COMP Cams 6300 Hi-Tech Belt Drive Systems User Manual

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #188

Revised 3/14/08

INSTRUCTIONS

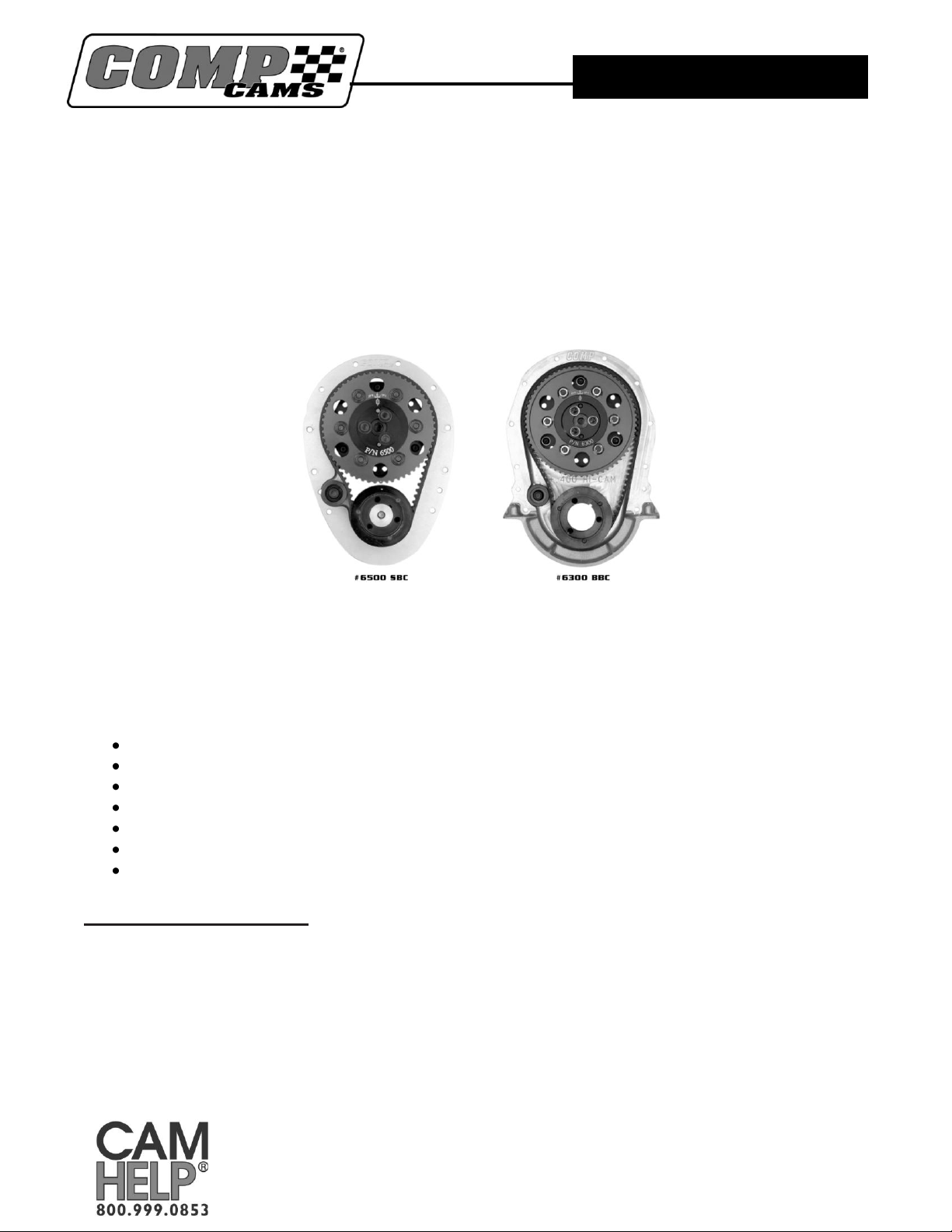

Hi-Tech™ Belt Drive Systems

Small Block Chevrolet #6500, 6502, 6504, 6506 & 6507

Big Block Chevrolet #6200 and 6300

Thank you for choosing COMP Cams® products; we are proud to be your manufacturer of choice. Please read

this instruction sheet carefully before beginning installation, and also take a moment to review the included

limited warranty information.

COMP Cams® belt drives represent the ultimate in cam timing systems. Our belt drives are designed to absorb a

significant amount of crankshaft harmonics, which will affect valve motion if they reach the valve train. COMP

Cams® belt drives require less power to operate than conventional belt drives. Last but not least, our belt drives

have proven to be more durable than either gear or chain drives.

Excellent for all NASCAR and NHRA applications

Unique camshaft thrust adjustment system does not require the use of shims to set end play

Belt idler reduces belt “flap”

High performance belt

Idlers available in different diameters for align bored blocks

Adjustable camshaft timing with simple Vernier sprocket

Double lip oil seals ensure maximum crankcase vacuum

Installation Instructions:

NOTE: The COMP Cams® Chevrolet belt drive system can be installed on an assembled engine.

However, the installing mechanic should be prepared to remove the camshaft for the purpose of

drive hub installation and end play adjustment.

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #188

Revised 3/14/08

Step 1: Disassemble the unit. It comes from the factory with several components assembled for protection during

shipping. Unbolt the camshaft pulley from the drive flange and separate the flange from the cam hub. This is done

by removing three 5/16 cap screw head bolts and using a drift punch or driver to separate the flange and hub (fig.

1). Remove the belt tensioner from the rear belt cover. Also, remove the camshaft endplay adjustment housing

(three Allen bolts)

Step 2: Trial fit front cover to make sure it clears the block. Much detail has been

given to fitment and most covers will not require modification. If required, use a die

grinder or mill to remove excess material from cover and/or block. Take steps to

prevent removed material from contaminating engine.

Step 3: Install front cover on engine using supplied gaskets and fasteners. Torque the

front cover bolts to 7-10 ft lbs of torque.

Step 4: Install crank pulley on crankshaft snout. Lubricate

the bore and seal area of the crank pulley with COMP

Cams® pro cam lube, part # 152. Use COMP® part #4789 crank gear installation tool and

#4920 harmonic balancer installation tool to press pulley onto snout or a section of 2-1/4"

o.d. x .375" wall aluminum tubing (fig. 2) as a driver. Caution: Be certain that the

crankshaft snout is not marred and that the crank hub seats squarely on the crank’s

shoulder step.

Step 5: Ensure that the front face of the camshaft is clean and free of surface burrs.

Any minor imperfections may be removed with a fine grit knife sharpening stone.

Install cam hub on camshaft (you may need to tap into place using a plastic mallet,

etc.). If needed, brace the camshaft by its bearing journals in a vise, being sure to pad

the jaws with wood or plastic to prevent damage to the camshaft. Use supplied 5/16" x

1" cap screws to secure hub. Add a small amount of medium strength thread locking

adhesive and tighten bolts to 18-22 ft lbs of torque (fig. 3).

Step 6: Lubricate roller thrust bearing with engine oil and install on backside of cam

hub. You can slide the bearing over the camshaft. Be sure that black-colored side of the

thrust bearing seats on the cam hub (fig. 4).

Step 7: Install camshaft in engine and place other roller thrust bearing on front side of

the hub (with black surface of bearing contacting the hub).

Step 8: Make sure cam hub and bearings are seated squarely on face of the engine block.

Any irregularities may cause a premature bearing and/or hub failure.

Step 9: Remove o-ring from camshaft end play

adjustment housing, install housing on the cam hub and

make sure seal is properly seated. Rotate housing

clockwise until it bottoms out on ramp. Gradually rotate

housing counterclockwise until desired camshaft

endplay is achieved. An endplay range of .002" to .007"

is suggested. However, this is ultimately left to the

discretion of the installing mechanic (fig. 5). The

assembly is designed so that each adjustment point

during rotation (where bolt holes line up) is equal to

.005". Once the desired endplay has been achieved, mark the housing and front cover at the appropriate bolt hole

with a felt tip pen as an indicator for reassembly (fig. 6). A scribe may also be used to mark the housing and front

Loading...

Loading...