Page 1

Assembly Manual

Copyright Compass Model 2008

As we continue to improve our products; this manual may not reflect all recent product amendments.

For more information, please refer to www.compassmodel.com

Version 2.0

Created : 10/26/2009

Features :

Fly at your own risk !

- Best 3D Performance

- Precision ECCPM 120° Metal Swashplate

- Easy Maintenance

- 80% Preassembled

- Low Parts Count

- Wear Resistant Parts

Equipped with extra Strong Frames, Aluminum Rotor Head, Aluminum Tail Rotor and a

Metal Swashplate the Atom 500 not only looks great but is long lasting.

Page 2

Introduction

Congratulations on your purchase of the Compass Model Atom 500 Electric Powered Helicopter.This model has been

designed using the latest in state-of-the-art design technology. To achieve the best performance and reliability from this

model, please read through these instructions carefully so you become familiar with the contents of this kit before assembly.

AMA Information

We strongly encourage all prospective and current R/C aircraft pilots to join the Academy of Model Aeronautics. TheAMA is

a non-profit organization that provides services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled Model Aviation, as well as liability insurance plan to cover against possible accident or injury. All AMA

charter aircraft clubs require individuals to hold a current AMA sporting license prior to operation of their models. For

further information, you can contact theAMAat:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN47302

Warning

The radio-controlled model helicopter contained in this kit is not a toy, but a sophisticated piece of equipment. This product

is not recommended for use by children. Radio-controlled models such as this are capable of causing both property damage

and/or bodily harm to both the operator/assembler and/or spectator if not properly assembled and operated. Compass

Model Ltd. assumes no liability for damage that could occur from the assembly and/or use/misuse of this product.Although

theAtom 500 is powered by a quiet, smooth-running electric motor, it should be assembled and operated with the same care

as its larger glow engine counterparts.When operating yourAtom 500, please exercise caution and safety.

Warranty

The warranty covers defects in material or workmanship or missing components to the original purchaser for 30 days from

the date of purchase. Compass Model Ltd will replace or repair, at our discretion, the defective or missing component.

Defective components must be returned to our Distributor prior to replacement.

Any part, which has been improperly installed, abused, crash damaged or altered by unauthorized agencies is not covered.

Under no circumstances will the buyer be entitled to consequential or incidental damages. The components used in this kit

are made from special materials designed for special applications and design strengths. Werecommend that all replacement

parts be original parts manufactured by Compass Model Ltd to ensure proper and safe operation of your model. Any part

used which was manufactured by any firm other than Compass Model Ltd VOIDS all warranties of this product by Compass

Model Ltd.

Warranty Procedures

Mail all warranty information within 15 days of original purchase date. If service is required, send the component in

question (if not missing) together with a photocopy of your bill of sale and an accurate description of the problem and part.

Ship components fully insured and prepaid. Compass Model Ltd is not responsible for any shipping damages. We will, at our

discretion, notify you of any costs involved, or ship it COD. You are required to pay all postage, shipping and insurance

charges.

R/C Helicopter Safety

A model helicopter must be built exactly in accordance with the assembly instructions. Compass Model Ltd has spent much

time and efforts refining this product to make it reliable in operation and easy to build. Vibration and stress levels are high and

all fasteners and attachments must be secure for safe operation. Safe operation is the responsibility of the builder/flyer and

starts with careful construction and continues with selection and installation of reliable radio equipment and motor/engine.

The need for safety is nowhere greater than at the flying field. A number of guidelines for safe flight have been developed by

experienced flyers and are set down here. It is urged that they be read, understood and followed.

Attention:

rules to apply in your country/Flying field.

each country has his own security application which cannot be laid down here so prior to any flight request the

Page 3

Guidelines for Safe R/C Helicopter Flight

• Fly only at approved flying fields and obey field regulations.

• Follow frequency control procedures. Interference can be dangerous to all.

• Obtain assistance from experienced pilots.

• The Guidance provided by experienced pilots is valuable and sometimes necessary.

• Know your radio. Check all transmitter functions before each flight.

• Be aware that rotating blades are very dangerous and can cause serious injury.

• Never fly near or above spectators or other modelers.

• Do not fly r/c helicopter models near buildings, high voltage cables, trees or other obstacles.

• If a beginner, get help trimming the model first and flight training later.

• Don’t “track” the main blades by holding the tail boom. This is a temptation to builders who cannot hover yet and is very dangerous.

• Follow all recommended maintenance procedures for model, radio and motor.

• Only turn off the radio after the engine is shut down.

Necessary Items

In order to operate this model, you need to purchase the following items not kit-included.

6 channel or up radio and receiver.

3 mini servos.

1 gyro with rudder servo.

6S LiPo battery 2100mah~3300mah.

or 2 pack 3s LiPo battery with same capacity.

Main Rotor

Length: up to 430mm

Hex Wrench Set

(1.5mm,2mm,2.5mm,3mm)

Threadlock

Cutter Knife

Grease

Needle Nose Pliers

Mini Servos

Bearing Retainer

Screw Driver

Pitch Gauge

Ball Link Sizing Tool Ball Plier

Swash PlateTool

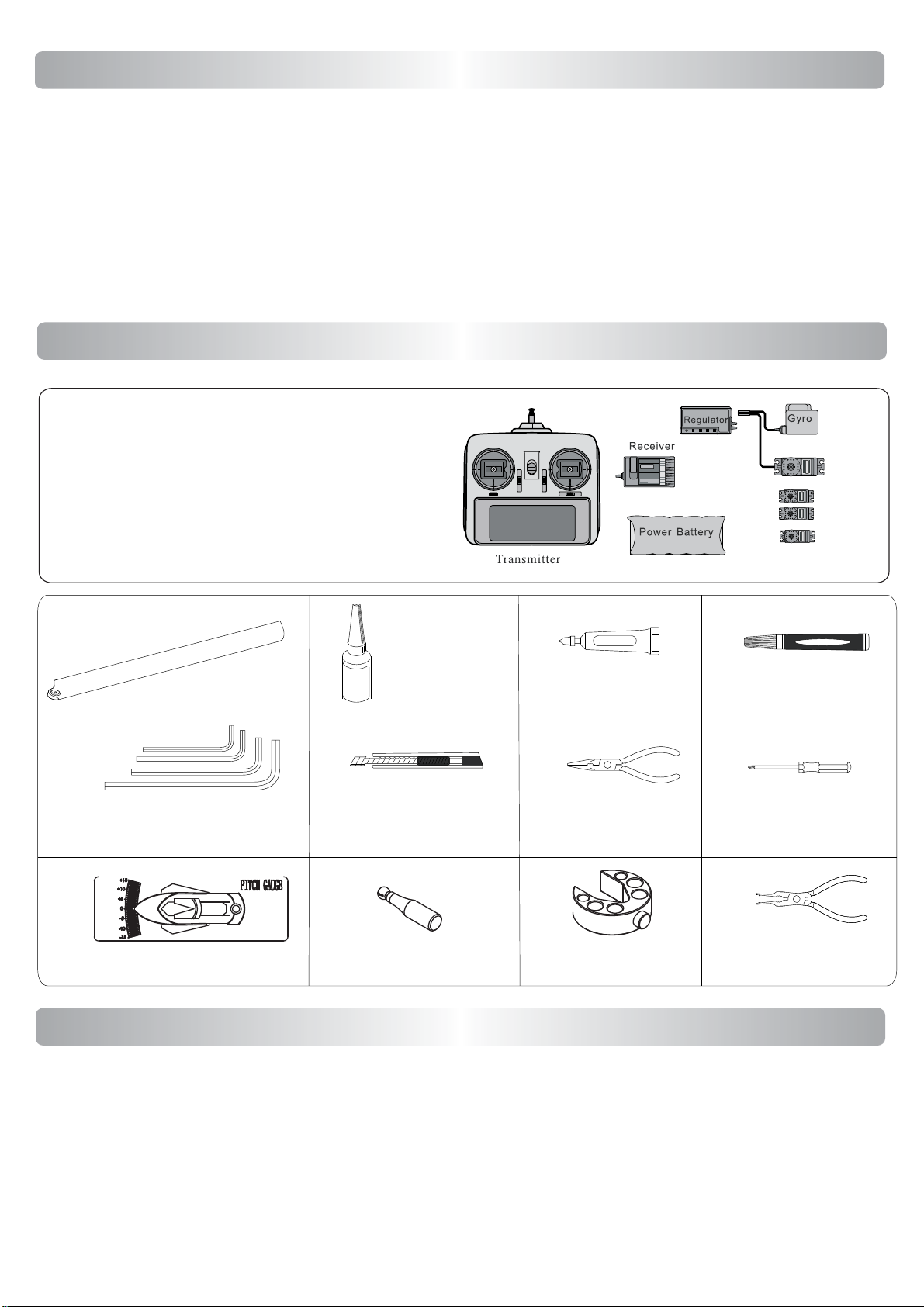

Preassembly Information

When first opening your Atom kit, you will notice that all of the parts are packaged and numbered to coordinate with the

assembly step numbers of this instruction manual. All small hardware (nuts, bolts, washers, etc.) for each step are packaged

separately within the main parts bags. When beginning a section, you will need to open only the bag with the corresponding

number to the section you are about to start. It is suggested that you place all of the hardware in an open container (e.g., servo

case) during assembly so as not to lose any of the small parts. It may also be helpful to familiarize yourself with the various

sizes of screws, bolts, nuts, etc., as illustrated in the appropriate assembly section before you begin assembly. In most cases, at

the end of each assembly section, there should be no parts remaining. Great care has been taken in filling the bags with the

correct quantity of parts and hardware for each section. However, occasional mistakes happen. In the event that you find a

parts shortage or are in need of technical assistance, please contact your local Compass Model parts dealer.

Page 4

In The Box

This model is packed according to assembling steps. Do not open all the bags at one time.

Open only one bag for each step of assemply when building.

Atom 500

Step 1 Step 2 Step 3

Step 4 Step 5

Carbon Frame Set 60A ESC

Compass Carbon Blades

Atom 500R Differences

Rotor Head Assembly

Long Items

Step 7 Step 10

Tail Assembly

Step 5 (With Flybar Weight)

G10 Frame Set 40A ESC

Compass FG Blades

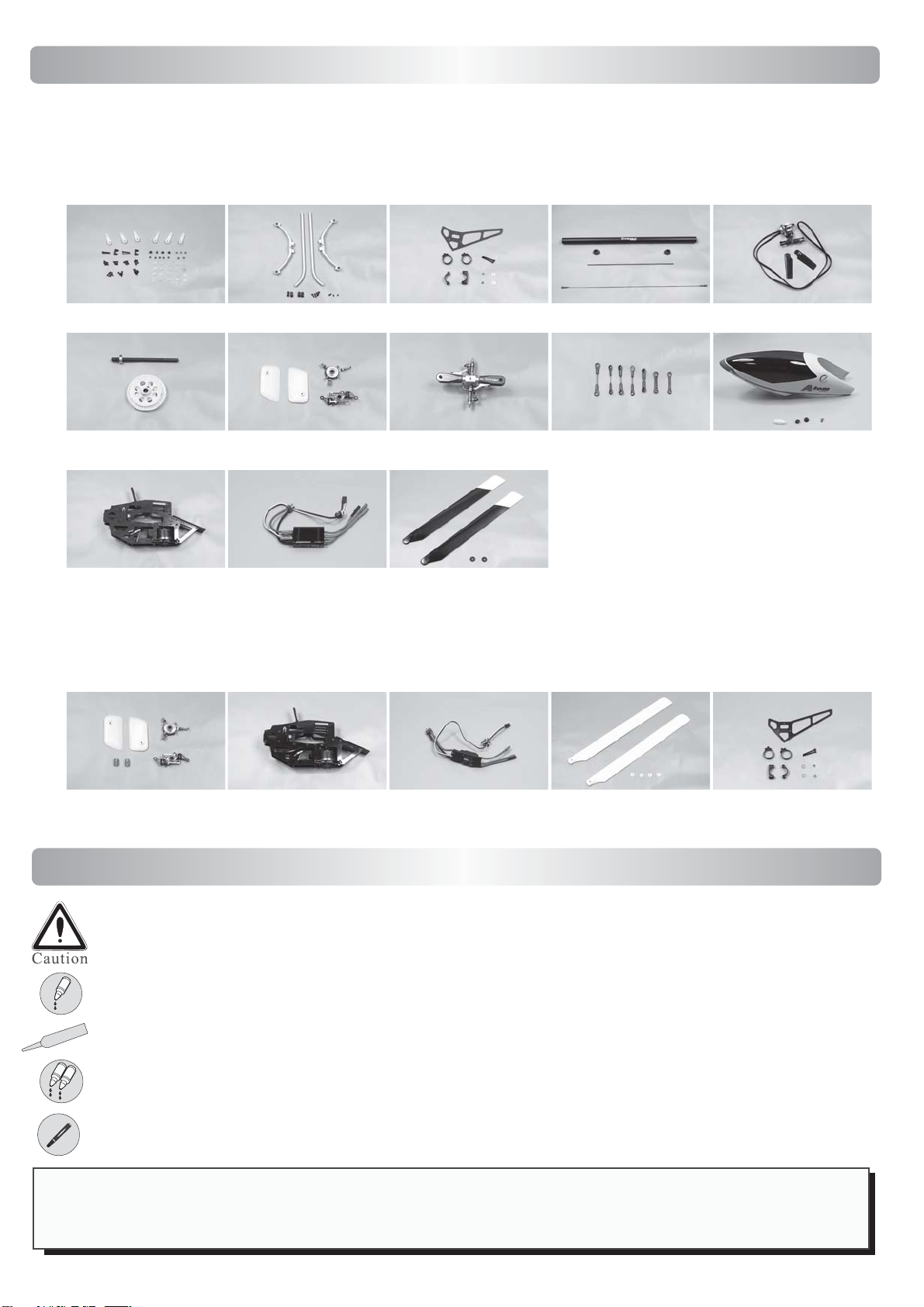

Symbols & assembling

Failure to follow these instructions may result in damage, personal injury or danger.

Use Blue Threadlock

G

Use Grease

A

B

Use AB Glue

Use Bearing Retainer

* Always apply blue Threadlock when fixing Bolts on Metal parts.

* Always apply green retainer where bearings have to be fit into metal parts.

* Do not over-tighten self tapping screws into plastic parts or you will strip the threads!

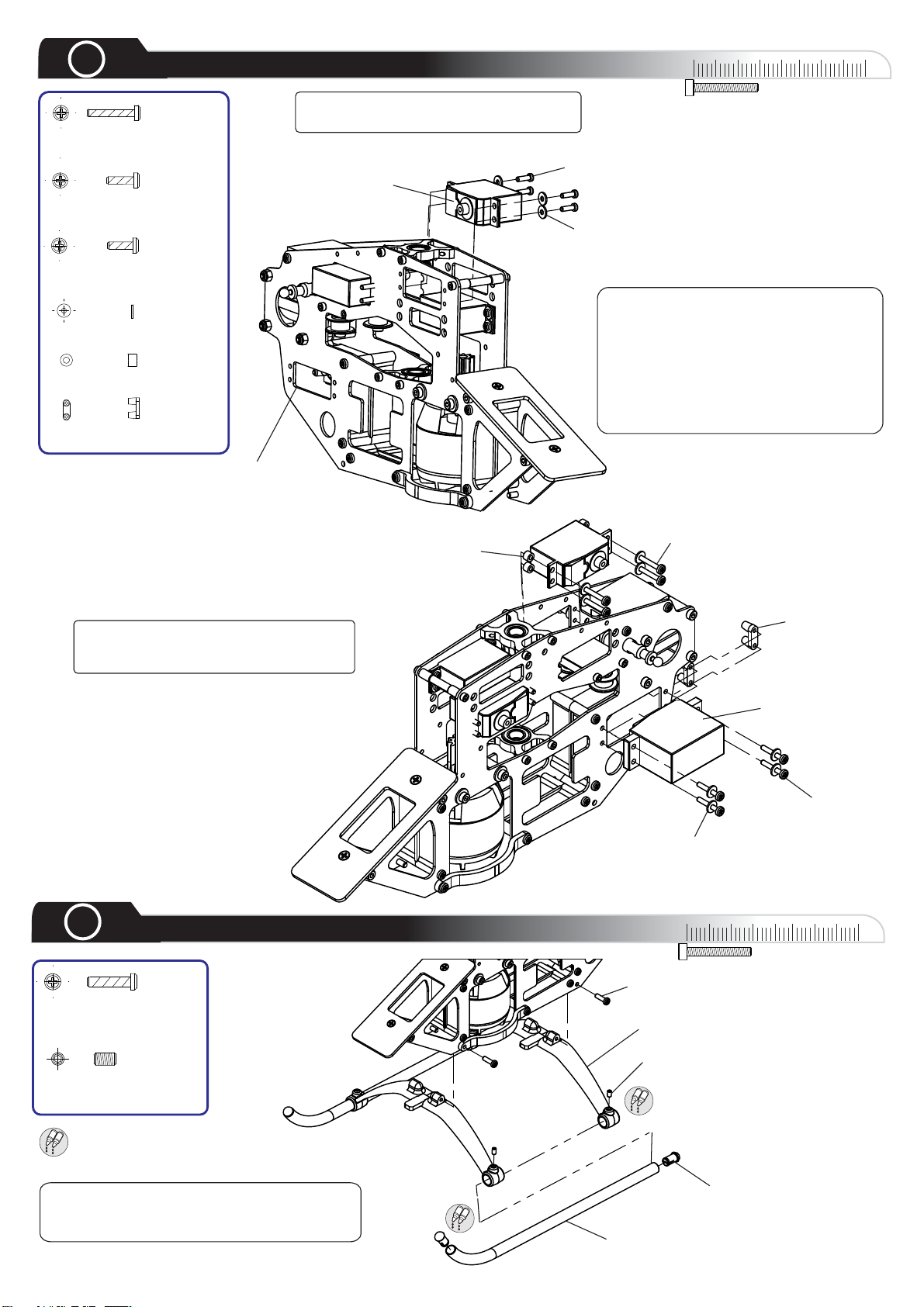

Step 3

Page 5

1

Servo

M2.5x16 Self Tapping

Bolt X 4

M2.5x10 Self Tapping

Bolt X 4

M2.5x8 Self Tapping

Bolt X 8

2.5mm Washer X 16

Plastic Spacer x 4

Serv o Nut x 2

Hole for

Mini Rudder Servo

The Servo installation is done without

the supplied Servo Rubbers.

Mini Servo

0

10

20

M2.5x8 Self-Tapping Bolt

2.5mm Washer

The Swashplate Servos are installed

in between the 2 frames. The Self

Tapping Bolts are screwed from the

inside, while the Self Tapping Bolts

for the Rudder Servo are screwed

from the out side. The supplied Servo

Nuts are only used for the Rudder

Servo.

30

40

The 4 Plastic Spacers are used to

bring the Elevator Servo Arm in

Line with the Swashplate Link Ball.

2

Landing Gear

M3 x10 Self Tapping

Bolt X 4

Plastic Spacer

M2.5x10 Self Tapping Bolt

Servo Nut

Standard Size

Rudder Servo

M2.5x16 Self

Tapping Bolt

2.5mm Washer

0

10

20

M3x10 Self Tapping Bolt

Landing Gear Struts

30

40

M3x5 S et Screw X 4

A

B

Use AB Glue

Tip: Do not over tighten the four 3 x 5mm

set screws as it can damage the landing

struts.

M3x5 Set Screw

A

B

Skid Cap

A

B

Landing Gear Skid

Page 6

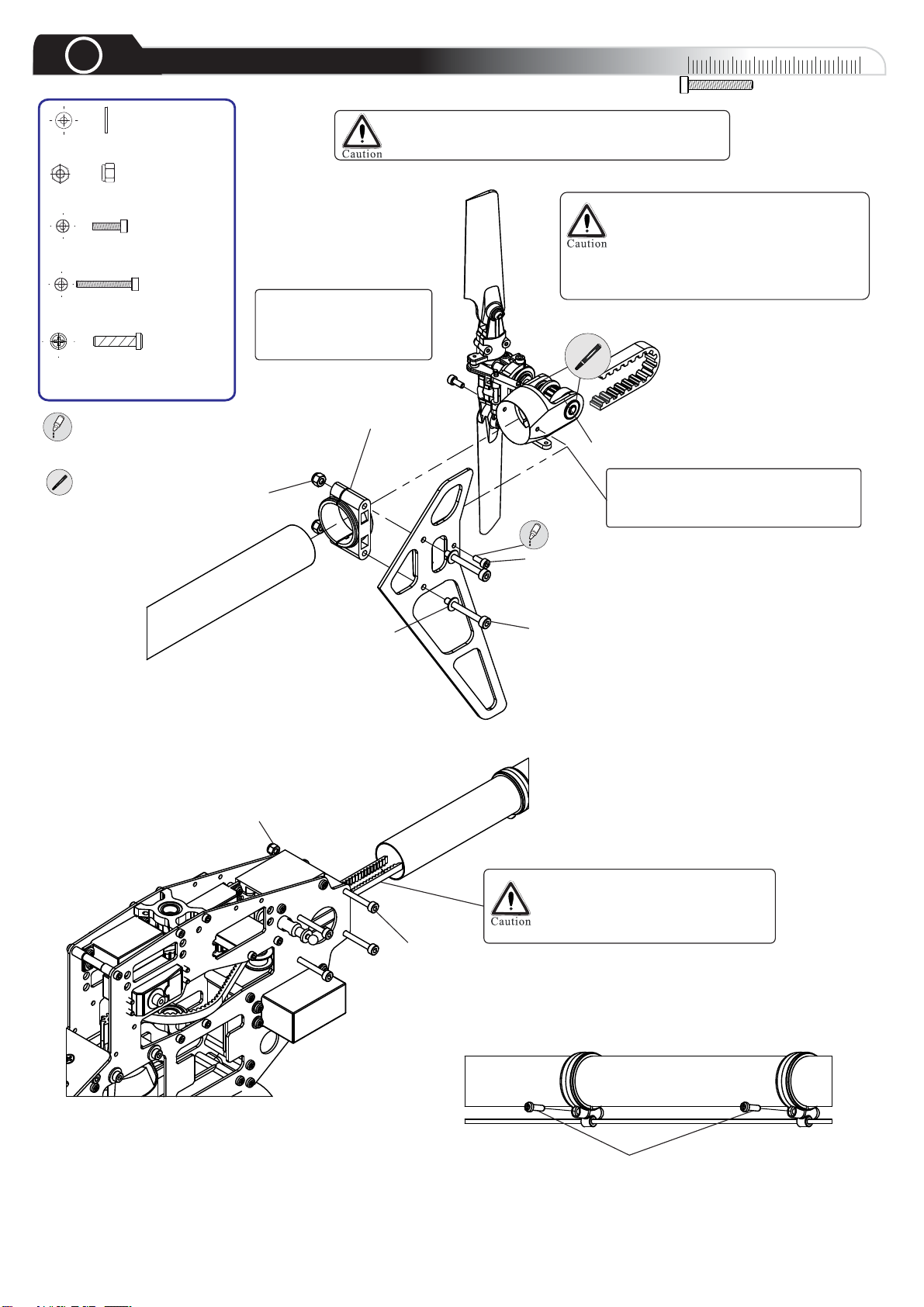

3

M3 Washer x2

Boom & Tail Rotor

0

Crimping Belt damages the Tensile Cords

and will result in premature failure.

10

30

20

40

M3 Nylon Lock Nut x6

M2.5x6 Cap Head Bolt x2

M3x40 Cap Head Bolt x4

M2.5 x8 Self Tapping

Bolt X 2

Use Threadlock

Bearing Retainer

Insert theTail Boom

fully into the Tail Gear

Case before tightening

the 2.5x6mm Bolts.

Vertical Fin Mount

M3 Nylon

Nut

M3 Washer

Be careful not to over tighten the

Bolts when attaching theTail Rotor

Blades.The Tail Blades should be

able to move with a slight amount

of resistance within theTail Blade

Holders.

Tail Set

These Bolts are only used to

compress the boom, please do

not screw them the whole way in.

M2.5x6 Cap

Head Bolt

M3x25 Cap

Head Bolt

M3 Nylon Nut

See Page Team Tips!

Slide theTail Boom through the

Tail Boom Mount. Twist theTail

Belt 90° to the right before

inserting it to the Idler Pulleys.

M3x40 Cap

Head Bolt

M2.5x8 SelfTapping Bolt

Page 7

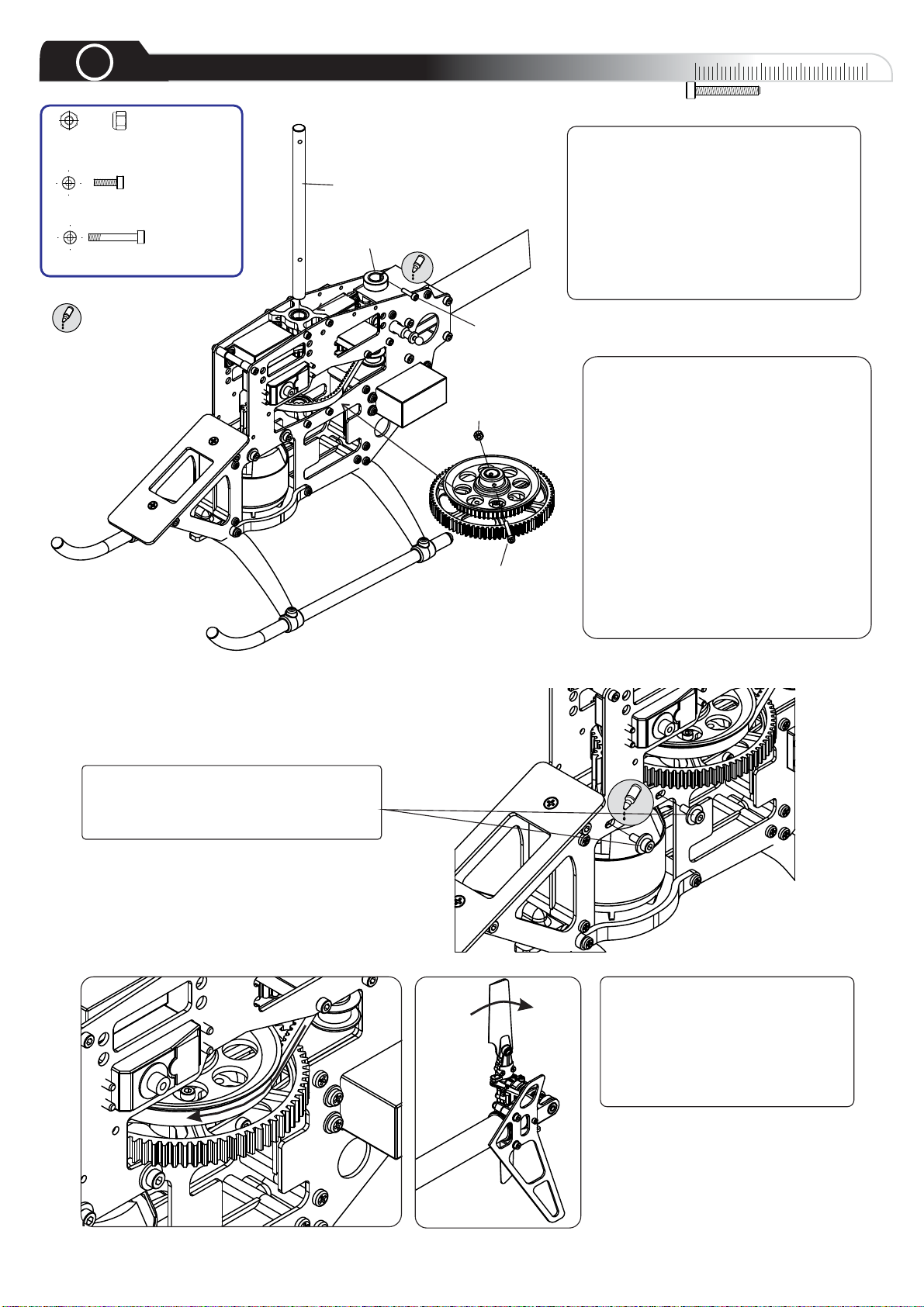

4

Main Gear

0

10

30

20

40

M2.5 Nylon Lock Nut x1

M2.5x10 Cap Head Bolt x1

M2.5x18 Shanked Bolt x1

Use Threadlock

Main Shaft

Mast Collar

M2.5x10 Cap

Head Bolt

2.5mm Nylon

Lock Nut

M2.5x18 Shanked

Bolt

See Page Team Tips!

Lift the Main Shaft Collar upwards and

secure to the Main Shaft by slightly

tighten the Lock Screw. It is necessary

to align the Lock Screw through the

hole in the side of the Main Frame.

While securing the Lock Screw, make

sure that you are pushing down on the

Main Shaft so that there will be no

up/down play in the Main Shaft once

the collar is secured.

Gear BacklashAdjustment:

For smooth operation and

performance, it is necessary to adjust

the Gear Backlash properly. Excess

Gear Backlash can cause premature

Gear Wear and damage. Insufficient

Gear Backlash can cause vibration,

as well as overheating of the Motor

and Speed Controller.Adjust the Gear

Backlash by placing one piece of

paper between the Gears to set the

distance. When the Bolts are secure,

remove the paper andtest the Gear

Backlash to insure that there is a

slight amount of free movement

between the gears.

To adjust the correct backlash between

the Motor Pinion and the Main Gear

loose the 4 Motor Mount Bolts, then fix

them tightly with Threadlock.

Check the correct rotation of the

Tail Rotor Blades. The Blade on

the Top moves to the rear. If the

Tail Rotor rotates incorrectly,

simply pull out the main shaft and

twist the Belt in the other

direction.

Page 8

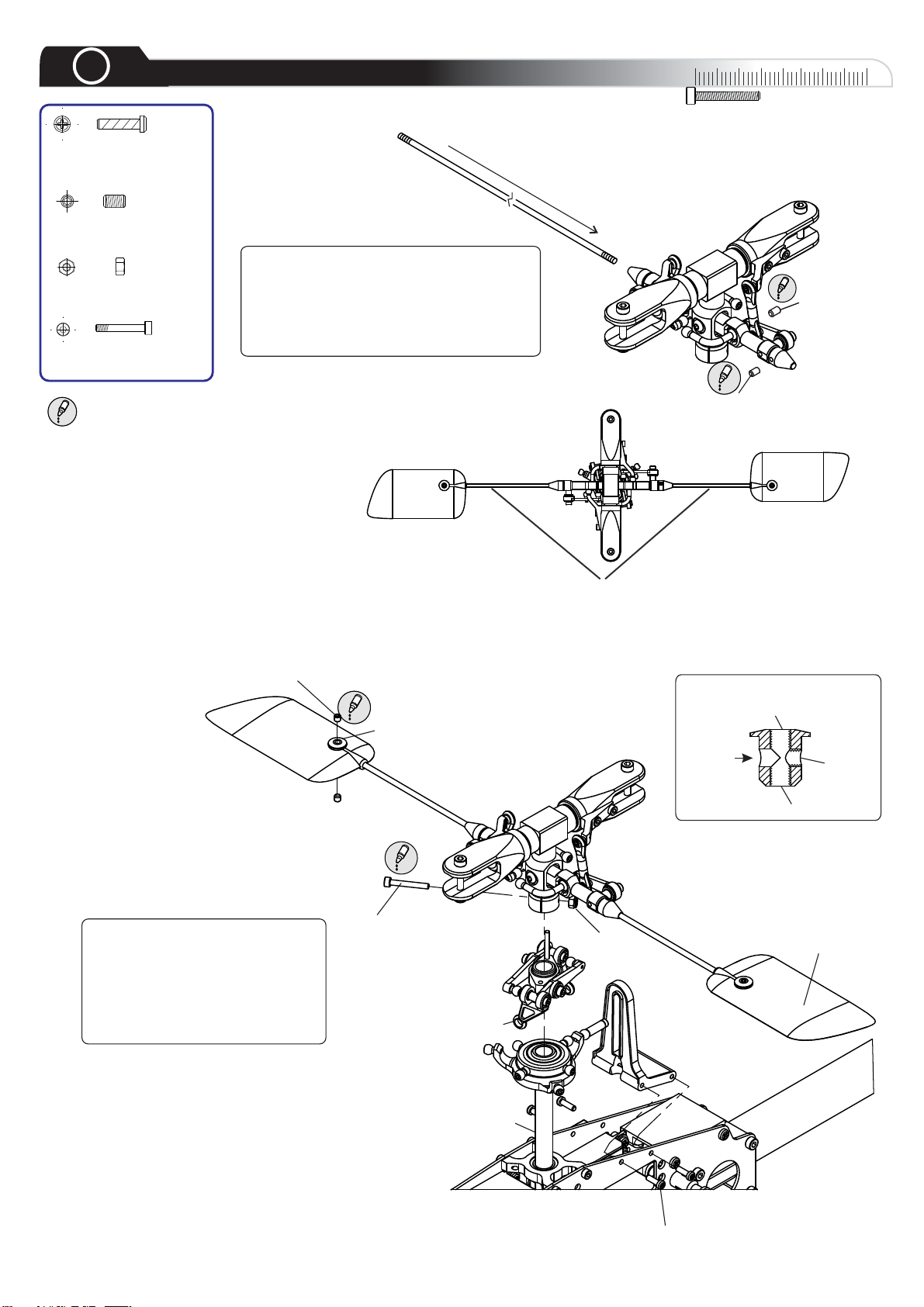

5

M2.5 x8 Self Tapping

Bolt X 4

M3x3 Set Screw x8

2.5mm Nut x1

M2.5x16 Shanked

Bolt x1

Rotor,Washout & Swashplate

P

u

s

h

t

h

e

F

In this step, push the Flybar trough the

Flybar Collar, Flybar Holder and the

Flybar ControlArms using the 3x3mm

set screws to fix theArms and Collars

onto the Flybar, care that both sides of

the Flybar are of equal length.

0

10

l

y

b

a

r

i

n

30

20

M3x3

Set Screw

40

Use Threadlock

See Page Team Tips!

M3x3 Set Screw

Adjust so that each side has exactly the same length

Paddle Insert

M3x3 Set Screw

Paddle Insert

Thread

Flybar

Thread

Thread

Be sure to note the correct

direction of the Flybar Paddles

as shown in the diagram. It is

very important to insure that the

Paddles are in parallel to each

other, as well as to the Flybar

ControlArm Assembly.

See Page Team Tips!

M2.5x16

Shanked Bolt

Washout Link

Main Shaft

2.5mm Nut

M2.5 x8 Self Tapping Bolt

Paddle

Page 9

6

Equipment illustration

0

10

30

20

40

Esc

ESC

Pitch

To Motor

Velcro Tape

Aileron

Elevator

6S Battery

Rudder

Receiver

BEC power line

Ch6

00

00

7

The following Linkage lengths indications are basic values. PLEASE BEAWARE THATTHEY COULD VARY

depend on used Servos andArms. Some fine adjustments are still needed in following setup steps.

Please cut away 4.5mm

from each Ball Link.

Linkage

19mmx2

10

Please cut away 4.5mm

from each Ball Link.

4.5mm

30

20

40

4.5mm

29mm

26mmx2

Page 10

Servo Screw

Servo Arm

2x6mm Cap Head

Bolt

Stainless Balls

For Sport Flying

45.5mm

For 3D Flying

Do not apply plier to resize Ball Links. Pliers could

cause hidden damage to Ball Links and result in

failure when operation.

8

Setup

39.5mmx2

40.5mm

Compass Model Ball Links are build up on

the tight side this allows you to adjust them

to your personal needs. For this we suggest

to use a Ball Link sizing tool.

00

00

10

30

20

40

Pitch

General Flight

5

4

3

2

1

3D Style

5

4

3

2

1

Throttle Pitch

100%

13 deg

85%

70%

4~5 deg

35%

0%

-4 deg

Throttle Pitch

100%

100%

100%

100%

100%

13 deg

6.5 deg

0 deg

-6.5 deg

-13 deg

The Atom 500 total pitch range is

about 26°. If you set the pitch too high

than flight time will be shortened.

Throttle Curve

100%

80%

60%

40%

20%

0%

12345

Throttle Curve

100%

80%

60%

40%

20%

0%

12345

Swash Type Setting

JR Futaba

Swash Type SWH

S3 120 SR3

Aile Elev Pitch

45% 50% 45%

Esc Setup

Timing: 22.5 deg

No Brakes

Very Soft Start

Page 11

A

B

Parallel

Make sure that the Flybar ControlArms and Paddles are in line as shown in the diagram.

Attention:

To do all Basic Setups first UNPLUG

ESC from the receiver then use a 4.8V

Receiver Battery for the setup.

Horizontal

Turn on theTransmitter, set the Throttle Stick into center position for 0 ° Pitch. Use the Subtrim menu to

adjust the 3 Swash ServoArms to level.

Horizontal

C

WashoutArm

Horizontal

Swashplate

Horizontal

Level the Swashplate by adjusting the links from the ServoArms to the Swashplate. Use a

Compass SwashplateTool as guide.Then set level the Washout Arms.

06 0501Swashplate Tool-

D

By adjusting the Links between Swashplate and MixingArms set the MixingArms to a 5° downward position.

Adjust the Links between the MixingArms and the Main Blade Holder to set the Main Blade Pitch to 0°.

°

5

MixingArm

0 Pitch°

Page 12

E

13mm

90°

7°

Use this Hole for Tail Link Ball

With Rudder Stick in middle position, set the Rudder Servo Arm at 90° to the Tail Control Link. Set the Tail

Blades to 7° Pitch.

9

Servo Direction Check

10

30

20

40

00

00

Turn the Transmitter on, your position has to be right behind the helicopters Tail. Make sure that the Swashplate

Mode is set to CCPM 120°. Move the Sticks according to the drawings and check the reaction of the Swashplate

and the Tail Pitch Plate. Check as well your Throttle settings.Adjust your Transmitter settings accordingly.

Mod 1

Mod 2

Swashplate Reaction

Tilt Right

Tilt Left

Aileron Check

Elevator Check

Pitch Check

Tilt Forward

Tilt

Backward

Ascent

Swash Plate

Descent

Rudder Check

Slide left

Tail Pitch Plate

Slide Right

Page 13

10

Canopy

M2.5x6 Self Tapping

Bolt X 2

A

A

B

B

Use AB Glue

ABA

B

M2.5x6 Self

Tapping Bolt

Place the Canopy onto the Frames and mark

the right position of the Canopy Inserts. Apply

AB Glue to fix the Canopy Insert onto the

canopy.

11

Rotor Direction

Canopy

Drill a 6.5mm D

Hole here

Canopy Insert

00

00

10

00

00

10

30

20

20

40

30

40

When the Rotor spins clockwise the Tail Blades should turn

clockwise as well watching the Tail Rotor from the Tail Fin side.

If not Belt is installed the wrong way and has to be corrected.

00

00

12

Pre Flight Check

10

1. Ensure that receiver & transmitter battery are fully charged.

2 Check all bolts and screws are tight..

3 Repeat step 9 to check all servo functions are correct..

4 Ensure tail and gyro direction are correctly set..

5. Check that main blades, paddles and tail blades are installed in the right direction.

6. Check that there are no missing or damaged parts, never fly with any damaged parts.

7. Make sure all electronic devices are firmly fastened and connected.

8. Before starting the motor, make sure the IDLE switch is OFF and throttle stick is in the low position.

9. Only turn off the transmitter after turning off the receiver.

30

20

40

Page 14

Team Tips

General:

The Ball Links on theAtom need to be resized.These Ball Links will NOT break in over time. they

will stay tight and will cause unwanted interactions.

Step 3

:

It is very important to resize the Ball Links for smooth travel, especially on the tail; because issues

like tail wag, sluggish tail, or inconsistent Piro-rate will occur.

To improve '3D'Tail Rotor authority we suggest doing the “Tail Blade Grip Flip”.The result is

a increased stability in 3D flying.

Step 4

:

It is vital not to over tighten the Main Gear Bolt, or it can cause theAutorotation Gear to slightly

warp.This can cause a premature Belt failure, or reduce the lifetime of the Belt.

Step 5

:

LeaveAbout 0.1mm space between the Flybar Collar and the Flybar Holder, this avoids the

Flybar to snap when flying.

Thrust Bearing Direction

Main grips are factory preassembled; in case of reassembling

make absolutely sure you use the correct “ID” ring at the correct

position. Placethe large IDTowards the Main Shaft and the

small I.D.Towards the Blades during assembly.

Main Grip

Apply Grease Here

Larger ID

(IN)

Smaller ID

(OUT)

Page 15

Parts List

Atom 500

Version 2.5/2009

How to order your parts!

1. Check part number on the drawing

2. Use the part number to find the ORDER number on the list

3. Only use ORDER number for your parts order

Copyright Compass Model 2009

As we continue to improve our products, this part list may not reflect all recent product amendmends.

For more information, please refer to www.compassmodel.com

Page 16

06-8104

06-0106N

80-2516

06-0102

61-3062

06-0114

06-5101

80-0206

97-0715

02-0701

06-0108

06-0109

80-2506

60-6124

91-0025

06-0101

91-0003

79-0306

80-0322S

79-0408

63-61245

82-621003

60-6124

82-4101

81-0303

06-0513

81-0303

81-0304

81-0303

06-0514

80-0206S

02-0701

06-0507

81-0303

06-0508

60-2562

61-2562

82-2540

61-2562

80-2512

Main Grip

Thrust Bearing Direction

Apply Grease Here

Larger ID

Smaller ID

(IN)

(OUT)

06-0512

06-0510

06-0511

06-0504

06-0507

80-0206S

02-0701

06-0505

Main grips are factory preassembled; in

case of reassembling make absolutely

sure you use the correct “ID” ring at the

correct position. Place the large ID

Towards the Main Shaft and the small I.D.

Towards the Blades during assembly.

Page 17

Part No. Part Description Order No. Order Description Remark

02-0701 Stainless Link Ball

06-0101 Main Blade Holder

06-0102 Rotor Hub Washer

06-0106N Rotor Hub

06-0108 Main Blade Holder Arm

06-0109 Delrin Dampner

06-0114 Spindle Shaft

06-0504 Flybar Holder

06-0505 Mixing Arm

06-0507 Flybar Control Arm

06-0508 Mixing Arm Collar

06-0510 Flybar

06-0511 Flybar Collar

06-0512

06-0513 Paddle Insert

06-0514 Flybar Weight (Atom 500R)

06-5101 Main Blade Holder complete

06-8104 Rotor Complete

60-2562 Ball Bearing 2.5x6x2.5

60-6124 Ball Bearing 6x12x4

61-2562 Flanged Bearing 2.5x6x2.6

61-3062 Flanged Bearing 3x6x2

63-61245 Thrust Bearing 6x12x4.5

79-0306 Button Head Bolt M3x6

79-0408 Button Head Bolt M4x8

80-0206S Cap Head Bolt 2x6 (Link Balls)

80-0322S Cap Head Bolt M3x22 (shanked)

80-2506 Cap Head Bolt M2.5x6

80-2512 Cap Head Bolt M2.5x12

80-2516 Cap Head Bolt M2.5x16

81-0303 Set Screw M3x3

81-0304 Set Screw M3x4

82-2540 Washer 2.5x4.1x0.2

82-4101 Washer 4.1x10x1

82-621003 Washer 6.2x10x0.3 (spindle)

91-0003 Nylon Nut M3

97-0715 Rubber O-Ring 10x7x1.5

Paddle 11gr (default)

Paddle 7gr (3D)

02-0701

06-5101

06-0106Z

06-0106Z

06-0108S

06-0109

06-0114

06-0504

06-0505Z

06-0507

06-0505Z

06-0510

06-0511

06-0512H

06-0512L

06-0512H

06-0514S

06-5101

06-8104

60-2562

60-6124

61-2562

61-3062

63-61245

79-0306

79-0408

80-0206S

80-0322s

80-2506

80-2512

80-2516

81-0303

81-0304

82-2540

82-4101

82-621003

91-0003

97-0715

Stainless Link Balls 10 pcs/bag

Main Blade Holder set (Atom 500) 1 set/bag

Rotor Hub set (Atom 500) 1 set/bag

Rotor Hub set (Atom 500) 1 set/bag

Main Blade Holder Arm set (Atom 500) 2 set/bag

Delrin Dampner (Atom 500) 2 pcs/bag

Spindle Shaft set (Atom 500) 3 pcs/bag

Flybar Holder w. Bearings (Atom 500) 1 set/bag

Mixing Arm set (Atom 500) 2 set/bag

Flybar Control Arm set (Atom 500) 2 pcs/bag

Mixing Arm set (Atom 500) 2 pcs/bag

Flybar set (Atom 500) 3 pcs/bag

Flybar Collar set (Atom 500) 1 set/bag

Paddle set 11g default (Atom 500) 1 set/bag

Paddle 7gr 3D (Atom 500) 1 set/bag

Paddle Insert set (Atom 500) 1 set/bag

Flybar Weight set (Atom 500R) 1 set/bag

Main Blade Holder complete set (Atom 500) 1 set/bag

Rotor set complete w. Flybarholder (Atom 500) 1 set/bag

Ball Bearings 2.5x6x2.5 2 pcs/bag

Ball Bearings 6x12x4 2 pcs/bag

Flanged Bearings 2.5x6x2.6 4 set/bag

Flanged Bearings 3x6x2 4 set/bag

Thrust Bearings 6x12x4.5 2 pcs/bag

Button Head Bolts M3x6 10 pcs/bag

Button Head Bolts M4x8 10 pcs/bag

Cap Head Bolts 2x6 (Link Balls) 10 pcs/bag

Cap Head Bolts M3x22 (shanked) 2 pcs/bag

Cap Head Bolts M2.5x6 10 pcs/bag

Cap Head Bolts M2.5x12 10 pcs/bag

Cap Head Bolts M2.5x16 2 pcs/bag

Set Screws M3x3 10 pcs/bag

Set Screws M3x4 10 pcs/bag

Washers 2.5x4.1x0.2 10 pcs/bag

Washers 4.1x10x1 10 pcs/bag

Washers 6.2x10x0.3 (spindle) 10 pcs/bag

Nylon Nuts M3 10 pcs/bag

Rubber O-Ring set10x7x1.5 4 pcs/bag

Page 18

61-2052

80-0205

80-2510

61-2052

82-2540

61-2562

82-2540

02-0701

06-0503

06 8502-

06-0518

80-0206S

61-2562

06-0520

80 0206-

80-2510

80-2518

06-0607

06 0410S-

06-8421

06-0608

91 0025-

06-4502

80-2508

06-4603

06 8602-

60-10153

62-101412

06-0603

6 -1010 53

06-0605

Page 19

Part No. Part Description Order No. Order Description Remark

02-0701 Stainless Link Ball

06-0410S Swashplate Pin

06-0503 Washout Base

06-0518 Washout Link

06-0520 Washout Control Arm

06-0603 Autorotation Hub

06-0605 Autorotation Sleeve

06-0607 Main Shaft (Ø 8mm)

06-0608 Main Shaft Lock Clamp (Ø 8mm)

06-4502 Main Pulley

06-4603 Main Gear

06-8421 Swashplate

06-8502 Washout complete

06-8602 Main Gear w. Pulley Assembly

60-10153 Ball Bearing 10x15x3

61-2052 Flanged Bearing 2x5x2.5

61-2562 Flanged Bearing 2.5x6x2.6

62-101412 One Way Bearing 10x14x12

80-0205 Cap Head Bolt M2x5

80-0206S Cap Head Bolt 2x6 (Link Balls)

80-2508 Cap Head Bolt M2.5x8

80-2510 Cap Head Bolt M2.5x10

80-2518 Cap Head Bolt M2.5x18

82-2540 Washer 2.5x4.1x0.2

91-0025 Nylon Nut M2.5

02-0701

06-0410S

06-0503S

06-0518

06-0520Z

06-0603Z

06-0605

06-0607

06-0608S

06-4502

06-4603

06-8421

06-8502

06-8602

60-10153

61-2052

61-2562

62-101412

80-0205

80-0206S

80-2508

80-2510

80-2518

82-2540

91-0025

Stainless Link Balls 10 pcs/bag

Swashplate Pin Set (Atom 500) 1 set/bag

Washout Base set (Atom 500) 1 set/bag

Washout Links (Atom 500) 2 pcs/bag

Washout Control Arm set (Atom 500) 1 set/bag

Autorotation Hub w. Bearing (Atom 500) 1 set/bag

Autorotation Sleeve (Atom 500) 1 pcs/bag

Main Shaft (Atom 500 Ø 8mm) 1 pcs/bag

Main Shaft Lock Clamp set (Atom 500 Ø 8mm) 1 set/bag

Main Pulley (Atom 500) 1 pcs/bag

Main Gear (Atom 500) 1 pcs/bag

Swashplate complete (Atom 500) 1 set/bag

Washout set complete (Atom 500) 1 set/bag

Main Gear w. Pulley Assembly (Atom 500) 1 set/bag

Ball Bearings 10x15x3 2 pcs/bag

Flanged Bearings 2x5x2.5 4 pcs/bag

Flanged Bearings 2.5x6x2.6 4 pcs/bag

One Way Bearing 10x14x12 1 set/bag

Cap Head Bolts M2x5 10 pcs/bag

Cap Head Bolts 2x6 (Link Balls) 10 pcs/bag

Cap Head Bolts M2.5x8 10 pcs/bag

Cap Head Bolts M2.5x10 10 pcs/bag

Cap Head Bolts M2.5x18 2 pcs/bag

Washers 2.5x4.1x0.2 10 pcs/bag

Nylon Nuts M2.5 10 pcs/bag

Page 20

06-8203

07 0818-

82 3- 504

61 3084-

06 0811-

78 0308-

(- )06 4308

(- )06 4310

06 0302-

06 4309-

02 1805-

06 0830R-

06 0822-

06 0606-

9 00031-

60 8165-

06 0905-

02 0849-

80 0306-

C5016

f

06 0822-

02 0845-

06 0843-

f

e

e

e

02 825-1

02 0805-

-

06 8203

a

a

c

c

b

06 0828-

61 3084-

80 0314-

81 0316-

d

d

a

a

a

a

a

a

b

e

e

e

06 0305-

e

e

06 0830L-

a:

80 2506-

80 0308-

b:

c:

82 3201-

d:

95 2508-

e:

95 031080 0306-

f:

80 0340-

06 0812-

02 0820-

06 0827-

06 0818-

81 0305-

Page 21

Part No. Part Description Order No. Order Description Remark

02-0805 Cross Member

02-0820 Skid End Caps

02-0845 Frame Member

02-0849 Frame Member

02-1805 Cross Member

02-1825 Tail Boom Mount

06-0302 Motor Mount

06-0305 Frame Connector(Plastic)

06-0606 Bearing Block

06-0811 Battery Tray

06-0812 Canopy Standoff

06-0818 Landing Gear Skid

06-0822 Cross Member

06-0827 Landing Gear Strut

06-0828 Guide Pulley

06-0830L Main Frame Left Atom R (G10)

06-0830LT Main Frame Left (Carbon)

06-0830R Main Frame Right Atom R (G10)

06-0830RT Main Frame Right (Carbon)

06-0843 Gyro Mount

06-0905 Swashplate Guide

06-4308 Pinion Gear 8T (Atom R)

06-4309 Pinion Gear 9T (default)

06-4310 Pinion Gear 10T (3D extreme)

06-8203 Guide Pulley set

07-0818 Guide Pulley Mount

60-8165 Ball Bearing 8x16x5

61-3084 Flanged Bearing 3x8x4

78-0308 Flat Head Bolt M4x8

80-0306 Cap Head Bolt M3x6

80-0308 Cap Head Bolt M3x8

80-0314 Cap Head Bolt M3x14

80-0340 Cap Head Bolt M3x40

80-2506 Cap Head Bolt M2.5x6

81-0305 Set Screw M3x5

81-0316 Set Screw M3x16

82-3201 Washer 3.2x10x1.2

82-3504 Washer 3.2x5.2x0.4

91-0003 Nylon Nut M3

95-0310 Self Tapping Screw M3x10

95-2508 Self Tapping Screw M2.5x8

C5016 BL Motor for Atom 500 6S

02-0805

02-0820

02-0849S

02-0849S

02-1805

02-1825S

06-0302S

06-0305

06-0606Z

06-0811S

06-0812

06-0818S

06-0822

06-0827

06-0828Z

06-0830L

06-0830LT

06-0830R

06-0830RT

06-0843

06-0905

06-4308

06-4309

06-4310

06-8203

07-0818

60-8165

61-3084

78-0308

80-0306

80-0308

80-0314

80-0335

80-2506

81-0305

81-0316

82-3201

82-3504

91-0003

95-0310

95-2508

C-5016

Cross Member set 5 pcs/bag

Skid End Caps 4 pcs/bag

Frame Member set 2 pcs/bag

Frame Member set 2 pcs/bag

Cross Member set 2 pcs/bag

Tail Boom Mount w, Bolts 1 set/bag

Motor Mount w. Bolts 1 set/bag

Frame Connectors Plastic w. Bolts 2 pcs/bag

Bearing Block w. Bearing (Atom 500) 1 pcs/bag

Battery Tray w, Bolts (Atom 500) 1 pcs/bag

Canopy Standoff set (Atom 500) 2 pcs/bag

Landing Gear Skids w. Caps (Atom 500) 2 pcs/bag

Cross Member set (Atom 500) 2 pcs/bag

Landing Gear Struts (Atom 500) 2 pcs/bag

Guide Pulley set (Atom 500) 2 set/bag

Main Frame Left Atom R (G10) 1 pcs/bag

Main Frame Left (Carbon) 1 pcs/bag

Main Frame Right Atom R (G10) 1 pcs/bag

Main Frame Right (Carbon) 1 pcs/bag

Gyro Mount 1 pcs/bag

Swashplate Guide (Atom 500) 1 pcs/bag

Pinion Gear 8T (Atom R) 1 set/bag

Pinion Gear 9T (default) 1 set/bag

Pinion Gear 10T (3D extreme) 1 set/bag

Guide Pulley set (Atom 500) 1 set/bag

Guide Pulley Mount set 1 set/bag

Ball Bearings 8x16x5 2 pcs/bag

Flanged Bearings 3x8x4 2 pcs/bag

Flat Head Bolts M4x8 10 pcs/bag

Cap Head Bolts M3x6 10 pcs/bag

Cap Head Bolts M3x8 10 pcs/bag

Cap Head Bolts M3x14 10 pcs/bag

Cap Head Bolts M3x40 10 pcs/bag

Cap Head Bolts M2.5x6 10 pcs/bag

Set Screws M3x5 10 pcs/bag

Set Screws M3x16 10 pcs/bag

Washers 3.2x10x1.2 10 pcs/bag

Washers 3.2x5.2x0.4 10 pcs/bag

Nylon Nuts M3 10 pcs/bag

Self Tapping Screws M3x10 10 pcs/bag

Self Tapping Screws M2.5x8 10 pcs/bag

BL Motor for Atom 500 6S 1 set/bag

Page 22

06-5210

06 0210A-

80 0208-

80 2512-

60 4094-

81 0305-

06 0209-

80 2508-

82 2507-

63 4094-

06 0216-

80 0206s-

02 0701-

06 0210B-

06 0208-

06 0213-

06 0205-

06 0204-

61 6103-

06 0222-

06 0206-

06-5206

61 6103-

06 0207-

98 1263-

61 4104-

82 4264-

06 4205-

06 4204-

61 4104-

06 0214-

06 0212-

Page 23

Part No. Part Description Order No. Order Description Remark

02-0701 Stainless Link Ball

06-0204 Tail Pitch Plate

06-0205 Tail Blade Link

06-0206 Tail Pitch Slider

06-0207 Tail Slider Ring

06-0208 Tail Pitch Lever (crank)

06-0209 Tail Rotor Hub

06-0210AB Tail Blade Holder

06-0212 Tail Gear Box

06-0213 Tail Pitch Lever (H)

06-0214 Tail Shaft

06-0216 Tail Blade

06-0222 Guide Pin Bolt

06-4204 Tail Pulley

06-4205 Tail Pulley Cover

06-5206 Tail Control set complete

06-5210 Tail Rotor set complete

60-4094 Ball Bearing 4x9x4

61-4104 Flanged Bearing 4x10x4

61-6103 Flanged Bearing 6x10x3

63-4094 Thrust Bearing 4x9x4

80-0206S Cap Head Bolt 2x6 (Link Balls)

80-0208 Cap Head Bolt M2x8

80-2508 Cap Head Bolt M2.5x8

80-2512 Cap Head Bolt M2.5x12

81-0305 Set Screw M3x5

82-2507 Washer 2.7x8x0.8

82-4264 Washer 4.2x6.4x.026

98-1263 Belt (Atom 500)

02-0701

06-0204S

06-0205S

06-0206Z

06-0207

06-0213S

06-0209

06-0210AB

06-0212Z

06-0213S

06-0214

06-0216

06-0222

06-4204S

06-4204S

06-5206

06-5210

60-4094

61-4104

61-6103

63-4094

80-0206S

80-0208

80-2508

80-2512

81-0305

82-2507

82-4264

98-1263

Stainless Link Balls 10 pcs/bag

Tail Pitch Plate w. Pin (Atom 500) 1 set/bag

Tail Blade Links w, Pin (Atom 500) 2 set/bag

Tail Pitch Slider w. BB (Atom 500) 1 set/bag

Tail Slider Ring (Atom 500) 1 pcs/bag

Tail Pitch Lever set (Atom 500) 1 set/bag

Tail Rotor Hub (Atom 500) 1 pcs/bag

Tail Blade Holder (Atom 500) 2 pcs/bag

Tail Gear Box 1 set/bag

Tail Pitch Lever set (Atom 500) 1 set/bag

Tail Shaft set (Atom 500) 2 pcs/bag

Tail Blade set 2 pcs/bag

Guide Pin Bolts 2 pcs/bag

Tail Pulley set (Atom 500) 1 set/bag

Tail Pulley set (Atom 500) 1 set/bag

Tail Control set complete (Atom 500) 1 set/bag

Tail Rotor set complete (Atom 500) 1 set/bag

Ball Bearings 4x9x4 5 pcs/bag

Flanged Bearings 4x10x4 2 pcs/bag

Flanged Bearings 6x10x3 2 pcs/bag

Thrust Bearings 4x9x4 2 pcs/bag

Cap Head Bolts 2x6 (Link Balls) 10 pcs/bag

Cap Head Bolts M2x8 10 pcs/bag

Cap Head Bolts M2.5x8 10 pcs/bag

Cap Head Bolts M2.5x12 10 pcs/bag

Set Screws M3x5 10 pcs/bag

Washers 2.7x8x0.8 10 pcs/bag

Washers 4.2x6.4x.026 10 pcs/bag

Belt (Atom 500) 1 pcs/bag

Page 24

F 06 0430--

(F 06 0430T)--

06-8202

06-0823AB

06-0852

02 0853-

06 0851-

06-0826

06 0707FU-

(06 0707JR)-

91 003-0

420- 455

VBT270

80-0325

8 -32201

06-0817

02-0818

40 2015-

Linkages

40 2010-

02 0701-

40 2010-

40 2025-

40 2025-

40 2030-

02 0709-

06 0707FU-

(06 0707JR)-

Page 25

Part No. Part Description Order No. Order Description Remark

02-0709 Ball Links

02-0818 Tail Linkrod Guide

02-0853 Canopy Dampner

06-0817 Tail Fin G10

06-0817T Tail Fin Carbon

06-0823AB Vertical Fin Clamp

06-0826 Tail Boom

06-0851 Canopy Insert

06-0852

06-8202 Tail Gear Box set

06-0707FU Servo Arm (FUTABA)

06-0707JR Servo Arm (JR)

40-2455 Tail Link Rod

40-2010 Link Rod 10mm

40-2015 Link Rod 15mm

40-2025 Link Rod 25mm

40-2030 Link Rod 30mm

80-0325 Cap Head Screw M3x25

82-3201 Washer 3.2x10x1.2

91-0003 Nylon Nut M3

VBT270 Velcro Binding Tape 270x20

F-06-0430 Compass FG Blade 430mm

F-06-0430T Compass Carbon Blade 430mm

Painted FG Canopy (Atom yellow)

FG Canopy White (Atom)

02-0709

02-0818S

02-0853

06-0817

06-0817T

06-0823AB

06-0826

06-0851

06-0852S

06-0852W

06-8202

06-0707FU

06-0707JR

40-2455

E-LG-04

E-LG-04

E-LG-04

E-LG-04

80-0325

82-3201

91-0003

VBT270

F-06-0430

F-06-0430T

Ball Links 10 pcs/bag

Tail Linkrod Guide set 4 pcs/bag

Canopy Dampner 4 set/bag

Tail Fin G10 1 pcs/bag

Tail Fin Carbon 1 pcs/bag

Vertical Fin Clamp 1 set/bag

Tail Booms (Atom 500) 2 pcs/bag

Canopy Inserts 1 set/bag

Painted FG Canopy (Atom yellow) 1 set/bag

FG Canopy White (Atom) 1 set/bag

Tail Gear Box set Complete (Atom 500) 1 set/bag

Servo Arm set (FUTABA) 1 set/bag

Servo Arm set (JR) 1 set/bag

Tail Link Rod 1 pcs/bag

Link Rod set (Atom 500) 1 set/bag

Link Rod set (Atom 500) 1 set/bag

Link Rod set (Atom 500) 1 set/bag

Link Rod set (Atom 500) 1 set/bag

Cap Head Screws M3x25 10 pcs/bag

Washers 3.2x10x1.2 10 pcs/bag

Nylon Nuts M3 10 pcs/bag

Velcro Binding Tape 270x20 4 pcs/bag

Compass FG Blade set 430mm 1 pair/bag

Compass Carbon Blade set 430mm 1 pair/bag

Special Thanks To:

John Lancaster

Dirk Everaert

Jelte De Vries

David Ketelhut

Devin LeBlanc

Jenkins Cortez

Jonas Schelpe

Brian Tran

Page 26

COMPASS MODEL (HK) LIMITED

www.compassmodel.com

Loading...

Loading...