COMP Cams 3122 TB Ford Timing Set User Manual

Ford Timing Set Installation Instructions

Thank you for choosing COMP Cams® products! We know you have options in valve train

component selection and we are proud to be your manufacturer of choice. Please read this instruction

sheet carefully before beginning installation, and also take a moment to review the included limited

warranty information.

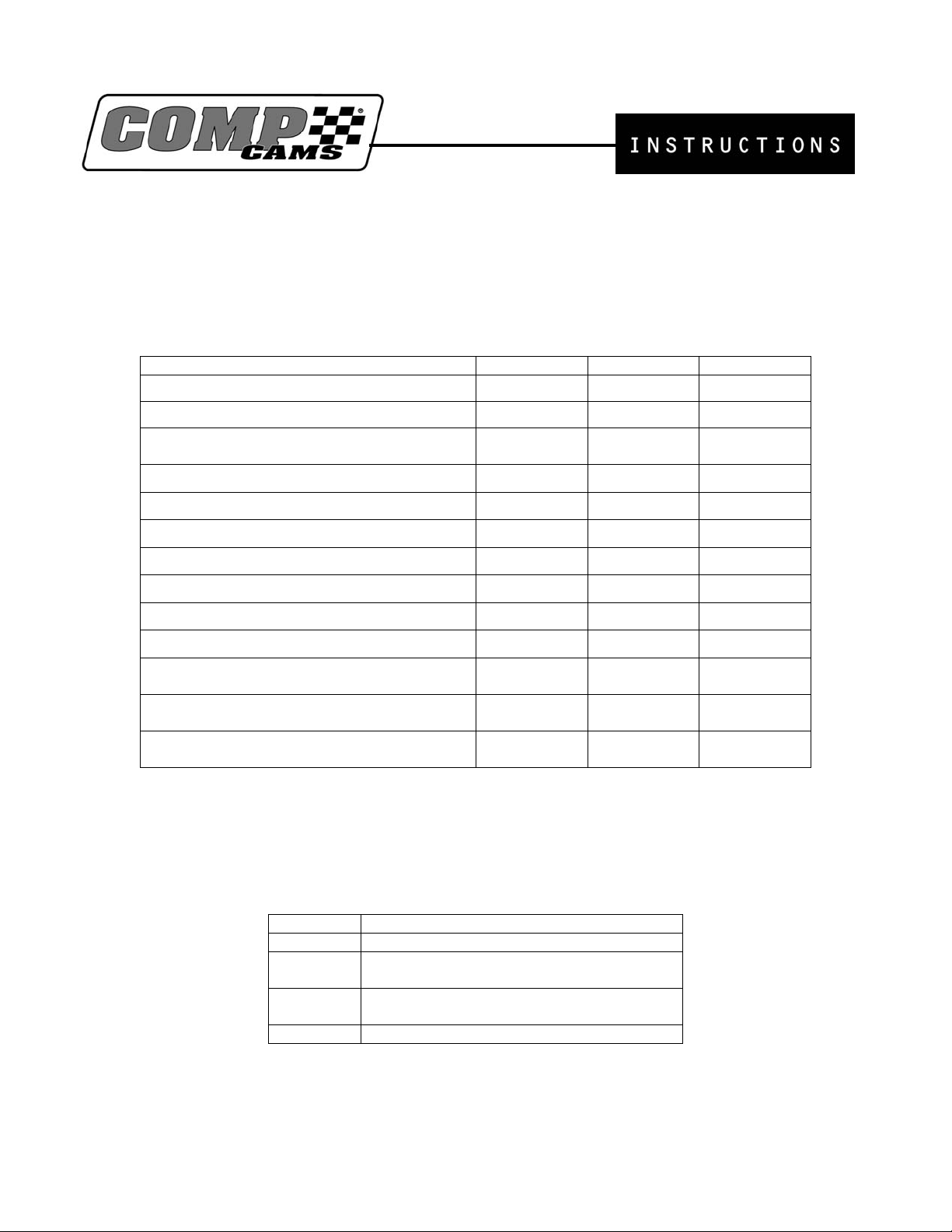

Engine Application High Energy Magnum Hi-Tech

Ford V6, 144-200 3223

Ford V6, 171 (2600-2800cc) 3236

Ford V8, 255, 289, 302 & Boss 302, 1965-1988 2120 3120

Ford V8, 289-351W & Boss 302, pre 1972 3220

Ford V8, 302-351W, 1972 & up 3230

Ford V8, 352-428, 1964-1974 3208 2108 3108

Ford V8, 351C, 351M, 400M, 1970-1982 3221 2121 3121

Ford V8, 429-460, 1968-1971 3222 2122 3122

Ford V8, 429-460, 1972-1987 2130 3130

Ford V8, 429-460 w/nine keyway crank gear 2134*

Ford V8, 351W, 351W H.O., 1969-¹84 2135 3135

Ford V8, 5.0L 302 H.O., 1980-March 21, 1984 2131 3131

Ford V8, 5.0L 302, 351W, March 22, 1984-1992 2138 3138

Notes:

* #2120 or #3120 should not be installed on 351W engines as they are designed for 255, 289, 302 or Boss 302 engines.

* If installing part #2120 or 3120 a one-piece fuel pump eccentric (Ford #C3AZ-6287-B) must be used.

* If installing part #2135 or 3135 a two-piece fuel pump eccentric must be used.

* Uses a link belt type timing chain, not a double roller.

Thrust Bearings

Part # Description

3108 TB Ford 390-428 thrust plate and bearings

3120 TB Ford 289-351W thrust plate and bearings. Dir ect

replacement for OEM cam plate single bearing.

3135 TB Ford 289-351W HP thrust plate and bearings.

Machining and tooling required

3122 TB* Ford 351C, 429-460 thrust plate and bearings

Part #179

Revised 6/27/05

The following instructions begin after the timing cover and old timing set have been removed.

Installation Instructions

1. Clean everything! Make sure that the engine mounting surfaces and your new timing set have been

thoroughly cleaned with a good solvent.

2. If you are using a timing set with three keyways, select the appropriate keyway for your camshaft

timing specifications. COMP Cams ® recommends the standard timing position for most applications.

This position uses the round or “O” timing and keyway marks. Standard Timing Location: This is the

same as original O.E.M. setting. Use keyway and crankshaft gear tooth marked “O”.

4 Degree Advance: Use keyway and crankshaft tooth marked . Note: The or advanced

4 Degree Retard: Use keyway and crankshaft gear tooth marked . Note: The or

3. Install your lower timing gear on the crankshaft making sure that the timing marks are facing out

toward you.

4. Now that the lower timing gear has been installed check the timing mark alignment in your engine

manual. Rotate the crankshaft using your crankshaft socket until the timing mark on the gear is in

the proper position (12 o’clock). For 240-300 6 cyl. see Note 1 before proceeding!

5. If your engine is equipped with a camshaft retaining plate or thrust plate, it should be installed at this

time. Note that many Ford thrust plates are marked “back – bottom”. Before final installation check to

make sure that the thrust plate is fitted correctly. 351W owners see Note 2 before proceeding!

6. Temporarily install your camshaft timing gear and rotate the camshaft until the timing mark on the

camshaft gear is in the proper position per your engine manual instructions (6 o’clock).

Tools and supplies needed:

1. Basic hand tools as required for your particular camshaft and

balancer bolts

2. Torque wrench

3. Pro Cam Lube (part #153 or #154) or suitable replacement

4. Camshaft Degree Kit (part #4796 including degree video)

5. Crankshaft Socket (part #4798 for Ford 302-351W, 429-460)

6. Thread locking compound

7. Engine repair manual for your particular engine

position should not be used without degreeing the camshaft. Many camshafts have the proper

advance built in. Advancing the cam will reduce intake valve to piston clearance and increase

exhaust piston to valve clearance.

retarded position should not be used without degreeing the camshaft. Many cams have the

proper advance built in. Retarding the cam will reduce exhaust valve to piston clearance and

increase intake piston to valve clearance.

Loading...

Loading...