Page 1

Page 1 of 28

INSTRUCTION MANUAL

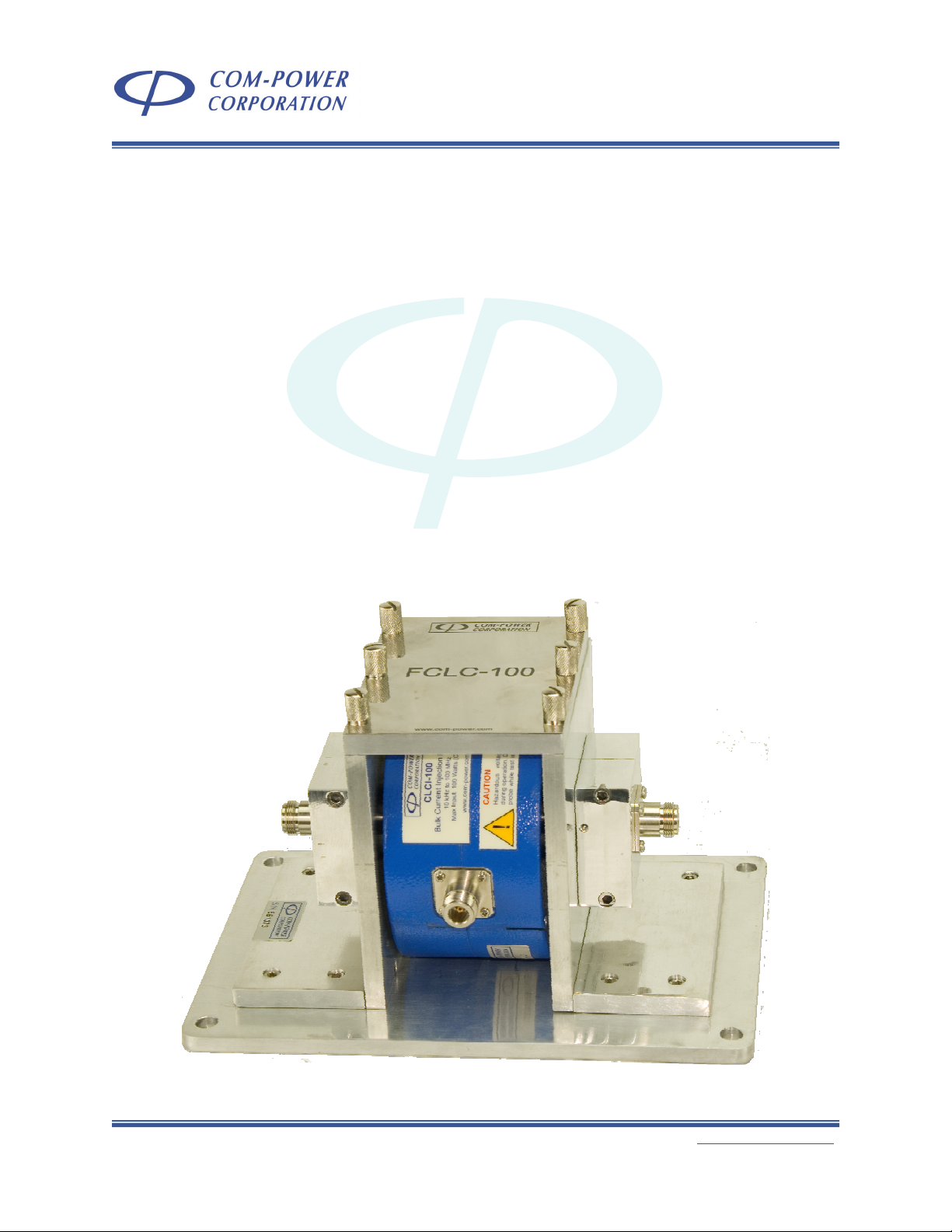

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

INSTRUCTION MANUAL

For

BULK CURRENT

INJECTION PROBE

Model: CLCI-100

and

CALIBRATION FIXTURE

Model: FCLC-100

(optional)

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 2

Page 2 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

Table of Contents

1.0 Introduction ........................................................................................................... 4

2.0 Products Available from Com-Power ................................................................. 5

3.0 Product Information .............................................................................................. 6

3.1 Incoming Inspection ....................................................................................................... 6

3.2 Package Inventory ......................................................................................................... 6

3.3 Product Safety Information ........................................................................................... 7

3.3.1 Product Hazard Symbols Definitions........................................................................................... 7

3.3.2 Product Warning/Caution Statements...................................................................................... 7

3.3.3 General Safety Instructions .......................................................................................................... 7

3.4 Product Features ............................................................................................................. 8

3.4.1 Description of CLCI-100 Bulk Current Injection Probe Features ............................................ 8

3.4.2 Description of FCLC-100 Calibration Fixture Features............................................................. 9

3.5 Product Specifications ................................................................................................. 10

3.5.1 Specifications for CLCI-100 Bulk Current Injection Probe..................................................... 10

3.5.2 Specifications for FCLC-100 Calibration Fixture ..................................................................... 10

3.6 Product Dimensional Diagrams .................................................................................. 11

3.6.1 Dimensions of CLCI-100 Bulk Current Injection Probe........................................................... 11

3.6.2 Dimensions of FCLC-100 Calibration Fixture ........................................................................... 12

4.0 Using the CLCI-100 Probe with the FCLC-100 Fixture....................................... 13

4.1 Installation of CLCI-100 Probe into FCLC-100 Fixture ............................................. 13

4.2 Insertion Loss/Coupling Factor Measurement.......................................................... 14

4.3 Transfer Impedance Factors .......................................................................................15

4.4 Conducted Immunity Test Level Calibration (IEC 61000-4-6) ................................ 16

4.4.1 Test Generator Equipment (Method A vs Method B) ........................................................... 16

4.4.2 Calibration-related Calculations .............................................................................................. 18

4.4.2.1 Test Level Calculations ............................................................................................................... 18

4.4.2.2 Test Level Offset Calculations ................................................................................................... 19

4.4.2.3 Test Frequency Calculations .....................................................................................................19

4.4.3 Equipment Setup ......................................................................................................................... 20

4.4.4 Level Setting Process................................................................................................................... 22

4.4.5 Amplifier Saturation Check........................................................................................................ 23

4.4.6 Running the Test .......................................................................................................................... 24

4.5 Conducted Susceptibility Test Level Calibration (50Ω System)............................. 26

5.0 Warranty............................................................................................................... 27

6.0 Typical CLCI-100 Calibration Data.................................................................... 28

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 3

Page 3 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

List of Figures

FIGURE 1 - CLCI-100 Bulk Current Injection Probe Features 8

FIGURE 2 - FCLC-100 Calibration Fixture Features 9

FIGURE 3 - Dimensional Diagram for CLCI-100 Bulk Current Injection Probe 11

FIGURE 4 - Dimensional Diagram for FCLC-100 Calibration Fixture 12

FIGURE 5 - Installation of CLCI-100 Probe into FCLC Calibration Fixture 13

FIGURE 6 - Setup for Insertion/Coupling Loss in a 50Ω System (100Ω Loop) 14

FIGURE 7 - Setup for Insertion/Coupling Loss in a 150Ω System (300Ω Loop) 14

FIGURE 8 - Equivalent Schematic of Calibration Circuit 15

FIGURE 9 - Examples of Test Generator Systems 16

FIGURE 10 - Setup for Calibration Accessories for 150Ω System 20

FIGURE 11 - IEC 61000-4-6 (Method A) Test Level Calibration Setup 20

FIGURE 12 - IEC 61000-4-6 (Method B) Test Level Calibration Setup 21

FIGURE 13 - IEC 61000-4-6 (Method A) Test Setup 24

FIGURE 14 - IEC 61000-4-6 (Method B) Test Setup 25

FIGURE 15 - Test Level Calibration into 50 ohm System 26

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 4

Page 4 of 28

1.0 Introduction

This manual includes descriptions of the CLCI-100 Bulk Current Injection Probe

connections, product specifications, safety precautions, operational instructions,

calibration instructions, measurement guidelines and warranty information.

Information contained in this manual is the property of Com-Power Corporation. It is

issued with the understanding that the material may not be reproduced or copied

without the express written permission of Com-Power.

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 5

Page 5 of 28

d

S

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

2.0 Products Available from Com-Power

Antennas

AntennaKits AbsorbingClamps

INSTRUCTION MANUAL

Coupling/Decoupling

Networks(CDN)

CombGenerators

ImpedanceStabilization

Networks(ISN)

Preamplifiers

TransientLimiters

CurrentProbes

LineImpedanceStabilization

Networks(LISN)

PowerAmplifiers

Turntables

EmissionsTest

Systems

AntennaMasts

pectrumAnalyzers

AntennaTripods

ConductedImmunity

TestSystems

Near‐Fiel

ProbeSets

ProductSafetyTest

Equipment

TelecomTest

Systems

www.com-power.com

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 6

Page 6 of 28

3.0 Product Information

3.1 Incoming Inspection

If there is any evidence of shipping damage. If shipping damage to the product

or any of its accessories is suspected, or if the package contents are not

complete, contact Com-Power or your Com-Power distributor.

Please check the contents of the shipment against the package inventory in

section 3.2 to ensure that you have received all applicable items.

3.2 Package Inventory

STANDARD ITEMS:

9

CLCI-100 Bulk Current Injection Probe

9 Calibration Certificate and Associated Data

OTIONAL ITEMS:

9

FCLC-100 Calibration Fixture

9 ADA-515-2 150Ω to 50Ω Adapter Set

9 ATTN-06-100W Power Attenuator (6 dB, 100W)

9 ATTN-30-100W Power Attenuator (30 dB, 100W)

9 TERM-100W Termination (50Ω)

9 DCD-1000-100W Dual Directional Coupler

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 7

Page 7 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.3 Product Safety Information

3.3.1 Product Hazard Symbols Definitions

The hazard symbols appearing on the product exterior are defined below.

The yellow triangle with an exclamation mark indicates the presence of

important operating and/or maintenance (servicing) instructions in the

literature accompanying the product.

3.3.2 Product Warning/Caution Statements

CAUTION: Hazardous voltages present during operation. Do not handle probe while test is in

progress.

3.3.3 General Safety Instructions

The following safety instructions have been included in compliance with safety standard

regulations. Please read them carefully.

• READ AND RETAIN INSTRUCTIONS - Read all safety and operating instructions before

operating the instrument. Retain all instructions for future reference.

• HEED WARNINGS - Adhere to all warnings on the instrument and operating instructions.

• FOLLOW INSTRUCTIONS - Follow all operating and use instructions.

• WATER AND MOISTURE - Do not use the instrument near water.

• WALL OR CEILING MOUNTING - Do not mount the instrument on a wall or ceiling.

• HEAT - The instrument should be situated away from heat sources such as heat registers or

other instruments which produce heat.

• POWER SOURCES - Connect the instrument only to the type of power source described in

the operating instructions or as marked on the instrument.

• POWER CORD PROTECTION - Place power supply cords so that they are not likely to be

walked on or pinched by items placed on them or against them.

• CLEANING – Clean the instrument only as recommended by the manufacturer.

• DEFECTS AND ABNORMAL STRESS - Whenever it is likely that the normal operation has been

impaired, make the equipment inoperable and secure it against further operation.

• DAMAGE REQUIRING SERVICE - Instrument should be serviced by qualified personnel when:

9 The power supply cord or the plug has been damaged.

9 Objects have fallen or liquid has been spilled into the instrument.

9 The instrument has been exposed to rain.

9 The instrument does not appear to operate normally.

9 The instrument has been dropped, or the enclosure has been damaged.

• SITTING OR CLIMBING - Do not sit or climb upon the instrument or use it as a step or ladder.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 8

Page 8 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.4 Product Features

3.4.1 Description of CLCI-100 Bulk Current Injection Probe Features

1

(clamp closed)

SIDE VIEW

CLCI-100

Bulk Current Injection Probe

10 kHz to 100 MHz

Max Input: 100 Watts (CW)

www.com-power.com

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

TOP VIEW

2

(clamp open)

3

1

4

1

2

3

3

4

3

3

4

FIGURE 1 - CLCI-100 Bulk Current Injection Probe Features

Input/Output Port

1

When used for bulk current injection, this is the input port of the probe. When used as a

measuring device, this is the probe’s output port. It is fitted with an N-type coaxial

connector.

Spring-loaded Clasps

2

These two (2) clasps, when secured over their respective brackets, lock the clamp into its

closed position

Clasp Brackets

3

These two (2) brackets anchor the respective clasp brackets in order to lock the clamp into

its closed position.

Clamp Window

4

This clamp window is aperture in the center of the clamp through which the wire(s),

cable(s) or cable bundle(s) to be tested are passed through.

2

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 9

Page 9 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.4.2 Description of FCLC-100 Calibration Fixture Features

4

5

4

3

2

1

3

3

4

FCLC-100

4

www.com-power.com

4

4

FIGURE 2 - FCLC-100 Calibration Fixture Features

Fixture Opening

1

The CLCI-100 is installed within this opening so that the center conductor rod of the fixture

passes through the approximate center of the probe aperture.

Center Conductor Rod

2

This is the fixture’s center conductor.

Calibration Fixture Coaxial Ports

3

These are female N-type coaxial connectors providing input/output connections to the

fixture.

Thumb Screws for Removable Top Plate

4

These (6) screws secure the fixture’s top plate to the fixture assembly.

Removable Top Plate of Fixture

5

In order to install/remove the clamp into/from the calibration fixture, the top plate must be

removed by removing the six (6) thumb screws. The top cover and thumb screws must be

replaced prior to the performance of tests.

3

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 10

Page 10 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.5 Product Specifications

3.5.1 Specifications for CLCI-100 Bulk Current Injection Probe

Technical

Transfer Impedance Factors see graph(s) located in Section 6

Product

Model

Frequency Range

Standard(s) IEC 61000-4-6, MIL-STD 461x, RTCA-DO-160x, etc

Impedance

Maximum Input Power

Bulk Current Injection Probe

CLCI-100

10 kHz to 100 MHz

50Ω (nominal)

100 Watts (continuous)

Mechanical

Coaxial RF Connector

Dimensions (H)x(W)x(L)

Probe Aperture Diameter

Weight

N-type (female)

5” x 2.75” x 5.78”

1.575”

(4 cm)

4.5 lbs (2.04 kg)

(12.75 x 7 x 14.7 cm)

Environmental

Operating Temperature

40°F to 104°F (5°C to 40°C)

3.5.2 Specifications for FCLC-100 Calibration Fixture

Technical

Product

Model

Frequency Range

Standard(s) IEC 61000-4-6, MIL-STD 461x, RTCA-DO-160x, etc

Impedance

VSWR

(empty fixture –

no probe installed)

Calibration Fixture

FCLC-100

10 kHz to 100 MHz

50Ω (nominal)

0.01-2.5 MHz

2.5-10 MHz

10-30 MHz

30-100 MHz ≤ 1.4 : 1

≤ 1.01 : 1

≤ 1.04 : 1

≤ 1.1 : 1

Mechanical

Coaxial RF Connectors

Dimensions (H)x(W)x(L)

Weight (empty fixture)

(2) N-type (female)

6.4” x 7” x 10”

(16.3 x 17.8 x 25.5 cm)

8 lbs. (3.63 kg)

Dimensional Accommodations for Current Probes

Max. Probe Diameter

Min. Probe Aperture Diameter

Max. Probe Width

5.63” (14.3 cm)

0.79” (2 cm)

2.83” (7.2 cm)

Environmental

Operating Temperature

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

40°F to 104°F (5°C to 40°C)

REV051917

Page 11

Page 11 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.6 Product Dimensional Diagrams

3.6.1 Dimensions of CLCI-100 Bulk Current Injection Probe

(7 cm)

(12.75 cm)

(W)

2.75”

(H)

5”

CLCI-100

Bulk Current Injection Probe

10 kHz to 100 MHz

Max Input: 100 Watts (CW)

www.com-power.com

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

TOP VIEW

SIDE VIEW

1.57”

(4 cm)

(L)

5.78”

(14.7 cm)

FIGURE 3 - Dimensional Diagram for CLCI-100 Bulk Current Injection Probe

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 12

Page 12 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

3.6.2 Dimensions of FCLC-100 Calibration Fixture

(W)

(17.8 cm)

7”

FCLC-100

(H)

6.4”

(16.3 cm)

www.com-power.com

TOP VIEW

SIDE VIEW

5”

(12.8 cm)

2.95”

(7.5 cm)

(L)

10”

(25.5 cm)

FIGURE 4 - Dimensional Diagram for FCLC-100 Calibration Fixture

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 13

Page 13 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.0 Using the CLCI-100 Probe with the FCLC-100 Fixture

Calibration fixtures provide a means by which current probes, including bulk current

injection (BCI) probes, can be calibrated to determine the transfer impedance,

insertion/coupling loss. Fixtures are also used to establish, or calibrate, power drive levels

into 50Ω or 150Ω systems for various conducted susceptibility/immunity tests performed

using BCI probes. These applications are discussed in more detail in the following

sections.

The FCLC-100 Fixture is specifically designed for use with the CLCI-100 BCI probe. The

intent of the fixture is to maintain the coaxial structure of the transmission line, while

allowing the probe to be installed around the center conductor of the coaxial line.

4.1 Installation of CLCI-100 Probe into FCLC-100 Fixture

Illustrated in Figure 5 is the procedure to be followed for installing the CLCI-100 BCI

Probe into the FCLC Calibration Fixture.

STEP 1

UNSCREW SIX (6)

THUMBSCREWS

ON TOP OF

FIXTURE AND

REMOVE

TOP PLATE

STEP 2

OPEN CLAMP

AS SHOWN ABOVE

AND LOWER

CLAMP INTO

CENTER OF

FIXTURE

STEP 3

ROTATE CLAMP

APPROX. 90

DEGREES, SO THAT

PROBE’S RF

CONNECTOR FACES

OUTWARD ON EITHER

OPEN SIDE OF

THE FIXTURE

STEP 4

CLOSE PROBE

AROUND FIXTURE

CENTER

CONDUCTOR,

HOOK BOTH

SPRING-LOADED

CLASPS ONTO

RESPECTIVE

BRACKETS AND

LOCK CLASPS

STEP 5

REPLACE TOP

PLATE OF

TEST

FIXTURE

STEP 6

REPLACE AND

TIGHTEN THE SIX (6)

THUMBSCREWS

FIGURE 5 - Installation of CLCI-100 Probe into FCLC Calibration Fixture

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 14

Page 14 of 28

C

00

kH

kHz

t

to

10

10

0M

0 M

H

Hz

put

(CW

)

com

po

er

com

ON

d

l

t

op

e

g

.

C

00

kH

kHz

t

to

10

10

0M

0 M

H

Hz

put

(CW

)

com

po

er

com

ON

d

l

t

op

e

g

.

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.2 Insertion Loss/Coupling Factor Measurement

Illustrated in Figures 6 and 7 are typical setups for the measurement of a current

probe’s insertion loss, also known as coupling factor. Figure 6 shows the setup for

a 50 ohm system (100 ohm loop); and Figure 7 shows the setup for a 150 ohm

system (300 ohm loop).

The insertion loss/coupling factor is essentially the difference between the voltage

present on the conductor(s) passing through the current probe aperture and the

voltage present at the output of the probe. These two quantities are depicted as

and V2, respectively, in Figure 8; where V2 - V1= Insertion Loss/Coupling Factor.

V

1

Network Analyzer

with

S-Parameter Capabilities

- or -

Spectrum Analyzer/EMI Receiver

with

Tracking Generator

- or -

Synthesized Signal Generator

and

Spectrum Analyzer/Receiver

RF

OUTPUT

RF

INPUT

Network Analyzer

with

S-Parameter Capabilities

- or -

Spectrum Analyzer/EMI Receiver

with

Tracking Generator

- or -

Synthesized Signal Generator

and

Spectrum Analyzer/Receiver

RF

OUTPUT

RF

INPUT

CLCI-100

10 kHz to 100 MHz

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

FRONT VIEW

TOP VIEW

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

ress

.

tages presen

w

eration. Do not handl

I-1

-

10 dB

10 dB

10 dB

GROUND PLANE

FCLC-100

: 100 Watts

L

CLCI-100

10 kHz to 100 MHz

www.com-power.com

www.

Max Input: 100 Watts (CW)

Max In

Bulk Current Injection Probe

Bulk Current Injection Probe

www.com-power.com

10 dB

ous vo

AUTI

ur

azar

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

probe while test is in pro

50Ω

NORMALIZATION CALIBRATION - 50Ω SYSTEM (100Ω LOOP)

FIGURE 6 - Setup for Insertion/Coupling Loss in a 50Ω System (100Ω Loop)

Network Analyzer

with

S-Parameter Capabilities

- or -

Spectrum Analyzer/EMI Receiver

with

Tracking Generator

- or -

Synthesized Signal Generator

and

Spectrum Analyzer/Receiver

RF

OUTPUT

RF

INPUT

10 dB

10 dB

Network Analyzer

with

S-Parameter Capabilities

- or -

Spectrum Analyzer/EMI Receiver

with

Tracking Generator

- or -

Synthesized Signal Generator

and

Spectrum Analyzer/Receiver

RF

OUTPUT

RF

INPUT

ADA-

10 dB

515-2

GROUND PLANE

CLCI-100

10 kHz to 100 MHz

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

FRONT VIEW

TOP VIEW

.

w

I-1

-

FCLC-100

: 100 Watts

L

CLCI-100

10 kHz to 100 MHz

www.com-power.com

www.

Max In

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

Bulk Current Injection Probe

www.com-power.com

10 dB

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

ress

tages presen

eration. Do not handl

ous vo

AUTI

ur

azar

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

probe while test is in pro

ADA515-2

50Ω

NORMALIZATION CALIBRATION -150Ω SYSTEM (300Ω LOOP)

FIGURE 7 - Setup for Insertion/Coupling Loss in a 150Ω System (300Ω Loop)

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 15

Page 15 of 28

V

1

I

P

V

2

Z

T

= Transfer Impedance (in dBΩ)Ω)

V

1

= RF voltage on the coaxial line (in dBμV)

V

2

= RF output voltage of the probe in (in dBμV)

I

P

= measured current (in dBμA)

34

= dB ratio between voltage and current in a 50

Ω system

= 20*log(50Ω)

where:

Z

TV2

I

P

= -

L

ins

= Insertion Loss/Coupling Loss (in dB)

34L

ins

Z

T

= +

V

1

V

2

L

ins

= -

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.3 Transfer Impedance Factors

When performing current measurements, the conductor(s) under test are passed

through the aperture of the current probe. The RF port of the current probe is

connected to the 50 ohm RF input of a spectrum analyzer or EMI receiver, where

a voltage value is measured.

The transfer impedance factor includes the loss of the probe (see section 4.2),

and also converts the measured voltage value to a current value corresponding

to the current flowing on the conductor(s) under test.

Illustrated in Figure 8 is a diagram of the equivalent calibration circuit, along with

the associated calculations.

50Ω

probe while test is in progress.

CAUTION

Hazardous voltages present

during operation. Do not handle

Bulk Current Injection Probe

Max Input: 100 Watts (CW)

www.com-power.com

10 kHz to 100 MHz

CLCI-100

50Ω

50Ω

ins

34

ins

where:

= Transfer Impedance (in dB

= Insertion Loss/Coupling Loss (in dB)

ins

= RF voltage on the coaxial line (in dBμV)

= RF output voltage of the probe in (in dBμV)

= dB ratio between voltage and current in a 50

34

= 20*log(50Ω)

= measured current (in dBμA)

FIGURE 8 - Equivalent Schematic of Calibration Circuit

Ω system

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 16

Page 16 of 28

INPUT

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4 Conducted Immunity Test Level Calibration (IEC 61000-4-6)

Calibration of test levels per IEC 61000-4-6 is performed with the CLCI-100 Bulk

Current Injection Probe installed in the FCLC-100 Calibration Fixture. The

calibration is performed into a 150 ohm system, rather than the standard 50 ohm

system employed by other standards, such as Mil-Std 461 and RTCA DO-160.

To realize a 150 ohm system, ADA-515-2 150Ω to 50Ω Adapters are installed on

either side of the test fixture.

4.4.1 Test Generator Equipment (Method A vs Method B)

Per the IEC 61000-4-6 standard, there are two acceptable procedures for

quantifying the Test Generator power when the appropriate test level is

measured during the calibration at any given frequency, so that the same

level can be reproduced during the actual testing process. For the

purposes of this procedure, we will refer to these as METHOD A (Signal

Generator Output Method) and METHOD B (Forward Power Method).

Illustrated in Figure 9 are example diagrams of the respective test

generator systems.

OUTPUT

RF POWER

METER

POWER

AMPLIFIER

INPUT OUTPUT

PWR SENSOR

6 dB Attenuator

to ...

RF Port

of BCI

Probe

SIGNAL

GENERATOR

OUTPUT

POWER

AMPLIFIER

INPUT OUTPUT

6 dB Attenuator

to ...

RF Port

of BCI

Probe

SIGNAL

GENERATOR

FIGURE 9a -

EXAMPLE OF TEST GENERATOR EQUIPMENT

METHOD A

(Signal Gen. Output Method)

FIGURE 9b -

EXAMPLE OF TEST GENERATOR EQUIPMENT

METHOD B

(Forward Power Method)

FIGURE 9 - Examples of Test Generator Systems

For each method, the RF power is injected into RF port of the bulk current

injection probe, and the amplitude is measured at the output of the 150Ω

to 50Ω Adapter (ADA-515-2) connected to one side of the test fixture

(through a power attenuator). For each test frequency, the amplitude of

the injected RF is adjusted incrementally until the measured amplitude

reaches the appropriate level (U

mr

).

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 17

Page 17 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

Method A: For method A, once the appropriate amplitude is

measured during calibration process, the signal

generator output level is recorded with respect to the

test frequency.

During the test, the signal generator output level at any

given test frequency is equal to the respective signal

generator output level recorded during the calibration.

Method B: For method B, once the appropriate amplitude is

measured during the calibration process, the forward

power of the test generator is recorded. The forward

power is measured with an RF power meter and power

sensor, typically connected to the forward port of a

directional coupler installed in series with the RF output

of the power amplifier.

During the test, the signal generator output level is

adjusted so that the forward power measured on the

power meter at any given frequency is equal to the

respective forward power level recorded during the

calibration.

In the following sections, instructions are included for both methods:

Instructions common for both METHOD A and METHOD B are shown in

BLACK text.

Any instructions which apply only for METHOD A are shown in GREEN text.

Any instructions which apply only for METHOD B are shown in BLUE text.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 18

Page 18 of 28

U

mr

=

U

o

6

(in linear quantities)

U

mr

=

U

o

(in logarithmic quantities)

- or - -

15.6 dB

U

mr-30dB

=

U

o

=

=

U

mr

=

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.2 Calibration-related Calculations

The following sets of calculations are indispensible to the proper

application of the calibration process. These calculations apply only to

calibrations performed per the IEC 61000-4-6 standard. Please refer to

the IEC 61000-4-6 standard for further information.

4.4.2.1 Test Level Calculations

Prior to the start of the calibration process, (Umr) must be

calculated. (U

output of the ADA-515-2 150Ω to 50Ω Adapter connected to

one side of the test fixture, and must not be confused with the

open circuit test level (U

Vrms, 10 Vrms, etc.) The relationship between (U

given below:

) represents the voltage to be measured at the

mr

) for the calibration (i.e.: 1 Vrms, 3

o

) and (Uo) is

mr

U

mr

(in linear quantities)

- or -

mr

15.6 dB

(in logarithmic quantities)

So, for instance, if calibration is being performed for a test level

of 10 Vrms:

Open Circuit Test Level

U

10 V

rms

dBμV140

Voltage at Output of 150Ω to 50Ω Adapter

=

U

(U

mr

U

- 15.6 dB)

o

o

/6)

mr

1.67 V

dBμV124.5

rms

=

(U

mr

Due to the fact that, in our example, there is a 30 dB attenuator

between the output of the 150Ω to 50Ω Adapter and the input

of the spectrum analyzer, the (U

) value must also be

mr

corrected for the attenuation.

Voltage at Output of 30 dB Attenuator

Connected to 150Ω to 50Ω Adapter

0.053 V

mr-30dB

rms

(U

dBμV94.5

mr-30dB

=

U

mr

- 30 dB)

NOTE: Attenuators other than 30 dB may also be used, assuming

that any corrections will be adjusted accordingly.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 19

Page 19 of 28

TEST

FREQUENCY

STEP SIZE

TEST

FREQUENCY

STEP SIZE

TEST

FREQUENCY

STEP SIZE

TEST

FREQUENCY

STEP SIZE

TEST

FREQUENCY

STEP SIZE

(MHz) (kHz) (MHz) (kHz) (MHz) (kHz) (MHz) (kHz) (MHz) (kHz)

1 0.15 1.5 11 0.165693319 1.656933188 21 0.183028506 1.83028506 31 0.202177337 2.021773373 41 0.22332956 2.2332956

2 0.1515 1.515 12 0.167350252 1.67350252 22 0.184858791 1.848587911 32 0.204199111 2.041991107 42 0.225562856 2.255628556

3 0.153015 1.53015 13 0.169023755 1.690237545 23 0.186707379 1.86707379 33 0.206241102 2.062411018 43 0.227818484 2.278184842

4 0.15454515 1.5454515 14 0.170713992 1.707139921 24 0.188574453 1.885744528 34 0.208303513 2.083035128 44 0.230096669 2.30096669

5 0.156090602 1.560906015 15 0.172421132 1.72421132 25 0.190460197 1.904601973 35 0.210386548 2.103865479 45 0.232397636 2.323976357

6 0.157651508 1.576515075 16 0.174145343 1.741453433 26 0.192364799 1.923647993 36 0.212490413 2.124904134 46 0.234721612 2.347216121

7 0.159228023 1.592280226 17 0.175886797 1.758867967 27 0.194288447 1.942884472 37 0.214615318 2.146153175 47 0.237068828 2.370688282

8 0.160820303 1.608203028 18 0.177645665 1.776456647 28 0.196231332 1.962313317 38 0.216761471 2.167614707 48 0.239439516 2.394395165

9 0.162428506 1.624285058 19 0.179422121 1.794221214 29 0.198193645 1.98193645 39 0.218929085 2.189290854 49 0.241833912 2.418339117

10 0.164052791 1.640527909 20 0.181216343 1.812163426 30 0.200175581 2.001755815 40 0.221118376 2.211183763 50 0.244252251 2.442522508

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.2.2 Test Level Offset Calculations

If the CLCI-100 Bulk Current Injection Probe will be used for

multiple test levels (1 Vrms, 3 Vrms, 10 Vrms, etc.), calibration

should be performed at the highest test level. Calibration data

for the lower test levels can then be calculated as shown

below:

U

offset

(in dB)

=

20*log

where:

U

U

The offset factor calculated above can then be applied to the

calibration data as shown below:

SGout

calc

calc

FWDpwr

FWDpwr

(in dBxx)

(in dBm)

SGout

SGout

FWDpwr

where:

U

(

U

calc

=

calibration test level

cal

=

calculated test level

calc

=

=

=

calc

=

cal

=

calc

=

cal

cal

(in Vrms)

(in Vrms)

SGout

FWDpwr

calculated signal generator output for lower test level

signal generator output determined during calibration at highest test level

calculated forward power for lower test level

forward power measured during calibration at highest test level

)

cal

cal

- or -

(in dBxx)

(in dBm)

-

U

U

-

offset

OFFSET

U

(in dB)

OFFSET

=

(in dB)

(in dB)

(in dB)

U

-

calc

(in dB)

U

cal

4.4.2.3 Test Frequency Calculations

The frequency range of the test is, in most cases, 150 kHz to 80

MHz; and, in some cases, 150 kHz to 230 MHz. The calibration

and test is performed at discrete, logarithmically spaced

frequencies (as opposed to a frequency sweep). The

logarithmic spacing of the test frequencies means that the

actual step size increases after each step. The maximum step

size at any given frequency is equal to 1% of the present

frequency. Below is a truncated example of the test

frequencies, showing the respective step sizes.

Step Size = Present Frequency * 0.01

Next Test Frequency = Present Frequency + (Present Frequency * 0.01)

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 20

Page 20 of 28

C

00

jec

i

e

t

to

10

10

0M

0 M

H

Hz

put

com

po

er

com

ON

d

l

t

.

C

00

jec

i

t

to

10

10

0M

0 M

H

Hz

(

)

com

po

er

com

U

ON

d

l

e

.

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.3 Equipment Setup

On a conductive ground plane, connect the FCLC-100 Calibration Fixture

with the CLCI-100 Bulk Current Injection Probe installed to the Calibration

Accessories, Adapters and Attenuators as shown in Figures 10. The

bottom surface of test fixture should be flush against the top surface of the

ground plane, and should either be: bolted directly to the ground plane

(through their respective mounting holes); or should be bonded to the

ground plane using copper tape with conducted adhesive (3M #1181 HD

recommended).

ADA515-2

GROUND PLANE

.

on Prob

t

w

I-1

-

FCLC-100

: 100 Watts

L

CLCI-100

10 kHz to 100 MHz

www.com-power.com

www.

ax In

ulk Current In

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

www.com-power.com

tages presen

ous vo

AUTI

uring operation. Do not handle

azar

robe while test is in progress

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

ADA515-2

FIGURE 10 - Setup for Calibration Accessories for 150Ω System

As shown in Figure 11 (for METHOD A); or, as shown in Figure 12 (for

METHOD B), as appropriate, complete the calibration setup.

CLCI-100

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

10 kHz to 100 MHz

SPECTRUM

ANALYZER/

EMI RECEIVER

INPUT

SIGNAL

GENERATOR

OUTPUT

POWER

AMPLIFIER

INPUT OUTPUT

30 dB Attenuator

ADA515-2

GROUND PLANE

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

FRONT VIEW

CW

.

tages present

on Probe

t

w

TI

I-1

-

ous vo

FCLC-100

L

A

uring operation. Do not handl

azar

CLCI-100

CAUTION

Hazardous voltages present

during operation. Do not handle

10 kHz to 100 MHz

www.com-power.com

www.

Max Input: 100 Watts

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

Bulk Current In

www.com-power.com

6 dB Attenuator

probe while test is in progress.

probe while test is in progress

ADA515-2

50Ω Termination30 dB Attenuator

50Ω Termination

FIGURE 11 - IEC 61000-4-6 (Method A) Test Level Calibration Setup

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 21

Page 21 of 28

C

00

jec

i

e

kH

kHz

t

to

10

10

0M

0 M

H

Hz

(

)

p

m

d

l

ges

pr

ing

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

CLCI-100

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

10 kHz to 100 MHz

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

SPECTRUM

ANALYZER/

EMI RECEIVER

INPUT

30 dB Attenuator

ADA515-2

GROUND PLANE

FRONT VIEW

CW

on Prob

t

ower.co

I-1

FCLC-100

L

CLCI-100

ww.com-

10 kHz to 100 MHz

www.com-power.com

ax Input: 100 Watts

ulk Current In

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

www.com-power.com

esent

N

ta

ous vo

operation. Do not handle

CAUTION

Hazardous voltages present

during operation. Do not handle

Hazar

dur

robe while test is in progress.

probe while test is in progress.

ADA515-2

50Ω Termination

SIGNAL

GENERATOR

POWER

AMPLIFIER

6 dB Attenuator

INPUT OUTPUT

OUTPUT

PWR SENSOR

FIGURE 12 - IEC 61000-4-6 (Method B) Test Level Calibration Setup

RF POWER

METER

INPUT

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 22

Page 22 of 28

TEST

FREQ

(fx)

SIGNAL

GEN

OUTPUT

SGout

TEST

FREQ

(fx)

FORWARD

POWER

FWDpwr

(MHz) (dBxx) (MHz) (dBxx)

1 0.15 xx.xx 1 0.15 xx.xx

2 0.1515 xx.xx 2 0.1515 xx.xx

3 0.153015 xx.xx 3 0.153015 xx.xx

633 or 739 80 or 230 xx.xx 633 or 739 80 or 230 xx.xx

#

#

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.4 Level Setting Process

1) With the calibration test setup configured as shown in Figure 11 or

Figure 12, set the frequency of the signal generator to 150 kHz (without

modulation).

2) WITHOUT exceeding [the 1 dB gain compression point of the power

amplifier minus 5.1 dB], adjust the amplitude setting of the signal

generator until the amplitude measured on the spectrum analyzer is

equal to the (U

test level (U

) for which calibration is being performed (see section

o

4.4.2.1).

3) Record either:

(a) the frequency (fx) and amplitude setting of the signal generator

(SGout)

-or-

(b) the frequency (fx) and forward power measured using the power

meter/sensor (FWDpwr).

See examples of calibration data

tables on the right.

) value (±1.5 dB) calculated for the open circuit

mr-30dB

CALIBRATION DATA TABLE EXAMPLES

4) Increase the frequency by a maximum of 1% of the present frequency

(see section 4.4.2.3).

5) Repeat steps (2) through (4) until the next frequency in the sequence

would exceed the highest frequency of the test. For tests up to 80

MHz, there should be at least 633 test frequencies; and for tests up to

230 MHz, there should be at least 739 test frequencies.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 23

Page 23 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.5 Amplifier Saturation Check

1) With the calibration test setup configured as shown in Figure 11 or

Figure 12, set the frequency of the signal generator to 150 kHz (without

modulation).

2) Adjust the signal generator output to either:

a) the respective SGout value determined during calibration for the

present test frequency;

-or-

b) the level at which the power indicated by the power meter is

equal to the respective FWDpwr value determined during

calibration for the present test frequency.

3) Record the amplitude measured on the spectrum analyzer as (U

mr

).

4) Increase the signal generator output by 5.1 dB, and record the

amplitude measured on the spectrum analyzer as (U

difference between (U

) and U

mr

) must be between 3.1 dB and 7.1

mr(inc)

mr(inc)

). The

dB.

5) Increase the frequency of the signal generator to the next test

frequency.

6) Repeat steps (2) through (5) until the next frequency in the sequence

would exceed the highest frequency of the test.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 24

Page 24 of 28

I

max

=

U

o

150Ω

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.4.6 Running the Test

Examples of the test setup are shown in Figure 13 (for METHOD A) and

Figure 14 (for METHOD B).

The same Test Generator equipment used for the calibration is used to

inject the RF energy onto the EUT lines under test via the CLCI-100 Bulk

Current Injection probe. The calibration data table is used to set the

signal generator output at any given frequency to either:

a) the respective SGout value determined during calibration for the

present test frequency; or,

-or-

b) the level at which the power indicated by the power meter is

equal to the respective FWDpwr value determined during

calibration for the present test frequency.

Typically, the test is performed from the lowest test frequency to the

highest test frequency, one test frequency at a time, with a one to three

second dwell time at each test frequency. The RF carrier is typically 80%

amplitude modulated with a 1 kHz sine wave.

As the calibration is performed into a 150 ohm system, and the

impedance of the line(s) under test is largely uncontrolled, the injected

current must be monitored during the test using a current monitoring

device to ensure that the current does not exceed the (I

max

) limit:

I

max

150Ω

AUXILIARY

EQUIPMENT

(AE)

SIGNAL

GENERATOR

OUTPUT

POWER

AMPLIFIER

INPUT OUTPUT

GROUND PLANE

CLCI-100

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

10 kHz to 100 MHz

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

6 dB Attenuator

CLCE-400

10 kHz to 400 MHz

www.com-power.com

RF CURRENT PROBE

EQUIPMENT

UNDER

TEST (EUT)

SPECTRUM

ANALYZER/

EMI RECEIVER

INPUT

FIGURE 13 - IEC 61000-4-6 (Method A) Test Setup

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 25

Page 25 of 28

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

AUXILIARY

EQUIPMENT

(AE)

CLCI-100

Bulk Current Injection Probe

10 kHz to 100 MHz

Max Input: 100 Watts (CW)

www.com-power.com

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

CLCE-400

10 kHz to 400 MHz

www.com-power.com

RF CURRENT PROBE

EQUIPMENT

UNDER

TEST (EUT)

SIGNAL

GENERATOR

POWER

AMPLIFIER

GROUND PLANE

SPECTRUM

ANALYZER/

EMI RECEIVER

6 dB Attenuator

INPUT

INPUT OUTPUT

OUTPUT

PWR SENSOR

RF POWER

METER

INPUT

FIGURE 14 - IEC 61000-4-6 (Method B) Test Setup

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 26

Page 26 of 28

C

00

j

i

e

kH

kHz

t

to

10

10

0M

0 M

H

Hz

(

)

p

m

d

l

g

g

i

i

i

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

4.5 Conducted Susceptibility Test Level Calibration (50Ω System)

Illustrated in Figure 15 is a typical test setup for test level calibrations performed

into a 50 ohm system. This calibration is typically employed for tests according to

Mil-Std 461, RTCA DO-160, and other standards.

Please refer to the applicable standards for guidance on the performance of

these calibrations/tests.

CLCI-100

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

10 kHz to 100 MHz

www.com-power.com

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

SPECTRUM

ANALYZER/

EMI RECEIVER

#1

INPUT

SIGNAL

GENERATOR

OUTPUT

FIGURE 15 - Test Level Calibration into 50 ohm System

POWER

AMPLIFIER

INPUT OUTPUT

FRONT VIEW

n progress.

CW

es present

s

ta

on Prob

le test

ower.co

ect

I-1

ous vo

operation. Do not handle

30 dB Attenuator 50Ω Termination

FCLC-100

L

CLCI-100

ww.com-

10 kHz to 100 MHz

www.com-power.com

ax Input: 100 Watts

ulk Current In

Max Input: 100 Watts (CW)

Bulk Current Injection Probe

www.com-power.com

robe wh

CAUTION

Hazardous voltages present

during operation. Do not handle

probe while test is in progress.

CAUTION

Hazar

durin

GROUND PLANE

SPECTRUM

ANALYZER/

EMI RECEIVER

#2

INPUT

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 27

Page 27 of 28

5.0 Warranty

Com-Power warrants to its Customers that the products it manufactures will be free from

defects in materials and workmanship for a period of three (3) years. This warranty shall

not apply to:

Transport damages during shipment from your plant.

•

Damages due to poor packaging.

•

Products operated outside their specifications.

•

Products Improperly maintained or modified.

•

Consumable items such as fuses, power cords, cables, etc.

•

Normal wear

•

Calibration

•

Products transported outside the United States without the prior

•

knowledge of Com-Power.

INSTRUCTION MANUAL

CLCI-100 BULK CURRENT INJECTION PROBE

with FCLC-100 CALIBRATION FIXTURE

In addition, Com-Power shall not be obliged to provide service under this warranty to

repair damage resulting from attempts to install, repair, service or modify the instrument

by personnel other than Com-Power service representatives.

Under no circumstances does Com-Power recognize or assume liability for any loss,

damage or expense arising, either directly or indirectly, from the use or handling of this

product, or any inability to use this product separately or in combination with any other

equipment.

When requesting warranty services, it is recommended that the original packaging

material be used for shipping. Damage due to improper packaging will void warranty.

In the case of repair or complaint, Please visit our website www.com-power.com and fill

out the RMA form (http://com-power.com/repairservicereq.asp). Our technical

assistance personnel will contact you with RMA number. The RMA number should be

displayed in a prominent location on the packaging and on the product, along with a

description of the problem, and your contact information.

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Page 28

Page 28 of 28

Typical Insertion Loss Values / Transfer Impedance Factors

Meter Reading (dBuV) - Transfer Impedance Factor (dBΩ) = Current Reading (dBuA)

0

5

10

15

20

25

30

35

0.01 0.1 1 10 100

Frequency (MHz)

Insertion Loss (dB)

-1

4

9

14

19

24

29

34

Transfer Impedance

Factor (dBΩ)

CLCI-100 BULK CURRENT INJECTION PROBE

6.0 Typical CLCI-100 Calibration Data

INSTRUCTION MANUAL

with FCLC-100 CALIBRATION FIXTURE

19121 El Toro Rd ● Silverado, California 92676 ● (949) 459-9600 ● com-power.com

REV051917

Loading...

Loading...