COMP Cams 10254 Ford Modular V8 Camshaft Gear Set User Manual

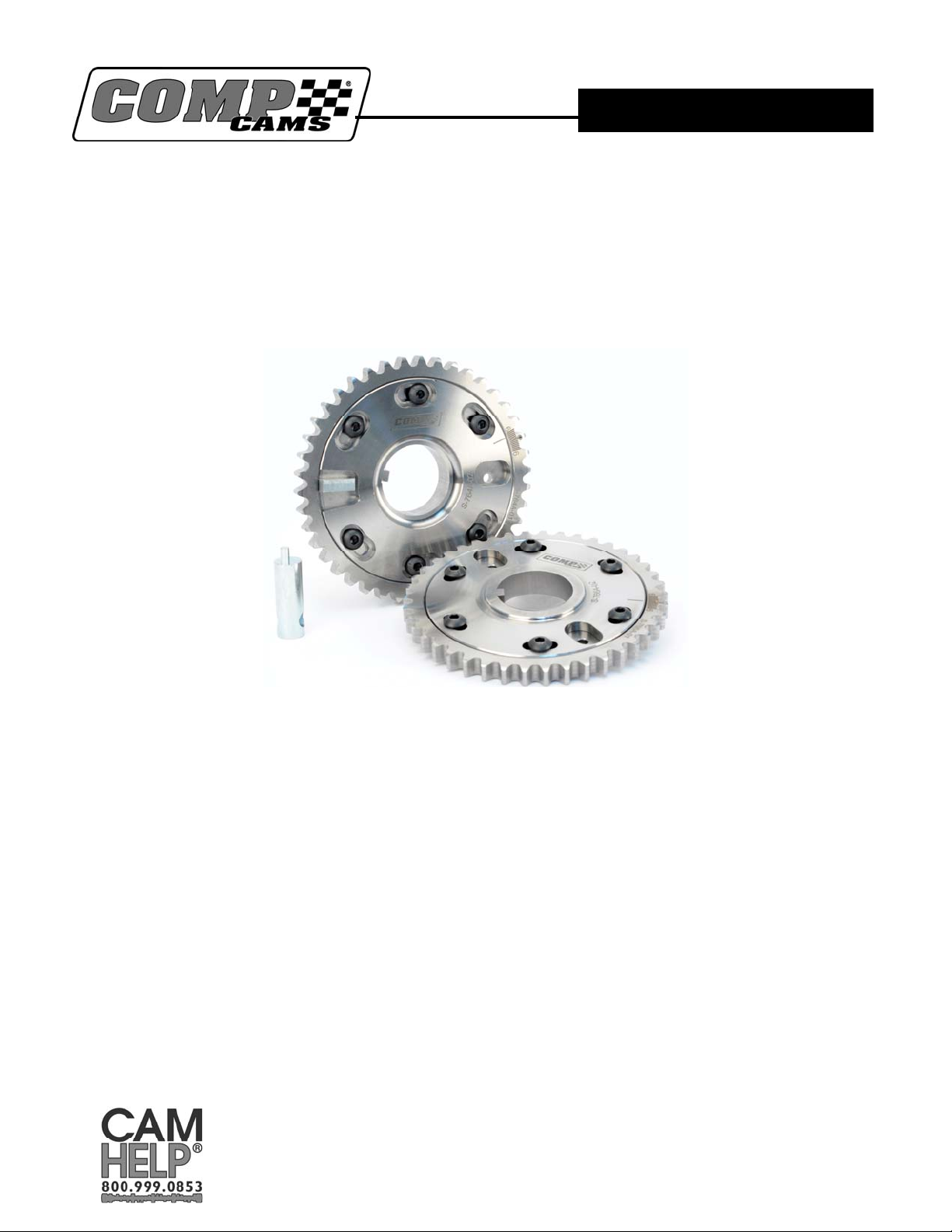

#10254 Ford Modular V8 Camshaft Gear Set

Thank you for choosing COMP Cams® products; we are proud to be your manufacturer of choice.

Please read this instruction sheet carefully before beginning installation, and also take a moment to

review the included limited warranty information.

INSTRUCTIONS

Note: Installation is identical to the Ford factory procedure with the following exceptions:

1. Installation – Rotate the crankshaft until the timing mark is facing the 6 o’clock position,

and the keyway is in the 11 o’clock position, making sure that the timing marks on the

camshaft gears are pointing above the cylinder head. This will put the #1 piston at Top

Dead Center (TDC). Remove the factory camshaft gears, and replace them with your new

COMP Cams® Adjustable Gear Set. Be sure to verify that the adjusters are set to 0º

before reinstalling the timing chains. To install the timing chains, line up the colored

links on the chains with the timing marks on the crank and cam gears, and then install and

release the timing chain tensioners. COMP Cams® strongly recommends that you degree

the left and right cams in order to verify that the chains are installed correctly before

proceeding with any further adjustments. Important: be sure to use the factory cam gear

spacers (Ford PN F3AZ-6265-A). Refer to a factory engine manual for torque specs and

assembly/disassembly procedures. Note: The left hand (driver side) features the cam

sensor pickup. The right hand (passenger side) has two locations for using your

adjusting tool and no cam sensor pickup.

Phone: (901) 795-2400 Fax: (901) 366-1807

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

www.compcams.com

Part #COMP4-169

Revised 3/29/13

2. Making adjustments – Using a wrench to prevent the camshaft from turning, loosen the

six (6) adjustment bolts to allow the center hub of the gear to rotate – note that continuing

to hold the cam with a wrench will prevent it from turning once the adjuster bolts are loose

– this will help to prevent valve train damage. Use the wrench to rotate the cam to the

desired setting (the gears have a 0º - 6º range of adjus tment for either advance or retard),

and tighten the adjusting bolts on both camshafts. Remember that it is absolutely

necessary to adjust both camshafts when changing your cam timing – for example, if

you adjust the left camshaft to 4° advanced, you must also adjust the right camshaft to

4° advanced! Failure to do so will result in severe engine damage.

Rotating the camshaft clockwise will advance the cam timing, and rotating it

counterclockwise will retard the cam timing. Be sure to degree the cams whenever you

make an adjustment in order to verify that your camshafts have been set as intended.

Caution! – when adjusting your camshaft timing, be sure to verify that you have

adequate valve to valve and piston to valve clearance – severe engine damage will

result from inadequate clearance.

3. Final assembly – Once both cams have been properly adjusted, remove each adjusting bolt

one at a time. Apply a small amount of thread lock to each attaching screw, and torque to

125 in-lbs (10 ft-lbs.)

Loctite must be used on all hardware!

Note: the adjusting bolts are made extra long in order to facilitate ease of adjustment

– it is critical that you verify that you have adequate running clearance for the bolts –

if not, you must grind the bolts for clearance before starting your engine, or severe

engine damage may result.

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #COMP4-169

Revised 3/29/13

Loading...

Loading...