Page 1

NOTICE

The information in this guide is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR

TECHNICAL OR EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN;

NOR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM

THE FURNISHING, PERFORMANCE, OR USE OF THIS MATERIAL.

This guide contains information protected by copyright. No part of this guide may be

photocopied or reproduced in any form without prior written consent from Compaq

Computer Corporation.

© 1995 Compaq Computer Corporation.

All rights reserved. Printed in the U.S.A.

Compaq, Systempro, Deskpro, Compaq Insight Manager,

Registered U.S. Patent and Trademark Office.

ProSignia, Systempro/XL, ProLiant, NetFlex, ROMPaq, and QVision are trademarks of

Compaq Computer Corporation.

The software described in this guide is furnished under a license agreement or

nondisclosure agreement. The software may be used or copied only in accordance with

the terms of the agreement.

Product names mentioned herein may be trademarks and/or registered trademarks of their

respective companies.

MAINTENANCE AND SERVICE GUIDE

Compaq ProLiant 4500R Rack-Mountable Servers

First Edition (May 1995)

Text Number 188471-001

Page 2

CHMP

Page 3

v

PREFACE

This Maintenance and Service Guide is a troubleshooting guide that can be used for

reference when servicing the Compaq ProLiant 4500R Family of Servers.

Compaq Computer Corporation reserves the right to make changes to Compaq

ProLiant Servers without notice.

Symbols

The following text and symbols mark special messages throughout this guide:

WARNING: Text set off in this manner indicates that failure to follow

directions in the warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow

directions could result in damage to equipment or loss of data.

IMPORTANT: Text set off in this manner presents clarifying information or

specific instructions.

NOTE: Text set off in this manner presents commentary, sidelights, or interesting

points of information.

Technician Notes

WARNING: Only authorized technicians trained by Compaq should

attempt to repair this equipment. All troubleshooting and repair procedures are detailed to allow only subassembly/module level repair. Because of the complexity of the individual boards and subassemblies, no

one should attempt to make repairs at the component level or to make

modifications to any printed wiring board. Improper repairs can create a

safety hazard. Any indications of component replacement or printed

wiring board modifications may void any warranty.

CAUTION: To properly ventilate your system, you must provide a

minimum of 30 inches (76.2 cm) of clearance at the back and 25 inches

(63.5 cm) of clearance at the front of the rack.

CAUTION: The computer is designed to be electrically grounded.

To ensure proper operation, plug the AC power cord into a properly

grounded AC outlet only.

Maintenance and Service Guide

Page 4

vi Preface

Locating Additional Information

The following documentation is available to support these products:

n User Documentation

n Compaq Service Quick Reference Guide

n Service Training Guides

n Compaq Service Advisories and Bulletins

n Compaq QuickFind

n Compaq Insight Manager 2.0

Maintenance and Service Guide

Page 5

vii

CONTENTS

Chapter 1

ILLUSTRATED PARTS CATALOG

Compaq ProLiant 4500R Rack-Mountable Server 1-1

Exploded View of the Compaq ProLiant 4500R Mechanical Parts 1-1

Exploded View of the Compaq ProLiant 4500R System Components 1-2

Spares Parts List 1-3

Chapter 2

REMOVAL AND REPLACEMENT PROCEDURES

RACK-MOUNTABLE PRODUCTS SERVICE GUIDELINES 2-1

GENERAL REMOVAL AND REPLACEMENT GUIDELINES 2-1

ELECTROSTATIC DISCHARGE INFORMATION 2-2

PREPARATION PROCEDURES 2-2

REMOVAL AND REPLACEMENT PROCEDURES 2-3

Extending the Server/Removing the Cover Plate 2-3

Removing the Y Brace and Card Bracket 2-4

Mass Storage Devices 2-4

Removable Media Storage Devices 2-4

Hot-Pluggable Hard Drives 2-5

Important Guidelines About Replacing Hot-Pluggable Hard Drives 2-6

Replacing Hot-Pluggable Hard Drives 2-7

Cable Folding and Routing Diagrams 2-8

Cable Diagram for Diskette Drive 2-8

Cable Diagram for Removable Media Storage Devices 2-8

Cable Diagram for Internal Fast-Wide SCSI-2 Devices 2-9

Boards 2-10

Hot-Pluggable Drive Backplane Board 2-10

Memory 2-11

Processor and Option Boards 2-13

System Boards 2-14

Power Supply 2-15

Miscellaneous Parts 2-17

Cooling Fan 2-17

Speaker 2-18

Battery 2-19

Maintenance and Service Guide

Page 6

viii Contents

Chapter 3

DIAGNOSTIC TOOLS

Utility Access 3-1

POWER-ON SELF-TEST (POST) 3-2

POST Error Messages 3-3

DIAGNOSTICS (DIAGS) 3-13

Diagnostic Error Codes 3-13

DRIVE ARRAY ADVANCED DIAGNOSTICS (DAAD) 3-25

Starting DAAD 3-25

DAAD Diagnostic Messages 3-26

RAPID RECOVERY SERVICES 3-35

Automatic Server Recovery 3-35

Configuring the Server for Automatic Server Recovery (ASR) 3-37

Server Health Logs 3-39

System Configuration History Files 3-41

ROMPaq 3-41

Chapter 4

SWITCH AND JUMPER INFORMATION

System Board 4-1

System Maintenance Switch SW1 4-2

SCSI Devices 4-2

Compaq NetFlex-2 Controller 4-5

Chapter 5

PHYSICAL AND OPERATING SPECIFICATIONS

System Unit Specifications 5-2

Power Supply Specifications 5-3

Redundant Power Supply Specifications 5-4

SIMM Specifications 5-5

19-Inch Rack Specifications 5-5

Integrated Fast SCSI-2 Controller 5-6

Integrated 32-Bit Fast SCSI-2/E Controller 5-6

Integrated Fast-Wide SCSI-2 Controller 5-7

32-Bit Fast-Wide SCSI-2/E Controller 5-7

SMART SCSI Array Controller 5-8

NetFlex-2 ENET-TR Controller 5-8

NetFlex-2 DualPort ENET Controller 5-10

NetFlex-3/E Controller 5-10

Maintenance and Service Guide

Page 7

Contents

ix

Chapter 5 Continued...

550-MB Pluggable Fast SCSI-2 Drive Specifications 5-10

1.05-GB Pluggable Drive Specifcations 5-11

2.1-Gigabyte Pluggable Drive Specifications 5-11

4.3-GB Pluggable Drive Specifications 5-11

Internal CD-ROM Drive Specifications 5-12

Tray Load CD-ROM Drive Specifications 5-13

Diskette Drives Specifications 5-14

Maintenance and Service Guide

Page 8

Chapter 1

1-1

ILLUSTRATED PARTS

CATALOG

This chapter provides maintenance and service information for the

Compaq ProLiant 4500R Rack-Mountable Server.

Figure 1-1. Exploded View of the Compaq ProLiant 4500R Server Mechanical Parts

Maintenance and Service Guide

Page 9

1-2 Illustrated Parts Catalog

Figure 1-2. Exploded View of the Compaq ProLiant 4500R Server System

Components

Maintenance and Service Guide

Page 10

Illustrated Parts Catalog

1-3

Table 1-1

Spares Parts List – ProLiant 4500R Rack-Mountable Server

Description Spare Part #

CHASSIS

1 Cover Plate 165683-001

2 Y Brace 169181-001

3 Card Bracket 199729-001

4 Base Frame 169180-001

5 Front Bezel 165692-001

6 Power Switch and LED Bracket 165688-001

6a Power Switch Cover 146779-001

7 Handles 165690-001

8 Drive Guide and Ground Spring (Qty 5 each) 146771-001

9 Speaker 148590-001

10 Fan Jumper (Qty 5) 165691-001

11 Removable Media Bay Trim / Hot-Pluggable Bay Trim 187336-001

12 Cable Management Arm 187367-001

13 Cable Management Arm Bracket 187396-001

14 Fan (Qty 1) 165682-001

15 Modem Bracket 148723-001

16 Bezel Kit (1/6, 1/3, 1/2 Height - Qty 5 each) and Empty

Hot-Pluggable Drive Cover

17 Duplex Option Plate 190170-001

18 Air Baffle Shield 187556-001

19 Option Slot Cover (Qty 5) 141081-001

20 Sliding Rails - 24" (Pair) 165689-003*

21 Thumb Screw Assembly (Qty 3) 148594-001

22 Snap-in card guide 124539-001

23 Snap-in card guide 141181-001

SYSTEM

24 Power Supply 188407-001

25 Redundant Power Supply 488 W (Optional) 165628-001*

BOARDS

26 5/100 Processor Board 184793-001

27 System I/O Board 188414-001

28 Hot-Pluggable Drive Backplane Board 169185-001

29 SCSI Pass-thru Board 199612-001

MEMORY

30 Memory Expansion Board 139947-001

31 4-MB SIMM (80ns) 118741-001

8-MB SIMM (80ns) 128954-001*

16-MB SIMM (80ns) 139143-001*

32-MB SIMM (80ns) 139949-001*

4-MB SIMM (70ns) 141754-001*

8-MB SIMM (70ns) 141755-001*

16-MB SIMM (70ns) 149947-001*

* Not Shown

211449-001

Continued

Maintenance and Service Guide

Page 11

1-4 Illustrated Parts Catalog

ProLiant 4500R Rack-Mountable Spare Parts List Continued

Description Spare Part #

32-MB SIMM (70ns) 149948-001*

64-MB SIMM (70ns) 188489-001*

4-MB SIMM (60ns) 139139-001*

8-MB SIMM (60ns) 139140-001*

16-MB SIMM (60ns) 139141-001*

32-MB SIMM (60ns) 139142-001*

MASS STORAGE

32 1.44-MB, 3.5" Diskette Drive (Standard) 144207-201

33 1.44-MB, 3.5" Diskette Drive (Option) 112565-001*

34 1.2-MB, 5.25" Diskette Drive 112566-001

35 550-MB Pluggable Fast-SCSI-2 Drive 146799-001

36 1.05-GB Pluggable Fast-SCSI-2 Drive 146717-001

37 2.1-GB Pluggable Fast-SCSI-2 Drive 199428-001

38 4.3-GB Pluggable Fast-SCSI-2 Drive 199584-001*

39 2.1-GB Pluggable Fast-Wide SCSI-2 Drive 199643-001*

40 4.3-GB Pluggable Fast-Wide SCSI-2 Drive 199598-001*

41 Hot-Pluggable Tray Adapter (Fast-Wide SCSI-2) 199656-001*

42 Hot-Pluggable Tray Adapter (Fast-SCSI-2) 146781-001

43 Tray Load CD-ROM Drive 142223-201

44 Caddy Load CD-ROM Drive 133881-001*

45 2/8-GB DAT Drive 142074-201

46 525-MB ACA Tape Drive 142073-201

47 4/16-GB TurboDAT Drive 199464-201

48 TurboDAT Autoloader 199466-201

49 1.2-GB Tape Drive 199615-201*

KEYBOARDS

50 Keyboard, U.S. English 160648-101*

Keyboard, U.K. English 160648-103*

Keyboard, German 160648-104*

Keyboard, French 160648-105*

Keyboard, Italian 160648-106*

Keyboard, Spanish 160648-107*

Keyboard, Danish 160648-108*

Keyboard, Norwegian 160648-109*

Keyboard, Swedish/Finnish 160648-110*

Keyboard, Swiss 160648-111*

Keyboard, French Canadian 160648-112*

Keyboard, Portuguese 160648-113*

Keyboard, Turkish 160648-114*

Keyboard, Greek 160648-115*

Keyboard, Latin American 160648-116*

Keyboard, Arabic 160648-117*

Keyboard, Belgian 160648-118*

Keyboard, BHCSY 160648-120*

Keyboard, Hungary 160648-121*

Keyboard, Polish 160648-122*

Keyboard, Slovakia 160648-123*

* Not Shown

Continued

Maintenance and Service Guide

Page 12

Illustrated Parts Catalog

1-5

ProLiant 4500R Rack-Mountable Spare Parts List Continued

Description Spare Part #

Keyboard, Russia 160648-124*

Keyboard, Czech 160648-129*

CABLE KITS

51 LED Cables 165680-001

52 2-Device Internal Cable with Terminator, 36” 165706-001

53 Internal Fast-Wide SCSI-2 Cable (32") 189637-004

54 Floppy Cable 165681-001

55 External SCSI Signal Cable 12' 146776-004

56 External 100-Pin to 50-Pin Cable 142159-001

57 Loop Back Cable (2 CH NIC) 142254-001*

58 Loop Back Cable (NetFlex) 142054-001*

59 2 Channel Ethernet "Y" Cable 197134-001*

MISCELLANEOUS

60 Maintenance and Service Guide 188494-001*

61 Administrator's Guide, English 188485-001*

Administrator's Guide, German 188485-041*

Administrator's Guide, French 188485-051*

Administrator's Guide, Italian 188485-061*

Administrator's Guide, Spanish 188485-071*

Administrator's Guide, Japanese 188485-191*

Administrator's Guide, Dutch 188485-331*

62 System ROMpaq 143198-001*

63 Option ROMpaq 142207-001*

64 RTC Chip with Battery 149344-001*

65 Shipping Box 187582-001*

66 120V AC Power Cord 12’ 187335-001*

67 Power Cord, Denmark 184469-001*

Power Cord, Italy 184470-001*

Power Cord, UK 184471-001*

Power Cord, France/Spain/German 184472-001*

68 Drive Backplane ROM 146705-001

OPTIONS

69 SMART Controller 181132-001*

70 Fast-SCSI-2/E Controller 142040-001*

71 Fast-Wide SCSI-2/E Controller 199634-001*

72 NetFlex Controller 142041-001*

73 NetFlex-2 Controller 142222-001*

74 NetFlex-3/E Controller 169801-001*

75 NetFlex-3 100 Base-TX Upgrade Module 169805-001*

76 NetFlex-3 100 VG-AnyLAN Upgrade Module 169803-001*

77 Token Ring Module 142042-001*

78 DualPort Ethernet Controller 142151-001*

79 2400 Baud LTE Modem 121250-001*

80 2400 Baud LTE Modem (DAA) 127831-001*

81 SpeedPaq Modem (US only) 199906-001*

* Not Shown

Maintenance and Service Guide

Page 13

Chapter 2

2-1

REMOVAL AND REPLACEMENT

time. A rack may become unstable if more than one component is extended for

PROCEDURES

This guide provides detailed maintenance and service information for the

Compaq ProLiant 4500R Rack-Mountable Server.

RACK MOUNTABLE PRODUCTS SERVICE

GUIDELINES

Follow these guidelines when removing or replacing components.

WARNING: Before loading any components in the rack, be sure that the rack

leveling feet are extended to the floor, that the rack is stable and level, and that

the full weight of the rack rests evenly on the leveling feet, not on the casters.

Be sure that you have either attached the stabilizing feet or coupled multiple

racks.

WARNING: Always ensure that the rack is adequately stabilized before

extending a component outside the rack, and extend only one component at a

any reason.

WARNING: Be careful when pressing the component rail latches on both

sides of the component. Pressing the latches in at the same time while sliding

the component in on its rails, could pinch your fingers in the latch.

n Allow a minimum clearance of 30 inches between the wall and the rack to provide adequate

access.

n Load the heaviest components first, and load the rack from the bottom up. Refer to the Rack

Builder software to provide optimal installation order.

n Ensure that the rails are properly aligned. Push the component completely into the rack and

secure it in place with the four thumb screws on the component face plate before working on

the next component.

n Make sure the previously installed component is secured to the rack by its thumb screws; then

install the next component.

GENERAL REMOVAL AND

REPLACEMENT GUIDELINES

This manual provides subassembly/module-level removal and replacement procedures. After

completing all necessary removal and replacement procedures, run the DIAGNOSTICS program

to verify that all components operate properly. In addition, it may be necessary to run the

Compaq System Configuration utility when installing new hardware.

To service Compaq ProLiant 4500R Servers, you need:

n Torx T-10 screwdriver

n Torx T-15 screwdriver

n Ethernet loopback plug

n NetFlex loopback plug

Maintenance and Service Guide

Page 14

2-2 Removal and Replacement Procedures

n System Configuration utility

n Diagnostics software

n Drive Array Advanced Diagnostics software

ELECTROSTATIC DISCHARGE

INFORMATION

A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper

packaging and grounding techniques are necessary precautions to prevent damage. To prevent

electrostatic damage observe the following precautions:

n Transport products in static-safe containers such as conductive tubes, bags, or boxes.

n Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

n Cover work stations with approved static-dissipating material. Provide a wrist strap

connected to the work surface and properly grounded tools and equipment.

n Keep work area free of non-conductive materials such as ordinary plastic assembly aids and

foam packing.

n Always be properly grounded when touching a static-sensitive component or assembly.

n Avoid touching pins, leads or circuitry.

n Always place drives PCB assembly side down on the foam.

n Use conductive field service tools.

PREPARATION PROCEDURES

Before beginning any of the removal and replacement procedures (excluding Hot-Pluggable hard

drives), complete the following steps:

1. Power the system down cleanly according to your operating system.

2. Turn the server off.

CAUTION: Never turn a storage system off before the server controlling it has

been turned off. Doing so will cause the controller to mark the drives as failed.

3. Turn the Storage System off.

4. Disconnect the AC power cord from the AC outlet, then from the system.

5. Disconnect all external peripheral devices from the computer.

WARNING: High voltage is present. Extreme care must be taken when

running the Rack-Mountable Server System without the system unit cover

on.

Maintenance and Service Guide

Page 15

Removal and Replacement Procedures

2-3

REMOVAL AND

REPLACEMENT PROCEDURES

Server Access

WARNING: High voltage is present. Extreme care must be taken when

running the Rack-Mountable Server System without the system unit cover

on.

Extending the Server/Removing the Cover Plate

Figure 2-1. Extending the Server from the Rack and Removing the Cover Plate

1. Unscrew the front panel thumbscrews (4) to release the server from the rack.

2. Using the handles, pull the server out from the rack to the locked position.

WARNING: Never extend more than one piece of equipment at a time. Doing

so could cause the rack system to become unstable.

3. Turn the 1/4-turn release screws (3) on the front panel.

4. Slide the cover plate back and up.

Maintenance and Service Guide

Page 16

2-4 Removal and Replacement Procedures

Removing the Y Brace and Card Bracket

Figure 2-2. Removing the Y Brace and Card Bracket

1. Unscrew the 1/4-turn release screws (3) on the Y brace and lift the brace out.

2. Unscrew the 1/4-turn release screw (1) on the card bracket and tilt the bracket up and then

out.

Mass Storage Devices

The ProLiant 4500R Server has two areas for mass storage devices: the removable media area and

Hot-Pluggable hard drive bays.

Removable Media Storage Devices

Figure 2-3. Removing a Storage Device from the Removable Media Area

1. Extend server out from the rack to the locked position and remove cover plate.

Remove Y brace and card bracket.

2.

Maintenance and Service Guide

Page 17

Removal and Replacement Procedures

2-5

3. Slide base frame back to access cables in drive cage.

Storage Bays

Lift protective cover and disconnect power and signal cables to device.

4.

Remove media trim piece retaining screws (2) from front bezel.

5.

Remove the storage device retaining screws (2) and slide out.

6.

Reverse steps for installation.

7.

The following table shows the supported mass storage devices and their supported locations.

Table 2-1

Removable Media Bay Configurations

Mass Storage Device

1.44-MB, 3.5" Diskette Drive

1.2-MB, 5.25" Diskette Drive

2/8-GB DAT (Digital Audio Tape) Drive

525-MB ACA Tape Drive

CD-ROM Drive

4/16-GB TurboDAT Drive

1.2-GB Tape Drive

TurboDAT Drive w/ Autoloader (Requires bays 5 and 6)

7 6 5

ü ü

ü

ü ü

ü ü

ü

ü ü

ü ü

ü ü

Hot-Pluggable Hard Drives

Hot-Pluggable hard drives used in combination with the Compaq Smart SCSI Array Controller

can be replaced while the power is still on.

NOTE: It is not necessary to set the SCSI ID jumpers on a Compaq replacement HotPluggable hard drive. The SCSI ID is set automatically by the backplane board and the

Hot-Pluggable tray when the drive is installed.

CAUTION: Before removing any Hot-Pluggable hard drive, read the guidelines listed in

the following section.

Maintenance and Service Guide

Page 18

2-6 Removal and Replacement Procedures

Important Guidelines About Replacing

Hot-Pluggable Hard Drives

When a drive configured for fault tolerance is replaced, the replacement drive will automatically

begin being restored when it is installed. When a drive is in the process of being restored, the

On-line LED will flash green. The LED will continue to flash until the drive is completely

restored.

Figure 2-4. Hot-Pluggable Hard Drive LED Indicators

When replacing Hot-Pluggable hard drives, these guidelines must be followed:

n Never remove more than one drive at a time. When a drive is replaced, the controller uses

data from the other drives in the array to reconstruct data on the replacement drive. If more

than one drive is removed, a complete data set is not available to reconstruct data on the

replacement drive(s).

n Never remove a working drive when another drive has failed. Drives that have been

failed by the controller are indicated by the amber Drive Failure LED on the drive tray.

Permanent data loss will occur if a working drive is removed when replacing a failed drive.

n Never remove a drive while another drive is being rebuilt. A drives' On-line LED will be

flashing green whenever it is being rebuilt. A replaced drive is restored from data stored on

the other drives.

n Never turn a ProLiant Storage System off while the Server controlling it is powered on.

Doing so will cause the server's SMART Controller to mark the drives as "failed." This

could result in permanent data loss.

n If an on-line spare drive is installed, wait for it to complete rebuilding before replacing

the failed drive. When a drive fails, the on-line spare will become active and begin being

rebuilt as a replacement drive. Once the on-line spare has completed being rebuilt (On-line

LED will be on solid), the failed drive should be replaced with a new replacement drive. Do

not replace the failed drive with the on-line spare.

n A POST error message (1786) will occur when the system is turned on if a drive(s) has

been replaced while the system is OFF. When this occurs you will be prompted to:

PRESS F1 TO BOOT THE SYSTEM AND REBUILD THE REPLACED DRIVE OR,

PRESS F2 TO BOOT THE SYSTEM AND NOT REBUILD THE DRIVE(S).

CAUTION: Pressing F2 will cause permanent data loss to the entire logical drive. F2

should be pressed only if all of the drives have been replaced or if complete data loss

is desired.

Maintenance and Service Guide

Page 19

Removal and Replacement Procedures

2-7

Replacing Hot-Pluggable Hard Drives

Drives are accessed from the front of the rack and do not require that the server be extended from

the rack.

Figure 2-5. Replacing a Hot-Pluggable Hard Drive

To Remove Drive

1. Press the releases on the ejector levers and swing levers out as shown.

This will pull the drives out of the backplane connector.

2. Slide the Hot-Pluggable hard drive out.

To Install a Drive

1. Slide the hot-pluggable hard drive all the way into the drive cage.

2. Swing the ejector levers in to seat the drive tray's connector into the backplane connector.

Maintenance and Service Guide

Page 20

2-8 Removal and Replacement Procedures

Cable Folding and Routing Diagrams

CAUTION: When routing cables, always make sure that the cables are not in

a position where they will be pinched or crimped.

Cable Diagram for Diskette Drive

Figure 2-6. Diskette Drive - Cable Folding and Routing

Cable Diagram for Removable Media Storage Devices

(2-Device with Termination)

Maintenance and Service Guide

Page 21

Removal and Replacement Procedures

2-9

Figure 2-7. Removable Media Storage Devices - Cable Folding and

than one single-channel SCSI controller. A multi-channel controller, such as the

Routing

Cable Diagram for Internal Fast-Wide SCSI-2 Devices

and Removable Media Storage Devices

Figure 2-8. Internal Fast-Wide SCSI-2 Devices and Removable Media

Storage Devices - Cable Folding and Routing

IMPORTANT: All SCSI hard drives on the same SCSI bus must be internal

(within the server) or in an external storage system, but not both. A

configuration with both internal and external SCSI hard drives requires more

Compaq SMART SCSI Array Controller, supports both internal and external

SCSI hard drives on separate SCSI buses.

IMPORTANT: All integrated 32-Bit SCSI-2 Controllers must be terminated by

connecting one of the following to the Fast-SCSI-2 or Fast-Wide SCSI-2

connector on the system board:

- Terminated SCSI cable

- SCSI cable that is also attached to the lower SCSI-2 connector of a

hot-pluggable backplane

- 50-pin Active Terminator (Spare Part No. 169178-001)

Maintenance and Service Guide

Page 22

2-10 Removal and Replacement Procedures

Boards

This section will describe how to remove and replace the Hot-Pluggable hard drive backplane

board, memory modules, processor and option boards.

Hot-Pluggable Drive Backplane Board

Figure 2-9. Removing the Backplane Board

1. Label and remove all hard drives.

CAUTION: Be sure to label the drives before removing so that they can be

replaced in their original positions. Failure to do so will result in permanent

data loss.

2. Extend the server out from the rack to the locked position.

3. Remove cover plate.

4. Remove Y brace.

5. Extend sub panel back.

6. Label and remove signal cables.

7. Remove retaining screws (10).

8. Remove board.

9. Reverse steps for installation.

Maintenance and Service Guide

Page 23

Removal and Replacement Procedures

2-11

Memory

The ProLiant 4500R Server comes standard with 16 megabytes of system memory. Memory can

be expanded to a maximum of 1.024 gigabytes by installing a matched set of four 4-, 8-, 16-, 32-,

or 64-megabyte 60-, 70-, or 80-ns JEDEC standard SIMM modules in the eight SIMM sockets on

the system board for a total of 512 megabytes and the eight SIMM sockets on the 512-megabyte

Memory Expansion Board.

Figure 2-10. Removing the SIMM Module

1. Extend the server from the rack.

Remove the cover plate.

2.

Remove the Y brace and card bracket.

3.

Press the SIMM connector latches outward [A].

4.

Tilt the SIMM module forward [B].

5.

Lift the SIMM module out [C].

6.

To replace the SIMM module, reverse these steps.

7.

IMPORTANT: Run Compaq System Configuration Utility if installed memory

size has changed. A POST error message will be displayed at power up

prompting you to run the System Configuration Utility.

The following guidelines MUST be followed when installing or replacing memory:

n SIMMs must be installed in matched sets of four at time; for example: four 16-megabyte

modules.

n Matched SIMMs must be the same size and speed.

n Install SIMM sets in bank 1 first, then in bank 2.

CAUTION: Use only JEDEC standard SIMMs. Non-JEDEC SIMMs may

adversely affect data integrity.

Maintenance and Service Guide

Page 24

2-12 Removal and Replacement Procedures

NOTE: The Compaq ProLiant 4500R requires that RAM be installed in

correcting (ECC) memory is based on the parity scheme; one byte data, one bit

Compaq SIMMs or JEDEC-compliant SIMMs that conform to this parity scheme

increments of four SIMMs at a time. The SIMMs must be the same size and

speed. The specific SIMM bit pattern required to support error checking and

parity. The data byte and parity are constructed of DRAMs that are "n"

locations deep by 4-bits wide or 1-bit wide and "n" can be any number (that is,

"n" locations deep x 4-bits wide or "n" locations deep x 1-bit wide.) Use

only.

The following table shows typical memory configurations for the Compaq ProLiant 4500R Server.

Table 2-2

Example of SIMM Upgrade Combinations

System Board Expansion Board

Total Memory Bank 1 Bank 2 Bank 3 Bank 4

16 MB 4x4 MB

32 MB 4x8 MB

64 MB 4x8 MB 4x8 MB

64 MB 4x16 MB

128 MB 4x16 MB 4x16 MB

128 MB 4x8 MB 4x8 MB 4x8 MB 4x8 MB

128 MB 4x32 MB

192 MB 4x32 MB 4x16 MB

192 MB 4x16 MB 4x16 MB 4x16 MB

256 MB 4x64 MB

512 MB 4x64 MB 4x64 MB

512 MB 4x32 MB 4x32 MB 4x32 MB 4x32 MB

1024 MB 4x64 MB 4x64 MB 4x64 MB 4x64 MB

Maintenance and Service Guide

Page 25

Removal and Replacement Procedures

2-13

Processor and Option Boards

Figure 2-11. Removing the Processor and Option Boards

To Replace Option Board

1. Extend server from the rack to the locked position.

2. Remove cover plate.

3. Remove Y brace.

4. Remove any cables connected to the option board.

5. Remove retaining screw and pull board straight out.

6. Reverse steps for option board installation.

To Replace Processor Board

1. Extend server from the rack to the locked position.

2. Remove cover plate.

3. Remove Y brace and card bracket.

5. Pull board straight out.

6. Reverse steps for processor board installation.

Maintenance and Service Guide

Page 26

2-14 Removal and Replacement Procedures

System Boards

Figure 2-12. Removing the System Board

1. Extend server from the rack to the locked position.

2. Remove the cover plate.

3. Remove the Y brace and card guide brace.

4. Remove all boards including processor board, memory SIMMs, and expansion boards.

5. Disconnect all cables from the system board.

6. Remove the retaining screws and push the three I/O panel release tabs.

7. Slide the board toward the front of the chassis and lift the board out.

8. Reverse these steps to replace system board.

Maintenance and Service Guide

Page 27

Removal and Replacement Procedures

2-15

Figure 2-13. System Board Connectors

Power Supply

1. Turn the power off and disconnect the power cord from the rear of unit.

2. Extend the server from the rack to the locked position and remove cover plate.

3. Remove the Y brace.

4. Disconnect the power supply signal cable from the system board.

5. Disconnect all power connector from boards and peripheral devices.

Figure 2-14. Removing the Power Supply Power Connector and Switch

6. Remove interlock power switch bracket retaining screws (2).

Maintenance and Service Guide

Page 28

2-16 Removal and Replacement Procedures

7. Pull the bracket out and remove the power switch, safety interlock switch connectors, and

cable

from the bracket (refer to Figure 2-16).

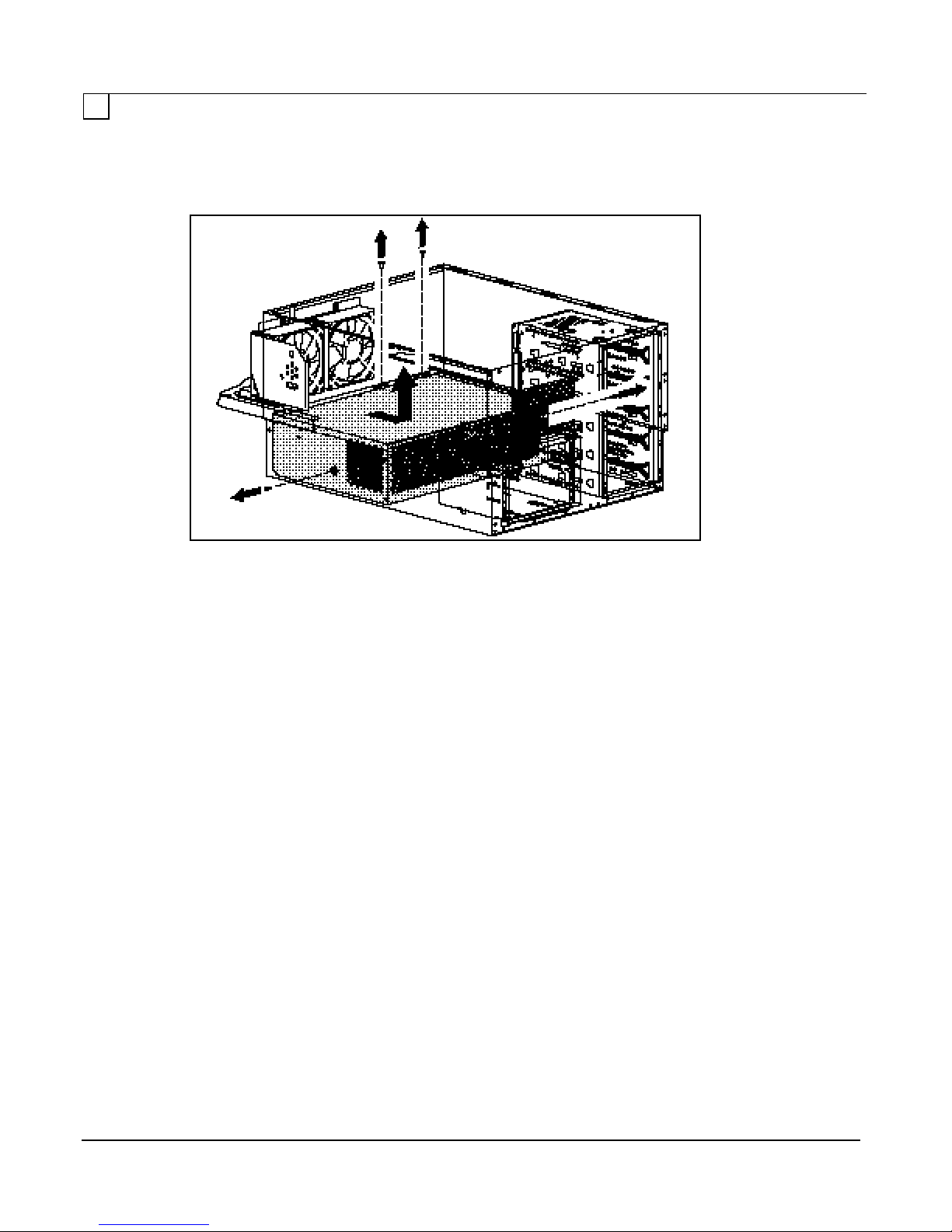

Figure 2-15. Removing the Power Supply

8. Slide the base frame back all the way to access the power supply.

9. Remove screws at sides (2) and rear (2) of the power supply.

10. Lift the power supply out, pulling the switch and cable through the chassis.

11. Reverse steps for replacement.

NOTE: When replacing the power supply, make sure that the power switch

cable is properly threaded through the bracket’s strain relief as shown in

Figure 2-16.

Maintenance and Service Guide

Page 29

Removal and Replacement Procedures

2-17

Figure 2-16. Power Supply Switch Cable Strain Relief

Maintenance and Service Guide

Page 30

2-18 Removal and Replacement Procedures

Miscellaneous Parts

Cooling Fan

Figure 2-17. Removing the Processor Fan

Figure 2-18. Removing the Option Board Fan

1. Extend the server from the rack to the locked position.

2. Remove the cover plate.

3. Remove the Y brace and card guide bracket.

4. Disconnect the fan cable from the system board.

NOTE: The fan connectors are not interchangeable. Be sure to connect the fan

cable to the specific header as shown.

Maintenance and Service Guide

Page 31

Removal and Replacement Procedures

2-19

5. Remove the fan retaining screw (1).

6. Slide the subpanel forward far enough to gain access to the fan.

7. Remove fan.

8. Reverse steps to install new fan.

Speaker

Figure 2-19. Removing the Speaker

1. Extend the server out from the rack to the locked position and remove cover plate.

2. Remove the Y brace.

3. Disconnect the speaker cable from the system board.

4. Slide the subpanel forward far enough to gain access to the speaker.

5. Squeeze the speaker retaining spring clip pull forward to release the speaker.

6. Remove the speaker.

7. Reverse steps to install the new fan.

Maintenance and Service Guide

Page 32

2-20 Removal and Replacement Procedures

Battery

replacement battery/clock modules supplied by Compaq Computer Corporation.

Disposal of the battery/clock module should be accomplished within compliance

Figure 2-20. Removing the Battery/Clock Module

WARNING: The battery/clock module contains a lithium battery that may

explode if mishandled. Do not abuse, recharge, disassemble, or dispose of in

fire or heat above 90

°C, incinerate, or expose to water or fire. Use only

of local regulations or returned to Compaq Computer Corporation by

established parts return methods.

NOTE: After replacing the battery, the Compaq System Configuration Utility

must be run.

Maintenance and Service Guide

Page 33

Chapter 3

3-1

DIAGNOSTIC TOOLS

This chapter describes software and firmware diagnostic tools available for the Compaq Server

products. These include:

n Power-On Self-Test (POST)

n Diagnostics (DIAGS)

n Drive Array Advanced Diagnostics (DAAD)

n Automatic Server Recovery

n ROMPaq utilities to upgrade flash ROMs

Utility Access

The SmartStart Installation Program CD contains the SmartStart program and many of the

Compaq utilities needed to maintain your system, including:

n System Configuration Utility

n Drive Array Advanced Diagnostics Utility

n ROMPaq Firmware Upgrade Utilities

NOTE: The Diagnostics Utility is shipped on a separate diskette.

CAUTION: Do not select the "Automatic Configuration" when running the

SmartStart Installation Program CD. This will result in data loss to the entire

system.

There are several ways to access these utilities:

1. Run the Utilities on the System Partition.

If the system was installed using the SmartStart utility, the Compaq utilities will

automatically be available on the system partition. The system partition could also have been

created during a manual system installation.

To run the utilities on the system partition, boot the system and press F10 when the cursor

moves to the upper right corner of the screen. (If the cursor does not move to the upper right

corner of the screen, the system partition does not exist.) Then select the utilities from the

menu as described below. The ROMPaq Firmware Upgrade Utility is available under the

"Diagnostics and Utilities" menu.

2. Run the Utilities on the System Diskette.

The utilities can also be run from their individual diskettes. If you have a utility diskette

newer than the version on the SmartStart CD, use that diskette.

You may also create a diskette version of the utility from the SmartStart CD. To create

diskette versions of the utilities from the CD:

n Boot the SmartStart CD.

n Select the "Manual Configuration and Server Utilities" button.

Maintenance and Service Guide

Page 34

3-2 Diagnostic Tools

n Select the "Create Diskettes from CD" menu item.

n Select the diskette you would like to create from the list and follow the instructions on the

screen to create the diskette.

3. Boot the SmartStart CD.

n Select the "Manual Configuration and Server Utilities" button.

n Select the utility wanted from the menu.

n The System Configuration Utility is available under the "System Configuration" menu

item.

n The Drive Array Diagnostics Utility is available under the "Diagnostics and Utilities"

menu.

n The ROMPaq Firmware Upgrade Utilities can be run only from the System Partition or

from the ROMPaq diskette. See steps 1 and 2.

POWER-ON SELF-TEST (POST)

POST is a series of diagnostic tests that run automatically on Compaq computers when the system

is turned on. POST checks the following assemblies to ensure that the computer system is

functioning properly:

n Keyboard

n Power supply

n System board

n Memory

n Memory expansion boards

n Controllers

n Diskette drives

n Hard drives

If POST finds an error in the system, an error condition is indicated by an audible and/or visual

message. If an error code is displayed on the screen during POST or after resetting the system,

follow the instructions in Table 3-1. The error messages and codes listed in Table 3-1 include all

codes generated by Compaq products. Your system will generate only those codes that are

applicable to your configuration and options.

Maintenance and Service Guide

Page 35

Diagnostic Tools

3-3

Table 3-1

POST Error Messages

Error Code Beeps Probable Source of

Problem

A Critical Error

occurred prior to this

power-up

101-ROM Error 1L,1S System ROM checksum. Run Diagnostics.

101-I/O ROM Error None Options ROM checksum. Run Diagnostics.

102-System Board

Failure

104-ASR Timer

Failure

162-System Options

Not Set

163-Time & Date

Not Set

164-Memory Size

Error

170- Expansion

Device Not

Responding

172- Configuration

Nonvolatile Memory

Invalid

172-1 Configuration

Nonvolatile Memory

Invalid

None A catastrophic system

error, which caused the

server to crash, has

been logged.

None DMA, timers, etc. Replace the system

None System board failure. Run Diagnostics.

2S Configuration incorrect. Run the System

2S Invalid time or date in

configuration memory.

2S Configuration memory

incorrect.

None EISA or PCI Expansion

board failure.

None Nonvolatile configuration

corrupt or jumper

installed.

None Nonvolatile configuration

corrupt.

Action

Run Diagnostics.

Replace failed assembly

as indicated.

Replace failed assembly

as indicated or contact

your service provider.

Replace failed assembly

as indicated or contact

your service provider.

board. Run the Compaq

System Configuration

Utility.

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Check board for secure

installation. Replace the

failed board if necessary.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Continued

Maintenance and Service Guide

Page 36

3-4 Diagnostic Tools

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

173- Slot ID

Mismatch

None Board replaced, but

configuration not

updated.

174Configuration/Slot

None EISA or PCI board not

found.

Mismatch Device

Not Found

175Configuration/Slot

Mismatch Device

None EISA or PCI board

added, configuration not

updated.

Found

176-Slot with Not

Readable ID Yields

Valid ID

177-Configuration

Not Complete

178-Processor

Configuration Invalid

None EISA or PCI board in slot

that should contain an

ISA board.

None Incomplete System

Configuration.

None Processor type or step

does not match

configuration memory.

179-System

Revision Mismatch

None A board was installed

that has a different

revision date.

201-Memory Error None RAM failure. Run Diagnostics.

203-Memory

None RAM failure. Run Diagnostics.

Address Error

205-Cache Memory

None Cache memory error.

Error

Option-Cache

Memory Error

206-Cache

None Cache controller failure. Run Diagnostics.

Option Cache Memory

Error.

Controller Error

Action

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Replace the processor

board in the slot

indicated.

Replace the option cache

board.

Continued

Maintenance and Service Guide

Page 37

Diagnostic Tools

3-5

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

207-Invalid Memory

Configuration -

None Memory module installed

incorrectly.

Check SIMM

Installation

208-Invalid Memory

Speed - Check

SIMM Installation

1L,1S The speed of the

memory is too slow,

where:

xx00 = expansion board

SIMMs are too slow, or

00yy = system board

SIMMs are too slow.

xx and yy have

corresponding bit set.

211-Cache Switch

Set Incorrectly

None Switch not set properly

during installation or

upgrade.

212-System

1S Processor in slot x failed. Run Diagnostics and

Processor

Failed/Mapped out

213-Cache size

Error

None Invalid optional cache

size.

(ProSignia VS only)

213-System

Processor Not

Installed

1S System processor

configured for slot

indicated is missing.

301-Keyboard Error None Keyboard failure. Turn off the computer,

301-Keyboard Error

None Keyboard failure. Replace the keyboard.

or Test Fixture

Installed

ZZ-301-Keyboard

Error

None Keyboard failure. (ZZ

represents the Keyboard

Scan Code.)

Action

Verify placement of

memory modules.

The speed of the

memory modules must

be 60 or 70 ns. Verify the

speed of the memory

modules installed and

replace.

Verify switch settings.

replace failed processor.

Replace cache with 256K

cache.

Install processor in the

slot indicated or run the

System Configuration

Utility to remove the

processor from the .CFG

file.

then reconnect the

keyboard.

1. A key is stuck. Try to

free it.

2. Replace the

keyboard.

Continued

Maintenance and Service Guide

Page 38

3-6 Diagnostic Tools

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

303-Keyboard

Controller Error

304-Keyboard or

System Unit Error

40X-Parallel Port X

Address Assignment

Conflict

402-Monochrome

Adapter Failure

501-Display Adapter

Failure

601-Diskette

Controller Error

605-Diskette Drive

Type Error

702-A coprocessor

has been detected

that was not

reported by CMOS.

703-CMOS reports a

coprocessor that has

not been detected

None System board, keyboard,

or mouse controller

failure.

None Keyboard, keyboard

cable, or system board

failure.

2S Both external and

internal ports are

assigned to parallel port

X.

1L,2S Monochrome display

controller.

1L,2S Video display controller. Replace the video board.

None Diskette controller

circuitry failure.

2S Mismatch in drive type. Run the System

None Installed coprocessor not

configured.

2S Coprocessor or

configuration error.

Action

Check with your

Authorized Compaq

Reseller.

1. Make sure the

keyboard is

attached.

2. Run Diagnostics to

determine which is in

error.

3. Replace the part

indicated.

Run the System

Configuration Utility.

Replace the

monochrome display

controller.

1. Make sure the

diskette drive cables

are attached.

2. Replace the diskette

drive and/or cable.

3. Replace the system

board.

Configuration Utility to

set diskette type

correctly.

Run the System

Configuration Utility and

correct.

1. Run the System

Configuration Utility

and correct.

2. Replace the

coprocessor.

Continued

Maintenance and Service Guide

Page 39

Diagnostic Tools

3-7

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

1151-Com Port 1

Address Assignment

Conflict

1152-Com Port 2, 3,

or 4 Address

Assignment Conflict

1600-Server

Manager/R Failure

1610-Temperature

violation detected.

Waiting for system

to cool

1611-Fan failure

detected

1612-Primary power

supply failure.

1730-Fixed Disk 0

does not support

DMA Mode

1731-Fixed Disk 1

does not support

DMA Mode

1740-Fixed Disk 0

failed Set Block

Mode command

1741-Fixed Disk 1

failed Set Block

Mode command

1750-Fixed Disk 0

failed Identify

command

1751-Fixed Disk 1

failed Identify

command

1760-Fixed Disk 0

does not support

Block Mode

2S Both external and

internal serial ports are

assigned to COM1.

2S Both external and

internal serial ports are

assigned to COM2,

COM3 or COM4.

None Server Manager/R board

failure. Error code

displays after error

message.

2S Ambient system

temperature too hot.

2S Required fan not installed

or spinning.

2S Primary power supply

has failed.

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

None Fixed disk drive error. Run the System

Action

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run Diagnostics.

Replace failed assembly

as indicated or contact

your service provider.

Check fan in system

environment.

Check fans.

Replace power supply as

soon as possible.

Configuration Utility and

correct.

Configuration Utility and

correct.

Configuration Utility and

correct.

Configuration Utility and

correct.

Configuration Utility and

correct.

Configuration Utility and

correct.

Configuration Utility and

correct.

Continued

Maintenance and Service Guide

Page 40

3-8 Diagnostic Tools

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

1761-Fixed Disk 1

does not support

Block Mode

1771-Primary Disk

Port Address

Assignment Conflict

1772-Secondary

Disk Port Address

Assignment Conflict

1773-Primary Fixed

Disk Port

Assignment Conflict

1776-Drive Array SCSI Port

Termination Error

1777-Drive Array

Error

1778-Drive Array

resuming Automatic

Data Recovery

process

1779-Drive Array

Controller detects

replacement drives

None Fixed disk drive error. Run the System

None Internal and external

hard drive controllers are

both assigned to the

primary address.

None Address Assignment

Conflict. Internal and

external hard drive

controllers are both

assigned to the

secondary address.

None Fixed disk drive error. Run the System

None External and internal

SCSI drives are both

configured to Port 1.

None Cooling fan failure,

internal temperature alert

or open cover.

None This message appears

whenever a controller

reset or power cycle

occurs while Automatic

Data Recovery is in

progress.

None Intermittent drive failure

and/or possible loss of

data.

Action

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Run the System

Configuration Utility and

correct.

Configuration Utility and

correct.

Re-configure drives.

Inspect for cooling fan

failure or open cover.

No action necessary.

If this message appears

and drive X has not been

replaced, this indicates

an intermittent drive

failure. This message

also appears once

immediately following

drive replacement

whenever data must be

restored from backup.

Continued

Maintenance and Service Guide

Page 41

Diagnostic Tools

3-9

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

1780-Disk 0 Failure None Hard drive/format error. Run Diagnostics.

1781-Disk 1 Failure None Hard drive/format error Run Diagnostics.

1782-Disk Controller

Failure

1784-Drive Array

Drive Failure,

None Hard disk drive circuitry

error.

None Defective drive and/or

cables.

Physical Drive

1785-Drive Array not

None Configuration error. Run the System

Configured

1786-Drive Array

Recovery Needed

The following

None Interim Data Recovery

mode. Data has not been

recovered yet.

drive(s) need

Automatic Data

Recovery: Drive X.

Select "F1" to

continue with

recovery of data to

drive(s). Select "F2"

to continue without

recovery of data to

drive(s).

1787-Drive Array

Operating in Interim

Recovery Mode.

Physical drive

replacement

needed: Drive X

None Hard drive X failed or

cable is loose or

defective. Following a

system restart, this

message reminds you

that drive X is defective

and fault tolerance is

being used.

Action

Replace failed assembly

as indicated or contact

your service provider.

Replace failed assembly

as indicated or contact

your service provider.

Run Diagnostics.

Replace failed assembly

as indicated or contact

your service provider.

Check for loose cables.

Replace defective drive X

and/or cable(s).

Configuration Utility and

correct.

Press F1 key to allow

Automatic Data

Recovery to begin. Data

will automatically be

restored to drive X now

that the drive has been

replaced or now seems

to be working.

-OrPress the F2 key and the

system will continue to

operate in the Interim

Data Recovery mode.

1. Replace drive X as

soon as possible.

2. Check loose cables.

3. Replace defective

cables.

Continued

Maintenance and Service Guide

Page 42

3-10 Diagnostic Tools

POST Error Messages Continued

lose all the data on them.

Error Code Beeps Probable Source of

Problem

*1788-Incorrect

Drive Replaced:

Drive X Drive(s)

were incorrectly

replaced: Drive Y

None Drives are not installed in

their original positions, so

the drives have been

disabled. See note

below.

Select "F1" to

continue - drive

array will remain

disabled. Select "F2"

to reset

configuration - all

data will be lost.

*NOTE: The 1788 error message might also be displayed inadvertently due to a bad

power cable connection to the drive or by noise on the data cable. If this message was

due to a bad power cable connection, but not due to an incorrect drive replacement,

repair the connection and press F2.

-OrIf this message was not due to a bad power cable connection, and no drive replacement

took place, this could indicate noise on the data cable. Check cable for proper routing.

1789-Drive Not

Responding,

None Cable or hard drive

failure.

Physical Drive

Check cables or

replace physical

drive X.

Select "F1" to

continue - drive

array will remain

disabled.

Select "F2" to fail

drive(s) that are not

responding Interim Recovery

Mode will be enabled

if configured for fault

tolerance.

1790-Disk 0 Error None Hard drive error or wrong

drive type.

1791-Disk 1 Error None Hard drive error or wrong

drive type.

Action

Reinstall the drives

correctly as indicated.

Press F1 to restart the

computer with the drive

array disabled.

-OrPress F2 to use the

drives as configured and

1. Check the cable

connections.

2. If cables are

connected, replace

the drive.

3. If you do not want to

replace the drives

now, press F2.

Run the System

Configuration Utility and

Diagnostics and correct.

Run the System

Configuration Utility and

Diagnostics and correct.

Continued

Maintenance and Service Guide

Page 43

Diagnostic Tools

3-11

POST Error Messages Continued

Battery Charge Low.

temporarily disabled.

Error Code Beeps Probable Source of

Problem

1792-Drive Array

Reports Valid Data

Found in Array

Accelerator.

Data will

automatically be

written to drive

array.

1793-Drive Array Array Accelerator

Battery Depleted Data Lost

(Error message

1794 also displays.)

1794-Drive Array Array Accelerator

Array Accelerator is

Array Accelerator

will be re-enabled

when battery

reaches full charge.

1795-Drive Array Array Accelerator

Configuration Error.

Data does not

correspond to this

drive array. Array

Accelerator is

temporarily disabled.

None This indicates that while

the system was in use,

power was interrupted

while data was in the

Array Accelerator

memory. Power was then

restored within eight to

ten days, and the data in

the Array Accelerator

was flushed to the drive

array.

None This indicates that while

the system was in use,

power was interrupted

while data was in the

Array Accelerator

memory.

Array Accelerator

batteries failed. Data in

Array Accelerator has

been lost.

None This is a warning that the

battery charge is below

75%. Posted writes are

disabled.

None This indicates that while

the system was in use,

power was interrupted

while data was in the

Array Accelerator

memory.

The data stored in the

Array Accelerator does

not correspond to this

drive array.

Action

No action necessary; no

data has been lost.

Perform orderly system

shutdowns to avoid data

remaining in the Array

Accelerator.

Power was not restored

within eight to ten days.

Perform orderly system

shutdowns to avoid data

remaining in the Array

Accelerator.

Replace the Array

Accelerator board if

batteries do not recharge

within 36 power-on

hours.

1. Match the Array

Accelerator to the

correct drive array.

-Or-

2. Run the System

Configuration Utility

to clear the data in

the Array

Accelerator.

Continued

Maintenance and Service Guide

Page 44

3-12 Diagnostic Tools

POST Error Messages Continued

Error Code Beeps Probable Source of

Problem

1796-Drive Array - Array

Accelerator Not

Responding.

Array Accelerator is

temporarily disabled.

1797-Drive Array - Array

Accelerator Read Error

Occurred.

Data in Array Accelerator

has been lost.

Array Accelerator is

disabled.

1798-Drive Array - Array

Accelerator Write Error

Occurred.

Array Accelerator is

disabled.

1799-Drive Array - Drive(s)

Disabled due to Array

Accelerator Data Loss.

Select "F1" to continue with

logical drives disabled.

Select "F2" to accept data

loss and to re-enable

logical drives.

(Run System Configuration

Utility = "F10" key)

(RESUME = "F1" KEY) None As indicated to

None Array Accelerator is

defective or has been

removed.

None Hard parity error

while reading data

from posted writes

memory.

None Hard parity error

while writing data to

posted writes

memory.

None Volume failed due to

loss of data in

posted-writes

memory.

2L,2S Power is cycled.

Temperature too hot.

Processor fan not

installed or spinning.

None A configuration error

occurred during

POST.

continue.

Action

1. Check that the Array

Accelerator is

properly seated.

2. Run the System

Configuration Utility

to re-configure the

Compaq IDA-2

without the Array

Accelerator.

Enable Array

Accelerator.

Enable Array

Accelerator.

Press F1 to continue with

logical drives disabled or

F2 to accept data loss

and re-enable logical

drive.

Check fans.

Press F10 to run System

Configuration Utility.

Press the F1 key.

Maintenance and Service Guide

Page 45

Diagnostic Tools

3-13

DIAGNOSTICS (DIAGS)

Diagnostic error codes occur if the system recognizes a problem while running the Diagnostics

program. These error codes help identify possible defective subassemblies.

Tables 3-2 through 3-17 list possible error codes, a description of the error condition, and the

action required to resolve the error condition.

In each case, the Recommended Action column lists the steps necessary to correct the problem.

After completing each step, run the Diagnostics program to verify whether the error condition has

been corrected. If the error code reappears, perform the next step, then run the Diagnostics

program again. Follow this procedure until the Diagnostics program no longer detects an error

condition.

If you encounter an error condition, complete the following steps before starting problem isolation

procedures:

1. Ensure that there is proper ventilation. The computer should have approximately 12 inches

(30.5 cm) clearance at the front and back of the system unit.

2. Turn off the computer and peripheral devices.

3. Disconnect any peripheral devices other than the monitor and keyboard. Do not disconnect

the printer if you want to test it or use it to log error messages.

4. Delete the power-on password, if set. You will know that the power-on password is set when

a key icon appears on the screen when POST completes. If this occurs, you must enter the

password to continue. To delete the password, type the current password and press the

Enter key.

5. If you do not have access to the password, you must disable the power-on password by using

the Password Disable switch on the system board.

6. Install a loopback plug when instructed to by Diagnostics (Part Number 142054-001).

7. Run the latest version of Diagnostics.

Table 3-2

Primary Processor Test Error Codes

Error

Code Description Recommended Action

101-xx CPU test failed Replace the processor board

and re-test.

103-xx

104-xx

105-xx

106-xx

DMA page registers test failed

Interrupt controller master test failed

Port 61 error

Keyboard controller self-test failed

Replace the processor board and

re-test for error codes 103-xx

through 106-xx.

Continued

Maintenance and Service Guide

Page 46

3-14 Diagnostic Tools

Table 3-2 Primary Processor Test Error Codes Continued

1. Replace the battery/clock module

Programmable timer load data test failed

2. Replace the speaker and re-test.

Error

Code Description Recommended Action

107-xx

108-xx

109-xx

110-xx

111-xx

112-xx

113-xx

114-xx Speaker test failed The following steps apply to 114-xx

116-xx Cache test failed Replace the system board

199-xx Installed devices test failed The following steps apply to 199-xx

CMOS RAM test failed

CMOS interrupt test failed

CMOS clock load data test failed

Refresh detect test failed

Speed test slow mode out of range

Protected mode test failed

The following steps apply to error

codes 107-xx through 109-xx.

and re-test.

2. Replace the system board

and re-test.

Replace the system board and

re-test for error codes 110-xx

through 113-xx.

error codes:

1. Verify the speaker connection

and re-test.

3. Replace the system board

and re-test.

and re-test.

error codes:

1. Check the system configuration

and re-test.

2. Verify cable connections

and re-test.

3. Check switch and/or jumper

settings and re-test.

4. Run the Configuration utility

and re-test.

5. Replace the processor board

and re-test.

6. Replace the system board

and re-test.

Maintenance and Service Guide

Page 47

Diagnostic Tools

3-15

Table 3-3

Memory Test Error Codes

Error

Code Description Recommended Action

200-xx Invalid memory configuration Reinsert memory modules in

correct location and re-test.

201-xx

202-xx

203-xx

204-xx

205-xx

206-xx

210-xx

Memory machine ID test failed

Memory system ROM checksum failed

Memory write/read test failed

Memory address test failed

Walking I/O test failed

Increment pattern test failed

Random pattern test failed

The following steps apply to error

codes 201-xx and 202-xx:

1. Replace the system ROM

and re-test.

2. Replace the processor board

and re-test.

3. Replace the memory expansion

board and re-test.

The following steps apply to error

codes 203-xx through 210-xx:

1. Replace the memory module

and re-test.

2. Replace the processor board

and re-test.

3. Replace the memory expansion

board and re-test.

Table 3-4

Keyboard Test Error Codes

Error

Code Description Recommended Action

301-xx

302-xx

303-xx

304-xx

Keyboard short test, 8042 self-test failed

Keyboard long test failed

Keyboard LED test, 8042 self-test failed

Keyboard typematic test failed

The following steps apply to error

codes 301-xx through 304-xx:

1. Check the keyboard connection.

If disconnected, turn off the

computer and connect the

keyboard and re-test.

2. Replace the keyboard and retest.

3. Replace the system board

and re-test.

Maintenance and Service Guide

Page 48

3-16 Diagnostic Tools

Table 3-5

Parallel Printer Test Error Codes

Error

Code Description Recommended Action

401-xx

402-xx

403-xx

498-xx

Printer failed or not connected

Printer data register failed

Printer pattern test failed

Printer failed or not connected

The following steps apply to error

codes 401-xx through 498-xx:

1. Connect the printer and re-test.

2. Check the power to the printer

and re-test.

3. Install the loopback connector

and re-test.

4. Check the switch on the

Serial/Parallel Interface board (if

applicable) and re-test.

5. Replace the Serial/Parallel

Interface board (if applicable)

and re-test.

6. Replace the system board

and re-test.

Maintenance and Service Guide

Page 49

Diagnostic Tools

3-17

Table 3-6

Video Display Unit Test Error Codes

Error

Code Description Recommended Action

501-xx

502-xx

503-xx

504-xx

505-xx

506-xx

507-xx

508-xx

509-xx

510-xx

511-xx

512-xx

514-xx

516-xx

Video controller test failed

Video memory test failed

Video attribute test failed

Video character set test failed

Video 80 x 25 mode 9 x 14 character

cell test failed

Video 80 x 25 mode 8 x 8 character

cell test failed

Video 40 x 25 mode test failed

Video 320 x 200 mode color set 0

test failed

Video 320 x 200 mode color set 1

test failed

Video 640 x 200 mode test failed

Video screen memory page test failed

Video gray scale test failed

Video white screen test failed

Video noise pattern test failed

The following steps apply to error

codes 501-xx through 516-xx:

1. Replace the monitor and re-test.

2. Replace the Advanced VGA

board and re-test.

3. Replace the system board

and re-test.

Maintenance and Service Guide

Page 50

3-18 Diagnostic Tools

Table 3-7

1. Replace the diskette and re-test.

2. Check and/or replace the diskette

Diskette Drive Error Test Codes

Error

Code Description Recommended Action

600-xx

601-xx

602-xx

603-xx

604-xx

605-xx

606-xx

607-xx

608-xx

609-xx

610-xx

694-xx

697-xx

698-xx

699-xx Diskette drive/media ID error The following steps apply to 699-xx

Diskette ID drive types test failed

Diskette format failed

Diskette read test failed

Diskette write/read/compute test failed

Diskette random seek test failed

Diskette ID media failed

Diskette speed test failed

Diskette wrap test failed

Diskette write protect test failed

Diskette reset controller test failed

Diskette change line test failed

Pin 34 is not cut on 360 KB diskette drive

Diskette type error

Diskette drive speed not within limits

The following steps apply to error

codes 600-xx through 698-xx:

power and signal cables

and re-test.

3. Replace the diskette drive

and re-test.

4. Replace the system board

and re-test.

error codes:

1. Replace the media and re-test.

2. Run the Configuration utility

and re-test.

Error

Code Description Recommended Action

802-xx

824-xx

Maintenance and Service Guide

Table 3-8

Monochrome Video Board Test Error Codes

Video memory test failed

Monochrome video text mode test failed

The following steps apply to error

codes 802-xx and 824-xx:

1. Replace monitor and re-test.

2. Replace the Advanced VGA

board and re-test.

3. Replace monochrome board

and re-test.

4. Replace the system board

and re-test.

Page 51

Diagnostic Tools

3-19

Table 3-9

Serial Test Error Codes

Error

Code Description Recommended Action

1101-xx

1109-xx

Serial port test failed

Clock register test failed

The following steps apply to error

codes 1101-xx and 1109-xx:

1. Check the switch settings on the

Serial/Parallel Interface board (if

applicable) and re-test.

2. Replace the Serial/Parallel

Interface board (if applicable)

and re-test.

3. Replace the system board

and re-test.

Table 3-10

Modem Communications Test Error Codes

Error

Code Description Recommended Action

1201-xx

1202-xx

1203-xx

1204-xx

1206-xx

1210-xx

Modem internal loopback test failed

Modem time-out test failed

Modem external termination test failed

Modem auto originate test failed

Dial multi-frequency tone test failed

Modem direct connect test failed

The following steps apply to error

codes 1201-xx through 1210-xx:

1. Refer to the modem

documentation for correct setup

procedures and re-test.

2. Check the modem line

and re-test.

3. Replace the modem and re-test.

Maintenance and Service Guide

Page 52

3-20 Diagnostic Tools

Table 3-11

Fixed Disk Drive Test Error Codes

Error

Code Description Recommended Action

1700-xx

1701-xx

1702-xx

1703-xx

1704-xx

1705-xx

1708-xx

1709-xx

1710-xx

1715-xx

1716-xx

1717-xx

1719-xx

1736-xx

1799-xx

* Error Checking and Correcting

Fixed disk ID drive types test failed

Fixed disk format test failed

Fixed disk read test failed

Fixed disk write/read/compare test failed

Fixed disk random seek test failed

Fixed disk controller test failed

Fixed disk format bad track test failed

Fixed disk reset controller test failed

Fixed disk park head test failed

Fixed disk head select test failed

Fixed disk conditional format test failed

Fixed disk ECC* test failed

Fixed disk drive power mode test failed

Drive Monitoring failed

Invalid fixed disk drive type failed

The following steps apply to error

codes 1700-xx through 1799-xx:

1. Run the Configuration Utility and

verify the drive type.

2. Replace the fixed disk drive

signal and power cables and retest.

3. Replace the fixed disk drive

controller and re-test.

4. Replace the fixed disk drive

and re-test.

5. Replace the system board

and re-test.

Table 3-12

CD-ROM Drive Test Error Codes

Error

Code Description Recommended Action

1800-xx

1803-xx

1805-xx

1806-xx

1808-xx

1823-xx

CD-ROM ID failed

CD-ROM Power failed

CD-ROM Read failed

CD-ROM SA/Media failed

CD-ROM Controller failed

CD-ROM random read failed

The following steps apply to error

codes 1800-xx through 1823-xx:

1. Replace the CD-ROM and retest.

2. Check and/or replace the signal

cable and re-test.

3. Check the switch settings on the

adapter board (if applicable).

4. Replace the tape adapter board

(if applicable) and re-test.

5. Replace the CD-ROM drive

and re-test.

6. Replace the system board

and re-test.

Maintenance and Service Guide

Page 53

Diagnostic Tools

3-21

Table 3-13

Tape Drive Test Error Codes

Error

Code Description Recommended Action

1900-xx

1901-xx

1902-xx

1903-xx

1904-xx

1905-xx

1906-xx

Tape ID failed

Tape servo write failed

Tape format failed

Tape drive sensor test failed

Tape BOT/EOT test failed

Tape read test failed

Tape write/read/compare test failed

The following steps apply to error

codes 1900-xx through 1906-xx:

1. Replace the tape cartridge

and re-test.

2. Check and/or replace the signal

cable and re-test.

3. Check the switch settings on the

adapter board (if applicable).

4. Replace the tape adapter board

(if applicable) and re-test.

5. Replace the tape drive

and re-test.

6. Replace the system board

and re-test.

Maintenance and Service Guide

Page 54

3-22 Diagnostic Tools

Table 3-14

Advanced VGA Board Test Error Codes

Error

Code Description Recommended Action

2402-xx

2403-xx

2404-xx

2405-xx

2406-xx

2407-xx

2408-xx

2409-xx

2410-xx

2411-xx

2412-xx

2414-xx

2416-xx

2417-xx

2418-xx

2419-xx

2420-xx

2421-xx

2422-xx

2423-xx

2424-xx

2425-xx

2431-xx

2432-xx

2448-xx

2451-xx

2456-xx

Video memory test failed

Video attribute test failed

Video character set test failed

Video 80 x 25 mode 9 x 14 character

cell test failed

Video 80 x 25 mode 8 x 8 character

cell test failed

Video 40 x 25 mode test failed

Video 320 x 320 mode color set 0

test failed

Video 320 x 320 mode color set 1

test failed

Video 640 x 200 mode test failed

Video screen memory page test failed

Video gray scale test failed

Video white screen test failed

Video noise pattern test failed

Lightpen text mode test failed, no

response

ECG/VGC memory test failed

ECG/VGC ROM checksum test failed

ECG/VGC attribute test failed

ECG/VGC 640 x 200 graphics mode test

failed

ECG/VGC 640 x 350 16-color set test

failed

ECG/VGC 640 x 350 64-color test failed

ECG/VGC monochrome text mode test

failed

ECG/VGC monochrome graphics mode

test failed

640 x 480 graphics test failure

320 x 200 graphics (256-color mode) test

failure

Advanced VGA Controller test failed

132-column Advanced VGA test failed

Advanced VGA 256-Color test failed

The following steps apply to error

codes 2402-xx through 2456-xx:

1. Run the Configuration utility.

2. Replace the monitor and re-test.

3. Replace the Advanced VGA

board or other video board

and re-test.

4. Replace the system board

and re-test.

Continued

Maintenance and Service Guide

Page 55

Diagnostic Tools

3-23

Table 3-14 Advanced VGA Board Test Error Codes Continued

1. Check the controller installation in

5. Check the MAU, cabling, or other

Error

Code Description Recommended Action

2458-xx

2468-xx

2477-xx

2480-xx

Advanced VGA Bit BLT Test

Advanced VGA DAC Test

Advanced VGA Data Path Test

Advanced VGA DAC Test

The following steps apply to error

codes 2458-xx through 2480-xx:

1. Run Setup.

2. Replace the system board

and re-test.

Table 3-15

NetFlex-2 ENET-TR Controller and

NetFlex-2 Token Ring Controller Test Error Codes

Error

Code Description Recommended Action

6000-xx

6001-xx

6002-xx

6014-xx

6016-xx

6028-xx

6029-xx

6089-xx

Network card ID failed

Network card setup failed

Network card transmit failed

Network card Configuration failed

Network card Reset failed

Network card Internal failed

Network card External failed

Network card Open failed

The following steps apply to error

codes 6000-xx through 6089-xx:

the EISA slot.

2. Check the interrupt type and

number setting.

3. Check the media connection at