COMP Cams 35-1001 Ford 302 HO Hydraulic Roller Lifter Kit User Manual

#35-1001 Ford 302 HO Hydraulic Roller Lifter Kit

Thank you for choosing COMP Cams® products; we are proud to be your manufacturer of choice.

Please read this instruction sheet carefully before beginning installation, and also take a moment to

review the included limited warranty information.

Before You Start

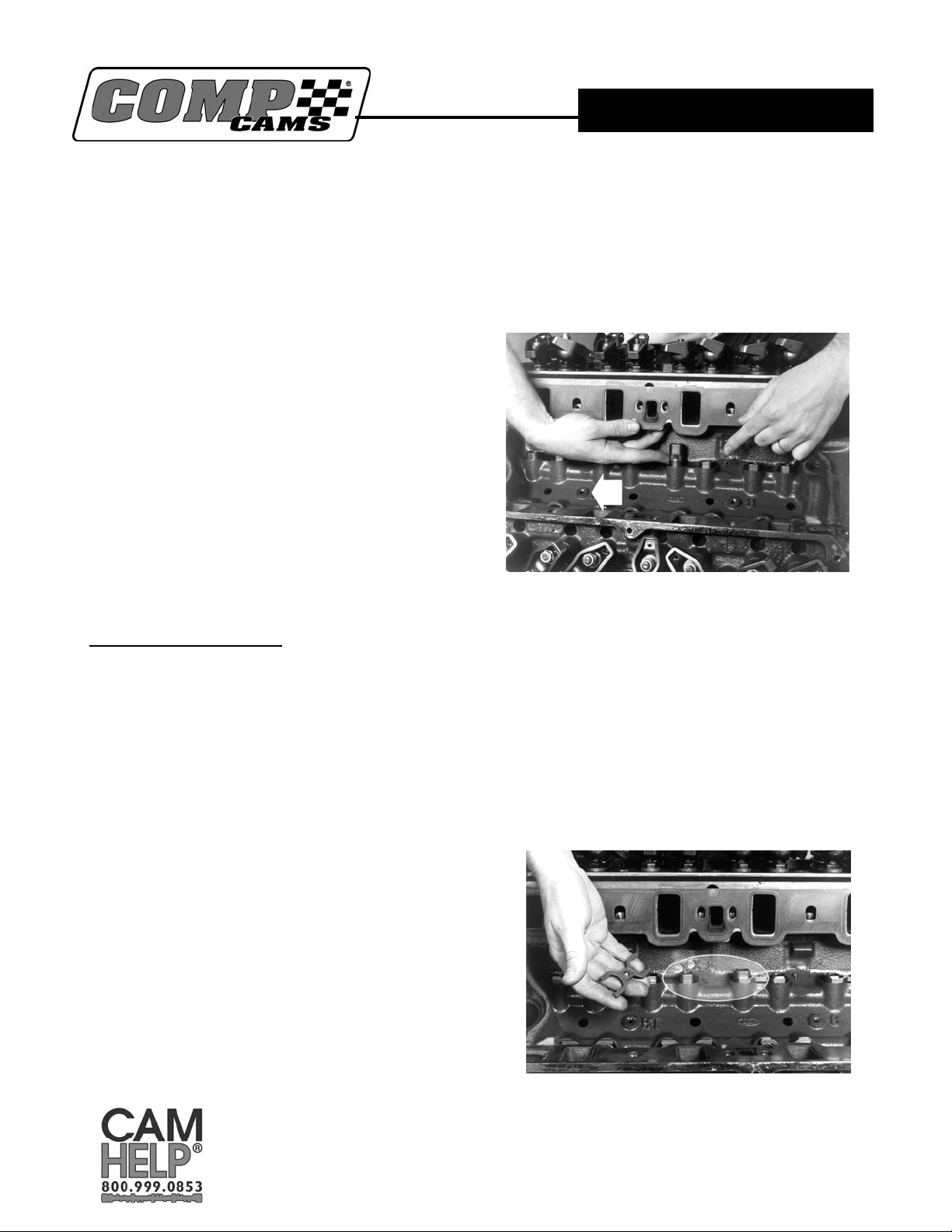

This kit is designed to allow the installation of

hydraulic roller cams in standard Ford 302 HO V8

engines originally equipped with hydraulic roller

cams. In order to use this kit, your engine must have

two bosses cast into the block (fig. 1) in the lifter

valley area. These bosses may or may not be drilled

and tapped for 1⁄4"-20 bolts. If yours are not drilled

and tapped, then you must be prepared to do so

during this installation process. Once you have

installed your COMP Cams® Magnum Hydraulic

Roller Camshaft per the camshaft installation and

degreeing instructions supplied with the cam, you

are ready to install the hydraulic roller lifters.

Installation Instructions:

1. Installing the lifters - Slide the lifters into the lifter bores just like a regular lifter, and then rotate

them until the flat surfaces on the sides of each lifter all face inward toward the lifter valley. Each lifter

has two flats, one on each side. It does not matter which flat faces the valley and which faces the

cylinders. You may encounter some difficulty in trying to install the end lifters in each bank due to

interference from an ear on each end of the head gaskets. Gently bend this ear out of the way, install

the lifters, and bend the ear back into place. The purpose of this ear is to help locate the intake gasket

during manifold assembly, so do not bend or remove it permanently.

2. Installing the lifter guides - The purpose of the

guides is to prevent the lifters from rotating,

therefore keeping the lifter wheels rolling over the cam

lobes as opposed to sliding. With all the flats on the

lifter in line, install one of the eight lifter guides over

each pair of lifters in the valley. They should be

installed with the word “UP” that is stamped into each

guide facing up. It does not matter whether the “UP”

stamp is toward the front or the rear of the block.

The forks on each end of the guides should nest over

the top of the flats on either side of each lifter. Also,

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

COMP Cams®

INSTRUCTIONS

Part #178

Revised 7/17/06

the lifter guides should sit perfectly flat on the milled top surface of the lifter bore pairs. If they do not,

stop and figure out why before proceeding. Failure to do so may result in significant engine damage.

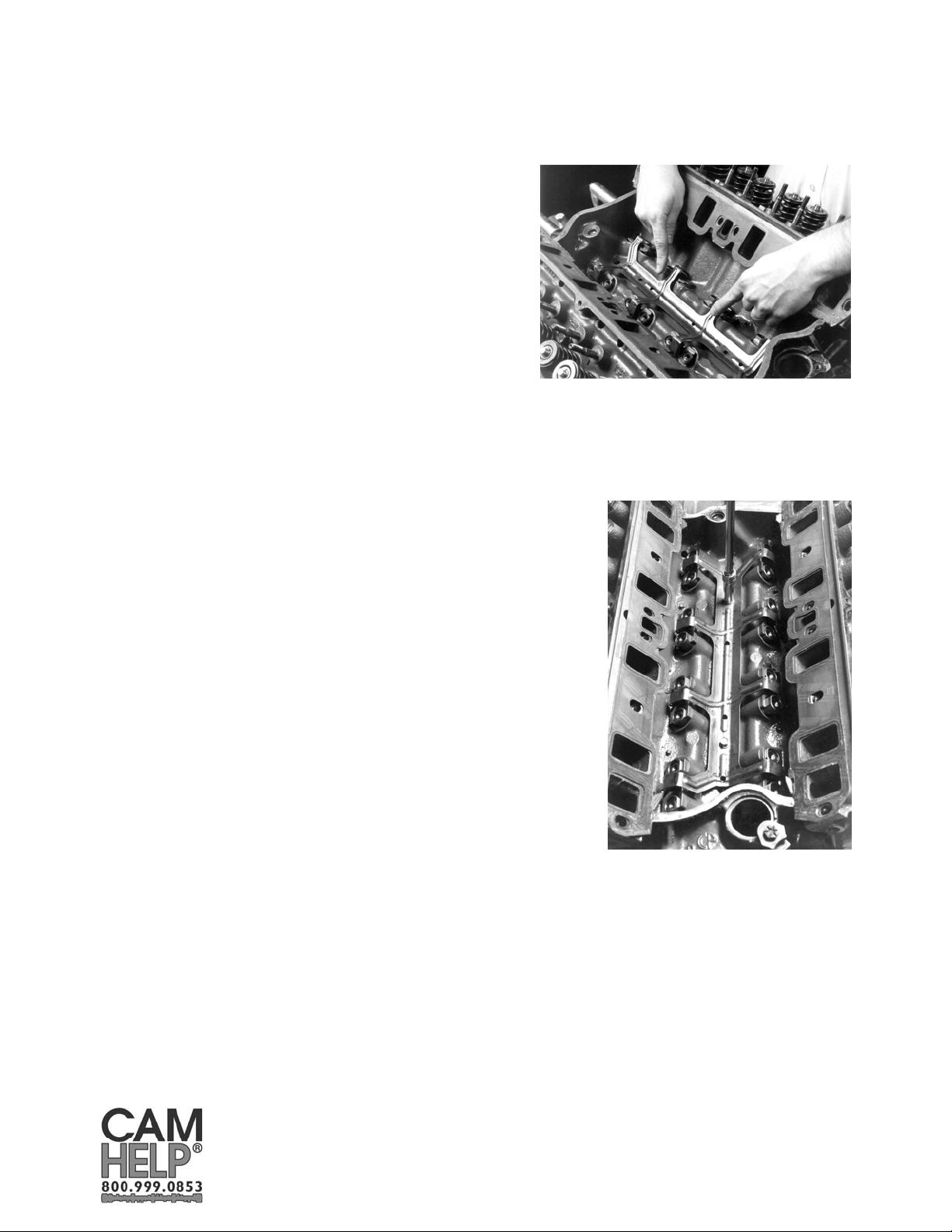

3. Installing the lifter retention hardware - Place the

stamped steel lifter retainer in the valley of the block and

see which of the two holes in the retainer line up with

the tapped holes in the cast bosses in the valley. The

fingers of the retainer should be between the pairs of

lifters and riding on the raised ball area of the lifter

guides. It may be necessary to rotate the retainer end for

the end to get the holes to line up. If your bosses are not

drilled and tapped, use the lifter retainer as a guide for

marking the proper location of the future holes. Be sure

that the retainer fingers are centered between the lifter

pairs and riding on the raised ball area of the lifter guides before marking the hole locations. Mark the

holes with a center punch, remove the retainer, and drill and tap the holes as necessary. Do not allow

any metal shavings created during the drilling and tapping process to remain in the engine. Severe

engine damage may result.

4. Final assembly of lifter retainer - Lower the retainer into the

valley, centering the correct holes over the bosses and making

sure once again that the fingers of the retainer are between pairs

of lifters and riding on the raised ball area of the lifter guides.

Start both of the retainer bolts supplied in the kit by hand and

torque to 20 ft lbs.

5. Final check - Spin the engine over by hand at the crankshaft

with a wrench (or COMP Cams® Part #4798 crank socket) and

watch closely the movement of the lifters. As the lifters move up

and down, the lifter guides should remain perfectly flat on the

tops of the lifter bores. They should not be pushed up at all by the

up and down motion of the lifters. If they do, the camshaft does

not have the correct base circle size to be used with these lifters.

Stop here and replace the cam with the proper one before

proceeding, running the engine with this condition in existence

will result in major engine damage.

The installation of your COMP Cams® Ford 302 HO Hydraulic Roller Lifter Kit is now complete.

Refer to the camshaft installation and degreeing instructions that came with your cam for further

instructions on pushrod installation and valve adjustment that are needed to complete your project.

Order COMP Cams® Camshaft Degree Kit (Part #4796) to make these adjustments easier.

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #178

Revised 7/17/06

Loading...

Loading...