Page 1

ProLiant 3000

Setup and Installation Guide

Second Edition (April 1998)

Part Number 296908-002

Compaq Computer Corporation

Page 2

Notice

The information in this publication is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR

EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN, NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OF THIS MATERIAL. THIS INFORMATION IS PROVIDED “AS IS” AND COMPAQ

COMPUTER CORPORATION DISCLAIMS ANY WARRANTIES, EXPRESS, IMPLIED OR

STATUTORY AND EXPRESSLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, GOOD TITLE AND AGAINST

INFRINGEMENT.

This publication contains information protected by copyright. No part of this publication may be

photocopied or reproduced in any form without prior written consent from Compaq Computer

Corporation.

1998 Compaq Computer Corporation.

All rights reserved. Printed in the U.S.A.

The software described in this guide is furnished under a license agreement or nondisclosure agreement.

The software may be used or copied only in accordance with the terms of the agreement.

This publication does not constitute an endorsement of the product or products that were tested. The

configuration or configurations tested or described may or may not be the only available solution. This

test is not a determination of product quality or correctness, nor does it ensure compliance with any

federal, state, or local requirements. Compaq does not warrant products other than its own strictly as

stated in Compaq product warranties.

Compaq, Fastart, Compaq Insight Manager, Systempro, Systempro/LT, ProLiant, Qvision, SmartStart,

and NetFlex, registered United States Patent and Trademark Office.

Netelligent, ProSignia, Systempro/XL, and SoftPaq are trademarks and/or service marks of Compaq

Computer Corporation.

Microsoft, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Product names mentioned herein may be trademarks and/or registered trademarks of their respective

companies.

Compaq ProLiant 3000 Setup and Installation Guide

Second Edition (April 1998)

Part Number 296908-002

Page 3

Contents

About This Guide

How this Manual is Organized.................................................................................................. viii

Text Conventions ........................................................................................................................ ix

Symbols in Text............................................................................................................................ x

Product Safety Information.......................................................................................................... x

Symbols on Equipment.........................................................................................................x

Getting Help............................................................................................................................... xii

Compaq CDs.......................................................................................................................xii

Other Hardcopy Documents...............................................................................................xiii

Compaq Web Site ..............................................................................................................xiii

Telephone Numbers...........................................................................................................xiv

Chapter 1

Compaq ProLiant 3000 Server Features

Standard Features......................................................................................................................1-1

Processor Boards................................................................................................................ 1-1

Cache Memory and System Architecture ..........................................................................1-2

System Memory.................................................................................................................1-2

Expansion Slots.................................................................................................................. 1-2

Media Bays......................................................................................................................... 1-3

Keyboard............................................................................................................................1-3

Video..................................................................................................................................1-3

SCSI ................................................................................................................................... 1-4

High-Availability Features................................................................................................. 1-4

System Management.......................................................................................................... 1-4

ROM...................................................................................................................................1-5

Fans ....................................................................................................................................1-5

Power Supply.....................................................................................................................1-5

Warranty.............................................................................................................................1-5

Management and Configuration Tools......................................................................................1-6

SmartStart...........................................................................................................................1-6

Disk Drive Fault Tolerance................................................................................................1-7

Compaq Insight Manager...................................................................................................1-7

Automatic Server Recovery-2 (ASR2)..............................................................................1-8

iii

ProLiant 3000 Setup and Installation Guide

Page 4

iv About This Guide

Compaq ProLiant 3000 Server Features

Security Features.......................................................................................................................1-8

Compaq Integrated Remote Console .................................................................................1-9

Compaq Integrated Management Display .........................................................................1-9

Supported Drive Configurations .............................................................................................1-10

Interlock Switches...................................................................................................................1-11

continued

Chapter 2

Installation Overview

Server Warnings and Precautions .............................................................................................2-2

Pre-installation Planning...........................................................................................................2-3

Power Requirements ..........................................................................................................2-3

Grounding .......................................................................................................................... 2-4

Server Temperature Requirements.....................................................................................2-4

Installation Procedure................................................................................................................2-5

Installing a Rack Mount Model .........................................................................................2-5

Installing a Tower Model...................................................................................................2-6

Chapter 3

Rack-Mount Server Installation

Rack Warnings and Precautions................................................................................................ 3-1

Rack Temperature Requirements.............................................................................................. 3-3

Airflow Requirements...............................................................................................................3-4

Unpacking the Server................................................................................................................3-5

Locating Materials and Documentation.............................................................................3-5

Preparing the Mounting Brackets and Slide Rail Assemblies ..................................................3-8

Attaching the Bracket Rail to the Mounting Bracket .......................................................3-9

Attaching the Mounting Bracket Slide Assembly to the Rack....................................... 3-14

Measuring with the Template ..........................................................................................3-14

Inserting Cage Nuts in the Rack Frame...........................................................................3-16

Attaching the Mounting Bracket Assembly to the Rack ................................................3-17

Attaching Component Rails to the Server .......................................................................3-20

Attaching the Cable Management Arm Bracket.....................................................................3-21

Loading the Rack Server.........................................................................................................3-22

Attaching the Cable Management Arm..................................................................................3-24

Attaching the Optional Cable Support...................................................................................3-26

Optional Installation Service...................................................................................................3-27

Page 5

Chapter 4

Installing Hardware Options

Accessing Non Hot-Plug Areas.................................................................................................4-2

Accessing Processors, Memory Board, and System Board............................................... 4-2

Accessing the Drive Cage Back Plane.............................................................................4-11

Replacing the Side Access Panel.....................................................................................4-19

Interlock System .............................................................................................................. 4-20

Accessing DIMM Sockets on the System Board............................................................4-21

Accessing Hot-Plug Areas ......................................................................................................4-23

Accessing the Hot-Plug SCSI Drives .............................................................................. 4-23

SCSI ID Numbers ............................................................................................................4-25

Pre-Failure Warranty............................................................................................................... 4-27

Insight Manager Alert......................................................................................................4-27

Chapter 5

Server Configuration and Utilities

Configuring the Server with SmartStart.................................................................................... 5-1

Using the System Configuration Utility.................................................................................... 5-3

Resolving Resource Conflicts................................................................................................... 5-4

Starting the System Configuration Utility.................................................................................5-5

System Configuration Utility Main Menu ................................................................................5-6

System Configuration Menu.............................................................................................. 5-6

System Partition.................................................................................................................5-8

Creating a New System Partition....................................................................................... 5-9

Verifying the System Partition.........................................................................................5-10

Upgrading the System Partition....................................................................................... 5-10

Configuration Backup.............................................................................................................5-11

Configuration Backup and Configuration History Files.................................................. 5-11

Configuring PCI Boards Automatically.................................................................................5-13

Removing Boards....................................................................................................................5-13

Installing an Operating System...............................................................................................5-13

SMP Operating System Support......................................................................................5-14

Loading Compaq Device Drivers............................................................................................5-15

Novell NetWare Device Drivers form Compaq...............................................................5-15

Microsoft Windows NT Device Drivers from Compaq ..................................................5-16

SCO OpenServer and SCO UnixWare Device Drivers from Compaq............................ 5-17

IBM OS/2 Device Drivers from Compaq........................................................................5-18

Banyan VINES Device Drivers from Compaq................................................................5-19

Diagnostics and Other Utilities...............................................................................................5-20

v

ProLiant 3000 Setup and Installation Guide

Page 6

vi About This Guide

Chapter 6

Integrated Management

Integrated Management Display ...............................................................................................6-1

Normal Run-time Behavior................................................................................................ 6-1

Navigation Buttons ............................................................................................................6-3

Display Symbols ................................................................................................................6-4

System Behavior with Error Events................................................................................... 6-5

Menu Structure...................................................................................................................6-6

Integrated Management Log .....................................................................................................6-7

Multiple Ways of Viewing the Log ...................................................................................6-8

List of Events ...................................................................................................................6-11

Appendix A

Power Cord Set Requirements

General Requirements.............................................................................................................. A-1

Appendix B

Regulatory Compliance Notices

Federal Communications Commission Notice......................................................................... B-1

Class A Equipment............................................................................................................ B-2

Class B Equipment............................................................................................................ B-2

Declaration of Conformity for Products Marked with FCC Logo, United States Only... B-3

Modifications .................................................................................................................... B-3

Cables................................................................................................................................ B-3

Canadian Notice(Avis Canadien)............................................................................................. B-4

Class B Equipment............................................................................................................ B-4

European Union Notice............................................................................................................ B-4

Japanese Notice........................................................................................................................ B-5

Australian Notice...................................................................................................................... B-5

Laser Devices........................................................................................................................... B-5

Laser Safety Warnings...................................................................................................... B-6

Compliance with CDRH Regulations............................................................................... B-6

Compliance with International Regulations...................................................................... B-6

Laser Product Label .......................................................................................................... B-7

Laser Information.............................................................................................................. B-7

Battery Replacement Notice..................................................................................................... B-8

Page 7

Appendix C

Internal CD-ROM Drive

Index

vii

ProLiant 3000 Setup and Installation Guide

Page 8

viii About This Guide

About This Guide

The Compaq ProLiant 3000 Setup and Installation Guide is intended to help you

set up your server for optimal performance. Use this guide with the technical

information on the configuration and installation poster, the hood labels, the

Systems Reference Library CD, the SmartStart and Support Software CD, and the

Management CD for complete and comprehensive reference source materials. For

the first time, you can now easily and quickly access much of the server’s

configuration and installation technical information by using the poster or the hood

labels.

How this Manual is Organized

This guide describes the features, configuration, diagnostics, and technical

specifications of your new server. It is divided into the following chapters:

Chapter 1 - Provides an overview of the Compaq ProLiant 3000 server

and its features.

Chapter 2 - Provides a summary of the installation procedure.

Chapter 3 - Covers the initial Compaq ProLiant 3000 rack-mount

installation.

Chapter 4 - Covers Compaq ProLiant 3000 option and upgrade

installation.

Chapter 5 - Covers Compaq ProLiant 3000 configuration and utilities.

Chapter 6 - Covers operation and use of the Integrated Management

Display (IMD) and Integrated Management Log (IML).

Appendixes - Cover power cord specifications and regulatory

compliances.

Page 9

Text Conventions

This document uses the following conventions to distinguish elements of text:

Keys Keys appear in boldface. A plus sign (+) between two

USER INPUT User input appears in a different typeface and in

FILENAMES File names appear in uppercase italics.

ix

keys indicates that they should be pressed

simultaneously.

uppercase.

Menu Options,

Command Names,

Dialog Box Names

COMMANDS,

DIRECTORY NAMES,

and DRIVE NAMES

Type When you are instructed to type information, type the

Enter When you are instructed to enter information, type the

These appear in initial capital letters.

These always appear in uppercase

information without pressing the Enter key.

information and then press the Enter key.

ProLiant 3000 Setup and Installation Guide

Page 10

x About This Guide

Symbols in Text

These symbols may be found in the text of this guide. They have the

following meanings.

WARNING: Indicates that failure to follow directions in the warning could

!

result in bodily harm or loss of life.

CAUTION: Indicates that failure to follow directions could result in damage

to equipment or loss of information.

IMPORTANT: Presents clarifying information or specific instructions.

NOTE: Presents commentary, sidelights, or interesting points of information.

Product Safety Information

Symbols on Equipment

These icons may be located on equipment in areas where hazardous conditions

may exist.

Any surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards.

Enclosed area contains no operator serviceable parts.

WARNING: To reduce the risk of injury from electrical shock

hazards, do not open this enclosure.

Page 11

Any RJ-45 receptacle marked with these symbols indicates a

Network Interface Connection.

WARNING: To reduce the risk of electrical shock, fire, or

damage to the equipment, do not plug telephone or

telecommunications connectors into this receptacle.

Any surface or area of the equipment marked with these

symbols indicates the presence of a hot surface or hot

component. If this surface is contacted, the potential for injury

exists.

WARNING: To reduce the risk of injury from a hot component,

allow the surface to cool before touching.

Power Supplies or Systems marked with these symbols

indicate the equipment is supplied by multiple sources of

power.

WARNING: To reduce the risk of injury from electrical

shock, remove all power cords to completely disconnect

power from the system.

xi

ProLiant 3000 Setup and Installation Guide

Page 12

xii About This Guide

Getting Help

If you have a problem and have exhausted the information in this guide, you

can get further information and other help in the following locations.

Compaq CDs

Compaq Systems Reference Library CD

Compaq Systems Reference Library CD is located in the Reference Information

pack and includes the following online documents:

Diagnostics

Integration TechNotes

Part number lists

SCSI and other options guides

Server Maintenance and Service Guides (MSGs)

Server reference guides

Compaq SmartStart and Support

Software CD

Compaq SmartStart and Support Software CD is located in the Server Setup and

Management pack and contains:

System Configuration Utility software

ROMPaq

Drivers

Page 13

Compaq Management CD

Compaq Management CD is located in Server Setup and Management pack

and contains:

Insight Manager Utility software

Online Help for the Insight Manager Utility

Other Hardcopy Documents

The following hardcopy documents are provided with the server:

Hood labels located on the inside of Side Access Panel and Top Access Panel

Cabling Guidelines for Compaq ProLiant 3000 Servers

Compaq ProLiant 3000 Hardware Installation and

Configuration Poster

Compaq Web Site

The Compaq Web Site has information on this product as well as the latest

drivers and Flash ROM images. You can access the Compaq Web Site by

logging on to the Internet at http://www.compaq.com.

xiii

ProLiant 3000 Setup and Installation Guide

Page 14

xiv About This Guide

A

A

A

A

Telephone Numbers

For the name of your nearest Compaq Authorized Reseller:

In the United States, call 1-800-345-1518

In Canada, call 1-800-263-5868

For Compaq technical support:

In the United States and Canada, call 1-800-386-2172

Elsewhere, call one of the numbers listed in the following table.

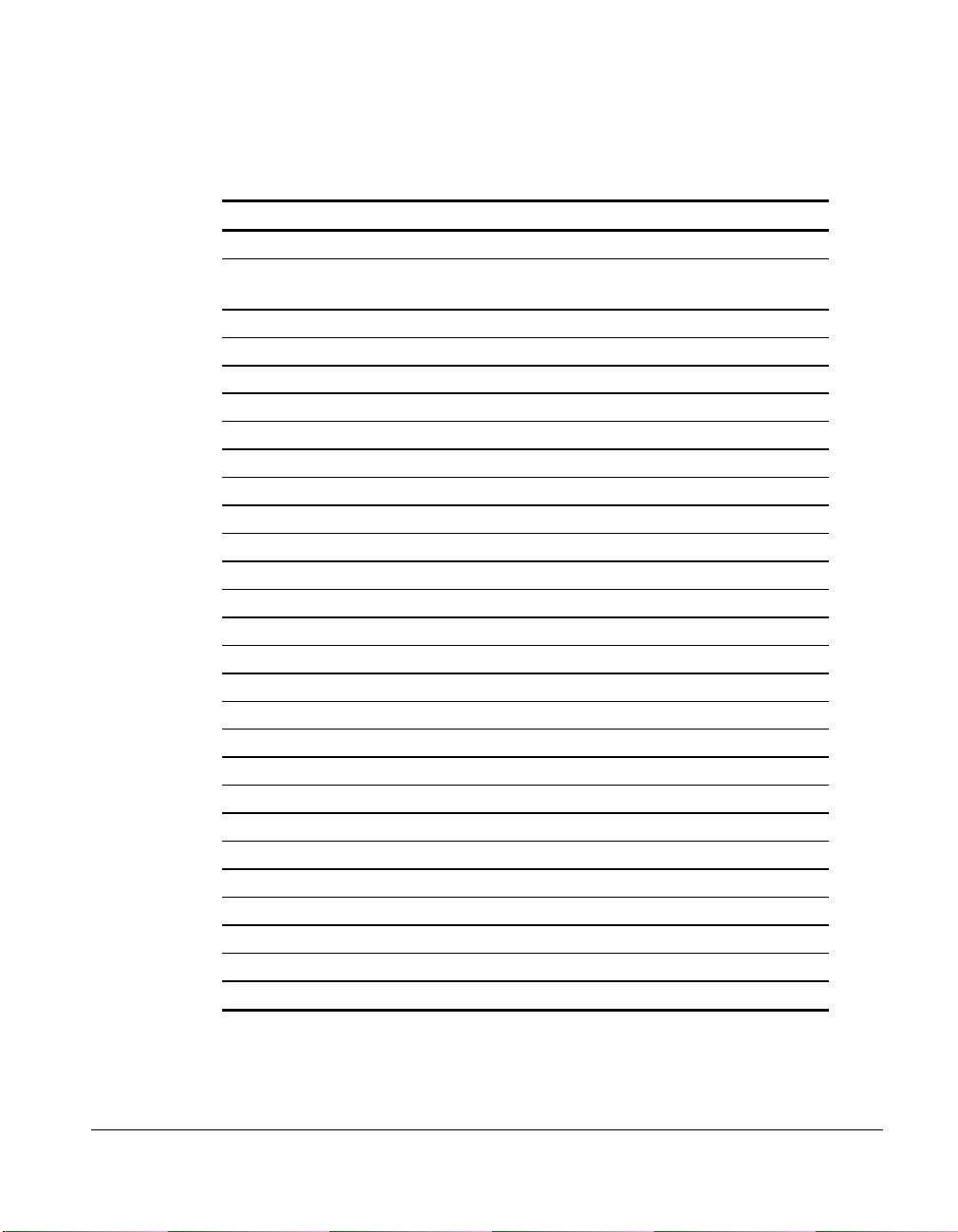

Location Voice FAX

PD 65-7503030 65-7504909

rgentina 54-1 313 3100 54-1 313 3100 Ext 21

ustralia 61-2-9911-1955 61-2-9911-1900

ustria 0222-87816-16 0222-87816-82

Bahrain 973-210-214

Belgium (02) 716-96-96 (02) 725-22-13

Brazil 55 11 5505-3600 55 11 5505-3922

Canada 1-800-386-2172

Caribbean 1-800-345-1518

Central America 281-378-2206

Chile 562-274-3007

China 86-10-834-6721 86-10-834-6713

Colombia 571-345-0266 571-312-0157

Czech Republic 42-2-232-8772 42-2-232-8773

Denmark 45-90-4545 45-90-4595

Ecuador 593-2504540

Compaq Worldwide Technical Support Telephone Numbers

Ext 4336

continued

Page 15

Compaq Worldwide Technical Support Telephone Numbers

V

continued

Location Voice FAX

Europe/Middle East/Africa (49) 089-9933-2891

Finland 9800-206-720

(+358-800-1-206720)

90-6155-9899

(+358-0-61559899

France (33 1) 41-33-4455 (33 1) 41-33-4263

Germany 0180-5-212111 089-9933-3399

Hong Kong 852-90116633 852-28671734

Hungary 36-1-201-8776 36-1-201-9696

India (91-80) 559-6023

Italy 392-57-90300 392-575-00686

Japan 0120-101589 +81 3-5402-5959

Korea 82-2-523-3575 82-2-3471-0321

Malaysia (603) 718-1636

Mexico (525) 229-7910 (525) 229-7988

Netherlands 06-91681616 06-8991116

New Zealand 649-307-3969

Norway 22-072-020 22-072-021

Poland 48-2-630-3535 48-2-630-3553

Portugal 351-1-4120132 351-1-4120654

Singapore 65-7503030 65-7504909

South Africa +27-11-728-6999 +27-11-728-3335

Spain 341-640-1302 341-640-0124

Sweden (46) 8 703 5240 (46) 8 703 5222

Switzerland 411 838 410/2222 01-837-0969

Taiwan (886) 2-3761170 (886) 2-7322660

Thailand 62-2-679-6222 62-2-679-6220

United Kingdom 44-81-332-3888 44-81-332-3409

United States 1-800-386-2172 1-800-345-1518

enezuela (582) 953.69.44 (582) 952.86.70

xv

ProLiant 3000 Setup and Installation Guide

Page 16

xvi About This Guide

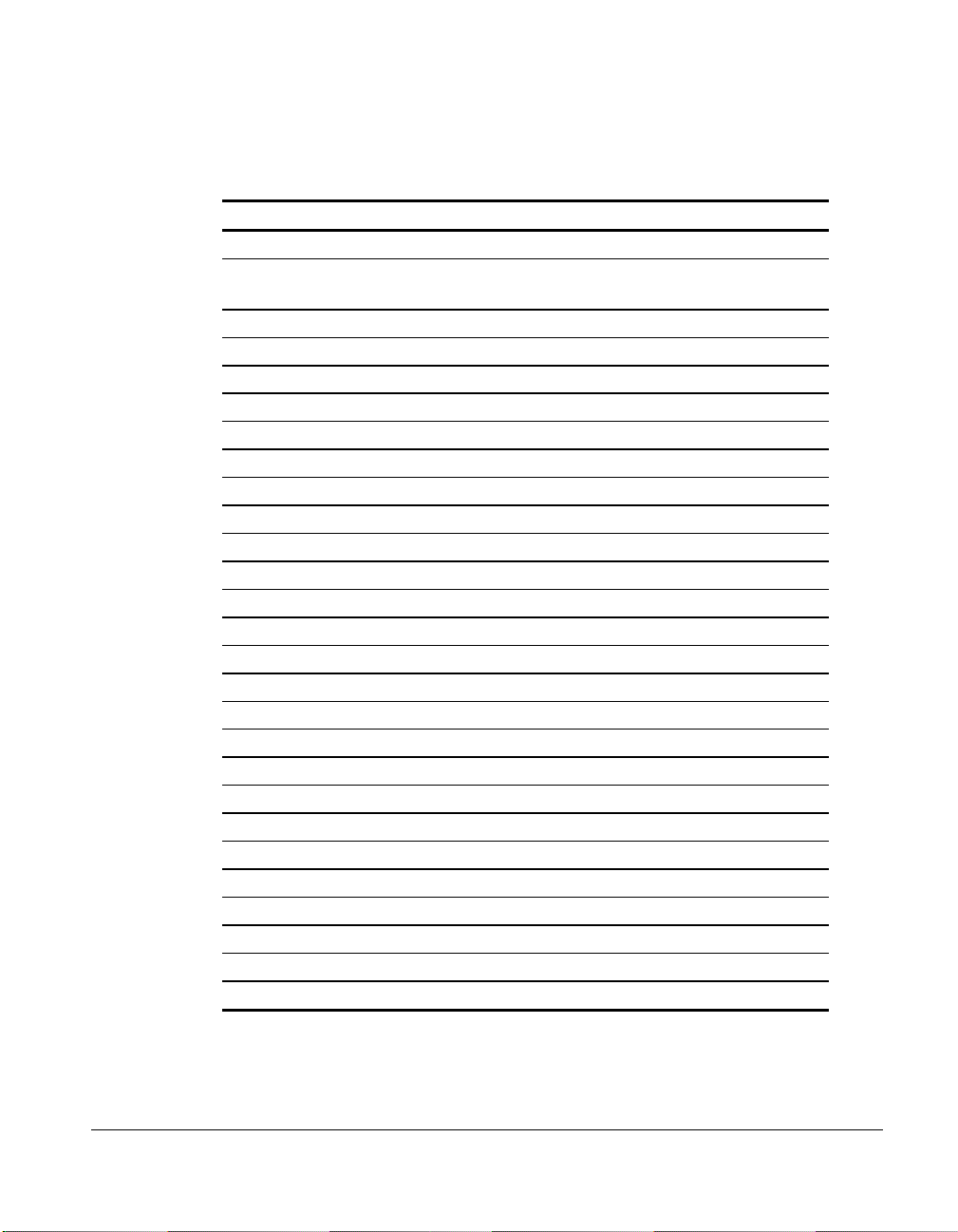

Compaq Worldwide Technical Support Telephone Numbers

continued

Location Voice FAX

Europe/Middle East/Africa (49) 089-9933-2891

Finland 9800-206-720

France (33 1) 41-33-4455 (33 1) 41-33-4263

Germany 0180-5-212111 089-9933-3399

Hong Kong 852-90116633 852-28671734

Hungary 36-1-201-8776 36-1-201-9696

India (91-80) 559-6023

Italy 392-57-90300 392-575-00686

Japan 0120-101589 +81 3-5402-5959

Korea 82-2-523-3575 82-2-3471-0321

Malaysia (603) 718-1636

Mexico (525) 229-7910 (525) 229-7988

Netherlands 06-91681616 06-8991116

New Zealand 649-307-3969

Norway 22-072-020 22-072-021

Poland 48-2-630-3535 48-2-630-3553

Portugal 351-1-4120132 351-1-4120654

Singapore 65-7503030 65-7504909

South Africa +27-11-728-6999 +27-11-728-3335

Spain 341-640-1302 341-640-0124

Sweden (46) 8 703 5240 (46) 8 703 5222

Switzerland 411 838 410/2222 01-837-0969

Taiwan (886) 2-3761170 (886) 2-7322660

Thailand 62-2-679-6222 62-2-679-6220

United Kingdom 44-81-332-3888 44-81-332-3409

United States 1-800-386-2172 1-800-345-1518

Venezuela (582) 953.69.44 (582) 952.86.70

90-6155-9899

(+358-800-1-206720)

(+358-0-61559899

Page 17

Chapter 1

Compaq ProLiant 3000 Server

Features

Compaq ProLiant 3000 servers deliver state-of-the-art Intel Pentium II

processor technology, expanded storage capacity, dual memory controllers,

dual peer PCI buses, and advanced high-availability features.

Performance is maximized with up to two Pentium II processors, a new system

architecture that improves overall system bandwidth, and up to 512 megabytes

(for 300MHz models) or up to 3 gigabytes (for 333MHz models) of buffered

EDO ECC memory. Input/output performance is enhanced by features such as

Wide-Ultra SCSI-3 hard drives.

Compaq ProLiant 3000 servers provide state-of-the-art reliability and highavailability features, including redundant hot-pluggable power supplies and

hot-pluggable Wide-Ultra SCSI-3 drives.

To facilitate upgrade and repair tasks, Compaq designed the ProLiant 3000

server so that no tools are required to enter the chassis.

1-1

Standard Features

The following features are standard on all Compaq ProLiant 3000 models,

unless otherwise noted.

Processor Boards

■ Support for up to two Intel Pentium II processors (1 processor per

processor board) with corresponding processor power modules, and

512K cache

■ Upgradable to future Intel Pentium II processors

ProLiant 3000 Setup and Installation Guide

Page 18

1-2

Compaq ProLiant 3000 Server Features

Cache Memory and System Architecture

■ 512-KB secondary (L2) cache

■ Compaq ProLiant 3000 System Architecture with Dual Memory

controllers and Dual Peer PCI buses

System Memory

■ 64-MB standard, extended data out (EDO), error checking and

correcting (ECC) DIMMs

■ Supports EDO buffered, 60-ns or faster, 32-, 64-, 128-, or 256-MB, , 4-K

or 8-K refreshed DIMMs.

NOTE: Memory option kits contain two DIMMs to equal the total memory.

For example, the 32-MB option kit contains two 16-MB DIMMs.

■ Expandable to 512 MB (for 300 MHz models) or 3 GB (for 333MHz

models)

■ Supports up to 6 memory banks, each bank consisting of 2 DIMMs. One

bank is installed or removed at a time. Each bank must have each two

DIMMs of the same size and speed.

Expansion Slots

Eight I/O expansion slots:

■ Five dedicated PCI slots

■ Three shared PCI/EISA slots

■ Pre-installed Compaq Netelligent 10/100 TX PCI UTP Controller

Page 19

Media Bays

Keyboard

1-3

The Compaq ProLiant 3000 server can house up to 12 mass storage devices.

■ Internal Drives - the server can be configured in either Simplex or

Duplex drive cage configurations. Simplex mode configures the drive

cage into a single drive cage attached to a single SCSI channel. Duplex

mode configures the drive cage into two separate drive cages that are

connected to separate SCSI channels. For further information about

media bay configurations, refer to Chapter 4, “Installing Hardware

Options,”

❏ Simplex mode: Seven 1-inch drives or six 1.6-inch drives

❏ Duplex mode: Eight 1-inch drives or six 1.6-inch drives

■ Preinstalled 16X IDE CD-ROM drive

■ Two additional half-height drive bays (removable media area)

■ Preinstalled 3 ½” 1.44-MB diskette drive

Video

The keyboard connector is hot-pluggable. Any standard keyboard can be

plugged in without powering down the system.

■ Integrated PCI Video Controller provides maximum resolution of 1024

x 768, 256 color, non-interlaced

■ 16 to 256 colors, depending on graphics mode. 1 MB video DRAM

standard

■ Supports SVGA, VGA, and EGA graphics resolution

ProLiant 3000 Setup and Installation Guide

Page 20

1-4

Compaq ProLiant 3000 Server Features

SCSI

■ Dual Channel Integrated Wide-Ultra SCSI-3 controller

■ The following optional controller boards are currently supported for

controller duplexing or expanding storage capacity (see

http://www.compaq.com for updates on device support)

❏ Wide-Ultra SCSI-3 Controller

❏ SMART-2 Array Controller

❏ SMART-2SL Array Controller

High-Availability Features

■ Hot-Plug SCSI drive bays

■ Hot-Plug Redundant Power supplies

■ Optional redundant NIC and SCSI controllers

■ Optional redundant fans

System Management

■ The Server Parameter Tracking utility provides timely server

environment and subsystem information by using a combination of

hardware, firmware, and industry standard management software.

Information provided by this utility includes fault, performance, and

configuration status.

■ The Server Fault Tolerance feature provides many disk subsystem and

memory system error correction fault tolerance options.

■ The Rapid Recovery Services provides fast identification and resolution

of complex faults. Highlights of this integrated server management

feature include: Integrated Management Logs, Automatic Server

Recovery- 2 (ASR-2), and Compaq Integrated Remote Console.

Page 21

■ Integrated Management Display (IMD) offers a text-based user

■ Integrated Management Log (IML) provides a detailed log of key

ROM

■ Software upgradable firmware including diagnostics

■ ROMPaq Utility used to upgrade ROM

Fans

■ Standard: Two 120-mm fans and one 92-mm CPU auxiliary fan

■ Optional: Two 120-mm redundant fans

Power Supply

1-5

interface. The IMD displays and stores key system events at the server

so that critical information is at your fingertips.

system events. This log is accessible through Insight Manager, the

Remote Insight board, the Compaq Survey utility, the Compaq IML

Management utility, and the IMD.

Warranty

■ Standard: One hot-plug 750-W (at 220V) power supply

■ Optional: One hot-plug 750-W (at 220V) redundant supply (RPS)

■ Pre-Failure Warranty on processors, memory, hard drives, and power

supplies

ProLiant 3000 Setup and Installation Guide

Page 22

1-6

Compaq ProLiant 3000 Server Features

Management and Configuration

Tools

Compaq offers an extensive set of features and optional tools to support

effective server management and configuration. These features are described:

■ SmartStart

■ Fault Tolerance

■ Compaq Insight Manager

■ Automatic Server Recovery-2 (ASR-2)

■ Integrated Management Display (IMD) standard

■ Integrated Management Log

■ PCI bus utilization

■ Integrated Remote Console (IRC)

SmartStart

SmartStart is the intelligent way to configure your Compaq server with major

operating system software. SmartStart helps you achieve a well-integrated

server that ensures maximum dependability and supportability. For further

information about configuration, see Chapter 5, “Server Configuration and

Utilities.”

Page 23

Disk Drive Fault Tolerance

Disk drive fault tolerance for Compaq servers is covered in more detail in the

Compaq Server Online Reference Guide on the Systems Reference Library

(SRL) CD. The following Redundant Array of Inexpensive Disks (RAID) types

are supported:

■ RAID 0 - no fault tolerance

■ RAID 1 - mirroring

■ RAID 4 - data guarding

■ RAID 5 - distributed data guarding

Compaq Insight Manager

Compaq Insight Manager is an easy-to-use intuitive software utility for

collecting server information. This information is used by Insight Manager to

perform the following functions:

■ Sends fault condition alerts to a predetermined destination

■ Monitors fault conditions and server performance

1-7

■ Controls server security and configuration

■ Remotely controls servers

■ Initiates rapid recovery services

In Compaq servers, every hardware subsystem, such as disk storage, system

memory, and system processor, has a robust set of management capabilities.

Compaq Full-Spectrum Fault Management prevents faults before they happen,

keeps the system up and running in the unlikely event of a failure, and delivers

rapid server recovery to normal operation after a fault. See Chapter 5, “Server

Configuration and Utilities,” for more information.

ProLiant 3000 Setup and Installation Guide

Page 24

1-8

Compaq ProLiant 3000 Server Features

Automatic Server Recovery-2 (ASR2)

If there is a critical system failure, Automatic Server Recovery-2 allows you to

restart the server and page a designated system administrator. For more

information, see the Compaq Server Online Reference Guide on the Systems

Reference Library CD (SRL).

Security Features

■ Power-On Password

■ Administrator Password

■ Network Server Mode

■ Diskette Boot Control

■ Power Switch Disable (operating system dependent)

■ Serial/Parallel Interface Control

■ Remote Access Password

Refer to the Compaq Server Online Reference Guide on the Systems Reference

Library (SRL) CD for more information on these security features.

Page 25

Compaq Integrated Remote Console

When the Compaq ProLiant 3000 server is equipped with an optional supported

modem, you can perform a wide range of configuration activities using the

standard Compaq Integrated Remote Console (IRC). Some of the IRC features:

■ Accessible using ANSI terminal

■ Operates independently of the operating system

■ Provides for remote server reboot

■ Provides access to system configuration

■ Uses out-of-band communication with dedicated management modem

installed in the server

For more information about the IRC, see the Integrated Remote Console User

Guide shipped with the server.

Compaq Integrated Management Display

The Integrated Management Display (IMD) is an LCD display panel that assists

you in diagnosing and servicing the server without using a keyboard and

monitor.

1-9

The features of the Integrated Management Display include:

■ Flexibility - The Integrated Management Display rotates to support both

tower and rack configurations.

■ Manageability - Typical service and administrative information

displayed includes:

❏ POST (Power-On Self-Test) messages

❏ User-defined administrative information

❏ POST and run-time error events

❏ System information

ProLiant 3000 Setup and Installation Guide

Page 26

1-10

Compaq ProLiant 3000 Server Features

■ Ease of Use - The Integrated Management Display provides a 16x4

character display and four button control panel to easily navigate

through menus.

For information about using the IMD, see Chapter 6, “Advanced Feature

Operation.”

Supported Drive Configurations

Standard server configurations can include as many as seven SMART-2 or

SMART-2SL Controllers, depending on the installed network operating system.

The SMART-2 controller can support two Compaq ProLiant Storage Systems

or one Compaq ProLiant Storage System and up to eight internal, hot-pluggable

hard drives. The SMART-2SL controller can support one Compaq ProLiant

Storage System or seven internal, hot-pluggable hard drives.

A maximum practical SCSI configuration, optimizing performance and storage,

could include the following:

■ One network interface controller (NIC)

■ Seven SMART-2 or SMART-2SL Controllers

■ Twelve Compaq ProLiant Storage Systems

■ Ninety 9.1 GB drives

This configuration would yield a total storage capacity of 819 gigabytes.

Page 27

Interlock Switches

Compaq ProLiant Servers contain built-in interlock switches. This feature:

■ Automatically turns the power off when you remove the server side or

top covers ensuring your personal safety.

■ Protects thermally sensitive components by providing optimal air flow

throughout the unit; therefore, removing this cover turns the power off

to prevent any undesirable temperature conditions that could result in

damage to the equipment.

The interlock switch does not limit access to the hot-pluggable SCSI drives and

power supplies. Do not attempt to bypass or defeat this device.

1-11

WARNING: To reduce the risk of personal injury from contact

with hazardous energy, the equipment is provided with safety

interlocks. Do not try to defeat these safety interlocks. If an

access cover is removed, the power supply is disabled until the

cover is properly replaced.

ProLiant 3000 Setup and Installation Guide

Page 28

Chapter 2

Installation Overview

This chapter presents an overview of the installation and configuration

procedure for Compaq ProLiant 3000 servers. You are referred to later

chapters in this guide for detailed discussions of rack installation, hardware

option installation, and configuration. Topics in this chapter include:

■ Server Warnings and Precautions - This section presents the

precautions and warnings necessary to ensure safe installation of your

server.

■ Pre-installation Planning - This section discusses the power,

grounding, and temperature requirements of the Compaq ProLiant 3000

server.

■ Installation Procedure - This section is a summary of the steps you

will follow to install your Compaq ProLiant 3000 server.

2-1

ProLiant 3000 Setup and Installation Guide

Page 29

2-2

Installation Overview

Server Warnings and Precautions

WARNING: To reduce the risk of personal injury from hot surfaces,

allow the hot plug drives and internal system components to cool before

touching.

WARNING: To reduce the risk of electric shock or damage to the

equipment:

■ Do not disable the power cord grounding plug. The grounding plug is

an important safety feature.

■ Plug the power cord into a grounded electrical outlet that is easily

accessible at all times.

■ Install the power supply before connecting the power cord to the

power supply.

■ Unplug the power cord before removing the power supply from the

server.

■ If the system has multiple power supplies, disconnect power from the

system by unplugging all power cords from the power supplies

CAUTION: Be sure that the power outlet you plug your power cord into

is easily accessible and located as close as possible to the equipment

operator. When you need to disconnect power to the equipment, be sure

to unplug the power cord from the power outlet.

CAUTION: Protect the server from power fluctuations and temporary

interruptions with a regulating uninterruptible power supply (UPS). This

device protects the hardware from damage caused by power surges and

voltage spikes and keeps the system in operation during a power failure.

CAUTION: The Compaq ProLiant Server

must always be operated with

the system unit cover on. Proper cooling will not be achieved if the

system unit cover is removed.

IMPORTANT: Because of the 100 to 120 VAC electrical rating of each power

supply, some local electrical authorities may require either one 15-Ampere circuit for

each power supply or one 20-Ampere circuit for each

pair of power supplies.

Page 30

Pre-installation Planning

This section discusses the power, grounding, and temperature requirements of

the Compaq ProLiant 3000 server.

Power Requirements

WARNING: To reduce the risk of personal injury, fire, or

damage to the equipment, do not overload the AC supply

branch circuit that provides power to the server. Consult the

electrical authority having jurisdiction over your facility wiring

and installation requirements.

■ The power load needs to be balanced between available AC supply

branch circuits.

■ The overall system AC current load must not exceed 80 percent of the

branch circuit AC current rating.

■ If power strips are used, the load should not exceed 80 percent of the

power strip's marked electrical current rating.

2-3

The installation of this equipment shall be in accordance with Local/Regional

electrical regulations governing the installation of Information Technology

Equipment by licensed electricians. This equipment is designed to operate in

installations covered by the National Electric Code (ANSI/NFPA 70, 1993) and

the code for Protection of Electronic Computer/Data Processing Equipment

(NFPA-75, 1992).

ProLiant 3000 Setup and Installation Guide

Page 31

2-4

Installation Overview

This product is also designed for IT power system with Phase to Phase voltage

230 V.

For electrical power ratings on options, refer to the product's rating label or user

documentation supplied with that option.

Grounding

For proper operation and safety, this equipment is required to be properly

grounded in accordance with NFPA 70-1993, Article 250. All power

distribution devices, branch wiring, and receptacles must be "Listed" grounding

type devices.

When using power strips for electrical distribution, ensure that ground integrity

is maintained for each connection made. Plug each component into a reliably

grounded outlet.

Server Temperature Requirements

To ensure continued safe and reliable operation of the equipment, locate the

system in a well-ventilated, climate-controlled environment.

The Compaq Maximum Recommended Ambient Operating Temperature

(TMRA) for most server products is 35°C (95°F). Therefore, the temperature in

the room where the rack is located should not exceed 35°C (95°F).

Page 32

Installation Procedure

There are two installation procedures presented in the following paragraphs.

Each procedure is a summary of the steps you will follow to install your

Compaq ProLiant 3000 server. The procedure you will use depends on whether

you are installing a rack-mount model or a tower model server. Detailed

instructions for each of the numbered steps are included in later chapters of this

guide.

Installing a Rack Mount Model

1. Select an appropriate site for your rack. See the Rack Planning and

Installation Guide for site selection criteria.

2. Make sure that that stabilizer feet are installed on the rack.

3. Unpack the server.

4. Unpack the rack mounting hardware.

5. Install any hardware options in the server. See Chapter 4 and the options

kits for detailed instructions.

6. To make the server lighter and more manageable, do not install SCSI

drives in the server until after you load the server into the rack. You

may also lighten the server by removing the power supplies and

reinstalling them after you have mounted the server in the rack.

2-5

7. Set switches: processor board switches, system board switches, and

SCSI ID settings.

8. Attach rack mounting hardware to the rack and to the server. See

Chapter 3 for detailed instructions.

9. Slide the server into the rack. See Chapter 3.

10. Attach the cable management arm to the cable management arm bracket.

See Chapter 3.

11. Attach the optional cable support to the back of the rack. The cable

support is needed only if you are routing cables from one side of the

rack to the other. See Chapter 3.

ProLiant 3000 Setup and Installation Guide

Page 33

2-6

Installation Overview

12. Connect cables: keyboard, mouse, monitor, network, and power cables.

See Cabling Guidelines for Compaq ProLiant 3000 Servers.

13. Turn on the computer and insert the SmartStart and Support Software

CD to configure and manage the server. When the server boots from the

SmartStart program, it automatically starts the System Configuration

Utility. See Chapter 5 for detailed information.

14. Order Activation Keys.

15. Register your server.

For complete details on the SmartStart program, read the SmartStart installation

card included in your SmartStart package.

After the SmartStart program has finished configuring your system, you have

completed the installation of your new Compaq server.

Installing a Tower Model

1. Unpack the server.

2. Install any hardware options in the server. See Chapter 4 and the options

kits for detailed instructions.

3. Set system board switches

4. Connect cables: keyboard, mouse, monitor, network, and power cables.

See Cabling Guidelines for Compaq ProLiant 3000 Servers.

5. Turn on the computer and insert the SmartStart and Support Software

CD to configure and manage the server. When the server boots from the

SmartStart program, it automatically starts the System Configuration

Utility. See Chapter 5 for detailed information.

6. Order Activation Keys.

7. Register your server.

Page 34

For complete details on the SmartStart program, read the SmartStart installation

card included in your SmartStart package.

After the SmartStart program has finished configuring your system, installation

of your new Compaq server is complete.

2-7

ProLiant 3000 Setup and Installation Guide

Page 35

Chapter 3

Rack-Mount Server Installation

This chapter covers the following information:

■ How to attach the mounting hardware to the server and to the rack

■ How to install the server into the rack

You may choose Compaq’s optional installation service to install your rack

products. See “Optional Installation Service” at the end of this chapter.

For more information about Compaq rack-mountable products, refer to the

following Compaq documentation included with the server:

■ Rack Planning and Installation Guide

This guide provides you with complete details on Compaq racks and

rack-mountable products.

■ Rack Builder media

This program allows you to build an online version of your proposed

rack configurations. You can add icons of the rack model server and

other rack-mount components to a graphic of the rack you intend to use.

You can print reports of your simulations that include a list of all the

Compaq parts and part numbers that are required for complete

installation.

3-1

■ Rack-Mountable Compaq ProLiant Server Installation Video

This video is about thirty minutes long and contains handy tips and

tricks to help you efficiently and safely install your rack-mountable

products.

Rack Warnings and Precautions

Before beginning these procedures, make sure you understand the following

warnings and caution.

ProLiant 3000 Setup and Installation Guide

Page 36

3-2

Rack-Mount Server Installation

WARNING: To reduce the risk of personal injury or damage to the

equipment, at least two people are needed to safely unload the rack

from the pallet. An empty 42U rack weighs 253 LB (115 kg), is over

seven ft (2.1m) tall, and may become unstable when being moved

on its casters. Do not stand in front of the rack as it rolls down the

ramp from the pallet, but handle it from the sides.

WARNING: Because the rack allows you to stack computer

components on a vertical rather than a horizontal plane, you must

take precautions to provide for rack stability and safety. It is

important that you follow these basic instructions to protect both

personnel and property, and that you heed all cautions and

warnings throughout the installation instructions.

WARNING: Always load the heaviest item first and always load

the rack from the bottom up. This will make the rack "bottomheavy" and help prevent the rack from becoming unstable. See

"Rules for the Rack Builder" on the Rack Builder diskette for the

rules that govern the vertical placement of rack-mounted

components.

WARNING: A rack may become unstable if more than one

component is extended for any reason. To reduce the risk of

personal injury, always ensure that the rack is adequately stabilized

before extending a component outside the rack, and extend only

one component at a time.

WARNING: Before beginning to work on the rack, be sure that

the leveling jacks are extended to the floor, that the full weight of

the rack rests on the level floor, and that either stabilizers are

installed or that multiple racks are coupled together for stability.

CAUTION: Do not place anything on power cords or cables.

Arrange them so that no one may accidentally step or trip over

them. Do not pull on a cord or cable. When unplugging from the

electrical outlet, grasp the cord by the plug.

WARNING: To avoid the risk of personal injury or damage to the

equipment, a minimum of two people MUST lift the server into the

rack. The server weighs about 50 pounds (22.6 kilograms). If the

unit is to be loaded above chest level, a third person must assist in

aligning the rails while the other two support the unit.

Page 37

Rack Temperature Requirements

The operating temperature inside the rack will always be higher than the room

temperature, and is dependent on the configuration of equipment in your rack.

The TMRA for each piece of equipment should be checked before installation.

The maximum internal rack temperature for your configuration should not

exceed the values in the following table:

Table 3-1

Rack Internal Temperature Maximums

Equipment Included Maximum InternalRack Temperature

Rack-Mountable ProLiant Servers 50°C/122°F

Compaq Rack-Mountable options 40°C/104°F

Other manufacturers' options See other manufacturers' specifications

CAUTION: To reduce the risk of damage to the equipment

when installing third-party options:

■ Ensure that the option equipment does not impede airflow to

the Rack-Mountable ProLiant Servers or increase the internal

rack temperature

beyond the Compaq specified maximum rating.

3-3

■ Ensure that the Manufacturer’s Maximum Recommended

Ambient Operating Temperature of the option equipment is

not exceeded when installed in the rack.

ProLiant 3000 Setup and Installation Guide

Page 38

3-4

Rack-Mount Server Installation

Airflow Requirements

Compaq ProLiant rackmountable servers draw cool air in through the front door

and exhaust warm air out the rear. Therefore, the front door of the rack must be

adequately ventilated to allow ambient room air to enter the cabinet, and the

rear door must be adequately ventilated to allow the warm air to escape from

the cabinet. Do not block the ventilation apertures.

CAUTION: If a third-party rack is used, the following minimum

requirements should be observed to ensure adequate airflow and

to prevent damage to the equipment:

Front: The front must have a minimum of 25 inches of

unrestricted ventilation.

Side: The clearance between the installed module and the side

panels of the rack should be a minimum of 2.75 inches.

Rear: The clearance between the back of the rack and the wall

should be a minimum of 30 inches. The equipment should

be operating without a rear door.

NOTE: If all of the vertical space in the rack is not filled by components, the gaps

that are left cause a change in airflow through the rack and across the components.

These gaps should be covered with blanking panels.

Page 39

Unpacking the Server

Unpack the server box and locate the materials and documentation necessary to

install your rack-mountable server.

Locating Materials and Documentation

All of the equipment needed to install the ProLiant 3000 server in the rack is

included with the rack and with the server

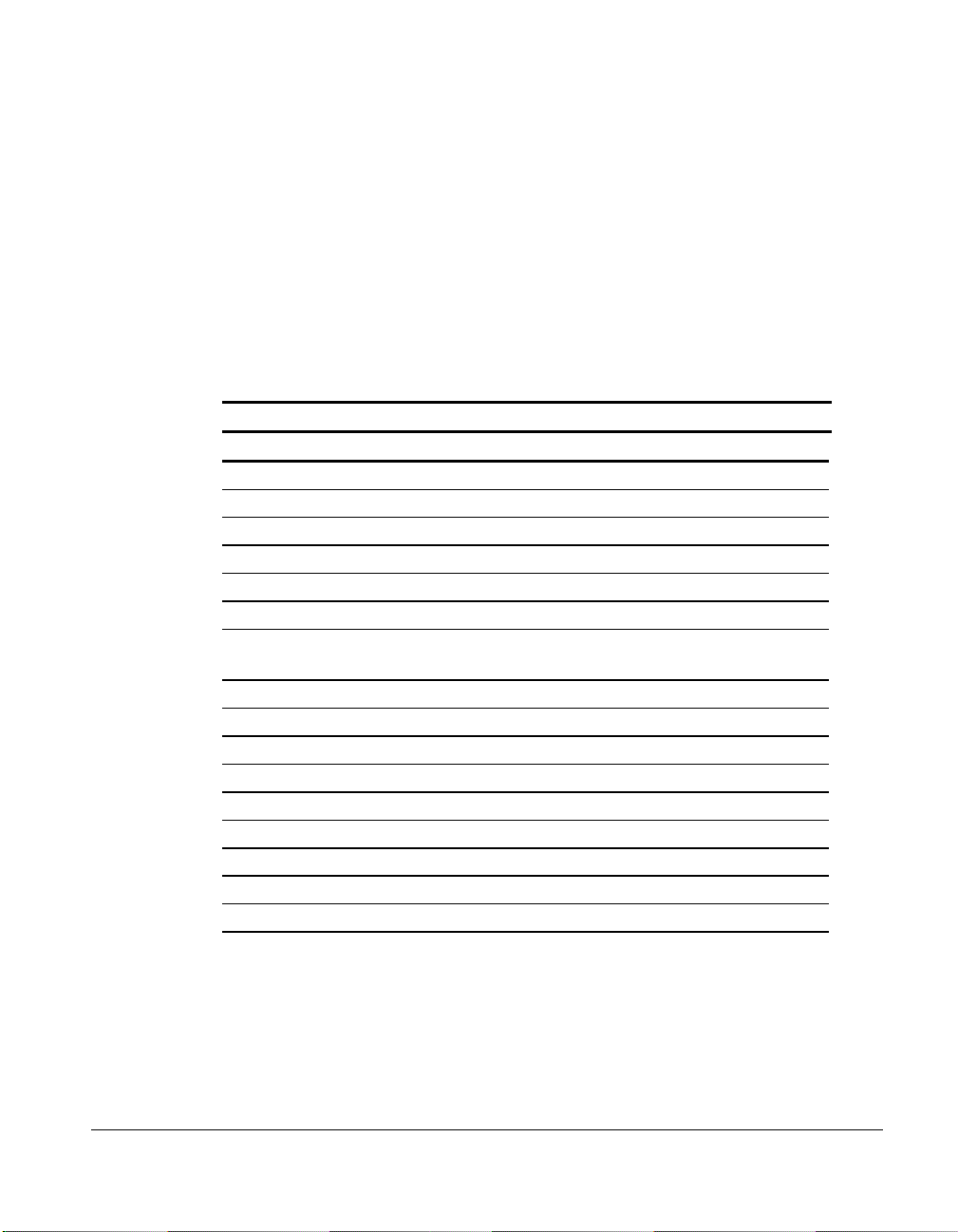

1

6

3-5

2

3

7

Figure 3-1.

4

5

Rack mounting hardware included with the server

ProLiant 3000 Setup and Installation Guide

Page 40

3-6 Rack-Mount Server Installation

Contents of the rack model server box include

■ Compaq ProLiant 3000 server

■ Cables - see Cabling Guidelines for Compaq ProLiant 3000 Servers

■ Rack mounting hardware (numbers reference Figure 3-1)

1

One pair slide rail mounting brackets

2

One pair 26-inch slide rail assemblies

3

Cable management arm bracket

4

Cable management arm

5

Cable management arm screws

6

Plastic rail covers (2)

Cable management arm support bracket

❏ Template that can be used to mark the rack for proper

attachment of the rack mounting brackets (not shown)

■ Documentation and software

❏ Server Setup and Management Package

❏ Reference Information Package

❏ Rack Planning and Installation Guide

❏ Rack Builder media

❏ Rack Installation Video

❏ CompaqCare folder

❏ Compaq Product Quality Statements

❏ Owner’s Registration folder

Page 41

In addition to these supplied items, you may need:

■ Torx T-15 screwdriver

■ Phillips screwdriver

■ Slotted screwdriver

■ Application software diskettes, such as SmartStart

■ Options to be installed, such as

❏ Optional uninterruptible power supply (UPS)

❏ Optional monitor, keyboard, etc.

3-7

ProLiant 3000 Setup and Installation Guide

Page 42

3-8

Rack-Mount Server Installation

Preparing the Mounting Brackets

and Slide Rail Assemblies

Each pair of mounting brackets, with attached slide rail assemblies, supports

one rack-mountable server.

Figure 3-2.

Each slide rail assembly consists of an outer bracket rail and an inner

component rail (see the following figure). These pieces can be separated; the

bracket rails attach to the rack mounting brackets (shown in the previous

figure), and the component rails attach to the sides of the server chassis.

Rack mounting brackets; alignment tabs identify the front flanges

Page 43

3-9

Figure 3-3.

Slide rail assembly (outer bracket rail and inner component rail)

IMPORTANT: To make the installation of the mounting bracket easier,

attach the bracket rail to the rack mounting bracket before attaching the

mounting bracket assembly to the rack. This way, the joined mounting

bracket and bracket rail can be fastened to the rack as one assembly.

Attaching the Bracket Rail

to the Mounting Bracket

Please read all of the following eight steps before you begin.

1. Unpack the hardware mounting kit. Lay the two-piece slide rail

assembly (outer bracket rail and inner component rail) and fasteners on a

flat surface along with the mounting brackets and fasteners that came

with the rack.

2. Extend the component rail from the bracket slide rail until the

component rail release latch clicks. Holding down the latch, slip this

piece out of each bracket rail, as shown in the following figure.

ProLiant 3000 Setup and Installation Guide

Page 44

3-10

Rack-Mount Server Installation

Figure 3-4.

Removing the component rail from the bracket rail

3. Put the component rails to one side. You will attach them to the rack

server chassis later, in the section, "Attaching Component Rails to the

Server."

The next figure shows the separated bracket rail with its inner sliding piece and

the flat, one-piece component rail.

Figure 3-5.

Separated bracket rail (top) and component rail

Page 45

The bracket rail consists of a fixed outer rail that screws to the rack mounting

bracket, and an inner slide on a steel ball bearing movement. This inner slide

does not detach.

3-11

Figure 3-6.

Bracket rail with inner slide. The front of the rail is highlighted.

4. Lay the bracket rail inside the mounting bracket with the front of both

pieces oriented in the same direction. Align the front screw holes in the

mounting bracket and the bracket rail.

To identify the front of the mounting bracket and the bracket rail:

❏ The front of the mounting bracket has alignment tabs on its flange.

❏ The front of the bracket rail allows the inner slide to move forward

on ball bearings.

ProLiant 3000 Setup and Installation Guide

Page 46

3-12

Rack-Mount Server Installation

5. Extend the inner slide from the front of the bracket rail. With this piece

6. Fasten the bracket rail to the mounting bracket with one 8-32 x 1/4-inch

7. Adjust the inner slide to access the other two screw holes, one at a time,

The following figure shows inserting the screws into the appropriate holes. The

screws will line up with the 26-inch markings stamped along one edge of the

mounting bracket. These marks identify the mounting holes for the 26-inch

slides used in Compaq racks. (The other markings stamped along the opposite

edge are for use with slides that support other components.)

extended, you will see two screw holes aligned in the mounting bracket

and the bracket rail. These are the two exposed holes near the back end

of the bracket rail and the front hole accessible through a slot in the

inner slide.

slotted screws.

of the following figure.

through the slotted opening in the inner slide. Use two more 8-32 x 1/4inch slotted screws to fasten the bracket rail to the mounting bracket.

See steps and of the following figure.

(Do not use nuts or washers with the screws.) See step

Page 47

3-13

1

2

3

26

22

Figure 3-7.

Attaching the bracket rail to the mounting bracket

You will use a total of four 8-32 x 1/4-inch slotted screws to fasten the bracket

rail to the mounting bracket. When all five screws are fastened, the mounting

bracket and bracket rail form a mounting bracket slide assembly that you will

attach to the rack.

8. Repeat steps 4 through 7 with the other bracket rail and mounting

bracket. You now have a pair of mounting bracket slide assemblies to be

attached to the rack.

ProLiant 3000 Setup and Installation Guide

Page 48

3-14

Rack-Mount Server Installation

Attaching the Mounting Bracket

Slide Assembly to the Rack

WARNING: To reduce the risk of personal injury or damage

to the equipment, be sure that the rack leveling feet are

extended to the floor and support the full weight of the rack.

Each rack must be level and stable. Racks that are not coupled

together require the installation of stabilizers. This must be

done before you perform any work on the rack.

See the

on leveling feet and stabilizers.

Measuring with the Template

The template provided with the server offers an easy and reliable way to

properly position the server in the rack. Use the tabs on the template to suspend

it from the lower hole of a two-hole set of perforations in the vertical side rails.

Pencil mark the attachment points for the mounting bracket assemblies, the

cage nuts for the face-plate thumbscrews, and the top of the server. Use the tick

marks on the rack side rails to insure level installation of the server. See

illustrations and instructions printed on the template.

IMPORTANT: Determine the server's place in the rack before you start

installing the mounting bracket assemblies. To remind you of the proper

placement of the server in the rack, refer to the Rack Builder report you

printed when you planned your rack configuration. Always mount the

heaviest item on the bottom of the rack and work from the bottom to the top.

1. Starting at the bottom of the rack, or at the top of a previously mounted

component, measure the screw hole locations for the server's mounting

bracket assemblies. Pencil mark the locations on the outside of the rack.

Do this on both the front and the back of the rack.

Rack Planning and Installation Guide

for more information

Page 49

IMPORTANT: The template is two-sided (front and back) and printed with

arrows that show you where the screws will be inserted, both for the

mounting bracket assemblies and for the thumbscrews that will secure the

server's face plate to the front of the rack.

Align the template carefully with the holes on the rack, to determine the

exact placement of the screws.

2. When you mark the positioning of the mounting bracket screws, also

mark the positioning in the front of the rack for the cage nuts. These are

two slots marked "C" on the template. The cage nuts will hold the

thumbscrews through the server's face plate.

Be sure to follow the alignment instructions on the template, and keep the sides

of the template squared up with the sides of the rack. Tick marks on the rack’s

vertical rails will help you maintain the proper alignment.

Be sure to follow the alignment instructions on the template, and keep the sides

of the template squared up with the sides of the rack. Tick marks on the rack’s

vertical rails will help you maintain the proper alignment.

3-15

ProLiant 3000 Setup and Installation Guide

Page 50

3-16

Rack-Mount Server Installation

Figure 3-8.

3. After marking the front of the rack, turn the template over and mark the

back rails of the rack. Open the rear door of the rack to access the back

rails.

4. On the back of the rack, mark the rail to show the top of the template.

This will help you align a template for the next component.

Measuring with the template

Inserting Cage Nuts in the Rack Frame

After marking the positions for the fasteners in both the front and back of the

rack, use the fitting tool to insert cage nuts on the inside of the rails at the

marked locations. The cage nuts and fitting tool are included in the hardware kit

supplied with the rack.

1. Position the cage nut as shown in the following figure, on the inside of

the rail.

2. Hook one of the lips of the cage nut through the square rail perforation.

Page 51

3. Insert the tip of the fitting tool through the other side of the perforation

and hook the opposite lip of the cage nut.

3-17

Figure 3-9.

4. Using the fitting tool as a lever, pry the cage nut into position.

5. Repeat for each cage nut.

Inserting cage nuts

Attaching the Mounting Bracket Assembly

to the Rack

The tabs on the front of the mounting bracket help to align it with the front of

the rack frame. Cage nuts are not used for the front attachment of the mounting

bracket.

ProLiant 3000 Setup and Installation Guide

Page 52

3-18

Rack-Mount Server Installation

1. Attach a mounting bracket assembly to the front of the rack first, using

one M6 x 1.0-12L Phillips screw in the bottom hole of the bracket. Do

not use the washers supplied with the Compaq rack.

IMPORTANT: Use only the bottom hole of the bracket as shown

in Figure 3-10

Figure 3-10.

Attaching mounting bracket assembly to the front of the rack

2. Carefully align the mounting bracket assembly with the rear rack frame.

3. Secure the back end of the mounting bracket assembly to the back corner

brace of the rack with one M6 x 1.0-12L Phillips screw through the

bottom hole of the bracket and the cage nut, as shown in the following

figure.

Page 53

Top View

CZR4-012.eps

3-19

Figure 3-11.

Cage nut and back of mounting bracket assembly installed

4. After attaching both mounting bracket assemblies to the rack, prepare the

server for mounting in the rack.

ProLiant 3000 Setup and Installation Guide

Page 54

3-20

Rack-Mount Server Installation

Attaching Component Rails to the Server

1. Place the tab on a component rail at the front of the server chassis. The

holes in the component rail will line up only one way with the chassis.

2. Attach the flat side of a component rail to each side of the server chassis

with five 8-32 x 1/4-inch Phillips screws. Do not use washers with the

screws.

Figure 3-12.

Attaching a component rail to the server

Page 55

Attaching the Cable Management

Arm Bracket

The cable management arm bracket fastens to the top right rear of the rack

server's chassis. The bracket provides an attachment point for the cable

management arm from the server to the rear frame of the rack.

Attach the cable management arm bracket to the back of the server with two

6-32 x 1/4 Phillips screws.

Attach the rack rail covers to the rack.

3-21

Figure 3-13.

Attaching a cable management arm bracket to the server

ProLiant 3000 Setup and Installation Guide

Page 56

3-22

Rack-Mount Server Installation

Loading the Rack Server

Load and secure the server to the rack with the face plate thumbscrews before

continuing to attach any more mounting bracket assemblies. Ensure that this

pair of brackets is perfectly aligned and installed and that the server fits before

you continue.

IMPORTANT: To make the server lighter and more manageable, do not

install drives in the server until after you load the server into the rack. You

may also temporarily remove power supplies and reinstall them after you

have mounted the server in the rack.

WARNING: To reduce the risk of personal injury or damage to

the equipment, a minimum of two people MUST lift the server

into the rack. The server weighs 50 pounds (22.6 kilograms). If

the unit is to be loaded above chest level, a third person must

assist in aligning the rails while the other two support the unit.

Page 57

1. Pull the slide rails forward from the mounting brackets.

2. Carefully align the server's component rails with the rack's slide rails

and slide the server into the rack.

CAUTION: Be sure to keep the component parallel to the floor

when sliding the component rails into the slide rails. Tilting the

component up or down could result in damage to the rails.

3-23

Figure 3-14.

Loading the rack server

ProLiant 3000 Setup and Installation Guide

Page 58

3-24

Rack-Mount Server Installation

3. Depress the component rail release latch on either side of the server and

4. Secure the server face plate to the front of the rack by screwing the

WARNING: To reduce the risk of personal injury, be careful

when pressing the component rail release latches and sliding the

component into the rack. The slide rails could pinch your

fingertips.

slide the server into the rack.

IMPORTANT: The first time you slide the component into the rack, you

may have to apply some pressure. After the first time, the ball bearings in the

slide will move easily.

IMPORTANT: When servicing the server, fully extend the component until

the latches lock. To return the server to the rack, depress the latches and

slide the server into the rack.

thumbscrews into the cage nuts.

5. Tighten the thumbscrews before you close the rack door to prevent the

door from hitting protruding thumbscrews.

Attaching the Cable

Management Arm

A double-hinged cable management arm and fasteners ship with each server.

The cable management arm attaches to the server's cable management arm

bracket and to the rear frame of the rack. All cables to and from the server are

tied to this arm. The two hinges allow the cable management arm with attached

cables to swing out of the way when you need to access the server pull-out

trays.

Page 59

1. For easier handling, first slide the server into the rack, then attach the

cable management arm to the cable management arm bracket. If you

attach the arm before loading the server in the rack, the arm may swing

around and interfere with the loading process.

2. After you have loaded the server into the rack, attach one end of the

cable management arm to the server's cable management arm bracket

using two M6 x 1.0-12L Phillips screws. Align the arm to the bracket as

shown in the following figure.

3-25

Figure 3-15.

Attaching the cable management arm to the

cable management arm bracket

3. Align the other end of the cable management arm on the outside of the

rear brace of the rack. Align a screw retaining plate on the inside of the

rack. Attach the arm to the rack with two 10-32 x 5/8-inch Phillips

washer-face hex-head screws.

ProLiant 3000 Setup and Installation Guide

Page 60

3-26

Rack-Mount Server Installation

Figure 3-16.

Attaching the cable management arm to the rear brace of

the rack

Attaching the Optional

Cable Support

The optional cable support attaches to both sides of the rack’s rear. All cables to

and from the server are tied to this support, which allows the server cables to

stretch from the right rear of the server across to the cable channel on the other

side of the rack, where the other cables are all bundled in the cable channel.

The cable support is needed only if you intend to route cables from one side of

the rack to a cable channel on the other side of the rack.

Attach the cable support to both rear braces of the rack using four

M6 x 1.0-12L Phillips screws.

Page 61

3-27

Figure 3-17.

Attaching the cable support to the rack

Optional Installation Service

The installation service covers the entire hardware installation from unpacking

the components to routing the cables and running a test of the system. In the

United States, Compaq will make all of the arrangements to have the rack

system installed by qualified Guaranteed Service Providers. An order form

with pricing is available from PaqFax, the Compaq fax retrieval service.

Call 1-800-345-1518, select PaqFax, and request Document No. 4552.

Installation may also be ordered from and provided directly by Authorized

Compaq Service Providers.

ProLiant 3000 Setup and Installation Guide

Page 62

Chapter 4

Installing Hardware Options

This chapter is divided into two major parts as follows:

■ Accessing Non Hot-Plug Areas - you must shut down the server power

in order to install options, upgrades or replacements in the following

areas:

❏ Processor boards and sockets

❏ Memory board and sockets

❏ System Board

❏ Drive Cage Backplane Board

❏ Power Supply Backplane Board

❏ Three shared PCI/EISA slots

❏ Five PCI slots

❏ Fans

4-1

■ Accessing Hot-Plug Areas - you can install hot-plug options, upgrades

or replacements without shutting down the power in the following areas:

❏ SCSI drive bays

❏ Power supplies

NOTE: The illustrations in this chapter may vary slightly depending on whether

you have a tower model or rack model.

ProLiant 3000 Setup and Installation Guide

Page 63

4-2

Installing Hardware Options

Accessing Non Hot-Plug Areas

To install options, upgrades or replacements in these areas, you must first shut

down the server power.

Accessing Processors, Memory Board, and

System Board

WARNING: To reduce the risk of injury from

electrical shock, remove all power cords to

completely disconnect power from the system.

WARNING: To reduce the risk of electric shock or damage to

the equipment:

■ Do not disable the power cord grounding plug. The

grounding plug is an important safety feature.

■ Plug the power cord into a grounded (earthed) electrical

outlet that is easily accessible at all times.

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the internal system components to cool before

touching.

WARNING: To reduce the risk of personal injury from contact

with hazardous energy, the equipment is provided with safety

interlocks. Do not attempt to defeat this safely interlock. See

the topic “Interlock System” later in this chapter for more

information.

CAUTION: Electrostatic discharge can damage electronic

components. Be sure you are properly grounded before