Page 1

Page 2

Page 3

Introduction

Congratulations on your purchase of the Compass Model Atom 7HV Electric Powered Helicopter. This model has been

designed using the latest in state-of-the-art design technology. To achieve the best performance and reliability from this

model, please read through these instructions carefully so you become familiar with the contents of this kit before assembly.

AMA Information

We strongly encourage all prospective and current R/C aircraft pilots to join the Academy of Model Aeronautics. TheAMAis

a non-profit organization that provides services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled Model Aviation, as well as liability insurance plan to cover against possible accident or injury. All AMA

charter aircraft clubs require individuals to hold a current AMA sporting license prior to operation of their models. For

further information, you can contact the AMA at:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN47302

Warning

The radio-controlled model helicopter contained in this kit is not a toy, but a sophisticated piece of equipment. This product

is not recommended for use by children. Radio-controlled models such as this are capable of causing both property damage

and/or bodily harm to both the operator/assembler and/or spectator if not properly assembled and operated. Compass

Model Ltd. assumes no liability for damage that could occur from the assembly and/or use/misuse of this product.Although

the Atom 7HV is powered by a quiet, smooth-running electric motor, it should be assembled and operated with the same

care as glow engine helicopters. When operating your Atom 7HV, please exercise caution and safety.

Warranty

The warranty covers defects in material or workmanship or missing components to the original purchaser for 30 days from

the date of purchase. Compass Model Ltd. will replace or repair, at our discretion, the defective or missing component.

Defective components must be returned to our Distributor prior to replacement.

Any part, which has been improperly installed, abused, crash damaged or altered by unauthorized agencies is not covered.

Under no circumstances will the buyer be entitled to consequential or incidental damages. The components used in this kit

are made from special materials designed for special applications and design strengths. We recommend that all replacement

parts be original parts manufactured by Compass Model Ltd. to ensure proper and safe operation of your model. Any part

used which was manufactured by any firm other than Compass Model Ltd. VOIDS all warranties of this product by Compass

Model Ltd.

Warranty Procedures

Mail all warranty information within 15 days of original purchase date. If service is required, send the component in

question (if not missing) together with a photocopy of your bill of sale and an accurate description of the problem and part.

Ship components fully insured and prepaid. Compass Model Ltd. is not responsible for any shipping damages. We will, at

our discretion, notify you of any costs involved, or ship it COD. You are required to pay all postage, shipping and insurance

charges.

R/C Helicopter Safety

A model helicopter must be built exactly in accordance with the assembly instructions. Compass Model Ltd. has spent much

time and efforts refining this product to make it reliable in operation and easy to build. Vibration and stress levels are high and

all fasteners and attachments must be secure for safe operation. Safe operation is the responsibility of the builder/flyer and

starts with careful construction and continues with selection and installation of reliable radio equipment and motor/engine.

The need for safety is nowhere greater than at the flying field. A number of guidelines for safe flight have been developed by

experienced flyers and are set down here. It is urged that they be read, understood and followed.

Attention:

rules to apply in your country/Flying field.

each country has its own security application which cannot be laid down here so prior to any flight request the

Atom 7HV LimitationsAttention :

Atom 7HV Max. rotor head rpm: 2100 U/min

Atom 7HV Max. collective pitch range: +/- 12°

Page 4

Guidelines for Safe R/C Helicopter Flight

• Fly only at approved flying fields and obey field regulations.

• Follow frequency control procedures. Interference can be dangerous to all.

• Obtain assistance from experienced pilots.

• The Guidance provided by experienced pilots is valuable and sometimes necessary.

• Know your radio. Check all transmitter functions before each flight.

• Be aware that rotating blades are very dangerous and can cause serious injury or even death.

• Never fly near or above spectators other modelers or animals.

• Do not fly r/c helicopter models near buildings, high voltage cables, trees or other obstacles.

• If you are a beginner, get help trimming and adjusting the model before you start the flight training.

• Don’t “track” the main blades by holding the tail boom. This is a temptation to builders who cannot hover yet and is very dangerous.

• Follow all recommended maintenance procedures for model, radio and motor.

• Only turn off the radio after the brushless motor is disconnected.

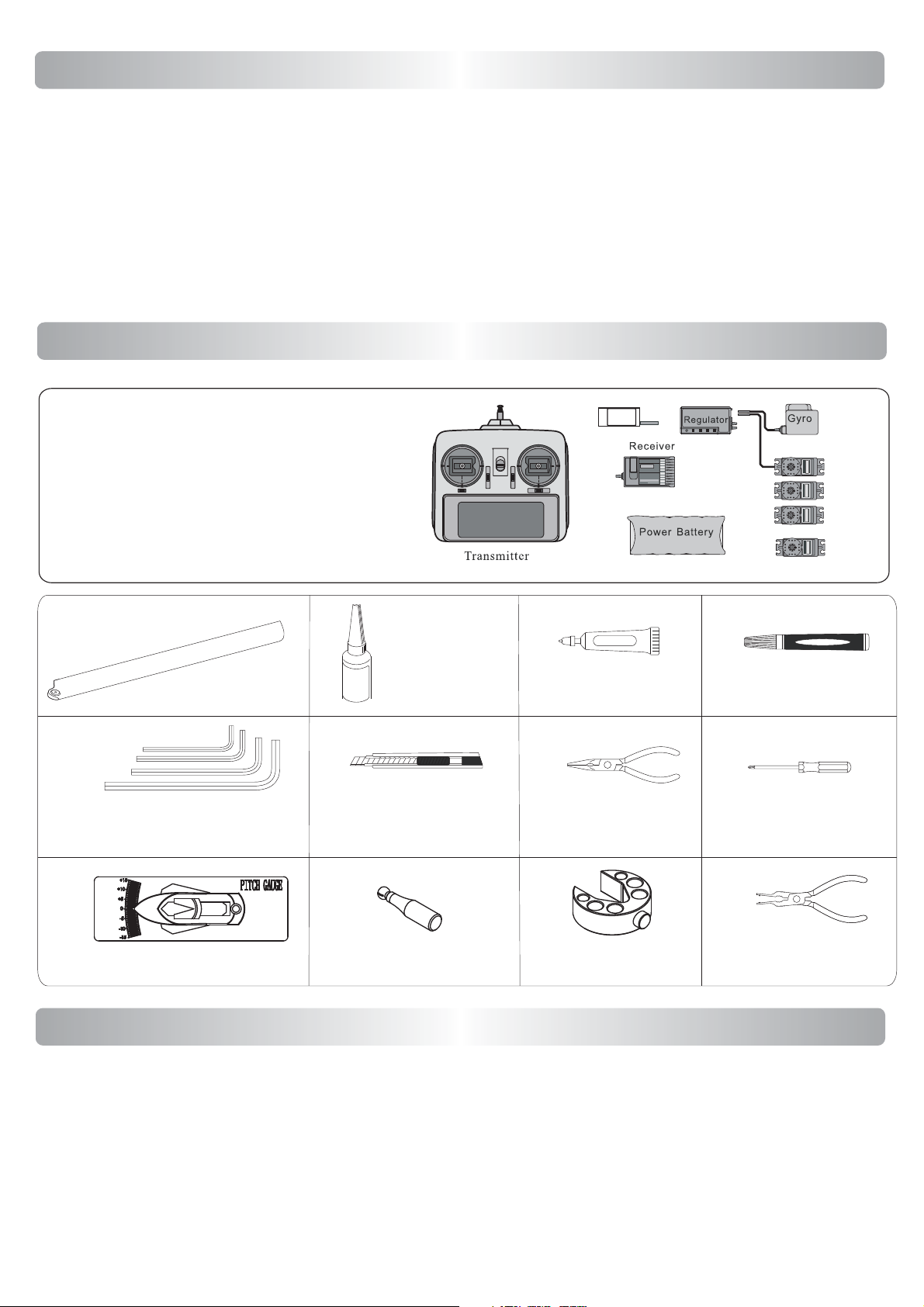

Necessary Items

In order to operate this model, you need to purchase the following items not kit-included.

6 channel or up radio and receiver.

3 standard servos.

1 rudder servo.

1 Flybarless Unit

1x LiPo Battery 12S or 2 6s Packs

1x HV BEC or Receiver Battery

Main Rotor

Length: up to 710mm

Hex Wrench Set

(1.5mm,2mm,2.5mm,3mm, 5mm)

Threadlock

Cutter Knife

BEC

Grease

Needle Nose Pliers

Standard Servos

Bearing Retainer

Phillips Screw Driver

Pitch Gauge

Ball Link Sizing Tool Ball Link

Swash Plate Tool

Plier

Pre-assembly Information

When first opening your Atom kit, you will notice that all of the parts are packaged and numbered to coordinate with the

assembly step numbers of this instruction manual. All small hardware (nuts, bolts, washers, etc.) for each step are packaged

separately within the main parts bags. When beginning a section, you will need to open only the bag with the corresponding

number to the section you are about to start. It is suggested that you place all of the hardware in an open container (e.g., servo

case) during assembly so as not to lose any of the small parts. It may also be helpful to familiarize yourself with the various

sizes of screws, bolts, nuts, etc., as illustrated in the appropriate assembly section before you begin assembly. In most cases, at

the end of each assembly section, there should be no parts remaining. Great care has been taken in filling the bags with the

correct quantity of parts and hardware for each section. However, occasional mistakes happen. In the event that you find a

parts shortage or are in need of technical assistance, please contact your local Compass Model parts dealer.

Page 5

In The Box

This model is packed according to assembling steps. Do not open all the bags at one time.

Open only one bag for each step of assemply when building.

Frame Set

Step 3 Tail Set Step 4

Motor Set

Step 1 Step 2

Rotor Set

Swash Set

Linkages

Blades

Canopy

Symbols & Assembling

Mishandling due to failure to follow these instructions may result in damage, personal injury or danger.

Use Blue Threadlock

G

Use Grease

A

B

Use AB Glue

Use Bearing Retainer

* Always apply blue Threadlock when fixing Bolts on Metal parts.

* Always apply green retainer where bearings has to be fit into metal parts.

* Do not over-tighten self tapping screws into plastic parts or you will strip the threads!

Page 6

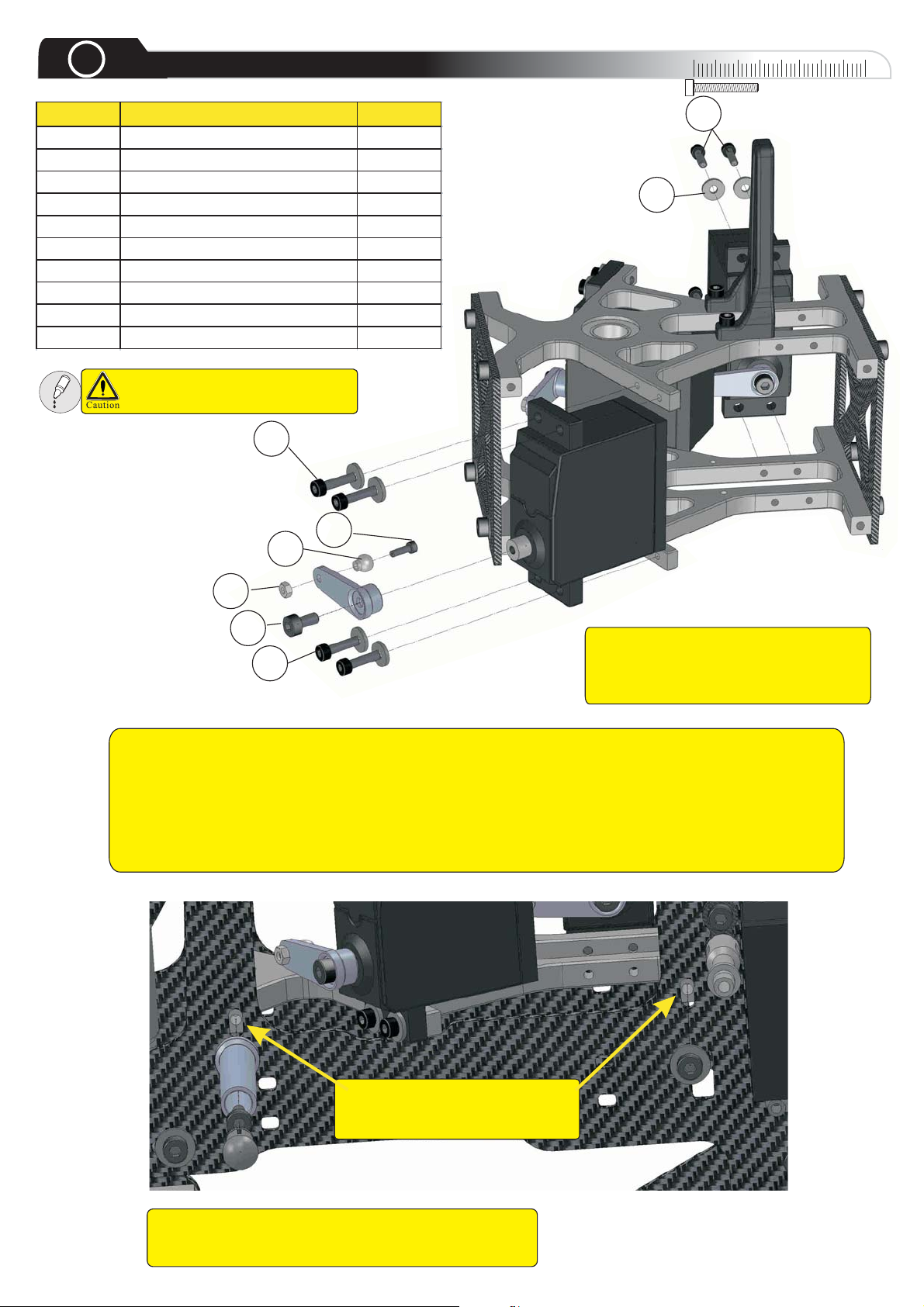

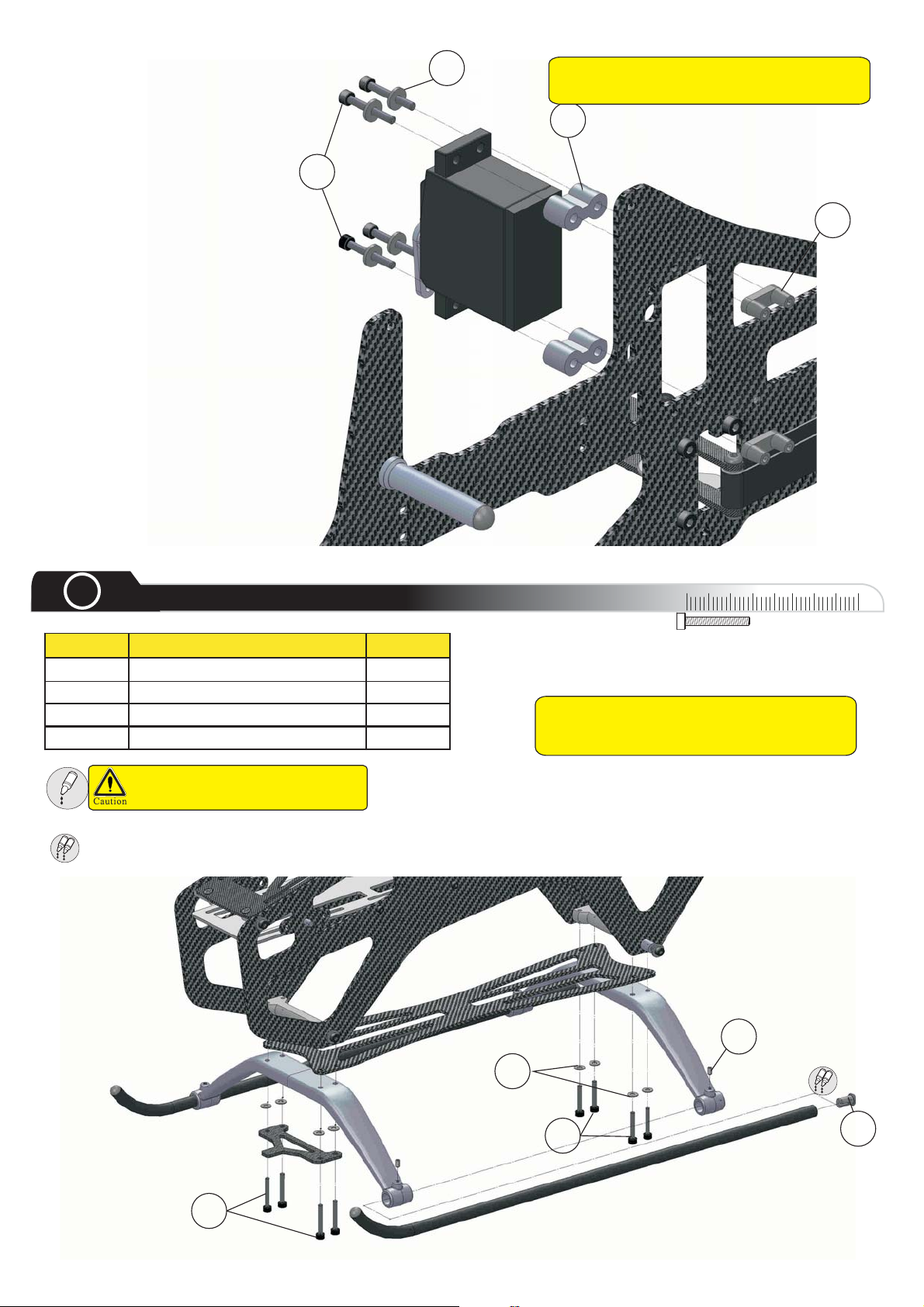

1

Pos Description Qty

1 M2.5x10 Socket Head Bolt 12

1 M2.5x12 Socket Head Bolt 12

2 M2x8 Socket Head Bolt 4

3 Stainless Ball 4

4M2Nut 4

5ServoBolt 4

6 Servo Spacer 2

7 M2.5x20 Socket Head Bolt 4

8ServoNut 2

9 2.5mm Washer 12

Servo

Use medium threadlock on all

screws going into metal parts

Swashplate Servo

0

10

1

9

1

30

20

40

Installation

For mounting the swashplate servos to the bearing blocks, tighten all bolts of the upper bearing block

with medium threadlock. Fix the servos at the upper bearing block. Install the main shaft through all

bearing blocks and push the middle bearing block up against the bottom of the cyclic servos. Tighten the

four screws in the X-shaped parts that secure the middle bearing block. Now slide the main shaft up and

down to make sure the bearing blocks are all aligned. If the main shaft doesn't slide freely, loosen the

screws of the bearing blocks and tight them in a cross pattern. The bearing blocks must be aligned

parallel to each other. You can control this by comparing the height of the bearing block in the long holes

of the side frame. Do not forget to apply new threadlock when loosened a screw!

2

3

4

5

1

The Servo installation is done without

the supplied Servo Rubbers. If you

want to use the Rubber, please use

M2.5x12 Bolts, instead of M2.5x10.

Remove the black cap of the canopy standoff to loosen

and tighten the screw for adjusting the bearing block.

Use these long holes to adjust

the middle bearing block to fit

different servos.

Page 7

Pos Descripti on Qty

1 M3x20 Socket Head Bolt 8

2 3mm Washer 8

3 3x5mm Set Screw 4

4SkidCaps 4

Tail Servo

Installation

9

Tip: Do not over tighten the four servo

screws as it may damage the plastic parts.

6

7

8

2

A

B

Use AB Glue

Landing Gear

Use medium threadlock on all

screws going into metal parts

0

10

30

20

Tip: Do not over tighten the four 3 x 5mm

set screws as it can damage the landing

struts.

40

1

3

A

2

1

B

4

Page 8

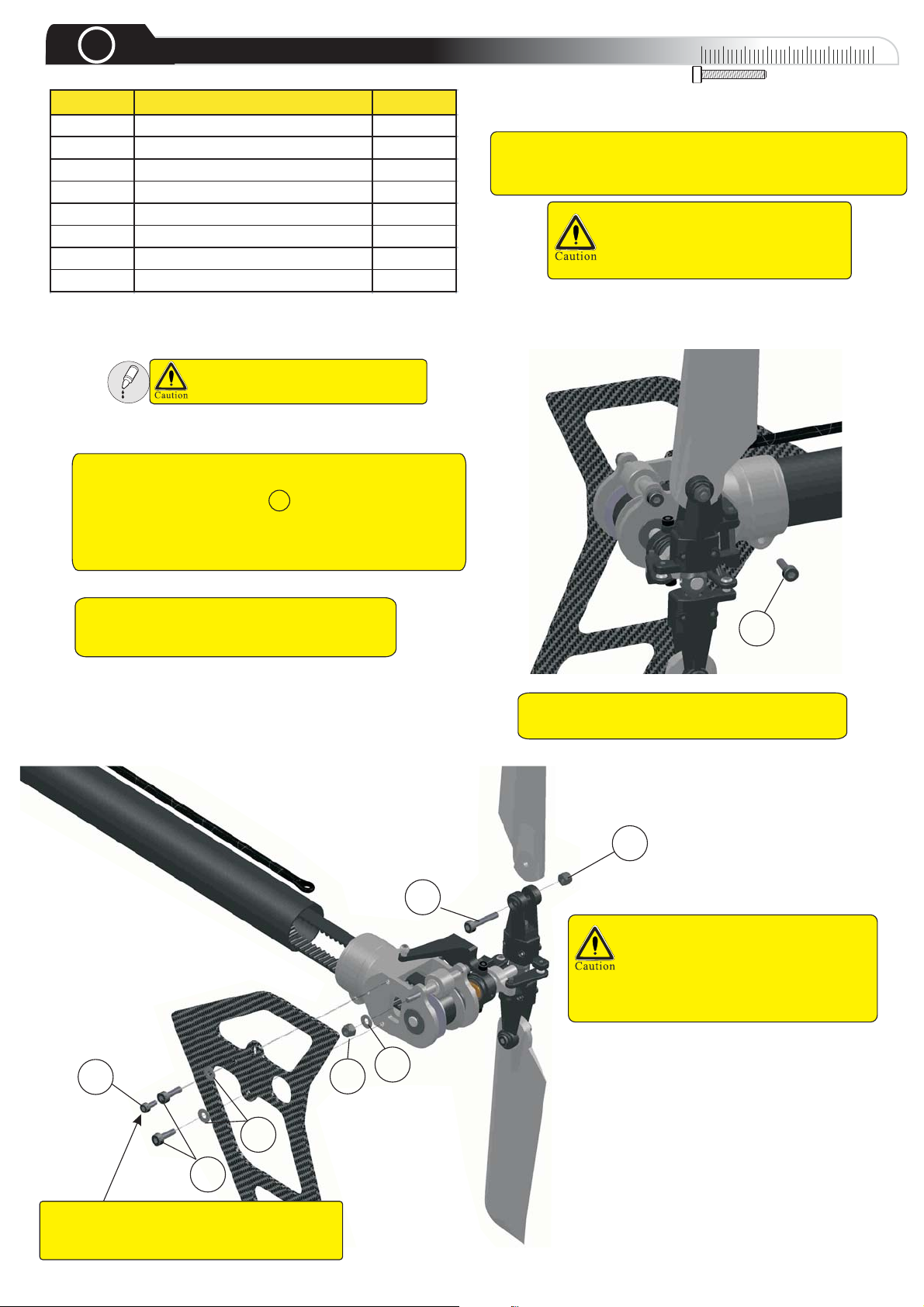

3

Pos Description Qty

1 M3x75 Socket Head Bolt 4

2 3mm W asher 11

3M3NylonNut 8

4 M3X16 Socket Head Bolt 2

5 M3X25 Socket Head Bolt 3

6 M3X10 Socket Head Bolt 3

7 Boom Support Collar 2

8 M2.5X6 Socket Head Bolt 2

Slide the tail case completely onto the boom, align it to

the Compass writing and fix it with the clamp on the rear

side. The two locking bolts ( 8 )must be screwed

completely into the case to pierce the boom. After this

step, the angle of the writing can not be adjusted any

more!

Boom & Tail Rotor

Use medium Threadlock on all

screws going into metal parts

0

10

To pull the belt through the tail boom, slide a cord through

the boom and fix the belt very carefully at the cord. You can

also use a strand and bend a hook at one of the ends.

Crimping the belt damages the

tensile cords and will result in

premature failure!

30

20

40

Tip: Do not tighten the bolt of the belt

idler pulley yet, it will be adjusted later.

6

Tip: You can use a very small drop of thin

CA glue to secure the pin in the tail pulley.

3

4

Be careful not to over tighten the

bolts when attaching the tail rotor

blades. The tail blades should be

able to move with a slight amount

of resistance within the tail blade

holders.

8

3

Take special care to get the boom long

enough into the tail assembly for correct tail

length before you tight this bolt.

6

2

2

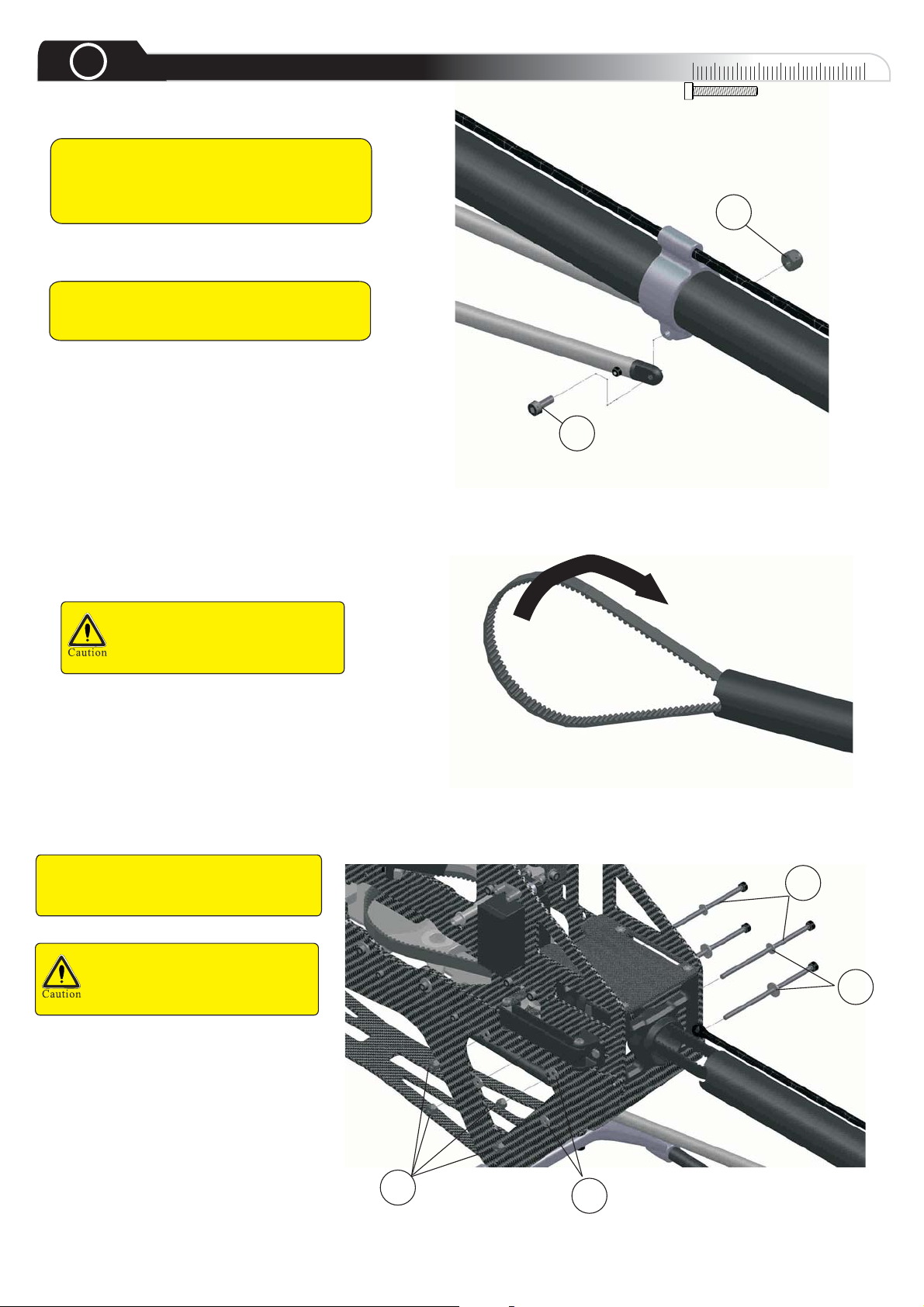

Page 9

3

Boom & Tail Rotor

Tip: Slide the tail boom clamp over the

boom. Unscrew one of the ball links on the

tail control rod. Screw it back on the

control rod after installing it.

Tip: Just instal l the screw, struts and nut

temporary without tightening them to

much.

0

10

3

5

30

20

40

Twist the tail belt 90° to the

right before inserting it

between the idler pulleys.

Slide the Tail Boom through the tail

boom mount and between the idler

pulleys

Do not crimp the tail belt and

be sure that it is not turned in

the wrong direction or more

1

2

3

2

Page 10

Use medium threadlock on all

screws going into metal parts

The boom support collar (7)

has one beveled side. This

must face outside. Be careful

when fixing the tail boom

braces and arrange the

collars to them.

7

2

Beveled Side

5

Tip: Clip on the ball link on the tail

control arm. Look which part of the tail

control rod slides in the guide of the tail

boom clamp to get the correct position for

the heat shrink. Clip it off again and pull

the tail control rod as far as possible to the

rear. Slide the heat shrink over the tail

control rod and shrink it carefully with a

lighter.

Heat Shrink Plastic

m

m

0

3

1

Page 11

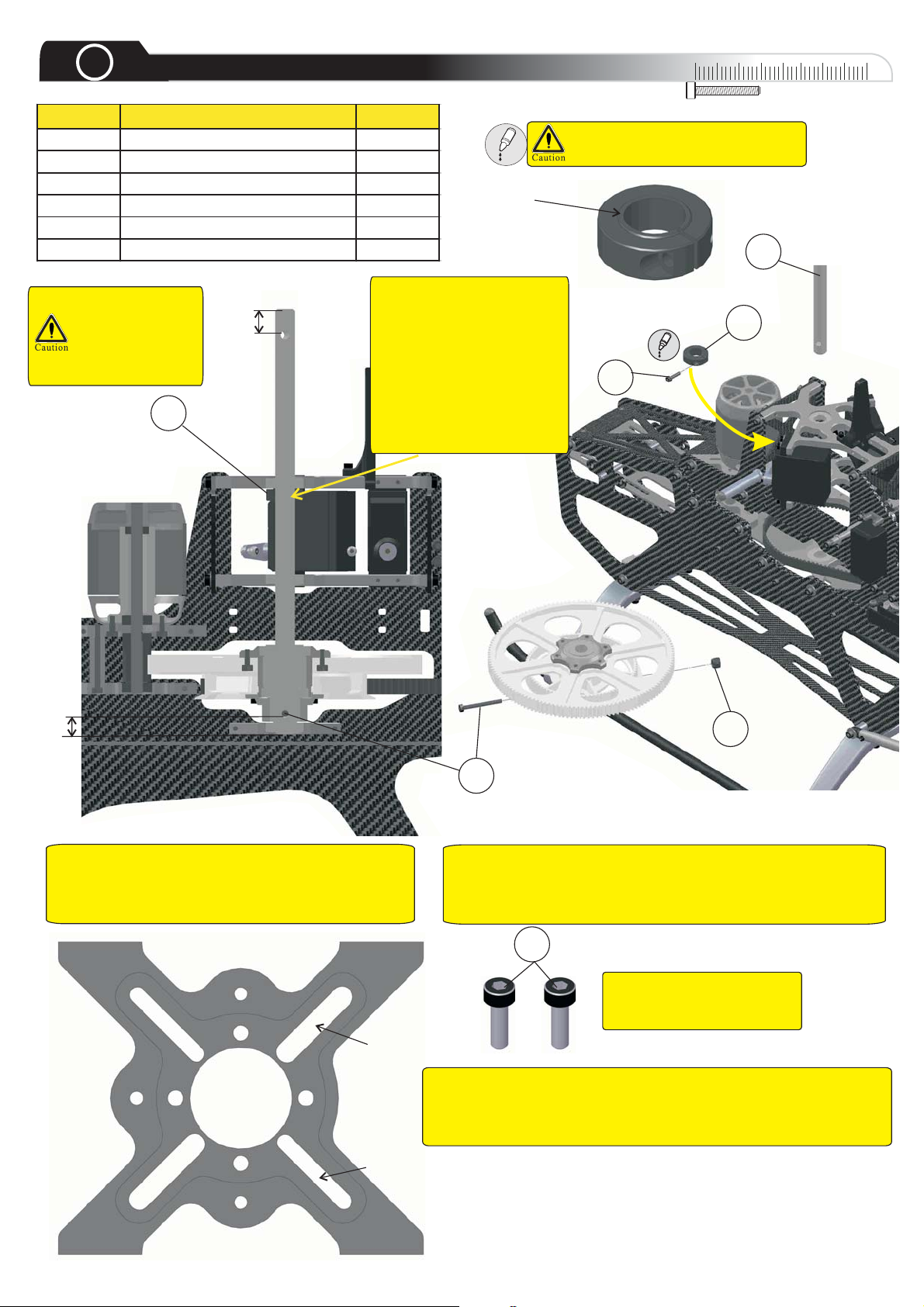

4

Pos Description Qty

1 Main Shaft Clamp 1

2 M2.5x 10 Soc ket Head Bolt 1

3MainShaft 1

4 M3X30 Sock et Head Bolt 1

5M3NylonNut 1

6 M4x10 Socket Head Bolt 2

Main Gear

rim

0

10

20

Use medium threadlock on all

screws going into metal parts

3

30

40

Do not over

tighten the screw

in the main shaft

clamp, but fix it

securely.

8.5mm

After installing the main

11mm

1

gear, mount the main

shaft clamp below the

upper bearing block with

the rim facing towards

the bearing. Push the

main shaft down and the

main shaft clamp up. The

must be zero clearance.

1

2

5

If you have to change the main gear, do not

overtighten the bolts going into the hub or it may

draft the main gear. Tighten the bolts in a cross

pattern.

4

To intall the main gear, push the tail boom all the way in.

Pull the tail belt out at one side of the chassis and mount it

on the main pulley. Then slide the main gear into the frame

and align the holes over each other to fit the jesus bolt.

6

2 extra M4x10 Bo lts are

equipped here in case for

optional motors.

4mm slot

To mount Motors with different hole measurements, use 2 of

the 4 slots in the motorplate. The 4mm slots for motors with

M4 screws and th e 3mm slots for motors with M 3 screws.

Only 2 screws are necessary in this case.

3mm slot

Page 12

Motor And Drive Tips

Use medium threadlock on all

screws going into metal parts

Gear backlash adjustment:

For smooth operation and

performance, it is necessary to adjust

the gear backlash properly. Excess

gear backlash can cause premature

gear wear and damage. Insufficient

gear backlash can cause vibration, as

well as overheating of the Motor and

speed controller. Adjust the gear

backlash by placing one piece of

paper between the gears to set the

distance. When the bolts are secure,

remove the paper and test the gear

backlash to insure that there is a

slight amount of free movement

between the gears.

To adjust the correct backlash between

the motor pinion and the main gear

loose the 4 motor mount bolts on each

side , then fix them tightly with

threadlock.

Tip: Use a pressure resistant extra sticky grease on the maingear to reduce abrasive wear and

noise. Grease it every five flights for the first 20 flights. Check the gear backlash especially in the

first 20 flights. Apply some grease when you recognize that the main gear gets „dry“.

Tip: Choose a low kv motor so you can use 14t or higher pinion for good contact with the main gear

to prevent excessive wear on the main gear.

Motor Setup And Maintenance Tips: Use at least 5.5mm gold connectors with an even

surface for your motor wires and ESC wires. Use heat shrink and look for a good isolation. Check

all wires and connectors regularly for good fitting and damage. Damaged wires and connectors can

cause severe damage to your model and equipment! Oil the motor bearings each 10 flights and

change them if they make strange noises or when the motor gets clearance at the shaft or bell.

Soldering Tips: Use a soldering iron with atleast 80W and SN60PB40 brazing-solder. The

temperature should be around 380°C. Use a non-conductive heat resistant surface and clamps or

pliers to hold the connectors and wires. Do not heat the connectors and wires to long. The braze

point must be shiny and even. If you have problems with the soldering, ask a experienced modeler

for help. Due to extreme high currents of up to 200Amps and mechanical stress to the connections,

good soldering points are very important to guarantee a safe function of your power system.

Page 13

Use blue threadlock on all

screws going into metal parts.

swing range

Tip: Check the rubber from time to time

for cracks and refractory material.

Tip: Fix the tail boom clamp later, so you

can adjust the angle for a perfect smooth

running tail control.

Tip: If the rubber gets older,

you can increase the tension

by opening the two screws in

the holder and sliding it to the

rear in the long holes.

Adjusting the belt tensioner is pretty easy. Just

remove the rubber ring and adjust the tension as

usual. After remounting the band, the tensioner

should swing in 1/3 of his possible travel– if it

swings more in then the tension is to lose.

Increase it by removing the band again and move

the tail boom further to the rear. Use the four

screws in the tail boom mount to fix the boom.

Check the belt tension sometimes.

Readjustments may be needed after a while or

big temperature differences.

Adjust the belt idler pulley with a distance of

0.2-0.3mm to the tightened belt. Do not over

tighten the screw as it may result in a bent tail

case and sluggish bearings.

Page 14

5

Pos Descripti on Qty

1 M4x25 Socket Head Bolt 1

2 M4x30 Socket Head Bolt 2

3 Preassembled Rotor Head 1

4 3mm Washer 4

5 4x8x3 Flanged Bearing 4

6M4NylonNut 1

7 M3x14 Socket Head Bolt 2

8 Swashplate Guide 1

9 M2.5x10 Socket Head Bolt 2

Rotor,Washout & Swashplate

0

10

30

20

40

Use medium threadlock on all

screws going into metal parts

Mount the mainrotorhead

using the upper hole

VERY IMPORTANT:

Be careful not to

overtighten the two

clamping screws (7) in

the main rotor hub.

1

3

2

4

5

5

4

6

The Jesusbolt (6) just

carries the torque.

Tighten it firm but do

not use to much force.

Do not overtighten the two

M4x30 socket head bolts (2)

as it may result in sluggish

bearings in the A-arm

Install the linkage for the

elevator servo at the

swashplate before you

mount the swashplate

guide.

The feathering/spindle shaft

screws are not secured. You

have to clean the shaft from

the inside and the screws

with alcohol and secure them

tightly with threadlock!

Use some light oil on the

main shaft for a smooth

travelling swashplate and

clean it regularly.

7

9

8

Main grips are factory preassembled; in case of reassembling

make absolutely sure you use the correct “ID”(inner diameter)

ring at the correct position. Place the large ID towards the main

shaft and the small ID towards the blades during assembly.

Thrust Bearing Direction

Main Grip

Apply Grease Here

Larger ID

(IN)

Smaller ID

(OUT)

Page 15

6

Suggested Equipment Position

Take some time for the wiring.

Good fixing of the components

and wires is important for a safe

operation of your rc-equipment.

Read the following wiring tips

carefully.

Brushless Motor

Esc

Aileron

Pitch

0

Elevator

10

Rudder

30

20

40

12S Battery

Please read the manual of your

FBL-Unit, transmitter and

receiver very attentively. Each

FBL-Unit is different, follow the

manuals step by step and ask for

help if you have problems with the

programming and installation.

Receiver

FBL Unit

ESC

BEC

To M o t o r

FBL

Ch6

Page 16

7

Linkage Length & Setup

00

00

10

30

20

40

Do not apply plier to resize Ball Links. Pliers could

cause hidden damage to Ball Links and result in

failure when operation.

Use medium threadlock on all screws

going into metal parts and nuts.

Do not use pliers or screwdrivers to

screw the ball links onto the linkages.

It can damage the ball links and

result in failure. Screw them on by

hand or use special tools.

1

7

.

5

m

m

Compass Model ball links are build up on

the tight side. This allows you to adjust them

to your personal needs. Use a ball link

sizing tool to adjust the ball links. Clip the

ball link on the corresponding ball where it

will be later and test if it moves freely. If not,

clip it on the ball link sizing tool and rotate it

a few turns in different angles. Test it again

on the ball. When you level the whole

linkage horizontally, the linkage should

almost flip downwards by ist own weight. Do

the resizing in small steps and test the

fitting every time. If any ball link has

clearance on the ball, change it and do not

use it again.

All ball links must be clipped on the

balls with the Compass writing

facing to the outside.

Check all ball links for clearance

and damages everytime you go

flying and change worn ball links

early.

Tip: You can make your own ball link sizing tool. Just use a Dremel with a

thin cutting wheel to cut two slots opposite to each other into a ball

you don´t need. Stick a screw through the ball and screw a nut on the

other side to fix the ball. You can clip ball links onto this tool and use

it as described above.

5

0

.

5

m

m

The length of the

plastic drive tube can

be changed easily by

turning the ball link in

5

and out.

4

.

2

5

m

m

Linkage Lengths:

Servo Horn to Servo center: about 17.5mm

Servo to Swash: about 57mm inner edge to inner edge

Swash toA connector: 58mm inner edge to inner edge as per

picture.

Page 17

Tail Setup

Headspeed 1400-1800 Headspeed 1800-2100

Travel A Trav el B Travel A Travel B

Stock Plastic 2mm 17mm 2mm 16.5mm

KB DD 104m m 2mm 17mm 2mm 16. 5m m

Compass 115mm 3.5mm 16mm 4mm 16mm

Mo st CF 10 5mm 3mm 17mm 3mm 16. 5m m

90°

1

1

7

7

.

.

5

5

At zero position, the servo arm should

be at 90°. Use the b est fitting servo

arm and read the manual of your FBLUnit how to adjust the servo midposition.

Adjust the linkage length so that the slider is

parelel to the tail case side wall.

It is important to limit the servo travel to the endpoints of the slider shown below. Too much

travel can cause a stall and lead to a loss of tail authority.

A

Clockwise Position

Set the limit of the tail servo to A from slider to

bearing.The table blow gives the value of Afor

different blades and rotor head rpm.

With the tail pitch slider in this position, the

helicopter will turn clockwise.

Counter Clockwise Position

Set the limit of the tail servo to B from slider to

bearing.

different blades and rotor head rpm.

With the tail pitch slider in this position, the

helicopter will turn counter clockwise.

The table blow gives the value of B for

B

Adjusting the gyro direction:

To adjust the gyro direction, read the manual of your fbl unit. Look at the heli from behind.

When you turn the nose to the left (counter clockwise), the tail pitch slider must go towards the tail rotor hub

and away from the tail case.

When you turn the nose to the right (clockwise), the tail pitch slider must move towards the tail case and the

bearing.

Doule check this step!

Page 18

Wiring Tips

Never use RC-components with damaged

wires. Check all wires for damaged isolation

and breakage. Control all servo connectors for

a tight fit and be sure no wire is loose in the

connector.

All wires must be protected against damage

through sharp edges of the carbon frame and

metal parts. Zip ties can also cause damage to

the wires.

Tip: Cut open a piece of fuel line to cover sharp edges.

You can also use fuel lines to cover zip ties to

prevent them from damaging the wires.

Carbon fibre and metal parts are

conductive . Open wires, contacts and

open gaps between two contacts

touching the frame can cause a short

curcuit and damage to the RC-Equipment.

the RC-Equipment.

Tip: The be st way t o protect your wire s is to us e

braiding sleeve such as those used for

computer wiring or casemodding. Seal the

ends of the sleeve with heat shrink to prevent

them from unraveling. You can also you use

heat shrink to protect wires where zip ties

overlie.

Keep all wires as short as possible. Avoid unnecessary extensions and connections, but use extensions if a

wire is almost to short to avoid mechanical tension in the wiring. Never tighten a wire to much. Be sure that

nothing pulls at a wire. It is very important to have zero tension between wires, plugs and RC-Components.

Do not pull out connectors by pulling at the

wires!

Do not fold any wire, place them in curves.

Tip: Secure connectors with heat glue at the receiver and

Keep all wires away from rotating parts,

linkages and servo arms.

Tip: Use a plier to bend zip ties before you use

them. It wil be easier to get them around a corner.

FBL-Unit. Avoid contact of the glue with stickers and

the wires. The glue is easy to remove.

Be careful when heating heatshrink on wires,

don´t heat it up to long or with to much heat

or it may damage the isolation.

Control all wires and connections regularly to discover hidden damages and defective

contacts early. Never go flying if any failure occurs!

Page 19

FBL Setup Tips

Please read the manual for the current

software version of your FBL-Unit carefully

and follow all instructions. We can't give

you any specific tips because most brands

of FBL-Units change their software from

time to time and your setup depends on

many other factors like used blades and

servos. Please check our website to find

some setups from our Teampilots.

Tip: All servo horns must be at 90° (horizontally). Try all

possible positions of the servo horn to get as close as

possible to 90° at neutral servo position. Keep all

swashplate linkages at exactly the same length. Level

the swashplate horizontally in all directions, therefore

read the manual of your FBL-Unit and follow the

instructions!

Tip: For easy measurement of the pitch angles

during the setup, please use something long

and straight (like a flybar or CF-Tube) and put it

on the upper servo mount behind the servorods.

With this trick you can easily use the pitchgauge

to check the collective and cyclic angles.

If you have vibrations it is better to find the source than using a softer tape.All wiring to the FBL-Unit must be

done without tension and not to stiff. If you use some kind of cover to protect the wires, please remove it on the

last 3-5cm to make sure that vibrations can’t be carried to the unit – which will cause strange behaviour like

unwanted movements of the helicopter.

Remove all kind of grease and oil from the radio tray and the bottom of the FBL-Unit with alcohol or something

similar.

Please place your FBL-Unit extremely carefully in your helicopter. It is important that the unit is in a perfect 90°

angle to all axes to get best performance. Awrong mounted unit can cause a wobble during piro-manouvers.

A perfect CG (Center of Gravity) is very important to get a perfect flying model. The CG must be

exactly under the mainshaft. Adjust the CG by positioning the battery to the front or to the rear on

the battery tray. You can also change the position of the battery tray with the three mounting holes

in the side frames. The CG should be measured with all parts including the canopy.

Tip: There are two methods to find out where the CG is. The first method is to hold the model under the main

blade grips and look if it tilts forwards or backwards.

You can also hold the model at the main blade grips and fixed main rotor blades with the main shaft

leveled horizontally. Look with the canopy facing to the right and then facing to the left (due to the free

wheel) if the nose or tail tilts down.

If the nose tilts down, you have to put the battery more to the rear, do the opposite when the tail tilts

downwards.

Page 20

FBL Setup Tips 2

Look at the helicopter from the side to test

the gyro direction.elevator

Double check the gyro directions of your fbl unit!

Incorrect gyro directions will cause a crash!

Checking the swasplate and tail gyro

directions is a part of the preflight check!

Tilt the helicopter forwards as shown in the

picture. The swashplate must tilt backwards.

Watch the helicopter from the front/canopy

to test the gyro direction.aileron

Tilt the helicopter backwards as shown in

the picture. The swashplate must tilt forwards.

Tilt the helicopter to the left, the swashplate

must tilt to the right as shown in the picture.

Tilt the helicopter to the right, the swashplate

must tilt to the left as shown in the picture.

Page 21

8

The picuture below shows how the swashplate has to move in mode 1 or mode 2.

Control Check

Mode 1

Mode 2

Aileron Check

Swashplate Reaction

Tilt Right

Tilt Left

Tilt

Forward

Tilt

Backward

Elevator Check

Pitch Check

Ascent

Swash Plate

Descent

Tail Pitch Plate

Rudder Check

Slide left

Slide Right

Page 22

9

Pos Descripti on Qty

1 M2.5x8 Self Tapping Bolt 2

2 Canopy Insert 1

3 M3x8 Socket Head Bolt 2

4 Thumb Screw 2

5 Canopy Rubber Grommets 2

ABA

B

Use AB Glue

Canopy

Place the canopy onto the frames

and mark the right position of the

canopy insert. Mark the positions

of the holes in the anopy on the

Insert for drilling. Use a 2mm drill

and drill straight through the

insert. UseAB glue to fix the insert

and screw it from the outside into

the canopy.

00

00

10

4

ABA

B

30

20

40

1

2

3

5

10

Grounding

Belt-driven tailrotors can produce a high amount of electricity.

The discharge can cause a blockage of the radio signal and the

RC-Components. If you have transmission problems and/or

problems like hard tail kicks and lockouts during flight, you have

to ground the tail. We recommend to ground each helicopter for

safety reasons if you are not sure if everything works without

failures.

To ground the helicopter, use a piece of fine sandpaper to remove a little bit of

the black anodizing between the two tail boom clamps in the frame with care. Do

not modify the tailboom behind the tail boom clamps! Use a piece of silicon wire

with a diameter of at least 1mm² and skin one end. Attach the open end to the tail

boom with one or two zip ties. Lay the wire to the motor, skin the other end and

attach the wire to one motor screw by jamming the open end under the screw.

00

00

10

30

20

40

Do not use a file, rasp, knife or

coarse sandpaper to remove the

anodizing. Deep scratches will

damage the structure of the tail

boom and can cause a breakage

of the tail boom!

Page 23

00

00

10

11

Rotor Direction & Blades

20

When the main rotor spins clockwise the tail blades should

turn clockwise as well watching the tail rotor from the tail fin

side. If not, the belt is twisted and has to be corrected.

Be sure that the main rotor and tail rotor blades are installed in

the right direction. The leading edge has to show into the rotor

directions.

Do not overtighten the blades. The main rotor blades should not be able to retract when you hold the

helicopter sideways with the mainshaft and both blades horizontally. Do not thighten the blades much

stronger than this and use the washers delivered with the blades.

30

40

12

Do not grind the blades if they

don´t fit.Ask the manufacturer

for other washers.

Blade Tracking

Use the same amount of washers

with the same thickness over

and under the blades!

00

00

10

20

30

The get a helicopter without vibration issues and, perfect flight abilities and low power consumption, you

have to track the main rotor blades. The first step is to have identical lengths from the end of the ball link

on the plastic drive tube to the metal arm.

In most cases, the blade tracking will be fine after doing this. To check it during the flight, get the help of

an other pilot for safety reasons. Get in a hover and ask him to watch the rotor disk. Both blades must be

in one line. If there are two disks or the blades appear thicker than they are, you have to readjust the

blade tracking by turning in and out the ball links in the plastic drive tubes. Mark one blade or blade grip

and turn in or turn out the ball link of this blade by one turn. Remember the direction. Hover the

helicopter again, if it gets worse, turn back the ball link and rotate it one turn in. If it get´s better but is not

perfect, turn the ball link of the other blade out by one turn and hover again. The blade tracking should

be perfect now. If not, an issue with the rotor blades is likely. Do not fly with these blades. Also check all

linkages, balls, ball links and the swashplate links for clearance.

40

Do not check the blade tracking

on the ground alone or with

negative pitch.

Read the following pages before

you go to test thi s!

Do not fix the helicopter to the

ground or any object.

Keep some distance to the

model and do not test this

indoors!

Page 24

COMPASS MODEL (HK) LIMITED

www.compassmodel.com

Page 25

Parts List

7 HV

Version 3.0/2012

Copyright @Compass Model 2012

As we continue to improve our products, this part list may not reflect all recent product amendments.

For more information, please refer to www.compassmodel.com

Page 26

91-0004

80-0312

09-7067S

09-0109

80-0421

82-4264

80-0430

05-0119

09-7101

05-0117

80-0325

80-5285

09-7069S

09-7025S

79-0512

82-5131

60-8165

82-821003

63-8165

05-0102S

91-0005

09-7068S

80-0304

80-0312

82-4264

09-7067S

09-7068S

61-4083

09-7069S

05-0102S

81-0328

02-0709S

09-7025S

Page 27

Part No. Part Description Qty,

02-0709S Ball Links

05-0102S Metal Main Grips 7Hv 1 pcs/bag

05-0117 Spindle

05-0119 Spindle Washer (90)

09-0109 7Hv Dampner 2 pcs/bag

09-7025S 7Hv Fbl Drive Tube 1 pcs/bag

09-7067S 7Hv Center Hub 1 pcs/bag

09-7068S 7Hv Main Grip Arm 1 pcs/bag

09-7069S 7Hv Fbl Arm Connector 1 pcs/bag

09-7101 7Hv Fbl Connector Collar 2 pcs/bag

60-8165 Ball Bearings 8X16X5

61-4083 Flanged Bearings 4X8X3

63-8165 Thrust Bearings 8X16X5

79-0512 Button Head Bolts M5X12

80-0304 Cap Head Bolts 3X4 2 pcs/bag

80-0312 Cap Head Bolts M3X12

80-0325 Cap Head Bolts M3X25

80-0421 Cap Head Bolts M4X21

80-0430

80-5285 Shanked Bolts M5X28.5

81-0328 Set Screws M3X28

82-4264 Washers 4.2X6X0.4

82-5131 Washers 5.1X13X0.1

82-821003 Washers 8.2X10X0.3

91-0004 Nylon Lock Nuts M4

91-0005 Nylon Lock Nuts M5

Cap Head Bolts M4X30

10 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

4 pcs/bag

2 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

2 pcs/bag

10 pcs/bag

2 pcs/bag

10pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

2 pcs/bag

Page 28

02-5264

90-0201

91-0003

60-4094

91-0003

60-3092

82-3402

63-4094

02-0264AB

80-0314

02-0225

09-7048

60-7113

02-1211

02-8205

60-7113

05-0229S

02-0214

80 0310-

06-0222

02-0213

80-0208S

02-0209

02-0701

80-0338

61-5134

81-0305

02-0205

84-0214

80-0208

98-2040B

82-327408

91-0003

06-0223

09-8023

09-7023

09-8051

09-7079

06-0223

80-0310

09-7051

09-7075

09-7066S

09-7050

09-7007

82-3201

80-0310

80-2510

Page 29

Part No. Part Description Qty,

02-0205 Tail Blade Links W. Pin

02-0209 Tail Rotor Hub 1 pcs/bag

02-0213 Tail Pitch Slider

02-0214 Tail Shafts

02-0225 Grooved Pin 2X10 4 pcs/bag

02-0264AB Tail Blade Holder Set 2 pcs/bag

02-0701 Stainless Link Balls 10 pcs/bag

02-1211 Tail Pitch Plate W, Bb 1 pcs/bag

05-0229S Tail Pitch Slider W,Bb 1 pcs/bag

06-0222 Guide Pin Bolts

06-0223 Pin 2X24 4 pcs/bag

09-7007 Tail Fin

09-7023 Tail Pitch Connector

09-7048 Tail Pitch Arm

09-7050 Tail Gear Box Frames

09-7051 Tail Gear Box

09-7066S Tail Guide Wheel

09-7075 Tail Pulley

09-7079 7hv Tail Hinge

09-8023

09-8051 7Hv Metal Gear Box

02-8205 Tail Pitch Control unit

02-5264 Tail rotor hub assembly (plastic)

60-3092 Ball Bearings 3X9X2.5

60-4094 Ball Bearings 4X9X4

60-7113 Ball Bearings 7X11X3

61-5134 Flanged Bearings 5X13X4

63-4094 Thrust Bearings 4X9X4

80-0206s Cap Head Bolts 2X6

80-0208 Cap Head Bolts M2X8 10 pcs/bag

80-0208S

80-0310 Cap Head Bolts M3X10 10 pcs/bag

80-0314 Cap Head Bolts M3X14 10 pcs/bag

80-0338 Cap Head Bolts M3X38 10 pcs/bag

80-2510 Cap Head Bolts M2.5X10 10 pcs/bag

81-0305 Set Screws M3X5

82-327408 Washers 3.2X7.4X0.8

82-3402 Washers 3.3X5.2X0.3

84-0214 Spring Pin 2X14

90-0201 Nuts M2

91-0003 Nylon Lock Nuts M3

98-2040B 3M 8Mm Wide 2040 Belt

7Hvtail Pitch Lever Set

Cap Head Bolts 2X8 special made

for ball

2 pcs/bag

1 pcs/bag

2 pcs/bag

2 pcs/bag

1 pcs/bag

1 pcs/bag

1pcs/bag

1 set/bag

1 pcs/bag

1 set/bag

1 set/bag

1pcs/bag

1 set/bag

1 set/bag

1 set/bag

1 set/bag

4 pcs/bag

5 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

1 pcs/bag

Page 30

80-0332

09-7058

09-7102

60-6155

09-7053

07-4312(12T)

07-4313

07-4314(14T)

81-0404

80-0410

(for optional motors)

80-0308

09-7059

08-4928

60-8196

02-0701S

05-0606S

80-0310

05-0602Z

60-15245

05-8401

02-0701

80-0225

09-7056

09-7103

60-17265

62-162216

05-4602

08-4926

60-8196

08-4927

C-4926

80-0512SS

80-2508

91-0004

81-0404

80-0308

09-7026

09-7070

80-0430

Page 31

Part No. Part Description Qty,

08-4926

Motor Shaft for 4926 motor

1pcs/bag

02-0701 Stainless Link Balls

02-0701S Solid Link Balls 10 pcs/bag

Autorotation Hub W,One Way

05-0602Z

05-0606S Mast Lock Clamp

05-4602 Main Gear 1pcs/bag

05-8401 7Hv Swash Plate 1set/bag

07-4312 Pinion Gear (12T) 1 set/bag

07-4313 Pinion Gear (13T) 1 set/bag

07-4314 Pinion Gear (14T) 1 set/bag

09-7026 7Hv Main Pulley

09-7053 7Hv Motor Mount Spacer 3pcs/bag

09-7056 Swash Plate Pin

09-7058 7Hv Motor Mount Top

09-7059 7Hv Motor Mount Bottom

09-7070 Main Pulley Hub

09-7102 7Hv Main Shaft

09-7103 Autorotation Sleeve

Bearing

10 pcs/bag

1pcs/bag

1 pcs/bag

1pcs/bag

1set/bag

1 pcs/bag

1 pcs/bag

1 pcs/bag

2pcs/bag

1pcs/bag

08-4927 Motor shell for SZ4926

08-4928 Motor cover for SZ4926

60-15245 Ball Bearings 15X24X5

60-17265 Ball Bearings 17x26x5

60-6155

60-8196

62-162216

80-0512SS

80-0225 Cap Head Bolts 2X25

80-0308 Cap Head Bolts M3X8

80-0310 Cap Head Bolts M3X10

80-0332 Cap Head Bolts M3X32

80-0410 Cap Head Bolts M4x10

80-0430 Cap Head Bolts M4X30

80-2508 Cap Head Bolts M2.5X8 10 pcs/bag

81-0404 Set Screws M4X4 10 pcs/bag

91-0004 Nylon Lock Nuts M4 10 pcs/bag

SZ4926 12S Motor for 7hv kv510 1 pcs/bag

Ball Bearings 6X15X5

Ball Bearings 8x19x6

One way bearing 16x22x16

Stainless Cap Head bolt M5x12

1pcs/bag

1pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

1 pcs/bag

2 pcs/bag

1pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

Page 32

85-0001

a:78-0310

b:80-0308

c:80-2506

d:82-3201

e:91-0003

09-7018

09-7042Z

a

09-7001Ra

09-7073

09-7011

60-10195

80-0375

b

a

d

a

d

09-7005

a

80-2520

09 7024-

02-0918

a

e

a

09-7004

09-7045S

09-7002a

09-7008S

a

09-7044

a

09-7060

79-0310

d

b

09-7001L

a

80-0306

09-7092

d

d

b

d

e

b

b

b

09-7109

d

c

b

d

d

b

c

e

d

d

b

d

d

d

b

b

d

c

c

b

02-0820

09-7061

09-7055

d

d

80-0310

91-0003

80-0325

09-7082

79-0306

d

e

d

e

09-7062

80-0322

82-3507

60-3095

09-7064

09-7071A

60-3095

82-3507

80-0330

09-7078S

79-0308

82-3504

61-3062

09-7009

82-3507

09-7062

09-7009

61-3062

79-0308

91-0003

09-7081

79-0310

09-7078S

78-0310

Page 33

Part No. Part Description Qty,

p

g

02-0820 Skid End Caps

02-0918 Servo Nuts

09-7001La Upper Frame Left 1 pcs/bag

09-7001Ra Upper Frame Right 1 pcs/bag

09-7002a Lower Frame

09-7004 Receiver Mount 1 pcs/bag

09-7005 7Hv Gyro Mount

09-7008S Battery Tray 1 set/bag

09-7009 Guide Wheel Frame 2 pcs/bag

09-7011 Canopy Break-Off 2pcs/bag

09-7018 Battery Lock 1 set/bag

09-7024 Servo Spacer

09-7042Z Bearing Block W, Bearing 1 set/bag

09-7044 Battery Tray Connector

09-7045S Receiver Stand Off

09-7055 Boom Support Collar

09-7060 7Hv Boom Clamp

09-7061 Battery Tray Stand Off

09-7062 Belt Tension Collar

09-7064 Guide Wheel Collar

09-7071A

09-7073 Canopy Stand Off

09-7078S Belt Tension Mount

09-7081 Rubber Band Mount

09-7082 Rubber Band Seat

09-7092 Rubber Band

09-7109 Canopy Spacer

60-10195 Ball Bearings 10X19X5

60-3095 Ball Bearings 3X9X5 2 pcs/bag

61-3062 Flanged Bearings 3X6X2 4 set/bag

78-0310 Flat Head Bolts M3X10 10 pcs/bag

79-0306 Button Head Bolts M3X6 10 pcs/bag

79-0308 Button Head Bolts M3X8 10 pcs/bag

79-0310 Button Head Bolts M3X10 10 pcs/bag

80-0306 Cap Head Bolts M3X6

80-0308 Cap Head Bolts M3X8

80-0310 Cap Head Bolts M3X10

80-0322 Cap Head Bolts M3X22

80-0325 Cap Head Bolts M3X25

80-0330 Cap Head Bolts M3X30 10 pcs/bag

80-0375 Cap Head Bolts M3X75 4 pcs/bag

80-2506 Ca

80-2520 Cap Head Bolts M2.5X20

82-3201 Washers 3.2X10X1

82-3504 Washers 3.2X5.2X0.4

82-3507 Washers 3.2X5.2X0.7

85-0001 Clamp pin

91-0003 Nylon Lock Nuts M3

7Hv Belt Guide Wheel(new)

Head Bolts M2.5X6 10 pcs/ba

4 pcs/bag

5 pcs/bag

1 pcs/bag

1 pcs/bag

2 pcs/bag

1 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

2 pcs/bag

4pcs/bag

2 set/bag

2 pcs/bag

1 set/bag

1 pcs/bag

1 pcs/bag

1 pcs/bag

1pcs/bag

4 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

2pcs/bag

10 pcs/bag

Page 34

09-7003

09-7041

09-7022

80-2510

80-0308

09-7200P

(Painted)

09-7200W

(Unpainted)

02 0853-

02 0810SG(Gold)-

02 0810B(Blue)-

80-0308

82-3504

80-0308

80-0208S

90-0201

02-0701

09-7006

80-2510

82-3504

09-7047

05-0833

81-0305

80-0308

82-3504

E-LG-09

02-0709S

09-7012

09 BC-

06 0851-

91-0004

09-0820

85-0002

09 7021-

80-0325

09-7080

02 0709-

09 7072-

09-7010

80-0320

02-0820

80-0316

02-0821C

05-0814

02-0820

VBT300

02 0813-

80 2508-

F-40-4700

Page 35

Part No. Part Description Qty,

02-0701 Stainless Link Balls

02-0709S Ball Links 2.5Mm 10 pcs/bag

02-0810B Thumb Screw (Blue)

02-0810SG Thumb Screw (Gold)

02-0813S

02-0820 Skid End Caps 4 pcs/bag

02-0821C

02-0853 Canopy Rubber Grommets 10 pcs/bag

05-0814s Skids With Caps 2pcs/bag

05-0833 Struts 2pcs/bag

06-0851 Canopy Insert

09-0820S Boom Support W Terminal

09-7003 Spacer Frame 1pcs/bag

09-7006 Bottom Board

09-7010 Canopy Board

09-7012S Tail Link Rod

09-7021 7Hv Tail Link Support

09-7022 7Hv Swashplate Guide

09-7041 Upper Servo Mount

09-7047 Strute Mount

09-7072

09-7080

09-7200P 7Hv Painted Canopy

09-7200W 7Hv White Canopy

09-BC Blade Caddie(7Hv)

F-40-4700 Main Blade 700mm

80-0208s Cap Head Bolts 2X8

80-0305 Cap Head Bolts M3X5 10 pcs/bag

80-0308 Cap Head Bolts M3X8

80-0316 Cap Head Bolts M3X16

80-0320 Cap Head Bolts M3X20 10 pcs/bag

80-0325 Cap Head Bolts M3X25 10 pcs/bag

80-2508 Cap Head Bolts M2.5X8 10 pcs/bag

80-2510 Cap Head Bolts M2.5X10 10 pcs/bag

81-0305 Set Screw 3x5 10 pcs/bag

82-3504 Washers 3.2X5.2X0.4

85-0002 Heat Shrink Plastic

90-0201 Hex Nuts 2mm

91-0004 Nylon Lock Nuts M4

E-LG-09 7Hv Linkage Set

VBT300 Velcro Tape 300Mm X 20Mm

Tail Boom Brace Connectors W,

Bolts

Skid dampener 4 pcs/bag

7Hv Tail Boom

7Hv Tail Link Cap

10 pcs/bag

4pcs/bag

4pcs/bag

4 pcs/bag

1 set/bag

2set/bag

1pcs/bag

1pcs/bag

1set/bag

1pcs/bag

1pcs/bag

1pcs/bag

1pcs/bag

1pcs/bag

2pcs/bag

1pcs/bag

1pcs/bag

1pcs/bag

1 set/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

10 pcs/bag

4pcs/bag

10 pcs/bag

10 pcs/bag

1 set/bag

4 pcs/bag

Page 36

COMPASS MODEL (HK) LIMITED

www.compassmodel.com

Loading...

Loading...