Page 1

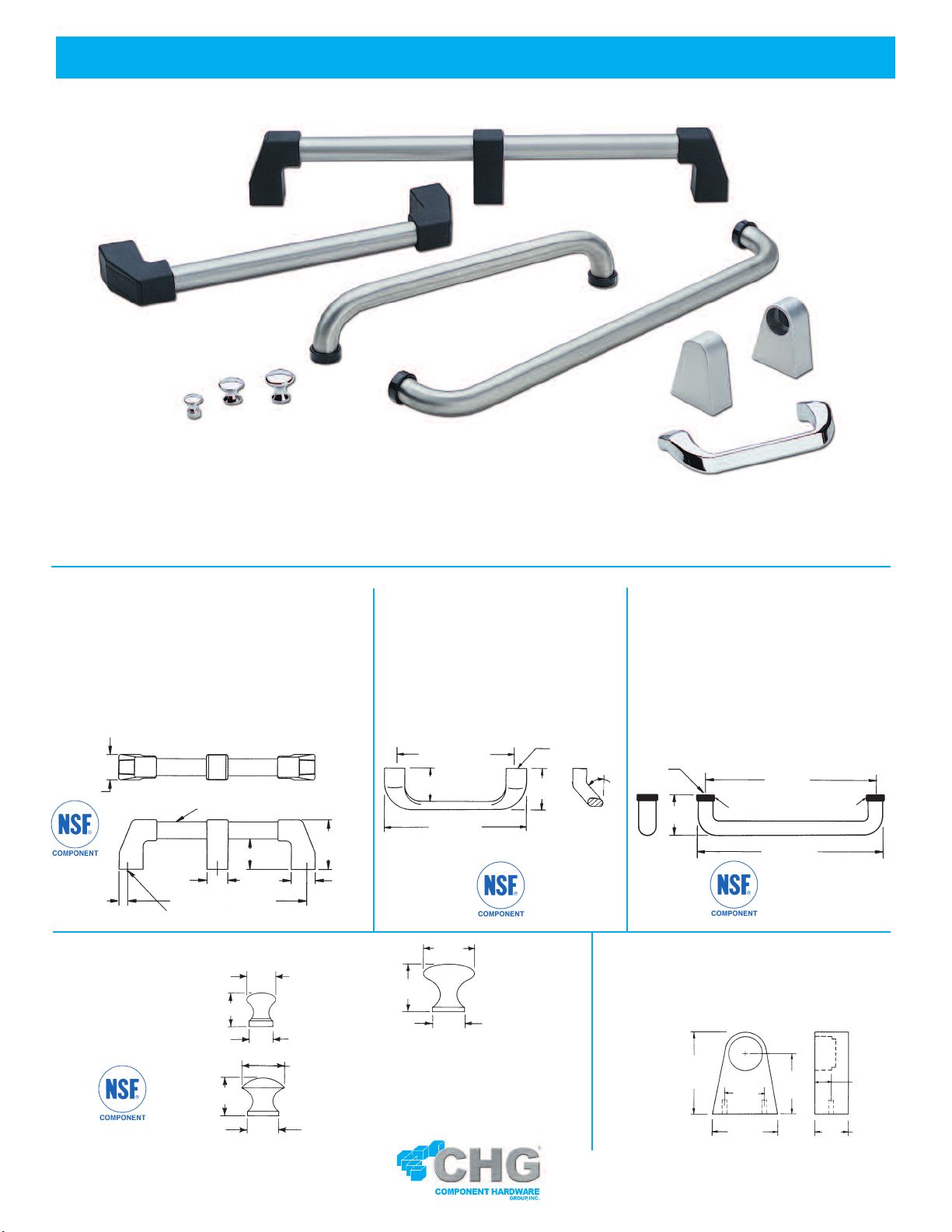

CABINET HARDWARE

®

Page 2

ALPHABETICAL INDEX

DESCRIPTION PAGE

B

BALL BEARING ASSEMBLIES . . . . . . . . . . . . . . . . .G29

BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . .G26 thru G29

BOLT, SECURITY . . . . . . . . . . . . . . . . . . . . . . . . . . . G15

BRACKETS, HANDLE . . . . . . . . . . . . . . . . . . . . . . . . .G4

BUMPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G25

C

CASH BOXES, CASH DRAWERS . . . . . . . . . . . . . . .G23

CATCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G14, G15

CARDHOLDER-PULL . . . . . . . . . . . . . . . . . . . . . . . . .G8

CONCAVE BEARINGS . . . . . . . . . . . . . . . . . . . . . . .G28

D

DOOR GUIDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G30

DOOR STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G30

DRAWER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . .G22

DRAWER BOTTOM PLATES . . . . . . . . . . . . . . . . . .G22

DRAWER BRACKETS . . . . . . . . . . . . . . . . . . . . . . .G24

DRAWER FRONTS . . . . . . . . . . . . . . . . . . . . . . . . . .G24

DRAWER PANS . . . . . . . . . . . . . . . . . . . . . . . . . . . .G21

DRAWER SLIDES . . . . . . . . . . . . . . . . . . .G16 thru G20

DRAWER SPACERS . . . . . . . . . . . . . . . . . . . . . . . .G22

F

FLAT BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . .G27

G

GRAB BARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G2

GROMMETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G25

GUIDE PINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G30

H

HANDLE BRACKETS . . . . . . . . . . . . . . . . . . . . . . . . .G4

HANDLES . . . . . . . . . . . . . . . . . . . . . . . . . . .G3, G4, G8

DOOR HANDLES . . . . . . . . . . . . . . . . . . . . . . . . . . . .G1

HAND RAILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G2

HASP & STAPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G8

HINGES . . . . . . . . . . . . . . . . . . . . . . . . . . . .G9 thru G11

CONTINUOUS HINGES . . . . . . . . . . . . . . . . . . . . . . .G9

DESCRIPTION PAGE

H

CONCEALED CABINET HINGES . . . . . . . . . . . . . . .G11

CONCEALED PIVOT HINGES . . . . . . . . . . . . . . . . .G11

LATCH HINGES . . . . . . . . . . . . . . . . . . . . . . . . . . . .G11

BUTT HINGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G11

PIVOT HINGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G11

LIFT-OFF HINGES . . . . . . . . . . . . . . . . . . . . . . . . . .G10

K

KNOBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G4

L

LATCHES . . . . . . . . . . . . . . . . . . . . . . .G7, G8, G9, G10

LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G12, G13

O

OVERHEAD TRACK COMPONENTS . . . . . . . . . . . .G30

P

PADDLE LATCHES . . . . . . . . . . . . . . . . . . . . . . . . . . .G7

PULL/PUSH PLATES . . . . . . . . . . . . . . . . . . . . . . . . .G1

PULLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G5, G6, G8

PULLEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G29

R

RUBBER TIRE BEARINGS . . . . . . . . . . . . . . . . . . .G28

S

SECURITY BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . .G15

SHEAVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G30

SLIDING DOOR COMPONENTS . . . . . . . . . . . . . . .G30

STUD, FEMALE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G6

SUPPORTS, HANDLE . . . . . . . . . . . . . . . . . . . . . . . .G4

T

THUMBSCREW FASTENER . . . . . . . . . . . . . . . . . . .G5

W

WHEELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G29

All photographs and illustrations are considered to be a representation of the actual item. In some cases there may be slight variations.

This catalog, copy, part numbers and unique method of illustrating products is copyright Component Hardware Group. All rights reserved.

No portion of this catalog may be reproduced in any form or by any means in whole or in part, without the written consent of Component

Hardware Group, Inc. Component Hardware Group, Inc. reserves the right to make any and all changes and to discontinue

any of its products without notice. Not responsible for typographical errors.

© COPYRIGHT 2009, COMPONENT HARDWARE GROUP, INC.

#CAT-X027 05/09–3M PRINTED IN THE U.S.A.

NUMERICAL INDEX ON INSIDE BACK COVER

Page 3

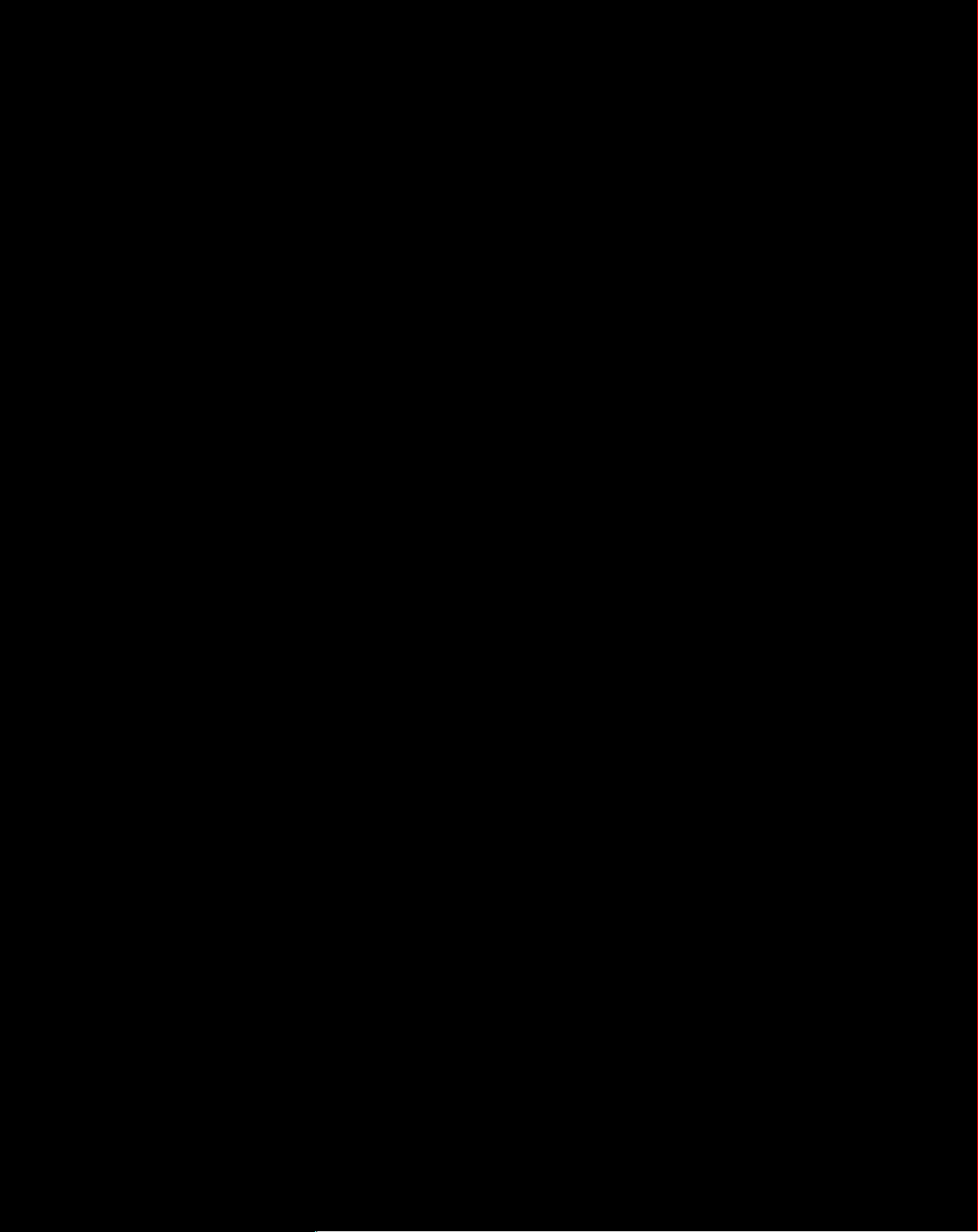

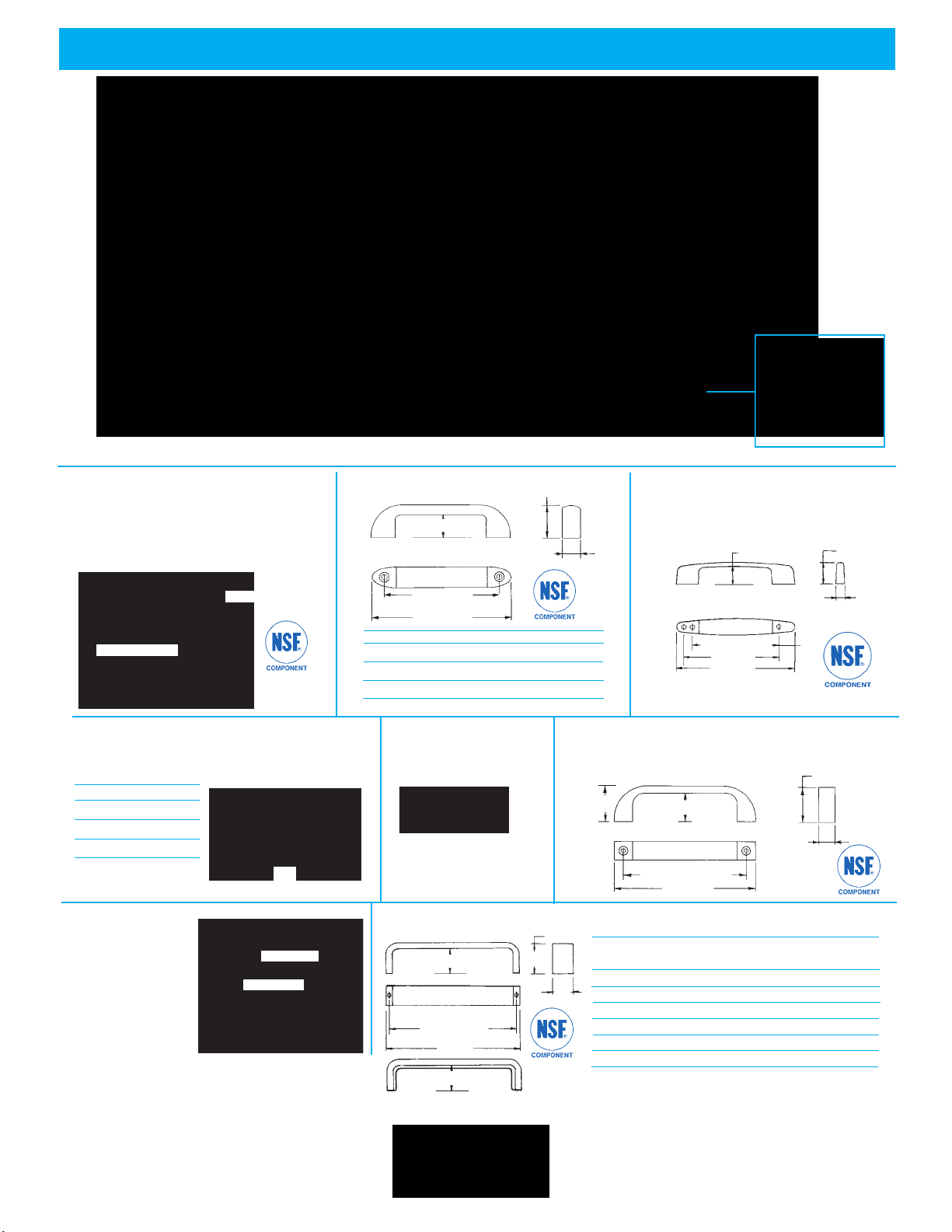

door handles & pull/push plates

16”

(406mm)

4”

(101mm)

3”

(76mm)

7-1/2”

(190.5mm)

7-1/2”

(190.5mm)

4”

(102mm)

1”

(25mm)

1-3/4”

(44.5mm)

P75-X019

PUSH PLATE

P75-X018

PULL PLATE

1/2” 18 GUAGE THICKNESS

1” TUBING

(25.4mm)

4”

(101.6mm)

1/2”

(12.7mm)

1/4”

(6.3mm)

6 HOLES

16”

(406mm)

10”

(254mm)

6 HOLES

2-1/2”

(63.5mm)

Antimicrobial

By CHG

SANIGUARD

7-1/2”

(190.5mm)

3”

(76.2mm)

7-1/2”

(190.5mm)

1/2”

(12.7mm)

1/4”

(6.3mm)

4”

(101.6mm)

1/2”

(12.7mm)

3”

(76.2mm)

16”

(406mm)

7-1/2”

(190.5mm)

7-1/2”

(190.5mm)

1/2”

(12.7mm)

Antimicrobial

By CHG

SANIGUARD

A

REF. A

SaniGrasp™ DOOR HANDLE

n Heavy Duty Construction n Mounting Hardware Included

n Full 1” Angled Tubular Pull for Opening Ease with the Forearm

n Hole Patterns to Match Most Standard Door Push-Pull Plates

Make Retro-Fit Easy n Provided with SANIGUARD

®

Antimicrobial

Product Protection n Eliminates the Need to Use Your Hand to Open

Restroom Door After Washing Your Hands

n ADA and ABA Compliant

MODEL NO. SG-101

B

REF. B

PULL/PUSH PLATES

n All Stainless Steel Construction n Retro-fits to most common

push/pull plate hole-patterns n SANIGUARD®treatment inhibits the

growth of bacteria, molds and fungi, which can cause odors, staining

and product deterioration and eliminates fingerprints n SANIGUARD

product protection will last for the useful life of the product

MODEL NO. P75-4000

MODEL NO. P75-5000

®

P75-5000

NOTE: SANIGUARD®PRODUCT PROTECTION IS DESIGNED TO KEEP THE PRODUCT FRESHER AND CLEANER BETWEEN NORMAL

CLEANING ROUTINES. IT IS NOT A DISINFECTANT AND WILL NOT PROTECT USERS OR OTHERS AGAINST FOOD-BORNE ILLNESS OR

DISEASE. ALWAYS USE GOOD HYGIENE AND CLEANING PRACTICES.

www.chg usa.c om

G1

Page 4

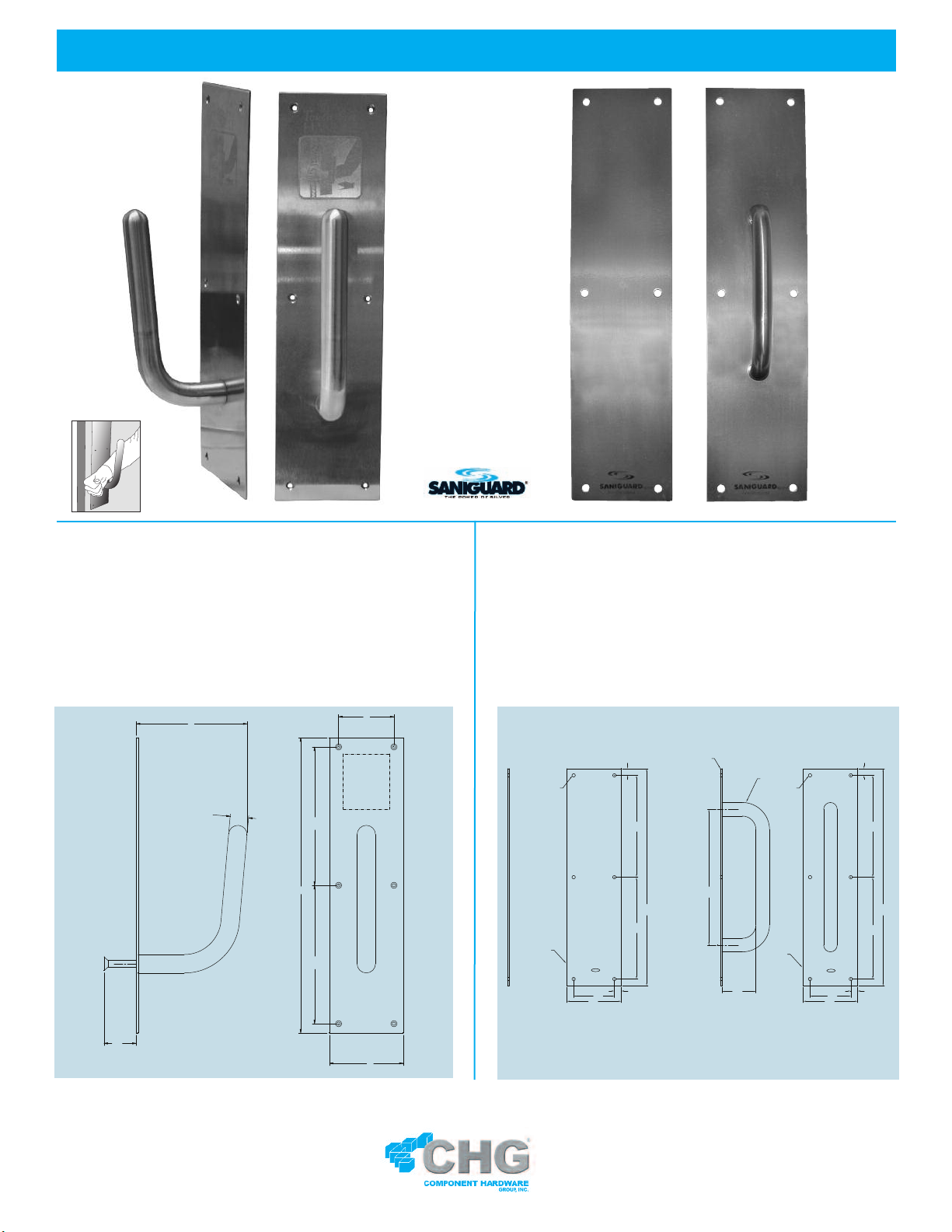

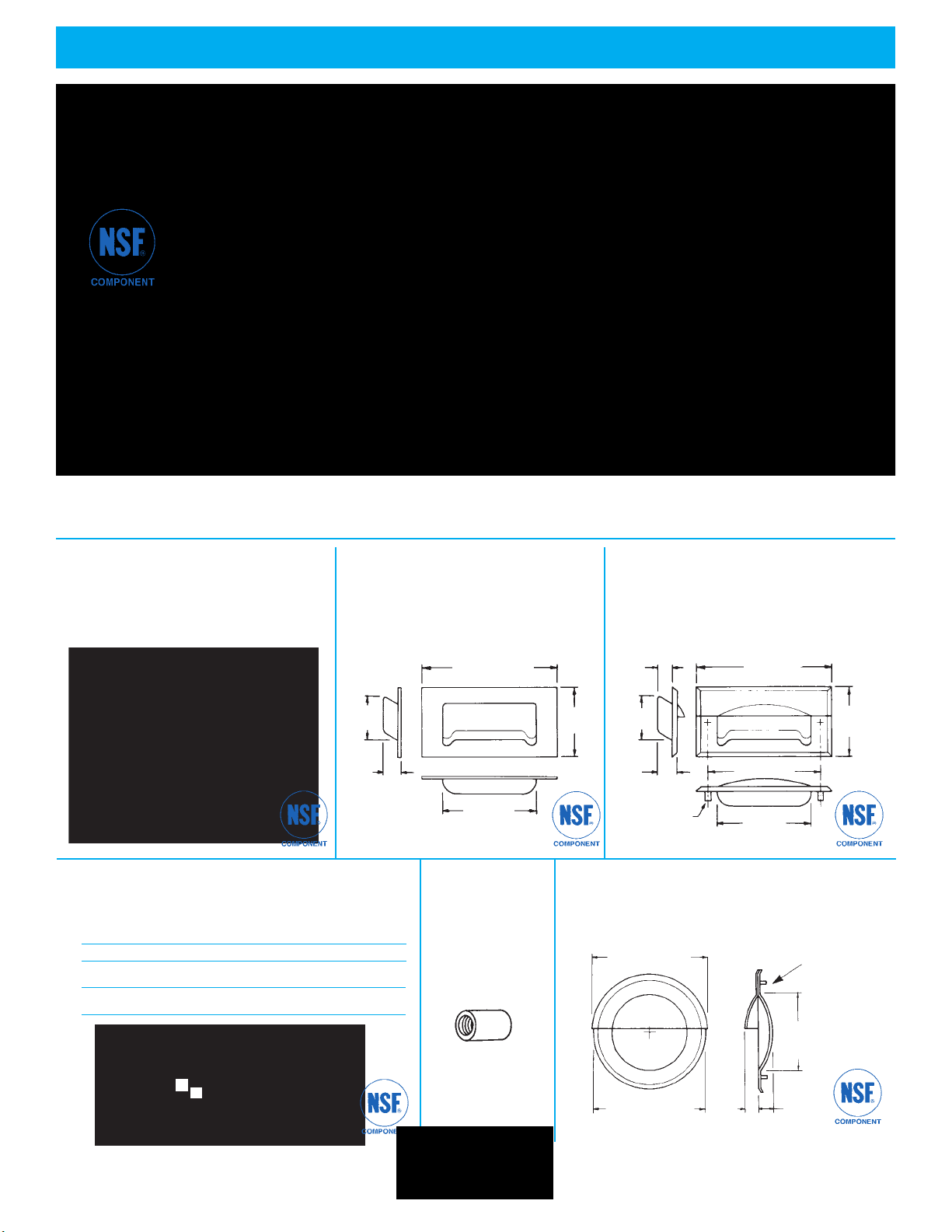

grab bars

KNURLED

FINISH

3”

(

77.5mm)

3

-1/2”

(88.9mm)

LENGTH

(R

1

.

2

5

)

1

2

0

°

T

Y

P

1

2

0

°

T

Y

P

(3) 0.25 HOLES EQUALLY SPACED ON A 2.50 BOLT CIRCLE

FOR (3) S/S #10 PHILIPS PHS X 1 3/4" LG.

30”

30”

5/8”

5/8”

3”

(77.5mm)

LENGTH

(

R

1

.

2

5

)

1

2

0

°

T

Y

P

1

2

0

°

T

Y

P

(3) 0.25 HOLES EQUALLY SPACED ON A 2.50 BOLT CIRCLE

FOR (3) S/S #10 PHILIPS PHS X 1-3/4" LG.

3-1/2”

(

88.9mm)

A

C

D

B

GRAB BARS AND HAND RAILS

REF. A REF. B

SMOOTH FINISH GRAB BAR

DIMENSION

12" (305mm)

16" (406mm)

18" (457mm)

24" (610mm)

30" (762mm)

32" (813mm)

36" (914mm)

42" (1067mm)

48" (1219mm)

MODEL NO.

GBS15-1112-Q

GBS15-1116-Q

GBS15-1118-Q

GBS15-1124-Q

GBS15-1130-Q

GBS15-1132-Q

GBS15-1136-Q

GBS15-1142-Q

GBS15-1148-Q

KNURLED FINISH GRAB BAR

DIMENSION

12" (305mm)

16" (406mm)

18" (457mm)

24" (610mm)

30" (762mm)

32" (813mm)

36" (914mm)

42" (1067mm)

48" (1219mm)

MODEL NO.

GBS15-4112-Q

GBS15-4116-Q

GBS15-4118-Q

GBS15-4124-Q

GBS15-4130-Q

GBS15-4132-Q

GBS15-4136-Q

GBS15-4142-Q

GBS15-4148-Q

Stainless steel, 1-1/2” diameter grab bars. Available in smooth or knurled finish, complete

with concealed mounting flange and press-on flange cover. All grab bars are permanently

coated with SANIGUARD

NOTE: SANIGUARD

FRESHER AND CLEANER BETWEEN NORMAL CLEANING ROUTINES. IT IS NOT A

DISINFECTANT AND WILL NOT PROTECT USERS OR OTHERS AGAINST FOOD-BORNE

ILLNESS OR DISEASE. ALWAYS USE GOOD HYGIENE AND CLEANING PRACTICES.

®

treatment.

®

PRODUCT PROTECTION IS DESIGNED TO KEEP THE PRODUCT

REF. C

PRISON STYLE GRAB BAR

DIMENSION

12" (305mm)

16" (406mm)

18" (457mm)

24" (610mm)

30" (762mm)

32" (813mm)

36" (914mm)

42" (1067mm)

48" (1219mm)

REF. D

MODEL NO.

GBS15-1112-QP

GBS15-1116-QP

GBS15-1118-QP

GBS15-1124-QP

GBS15-1130-QP

GBS15-1132-QP

GBS15-1136-QP

GBS15-1142-QP

GBS15-1148-QP

SMOOTH L-SHAPED GRAB BAR

DIMENSION

30" x 30" GRAB BAR

40" x 30" GRAB BAR

MODEL NO.

GBS15-113030Q

–

KNURLED L-SHAPED GRAB BAR

DIMENSION

30" x 30" GRAB BAR

40" x 30" GRAB BAR

MODEL NO.

GBS15-413030Q

GBS15-414030Q

GBS15-113030Q

G2

www.chg usa.c om

Page 5

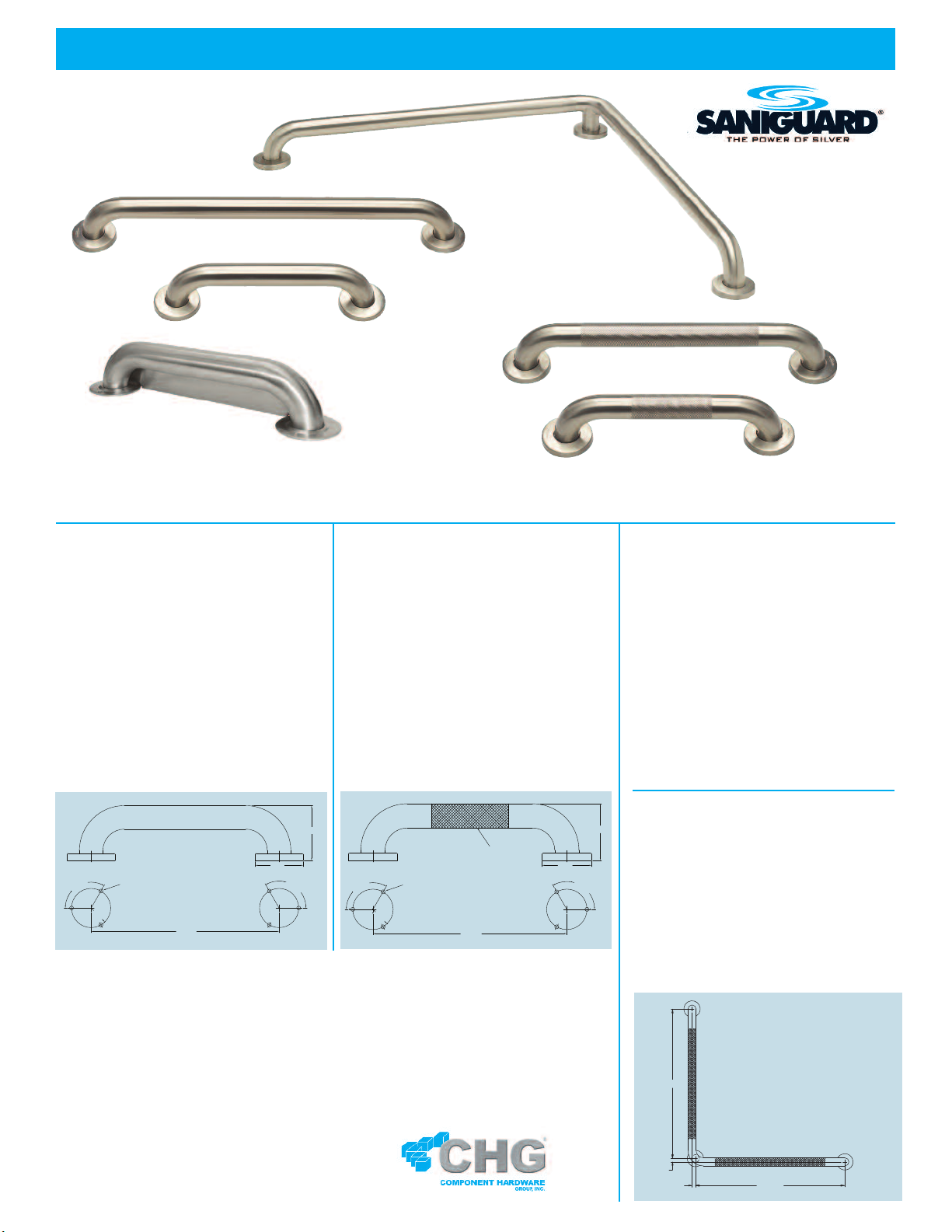

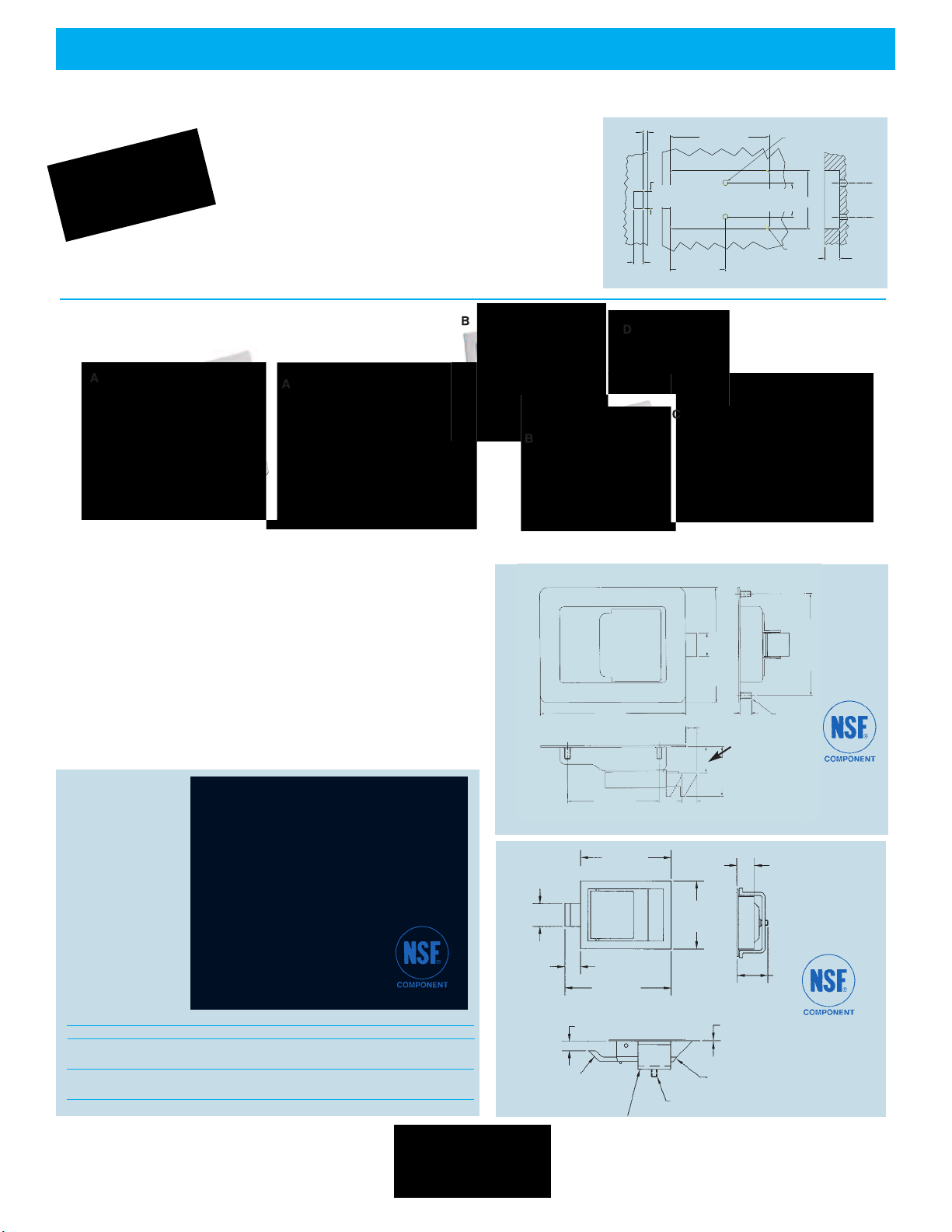

handles

1”

(25mm)

7/8”(22mm)

1-13/32”(36mm)

O.A. LENGTH

A

B

O.A. LENGTH

HANDLES

SCULPTURED HANDLES

featuring...

SOLID METAL CASTING POLISHED CHROME FINISH

FRONT or REAR FASTENING TWO LENGTHS AVAILABLE

MODEL NO. O.A. LENGTH “A” DIM. “B” DIM.

P48-1010 14-5/8”(371mm) 13-7/16”(340mm) 12-7/16”(316mm)

P48-1012 12-13/16”(325mm) 11-5/8”(295mm) 10-5/8”(270mm)

NOTES:”A” DIMENSION REPRESENTS HOLE CENTERS FOR FRONT MOUNTING #10

SCREWS. “B” DIMENSION REPRESENTS THREADED HOLE CENTERS TO RECEIVE

1/4-20 SCREWS FOR REAR MOUNTING. DECORATIVE TRIM INSERTS ARE SUPPLIED

TO CONCEAL FRONT MOUNTING SCREWS. EXTRA TRIM INSERTS ARE AVAILABLE

AND MAY BE ORDERED AS P48-X002.

DECORATIVE HANDLES

featuring...

DUAL MOUNTING...FRONT OR REAR

TWO STANDARD LENGTHS AVAILABLE

HEAT RESISTANT HEAVY DUTY CONSTRUCTION

ANODIZED ALUMINUM HANDLE with NYLON SUPPORTS

1-7/16”

(37mm)

O.C. MOUNTING

DIM

NOTES: PRE-ASSEMBLED HANDLES WILL ACCEPT SCREWS FOR FRONT MOUNTING.

INTERNAL BRASS BUSHINGS ACCEPT STANDARD 1/4-20 MACHINE SCREWS FOR

REAR FASTENING. A PRESSURE SENSITIVE BLACK VINYL INSERT CONCEALS

SCREW HOLES. OTHER LENGTHS AVAILABLE UPON APPLICATION ON QUANTITY

ORDERS.

www.chg usa.c om

MODEL NO. O.A. LENGTH O.C. MOUNTING DIM.

P49-1500-6 7-11/16”(195mm) 6”(152mm)

P49-1500 12-1/4”(311mm) 10-5/8”(270mm)

G3

Page 6

handles & knobs

A

A

C

E

D

HANDLES & KNOBS

REF. A REF. B

Fiberglass Reinforced End Brackets(pr.)

Concealed mounting feature. Front or rear mount.

MODEL NO. P49-2100

END BRACKET (PAIR)

REF. D

ALL KNOBS TAPPED TO

RECEIVE #8-32 SCREWS.

HANDLE BRACKETS

Heavy-Duty Nylon

and Center Support Bracket (ea.)

Ideal for mobile carts.

Temperature range to 300°F (149°C).

MODEL NO. P49-2200

CENTER SUPPORT

BRACKET (EACH)

1-1/2”

(38mm)

1” O.D. TUBING SUPPLIED BY CUSTOMER.

TUBING LENGTH IS (A) MINUS 1-9/16” (39mm)

1-13/16”(46mm)

CENTERLINES OF

5/8”

(16mm)

1/2”

(13mm)

CHROME

1-7/32”

(31mm)

MOUNTING HOLES (A)

MOUNTING HOLES FOR 3/8” OR M10 HARDWARE

PLATED

KNOBS

11/16”

(17mm)

7/8”(22mm)

3/4”(19mm)

NO. P80-3020

SOLID BRASS

7/16”

(11mm)

NO. P80-3000

SOLID BRASS

2-15/16”

(75mm)

1-13/32”

(36mm)

MATERIAL: CHROME PLATED DIE CAST METAL

1”

(25mm)

C

OFFSET

HANDLE,

Chrome Plated

MODEL NO. P40-1010

1-3/4”

(44mm)

1/4-20

(127mm) O.C.

1-1/2” (38mm)

6-1/8”

(155mm)

O.A.

1”

(25mm)

5/8”

(16mm)

5”

NO. P80-3030

SOLID BRASS

TH’D

B

REF. C

HEAVY- DUTY

TUBULAR HANDLES

Stainless Steel, Satin Finish

MODEL NO. P47-1012

12-7/8”(327mm) O.A. 12”(305mm ) O.C.

MODEL NO. P47-1018

18-7/8”(479mm) O.A. 18”(457mm) O.C.

45°

REF. E

MATERIAL: 7/8”(22mm) O.D. STAINLESS STEEL

1/4-20

TH’D

2-5/8”

(67mm)

HANDLE SUPPORTS,

FORMED TUBING

O.C.

PHENOLIC STAND-OFFS

PROVIDED

O.A.

Aluminum for 1”(25mm) O.D. Tubing

EACH SUPPORT IS TAPPED TO RECEIVE (2) 1/4-20 SCREWS

MODEL NO. P49-1010 (ONE PAIR)

MATERIAL:

DIE CAST

ALUMINUM

WITH SATIN

TEXTURED

FINISH

2-1/2”

(63mm)

1-1/4”

(32mm)

1-7/8”

(48mm)

1/2”

(13mm)

G4

5/8”(16mm)

www.chg usa.c om

2”

(50mm)

1”

(25mm)

Page 7

pulls

D

A

B

B

B

C

HANDLE, Black Nylon Fiberglass

Reinforced with Solid Brass Tapped Inserts

IDEAL FOR HEATED CABINETS.

RATED TO 300°F (149°C TEMPERATURE).

FULL 1-3/8” GRIP CLEARANCE

REF. A

MODEL NO. P53-1012

1-3/8”(35mm)

5-5/8”(143mm)

#10-24 x 5/16 deep

5”(127mm)

REF. D

1-5/8”(41mm)

1”(25mm)

WIRE PULLS, Solid Brass

with Satin Chrome Finish

MODEL NO.

P45-3000

P45-3500

P45-4000

REF. G

“A”

3” (76mm)

3-1/2” (89mm)

4” (102mm)

#8-32

.500”

DEEP

“A”

ALUMINUM

PULL,

1-1/2”(38mm)

Satin Anodized

FULL 1-1/2” GRIP

CLEARANCE

MODEL NO.

4-1/4”(108mm)

5-1/4”(133mm)

1/4-20 x 5/8 deep

4-3/4”(121mm)

P44-5000

D

D

E

PULLS

REF. B

PULLS, Die Cast or Nylon

13/16”(20mm)

#10-24 THREADS

4”

(101.6mm) O.C.

4-3/4” (120mm)

1.3”

(32mm)

5/16”

(8mm)

DIA.

2”

(51mm)

MODEL NO.

P50-1010

P50-1011

P52-1010*

MATERIAL

DIE CAST

DIE CAST

NYLON

*FURNISHED WITH THREADED BRASS INSERTS

REF. E

THUMBSCREW

FASTENER

STAINLESS STEEL

1/2” (13mm)

MODEL NO. P51-1024

USED TO MEET N.S.F. REQUIREMENTS

WHERE HANDLES & PULLS MUST BE

FASTENED OR REMOVED WITHOUT

THE USE OF TOOLS

REF. H, I, J

BAR PULLS,

A

#8-32 THREADS

B

C

F

#1/4-20 THREADS

FINISH

POLISHED CHROME

BUFFED SATIN

GLOSS BLACK

3/8”

(9mm)

#10-24

D

F

G

H

BEVELED BODY FOR

ADDED COMFORT

PULLS,

15/16” (24mm)

I

J

REF. C

Die Cast...Chrome Plated

MODEL NO. P51-1010

5/8” (16mm)

#8-32 THREADS

2-3/4”(70mm)O.C.

3”(76mm)

3-15/16”

(100mm)

(16mm)

REF. F

5/8”

PULLS, Aluminum Alloy...Satin Finish

MODEL NO. P44-1010

1”

(25mm)

Stainless Steel...Satin Finish

DWG.

REF.

A 1”(25mm) 1” (25mm) –––

E

B 5”(127mm) O.C. 4” (101.6mm) O.C. 6”(152mm)

C 5-1/4”(133mm) 4-1/4”(108mm) 6-1/2”(165mm)

D 1-1/4”(32mm) 1-1/4”(32mm) 2”(51mm)

E 5/8”(16mm) 5/8”(16mm) 1-1/16”(27mm)

F ––– ––– 1-9/16”(40mm)

13/16”(20mm)

#8-32 THREADS

4”(101.6mm) O.C.

4-5/8”

(117mm)

MATERIAL: 1/4”(6mm) THICK

SOLID STAINLESS STEEL

MODEL NO. MODEL NO. MODEL NO.

P46-1010 P46-1012 P46-5006*

PHOTO REF. I PHOTO REF. H PHOTO REF. J

1”(25mm)

1/2”

(13mm)

* NOT NSF LISTED

3/4” (19mm)

5/16” (8mm)

www.chg usa.c om

G5

Page 8

recessed pulls

B

A

C

D

A

REF. B

DOOR PULL, Stainless Steel

with Frame Beveled Edge

MODEL NO. P62-1010

RETAINING LOCKNUTS PROVIDED

1/2”(13mm)

1-3/4”

(44mm)

5/8”

(16mm)

#10-24 x 3/8”(10mm)

TH’D STUDS

4-3/4”

(120mm)

4”(101.6mm)

3-1/2”

(89mm)

2-7/16”

(62mm)

RECESSED PULLS

REF. C

DOOR PULL,

Flush Type for Welding

MODEL NO. P62-1014

1-3/4”

1-3/4”

(44mm)

(44mm)

5/8”

5/8”

(16mm)

(16mm)

Stainless Steel

4-3/4” (120mm)

3-1/2”

3-1/2”

(89mm)

(89mm)

2-7/16”

2-7/16”

(62mm)

(62mm)

E

REF. D

F

DRAWER PULL, Stainless Steel

Full Grip Type with

Frame Beveled Edge

MODEL NO. P63-1012

RETAINING LOCKNUTS PROVIDED

1/2”(13mm)

1-3/4”

(44mm)

5/8”

(16mm)

#10-24 x 3/8”

(10mm)

TH’D STUDS

4-13/16”

(122mm DIA.)

4”(101.6mm)

3-1/2”

(89mm)

2-7/16”

(62mm)

REF. A

RECESSED DOOR PULL

Black ABS Thermoplastic Shock Resistant

ONE PIECE CONSTRUCTION FOR FAST, EFFICIENT INSTALLATION

MODEL NO. A B C D E F

P73-1000

P73-2000

(127mm) (138mm) (25mm) (37mm) (40mm) (16mm)

(178mm) (189mm) (33mm) (44mm) (52mm) (22mm)

G6

Snap-in Style

5” 5-7/16” 1” 1-7/16” 1-9/16” 5/8”

7” 7-7/16” 1-5/16” 1-3/4” 2-1/16” 7/8”

D

C

A

B

F

REF. E

REF. F

ROUND PULL, Stainless Steel

FEMALE

STUD

PANEL

THICKNESS

18 GA

22 GA

E

Converts Male Stud

To Female

IDEAL FOR USE ON

WOOD CABINETS

#10-24 THʼD X 5/8”

(16mm) LG.

MODEL NO.

P50-5000

www.chg usa.c om

with Beveled Edge Mount

MODEL NO. P60-1010

RETAINING LOCKNUTS PROVIDED

4-13/16”

(122mm) DIA.

3-1/2”

(89mm)

4-11/16”

(119mm) DIA.

5/8”

(16mm)

9/16”

(14mm)

(3) #10-24 X

3/8”(10mm)

TH’D STUDS

EQUALLY

SPACED

ON 4”(101mm)

DIA.

Page 9

heavy-duty stainless steel slide & paddle latches

FLUSH MOUNT HEAVY- DUTY STAINLESS STEEL SLIDE LATCH

BRUSHED STAINLESS STEEL FINISH

RUGGED STAINLESS CONSTRUCTION WITH

BRUSHED ALUMINUM GRIP

ALLOWS FOR CLEAN, FLUSH MOUNTING

ECONOMICALLY PRICED

UNIQUE REAR MOUNTING BRACKET PROVIDES

MODEL NO.

P90-9000

FAST INSTALLATION

IDEAL FOR MOBILE CARTS AND ACCESS DOORS

WHERE CONVENTIONAL SURFACE MOUNTED

HARDWARE IS INAPPROPRIATE

A

A

HEAVY- DUTY STAINLESS STEEL PADDLE LATCHES

BRUSHED STAINLESS STEEL FINISH

RUGGED ALL STAINLESS CONSTRUCTION

ALLOWS FOR CLEAN, FLUSH MOUNTING

ECONOMICALLY PRICED

CONVENIENT SIZE LATCHES OFFER A WIDE

RANGE OF APPLICATION

UNIQUE REAR MOUNTING BRACKET PROVIDES

FAST INSTALLATION

IDEAL FOR MOBILE CARTS AND ACCESS DOORS

WHERE CONVENTIONAL SURFACE MOUNTED

HARDWARE IS INAPPROPRIATE

1-29/32”

(48.4mm)

1-13/32”

(35.7mm)

F

G

0.63”

(1.mm)

.048”

(1.6mm)

REF. A

A

MODEL NO.

P90-5000-C

WITH LOCK

4-7/8”

(124mm)

3-5/16”

(84mm)

E

I

SLIDE

(98mm)

2-11/16”

(68mm)

D

3-7/8”

7/16”(11mm) MAX

1/32”(1mm) MIN

MTG KIT

5-3/8”

(137mm)

(13mm)

3-5/8”

(92mm)

C

1/2”

5/16”

(8mm)

LATCH ASSʼY

MODEL NO.

P90-5000

W/O LOCK

REF. B

MODEL NO.

P90-2000-C

WITH LOCK

MODEL NO.

P90-2000

W/O LOCK

REF. MODEL NO. A B C D E F G H I

P90-5000

A

P90-5000-C

P90-2000

B

P90-2000-C

1-5/32”

(29mm)

3/4”

(19mm)

H

B

1-1/32”

(26mm)

3/4”

(19mm)

7/16”

(11mm)

5/16”

(11mm)

5/32”

(3.9mm)

9/16”

(14.3mm)

5/16”

(7.9mm)

B

D

1-27/32”

(46.8mm)

3-5/16”

(84.13mm)

(4.7mm)

1-1/8”

(28.5mm)

1-15/16”

(49.2mm)

3/16”

1/2”

(12.7mm)

C

B

3-5/16”

(84mm)

#10-24

STUD

REF. C

MODEL NO.

P91-5000

13/32”

(10mm)

REF. D

MODEL NO.

P90-1000

9/16”

(14mm)

3/8”

(9.5mm)

(6.3mm)

1/4”

SLIDE

4-3/4”

(121mm)

3”

(76mm)

2-5/8”

(66mm)

RETAINING

BRACKET

2-3/16”

(55mm)

3/8”

(10mm)

1/2”(13mm)

SCREW

(95mm)

TRAVEL

1-5/8”

(41mm)

3/4”

(19mm)

3-3/4”

3/8”(10mm)

1-5/8”

(41mm)

.036”

(.9mm)

LATCH

ASSEMBLY

7/8”

(22mm)

15/16”

(24mm)

www.chg usa.c om

G7

Page 10

pulls & catches

HASP & STAPLE, Stainless Steel

MODEL NO. M80-2500

2-1/2” x 1” x .072

(63mm x 25mm x 2mm)

1-1/4”

3-3/8”

(86mm)

(31mm)

9/16”

(14mm)

MODEL NO. LENGTH WIDTH HOLES

M10-8332

M10-8333

M10-8333

Heavy Duty, STRAIGHT BACK

DROP HANDLE, Stainless Steel

1-3/4”

(44mm) 2-3/4”

1-1/4”(32mm)

ACTION CATCHES

Stainless Steel

3-3/8”

(86mm)

4”

(101mm)

MODEL NO. M80-3500

3-1/2” x 1-1/2” x .077

(89mm x 38mm x 2mm)

DRAWER-TITE

2-1/4”

(57mm)

3-3/8”

(86mm)

(70mm)

1”

(25mm)

1-1/4”

(31mm)

PULLS & CATCHES

CARDHOLDER & PULL, Stainless Steel

1”

(25mm)

1”

(25mm)

.132

(3mm)

.195

(5mm)

9/16”

(14mm)

5/16”

(8mm)

2-1/4”

(57mm)

M10-8332

MODEL NO.

P68-1010

2-1/4”

(57mm)

2-1/4”

(57mm)

MODEL NO. P88-1010

1-7/16”(36mm)

15/16”

(23mm)

2-1/32”

(51mm)

OVERALL SIZE: 2-15/16” x 1-5/16”

CARD SIZE: 2-1/8” X 1-1/8”

LINK-LOCKING LATCH,

Stainless Steel

MODEL NO. M11-8201

HEIGHT: 2-1/4”(57mm)

WIDTH: 1-7/16”(36mm)

PROFILE: 1/2” (12mm)

PULL DOWN PRESSURE: 90 LBS. (41kg)

LOAD CAPACITY: 300 LBS. (136kg)

(74mm x 33mm)

(54mm x 28mm)

STRAIGHT BACK

DROP HANDLE, Stainless Steel

3-1/2”

(89mm)

1-1/4” (32mm)

3-3/8”

(86mm)

3/8” (8mm)

1/4”

(6mm)

MODEL NO.

P70-1010

1-3/8”

(35mm)

G8

www.chg usa.c om

Page 11

cabinet latches, handles latches & continuous hinges

CABINET LATCHES, HANDLES LATCHES & CONTINUOUS HINGES

PROVIDED WITH FLUSH, 1/8”(3.2mm) and 3/8”(9.5mm) KEEPERS

1/2”

(12.7mm)

11/32”

(8.7mm)

1-13/32”

(35.7mm)

7/8”

(22.2mm)

7/32”(5.5mm)

HEAVY DUTY

MODEL NO. M15-9211

3-1/8”

(79mm)

4-1/2”

(114mm)

1-11/16”

(43mm)

1-5/8”

(42mm)

CABINET LATCHES

CHROME PLATED DIE CAST ZAMAK

1-1/8”

(28.5mm)

9/32”

(7.1mm)

11/16”

(17.4mm)

7/8”

(22.2mm)

1-7/8”

(47.5mm)

2-5/16”

(47.5mm)

1-7/8”

(47.6mm)

MODEL NO. M15-9210

HANDLE LATCHES

Chrome Plated Die Cast Metal

3-1/2”

(89mm)

O.A. 89mm

3/8-24 Square

Threaded Shaft

3-1/2”

(89mm)

O.A. 89mm

3/8-24 Square

Threaded Shaft

TYPE “TEE” HANDLE LATCH with CYLINDER LOCK

MODEL NO. M37-1105

TYPE “TEE” HANDLE LATCH without LOCK

MODEL NO. M37-1305

TYPE “ELL” HANDLE LATCH with CYLINDER LOCK

MODEL NO. M37-1107

TYPE “ELL” HANDLE LATCH without LOCK

MODEL NO. M37-1307

NOTE: ALL HINGES ARE PROVIDED WITH A 3/8 - 24 x 3-1/2”

(89mm) LONG THREADED SHAFT COMPLETE WITH PAWL,

RETAINER PLATE, LOCKWASHER AND JAMNUT. STANDARD

GRIP RANGE IS 5/8” TO 3/4”(16mm TO 19mm). HANDLES ARE

RIGHT HANDED. LOCKING MODELS ARE FURNISHED KEYED

ALIKE. ADAPTABLE FOR THREE POINT LATCHING.

3/8”(9.5mm)

11/16”

(17.4mm)

1-1/2”

(38.1mm)

1-13/16”

3/16”(4.7mm)

(46mm)

STANDARD DUTY

1-1/2”

(38.1mm)

MODEL NO. WIDTH LENGTH GAUGE PIN DIA.

M48-0112

M48-0121

M48-0122

M48-0131

M48-0132

M48-0142

M48-0143

M48-0144

M48-0154

M48-0134

NOTE:

HINGE FURNISHED WITHOUT HOLES.

OTHER SIZES AVAILABLE UPON

REQUEST.

CONTINUOUS HINGE

Stainless Steel (18-8)

with STAINLESS STEEL PIN

3/4”

(19mm)

1-1/16”

(27mm)

1-1/16”

(27mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

2”

(50mm)

2”

(50mm)

2”

(50mm)

2-1/2”

(63mm)

1-1/2”

(38mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

72”

(1820mm)

.035

(.8mm)

.035

(.8mm)

.040

(1mm)

.035

(.8mm)

.040

(1mm)

.040

(1mm)

.050

(1.2mm)

.060

(1.5mm)

.060

(1.5mm)

.060

(1.5mm)

WIDTH

.086

(2.2mm)

.086

(2.2mm)

.086

(2.2mm)

.090

(2.3mm)

.090

(2.3mm)

.120

(3mm)

.120

(3mm)

.120

(3mm)

.187

(4.7mm)

.125

(3.1mm)

www.chg usa.c om

G9

Page 12

latches & hinges, lift-off

8-3/4”

1-13/16”

4-13/16”

2”

3”

2-1/4”

5/8” SQUARE

2-3/8”

1-3/8”

8-1/4”

2-9/16”

7-3/8”

OPEN

THREE POINT LATCH

THREE POINT LATCH

Stainless Steel

All stainless steel construction.

Positive dead bolt locking

Holds door closed in 3 places-

top, center, & bottom to minimize

leakage and save energy

Strongest latch made

Spring loaded over-center latching

Positive inside release mechanism

RIGHT HAND HINGE ILLUSTRATED

HINGES, LIFT-OFF

LIFT-OFF FLAG HINGE, Stainless Steel

LENGTH OPEN GAUGE PIN DIA. HAND MODEL NO.

1-3/4”

(44mm)

1-3/4”

(44mm)

2”

(50mm)

2”

(50mm)

1-1/4”

(32mm)

1-1/4”

(32mm)

NOTES: ALL HINGES ARE FURNISHED WITHOUT HOLES

(1.5mm)

(1.5mm)

LENGTH

2”(50mm)

2”(50mm)

3”(75mm)

3”(75mm)

2”(50mm)

2”(50mm)

.075

(2mm)

.075

(2mm)

.075

(2mm)

.075

(2mm)

.060

.060

3/16”

(4.7mm)

3/16”

(4.7mm)

3/16”

(4.7mm)

3/16”

(4.7mm)

1/8”

(3mm)

1/8”

(3mm)

R.H.

L.H.

R.H.

L.H.

R.H.

L.H.

R74-8000-RH

R74-8001-LH

R74-8100-RH

R74-8101-LH

R74-9000-RH

R74-9001-LH

MODEL NO. W37-3000-SS

LIFT-OFF FLAG HINGE

Stainless Steel

SWEDGED KNUCKLE NON-HANDED

STAINLESS STEEL and NYLON BEARING

ELIMINATES MORTISING OF DOOR OR JAMB

MINIMUM DOOR CLEARANCE REQUIRED

STANDARD DUTY...MODEL NO. M75-1002

2-1/16”(52mm) LG. x 1-3/32”(28mm) x .075(2mm)

3/16”(4.7mm) PIN DIA.

HEAVY DUTY...MODEL NO. M75-5003

3”(76mm) LG. x 1-3/8”(35mm) x .075(2mm)

1/4”(6.3mm) PIN DIA.

TOP VIEW

LENGTH

G10

www.chg usa.c om

Page 13

hinges

C

D

A

B

REF. A

CONCEALED PIVOT HINGES,

Stainless Steel

1-3/8”

(35mm)

MODEL NO.

R76-1000

(7.92mm)

7/8”

(22mm)

5/16”

(9.5mm)

5/16”

(7.92mm)

LOCK

WASHER

PIVOT HINGE

Ø 3/8”

1-3/4”

(44mm)

PIN

5/16”

(7.92mm)

BUSHING

7/8”

(22mm)

2-7/8”

(73mm)

1-3/16”

(30mm)

MOUNTING HOLES

FOR #10 PHMS (2)

OBLONG MOUNTING HOLES FOR EASY DOOR ADJUSTMENT

SELF-LUBRICATING BRONZE PIVOT BUSHING

REMOVABLE PIVOT PIN ALLOWS DOOR TO BE REMOVED WITHOUT

DISASSEMBLING ENTIRE BRACKET

SUPPLIED AS A SET...REVERSIBLE FOR LEFT OR RIGHT-HANDED

DOORS

INTERCHANGEABLE WITH KASON #1510/11 AND #1530/31

REF. C

BUTT HINGES, Stainless Steel

MODEL NO. M74-2078

2” (50mm) LG. x 2” (50mm) OPEN x 14 GA. (2mm)

3”(76mm) LG. x 3”(76mm) OPEN x 14 GA. (2mm)

.187 (5mm) PIN DIA.

MODEL NO. M74-3078

.187 (5mm) PIN DIA.

HINGES

REF. B

3/8”

(9.5mm)

REF. D

7/16”

(11mm)

DOOR

BRKT

3/4”

(19mm)

LATCH HINGES, Stainless Steel

B

C

MODEL NO.

M12-9292

M12-9293

M12-9294

M12-9295

A

A B C D GAUGE

7/8” 1/8” 1/2” 3/16” .035

(22mm) (3.1mm) (12.7mm) (4.7mm) (.8mm)

1-3/8” 5/32” 3/4” 1/4” .040

(35mm) (3.9mm) (19mm) (6.3mm) (.1mm)

2” 3/16” 7/8” 3/8” .050

(50mm) (4.7mm) (22.2mm) (9.5mm) (1.2mm)

2-3/4” 1/4” 1” 1/2” .062

(70mm) (6.3mm) (25.4mm) (12.7mm) (1.5mm)

D

PIVOT HINGES, Nickel Plated Steel

3/8”

(9.5mm)

3”

(76.2mm)

(25.4mm)

1-5/16”

(33.3mm)

SIDE VIEW

1”

1/4”

(6.3mm)

CSK &

HOLE

FOR #10

OR M5

11/16”

(17mm)

3/4”

(19mm)

1-7/8” (47mm)

1-5/8” (41mm)

JAM

BRKT

3-5/16”

(84mm)

1/2”

(12.7mm)

3-5/16”

(84mm)

NOTE: HINGES ARE FURNISHED WITHOUT HOLES.

SMALL OFFSET

MODEL NO. R75-6661

www.chg usa.c om

LARGE OFFSET

MODEL NO. R75-6662

G11

Page 14

locks

LOCKS

UTILITY LOCKS, Stainless Steel Faced

DISC TUMBLER

FOUR BARREL LENGTHS AVAILABLE

PERMITS MATERIAL THICKNESS TO 1-3/16”(30mm)

KEY REMOVABLE IN LOCKED OR UNLOCKED POSITION

FURNISHED WITH TWO BRASS KEYS

UTILITY LOCKS, STAINLESS STEEL FACED

MODEL NO. A B C KEYING

P30-4750 9/32”(7mm) 5/8”(16mm) 7/8”(22mm) ALIKE

P30-4751 9/32”(7mm) 5/8”(16mm) 7/8”(22mm) DIFFERENT

P30-4752 9/32”(7mm) 5/8”(16mm) 7/8”(22mm)

P30-4760 11/16”(17mm) 7/8”(22mm) 1-1/8”(28mm) ALIKE

P30-4761 11/16”(17mm) 7/8”(22mm) 1-1/8”(28mm) DIFFERENT

P30-4762 11/16”(17mm) 7/8”(22mm) 1-1/8”(28mm)

P30-4770 15/16”(24mm) 1-1/8”(28mm) 1-3/8”(35mm) ALIKE

P30-4771 15/16”(24mm) 1-1/8”(28mm) 1-3/8”(35mm) DIFFERENT

P30-4772 15/16”(24mm) 1-1/8”(28mm) 1-3/8”(35mm)

P30-4780 1-1/8”(28mm) 1-3/8”(35mm) 1-5/8”(41mm) ALIKE

P30-4781 1-1/8”(28mm) 1-3/8”(35mm) 1-5/8”(41mm) DIFFERENT

P30-4782 1-1/8”(28mm) 1-3/8”(35mm) 1-5/8”(41mm)

TO ORDER ADDITIONAL KEYS (KEYED-ALIKE-TYPE 302) USE PART NO. P30-0302

TO ORDER MASTER KEYS USE PART NO. P30-1000

NOTE: CAMS OPERATE IN 180° SEMI-CIRCLE. 90° OPERATING CAMS AVAILABLE UPON APPLICATION (ALSO AVAILABLE AS KEYED ALIKE IN SERIES).

SPUR WASHERS FOR WOOD DRAWERS AVAILABLE ON SPECIAL ORDER.

DIFFERENT and

MASTERKEYED

DIFFERENT and

MASTERKEYED

DIFFERENT and

MASTERKEYED

DIFFERENT and

MASTERKEYED

7/8”

(22mm)

B

“A”

MAX

.085

(.2mm)

C

1-1/2”

(38mm)

5/8”

(10mm)

.635 (16mm)

TYPICAL CYLINDER

HOLE DIMENSIONS

.760 (19mm)DIA.

G12

www.chg usa.c om

Page 15

locks

DRAWER LOCK

EASY TO INSTALL

FIVE DISC TUMBLER

NON FERROUS SATIN CHROME BARREL AND CASE

FURNISHED WITH TWO BRASS KEYS

5/8”(16mm)

1-7/16”

(36.3mm)

2”(50mm)

CʼSUNK FOR #6 SCREWS

11/32” (9mm) THROW

7/8”

(22mm)

1-1/2”

(38mm)

3/4”

(19mm)

7/8”

(22mm)

MODEL NO.

P10-0370

5/32” (4mm)

SLIDING DOOR LOCK, Adjustable

POLISHED CHROME FINISH TAMPERPROOF

FOR GLASS DOORS UP TO 11/16” (17mm) THICK

WOOD, WOOD FRAMED, OR METAL DOORS UP TO

1”(25mm) THICK

RATCHET BAR IS TIGHTENED IN POSITION WITH

THUMBSCREW

MODEL NO. P22-0006

1-1/16”

(27mm)

1-1/16”

(27mm)

13/16”

(21mm)

7/8”

(22mm)

(16mm)

5/8”

4-3/8”(111mm)

3/4”

(19mm)

LOCKS

T-BOLT LOCK, Stainless Steel Faced

FIVE DISC TUMBLER

FOR HOLLOW METAL DRAWERS AND FOAMED IN

PLACE DOORS

HEAVY-DUTY VERTICAL DEAD BOLT REMOVABLE

FOR INSTALLATION

FURNISHED WITH TWO BRASS KEYS

PLUNGER LOCK

NICKEL PLATED FIVE DISC TUMBLER

FOR BYPASSING DOORS APPROX. 3/4”(19mm) THICK

AND OVER

SUPPLIED WITH EASY TO INSTALL “PUSH-IN” BOLT RECEIVER

LOCKING CYLINDER CANNOT BE REMOVED FROM HOUSING

WITHOUT KEY

5/16”(8mm)THROW

7/8”

(22mm)

2”

(50mm)

29/32”

(23mm)

9/32”

(7mm)

MAX.

(38.7mm)

37/64”

(15mm)

13/16”

(21mm)

1-1/2”

CʼSUNK FOR

#10 SCREWS

11/64”

(4mm)

7/8”

(22mm)

27/32”

(21mm)

25/32”

(20mm)

1-13/32”

(36mm)

TYPICAL CYLINDER

HOLE DIMENSIONS

MODEL NO. P11-0480

MODEL NO. P20-0490

1-1/16”

(27mm)

3/32”

(2mm)

(11mm)

3/8”

(9mm)

7/16”

.635(16mm)

.760(19mm) DIA.

1/2”(13mm)

1/2”(13mm)

www.chg usa.c om

G13

Page 16

magnetic catches

CABINET CATCH

Magnetic

HEAVY DUTY

DOUBLE MAGNET

30 LBS. (13.6 kg) PULL

MODEL NO. M32-2401

MATERIAL: ALUMINUM

WITH CONCEALED MAGNETS

CABINET CATCH

Magnetic, Snap-In Type

2-5/16”

(58mm)

13/16”

(20mm)

7/16”

(11mm)

MODEL NO. M36-0201

MATERIAL: BLACK POLYPROPYLENE

WITH CONCEALED MAGNETS

11.8 LBS. (5.4kg) PULL

NOTE: SELF ADHERING STEEL STRIKE PLATES AVAILABLE UPON REQUEST

MAGNETIC CATCHES

11/16”

(17mm)

3-1/8”

(79mm)

9/16”

(14mm)

CABINET CATCH

Magnetic, Snap-In Type

2-5/16”

(58mm)

7/8”

(22mm)

MODEL NO. M36-0801

MATERIAL: BLACK POLYPROPYLENE

WITH CONCEALED MAGNETS

29.5 LBS. (13.4kg) PULL

(25mm)

13/16”

(20mm)

3-1/8”

(79mm)

1”

CABINET CATCH

Magnetic

SINGLE MAGNET

MODEL NO. M30-2400

12 LBS. (5.4 kg) PULL

SIZE: 2” x 1-1/16” X 1/2”

(51mm x 27mm x 13mm)

DOUBLE MAGNET

MODEL NO. M30-5920

20 LBS. (9 kg) PULL

SIZE: 2” x 1-1/16” x 3/4”

(51mm x 27mm x 19mm)

MATERIAL: ALUMINUM WITH CONCEALED MAGNETS

CABINET CATCH

Magnetic, Snap-In Type

1-5/16”

(33mm)

1”

(25mm)

MODEL NO. M36-0611

MATERIAL: BLACK POLYPROPYLENE

WITH CONCEALED MAGNETS

13 LBS. (5.9kg) PULL

NOTE: MTG.

SURFACE

REQUIRES

A 7/8”(22mm)

DIA. HOLE

5/8”

(16mm)

5/8”(16mm) LG.

SLOT FOR

#6 SCREW

1-5/8”

(41mm)

3/4”

(19mm)

2”

(50mm)

CABINET CATCH

Magnetic, Concealed Type

1”

(25mm)

2-5/16”

2-3/4”

(70mm)

HEAVY DUTY

CERAMIC MAGNET

MODEL NO. M35-1000

SINGLE CATCH MAGNET

14 LBS. (6.4kg) PULL

(STEEL BACKING PLATE REQUIRED)

MODEL NO. M35-2000

FURNISHED AS SET OF TWO WITH ATTRACTING

POLARITY FOR A STRONGER PULL.

MATERIAL: ZINC PLATED STEEL WITH

CONCEALED MAGNETS • 18 LBS. (8.2kg.) PULL

1/2”

(12.7mm)

(59mm)

1/4”

(6.3mm)

G14

www.chg usa.c om

Page 17

mechanical catches

DOOR CATCH

Heavy Duty, 4 Way*

with ADJUSTABLE SPRING

LOADED BALL TENSION

3/4”

(19mm)

3”

(76mm)

2-1/2”

(63mm)

11/16”

(17mm)

MODEL NO. M22-2430

MATERIAL: SOLID BRASS

WITH SATIN NICKEL FINISH AND

STAINLESS STEEL BALLS

*CATCH MAY BE USED FOR MORTISE

OR SURFACE MOUNT APPLICATION

BULLET

CATCHES

with

FIXED TENSION

SIZE

DIA. X LENGTH

1/4” x 5/16”

(6mm x 8mm)

3/8” x 7/16”

(9.5mm x 11mm)

MATERIAL: STEEL, NICKEL PLATED

ø

1/4(6.3mm

1-3/4”

(44mm)

1-1/4”

(32mm)

7/16”

(11mm)

MODEL

NO.

M25-9460

M25-9469

MECHANICAL CATCHES

DOOR CATCH

Standard Duty

with ADJUSTABLE SPRING

LOADED BALL TENSION

/2

1

3/8

(9.5mm)

1-7/16

(36mm)

1

(25mm)

ø

9/64(3.6m

MODEL NO. M22-2420

MATERIAL: SOLID BRASS

WITH SATIN NICKEL FINISH

STAINLESS STEEL BALLS AND SPRINGS

2-3/8

(60mm

1-

15/16

7/16

(11mm)

with SPRING LOADED

NYLON ROLLER

3/4”

(19mm)

MODEL NO. M24-2260

MATERIAL: ZINC PLATED STEEL

SURFACE

BOX CATCH

DOOR CATCH

Heavy-Duty

ADJUSTABLE TENSION

MODEL NO. M27-2490

8 LBS. (3.6kg) PULL

SIZE: 1” X 4” (25mm x 101mm)

MATERIAL: STEEL, NICKEL PLATED

1-1/4”

(32mm)

1/2”

(13mm)

DOOR CATCH

Friction Type

with SPRING STEEL ACTION

1-1/2”

(38mm)

1/2”

(13mm)

3/8”

(9.5mm)

MODEL NO. M20-2590

MATERIAL: ZINC PLATED SPRING STEEL

CABINET CATCH

Friction Type

with SPRING ACTION

NYLON ROLLERS

1-1/16”

(27mm)

1-1/4”

(32mm)

MODEL NO. M21-2580

MATERIAL: ZINC PLATED STEEL

1-3/16”

(30mm)

www.chg usa.c om

G15

Page 18

drawer slides

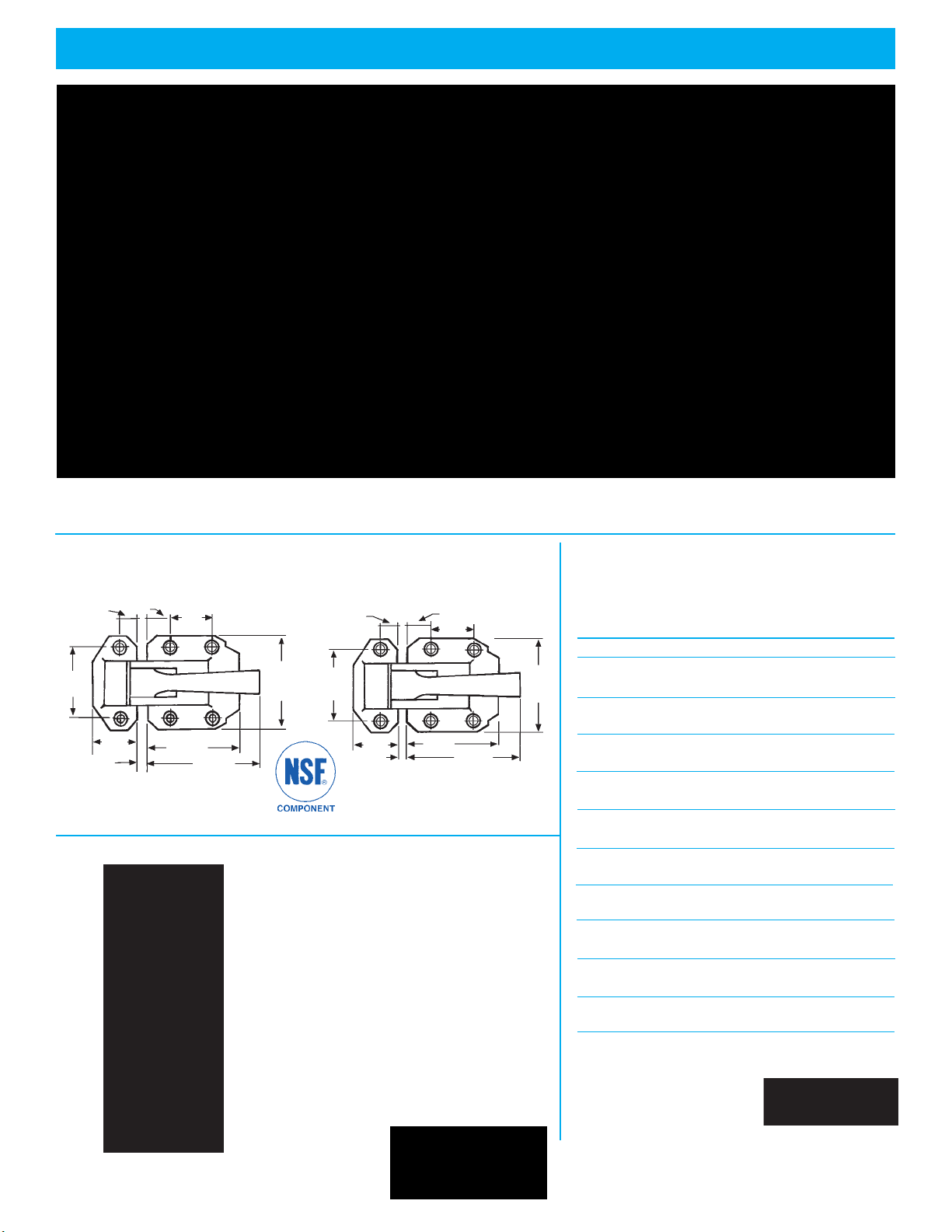

DRAWER SLIDES, EXTRA HEAVY -DUTY

S52 SERIES

NSF LISTED

STAINLESS STEEL FULL EXTENSION

200 LBS. (100 kg.) LOAD CAPACITY

SLIDES AND ROLLERS EASILY REMOVED

INCLUDES 8 BALL BEARING ASSEMBLIES

RETAINER PLATES...KEEPS SLIDES IN POSITION EVEN

WHEN DRAWERS ARE REMOVED

POSITIVE STOPS

SPECIFICATIONS

MOUNTING . . . . . . . . . . .side

SPACE REQUIRED . . . . . .25/32” (20mm)

HEIGHT . . . . . . . . . . . . . . .2-7/16” (62mm)

DRAWER EXTENSION . . .full travel

LOAD CAPACITY . . . . . . .200 lbs. (100kg) per pair with stainless steel bearings

. . . . . . . . . . . . . . . . . . . . . .150 lbs. (68kg) per pair with Delrin bearings

MATERIAL . . . . . . . . . . . . .14 ga. (2mm) stainless steel

ACTION . . . . . . . . . . . . . . .solid Delrin or stainless steel ball bearing wheels

. . . . . . . . . . . . . . . . . . . . . .with removable stainless steel screws

NOTE: LOAD RATING BASED ON 20”(500mm) SLIDE LENGTH

PACKAGED 6 PAIR PER CARTON

2-7/16”

(62mm)

CABINET

SIDE

3/4”

(19mm)

1/64”

(4mm)

3/8”

(10mm)

5/64”

(2mm)

DRAWER

SIDE

1-1/4”

(31mm)

S52 SERIES STAINLESS STEEL

FULL EXTENSION DRAWER SLIDES

WITH STAINLESS STEEL BEARINGS

MODEL NO.

S52-0020

S52-0022

S52-0024

S52-0026

NOTE: BOTH MODELS ARE FURNISHED WITH REMOVABLE STAINLESS

STEEL THREADED FASTENERS

SIZE

20” (500mm)

22” (550mm)

24” (600mm)

26” (650mm)

SLIDES WITH DELRIN BEARINGS

G16

S52 SERIES STAINLESS STEEL

FULL EXTENSION DRAWER

MODEL NO.

S52-2020

S52-2022

S52-2024

S52-2026

SIZE

20” (500mm)

22” (550mm)

24” (600mm)

26” (650mm)

www.chg usa.c om

WHEN ORDERING...MEASURE FROM INSIDE FACE

CROSS SECTION

TO EXTREME REAR OF DRAWER

NOTE: STAINLESS STEEL BALL BEARING ASSEMBLIES

W/REMOVABLE STAINLESS STEEL THREADED FASTENERS

(MODEL NO. S52-X001) AND DELRIN BEARING

COMPLETE W/REMOVABLE STAINLESS STEEL

THREADED FASTENERS (MODEL NO. S52-X101)

MAY BE ORDERED SEPARATELY...SEE PAGE G27

Page 19

drawer slides

S26 STAINLESS STEEL SERIES

NSF LISTED

STAINLESS STEEL

FULL EXTENSION

100 LBS. (50kg) LOAD CAPACITY

EASY INSTALLATION

SLIDES & ROLLERS EASILY REMOVED

FOR CLEANING

INCLUDES 8 S.S. BALL BEARING ASSEMBLIES

RETAINER PLATES...KEEPS SLIDES IN POSITION

EVEN WHEN DRAWERS ARE REMOVED

POSITIVE STOPS

SPECIFICATIONS

MOUNTING . . . . . . . . . . . . . .side

SPACE REQUIRED . . . . . . .5/8” (15mm)

HEIGHT . . . . . . . . . . . . . . . . .1-27/32” (21.4mm)

DRAWER EXTENSION . . . .full travel

LOAD CAPACITY . . . . . . . . .100 lbs. (45kg) per pair

ACTION . . . . . . . . . . . . . . . .stainless steel ball bearing wheels

with removable stainless steel screws

PACKAGED 10 PAIR PER CARTON

NOTE: LOAD RATING BASED ON 20”(500mm) SLIDE LENGTH

S26 SERIES STAINLESS STEEL

FULL EXTENSION DRAWER SLIDES

WITH STAINLESS STEEL BEARINGS

MODEL NO.

S26-0014

S26-0016

S26-0018

S26-0020

S26-0022

S26-0024

S26-0026

NOTE: STAINLESS STEEL BALL BEARING ASSEMBLIES

WITH REMOVABLE STAINLESS STEEL THREADED

FASTENERS MAY BE ORDERED SEPARATELY.

SEE PG.G27 (MODEL NO. S26-Y001)

SIZE

14” (350mm)

16” (400mm)

18” (450mm)

20” (500mm)

22” (550mm)

24” (600mm)

26” (650mm)

1-27/32”

(47mm)

1/64”

(.4mm)

WHEN ORDERING...MEASURE FROM INSIDE

FACE TO EXTREME REAR OF DRAWER

S10 ECONOMICAL SERIES

NSF LISTED

ECONOMICAL ZINC PLATED STEEL

FULL EXTENSION

100 LBS. (50kg) LOAD CAPACITY

EASY INSTALLATION

SLIDES & ROLLERS EASILY REMOVED

INCLUDES 8 BALL BEARING ASSEMBLIES

RETAINER PLATES...KEEPS SLIDES IN POSITION

POSITIVE STOPS

SPECIFICATIONS

MOUNTING . . . . . . . . . . . . . .side

SPACE REQUIRED . . . . . . .5/8” (15mm)

HEIGHT . . . . . . . . . . . . . . . . .1-27/32” (21.4mm)

DRAWER EXTENSION . . . .full travel

LOAD CAPACITY . . . . . . . . .100 lbs. (45kg) per pair

MATERIAL . . . . . . . . . . . . . .cold rolled zinc plated steel

ACTION . . . . . . . . . . . . . . . .zinc plated steel ball bearing wheels

PACKAGED 10 PAIR PER CARTON

NOTE: LOAD RATING BASED ON 20”(500mm) SLIDE LENGTH

5/8”

(15mm)

CROSS SECTION

5/64”

(.2mm)

DRAWER

17/32”

(13.5mm)

FOR CLEANING

EVEN WHEN DRAWERS ARE REMOVED

with removable zinc plated

steel screws

S10 SERIES ZINC PLATED

FULL EXTENSION DRAWER SLIDES

WITH ZINC PLATED BEARINGS

MODEL NO.

S10-0014

S10-0016

7/8”

(21mm)

S10-0018

S10-0020

S10-0022

S10-0024

S10-0026

NOTE: ZINC PLATED STEEL BALL BEARING

ASSEMBLIES WITH REMOVABLE ZINC PLATED STEEL

THREADED FASTENERS MAY BE ORDERED

SEPARATELY...SEE PG. G27 (MODEL NO. S10-Y001)

SIZE

14” (350mm)

16” (400mm)

18” (450mm)

20” (500mm)

22” (550mm)

24” (600mm)

26” (650mm)

www.chg usa.c om

G17

Page 20

drawer slides

S25 STAINLESS DRAWER SLIDES

S25 SERIES

NSF LISTED

STAINLESS STEEL

BALL BEARING ACTION

150 LBS. (68kg) LOAD CAPACITY

POSITIVE STOPS

FINGER TIP LEVER DRAWER RELEASE

SPECIFICATIONS

MOUNTING . . . . . . . . . . . . . . . . . .side

SPACE REQUIRED . . . . . . . . . . . .9/16”(14mm)

HEIGHT . . . . . . . . . . . . . . . . . . . . .3”(75mm)

DRAWER EXTENSION . . . . . . . . .length of slide minus 4 -1/4”(107mm)

LOAD CAPACITY . . . . . . . . . . . . .150 lbs. (68kg) per pair**

ACTION . . . . . . . . . . . . . . . . . . . . .stainless steel ball bearing wheels

with removable stainless steel screws

PACKAGED 10 PAIR PER CARTON

*S25 SERIES STAINLESS STEEL

DRAWER SLIDES WITH

STAINLESS STEEL BEARINGS

SIZE MODEL NO.

S25-0012 12”(300mm)

S25-0014 14”(350mm)

S25-0016 16”(400mm)

S25-0018 18”(450mm)

S25-0020 20”(500mm)

S25-0022 22”(550mm)

S25-0024 24”(600mm)

S25-0026 26”(650mm)

S25-0028 28”(700mm)

*EQUIVALENT TO STANDARD-KEIL SERIES 1425

**LOAD RATING BASED ON 18” SLIDE LENGTH

NOTE: WHEN ORDERING, MEASURE FROM INSIDE FACE TO

EXTREME REAR OF DRAWER

*S25 SERIES STAINLESS STEEL

DRAWER SLIDES WITH

S/S BEARINGS W/ NYLON TIRE

SIZE MODEL NO.

S25-2012 12”(300mm)

S25-2014 14”(350mm)

S25-2016 16”(400mm)

S25-2018 18”(450mm)

S25-2020 20”(500mm)

S25-2022 22”(550mm)

S25-2024 24”(600mm)

S25-2026 26”(650mm)

S25-2028 28”(700mm)

S25 SERIES

3”

(76mm)

9/16”

(14mm)

CROSS SECTION

G18

www.chg usa.c om

Page 21

drawer slides

DRAWER SLIDES, 1/2”(13mm) CLEARANCE

S15 SERIES

ZINC PLATED STEEL

75 LBS. (40kg) LOAD CAPACITY

ALLOWS DRAWER TO BE EASILY REMOVED

SPECIFICATIONS

MOUNTING . . . . . . . . . . .side

SPACE REQUIRED . . . . .1/2”(13mm)

HEIGHT . . . . . . . . . . . . . .3” (76mm)

DRAWER EXTENSION . .length of slide minus 4-1/4” (107mm)

LOAD CAPACITY . . . . . .75 lbs. (40kg) per pair

MATERIAL . . . . . . . . . . . .cold rolled steel, zinc plated,

ACTION . . . . . . . . . . . . . .nylon ball bearing rollers

ADDITIONAL FEATURES positive stops, finger tip release,

NOTE: LOAD RATING BASED ON 18” (450mm) SLIDE LENGTH

PACKAGED 10 PAIR PER CARTON

S15 SERIES STEEL ZINC PLATED

DRAWER SLIDES

MODEL NO.

S15-1012

S15-1014

S15-1016

S15-1018

S15-1020

S15-1022

S15-1024

S15-1026

NOTE: WHEN ORDERING, MEASURE FROM

INSIDE FACE TO EXTREME REAR OF DRAWER .

clear chromate

removable

SIZE

12”(300mm)

14”(350mm)

16”(400mm)

18”(450mm)

20”(500mm)

22”(550mm)

24”(600mm)

26”(650mm)

3”

(76mm)

1/2”

(13mm)

S35 SERIES

ZINC PLATED STEEL FULL EXTENSION

100 LBS. (50kg) LOAD CAPACITY NO DEFLECTION

ALLOWS DRAWER TO BE EASILY REMOVED

SPECIFICATIONS

MOUNTING . . . . . . . . . . .side

SPACE REQUIRED . . . . .1/2”(13mm)

HEIGHT . . . . . . . . . . . . . .2-3/8” (60mm)

DRAWER EXTENSION . .full travel

LOAD CAPACITY . . . . . .100 lbs. (50kg) per pair

MATERIAL . . . . . . . . . . . .cold rolled steel, zinc plated,

ACTION . . . . . . . . . . . . . .front intermediate wheel: nylon tire, steel

ADDITIONAL FEATURES positive mechanical stop, full extension

NOTE: LOAD RATING BASED ON 18” (450mm) SLIDE LENGTH

PACKAGED 10 PAIR PER CARTON

S35 SERIES ZINC PLATED STEEL-

FULL EXTENSION DRAWER SLIDES

SIZE MODEL NO.

S35-1016 16”(400mm)

S35-1018 18”(450mm)

S35-1020 20”(500mm)

S35-1022 22”(550mm)

S35-1024 24”(600mm)

S35-1026 26”(650mm)

NOTE: WHEN ORDERING, MEASURE FROM

INSIDE FACE TO EXTREME REAR OF DRAWER .

clear chromate

ball bearing

rear intermediate wheel: nylon roller outer

channel assembly: steel ball bearing

with virtually no deflection, removable

2-3/8”

(60mm)

1/2”

(13mm)

www.chg usa.c om

G19

Page 22

drawer slides

DRAWER SLIDES, 3/4”(19mm) CLEARANCE

S30 SERIES

ZINC PLATED STEEL FULL EXTENSION

75 LBS. (40kg) LOAD CAPACITY

ALLOWS DRAWER TO BE EASILY REMOVED

SPECIFICATIONS

MOUNTING . . . . . . . . . . . .side

SPACE REQUIRED . . . . .3/4”(19mm)

HEIGHT . . . . . . . . . . . . . . .2-1/32”(52mm) with rollers

DRAWER EXTENSION . .full travel, controlled by roller replacement

LOAD CAPACITY . . . . . . .75 lbs. (40kg) per pair

MATERIAL . . . . . . . . . . . .zinc plated steel

ACTION . . . . . . . . . . . . . .nylon or non-corrosive metal rollers

ADDITIONAL FEATURES non-handed, removable (with rollers),

NOTE: LOAD RATING BASED ON 18”(450mm) SLIDE LENGTH

PACKAGED 10 PAIR PER CARTON

S30 SERIES ZINC PLATED STEEL

FULL EXTENSION DRAWER SLIDES

SIZE

18”(450mm)

20”(500mm)

22”(550mm)

24”(600mm)

1-1/4”(32mm) without rollers

rubber stops

MODEL NO.

WITH NYLON

ROLLERS

S30-1018

S30-1020

S30-1022

S30-1024

MODEL NO.

WITH METAL

ROLLERS

S30-3018

S30-3020

S30-3022

S30-3024

MODEL NO.

WITHOUT

ROLLERS

S30-2018

S30-2020

S30-2022

S30-2024

1-1/4”

(32mm)

WITHOUT ROLLERS

2-1/32”

(52mm)

3/4”

(19mm)

NOTE: WHEN ORDERING, MEASURE FROM INSIDE FACE TO EXTREME REAR OF DRAWER.

G20

WITH ROLLERS

CROSS SECTION

www.chg usa.c om

Page 23

drawer pans

DRAWER PANS

BREAD DRAWER PANS

HEAVY-DUTY

THERMOPLASTIC

FULL 10”(250mm) DEEP

FULL 1/4”(6mm) THICK FLANGE

ECONOMICAL ODORLESS COVED CORNERS

SMOOTH INTERIOR...STIPPLE EXTERIOR

LIGHTWEIGHT SANITARY

HEAVY-DUTY THERMOPLASTIC

BREAD DRAWER PANS

MODEL NO. NOMINAL DIMENSIONS FLANGE SIZE

S83-2020

20” x 20” x 10”

(500mm x 500mm x 250mm)

PACKAGED 2 TO A MASTER CARTON

DRAWER PANS

HEAVY-DUTY

THERMOPLASTIC

21-3/4” x 21-3/4”

(550mm x 550mm)

DRAWER PANS

STAINLESS STEEL

TYPE 18-8 STAINLESS STEEL

WITH POLISHED FINISH

COVED CORNERS TWO SIZES AVAILABLE

FOR USE IN FOOD SERVICE TABLES

AND FOOD WARMERS

IDEAL FOR UTENSILS

AND FROZEN FOOD STORAGE

MEETS NSF CRITERIA

STAINLESS STEEL DRAWER PANS

MODEL NO. NOMINAL DIMENSIONS FLANGE SIZE

S81-1520-C

S81-2020-C

NOTE: OTHER DEPTHS AVAILABLE UPON APPLICATION.

15” x 20” x 5”

(380mm x 500mm x 130mm)

20” x 20” x 5”

(500mm x 500mm x 130mm)

PACKAGED 6 TO A MASTER CARTON

16 x 21-1/2”

(415mm x 550mm)

21-1/2” x 21-1/2”

(550mm x 550mm)

HEAVY-DUTY THERMOPLASTIC

DRAWER PANS

MODEL NO. NOMINAL DIMENSIONS FLANGE SIZE

S80-1520

S80-2020

15” x 20” x 5”

(380mm x 500mm x 130mm)

20” x 20” x 5”

(500mm x 500mm x 130mm)

PACKAGED 6 TO A MASTER CARTON

16-1/4” x 21-3/4”

(415mm x 550mm)

21-3/4” x 21-3/4”

(550mm x 550mm)

www.chg usa.c om

G21

Page 24

stainless steel drawer assembly

SPACER

DRAWER

FRAME

BOTTOM

PLATE

STAINLESS STEEL DRAWER ASSEMBLY

I TYPE 304 STAINLESS STEEL, HEAVY DUTY, WELDED

CONSTRUCTION THROUGHOUT

I RUGGED 18 GA. OUTER DRAWER HOUSING WITH 16 GA.

INTERNAL FRAME ASSEMBLY

I INCLUDES 16 GA. WELDED STAINLESS STEEL INSULATED

FRONT...MINIMIZING UTENSIL NOISE AND PROVIDING

QUIET OPERATION

I UNIQUE UNI-BODY CONSTRUCTION ALLOWS UNITS TO BE

STACKED

I CONVENIENT, PRECISE MOUNTING HOLES OFFER QUICK,

EASY INSTALLATION

I 200 LB. CAPACITY

15” S/S DRAWER ASSEMBLY

MODEL NO. DESCRIPTION LOCK PAN

*S90-0015-N 15”(381mm) FRONT - S/S

*S90-0015-C-N 15”(381mm) FRONT CYLINDER S/S

S91-0015 15”(381mm) FRONT - PLASTIC

S91-0015-C 15”(381mm) FRONT CYLINDER PLASTIC

20” S/S DRAWER ASSEMBLY

MODEL NO. DESCRIPTION LOCK PAN

*S90-0020-N 20”(508mm) FRONT - S/S

*S90-0020-C-N 20”(508mm) FRONT CYLINDER S/S

S91-0020 20”(508mm) FRONT - PLASTIC

S91-0020-C 20”(508mm) FRONT CYLINDER PLASTIC

*NSF LISTING APPLIES TO DRAWER ASSEMBLIES UTILIZING STAINLESS

STEEL PANS.

STAINLESS STEEL BOTTOM PLATE (OPTIONAL)

MODEL NO. DESCRIPTION

S90-X030 20” x 20”

S90-X031 15” x 20”

*USED TO DROP THE DRAWER BELOW NORMAL 2” RETURN ON TABLE TOP OR AS A MULLION BETWEEN DRAWERS

I SELF-CLOSING DRAWER FEATURE

I ENTIRE DRAWER ASSEMBLY DEBURRED AND READY TO INSTALL

I COMPLETE WITH HEAVY GAUGE REMOVABLE STAINLESS STEEL OR

PLASTIC PAN

I FULL EXTENSION- 90° PULL ALLOWS CONVENIENT ACCESS AND IS EASY

TO KEEP CLEAN

I AVAILABLE WITH OR WITHOUT CYLINDER LOCK ASSEMBLY

I SPECIFICATION GRADE, MEETS MOST ARCHITECTURAL REQUIREMENTS

1-1/2”

(38mm)

19-15/16”

(506mm)

1”

(25mm)

6-3/4”

(171mm)

D

SLOTTED

MOUNTING

HOLES

5/16”

(8mm)

6-7/8”

(175mm)

MODEL NO.

S90-0015

S90-0020

A

B

22-15/16”

(583mm)

DIM. FOR

15” ASS’Y

DIM. FOR

20” ASS’Y

C

9/16”

(14mm)

A B C D

17-3/4” 16-1/2” 13-5/8” 19-9/16”

(451mm) (419mm) (346mm) (497mm)

23-3/8” 22-1/8” 19-1/4” 25-1/16”

(594mm) (562mm) (489mm) (636mm)

STAINLESS STEEL SPACER (OPTIONAL)*

MODEL NO. DESCRIPTION

S90-X032 20” x 20” x 2 1/2”

S90-X033 15” x 20” x 2 1/2”

1/2”

(12mm)

G22

www.chg usa.c om

Page 25

cash drawer assembly

C

B

A

STAINLESS STEEL CASH DRAWER ASSEMBLY

REF. A

CASH DRAWER ASSEMBLY WITHOUT TRAY

MODEL NO. S95-Y001

STAINLESS STEEL SPECIFICATION GRADE CASH DRAWER

ASSEMBLY SOLID STAINLESS STEEL CONSTRUCTION

FULL EXTENSION DRAWER SLIDE OFFERS EASE OF OPERATION

ALL DRAWERS FURNISHED WITH STAINLESS STEEL FACED

CYLINDER LOCKS DESIGNED FOR EASY UNDERCOUNTER

MOUNTING SMOOTH AND QUIET OPERATION

D

REF. C

CASH DRAWER ASSEMBLY WITHOUT TRAY

MODEL NO. CD-1000

BLACK POWDER COATED FINISH CENTER

SECURITY DRAWER KEY-LOCK STANDARD ABS

PLASTIC 5 COIN/5 BILL REMOVEABLE MONEY TRAY

INSERT ADJUSTABLE BILL SEPARATOR FOR

FOREIGN CURRENCY STAINLESS STEEL MONEY

CLIPS STAINLESS STEEL COIN BREAKING PLATE

DRAWER BELL NON-SKID 1/2” RUBBER FEET

16-5/8” (422mm)

13-1/2” (343mm)

16-1/4” (413mm)

14-1/4” (362mm)

4”

(102mm)

(4) 1/4”(6mm)

MTʼG HOLES

REF. B

CURRENCY TRAY WITH COVER

MODEL NO. S95-Y002

REMOVABLE CURRENCY TRAY WITH DROP HANDLE

FOR EASY REMOVAL DESIGNED TO ACCOMMODATE

PORTABLE CASH NEEDS-IDEAL FOR DRAWERS, SAFES

AND DESKS POSITIVE SPRING ACTION MONEY HOLD

DOWN LOCK WITH STAINLESS STEEL CYLINDER

CASH DRAWER WITH COMPLETE TRAY

MODEL NO. S95-1000

3/4”

(19mm)

16-5/8”

REF. D

CURRENCY TRAY

MODEL NO. CD-Y004

NON-STOCK, AVAILABLE ON APPLICATION

15-7/8”

3-7/8”

www.chg usa.c om

G23

Page 26

drawer fronts & brackets

DRAWER FRONTS & BRACKETS

DRAWER FRONTS

HEAVY-DUTY

STAINLESS STEEL

TYPE 18-8 STAINLESS STEEL 20 GAUGE

No. 4 POLISHED FINISH

FULL GRIP...BEVELED EDGE PULL

FURNISHED WITH (6) #10-24 WELD STUDS

HEAVY-DUTY STAINLESS STEEL

DRAWER FRONTS

MODEL NO. DIMENSIONS WELD STUD CENTERS

J85-1500

J85-2000

17-5/8” x 6-1/2”

(450mm x 165mm)

23-1/8” x 6-1/2”

(590mm x 165mm)

14” x 3”

(355mm x 76mm)

19-5/8” x 3”

(498mm x 76mm)

ANGLE BRACKET

DRAWER ASSEMBLY KIT

CONVENIENT...READY TO USE

ONE SIZE FITS BOTH

J85-1500 and J85-2000 DRAWER FRONTS

ANGLE BRACKET DRAWER ASSEMBLY KIT

MODEL NO. J85-1000

THE ANGLE BRACKET DRAWER ASSEMBLY KIT IS AN

OPTIONAL ACCESSORY FOR MOUNTING DRAWER

FRONT TO DRAWER HOUSING.

1/4”(6.3mm)

DIA. HOLE

1/2”

(25mm)

2”

(50mm)

3-1/2”

(89mm)

2”

(50mm)

4”

(100mm)

(25mm)

1”

G24

www.chg usa.c om

1”

(25mm)

5”

(125mm)

Page 27

bumpers & grommets

RECESSED BUMPERS

FIG.

MODEL NO.

1

2

Q20-2081

Q20-2095

A

5/8”(16mm)

15/16”(24mm)

GROMMETS

FIG.

MODEL NO.

3

3

3

4

Q24-0220

Q24-0225

Q24-0230

Q24-0320

A

9/16”(14mm)

5/8”(16mm)

13/16”(20mm)

9/16”(14mm)

LARGE DIAMETER GROMMETS

FIG.

MODEL NO.

5

5

Q24-0420

Q24-0520

A

1-7/8”(48mm)

2-7/8”(75mm)

BUTTON BUMPERS

FIG..

MODEL NO.

6

6

7

Q26-3062

Q26-4071

Q26-4072

A

3/8”(10mm)

1/2”(13mm)

1/2”(13mm)

PRESSURE SENSITIVE BUMPERS

FIG.

MODEL NO.

8

8

Q21-5003

Q21-5017

HEIGHT

.20”(5mm)

.38”(10mm)

BUMPERS & GROMMETS

B

5/16”(8mm)

3/8”(10mm)

B

1/4”(6mm)

3/8”(10mm)

1/2”(13mm)

1/4”(6mm)

B

1-1/8”(29mm)

2-1/8”(54mm)

B

1/4”(6mm)

3/8”(10mm)

3/8”(10mm)

DIAMETER

.44”(11mm)

.75”(20mm)

C

3/16”(5mm)

1/8”(3mm)

C

1/4”(6mm)

1/4”(6mm)

9/32”(7mm)

5/16”(8mm)

C

3/8”(10mm)

7/16”(11mm)

C

1/4”(6mm)

3/16”(5mm)

3/16”(5mm)

D

1/8”(3mm)

3/16”(5mm)

D

1/16”(1.5mm)

1/16”(1.5mm)

1/16”(1.5mm)

1/8”(3mm)

D

1/16”(1.5mm)

1/16”(1.5mm)

D

5/16”(8mm)

1/8”(3mm)

3/16”(5mm)

E

1/4”(6mm)

3/8”(10mm)

E

3/8”(10mm)

1/2”(13mm)

5/8”(16mm)

3/8”(10mm)

E

1-1/2”(38mm)

2-1/2”(64mm)

E

3/64”(2mm)

1/16(1.5mm)

3/16”(5mm)

F

3/16”(5mm)

5/32”(4mm)

F

3/64”(2mm)

1/16”(1.5mm)

1/16”(1.5mm)

A

F

B

C

C

HGT

FIG. 2

C

FIG. 7

E

D

C

F

E

A

C

B

C

FIG. 3

FIG. 4

B

FIG. 8

A

F

FIG. 1

FIG. 6

D

B

E

A

B

D

A

E

B

D

A

B

D

D

C

A

A

B

E

FIG. 5

F

E

DIA.

D

www.chg usa.c om

NOTE: ALL BUMPERS AND GROMMETS

ARE SOLID RUBBER.

G25

Page 28

ball bearing systems

BALL BEARING SYSTEMS

BALL BEARING SYSTEMS...A COMPREHENSIVE GUIDE TO BEARING SELECTION

SPECIFICALLY FOR FOOD SERVICE EQUIPMENT APPLICATIONS

COMPONENT HARDWARE HAS DESIGNED AN INNOVATIVE BALL BEARING SYSTEM WITH A DUAL FEATURE.

FIRST...A SYSTEM THAT SATISFIES THE OFTEN ENCOUNTERED PRICE AND DELIVERY PROBLEM WHEN PURCHASING EVEN

STANDARD SIZE BEARINGS IN SMALL QUANTITIES. THIS SYSTEM PERMITS OFF THE SHELF DELIVERY AND SMART PRICES

NO MATTER HOW SMALL THE ORDER QUANTITY.

SECOND...AND PERHAPS THE BEST...A BEARING SYSTEM THAT PERMITS THE USER TO CONFIGURE ESSENTIAL

BEARING COMPONENTS TO ASSEMBLE A WIDE RANGE OF BEARING SIZES AND STYLES TO MEET INDIVIDUAL DESIGN

REQUIREMENTS.

LISTED ON THIS PAGE IS A SELECTION OF BEARINGS, SCREW STUDS AND RIVETS WHICH ALLOWS YOU TO CHOOSE A

BEARING ASSEMBLY TO SUIT YOUR SPECIFIC REQUIREMENTS.

INSTRUCTIONS: SELECT ANY BEARING WITH HOLE. IF SHOULDER IS REQUIRED CHOOSE SHOULDER SPACER(S) AS

REQUIRED. SELECT THE RIVER OR SCREW STUD WITH LENGTH TO SATISFY SHOULDER, SHAFT CLEARANCE AND

THICKNESS OF BEARINGS. (SEE ILLUSTRATION)

SCREW STUD

OR

RIVET

SHOULDER SPACER

(IF REQUIRED)

SELECTED BEARING

B20-1013

B20-1019 B20-1230

B20-1028 B20-1819

B20-1032 B23-1013

B20-1219 B24-1013

SHAFT

CLEARANCE

1/32”

(.7mm)

OVERALL

FULL BEARING ASSEMBLY

LENGTH

1/4-20

STAINLESS STEEL

SCREW STUDS

MODEL NO. LENGTH

B30-X003 1”(25mm)

B30-X004 5/8”(16mm)

B30-X008 3/4”(19mm)

LENGTH

1/2”(12.7mm) DIA.

STAINLESS STEEL

SHOULDER SPACERS

MODEL NO. THʼK

B10-X004 7/32”(5.5mm)

B10-X008 3/32”(2.3mm)

B10-X009 1/32”(.8mm)

STAINLESS STEEL

RIVETS

MODEL NO. LENGTH

B10-X012 1/2”(13mm)

B10-X013 3/4”(19mm)

G26

www.chg usa.c om

Page 29

flat bearings

1/32”

(.8mm)

1/32”

(.8mm)

(.8mm)

440

S/S

BALLS

1/32”

FLAT BEARINGS

FLAT BEARINGS with HOLE

B

A

D

C

B

A

C

1/4”

(6.3mm)

D

B

1/4-20

MODEL NO.

B20-1013

B20-1019

B20-1032

B20-1028

B20-1819

B20-1230

B20-1219

MODEL NO.

B10-1013

B10-1016

B10-1025

B10-1034

B10-1822

B10-1210

A

MODEL NO.

C

A

D

#10-32

D

THDS

1/2”

(13mm)

B30-1013

B30-1210

B30-1034

MODEL NO.

B40-1240

B

C

INNER RACE

STEEL

STEEL

STEEL

STEEL

STEEL

STAINLESS STʼL

STAINLESS STʼL

OUTER RACE

STEEL

STEEL

STEEL

STEEL

NYLON & STEEL

STAINLESS STʼL

STAINLESS STʼL

FLAT BEARINGS with RIVET

INNER RACE

STEEL

STEEL

STEEL

STEEL

STEEL

STAINLESS STʼL

OUTER RACE

STEEL

STEEL

STEEL

STEEL

NYLON & STEEL

STAINLESS STʼL

FLAT BEARINGS with SCREW STUD

INNER RACE

STEEL

STAINLESS STʼL

STEEL

OUTER RACE

STEEL

STAINLESS STʼL

STEEL

FLAT BEARINGS with TAPPED HOLE

INNER RACE

STAINLESS STʼL

NOTES: SPECIAL SIZE BEARINGS AVAILABLE UPON REQUEST. *BEARING LOAD RATINGS BASED ON 600 R.P.M.

OUTER RACE

STAINLESS STʼL

A

7/8”(22mm)

1”(25.4mm)

1”(25.4mm)

1-5/16”(33.3mm)

1”(25.4mm)

29/32”(23mm)

1-5/16”(33.3mm)

A

7/8”(22mm)

1”(25.4mm)

1-5/16”(33.3mm)

1-5/16”(33.3mm)

1”(25.4mm)

29/32”(23mm)

A

7/8”(22mm)

29/32”(23mm)

1-5/16”(33.3mm)

A

7/8”(22mm)

B

7/32”(5.5mm)

5/16”(7.9mm)

7/32”(5.5mm)

5/16”(7.9mm)

7/32”(5.5mm)

1/4”(6.3mm)

5/16”(7.9mm)

B

7/32”(5.5mm)

7/32”(5.5mm)

5/16”(7.9mm)

5/16”(7.9mm)

7/32”(5.5mm)

1/4”(6.3mm)

B

7/32”(5.5mm)

1/4”(6.3mm)

5/16”(7.9mm)

B

1/4”(6.3mm)

C

9/32”(7.1mm)

3/8”(9.5mm)

9/32”(7.1mm)

3/8”(9.5mm)

9/32”(7.1mm)

5/16”(7.9mm)

3/8”(9.5mm)

C

3/8”(9.5mm)

3/8”(9.5mm)

3/8”(9.5mm)

19/32”(15mm)

3/8”(9.5mm)

11/32”(8.7mm)

C

3/8”(9.5mm)

11/32”(8.7mm)

19/32”(15mm)

C

3/8”(9.5mm)

D

1/4”(6.3mm)

1/4”(6.3mm)

1/4”(6.3mm)

1/4”(6.3mm)

1/4”(6.3mm)

1/4”(6.3mm)

1/4”(6.3mm)

D

1/8”(3.1mm)

1/8”(3.1mm)

3/32”(6.3mm)

3/16”(4.7mm)

1/8”(3.1mm)

1/8”(3.1mm)

D

3/8”(9.5mm)

5/16”(7.9mm)

3/8”(9.5mm)

D

#10-32

LOAD*

42 lbs (19kg)

57 lbs (25kg)

57 lbs (25kg)

87 lbs (39kg)

53 lbs (24kg)

90 lbs (40kg)

87 lbs (39kg)

LOAD*

42 lbs (19kg)

57 lbs (25kg)

87 lbs (39kg)

87 lbs (39kg)

53 lbs (24kg)

90 lbs (40kg)

LOAD*

42 lbs (19kg)

90 lbs (40kg)

87 lbs (39kg)

LOAD*

80 lbs (35kg)

www.chg usa.c om

G27

Page 30

concave & rubber tire bearings

1/32”

(.8mm)

A

1/32”

(.8mm)

A

1/32”

(.8mm)

A

CONCAVE & RUBBER TIRE BEARINGS

1/32”

B

CONCAVE BEARING with HOLE

STEEL INNER and OUTER RACE

D

C

B

(6.3mm)

D

C

B

1/4-20

MODEL NO. A B C D LOAD*

B24-1013

1-3/16”

(30.1mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

CONCAVE BEARING with RIVET STUD

1/4”

STEEL INNER and OUTER RACE

MODEL NO. A B C D LOAD*

B14-1010

1-3/16”

(30.1mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

CONCAVE BEARING with SCREW STUD

STEEL INNER and OUTER RACE

1/4”

(6.3mm)

1/8”

(3.2mm)

80 lbs

(36kg)

80 lbs

(36kg)

MODEL NO. A B C D LOAD*

B34-1010

C

B34-1016

D

1-3/16”

(30.1mm)

1-3/16”

(30.1mm)

5/16”

(7.9mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

19/32”

(15mm)

3/8”

(9.5mm)

3/8”

(9.5mm)

80 lbs

(36kg)

80 lbs

(36kg)

MODEL NO. A B C D LOAD*

B23-1013

MODEL NO. A B C D LOAD*

B13-1010

MODEL NO. A B C D LOAD*

B33-1010

B33-1016

RUBBER TIRE BEARING with HOLE

STEEL INNER and OUTER RACE

1-5/16”

(33.3mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

1/4”

(6.3mm)

RUBBER TIRE BEARING with RIVET STUD

STEEL INNER and OUTER RACE

1-5/16”

(33.3mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

1/8”

(3.2mm)

RUBBER TIRE BEARING with SCREW STUD

STEEL INNER and OUTER RACE

1-5/16”

(33.3mm)

1-5/16”

(33.3mm)

5/16”

(7.9mm)

5/16”

(7.9mm)

3/8”

(9.5mm)

19/32”

(15mm)

3/8”

(9.5mm)

3/8”

(9.5mm)

87 lbs

(40kg)

87 lbs

(40kg)

87 lbs

(40kg)

87 lbs

(40kg)

(.8mm)

1/32”

(.8mm)

1/32”

(.8mm)

A

A

A

B

D

C

B

1/4”

(6.3mm)

C

D

B

1/4-20

C

D

G28

NOTES: SPECIAL SIZE BEARINGS AVAILABLE UPON REQUEST. *BEARING LOAD RATINGS BASED ON 600 R.P.M.

www.chg usa.c om

Page 31

ball bearing assemblies, pulley & wheels

BALL BEARING ASSEMBLIES, PULLEY & WHEELS

DELRIN BEARING AND STAINLESS STEEL

BALL BEARING ASSEMBLY

WITH REMOVABLE THREADED FASTENER

B

A

C

MODEL NO.

S26-Y001

S10-Y001

S52-X101

S52-X001

MATʼL.

ST. STʼL

Z.P. STʼL

DELRIN

ST. STʼL

TYPE

BALL

BʼRʼG

BALL

BʼRʼG

SOLID

BALL

BʼRʼG

A

.760

(19.3mm)

.760

(19.3mm)

1.095

(27.8mm)

1.095

(27.8mm)

.250

(6.3mm)

.250

(6.3mm)

.375

(9.5mm)

.375

(9.5mm)

C

B

.187

(4.7mm)

(10.6mm)

.187

(4.7mm)

(10.6mm)

.187

(4.7mm)

(12.7mm)

.187

(4.7mm)

(12.7mm)

MOLDED PLASTIC WHEEL

STAINLESS STEEL BALLS DOUBLE ROW BALL BEARINGS

1/4"(6.3mm) I.D. PLATED STEEL BUSHING

ANTI-CONTAMINATION SHIELDS

QUIET, NON-MARKING ACTION

.420

.420

.500

.500

F THʼD

D

E

D

E

.300

.300

.250

.250

THʼD

10-24

10-24

1/4-20

(7.6mm)

(7.6mm)

(6.3mm)

(6.3mm)

NYLON WHEEL PULLEY with STEEL RACES

.315

.035

NYLON/STEEL

WHEEL PULLEY

MODEL NO.

B25-1810

F

STAINLESS STEEL and STEEL WHEELS

(.8mm)

.250

(6.3mm)

IDEAL FOR DRAWER SLIDES AND CONVEYOR ASSEMBLIES

HEAT TREATED INNER AND OUTER RACEWAYS

ALL METAL CONSTRUCTION

STAINLESS STEEL

WHEEL

MODEL NO.

IR-0031

Ø .25 ID

STEEL WHEEL

(6.4mm)

ZINC PLATED

MODEL NO.

IR-2263

(8mm)

2.00

(50.8mm)

.136

(3.4mm)

.62 (15.7mm)

.81

(20.6mm)

Ø 1.94

(49.3mm)

MODEL NO.

IR-2191

MATERIAL:

ACETAL

AND

NYLON

1.90

(48.2mm)

.25

(6.3mm)

.63

(16mm)

.59

(14.9mm)

.94

(23.8mm)

www.chg usa.c om

STAINLESS STEEL

WHEEL

MODEL NO.

IR-1061

ZINC PLATED

STEEL with

OFFSET BUSHING

MODEL NO.

IR-2112

Ø .25 ID

(6.4mm)

(17.8mm)

.63

(16mm)

.70

Ø 1.94

(49.3mm)

G29

Page 32

sliding door components

MODEL NO. WHEEL TYPE

B58-5511 FLAT, STEEL PLATED, BALL BEARING

B58-5513 FLAT, NYLON SURFACE, STEEL INNER RACES,

MODEL NO. WHEEL TYPE

B58-5521 FLAT, STEEL PLATED, BALL BEARING

B58-5523 FLAT, NYLON SURFACE, STEEL INNER RACES,

MODEL NO.

B62-1093

FOR 3/4”(19mm)

SLIDING DOORS

MATERIAL: NYLON

O.A. SIZE: 1-3/4” X 2-1/8”

(44mm x 54mm)

SLIDING DOOR COMPONENTS

OVERHEAD TRACK COMPONENTS FOR SLIDING DOORS

FRONT DOOR SHEAVE, ZINC PLATED STEEL

3/4”(19mm) SIDE MOUNTED DOOR HANGER

BALL BEARING

REAR DOOR SHEAVE, ZINC PLATED STEEL

3/4”(19mm) SIDE MOUNTED DOOR HANGER

BALL BEARING

DOOR STOPDOOR GUIDE

MODEL NO.

B60-1086

MATERIAL:

STEEL,

ZINC PLATED

BUMPER:

SOLID RUBBER

15/16” (23.8mm)

1-3/4” (44.5mm)

(25mm)

1”

1”

(25mm)

3/4”

(19mm)

1-5/8”

(41mm)

2-1/8”(54mm)

Mount with #8 PHMS (2)

1-1/4”

(32mm)

1”(25mm) DIA.

BEARINGS

FRONT SHEAVE

SLIDING DOOR TRACK

EXTRUDED ALUMINUM

MODEL NO. LENGTH

B57-0048

B57-0060

B57-0072

B57-0120

B57-0144

SPRING LOADED with PUSH-ON SPEED NUTS

MODEL NO. B56-1096

3/16”

(5mm)

MATERIAL: CHROME PLATED BRASS

1-3/4”

(44mm)

REAR SHEAVE

16 GAUGE

GUIDE PINS

1-1/2” (38mm)

48” (1219mm)

60” (1524mm)

72” (1828mm)

120” (3048mm)

144” (3657mm)

1” (25mm)

5/16”

(8mm)

G30

www.chg usa.c om

Page 33

NUMERICAL INDEX

ODEL NO. PAGE NO. MODEL NO. PAGE NO. MODEL NO. PAGE NO. MODEL NO. PAGE NO. MODEL NO. PAGE NO.

M

B10-1013 . . . . . . . . G27

B10-1016 . . . . . . . . G27

B10-1025 . . . . . . . . G27

B10-1034 . . . . . . . . G27

B10-1210 . . . . . . . . G27

B10-1822 . . . . . . . . G27

B10-X004 . . . . . . . . G26

B10-X008 . . . . . . . . G26

B10-X009 . . . . . . . . G26

B10-X012 . . . . . . . . G26

B10-X013 . . . . . . . . G26

B13-1010 . . . . . . . . G28

B14-1010 . . . . . . . . G28

B20-1013. . . . G27, G26

B20-1019. . . . G27, G26

B20-1028. . . . G27, G26

B20-1032. . . . G27, G26

B20-1219. . . . G27, G26

B20-1230. . . . G27, G26

B20-1819. . . . G27, G26

B23-1013. . . . G28, G26

B24-1013. . . . G28, G26

B25-1810 . . . . . . . . G29

B30-1013 . . . . . . . . G27

B30-1034 . . . . . . . . G27

B30-1210 . . . . . . . . G27

B30-X003 . . . . . . . . G26

B30-X004 . . . . . . . . G26

B30-X008 . . . . . . . . G26

B33-1010 . . . . . . . . G28

B33-1016 . . . . . . . . G28

B34-1010 . . . . . . . . G28

B34-1016 . . . . . . . . G28

B40-1240 . . . . . . . . G27

B56-1096 . . . . . . . . G30

B57-0048 . . . . . . . . G30

B57-0060 . . . . . . . . G30

B57-0072 . . . . . . . . G30

B57-0120 . . . . . . . . G30

B57-0144 . . . . . . . . G30

B58-5511 . . . . . . . . G30

B58-5513 . . . . . . . . G30

B58-5521 . . . . . . . . G30

B58-5523 . . . . . . . . G30

B60-1086 . . . . . . . . G30

B62-1093 . . . . . . . . G30

CD-1000. . . . . . . . . G23

CD-Y004 . . . . . . . . G23

GBS15-1112-Q . . . . . G2

GBS15-1112-QP. . . . G2

GBS15-1116-Q . . . . . G2

GBS15-1116-QP. . . . G2

GBS15-1118-Q . . . . . G2

GBS15-1118-QP. . . . G2

GBS15-1124-Q. . . . . G2

GBS15-1124-QP . . . G2

GBS15-1130-Q. . . . . G2

GBS15-1130-QP . . . G2

GBS15-1132-Q. . . . . G2

GBS15-1132-QP . . . G2

GBS15-1136-Q. . . . . G2

GBS15-1142-Q. . . . . G2

GBS15-1142-QP . . . G2

GBS15-1148-Q. . . . . G2

GBS15-1148-QP . . . G2

GBS15-113030Q . . . G2

GBS15-4112-Q. . . . . G2

GBS15-4116-Q. . . . . G2

GBS15-4118-Q. . . . . G2

GBS15-4124-Q . . . . G2

GBS15-4130-Q . . . . G2

GBS15-4132-Q . . . . G2

GBS15-4136-Q . . . . G2

GBS15-4142-Q . . . . G2

GBS15-4148-Q . . . . G2

GBS15-413030Q . . . G2

GBS15-414030Q . . . G2

IR-0031 . . . . . . . . . G29

IR-1061 . . . . . . . . . G29

IR-2112. . . . . . . . . . G29

IR-2191 . . . . . . . . . G29

IR-2263 . . . . . . . . . G29

J85-1000 . . . . . . . . G24

J85-1500 . . . . . . . . G24

J85-2000 . . . . . . . . G24

M10-8332 . . . . . . . . . G8

M10-8333 . . . . . . . . . G8

M11-8201 . . . . . . . . . G8

M12-9292 . . . . . . . . G11

M12-9293 . . . . . . . . G11

M12-9294 . . . . . . . . G11

M12-9295 . . . . . . . . G11

M15-9210 . . . . . . . . . G9

M15-9211 . . . . . . . . . G9

M20-2590 . . . . . . . . G15

M21-2580 . . . . . . . . G15

M22-2420 . . . . . . . . G15

M22-2430 . . . . . . . . G15

M24-2260 . . . . . . . . G15

M25-9460 . . . . . . . . G15

M25-9469 . . . . . . . . G15

M27-2490 . . . . . . . . G15

M30-2400 . . . . . . . . G14

M30-5920 . . . . . . . . G14

M32-2401 . . . . . . . . G14

M35-1000 . . . . . . . . G14

M35-2000 . . . . . . . . G14

M36-0201 . . . . . . . . G14

M36-0611 . . . . . . . . G14

M36-0801 . . . . . . . . G14

M37-1105 . . . . . . . . . G9

M37-1107 . . . . . . . . . G9

M37-1305 . . . . . . . . . G9

M37-1307 . . . . . . . . . G9

M48-0112 . . . . . . . . . G9

M48-0121 . . . . . . . . . G9

M48-0122 . . . . . . . . . G9

M48-0131 . . . . . . . . . G9

M48-0132 . . . . . . . . . G9

M48-0134 . . . . . . . . . G9

M48-0142 . . . . . . . . . G9

M48-0143 . . . . . . . . . G9

M48-0144 . . . . . . . . . G9

M48-0154 . . . . . . . . . G9

M74-2078 . . . . . . . . G11

M74-3078 . . . . . . . . G11

M75-1002 . . . . . . . . G10

M75-5003 . . . . . . . . G10

M80-2500 . . . . . . . . . G8

M80-3500 . . . . . . . . . G8

P10-0370 . . . . . . . . G13

P11-0480 . . . . . . . . G13

P20-0490 . . . . . . . . G13

P22-0006 . . . . . . . . G13

P30-0802 . . . . . . . . G10

P30-1000 . . . . . . . . G10

P30-4750 . . . . . . . . G12

P30-4751 . . . . . . . . G12

P30-4752 . . . . . . . . G12

P30-4760 . . . . . . . . G12

P30-4761 . . . . . . . . G12

P30-4762 . . . . . . . . G12

P30-4770 . . . . . . . . G12

P30-4771 . . . . . . . . G12

P30-4772 . . . . . . . . G12

P30-4780 . . . . . . . . G12

P30-4781 . . . . . . . . G12

P30-4782 . . . . . . . . G12

P40-1010 . . . . . . . . . G4

P44-1010 . . . . . . . . . G5