Page 1

CAFETERIA COMPONENTS

®

Page 2

ALPHABETICAL INDEX

DESCRIPTION PAGE

A

AIR MIXING VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . .F19

AIR MIXING PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . .F19

B

BOTTLE OPENER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F12

BRACKETS

FIXED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F2

FOLD DOWN . . . . . . . . . . . . . . . . . . . . . . . . . .F3

LID COVER . . . . . . . . . . . . . . . . . . . . . . . . . . .F11

PROTECTOR . . . . . . . . . . . . . . . . . . . . . . . . . .F6

REMOVABLE . . . . . . . . . . . . . . . . . . . . . . . . . .F3

SNEEZE GUARD . . . . . . . . . . . . . . . . . . . . . . .F6

TRAY SLIDE . . . . . . . . . . . . . . . . . . . . . .F2,F3,F4

BURNERS

LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F16

MUSHROOM . . . . . . . . . . . . . . . . . . . . . . . . . .F16

REMOVABLE HEAD . . . . . . . . . . . . . . . . . . . .F16

RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F17

SADDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F16

BUSHINGS, KNURLED . . . . . . . . . . . . . . . . . .F9

C

CAP STRIPS & DIVIDER BARS . . . . . . . . . . . . . . . . . .F14

CHANNEL, DOUBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . .F7

CLAMP, GLASS FOR ROUND TUBING . . . . . . . . . . . . .F7

CONTROL PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .F24

CONVEYOR COMPONENTS . . . . . . . . . . . . . . . .F20, F21

CUP DISPENSERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F5

D

DRIP PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F10

E

ELBOWS, TUBULAR . . . . . . . . . . . . . . . . . . . . . . . . .F4, F8

ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . .F24

END CAPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F4, F11

ESCUTCHEON PLATE . . . . . . . . . . . . . . . . . . . . . . . . . .F9

EXPANDING FASTENERS . . . . . . . . . . . . . . . . . . . . . . .F9

F

FASTENERS, EXPANDING . . . . . . . . . . . . . . . . . . . . . . .F9

FIXTURES, SHOWCASE . . . . . . . . . . . . . . . . . . .F22, F23

FLANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F9

G

GAS BURNER COMPONENTS . . . . . . . . . . . . . . .F18, F19

GAS BURNERS . . . . . . . . . . . . . . . . . . . . . . . .F16 thru F19

GLASS CAPPINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F7

GLASS CLAMP FOR ROUND TUBING . . . . . . . . . . . . . .F7

DESCRIPTION PAGE

H

HOOKS, POT RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . .F8

HOLE PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F11

I

ICE SCOOP/BRACKET . . . .. . . . . . . . . . . . . . . . . . . . .F12

IN-LINE LIGHT CONNECTORS . . . . . . . . . . . . . . . . . . .F22

INSERTS, CORNER . . . . . . . . . . . . . . . . . . . . . . . . . . .F13

J

JET BURNER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . .F18

JET BURNER COMPONENTS . . . . . . . . . . . . . . . . . . .F19

L

LID COVER BRACKET ASSEMBLY . . . . . . . . . . . . . . .F11

LIGHTING COMPONENTS . . . . . . . . . . . . . . . . . .F22, F23

LIQUID WASTE DUMP . . . . . . . . . . . . . . . . . . . . . . . . .F12

M

MOULDINGS & DIVIDERS . . . . . . . . . . . . . . . . . . . . . .F15

P

PEDESTAL HOUSINGS . . . . . . . . . . . . . . . . . . . . . . . . .F24

PILOT LIGHT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . .F18

POT RACK COMPONENTS . . . . . . . . . . . . . . . . . . . . . .F8

PROTECTOR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . .F6

R

RECESSED HOUSINGS . . . . . . . . . . . . . . . . . . . . . . . .F24

RECEPTACLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F24

RECEPTACLE PLATES . . . . . . . . . . . . . . . . . . . . . . . . .F24

RINGS, FINISHING . . . . . . . . . . . . . . . . . . . . . . . . . . . .F10

ROLLER ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . .F21

ROLLER COMPONENTS . . . . . . . . . . . . . . . . . . .F20, F21

S

SCRAP BLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F12

SCRAP CHUTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F12

SHOWCASE FIXTURES . . . . . . . . . . . . . . . . . . . . . . . .F22

SINK CORNER INSERTS . . . . . . . . . . . . . . . . . . . . . . .F14

SLIM LINE FLUORSCENT LIGHT . . . . . . . . . . . . . . . . F23

SNEEZE GUARD COMPONENTS . . . . . . . . . . . . . . . . .F6

SUPPORTS, TUBULAR . . . . . . . . . . . . . . . . . . . . . . .F8, F9

SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F24

T

TRAY SLIDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F2

TRAY SLIDE COMPONENTS . . . . . . . . . . . . . . . . . .F2, F4

TUBING COMPONENTS . . . . . . . . . . . . . . . . . . . . . .F8, F9

U

U-BENDS, TUBULAR . . . . . . . . . . . . . . . . . . . . . . . . . . . .F4

© COPYRIGHT 2009, COMPONENT HARDWARE GROUP, INC.

#CAT-X026 05/09–3M PRINTED IN THE U.S.A.

NUMERICAL INDEX INSIDE BACK COVER

Page 3

tray slide and shelf brackets

®

COMPONENT

®

COMPONENT

A

B

TM

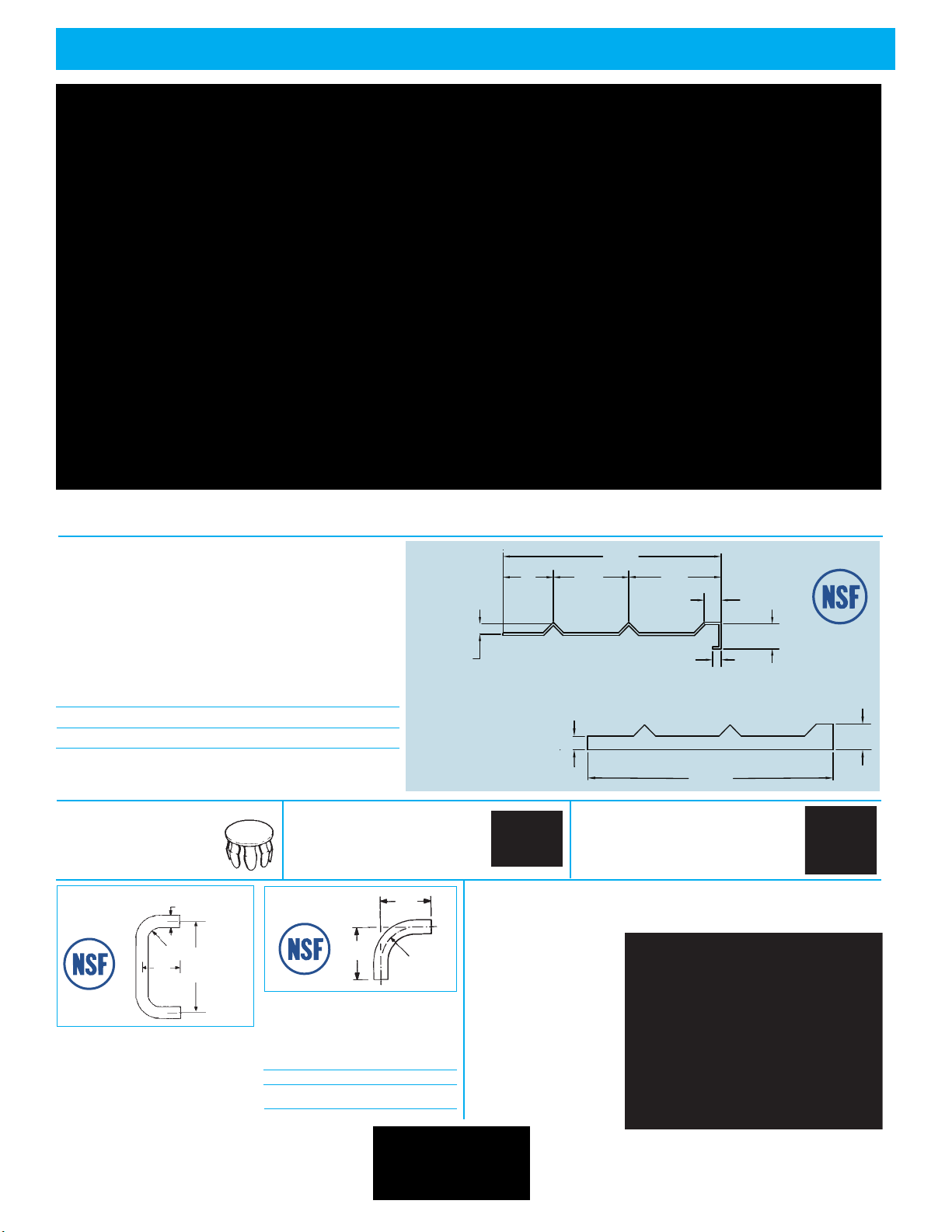

TRAY SLIDE and SHELF BRACKETS

REF. A

1-7/16”

(36mm)

3/8”

(10mm)

MODEL NO. “X” “Y” “Z”

J19-4960 4” (102mm) 4” (102mm) 4” (102mm)

J19-4962 4” (102mm) 4-1/2” (114mm) 4-1/2” (114mm)

REF. B

1-7/16”

(36mm)

STAINLESS STEEL

3-RAIL TRAY SLIDE BRACKET

“X”

4-1/4”

3-1/2”

(108mm)

(89mm)

MTG. HOLES 3/8” (10mm)

FOR SUPPORT OF 1” (25mm) O.D. RAILS

“Y”

SADDLE

MODEL NO. J19-4964

STAINLESS STEEL

4-RAIL TRAY SLIDE BRACKET

4”

(102mm)

3”

(76mm)

3”

(76mm)

“Z”

3”

(76mm)

REF. C

REF. D

7/8”

(22mm)

C

D

MODEL NO. J19-4960-LT

STAINLESS STEEL TRAY SLIDE BRACKET

WITHOUT SADDLES

1-7/16” (36mm)

3/8”(10mm)

4-1/4”

3-1/2”

(107mm)

(89 mm)

MTG. HOLES 1/4”(6.3mm)

12-1/2”

(317mm)

MODEL NO. J19-4966

STAINLESS STEEL FIXED SHELF BRACKET

(25mm)

1-1/4”

(32mm)

1”

2-1/2”

(63mm)

2-1/2”

(63mm)

MTG. HOLES 3/16”(5mm) DIA.

10-1/2” (267mm)

3-3/8”

(86mm)

3/4”

(19mm)

1-1/4”

(32mm)

MTG.

HOLES

3/8” (10mm)

F2

3-1/2”

(89mm)

(108mm)

3/8”

(10mm)

4-1/4”

3”

(76mm)

1-7/16”

(37mm)

4-7/16”

(113mm)

MTG. HOLES 1/4” (6mm)

ALL BRACKETS SHOWN ARE 8 GAUGE (.170” - 4.5mm), 300 SERIES, STAINLESS STEEL POLISHED TO A #4 SATIN FINISH

www.chg usa.c om

MTG. HOLES 1/4” (6mm) DIA.

Page 4

fold down / removable shelf brackets

®

COMPONENT

8-5/8” (219mm)

2-1/2” (63.5mm)

2-1/2” (63.5mm)

1” (25mm)

1/4” (6mm)

1/4” (6mm)

7”

(178mm)

11/64” (4.4mm)

1-1/4” (32mm)

1” (25mm)

1-1/2”

(38mm)

3-3/8”

(86mm)

2-1/2”

(63.5mm)

7/16”

(11mm)

3/16” R (4.8mm)

3/16” (4.8mm)

DIA. HOLE

(3) PLACES

1/16” (1.6mm)

7/64” (2.8mm)

1/4” x 3/8” (6.3mm x 9.5mm) SLOTTED MOUNTING HOLES (3) PLACES

E

A

B

C

B

D

TM

FOLD DOWN / REMOVABLE SHELF BRACKETS

REF. A

3-1/2”

(89mm)

REF. B

HEAVY DUTY

FOLDING

REMOVABLE

SHELF BRACKET

n

FOLDS DOWN WHEN

NOT IN USE

n

SHELVES EASILY

REMOVED

FOR CLEANING

MODEL NO. DESCRIPTION

J17-4270

J17-4273

STAINLESS STEEL FOLD DOWN

REMOVABLE SHELF BRACKET

n

SATIN FINISHnHEAVY DUTY

MODEL NO. J19-5000*

*SOLD AS A PAIR, KEYHOLE BASE WITH BRACKET

AND STRAIGHT PIN BASE WITH BRACKET

MATERIAL: 300 SERIES STAINLESS STEEL WITH A #4 FINISH

(190mm)

1-1/2”(38mm)

(156mm)

CHROME PLATED DIE CAST BRACKET

with 14 GA. (1.9mm) ZINC PLATED STEEL MOUNT

CHROME PLATED DIE CAST BRACKET

with 300 SERIES STAINLESS STEEL MOUNT

7-1/2”

6-1/8”

2-1/2”

(63mm)

REAR VIEW

7”

(178mm)

1/4” (6mm) DIA.

MTG. HOLES

1”

(25mm)

MTG. HOLES 1/4” x 3/8”

(6 x 10mm)

TO FOLD...

LIFT and FOLD.

TO REMOVE...

LIFT and FOLD,

SLIDE LEFT

and REMOVE.

1-3/4” (45mm)

1/2” (12mm)

3-15/16”

(100mm)

1-1/8” (29mm)

REAR VIEW

TO FOLD...

SLIDE

FORWARD

and FOLD DOWN

TO REMOVE...

SIMPLY LIFT UP

REF. C

MODEL NO. J19-4955

STAINLESS STEEL FOLD DOWN

3-RAIL TRAY SLIDE BRACKET

REF. D

1-1/2”

(38mm)

1”

(25mm)

2-1/2”

(63mm)

7/16”

(11mm)

ALSO AVAILABLE WITHOUT SADDLES...ORDER AS J19-4955-LT

(25mm)

FOR SUPPORT OF 1”(25mm) O.D. RAILS

1”

3-3/8”

(86mm)

4-1/8”

(105mm)

4”

(102mm)

MTG. HOLES

1/4” x 3/8” (6.3 x 10mm)

MODEL NO. J19-4967

4”

(102mm)

STAINLESS STEEL

FOLD DOWN SHELF BRACKET

REF. E

MODEL NO. J18-2000

HEAVY DUTY ZINC PLATED STEEL CONSTRUCTION

FOLD DOWN SHELF BRACKET

www.chg usa.c om

1-1/8”

(28mm)

3-3/32”

(79mm)

1/4”

(6.7mm)

1-3/64”

(28mm)

7/32”

(5.5mm)

5/16”

(7.9mm)

(51mm)

1-1/2”

(38mm)

2”

5-3/26”

(132mm)

3”

(76mm)

7-1/2”

(190mm)

SADDLE

F3

Page 5

tray slide components

53/64”

(.828mm)

15”

(381mm)

1-1/2”

(38mm)

®

COMPONENT

®

COMPONENT

®

COMPONENT

4-1/2”

(114mm)

5-1/2”

(140mm)

13”

(330mm)

3”

(76mm)

1/2”

(12.7mm)

1-1/2”

(38mm)

1”

(25.4mm)

5/8”

(15.9mm)

E

C

G

D

TM

A

B

H

F

H

TRAY SLIDE COMPONENTS

STAINLESS STEEL • ROLL FORMED

CONTINUOUS TRAY SLIDE

AVAILABLE IN 14 (1.9mm) AND 16 (1.5mm) GAUGE

DESIGNED TO PERMIT FABRICATOR TO SUIT

CONTINUOUS...PERFECT ALIGNMENT

MODEL NO. GAUGE LENGTH PKG.

J12-1400 14 GA. (1.9mm) 10 FT. (3000mm) 2/CTN

NOTE: OTHER LENGTHS AVAILABLE ON APPLICATION WITH QUANTITY ORDERS

REF. D

NICKEL PLATED STEEL

END CAP

FOR 1” (25mm) O.D. TUBING

MODEL NO. J16-0201

REF. G REF. H

16 GAUGE (1.5 mm) STAINLESS STEEL

“U” BENDS

FOR 1” (25mm) O.D. TUBING

DESIGNED FOR TRAY SLIDE RAILS

MODEL NO. J13-4488*

*CAN BE USED WITH NO.ʼs

J19-4960 & J19-4955

3 RAIL TRAY SLIDE BRACKETS

F4

STAINLESS STEEL

SPECIFIC JOB APPLICATIONS

SATIN POLISHED FINISH

REF. E

1” O.D. (25mm)

1-1/2”R

(38mm)

8”

4”

(203mm)

(100mm)

FOR 1”(25mm) & 1-5/8”(41mm) TUBING

DESIGNED FOR RAILS, SUPPORTS, ETC.

MODEL NO. O.D. A B C

J14-0117

J14-0119

NICKEL PLATED STEEL

FOR 1-5/8” (41mm) O.D. TUBING

MODEL NO. J16-0158

STAINLESS STEEL

90° ELBOWS

16 GA. (1.5mm)

1”

(25mm)

1-5/8”

(41mm)

END CAP

B

A

4”

4”

(100mm)

(100mm)

10”

10”

(254mm)

(254mm)

REF. A

*SPECIFICALLY DESIGNED WITH 5-1/4”(133mm) STRAIGHT PORTION TO

PERMIT FABRICATOR TO MODIFY ACCORDING TO INDIVIDUAL MOUNTING.

MODEL NO. J12-0001

STAINLESS STEEL

END PLATE

14 GA.(1.9mm) POLISHED

STAINLESS STEEL FINISH

REF. B

REF. F

SOLID STAINLESS STEEL

END CAP

STAINLESS STEEL

C

ECO

POLI

FINISH

PRO

TO PREVENT TRAY SLIDE

SAG

PRE-D

HOLES FOR FAST

1-1/2”R

(38mm)

4-5/8”R

(117mm)

www.chg usa.c om

CONVENIENT INSTALLATION

IDEA

CONTINUOUS TRAY SLIDE

HEAVY 14 GAUGE

TYPE 304

BRACKET

MODEL NO.

J19-1400

NOMICAL

SHED TO A #4 SATIN

VIDED WITH 91° ANGLE

RILLED MOUNTING

L FOR USE WITH

FOR 1” (25mm) O.D. 18 GA. (1.2mm) TUBING

(WELD APPLICATION)

MODEL NO. J16-0100

REF. C

5/8”

(15.9mm)

5/16”

(8mm)

6-1/8”

(15.5mm)

4-1/4” (108mm) 4-1/4” (108mm)

1-3/4”

(15.5mm)

10-13/16” (275mm)

1-1/16”

(27mm)

4-1/4” (108mm)

ø5/16” (8mm)

5/8”

(15.9mm)

Page 6

cup dispensers & accessories

®

COMPONENT

®

COMPONENT

TM

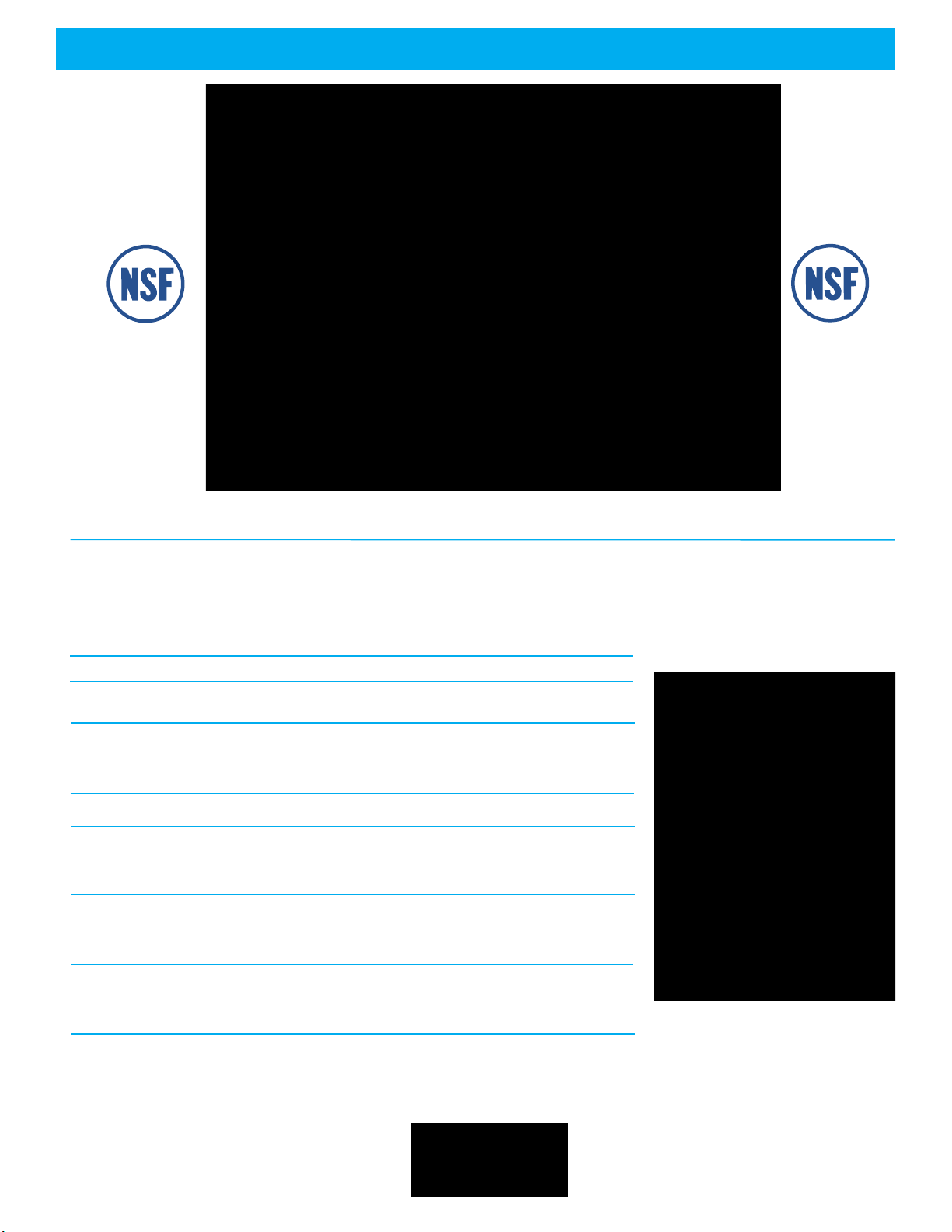

CUP DISPENSER AND ACCESSORIES

STAINLESS STEEL CUP DISPENSERS

ALL STAINLESS STEEL CONSTRUCTION - SATIN FINISH, 24 GAUGE (.6mm) TOP LOADING WITH SPRING TENSION

LOW PROFILE ... ONLY 9/32” (7mm) PROTRUSION ABOVE COUNTERTOP REMOVABLE ... 1/4 TURN RELEASES

DISPENSER FROM COUNTERTOP GASKETED COUNTER SEAL WAX AND FOAM CUP MODELS

STAINLESS STEEL COUNTER MOUNT CUP DISPENSERS

MODEL NO.

C3200CV

C3200CH

C3200CF

C3400CV

C3400CH

C3400CF

C3500CV

C3500CH

C3500CF

WALL MOUNT OR STAND MOUNT CUP DISPENSERS...TOP LOADING, GRAVITY FEED

TYPE CUP SIZE

VERTICAL

MOUNT

HORIZONTAL

MOUNT

FOAM CUP

VERTICAL

MOUNT

HORIZONTAL

MOUNT

FOAM CUP

VERTICAL

MOUNT

HORIZONTAL

MOUNT

FOAM CUP

LID DISPENSERS: STAND OR WALL MOUNT FOR EASY LOADING

6 to 12 oz.

(180 to 360ml)

6 to 12 oz.

(180 to 360ml)

6 to 12 oz.

(180 to 360ml)

12 to 24 oz.

(360 to 720ml)

12 to 24 oz.

(360 to 720ml)

12 to 24 oz.

(360 to 720ml)

32 to 46 oz.

(960 to 1380ml)

32 to 46 oz.

(960 to 1380ml)

32 to 46 oz.

(960 to 1380ml)

NOTE: VERTICAL MOUNT CUP DISPENSERS OPERABLE TO 45°

ACCESSORIES AVAILABLE FROM STOCK:

CUP DISPENSER STANDS

CUP RIM

DIA. (ADJ.)

2-7/32” to 3-3/16”

(56 to 81mm)

2-7/32” to 3-3/16”

(56 to 81mm)

2-7/32” to 3-3/16”

(56 to 81mm)

2-1/2” to 3-7/8”

(63 to 98mm)

2-1/2” to 3-7/8”

(63 to 98mm)

2-1/2” to 3-7/8”

(63 to 98mm)

4” to 4-7/8”

(100 to 124mm)

4” to 4-7/8”

(100 to 124mm)

4” to 4-7/8”

(100 to 124mm)

COUNTER

HOLE DIA.

REQ’D.

4-3/16”

(110mm)

4-3/16”

(110mm)

4-3/16”

(110mm)

4-11/16”

(120mm)

4-11/16”

(120mm)

4-11/16”

(120mm)

5-11/16”

(145mm)

5-11/16”

(145mm)

5-11/16”

(145mm)

OUTER

FLANGE

DIA.

5-3/8”

(135mm)

5-3/8”

(135mm)

5-3/8”

(135mm)

5-7/8”

(150mm)

5-7/8”

(150mm)

5-7/8”

(150mm)

6-3/4”

(170mm)

6-3/4”

(170mm)

6-3/4”

(170mm)

O.A.

LENGTH

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

24”

(610mm)

PATENTED ADJUSTABLE THROAT LETS YOU

ADAPT THE UNIVERSAL COLLAR TO ANY

DISPENSING NEED

All it takes is a simple screwdriver adjustment,

which keeps it locked in for any one type of cup

until you want to change to another size.

www.chg usa.c om

F5

Page 7

protector and sneeze guard components

®

COMPONENT

CBA

TM

F

E

D

PROTECTOR AND SNEEZE GUARD COMPONENTS

STAINLESS STEEL

PROTECTOR ASSEMBLY

STAINLESS STEEL CONSTRUCTION

FOLD DOWN BRACKET DESIGN

RIGID SUPPORT POST

STURDY BASES

SPECIFICATIONS:

STOCK SIZE: 14” (355mm) HIGH, 10” (250mm) SHELF,

10° SLANT FRONT

POSTS: SEAMLESS STAINLESS STEEL, 300 SERIES

BRACKETS: STAINLESS STEEL, 300 SERIES...

DIE FORMED FURNISHED WITH LOCKING FEATURE

TO HOLD BRACKET ASSEMBLY IN CLOSED

POSITION ...NYLON ROLLER AND END CHANNEL

TO ACCEPT WRAPPED GLASS FOR NOMINAL

1/4” (6mm) GLASS

MOUNTING: 5/16” x 2-1/4” (8 x 57mm) BOLT

FURNISHED FOR FASTENING FROM UNDERSIDE

STAINLESS STEEL

SNEEZE GUARD

BRACKETS

MODEL NO. J30-4465

INCLUDES PAIR OF BRACKETS...

(1) RIGHT HAND & (1) LEFT HAND

with (2) THUMBSCREWS FOR ADJUSTMENT

REF. A

10-3/8”

(263mm)

MODEL NO. J25-2100

(LEFT HAND)

STAINLESS STEEL PROTECTOR ASSEMBLY

WITH FOLD DOWN BRACKETS

REF. C

MODEL NO. J25-2200

(RIGHT HAND)

REF. D

13-1/4”

(336mm)

MODEL NO. J25-2300

(CENTER)

REF. B

5”

(125mm)

5/16”

(8mm)

10-3/8”

(263mm)

REF. E

STAINLESS STEEL

PROTECTOR BRACKETS

MODEL NO. J29-4482

(10-3/8” (263mm)

LG. BRACKETS, 1-- PAIR)

REF. F

STAINLESS STEEL BASE

MODEL NO. J36-4480

(2-1/4” (57mm) SQUARE BASE)

SPECIFICATIONS:

300 SERIES STAINLESS STEEL

SHOE PROVIDED TO ACCEPT

WRAPPED 1/4” (6.3mm) PLATE GLASS.

F6

5/16”

(8mm)

www.chg usa.c om

52°

Page 8

glass capping & channel

I

H

DE

G

GLASS CAPPING and CHANNEL

STAINLESS STEEL GLASS CAPPING

PREVENTS CHIPPING PROVIDES SECURE FIT

ATTRACTIVE POLISHED FINISH

MODEL NO.

B70-1001

B70-1002

B70-1003

B70-1005

B70-1007

B70-1008

*B70-1001-6

*6 FT. (1825mm) LENGTH. ALL OTHERS ARE 12 FT. (3650mm) LENGTHS.

STOCK LENGTH 12 FT. (3650mm) MINIMUM ORDER 144 FT. (13411mm)

REF.

A

B

C

D

E

F

A

STAINLESS

STEEL TYPE

300 SERIES

300 SERIES

300 SERIES

400 SERIES

400 SERIES

400 SERIES

300 SERIES

GAUGE

.022 (.6mm)

.022 (.6mm)

.022 (.6mm)

.019 (.5mm)

.019 (.5mm

.019 (.5mm)

.022 (.6mm)

C

AB

F

TM

REF. A

7/32”

(5.5mm)

7/16”

(11mm)

9/32”

(7.1mm)

REF. D

1/4”

5/16”

(8mm)

(6.3mm)

)

REF. G

DOUBLE CHANNEL

STOCK LENGTH 12 FT. (3650mm)

REF. B

7/16”

(11mm)

17/64”

(6.7mm)

REF. E

5/16”

(8mm)

EXTRUDED ALUMINUM

TRACK COMPONENT

MODEL NO. B74-0011

3/16”

(4.7mm)

3/8”

(10mm)

REF. C

REF. F

(11mm)

(19mm)

3/8”

(10mm)

7/16”

3/4”

29/32”

(23mm)

3/8”

(10mm)

7/8”

(22mm)

9/32”

(7.1mm)

3/8”

(10mm)

REF. H

STAINLESS STEEL TYPE 18-8

GLASS CLAMP FOR ROUND TUBING

MODEL NO.

B79-1000

1/4” GLASS

CLAMP, TOP

MODEL NO.

B79-1038

3/8” GLASS

CLAMP, TOP

NOTE: MOUNTING SCREW NOT PROVIDED

MODEL NO.

B79-2000-L

1/4” GLASS CLAMP,

BOTTOM LEFT

MODEL NO.

B79-2038-L

3/8” GLASS CLAMP,

BOTTOM LEFT

MODEL NO.

B79-2000-R

1/4” GLASS CLAMP,

BOTTOM RIGHT

MODEL NO.

B79-2038-R

3/8” GLASS CLAMP,

BOTTOM RIGHT

FIRMLY HOLDS GLASS WITHOUT DRILLING

UNIQUE LEDGE ON BOTTOM BRACKETS PROVIDES

A POSITIVE STOP TO MAKE INSTALLATION EASIER

LIGHT GRAY SILICONE PAD CUSHIONS GLASS,

WHILE PROVIDING MAXIMUM GRIPPING POWER

SLEEK DESIGN MAXIMIZES VIEWABLE SURFACE

AREA OF GLASS

3/8” OFFSET

IDEAL FOR PARTITIONS, DISPLAYS AND

SNEEZE GUARDS

SATIN FINISH MATCHES COUNTERTOPS

AND SUPPORTS

www.chg usa.c om

REF. I

MODEL NO.

B79-X014

BLACK DELRIN

ADAPTER FOR

SQUARE TUBING

APPLICATION

1/4” GLASS ONLY

F7

Page 9

pot rack components

®

COMPONENT

®

COMPONENT

®

COMPONENT

®

COMPONENT

TM

STAINLESS STEEL

POT RACK BAND

300 SERIES STAINLESS STEEL

POLISHED (180 GRIT)

PAPER INTERLEAVED

AVAILABLE IN TWO STOCK SIZES

MODEL NO. J95-2250

1/4” (6mm) x 2” (50mm) x 10 FT. (3000mm)

200 FT. /CTN., (60 meters),

TWENTY 10 FT. (3000mm) LGTHS.

MODEL NO. J95-2187

3/16” (4.7mm) x 2” (50mm) x 10 FT. (3000mm)

200 FT./CTN., (60 meters),

TWENTY 10 FT. (3000mm) LGTHS.

STAINLESS STEEL

SUPPORT

COLLAR

FOR 1-5/8” (41mm) O.D. TUBING

2”

(50mm)

POT RACK COMPONENTS

STAINLESS STEEL

SLIDING POT RACK HOOK

SINGLE PRONG

3-1/4”

(82mm)

1/4” DIA.

(6mm)

15/64”

(.6mm)

3-3/4”

(95mm

)

MODEL NO. J79-4115

STAINLESS STEEL

TUBULAR

COLLAR

FOR 1-5/8” (41mm) O.D. TUBING

2”

(50mm)

SLIDING POT RACK HOOKS

STAINLESS STEEL...MODEL NO. J77-4401

ZINC PLATED STEEL... MODEL NO. J77-4420

STAINLESS STEEL / ZINC PLATED STEEL

DOUBLE PRONG

1/4” DIA.

(6mm)

3-3/4”

(95mm)

15/64”

(.6mm)

5-3/8”

(136mm)

16 GAUGE (1.5mm)

STAINLESS STEEL

90° ELBOW

FOR 1-5/8” (41mm) O.D. TUBING

10”

(254mm)

F8

2-3/8”

(60mm)

MODEL NO. A16-0206-C

1-7/8”

(44mm

)

MODEL NO. A24-0206-C

1-7/8”

(47mm)

MODEL NO. J14-0119

10”

(254mm)

4-5/8”

(117mm)

www.chg usa.c om

Page 10

tubing accessories

®

COMPONENT

TM

STAINLESS STEEL

TUBULAR SHELF

SUPPORT

FOR 1-5/8”(41mm) O.D. TUBING

LONG LENGTH ADJUSTABLE

DOUBLE SET SCREW LOCKING

PLATED INSIDE LINER

SUITABLE FOR A WIDE ARRAY

OF CUSTOM APPLICATIONS

MODEL NO. A24-0207-C

(5-1/4” (133mm) LG.)

2”

(50mm)

EXPANDING FASTENERS

FOR FAST KD INSTALLATION

FOR ROUND OF SQUARE TUBING

MODEL TUBING

NO. SIZE

J57-7100 1”(25mm)

J57-7125 1-1/4”(32mm)

J57-7150 1-1/2”(38mm)

J57-7158 1-5/8”(41mm)

NOTE: J57-7100 USES 5/16”

BOLT. ALL OTHERS USE 1/2”

BOLTS.

TUBING ACCESSORIES

CHROME PLATED

OBLONG BASE END FLANGE

FOR 1” (25mm) O.D. TUBING

DIE CAST METAL CHROME PLATED

MODEL NO. J53-0125

STAINLESS STEEL

ROUND BASE FLANGE

STAINLESS STEEL TYPE 302

FOR 1”(25mm) O.D. TUBING FOR 1-1/4”(32mm) O.D. TUBING

MODEL NO. J52-0014 MODEL NO. J52-1250

PLATED STEEL

KNURLED BUSHING

PERMITS POSITIVE CONCEALED FASTENING

FOR 1”(25mm) O.D. TUBING

MODEL NO. J58-0100

16 GAUGE ONLY

PLATED STEEL

KNURLED BUSHING

PERMITS POSITIVE CONCEALED FASTENING

FOR 1-1/4”(32mm) O.D. TUBING...MODEL NO. J58-0014*

FOR 1-5/8”(41mm) O.D. TUBING...MODEL NO. J58-0158*

*16 GAUGE ONLY

STAINLESS STEEL

ESCUTCHEON PLATE FLANGE

12 GA. (2.6mm) STAINLESS STEEL W/ #4 SATIN FINISH

FOR 1-5/8”(40mm) O.D. TUBING

MODEL NO. J54-1583* MODEL NO. J54-1580

WITH (3) 1/4” (6mm) DIA. HOLES WITHOUT HOLES

1”

(25mm)

2”

(51mm)

1” (25mm)

1-1/4”

(32mm)

1-1/2”

(38mm)

FOR WELDED APPLICATION

FURNISHED WITH 1/4-20 THʼD

FURNISHED WITH 5/16-18 THʼD

3-1/2”DIA.

(89mm)

*2-9/16”

(66mm)

1”

(25mm)

1-1/4” (32mm)

1-3/4”

(44mm)

1-3/4”

(44mm)

1-1/4”

(32mm)

www.chg usa.c om

F9

Page 11

drip plate

TM

A

B

“A”

3-1/2”

(89mm)

REF. A

STAINLESS STEEL

DRIP PLATE

ECONOMY TYPE

24 GA.(.6mm) TYPE 302 WITH #4 FINISH

MODEL NO. “A” LENGTH

J81-5206-6-C 6”(152mm) 72”(1829mm)

J81-5207-6-C 7”(178mm) 72”(1829mm)

J81-5209-6-C 9”(229mm) 72”(1829mm)

ECONOMY DESIGN

ECONOMY TYPE

STAINLESS STEEL DRIP PLATE

PACKAGED 5 PCS. PER BOX

DRIP PLATE

BRASS NICKEL PLATED

FINISHING RINGS

NO. J86-4300

FOR 7/8”(22mm)

DIA. HOLE

NO. J86-4301

FOR 1”(25mm)

DIA. HOLE

“A”

3-3/4”

(95mm)

REF. B

STAINLESS STEEL

DRIP PLATE

NON-SPLASH

20 GA.(.9mm) TYPE 302 WITH #4 FINISH

MODEL NO. “A” LENGTH

J80-5107-6-C 7”(178mm) 72”(1829mm)

J80-5109-6-C 9”(229mm) 72”(1829mm)

HEAVY DUTY DESIGN

NON-SPLASH

STAINLESS STEEL DRIP PLATE

PACKAGED 5 PCS. PER BOX

F10

www.chg usa.c om

Page 12

end caps & lid cover brackets

E

A

C

B

F

F

D

TM

REF. A

THERMOPLASTIC

END CAPS

FOR ROUND TUBING

MATERIAL: BLACK NYLON

MODEL NO.

J16-1000-RD

J16-1250-RD

J16-2125-RD

J16-1500-RD

J16-1625-RD

1” (25mm)

1-1/4” (32mm)

1-1/4” (32mm)

1-1/2” (38mm)

1-5/8” (41mm)

END CAPS AND LID COVER BRACKETS

REF. B

THERMOPLASTIC

END CAPS

FOR SQUARE TUBING

MATERIAL: BLACK NYLON

O.D.

GAUGE

18 (1.2mm)

18 (1.2mm)

16 (1.5mm)

16 (1.5mm)

16 (1.5mm)

MODEL NO.

J16-1000-SQ

J16-1001-SQ

J16-1250-SQ

J16-1500-SQ

NOTE: * INDICATES OUTSIDE DIMENSIONS

REF. F

*DIM.

1” x 1”

(25 x 25mm)

1” x 1”

(25 x 25mm)

1-1/4” x 1-1/4”

(32 x 32mm)

1-1/2” x 1-1/2”

(38 x 38mm)

STAINLESS STEEL

GAUGE

18 (1.2mm)

16 (1.5mm)

18 (1.2mm)

16 (1.5mm)

LID COVER

BRACKET ASSEMBLY

EASY INSTALLATION

LIFT-OFF DESIGN

CAN BE FASTENED TO STAINLESS

STEEL LIDS OR PLASTIC BUBBLE

COVERS. DESIGNED FOR EASY

LIFT-OFF AND FOR HOLD-OPEN

POSITION FOR EASE OF SERVING.

MODEL NO. J32-1532

ASSEMBLY CONSISTS OF RIGHT &

LEFT HAND BRACKETS COMPLETE

WITH 4 PIVOT PINS WITH SCREW.

FOR STAINLESS STEEL PIVOT PINS...ORDER MODEL NO. J32-X001

FOR STAINLESS STEEL PIVOT SCREWS...ORDER MODEL NO. J32-X002

REF. C

NICKEL PLATED

END CAPS

FOR ROUND TUBING

MODEL NO.

J16-0201

FOR 1”(25mm)

O.D. TUBING

REF. D

SOLID STAINLESS

END CAPS

MODEL NO.

J16-0100

18 GA. (1mm)

FOR 1”(25mm) O.D. TUBING

(WELD APPLICATION)

PIVOT

SCREW

1/8”

(3mm)

5/8”

(16mm)

PIVOT PIN

8-32 HEX

HEAD SCREW

7/16”

(11mm)

HEX

.250 DIA.

(6.3mm)

MODEL NO.

J16-0158

FOR 1-5/8”(41mm)

O.D. TUBING

REF. E

NICKEL PLATED AND SOLID

STAINLESS SCREENED

HOLE PLUGS

MODEL NO. J16-0201-SP

FOR 1”(25mm) DIA. HOLE

MODEL NO. J16-0201-SPSS

FOR 1”(25mm) DIA. HOLE

MODEL NO. J16-0158-SPSS

FOR 1-5/8”(41mm) DIA. HOLE

(47mm)

2-5/16”

(59mm)

1-1/2”

(38mm)

1/4” DIA. HOLE

(6.3mm)

5/16”

(8mm)

1-7/8”

(16mm)

5/8”

www.chg usa.c om

F11

Page 13

corner inserts

TM

STAINLESS STEEL

COVE CORNER

INSERT

14 (1.8mm) GA. • TYPE 302

MODEL NO. J70-4701

FOR NOMINAL 1-1/2” (38mm) ROLLS

WITH 1” (25mm) INSIDE RADIUS

QUARTER SPHERES FOR NOMINAL

1-1/2” (38mm) AND 2” (51mm)

STAINLESS STEEL

TRIANGULAR INSERT

14 (1.8mm) GA. • TYPE 302

MODEL NO. J70-4801

COUNTER AND SINK INSERTS

3”

(76mm)

1” R

(25mm)

3-7/8”

(98mm)

1-1/2” (38mm)

ROLL WITH

FULL 80°

RETURN

1” R

(25mm)

4”

(100mm)

STAINLESS STEEL

BULL NOSE INSERT

14 (1.8mm) GA. • TYPE 302

1-1/2”(38mm) ROLL, A=1-3/8”(35mm), B=2-5/8”(66mm)

2”(51mm) ROLL, A=2-1/8”(54mm), B=3-3/4”(95mm)

MODEL NO. J72-4711

MODEL NO. J72-4731

1R”

(25mm)

COVE

1”R

(25mm)

COVE

A

1-1/2” (38mm)

ROLL WITH

FULL 220°

RETURN

B

3-3/8”

(87mm)

SQUARE CORNER INSERT

STAINLESS STEEL

COVE CORNER

INSERT

14 (1.8mm) GA. • TYPE 302

MODEL NO. J70-4691

FOR NOMINAL 1-1/2” (38mm) ROLLS

WITH 1” (25mm) INSIDE RADIUS

B

ROLL

COVE

1-1/2” (38mm) COVE, A=2-1/4”(57mm),

1-3/4” (44mm) COVE, A=2-7/8”(73mm),

1-5/8” (41mm) COVE, A=2-9/16”(65mm),

A

STAINLESS STEEL

14 (1.8mm) GA. • TYPE 302

MODEL NO. J74-4721

B=2-5/16”(59mm)

MODEL NO. J74-4723

B=2-11/16”(66mm)

MODEL NO. J74-4725

B=2-1/2”(63mm)

www.chg usa.c om

F13

Page 14

cap strips and divider bars

TM

D

C

A

B

CAP STRIP AND DIVIDER BAR

STAINLESS STEEL

CAP STRIP

FOR 1/16”(1.5mm) MATERIAL

MODEL NO. J63-1451

7 FT. (2130mm) LENGTH

MODEL NO. J63-1451-8*

8 FT. (2440mm) LENGTH

MODEL NO. J63-1451-9*

9 FT. (2745mm) LENGTH

MODEL NO. J63-1451-10*

10 FT. (3050mm) LENGTH

BRIGHT FINISH

* AVAILABLE ON APPLICATION AND 12 PIECE

MINIMUM FOR 8,9 & 10 FT LENGTHS

EXTENDED WIDTH

STAINLESS STEEL

CAP STRIP

FOR 1/16”(1.5mm) MATERIAL

MODEL NO. J63-1651-78

6.5 FT. (165mm) LENGTH

MODEL NO. J63-1651-120

10 FT. (254mm) LENGTH

SATIN FINISH

(8mm)

7/8”

(22mm)

5/16”

7/8”

(22mm)

REF. A

1-1/2”

(38mm)

(13mm)

REF. B

1/2”

7/8”

(22mm)

1-3/8”

(35mm)

7/32”

(5.5mm)

2-5/32”

(54.5mm)

7/16”

(11mm)

STAINLESS STEEL

DIVIDER BAR

WITH GALVANIZED BACK PLATE

FOR 1/16”(1.5mm) MATERIAL

MODEL NO. J64-1450

7 FT. (2130mm) LENGTH

MODEL NO. J64-1450-8*

8 FT. (2440mm) LENGTH

MODEL NO. J64-1450-9*

9 FT. (2745mm) LENGTH

MODEL NO. J64-1450-10*

10 FT. (3050mm) LENGTH

BRIGHT FINISH

* AVAILABLE ON APPLICATION AND 12 PIECE

MINIMUM FOR 8,9 & 10 FT LENGTHS

EXTENDED WIDTH

STAINLESS STEEL

DIVIDER BAR

WITH SS BACK PLATE

FOR 1/16”(1.5mm) MATERIAL

MODEL NO. J64-1651-78

6.5 FT. (165mm) LENGTH

MODEL NO. J64-1651-120

10 FT. (254mm) LENGTH

SATIN FINISH

F14

REF. C

AVAILABLE IN 78” AND 120” LENGTHS TO MINIMIZE SCRAPINDIVIDUALLY PLASTIC SLEEVED FOR PROTECTION OF FINISH

NEW EXTRA WIDE PROFILE FOR EASIER INSTALLATION ALL STAINLESS STEEL CONSTRUCTION

ACCEPTS 1/16” (1.5mm) WALL FLASHING MATERIAL #4 SATIN FINISHGRAIN OF FINISH MATCHES WALL LINING

CAP STRIP HAS HEMMED EDGE FOR SAFETY

REF. D

www.chg usa.c om

Page 15

TM

mouldings and dividers

I

I

H

E

E

F

G

STAINLESS STEEL

FLAT SNAP-ON MOULDING

MODEL NO. WIDTH

J60-2220* 1/2” (13mm)

J60-2240 3/4” (19mm)

J60-2260 1” (25mm)

J60-2270 1-1/4” (32mm)

J60-2280* 1-1/2” (38 mm)

J60-2320* 2” (51mm)

12 FT. (3657mm) LENGTHS

*NON-STOCK ITEM

MINIMUM ORDER 300 PIECES

STAINLESS STEEL

LINE UP

DIVIDER

MODEL NO. J65-4110

1/2” (13mm) FACE

12 FT. (3657mm) LENGTH

STOCK LENGTH 12 FT. (3657mm)

MINIMUM ORDER 300 PIECES

MOULDINGS AND DIVIDERS

400 SERIES

STAINLESS STEEL

SPECIAL SIZES

AVAILABLE

3/4”

(19mm)

3/4”

REF. E

1/2”

(13mm)

REF. F

(2.3mm)

3/32”

3/8” DIA.

(.375mm)

1/2”

(13mm)

REF. G

(19mm)

“A”

STAINLESS STEEL

SPLIT TUBE

MOULDING

20 GA. (1mm)

TYPE 304 - 2B FINISH

MODEL NO. J62-0012

12 FT. (3657mm) LENGTH

IDEAL FOR HEMMING/EDGING

MINIMUM ORDER 12 PIECES

REF. H

“A”

REF. I

STAINLESS STEEL

INSIDE CORNER

SNAP-ON MOULDING

MODEL NO. J62-2480

INSIDE RADIUS

12 FT. (3657mm) LENGTH

*NON-STOCK ITEM

MINIMUM ORDER 300 PIECES

STAINLESS STEEL

OUTSIDE CORNER

SNAP-ON MOULDING

MODEL NO. “A”

J61-2470 3/4”x 3/4” (19 x 19mm)

J61-2500 1-1/4” x 1-1/4”(32 x 32mm)

12 FT. LENGTH (3657mm)

*NON-STOCK ITEM

MINIMUM ORDER 300 PIECES

www.chg usa.c om

F15

Page 16

gas burners

D

C

B

E

TM

MUSHROOM

BURNERS

MUSHROOM BURNERS

MODEL NO.

G22-4310

G22-4320

NOTE: ORDER AIR MIXING PLATE SEPARATELY AS G44-4360

DIA.

3” (76mm)

4” (100mm)

BTU/HR

5,000

7,000

1-3 GAL. (3.8-11 LIT.)

3-4 GAL. (11-15 LIT.)

SADDLE BURNER

RAPID HEATING 7” (178mm) DIA. 30,000 BTU/HR

F

GAS BURNERS

DIA.

REC. FOR

3-1/2”

(89mm)

REF.

A

B

REMOVABLE

HEAD

BURNERS

FURNISHED COMPLETE

WITH AIR MIXING

CHAMBER AND ORIFICE

MODEL NO.

G24-4000

G24-5000

A

DIA.

REMOVABLE HEAD BURNERS

DIA.

4” (100mm)

5” (125mm)

BTU/HR

12,000

20,000

REC. FOR

5-8 GAL. (19-30 LIT.)

8-16 GAL. (30-60 LIT.)

LOOP BURNER

END INLET 30,000 BTU/HR

REF.

C

D

F16

7”

(178mm)

MODEL NO. G26-4200 (REF. E)

FURNISHED COMPLETE WITH AIR MIXING CHAMBER AND ORIFICE

www.chg usa.c om

7”

(178mm)

3-1/4”

(83mm)

15” (381mm)

17” (432mm)

MODEL NO. G27-1250 (REF. F)

FURNISHED COMPLETE WITH AIR MIXING CHAMBER

AND ORIFICE FOR NATURAL AND LP GAS

Page 17

ring burner assemblies

TM

1-1/4”

(32mm)

RING BURNER ASSEMBLIES

RING BURNER

WITH INSULATED

HANDLE BURNER VALVE

MODEL NO. G12-6550

RATING: 22,000 BTU/HR

1-1/2”

6-1/2”

(165mm)

5-1/2”

(140mm)

(38mm)

1-1/2”

(38mm)

RING BURNER

WITH ADJUSTABLE SLIP FIT ORIFICE

BURNER VALVE

MODEL NO. G10-6550

RATING: 22,000 BTU/HR

1-1/4”

(32mm)

6-1/2”

(165mm)

5-1/2”

(140mm)

1-1/2”

(38mm)

1-7/8”

(48mm)

15/16”

(24mm)

NOTE: MANIFOLD AND NIPPLE (3/4” N.P.T.) NOT SUPPLIED

6” RING BURNER ONLY MODEL NO. G12-X001

www.chg usa.c om

NOTE: MANIFOLD AND NIPPLE (3/4” N.P.T.) NOT SUPPLIED

F17

Page 18

gas burners

G

A

B

TM

REF. A

JET BURNER

COMPONENTS

ADJUSTABLE

PILOT LIGHT ASSEMBLY

MODEL NO. G20-6511

(12” (304mm) LG.)

MODEL NO. G20-6512

(18” (457mm) LG.)

REF. B

BURNER VALVE

COMPRESSION FIT

1/8” N.P.T. MALE INLET

FOR 5/16” (8mm) O.D. TUBING

MODEL NO. G40-6451

REF. C

ELBOW, BRASS

1/8” N.P.T.

FOR USE WITH G28-6491

MODEL NO. G30-6480

REF. D

C

F

D

E

GAS BURNERS

JET BURNER ASSEMBLY AND PILOT LIGHT

ANTI DRAFT HOOD

VALVE HANDLE

JET BURNER

COUPLING

ELBOW

LENGTH

PILOT LT. TUBE

ADJUSTABLE

PILOT VALVE

BURNER VALVE

MANIFOLD

(NOT SUPPLIED)

COUPLING, BRASS

1/8” N.P.T. FEMALE INLET

FOR 5/16” (8mm) O.D. TUBING

MODEL NO. G32-6470

REF. E

PILOT VALVE, BRASS

ADJUSTABLE

1/8” N.P.T. MALE INLET

FOR 1/4” (6.3mm) O.D. TUBING

MODEL NO. G34-6460

F18

JET BURNER ASSEMBLY & PILOT LIGHT

MODEL NO.

G14-6501

G14-6502

REF. F

LENGTH

12” (300mm)

18” (450mm)

JET BURNER, BRASS

MODEL NO. G28-6491

www.chg usa.c om

RATING

3700 B.T.U./H.R.

3700 B.T.U./H.R.

NOTE: SUPPLIED WITH A .021 DIA.

(.5mm) GUIDE HOLE. CONSULT

YOUR UTILITY SUPPLIER FOR

CORRECT ORIFICE DIAMETER.

REF. G

VALVE HANDLE

THERMOPLASTIC

MODEL NO. G50-5420

Page 19

gas burner components

C

D

B

A

K

GAS BURNER COMPONENTS

REF. A

ADJUSTABLE PILOT LIGHT ASSEMBLIES

MODEL NO. G20-6511

MODEL NO. G20-6512

(SPECIAL LENGTHS TO ORDER)

FOR USE WITH ALL BURNERS AND SIMILAR EQUIPMENT

AS WELL AS JET AND RING BURNER ASSEMBLIES

(12” (300mm) LG.)

(18” (457mm) LG.)

E

F

G

H

J

TM

REF. B

AIR MIXING CHAMBER

FREE FLOW CHAMBER WITH AIR MIXING PLATE

MODEL NO. G46-4360

MODEL NO. G46-4361

FURNISHED FOR 3/4” N.P.T. OUTLET

MAY ALSO BE FURNISHED WITH 1/2” OR 3/8” N.P.T. BUSHINGS

(FOR 1/8” N.P.T. ORIFICE)

(FOR SLIP FIT ORIFICE)

REF. C

BURNER VALVE EXTENSION

FITS STANDARD SLOTTED “D” BURNER VALVES

REF. G

COMPRESSION FIT FOR 5/16”(8mm) O.D. TUBING

REF. F

REF. E

VALVE HANDLE

CK THERMOPLASTIC

BLA

LL STANDARD VALVES

FOR A

WITHOUT INDICATOR

MODEL NO. G50-5420

3”(75mm) MAXIMUM ADJUSTMENT

MODEL NO. G48-0005

BURNER VALVES

1/8” N.P.T. MALE INLET

MODEL NO. G40-6451

MODEL NO. G40-6452

ADJUSTABLE SLIP FIT ORIFICE

REF. K REF. J

REF. D

REF. H

ADJUSTABLE SLIP FIT

ORIFICE

JUSTABLE ORIFICE

AD

R USE WITH G40-6452

FO

BURNER VALVE

MODEL NO. G36-4371

AIR MIXING PLATE

ZINC PLATED

MODEL NO. G44-4360

SPECIAL SIZES MAY BE SUPPLIED IN QUANTITY

BURNER VALVE

WITH BRASS HANDLE

8” N.P.T. MALE INLET

1/

x 3/8” N.P.T. FEMALE

MODEL NO. G38-5330

THREADED ORIFICE

MODEL NO. G36-4370

THIS PART IS SUPPLIED WITH AN .021(.5mm) DIAMETER

GUIDE, HOLE, DIFFERENT GASSES, FEEDING PRESSURES

AND ATMOSPHERIC PRESSURES, REQUIRE DIFFERENT

ORIFICE DIAMETERS. CONSULT YOUR UTILITY SUPPLIER

FOR CORRECT DIAMETER.

www.chg usa.c om

F19

Page 20

conveyor roller components

TM

CONVEYOR ROLLER COMPONENTS

PLASTIC CONVEYOR ROLLER BEARINGS

STOCKED FOR 1.90” (48mm) O.D. TUBING*

MOLDED POLYPROPYLENE

DOUBLE LABYRINTH SEALS

STAINLESS STEEL (18-8) BALLS

*3/4 (19mm) O.D., 1/8” (3mm), AND 1-9/16” (39mm)

STAINLESS STEEL 7/16” (11mm)

O.D. ROLLER BEARINGS

ARE AVAILABLE ON APPLICATION BASIS

HEX ROD

FOR CONVEYOR ROLLERS

ACCOMMODATES ARRAY OF SHAFTS

APPROVED FOR FOODSERVICE USE

MAY BE STEAM CLEANED

OPERATES AT TEMPERATURES UP TO 150°F (66°C)

PLASTIC CONVEYOR ROLLER BEARINGS

SHAFT SIZE**

5/16” (8mm) DIA.

3/8” (10mm) DIA.

1/2” (13mm) DIA.

5/16” (8mm) HEX

7/16” (11mm) HEX

** ADAPTER BUSHINGS ARE PROVIDED FOR SHAFTS LISTED. BEARINGS MUST BE

ORDERED WITH BUSHINGS. IF NONE IS SPECIFIED BUSHINGS FOR 7/16” (11mm)

HEX ROD WILL BE SUPPLIED. *NO BUSHING REQUIRED.

MODEL NO.

IR-1105

IR-1106

IR-1108

IR-1115

IR-1117*

PVC ROUND TUBING (GRAY)

FOR CONVEYOR ROLLERS

1.90” (48mm) O.D. FOR 1100 SERIES ROLLERS

F20

MODEL NO. B80-0716

6 FT. (1830mm) LENGTH

NOTE: OTHER SIZES ON APPLICATION

NOTE: STAINLESS STEEL, ALUMINUM, GALVANIZED STEEL TUBING

IS AVAILABLE IN 1.90” (48mm) O.D. X 20 FT. (7300mm, 6m)

www.chg usa.c om

MODEL NO. IR-1190

4 FT. (1220mm) LENGTH

LENGTHS ON AN APPLICATION BASIS.

Page 21

roller assemblies & components

TM

ROLLER ASSEMBLIES and COMPONENTS

MADE TO ORDER

COMPLETE ROLLER

ASSEMBLIES

COMPLETE ROLLER ASSEMBLIES (TUBING AND SERIES

1100 PLASTIC ROLLER BEARINGS) ARE AVAILABLE

FABRICATED TO INDIVIDUAL REQUIREMENTS.

THESE COMPLETE ASSEMBLIES PERMIT INDIVIDUAL

SPECIFICATIONS OF TUBING DIAMETER AND MATERIAL,

SHAFT MATERIAL, SHAFT SIZE AND A VARIETY OF

MOUNTINGS. THE VARIABLES INCLUDE...

TUBING DIAMETERS

.78, 1.18, 1.56, 1.90

(20mm, 28mm, 39mm, 48mm)

TUBING MATERIALS

PLASTIC (PVC), ALUMINUM AND STAINLESS STEEL

SHAFT MATERIALS

CARBON STEEL, ALUMINUM AND STAINLESS STEEL

TM

STAINLESS STEEL

CONVEYOR

COMPONENTS

STAINLESS STEEL

CONVEYOR BEARING

FLANGED BALL BEARING WHEEL ASSEMBLY

FOR 1-5/8” (41mm) O.D. 16 GA. (1.5mm) TUBING

MODEL NO. B29-0080

STAINLESS STEEL

HEX AXLE ROD

7/16”(11mm) SOLID HEX AXLE ROD

AVAILABLE IN 6 FT. (1830mm) LENGTHS

MODEL NO. B80-0716

FROM .192 TO .500 DIA. AND 5/16” OR 7/16” HEX

(5mm to 13mm) (8mm or 11mm)

PLAIN, THREADED, TAPPED AND SPRING LOADED

NOTE: WE WELCOME YOUR INQUIRIES FOR SPECIFIC DESIGNS TO

SATISFY YOUR INDIVIDUAL REQUIREMENTS. HOWEVER, NOT ALL

COMBINATIONS ARE POSSIBLE. PLEASE CONTACT OUR SALES

OFFICE FOR ASSISTANCE IN DESIGNING YOUR CUSTOM ROLLER

ASSEMBLIES. ALLOW 4-6 WEEKS FOR DELIVERY OF COMPLETE

SHAFT SIZES

MOUNTINGS

ROLLER ASSEMBLIES

.

www.chg usa.c om

TUBING NOT FURNISHED

F21

Page 22

showcase light fixtures

B

B

A

TM

SHOWCASE LIGHT FIXTURES

REF. A

STAINLESS STEEL

SHOWCASE FIXTURES

SATIN FINISHED STAINLESS STEEL COVER

U.V. SAFETY LENS COVER PREWIRED ASSEMBLY

FLUSH BALLAST BOX 120V MODELS

STAINLESS STEEL SHOWCASE FIXTURE

O.A. LENGTH

22”(559mm)

34”(864mm)

46”(1168mm)

58”(1372mm)

68”(1727mm)

NOTE: O.A. LENGTH INCLUDES CONDUIT ELBOW. EACH FIXTURE INCLUDES

REMOVABLE COVER, 39”(914mm) LG. PREWIRED LEADS, SLIP COUPLING,

BX CONNECTOR, COLLAR SUPPORT, FLEXIBLE CONDUIT, TUBING.

MODEL NO.

L77-3200-24

L77-3200-36

L77-3200-48

L77-3200-60

L77-3200-72

FLUORESCENT TUBES NOT INCLUDED.

LAMP SIZE

(1) 15”(381mm)

(1) 24”(610mm)

(1) 30”(762mm)

(2) 18”(457mm)

(2) 24”(610mm)

AMPS

.28

.31

.31

.57

.63

LAMP NO.

T8-F14

T8-F18

T8-F18

T8-F15

T8-F18

D

C

REF. B

FLUORESCENT LAMP

SAFETY SHIELDS

SAFELY...SECURELY SURROUNDS LAMPS

PREVENTING SHATTERED GLASS FROM SPREADING

MEETS ALL N.E.C., F.D.A. & U.S.D.A. CODES

SHATTERPROOF U.V. STABILIZED

FLUORESCENT LAMP SAFETY SHIELDS

LAMP

TYPE

T12

T12

T12

T12

T12

T8

T8

PIN

TYPE

BI-PIN

BI-PIN

BI-PIN

BI-PIN

BI-PIN

SINGLE

or BI-PIN

SINGLE

or BI-PIN

LAMP SIZE

24”(610mm)

33”(838mm)

36”(915mm)

48”(1219mm)

48”(1219mm)

18”(457mm)

36”(914mm)

PACKAGED 24/CTN. NO SPLIT CARTONS

SHIELD SIZE

22”(559mm)

31”(787mm)

34”(864mm)

44”(1118mm)

46”(1168mm)

16-3/8”(416mm)

34-3/8”(873mm)

TRADE

MODEL NO.

TP152-W

TP252-W

TP232-W

TP312-S

TP312-W

T60

T120

E

MODEL NO.

T76-1522

T76-2122

T76-2322

T76-3121

T76-3122

T77-6000

T77-1200

CHG

F22

CROSS SECTION

L77 SERIES

2-3/16”(56mm) HIGH

2-5/16”(59mm) WIDE

LISTED

#E240378

CONNECTORS

FOR JOINING SHOWCASE

FIXTURES IN SERIES

MODEL NO. L77-0001

REF. C

www.chg usa.c om

IN-LINE

UNIVERSAL STAINLESS STEEL

MOUNTING BRACKET

FOR L77 SERIES LIGHT FIXTURES

MODEL NO. L77-1000 MODEL NO. L77-1030

0° MOUNTING ANGLE 30° MOUNTING ANGLE

REF. D

REF. E

Page 23

slim line fluorescent light

SLIM LINE FLUORESCENT LIGHT

AND CUL APPROVED

UL

ILIZES COMPACT T4 SUPER SLIM FLUORESCENT TUBE (BULB INCLUDED)

UT

EXIBLE REMOVABLE COVER DURABLE LIGHT-WEIGHT HOUSING BUILT-IN ELECTRONIC BALLAST

FL

UMINUM REFLECTOR SUPER SLIM COMPACT AND EFFICIENT

AL

ON/O

MODEL NO. WATTAGE LENGTH LUMENS

L73-2004B-15

L73-2004B-16

L73-2004B-24

L73-2004B-28

TO LINK (8W/12W/16W UP TO 10PCS-20W/24W UP TO 6 PCS) DIRECT OR WITH IN LINE ADAPTER

EASY

FF SWITCH ON HOUSING MOUNTING HARDWARE, 6’ CORD SET AND IN-LINE ADAPTER INCLUDED

ANDARD 110V/60HzTEMPERATURE RANGE - 30º - 130º F (0º - 54ºC)

ST

ONAL: 230V/DC12V, SPARE BULBS (BY THE CASE), SPARE IN-LINE ADAPTERS

OPTI

L73 SERIES FLUORESCENT LIGHTS

8 15-1/2” 460-480

12 16-1/2” 680-720

20 24-1/2” 1200-1250

24 28-1/2” 1350-1400

1-3/4”

44mm

L73-2004B-32

28 32-1/2” 1450-1500

www.chg usa.c om

3/4”

19mm

F23

Page 24

electrical outlet components

A

C

CAST ALUMINUM

ELECTRIC OUTLET BOXES

BRUSHED SATIN FINISH

FOR 3/4” NPS OR 1/2” NPS

(ADAPTOR PROVIDED)

GROUND SCREW PROVIDED

U.L. LISTED #48 C6

MODEL NO. R58-1010

SINGLE FACED MODEL

B

H

E

F

D

G

ELECTRICAL OUTLET COMPONENTS

REF. D

PILOT LIGHT SWITCH

NEON LITE “T” RATED SINGLE POLE

MODEL NO. R65-3228

REF. E

FLUSH DUPLEX RECEPTACLE

3 WIRE “U” GROUND 125 VOLTS

MODEL NO. R69-1630 (15 AMPS)

MODEL NO. R69-1631 (20 AMPS)

MODEL NO. R69-1632* (30 AMPS)

MODEL NO. R58-1020

DOUBLE FACED MODEL

REF. A

5-1/2”

(140mm)

3-1/2”

(89mm)

3”

(76mm)

3/28”

(83mm)

#6-32

TM

*SINGLE RECEPTACLE

REF. B

STAINLESS STEEL

RECESSED HOUSINGS

300 SERIES STAINLESS STEEL

INTERNAL COVED CORNERS

PROVIDED WITH (4) 10-24 MOUNTING STUDS

ACCEPTS STANDARD J-BOX FOR TACK WELDING

4-5/8”

(117mm)

4”

(100mm)

MODEL NO. R73-1210

FOR “J” BOX MOUNTING

MODEL NO. R73-1212

FOR CONTROL SWITCH APPLICATION

F24

(WITHOUT CUT-OUT)

5-3/4” (146 mm)

9/32”

(7mm)

(25mm)

6-3/8” (162 mm)

1”

1/2” TYP.

(13mm)

REF. C

STAINLESS STEEL

CONTROL PANELS

THREE SIZES AVAILABLE

300 SERIES STAINLESS STEEL

MODEL NO.

R73-2201

R73-2202

R73-2203

2-5/8”

(66mm)

NOTE: HOLE PATTERNS TO SUIT

ROBERTSHAW CONTROLS AVAILABLE

www.chg usa.c om

“X” DIM.

5” (127mm)

8-5/16” (211mm)

11-3/4” (298mm)

3-9/16”

(90mm)

1-1/2”

(38mm)

ON REQUEST

“Y” DIM.

6” (152mm)

9-5/16” (236mm)

12-3/4” (324mm)

1-9/32”R

(32mm)

X

Y

NOT SHOWN

GROUND FAULT

CIRCUIT INTERRUPTER

125 VAC-15 AMPS AT RECEPTACLE

20 AMP FEED THROUGH

MODEL NO. R69-1633

WITH BROWN PLASTIC COVERPLATE.

STAINLESS STEEL COVERPLATE AVAILABLE.

ORDER SEPARATELY AS R71-0722

REF. F

STAINLESS STEEL

TOGGLE SWITCH PLATE

MODEL NO. R70-0720

REF. G

STAINLESS STEEL

BLANK PLATE

MODEL NO. R70-0723

REF. H

STAINLESS STEEL

DUPLEX RECEPTACLE PLATE

MODEL NO. R71-0721

Page 25

NUMERICAL PAGE INDEX

MODEL NO. PAGE NO.

A16-0206-C . . . . . . . . . . .F8

A24-0206-C . . . . . . . . . . F8

A24-0207-C . . . . . . . . . . .F9

B29-0080 . . . . . . . . . . . F21

B70-1001 . . . . . . . . . . . . .F7

B70-1001-6 . . . . . . . . . . . .F7

B70-1002 . . . . . . . . . . . . .F7

B70-1003 . . . . . . . . . . . . .F7

B70-1005 . . . . . . . . . . . . .F7

B70-1007 . . . . . . . . . . . . .F7

B70-1008 . . . . . . . . . . . . .F7

B74-0011 . . . . . . . . . . . . .F7

B79-1000 . . . . . . . . . . . . .F7

B79-1038 . . . . . . . . . . . . .F7

B79-2000-L . . . . . . . . . . . .F7

B79-2038-L . . . . . . . . . . . .F7

B79-2000-R . . . . . . . . . . .F7

B79-2038-R . . . . . . . . . . .F7

B79-X014 . . . . . . . . . . . . F7

B80-0716 . . . . . . . .F20, F21

C3200CF . . . . . . . . . . . . .F5

C3200CH . . . . . . . . . . . . .F5

C3200CV . . . . . . . . . . . . .F5

C3400CF . . . . . . . . . . . . F5

C3400CH . . . . . . . . . . . . .F5

C3400CV . . . . . . . . . . . . .F5

C3500CF . . . . . . . . . . . . .F5

C3500CH . . . . . . . . . . . . F5

C3500CV . . . . . . . . . . . . .F5

G10-6550 . . . . . . . . . . . .F17

G12-6550 . . . . . . . . . . . .F17

G12-X001 . . . . . . . . . . . .F17

G14-6501 . . . . . . . . . . . .F18

G14-6502 . . . . . . . . . . . .F18

G20-6511 . . . . . . . .F18, F19

G20-6512 . . . . . . . .F18, F19

G22-4310 . . . . . . . . . . . .F16

G22-4320 . . . . . . . . . . . .F16

G24-4000 . . . . . . . . . . . .F16

G24-5000 . . . . . . . . . . . .F16

G26-4200 . . . . . . . . . . . .F16

G27-1250 . . . . . . . . . . . .F16

G28-6491 . . . . . . . . . . . .F18

G30-6480 . . . . . . . . . . . .F18

G32-6470 . . . . . . . . . . . .F18

G34-6460 . . . . . . . . . . . .F18

G36-4370 . . . . . . . . . . . .F19

G36-4371 . . . . . . . . . . . .F19

G38-5330 . . . . . . . . . . . .F19

G40-6451 . . . . . . . .F18, F19

G40-6452 . . . . . . . . . . . .F19

G44-4360 . . . . . . . . . . . .F19

G46-4360 . . . . . . . . . . . .F19

G46-4361 . . . . . . . . . . . .F19

MODEL NO. PAGE NO.

G48-0005 . . . . . . . . . . . .F19

G50-5420 . . . . . . . .F18,F19

IR-1105 . . . . . . . . . . . . . .F20

IR-1106 . . . . . . . . . . . . . .F20

IR-1108 . . . . . . . . . . . . . .F20

IR-1115 . . . . . . . . . . . . . .F20

IR-1117 . . . . . . . . . . . . . .F20

IR-1190 . . . . . . . . . . . . . .F20

J12-0001 . . . . . . . . . . . . . .F4

J12-1400 . . . . . . . . . . . . . .F4

J13-4488 . . . . . . . . . . . . . .F4

J14-0117 . . . . . . . . . . . . . .F4

J14-0119 . . . . . . . . . . .F4, F8

J16-0100 . . . . . . . . . .F4, F11

J16-0158 . . . . . . . . . .F4, F11

J16-0158-SPSS . . . . . . .F11

J16-0201 . . . . . . . . . .F4, F11

J16-0201-SP . . . . . . . . . .F11

J16-0201-SPSS . . . . . . .F11

J16-1000-RD . . . . . . . . .F11

J16-1000-SQ . . . . . . . . .F11

J16-1001-SQ . . . . . . . . .F11

J16-1250-RD . . . . . . . . .F11

J16-1250-SQ . . . . . . . . .F11

J16-1500-RD . . . . . . . . .F11

J16-1500-SQ . . . . . . . . .F11

J16-1625-RD . . . . . . . . .F11

J16-2125-RD . . . . . . . . .F11

J17-4270 . . . . . . . . . . . . . .F3

J17-4273 . . . . . . . . . . . . . .F3

J18-2000 . . . . . . . . . . . . . .F3

J19-1400 . . . . . . . . . . . . . .F4

J19-4955 . . . . . . . . . . .F3,F4

J19-4955-LT . . . . . . . . . . .F3

J19-4960 . . . . . . . . . . .F2,F4

J19-4960-LT . . . . . . . . . . .F2

J19-4962 . . . . . . . . . . . . . .F2

J19-4964 . . . . . . . . . . . . . .F2

J19-4966 . . . . . . . . . . . . . .F2

J19-4967 . . . . . . . . . . . . . .F3

J19-5000 . . . . . . . . . . . . . .F3

J25-2100 . . . . . . . . . . . . . .F6

J25-2200 . . . . . . . . . . . . . .F6

J25-2300 . . . . . . . . . . . . . .F6

J29-4482 . . . . . . . . . . . . . .F6

J30-4465 . . . . . . . . . . . . . .F6

J32-1532 . . . . . . . . . . . . .F11

J32-X001 . . . . . . . . . . . .F11

J32-X002 . . . . . . . . . . . .F11

J36-4480 . . . . . . . . . . . . . .F6

J52-0014 . . . . . . . . . . . . . .F9

J52-1250 . . . . . . . . . . . . . .F9

J53-0125 . . . . . . . . . . . . . .F9

J54-1580 . . . . . . . . . . . . . .F9

MODEL NO. PAGE NO.

J54-1583 . . . . . . . . . . . . . .F9

J57-7100 . . . . . . . . . . . . . .F9

J57-7125 . . . . . . . . . . . . . .F9

J57-7150 . . . . . . . . . . . . . .F9

J57-7158 . . . . . . . . . . . . . .F9

J58-0014 . . . . . . . . . . . . . .F9

J58-0100 . . . . . . . . . . . . . .F9

J58-0158 . . . . . . . . . . . . . .F9

J60-2220 . . . . . . . . . . . . .F15

J60-2240 . . . . . . . . . . . . .F15

J60-2260 . . . . . . . . . . . . .F15

J60-2270 . . . . . . . . . . . . .F15

J60-2280 . . . . . . . . . . . . .F15

J60-2320 . . . . . . . . . . . . .F15

J61-2470 . . . . . . . . . . . . .F15

J61-2500 . . . . . . . . . . . . .F15

J62-0012 . . . . . . . . . . . . .F15

J62-2480 . . . . . . . . . . . . .F15

J63-1451 . . . . . . . . . . . . .F14

J63-1451-8 . . . . . . . . . . .F14

J63-1451-9 . . . . . . . . . . .F14

J63-1451-10 . . . . . . . . . .F14

J63-1651-78 . . . . . . . . . .F14

J63-1651-120 . . . . . . . . .F14

J64-1450 . . . . . . . . . . . . .F14

J64-1450-8 . . . . . . . . . . .F14

J64-1450-9 . . . . . . . . . . .F14

J64-1450-10 . . . . . . . . . .F14

J64-1651-78 . . . . . . . . . .F14

J64-1651-120 . . . . . . . . .F14

J65-4110 . . . . . . . . . . . . .F15

J70-4691 . . . . . . . . . . . . .F13

J70-4701 . . . . . . . . . . . . .F13

J70-4801 . . . . . . . . . . . . .F13

J72-4711 . . . . . . . . . . . . .F13

J72-4731 . . . . . . . . . . . . .F13

J74-4721 . . . . . . . . . . . . .F13

J74-4723 . . . . . . . . . . . . .F13

J74-4725 . . . . . . . . . . . . .F13

J77-4401 . . . . . . . . . . . . . .F8

J77-4420 . . . . . . . . . . . . . .F8

J79-4115 . . . . . . . . . . . . . .F8

J80-5107-6-C . . . . . . . . .F10

J80-5109-6-C . . . . . . . . .F10

J81-5206-6-C . . . . . . . . .F10

J81-5207-6-C . . . . . . . . .F10

J81-5209-6-C . . . . . . . . .F10

J86-4300 . . . . . . . . . . . . .F10

J86-4301 . . . . . . . . . . . . .F10

J92-1000 . . . . . . . . . . . . .F12

J92-5000 . . . . . . . . . . . . .F12

J92-9360 . . . . . . . . . . . . .F12

J95-2187 . . . . . . . . . . . . . .F8

J95-2250 . . . . . . . . . . . . . .F8

MODEL NO. PAGE NO.

K30-1000 . . . . . . . . . . . .F12

L73-2004B-15 . . . . . . . .F23

L73-2004B-16 . . . . . . . . F23

L73-2004B-24 . . . . . . . . F23

L73-2004B-28 . . . . . . . . F23

L73-2004B-32 . . . . . . . . F23

L77-0001 . . . . . . . . . . . .F22

L77-1000 . . . . . . . . . . . .F22

L77-1030 . . . . . . . . . . . .F22

L77-3200-24 . . . . . . . . . .F22

L77-3200-36 . . . . . . . . . .F22

L77-3200-48 . . . . . . . . . .F22

L77-3200-60 . . . . . . . . . .F22

L77-3200-72 . . . . . . . . . .F22

R58-1010 . . . . . . . . . . . .F24

R58-1020 . . . . . . . . . . . .F24

R65-3228 . . . . . . . . . . . .F24

R69-1630 . . . . . . . . . . . .F24

R69-1631 . . . . . . . . . . . .F24

R69-1632 . . . . . . . . . . . .F24

R69-1633 . . . . . . . . . . . .F24

R70-0720 . . . . . . . . . . . .F24

R70-0723 . . . . . . . . . . . .F24

R71-0721 . . . . . . . . . . . .F24

R71-0722 . . . . . . . . . . . .F24

R73-1210 . . . . . . . . . . . .F24

R73-1212 . . . . . . . . . . . .F24

R73-2201 . . . . . . . . . . . .F24

R73-2202 . . . . . . . . . . . .F24

R73-2203 . . . . . . . . . . . .F24

SIS-1000 . . . . . . . . . . . . F12

SIS-6400 . . . . . . . . . . . . F12

T76-1522 . . . . . . . . . . . .F22

T76-2122 . . . . . . . . . . . .F22

T76-2322 . . . . . . . . . . . .F22

T76-3121 . . . . . . . . . . . .F22

T76-3122 . . . . . . . . . . . .F22

T77-6000 . . . . . . . . . . . .F22

T77-1200 . . . . . . . . . . . .F22

T80-0485 . . . . . . . . . . . .F12

Page 26

®

1890 SwarthmoreAvenue, PO Box 2020 Lakewood, NJ 08701

tel. 800-5 26-3694, 732-363 -4700 , fa x.732-36 4-8110

www.chgusa.com

Loading...

Loading...