COMP Cams 2011+ 5.0L Ford 4v Camshaft User Manual

1

INSTRUCTIONS

2011+ 5.0L Ford 4v (Coyote) Camshaft Installation Instructions

Thank you for choosing COMP Cams® products; we are proud to be your manufacturer of choice. Please read

this instruction sheet carefully before beginning installation, and also take a moment to review the included

limited warranty information.

Important Installation Note:

Specialty Parts & Tools Required;

1) COMP Cams® VCT Limiters (#5493)

2) Crankshaft Turning Socket (COMP Cams #4793)

3) 1 ½" Open End Wrench

4) Vise

5) Torque Angle Gauge

6) 10mm Socket (12 point)

Replacement Bolts Needed;

There are many torque-to-yield bolts that should not be reused during this installation. It is a good idea to have the

replacements on hand before starting the installation process!

To order them from a dealership you will need to order the following bolts;

1) N806183-S437 – Camshaft main cap bolts, 40 needed (10 for each camshaft being installed)

2) BR3Z-6279-A – Camshaft bolts, 12 needed (3 for each camshaft)

3) BR3Z-6A340-A – Crankshaft pulley bolt

Camshaft Removal Preparation

1.

Prepare a clean work area and assemble the tools needed for the camshaft installation. It is suggested to

use an automotive manual to help determine which items must be removed from the engine in order to

expose, remove, and reinstall the timing chains, camshaft actuators/phasers, and camshafts. A good,

complete automotive manual will save time and frustration during the installation.

2. Disconnect the negative post of your battery.

3. Remove any coil covers from the engine.

4. Unplug the coils and loosen the bolt holding them into the valve cover, pull the coils out. Then remove

the Variable Cam Timing (VCT) actuator electrical connectors from both banks of the engine.

5. Remove the valve covers from both sides of the engine.

Phone: (901) 795-2400 Fax: (901) 366-1807

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

www.compcams.com

Part #COMP4-145

Revised 4/11/11

6. Remove all eight spark plugs, this will ease rotation of the engine later.

7. Remove water pump, front drive accessories and timing chain cover. Make sure to label, or take pictures

of, bolts and their respective positioning to help during reinstallation.

Before You Start Camshaft Removal

This new engine requires different crank locations when

reassembling each bank. During the main timing chain reassembly

you will assemble the left bank (driver side) first, and then the right

bank (pass. side), remembering that the crank positioning is

different for each bank.

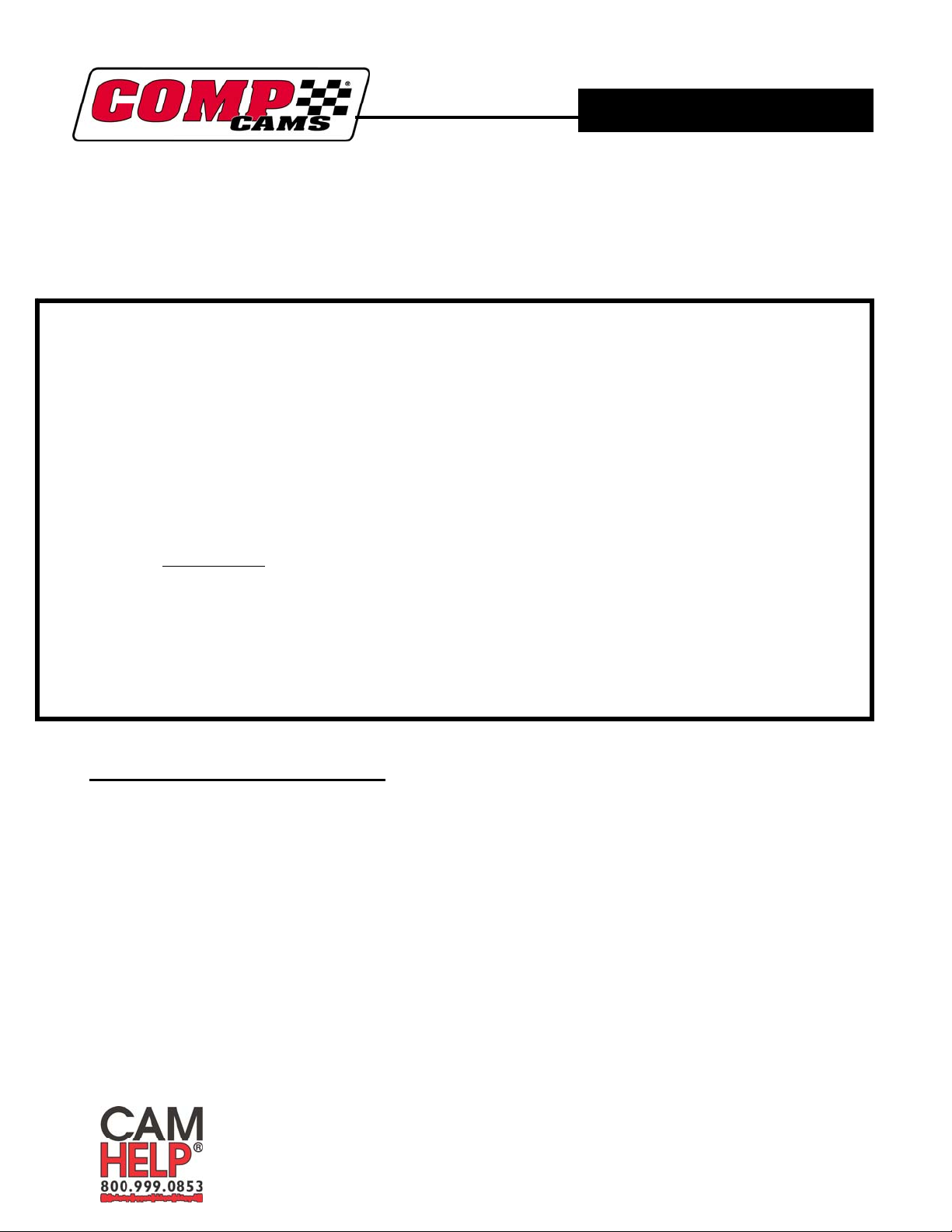

Take a moment to notice the difference between the crankshaft

keyway and the crankshaft timing marker (Fig. A).

1) The crankshaft keyway will be used for positioning of the

crank during camshaft and timing chain installation.

2) The crankshaft timing marker will be used for checking

chain alignment and final timing verification.

Fig. A

Fig. B

Camshaft Removal and Re-installation

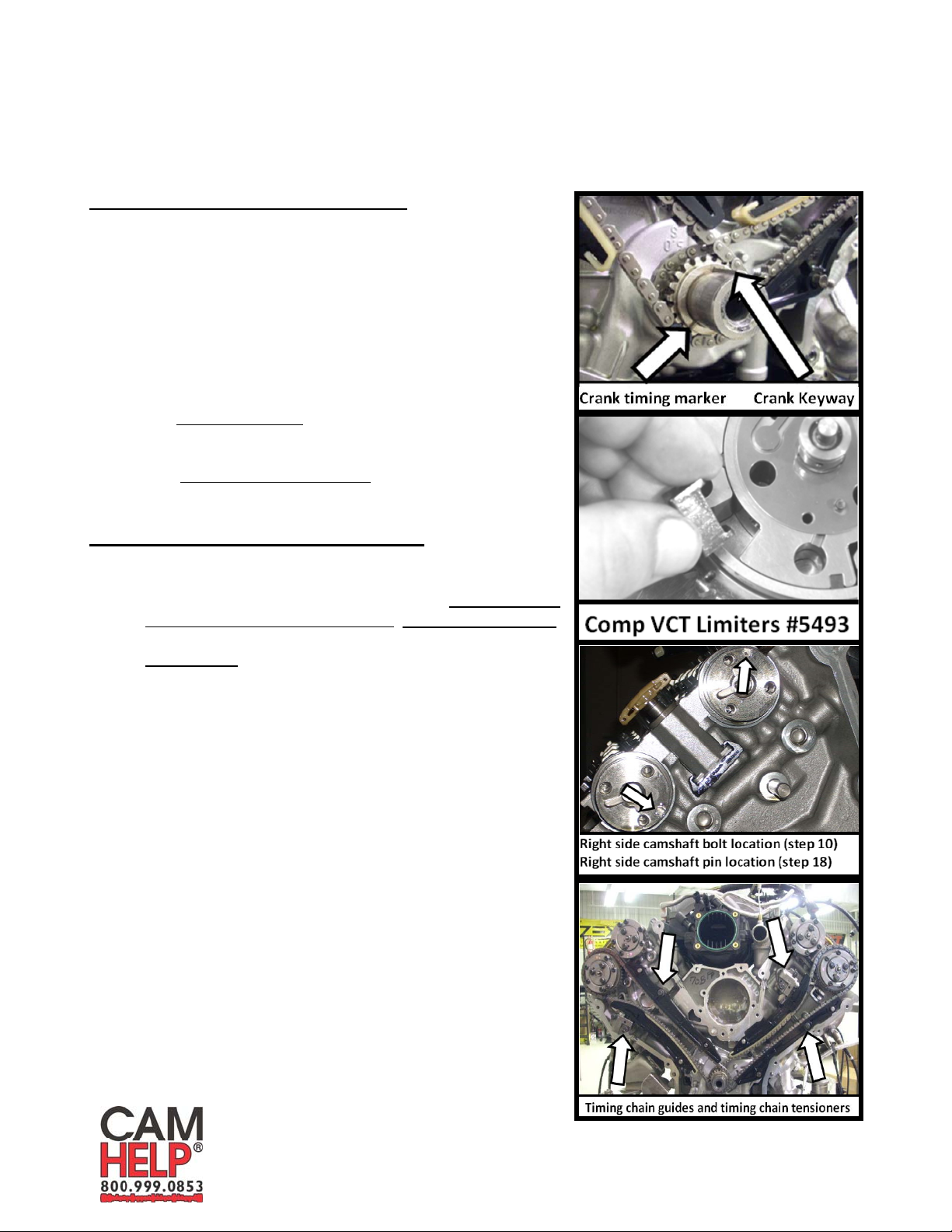

8. Install COMP Cams® VCT Limiters (#5493) per

instructions, stop after completing step 20. Do not reinstall

the camshaft to VCT bolts in step 21. Repeat for each cam.

WARNING:

you MUST install the COMP Cams® VCT/Phaser Limiters

or Adjustable Locking Plates to ensure that you do not crash

your pistons and valves together. Not limiting the

VCT/Phaser travel will result in catastrophic engine damage

(Fig. B.).

9. Rotate the crankshaft until the crankshaft keyway (do not

confuse this with the timing mark) is positioned at the

twelve o’clock position. (Use COMP Cams® #4793

Crankshaft Socket)

10. Ensure the camshaft bolts are positioned, as pictured in Fig.

C. If the camshaft bolts are not in a similar position to the

picture, rotate the crank 360° and check again.

11. Remove main timing chain tensioners, timing chain guides,

and main timing chains. (Fig. D) Use a 1½" open end

wrench on the flats on the camshaft, just behind the first

journal cap, to hold each camshaft while loosening the

tensioner bolts. It is advised to have assistance on this part

because the camshafts can try to rotate if not held by the

wrench. This could cause piston to

When installing COMP Cams® camshafts,

valve contact.

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Fig. C

Fig. D

Part #COMP4-145

Revised 4/11/11

2

12. Remove the 6 cam bolts corresponding to the side you are working on. Use the 1 ½" wrench to hold the

cams in place.

13. Rotate crankshaft to the nine o’clock, relaxed position, as

pictured on this page. If the camshaft bolts are not in a

similar position to the picture, rotate the crank 360° and

check again. Repeat steps 10-12 for the left bank.

Fig. E

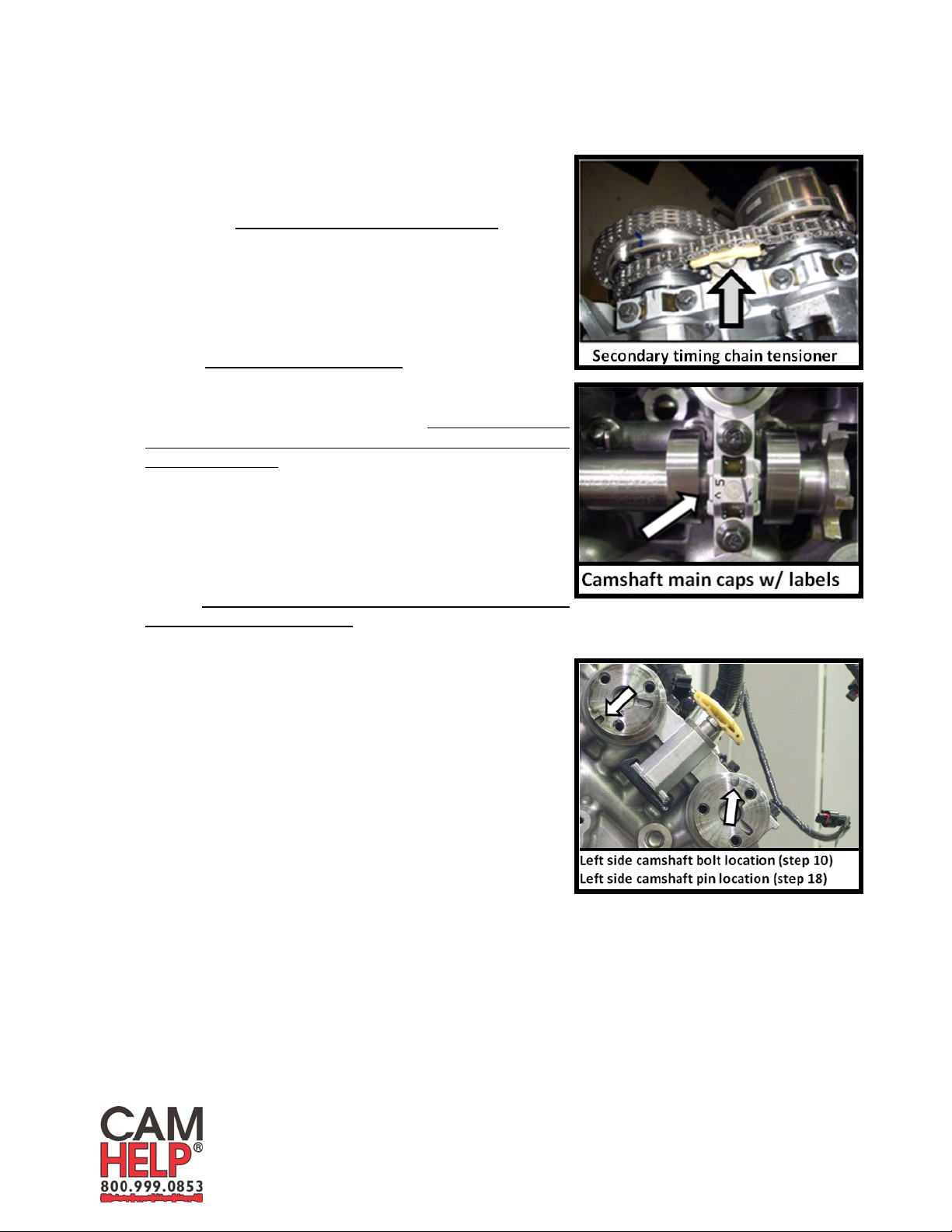

14. Depress the secondary timing chain tensioner and carefully

slide off both of the VCT (phasers) and secondary chain

together as an assembly. This process is also much easier

with another person helping. Take extra time because

dropping the phaser assembly could easily damage the

phasers. Repeat for the other bank.

(See Fig. E)

15. Make note the OEM has labeled each main cap with a

Fig. F

number and direction with an arrow. These caps are not

interchangeable. They must be reinstalled exactly where they

were removed from. (See Fig. F)

16. On the left bank, using the left bank removal sequence on

page 7. Loosen the bolts, labeled 1-20, 1 full turn. Then

repeat the sequence loosening the bolts one turn per pass until

the caps are all loose. Loosen the bolts the rest of the way and

discard. These main bolts are torque-to-yield and can not be

reused. Repeat for the right bank using the right bank

removal sequence on page 8.

17. Lift off the main caps and set aside, remembering they must

be installed exactly where they were remove from. Make

sure you keep the left and right bank caps separated so they

Fig. G

do don’t get crossed during re-assembly.

18. Remove OEM camshafts and set the new COMP Cams®

camshafts in place with the pin locations as pictured on this

page. Lubricate main cap the bolts, cam journals, and cam

lobes generously with supplied COMP Cams® Assembly

Lube #103.

19. To reinstall the camshaft main caps start with new bolts

Ford number N806183-S437 on the Left Bank and use the

sequence on page 7 (Page 8 for right side) while making several passes using 1 turn each pass to

carefully ease the camshaft into the journal saddles on the cylinder head. Once all the caps have lightly

seated, torque the final pass to 4.4 ft./lb. (53 in./lb.) and then, using a torque angle gauge, add 45° of

additional clockwise rotation to finish. Repeat for the Right Bank. Note: Be careful to not over torque

these bolts!

Phone: (901) 795-2400 Fax: (901) 366-1807

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

www.compcams.com

Part #COMP4-145

Revised 4/11/11

3

Loading...

Loading...