Page 1

Enclosure 4200 Family

LVD Disk Enclosure

User Guide

Part Number: EK–SW2ZS–UA. B01 / 148451-002

Second Edition (December 1999)

Part Number: EK–SW2ZS–UA. B01 / 148451-002

Compaq Computer Corporation

Page 2

Notice

While Compaq Computer Corporation believes the information included in this manual is correct as

of the date of publicat ion, it is subject to change without notice. Compaq mak es no representations

that the int erconn ect i on of its pr oduc ts in the manner descri be d in this doc umen t wil l not inf ringe on

existi ng o r fut ure paten t r ight s, nor do th e de scri pti ons co nt ained in thi s docu ment imp ly the gr ant ing

of licenses to make , use, or sell equipment or software in accordance w ith the description. N o

responsibility is assumed for the use or relia bility of the firmwa re on equipmen t not supplied by

Compaq or it s affil iated comp anies. Posse ssion, use, or copying of the software described in this

documentation is authorized only pursuant to a valid written license from Compaq, an authorized

sublicensor, or the identified licensor.

© 1999 Digital Equipment Corporation.

All right s reserved . Pr in te d in the U.S .A .

Compaq, StorageWorks w ordmark, D IGITAL, and StorageWork s

Registered in United States Pa tent and Trademarks O ffice and other ju risdicti ons.

All other trademar ks and registered trademarks are the propert y of their respecti ve owners.

Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Second Edition (December 1999)

Part Number: EK–SW2ZS–UA. B01 / 148451-002

Page 3

About This Guide

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

How this Guide is Arranged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Chapter 1

Introducing the Enclosure

Disk Enclosure Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

SCSI Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

High Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Variable Speed Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Status Monitoring and Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Enclosure Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Major Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Element Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Element Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Contents

Chapter 2

Starting the Enclosure

Connecting the SCSI Bus Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Applying Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Verifying Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Chapter 3

I/O Modules

Common Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Configuring the Enclosure SCSI Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Page 4

iv Compaq Enclosure 4200 Family LVD Disk Enclosure User Guide

Module Power Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

SCSI Bus Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Terminator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

SCSI Bus Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Replacing an I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Single-Bus Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Single-Bus I/O Module Status Displa ys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Single-Bus SCSI Address Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Dual-Bus I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Dual-Bus I/O Module Status Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Dual-Bus SCSI Address Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Chapter 4

Environmental Monitoring Unit

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Fault Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Enclosure Status Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Device Swap Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Device Fault Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Replacing an EMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Chapter 5

Disk Drives

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Drive Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Drive Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Drive Blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

Replacing a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

Chapter 6

Enclosure Power and Cooling

Enclosure Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Temperature Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Blower Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Page 5

Replacing a Power Supply or Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Chapter 7

Replacing CRUs

Ordering a CRU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Basic Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Initial Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Replacing a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

Replacing the Variable Speed Blower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Replacing the EMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Replacing a Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Replacing the I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

Appendix A

Regulatory Notices

FCC Class B Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Country-Specific Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Appendix B

Specifications

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–4

Contents v

Glossary

Index

Page 6

vi Compaq Enclosure 4200 Family LVD Disk Enclosure User Guide

Figure 1–1. 14-drive enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Figure 1–2. Disk enclosure (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Figure 1–3. 14-drive enclosure bays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Figure 1–4. Enclosure status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Figure 1–5. Rear -mounted elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Figure 2–1. Single-bus I/O module ca ble connector . . . . . . . . . . . . . . . . . . . . . . . 2–2

Figure 2–2. Dual-bus I/O module cable connectors. . . . . . . . . . . . . . . . . . . . . . . . 2–3

Figure 2–3. Typical front status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Figure 2–4. Rear status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Figure 3–1. Single-bus I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Figure 3–2. Dual-bus I/O module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Figure 3–3. SCSI Bus A connector symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Figure 3–4. SCSI Bus B connector symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Figure 3–5. Single-bus I/O module components . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Figure 3–6. Dual-bus I/O module components. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Figure 4–1. Model 4200-series LVD disk enclosure EMU . . . . . . . . . . . . . . . . . . 4–1

Figure 4–2. Model 4200-series LVD disk enclosure EMU location . . . . . . . . . . . 4–2

Figure 4–3. Drive and Enclosure status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Figure 5–1. 1-Inch disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Figure 5–2. Disk drive LEDs display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Figure 5–3. 1-Inch drive blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

Figure 6–1. Power supply and blower assembly components . . . . . . . . . . . . . . . . 6–1

Figure 7–1. Typical CRU product label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Figure A–1. Typical enclosure certification label . . . . . . . . . . . . . . . . . . . . . . . . A–2

Figures

Page 7

Table 1–1 CRU Replacement Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

Table 2–1 Encl osure –Host Controller Maximum Cable Lengths . . . . . . . . . . . . . . . . . 2–3

Table 2–2 Drive Enclo s ur e—Host C on t rol l er S CSI Cable s . . . . . . . . . . . . . . . . . . . . . 2–4

Table 2–3 Installing SCSI Bus Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Table 3–1 Single-Bus Status LED Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Table 3–2 Single Bus SCSI Bus IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Table 3–3 Dual-Bus Status LED Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Table 3–4 Dual Bus SCSI Bus IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Table 5–1 Drive LED Status Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Table 6–1 Power Supply and Blower Status Dis plays . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Table 7–1 Common Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Table 7–2 Installing a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

Table 7–3 Blower Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Table 7–4 EMU Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Table 7–5 Power Supply Replacement Pr oce dure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Table 7–6 I/O Module Replacement P r ocedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

Table B–1 Disk Enclosure Physical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

Table B–2 Element Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

Table B–3 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

Table B–4 Shipping or Short Term Storage Specifications. . . . . . . . . . . . . . . . . . . . . B–4

Table B–5 AC and DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–4

Tabl es vii

Tables

Page 8

Page 9

About This Guide

Intended Audience

This publication is designed for use by Com paq StorageWorks user s who are responsible for installing

and maintaining the rack mounted (models 4214R and 4254R) and the tower mo unted (models 4214T,

and 4254T) Ultra2 SCSI low voltage differential (LVD) disk enclosures.

How this Guide is Arranged

This manual disc usses the product features and operations from the general to the specific. The major

sections of this publication include:

Chapter 1, “Introducing the Enclosure”

This chapter is a description of the LVD disk enclosure features and element s.

Chapter 2, “Starting the Enclosure”

This chapter disc usses operating an LVD disk enclosure.

Chapter 3, “I/O Modules”

This chapter disc usses the I/O modules functions, operation, and status displays.

Page 10

x Compaq Enclosure 4200 Family LVD Disk Enclosure User Guide

Chapter 4, “Environmental Monitoring Unit”

This chapter desc ribes the EMU and the high av ailabili ty fault bus .

Chapter 5, “Disk Drives”

This chapter describes the disk drives, operation, and status reporting.

Chapter 6, “Enclosure Power and Cooling”

The chapter describes the power supply and blower operation and status reporting.

Chapter 7, “Replacing CRUs”

This chapter describes the procedures for repla cing customer replaceable units (CRUs).

Appendix A, “Regulatory Notices”

This appendix defines the country-specific regulato ry st andards for this product.

Appendix B, “Specifications”

This appendix describes the phys ica l, environmental, and ele ctrical specifications of the LVD disk

enclosure and elements.

Glossary

The glossary defines terms common to t his product.

Index

An alphabetical refe rence to major subjects.

Page 11

About This Guide xi

Documentation Conventions

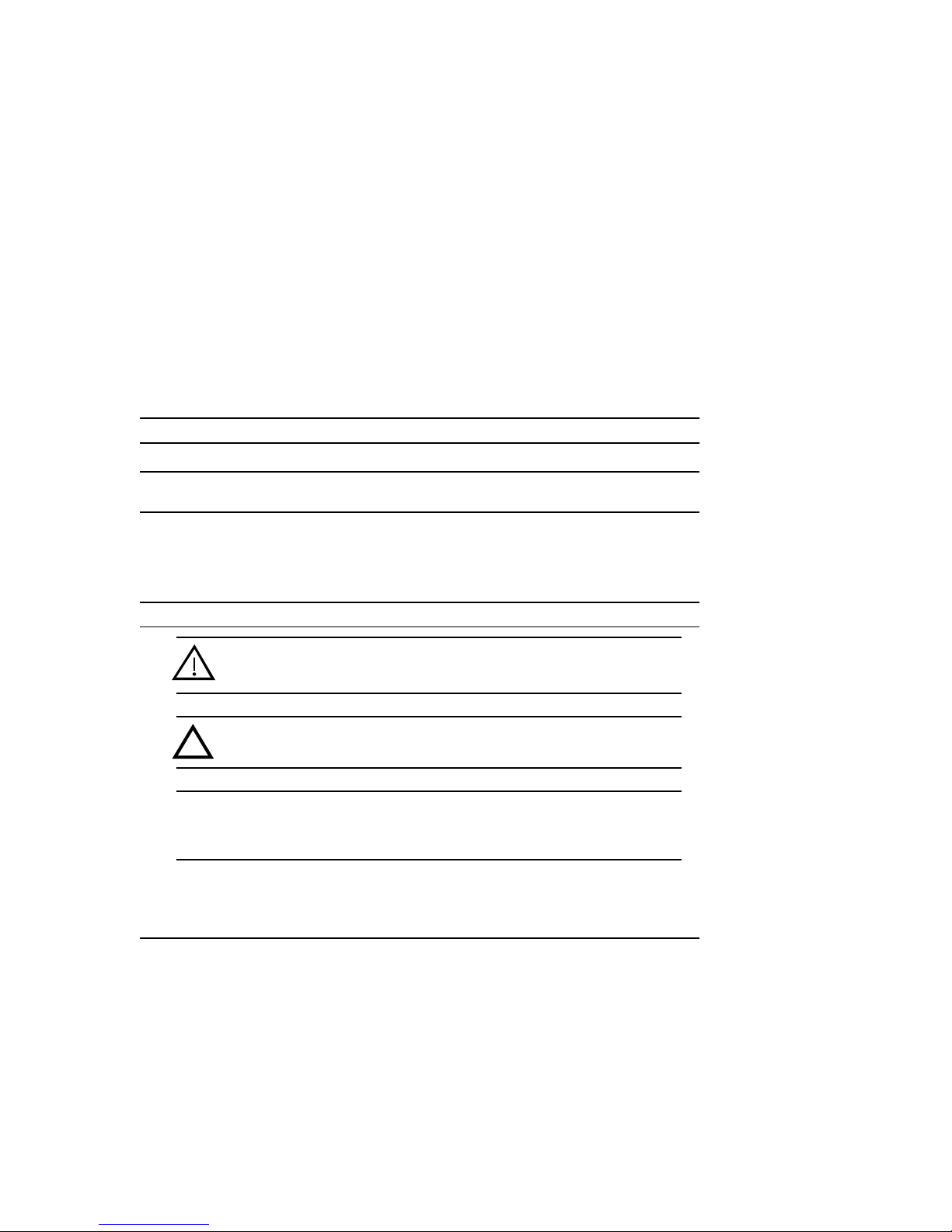

Table 1 is a list of the documentation conventions and symbols used in this publication.

Table 1 Text Symbols

Text Entries

Boldfa c e ty p e—Boldface type indicates the first instance of terms being defined in the text, the

glossary, or both.

italic type—Italic type indicates one of the following.

■ Emphasis

■ A publication title

■ A glossary cross-reference to another glossary entry.

Special Information

WARNING: Warning contains information essential to people’s safety. It advises

users to take or avoid a specific action could result in physical harm to the user.

CAUTION: A Caution contains information that the user needs to know to avoid

damaging the software or hardware.

IMPORTANT: An important note provides information essential to the completion of a task.

Users can disregard information in a note and still complete a task, but they should not

disregard an important note.

NOTE: A note includes information than emphasizes or supplements important points of the

main text. A note supplies information that may apply only in special cases—for example,

memory limitations, equipment configurations, or details that apply to specific versions of a

program.

Page 12

xii Compaq Enclosure 4200 Family LVD Disk Enclosure User Guide

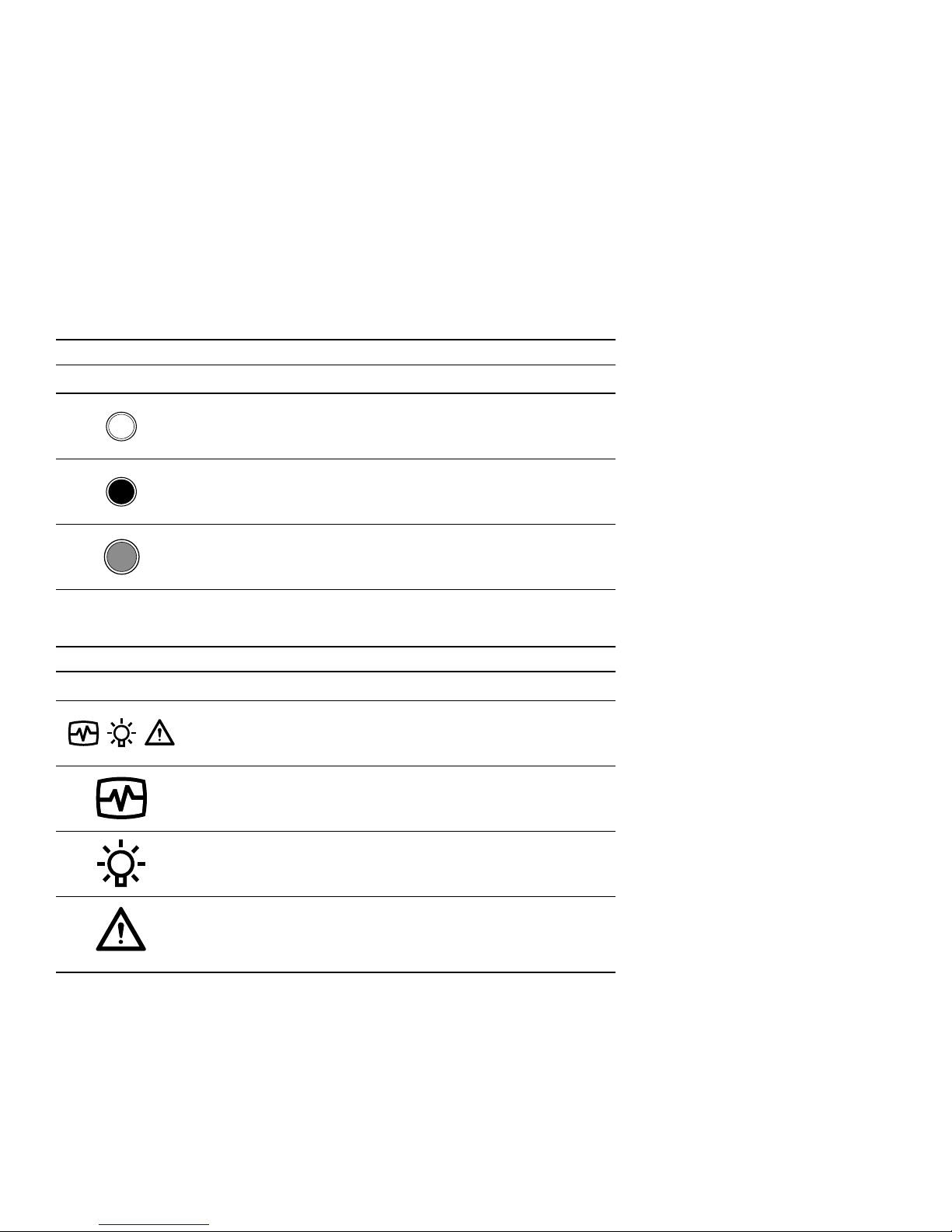

Table 1 Text Symbols (Continued)

Status LED Symbols

LED is OFF.

LED is O

N.

LED is F

LASHING

Table 2 is a list of the symbols that appear on devices and in this publication.

Table 2 Device Symbols

Enclosure Symbols

Enclosure LED label

(Symbol definitions follow.)

Enclosure Status (green)

Enclosure Power (green)

Enclosure Fault (amber)

NOTE: This signal indicates there is an enclosure fault. This does not

indicate that there is possibility of personal injury and is therefore NOT a

WARNING.

Page 13

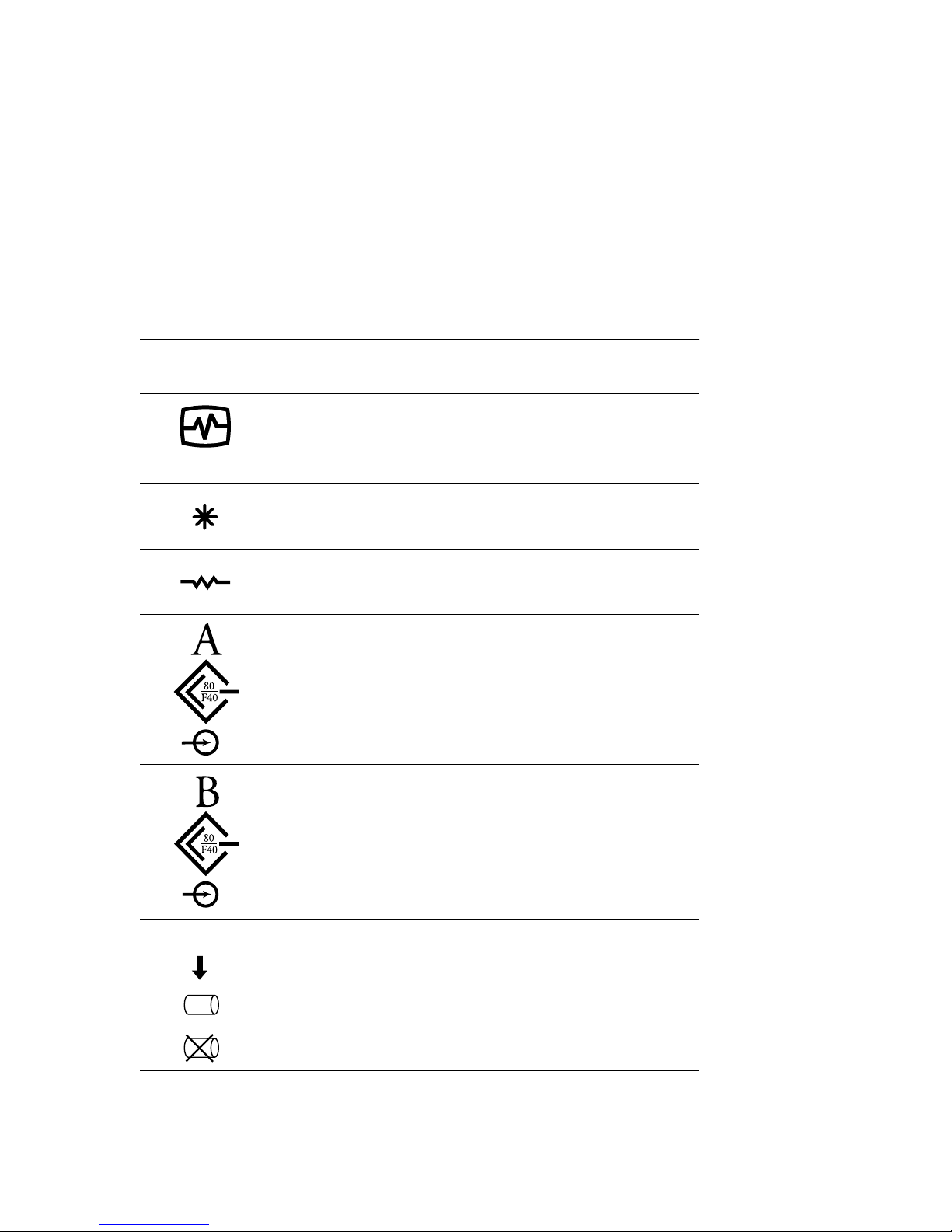

EMU Symbols

I/O Module Symbols

About This Guide xiii

Table 2 Device Symbols (Continued)

EMU Status LED symbol (green)

Power Statu s (ON) LED (green)

Terminator Status LED (green)

SCSI Bus A Connector

Ultra2 SCSI Bus

Input Connector

ISCSI Bus B Connector

Ultra2 SCSI Bus

Input Connector

Drive LED Symbols

Drive Activity LED

Drive Online LED

Drive FAILURE LED

Page 14

xiv Compaq Enclosure 4200 Family LVD Disk Enclosure User Guide

Related Documents

Table 3 lists publications that contain additional informati on relevant to the LVD disk enclosure

products.

Table 3 Related Publications

Publication Title Part Number

Compaq StorageWorks

Disk Enclosure RETMA Rack Mounting Kit Installation Card

Compaq StorageWorks

Disk Enclosure RETMA Rack Mounting Template

Hot-Pluggable Wide-Ultra2 SCSI Hard Drives Installation Card

127430-001

102943-001

386195-001

Compaq StorageWorks

Replacing a Disk Enclosure Environmental Monitoring Unit Installation Guide

Compaq StorageWorks

Replacing a Disk Enclosure Power Supply Installation Guide

Compaq StorageWorks

Replacing a Disk Enclosure Ultra2 SCSI I/O Module Installation Guide

Compaq StorageWorks

Replacing a Disk Enclosure Variable Speed Fan Installation Guide

Compaq StorageWorks

Tower Model 4200T-Series User Guide

148455-001

148454-001

148453-001

148452-001

122942-001

Page 15

Chapter 1

Introducing the Enclosure

This chapter describes the StorageWorks Enclosure 4200 family of low voltage

differential (LVD) disk enclosures (see Figure 1–1 and Figure 1–2). These enclosures

support Wide-Ultra and Wide-Ultra 2 small computer system interface (SCSI )

protocols. The internal bus supports only LVD drives. The external bus (the enclosure to

the host controller bus) support s either Wide-Ultra2 (LVD) and or Wide-Ultra

single-ended (SE) SCSI protocols. The information in this publication is based on using

the Wide Ultra2 LVD SCSI protocol, the most ef ficient means of transferring data.

Figure 1–1. 14-drive enclosure

CXO6854A

Page 16

1–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

CXO7082A

Figure 1–2. Disk enclosure (rear view)

Disk Enclosure Features

The Model 4214- and Model 4254-series enclosures support fourteen, 1-inch, 3.5-inch

form factor hard disk drives or drive blanks. Thes e en cl o s ur es are available in eith er a

rack mountable version (4214R) or in a tower version (4214T). A rack (cabinet) mounted

enclosure requires a RE TMA 3U vertical opening (5.25-i nches) where a “U” is 1.75

inches.

CAUTION: To ensure proper cooling, all drive bays must have either a drive or drive

blank installed.

The enclosure provi des s everal features, including:

■ Hot-pluggable drives, envir onmenta l monitoring un i t (EMU), blowers, and power

supplies are replaceable without stopping SCSI bus data transfers.

NOTE: An element with a port colored latch, tab, or handle is hot pluggable.

Pluggable I/O module and SCSI bus cabl es require stopping all data trans f ers , but do

■

not require removing power before replacing.

■ Depending upon the host controller, the I/O module is capable of supporting

Wide-Ultra2 SCSI (LVD) or Wide-Ultra SCSI (SE) bus operations.

Page 17

SCSI Buses

Introducing the Enclosure 1–3

These encl o su r es do not support the following storage devices:

■ Tape drives

■ CD-ROMs

■ Solid state drives

The enclosure has guides that ensure the drives, EMU, I/O module , and power supplies

(the enclosure elements) align and properly mate with the backplane con nec tors. A

blower guide post on the blower ensures that the blower properly mates with the power

supply. The elements an d th e metal enclosur e provid e electromagnetic interference

(EMI) suppression and control air flow within the enclosure.

The enclosure supports only Wide-Ultra2 SCSI, wide (16-bit), internal LVD buses.

Depending on the host int erfac e, the e xte rnal SCSI b us , the b us from the I/O modul e to the

host can be either Wide-Ultra or Wide-Ultra2, LVD or SE. The SCSI bus type determines

the length of this bus, and therefore, the maximum cable length. The standard Compaq

cable length of 12 ft (3.7 m) ensures satisfactory operation. As for all SCSI buses, the

shorter the cabl e, the mo r e efficient the bus ope ration .

Each enclosure has two internal SCSI buses, with half of the devices on each bus. The

single-b us I/O modu le place s al l the devices o n a si ngle-b us of eit her 10 or 14 devices. The

dual-bus I/O module maintains two internal buses with either 5 or 7 devices on each bus.

High Availability

The high availabil ity features of t he e nclosure are a function of the blowers and the power

supplies.

Variable Speed Blowers

All enclosures have two variable speed blo w ers. In all configurations, the failure of one

blower automatically causes the other blower to operate at a high speed. This ens ures that

the failure of a single b lower does not di sable the enclosure .

NOTE: The maximum bus length is the inverse of the transmission speed. The faster the

transmission rate, the shorter the bus length. For more information about the supported SCSI

bus lengths, see Chapter 3.

Page 18

1–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Power Supplies

In a single pow er s upply configura tion, the fail ure of a po wer supply disabl es the

enclosure. Use the optional redundant power supply configuration to prevent this. In this

config uration, the failure of a single power sup ply or blower does not disable the

enclosure.

Data Integrity

Data inte grity could b e c ompromised if dat a transfers occ ur when there is no DC powe r to

the I/O module or the drives, To avoid inducing error s, the power pins on thes e el ements

are longer than th e data pins. This ensures that power is always present when a data

transfer occurs.

Status Monitoring and Display

The major status monitoring capabilities of these enclosures include:

■ Displaying the enclosure status on the enclosure LEDs

■ Displaying the element status on t he power supply, EMU, drive, and I/O module LEDs

■ Detecting the installation of a blo w er, power suppl y, disk drive, or I/O module

■ Detecting the blower removal of a blower, power supply, disk drive, or I/O module

■ Sensing enclos ure te mperatures

■ Sensing power sup ply voltage, curre nt, and total po wer

Enclosure Layout

The physical la yout of the enclosure is th e same in a rack or a tower. The dri ves mount in

the bays in the front of the enclosure. These bays are numbered from the left (bay

the right (see Figure 1–5 and Figure 1–3). The common method of referring to a drive is

by the bay number. The drive in bay

forth.

CAUTION: There is no direct correlation between the bay number and SCSI bus ID.

The SCSI bus IDs are a function of the bus type (single or dual) and the number of

drives See Chapter 3 for SCSI bus IDs.

1

is drive 1, the drive in bay 8 is drive 8, and so

1

) to

Page 19

1

3

5

2

4

Figure 1–3. 14-drive enclosure bays

7

9

6

8

11

10

12

13

14

15

CXO6728A

Introducing the Enclosure 1–5

1—-

Drive Bays

?

— Enclosure Stat us LEDs

(see Figure1–4)

Page 20

1–6 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

The enclosure status LEDs are located in the front, lower-right corner of the enclosures

(see

Figure 1–4).

Enclosure Status (FLASHING)

Enclosure Power (O

Enclosure Fault (O

Figure 1–4. Enclosure status LEDs

N)

FF)

The I/O module, po wer supplies, blo w ers, EMU, and cables mount in the rear of the

enclosure (see Figure 1–5).

1

EMU

2

Blower 1

3

Power Supply Bay 1, or

Blower Mounting Assembly

4

Blower 2

5

Power Supply Bay 2

6

Single- or Dual-Bus I/O

1

Module

1

2 3 4 5 6

CXO6979A

Figure 1–5. Rear -mounted elements

1. In a singl e power supply configuration, the blower mount s on the blow er mounting assembly.

Page 21

Major Elements

The elements required fo r p roper oper ation of each enclosure include:

■ An EMU

■ Two power supplies, or

1 power supply a nd 1 blower mounting asse mb ly

■ Tw o b low ers

■ A single- or a dual-bus I/ O modul e

■ A dis k drive or disk driv e blank in each bay

Element Functions

A full description of the individual elements an d their functions can be found in the

individual chapters.

Element Replacement

The methods used to replace an element depend upon the following factors:

■ Coul d element replacement affect SCSI bus operation?

When the element being rep laced does not interrupt data transfer nor affect the

operat io n of an o th e r el em en t, the element is “hot-pluggable.”

Introducing the Enclosure 1–7

If replacement of the element, could affect data transfers or the operation of another

element, the element replace me nt method is “pluggable.”

■ Are there any personal safety issues involved?

Whenever there is an issue involving personal safety, such as an electrical hazard, then

the element replacemen t r equires stopping all data t r ansfers the SCSI b u s and

removing power from the enclosure.

■ Are special tools or techniques required?

When element replacement can be completed without employing special tools or

techniques, then the element is a customer replaceable unit (CRU).

When special tool s or techniques are required to replace an element, then the unit is a

field repla ce able unit (FRU). Only qualified, Compaq field service personnel are

authorized to replace FRUs. There are no FRUs for these products.

Table 1–1 identifies the rep lacement method for each el ement.

Page 22

1–8 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Tab l e 1 –1 CRU Replacement Methods

Element Method

Drive

Hot-pluggable

EMU

Blower

I/O Module

Power Supply–Dual

Power Supply–Single

SCSI Bus Cables

1. Replacing an I/O module requires stopping all data transfers.

2. In a singl e power supply configuratio n, the enclosure is disabled when th e power

supply fails.

3. Connecti n g or disconnecting a SCSI bus cable re quires stopping all dat a transfers.

Hot-pluggable

Hot-pluggable

Pluggable

Hot-pluggable

No Power Applied

Pluggable

1

3

2

Page 23

With the enclosure ins talle d in a a r ack or tow er it is necessary t o :

1. Connect the SCS I bus cables.

2. Apply power.

3. Verify proper operation.

Connecting the SCSI Bus Cables

Connecting the enclosure to a host adapter or S CSI bus controll er is si mply a matter of

connecting cables to the I/O module. All I/O modul es have 68-pin, very high density

cable int e rco n nect (VHDCI) connectors.

Chapter 2

Starting the Enclosure

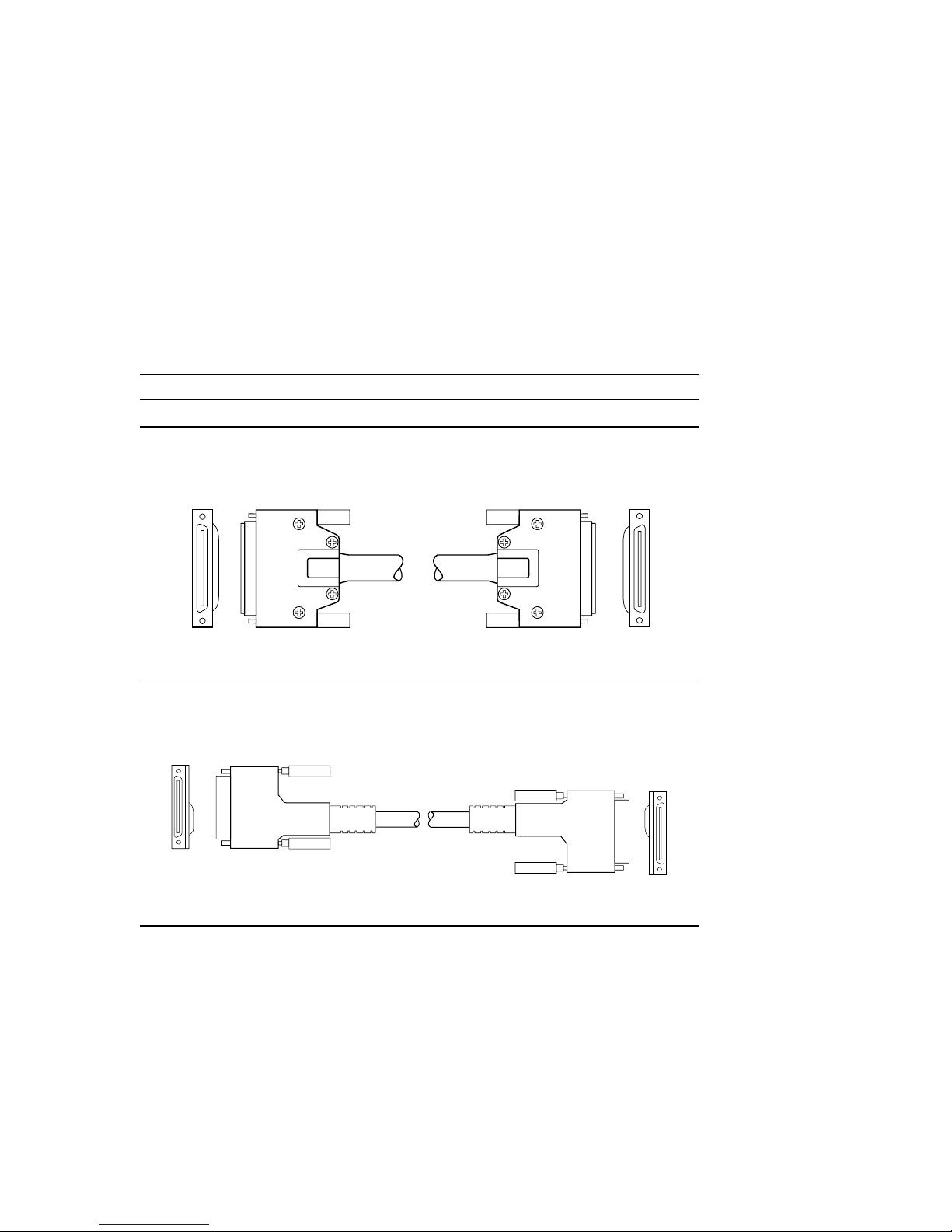

Figure 2 –1 shows the cable connectors for a single-bus configuration. Figure 2–2 sh ow s

the connectors for a dual-bus configuration.

CAUTION: Connecting or disconnecting a SCSI bus cable while data is being

transferred causes the loss of data.

To prevent errors, always stop all data transfers on the SCSI bus before connecting or

disconnecting a cable.

Page 24

2–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

3

1

2

3

CXO7062A

SCSI Bus A connector

Figure 2–1. Single-bus I/O module cable connector

Page 25

Starting the Enclosure 2–3

.

2

SCSI Bus A connector

4

SCSI Bus B connector

1

2

3

4

CXO7063A

Figure 2–2. Dual-bus I/O module cable connectors

The maximum cable length is a function of the bus type (LVD or SE). See Table 2–1 for

the maximum Compaq supported SCSI bus cable lengths.

Table 2–1 Enclosure–Host Controller Maximum Cable Lengths

Bus Type Speed Cable Length

LVD Bus

Wide Ultra SCSI

Wide Ultra2 SCSI

Single-Ended Bus

Wide Ultra SCSI

40 Mb/s 12 m (39.4 ft)

80 Mb/s 12 m (39.4 ft)

40 Mb/s 3.7 m (12 ft)

Page 26

2–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Table 2–2 describes the compatible host controller to LVD disk enclosure cables.

Table 2–2 Drive Enclosure—Host Controller SCSI Cables

Description Lengt h

SCSI Cable—68-pin VHDCI to 68-pin VHDCI

68-conductor SCSI cable with:

2—VHDCI straight male connectors with thumb screws.

SCSI Cable—68-pin VHDCI to 68-pin VHDCI

68-conductor SCSI cable with

2 Vertical Offset VHDCI straight plug connectors with jack screws

3 m (9.8 ft)

CXO5702B

3.7 m (12 ft)

CXO6954A

Page 27

Starting the Enclosure 2–5

Table 2–2 Drive Enclosure—Host Controller SCSI Cables (Continued)

Description Lengt h

Adapter Cable—68-pin High Density to 68-pin VHDCI

68-conductor SCSI cable with

1 High-Density straight plug connector with jack screws

1 Vertical Offset VHDCI straight plug connector with jack screws

3.7 m (12 ft)

CXO6955A

Page 28

2–6 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Tab l e 2 –3 Installing SCSI Bus Cables

1. Stop all SCSI bus data transfers.

2. Align the D-shaped cable connector with D-shaped I/O module connector

1

2

3

3. Firmly seat the cable connector on the module connector.

4. Finger tighten the thumbscrews to fully seat the connector.

5. Restart data transfers over the SCSI bus.

Applying Power

There are no disk encl osure power control switches. Connecting an AC po wer cord from a

power source to the power supply is all that is required. When a power supply has an AC

input, it develops and distributes DC voltages within the enclosure.

3

CXO7062A

Page 29

Verifying Operation

Elements begin operating when power is applied. Ch ec k the en closure status LEDs in the

front, lower rig ht corne r (see Figure 2–3). If the display is not exactly as s ho wn, the re is an

element error con dition. Check the drive and enclosure status LEDs on the front and the

EMU, power suppli es , blowers, and I/O module status LEDs on the rear (see Figur e 2–4)

to determine the defective element.

NOTE: Either of drive displays in Figure 2–3 indicate a properly functioning disk.

Starting the Enclosure 2–7

Figure 2–3. Typical front status LEDs

CXO6919B

Page 30

2–8 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Figure 2–4. Rear status LEDs

CXO6982B

Page 31

Chapter 3

I/O Modules

This chapter discusses the operation and function of the single- (see Figure 3–1) and

dual-bus (see Fi gure 3–2) LVD disk enclosure plugga ble I/ O modules (c ommonly re ferred

to as the “module”). The first part discuss es the general and common features of all

modules. Individual sections discuss the single-bus and dual-bus module functions and

features.

Figure 3–1. Single-bus I/O module Figure 3–2. Dual-bus I/O module

CXO7054A

CXO7053A

Page 32

3–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Common Features

The followi ng features are common to both the si ngle- and the dual-bus I/O modules.

These modules are pluggable elements. Replacing ei ther I/O modules or the cables

requires stopping all data transfers to prev ent the loss of data.

CAUTION: To prevent the loss of data it is necessary to stop all data transfers when

connecting or disconnecting a SCSI bus cable or removing and installing an I/O

module.

Each enclosure requires an I/O module for operation with a wide (16-bit) Ultra2 LVD

SCSI controller. The module is the CRU that connect s the enclosure to th e hos t controller

through a 68-pin, VHDCI connector and a SCSI bus cable. This module can support a

maximum of 14 drives in a single enclosur e or on a single-bus.

Each enclosure has two SCSI buses. Half of the drive bays are on each bus. The I/O

module type (single- or dual-bus) determines the enclosure bus configuration.

■ When using the single-bus I/O module with al l the addressable devices on the sa me

bus (SCSI b us A). This configuration requires one controller or host adapter.

■ When using the dual-bus I/O module half the addressable devices are on SCSI bus A

and the other half are on SCSI Bus B. This configuration requires two controllers or

host adap t ers .

See “Single-Bus SCSI Address Maps” and “Dual-Bus SCSI Address Maps” for

information about the drive SCSI bus addresses.

Configuring the Enclosure SCSI Bus

Installi ng an I/O module automatically configure s the enclosure for eithe r single- or

dual-bus operation. Such installation automatically changes the drive SCSI bus IDs.

CAUTION: To avoid the possibility of losing data, always backup data before installing

a different type I/O module.

Page 33

Module Power Protection

A +5 VDC sensor in the module detec ts overcurr ent conditions. Should this error occur,

the sensor disconnects the volta ge from the module and the power LED is O

disables the modul e until one of the following conditions occurs:

■ The overcurrent condition no longer exists.

■ The defective module is replaced.

SCSI Bus Termination

A SCSI bus is defined by two bus terminators. The external bus has termina tors on the

controller and on the module. Each internal bus has a termina tor on the modu le and on the

backplane. The module connects th e external bus and the internal b u s together. On each

module, there is a green LED (see Figure 3–5) that defines the status of the module

external bus terminator as ei th er termi n ated or unterminated.

I/O Modules 3–3

FF. This

When the module exte rnal SCSI bus is unterminated (the ass ociated LED is O

cannot be transferred.

FF) data

Page 34

3–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Status LEDs

The green LEDs display the st atus of the external SCSI bus terminators and the I/O

module power.

Terminator LED

The I/O module label ide ntifies the SCSI bus LED with a letter (A or B)

above the LED and the terminator symbol below the LED.

■ The LED is ON when the external SCSI bus is terminated and usable.

■ The LED is OFF when the external SCSI bus is unterminated, and therefore unusable.

Power LED

This LED displays the status of the module power . The module label has an

asterisk symbol adjacent to power LED.

■ The LED is ON when the module +5 VDC is correct.

■ The LED is OFF when the module +5 VDC is incorrect or miss ing.

SCSI Bus Connectors

The I/O module label ide ntifies each 68–pin, VHDCI SCSI bus connector wit h one of the

labels shown in Figure 3–3 and Figure 3–4:

Figure 3–3. SCSI Bus A connector symbol Figure 3–4. SCSI Bus B connector symbol

Page 35

Replacing an I/O Module

To replace an I/O module, you must complete the proce dures outlined in Chapter 6,

“Replacing CRUs.”

Single-Bus Module

This section describes th e c omponents and unique features of the single-bus module. T his

module (see Figure 3–5) has one VHDCI connector and two LEDs.

1

1

Latch

2

Status LEDs

EFT– Power

L

RIGHT–SCSI Bus A

termination status

3

SCSI Bus A connector

I/O Modules 3–5

3

Figure 3–5. Single-bus I/O module components

2

CXO7062A

Page 36

3–6 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Single-Bus I/O Module Status Displays

Table 3–1 describes the single-b us I/O module LED status disp lays.

Tab l e 3 –1 Single-Bus Status LED Displays

LED is ON LED is OFF LED is FLASHING

When the I/O module is operational, the display may be

SCSI bus is terminated (LED ON)

Module power present (LED O

When the I/O module is nonoperational, the display may be

SCSI bus is unterminated (LED OFF)

Module power present (LED O

N)

N).

No module power (All LEDs O

Module nonoperational

FF)

Single-Bus SCSI Address Maps

The module assigns a SCSI add r ess to each drive bay in the enclosure using a SCSI

address map (see Table 3–2).

Table 3–2 Single Bus SCSI Bus IDs

Bay 1234567891011121314

14–Disk Enclosure

SCSI

ID

00 01 02 03 04 05 08 09 10 11 12 13 14 15

Page 37

Dual-Bus I/O Module

This sectio n des cribes the unique fe atures and components of the dual-bus modul e. This

module (see Figure 3–6) is easily identifiable by the two VHDCI connectors and the three

LEDs.

1

2

3

1

Latch

2

SCSI Bus A connector

3

Status LEDs

EFT–Power

L

IDDLE—SCSI bus A

M

termination status

R

IGHT–SCSI bus B

termination status

4

SCSI Bus B connector

I/O Modules 3–7

4

Figure 3–6. Dual-bus I/O module components

CXO7063A

Page 38

3–8 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Dual-Bus I/O Module Status Displays

Table 3–3 describes.dual-bus I/O module status LEDs displays.

Tab l e 3–3 Dual-Bus Status LED Displays

LED is ON LED is OFF LED is FLASHING

When the I/O module is operational and the external SCSI bus is terminated, the display

may be:

Module power present (LED ON)

SCSI bus A terminated (LED O

SCSI bus B terminated (LED O

When the I/O module is operational and the external SCSI bus is unterminated, the

display may be:

Module power present (LED ON)

SCSI bus A unterminated (LED O

SCSI bus B terminated (LED On)

N)

N)

FF)

Module power present (LED O

N)

SCSI bus A terminated (LED On)

SCSI bus B unterminated (LED O

Module power present (LED O

Backplane Terminator A unterminated (LED O

Backplane Terminator B unterminated (LED O

FF)

N)

FF)

FF)

When the I/O Module is nonoperational, the display may be:

No module power (All LEDS OFF )

Module nonoperational

Page 39

I/O Modules 3–9

Dual-Bus SCSI Address Maps

The module assign s a SCSI address to each dri ve bay in the enclosur e us ing a SCSI

address map (see Table 3–4).

Tab l e 3 –4 Dual Bus SCSI Bus IDs

Bay 1234567891011121314

14–Disk Enclosure

SCSI

ID

00 01 02 03 04 05 08 00 01 02 03 04 05 08

SCSI Bus A SCSI Bus B

Page 40

Page 41

Chapter 4

Environmental Monitoring Unit

The Compaq Stor age Works Environment al Moni toring Unit, the E MU, ( see Figure4–1) is

an integral part of ever y Model 4200 series LVD enclosure. This element per forms several

functions, including monitoring the enclosure operat ion, detecting and indicating errors,

and displaying the EMU and enclosure status.

1

EMU stat u s LE D (g re en)

1

F

LASHING

—EMU Operational

O

N—Internal EMU problem

FF—Internal EMU problem

O

2

Tower LCD panel cable connector

1

For transferring error messages to

LCD panel.

Figure 4–1. Model 4200-series LVD disk enclosure EMU

1. When FLASHING rapidly, the EMU is operational and there is a single–ende d drive

insta lle d in th e en c lo su re.

2

CXO7131A

Page 42

4–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

The EMU mounts in the bay at the left rear of the enclosure (see Figure 4–2).

1

EMU

Functions

1

Figure 4–2. Model 4200-series LVD disk enclosure EMU location

2 3 4 5 6

CXO6979A

The EMU functions includ e:

■ In conjunction with the I/O module, assigning device SCSI bus addresses

■ Monitoring the enclosure operation

■ Detecting and reporting errors

■ Displaying the EMU and enclos ure status

■ Controlling the LEDs

■ In conjunction with Compaq SCSI adapter or RAID controll er, implementing

enclosure services protocols to report status

The enclosure functions and operations t he EMU monitors include:

■ Temperature

■ Power Supplies

■ Blowers

■ Drives

■ EMU internal functions

Page 43

Status LEDs

Environmental Monitoring Unit 4–3

The EMU status LED (see Figure 4–1) displays the status of the EMU and notifies the

user when there is a single-ended drive installed. The thre e status LEDs (see Figure 4–3)

display the status of the EMU and the enclosure, the enclosure powe r, and an enclosure

fault.

EMU and Enclosure

LASHING)

Status (F

Enclosure Power

(O

N)

Enclosure Fault

FF)

(O

CXO7132A

Figure 4–3. Drive and Enclosure status LEDs

The EMU also monito rs the dri v e, power supply, and blower L EDs. The ope ration of thes e

LEDs are describe d in the individua l element chapters.

Page 44

4–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Temperature

The EMU monitors the internal temperature using enclosure mounte d sensors.

■ When the enclosure internal temperature i s 45 °C (113°F) or mor e, the E M U turns ON

the amber Enclosure Fault LED.

■ A power supply automatically shutdown if the interna l power supply temperature

exceeds 85°C (180°F).

■ When the Compaq Insight Manager (CIM) is installe d, it reports an alarm condition

when the ambient temperat u r e re ac h es 5 0°C (122°F).

NOTE: The internal enclosure temperature and the ambient temperature are not the

same. The ambient temperature is the air temperature in an area where the enclosure is

installed. It is also referred to as the enclosure intake air temperature, or room

temperature. The enclosure internal temperature may be significantly higher.

Fault Bus

The active enclosure mana gement services protocol is determined by the Compaq SCSI

adapter or the RAID controller attached to the enclosure. The fault bus is a protocol

supported by the EMU.

The Ultra2 SCSI bus co ntrolle rs and a dapters can co ntrol RAID subsystems , such as thos e

using StorageWorks Model 4200 LVD disk enclosures. Although the bus is a data

interchange facility it does not provide the feat ures necessary to permi t a co ntroller to

monitor enclos ure an d st orage device status. The fault bus provides this funct ion. The

LVD enclosure family and the EMU support the fault bus as described in the following

sections.

The LVD enclosure implementation of the fault bus consis ts of the enclosure status

(SHELF_OK), the device swap (SWAP L), and two fault signals (FAULT_DATA and

FAULT_CLK) signals. These signals provide the controller with the capability to

effectively monitor specific RAID storage subsystem faults. These fault signals can, in

conjunction with the EMU, control the device st atus LEDs to provide visual indicatio ns of

error conditions.

Enclosure Status Signal

This fault bus signal (SHELF_OK) changes state to indicate a change in either an

enclosure powe r supply or cooling blower status.

Page 45

This signal is asserted (high) when all the power supplies and blowers are oper ating

properly. Should any power supply or blower be operating outside of a specif i ed range thi s

signal level is low until the fault is corrected.

Device Swap Signal

This fault bus signal (SWAP) detects the removal or insertion of a storage device on a

SCSI bus caus ing the signa l to gene rate a logic lo w puls e. The SWAP signal for each SCSI

bus indica t es a ch an g e in th e st at u s of th e sto r a ge devi c es on th at bus.

Device Fault Signal

The EMU can control the device status LEDs in the following manner:

■ When the controller detects a device fault, it can cause the EMU to FLASH the spec ific

device status LED at a fast rate.

■ T he c ontr o ll er ca n ca use the EMU to FLASH a sp ecific de vi ce st atu s LED at a slow rate

to identify or “locate” a device.

Environmental Monitoring Unit 4–5

Replacing an EMU

To replace an EMU, you must co mpl ete the procedures outlined in Chapter 6, “Replacing

CRUs.”

Page 46

Page 47

Chapter 5

CXO6696A

Disk Drives

The enclosure supports Compaq hot-pluggable , Wide-Ultra2 SCSI, LVD disk drives. This

chapter descri bes the disk dri ve features, functions, and characte ristics.

The 14-disk enclo sure supports 1.0-inch, 3.5-inch form factor drives mounted in a carrier

Figure 5 –1.

CAUTION: Controlling airflow within the enclosure requires installing a disk

drive or a drive blank in each drive bay.

To avoid overheating, never remove more than 1 drive or drive blank from an

operating enclosure at the same time.

Figure 5–1. 1-Inch disk drive

Page 48

5–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Status Reporting

All drives have three status LEDs (see Figure 5–2) to define the operational status of the

driv e. T o determine the drive status you must observe all three LEDs ( see Table 5–1).

Drive Activity LED

This green LED F

synchronization with the other two LEDs

in response to the EMU locate

command.

Depending on the host controller, this

LED can either F

unison with On-Line LED when there is

SCSI bus activity.

This LED is O

activity.

On-line LED

When the +5 VDC is available and the

disk is properly installed, this green LED

is O

N. When these conditions are not

met, the LED is O

This LED F

with the other two LEDs in response to

the EMU locate command.

Depending on the host controller, this

LED can either F

unison with On-Line LED when there is

CXO6695A

SCSI bus activity.

Drive Failure LED

This amber LED F

synchronization with the other two LEDs

in response to the EMU locate

command.

Depending on the host controller, this

amber LED can F

controller detected error condition.

LASHES in

LASH by itself or in

FF when there is no bus

FF.

LASHES in synchronization

LASH by itself or in

LASHES in

LASH when there is a

Figure 5–2. Disk drive LEDs display

Page 49

Drive Status

The two g reen and one amber LEDs are either ON, OFF, or FLASHING. Since the status

LED displays are easily interpreted, they are the most commonly used indicators of dr ive

status. In some configurations, the host controller can control the status LEDs. The

symbols for these conditions are shown in Table 5–1.

Table 5–1 Drive LED Status Displays

LED is ON LED is OFF LED is FLASHING

Display Status Drive Replacement

When the drive is operational the display may be one of the following:

When this display occurs at initial statup it may mean:

The operational drive is not being accessed.

The drive status is one of the following:

■ The drive is a replacement drive to be rebuilt,

■ The drive is an inactive spare disk.

■ The drive is spinning up during POST.

■ The SCSI controller cannot control LED.

It should change within a few minutes, otherwise the drive is

nonoperational.

The operational drive is not being accessed.

Drive is being rebuilt or Array Capacity expansion in progress

O NOT REPLACE DRIVE

D

Do not replace drive

Disk Drives 5–3

The operational drive is not being accessed.

The drive is configured as part of an array

Drive selected using the Array Configuration Utility. Do not replace drive

The drive is operational and active.

The drive is configured as part of an array

Do not replace drive

Drive may be replaced

Page 50

5–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Table 5–1 Drive LED Status Displays (Continued)

LED is ON LED is OFF LED is FLASHING

Display Status Drive Replacement

The operational drive is being accessed. or spinning-up.

The drive status is one of the following:

■ Replacement drive to be rebuilt,

■ The drive is an inactive spare disk.

■ The drive is spinning up during POST.

■ The SCSI controller cannot control LED.

The operational drive is being accessed.

The drive status is one of the following:

■ Drive is being rebuilt

■ Array Capacity expansion in progress

The drive is operational and active

The drive is configured as part of an array.

When the drive is nonoperational, the display may be one of the following:

The drive is nonoperational.

There is no power to the drive.

Do not replace drive

Do not replace drive

Do not replace drive

Drive may be replaced

There is a drive error and the drive is not active.

Check the GUI for a definition of the problem.

Drive Power

Backplane overcurrent sensors monitor the +5 VDC and +12VDC drive voltages . When

there is a drive overcurrent condition the sensor disconnects the voltage from the drive.

This disable s the dri ve , ensu ring t hat no dat a is writ ten to i t. The dri ve i s dis abled un til one

of the following conditions occ urs:

■ The defective drive is replaced.

■ The overcurrent condition no longer exists.

Drive may be replaced

Page 51

Drive Blank

To maintain the proper enclosure airflow, there must be a drive or a driv e blank in each

driv e bay. The f unction of the dri ve blank Figure 5–1 is to control airflow within a bay.

Disk Drives 5–5

CXO6824A

Figure 5–3. 1-Inch drive blank

Page 52

5–6 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Replacing a Disk

To replace a disk, you must order a replacement using the spare part number (see Chapter

6, “Replaci ng CRUs”).

The disk replacement kit contains detailed replacement instructions.

CAUTION: Removing more than one disk dr ive at a time can cause the enclosure to

overheat. Never remove more than one disk drive at a time.

NOTE: Removing a drive from the enclosure affects the air flow in the enclosure. This can result

in an overheating condition that could affect disk reliability. Compaq recommends installing a

disk drive of equal or greater capacity, or a disk drive blank as soon as possible.

NOTE: For the latest information and instructions about Compaq hard drives, such as

compatibility and installation instructions, refer to the Technical Information area of the

following Compaq website:

http://www.compaq.com/products/servers/storage/enterprise-class.html

Page 53

Chapter 6

Enclosure Power and Cooling

This chapter describes the function and general operation of the enclosure power supply

and Blowers. See Figure 6–1 for major component locations.

1

1

6

5

Power Supply Element

2

AC Input Connector

3

Module Latch

4

Status blower LED

5

Blower Tabs

Figure 6–1. Power supply and blower assembly components

6

Blower Element

3

2

4

5

CXO6809A

Page 54

6–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Enclosure Power

The power supply and blower assem bly mount in the rear of the enclosure. The supply is

auto-ranging and operates on an A C input voltage of 100 to 240 VAC ±10% , 50 to 60 Hz

± 5% (90 to 264 VAC, 47 to 63 Hz).

The DC outputs of this supply are:

■ + 5.1 VDC for the EMU, I/O module, backplane, an d drives

■ +12.1 VDC for the drives.

■ +12.5 VDC for the blower.

The nominal output of each supply is 377W, with a peak output of 475W. Either power

config uration, single or dua l, can support an enclosure with a full complement of disks,

blowers, EMU, and I/O module.

■ A s ingle power supply, the standard configuration, supports seque ntial drive spin-up.

■ T he Compaq recommended dual po wer supply conf igurati on can support simultaneous

drive spin-u p .

The power supply circuitry provides protection against:

■ Overloads

■ Short circuits

■ T hermal protection against cooling system faults .

Power su pply st at u s an d d iagnos t i c in f o rm ation is r ep o r ted to the EMU wi th vol ta ge,

current, and temp erature signals.

See Appendix B, “for the enclosure power specifications.

Power Options

The enclosure can accommodate one or two power supplies. One power s upply is

sufficient to power the enclosure with a full complement of drives.

NOTE: Installing two power supplies, a redundant power configuration, eliminates the power

supply as a single point of enclosure failure. This is the preferred, high-availability configuration.

For complete power redundancy, each supply should be connected to a separate AC power

source.

Page 55

The blower mounting assembly is the e lem ent for mounting the second blower. This

element has no powe r circuitry. It does conta in a circuit board for processing signals to

and from the blower.

Temperature Sensing

The power supply uses the internal temperatur e of the supply to set th e speed of the

blower. The power supply blank can also set the blower speed. The higher the power

supply temperature, the faster the speed of the blower. Should the power supply

temperature e xceed a preset val ue, the power supply is shut down.

Blower Interface

The blower mounts on the rear of the power supply. A power supply connector is the

interface between the b lower and the enclosure. The interfac e signals in clude:

■ Blower speed control to the blower

■ Blower speed to the EMU through the powe r supply

■ Power supply high-s peed enable

■ Blower operating voltage

Enclosure Power and Cooling 6–3

Blowers

The power supply-mounted blowers cool the enclosur e by circulating air through the

enclosure and elements. The rate at which air moves, the airflow, determines the amount

of cooling. Th is airflo w is a function of blower speed (rpm). Thes e blower blowers, under

the control of the EMU or the associated power supply, can operate at multiple speeds.

This ensu res tha t w h en the enclosure temperature changes , the blowers ca n au tomati cally

adjust th e airflow.

Should a blower fail

of the operational blower to high speed. Simultaneously, the error condition is reported to

the user in several ways.

NOTE: The failure of the power supply 12.5 VDC circuit disables the associated blower.

1. Operating at too low a speed or stopped.

1

, EMU and power supply circuitry automatically increase the speed

Page 56

6–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Status Reporting

The green status LED on the blower displays the status of either the power supply or the

blower. See Table 6–1 for definitions of the LED displays.

Tab l e 6 –1 Power Supply and Blower Status Displays

LED Status

Operational Status

Both the power supply and the blower are operational.

The EMU is locating either the power supply or the blower.

Nonoperational Status

Either the power supply or the blower is nonoperational.

When there is a blower problem, the other blower runs at high-speed.

Replacing a Power Supply or Blower

To replace a power supply or blower, you must order a replacement using the spare part

number (see Chapter 7, “Replacing CRUs”).

CAUTION: As long as there is one operational power supply, you can replace a

defective supply without stopping data transfers. This is true whether the power

supply has failed or is failing.

Each power suppl y or blower replac ement kit contain s detailed replacement instructions.

Page 57

Each replacement CRU kit contains detailed replacement instructions. This chapter

describes the gene ral replacement procedures.

Ordering a CRU

To order a CR U, you must use the Compaq spare part numb er.This number is located in

the upper-right corner of the product labe l (see Figure 7–1).

Chapter 7

Replacing CRUs

Figure 7–1. Typical CRU product label

This the firs t six ch ar ac ters of the p ar t nu m b er id entify th e CRU. The last th re e d efin e th e

revisi on level.

ESD Protection

When you replace a CRU, you must take precautions to prevent the possibility of

electrostatic discharge (ESD) damaging sensitive electronic items.

1. Always transport a nd store CRUs in a sta tic-safe contai ner.

CXO7083A

Page 58

7–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

2. Do not remove the CRU from the static-free container until you are ready to install it.

3. Avoid touc hing the CRU connector pins, lead s, or circ uitry.

Basic Replacement Procedures

The procedures in Table 7–1 apply to all the CRU replacement proc edures.

CAUTION: The hot-pluggable power supplies, blowers, EMU, and drives DO NOT

require halting all data transfers on the SCSI bus.

Replacing an I/O module or a SCSI bus cable always requires halting all data transfers

on the SCSI bus.

Table 7–1 Common Replacement Procedures

1. Always transport and store CRUs in a static-safe container.

Before starting the replacement procedure

CAUTION: To prevent ESD damage, never touch the CRU connector pins, leads, or

circuitry.

2. Remove the defective CRU from the enclosure.

3. Remove the replacement CRU from the static safe container and verify that it is a compatible

replacement (refer to Figure 7–1).

4. Align the CRU with the enclosure guide slots.

5. Slide the CRU into the enclosure until it is against the backplane connector.

6. Fully seat the CRU in the enclosure and verify that if operating properly.

After replacing the CRU

7. Place the defective CRU in the static safe container for shipment.

Page 59

Initial Installation

When you are installing an enclosure in a rack or tower you must observe the following

warning.

WARNING: An assembled enclosure (all elements installed) weighs more than 65 lb

(29.5 kg). Moving the assembled enclosure requires a minimum of two individuals.

To safely and easily install the enclosure requires removing the drives, power supply

and blowers, EMU, and I/O module. This reduces the enclosure weight to

approximately 24 lb (11.3 kg). Even though a single person can lift this weight, the

physical size makes it very difficult to install.

Compaq requires a minimum of two individual to install an empty enclosure in a rack

or tower.

The handles cannot support the weight of the enclosure. Only use these handles to

position the enclosure in the mounting brackets. DO NOT use the handles to lift the

enclosure.

Use the proc edures in the fo llowing sections to rem ove al l the elements to make the

enclosure easier to handle. Once the enclosure is mounted you can replace the elements.

Replacing CRUs 7–3

Page 60

7–4 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Replacing a Drive

If a disk driv e fa ils, you must repl ace it with a dri ve or a dri ve bl ank usi ng the proc edure in

Table 7–2.

NOTE: For the latest information and instructions about Compaq hard drives, such as

compatibility and installation instructions, refer to the Technical Information area of the

following Compaq website.

http://www.compaq.com/products/servers/storage/enterprise-class.html

CAUTION: Removing more than one disk dr ive at a time can cause the enclosure to

overheat. Never remove more than one disk drive at a time.

Removing a drive from the enclosure affects the air flow in the enclosure. This can

result in an overheating condition that could affect disk reliability. Compaq

recommends installing a disk drive of equal or greater capacity, or a disk drive blank

as soon as possible

Table 7–2 Installing a Drive

1. Press the Ejector button 1 in and pivot the Release Lever

1

2

2. Pull out on the drive until it is disconnected from the backplane connector.

DO NOT REMOVE THE DRIVE FROM THE ENCLOSURE WHILE THE MEDIA IS ROTATING.

2

to the full, open positi ons.

CXO6826A

Page 61

Replacing CRUs 7–5

Table 7–2 Installing a Drive (Continued)

3. When you are sure that the disk is no longer spinning, remove the drive from the enclosure.

4. Insert the replacement drive or the drive blank part-way into the until it is against the backplane

connector

5. To install a drive blank, press it firmly in to seat it in the connector

2

6. To install a drive, push in on the drive while pivoting the Release Lever

position.

to the full upright

7. Push the Release Lever in until it engages the Ejector button

8. Observe the drive status LEDs (see Chapter 6) to ensure the replacement drive is functioning

properly.

1

.

Page 62

7–6 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Replacing the Variable Speed Blower

NOTE: Removing a blower does not change the airflow within the enclosure. However, do not

remove a blower until the replacement blower is available.

Complete the procedures in Table 7–3 to replace a variabl e spee d blower.

Table 7–3 Blower Replacement Procedure

WARNING: The blower blades rotate at a high speed and do not stop immediately

when power is removed. Avoid touching the rotating blades when removing the

blower.

1. Remove the blower from the power supply by pushing in on the two blower tabs 1 and while

pulling the blower element to the rear.

1

1

CXO6852A

Page 63

Replacing CRUs 7–7

Table 7–3 Blower Replacement Procedure (Continued)

CAUTION: Pressing on the center section of the blower 3 can damage the

blades. Only press on the outer shroud when installing the blower.

2. Align the blower guide post 2 with power supply connector 1. Slide the blower into blower base

4

until the tabs

1

snap into place.

4

2

4

3

CXO6853A

3. The following are indications that the replacement blower is operating properly.

■ The blower starts operating immediately.

■ The blower LED is O

N.

Page 64

7–8 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Replacing the EMU

NOTE: Removing an EMU significantly changes the airflow within the enclosure. Therefore,

always replace it as soon as possible.

The basic procedure for replacing an EMU is the same regardless of the system.

Complete the procedures in Table 7–3 to replace an EMU.

Table 7–4 EMU Replacement Procedure

1. Grasp the EMU handle and pull the EMU out of the enclosure.

2. Insert the replacement EMU in the enclosure.

3. Press the EMU firmly in to seat it in the connector

4. The EMU should start operating immediately.

CXO6911A

Page 65

Replacing a Power Supply

CAUTION: Removing a power supply significantly changes the airflow within the

enclosure. The system could shutdown unless the power supply is replaced within 5

minutes.

NOTE: Replacement power supply assemblies do not include a variable speed blower.

Therefore you must remove the operational blower from the defective power supply and install

it on the new supply before you remove the defective power supply.

Complete the procedures in Table 7–3 to replace a power supply.

Tab l e 7 –5 Power Supply Replacement Procedure

1. When you are replacing the supply in a single power supply configuration before it has failed, you

must stop all data transfers.

2. Disconnect the AC power cord from the defective supply.

WARNING: The blower blades rotate at a high speed and do not stop immediately

when power is removed. Avoid touching the rotating blades when removing the

blower.

Replacing CRUs 7–9

3. Remove the operational blower from the defective power supply by pushing in on the two blower

tabs

1

and while pulling the blower element to the rear.

1

1

CXO6852A

Page 66

7–10 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Tab l e 7 –5 Power Supply Replacement Procedure (Continued)

CAUTION: A Pressing on the center section of the blower

press on the outer shroud when installing the blower.

3

can damage the blades. Only

4. Align the blower guide post 2 with power supply connector 1. Slide the blower into blower base

4

until the tabs

1

snap into place.

4

2

4

3

CXO6853A

Page 67

Replacing CRUs 7–11

Tab l e 7 –5 Power Supply Replacement Procedure (Continued)

5. While lifting up on the module latch 3, grasp the blower element shell 6 and pull the power

supply to the rear.

1

6

5

2

CAUTION: Pressing in on the center section of the blower shroud can damage the blower

blades. To avoid damaging the blower, only press on the outer portion of the blower shroud.

6. While lifting up on the module latch 3, push in on the power supply 1 and the outer blower

6

shroud

7. Press the module latch down to secure the supply in the enclosure.

8. Connect the AC power cord and observe the power supply for proper operation.

■ The blower starts operating immediately.

■ The blower LED is O

■ The blower on the other supply is no longer be operating at high-speed.

until it is fully seated in the enclosure

N.

4

3

CXO6809A

Page 68

7–12 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Replacing the I/O Module

CAUTION: Interrupting the SCSI bus by replacing an I/O module could cause the loss

of data. Therefore, you must stop all SCSI bus data transfers before replacing a

module.

You must stop transfers on both SCSI buses when the enclosure is configured for dual

bus operation.

NOTE: Removing an I/O module significantly changes the airflow within the enclosure.

Therefore, always replace it as soon as possible.

The basic pr ocedure for r eplacing an I /O modul e is the s ame re gardle ss type. Comple te th e

procedure in Table 7–3 to replace an I/O module.

Table 7–6 I/O Module Replacement Procedure

1. After backing up the stored data, stop all data transfers.

2. Stop all transfers on the SCSI bus.

3

3. Disconnect the SCSI bus cable from the module connector

For a dual-bus I/O module, label the cables as remove them.

4. While grasping the module handle, press down on the module latch

the enclosure.

1

2

3

CXO7062A

.

1

and pull the module out of

Page 69

Replacing CRUs 7–13

Tab l e 7 –6 I/O Module Replacement Procedure (Continued)

5. Slide the replacement module into the enclosure.

1

6. While grasping the module handle, press the module latch

enclosure until it is fully seated.

7. Connect the cable connector to the same connectors (see Step 2).

8. Activate the SCSI bus and observe the LEDs to verify that the module is functioning properly.

down and push the module into the

Page 70

Page 71

FCC Class B Certification

This equipment has been tested and f ound to comply with the limits for a Class B digital

devi ce, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable prot ection against harmful interference in a residential installation.

Any changes or modifications made to this equipment may void the users authority to

operate this equipment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to

radio communicati ons. Ho we ve r , the re is no gua rantee that interfe rence will not oc cur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to tr y to cor rect the interferenc e by one or more of the follow ing

measures:

Appendix A

Regulatory Notices

■ Reorient or relocate the receiving antenna.

■ Increase the separation between the equip ment and recei ver.

■ Connect the eq ui p m e nt into an ou t le t on a circu i t di ff er en t from tha t to wh i ch th e

receiver is connected.

■ Consult the dealer or an e xperienced radio/TV technician for help.

Page 72

A–2 Compaq StorageWorks Enclosure 4200 Family LVD Disk Enclosure User Guide

Country-Specific Certifications

Compaq tests all the electronic products for compliance with country-specific regulatory

requirements either as an individual item or as part of an assembly. The produc t label (see

Figure A–1) specifies the re gulations with which the product complies.

NOTE: Elements without an individual product certification label are qualified as part of the next

higher assembly (for example, enclosure, rack, or tower).

CXO7084A

Figure A–1. Typical enclosure certification label

NOTE: The certification symbols on the label depend upon the certification level. For example,

the FCC Class A certification symbol is not the same as the FCC Class B certification symbol.

Page 73

This appendix defines the physical, environmental, and power specifications and the

environmental specifications of the disk enclosure and the elements.

Physical Specifications

WARNING: The weight of the disk enclosure with the elements installed

always requires at least two individuals to move it. Compaq recommends

using fork lifts or hand trucks to move an enclosure in its shipping container.

Appendix B

Specifications

Table B–1 defines the dimensio ns and weights of the enclosure. Table B–2 defines the

dimensions of th e EMU, blowers, I/O module , a nd power supply.

Page 74

B–2 Compaq StorageWorks 4200 Family LVD Disk Enclosure User Guide

Tab l e B–1 Disk Enclosure Physical Specification

Horizontal Orientation Vertical Orientation

Empty Installed Shipping Carton Shipping Carton and

Height

5.16 in (13.1 cm) 5.16 in (13.1 cm) 25.25 in (64.1 cm) 30.25 in (76.8 cm)

Pallet

Depth

Width

Weight

17.625 in (44.8 cm) 17.625 in (44.8 cm) 23.5 in (59.7 cm) 40.0 in (101.6 cm)

19.875 in (50.5cm) 19.875 in (50.5cm) 12.5 in (31.8 cm) 24 in (61 cm)

24 lb (11 kg) 68 lb (31 kg) 96 lb (44 kg) 108 lb (49 kg)

Table B–2 Element Physical Specifications

Vertical Orientation Horizontal Orientation

Installed Shipping Carton

Environmental Monitoring Unit (EMU)

Height

Depth

Width

Weight

Height

Depth

4.5 in (11.4 cm) 8.5 in (21.6 cm)

9.5 in (24.1 cm) 13.0 in (33.0 cm)

1.375 in (3.5 cm) 4.5 in (11.4 cm)

1.3 lb (0.6 kg) 2.3 lb (1.0 kg)

Variable Speed Blower (without power supply)

5.5 in (14.0 cm) 7.5 in (19.0 cm)

3.25 in (6.4 cm) 8.75 in (22.2 cm)

Width

Weight

6.25 in (15.9 cm) 8.0 in (20.3 cm)

1.0 lb (0.5 kg) 2.0 lb (0.9 kg)

Page 75

Height

Specifications B–3

Table B–2 Element Physical Specifications (Continued)

Vertical Orientation Horizontal Orientation

Installed Shipping Carton

I/O Module

4.5 in (12.7 cm) 8.5 in (21.6 cm)

Depth

Width

Weight

Height

Depth

Width

Weight

9.5 in (24.1 cm) 13.0 in (33.0 cm)

1.625 in (4.1 cm) 4.5 in (11.4 cm)

1.3 lb (0.6 kg) 2.3 lb (1.0 kg)

Power Supply (without blower)

4.5 in (12.7 cm) 11.5 in (29.2 cm)

9.5 in (24.1 cm) 16.75 in (42.6 cm)

6.25 in (15.9 cm) 13.0 in (33.0 cm)

4.0 lb (1.8 kg) 6.0 lb (2.7 kg)

Environmental Specifications

To ensure optim um prod uct operation you must maintain the operational environmental

specifications listed in Table B–3. Especially critical is the ambient temperature.

Table B–3 Operating Specifications

Ambient Temperature: 10°Cto+35°C(+50°Fto+95°F) with an average rate of change of 1°C/hour

maximum and a step change of 3°Cor less

Maintaining the optimum ambient temperature within the specified range ensures that the internal