Page 1

Compaq DAT AutoLoader

Reference Guide

Third Edition (January 2000)

Part Number 326817-003

Compaq Computer Corporation

Page 2

Notice

The information in this publication is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR

EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN, NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OF THIS MATERIAL. THIS INFORMATION IS PROVIDED “AS IS” AND COMPAQ

COMPUTER CORPORATION DISCLAIMS ANY WARRANTIES, EXPRESS, IMPLIED OR

STATUTORY AND EXPRESSLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, GOOD TITLE AND AGAINST

INFRINGEMENT.

This publication contains information protected by copyright. No part of this publication may be

photocopied or reproduced in any form without prior written consent from Compaq Computer

Corporation.

© 2000 Compaq Computer Corporation.

All rights reserved. Printed in the U.S.A.

The software described in this guide is furnished under a license agreement or nondisclosure agreement.

The software may be used or copied only in accordance with the terms of the agreement.

Compaq, Deskpro, Fastart, Compaq Insight Manager, Systempro, Systempro/LT, ProLiant, ROMPaq,

SmartStart, ProSignia, registered United States Patent and Trademark Office.

Microsoft, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Pentium is a registered trademark and Xeon is a trademark of Intel Corporation.

Other product names mentioned herein may be trademarks and/or registered trademarks of their

respective companies.

Compaq DAT AutoLoader Reference Guide

Third Edition (January 2000)

Part Number 326817-003

Page 3

Contents

About This Guide

Text Conventions.......................................................................................................vii

Symbols in Text....................................................................................................... viii

Symbols on Equipment............................................................................................ viii

Rack Stability .............................................................................................................ix

Getting Help ................................................................................................................x

Compaq Technical Support ..................................................................................x

Compaq Website ..................................................................................................x

Compaq Authorized Reseller................................................................................x

Chapter 1

Overview

Introduction to the DAT AutoLoader ...................................................................... 1-1

Features.................................................................................................................... 1-2

The SCSI Interface .................................................................................................. 1-3

Controller Requirements................................................................................... 1-3

Reliability of Backup Devices ................................................................................. 1-3

Projected Duty Cycle........................................................................................ 1-4

Capacity................................................................................................................... 1-4

Data Compression ............................................................................................ 1-4

Cassette Formats...................................................................................................... 1-5

DDS Logo Media ............................................................................................. 1-6

Write-Protecting a Cassette .............................................................................. 1-7

Life Expectancy of Cassettes............................................................................ 1-7

Page 4

iv

Chapter 2

Installation

DAT AutoLoader Installation .................................................................................. 2-1

Software and Tool Requirements...................................................................... 2-1

Setting the SCSI ID........................................................................................... 2-3

Switch Settings......................................................................................................... 2-3

Preparing the Computer ........................................................................................... 2-6

Installing the DAT AutoLoader ............................................................................... 2-6

Reassembling the Computer .................................................................................... 2-8

Connecting the Tabletop AutoLoader...................................................................... 2-9

Completing the Installation.................................................................................... 2-10

Chapter 3

Installing Software Drivers

Device Drivers ......................................................................................................... 3-1

Microsoft Windows NT ........................................................................................... 3-2

Novell NetWare ....................................................................................................... 3-3

ASPI Support ........................................................................................................... 3-3

Compaq Tru64 UNIX .............................................................................................. 3-4

OpenVMS ................................................................................................................ 3-4

SCO OpenServer...................................................................................................... 3-4

Configuring the SCSI ID for SCO OpenServer................................................ 3-5

SCO UnixWare ........................................................................................................ 3-6

SunSoft Solaris......................................................................................................... 3-7

Banyan VINES......................................................................................................... 3-8

Chapter 4

Operation

Introduction to Magazines and Cassettes................................................................. 4-1

Labeling Cassettes and the Magazine ............................................................... 4-2

Loading the Magazine with Cassettes...................................................................... 4-2

Eight-Cassette Configuration............................................................................ 4-3

Seven-Cassette Configuration........................................................................... 4-4

Single-Cassette Configuration .......................................................................... 4-4

To Load the Magazine With Cassettes..............................................................4-5

Loading the Magazine into the AutoLoader ............................................................ 4-6

Removing the Cassettes from the Magazine............................................................ 4-6

Ejecting the Magazine ...................................................................................... 4-7

Modes of Operation .................................................................................................4-9

Front Panel............................................................................................................. 4-10

Liquid Crystal Display (LCD) ...............................................................................4-11

LCD Messages....................................................................................................... 4-12

LCD Menu Screens................................................................................................ 4-16

Page 5

Chapter 5

Cleaning

Importance of Routine Cleaning.............................................................................. 5-1

Errors Resulting from Cleaning Neglect.................................................................. 5-2

Importance of Compaq-Approved Tape Cassettes .................................................. 5-3

DAT AutoLoader Cleaning Recommendations....................................................... 5-3

Procedure for Cleaning the Heads in Stacker Mode................................................ 5-4

Procedure for Cleaning the Heads in Random Mode .............................................. 5-4

Chapter 6

Troubleshooting

Quick Checklist ....................................................................................................... 6-1

Hardware .......................................................................................................... 6-1

Software............................................................................................................ 6-2

Installation Troubleshooting.................................................................................... 6-3

Troubleshooting After Installation........................................................................... 6-4

For Tru64 Unix................................................................................................. 6-4

For Novell NetWare ......................................................................................... 6-4

For Microsoft Windows NT Systems............................................................... 6-5

For SCO OpenServer Systems.......................................................................... 6-5

For IBM OS/2 Systems..................................................................................... 6-6

Resolving Operating Problems ................................................................................ 6-6

Resolving Magazine Problems ................................................................................ 6-6

Correcting Intermittent Failures............................................................................... 6-7

v

Appendix A

Regulatory Compliance Notices

Regulatory Compliance Identification Numbers .....................................................A-1

Federal Communications Commission Notice ........................................................A-1

Class B Equipment ...........................................................................................A-2

Modifications....................................................................................................A-3

Canadian Notice (Avis Canadien) ...........................................................................A-4

Class B Equipment ...........................................................................................A-4

European Union Notice ...........................................................................................A-4

Japanese Notice .......................................................................................................A-5

Taiwanese Notice.....................................................................................................A-5

Appendix B

Electrostatic Discharge

Grounding Methods.................................................................................................B-2

Page 6

vi

Appendix C

Specifications

Dimensions and Weight.......................................................................................... C-1

Temperature and Humidity Range.......................................................................... C-2

Power Requirements ............................................................................................... C-2

Air-Cooling Requirement ....................................................................................... C-2

Suspended Particulate ............................................................................................. C-3

Index

Page 7

This guide is designed to be used as step-by-step instructions for installation

and as a reference for operation, troubleshooting, and future upgrades.

Text Conventions

This document uses the following conventions to distinguish elements of text:

Keys

About This Guide

Keys appear in boldface. A plus sign (+) between

two keys indicates that they should be pressed

simultaneously.

USER INPUT

FILENAMES

Menu Options,

Command Names,

Dialog Box Names

COMMANDS,

DIRECTORY NAMES,

and DRIVE NAMES

Type When you are instructed to

Enter When you are instructed to

User input appears in a different typeface and in

uppercase.

File names appear in uppercase italics.

These elements appear in initial capital letters.

These elements appear in uppercase.

the information

the information and then press the

without

pressing the

information, type

type

Enter

information, type

enter

Enter

key.

key.

Page 8

viii Compaq DAT AutoLoader Reference Guide

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING:

in the warning could result in bodily harm or loss of life.

CAUTION:

could result in damage to equipment or loss of information.

IMPORTANT:

instructions.

Text set off in this manner presents commentary, sidelights, or interesting points

NOTE:

of information.

Text set off in this manner indicates that failure to follow directions

Text set off in this manner presents clarifying information or specific

Symbols on Equipment

These icons may be located on equipment in areas where hazardous conditions

may exist.

Any surface or area of the equipment marked with these symbols

indicates the presence of electric shock hazards. Enclosed area

contains no operator-serviceable parts.

WARNING:

do not open this enclosure.

Text set off in this manner indicates that failure to follow directions

To reduce the risk of injury from electric shock hazards,

Any RJ-45 receptacle marked with these symbols indicates a Network

Interface Connection.

WARNING:

equipment, do not plug telephone or telecommunications connectors

into this receptacle.

To reduce the risk of electric shock, fire, or damage to the

Page 9

About This Guide ix

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

Rack Stability

WARNING:

the surface to cool before touching.

WARNING:

be sure that:

To reduce the risk of injury from a hot component, allow

Power supplies or systems marked with these symbols indicate

the equipment is supplied by multiple sources of power.

WARNING:

remove all power cords to completely disconnect power from

the system.

Any product or assembly marked with these symbols indicates that

the component exceeds the recommended weight for one individual

to handle safely.

WARNING:

equipment, observe local occupational health and safety

requirements and guidelines for manual material handling.

To reduce the risk of personal injury or damage to the equipment,

To reduce the risk of injury from electric shock,

To reduce the risk of personal injury or damage to the

The leveling jacks are extended to the floor.

■

The full weight of the rack rests on the leveling jacks.

■

The stabilizing feet are attached to the rack if it is a single rack

■

installation.

The racks are coupled together in multiple rack installations.

■

A rack may become unstable if more than one component is extended for

■

any reason. Extend only one component at a time.

Page 10

x Compaq DAT AutoLoader Reference Guide

Getting Help

If you have a problem and have exhausted the information in this guide, you

can get further information and other help in the following locations.

Compaq Technical Support

In North America, call the Compaq Technical Phone Support Center at

1-800-OK-COMPAQ. This service is available 24 hours a day, 7 days a week.

For continuous quality improvement, calls may be recorded or monitored.

Outside North America, call the nearest Compaq Technical Support Phone

Center. Telephone numbers for world wide Technical Support Centers are

listed on the Compaq website. Access the Compaq website by logging on to

the Internet at:

http://www.compaq.com

Be sure to have the following information available before you call Compaq:

Technical support registration number (if applicable)

■

Product serial number

■

Product model name and numbers

■

Applicable error messages

■

Add-on boards or hardware

■

Third-party hardware or software

■

Operating system type and revision level

■

Compaq Website

The Compaq website has information on this product as well as the latest

drivers and Flash ROM images. You can access the Compaq website by

logging on to the Internet at:

http://www.compaq.com

Compaq Authorized Reseller

For the name of your nearest Compaq Authorized Reseller:

In the United States, call 1-800-345-1518.

■

In Canada, call 1-800-263-5868.

■

Elsewhere, see the Compaq website for locations and telephone

■

numbers.

Page 11

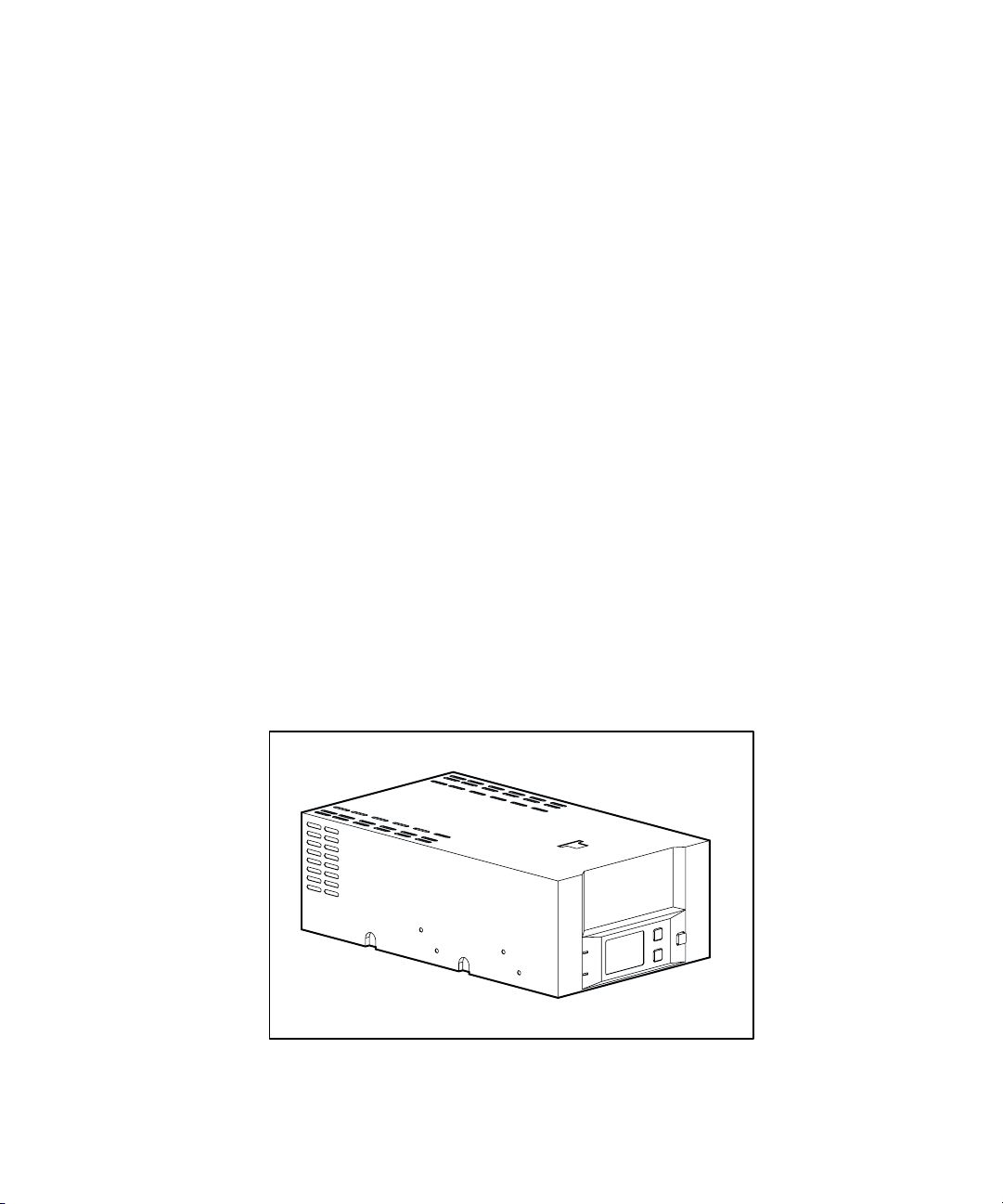

Introduction to the DAT AutoLoader

The Compaq 20/40 Gigabyte (GB) DAT 8-Cassette AutoLoader combines a

changer mechanism with a DDS-4 cassette drive mechanism. The DAT

AutoLoader houses up to eight DDS cassettes in a removable magazine, which

enables you to back up weeks and months of data automatically. High-speed

file retrieval and cassette swapping typically allow access to any file in an

average of 95 seconds. The DAT AutoLoader supports both sequential and

random access modes, with minimum interruption time between cassettes.

Chapter

1

Overview

Figure 1-1. Compaq 20/40 GB DAT 8-Cassette AutoLoader

Page 12

Compaq DAT AutoLoader Reference Guide

1-2

Features

The Compaq 20/40 GB DAT 8-Cassette AutoLoader offers the following

features:

Any DDS-1, DDS-DC, DDS-2 DDS-3 or DDS-4 cassette can be read or

■

written to, whether data compression is switched on or off.

The drive is capable of additional sophisticated techniques of

■

error-correction for dealing with cassettes, which are not up to

specification.

When using DDS-4 media, the drive reads and writes the DDS-4 format

■

with a much higher capacity.

An improved internal cleaning sweeper reduces the frequency of

■

cleaning the heads by a factor of eight.

The TapeAlert feature allows software and operating systems to warn

■

users of conditions which may occur, such as a cassette nearing the end

of its useful life, and to recommend actions that the user can take to

recover from the situation.

A Liquid Crystal Display (LCD) gives clear and comprehensive

■

indications of the status of the DAT AutoLoader.

A low-cost magazine carrying up to eight DDS cassettes, giving a

■

magazine capacity of 320 gigabytes for DDS-4 cassettes using 2:1 data

compression.

Compatibility with the SCSI-2 Medium Changer command set.

■

A common SCSI-2 interface for the drive and changer.

■

A standard 5 1/4-inch full-height form factor.

■

A cassette odometer displaying the amount of cassette used.

■

Page 13

The SCSI Interface

The Compaq 20/40 GB DAT 8-Cassette AutoLoader uses SCSI-2 as the

interface to connect the host system.

Overview

1-3

IMPORTANT:

In the information that follows, the term SCSI implies SCSI-2.

The SCSI implementation provides the DAT AutoLoader with a standard set

of features and functions. These include the following:

LVD Wide SCSI connection

■

Synchronous data transfers

■

Asynchronous data transfers

■

Implementation of all mandatory and most optional commands of the

■

Sequential Access command set

Full implementation of mandatory Medium Changer commands

■

Controller Requirements

Compaq recommends equipping the computer with an LVD 32-bit Fast

SCSI-2 Controller or higher. Any of these controllers fully support the

Compaq 20/40 GB DAT 8 Cassette AutoLoader.

IMPORTANT:

computer) or in an external storage device, but not both. The exception is a CD-ROM

drive, which may be internal when other devices are external or vice versa.

All SCSI devices on the same bus must either be internal (within the

Reliability of Backup Devices

The reliability of any backup device is directly related to its duty cycle (the

number of hours per day that the device is in use). For example, if a tape drive

designed for 24-GB backups is being used to back up a 100-GB computer, the

result on that drive will be a need for accelerated preventive maintenance

(especially head cleaning), premature aging, and reliability problems. See

Chapter 5 for more information on cleaning requirements.

Page 14

Compaq DAT AutoLoader Reference Guide

1-4

Projected Duty Cycle

The projected duty cycle of the Compaq 20/40 GB DAT 8-Cassette

AutoLoader is an important consideration in determining the amount of time

required for backup of a given system, as well as how often it is necessary to

clean the tape drive’s read/write heads.

For example, a nightly, unattended complete 18-GB backup is well within the

capacity of one 20/40 GB DAT drive. However, at a backup rate of

approximately 8GB/hour, that tape drive is in operation for approximately 2

1/4 hours every night of the week. With this amount of usage, the tape drive’s

read/write heads should be cleaned every 4 to 6 weeks. If the drive heads are

not cleaned soft errors and overall backup time increases and eventually

causes the drive to fail.

Capacity

The best method for building hardware reliability into a backup strategy is to

ensure that the backup hardware is matched to the computers. Table 1-1 relates

various computers with the appropriate tape drives. If you need special, partial

backups in addition to the routine backups, select the next larger drive size.

Data Compression

The Compaq 20/40 GB DAT 8-Cassette AutoLoader ships from the factory

with data compression enabled for writing. The drive is equipped with onboard

DDS-DC hardware, using the Data Compression Lempel Ziv (DCLZ)

algorithm. In this mode, data is always compressed when writing to the

cassette, but the drive is capable of reading both compressed and

uncompressed cassettes.

Table 1-1

Tape Drive Capacity

Compaq Tape AutoLoader Computer Capacity

2/4 GB DAT 2-4 GB or less

4/8 GB DAT 4-8 GB or less

12/24 GB DAT 12-24 GB or less

20/40 GB DAT 20-40 GB or less

Page 15

The DAT AutoLoader uses jumper pins and/or dip switches for settings. Some

hardware settings may be overridden by way of software. Consult your backup

application software documentation for the data compression enabling and

disabling procedure.

For information on jumper pin settings for data compression, see “Configuring

the AutoLoader” in Chapter 2.

Cassette Formats

The Compaq 20/40 GB DAT 8-Cassette AutoLoader supports

industry-standard Digital Data Storage (DDS), Digital Data Storage Data

Compression (DDS-DC), Digital Data Storage-2 (DDS-2), Digital Data

Storage-3 (DDS-3), and Digital Data Storage-4 (DDS-4) formats.

Overview

1-5

IMPORTANT:

purchased from vendors that have been approved by Compaq (See Table 1-2 for list of

approved cassettes).

For product reliability Compaq recommends using only cassettes

These formats were introduced by the DDS Manufacturers’ Group and are

approved by the American National Standards Institute (ANSI) and the

European Computer Manufacturers’ Association (ECMA). The DDS-DC

format is a superset of the DDS format, ensuring backward compatibility with

uncompressed cassettes.

To use the full potential of a DDS-format drive, you should use matching

cassettes, that is, DDS-4 cassettes for DDS-4 drives. This allows the drives to

store the maximum amount of data on a cassette. Refer to Table 1-2 for a list

of Compaq approved cassettes.

Table 1-2

Compaq Approved Cassettes

DDS1 DDS2 DDS3 DDS4

Sony 60m (DG-60M) Sony 125m, (DGD-125m)

Fuji 90m, (DG-90M) Fuji 120m, (DG-120M) Fuji 125m, (DG3-125m) Fuji 150m, (DG4-150m)

Maxell 120m, HS 4/120s Maxell 125m, HS 4/125s Maxell 150m, HS 4/150s

Note:

A DDS-4 drive can read and write to DDS-3, DDS-2, or DDS-1 cassettes.

Page 16

Compaq DAT AutoLoader Reference Guide

1-6

DDS Logo Media

To identify computer-grade DDS media easily, look for the DDS logos (See

Figure 1-2), including ! DDS-1, " DDS-2, # DDS-3, and $DDS-4. These

indicate that the media meets the DDS specifications laid down by the ECMA,

ISO/IEC and ANSI standards.

Figure 1-2. DDS Logo Media

1

2

3

4

The Media Recognition System (MRS) enables drives to identify DDS-grade

media. DDS MRS cassettes have a series of stripes on the transparent leader at

the beginning of the cassette. The drive can be configured to treat non-MRS

cassettes as write-protected. In other words, the drive is only allowed to read

non-MRS cassettes, not write to them.

Page 17

Write-Protecting a Cassette

Overview

1-7

IMPORTANT:

updated during the unload procedure. If the cassette is write-protected, the cassette log

will not be updated and will be inaccurate.

The cassette log, which contains a history of usage of the cassette, is

Cassettes can be write-protected by ! sliding the tab on the rear of the cassette

to the left so that the hole is open (See Figure 1-3). In this state, data can be

read from the cassette but not written to it. To remove write-protection, "

slide the tab to the right so that the hole is closed.

1

Figure 1-3. Write-protecting a cassette

(➊ = Write-protection ON, ➋ = Write-protection OFF)

2

Life Expectancy of Cassettes

All DDS-certified media are designed to withstand at least 2000 passes. Under

optimum environmental conditions (50% relative humidity, 22°C), this is

equivalent to about 100 to150 backup operations. The life expectancy takes

into account that an area of a cassette may have several passes during a

backup, either because streaming (the optimum performance rate where data is

sent to the drive at approximately the same speed as it is written to the cassette

media) cannot be maintained, or because the backup software package

repeatedly accesses certain areas of a cassette.

Certain extreme (worst case) conditions reduce the recommended maximum

number of backup operations. These conditions are as follows:

Environmental conditions — Sustained use at the low end of the

■

humidity specification reduces the cassette life.

Page 18

Compaq DAT AutoLoader Reference Guide

1-8

■

Computer performance — The lower the performance of the computer,

the more likely that streaming cannot be maintained and that an

increase in the number of passes over given areas of a cassette

will occur.

Backup Software — The backup software may frequently access certain

■

areas of a cassette, or there may be a high system overhead that can

cause streaming to stop. Both of these factors increase the number of

cassette passes in a given area.

Because these parameters vary from system to system, it is difficult to give a

definitive statement of the number of backup operations achievable using a

particular cassette.

As a guideline, Compaq recommends using a cassette for approximately 75

backup operations in worst-case conditions such as those listed above.

Page 19

DAT AutoLoader Installation

This chapter describes the procedure to install a Compaq 20/40 GB DAT

8-Cassette AutoLoader in a Compaq computer. In addition, at the end of the

chapter there are instructions for connecting the tabletop DAT AutoLoader to

a Compaq computer.

Installation involves the following steps:

1. Configuring the DAT AutoLoader

Chapter

2

Installation

2. Preparing the computer

3. Installing the DAT AutoLoader

4. Reassembling the computer

5. Completing the installation

Software and Tool Requirements

The following items are required for Compaq 20/40 GB DAT 8-Cassette

AutoLoader installations:

Torx T-10 screwdriver

■

Torx T-15 screwdriver

■

Page 20

2-2 Compaq DAT AutoLoader Reference Guide

■

Compaq SmartStart and Support Software CD

■ Configuring the AutoLoader

The default hardware settings are set for a Compaq system (see Figure 2-1).

The settings in the DAT AutoLoader can be changed if required by a particular

system.

Figure 2-1. Autoloader jumper pins

Table 2-1

Hardware Settings

Jumper Description Default

1

2

3

4

5

6

Note: The default SCSI ID is set to 6. For other settings see, Table 2-2

SCSI ID Bit 0 OFF

SCSI ID Bit 1 ON

SCSI ID Bit 2 ON

Reserved OFF

Reserved OFF

Parity Enable ON

Page 21

Setting the SCSI ID

Each SCSI device on the same SCSI bus must have a unique SCSI ID. Use the

jumper block located on the back of the DAT AutoLoader to set the SCSI ID.

For SCSI ID jumper settings see Table 2-2.

SCSI ID Bit 2 Bit 1 Bit 0

Table 2-2

SCSI Jumper Pins

Installation

2-3

7*

Note:

SCSI ID 7 is reserved for the SCSI controller.

Switch Settings

When the DAT AutoLoader is powered on, it reads a set of configuration

switches on the underside of the drive. See the following sections for switch

descriptions and settings.

0

1

2

3

4

5

6

000

001

010

011

100

101

110

111

Page 22

Compaq DAT AutoLoader Reference Guide

2-4

Figure 2-2. AutoLoader configuration switches

Switch Number Description Default

1 Reserved OFF

Table 2-3

Switch Settings

2 Reserved OFF

3 Reserved OFF

4 Reserved OFF

5 Terminator Power OFF

6 Reserved OFF

7 DC Control-1 OFF

8 DC Control-2 OFF

Note:

Switch 1 must remain in the OFF position.

Page 23

Installation

Default setting compression at power-on enable the host to control

compression.

Table 2-4

Data Compression Definitions

DC Control-1 DC Control-2 Definition

OFF OFF Compression disabled at power-on. The host is

allowed to control compression.

OFF ON Compression disabled at power-on. The host is not

allowed to control compression.

ON OFF Compression enabled at power-on. The host is

allowed to control compression.

ON ON Compression enabled at power-on. The host is not

allowed to control compression.

2-5

Page 24

Compaq DAT AutoLoader Reference Guide

2-6

Preparing the Computer

CAUTION:

sure you are properly grounded before beginning this procedure. See Appendix B,

“Electrostatic Discharge” for further information.

To prepare the computer:

1. Perform a normal system shutdown.

2. Turn OFF the computer and all peripheral devices.

3. Disconnect the AC main power cord from the outlet, then from the

computer and from all peripheral devices.

4. Disassemble the system to expose the drive bay (see documentation

included with your computer for instructions on accessing the

removable media drive bays).

Electrostatic discharge (ESD) can damage electronic components. Be

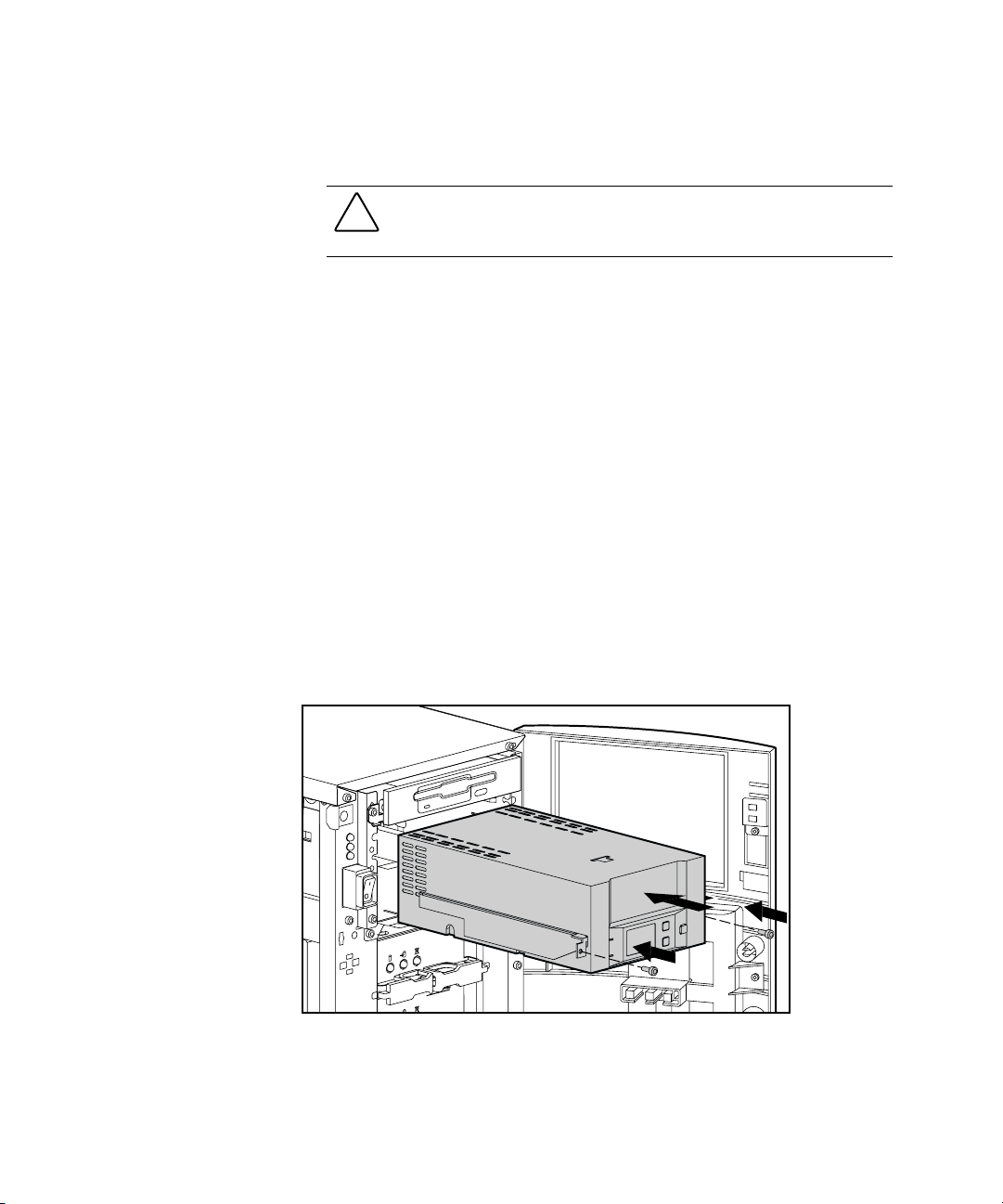

Installing the DAT AutoLoader

NOTE:

Your computer may differ slightly from the following illustrations.

To install the Autoloader with drive rails:

1. Slide the DAT AutoLoader partially into an available removable media

bay.

Figure 2-3. Installing the DAT AutoLoader with drive rails

Page 25

2. Connect the SCSI signal cable and the power cable (supplied).

(See Figure 2-5.)

3. Carefully slide the DAT AutoLoader the remainder of the way in,

adjusting the connecting cables if needed to allow the AutoLoader to be

fully inserted.

4. Insert two screws in the front plate using a Torx-15 screwdriver.

To install the Autoloader without drive rails:

1. Remove all screws from drive rails using a Torx-15 screwdriver.

2. Slide the AutoLoader partially into an available removable media bay.

Installation

2-7

Figure 2-4. Installing the DAT AutoLoader without drive rails

3. Connect the SCSI signal cable and the power cable (supplied).

(See Figure 2-5.)

4. Carefully slide the DAT AutoLoader the remainder of the way in,

adjusting the connecting cables if needed to allow the AutoLoader to be

fully inserted.

5. Use the screws that were removed from the drive rails and insert two of

them into the threaded mounting holes on each side.

NOTE:

Some drives may not be accessible on both sides. Secure the sides that are

accessible.

Page 26

Compaq DAT AutoLoader Reference Guide

2-8

Figure 2-5. Connecting signal and power cables

Reassembling the Computer

To reassemble the computer:

1. Replace the access panel.

2. Reconnect the peripheral devices to the computer.

WARNING:

do not disable the power cord grounding feature. This equipment is designed for

connection to a grounded (earthed) power outlet. The grounding plug is an

important safety feature.

3. Plug the AC main power cord into the computer, then plug the cord into

a grounded AC outlet.

4. Turn ON all peripheral devices.

5. Turn ON the computer.

To reduce the risk of electric shock or damage to your equipment,

Page 27

Connecting the Tabletop AutoLoader

For the tabletop DAT AutoLoader, follow the procedures below to connect to

a Compaq computer:

1. Set the SCSI ID using the switch at the rear of the DAT AutoLoader

(See Figure 2-6). The SCSI ID switch can be adjusted by using a pencil

or similar object to click the “+” and “-” buttons. The SCSI ID default

is 6.

Installation

2-9

1

Figure 2-6. External AutoLoader SCSI and options switches

2. Set the configuration switches located on the bottom 1 of the

AutoLoader, if required. See the previous section, “Switch Settings,” for

switch descriptions and settings.

3. Connect the SCSI signal cable from the computer to one of the two

SCSI connectors at the rear of the tabletop DAT AutoLoader.

4. Connect the external terminator (provided with the tabletop DAT

AutoLoader kit) to the unused SCSI connector.

Page 28

Compaq DAT AutoLoader Reference Guide

2-10

NOTE:

mode. The color red does not indicate an error. (See Figure 2-7.)

Figure 2-7. Terminator

The Compaq-provided LVD/SE terminator will be lit solid red in the single-ended

1

IMPORTANT:

Connect the SCSI cable between the AutoLoaders and then connect the terminator to the

unused connector on the second AutoLoader.

To “daisy chain” another DAT AutoLoader, remove the external terminator.

5. Connect the power cord.

Completing the Installation

To complete the installation of the Compaq 20/40 GB DAT 8-Cassette

AutoLoader, install the device drivers. See Chapter 3, “Installing Software

Drivers,” for specific driver installation information.

Page 29

Chapter

Installing Software Drivers

The following operating environments support the AIT tape drives:

Microsoft Windows NT

■

Novell NetWare

■

Compaq Tru64 UNIX

■

OpenVMS

■

SCO OpenServer

■

SCO UnixWare

■

3

SunSoft Solaris

■

Banyan VINES

■

Device Drivers

Drivers are located on the Support Software Diskettes and on the Compaq

SmartStart and Support Software CD. The drivers on the Support Software

Diskettes may be newer versions than drivers you currently are using with new

functionality and upgraded utilities. You can use SmartStart to create Support

Software Diskettes for specific operating systems.

Page 30

Compaq DAT AutoLoader Reference Guide

3-2

Microsoft Windows NT

Drivers for the SCSI controllers and tape drive hardware are located on

Support Software Diskettes and on the Compaq SmartStart and Support

Software CD. The Support Software ships with each computer or can be

downloaded from the Compaq website. The software tape device driver is

located either with your tape backup software or with the operating system.

Refer to your backup application installation guide for more information

regarding additional software that might be needed

.

Table 3-1

Microsoft Windows NT

Controller Software Driver Information

32-Bit Fast SCSI-2 Controllers

■

32-Bit Fast-Wide SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

IMPORTANT:

your initial Windows NT installation, install the SCSI device driver for the controller

installing the tape class driver.

If the SCSI controller to which your drive is attached was not present during

Refer to "Compaq SCSI Controller Support" in

NTREADME.HLP

the

Support Software for Microsoft Windows NT

diskette, Version 1.21 or later.

file on the Compaq

before

Refer to “Compaq Tape Support” in the NTREADME.HLP file on the Compaq

Support Software for Microsoft Windows NT diskette.

Page 31

Novell NetWare

Drivers for the SCSI controller and tape drive hardware are located on Support

Software Diskettes and on the Compaq SmartStart and Support Software CD.

The Support Software ships with each computer or can be downloaded from

the Compaq website. The software tape device driver is located either with

your tape backup software or with the operating system. Refer to your backup

software application installation guide for more information regarding

additional software that might be needed

32-Bit Fast SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

Be sure to load drivers in accordance with the Compaq controller being used.

Installing Software Drivers

.

Table 3-2

Novell NetWare

Controller Software Driver Information

README.COM

Run the

Novell Software Support Diskettes (NSSD)

for driver installation instructions.

file on any of the

3-3

There are additional driver issues if you wish to use applications requiring the

Advanced SCSI Programming Interface (ASPI) support. For more information

see the following section.

ASPI Support

The README.COM on the Novell Software Support Diskette (NSSD)

outlines the specific drivers you need to support ASPI tape backup

applications.

If you are using a tape backup application that uses the ASPI, such as

ARCserveIT from Compaq or VERITAS BackupExec, refer to the information

provided with your application NLM to determine whether it uses ASPI.

The Compaq ASPI drivers, CPQSASPI.NLM Device Driver Functional

Specification (DDFS) and NWASPI.NLM NetWare Peripheral Architecture

(NWPA), provide ASPI support for the Compaq SCSI architecture for

applications that require this interface.

All of the required drivers for ASPI tape support are provided on the Novell

Software Support Diskette (NSSD). The Support Software ships with each

computer or can be downloaded from the Compaq website.

Page 32

Compaq DAT AutoLoader Reference Guide

3-4

The SCSI.RDM file on the NSSD diskette gives complete instructions on how

to load these drivers and troubleshoot any problems.

Compaq Tru64 UNIX

Drivers for the SCSI controller and tape drive hardware are located on Support

Software Diskettes and on the Compaq SmartStart and Support Software CD.

The Support Software ships with each computer or can be downloaded from

the Compaq website. Software support is version 4.0F or later.

The Tru64 UNIX operating system uses Dynamic Device Recognition (DDR),

which allows the operating system to recognize the DAT drive without a

software tape device driver.

If the following message is seen on any version of Tru64 UNIX, it should be

considered an informational message only. No action is required.

ctape_ioctl: unmapped scsi density code (0x30)-DDR entry needed

NOTE:

If the drivers are unseen after installation, you need to rebuild the kernal. See

Chapter 6, “Troubleshooting,” for additional information on where to go for help.

OpenVMS

Drivers for the SCSI controller and tape drive hardware are located on Support

Software Diskettes and on the Compaq SmartStart and Support Software CD.

The Support Software ships with each computer or can be downloaded from

the Compaq website. Software support is version 7.12 or later.

The OpenVMS operating system uses Dynamic Device Recognition (DDR),

which allows the operating system to recognize the AIT drive without a

software tape device driver.

SCO OpenServer

The drivers required to support the DAT tape drive under SCO UNIX are:

The SCO SCSI tape (

■

see the SCO System Administrator’s Guide for information on how to

configure the driver.

An appropriate SCSI controller driver.

■

) driver, which is built into SCO OpenServer;

stp

Page 33

Installing Software Drivers

Drivers for the SCSI controllers and tape drive hardware are located on the

Support Software Diskettes and on the Compaq SmartStart and Support

Software CD. The Support Software ships with each computer or can be

downloaded from the Compaq website. The software tape device driver is

located either with your tape backup software or with the operating system.

Refer to your backup application installation guide for more information

regarding additional software that might be needed

.

Table 3-3

SCO OpenServer

Controller Software Driver Information

3-5

32-Bit Fast SCSI-2 Controllers

■

32-Bit Fast-Wide SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

In addition, the appropriate version of the Compaq Extended Feature

Supplement (EFS) for SCO OpenServer is required:

For SCO OpenServer 5, use Compaq EFS version 5.16 or later.

■

EFS for SCO OpenServer is available on both the Compaq SmartStart and

Support Software CD and is installed and configured automatically during a

SmartStart installation.

Configuring the SCSI ID for SCO OpenServer

In the pre-configured kernel used to install SCO OpenServer, the following

SCSI IDs are automatically set:

Disk = 0

■

Tape = 2

■

CD-ROM = 5

■

Refer to the appropriate

Compaq Support Software CD.

The name of the driver is

README

CHA.

on the

To determine the SCSI ID of the new tape drive (if not known):

Run System Configuration and look under “Review or Modify

1.

Hardware Settings,” then “View and Edit Details.” The values reported

for controller number, target ID, LUN, and bus number are used during

mkdev tape.

Boot the computer to single user mode and run the

2.

mkdev tape

command.

Page 34

Compaq DAT AutoLoader Reference Guide

3-6

Remove the default tape device from controller 0, ID 2.

3.

Add the new tape drive to the configuration.

4.

Relink the kernel and reboot the computer to multi-user mode.

5.

Run the

6.

correct. The information appears in a line such as:

%tape - - - type= S ha=0 id=2 lun=0 ht= ...

In the above example, “id=2” indicates that the SCSI ID is 2.

See the section “Setting the SCSI ID,” in Chapter 2 for more information on

setting the SCSI ID.

IMPORTANT:

controller in the system. Remove the generic tape at ID2, then add the correct tape driver

using correct ID, bus, and LUN values.

SCO UnixWare

The drivers required to support Compaq SCSI tape drives under SCO UNIX

are the SCO SCSI tape (stp) driver and an appropriate SCSI controller driver.

The stp driver is built into SCO UNIX. Consult the SCO System

Administrator’s Guide for directions on how to configure the SCSI tape driver.

The table below describes the drivers required to support current Compaq

SCSI controllers.

hwconfig

command to ensure the new tape configuration is

SCO OpenServer’s install kernel only communicates with the first SCSI

Table 3-4

SCO UnixWare

Controller Software Driver Information

32-Bit Fast SCSI-2 Controllers

■

32-Bit Fast-Wide SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

Refer to the documentation accompanying

the Compaq Support Software for SCO

UnixWare. Versions 2.x to 7.x. or Compaq

EFS 2.2x for UnixWare 2.1 or Compaq EFS

7.2x for UnixWare 7.x. The required driver is

CPQSC.

Page 35

EFS for SCO UnixWare is available on the Compaq Support Software CD and

on Compaq SmartStart. The Compaq EFS for SCO UNIX is installed and

configured automatically during a SmartStart installation.

Compaq SmartStart and Support Software ships with each computer or can be

downloaded from the Compaq website.

SunSoft Solaris

The table below provides information on identifying appropriate drivers for

SCSI controllers.

Installing Software Drivers

Table 3-5

SunSoft Solaris

Controller Software Driver Information

3-7

32-Bit Fast SCSI-2 Controllers

■

32-Bit Fast-Wide SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

For Solaris 2.5.1, refer to the online

documentation on the Solaris 2.5.x OS CD

and Driver Update II (DUII) version 1.2.1 or

higher.

For Solaris 2.6, refer to the online

documentation on the Solaris 2.6 OS CD and

Driver Update 3 (DU3) version 1.2.1 or higher.

For Solaris 2.7, refer to the Solaris 2.7

Installation Manual. The required driver is

CPQNCR.

Page 36

Compaq DAT AutoLoader Reference Guide

3-8

Banyan VINES

The table below provides information on identifying appropriate drivers for

Compaq SCSI controllers.

Table 3-6

Banyan VINES

Controller Software Driver Information

32-Bit Fast SCSI-2 Controllers

■

32-Bit Fast-Wide SCSI-2 Controllers

■

Wide-Ultra SCSI Controllers

■

LVD Wide SCSI Controllers

■

Refer to the documentation from Banyan

regarding the “Compaq Fast SCSI-2 / 53C710

EISA SCSI” driver.

To ensure proper controller support, the

Compaq Peripheral Adapter Support Software

for Banyan VINES 6.x, 7.x, and 8.x, version

3.05 or later is required. Refer to the SSD

documentation file,

the “Compaq Wide-Ultra SCSI Controller”

driver.

README.SSD

regarding

Page 37

Chapter

Operation

This chapter describes the following operations of the Compaq DAT

AutoLoader:

Introduction to magazines and cassettes

■

Loading the magazine with cassettes

■

Loading the magazine into the AutoLoader

■

Ejecting magazines and cassettes

■

Modes of operation

■

Identifying the front panel

■

4

LCD message categories

■

LCD menu screens

■

Introduction to Magazines and Cassettes

When purchasing DDS cassettes:

Always use cassettes labeled “DDS Media Recognition System” in the

■

drive. To use the full potential of the drive, make sure that they are

DDS-4 cassettes.

■

Never use DAT cassettes because the media is not certified and they can

have a different specification that can cause them to jam in the

mechanism (see Chapter 1 for cassette specifications).

Page 38

4-2 Compaq DAT AutoLoader Reference Guide

Labeling Cassettes and the Magazine

Each cassette and the magazine should be labeled prior to use. To label a

cassette follow the manufacturer’s instruction included with each cassette. To

label the magazine, place the label on 1 space provided (see Figure 4-1).

Figure 4-1. Magazine identification

To prevent jams:

■ Insert cassettes all the way into the magazine.

■ Ensure the label corners are affixed firmly on the cassettes and

magazine ➊.

■ Only paste labels to the surface and make sure there are no curled edges.

■ Never paste labels on top of other labels.

IMPORTANT: Cassettes should be stored in their magazines so that they are kept

together and in the correct order when multi-volumes are backed up.

Loading the Magazine with Cassettes

The magazine holds eight cassettes. There are only three allowable magazine

configurations:

■ Eight-cassette configuration

■ Seven-cassette configuration

■ Single-cassette configuration

Page 39

Operation

4-3

IMPORTANT:

recognize all the cassettes.

If the magazine is loaded any other configuration the AutoLoader will not

Eight-Cassette Configuration

Compaq recommends using this configuration. Place cassettes in all eight

positions. Eight data cassettes can be used or seven data cassettes and one

cleaning cassette (placed in position 8 only) can be used.

Figure 4-2. Magazine with tape positions

7 6 5

Front

Figure 4-3. Eight cassette positions

8 4

1 2 3

Rear

Page 40

Compaq DAT AutoLoader Reference Guide

4-4

Seven-Cassette Configuration

Cassettes are inserted in all positions except position 8.

7 6 5

Front

1 2 3

Figure 4-4. Seven cassette positions

Single-Cassette Configuration

For this operation the cassette must be inserted in position 8. It can be either a

data cassette or a cleaning cassette.

Front

Figure 4-5. Single cassette position

IMPORTANT:

■

■

8

The AutoLoader will:

Default to a single cassette configuration if there is a cassette in position 8 but less

than 7 cassettes in the other positions

Eject the magazine if there isn’t a cassette in position 8 and all the other positions

are not full.

4

Rear

Rear

Page 41

To Load the Magazine With Cassettes

For backup and restore place labeled cassettes into the magazine as described

below:

Figure 4-6. Inserting cassettes 3, 2, and 1 into the magazine (Slot 3)

Insert the cassettes into the magazine positions in the following order:

1.

3, 2, and 1 (in slot 3). See Figure 4-6.

Operation

4-5

NOTE:

Insert the DDS4 logo side up with the logo end going in first.

Figure 4-7. Inserting cassettes 4,5,6 and 7 into the magazine (Slot 1)

Insert the next four data cassettes in positions: 4, 5, 6, and 7 (in slot 3).

2.

See Figure 4-7.

Page 42

Compaq DAT AutoLoader Reference Guide

4-6

For an eight-cassette configuration, insert a cassette in position 8.

3.

CAUTION:

placed during backup.

The cassettes must be loaded in the order they were originally

Loading the Magazine into the AutoLoader

Insert the magazine into the front opening on the AutoLoader in the direction

of the arrow. The AutoLoader pulls the magazine in the rest of the way.

Figure 4-8. Loading the magazine into the DAT AutoLoader

The AutoLoader does a rotation check of the cassettes. If there is an incorrect

cassette configuration the AutoLoader ejects the magazine. See “Loading the

Magazine with Cassettes” for the correct configurations.

Removing the Cassettes from the Magazine

NOTE:

Compaq recommends storing the magazine with the cassettes loaded to ensure

they are in the correct order.

Hold down the magazine stopper ➊ in the direction of the arrow while

1.

removing cassettes.

Page 43

Figure 4-9. Slide stopper

2. To remove cassettes in positions 1 through 5 use the access slots on the

bottom of the magazine to slide the cassettes out the front of the

magazine.

3. Turn the magazine opening slots up. Gently tap the unit until the

cassettes in positions 6 and 7 drop to the bottom slots.

Operation 4-7

4. Repeat steps 1 and 2.

5. Press the magazine stopper down to pull the cassette from position 8.

Ejecting the Magazine

To eject a cassette magazine from the DAT AutoLoader, press the Eject

button or issue an UNLOAD command from the host. The following sequence

of events occurs:

1. The tape is rewound to BOP (Beginning of Partition).

2. If the tape is write-enabled, the copy of the tape log held in RAM is

written back to the tape.

3. The tape is then rewound to BOM (Beginning of Media) and

unthreaded.

4. The AutoLoader replaces the cassettes in the magazine in the correct

order.

5. The magazine is ejected.

Page 44

Compaq DAT AutoLoader Reference Guide

4-8

If the host sends an UNLOAD command (LOAD/UNLOAD with the LOAD

bit set to 0), the same procedure is completed, but the magazine is not ejected

at the end.

If you press the Eject button during the 30 seconds when the DAT

AutoLoader checks magazine positions following insertion of a magazine, the

magazine is ejected immediately, even if Medium Removal Prevention is in

force.

If the host has previously sent a PREVENT MEDIA REMOVAL command,

the unloading action is different in two ways:

The Eject button is disabled and has no effect. It does not initiate an

■

unload sequence.

An UNLOAD command puts the drive into a semi-loaded state. It takes

■

the drive offline and unthreads the tape, but does not eject it.

The effects of PREVENT MEDIA REMOVAL continue until an ENABLE

MEDIA REMOVAL command is received, or the drive is reset.

Forcing Cassette Ejection

CAUTION:

end up invalidly formatted because EOD (End of Data) may not have been

written. Force ejection only as a last resort to recover a cassette. Never use it as

a quick way of ejecting a cassette.

You can lose data if you force ejection of a tape. The tape may also

If you press the Eject button when the drive is busy, it may be a long time

before the drive responds to the request, because it is finishing the task it is

performing first. This method ensures that the task is terminated in a

controlled manner, and no data is lost.

However, if you need to unload a cassette urgently, even at the risk of losing

data, you must force ejection as follows:

Hold the Eject button down for at least 5 seconds. The LCD displays

1.

“Force Eject.”

The DAT AutoLoader waits 35 seconds to give the normal ejection

2.

procedure a chance to occur.

Once this time has elapsed, if there is a tape loaded in the drive, it is

3.

immediately unthreaded and the cassette is ejected, regardless of what

operation the drive was performing. The cassette is then returned to its

position in the magazine, and the drive is reset as though the power has

been cycled.

Page 45

Operation

Because the forced ejection may interrupt any operation, it is possible

that the drive will not write EOD (End of Data) before the cassette is

ejected. This will cause loss of data, and result in a cassette with an

invalid format. However, it should still be possible to read such a

cassette up to the point where the ejection interrupted the writing.

If no cassette is loaded in the drive, the DAT AutoLoader assumes that

4.

you want to eject the magazine. Following the 35 seconds, it does eject

the magazine. The DAT AutoLoader is then reset as though power had

been cycled.

4-9

IMPORTANT:

in effect, and can abort any SCSI operations in which the DAT AutoLoader is engaged.

Forced ejection overrides any SCSI PREVENT MEDIA REMOVAL that may be

Modes of Operation

The DAT AutoLoader can operate in either Stacker or Random mode.

Stacker Mode

In Stacker mode (also known as sequential mode), a cassette can be selected

using the Select and Enter buttons on the front panel. When a cassette is

ejected from the embedded drive after a host UNLOAD command, the DAT

AutoLoader automatically moves the next available cassette from the

magazine into the drive. In this mode the DAT AutoLoader does not depend

on the host computer to send SCSI MEDIUM CHANGER commands to move

cassettes to and from the magazine.

Random Mode

The AutoLoader enters this mode when it receives a SCSI MOVE MEDIUM

command. The Select button is disabled. The Eject button or SCSI UNLOAD

command will cause the AutoLoader to exit this mode.

Page 46

4-10 Compaq DAT AutoLoader Reference Guide

Front Panel

Figure 4-10. Identifying the front panel features

Callout Description Feature

1

2

3

4

5

6

7

Tape LED Shows when a cassette is present

Busy LED Shows when activity is taking place

Magazine Position Where the magazine is inserted and ejected

Select button Selects a cassette for use

Eject Button Starts the unload process then ejects

Enter Button Confirms cassette selection

Liquid Crystal Display Shows the status of the AutoLoader

Page 47

Liquid Crystal Display (LCD)

The LCD display provides information about the DAT AutoLoader.

NOTE: The exact display shown can never occur; all the sections are shown at the same

time to show their location.

Operation 4-11

Figure 4-11. Front panel LCD display

Callout Feature Callout Feature

1

2

3

4

Cassette numbers

Data Compression

Type of Cassette in drive

Write Protect Indicator

5

6

7

Cassette position in drive

Cassette motion in drive

Text Area (up to 4 lines)

Page 48

Compaq DAT AutoLoader Reference Guide

4-12

LCD Messages

Front panel LCD messages are provided in list Table 4-1.

Table 4-1

LCD Messages - Alphabetical Listing

LCD Message Message

Type

Cassette Stuck In

Drive

Cleaning

in

Process

Cleaning

Failed

CleanReq

CleanReq Error It is time to clean the heads on the drive or a high error rate

Drv HW

Error

04xxxxxx

Eject

Prevent

Error A cassette is stuck in the drive.

Status A cleaning cassette has been loaded into the drive

mechanism and is cleaning the heads. The cleaning cassette

will be automatically returned to the magazine when the

cleaning cycle is complete.

Error The cleaning cassette is used up. Replace the cleaning

cassette and discard the old one.

has been detected reading or writing. Move the cleaning

cassette from the magazine to the drive (if necessary, load a

cleaning cassette into the magazine). The cleaning cycle will

automatically start once the cleaning cassette is loaded in the

drive. See “Cleaning in Process.”

Error This is an embedded-drive hardware error. In some cases the

SCSI error code generated will be displayed on the 3

M4sxxsxx where the xx’s represent the additional sense code

and qualifier.

Info This is displayed when the SCSI command “PREVENT MEDIA

REMOVAL” has been set, and the

pressed. Th SCSI command prevents the cassette or

magazine from ejecting.

Meaning

Eject

button has been

rd

line as

Ejecting

Magazine

Info

This is displayed after the

magazine is being ejected.

Eject

button is pressed and the

continued

Page 49

Table 4-1

LCD Messages - Alphabetical Listing

LCD Message Message

Type

continued

Meaning

Operation

4-13

Erase

Tape x

Illegal

Cassette

Config

Illegal

Magazine

Config

Init

Element

Status

Ldr HW

Error

ResetReq

04xxxxxx

Load

Tape x

Locate

Tape x

Status The drive is erasing data from the cassette x where x

represents the cassette number.

Error This is an error message. A cassette was inserted in the

magazine incorrectly. The magazine will be ejected with the

incorrect cassette in position 7 or 8. Remove all cassettes

and reinsert them correctly, making sure they are put back in

the original positions they were in when first loaded in the

magazine.

Error This is an error message. This occurs when there is at least

one, but less than seven cassettes in positions 1 through 7.

The magazine will eject. Reload according to one of the

configurations in the section, “Loading the Magazine With

Cassettes.”

Info The AutoLoader is moving all cassettes back to their original

positions.

Error This is an AutoLoader hardware error. In some cases the 4

line can display additional information about the problem or it

can display the SCSI error code generated as M4sxxsxx

where the xx’s represent the additional sense code and

qualifier.

Status Loads cassette x into the drive, where x represents the

number of the cassete being loaded.

Status The drive is finding a location on the tape specified by the

host. x represents the number of the cassette.

th

Magazine

Eject

Magazine

Loading

Medium

Error

03xxxxxx

Move

Medium

x => Drv

Status The DAT AutoLoader is ejecting the magazine.

Status Indicates a magazine has been inserted and is moving into

position in the AutoLoader.

Error This is a medium error. There was a problem reading or

writing data to the cassette. A SCSI error code can be

displayed on the 3

rd

line as M3sxxsxx where the xx’s

represent the additional sense code and qualifier.

Error Moves cassette x from the magazine to the drive, where x

represents the cassette number.

continued

Page 50

Compaq DAT AutoLoader Reference Guide

4-14

Table 4-1

LCD Messages - Alphabetical Listing

LCD Message Message

Move

Medium

x => Mag

No Magazine Status There is no magazine in the AutoLoader. The DAT AutoLoader

continued

Meaning

Type

Error Moves cassette x from the drive to the magazine, where x

represents the cassette number.

is ready for a magazine to be inserted.

Read

Tape x

Ready Status A magazine has been loaded in the AutoLoader and the

Ready

Tape x

Scan 1

Scan 2, etc

Select

Prevent

Select x

Load

Tape x

Select x

Push ENT

Select x

Unload

Tape y

Status Cassette x is being read.

x represents the number of the cassette.

Autoloader has completed scanning the cassettes and is

ready for operation.

Status Cassette x has been loaded into the drive and is ready for

operation. x represents the number of the cassette.

Status The DAT AutoLoader is examining the cassettes in the

magazine to check for proper magazine loading and

configuration.

Info This message is displayed if the SCSI command “PREVENT

MEDIA REMOVAL (LUN=0)” has been sent and the

button is pressed.

Info The cassette that has been selected is moving from the

magazine into the drive.

Info

Pressing the

Select

If

cassette, else the “Push ENT” will also be displayed. To load

cassette x press the

couple seconds, the command is cancelled. x represents the

cassette number.

Info Cassette y is being returned to the magazine from the drive

so that cassette x can be loaded.

x and y represent different cassette numbers.

Select

button displays the message “Select x”.

is pressed again, x will increment to the next

Enter

button. If no button is pushed for a

Select

Send Diag

Checking

Mecha

Status The diagnostics are checking the AutoLoader mechanics,

such as the elevator, and so on.

continued

Page 51

Table 4-1

LCD Messages - Alphabetical Listing

LCD Message Message

Type

continued

Meaning

Operation

4-15

Space

Tape x

TSL10000

Self-Test

Complete

Unload

Tape x

Updating

Firmware

Verify

Tape x

Write

Tape x

Status The drive is moving the cassette x media to a specific

location on the media. x represents the cassette number.

Status The DAT AutoLoader has performed its power-on self-test.

Status A cassette is being ejected from the drive and returned to the

magazine.

x represents the cassette number.

Status Firmware upgrade data is being read either from a cassette

or the SCSI bus.

Status The drive is verifying data on cassette x.

x represents the cassette number.

Status The drive is writing data to cassette x.

x represents the cassette number.

Page 52

Compaq DAT AutoLoader Reference Guide

4-16

LCD Menu Screens

To enter the menu mode, press and hold the select button for 5 seconds. The

AutoLoader will exit the menu mode if no button is pressed within a 5-second

period.

Menu Screen Features

Table 4-2

LCD Menu Screens

>Version

Auto Load

Unload

Contrast

Orientation

Language

TSL10000

SCSI ID#5

Ver.0000

S/NLxxxxxxxx

S/NDxxxxxxxx

Auto Load

>OFF

ON

Unload

Continuous

>OFF

ON

Contrast

Adjustment

The main menu screen. Pressing the

to the next item on the menu: Prdrives.

Pressing the

The version screen displays information about the autoloader including

autoloader and drive serial numbers.

The auto load screen allows the auto load feature to be turned on or off.

Pressing the

Enter

the

AutoLoader is in the one cassette mode, the AutoLoader automatically

loads the cassette into the drive.

The Unload Continuous OFF selection only affects the AutoLoader when:

1) the AutoLoader is loaded with 8 cassettes, in the 8 cassette mode, 2)

cassette #8 is in the drive and 3) a SCSI unload command is issued. The

Autoloader will unload cassette #8 and stop.

If Unload Continuous is ON, the AutoLoader will unload cassette #8 and

then load cassette #1 into the drive. Pressing the

the arrow to the next item on the menu. Pressing the

selects that mode.

The contrast adjustment screen allows the display’s contrast to be

adjusted. Pressing the

contrast is reached. Pressing

minimum contrast. The number of darkened bars (see Figure 4-10,

Cassettes position) on the bottom indicates the relative magnitude of the

contrast.

Enter

button selects that sub menu.

Select

button moves the arrow to the other mode. Pressing

button selects that mode. When auto load is ON and the

Select

Select

button advances the arrow

SELECT

button moves

ENTER

button

button increases contrast until maximum

Select

again changes the display to

continued

Page 53

Table 4-2

LCD Menu Screens

Menu Screen

continued

Operation

4-17

Orientation

>Horizontal

R-side down

L-side down

Language

>English

French

German

Spanish

The orientation screen allows a different display orientation to be

selected when the drive is mounted on a different axis. Pressing the

Select

button will advance the arrow to the next item on the menu.

Pressing the

This is the language screen. Pressing the

arrow to the next language on the menu. Pressing

that language. Then all messages will be displayed in that language.

Enter

button will select that orientation.

Select

button advances the

Enter

button selects

Page 54

Chapter

5

Cleaning

Reliable backup of your system is the product of at least four components:

A reliable tape drive

■

Quality tape cassettes

■

Regular backup schedule with backup media stored offsite

■

Routine tape drive maintenance

■

The Compaq 20/40 GB DAT 8-Cassette AutoLoader is designed to operate

reliably under worst case conditions; however, it requires simple routine

maintenance to operate efficiently. Regular cleaning is the most essential step

in properly maintaining a tape drive and preventing errors.

For more information about cleaning Compaq tape drives, refer to the Compaq

website address: http://www.compaq.com. Once on the site, search for

“Whitepapers.”

Importance of Routine Cleaning

IMPORTANT:

Failure to follow recommended cleaning procedures could result in serious damage to

your tape drive. Compaq recommends a routine cleaning every 100 hours of use.

Routine cleaning of a tape drive minimizes buildup on the read/write heads so

that fewer cleaning cycles are required to keep the tape drive in good working

order. When a tape drive is cleaned according to a regular schedule, one

cleaning cycle typically removes accumulated dirt and particle deposits. If the

Regular cleaning is vital to trouble-free operation of any tape device.

Page 55

Compaq DAT AutoLoader Reference Guide

5-2

drive is not cleaned regularly, however, up to 4 cleaning cycles may be

necessary to fully clean the drive.

Compaq recommends a routine cleaning schedule every 100 hours of use. In

addition, the drive should be cleaned whenever the front panel LCD indicates.

Not all tape drives require the same frequency of cleaning to keep them

operating efficiently. Factors such as the design of the tape drive and the

quality of the tape media used for backups affect cleaning frequency.

Errors Resulting from Cleaning Neglect

Following are some of the errors that can result from failure to observe routine

maintenance and cleaning of tape drives:

Dropouts — Caused by weak signal strength from dirty read/write

■

heads, a dropout can result in reduced tape capacity and backup

performance.

Media errors — The backup tapes can be jammed, torn, or otherwise

■

damaged by a dirty read/write head.

Read or write errors — Because of a dirty read/write head, data may not

■

have been recorded on the tape during backup. Even if the data is on the

backup tape, retrieval may not be possible if the dirty head cannot read

the data.

Format failures — During backup, data is laid on the tape in a certain

■

format for easy retrieval. A dirty write head can cause format failures,

which means that data can be lost or impossible to retrieve.

Bad blocks — Because of media damage (see Media errors above), the

■

tape may not accept backup data. Also, the read/write head may be

unable to retrieve data from bad blocks.

Page 56

Importance of Compaq-Approved Tape Cassettes

Compaq-approved tape cassettes are thoroughly tested to meet high-quality

standards. Before Compaq recommends a tape cassette, the quality and

reliability of the magnetic media and the cassette are evaluated. Do not use

unapproved tape cassettes because they may not be compatible with Compaq

tape drives.

See Chapter 1 for a list of Compaq-approved tape cassettes.

DAT AutoLoader Cleaning Recommendations

Of the tape drives available today, DAT drives are more susceptible to buildup

of contaminants. If a DAT drive is not kept clean, increased errors will occur.

Recommendations for cleaning DAT drives are as follows:

If the CLEANREQ message is displayed on the front panel.

■

When using new tape cassettes, clean the drive heads with a cleaning

■

cassette after every 8 hours of use for 5 initial cleanings.

Cleaning

5-3

When using tape cassettes that have already been used 5 times, clean the

■

drive heads with a cleaning cassette after every 100 hours of use.

If you begin to experience read or write errors, format failures, or a

■

number of bad blocks, clean the head and capstan 3 more times before

concluding that either the tape or the tape drive is defective.

In a dusty environment, one cleaning cycle may not fully clean the DAT

■

AutoLoader drive read/write heads. If backup software reports errors,

clean the drive again. No more than four cleanings will be required to

ensure that heads are fully clean.

Cleaning cassettes can be used approximately 50 times. An expired cleaning

NOTE:

cassette will eject immediately without cleaning.

CAUTION:

cleaning solution to clean DAT drives.

cotton swab. Fibers from a cotton swab can cause permanent damage to the

head.

No other periodic maintenance is required.

clean read/write heads with a

Do Not

Do Not

use alcohol or

Page 57

Compaq DAT AutoLoader Reference Guide

5-4

Procedure for Cleaning the Heads in Stacker Mode

Place the cleaning cassette into one of the magazine positions (for

1.

example, position 8) and insert the magazine into the DAT AutoLoader.

Use the Select button to select the magazine position in which you

2.

placed the cleaning cassette.

Press the Enter button to load the cleaning cassette into the drive. The

3.

DAT AutoLoader will then automatically perform a cleaning cycle.

At the end of the cleaning cycle, the drive automatically ejects the

4.

cassette and the AutoLoader replaces it in the magazine.

Note the date on the label on the cleaning cassette, so that there is a

5.

record of how many times it has been used. After 50 uses, discard the

cassette.

IMPORTANT:

amount of data that can be backed up to the magazine, since it will only have seven

positions available for data cassettes.

If a cleaning cassette is left permanently in the magazine, it will reduce the

Procedure for Cleaning the Heads in Random Mode

The host sends a MOVE MEDIUM command to move the cleaning

1.