Page 1

INTELLISTRIPE 380

USB/RS-232

DESKTOP MOTORIZED READER-ENCODER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875275-3

AUGUST 2007

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Copyright© 2001-2007

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

IntelliStripe is a registered trademark of MagTek, Inc.

USB (Universal Serial Bus) Specification is Copyright© 1998 by Compaq Computer

Corporation, Intel Corporation, Microsoft Corporation, NEC Corporation.

REVISIONS

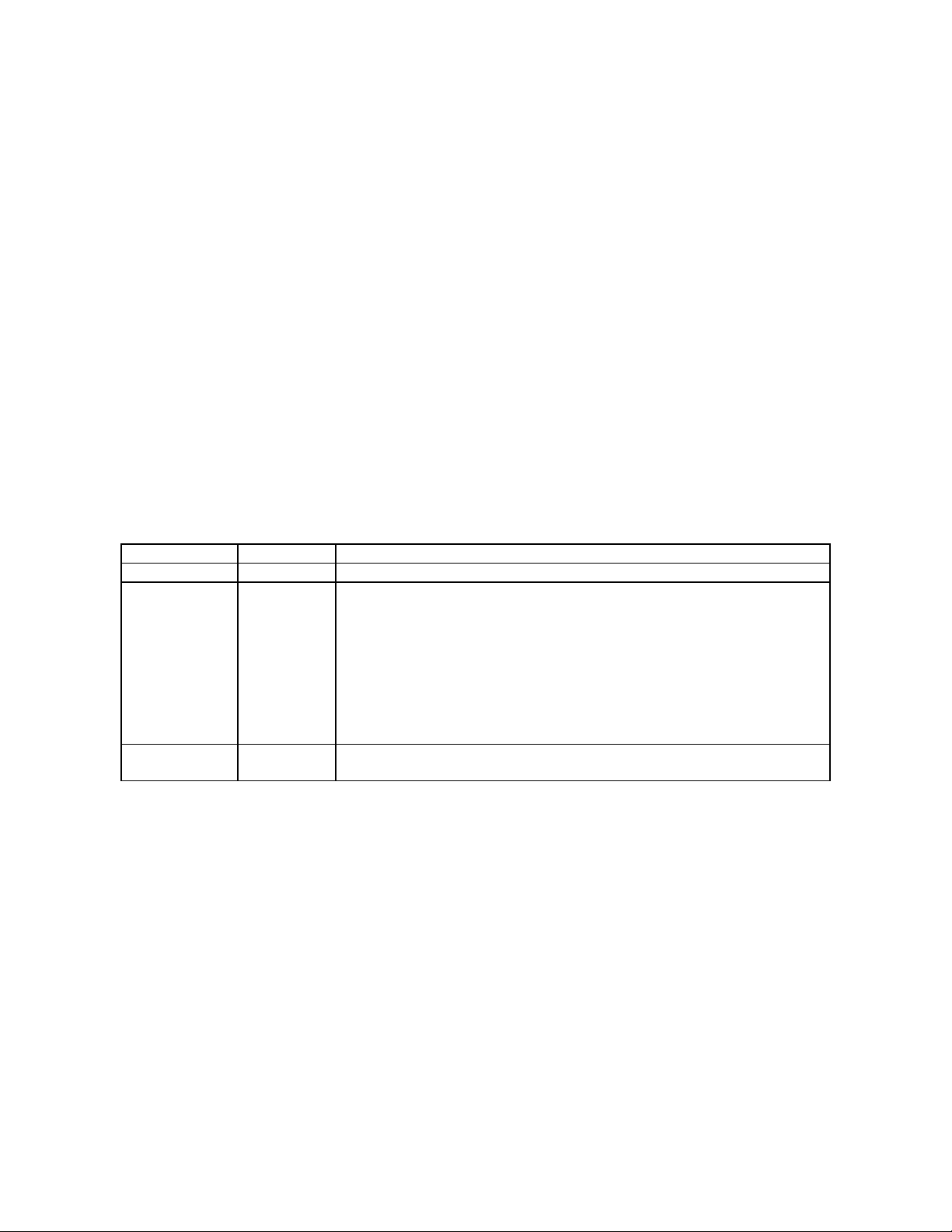

Rev Number Date Notes

1 16 Oct 03 Initial Release

2 05 Nov 03 Editorial throughout. Sec 1, Configurations: changed 2 part

numbers, clarified power supply description; Features: removed JIS,

to optional SAM and TRSM added “contact for further info”; clarified

Rotary Pulse Generator; Removed descriptions of TRSM, Sam

Ranch PCB, Power-on LED, Access to SAM Ranch sockets;

Specifications: changed card speed to 7-10 ips. Sec 2, Figures 2-4

and 2-5: changed part number for power cord and changed voltage

from 100-240 to 110V. Sec 3: deleted Figs 3-4, 3-5, 3-6, 3-7, and 3-8

and related text for SAM Ranch.

3 22 Aug 07 Added Encode Coercivity Ranges to specifications to show HiCo

encode capability for 2750 Oe

ii

Page 3

REGISTERED TO ISO 9001:2000

MagTek Part Number 99875275-1

1710 Apollo Court, Seal Beach, CA 90740 25 February 2003

Voice: 562-546-6400 Fax: 562-546-6301

SOFTWARE LICENSE AGREEMENT

IMPORTANT: YOU SHOULD CAREFULLY READ ALL THE TERMS, CONDITIONS AND RESTRICTIONS OF THIS LICENSE

AGREEMENT BEFORE INSTALLING THE SOFTWARE PACKAGE. YOUR INSTALLATION OF THE SOFTWARE PACKAGE

PRESUMES YOUR ACCEPTANCE OF THE TERMS, CONDITIONS, AND RESTRICTIONS CONTAINED IN THIS AGREEMENT. IF

YOU DO NOT AGREE WITH THESE TERMS, CONDITIONS, AND RESTRICTIONS, PROMPTLY RETURN THE SOFTWARE

PACKAGE AND ASSOCIATED DOCUMENTATION TO ABOVE ADDRESS ATTENTION: CUSTOMER SUPPORT.

TERMS, CONDITIONS AND RESTRICTIONS

MagTek, Incorporated (the "Licensor") owns and has the right to distribute the described software and documentation, collectively referred to

as the "Software".

LICENSE: Licensor grants you (the "Licensee") the right to use the Software in conjunction with MagTek products.

LICENSEE MAY NOT COPY, MODIFY OR TRANSFER THE SOFTWARE IN WHOLE OR IN PART EXCEPT AS EXPRESSLY

PROVIDED IN THIS AGREEMENT. Licensee may not decompile, disassemble or in any other manner attempt to reverse engineer the

Software. Licensee shall not tamper with, bypass or alter any security features of the software or attempt to do so.

TRANSFER: Licensee may not transfer the Software or license to the Software to another party without prior written authorization of the

Licensor. If Licensee transfers the Software without authorization, all rights granted under this Agreement are automatically terminated.

COPYRIGHT:

purposes. All other copies of the Software are in violation of this Agreement.

TERM:

this Agreement if Licensee fails to comply with any of the terms, conditions or restrictions contained herein. Should Licensor terminate this

Agreement due to Licensee's failure to comply, Licensee agrees to return the Software to Licensor. Receipt of returned Software by the

Licensor shall ma

This Agreement is in effect as long as Licensee continues the use of the Software. The Licensor also reserves the right to terminate

LIMITED WARRANTY:

from defects in material or workmanship under normal use. THE SOFTWARE IS PROVIDED AS IS WITHOUT WARRANTY OF ANY

KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Because of the diversity of conditions and PC hardware under

which the Software may be used, Licensor does not warrant that the Software will meet Licensee specifications or that the operation of the

Software will be uninterrupted or free of errors.

IN NO EVENT WILL LICENSOR BE LIABLE FOR ANY DAMAGES, INCLUDING ANY LOST PROFITS, LOST SAVINGS OR

OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE THE SOFTWARE.

Licensee's sole remedy in the event of a defect in material or workmanship is expressly limited to replacement of the Software disk(s) if

applicable.

GOVERNING LAW: If any provision of this Agreement is found to be unlawful, void or unenforceable, that provision shall be removed

from consideration under this Agreement and will not affect the enforceability of any of the remaining provisions. This Agreement shall be

governed by the laws of the State of California and shall insure to the benefit of MagTek, Incorporated, its successors or assigns.

The Software is copyrighted. Licensee may not copy the Software except for archival purposes or to load for execution

rk the termination.

Licensor warrants to the Licensee that the disk(s) or other media on which the Software is recorded to be free

ACKNOWLEDGMENT:

ITS TERMS, CONDITIONS AND RESTRICTIONS AND AGREES TO BE BOUND BY THEM. LICENSEE ALSO AGREES THAT

THIS AGREEMENT SUPERSEDES ANY AND ALL, VERBAL AND WRITTEN, COMMUNICATIONS BETWEEN LICENSOR AND

LICENSEE OR THEIR ASSIGNS RELATING TO THE SUBJECT MATTER OF THIS AGREEMENT.

LICENSEE ACKNOWLEDGES THAT HE HAS READ THIS AGREEMENT, UNDERSTANDS ALL OF

QUESTIONS REGARDING THIS AGREEMENT SHOULD BE ADDRESSED IN WRITING TO MAGTEK, INCORPORATED,

ATTENTION: CUSTOMER SUPPORT, AT THE ABOVE ADDRESS OR E-MAILED TO support@magtek.com

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 Of The FCC Rules. Operation of this device is subject to the following

two conditions: (1) This device may not cause harmful interference. And (2) This device must accept any

interference received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de las classe A prescrites dans le Réglement sur le brouillage radioélectrique

édicté par les ministère des Communications du Canada.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

iv

Page 5

TABLE OF CONTENTS

SECTION 1. FEATURES AND SPECIFICATIONS.....................................................................................

CONFIGURATIONS.................................................................................................................................

FEATURES...............................................................................................................................................

APPLICABLE DOCUMENTS ...................................................................................................................

Standards .............................................................................................................................................

MagTek Documents .............................................................................................................................

SOFTWARE ACCESSORIES..................................................................................................................

COMPONENTS........................................................................................................................................

Motorized Card Transport.....................................................................................................................3

Lead-in Roller System.....................................................................................................................................3

Front Opto-Sensor...........................................................................................................................................3

Encode Opto-Sensor........................................................................................................................................3

Card-Landed Mechanical Switch Sensor........................................................................................................3

Spring-Loaded Card Registration Guide(s).....................................................................................................

Ability To Transport 0.010 ”to 0.035” Cards..................................................................................................

Card Entry/Orientation....................................................................................................................................

Magstripe Read/Encode ..................................................................................................................................

SmartCard .......................................................................................................................................................

Packing/Enclosure................................................................................................................................

Small Footprint................................................................................................................................................

Cable Management..........................................................................................................................................

Jam Clearance – Ejector Rod..........................................................................................................................

Access to Optional SAMs...............................................................................................................................

Tamper Resistant Security Module (TRSM), Optional ...................................................................................

Electronics and PCBs...........................................................................................................................

Main PCB Components...................................................................................................................................

Host Serial Port ...............................................................................................................................................

USB Port .........................................................................................................................................................

Auxiliary Serial Port........................................................................................................................................

Power Input.....................................................................................................................................................

Polarization and Securement of Serial Port Cables.........................................................................................

Opto-Sensor Inputs..........................................................................................................................................

Rotary Pulse Generator ...................................................................................................................................

External SAM Ranch Interface, Optional........................................................................................................

Dual Color LED..............................................................................................................................................

ISO-8 Smartcard Connector with Landing Switch..........................................................................................

3-Track Read/Encode Magnetic Head.............................................................................................................

DC Motor........................................................................................................................................................

Microcontroller LED Indicator........................................................................................................................

External Auto-Ranging Power Pack.....................................................................................................

Auto-Ranging Input.........................................................................................................................................

Output Rating..................................................................................................................................................

Firmware...............................................................................................................................................

Memory Cards.................................................................................................................................................

FLASH Download Protection.........................................................................................................................

SPECIFICATIONS..................................................................................................................................

SECTION 2. INSTALLATION....................................................................................................................

MOUNTING............................................................................................................................................

Footpad Mounting...............................................................................................................................

Mounting Hole Screws........................................................................................................................

Lock-in-place-slots..............................................................................................................................

1

1

1

2

2

2

2

2

4

4

4

4

5

5

5

6

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

8

8

8

9

9

9

9

9

9

10

11

11

11

11

11

v

Page 6

Flange.................................................................................................................................................

MagTek Mounting Plate......................................................................................................................

REAR PANEL AND CABLE CONNECTIONS........................................................................................

SECTION 3. OPERATION AND MAINTENANCE....................................................................................

OPERATION...........................................................................................................................................

PREVENTIVE MAINTENANCE..............................................................................................................

CORRECTIVE MAINTENANCE.............................................................................................................

Ejector Rod for Card Jams.................................................................................................................

APPENDIX A. DIMENSIONS FOR MOUNTING.......................................................................................

MOUNTING............................................................................................................................................

Footpad Mounting...............................................................................................................................

Mounting Hole Screws........................................................................................................................

Lock-in-place-slots..............................................................................................................................

Flange.................................................................................................................................................

11

11

12

19

19

19

19

19

21

21

21

21

21

21

vi

Page 7

TABLE OF FIGURES

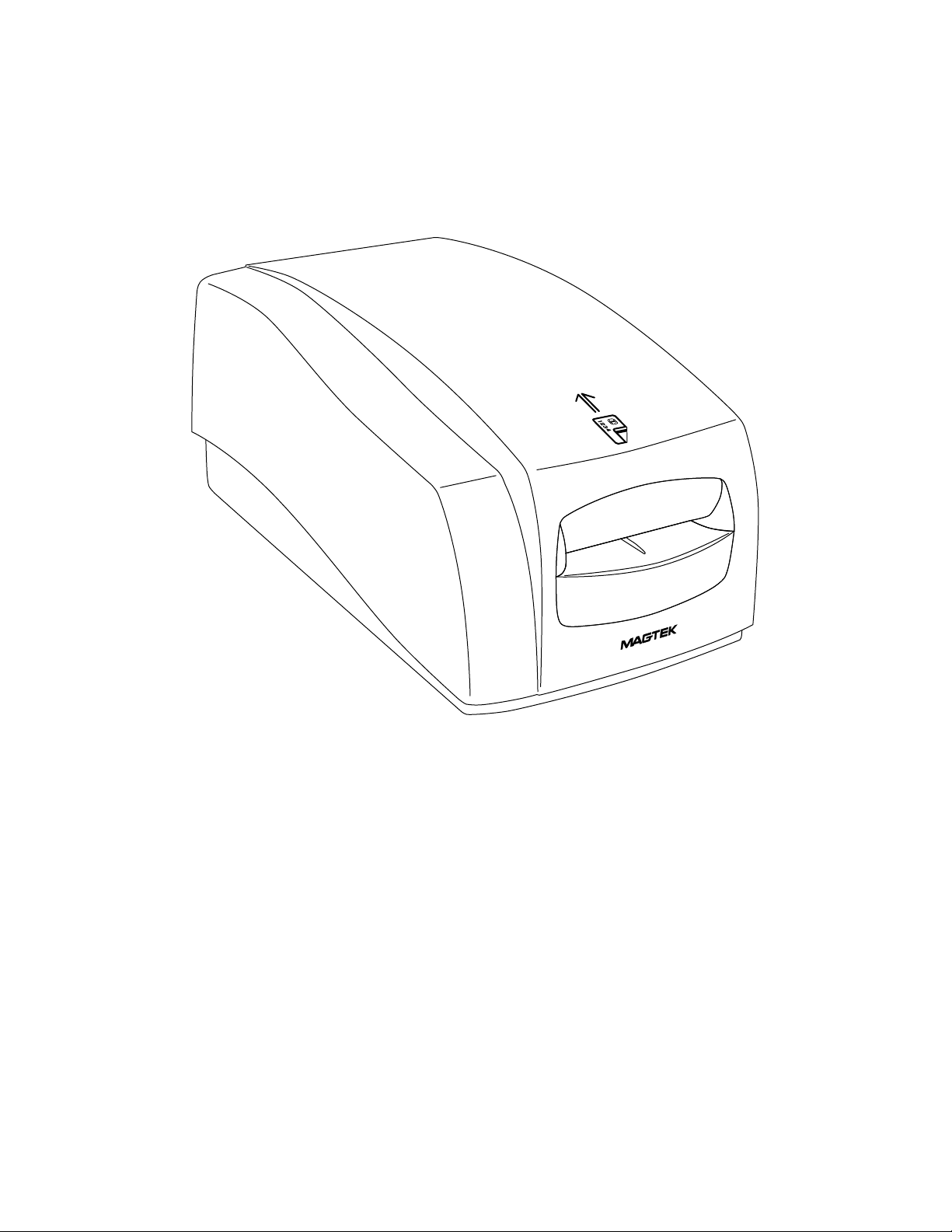

Figure 1-1. IntelliStripe 380---------------------------------------------------------------------------------------------------

Table 1.1. Specifications------------------------------------------------------------------------------------------------------

Figure 2-1. Dimensions for Mounting Holes for 3-Screw Set and Foot Pads------------------------------------

Figure 2-2. Dimensions for Mounting Holes for Lock-in-Place Slots-----------------------------------------------

Figure 2-3. Rear Panel and Cover------------------------------------------------------------------------------------------

Figure 2-4. Cable Connections - RS-232---------------------------------------------------------------------------------

Table 2-1. Pin List for IntelliStripe 380 to Host PC Cable P/N 16051417-----------------------------------------

Figure 2-5. Cable Connections - USB-------------------------------------------------------------------------------------

Table 2-2. Cable Connections – USB Signal ----------------------------------------------------------------------------

Table 2-3. Cable Connections – USB Power----------------------------------------------------------------------------

Figure 2-6. Rear Panel Cover Replaced – RS-232 Connection-----------------------------------------------------

Figure 2-7. Rear Panel Cover Replaced – USB Connection---------------------------------------------------------

Figure 3-1. Card Orientation-------------------------------------------------------------------------------------------------

Figure 3-2. Ejector Rod Removal from Storage-------------------------------------------------------------------------

Figure 3-3. Card Removal----------------------------------------------------------------------------------------------------

Figure A-1. Mounting Dimensions 1----------------------------------------------------------------------------------------

Figure A-2. Mounting Dimensions 2----------------------------------------------------------------------------------------

Figure A-3. MagTek Mounting Plate, I380, 1-----------------------------------------------------------------------------

Figure A-4. MagTek Mounting Plate, I380, 2-----------------------------------------------------------------------------

TABLES

viii

10

12

12

13

14

14

15

15

16

16

17

19

20

20

22

23

24

25

Table 1.1. Specifications------------------------------------------------------------------------------------------------------

Table 2-1. Pin List for IntelliStripe 380 to Host PC Cable P/N 16051417-----------------------------------------

Table 2-2. Cable Connections – USB Signal ----------------------------------------------------------------------------

Table 2-3. Cable Connections – USB Power----------------------------------------------------------------------------

10

14

15

16

vii

Page 8

viii

Figure 1-1. IntelliStripe 380

Page 9

SECTION 1. FEATURES AND SPECIFICATIONS

The IntelliStripe® 380, Desktop Motorized Reader-Encoder reads and encodes magnetic-stripe

cards and smartcards.

CONFIGURATIONS

Part numbers and descriptions for the basic configuration are as follows:

16050408 IntelliStripe 380

16050410 IntelliStripe 380, Magstripe Only

16051417 I/O Cable, 10-pin RJ45 connector connects to host 9-pin connector with

12V/Ground connector for Power Supply.

16051422 USB Cable, 5-pin mini B plug, connects to host 4-pin USB Type A Plug with the

10-pin RJ45 and 12V/Ground connector for Power Supply.

64300091 Power Supply 12 VDC, 4 A output, 100 –240 VAC auto ranging input.

71100001 AC power cord, P/N is for use in North America. Other users must supply their

own cord, or contact MagTek for international cords.

FEATURES

The IntelliStripe 380 provides the following key features:

• 3-Track magstripe read and encode with support for HiCo and LoCo cards.

Also supports Drivers License and Custom format encode scheme.

• EMV T=0, T=1 Smartcard Interface. Also supports popular memory cards.

• Optional support for 6-socket SAM Ranch using a piggyback PCB.

• RS-232 or USB primary host interface using MCP protocol.

• Auxiliary RS-232 interface to support an external interface.

• Small and attractive desktop enclosure with easy access to Optional SAM(s).

Also provides facilities for cable strain-relief and card-jam clearing.

• FLASH programmable

• Dual Color LED status indicator.

• Single cable with remote power pack. Power is routed through communications cable.

• Optional Tamper Switch

1

Page 10

IntelliStripe 380

APPLICABLE DOCUMENTS

Standards

ISO 7811-2, -3, -4, -5 Identification cards tracks 1-3

ISO 7810 Physical specifications

ISO 7816 Smartcard specifications

EMV 1996 Europay-Mastercard-Visa 1996 Level I Specification

EMV 2000 Europay-Mastercard-Visa 2000 Level I Specification

MagTek Documents

MCP Serial Transport Protocol, P/N 99875163

IntelliStripe 380, Command Reference Manual, P/N 99875217

SOFTWARE ACCESSORIES

The following Software Modules may be required and will assist in the development of

application software. In addition, this software can provide an initial test platform for checkout

of the IntelliStripe 380.

• IntelliStripe Picture Demo with MCP Driver:

P/N 30037472 (CD) or P/N 99510015 (Web Release)

This software will install both a Demo program and the MCP driver.

The Demo program is useful for initial checkout of the Reader’s functionality. The

MCP driver is recommended for use as the communications interface on Windows

based host systems. Application programmers can interface to the MCP driver via a

MagTek defined API.

• Source Code for Picture Demo Program:

P/N 30037436

Visual Basic 6.0 source code for the Picture Demo program.

This will be useful to Application Programmers, as it shows examples of how to

interface with the MCP drivers and how to use the various commands.

COMPONENTS

The components are grouped in the following categories: The Motorized Card Transport,

Packaging/Enclosure, and Electronics and PCB, Optional SAM Ranch PCB, External Autoranging Power Pack, and Firmware.

2

Page 11

Section 1. Features and Specifications

Motorized Card Transport

The Card Transport is based on an existing MagTek magstripe/encode module. This module

incorporates the following features:

Lead-in Roller System

The primary purpose of the Lead-in Roller System is to grab the card from the user during card

insertion and to make sure the card is mechanically under motor control before reaching the

read/write head and its associated drive rollers.

As a secondary function, the Lead-in Drive Roller will also assist in allowing for a more reliable

exit positioning of the card during an eject sequence. The Lead-in Roller allows for the

possibility of pulling the card back into the reader if required.

Front Opto-Sensor

The Front Opto-Sensor is located near the entrance of the card path. The primary function of this

sensor is to provide information that a card has been inserted into the Reader and to inform the

microcontroller to initiate motor and card-handling activities.

As a secondary function, this sensor also provides feedback regarding card location during a card

eject and/or jam-clear sequence.

Encode Opto-Sensor

This sensor is located approximately 0.300” before the crown of the magnetic read/write head.

The primary purpose of this sensor is to provide the microcontroller with the position of the

leading edge of the card just before encoding. This information, in conjunction with the Rotary

Pulse Generator (RPG), allows for a higher degree of positional accuracy just before initiation of

the magnetic encode process.

As a secondary function, this sensor also provides feedback regarding card location during a

card-eject and/or jam-clear sequence.

Card-Landed Mechanical Switch Sensor

This switch is integrated as part of the ISO-8 smartcard contact block, and the sensor provides an

indication when the leading edge of a card has reached physical travel limit for rearward travel

and has successfully engaged with the smartcard contacts which allows for a successful

smartcard interface session.

3

Page 12

IntelliStripe 380

Spring-Loaded Card Registration Guide(s)

The spring-loaded guide ensures that the reference edge of the card is mechanically referenced to

the magnetic read/write head, so that the magnetically encoded track data is physically located

on the magstripe in accordance with the specifications of ISO 7811.

Ability To Transport 0.010 ”to 0.035” Cards

Cards that meet the ISO 7810 card thickness of 0.027” to 0.033 will work properly with both

magnetic and smartcard elements of this system. However, card thickness of 0.010” to 0.035”

should not be expected to work properly in regard to magnetic and smartcard operations. These

cards only need be successfully transported without jamming in the Reader.

Card Entry/Orientation

Enter an ISO 7810-, 7811-, or 7816-compatible card into the Reader with the front surface of the

card up (side with the embossed characters and smartcard IC) and visible to the user during

insertion. The magstripe side of the card will face down and not be visible to the user during

insertion. The magstripe will be towards the right side of the Reader (as viewed from the front).

Magstripe Read/Encode

The Transport reads and encodes a magnetic stripe card that meets the requirements of the ISO

7810 and 7811 specifications. In addition, the device provides support for a variety of user

selectable data densities and data formats that fall within the boundaries of ISO 7810 and 7811.

Number of tracks: The magnetic encode section provides the ability to encode or read

three tracks of magnetic data as specified in ISO 7810 and 7811 in a single physical pass

of the card over the read/write head.

Note

This does not imply that both read and encode functions occur

simultaneously. It means that either a 3-track read OR a 3-track encode

sequence occurs during a single pass of the card over the magnetic head.

Direction of Magnetic Encode: To meet the requirements of ISO 7810 and 7811, the

magstripe card is encoded in a unidirectional movement, which starts at the defined

leading edge and continues toward the trailing edge of the card; this means that the card

is encoded as the card is moved from the front entrance of the Reader towards the rear of

the Reader.

4

Page 13

Section 1. Features and Specifications

Direction of Magnetic Read: The ISO 7810 and 7811 specifications allow for

bidirectional magnetic reading of the card. As such, the Reader provides services that

allow the card to be read in either direction.

Read Formats: In addition to reading cards that meet the ISO 7810 and 7811

specifications, the Reader reads AAMVA drivers license cards. Also, all 3 tracks of the

Reader reads any card that follows ISO 5-bit or 7-bit data formats and is within any bit

density in the range of 75 to 210 bpi.

Encoded Formats: In addition to encoding cards that comply with ISO 7811 encoding

formats, it is possible to customize encoding formats as follows:

• Encoded bit density is selectable at 75 or 210 bpi on all three tracks.

• The character is selectable for either 5-bit or 7-bit format on all three

tracks.

• The Start-Sentinel character is user selectable as either a (;) or a (=)

for 5-bit code or a (%) or (=) for 7-bit code.

SmartCard

The transport provides smartcard contacts that are compatible with ISO 7816 and EMV level 1

Standards. In addition, the smartcard contact block has a card landed switch that detects when an

ISO 7810 thickness card is properly pressed against the smartcard contact block.

Packing/Enclosure

The enclosure provides for proper functionality for user interface, cable routing, mechanical

mounting, jam clearance, optional SAM (Security Access Module) installation and Optional

TRSM (Tamper Resistant Security Module), and general maintenance.

Small Footprint

The unit has the smallest footprint required by the limited counter-top and desktop space

available at financial institutions.

5

Page 14

IntelliStripe 380

Cable Management

The following provisions are made for communication and power lines:

• Polarization and locking of cable connectors

• Strain relief of cables

• Wire routing functionality

• RJ series connectors for main and auxiliary RS-232 interfaces.

• Power is brought to the unit through the main RS-232 cable

• Power-pack is away from the unit and will attach to the main RS-232 cable

Jam Clearance – Ejector Rod

For easy removal of a jammed card, an ejector rod is accessible at the rear of the unit. To clear a

jam, the ejector rod is removed from the rear of the unit and inserted into an access hole on the

back panel of the reader to push a card out of the front slot of the unit.

Access to Optional SAMs

The unit provides quick and easy access to the optional SAM ranch (a PCB with 6 optional SAM

modules) through an access hatch at the base of the unit. Contact MagTek for further

information regarding optional SAM module.

Tamper Resistant Security Module (TRSM), Optional

The unit provides mechanical and electromechanical features that allow the enclosure to be used

within a TRSM environment per ISO 9564. Mechanical features visually indicate intrusion into

the enclosure, and electromechanical switches on the Main PCB signal that the mechanical

enclosure had been opened. This allows the electronics to erase the keys in its memory area

whether the unit is powered or not. Contact MagTek for further information regarding optional

TRSM.

Electronics and PCBs

The core electronic functions of the unit reside on a single PCB referred to as the Main PCB. As

an option, a second PCB referred to as the SAM Ranch may be plugged into the Main PCB.

Main PCB Components

The Main PCB Components are the microcontroller, RAM space, and ROM space.

Microcontroller: The main PCB is based upon a Philips XAS3 microcontroller. This

controller was used on previous MagTek products with previously developed firmware.

6

Page 15

Section 1. Features and Specifications

RAM Space: 40 K bytes

ROM Space: ROM Flash:

Main Program Memory: 512 K Bytes

Boot Loader Memory: 24 K Bytes

Configuration Memory: 8 K Bytes

Host Serial Port

The RS-232 Host Serial Port provides serial communications between the Reader/Encoder and

the Host Computer. In addition, the Host Serial Port carries DC power from the remote power

pack to the Reader/Encoder. The Host Serial Port is capable of communication speeds of up to

115 K bits/sec.

USB Port

The Host USB 1.1 Port provides communications between the Reader/Encoder and the Host

Computer. The USB Cable, 5-pin mini B Plug, connects to host 4-pin USB Type A Plug, with

10-pin RJ45 and 12V/Ground connector for Power Supply.

Auxiliary Serial Port

The Auxiliary Serial Port provides serial communications and power between the

Reader/Encoder and an external device. The Auxiliary Serial Port is capable of communication

speeds of up to 19.2 Kbits/sec. The port is also capable of carrying +12 VDC at up to 1 A for a

device connected to this port.

Power Input

The Reader/Encoder is powered by a 12 VDC power-pack. The +12 VDC power is carried to

the Reader/Encoder as part of the Host Serial cable.

All other voltages required by the Main PCB are generated onboard as required.

The input connector and cabling carry power to support the Reader/Encoder.

Polarization and Securement of Serial Port Cables

The ports, located at the rear of the Reader/Encoder, use RJ connectors with locking tabs, which

assist in securing the cable to the Reader/Encoder.

7

Page 16

IntelliStripe 380

Opto-Sensor Inputs

The Main PCB provides inputs for the three opto-sensors (Front, Encode, and Rear).

Rotary Pulse Generator

The Main PCB provides input for the MagTek 75/210 bpi Rotary Pulse Generator (RPG).

External SAM Ranch Interface, Optional

The Main PCB provides resources for interconnect, securement, and power of an optional SAM

Ranch PCB. The optional SAM Ranch PCB is accessed from the hatch door at the bottom of the

Encoder/Reader.

Dual Color LED

The Main PCB provides facilities for a dual color, red/green PCB. The LED is located on the

front bezel of the Encoder/Reader. When the unit is powered up, the LED will blink green or red

until the Host commands it to a different state. Green means the unit is ready for norm al

operation. Red means a card is jammed in the unit and should be manually removed.

ISO-8 Smartcard Connector with Landing Switch

The Main PCB provides resources to support an interface with an ISO-8 smartcard connector

with its associated landing switch. The electronics meet EMV Level 1 requirements.

3-Track Read/Encode Magnetic Head

The Main PCB supports an interface to a 3-Track Read/Encode Magnetic Head. A flex-cable

circuit connects the magnetic head to the Main PCB.

DC Motor

The Main PCB supports a bidirectional drive interface to a DC motor. The motor drives the card

in the forward and reverse directions in the transport. The motor can also be driven with a small

“holding” current to keep a card positioned over the Smart Card contact block during a Smart

Card session.

Microcontroller LED Indicator

The Main PCB supports a “watchdog” LED, which blinks on and off providing visual indication

that the microcontroller is in a normal state of operation. The LED can be viewed when the

bottom access hatch is removed from the enclosure.

8

Page 17

Section 1. Features and Specifications

External Auto-Ranging Power Pack

The Reader/Encoder is powered from an external power-pack, which is located near the Host

Computer System. Power is routed to the Reader/Encoder through the Host RS-232 cable.

Auto-Ranging Input

The external power pack features an Auto-ranging AC input that allows for direct connection to

either a 100 VAC or 220 VAC, 50 to 60 Hz.

Output Rating

The power pack is rated at approximately +12 VDC @ 4 A ± 5%.

Firmware

The firmware for the Reader/Encoder is based upon existing MCP protocol and command set.

Memory Cards

The firmware supports smartcard interfaces to memory cards.

FLASH Download Protection

To prevent illegal applications from being downloaded into the Reader/Encoder, the firmware

verifies that the downloaded FLASH program is provided (authorized) by MagTek. If the

program cannot ID itself correctly, the boot loader program abandons the FLASH load sequence

and returns a unique status code that identifies the situation to the Host.

9

Page 18

IntelliStripe 380

SPECIFICATIONS

The Specifications are listed in Table 1-1.

Table 1.1. Specifications

OPERATING

MSR Read-data Format

Specifications Supported

Encode Coercivity

Ranges

Input Voltage

Current Draw Idle: 300 mA

MTBF

Card Speed 7-11 ips

Interface RS-232, USB

Dimensions

Length

Width

Height

Weight 2.0 lb (0.9072 Kg)

Temperature

Operating

Storage

Humidity

Operating

Storage

Altitude

Operating

Storage

Mag-Stripe: ANSI/ISO 7810, 7811/AAMVA/ for tracks 1, 2, and 3

Smart Card: ISO 7816-1, -2, and -3

LoCo = 325 Oe +/- 75 Oe ( Range of 250 Oe to 400 Oe )

HiCo = 2750 Oe +/- 500 Oe ( Range of 2250 Oe to 3250 Oe )

+12 VDC ±5%

Max: 3.0 A (during HiCo encode sequence) and 1 A draw from an

Auxiliary Serial Port Device.

Electronics: 125, 000 hours

Magnetic Read Head: 1 million passes (500,000 insertion cycles)

Smartcard contacts: 1 million transactions

MECHANICAL

8.440” (includes Mounting Flange) (211.008 mm)

4.470” (111.754 mm)

3.85” (includes Mounting Flange) (97.79 mm)

ENVIRONMENTAL

o

F to 113 oF (5 oC to 45 oC)

41

o

F to 158 oF (-40 oC to 70 oC)

-40

5% to 95%

5% to 95% noncondensing

0-10,000 ft. (0-3,048 m.)

0-10,000 ft. (0-3,048 m.)

10

Page 19

SECTION 2. INSTALLATION

The installation of the IntelliStripe 380 Reader-Encoder consists of mounting the unit on a flat

surface, connecting the I/O RS-232 cable to the host serial port, the Auxiliary cable to a

peripheral device, and the Power Supply to the I/O cable and to a wall receptacle.

MOUNTING

The bottom of the unit is shown in Figure 2-1 and 2-2. The IntelliStripe 380 may be mounted in

one of three ways: 1) foot pads, 2) set of mounting holes for 3 screws (4 x 40), and 3) 4 lock-inplace slots.

Footpad Mounting

The footpads are mounted at the factory if it is the default. Simply place the unit on a level

surface with approximately 4 inches clearance from obstructions at the front of the unit for card

clearance. Leave enough room at the rear of the unit for cable clearance.

Mounting Hole Screws

Locate the 3 screw holes (4 x 40 screws) shown in Figure 2-1. The length of the screws depends

on the thickness of the mounting surface. Drill 3 holes in the mounting surface that match the set

of screw holes. The screws are mounted from under the mounting surface and into the bottom of

the IntelliStripe 380.

Lock-in-place-slots

Figure 2-2 shows the dimensions of the Lock-in-place slots, to be used with optional Baseplate

Mounting, P/N 16054403. (See Appendix A, Figure A-4.) The holes next to the lock-in-placeslots are for inserts. The holes are placed over mounted inserts and the unit is pulled the length

of the slots forcing the thickness of the bottom plate to lock the unit in place. Dimensions of the

slots and inserts are shown in Appendix A.

Flange

The flange shown in the illustration may be used to screw the unit to the mounting surface using

a #4 screw. It can be used with any mounting configuration.

MagTek Mounting Plate

MagTek offers an optional mounting plate. The plate dimensions are shown in Appendix A,

Figure A-4.

11

Page 20

IntelliStripe 380

5.789

1.616

.546

1.105

Mounting Screws #4-40 (3)

3.230

Foot Pads (4)

Figure 2-1. Dimensions for Mounting Holes for 3-Screw Set and Foot Pads

2.810

1.147

2.032

4.330

Lock-In-Place Slots (4)

.959

.375 (4)

.180 (4)

Ø .125

Mounting

Flange (1)

(use with

Lock-In-Place

mounting holes)

Figure 2-2. Dimensions for Mounting Holes for Lock-in-Place Slots

REAR PANEL AND CABLE CONNECTIONS

To access the rear panel and cable connections on the IntelliStripe 380, remove the rear panel

cover, shown in Figure 2-3, by squeezing the two mounting clips on the cover as indicated in the

illustration. To replace the back panel, insert the mounting clips into the guide slots and press

into the attachment slots as indicated in the illustration.

Also shown in the illustration are the Auxiliary and the Host RS-232 and USB connectors. The

ejector rod is used to remove jammed cards and is stored on the back panel as shown.

12

Page 21

Section 2. Installation

.

Guide Slots &

Attachment Holes

Card Ejector

Rod

Card Ejector Rod

Mounting

Flange

Rear Panel

Figure 2-3. Rear Panel and Cover

Connect the Host PC cable (P/N 16051417) to the RS-232 connector on the IntelliStripe 380 as

shown in Figure 2-4 for the RS-232 connection.

Connect the Host PC Cable to the PC. Connect the Power Supply Cord (part of P/N 64300091)

to the Host PC cable. Connect the North American 100-240v power cord (P/N 71100001) to the

power supply.

Caution

Do not plug the power supply into a wall receptacle yet.

13

Page 22

IntelliStripe 380

To PC

Power Supply (with cable)

P/N 64300091

Cable

P/N 16051417

North American 110V

Power Cord P/N 71100001

Figure 2-4. Cable Connections - RS-232

Table 2-1 lists the pins for the host cable P/N 16051417.

Table 2-1. Pin List for IntelliStripe 380 to Host PC Cable P/N 16051417

10P10C RJ Plug 2.5mm Power Jack DB-9 Female

1 PWR GND SHELL GND

2 +12 CENTER PIN +12

3 TXD 2 RXD

4 CTS 7 RTS

5 SIG GND 5 GND

6 PWR GND SHELL GND

7 RTS 8 CTS

8 +12 CENTER PIN +12

9 RXD 3 TXD

10 +12 CENTER PIN +12

4 DTR

6 DSR

14

Page 23

Section 2. Installation

Cable connections for the USB are Shown in Figure 2-5, and the pin lists are shown in Table 2-2

and Table 2-3.

IntelliStripe 380

Back Panel

Pin 1Pin 5

Pin 4

Pin 1Pin 10

P2

P1

P4

Cable

P/N 16051422

P3

Power Supply (with cable)

P/N 64300091

Pin 1

North American 110V

Power Cord P/N 71100001

Figure 2-5. Cable Connections - USB

Table 2-2. Cable Connections – USB Signal

CONNECTOR WIRE

P1

USB Type A Plug

1 V Bus Red 1

2 D- White 2

3 D+ Green 3

4 Gnd Black 5

Shell (Braid Shield) Shell (Braid Shield)

Signal Name Wire Color P2

Mini USB Type B Plug

15

Page 24

IntelliStripe 380

Table 2-3. Cable Connections – USB Power

P3 – 2.5 mm Power Jack Wire Color P4 – 10P10C RJ Plug

Shell Gnd Drain Wire 1 PWR GND

Center Pin +12 26AWG Wire (Black) 2 +12

Shell Gnd Braid Shield 6 PWR GND

Center Pin +12 26AWG Wire (Brown) 8 +12

Center Pin +12 26AWG Wire (Red) 10 +12

Check all connectors to ensure they are properly connected. Replace the Rear Panel Cover by

inserting the mounting clips into the guide slots and press into the attachment slots as indicated

in Figure 2-3.

After connectors are checked and the Rear Panel Cover replaced, the unit should look similar to

Figure 2-6 and 2-7.

Ejector Rod Hole

For Card Removal

Rear Panel Cover

Cable To Peripheral

P/N 16051415

Cable To PC

P/N 16051417

Figure 2-6. Rear Panel Cover Replaced – RS-232 Connection

16

Page 25

Section 2. Installation

Ejector Rod Hole

For Card Removal

Rear Panel Cover

Power And USB Cable

P/N 16051422

Figure 2-7. Rear Panel Cover Replaced – USB Connection

Plug in the power supply into a wall receptacle.

17

Page 26

IntelliStripe 380

18

Page 27

SECTION 3. OPERATION AND MAINTENANCE

The operation of the unit includes inserting and removing the card. Maintenance includes

keeping the unit clean and removing jammed cards from the unit.

OPERATION

The card is inserted with the magnetic stripe down and to the right as illustrated in Figure 3-1.

Perform any tasks on the PC as directed. The LED gives status or direction as defined by the

institution.

Figure 3-1. Card Orientation

PREVENTIVE MAINTENANCE

Preventive maintenance includes cleaning the unit periodically with a lint-free cloth. The

cleaning schedule depends on how clean or dirty the environment is.

CORRECTIVE MAINTENANCE

Ejector Rod for Card Jams

Corrective maintenance includes removing the card in case of power failure or card jam. In most

cases, resetting the unit will cause the card to automatically eject the card. To reset the unit

unplug the Power Supply connector (Figure 2-4) from the I/O connector and plug it back in.

If the card does not automatically eject, the card may be pushed out with a special tool, the

Ejector Rod, which is located in the Rear Panel of the unit, as shown in Figure 2-3.

19

Page 28

IntelliStripe 380

Shut power off by unplugging the power supply (Figure 2-4), and remove the card with the Rod

as follows:

1. Remove the Rear Panel Cover to access the Ejector Rod as indicated in Figure 3-2.

Ejector Rod Hole

For Card Removal

Rear Panel

Card Ejector Rod

Rear Panel Cover

Figure 3-2. Ejector Rod Removal from Storage

2. Look into the Hole for Card Removal in the back of the unit, shown in Figure 3-2, to see the

jammed card. This will indicate the approximate position where the notch on the Ejector Rod

will be positioned with respect to the card.

3. Insert the Rod into the Hole for Card Removal, as shown in Figure 3-3 and push the Rod until

the card appears in the slot at the front of the unit.

Card Ejector Rod

AUX

Figure 3-3. Card Removal

4. Manually remove the card when it appears in the slot in the front of the unit.

5. Reconnect the power cord.

20

Page 29

APPENDIX A. DIMENSIONS FOR MOUNTING

MOUNTING

The bottom of the unit is shown in Figure 2-1 and 2-2. The IntelliStripe 380 may be mounted in

one of three ways: 1) foot pads, 2) set of mounting holes for 3 screws (4 x 40), and 3) 4 lock-inplace slots.

The mounting dimensions of the 3 screw holes and the 4 lock-in-place slots are shown in Figure

A-1.

Footpad Mounting

The footpads are mounted at the factory if it is the default. Simply place the unit on a level

surface with approximately 4 inches clearance from obstructions at the front of the unit for card

clearance. Leave enough room at the rear of the unit for cable clearance.

Mounting Hole Screws

Locate the 3 screw holes (4 x 40 screws) shown in Figure 2-1. The length of the screws depends

on the thickness of the mounting surface. Drill 3 holes in the mounting surface that match the set

of screw holes. The screws are mounted from under the mounting surface and into the bottom of

the IntelliStripe 380.

Lock-in-place-slots

The overall dimensions of the unit are shown in Figure A-2.

The MagTek Mounting Plate, Figures A-3 and A-4, show the use of the Lock-in-place slots

(Refer also to Figures 2-2). In the example the holes are placed over mounted inserts and the

unit is pulled the length of the slots forcing the thickest part of the plate to lock the unit in place.

The value and tolerances of the plate at the end of the slots are .087” ±.005” (Figure A1), and the

value and tolerances of the “stem” of the mushroom-shaped inserts are .085” ±.005” as shown in

Figure A-4.

Flange

The flange shown in Figure 2-2 may be used to screw the unit to the mounting surface using a #4

screw. It can be used with any mounting configuration.

21

Page 30

IntelliStripe 380

Figure A-1. Mounting Dimensions 1

22

Page 31

Appendix A. Dimensions for Mounting

Figure A-2. Mounting Dimensions 2

23

Page 32

IntelliStripe 380

24

Figure A-3. MagTek Mounting Plate, I380, 1

Page 33

Appendix A. Dimensions for Mounting

Figure A-4. MagTek Mounting Plate, I380, 2

25

Page 34

Appendix A. Dimensions for Mounting

26

Loading...

Loading...