Page 1

EQUIPMENT LEGS AND

ACCESSORIES

Page 2

ALPHABETICAL INDEX

DESCRIPTION PAGE

A

ACCESSORIES ................................................A21, A22

ALUMINUM LEGS ......................................................A18

APPLIANCE LEGS ......................................A18 thru A20

B

BRACKETS, UNDERSHELF ......................................A22

BRACKETS, QUICK CORNERS ................................A21

C

CASTER LEG ASSEMBLIES ...................................... A8

CLAMPS, SPRING ......................................................A22

CROSS BRACE FITTINGS ........................................A21

CORNER BRACKETS ................................................A21

E

EQUIPMENT LEGS................................A9 thru A15, A18

ABS PLASTIC ..................................................A10

ECONOLINE ....................................................A11

HEAVY- DUTY..................................................A14

HEAVY- DUTY S/S ............................A12 thru A15

EXTRA WIDE, STAINLESS CLAD ................A15

SEISMIC/SECURITY..........................................A9

F

FITTINGS, CROSS BRACE ......................................A21

FOOT INSERTS,

ADJUSTABLE ......................................A3 thru A6

FLANGED ..........................................................A7

STAINLESS CLAD PLASTIC ............................A4

FOOT LEVELERS ......................................................A22

FORMED METAL LEGS..............................................A16

DESCRIPTION PAGE

P

PLATES, MOUNTING..................................................A22

PLASTIC LEGS, EQUIPMENT....................................A10

S

SECURITY LEGS ..........................................................A9

SHELF SUPPORTS ......................................................A2

SOCKETS, LEG ......................................................A1,A2

SPRING CLAMPS ......................................................A22

T

THREAD CONVERTER ..............................................A19

U

UNDERSHELF BRACKETS ........................................A22

H

HOLE PLUG ................................................................A22

HI-RISE®ADJUSTABLE FOOT INSERTS....................A5

H-FRAME ASSEMBLY.................................................A18

L

LEG ASSEMBLIES..............................................A17, A18

LEG SOCKETS ........................................................A2,A3

LEGS, APPLIANCE ......................................A18 thru A20

LEGS, EQUIPMENT ....................................A12 thru A15

LEVELERS, FOOT ......................................................A22

M

MOUNTING PLATES ..................................................A22

All photographs and illustrations are considered to be a representation of the actual item. In some cases there may be slight variations. This catalog, copy,

part numbers and unique method of illustrating products is copyrighted by (CHG) Component Hardware Group. All rights reserved. No portion of this catalog may

be reproduced in any form or by any means in whole or in part, without the written consent of CHG. CHG reserves the right to make any and all changes and to

discontinue any of its products without notice. Not responsible for typographical errors.

© COPYRIGHT 2009, (CHG) COMPONENT HARDWARE GROUP, INC.

#CAT-X021 05/09–3M PRINTED IN U.S.A.

Page 3

Stainless Steel Leg Sockets

C*

F

D

B**

E

TM

STAINLESS STEEL LEG SOCKETS

CONSTRUCTED OF 16 GA. (1.5mm) 300 SERIES, STAINLESS STEEL TUBING

PROVIDED WITH LOCKING SET SCREW TO ASSURE SECURE ASSEMBLY

MODELS AVAILABLE WITH WELDED STAINLESS STEEL MOUNTING PLATES

STAINLESS STEEL LEG SOCKETS

APPLICATION DIA. HEIGHT MODEL NO. REF.

1-3/4” (44 mm) A16-0206-C A

1-5/8”

(41mm)

O.D. TUBING

or

1-1/4”

I.P.S. PIPE

1-1/2”

(38mm)

O.D. TUBING

(50mm)

1-3/4”

(44mm)

3-1/4” (82mm) A18-0203-C C*

3-1/16” (78mm) A18-0206-C B

3-1/8” (79mm) A18-0406-C E

2”

3-1/16” (78mm) A18-9900-C B**

3-1/2” (89mm) A20-0206-C D

3-9/16” (90mm) A20-0406-C F

2-7/16” (62mm) A18-0202-C

2-1/2” (63mm) A18-0402-C G

B

A

2-7/16”

(62mm)

2-7/16”

(62mm)

HGT.

DIA.

REF. A

2-3/4”

(70mm)

G

DIA.

REF. D

HGT.

REF. B

(89mm)

HGT.

DIA.

3-1/2”

HGT.

DIA.

REF. E

2-7/16”

(62mm)

DIA.

REF. B***

3-1/2”

(89mm)

DIA.

REF. F

HGT.

HGT.

2”

(50mm)

DIA.

REF. C

REF. G

HGT.

*A1 8-0203-C IS F URNISHED WITHOUT FLAR ED TOP

*A18-0203-C IS FURNISHED WITHOUT FLAR ED TOP

NSF STANDARDS GOVERNING THE USE OF SET SCREWS IN NON-FOOD ZONES REQUIRES THE PLUGGING OF THE HEX SOCKET HOLE AFTER FINAL ASSEMBLY

AND TIGHTENING. THIS MAY BE ACCOMPLISHED BY APPLYING A HARDENING TYPE SILICONE SEALANT OR THE USE OFAHOLE PLUG.

STANDARD N.S.F. TYPE PUSH-IN PLASTIC HOLE PLUGS ARE AVAILABLE...SPECIFY A10-0020 WHEN ORDERING, SEE PAGE A24.

ADDITIONAL 5/16-24 SET SCREWS ARE AVAILABLE...SPECIFY A18-X001 WHEN ORDERING.

**FURNISH ED WITH2SET SCREWS. M OUN TING PLATE HAS (4) 5/16”(8mm) DIA. H OLE S O N 2-5/8”(6 6mm) C ENTERS.

**FURNISH ED WITH2SET SCREWS. M OUNTING PLATE HAS (4) 5/ 16”(8mm) DIA. H OLE S O N 2-5/ 8”(66mm ) C ENT ERS.

www.chgusa.com

A1

Page 4

Leg Sockets & Shelf Supports

A

A

B

TM

B

E

D

MILD STEEL

LEG SOCKETS

STRAIGHT OR FLARED MODELS AVAILABLE

AVAILABLE IN BRIGHT ZINC PLATED OR NATURAL

LOCKING SET SCREW PROVIDED

FOR SECURE ASSEMBLY

MILD STEEL LEG SOCKETS

APPLICATION HEIGHT MATERIAL MODEL NO. REF.

1-5/8”

(41mm)

O.D. TUBING

OR

1-1/4”

I.P.S. PIPE

REF. A

2-5/8”

(66mm)

3” (76mm) PLAIN STEEL

3” (76mm) ZINC PLATED

2-5/8” (66mm) PLAIN STEEL

2-5/8” (66mm) ZINC PLATED

1-7/8”

(48mm)

3”

(76mm)

A26-0206-C

A26-0207-C

A28-0206-C

A28-0207-C

REF. B

2-1/4”

(57mm)

B

B

A

A

STAINLESS STEEL

TUBULAR SHELF SUPPORTS

FOR 1-5/8”(41mm) O.D. TUBING

LONG AND SHORT LENGTH MODELS AVAILABLE

FURNISHED WITH LOCKING SET SCREWS

CAN BE USED FOR POT RACK BAND SUPPORT

STAINLESS STEEL TUBULAR SHELF SUPPORTS

APPLICATION

(41mm)

1-5/8”

O.D. TUBING

(41mm)

1-5/8”

O.D. TUBING

REF. D

1-7/8”

(48mm)

HEIGHT

1-7/8” (48mm)

5-1/4” (133mm)

5-1/4”

(133mm)

MODEL NO.

A24-0206-C

A24-0207-C

REF. E

REF.

D

E

A2

NSF STANDARDS GOVERNING THE USE OF SET SCREWS IN NON-FOOD ZONES REQUIRES THE PLUGGING OF THE HEX SOCKET HOLE AFTER FINAL ASSEMBLY

AND TIGHTENING. THIS MAY BE ACCOMPLISHED BY APPLYING A HARDENING TYPE SILICONE SEALANT OR THE USE OF A HOLE PLUG.

STANDARD N.S.F. TYPE PUSH-IN PLASTIC HOLE PLUGS ARE AVAILABLE...SPECIFY A10-0020 WHEN ORDERING, SEE PAGE A24.

ADDITIONAL 5/16-24 SET SCREWS ARE AVAILABLE...SPECIFY A18-X001 WHEN ORDERING.

www.chgusa.com

Page 5

ADJUSTABLE

FOOT INSERTS

FOR ROUND

TUBING

Conventional Round

& Hex Adjustable Toes

For Round Tubing and Pipe

Available in:

Natural Finish Zamak

Nickel Plated Zamak

Thermoplastic, Gray or Black

Stainless Steel Clad

Foot Inserts For Round Tubing

B

E

G

A

C

D

F

APPLICATION

1”

(25mm)

O.D. TUBING

16 GA. (1.5mm)

& 18 GA. (1.2mm)

(32mm)

1-1/4”

O.D. TUBING

16 GA. (1.5mm)

(38mm)

1-1/2”

O.D. TUBING

16 GA. (1.5mm)

(41mm)

1-5/8”

O.D. TUBING

16 GA. (1.5mm)

or

I.P.S. PIPE

1-1/4”

(50mm)

2”

O.D. TUBING

16 GA. (1.5mm)

TM

A10 & A11 SERIES ADJUSTABLE FOOT INSERTS

FOR ROUND TUBING AND PIPE

FOOT

DESCRIPTION

NICKEL PLATED

ZAMAK

NICKEL PLATED

ZAMAK

NATURAL FINISH

ZAMAK

STAINLESS STEEL

CLAD

THERMOPLASTIC

BLACK

THERMOPLASTIC

GRAY

NATURAL FINISH

ZAMAK

STAINLESS STEEL

CLAD

STAINLESS STEEL

CLAD

THERMOPLASTIC

BLACK

THERMOPLASTIC

GRAY

STAINLESS STEEL

CLAD

* SHOWN WITH OPTIONAL POSI-GRIP LOCKING RING

TYPE

HEX

HEX

HEX

HEX

HEX

HEX

HEX

HEX

ROUND

HEX

HEX

HEX

HEIGHT

11/16”

(17.5mm)

3/4”

(19mm)

1-1/4”

(32mm)

1-1/2”

(38mm)

1-3/8”

(35mm)

1-3/8”

(35mm)

1-1/4”

(32mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1-3/8”

(35mm)

1-3/8”

(35mm)

1”

(25mm)

ADJ. MODEL NO.

13/16”

(21mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

1-1/4”

(32mm)

1-1/16”

(27mm)

1-1/16”

(27mm)

1-1/8”

(28mm)

1-1/4”

(32mm)

1-1/4”

(32mm)

1-1/16”

(27mm)

1-1/16”

(27mm)

2”

(50mm)

A10-0221-C

A10-0421-C

A10-0611-C

A10-0651-C

A10-0631-C

A10-0641-C

A10-0811-C

A10-0851-C

A10-0852-C

A10-0831-C

A10-0841-C

A11-0851-C

LOAD RATING

LBS/FOOT(Kg/Ft)

1100 (500)

1400 (635)

2000 (900)

2000 (900)

200 (90)

200 (90)

2000 (900)

2000 (900)

2000 (900)

200 (90)

200 (90)

2300 (1040)

REF.

C

C

D

D

F

B

G*

G*

A

F

B

E

HEIGHT

SHOWN WITH OPTIONAL

LOCKING RING

*OPTIONAL

POSI-GRIP

LOCKING RING

MODEL NO.

A10-0010-C

SPRING STEEL WITH CLEATS

THAT GRIP AND BITE TUBING

TO LOCK FOOT TO TUBE.

AVAILABLE FOR MODEL NOʼS

A10-0811-C, A10-0851-C

AND A10-0852-C.

TM

800-526-3694

A3

Page 6

Engineered Plastic Adjustable Foot Inserts

REINFORCED

Engineered Plastic

Stainless Steel Clad

ADJUSTABLE

FOOT INSERTS

FOR 1-1/2”(38mm) AND

1-5/8”(41mm) ROUND TUBING

NSF Listed

Stainless Steel Type 304

Economical

Offers a full 1-1/4”(32mm) adjustment

Unique threading offers smooth, fast field adjustment

Each model designed to suit either 16 Ga. (1.5mm)

or 18 Ga. (1.2mm) round tubing

Specially designed engineered plastic construction

withstands todayʼs harsh chemical cleansers in

PATENTED

commercial kitchen environments

MODEL NO.

2-1/16”

(52mm)

A10-1000

A10-1500

APPLICATION

1-5/8” (41m m)

O.D TUBING

16 GA. (1.5mm)

& 18 GA. (1.2 mm)

1-1/2”(38mm)

O.D TUBING

16 GA. (1.5mm)

& 18 GA. (1.2 mm)

1-1/2”

(38mm)

2-11/16”

(69mm)

TYPE

HEX

HEX

HEIGHT

1-1/2”

(38mm)

1-1/2”

(38mm)

ADJ.

1-1/4”

(32mm)

1-1/4”

(32mm)

LOAD RATING

*OPTIONAL POSI-GRIP

LOCKING RING

SPRING STEEL WITH CLEATS

THAT GRIP AND BITE TUBING

TO LOCK FOOT TO TUBE.

HEIGHT

SHOWN WITH OPTIONAL

LOCKING RING

MODEL NOʼS A10-0811-C,

LBS./FOOT(KG/mm)

1000 lbs

(450 Kg)

1000 lbs

(450 Kg)

MODEL NO.

A10-0010-C

AVAILABLE FOR

A10-0851-C

AND A10-0852-C.

TM

A4

www.chgusa.com

Page 7

Adjustable Foot Insert Features Full 3” Adjustment

3 7/8"

(99mm)

1 1/2"

(38mm)

4 1/2"

(114mm)

EXTENSION

HEIGHT

HEIGHT

1 1/2"

(38mm)

3 7/8"

(99mm)

EXTENSION

4 1/2"

(114mm)

3 1/2"

(89mm)

®

HI-RISE

ADJUSTABLE FOOT INSERT

FULL 3”(76mm) ADJUSTMENT

NSF LISTED

RUGGED 2000 LB. LOAD RATING

STAINLESS STEEL FLANGED MODELS

AVAILABLE

Adjustable Foot Inserts, specified by Engineers

and Consultants, are specifically designed to

meet pending OSHA requirements which suggest maximum counter and table adjustments to

permit comfortable working environments.

• Ideal for lengthy cafeteria lines and counters

where floor pitch is a concern.

• Eliminates costly field modification

• Maximum height adjustment helps avoid

plumbing obstacles and other unforeseen

conditions during installation of equipment.

PATENTED

3”(76mm) ADJUSTABLE FOOT INSERT

TO SUIT 1-5/8”(41mm) O.D. TUBING 16 GA. (1.5mm)

MODEL NO. DESCRIPTION TYPE

A10-0881-C STAINLESS STEEL HEX

A10-0884-C W/ (2) 11/32” (9mm) DIA. FLANGED

S/S FLANGED

MOUNTING HOLES

OPTIONAL POSI-GRIP

LOCKING RING

ORDER SEPARATELY AS

MODEL NO. A10-0010-C

SEE PAGE A4 FOR DETAILS

HGT.

1-1/2”

(38mm)

1-1/2”

(38mm)

ADJ.

3”

(75mm)

3”

(75mm)

TM

LOAD

RATING

BS/FT (KG/mm)

2000

(900)

2000

(900)

800-526-3694

A5

Page 8

Foot Inserts For Square Tubing

D

B

B

C

A

C

FLANGED ADJUSTABLE FOOT INSERTS

For Round or Square Tubing or Pipe

Available in:

Stainless Steel Clad Nickel Plated Zamak

Available with or without Mounting Holes Certain Models Furnished Complete with

Posi-Grip to Lock Foot to Tube

A14 & A15 SERIES ADJUSTABLE FOOT INSERTS FOR SQUARE TUBING

APPLICATION

(25mm)

1”

SQ.TUBING

16 GA. (1.5mm)

OR

18 GA. (1.2mm)

(32mm)

1-1/4”

SQ. TUBING

16 GA. (1.5mm)

OR

18 GA. (1.2mm)

(38mm)

1-1/2”

SQ.TUBING

16 GA. (1.5mm)

OR

18 GA. (1.2mm)

50mm)

2”(

SQ.TUBING

16 GA. (1.5mm)

FOOT

DESCRIPTION

NICKEL PLATED

ZAMAK

NATURAL FINISH

ZAMAK

NICKEL PLATED

ZAMAK

NATURAL FINISH

ZAMAK

STAINLESS STEEL

CLAD

STAINLESS STEEL

CLAD

TYPE

HEX

HEX

HEX

HEX

HEX

HEX

HEIGHT

11/16”

(17.5mm)

1-1/4”

(32mm)

1-3/8”

(35mm)

1-1/4”

(32mm)

1-1/2”

(38mm)

1”

(25mm)

ADJ.

7/8”

(22mm)

1-1/8”

(28mm)

1”

(25mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

2”

(50mm)

MODEL NO.

A14-0221-C

A14-0411-C

A14-0421-C

A14-0611-C

A14-0651-C

A15-0851-C

LOAD

RATING

LBS/FT(KG/FT)

1200

(550)

2000

(900)

2000

(900)

2000

(900)

2000

(900)

2300

(1040)

TM

REF.

A

B

HEIGHT

C

D

A6

www.chgusa.com

Page 9

Flanged Foot Inserts For Round & Square Tubing

C

B

A

G

F

E

D

FLANGE DIA.

FLANGED ADJUSTABLE FOOT INSERTS

For Round or Square Tubing or Pipe

Available in:

Stainless Steel Clad Available with or without Mounting Holes

Nickel Plated Zamak Certain Models Furnished Complete with Posi-Grip

to Lock Foot to Tube

HEIGHT

APPLICATION

1”(25mm) SQUARE TUBING

16 GA. (1.5mm) & 18 GA. (1.2mm)

1-1/4”(32mm) SQUARE TUBING

16 GA. (1.5mm) OR 18 GA. (1.2mm)

1-1/4” I.P.S. PIPE OR 1-1/2”(38mm)

O.D. ROUND TUBING 16 GA. (1.5mm)

1-1/2”(38mm)

SQUARE TUBING

16 GA. (1.5mm)

OR 18 GA. (1.2mm)

1-5/8”(41mm) O.D. ROUND TUBING

FORMARINE APPLICATION 16 GA. (1.5mm)

1-5/8”(41mm)

O.D. ROUND TUBING

16 GA. (1.5mm)

O.D. ROUND TUBING 16 GA. (1.5mm)

16 GA. (1.5mm) OR 18 GA. (1.2mm)

2”(50mm)

2”(50mm) SQUARE TUBING

FLANGE

DESCRIPTION

1-3/16”(30mm) DIA.

NICKEL PLATED ZAMAK

2-1/8” (54mm)

NICKEL PLATED ZAMAK

3-1/2”(89mm) DIA. S/S

WITH MOUNTING HOLES**

3-1/2”(89mm) DIA. S/S

NO MOUNTING HOLES

3-1/2”(89mm) DIA. S/S

WITH MOUNTING HOLES**

2”(50mm) DIA. S/S

NO MOUNTING HOLES

3-1/2”(89mm) DIA. S/S

NO MOUNTING HOLES

3-1/2”(89mm) DIA. S/S

WITH MOUNTING HOLES**

3-1/2”(89mm) DIA. S/S

WITH MOUNTING HOLES**

3-1/2”(89mm) DIA. S/S

WITH MOUNTING HOLES**

HEIGHT

3/4” 1/2”

(17.5mm) (12mm)

1-3/8” 1”

(35mm) (25mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1-1/2”

(38mm)

1”

(25mm)

(25mm)

ADJ.

1-1/8”

(28mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

1-1/8”

(28mm)

2”

(50mm)

1”

2”

(50mm)

MODEL NO.

A14-0224-C

A14-0424-C

A10-0654-C

A14-0653-C

A14-0654-C

A10-9904-C

A10-0853-C

A10-0854-C

A11-0854-C

A15-0854-C

LOAD RATING

Lbs/Ft (Kg/mm)

1200

(550)

2000

(900)

2000

(900)

2000

(900)

2000

(900)

2000

(900)

2000

(900)

2000

(900)

2300

(1040)

2300

(1040)

REF.

A

B

D*

C*

C*

E

D

D*

F*

G*

* FLANGED FOOT MODELS HAVE 12 GA. (2.6mm) STAINLESS STEEL FLANGE WITH A #4 SATIN FINISH.

**PROVIDED WITH (2) 11/32” (9mm) DIA. MOUNTING HOLES, SPACED 2-1/2”(63mm) O.C.

800-526-3694

A7

Page 10

Caster Leg Assemblies

SAFETY SERIES

ADJUSTABLE

CASTER LEG ASSEMBLIES

1-5/8”(41mm) and 2”(50mm) O.D.

STAINLESS STEEL LEGS

with WELDED MOUNTING PLATES

or PROTRUDING STUDS

MEDIUM DUTY CASTERS with

3", 4" and 5" (75, 100 and 125mm) DIA.

POLYOLEFIN* WHEELS

BRAKE and NON-BRAKE MODELS

I SUPPLIED with SLOTTED HEAD

LOCKING SET SCREWS

to meet N.S.F. REQUIREMENTS

SAFETY SERIES CASTER LEG ASSEMBLIES were designed

specifically for fryers and other “HOT CONTENT” equipment

that rests on pitched floors and must be moved for cleaning

and servicing. To avoid dangerous content spillage, these casters

are engineered with a SPECIAL RETAINING FEATURE...the

caster CANNOT BE DISASSEMBLED FROM THE LEG while

adjusting equipment height or during the movement of equipment. Eliminates incidence of costly spills and serious accidents

from caster assemblies inadvertently coming apart.

HEIGHT

ADJ.

LEGS: 16 GA. (1.5mm), 300 SERIES STAINLESS STEEL, POLISHED TO A

#4 SATIN FINISH AND FURNISHED WITH (2) LOCKING SLOTTED HEAD

SET SCREWS (TO CONFORM TO NSF REQUIREMENTS).

MOUNTING PLATES: 11 GA. (3mm) PAINTED STEEL, 3-1/2”(89mm) SQUARE

WITH FOUR 5/16”(8mm) DIA. HOLES ON 2-5/8”(66mm) CENTERS.

CASTERS: MEDIUM DUTY WITH *POLYOLEFIN WHEELS WITH A

TREAD WIDTH OF 1-1/4”(32mm) AND AN OPERATING TEMPERATURE RANGE

OF -20°F TO 180°F (-29°C TO 82°C). HARDNESS OF 65

*Solid Polyolefin Wheels are lightweight, easy rolling wheels made

from one of the most durable thermoplastics. These wheels require

no bearings and are ideal for those corrosive conditions which

cause costly and continual bearing replacement. Polyolefin wheels

offer resistance to most oils, chemicals, grease, solvents and acids.

SPECIFICATIONS

+

ON SHORE D SCALE.

HEIGHT

ADJ.

5 DUROMETER

WHEEL

DIA.

3”

(76mm)

4”

(100mm)

5”

(125mm)

3”

(75mm)

4”

(100mm)

5”

(125mm)

WHEEL

.

DIA

5”

(125mm)

5”

(125mm)

1-5/8”(41mm) O.D. CASTER LEG ASSEMBLIES

SAFETY SERIES

MOUNTING

TYPE

3-1/2”

(90mm)

SQUARE

PLATE

1/2-13

STUD

MINIMUM

O.A. HEIGHT

6”

(150mm)

7-1/2”

(190mm)

8-1/2”

(215mm)

6”

(150mm)

7-1/2”

(190mm)

8-1/2”

(215mm)

ADJ.

1/2”

(13mm)

1”

(25mm)

1”

(25mm)

1/2”

(13mm)

1”

(25mm)

1”

(25mm)

NON-BRAKE

MODEL NO.

CC4477--00330066--CC

CC4477--00440066--CC

CC4477--00550066--CC

CC5500--00330066--CC

CC5500--00440066--CC

CC5500--00550066--CC

BRAKE

MODEL NO.

CC4477--00331166--CC

CC4477--00441166--CC

CC4477--00551166--CC

CC5500--00331166--CC

CC5500--00441166--CC

CC5500--00551166--CC

SAFETY SERIES

2”(50mm) O.D. CASTER LEG ASSEMBLIES

MOUNTING

TYPE

3-1/2”

(90mm)

SQUARE

PLATE

3/4-10

STUD

CASTER LEG ASSEMBLIES ARE NON-STOCK ITEMS.

OTHER MODEL AVAILABLE ON SPECIAL APPLICATION.

MINIMUM

O.A. HEIGHT

8-1/2”

(215mm)

8-1/2”

(215mm)

ADJ.

1”

(25mm)

1”

(25mm)

NON-BRAKE

MODEL NO.

CC8833--00550066--CC

CC8866--00550066 --CC

BRAKE

MODEL NO.

CC8833--00551166--CC

CC8866--00551166 --CC

LOAD RATING

PER CASTER

200 LBS.

(90Kg)

275 LBS.

(125Kg)

300 LBS.

(135Kg)

200 LBS.

(90Kg)

275 LBS.

(125Kg)

300 LBS.

(135Kg)

LOAD RATING

PER CASTER

300 LBS.

(135Kg.)

300 LBS.

(135Kg.)

A8

www.chgusa.com

Page 11

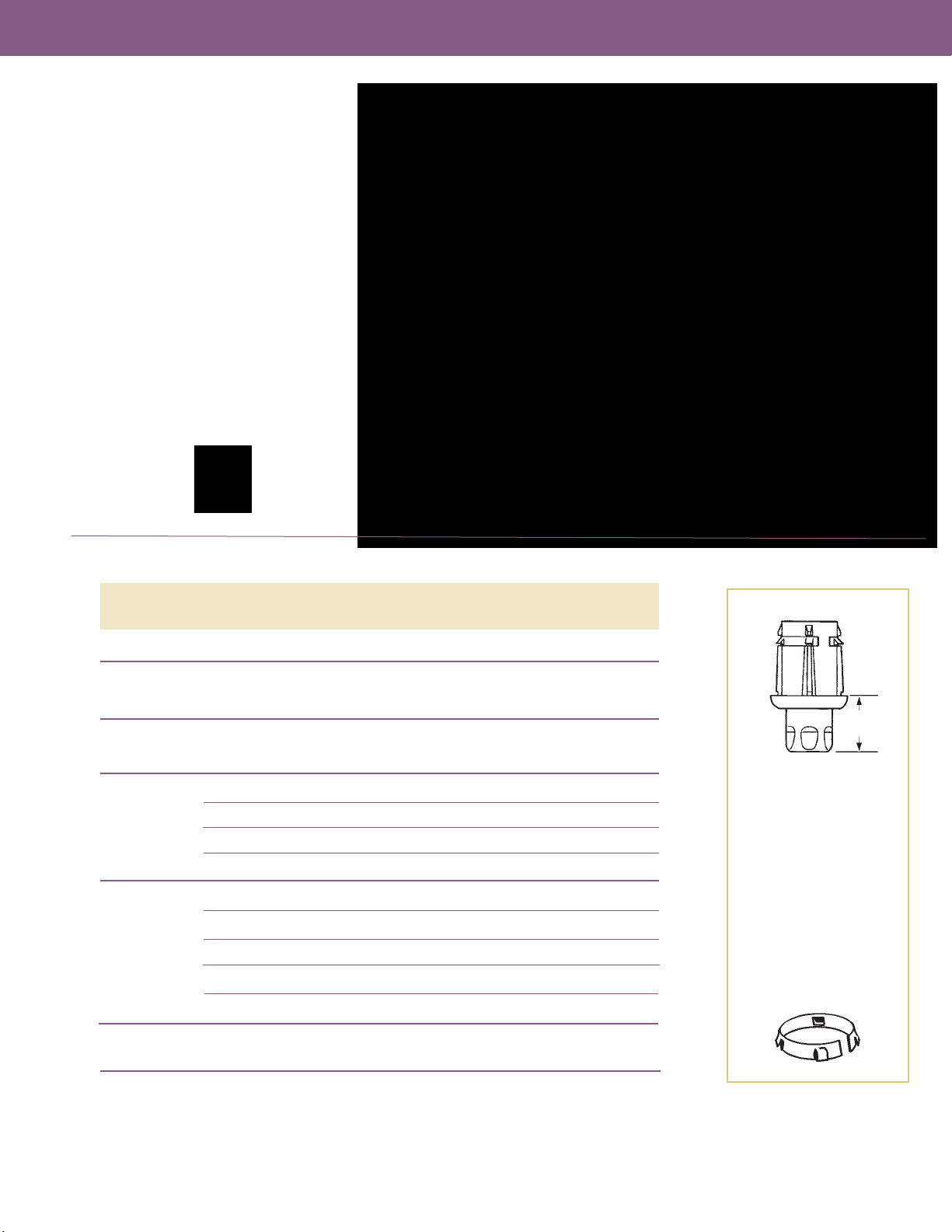

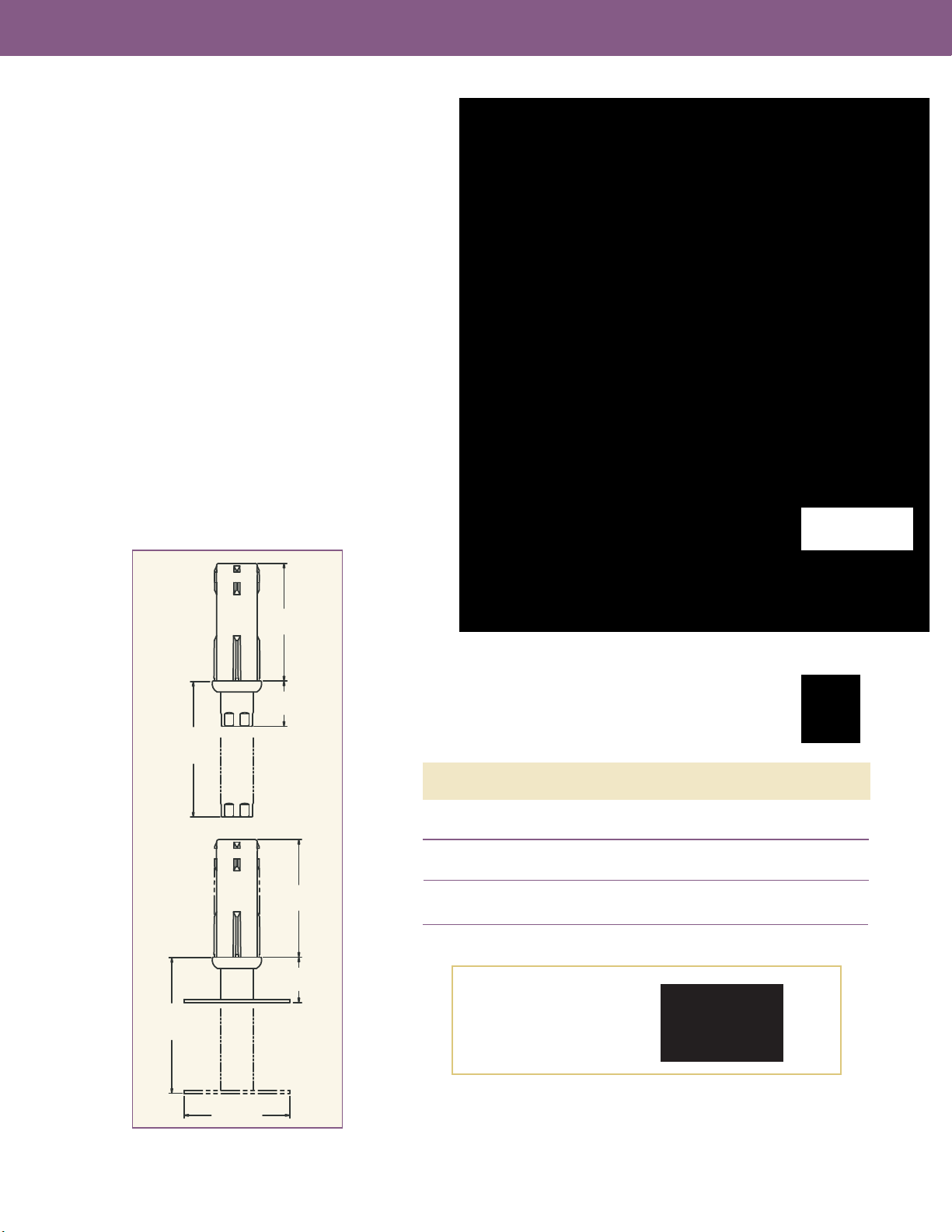

Security/Seismic Heavy-Duty Leg Assemblies

Easily modified to meet SMACNA

seismic restraint requirements.

First, drill a 5/8”(16mm) diameter

hole in flanged toe to accomodate

anchored floor rod. Then, simply

drill a 1/4” (6mm) diameter

horizontal hole through toe

portion which allows leg to be

pinned to anchored rod.

(Pin not furnished)

FLOOR FASTENED • STAINLESS STEEL

SECURITY/SEISMIC EQUIPMENT LEGS

MODEL NO. DESCRIPTION

A47-9932-C

A50-9939-C

A88-9902-C

A90-9902-C

1-5/8”(41mm) O.D. WITH WELDED MOUNTING PLATE

1-5/8”(41mm) O.D. WITH 1/2-13 PROTRUDING STUD

2”(50mm) O.D. WITH WELDED MOUNTING PLATE

2”(50mm) O.D. WITH 3/4-10 PROTRUDING STUD

SECURITY/SEISMIC

EQUIPMENT LEGS

STAINLESS STEEL

Security/Seismic Equipment Legs are specifically designed

for Marine, Prison and Institutional applications where

installations require Secured Floor Fastened Adjustable Legs

on equipment that may be subjected to sudden

movement or shifting. Equipment Legs are available in

both 1-5/8” (41mm) and 2” (50mm) O.D. models with a

protruding threaded stud or welded 3-1/2” (89mm) 11 gauge

(3mm) square steel mounting plate. The 3-1/2” (89mm) dia.

flanged foot has two 11/32” (9mm) dia. floor fastening holes

on 2-1/2” (63mm) centers.

(3mm)

ADJ.

3-1/2”

(89mm)1/8”

3/4”(19mm)

6”

(150mm)

ADJ.

THREADED STEEL STUD OR WELDED MOUNTING PLATE PROVIDED FOR EASY MOUNTING OF LEGS TO EQUIPMENT

FOOT INSERTS ARE PROVIDED WITH A 3-1/2”(89mm) DIA. 11 GA. (3mm) FLANGE LEGS ARE 6”(150mm) IN HEIGHT AND PROVIDE 1-1/2”(38mm) ADJUSTMENT

ALL LEGS MAY BE FURNISHED TO MEET SPECIFIC REQUIREMENTS WITH SPECIAL STUDS AND/OR MOUNTING PLATES

LEGS MAY BE FURNISHED IN SETS OF FOUR WITH CUSTOMERʼS PART NUMBERS FOR KD SHIPPING 2,000 LBS.

1-5/8”(41mm) AND 2”(50mm) O.D. 300 SERIES STAINLESS STEEL TUBING WITH A #4 FINISH

(900kg) PER LEG STATIC LOAD RATING MOUNTING PLATE HAS (4) 5/16” (66mm) CENTERS

SPECIFICATIONS

800-526-3694

A9

Page 12

ABS Plastic Equipment Legs

HIGH IMPACT ABS PLASTIC EQUIPMENT LEGS

FOR ICE MAKERS, REACH-INS, COMMERCIAL REFRIGERATORS,

COUNTERS & COMMERCIAL CABINETS

NSF LISTED

2000 LB. (900Kg) PER LEG STATIC LOAD RATING

BLACK MATTE FINISH

AVAILABLE WITH NON-REMOVABLE METAL TOE

WITH NON-MARRING ABS PLASTIC BASE OR

BLACK ABS NON-MARRING TOE

ABS PLASTIC EQUIPMENT LEGS

MOUNTING TYPE LEG COLOR FOOT TYPE MODEL NO.

1/2 - 13 PROTRUDING STUD BLACK BLACK AP61-2003-C

5/8 - 11 PROTRUDING STUD BLACK BLACK AP62-2003-C

2-3/8”

(60mm)

3/4” (19mm)

6”(150mm)

3/4”(19mm)

ADJUSTMENT

FOR OPTIONAL

MOUNTING PLATE

USE MODEL #A44-X301-C

1/2 - 13 FLUSH STUD WITH

#A44-X301-C 3-1/2” SQUARE BLACK BLACK

MOUNTING PLATE

1/2 - 13 FLUSH STUD WITH

#A44-X327-C 2-1/2 x 3-5/8” BLACK BLACK

RECTANGULAR

NON-REMOVEABLE

MOUNTING PLATE

1/2 - 13 PROTRUDING STUD BLACK NICKEL PLATED

5/8 - 11 PROTRUDING STUD BLACK NICKEL PLATED AP62-4003-C

1/2 - 13 FLUSH STUD WITH

#A44-X301-C 3-1/2” SQUARE BLACK NICKEL PLATED

MOUNTING PLATE ZAMAK

1/2 - 13 FLUSH STUD WITH

#A44-X327-C 2-1/2 x 3-5/8” BLACK NICKEL PLATED

RECTANGULAR ZAMAK

NON-REMOVEABLE

MOUNTING PLATE

AP SERIES

FULLY ADJUSTABLE TOE

6” MINIMUM HEIGHT WITH ADJUSTABLE TOE

CORROSION RESISTANT ZINC PLATING ON ALL STUDS

TOUGH, DURABLE, HIGH IMPACT RESISTANT ABS

NON-MARRING PLASTIC

ZAMAK

ZAMAK

* NON-STOCK ITEM

AP63-2003-C

AP64-2003-C*

AP61-4003-C

AP63-4003-C

AP64-4003-C*

MTG PLATE HAS (4) 5/16”(8mm) DIA.

HOLES ON 2-5/8” (66mm) CENTERS

3-1/2” (89mm)

SQUARE

6”

(150mm)

3/4”(19mm)

ADJUSTMENT

A10

www.chgusa.com

Page 13

Economy Zinc Die Cast Equipment Legs

2-3/8”

(60mm)

3/4”(19mm)

6”

(150mm)

1”

(25mm) ADJ.

POWDER COATED FINISH

PROVIDES A DURABLE , CHIP

RESISTANT FINISH. SPECIAL COLORS

AVAILABLE ON QUANTITY ORDERS.

ECONOLINE EQUIPMENT LEGS

DIE CAST ZAMAK

Available in finishes of...

NICKEL BLACK EPOXY FINISH GRAY EPOXY FINISH

with...REMOVABLE MOUNTING PLATE or PROTRUDING STUD

ECONOLINE DIE CAST EQUIPMENT LEGS

MOUNTING TYPE LEG FINISH FOOT TYPE MODEL NO.

AE61-2003-C*

AE61-2104-C

AE61-4002-C

AE61-5002-C

AE62-4002-C

AE62-2104-C*

AE62-5002-C

AE63-2003-C

AE63-4002-C

AE63-2104-C*

AE63-5002-C

* NON-STOCK ITEM

3-1/2”(89mm)

ALL MODELS HAVE A STATIC LOAD RATING

OF 2000 LBS. (900Kg) PER LEG

MTG PLATE HAS (4) 5/16”(8mm) DIA. HOLES

ON 2-5/8 ”(66mm) CENTERS.

FURNISHED WITH

1/2-13

PROTRUDING

STUD

FURNISHED WITH

5/8-11

PROTRUDING

STUD

FURNISHED WITH

1/2-13 FLUSH STUD

WITH #A44-X301-C

3-1/2” SQUARE

REMOVABLE

MOUNTING PLATE**

**See page A24

BLACK EPOXY

GRAY EPOXY

NICKEL

NICKEL

NICKEL

GRAY EPOXY

NICKEL

BLACK EPOXY

NICKEL

GRAY EPOXY

NICKEL

HEX

HEX

HEX

S/S HEX

HEX

HEX

S/S HEX

HEX

HEX

HEX

S/S HEX

SQUARE

6”

(150mm)

1”(25mm)

ADJ.

DIE CAST ZAMAK CONSTRUCTION THREADED STEEL STUD OR REMOVABLE MOUNTING PLATE PROVIDED FOR EASY MOUNTING OF LEGS TO EQUIPMENT

FOOT INSERTS ARE HEX SHAPED TO PERMIT QUICK HEIGHT ADJUSTMENT LEGS ARE 6”(150mm) IN HEIGHT AND PROVIDE 1-1/4”(32mm)ADJUSTMENT

ALL LEGS MAY BE FURNISHED TO MEET SPECIFIC REQUIREMENTS WITH SPECIAL STUDS AND/OR MOUNTING PLATES

LEGS MAY BE FURNISHED PACKAGED IN SETS OF FOUR WITH CUSTOMER'S PART NUMBER AS AN OPTION FOR KD SHIPPING

SPECIFICATIONS

800-526-3694

A11

Page 14

Stainless Steel Equipment Legs

B

A

C

D

C

HEAVY-DUTY

EQUIPMENT LEGS

STAINLESS STEEL

HEAVY-DUTY 2”(50mm) O.D.

TAPERED BODY with LARGE FLARED TOP

REMOVABLE MOUNTING PLATE

FLUSH or PROTRUDING STUD

STAINLESS STEEL EQUIPMENT LEGS

MODEL NO. DESCRIPTION REF.

A77-5048-C

A78-5048-C

A79-5048-C

FURN. WITH REMOVABLE MOUNTING PLATE A

FURN. WITH FLUSH 3/4-10 STUD

FURN. WITH 3/4-10 PROTRUDING STUD B

2-3/8”

(60mm)

3/4”

(19mm)

1/8”

(3mm)

6”

(150mm)

3-1/2”

(89mm)

SQUARE

MTG PLATE HAS

(4) 5/16”(8mm) DIA. HOLES

ON 2-5/8”(66mm) CENTERS

NOT SHOWN

HEAVY-DUTY

EQUIPMENT LEGS

STAINLESS STEEL

for WELDED APPLICATIONS

HEAVY-DUTY 2”(50mm) O.D.

STEPPED SHAPE or STRAIGHT SHAPE with

LARGE 2-3/8” (60mm) DIA. FLARED TOP

STAINLESS STEEL EQUIPMENT LEGS

MODEL NO. DESCRIPTION FOOT O.A. HEIGHT ADJ. REF.

A72-0811

A52-9907-C

STEPPED ROUND 6”(150mm) 1-3/4”(44mm) C

STRAIGHT HEX 6” (150mm) 1-3/4”(44mm) D

2-3/8”

(60mm)

6”

(150mm)

6”

(150mm)

2-3/8”

(60mm)

A12

1-3/4” ADJ.(44mm)

2”(50mm) O.D. 300 SERIES STAINLESS STEEL TUBING WITH A #4 FINISH THREADED STEEL STUD, WELDED OR REMOVABLE MOUNTING PLATE

PROVIDED FOR EASY MOUNTING OF LEGS TO EQUIPMENT LEGS ARE 6”(150mm) IN HEIGHT AND PROVIDE 1-3/4”(44mm) ADJUSTMENT

ALL LEGS MAY BE FURNISHED TO MEET SPECIFIC REQUIREMENTS WITH SPECIAL STUDS AND /OR MOUNTING PLATES LEGS MAY BE FURNISHED

PACKAGED IN SETS OF FOUR WITH CUSTOMERʼS PART NUMBER FOR KD SHIPPING 2000 LBS.(900Kg) PER LEG STATIC LOAD RATING

LEGS ARE FURNISHED

WITH HEX SHAPED

ADJUSTABLE FEET

THESE LEGS ARE NOT AVAILABLE WITH MOUNTING PLATES OR STUDS.

SPECIFICATIONS

1-3/4” ADJ.(44mm)

1-3/4” ADJ.(44mm)

www.chgusa.com

Page 15

Stainless Steel Equipment Legs

C

A

B

A

HEAVY- DUTY STAINLESS STEEL

EQUIPMENT LEGS

HEAVY-DUTY 2"(50mm) O.D.

REMOVABLE MOUNTING PLATE

or PROTRUDING STUD

STAINLESS STEEL EQUIPMENT LEGS

MODEL NO. HEIGHT DESCRIPTION REF.

A84-5048-C

A86-5048-C

A85-9706-C

3-1/2”(89mm)

SQUARE

6”(150mm) W/ REMOVABLE MOUNTING PLATE A

6”(150mm) W/ 3/4-10 PROTRUDING STUD B

6”(150mm) W/ 5/8-11 PROTRUDING STUD AND

NON-MARKING BLACK NYLON FLANGED TOE

2”

(50mm)

2”

(50mm)

3/4”

(19mm)

(3mm)

6”

(150mm)

1/8”

3/4”(19mm)

6”

(150mm)

C

B

HEAVY- DUTY STAINLESS STEEL

EQUIPMENT LEGS

HEAVY-DUTY 1-5/8"(41mm)

4"(100mm) and 6"(150mm) HIGH MODELS

with REMOVABLE MOUNTING PLATE

STAINLESS STEEL EQUIPMENT LEGS

MODEL NO. HEIGHT DESCRIPTION REF.

A48-5032-C

A48-5048-C

C

A50-9704-C

A50-5032-C

A50-5048-C

MODEL NO. A48-5032-C IS N.S.F. LISTED AS A HEAVY-DUTY APPLIANCE LEG.

MODEL NO. A48-5048-C IS N.S.F. LISTED AS A HEAVY-DUTY EQUIPMENT LEG.

3/4”

(19mm)

4”(10mm)

6”(150mm)

4”(100mm) W/ REMOVABLE MOUNTING PLATE

6”(150mm) W/ REMOVABLE MOUNTING PLATE

4”(100mm) W/ 1/2-13 PROTRUDING STUD &

NON-MARKING BLACK NYLON FLANGED TOE

4”(100mm) W/ 1/2-13 PROTRUDING STUD

6”(150mm) W/ 1/2-13 PROTRUDING STUD

HEIGHT

3-1/2”(89mm)

SQUARE

3/4”

(19mm)

HEIGHT

1-5/8”

(41mm)

1-5/8”

(41mm)

A

B

C

1-3/4”(44mm) ADJ.

REF. A

1-5/8”(41mm) AND 2”(50mm) O.D. 300 SERIES STAINLESS STEEL TUBING WITH A #4 FINISH THREADED STEEL STUD, WELDED OR REMOVABLE MOUNTING PLATE PROVIDED

FOR EASY MOUNTING OF LEGS TO EQUIPMENT FOOT INSERTS ARE HEX SHAPED TO PERMIT QUICK HEIGHT ADJUSTMENT LEGS ARE 6”(150mm) IN HEIGHT AND PROVIDE

3”(76mm) ADJUSTMENT ALL LEGS MAY BE FURNISHED TO MEET SPECIFIC REQUIREMENTS WITH SPECIAL STUDS AND / OR MOUNTING PLATES

LEGS MAY BE FURNISHED PACKAGED IN SETS OF FOUR WITH CUSTOMERʼS PART NUMBER FOR KD SHIPPING 2000 LBS.(900Kg.) STATIC LOAD RATING

2-3/4”

(70mm)

REF. C

REF. B

MOUNTING PLATES HAVE (4) 5/16”(8mm) DIA. HOLES ON 2-5/8”(66mm) CENTERS.

SPECIFICATIONS

1-3/4”(44mm)

ADJ.

REF. C

1-3/4”(44mm)

ADJ.

REF. A

1-1/2”

(38mm)

REF. B

800-526-3694

A13

Page 16

Stainless Steel Equipment Legs Feature Full 3” Adjustments

HEAVY-DUTY STAINLESS STEEL

EQUIPMENT LEGS

with FULL 3”(76mm) ADJUSTMENT

HEAVY DUTY 2”(50mm) O.D. NON-MARKING BLACK NYLON TOE

available with...

REMOVABLE MOUNTING PLATE WELDED MOUNTING PLATE

PROTRUDING STUD FLUSH STUD

3/4”(19mm)

HEAVY-DUTY STAINLESS STEEL EQUIPMENT LEGS

MODEL NO. DESCRIPTION

6”

(150mm)

3”

(76mm) ADJ.

A92-8048-C

A93-8048-C

A94-8048-C

A95-8048-C

FURNISHED WITH WELDED MOUNTING PLATE

FURNISHED WITH REMOVABLE MOUNTING PLATE

FURNISHED WITH 3/4-10 FLUSH STUD

FURNISHED WITH 3/4-10 PROTRUDING STUD

ALL MODELS HAVE A STATIC LOAD RATING

OF 2000 LBS. (900Kg) PER LEG.

* CAN ALSO BE USED FOR WELDED APPLICATION

*

3-1/2”

(89mm)

SQUARE.

6”

(150mm)

ADJ .

3”

(78mm)

ADJ .

MTG PLATE HAS (4) 5/16”(8mm) DIA. HOLES

ON 2-5/8”(66mm) CENTERS

A14

SPECIFICATIONS

2”(50mm) O.D. 300 SERIES STAINLESS STEEL TUBING WITH A #4 FINISH THREADED STEEL STUD, WELDED OR REMOVABLE MOUNTING PLATE

PROVIDED FOR EASY MOUNTING OF LEGS TO EQUIPMENT LEGS ARE 6”(150mm) IN HEIGHT AND PROVIDE 3”(76mm) ADJUSTMENT

LEGS MAY BE FURNISHED PACKAGED IN SETS OF FOUR WITH CUSTOMERʼS PART NUMBER FOR KD SHIPPING 2,000 LBS.(900Kg) PER LEG STATIC LOAD RATING

ALL LEGS MAY BE FURNISHED TO MEET SPECIFIC REQUIREMENTS WITH SPECIAL STUDS AND/OR MOUNTING PLATES

www.chgusa.com

Page 17

6”

(152.4mm)

2-1/2”

(63.5mm)

3/4-10 UNC-2A

STEEL STUD

.06 BELOW FLUSH

REF 5”

(127mm)

2-1/8”

(53.975mm)

1/40”

MAX (NSF) GAP

ALL AROUND

FILLET WELD

4 PLCS EQ SP

TYPICAL

FILLET WELD

2 PLCS EQ SP

TYPICAL

2-1/2”

(63.5mm)

ADJUSTMENT

SQ 2-5/8”

(66.675mm)

SQ 3-1/2”

(88.9mm)

OPTIONAL

MOUNTING PLATE

1/8”

(3.175mm)

5/16”

(7.938mm)

(.75mm)

Extra Wide Stainless Steel Clad Equipment Legs

2-1/2" HEAVY DUTY S/S EQUIPMENT LEGS

? 2-1/2” O.D. x 6” long

? Available with a 3/4” - 10“ flush or protuding stud

? Full 2-1/2” height adjustment

? Type 304 stainless steel construction

? 2500 lbs. static load capacity

? Extra wide 2-1/2” diameter provides a stable leg base

? Ideal for heavy ranges, ovens & food processing equipment

? Satin finish

A44-X341-C

FURNISHED WITH

3-1/2” (89mm)

SQUARE REMOVABLE

MOUNTING PLATE

A67-5048-C

FURNISHED WITH 3/4”

FLUSH STUD

A68-5048-C

FURNISHED WITH 3/4”

PROTRUDING STUD

800-526-3694

A15

Page 18

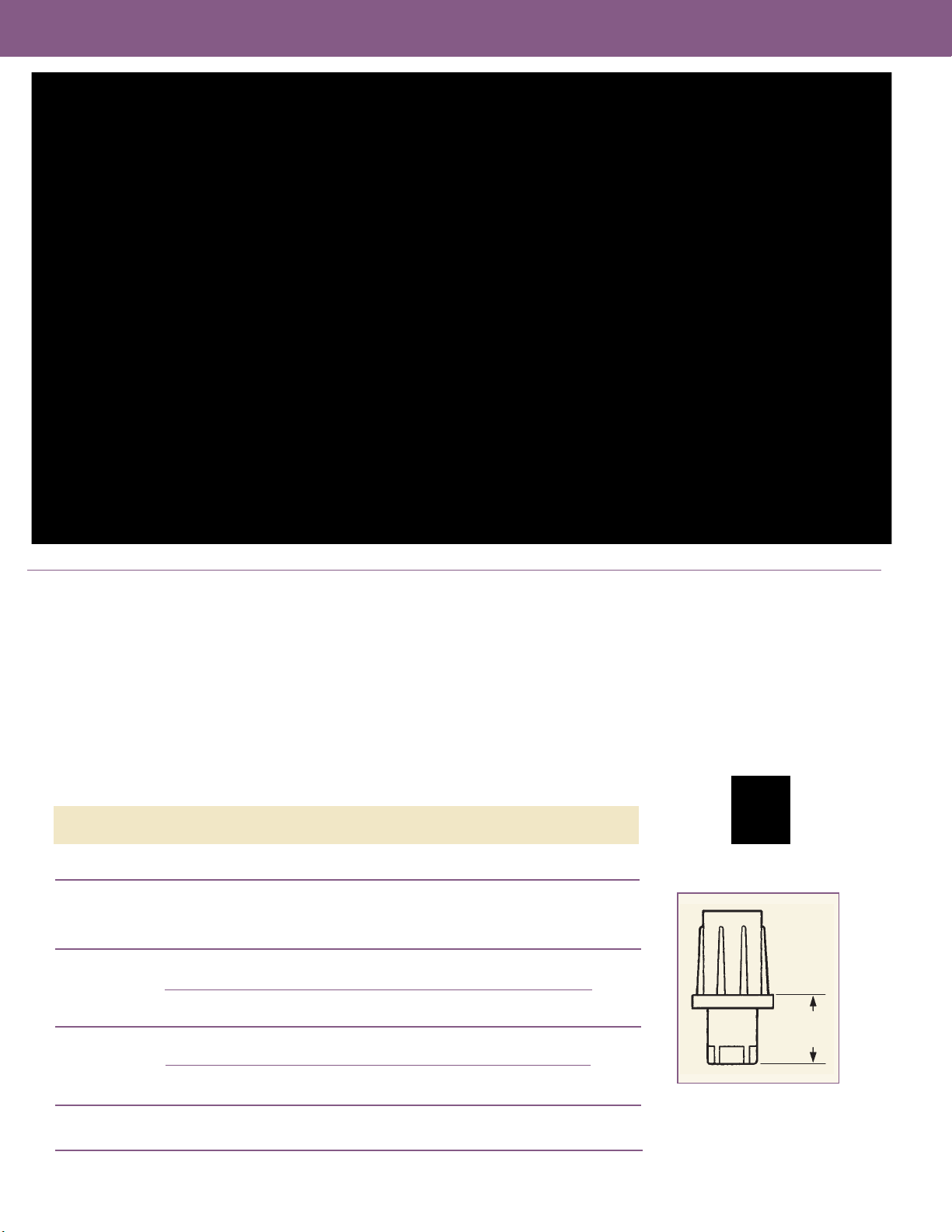

S/S One Piece Leg Assemblies With Full 3” Adjustment

1-5/8”(41mm) O.D.

STAINLESS STEEL LEG ASSEMBLIES

FULL 3” ADJUSTMENT FEATURE

FOR STANDARD APPLICATION

Economical... eliminates cutting, deburring, polishing and waste

STAINLESS STEEL ONE PIECE

WITH INTEGRAL ADJUSTABLE TOES

LEG DIA. LENGTH TOE TYPE MODEL NO.

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

INDUSTRY STANDARD SIZES SHIPPED FROM STOCK

EASILY CUT TO CUSTOM LENGTHS IN FABRICATORʼS SHOP

FURNISHED WITH ADJUSTABLE ROUND TOE AND PLAIN TOP

LEG ASSEMBLIES

STANDARD SHOP SIZES

6”

(150mm)

10”

(255mm)

20”

(510mm)

34”

(864mm)

36”

(914mm)

FULL 3” (76 mm) ADJUSTMENT

PERMITS KD SHIPMENT

ROUND

ROUND

ROUND

ROUND

ROUND

A46-6048-C

A46-6080-C

A46-6160-C

A46-6272-C

A46-6288-C

STAINLESS STEEL ONE PIECE FLANGED*

LEG ASSEMBLIES

WITH INTEGRAL ADJUSTABLE TOES

STANDARD SHOP SIZES

LEG DIA. LENGTH TOE TYPE MODEL NO.

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

1-5/8”

(41mm)

FULL 3” (76 mm) ADJUSTMENT AVAILABLE FROM STOCK

EASILY CUT TO CUSTOM LENGTHS IN FABRICATORʼS SHOP

FURNISHED WITH 3-1/2” (89mm) DIA. FLANGED TOE WITH 2 MOUNTING

HOLES AND PLAIN TOP PERMITS KD SHIPMENT

6”

(150mm)

10”

(255mm)

20”

(510mm)

34”

(864mm)

36”

(914mm)

3-1/2” (89mm) DIA. S/S

W/ (2) 11/32”(9mm) DIA.

MOUNTING HOLES**

3-1/2” (89mm) DIA. S/S

W/ (2) 11/32”(9mm) DIA.

MOUNTING HOLES**

3-1/2” (89mm) DIA. S/S

W/ (2) 11/32”(9mm) DIA.

MOUNTING HOLES**

3-1/2” (89mm) DIA. S/S

W/ (2) 11/32”(9mm) DIA.

MOUNTING HOLES**

3-1/2” (89mm) DIA. S/S

W/ (2) 11/32”(9mm) DIA.

MOUNTING HOLES**

A46-4048-C

A46-4080-C

A46-4160-C

A46-4272-C

A46-4288-C

A16

* FLANGED FOOT MODELS HAVE 12 GA. (2.6mm) STAINLESS STEEL FLANGE WITH A #4 SATIN FINISH.

ALL LEGS MAY BE FURNISHED PACKAGED IN SETS OF FOUR. IDENTIFIED WITH CUSTOMER PART NUMBER AS AN OPTION FOR KD SHIPPING.

** PROVIDED WITH (2) 11.32” (9mm) DIA. MTG. HOLES, SPACED 2-1/2” (63mm) O.C.

MATERIAL: 1-5/8” (41mm) DIA., 16 GA.(1.5mm) 300 SERIES STAINLESS STEEL TUBING

FINISH: #4 SATIN FINISH STANDARD TOE ADJUSTMENT: 3”(80mm) MINIMUM

STATIC LOAD RATING: 2,000 LBS. PER LEG STANDARD PACKAGING...25 PER CARTON

SPECIFICATIONS

www.chgusa.com

Page 19

Legs Assemblies

STAINLESS STEEL

1-5/8” (41mm) & 2” (50mm) O.D.

LEG ASSEMBLIES

FOR CUSTOM APPLICATION

L LENGTHS FROM 4” (100mm) to

AL

36” (900mm)

CHOOSE

TOPS AND ADJUSTABLE TOES

PER

FROM ARRAY OF OPTIONAL

MITS KD SHIPMENT

OPTIONAL TOES

FLANGED

NO HOLES

3

MATERIAL: 16 GA. (1.5 mm) 300 SERIES STAINLESS STEEL TUBING

FINISH: #4 SATIN FINISH STANDARD

TOE ADJUSTMENT: 1-1/2” (40mm) MINIMUM

MOUNTING PLATES: 11 GA. (3mm) PLATED STEEL, 3-1/2” (89mm) SQUARE

WITH (4) 5/16” (8mm) DIA. HOLES SPACED ON 2-5/8” (66mm) CENTERS

STATIC LOAD RATING: 2,000 LBS. PER LEG

STANDARD PACKAGING...25 PER CARTON

ALL LEGS MAY BE FURNISHED PACKAGED IN SETS OF FOUR,

IDENTIFIED WITH CUSTOMER PART NUMBER, ETC.

SPECIFICATIONS

NON-STOCK ITEMS

ORDERING INFORMATION FOR 1-5/8” (41mm) & 2” (50mm) O.D. LEG ASSEMBLIES

FOR 1-5/8” (41 mm) O.D. LEG ASSEMBLIES USE PREFIX...A46 THRU A50 (SHOWN SHADED YELLOW ON CHART).

AVAILABLE

FOR 2” (50 mm) O.D. LEG ASSEMBLIES USE PREFIX...A52 THRU A56.

CUSTOM LEG TOPS AVAILABLE

PLAIN

A46 A52

A46-3___

A52-3___

WELDED PLATE

A47 A53

A47-3___

A53-3___

REMOVABLE

PLATE

A48 A54

A48-3___

A54-3___

FLUSH

1/2-13 STUD

A49 A55

A49-3___

A55-3___

PROTRUDING

1/2-13 STUD

A50 A56

A50-3___

A56-3___

FLANGED

WITH HOLES

4

5

S/S ROUND

6

A46-4___

A52-4___

A46-5___

S/S/ HEX

A52-5___

A46-6___

ROUND FOOT INSERTS NOT AVAILABLE FOR 2”(500mm) DIA. LEG ASSEMBLIES

TO ORDER: SIMPLY SPECIFY LEG TOP AND ADJUSTABLE TOE DESIRED TOGETHER WITH THE LENGTH IN INCHES (millimeters) REQUIRED.

EXAMPLE: 1-5/8”(41mm) O.D. WITH PLAIN TOP...SPECIFY A46 NYLON TIP...SPECIFY -2 24”(600mm) LENGTH...SPECIFY 24”(600mm).

THE PART NUMBERS IN THE CHART PROVIDE BLANKS TO ACCOMMODATE ANY LENGTH OF LEG BETWEEN 4”(100mm) AND 36”(914mm)

IN 1/8” (3mm) INCREMENTS. COMPONENT HARDWARE WILL USE THESE BLANKS TO CONVERT YOUR INDIVIDUAL DESIGN

AND LENGTH REQUIREMENT INTO ITS OWN PART NUMBER.

A47-4___

A53-4___

A47-5___

A53-5___

A47-6___

A48-4___

A54-4___

A48-5___

A54-5___

A48-6___

A49-4___

A55-4___

A49-5___

A55-5___

A49-6___

800-526-3694

A50-4___

A56-4___

A50-5___

A56-5___

A50-6___

A17

Page 20

H Frame And Appliance and Equipment Legs

1-5/8” OD

TYPE

304, 16 GAUGE STAINLESS STEEL 1 5/8” OD UPRIGHTS

WITH 1 1/4” OD CROSS MEMBER COMPL

POLISHED SAT

PA

CKED TWO/CARTON FOR EASY KD SHIPMENT WIDE ARRAY OF

POP-IN ADJUSTABLE FOOT INSERTS AVAILABLE NO

(90-120 DAYS DELIVERY) QUANTITY

B

1-1/4” OD

C

L

C

A

C

L

C

L

MUST

H-FRAME ASSEMBLY

ETELY WELDED AND

IN FINISH ECONOMICAL CONVENIENT

ORDERS ONLY

SPECIFY DIMENSIONS A, B, C WHEN ORDERING

TOE OPTIONS

STAINLESS STEEL HEX

A10-0851-C

STAINLESS STEEL ROUND

A10-0852-C

PLASTIC HEX (BLACK)

A10-0831-C

PLASTIC HEX (GRAY)

A10-0841-C

METAL DIE CAST HEX

A10-0811-C

S/S 3” ADJUSTABLE HEX

A10-0881-C

STAINLESS STEEL

FLANGED (WITH

HOLES)

A10-0854-C

3” ADJUSTABLE

A10-0884-C

STAINLESS STEEL

FLANGED (NO HOLES)

A10-0853-C

4” (100mm) HIGH

N-STOCK

EQUIPMENT LEG

NICKEL PLATED ZAMAK

1-1/4” ADJUSTMENT

1/2-13 x 1/2” MOUNTING STUD

CUSTOM STAINLESS STEEL

A

OUTSTANDING PERFORMANCE AT AN AFFORDABLE PRICE

AV

MODEL NO.

AA61-4002-C

AA62-5002-C

AA10-0851-C

AA60-1653

AAE60-1653

AA60-1653-B

B

C

E

D

ALUMINUM LEGS

AL

UMINUM DIE CAST CONSTRUCTION PROVIDES

AILABLE FOR 6” EQUIPMENT LEG AND 2-2/1” AND 4”

APPLIANCE LEG APPLICATIONS

FINISH

NICKEL

NICKEL

S/S

CLAD

NICKEL

NICKEL

BLACK

TYPE

HEX

S/S HEX

POP IN

BULLET

FLANGE

FLANGE

FLANGE

HEIGHT

6”

(150mm)

6”

(150mm)

1-1/2”

(38mm)

4”

(100mm)

4”

(100mm)

4”

(100mm)

(25mm)

(25mm)

(32mm)

(25mm)

(25mm)

(25mm)

ADJ.

1”

1”

1-1/4”

1”

1”

1”

LOAD RATING

LBS./FOOT(KG/mm)

2000 lbs

(900 Kg)

2000 lbs

(900 Kg)

2000 lbs

(900 Kg)

2000 lbs

(900 Kg)

2000 lbs

(900 Kg)

2000 lbs

(900 Kg)

PROTRUDING

PROTRUDING

PROTRUDING

PROTRUDING

PROTRUDING

THREAD

1/2-13

5/8-11

–––

3/8-16

3/8-16

3/8-16

REF.

A

A

B

C

D

E

4”(100mm) HIGH

STATIC LOAD CAPACITY 2000 LBS

MODEL NO. FINISH FOOT TYPE

1-1/4”

3/4”(19mm)

6”

(150mm)

1”

(25mm) ADJ.

4”

(100mm)

1” ADJ.

(25mm)

SATIN

NICKEL

B

1-5/8 ” (41 mm) O.D. TUBING

D

3/8”

(9mm)

PROVIDED WITH 1-1/4”(32mm)

HEX

1-1/2”

(38MM)

16GA. (1.5 mm) OR

1-1/4 ” I.P.S. PIPE

1-1/4”

(32mm)

4”

(100mm)

1”(25mm)

ADJ.

DIA. FLANGED FOOT

AE41-4002-C

A

2-3/8”

(60mm)

POWDER COATED FINISH

PROVIDES A DURABLE , CHIP

RESISTANT FINISH. SPECIAL COLORS

AVAILABLE ON QUANTITY ORDERS.

C/E

(32mm)

PROTRUDING STUDS

HAVE 3/8-16 THREADS

3/8”

(9mm)

A18

www.chgusa.com

Page 21

Appliance Legs

A

B

B

A

A

REF. C

1”(25mm) HIGH

APPLIANCE LEGS

THERMOPLASTIC...

BLACK, GRAY or CHROME PLATED

HEAT RESISTANT DIE CAST ZINC

STATIC LOAD CAPACITY 200 LBS

MODEL NO.

A60-2105

1”(25mm) HIGH THERMOPLASTIC LEGS

STATIC LOAD CAPACITY 100 LBS

MODEL NO.

A60-2205

A60-2210*

A60-2305

A60-2405

*ACROSS

HEX

CORNERS

REF. E

EXISTING APPLIANCE LEG TO

CONVERT 1/4-20 PROTRUDING

MODEL NO. A60-1438

1”(25mm) HIGH

FINISH

CHROME

FINISH

BLACK

GRAY

CHROME

CHROME

*FURNISHED WITH 3/8 - 16

*7/8”(22mm)

1/2

(13mm)

1”

(25mm)

1/2” ADJ (13mm)

THREAD

CONVERTER

EASILY SCREWS ON

STUD THREAD

TO A 3/8-16 THREAD

FOOT TYPE

ROUND

FOOT TYPE

HEX

HEX

HEX

BLACK RUBBER

FLANGE

1/4-20

THD

1/2”DIA.

(13mm)

C

REF. B

E

2-1/2”(63mm) HIGH

APPLIANCE LEGS

THERMOPLASTIC...

BLACK or GRAY

2-1/2”(63mm) HIGH

THERMOPLASTIC LEGS

STATIC LOAD CAPACITY 200 LBS.

FOOT TYPE

“A” DIMENSION IS

1-7/16”(37mm)

ACROSS HEX CORNERS.

“B” DIMENSION IS

5/8” (16mm).

REF. D

MODEL NO.

A60-0431

A60-0441

3/8-16

THD

FINISH

BLACK

GRAY

A

B

2-1/2”

(63mm)

1” ADJ.

(25mm)

4” (100mm) HIGH

APPLIANCE LEGS

DIE CAST METAL with

SATIN NICKEL FINISH

4”(100mm) HIGH DIE CAST METAL LEGS

MODEL NO.

A60-1651

A60-1653

FINISH

SATIN NICKEL

SATIN NICKEL

C

HEX

HEX

FOOT TYPE

HEX

FLANGE

D

C

REF. A

4” (100mm) HIGH

APPLIANCE LEGS

THERMOPLASTIC...

BLACK, GRAY or CHROME PLATED

4”(100mm) HIGH

THERMOPLASTIC LEGS

STATIC LOAD CAPACITY 200 LBS

MODEL NO. FINISH FOOT TYPE

A60-0631

A60-0641

A60-0623

A60-0633

LEG TYPE *A B

A60-16XX 1-7/16” 3/8”

A60-06XX 1-3/4” 5/8”

A

THD

PROTRUDING STUDS HAVE 3/8-16 THREADS

BLACK

GRAY

CHROME

BLACK

SERIES (37mm) (9mm)

SERIES (44mm) (16mm)

*ACROSS HEX CORNERS

B

THD

4”

(100mm)

1” ADJ.

(25mm)

1-1/4”

(32mm)

HEX

HEX

FLANGE

FLANGE

A

(100mm)

B

4”

1” ADJ.

(25mm)

OPTIONAL NON-SKID PADS AVAILABLE: FOR A60 SERIES HEX TOE...ORDER AS A60-X003...FOR A60 SERIES FLANGED TOE ...ORDER AS A60-X001

800-526-3694

A19

Page 22

Appliance Legs

TM

2-1/2”(63mm)

& 4”(100mm) HIGH

ECONOMY SERIES

APPLIANCE LEGS

DIE CAST ZAMAK with

NICKEL PLATED MATTE FINISH

FLANGE FOOT

2000 LBS. (900Kg.) STATIC

LOAD CAPACITY PER LEG

MODEL NO.

AE60-1453

2-1/2”(63mm) HIGH

OPTIONAL NON-SKID FOOT PADS AVAILABLE

SPECIFY...AE60-X010 FOR GREY SILICONE

1-1/4”

(32mm)

3/8-16

THD

PROVIDED WITH 1-1/4”(32mm) DIA. FLANGED FOOT

5/8”(16mm)

2-1/2”

(63mm)

1”(25mm)

ADJ.

3/8-16

THD

MODEL NO.

AE60-1653

4”(100mm) HIGH

1-1/4”

(32mm)

3/8”(9mm)

4”

(100mm)

1”(25mm)

ADJ.

4”(100mm) HIGH

HEAVY DUTY APPLIANCE LEGS

DESIGNED FOR LARGE COUNTERTOP APPLIANCES

DIE CAST ZAMAK ADJUSTABLE FLANGE FOOT

ROUGH, RUGGED THERMOPLASTIC BODY WITH STEEL STUD

2000 LBS. (900Kg.) STATIC LOAD CAPACITY PER LEG

WRENCH FLATS FOR EASY INSTALLATION AND ADJUSTMENT

CHOICE OF BLACK OR NICKEL PLATED MATTE FINISHES

OPTIONAL NON-SKID FOOT PADS AVAILABLE

4ʼ(100mm) HIGH

HEAVY DUTY APPLIANCE LEGS

MODEL NO.

A70-1000

A70-1010

A70-1020

A70-1000-M

A70-1010-M

A70-2000

A70-2010

A70-2020

A70-2000-M

A70-2010-M

A71-1020

NOTE: OPTIONAL NON-SKID NEOPRENE FOOT PADS AVAILABLE...

SPECIFY PART NO. A70-X011 WHEN ORDERING

MOUNTING STUD

1/2-13 PROTRUDING

1/2-13 FLUSH

3/8-16 PROTRUDING

M12 PROTRUDING

M12 FLUSH

1/2-13 PROTRUDING

1/2-13 FLUSH

3/8-16 PROTRUDING

M12 PROTRUDING

M12 FLUSH

3/8-16 PROTRUDING

DESCRIPTION

MATTE BLACK

THERMOPLASTIC

BODY with MATTE

NICKEL PLATED

ZAMAK FLANGED

FOOT

MATTE

NICKEL PLATED

THERMOPLASTIC

BODY with MATTE

NICKEL PLATED

ZAMAK FLANGED

FOOT

HI-TEMP

THERMOPLASTIC

RATED TO

300°F CONSTANT,

350°F INTERMITTENT

(13mm)

(100mm)

1-1/4”(32mm)

ADJ.

PROVIDED WITH 2”(51mm) DIA.

TM

1/2”

(51mm)

4”

FLANGED FOOT

2”

A20

www.chgusa.com

Page 23

TM

Accessories

PATENTED

CROSS BRACE

FITTINGS

FOR 1-1/2”(38mm) O.D. LEGS

and 1-5/8”(41mm) O.D. LEGS

Designed to mate 1-1/2”(38mm) and 1-5/8”(41mm) O.D. vertical legs

and 1-1/4”(32mm) O.D. horizontal cross rails. These die cast aluminum

CROSS BRACE FITTINGS eliminate notching, welding and polishing.

Ideal for knock-down shipping.

END

CROSS BRACE FITTING

MODEL NO. A35-2020

(TO SUIT 1-1/2”(38mm) VERTICAL LEGS)

MODEL NO. A35-1020

(TO SUIT 1-5/8”(41mm) VERTICAL LEGS)

CORNER

CROSS BRACE FITTING

MODEL NO. A35-2010

(TO SUIT 1-1/2”(38mm) VERTICAL LEGS)

MODEL NO. A35-1010

(TO SUIT 1-5/8”(41mm) VERTICAL LEGS)

1-1/2”(38mm)

1-5/8”(41mm)

1-1/2” (38mm)

OR

1-5/8”(41mm)

OR

3”(76mm)

3”(76mm)

3”(76mm)

1-1/4”

(32mm)

1”(25mm)

TYPICAL

1-1/4”

(32mm)

TYPICAL

1”(25mm)

TYPICAL

QUICK CORNER

™

BRACKETS

FOR ADJUSTABLE UNDERSHELVES

FOR 1-1/2”(38mm) O.D. LEGS

and 1-5/8”(41mm) O.D. LEGS

QUICK CORNER BRACKETS are pre-finished die

cast aluminum components. They are easily fastened

to pre-notched sheet metal undershelves to provide

strong, secure, rigid undershelf support assemblies.

Adjusting screws are provided for setting the undershelf to any desired height. Welding, grinding and

polishing is eliminated and knock-down shipping is

facilitated. Corner and center brackets are designed

for either 1-1/2”(38mm) or 1-5/8”(41mm), O.D. tubing.

They tightly lock into simple notched sheet metal

openings. Diagrams are provided with instructions.

2-5/8”

(66mm)

1-3/4”

(44mm)

2-5/8”

(66mm)

CORNER BRACKET

MODEL NO. A37-2010

to suit 1-1/2”(38mm)

MODEL NO. A37-1010

to suit 1-5/8”(41mm)

1-1/2”(38mm)

OR

CENTER

1-5/8”(41mm)

CROSS BRACE FITTING

MODEL NO. A35-2030

(TO SUIT 1-1/2”(38mm) VERTICAL LEGS)

3”

(76mm)

MODEL NO. A35-1030

(TO SUIT 1-5/8”(41mm) VERTICAL LEGS)

NSF STANDARDS GOVERNING THE USE OF SET SCREWS IN NON-FOOD ZONES REQUIRES THE PLUGGING OF THE HEX SOCKET HOLE AFTER FINAL ASSEMBLY

AND TIGHTENING. THIS MAY BE ACCOMPLISHED BY APPLYING A HARDENING TYPE SILICONE SEALANT OR THE USE OF A HOLE PLUG.

STANDARD N.S.F. TYPE PUSH-IN PLASTIC HOLE PLUGS ARE AVAILABLE...SPECIFY A10-0020 WHEN ORDERING, SEE PAGE A24.

4”(100mm)

1-1/4”

(32mm)

TYPICAL

1”(25mm)

TYPICAL

2-5/8”

(66mm)

4-3/4”

(120mm)

CENTER BRACKET

MODEL NO. A37-2020

to suit 1-1/2”(38mm)

MODEL NO. A37-1020

to suit 1-5/8”(41mm)

1-3/4”

(44mm)

800-526-3694

A21

Page 24

Accessories

REMOVABLE

MOUNTING PLATES

11 GA.(3mm) ZINC PLATED STEEL

SQUARE

MOUNTING PLATES

3-1/2” x 3-1/2”

(89mm x 89mm)

THD

2-5/8”

FURNISHED WITH

(4) 5/16” (8mm)

DIA. MOUNTING

HOLES

MODEL NO. A44-X301-C (1/2-13 THʼD)

MODEL NO. A44-X309-C (5/8-11 THʼD)

MODEL NO. A44-X341-C (3/4-10 THʼD)

2-5/8”

(66mm)

(66mm)

ADJUSTABLE

FOOT LEVELERS

RUBBER CUSHIONED

NON-SKID NON-MARKING

5/16-18

THD

1-1/8”

(28mm)

MODEL NO.

A60- 2724

(38mm)

1-1/2”

7/16”

(11mm)

1/2-13

THD

(38mm)

MODEL NO.

1-1/2”

A60- 4444

RECTANGULAR

MOUNTING PLATES

2-1/2” x 3-5/8”

(63mm x 92mm)

1/2-13 THD

1-3/4”(44mm)

2-13/16”

(71mm)

FURNISHED WITH

(4) 11/32”(9mm) SLOTTED

MOUNTING HOLES

MODEL NO. A44-X327-C

HOLE PLUGS

TO COMPLY WITH N.S.F.

REQUIREMENTS...ALL SET

SCREW SOCKET OPENINGS

1-3/4”

(44mm)

5/8”

(16mm)

ASSEMBLY AND TIGHTENING

UNDERSHELF BRACKETS

MODEL NO. A34-1010

SET SCREW

MUST BE PLUGGED

AFTER FINAL

MODEL NO.

A10-0020

FOR 5/16” SET SCREWS

REMOVABLE/CONCEALED

NICKEL PLATED STEEL

FITS 1-5/8”(38mm) O.D. TUBING

1/2”(13mm)

1-1/4”(31mm)

UNDERSIDE VIEW

CORNER BRACKET

BRACKETS PROVIDED WITH 5/16”(8mm) DIA. HOLE

TO ACCEPT A98-4441 GUSSET BOLT

CENTER BRACKET

MODEL NO. A34-1012

KICK PLATE

SPRING CLAMP

FITS ON 1-1/4” PIPE,

1-5/8”(41mm) and

2”(50mm) O.D. TUBING

ZINC PLATED STEEL

MODEL NO.

A76-4460

(25mm)

3”(75mm)

1”

1/2”(13mm)

1-1/4”(31mm)

2-1/2”

(63mm)

(44mm)

1-3/4”

1-9/16”

(40mm)

A22

www.chgusa.com

Page 25

NUMERICAL INDEX

MODEL NO. PAGE NO. MODEL NO. PAGE NO. MODEL NO. PAGE NO.

A10-0010-C . . .A3,A4,A5

A10-0020 . . . .A1,A2,A22

A10-0221-C . . . . . . . . A3

A10-0421-C . . . . . . . . .A3

A10-0611-C . . . . . . . . .A3

A10-0631-C . . . . . . . . .A3

A10-0641-C . . . . . . . . .A3

A10-0651-C . . . . . . . . .A3

A10-0654-C . . . . . . . . .A7

A10-0811-C . . .A3,A4,A18

A10-0831-C . . . . .A3,A18

A10-0841-C . . . . .A3,A18

A10-0851-C . .A3,A4,A18

A10-0852-C . .A3,A4,A18

A10-0853-C . . . . .A7,A18

A10-0854-C . . . . .A7,A18

A10-0881-C . . . . .A5,A18

A10-0884-C . . . . .A5,A18

A10-1000 . . . . . . . . . . .A4

A10-1500 . . . . . . . . . . .A4

A10-9904-C . . . . . . . . .A7

A11-0851-C . . . . . . . . .A3

A11-0854-C . . . . . . . . .A7

A14-0221-C . . . . . . . . .A6

A14-0224-C . . . . . . . . .A7

A14-0411-C . . . . . . . . .A6

A14-0421-C . . . . . . . . .A6

A14-0424-C . . . . . . . . .A7

A14-0611-C . . . . . . . . .A6

A14-0651-C . . . . . . . . .A6

A14-0653-C . . . . . . . . .A7

A14-0654-C . . . . . . . . .A7

A15-0851-C . . . . . . . . .A6

A15-0854-C . . . . . . . . .A7

A16-0206-C . . . . . . . . .A1

A18-0202-C . . . . . . . . .A1

A18-0203-C . . . . . . . . .A1

A18-0206-C . . . . . . . . .A1

A18-0402-C . . . . . . . . .A1

A18-0406-C . . . . . . . . .A1

A18-9900-C . . . . . . . . .A1

A18-X001 . . . . . . . .A1,A2

A20-0206-C . . . . . . . . .A1

A20-0406-C . . . . . . . . .A1

A24-0206-C . . . . . . . . .A2

A24-0207-C . . . . . . . . .A2

A26-0206-C . . . . . . . . .A2

A26-0207-C . . . . . . . . .A2

A28-0206-C . . . . . . . . .A2

A28-0207-C . . . . . . . . .A2

A34-1010 . . . . . . . . . .A22

A34-1012 . . . . . . . . . .A22

A35-1010 . . . . . . . . . .A21

A35-1020 . . . . . . . . . .A21

A35-1030 . . . . . . . . . .A21

A35-2010 . . . . . . . . . .A21

A35-2020 . . . . . . . . . .A21

A35-2030 . . . . . . . . . A21

A37-1010 . . . . . . . . . .A21

A37-1020 . . . . . . . . . .A21

A37-2010 . . . . . . . . . .A21

A37-2020 . . . . . . . . . A21

A44-X301-C . . . .A10,A22

A44-X309-C . . . . . . . .A22

A44-X327-C . . . .A10,A22

A44-X341-C . . . . . . . .A22

A44-X347-C . . . . . . . .A15

A46-4048-C . . . . . . . .A16

A46-4080-C . . . . . . . .A16

A46-4160-C . . . . . . . .A16

A46-4272-C . . . . . . . .A16

A46-4288-C . . . . . . . .A16

A46-6048-C . . . . . . . .A16

A46-6080-C . . . . . . . .A16

A46-6160-C . . . . . . . .A16

A46-6272-C . . . . . . . .A16

A46-6288-C . . . . . . . .A16

A47-9932-C . . . . . . . . .A9

A48-5032-C . . . . . . . .A13

A48-5048-C . . . . . . . .A13

A50-5032-C . . . . . . . .A13

A50-5048-C . . . . . . . .A13

A50-9704-C . . . . . . . .A13

A50-9939-C . . . . . . . . .A9

A52-9907-C . . . . . . . .A12

A60-0431 . . . . . . . . . .A19

A60-0441 . . . . . . . . . .A19

A60-0623 . . . . . . . . . .A19

A60-0631 . . . . . . . . . .A19

A60-0633 . . . . . . . . . .A19

A60-0641 . . . . . . . . . .A19

A60-1438 . . . . . . . . . .A19

A60-1651 . . . . . . . . . .A19

A60-1653 . . . . . . . . . .A19

A60-2105 . . . . . . . . . .A19

A60-2205 . . . . . . . . . .A19

A60-2210 . . . . . . . . . .A19

A60-2305 . . . . . . . . . .A19

A60-2405 . . . . . . . . . .A19

A60-2724 . . . . . . . . . .A22

A60-4444 . . . . . . . . . .A22

A60-X001 . . . . . . . . . .A19

A60-X003 . . . . . . . . . .A19

A67-5048-C . . . . . . . .A15

A68-5048-C . . . . . . . .A15

A70-1000 . . . . . . . . . .A20

A70-1000-M . . . . . . . .A20

A70-1010 . . . . . . . . . .A20

A70-1010-M . . . . . . . .A20

A70-1020 . . . . . . . . . .A20

A70-2000 . . . . . . . . . .A20

A70-2000-M . . . . . . . .A20

A70-2010 . . . . . . . . . .A20

A70-2010-M . . . . . . . .A20

A70-2020 . . . . . . . . . .A20

A70-X011 . . . . . . . . . .A20

A71-1020 . . . . . . . . . .A20

A72-0811 . . . . . . . . . .A12

A76-4460 . . . . . . . . . .A22

A77-5048-C . . . . . . . .A12

A78-5048-C . . . . . . . .A12

A79-5048-C . . . . . . . A12

A84-5048-C . . . . . . . . A13

A85-9706-C . . . . . . . . A13

A86-5048-C . . . . . . . . .A13

A88-9902-C . . . . . . . . . .A9

A90-9902-C . . . . . . . . . .A9

A92-8048-C . . . . . . . . .A14

A93-8048-C . . . . . . . . .A14

A94-8048-C . . . . . . . . .A14

A95-8048-C . . . . . . . . .A14

AA10-0851-C . . . . . . .A18

AA60-1653 . . . . . . . . .A18

AA60-1653-B . . . . . . .A18

AA61-4002-C . . . . . . .A18

AA62-5002-C . . . . . . .A18

AAE60-1653 . . . . . . .A18

AE41-4002-C . . . . . . .A18

AE60-1453 . . . . . . . . .A20

AE60-1653 . . . . . . . . .A20

AE60-X010 . . . . . . . . .A20

AE61-2003-C . . . . . . .A11

AE61-2104-C . . . . . . .A11

AE61-4002-C . . . . . . .A11

AE61-5002-C . . . . . . .A11

AE62-2104-C . . . . . . .A11

AE62-4002-C . . . . . . .A11

AE62-5002-C . . . . . . .A11

AE63-2003-C . . . . . . .A11

AE63-2104-C . . . . . . .A11

AE63-4002-C . . . . . . .A11

AE63-5002-C . . . . . . .A11

AP61-2003-C . . . . . . .A10

AP62-2003-C . . . . . . .A10

AP63-2003-C . . . . . . .A10

AP64-2003-C . . . . . . .A10

AP61-4003-C . . . . . . .A10

AP62-4003-C . . . . . . .A10

AP63-4003-C . . . . . . .A10

AP64-4003-C . . . . . . .A10

C47-0306-C . . . . . . . . .A8

C47-0316-C . . . . . . . . .A8

C47-0406-C . . . . . . . . .A8

C47-0416-C . . . . . . . . .A8

C47-0506-C . . . . . . . . .A8

C47-0516-C . . . . . . . . .A8

C50-0306-C . . . . . . . . .A8

C50-0316-C . . . . . . . . .A8

C50-0406-C . . . . . . . . .A8

C50-0416-C . . . . . . . . .A8

C50-0506-C . . . . . . . . .A8

C50-0516-C . . . . . . . . .A8

C83-0506-C . . . . . . . . .A8

C83-0516-C . . . . . . . . .A8

C86-0506-C . . . . . . . . .A8

C86-0516-C . . . . . . . . .A8

A23

Page 26

1890 SwarthmoreAvenue, PO Box 2020 Lakewood, NJ 08701

tel. 800-5 26-3694, 732-363 -4700 , fa x.732-36 4-8110

www.chgusa.com

Loading...

Loading...