Page 1

User’s Manual

5525B/31/32 Line Matrix Printer

Page 2

READ THIS SOFTWARE LICENSE AGREEMENT BEFORE USING THIS PRINTER

Software License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND

CONDITIONS BEFORE USING THIS PRINTER. USING THIS

PRINTER INDICATES YOUR ACCEPTANCE OF THESE TERMS

AND CONDITIONS. IF YOU DO NOT AGREE TO THESE TERMS

AND CONDITIONS, PROMPTLY RETURN THE PRINTER AND

ALL ACCOMPANYING HARDWARE AND WRITTEN MATERIALS

TO THE PLACE YOU OBTAINED THEM, AND YOUR MONEY

WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encoded, machine-readable

data and program. The term “Software Product” includes the

Software resident in the printer and its documentation. The

Software Product is licensed (not sold) to you, and Compaq either

owns or licenses from other vendors who own, all copyright, trade

secret, patent and other proprietary rights in the Software Product.

License.

1. Authorized Use. You agree to accept a non-exclusive license

to use the Software resident in the printer solely for your own

customary business or personal purp ose s.

2. Restrictions.

a. To protect the proprietary rights of Compaq, you agree

to maintain the Software Product and other proprietary

information concerning the typefaces in strict

confidence.

b. You agree not to duplicate or copy the Software

Product.

c. You shall not sublic ense , sell, lea se, or othe rwi se

transfer all or any portion of the Software Product

separate from the printer, without the prior written

consent of Compaq.

d. You may not modify or prepare derivative works of the

Software Product.

e. You may not transmit the Software Product over a

network, by telephone, or electronically using any

means; or reverse engineer, decompile or disassemble

the Software.

f. You agree to keep confidential and use your best

efforts to prevent and protect the contents of the

Software Product from unauthorized disclosure or use.

3. Transfer. You may transfer the Software Product with the

printer, but only if the recipient agrees to accept the terms

and conditions of this Agreement. Your license is

automatically terminated if you transfer the Software Product

and printer.

Limited Software Product Warranty

Compaq warrants that for ninety (90) days after delivery, the

Software will perform in accordance with specifications published

by Compaq. Compaq does not warrant that the Software is free

from all bugs, errors and omissions.

Remedy

Your exclusive remedy and the sole liability of Compaq in

connection with the Software is replacement of defective software

with a copy of the same version and revision level.

Disclaimer of Warrantie s and Limitation of Remedies

1. THE PARTIES AGREE THAT ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY ARE EXCLUDED.

Compaq does not warrant that the functions contained in the

Software will meet your requirements or that the operation of

the Software will be uninterrupted or error free.

Compaq reserves the right to make changes and/or

improvements in the Software without notice at any time.

2. IN NO EVENT WILL COMPAQ BE LIABLE FOR LOST

PROFITS, LOST DATA, BUSINESS INTERRUPTIONS, OR

ANY OTHER DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE

OF OR INABILITY TO USE THIS PRODUCT, EVEN IF

COMPAQ HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES, OR ANY DAMAGES CAUSED BY THE

ABUSE OR MANIPULATION OF THE SOFTWARE. SOME

STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, SO THE ABOVE LIMITATION

MAY NOT APPLY TO YOU.

3. Compaq will not be liable for any loss or damage caused by

delay in furnishing a Software Product or any other

performance under this Agreement.

4. Our entire liability and your exclusive remedies for our liability

of any kind (including liability for negligence except liability for

personal injury caused solely by our negligence) for the

Software Product covered by this Agreement and all other

performance or nonperformance by us under or related to this

Agreement are limited to the remedies specified by this

Agreement.

5. California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be

terminated by agreement between you and Compaq or by Compaq

If you fail to comply with the terms of this License and such failure

is not corrected within thirty (30) days after notice. When this

License is terminated, you shall return to the place you obtained

them, the printer and all copies of the Software and documentation.

U.S. Government Rest ri cte d R igh ts

Use, duplication or disclosure by the Government is subject to

restrictions as set forth in the Rights in Technical Data and

Computer Software clause at FAR 242.227-7013, subdivision (b)

(3) (ii) or subparagraph (c) (1) (ii), as appropriate. Further use,

duplication or discl osure is su bject to res trictions applicable to

restricted rights software as set forth in FAR 52.227-19 (c) (2).

Acknowledgement of Terms and Conditions

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS

AGREEMENT, UNDERSTAND IT, AND AGREE TO BE BOUND

BY ITS TERMS AND CONDITIONS. NEITHER PARTY SHALL BE

BOUND BY ANY STATEMENT OR REPRESENTATION NOT

CONTAINED IN THIS AGREEMENT. NO CHANGE IN THIS

AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND SIGNED

BY PROPERLY AUTHORIZED REPRESENTATIVES OF EACH

PARTY. BY USING THIS PRINTER, YOU AGREE TO ACCEPT

THE TERMS AND CONDITIONS OF THIS AGREEMENT.

Page 3

5525B/31/32 Line Matrix Printer

User’s Manual

P/N 422721-001

Page 4

Compaq® makes no representations or warranties of any kind regarding

this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. Compaq shall not

be held responsible for errors contained herein or any omissions from

this material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution,

performance or use of this material. The information in this manual is

subject to change without notice.

This document contains proprietary information protected by copyright.

No part of this document may be reproduced, copied, translated or

incorporated in any other material in any form or by any means,

whether manual, graphic, electronic, mechanical or otherwise, without

the prior written consent of Compaq.

COPYRIGHT 1999, COMPAQ COMPUTER CORPORATION

All rights reserved.

Page 5

Table of Contents

1 Introduction.............................................11

Printer Overview..................................................................11

The Printer Family.........................................................11

Conventions in This Manual..........................................12

Warnings and Special Information................................13

Related Documents.......................................................13

Graphics Enhancements...............................................13

Taking Care of Your Printer ..........................................14

Protocols and Emulations .............................................14

2 Setting Up the Printer ............................. 15

Before You Begin ................................................................15

Power Requirements ..........................................................15

Select a Site ........................................................................16

Printer Dimensions ..............................................................17

Printer Component Locations..............................................18

Remove Packing Materials..................................................19

Adjust the Paper Supports ............................................22

Release the Paper Chains (Cabinet Model)..................23

Remove Tags................................................................24

Attach the Output Basket (Pedestal Model)..................26

Connect the Interface and Power Cords .............................27

Cabinet Model...............................................................27

Pedestal Model .............................................................29

Interface Connections ...................................................30

Install Basic Components....................................................31

Attach the Control Panel Overlays................................31

Load the Ribbon............................................................32

Load the Paper..............................................................34

5

Page 6

Table of Contents

Set the Top-of-Form ............................................................38

Procedure .....................................................................38

3 Operating the Printer...............................41

Powering On the Printer ......................................................41

Operating Modes.................................................................41

The Control Panel.................. ...... ....... ...... ....... ...... ..............42

Control Panel Keys .......................................................43

Operational Procedures.. ....... ..............................................47

Reloading Paper ...........................................................47

Unloading Paper ..........................................................55

Replacing the Ribbon....................................................57

Canceling a Print Job....................................................60

4 The Configuration Menus........................61

Configuration Overview .......................................................61

Changing and Saving Parameter Settings....................62

Default and Custom Configurations..............................62

Navigating the Menus ...................................................63

Changing Parameters Example....................................64

Saving Your New Configuration....................................66

Main Menu ....................................................................69

CONFIG. CONTROL...........................................................71

Menu.............................................................................71

ACTIVE EMULATION..........................................................73

EMULATION........................................................................74

PCL-II Emulation...........................................................75

LinePrinter Plus Emulation............................................79

P-Series Emulation .......................................................83

Proprinter XL Emulation ........................... ...... ....... .......87

Epson FX Emulation .....................................................90

IGP/PGL Submenu .......................................................93

IGP/VGL Emulation.....................................................101

MAINT / MISC ...................................................................112

6

Page 7

Table of Contents

Menu...........................................................................112

HOST INTERFACE ..........................................................113

Dataproducts Submenu ..............................................114

Serial Submenu............ ...............................................116

IEEE 1284 Parallel (Bidirectional) Submenu...............120

Ethernet Submenu ...................................................... 121

ETHERNET PARAMETERS ........... ...... ............................122

Menu........ ....... ...... ....... ...... ....................................... .. 122

PRINTER CONTROL .......................................................123

DIAGNOSTICS..................................................................125

RIBBONMINDER...............................................................128

5 Interfaces.............................................. 131

Overview............................................................................131

Dataproducts Long Line Interface .....................................132

Dataproducts Long Line Interface Signals ..................133

IEEE 1284 Parallel Interface .............................................134

Compatibility Mode......................................................134

Nibble Mode................................................................134

Byte Mode...................................................................134

Signals ........................................................................135

Terminating Resistor Configurations...........................138

RS-232 and RS-422 Serial Interfaces ...............................140

RS-232........................................................................140

RS-422........................................................................141

Host System Configuration................................................142

Dataproducts Long Lines Parallel Interface ................142

TCP/IP LAN Configuration ..........................................142

Serial Configuration ...... ...... ....... ...... ...... ....... ...... ....... ..143

Internal Ethernet Adapter Configuration............................144

Ethernet Configuration Using the Printer Front Panel.144

Configuring the Internal Ethernet Adapter for TCP/IP .......146

Host Software..............................................................146

Compiling Host Software.............................................147

7

Page 8

Table of Contents

Computer-aided Configuration with ezsetup

or npconfig ..................................................................151

Configuration Through the Network with ARP ............152

Configuration Through the Network with RARP..........154

Configuration Through the Network with BOOTP.......155

Restoring Factory Defaults..........................................155

Host Configuration ......................................................156

Direct Printing Without Spooler...................................156

Printing Via the Spooler ..............................................158

Custom Interface Scripts.............................................159

BSD UNIX...................................................................160

System V UNIX...........................................................164

npd Pseudo-device Interface ......................................166

Other TCP/IP Methods................................................171

Configuring The Internal Ethernet Adapter For Novell ......172

Host Software .............................................................172

Internal Ethernet Adapter............................................173

Host Configuration ......................................................174

PSERVER Setup (Pre-NetWare 4).............................175

RPRINTER Setup (Pre-NetWare 4)............................177

NetWare 4 Options ............... ....... ...... ....... ...... ....... .....180

Configuring the Internal Ethernet Adapter for Windows ....183

Print Methods Overview..............................................183

TCP/IP Setup..............................................................184

Configuring TCP/IP.....................................................186

Host Configuration ......................................................189

6 Troubleshooting ....................................195

Cleaning Requirements.....................................................195

Exterior Cleaning ........................................................195

Interior Cleaning..........................................................196

Diagnosing Problems ................................................... .....198

Printing a Hex Dump...................................................198

Fault Messages...........................................................200

8

Page 9

Table of Contents

A Printer Specifications ........................... 207

Ribbon Specifications.. ....... ...... ....... ...... ............................207

Paper Specifications..........................................................208

Printer Dimensions ............................................................209

Environmental Characteristics...........................................210

Electrical Characteristics ............................. ....... ...... ....... .. 211

Interfaces............... ...... ....... ...... ....... ...... ............................212

Printing Rates....................................................................212

B Downloading Firmware......................... 213

Loading Flash Memory ......................................................213

C ASCII Character Set............................. 219

D Communication and

Trademark Information ................. .. ... .. .. ....221

Communication Notices.....................................................221

Trademark Acknowledgments...........................................223

9

Page 10

Table of Contents

10

Page 11

1 Introduction

Printer Overview

This chapter provides a general overview of your printer and the

conventions used within this manual.

The Printer Family

The Compaq series of line matrix printers consist of 500, 1000, and

1500 lines per minute (lpm) models packaged in various configurations.

All of the models offer software versatility and the latest refinements in

line matrix printing technology. The print mechanisms are housed in

sound-insulated cabinets which make the printer family among the

quietest printers in the world.

Most line matrix printers have specialized architectures, which enable

the printer to emulate, or behave like, another printer. These

specialized architectures are restricted. Your printer, however, has a

flexible architecture that allows new features and emulations to be

added as they become available.

PCL

with each printer. LinePrinter Plus includes the Epson

Printronix

®

IGP

available as optional upgrades. No matter what emulation is installed,

your printer is easy to use. The message display and lights on the

control panel communicate with you directly and clearly. You can select

every function on your printer at the control panel, or you can send

commands from the host computer.

®

-II is the standard emulation. LinePrinter Plus® is also included

®

P-Series, and IBM Proprinter® III XL emulations. The

/PGL® and IGP/VGL graphics enhancement emulations are

®

FX-1050,

11

Page 12

Chapter 1 Printer Overview

The printer combines the use of Flash, RAM, and nonvolatile RAM for

program execution. The Flash is used for all program, font, and

emulation storage. New fonts, emulations, or program updates can be

downloaded to Flash memory via the parallel or serial interface. The

RAM is used for buffers, print image storage, and execution variables.

The non-volatile RAM stores configuration, statistics, and internal

parameters.

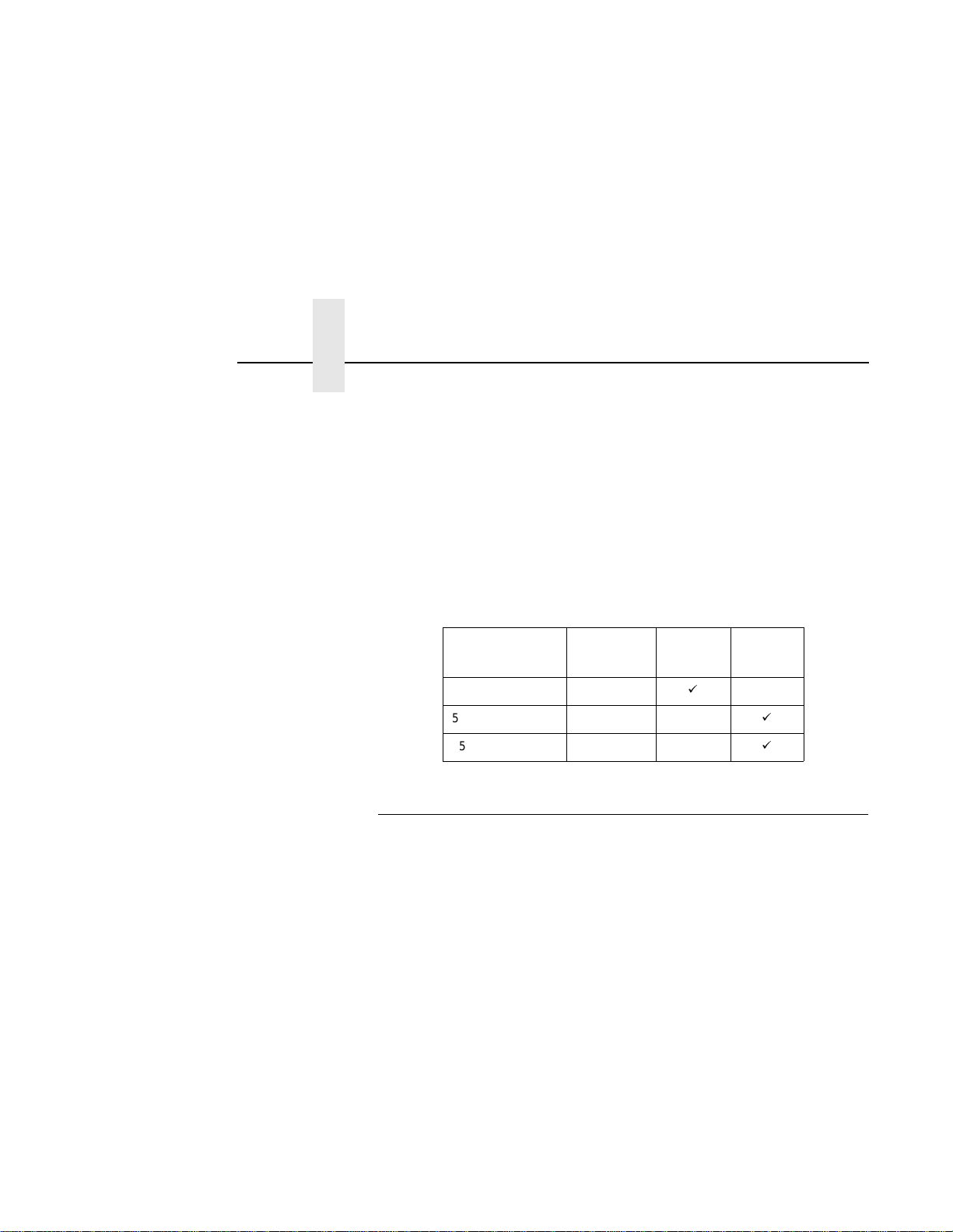

Refer to the following table for a complete listing of model numbers and

options.

Table 1. The Compaq Line Matrix Printer Family

Model

Number

5525B 500 lpm

5531 1000 lpm

5532 1500 lpm

Print Speed Pedestal Cabinet

á

á

á

Conventions in This Manual

All uppercase print indic ate s con tr ol pan el key s .

Example: Press the CLEAR key, then press the ON LINE key.

Quotation marks (“ ”) indicate messages on the Liquid Crystal Display

(LCD).

Example: Press the ON LINE key. “OFFLINE” appears on the LCD.

The + (plus) symbol represents key combinations.

Example: “Press

(DOWN) key at the same time.

= + >” means press the = (UP) key and the >

12

Page 13

Warnings and Special Information

Wa rnings and Special Inform ation

Read and comply with all information highlighted under special

headings:

WARNING

CAUTION

IMPORT ANT

Conditions that can harm you as well as damage the printer.

Conditions that can damage the printer or related equipment.

Information that is vital to the operation of the printer.

NOTE: Information affecting printer operation.

Related Documents

•

Maintenance Manual —

line matrix printer at the field service level of maintenance.

•

LinePrinter Plus Programmer's Reference Manual —

host control codes for the LinePrinter Plus emulations.

•

PCL-II Programmer's Reference Manual —

codes for the Printer Control Language emulation.

•

IGP/PGL Programmer's Reference Manual —

used with the optional IGP Printronix emulation enhancement

feature.

•

IGP/VGL Programmer's Reference Manual —

used with the optional Code V

•

PrintNetTM User’s Manual —

configuration, and operation.

Explains how to maintain and repair the

Covers the

Covers the host control

Provides information

TM

emulation enhancement feature.

Information about network protocols,

Provides information

Graphics Enhancements

The IGP/PGL and IGP/VGL emulations allow you to create and store

forms, generate logos, bar codes, expanded characters, and create

other graphics. Alphanumeric and bar code data are added as the form

is printed. These emulations are available as factory-installed or fieldinstalled options. For more information, contact your authorized service

representative.

13

Page 14

Chapter 1 Printer Overview

Taking Care of Your Printer

Your printer will produce high print quality jobs if it is well taken care of.

Periodic cleaning, handling the printer properly, and using the correct

printer supplies such as paper and ribbons ensures optimum

performance. Chapter 6 explains how to clean the printer, and printer

supplies are listed in Appendix A.

Whenever it is necessary to service the printer, remember these

important maintenance concepts:

• Use only the ribbons specified in Appendix A. Use of incorrect

ribbons can lead to ink migration problems, degraded print quality,

and expensive damage to the printer.

• Incorrect closure of the forms thickness lever can lead to smearing,

degraded print quality, paper jams, and damage to the platen and

shuttle assembly. Never close the forms thickness lever too tightly.

Protocols and Emulations

14

A

protocol

between the printer and its host computer. These rules consist of codes

that manipulate and print data and allow for machine-to-machine

communication. A printer and its host computer must use the same

protocol. As used in this manual, protocol and emulation mean the

same thing.

Most impact printers use single ASCII character codes to print text,

numbers, and punctuation marks. Some characters, both singly and in

groups of two or more, are defined as control codes. Control codes

instruct the printer to perform specific functions, such as underlining

text, printing subscripts, setting page margins, etc. The main difference

between most printer protocols is in the characters used to create

control codes and the ways in which these characters are formatted.

When the printer executes the character and control codes of a

particular printer protocol, it is “emulating” that printer. If the printer uses

the Proprinter XL protocol, for example, it is emulating a Proprinter XL

printer. If the printer is using the Epson FX printer protocol, for example,

we can also say it is in Epson FX emulation mode.

is a set of rules governing the exchange of information

Page 15

2 Setting Up the Printer

Before Y ou Begin

Read this chapter carefully before installing and operating the printer.

The printer is easy to install. However, for your safety, and to protect

valuable equipment, perform all the procedures in this chapter in the

order presented.

Power Requirements

The printer must be connected to a power outlet that supplies 88 to 135

Volts AC or 178 to 270 Volts AC at 47 to 63 Hz. The printer

automatically senses and adjusts itself to conform to the correct voltage

range.

Primary circuit protection is provided by the power switch, which is also

a circuit breaker. Consult an electrician if printer operation affects local

electrical lines. See “Printer Specifications” on page 207 for additional

power specifications.

IMPORT ANT

It is recommended that printer power be supplied from a separate

AC circuit protected at 10 amperes for 120 volts or 5 amperes for

230 volts at 50 or 60 Hertz.

15

Page 16

Chapter 2 Select a Site

Select a Site

Select a printer site that meets all of the following requirements:

• Permits complete opening of the printer cover and doors.

• For cabinet models, allows at least three feet of clearance behind

the printer. (This permits air to circulate freely around the printer

and provides access to the paper stacking area.)

• Has a standard power outlet that supplies 88-135 Volts AC or 178-

270 Volts AC power, at 47 to 63 Hz.

• Is relatively dust-free.

• Has a temperature range of 10° C to 40° C (50° F to 104° F), and a

relative humidity from 15% to 90% non-condensing.

• Is located within the maximum allowable cable length to the host

computer. This distance depends on the type of interface you plan

to use, as shown in Table 2.

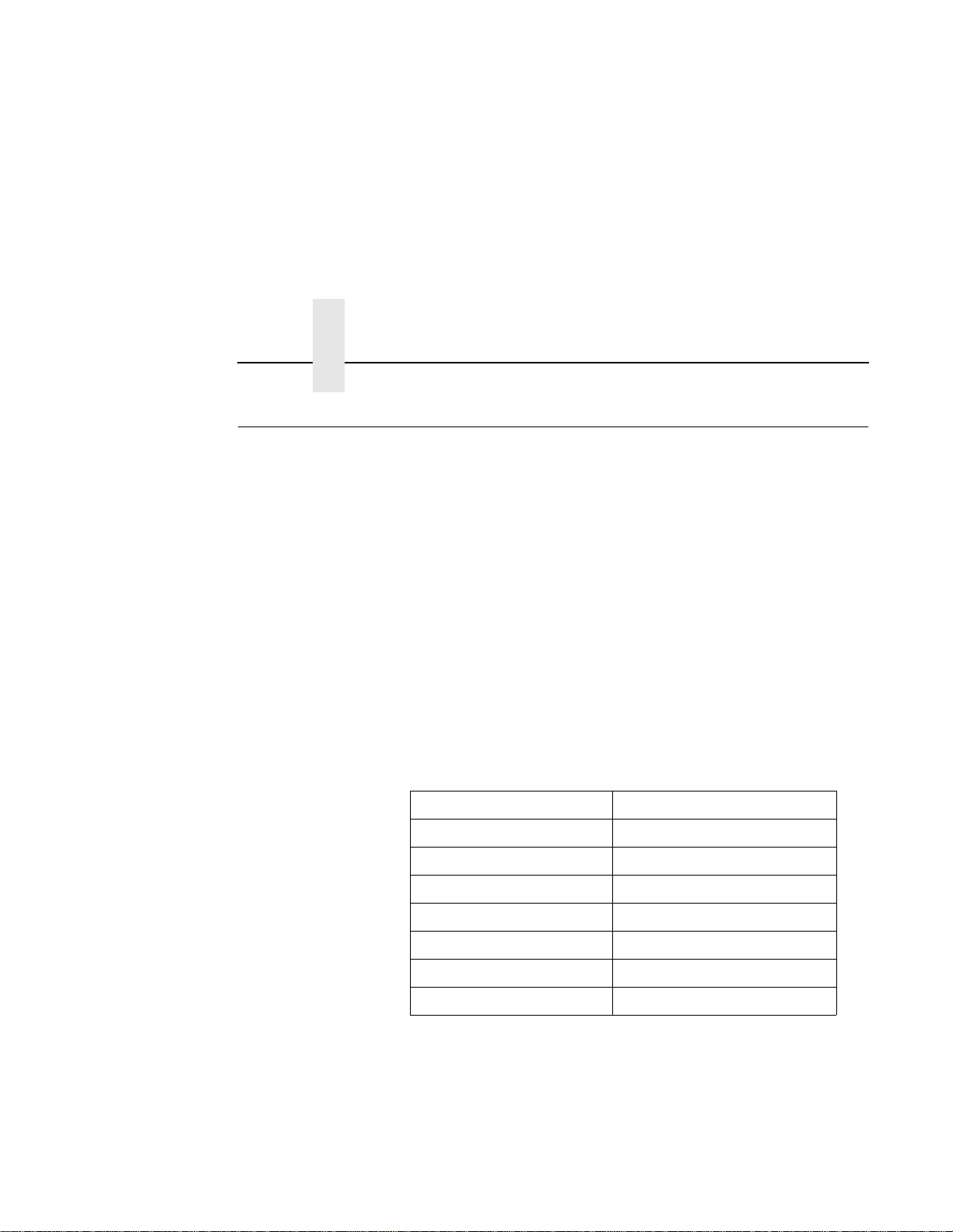

Table 2. Maximum Interface Connection Cable Length

16

Interface Type Maximum Cable Length

Dataproducts Parallel 12 meters (40 feet)

IEEE 1284 Parallel 10 meters (32 feet)

Serial RS-232 15 meters (50 feet)

Serial RS-422 1220 meters (4000 feet)

Dataproducts Long Line 150 meters (492 feet)

Ethernet 10Base-T 100 meters (328 feet)

Ethernet 10Base2 185 meters (607 feet)

Page 17

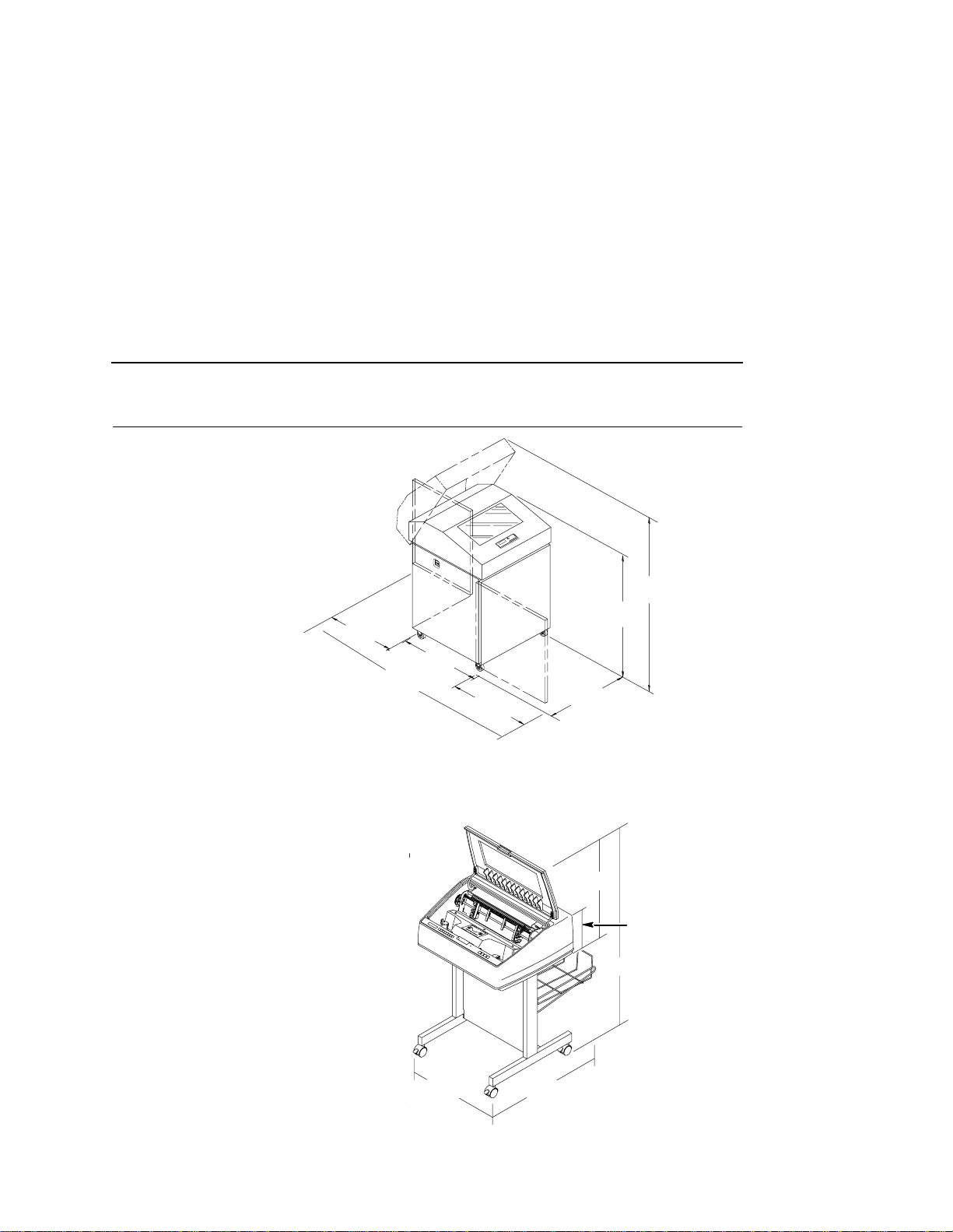

Printer Dimensions

57.5 in.

(146.1 cm)

41.0 in.

27.0 in.

(68.6 cm)

(210.8cm)

83.0 in.

29.0 in.

(73.7 cm)

27.0 in.

(68.6 cm)

(104 cm)

27.0 in.

(68.6 cm)

Figure 1. Printer Dimensions (Cabinet Model)

)

25 in.

(63.5 cm.)

10.5 in.

(26.67 cm.)

48.0 in.

(122 cm.)

24.6 in.

(62.48 cm.)

30 in.

(76.2 cm.)

Figure 2. Printer Dimensions (Pedestal Model)

17

Page 18

Chapter 2 Printer Component Locations

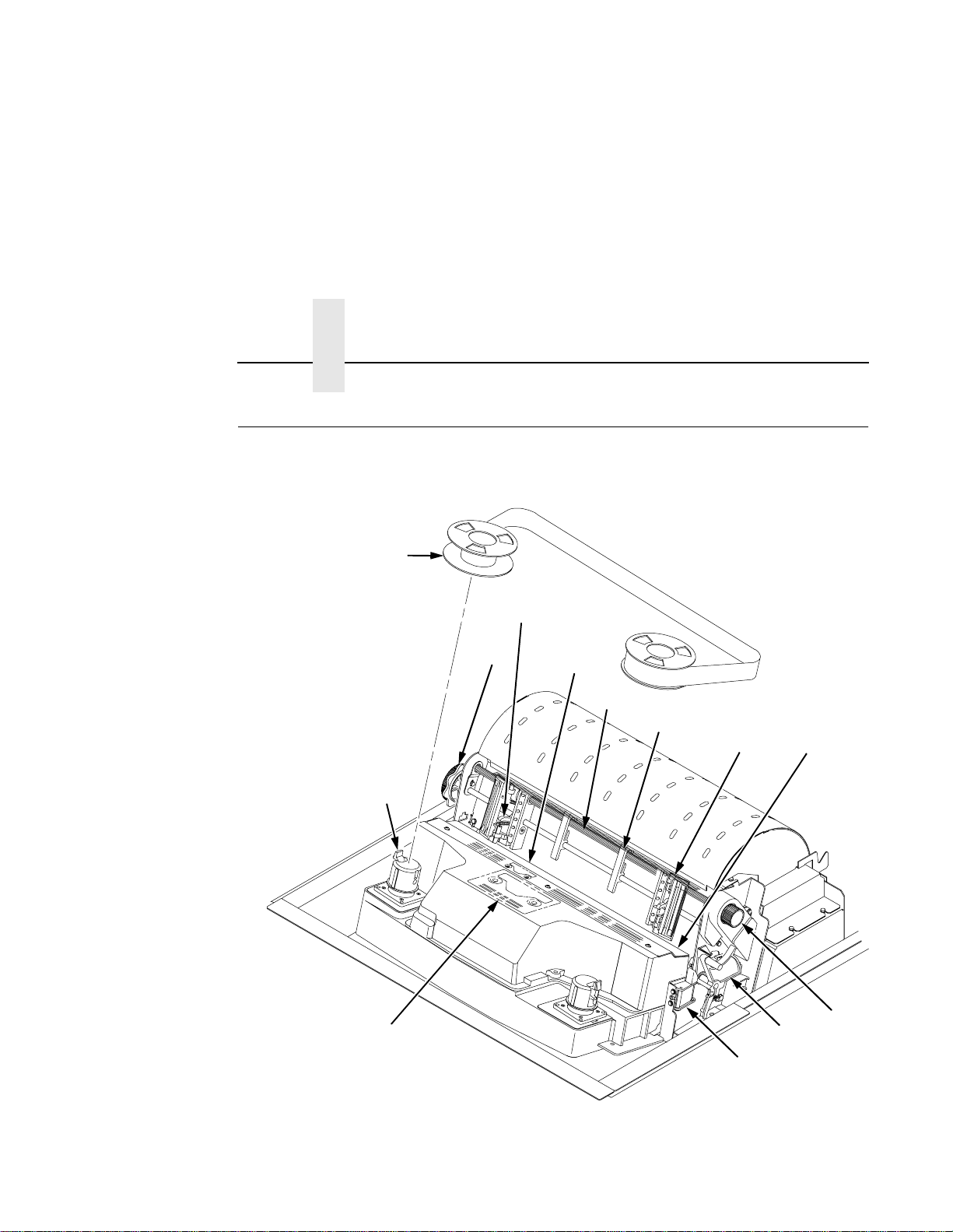

Printer Component Locations

Familiarize yourself with the names and locations of the printer

components, shown in Figure 3, before continuing with the rest of the

installation procedure.

2

4

13

3

1

5

6

7

8

12

9

10

11

18

Figure 3. Printer Component Locations

Page 19

Legend:

1) Hub Latch

2) Ribbon Spool

3) Horizontal Adjustment Knob

4) Tractor Lock

5) Paper Scale

6) Splined Shaft

7) Paper Support

8) Tractor

9) Hammer Bank Cover and Ribbon Mask

10) Vertical Position Knob

11) Forms Thickness Lever

12) Ribbon Guide

13) Ribbon Loading Path Diagram

Remove Packing Materials

CAUTION

To avoid shipping damage, reinstall the shipping restraints

whenever you move or ship the printer.

Save the cardboard packing, foam blocks, and bubble wrap along with

the other packing materials in case you need to move the printer. If it is

necessary to move the printer, reinstall the shipping restraints,

reversing the steps in this section.

19

Page 20

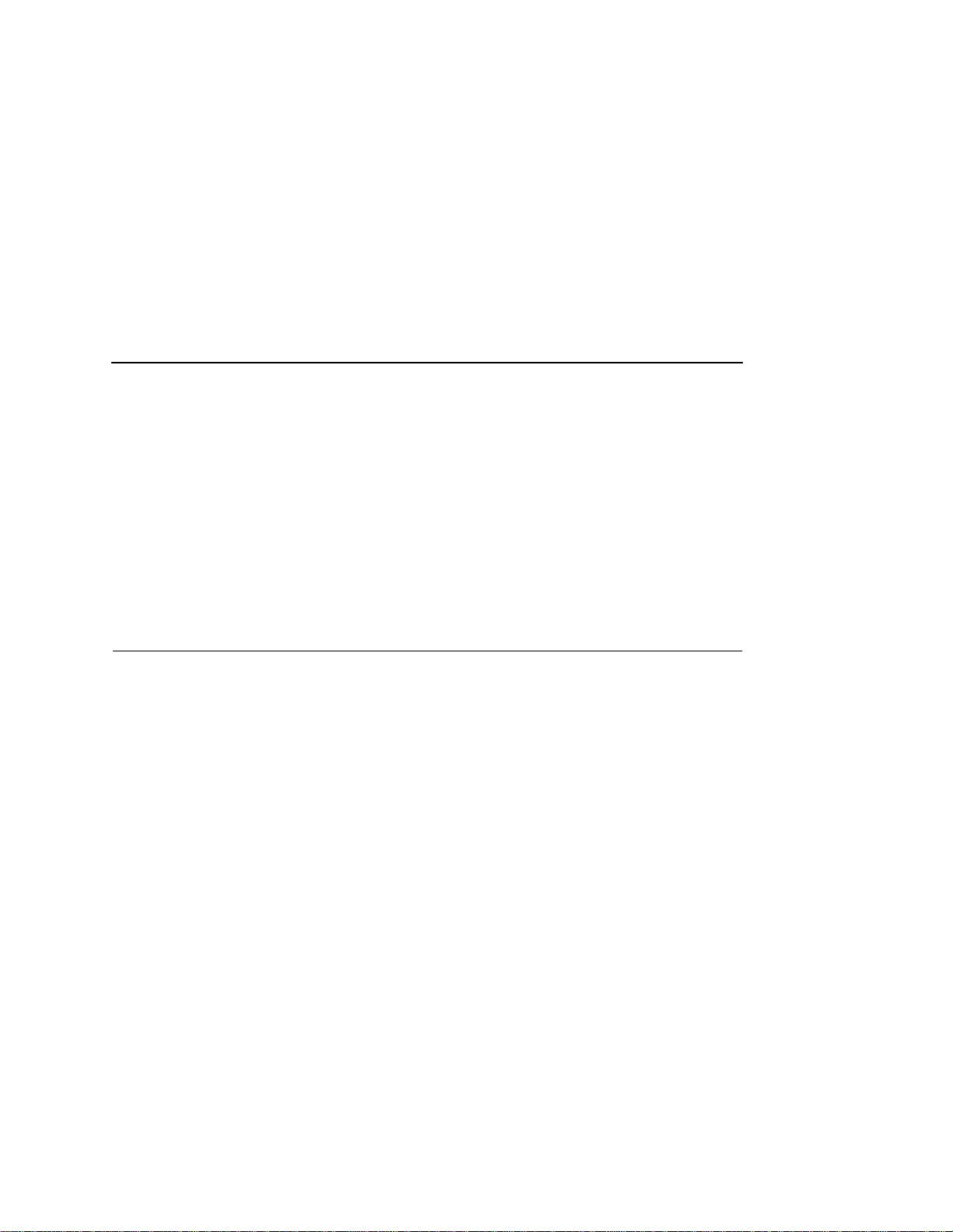

Chapter 2 Remove Packing Materials

1

3

2

20

1. Raise the printer cover.

2. Remove the cardboard packing (1).

3. Open the tractor doors. Push the tractor locks down. Slide the

tractors outward as far as they will go. The forms thickness lever (2)

should be in the fully open (raised) position.

4. Remove the envelope (3) containing the sample configuration

printout. Store the envelope in the pouch attached to the left interior

side of the cabinet.

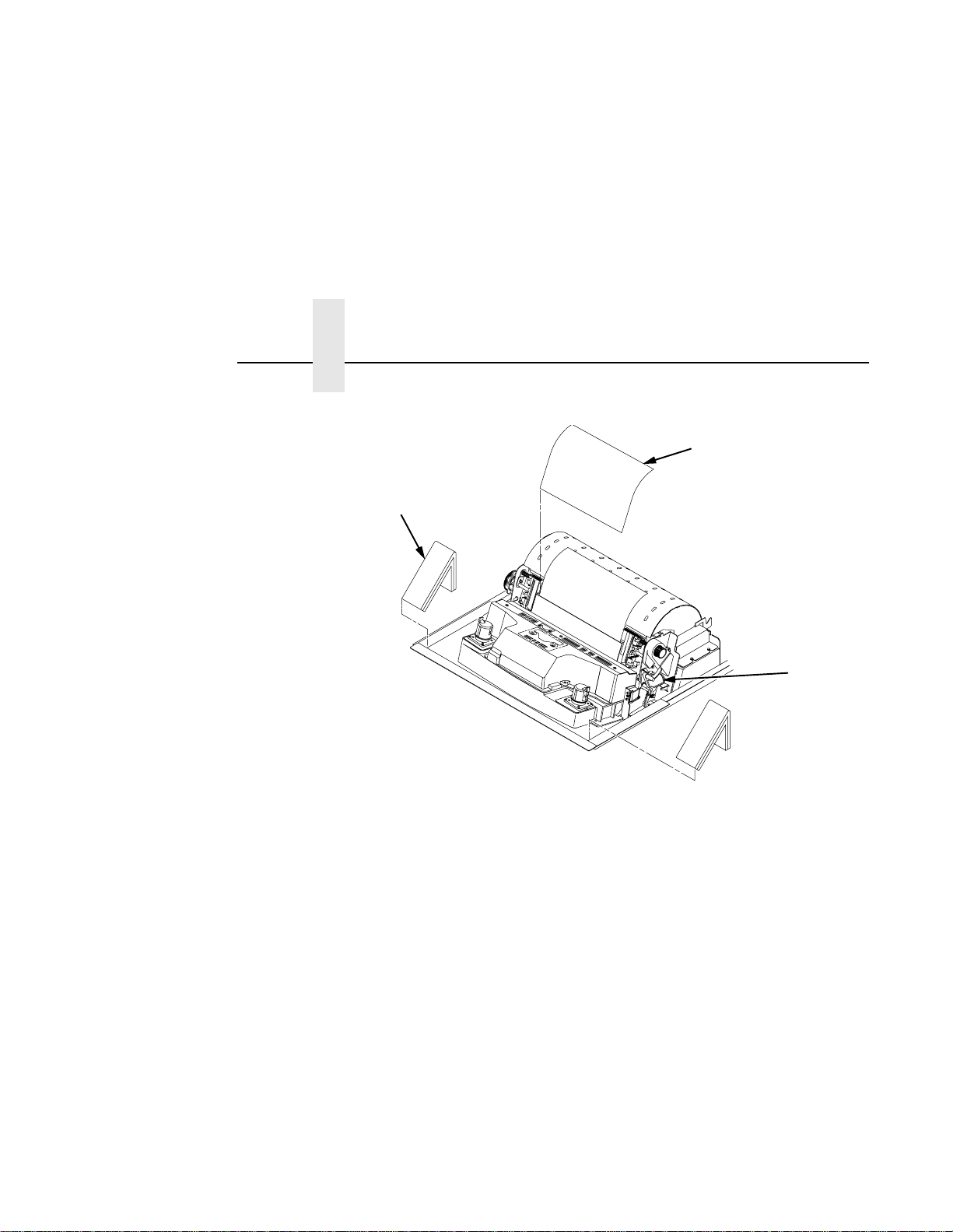

Page 21

6

5

4

7

5. Slide the paper supports (4) outward as far as they will go. Lift the

hammer bank protective foam (5) and remove it from between the

ribbon mask and the platen.

6. Remove the foam strips (6) and the tape securing the foam strips.

7. Rotate the forms thickness lever (7) downward to position “A”.

21

Page 22

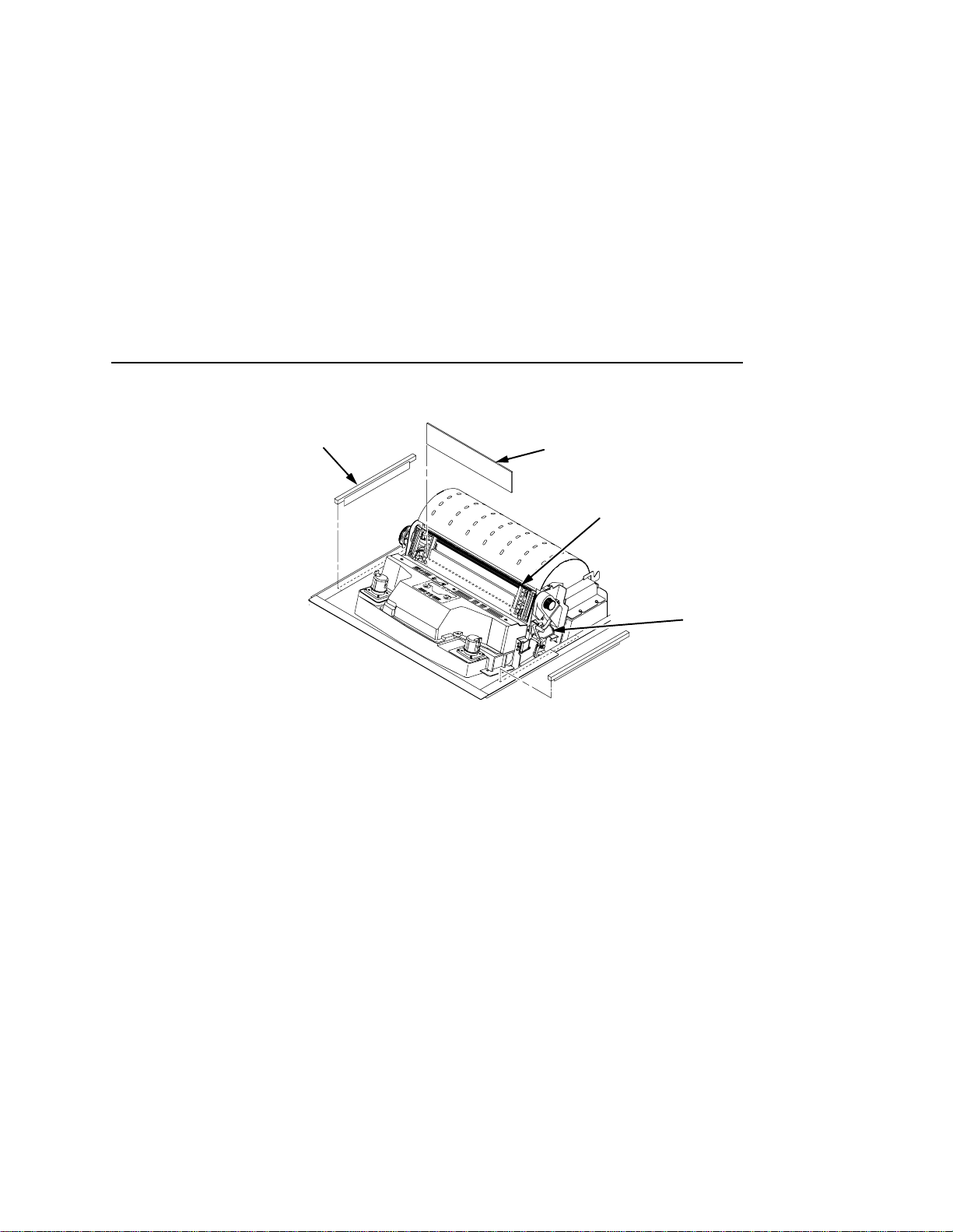

Chapter 2 Remove Packing Materials

8. Rotate the platen protective foam (8) toward the front of the printer

and out from under the support shaft.

8

22

Adjust the Paper Supports

2

1

2

1. Slide the paper supports (1) inward until they are approximately

four inches from the tractor doors (2).

Page 23

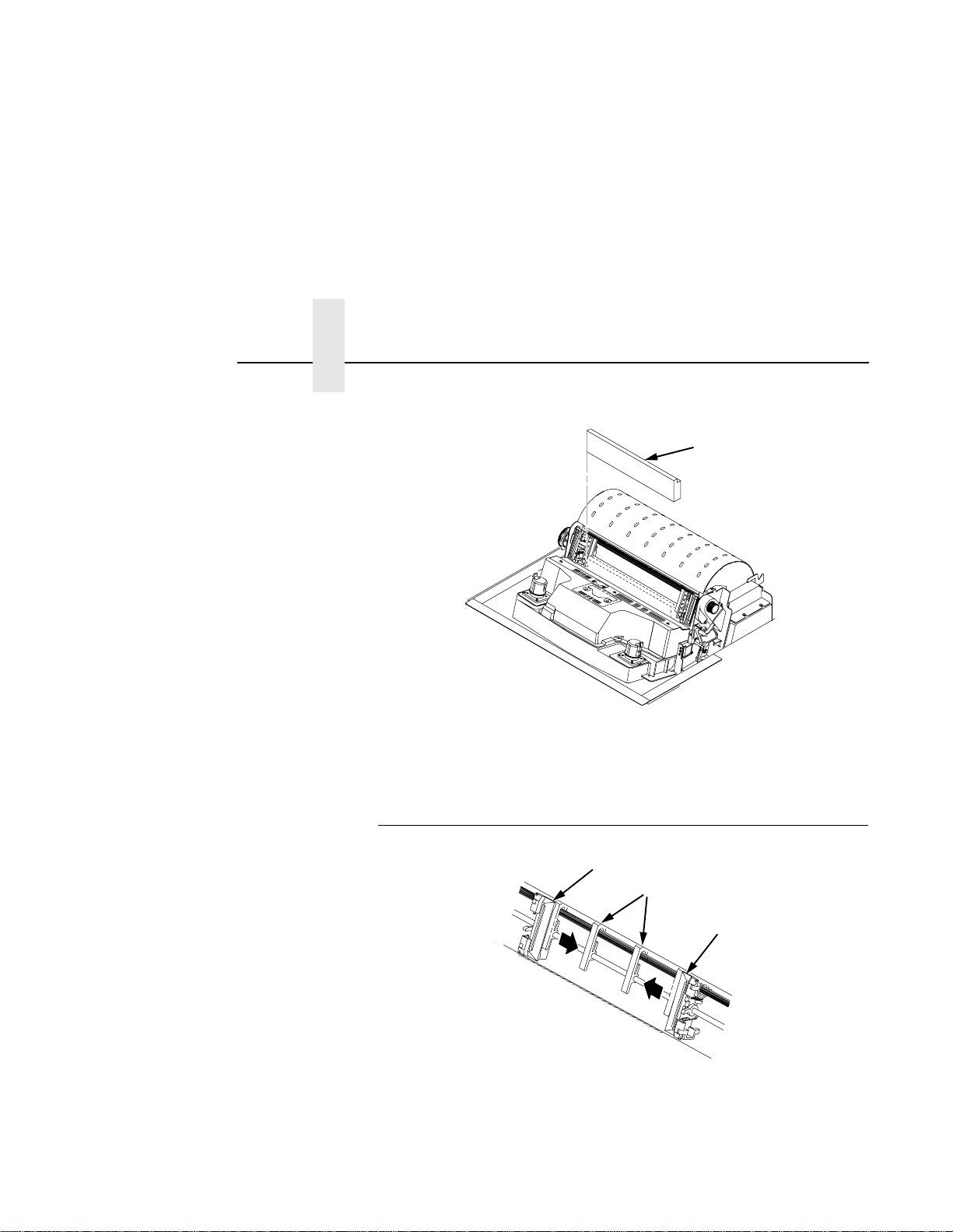

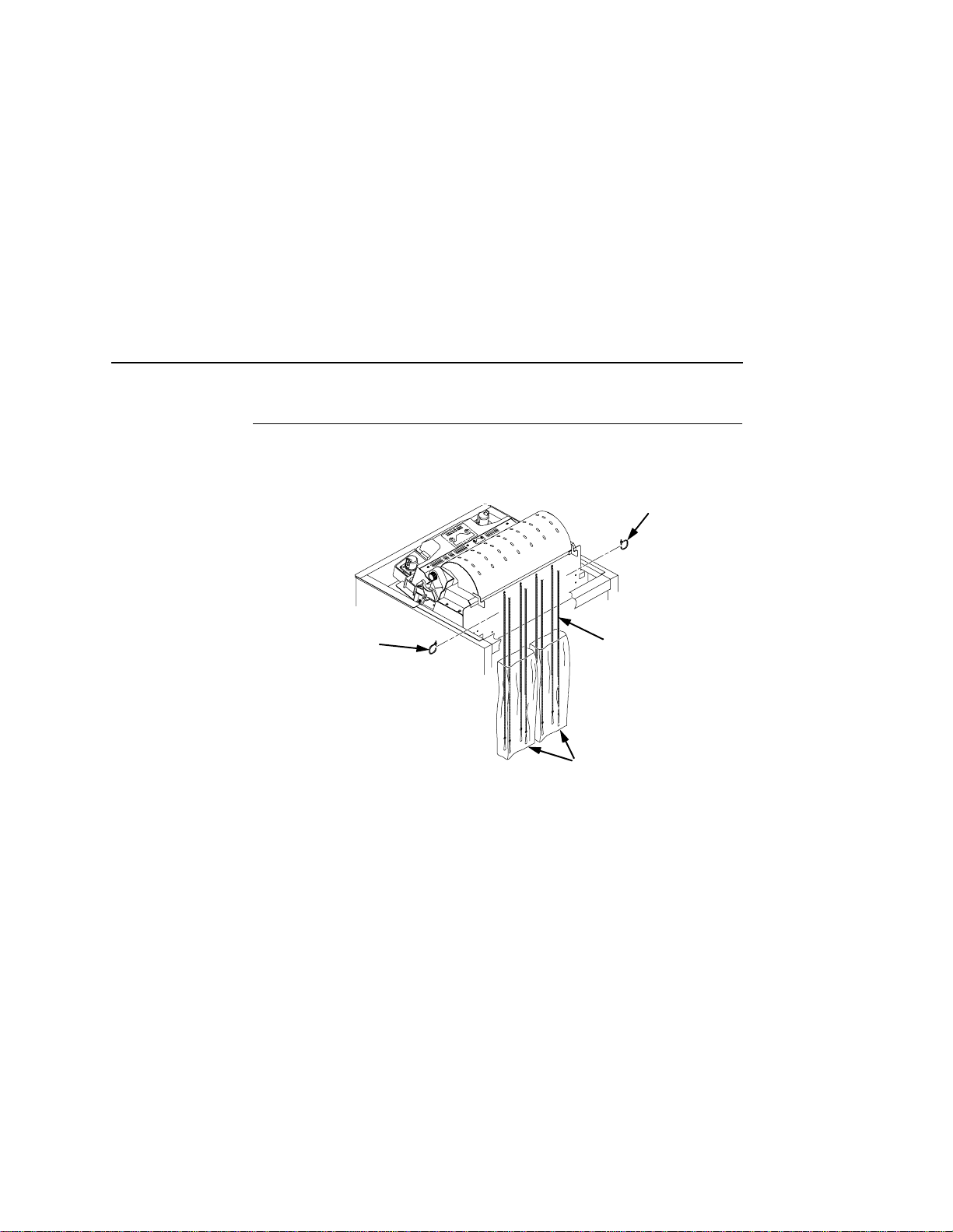

Release the Paper Chains (Cabinet Model)

Release the Paper Chain s (Cabinet Mode l)

1

1

1. Open the cabinet rear door.

2. Cut the tie wraps (1) and release the paper chains (2) from the

bags (3) at the top rear of the printer frame. Remove the tie wraps

and bags.

3. Make sure each chain hangs freely, with no kinks or knots.

2

3

23

Page 24

Chapter 2 Remove Packing Materials

Remove T ags

Cabinet Model

1

2

3

1

2

3

24

Figure 4. Removing Tags

(Left: 1000/1500 lpm models; Right: 500 lpm models)

1. Remove the tie wrap (1) attached to the passive stacker paper

fence (3). It is marked with a large, red tag (2).

2. Close the cabinet rear door.

Page 25

Pedestal Model

1

Remove Tags

3

2

Remove the tie wrap (1) attached to the output basket (3). It is marked

with a large, red tag (2).

25

Page 26

Chapter 2 Remove Packing Materials

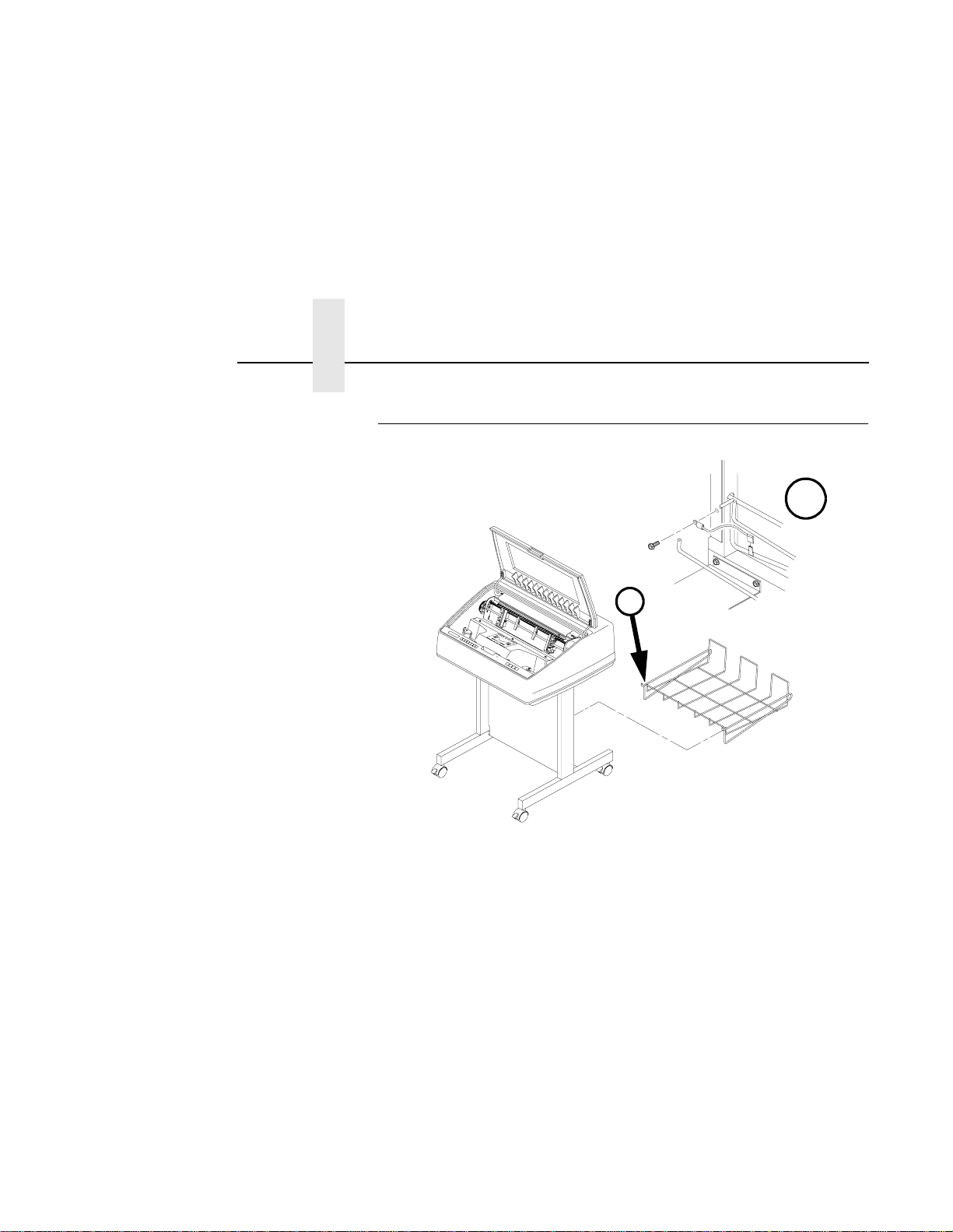

Attach the Ou tput Ba ske t (Pedest al M odel)

$

$

26

1. Place the output basket in the holes in the back of the printer.

2. Screw the ground wire attached to the output basket to the printer.

Page 27

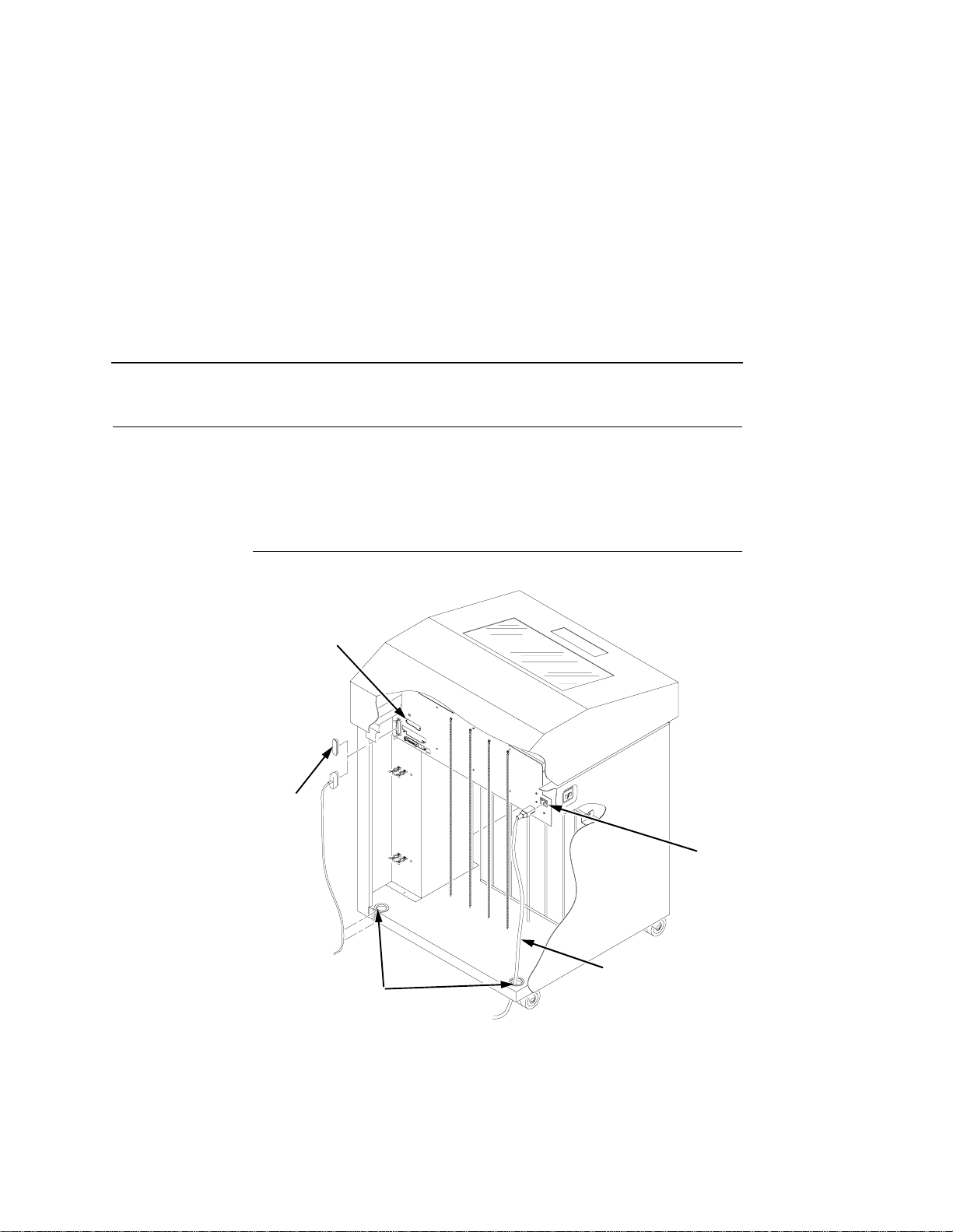

Connect the Interface and Power Co rds

Before you connect the interface and power cables, verify the voltage

source at the printer site conforms to the requirements specified in

“Power Requirements” on page 15.

Cabinet Model

1

Cabinet Model

2

3

Legend:

1) Host Interface Connectors

2) I/O Cover

3) Cable-Routing Notches

4) AC Power Cable

5) AC Power Connection

Figure 5. Interface and Power Locations

5

4

27

Page 28

Chapter 2 Connect the Interface and Power Cords

1. Make sure the printer power switch is set to O (Off).

2. Open the cabinet rear door, and remove the cover from the

selected I/O connector. (See “Interface Connections” on page 30.)

3. Locate the cable routing notch in the lower left corner of the back of

the cabinet (see Figure 5).

4. Hold the I/O cable below its connector and gently push the cable

through the opening in the grommet seated in the notch.

5. Pull the cable up through the notch until it reaches the I/O plate.

Attach the cable connector to the printer interface connector

previously selected in step 2 of this section. Secure the cable to the

printer using the upper and lower standoffs.

28

6. Open the cabinet front door and cut the strap that secures the box,

which contains the power cord, printer ribbon, control panel overlay

labels, and documentation.

7. Open the box and remove the power cord, overlays, and

documentation.

Page 29

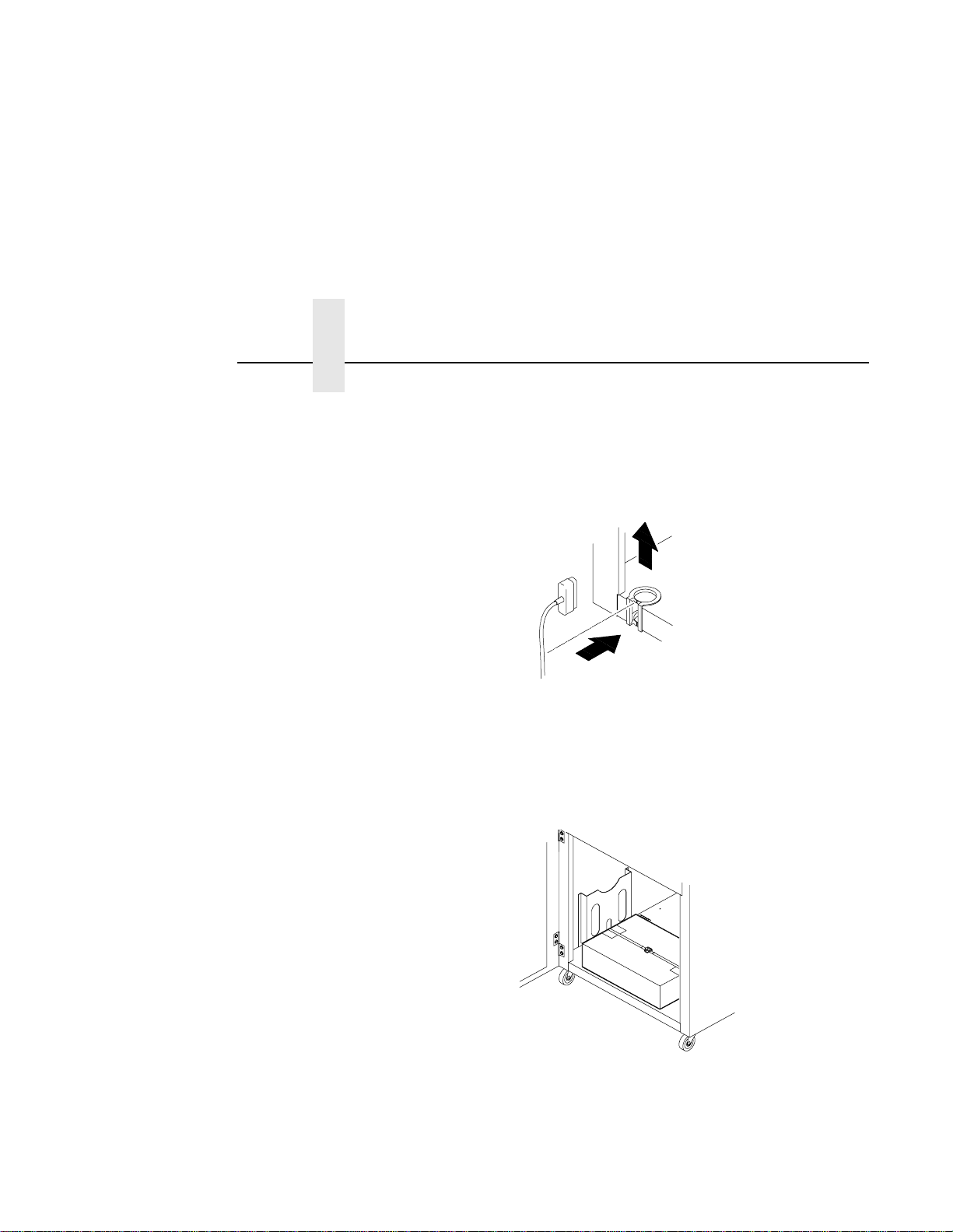

Pedestal Model

8. Guide the power cord up through the hole in the lower right back

corner of the cabinet (see Figure 5). Thread the power cord inside

the bracket where the gas spring is attached.

9. Plug the power cord into the printer AC power connector, then into

the AC power outlet.

Pedestal Model

1

2

3

Legend:

1) Parallel Connector

2) Auxiliary I/O

3) Serial Connector

4) Power Switch

5) AC Power Connector

4

5

1. Make sure the printer power switch is set to O (OFF).

2. Remove the cover from the I/O connector you have selected. (See

below.)

3. Attach the cable connector to the printer interface connector.

Plug the power cord into the printer AC power connector, then into the

AC power outlet.

29

Page 30

Chapter 2 Connect the Interface and Power Cords

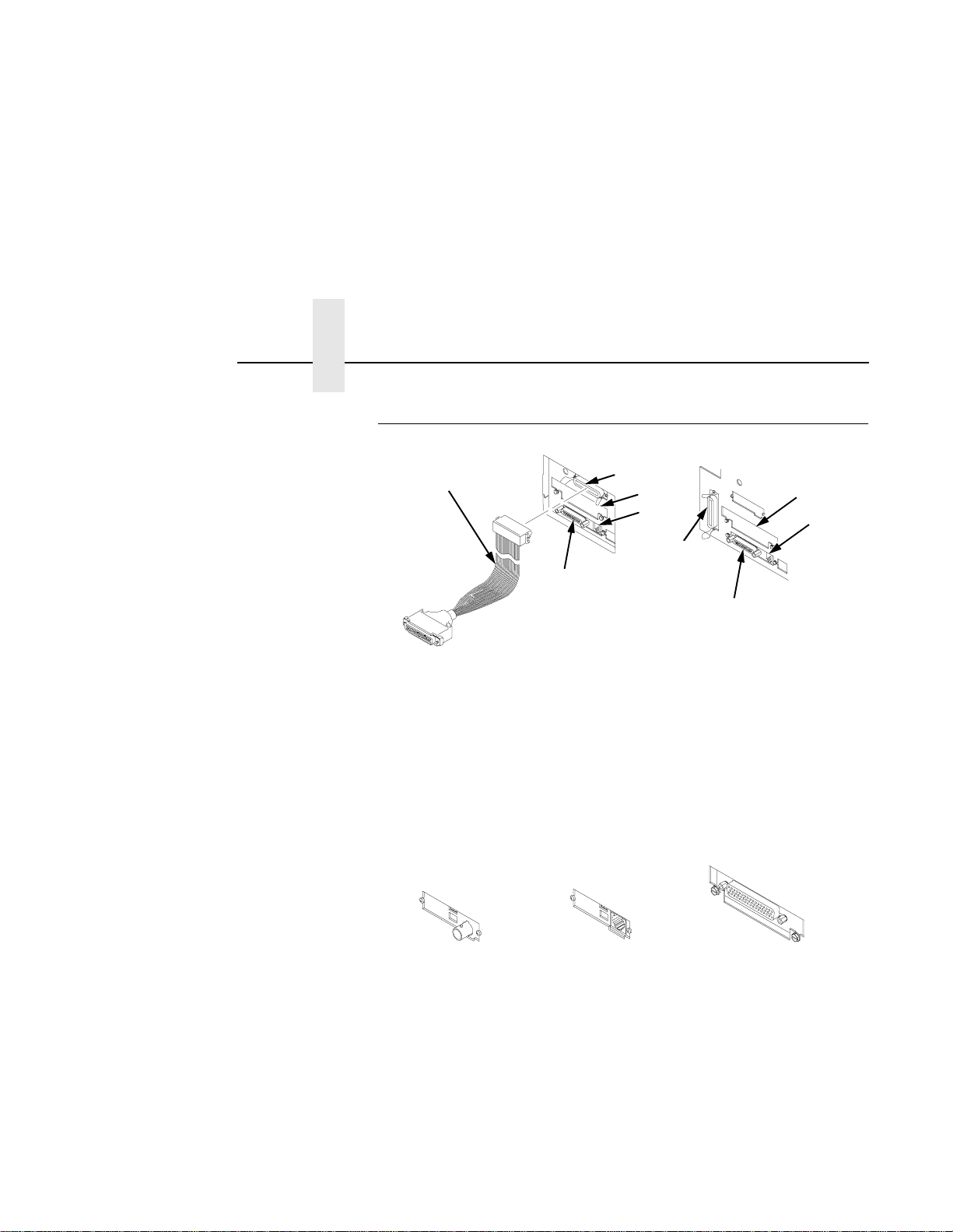

Interface Connections

5

4

Legend:

1) Parallel (not present on Network-based models)

2) Auxiliary I/O

3) Diagnostic

4) Serial RS-232/RS-422

5) Dataproducts Standard Adapter

1

2

3

1

Figure 6. Standard Interfaces

(Left: Pedestal Model; Right: Cabinet Model)

2

3

4

30

321

Legend:

1) Network 10Base2

2) Network 10Base-T

3) Dataproducts Long Line

Figure 7. Optional Interfaces for the Auxiliary I/O

1. Remove the cover from the I/O connector you have selected.

2. Attach the I/O cable connector to the printer interface connector.

Page 31

Install Basic Components

The following procedures describe how to attach the printed overlays to

the control panel and install the printer ribbon and paper.

Attach the Control Panel Overlays

1. Choose the overlay labels in the appropriate language.

2. Cabinet Models: Open the printer cover, peel off the protective

backing, and press the overlay into place.

3. Pedestal Models: Open the printer cover and insert overlay labels

by sliding them behind the control panel assembly in the

appropriate place.

Attach the Control Panel Overlays

Figure 8. Attaching Control Panel Overlays

(Left: Pedestal Models; Right: Cabinet Models)

31

Page 32

Chapter 2 Install Basic Components

Load the Ribbon

1. Refer to the ribbon path diagram molded onto the shuttle cover (see

“Printer Component Locations” on page 18).

2. Open the printer cover.

2

3. Raise the forms thickness lever (1) as far as it will go.

1

32

4. Open the tractor doors (2).

3

5. Squeeze the right hub latch (3) and place the full spool on the right

hub. Be sure the ribbon feeds off the outside of the spool. Press the

spool down until the hub latch snaps into place.

Page 33

Load the Ribbon

4

6. Thread the ribbon around the ribbon guide (4) and along the ribbon

path. Be sure to thread the ribbon between the hammer bank cover

and the ribbon mask.

7. Place the empty spool on the left hub. Press the spool down until

the hub latch snaps into place. Turn the empty spool by hand to

make sure the ribbon tracks correctly in the ribbon path and ribbon

guides.

33

Page 34

Chapter 2 Install Basic Components

Load the Paper

When you start this procedure, verify that the printer cover is open, the

forms thickness lever is raised, and the tractor doors are open. (See

“Printer Component Locations” on page 18).

Legend:

1) Edge Of Paper

2) Box

1. For cabinet models, align the paper supply with the label on the

floor. Make sure that the paper pulls freely from the box.

1

2

34

3

3

2. Feed the paper up through the paper slot (3). Hold the paper in

place with one hand (to prevent it from slipping down through the

paper slot) while pulling it through from above with your other hand.

Page 35

Load the Paper

5

4

6

3. Pul l the pape r (4) above and behind the ribbon mask, which is a

silver metal strip with a clear plastic edge protector. Load the paper

on the left tractor sprockets and close the tractor door (5).

CAUTION

To avoid damage to the printer caused by printing on the platen,

always position the left tractor unit directly to the left of the “1”

mark on the paper scale.

4. If adjustment is necessary, unlock (6) the left tractor. Slide the

tractor until it is directly to the left of the number “1” on the paper

scale (10) and lock it. You can also use the paper scale to count

columns.

7

5. Unlock the right tractor (7). Load the paper onto the right tractor

sprockets and close the tractor door.

35

Page 36

Chapter 2 Install Basic Components

9

6. Make sure the leading edge of the first sheet of paper is parallel to

the tractor splined shaft (8). If the paper is misaligned, reload it onto

the tractor sprockets until its edge is parallel to the splined shaft.

7. Slide the right tractor to remove paper slack or to adjust for various

paper widths. Lock the tractor.

8. After both tractors are secured, you may use the horizontal

adjustment knob (9) to make fine horizontal paper adjustments.

8

10

36

Page 37

Load the Paper

A

B

C

9. Lower the forms thickness lever. Set it to match the paper

thickness.

(The A-B-C scale corresponds approximately to 1-, 3-, and 6-part

paper thickness.)

NOTE: Do not set the forms thickness lever too tightly; excessive

friction can cause paper jams, ribbon jams with potential for

ribbon damage, smeared ink, or wavy print.

37

Page 38

Chapter 2 Set the Top-of-Form

Set the Top-of-Form

When paper is loaded into the printer, it must be told where you want

the top of your form to be. This procedure must be performed the first

time paper is introduced into the printer, as well as every time new

paper is loaded.

Procedure

1. Be sure the forms thickness lever is lowered. If the printer is off, set

the power switch to I (On).

2. Press ON LINE to place the printer in offline mode. The LCD will

then display “OFFLINE / CONFIG. CONTROL.”

3. Press FF several times to ensure the paper feeds properly beyond

the tractors and over the lower paper path. Ensure the paper folds

properly in the stacking area.

38

2

1

4. Raise the forms thickness lever (1) as far as it will go. This allows

you to turn the vertical position knob (2) freely in order to align the

top-of-form.

Page 39

Procedure

3

4

5. Locate the TOF indicator (3). It is the small tab located on both the

right and left tractor door.

6. Turn the vertical position knob (5) to align the top of the first print

line with the TOF indicator. For best print quality, it is recommended

the top-of-form be set at least 1/2 inch below the perforation (4).

5

39

Page 40

Chapter 2 Set the Top-of-Form

A

B

C

7. Lower the forms thickness lever. Set it to match the paper

thickness. (The A-B-C scale corresponds approximately to 1-, 3-,

and 6-part paper thickness.)

NOTE: Do not set the forms thickness lever too tightly; excessive

friction can cause paper jams, ribbon jams with potential for

ribbon damage, smeared ink, or wavy print.

40

8. Press SET TOF. The top-of-form position you have set moves

down to the print position.

9. Press CLEAR to remove any fault messages (such as “LOA D

PAPER”) from the message display.

10. Press ON LINE to place the printer in online mode.

Page 41

3 Operating the Printer

Powering On the Printer

When you power on the printer, it executes a self-test. The default

power-up state is online. When the self-test completes and the software

has initialized successfully, the status indicator light turns on, indicating

the printer is online. The default value of the type of emulation you have

installed appears in the display.

If there is a fault during the self-test, the status indicator flashes and a

specific fault message appears on the display (such as “LOAD

PAPER”). The alarm also sounds if it is configured to do so. See

“Troubleshooting” on page 195 for information on fault messages and

solutions.

Operating Modes

Online. In online mode, the printer can receive and print data sent from

the host. Pressing the ON LINE key toggles the printer from offline to

online mode. The status indicator is lit in online mode.

Offline. In offline mode, you may perform operator functions, such as

loading paper and setting top-of-form. You may also move within the

printer configuration menus. Pressing the ON LINE key toggles the

printer from online to offline mode. The status indicator is off in offline

mode.

Fault. In fault mode, a fault condition exists which must be cleared

before printing can continue. The status indicator flashes, the alarm

beeps (if configured to sound), and a descriptive fault message

displays.

41

Page 42

Chapter 3 The Control Panel

The current operating mode may be selected via control panel keys, or

may result from routine operations such as powering on the printer.

The Control Panel

Figure 9 and Figure 10 show the keys, displays and indicators as they

appear on the control panel. The following section provides descriptions

of each of the control panel keys and their functions.

Key combinations are indicated with the plus (+) sign. For example,

“Press

time.

= + >” means to press the = key and the > key at the same

3

4

5

6

1

;<

1

Figure 9. Control Panel, Cabinet Model

2

=>

34 6 8 10

579

2

78910

42

Figure 10. Control Panel, Pedestal Model

Page 43

Control Panel Keys

Legend:

1) Message Display

2) Status Indicator

3) CLEAR

4) SHIFT

5) SET TOF / L.P.I. ADJ.

6) ENTER / PAGE L. ADJ.

7) ON LINE

8) FF

9) LF

10) VIEW

Control Panel Keys

ON LINE

Toggles the printer between online and offline modes. If a fault

condition exists, pressing this key will clear the fault message and

return the printer from fault mode to offline mode.

NOTE: If the fault condition is not corrected

before

pressing this key,

the fault message will reappear when attempting to place the

printer online.

FF (Form Feed)

Causes the paper to advance to the top-of-form on the next page.

In online or offline mode, press and release to advance the paper to

top-of-form on the next page. If there is data in the printer buffers, the

data will print and then the paper will move to the next top-of-form.

In the fault state, FF does not advance the paper to the next top-ofform; instead, it will slew the paper 11 inches.

LF (Line Feed)

Advances the paper one line at a time. Unprinted data in the print buffer

will print before the paper moves.

With the printer offline, press and release to advance the paper one line

at a time. If there is data in the printer buffer, the data will print before

the line feed occurs. Press and hold to repeat forward paper movement.

LF does not operate in the fault or online states.

43

Page 44

Chapter 3 The Control Panel

VIEW

In offline or online mode, allows you to view and adjust the placement of

data on the page, or to remove peel-off labels.

With the printer online or offline, press and release to move paper

forward for inspection. The last data printed advances to the tractor

area. Press VIEW a second time to move the paper back to its previous

print position.

If the printer is online and printing, press VIEW to stop printing. The

paper advances. Press

forms alignment. Press VIEW. The paper moves back and printing

resumes.

Pressing ON LINE also moves the paper back to its original print

position and returns the printer to online.

CLEAR

Clears a fault message and returns the printer from fault mode to offline

mode.

= or > to move 1/72” vertically for fine vertical

44

After correcting the fault, press and release. The fault message is

cleared, and the printer returns to offline mode.

Other functions:

• Moves to the top of the configuration menu when the printer is in

the configuration menus.

• Cancels data in the buffer. Place the printer offline. From the host

system, stop the print job. Press CLEAR+ENTER. Reset the top-ofform (page 38).

• Press SHIFT+CLEAR to reset the PCL-II emulation.

Page 45

Control Panel Keys

SHIFT

The printer must be offline to perform the following functions:

• Press SHIFT+CLEAR to reset the PCL-II emulation.

• Press SHIFT+L.P.I. Adj to access the line spacing menu. Press

PREV or NEXT to scroll through the options.

• Press SHIFT+Page L. Adj to access the form length menu in lines

or inches. The page length is selected by lines/page or inches/

page, depending on which option is chosen in the PCL-II submenu.

• Press SHIFT+= to micro step the paper upward in 1/72 inch

increments.

• Press SHIFT+> to micro step the paper downward in 1/72 inch

increments.

SET TOF

Sets the top-of-form on the printer. This key is active only when the

printer is offline and will not operate if the printer is in a fault condition.

The paper moves down to the print position and aligns to the top-ofform. See page 38 for the complete top-of-form setting procedure.

NOTE: If there is any data in the buffer, the paper will move to the last

print position.

ENTER

When navigating the configuration menus, ENTER selects the currently

displayed option value as the active value. An asterisk (*) appears next

to the active value on the display. ENTER is also used for starting and

stopping printer tests and generating a configuration printout.

NOTE: The ENTER key must be unlocked in order to function. See

UP + DOWN, below.

45

Page 46

Chapter 3 The Control Panel

UP or DOWN ( = or > )

Moves up and down between levels in the configuration menus and

makes vertical forms adjustment. After pressing VIEW, press

adjust the paper up or down in 1/72 inch increments for fine vertical

forms alignment. After pressing ON LINE, press

levels in the configuration menus.

= or > to

= or > to move through

UP + DOWN (

Locks and unlocks the ENTER key.

PREV or NEXT (

Moves between the options on the current level of configuration menu.

In the configuration menu press

forward through the menu selections on the same level.

PREV + NEXT (

When both keys are pressed simultaneously, the printer performs a soft

reset of the LP+ emulation and the printer buffers are cleared.

= + > )

; or < )

; to scroll backward or press < to scroll

; + < )

46

Page 47

Operational Procedures

This section outlines certain basic procedures which need to be

performed when necessary in order to keep your printer operating.

Reloading Paper

Follow this procedure when “LOAD PAPER” displays. (This message

occurs when the last sheet of paper passes through the paper slot.)

This procedure reloads paper without removing the last sheet of the old

paper supply. This action retains the current top of form setting.

1. Raise the printer cover. Raise the forms thickness lever as far as it

will go. (See Figure 3 on page 18 for the location of the lever.)

2. Press CLEAR to turn off the alarm. Do not open the tractor doors or

remove the existing paper.

3. For cabinet models, open the front door. Align the paper supply

with the label on the floor. Ensure the paper pulls freely from the

box.

Reloading Paper

2

1

Legend:

1) Paper Slot (Cabinet Model)

2) Paper Slot (Pedestal Model; 8” below printer base)

Figure 11. Paper Slot Location

47

Page 48

Chapter 3 Operational Procedures

4. Locate the paper slot and feed the paper up through it (see Figure

11). It may be easier to feed one corner of the new paper up

through the slot first. When this corner can be grasped from the top,

rotate the paper back to the normal position.

NOTE: If you are using thick, multi-part forms and are unable to load

the new paper over the existing paper, go to step 14.

5. Hold the paper to prevent it from slipping down and through the

paper slot.

3

5

4

6

6. Pull the new paper (3) above and behind the ribbon mask, but in

front of the existing paper (4). The ribbon mask location is shown

on the ribbon path diagram (5). If necessary, gently press the

existing paper back.

7. Align the top edge of the new paper with the top perforation of the

existing paper (6).

8. Load the new paper over the existing paper. Open and load the

tractors one at a time to prevent the paper from slipping.

48

NOTE: Make sure that the top edge of the new paper lines up with the

top horizontal perforation of the last page.

Page 49

Reloading Paper

A

B

C

9. Lower the forms thickness lever. Set it to match the paper

thickness.

(The A-B-C scale corresponds approximately to 1-, 3-, and 6-part

paper thickness.)

NOTE: Do not set the forms thickness lever too tightly; excessive

friction can cause paper jams, ribbon jams with potential for

ribbon damage, smeared ink, or wavy print.

10. Press CLEAR to remove the “LOAD PAPER” fault message from

the display.

11. Press FF several times to make sure the paper feeds properly

beyond the tractors and over the lower paper guide. Feed sufficient

paper to ensure the paper stacks correctly.

12. Close the printer cover. Close the cabinet front door.

13. Press ON LINE

printing.

to place the printer in online mode and resume

49

Page 50

Chapter 3 Operational Procedures

Perform steps 14 through 30 only if you are unable to load the new

paper over the existing paper in step 4.

14. Open both tractor doors.

15. Remove the paper from the tractors. Allow the paper to fall into the

paper supply area.

7

7

50

16. Feed the paper up through the paper slot (7). Hold the paper to

prevent it from slipping down through the paper slot.

Page 51

Reloading Paper

9

8

17. Pull the paper (8) above and behind the ribbon mask. (The ribbon

mask location is shown on the ribbon path diagram.)

18. Load the paper on the left tractor and close the tractor door (9).

CAUTION

To avoid damage to the printer caused by printing on the platen,

always position the left tractor unit directly to the left of the “1”

mark on the paper scale.

19. Normally, you should not need to adjust the position of the left

tractor. If adjustment is necessary, unlock the left tractor. Slide the

tractor until it is directly to the left of the number “1” on the paper

scale and lock it. (You can also use the paper scale to count

columns.)

51

Page 52

Chapter 3 Operational Procedures

20. Move the paper supports (10 ) as necessary to support the paper

between the tractors.

10

11

52

12

21. Unlock the right tractor (11). Load the paper onto the sprockets and

close the tractor door (12). If necessary, slide the right tractor to

remove paper slack or to adjust for various paper widths. Then, lock

the tractor.

13

22. After both tractors are secured, you may use the horizontal

adjustment knob (13) to make fine horizontal paper adjustments.

Page 53

Reloading Paper

14

14

23. On pedestal models:

Using the vertical position knob to move the paper up, guide the

paper over the lower paper guide (14) and through the slot in the

top cover. Close the platen and the printer cover.

24. Press FF several times to make sure the paper feeds properly

beyond the tractors and over the lower paper guide (14). Feed

sufficient paper to ensure the paper stacks correctly.

25. On cabinet models: Open the cabinet rear door. Make sure the

paper is aligned with the label in the output area (inside the

cabinet). Close the front and rear doors.

53

Page 54

Chapter 3 Operational Procedures

15

16

17

26. Locate the TOF indicator (15). It is the small tab located on both the

right and left tractor door.

27. Turn the vertical position knob (16) to align the top of the first print

line with the TOF indicator. For best print quality, it is recommended

the top-of-form be set at least 1/2 inch below the perforation (17).

A

B

C

54

28. Lower the forms thickness lever. Set it to match the paper

thickness. (The A-B-C scale corresponds approximately to 1-, 3-,

and 6-part paper thickness. Adjust until you have the desired print

quality.)

29. Press CLEAR to clear any fault messages (such as “LOAD

PAPER”) from the Liquid Crystal Display.

Page 55

Unloading Paper

30. Press SET TOF. The top-of-form you have set moves down to the

print position. If there are data in the buffer, the paper moves

forward to the last print position on the next page.

31. Press ONLINE and close the printer cover.

Unloading Paper

1. Press ON LINE to place the printer in offline mode, and open the

printer cover.

2. For cabinet models, open the cabinet rear door.

3. Tear off the paper at the perforation.

4. Allow the paper to fall to the back of the printer and into the paper

stacking area.

5. For pedestal models, remove the stacked paper from the paper

tray.

6. For cabinet models, remove the stacked paper from the cabinet

floor.

55

Page 56

Chapter 3 Operational Procedures

2

1

CAUTION

56

7. To completely remove the paper from the printer:

a. Raise the forms thickness lever (1) as far as it will go, and open

both tractor doors (2).

Be careful when pulling any paper backward through the paper

path, especially when using a label stock. If you are not careful,

labels can detach and adhere to the printer within the paper path,

where only an authorized service representative can remove them.

b. Remove the paper from the tractors. For cabinet models, open

the cabinet front door. Gently pull the paper down through the

paper slot. Allow the paper to fall into the paper supply area.

c. Remove the paper from the paper supply area.

Page 57

Replacing the Ribbon

Replacing the Ribbon

1. Press ON LINE to place the printer in offline mode.

2. Open the printer cover.

2

3. Remove the old ribbon:

a. Raise the forms thickness lever (1) as far as it will go.

b. Press in on the hub latches (2) and lift the ribbon spools off the

hubs. Lift the ribbon out of the ribbon path.

4. Discard the old ribbon.

5. If necessary, clean the interior of the printer. (See “Cleaning

Requirements” on page 195.)

1

57

Page 58

Chapter 3 Operational Procedures

6. Install the new ribbon:

a. With the ribbon to the outside, place the full spool on the right

hub (3). Press down on the spool until the hub latch snaps in

place.

CAUTION

58

3

b. Thread the ribbon around the ribbon guide (4) and along the

ribbon path. (Refer to the ribbon path diagram on the shuttle

cover.) Be sure to thread the ribbon between the hammer bank

cover and the ribbon mask.

The ribbon must not be twisted. A twisted ribbon can lower print

quality, shorten ribbon life, or cause paper jams.

c. Place the empty spool on the left hub. Press down on the spool

until the hub latch snaps into place.

d. Hand turn the empty spool to make sure the ribbon tracks

correctly in the path and ribbon guides.

4

Page 59

Replacing the Ribbon

A

B

C

7. Lower the forms thickness lever. Set it to match the paper

thickness. (The A-B-C scale corresponds approximately to 1-, 3-,

and 6-part paper thickness.)

NOTE: Do not set the forms thickness lever too tightly; excessive

friction can cause paper jams, ribbon jams with potential for

ribbon damage, smeared ink, or wavy print.

8. Close the printer cover.

9. Press ON LINE to return the printer to online mode.

59

Page 60

Chapter 3 Operational Procedures

Canceling a Print Job

The procedure to cancel a print job depends on the printer emulation

and your application software. Contact your System Administrator for

additional information.

1. If the printer is online, press ON LINE to place the printer in offline

mode.

2. From the host system, stop the print job.

NOTE: If the print job is not stopped from the host system before

pressing CLEAR + ENTER, the print job continues with data

missing when the printer returns to online mode. Exercise

caution to prevent unwanted data loss occurrences, as this

function deletes unprinted data in the printer. This function is

active only in offline mode; the purpose of this function is to

eliminate the necessity of printing unwanted data when print

jobs are canceled.

3. Press CLEAR + ENTER.

4. Set the top-of-form (see “Set the Top-of-Form” on page 38).

60

Page 61

4 The Configuration

Menus

Configuration Over view

In order to print data, the printer must respond correctly to signals and

commands received from the host computer. Configuration is the

process of matching the printer’s operating characteristics to those of

the host computer and to specific tasks, such as printing labels, or

printing on different sizes of paper. The characteristics which define the

printer’s response to signals and commands received from the host

computer are called configuration parameters.

You can configure the printer using the configuration menus and the

control panel, or by sending control codes in the data stream from a

host computer attached to the printer. This chapter provides an

introduction to configuring the printer, as well as all the configuration

menus available (depending on which emulation you have installed in

the printer).

IMPORT ANT

Configuration directly affects printer operation. Do not change the

configuration of your printer until you are thoroughly familiar with

the procedures in this chapter.

61

Page 62

Chapter 4 Configuration Overview

Changing and Saving Parameter Settings

You may change a printer parameter setting, such as line spacing or

forms length, either by pressing keys on the control panel to configure

the printer’s resident set of configuration menus, or by sending

emulation control codes from a host attached to the printer (the host

data stream). An example procedure for using the control panel to

change parameter settings begins on page 64.

When control codes are sent from a host attached to the printer, they

override control panel settings. For example, if you set the line spacing

to 6 lpi with the control panel, and application software later changes

this to 8 lpi with a control code, the control code overrides the control

panel setting.

The parameter settings that you have changed using the menus and

control codes can be permanently stored in the printer’s memory if you

save them to printer memory using the “Save Config.” menu option. If

you do not save your changes, they will be lost when the printer is

powered off.

62

There are no host control codes that allow you to save a parameter as a

custom configuration.

Default and Custom Configurations

A configuration consists of a group of parameter settings, such as line

spacing, forms length, etc. Your printer provides a fixed default

configuration and also allows you to define several custom

configurations for use with particular print jobs.

The factory default configuration can be loaded, but it cannot be

altered.

Eight configurations can be modified for unique print job requirements.

The “Save Config.” option allows you to save eight groups of parameter

settings in memory as custom configurations numbered from 1 through

8. An explanation on how to save a set of parameter values as a

custom configuration using the “Save Config.” menu option begins on

page 66.

Page 63

Navigating the Menus

ON LINE

OR

OR

ENTER

+

Navigating the Menus

To manipulate configurations it is important to understand how to

navigate through the menus. Review the following instructions before

you begin making changes to the printer.

You must be offline to move within the menus.

Press to toggle between online and offline

modes.

Press to move up or down through the menu

levels.

Press to scroll through the available choices

on a chosen level.

Press to confirm selection.

Press to lock and unlock the ENTER key. The

ENTER key is locked by default, to prevent

you from accidentally changing the printer

configuration.

When the printer is online, the LCD displays ONLINE and the type of

emulation on the second line.

To experiment with navigating the menus, follow the example on the

next page as a tutorial.

63

Page 64

Chapter 4 Configuration Overview

Changing Param e ters Ex ample

OFFLINE

* = Factory Default

CONFIG.

CONTROL

. . .

PRINTER

CONTROL

Unidirectional

Disable*

Enable

PMD Fault

Enable*

Disable

Slow Paper

Slew

Disable*

Enable

Power Saver

Time

15 min.*

(15-60 min.)

A configuration consists of several parameters. The default factory

configuration has a starting set of parameters. In the configuration

menu above, and in all the configuration menus in this chapter, the

factory default values are indicated by an asterisk (*).

Your print jobs may require parameter values which vary from the

default settings. This section provides an example procedure for

changing individual parameter values.

64

The following procedure shows how to change and save the settings for

the Unidirectional and Slow Paper Slew options. Use these basic

guidelines to navigate the configuration menus and change other

parameters.

Page 65

Changing Parameters Example

ON LINE

+

UNTIL

OR

ENTER

UNTIL

OR

Step Press LCD Notes

1. Make sure the printer is on. Raise the printer cover.

2. OFFLINE

CONFIG. CONTROL

3. ENTER SWITCH

UNLOCKED

OFFLINE

CONFIG. CONTROL

4. OFFLINE

PRINTER CONTROL

5. PRINTER CONTROL

Unidirectional

6. Unidirectional

Disable*

7. Unidirectional

Enable

8. Unidirectional

Enable*

Allows you to make

configuration changes.

Cycle through the

choices.

The * indicates this choice

is active.

9. PRINTER CONTROL

Unidirectional

10. PRINTER CONTROL

Slow Paper Slew

11. Slow Paper Slew

Disable*

12. Slow Paper Slew

Enable

Press until the desired

parameter displays.

65

Page 66

Chapter 4 Configuration Overview

Step Press LCD Notes

13. Slow Paper Slew

14. ENTER SWITCH

15. ONLINE

16. Close the printer cover. The printer is ready for operation.

ENTER

+

ON LINE

Enable*

LOCKED

LinePrinter+

The parameters you have changed remain active as long as the printer

is on. When you turn off the printer, the parameters are erased from

memory unless you save them in a configuration. If you do not save the

configuration, the printer reverts to the default values next time the

printer is powered on.

The next section, “Saving Your New Configuration”, will explain how to

save configurations.

Saving Your New Configuration

Once you have changed all of the necessary parameters, it is

recommended you save them as a configuration that can be stored and

loaded for future use. If you do not save your configuration before you

power off the printer, all of your parameter changes are erased. The

Save Config. option allows you to save up to eight configurations to

meet different print job requirements. (Configurations 1 through 8 are

empty until you save values to them using the Save Config. option.)

The * indicates this choice

is active.

Locks the ENTER key.

Places the printer in

online mode.

66

Page 67

Saving Your New Configuration

ON LINE

+

UNTIL

OR

Once you have saved a custom configuration using this option, it is not

lost if you power off the printer. You can load a configuration for a

specific print job (see “Load Config.” on page 71). You can also modify

and resave it. You may want to print your configurations (see “Print

Config.” on page 72) and store them in a safe place, such as inside the

printer cabinet.

If the Protect Configs. parameter is enabled, and you try to resave an

existing configuration, the new configuration will not be saved until the

existing configuration has been deleted (see page 72).

NOTE: Once you change active emulations, any changes to the

previously selected emulation will be gone unless they have

been saved.

Step Press LCD Notes

1. Make sure the printer is on. Raise the printer cover.

2. OFFLINE

CONFIG. CONTROL

3. ENTER SWITCH

UNLOCKED

OFFLINE

CONFIG. CONTROL

4. CONFIG. CONTROL

Load Config.

5. CONFIG. CONTROL

Save Config.

6. Save Config.

1*

7. Save Config.

2

Allows you to make

configuration changes.

Cycle through the

choices.

67

Page 68

Chapter 4 Configuration Overview

Step Press LCD Notes

8. Save Config.

ENTER

2*

The * indicates this choice

is active.

NOTE: It is recommended you print the configuration. To print the configuration go to Step 9. To

skip this procedure and resume printer operation, go to Step 14.

9. CONFIG. CONTROL

Save Config.

10. CONFIG. CONTROL

UNTIL

Print Config.

11. Print Config.

Current

12. Print Config.

OR

13. OFFLINE

14. ENTER SWITCH

15. ONLINE

ENTER

+

ON LINE

2

CONFIG. CONTROL

LOCKED

Press until the desired

parameter displays.

The selected

configuration is printed.

Locks the ENTER key.

LinePrinter+

16. Close the printer cover. If you printed out the configuration, store it in a safe place. The printer is

ready for operation.

68

Page 69

OFFLINE

Main Menu

Main Menu

1

If installed

CONFIG.

CONTROL

page 71

Load Config.

Save Config.

Print Config.

Delete Config.

Power-up Config.

Protect Configs.

ETHERNET

PARAMS

page 122

IP Address

Gateway Address

Subnet Mask

MAC Address

1

ACTIVE

EMULATION

page 73

PCL-II

LP PLUS

IGP/PGL

IGP/VGL

Unidirectional

PMD Fault

Slow Paper Slew

Power Saver Time

1

1

PRINTER

CONTROL

page 123

EMULATION

page 74

PCL-II

LP PLUS

IGP/PGL

IGP/VGL

DIAGNOSTICS

Printer Tests

Test Width

Paper Out Dots

System Memory

Print Statistics

1

1

page 125

MAINT/MISC

page 112

Hex Dump Mode

Power-up State

Display Language

RIBBON

MINDER

page 128

New Ribbon

Ribbon Action

Ribbon Size

Ribbon Adjust

Fault Action

HOST

INTERFACE

page 113

Dataproducts

Serial

Ethernet

IEEE 1284

1

Figure 12. Configuration Main Menu

69

Page 70

Chapter 4 Configuration Overview

Brief descriptions follow for the first-level configuration menu options:

• CONFIG. CONTROL — These options allow you to save, print,

load, delete, name, and protect entire sets of configuration

parameters, as well as select the default power-up configuration.

• ACTIVE EMULATION — This menu allows you to select the active

emulation: PCL-II or LinePrinter+. The optional IGP/PGL or

IGP/VGL emulations can be selected if they are installed.

• EMULATION — This menu allows you to configure the options

which are available for the current operating (active) emulation. For

example, if LinePrinter+ is the active emulation, then the

LinePrinter+ emulation options can be configured using this menu.

• MAINT / MISC — These options provide miscellaneous functions,

such as printing a hex dump, selecting a display language, and

choosing whether the printer will power up in offline or online mode.

• HOST INTERFACE — These options allow you to select either the

®

Serial RS-232, Serial RS-422, Dataproducts

Ethernet

must match the interface cabling you installed while setting up your

printer, described in Chapter 2). This menu also allows you to

configure several par ame ter s for each int er fac e.

™

, or IEEE1284 parallel interface for the printer (which

Long Line,

• ETHERNET PARAMS — This option allows you to view and

change the IP Address, Gateway Address, and Subnet Mask. The

MAC Address may also be viewed.

• PRINTER CONTROL — These options allow you to select several

operating parameters for the printer, such as the speed at which

paper will advance when slewing.

• DIAGNOSTICS — These options include the diagnostic tests,

system memory, and statistics of the printer.

• RIBBONMINDER — The options in this submenu allow you to

™

enable the RibbonMinder

feature and set its parameters.

70

Page 71

CONFIG. CONTROL

The CONFIG. CONTROL menu allows you to control your printer’s

configurations according to the specifications necessary for your print

jobs.

Menu

CONFIG.

CONTROL

(from page 69)

Menu

* = Factory Default

Load Config.

Factory*

1-8

Save Config. Print Config.

1*

(1-8)

Current*

Factory

Power-up

All

1-8

Delete Config.

1*

(1-8)

Power-up

Config.

Factory*

1-8

Protect

Configs.

Disable*

Enable

Load Config.

The printer can store numerous configurations in memory. This

parameter allows you to select and load a specific configuration.

71

Page 72

Chapter 4 CONFIG. CONTROL

Save Config.

This option allows you to save up to eight unique configurations to meet

different print job requirements. This eliminates the need to change the

parameter settings for each new job. The configurations are stored in

memory, and will not be lost if you turn off the printer. If the Protect

Configs. parameter is enabled, the new configuration will not be saved

unless the existing configuration has been deleted first. The factory

default configuration cannot be changed. See “Saving Your New

Configuration” on page 66 for details.

Print Config.

This option is used to print a listing of various stored printer

configurations. It is recommended you store printouts of your

configurations in a safe place for quick referral.

Delete Config.

You can delete one or all of your eight customized configurations. The

factory default configuration cannot be deleted.

72

Power-Up Config.

You can specify which of the nine configurations (Factory or 1-8) will be

the power-up configuration.

Protect Configs.

You can specify whether or not a new configuration should overwrite an

existing configuration when you activate the Save Configs. parameter.

When disabled (default), the new configuration will overwrite the

existing configuration. When enabled, the new configuration will

overwrite the existing configuration, and the message “CONFIG.

EXISTS / Delete First” displays.

not

Page 73

ACTIVE EMULATION

ACTIVE

EMULATION

(from page 69)

Menu

* = Factory Default

1

Optional Emulation

IMPORT ANT

PCL-II*

LP PLUS IGP/PGL

1

IGP/VGL

1

The ACTIVE EMULATION function allows you to activate either the

PCL-II or LinePrinter Plus emulation, as well as the optional IGP/PGL or

IGP/VGL emulations, if they are installed. There are two methods for

selecting the desired emulation. The first is by selecting the emulation

directly from the printer menu. The second is by sending a host

command which will switch the emulation automatically (see the

appropriate

Programmer’s Reference Manual

for details

).

When changing from one emulation to the other, the printer will load the

power-up configuration. Thus, any configuration settings performed

before selecting these emulations and not saved in NVRAM will be lost.

In order to configure an emulation, the emulation must be selected

in the ACTIVE EMULATION menu. The emulation that is not

selected will not appear in the EMULATION menu (see

“EMULATION” on page 74).

73

Page 74

Chapter 4 EMULATION

EMULATION

The EMULATION menu is the gateway to configure the emulations

available with your printer. The control codes for each of these

emulations are described in their respective

Manuals

.

EMULATION

(from page 69)

Programmer’s Reference

* = Factory Default

1

Optional Emulation

PCL-II*

page 75

1

LP PLUS IGP/PGL

page 79 page 93 page 101

IGP/VGL

1

PCL-II Emulation

Hewlett-Packard’s Printer Control Language that is compatible with

Compaq systems.

LinePrinter Plus Emulations

• Epson FX. This LP Plus emulation is provided for compatibility with

the Epson FX-1050 printer control language.

• Proprinter XL. This LP Plus emulation is provided for compatibility

with the IBM Proprinter III XL printer control language.

• P-Series. This is the Printronix P-Series printer control language,

provided as part of LP Plus.

Optional Emulations

74

IGP/VGL (Code V) and IGP/PGL are optional graphics emulations.

They can be selected and configured only if you have purchased these