used. The actual

iUV600s production printer will have UV proof bottles and ink lines fitted. These will be black and dark

brown coloured.

M2 – IUV600s ink charge or little ink charge procedure

1- with machine off, press load/eject button and hold them down

2- press forward/reverse/next button and hold them down also

3- switch on machine and keep holding down the above mentioned buttons

4- After a short time the blue power light on control panel will flash and the screen will display

CHECK TEST, you can now let go of load/eject/for/rev/next

5- Screen will show RAM CAPACITY, press cancel

6- Screen will show CHECK TEST

7- Push the media tray all the way to the back of the machine

8- Press the load button and load LED will illuminate green

9- Screen will display RAM CAPACITY, press cancel

10- Screen will display CHECK TEST

11- Press NEXT 2 times until screen displays CLEANING

12- Press ENTER and machine will do a short 5 second clean

13- Screen will display NORMAL

14- Press the NEXT button several times until you see either LITTLE CHARGE or keep pressing

NEXT until you see INK CHARGE, then press ENTER

15- Once the ink charge has completed power down the machine, wait 20 seconds and power up

the machine in normal operation mode. You are now ready to print a nozzle test pattern

When the machine is new and you are doing a first time ink purge, we suggest you use INK Charge as

it will move more volume of ink and should fill the ink delivery system with ink with a single ink

charge.

WARNING, doing too many ink charges can aerate the print head, this may take several hours to

settle down.

WARNING, make sure the waste tank is empty and that it is situated properly underneath the waste

ink tube

54

Page 63

Initial Setup & Basic Operations Compress iUV600s Series User Guide

CAUTION

TIP

Please Note:

Bed/media 0/0 point is front/right

edge of the moving bed.

5.6.6 Loading Media for Printing

1. Pull the platen tray forwards to allow easy access to the platen as shown. Warning, do not

pull the platen abruptly, optimal movement should be no more than 6cm per second

If you are using paper for test printing purposes, uses paper masking tape to hold the edges of the

paper down. The use of a silicone sticky mat or vacuum bed is highly recommended, contact your

product representative for more information on these optional components.

As you are now ready to print your first test print or nozzle print, please review the steps undertaken

to get to this point, if you have doubts, consult with your product representative.

2. Place your print media onto the bed of the machine. This can either be flat sign media in

sheet form or a precut template populated with object that require to be decorated.

3. Pay close attention to the highest point of the media placed in the machine. Ideally, the

media should lay as flat and as even as possible.

55

Page 64

Compress iUV600s Series User Guide Initial Setup & Basic Operations

NOTE

CAUTION

Safety beam

Up/down

buttons

Slide media bed in by hand so

that the highest point of the

media sits perfectly underneath

the media safety beam

2.6.5 Checking media height

The Printer has an interactive protection system that monitors the height of the media on the media

tray by means of a safety beam that continually watches the gap between the print head and the

media. This is to help prevent damage to the print head caused by collision with the media or platen.

The safety system can be disabled by pressing and holding both the UP and DOWN keys until the

media status light turns yellow. In this condition the automatic safety system will be disabled and only

the DOWN button will be operational.

DO NOT pull or push the media tray manually unnecessarily as this can cause damage to drive

motors and internal electronics. Where possible use the load & eject buttons for movement of

the media tray.

If it is necessary to move the media tray manually, it must be done at a speed of no greater than

60mm/second (2 ¼ inches / second).

1. Push the platen tray forwards so that about half of the platen is inside the printer. If the

platen is too high the platen LED will turn red and the platen will lower its self. If the platen

LED is yellow the printer is in platen gap lock mode, press both the UP and DOWN buttons

together to turn the lock mode off. The platen LED should go green to indicate all is well and

the optimum print head gap is now set.

2. To set the correct height press and hold the UP button, the platen will begin to rise until the

internal safety beam detects that the platen height is correct. The platen LED will go red and

the platen will stop moving, release the UP button and the LED will turn green indicating that

the platen height is now set.

56

Page 65

Initial Setup & Basic Operations Compress iUV600s Series User Guide

CAUTION

Red LED illuminated indicates print

bed/media is not loaded, ensuring

correct beam protection is set press

the load button to load the

bed/media

Green LED illuminated indicates

bed/media has loaded properly

and print data can now be sent to

the printer

The platen LED has three different colours during operation. GREEN which indicates that the platen

should not be high enough to a collision between print head and media.. YELLOW indicates that the

automatic head protection system is OFF and there is a possibility of catastrophic collision damage to

the print head. When the indicator is RED the platen bed will begin lowering itself to try and protect

the print head from possible collision damage.

3. Press the LOAD button and the printer will emit a series of beeps and after a short delay the

platen will move into the printer. Do not impede the platen tray during operation as this may

damage the printer

4. When the printer has loaded the media the media LED will turn green indicating that the

printer is now ready to accept data from the computer to perform a print.

It is advisable to leave the head safety system operational at all times to assist in protecting the print

head. Print heads DO NOT CARRY ANY WARRANTY what so ever.

57

Page 66

Compress iUV600s Series User Guide Initial Setup & Basic Operations

TIP

FIGURE 2-5 GOOD NOZZLE TEST PRINT

TIP

2.6.6 Performing a Nozzle Check Test Print

The Printer has the ability to print a nozzle test print which will indicate the integrity of the nozzle

orifices. Blocked nozzles will cause the printer to produce poor quality output.

1. Load a sheet of clean paper for printing in accordance with Section 5.6.6 "Loading Media for

Printing" p.52 Follow the menu selection shown below to access the nozzle test print utility. In

order to visually see the white ink clearly in the nozzle pattern consider using a clear

transparency film

The summary of the key presses above to execute the Nozzle Check test print is: [Menu] [Enter]

[Forward] [Enter].

The printer will print a pattern which should resemble the picture below. Each horizontal line

represents the output from each of the nozzles. There will be an identical pattern printed directly

below this in white ink which will not be visible unless you print onto a clear sheet of film or thin

metal plate. As you can see from the picture each nozzle line is clear and horizontal with no gaps in

the staggered pattern and no two nozzle lines of the same colour being on the same horizontal line:

It is possible to perform nozzle test prints directly on to the platen surface as long as it is cleaned off

immediately afterwards. Nozzle prints done like this will allow the white output to be observed. It is

highly recommended to have the machine hood in the up position so that the LED lamps are

58

Page 67

Initial Setup & Basic Operations Compress iUV600s Series User Guide

deactivated. The nozzle check print will not cure in this case and can be cleaned using Isopropyl or

denatured alcohol.

59

Page 68

Compress iUV600s Series User Guide Initial Setup & Basic Operations

FIGURE 2-6 NOZZLE TEST PRINT - MISSING NOZZLES

FIGURE 2-7 NOZZLE TEST PRINT - MISPLACED NOZZLES

FIGURE 2-8 NOZZLE TEST PRINT - MISSING NOZZLE LINES

TIP

2.6.7 Examining a Nozzle Check Test Print

Compare the results of the nozzle Check Test Print to the pictures below. White ink is NOT shown

here.

This print shows missing nozzle line which indicates that there is either a blockage or an air pocket

preventing the individual nozzle(s) from ejecting any ink:

This print shows a misplaced (deflected) nozzle line which indicates that there is either a partial nozzle