Page 1

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

See the Notice for copyright and trademark information, and the Preface for symbol

conventions and Technician Notes.

Download ZIP file of complete MSG onto local hard drive.

This MSG will be periodically maintained and updated as needed.

To report a technical problem, contact your Regional Support Center or IM Help Center.

For content comments or questions, contact the Editor.

Page 2

NOTICE

The information in this guide is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS OR OMISSIONS

CONTAINED HEREIN, NOR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING,

PERFORMANCE, OR USE OF THIS MATERIAL.

This guide contains information protected by copyright. No part of this guide may be photocopied or reproduced in

any form without prior written consent from Compaq Computer Corporation. © 1998 Compaq Computer Corporation.

All rights reserved. Compaq, Presario Registered U. S. Patent and Trademark Office.

Microsoft, MS-DOS, and Windows are registered trademarks of Microsoft Corporation. Windows 95 is a trademark of

Microsoft Corporation. The software described in this guide is furnished under a license agreement or nondisclosure

agreement. The software may be used or copied only in accordance with the terms of the agreement. Product names

mentioned herein may be trademarks and/or registered trademarks of their respective companies.

Online Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

August 1998

Page 3

PREFACE

This Maintenance and Service Guide is a troubleshooting guide that can be used for reference when servicing the

Compaq 2200 and 2400 Series Computers.

Compaq Computer Corporation reserves the right to make changes to the Compaq 2200 and 2400 Series Computers

without notice.

Symbols

The following words and symbols mark special messages throughout this guide.

WARNING: Text set off in this manner indicates that failure to

follow directions in the warning could result in bodily harm or loss

of life.

CAUTION: Text set off in this manner indicates that failure to

follow directions could result in damage to equipment or loss of

data.

IMPORTANT: Text set off in this manner presents clarifying information or specific

NOTE:

Text set off in this manner presents commentary, sidelights, or interesting points of

information.

Technician Notes

WARNING: Only authorized technicians trained by Compaq should repair

this equipment. All troubleshooting and repair procedures are detailed to

allow only subassembly/module level repair. Because of the complexity of the

individual boards and subassemblies, the user should not attempt to make

repairs at the component level or to make modifications to any printed circuit

board. Improper repairs can create a safety hazard. Any indications of

component replacement or printed circuit board modifications may void any

warranty.

instructions.

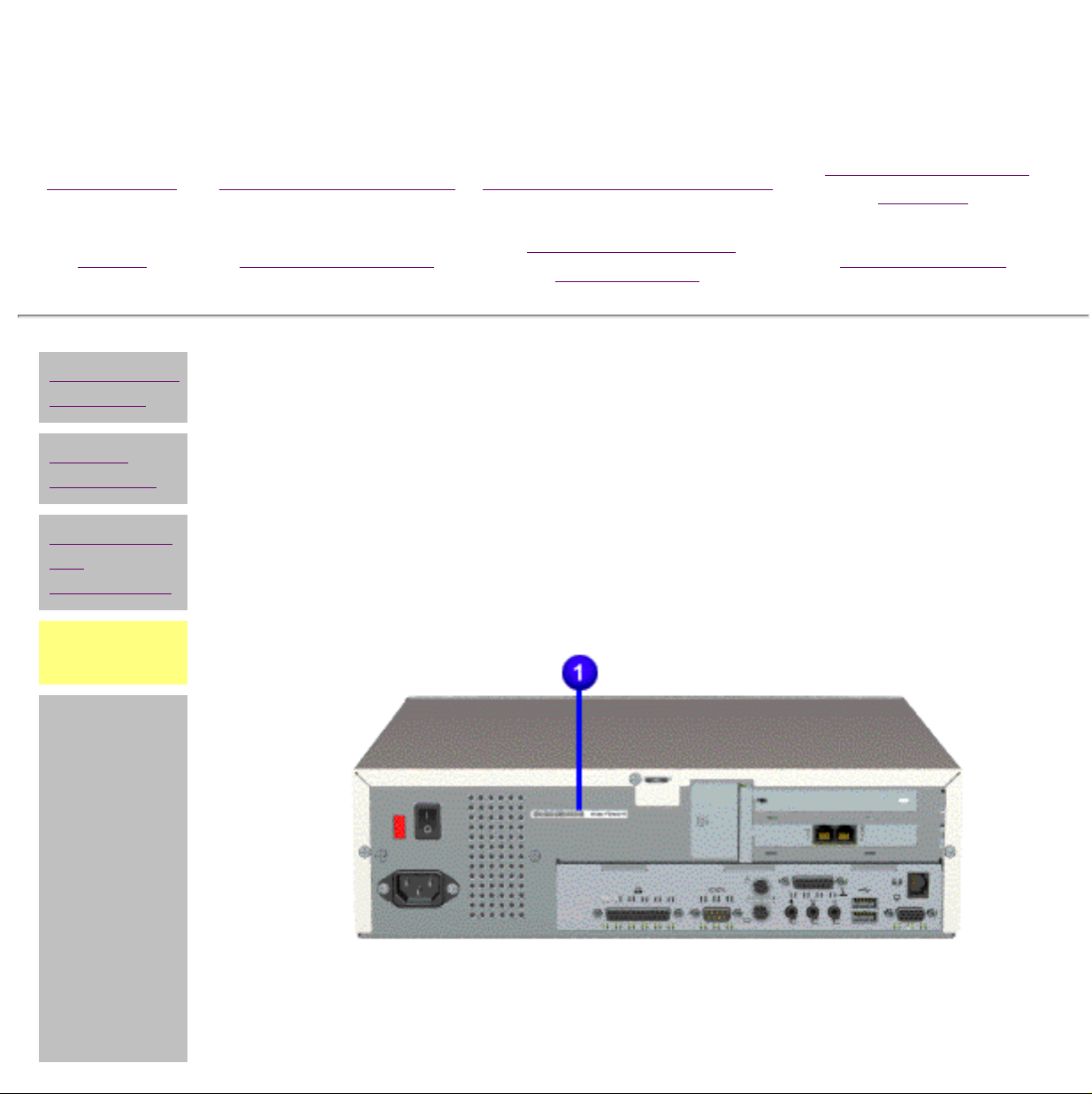

Serial Number

When requesting information or ordering spare parts, the computer serial number should be provided to Compaq.

This can be found on the rear of the computer to the right of the power supply vent.

Locating Additional Information

The following documentation is available to support this product:

■ Compaq Presario documentation set

■ Introducing Windows 95 Guide

■ Service Training Guides

■ Compaq Service Advisories and Bulletins

■ Compaq QuickFind

■ Compaq Service Quick Reference Guide

■ Compaq Help Center

Page 4

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Electrostatic

discharge

REMOVAL & REPLACEMENT

Jumper & Switch

Information

Preliminary Considerations

Service

particulars

Preparation

for

disassembly

Serial

number

Serial Number

The computer serial number should be provided to Compaq whenever

requesting information or ordering spare parts. The serial number is located on

the rear of the unit, to the right of the power supply vent.

Illustrated Parts

Catalog

Specifications

Page 5

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Electrostatic

discharge

Service

particulars

Preparation

for

disassembly

Serial

number

REMOVAL & REPLACEMENT

Preliminary Considerations

Electrostatic Discharge

A sudden discharge of static electricity from a finger or other conductor can destroy static-sensitive

devices or microcircuitry. Often the spark is neither felt nor heard, but damage occurs. An electronic

device exposed to electrostatic discharge (ESD) may not be affected at all and will work perfectly

throughout a normal cycle. Or it may function normally for a while, then degrade in the internal layers,

reducing its life expectancy.

Networks built into many integrated circuits provide some protection, but in many cases, the discharge

contains enough power to alter device parameters or melt silicon junctions.

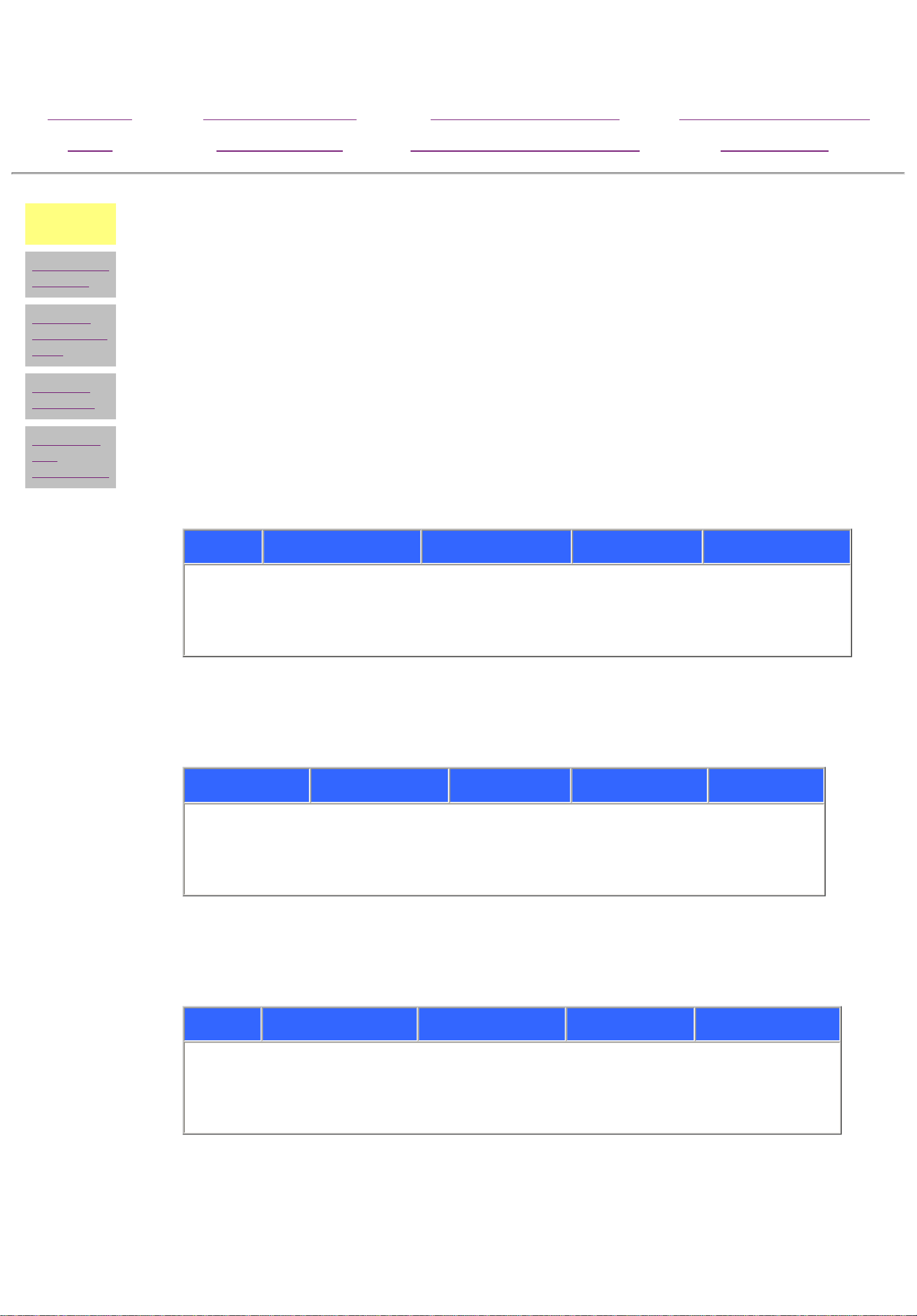

Generating Static

The table below shows the different amounts of static electricity generated by different activities .

Event

Walking across carpet 35,000 V 15,000 V 7,500 V

Walking across vinyl floor 12,000 V 5,000 V 3,000 V

10%

Relative Humidity

40% 55%

Motions of bench worker 6,000 V 800 V 400 V

Removing DIPS from plastic tubes 2,000 V 700 V 400 V

Removing DIPS from vinyl trays 11,500 V 4,000 V 2,000 V

Removing DIPS from Styrofoam 14,500 V 5,000 V 3,500 V

Removing bubble pack from PCBs 26,000 V 20,000 V 7,000 V

Packing PCBs in foam-lined box 21,000 V 11,000 V 5,000 V

NOTE: 700 volts can degrade a product!

Preventing Electrostatic Damage to Equipment

Many electronic components are sensitive to ESD. Circuitry design and structure determine the degree of

sensitivity. The following proper packaging and grounding precautions are necessary to prevent damage:

■ Protect all electrostatic parts and assemblies with conductive or approved containers

or packaging.

■ Keep electrostatic sensitive parts in their containers until they arrive at static-free

stations.

■ Place items on a grounded surface before removing them from their container.

■ Always be properly grounded when touching a sensitive component or assembly.

■ Place reusable electrostatic-sensitive parts from assemblies in protective packaging

or conductive foam.

Use transporters and conveyors made of antistatic belts and metal roller bushings. Mechanized

equipment used for moving materials must be wired to ground and proper materials selected to avoid

static charging. When grounding is not possible, use an ionizer to dissipate electric charges.

Return to the

top of the page.

Preventing Damage to Drives

To prevent static damage to hard drives, use the following precautions:

■ Handle drives gently, using static-guarding techniques.

Grounding Methods

The method for grounding must include a wrist strap or a foot strap at a grounded workstation. When

seated, wear a wrist strap connected to a grounded system. When standing, use footstraps and a

■ Store drives in the original shipping containers.

■ Avoid dropping drives from any height onto any surface.

■ Handle drives on surfaces that have at least one inch of shock-proof foam.

■ Always place drives PCB assembly side down on the foam.

grounded floor mat.

Static-Shielding Protection Levels

Method

Grounding Workstations

To prevent static damage at the workstation, use the following precautions:

Voltages

■ Cover the workstation with approved static-dissipative material. Provide a wrist strap

Antistatic Plastic Carbon-Loaded

Plastic

1,500 7,500 15,000

Metallized Laminate

connected to the work surface and properly grounded tools and equipment.

■ Use static-dissipative mats, heel straps, or air ionizers to give added protection.

■ Handle electrostatic sensitive components, parts, and assemblies by the case or PCB

laminate. Handle them only at static-free workstations.

■ Avoid contact with pins, leads, or circuitry.

■ Turn off power and input signals before inserting and removing connectors or test

equipment.

■ Use fixtures made of static-safe materials when fixtures must directly contact

dissipative surfaces.

■ Keep work area free of nonconductive materials such as ordinary plastic assembly

aids and Styrofoam.

■ Use field service tools, such as cutters, screwdrivers, and vacuums, that are

conductive.

■ Use a portable field service kit with a static dissipative vinyl pouch that folds out of a

work mat. Also use a wrist strap and a ground cord for the work surface. Ground the

cord to the chassis of the equipment undergoing test or repair.

Grounding Equipment

Use the following equipment to prevent static electricity damage to the equipment:

Wrist Straps are flexible straps with a minimum of 1 megohm ±10% resistance to the ground cords. To

provide proper ground, a strap must be worn snug against the skin. On grounded mats without bananaplug connectors, connect a wrist strap with alligator clips.

Heelstraps/Toestraps/Bootstraps can be used at standing workstations and are compatible with most

types of boots and shoes. On conductive floors or dissipative floor mats, use them on both feet with a

minimum of 1 megohm resistance between operator and ground. To be effective, the conductive strips

must be worn in contact with the skin.

Recommended Materials and Equipment

Other materials and equipment that are recommended for use in preventing static electricity include:

■ Antistatic tape

■ Antistatic smocks, aprons, or sleeve protectors

■ Conductive bins, and other assembly or soldering aids

■ Conductive foam

■ Conductive tabletop workstations with ground cord of 1 megohm of resistance

■ Static dissipative table or floor mats with hard tie to ground

■ Field service kits

■ Static awareness labels

■ Wrist straps and footwear straps providing 1 megohm ±10% resistance

■ Material handling packages

■ Conductive plastic bags

■ Conductive plastic tubes

■ Conductive tote boxes

■ Metal tote boxes

■ Opaque shielding bags

■ Transparent metallized shielding bags

■ Transparent shielding tubes

Return to the

top of the page.

Page 6

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Electrostatic

discharge

Service

particulars

Preparation

for

disassembly

Serial

number

REMOVAL & REPLACEMENT

Preliminary Considerations

Service Particulars

Listed below are some details that should be kept in mind during the disassembly and reassembly of the

computer.

Tool Requirements

■ Phillips screwdriver

■ Needle-nose pliers

■ Flat-bladed screwdriver

■ Compaq Utilities software

Screws

The screws used in these products are not interchangeable. If an incorrect screw is used during the

reassembly process, it could cause damage to the unit. Compaq strongly recommends that all screws

removed during the disassembly process be kept with the part that was removed, then returned to their

proper locations.

IMPORTANT: As each subassembly is removed from the computer, it should

be placed away from the work area to prevent damage.

Cables and connectors

Most cables used throughout the unit are ribbon cables. These must be handled with extreme care to

avoid damage. Apply only the tension required to seat or unseat the cables during insertion or removal

from the connector. Handle cables by the connector whenever possible. In all cases, avoid bending,

twisting, or tearing the cables, and ensure that they are placed in such a way that they cannot be caught

or snagged by parts being removed or replaced.

l

CAUTION: When servicing these computers, ensure that cables

are placed in their proper location during the reassembly process.

Improper cable placement can cause severe damage to the unit.

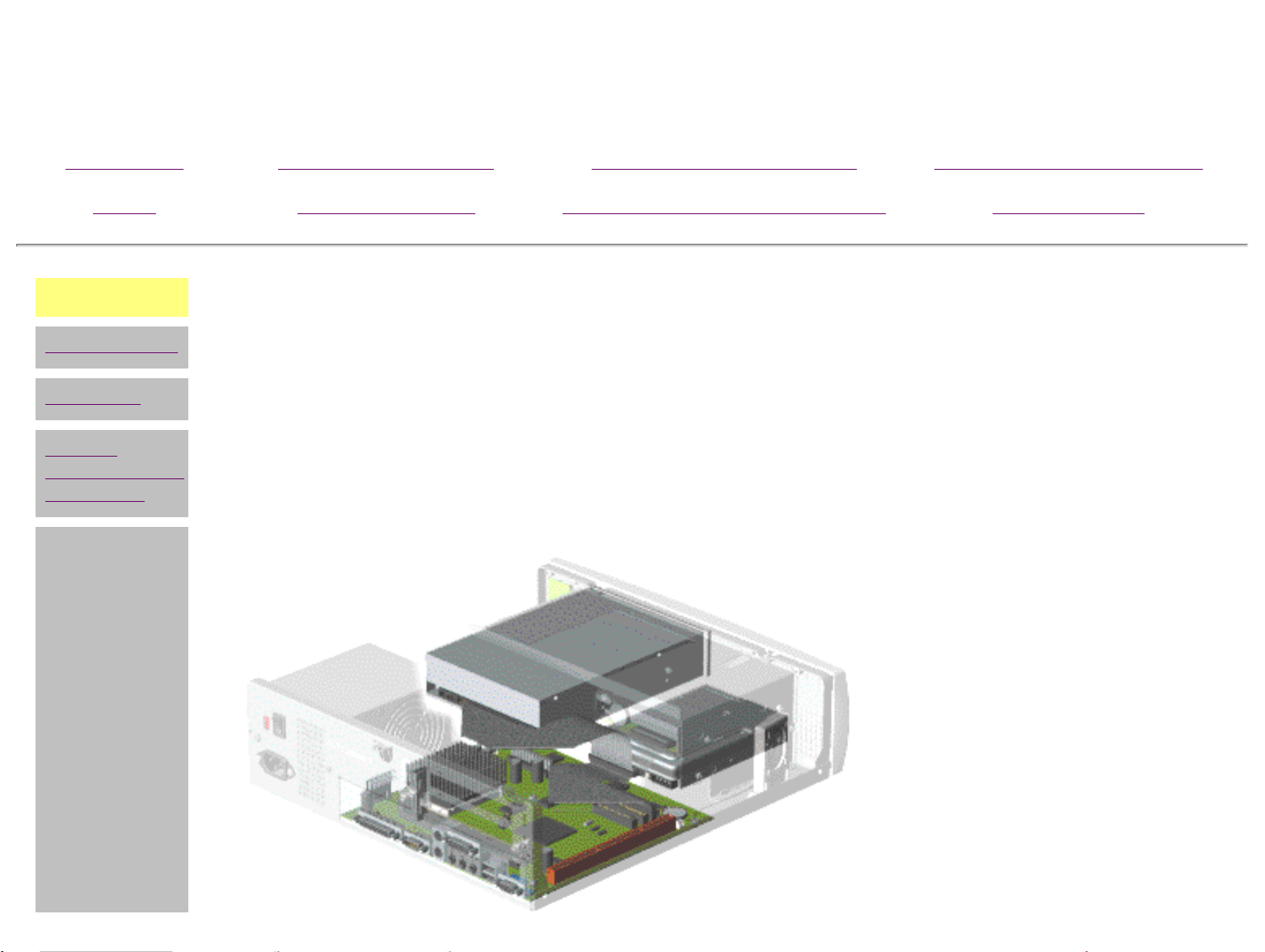

Ribbon Cable Positions

● CD drive

● Diskette drive

● Hard drive

Page 7

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

CD drive

Diskette drive

Hard drive

Service

considerations

index page

l

REMOVAL & REPLACEMENT

Preliminary Considerations

Service Considerations - Cable Positions

CD drive (and hard drive)

This cable connects to J10 on the system board.

Page 8

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

CD drive

Diskette drive

Hard drive

Service

considerations

index page

l

REMOVAL & REPLACEMENT

Preliminary Considerations

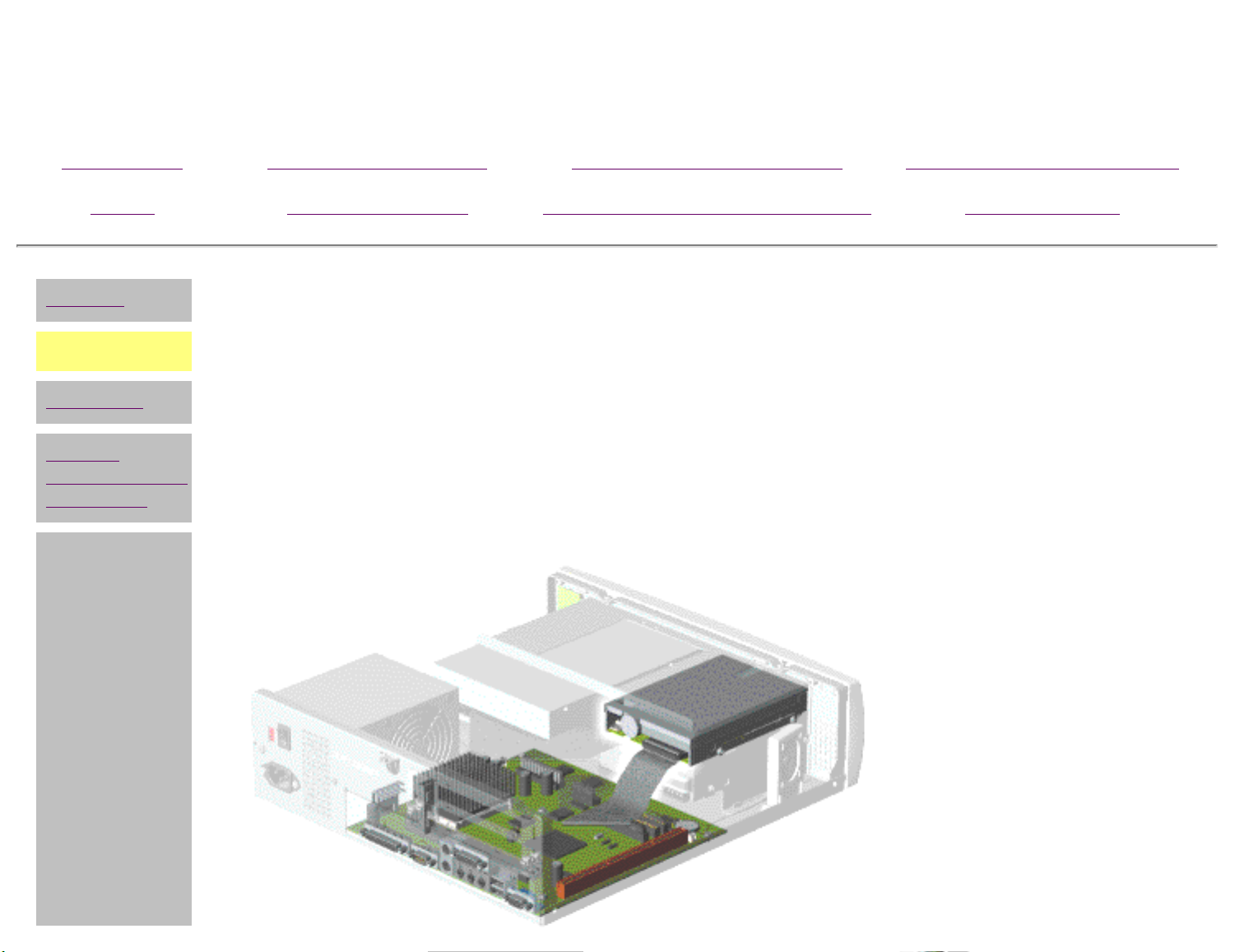

Service Considerations - Cable Positions

Diskette drive

This cable connects to J2 on the system board.

Page 9

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

CD drive

Diskette drive

Hard drive

Service

considerations

index page

l

REMOVAL & REPLACEMENT

Preliminary Considerations

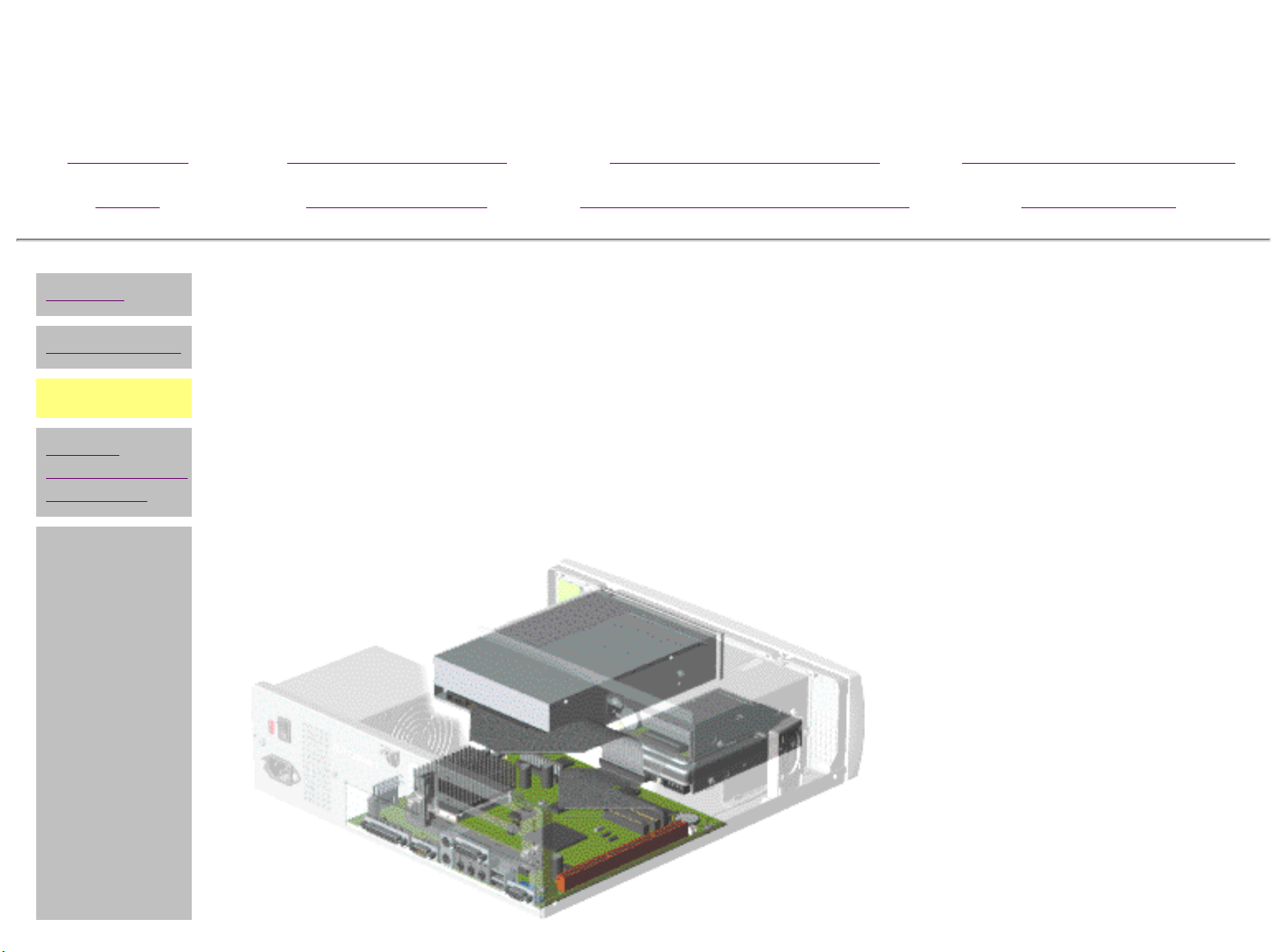

Service Considerations - Cable Positions

Hard drive (and CD drive)

This cable connects to J10 on the system board.

Page 10

Maintenance and Service Guide

NCtion.gif

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Electrostatic

discharge

Service

particulars

Preparation

for

disassembly

Serial

number

REMOVAL & REPLACEMENT

Preliminary Considerations

Preparation for Disassembly

To prepare the computer for removal and replacement procedures, please complete these

steps:

1 Remove any diskette, compact disc, or tape from the computer.

2 Close all programs, shut down the computer, and turn off the power switch.

3 Turn off any peripheral devices that are connected to the computer.

CAUTION: The computer power switch must be turned off

before disconnecting any cables.

4 Disconnect the power cord from the electrical outlet, and then from the computer.

WARNING: Do not open the hood until after the power cable has been

removed from the electrical outlet.

5 Disconnect all peripheral device cables from the computer.

IMPORTANT: During disassembly, label each cable as you remove

it. Be sure to note its position and routing.

Page 11

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description

Home Troubleshooting

PRODUCT DESCRIPTION INDEX PAGE

Models & model-specific features

CPU controls & lights Rear components,

Keyboard controls & lights Power cord set

Removal &

Replacement

Jumper & Switch

Information

connector pin assignments

requirements,

general requirements

country-specific requirements

Illustrated Parts

Catalog

Specifications

Page 12

--2262--------------------MX (300)-------------------------4.0------------------------------32-------------------------yes---

--2264--------------------MX (300)-------------------------4.0------------------------------32--------------------------no---

--2266--------------------MX (300)-------------------------4.0------------------------------64--------------------------no---

--2268--------------------MX (300)-------------------------4.0------------------------------64--------------------------no---

--2275-------------------K6-2 (333)------------------------6.0------------------------------64--------------------------no---

--2260--------------------MX (300)-------------------------2.1-------------------------32--------------------------no-----

--2262--------------------MX (300)-------------------------2.1-------------------------32--------------------------no-----

--2274-------------------K6-2 (300)------------------------4.0-------------------------48--------------------------no-----

--2280--------------------M2 (333)-------------------------3.2-------------------------32--------------------------no-----

--2282--------------------M2 (333)-------------------------3.2-------------------------32--------------------------no-----

--2260--------------------MX (300)-------------------------2.1------------------------------32--------------------------no---

--2262--------------------MX (300)-------------------------2.1---------------------------32,64------------------------yes---

--2270-------------------K6-2 (300)------------------------4.0------------------------------32--------------------------no---

--2274-------------------K6-2 (300)------------------------4.0------------------------------64--------------------------no---

--2276-------------------K6-2 (333)------------------------4.0------------------------------48-------------------------yes---

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls and

lights

Rear CPU

connectors

Power cord

set

requirements

PRODUCT DESCRIPTION

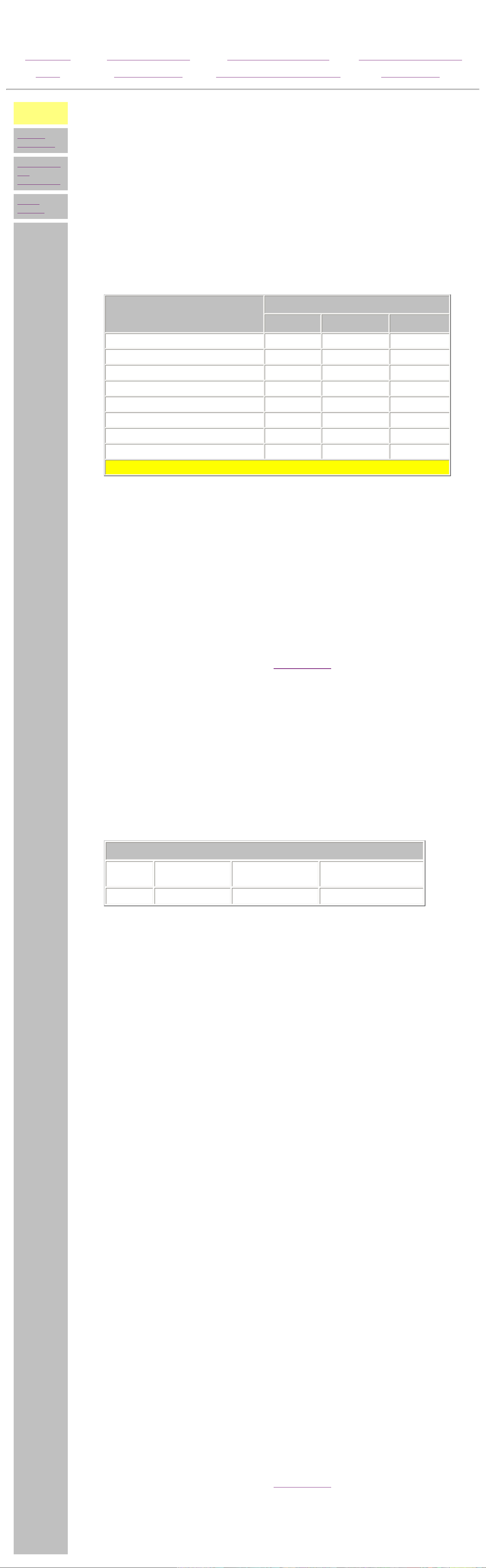

Models and Model-Specific Features

Compaq 2200 and 2400 Series Computers

Standard Configurations

Please Note:

All models have 512kB L2 cache and a 32x CD drive.

U.S., Latin America, Canada

Model Processor (MHz)* Hard Drive (GB) SDRAM (MB) NIC

Europe, Middle East, Africa

Model Processor

(MHz)*

Hard Drive

(GB)

SDRAM (MB) NIC

Asia/Pacific, Japan

Model Processor (MHz)* Hard Drive (GB) SDRAM (MB) NIC

*Megahertz-equivalent performance level. Based upon industry-standard benchmark

comparisons to the Pentium© II processor when tested in equivalently configured computer

systems.

Page 13

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Models and

features

PRODUCT DESCRIPTION

Jumper & Switch

Information

CPU Controls and Lights

CPU controls

and lights

Keyboard

controls and

lights

Rear CPU

connectors

Illustrated Parts

Catalog

Specifications

Floppy

drive

1

activity

light

Floppy

drive

2

access

door

Power cord

set

requirements

FG

Floppy

diskette

3

eject

button

CD drive

activity

4

light

CD drive

tray access

5

door

Manual

6

eject slot

CD

load/eject

7

button

Hard drive

activity

8

light

Sleep

9

status light

Instant on

10

button

Headphone

11

socket

Page 14

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls

and lights

Rear CPU

connectors

Power cord

set

requirements

PRODUCT DESCRIPTION

Keyboard Controls and Lights

1 Play/pause

2 Stop

3 Previous track

4 Next track

5 Sleep button

6 Mute

7 Volume down

8 Volume up

9 Favorite application

launch

● Click here for the top center of Space Saver keyboard.

● Click here for the top right corner of the Easy Access

Internet keyboard.

Page 15

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls

and lights

Rear CPU

connectors

Power cord

set

requirements

PRODUCT DESCRIPTION

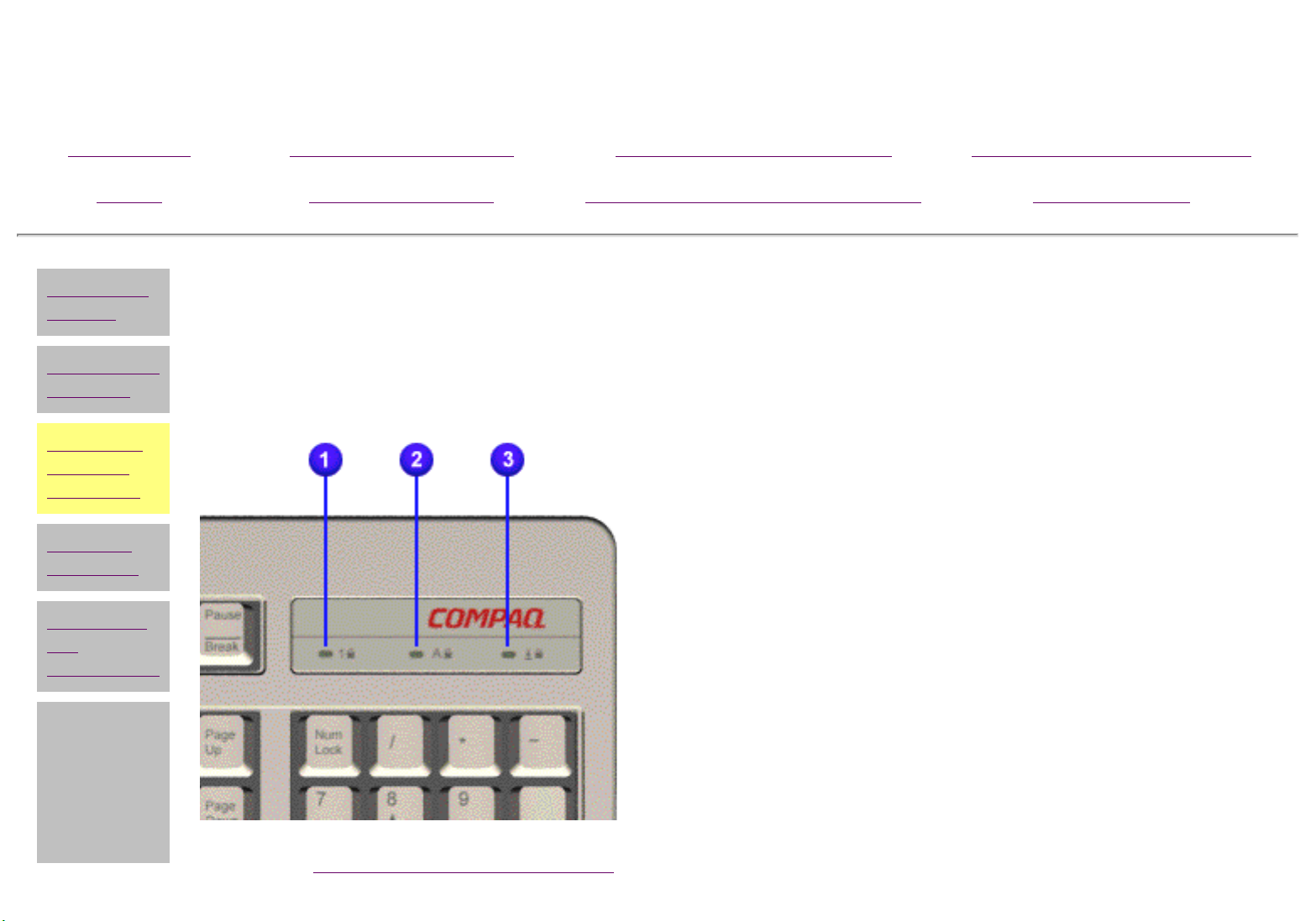

Keyboard Controls and Lights

Space Saver Keyboard

1 Num Lock Light

2 Caps Lock Light

3 Scroll Lock Light

l

go back to Keyboard controls & lights

main page.

Page 16

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls

and lights

Rear CPU

connectors

Power cord

set

requirements

l

PRODUCT DESCRIPTION

Keyboard Controls and Lights

Easy Access Internet Keyboard

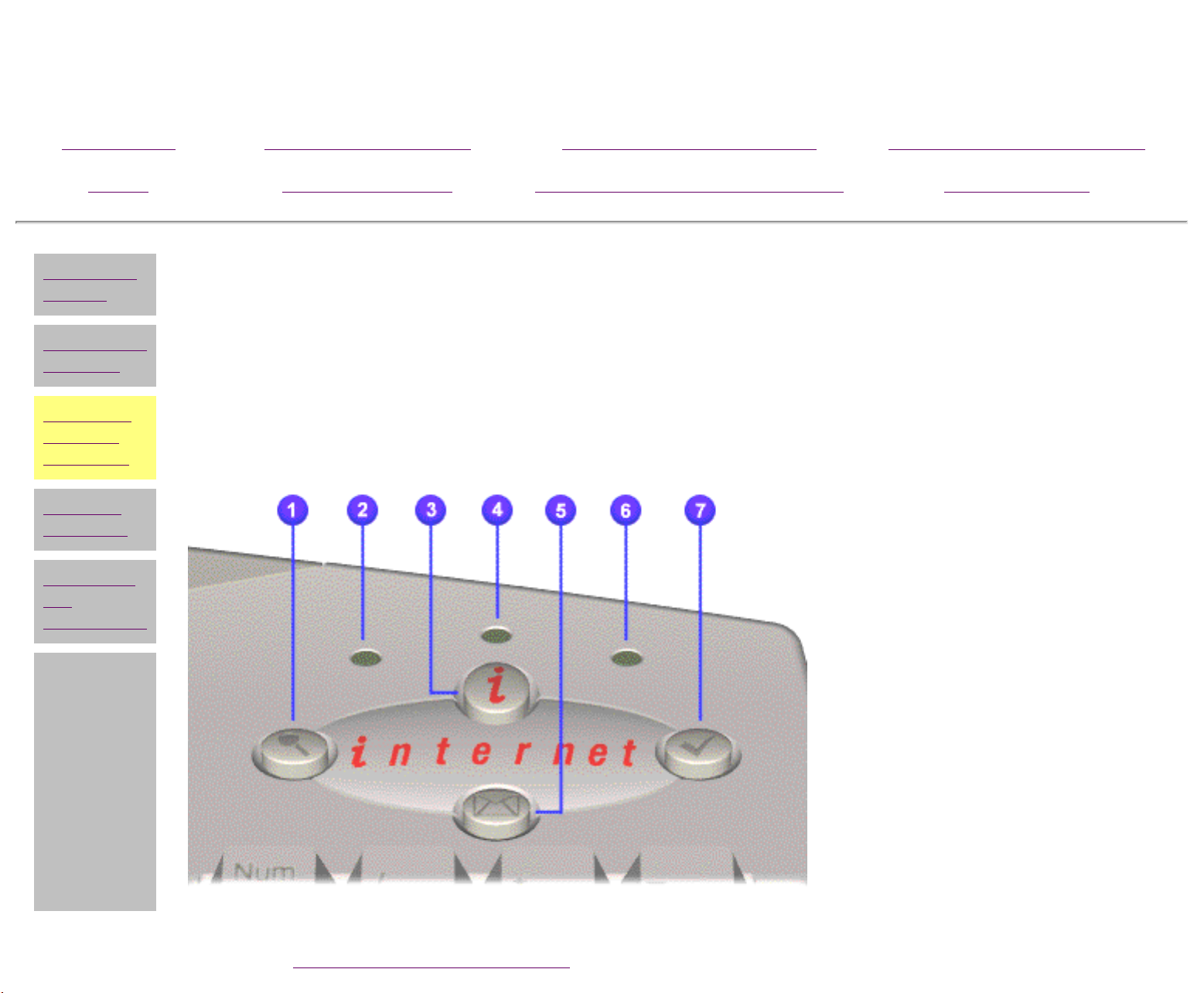

Upper right corner

1 Instant search

2 Num lock light

3 Instant Internet

4 Caps lock light

5 Instant e-mail

6 Scroll lock light

7 Featured Web site

go back to Keyboard controls & lights main page

Page 17

Maintenance and Service Guide

NCtion.gif

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls and

lights

CPU rear

connectors

Power cord

set

requirements

PRODUCT DESCRIPTION

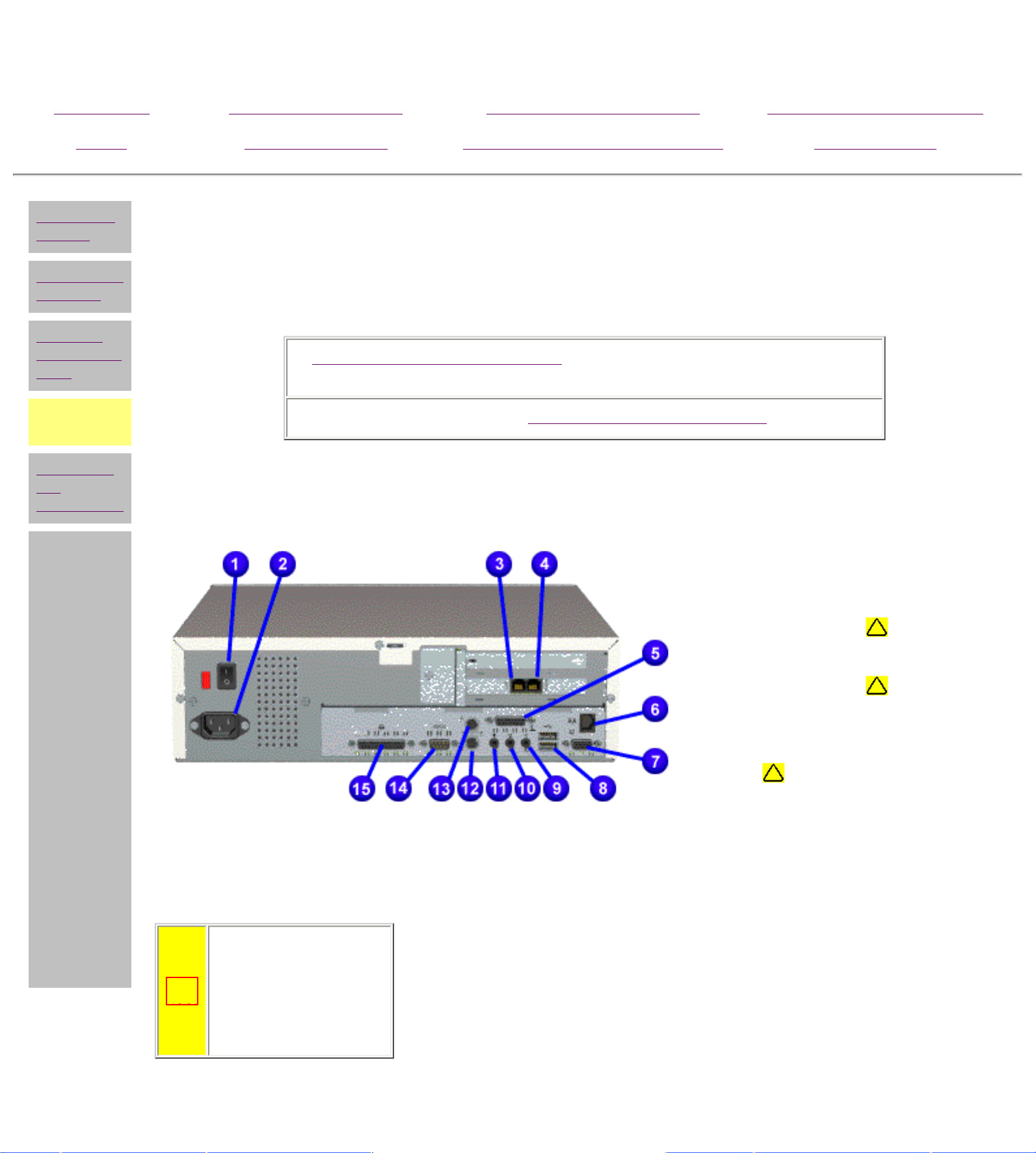

CPU Rear Connectors-2200 Series Models

Click the appropriate link:

Rear connector assignments for Educational Models 2412ES &

2416ES.

or 2200 series

Connector pin assignments.

1

Main power switch (on/off)

2

AC power inlet

Modem or phone

3

varies)

Modem or phone (location

4

varies)

5

MIDI/gamepad/joystick

6

NIC

7

VGA monitor

(on select models)

(location

8

USB (2 connectors)

9

Speaker out

10

Audio line out

CAUTION: Do not

plug a phone line

into the network

connector, it may

damage the

computer.

11

Microphone

12

Keyboard

13

Mouse

14

Serial port

15

Parallel/printer port

Page 18

Maintenance and Service Guide

NCtion.gif

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls and

lights

CPU rear

connectors

Power cord

set

requirements

PRODUCT DESCRIPTION

CPU Rear Connectors- 2412ES & 2416ES Models

1

Main power switch (on/off)

2

AC power inlet

3

NIC

4

MIDI/gamepad/joystick

5

VGA monitor

6

USB (2 connectors)

7

Speaker

8

Audio line out

(location may vary)

Click here to see the connector pin assignments .

or here to go back to

CPU rear connectors main page.

CAUTION: Do not plug a phone line into the network

connector, it may damage the computer

9

Microphone

10

Keyboard

11

Mouse

12

Serial port

13

Parallel/printer port

Page 19

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting

Models and

features

PRODUCT DESCRIPTION

CPU Rear Connectors

CPU controls

and lights

Keyboard

controls and

lights

CPU rear

connectors

Power cord

set

requirements

Connector Pin Assignments

Click on an item to see its pin assignments:

Audio line out

Audio line in Keyboard Parallel

Jumper & Switch

Specifications

Information

Flat panel

Mouse Serial

monitor

Speaker / headphone

out

CD drive data

l

cable

Fax/modem MIDI/joystick

Microphone Phone line to phone USB

Phone line to wall

VGA monitor

jack

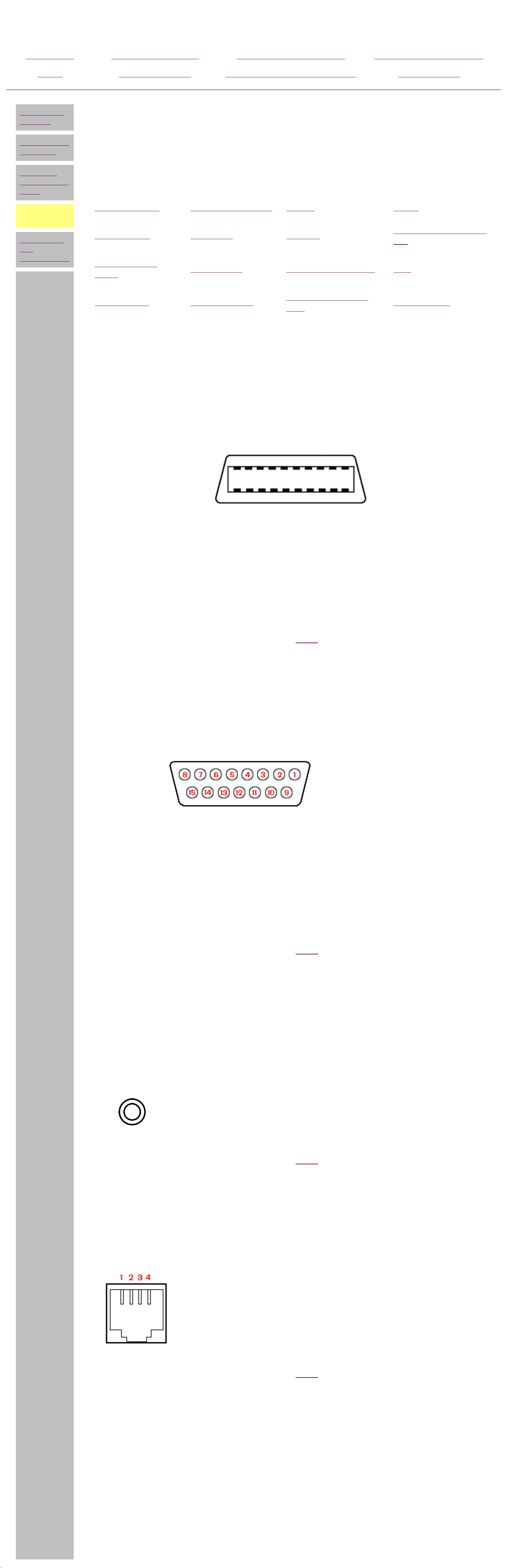

Parallel Connector

Pin Signal Pin Signal Pin Signal

1

Strobe*

7

Data Bit 5

13

Select

2

3

4

5

Data Bit 0

Data Bit 1

Data Bit 2

Data Bit 3

8

9

10

11

Data Bit 6

Data Bit 7

Acknowledge*

Busy

14

15

16

17

Auto Linefeed*

Error*

Initialize Printer*

Select In*

6

Data Bit 4

12

Paper Out

1825

Signal Ground

* Active low

Return to

the top.

Serial Connector

Pin Signal

1

2

3

Carrier Detect

Receive Data

Transmit Data

4

Data Terminal Ready

5

6

7

8

Signal Ground

Data Set Ready

Ready to Send

Clear to Send

9

Ring Indicator

Return to

the top.

Universal Serial Bus

Pin Signal

1

- Data

Keyboard &

2

3

4

+Data

Ground

+5 VDC

Return to

the top.

Mouse

Pin Signal

1

2

Data

Unused

3

4

Ground

+5 VDC

5

6

Clock

Unused

Page 20

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls and

lights

CPU rear

connectors

Power cord

set

requirements

l

PRODUCT DESCRIPTION

CPU Rear Connectors

Connector Pin Assignments

Click on an item to see its pin assignments:

Audio line out Flat panel monitor Mouse Serial

Audio line in Keyboard Parallel

CD drive data

Microphone Phone line to phone USB

cable

Phone line to wall

Fax/modem MIDI/joystick

jack

Speaker/headphone

out

VGA monitor

Flat-panel monitor

Pin Signal Pin Signal Pin Signal Pin Signal

1

2

3

TX2+

Ground

TX1+

6

7

8

TXC+

Logic ground

DDC data (SDA)

11

12

13

TX2Ground

TX1-

16

17

18

TXC+5VDC

DDC Clock (SCL)

4

5

TX0+

Ground

9

10

Reserved

Reserved

14

15

TX0Ground

19

20

Reserved

Reserved

Return to

the top.

MIDI/Joystick

Pin Signal Pin Signal Pin Signal

1

2

3

4

+5 VDC

Fire A (1)

X-Axis (1)

Ground

6

7

8

9

Y-Axis (1)

Fire B (1)

+5 VDC

+5 VDC

11

12

13

14

X-Axis (2)

MIDI Out

Y-Axis (2)

Fire B (2)

5

Ground

10

Fire A (2)

15

MIDI In

Return to

the top.

Line out

Line in

Speaker/Headphone Out

Microphone

Stereo 1/8"

Miniphone

Return to

the top.

Phone Line to Wall Jack

Phone Line to Phone

Pin Signal

1

2

Unused

Tip

3

Ring

4

Unused

Return to

the top.

Pin Signal Pin Signal Pin Signal

Internal Fax/Modem

1

2

Unused

Unused

3

4

Ring

Tip

5

6

Unused

Unused

Page 21

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Models and

features

CPU controls

and lights

Keyboard

controls and

lights

CPU rear

connectors

Power cord

set

requirements

l

PRODUCT DESCRIPTION

CPU Rear Connectors

Connector Pin Assignments

Click on an item to see its pin assignments:

Audio line out Flat panel monitor Mouse Serial

Audio line in Keyboard Parallel

CD drive data

Microphone Phone line to phone USB

cable

Phone line to wall

Fax/modem MIDI/joystick

jack

Speaker/headphone

out

VGA monitor

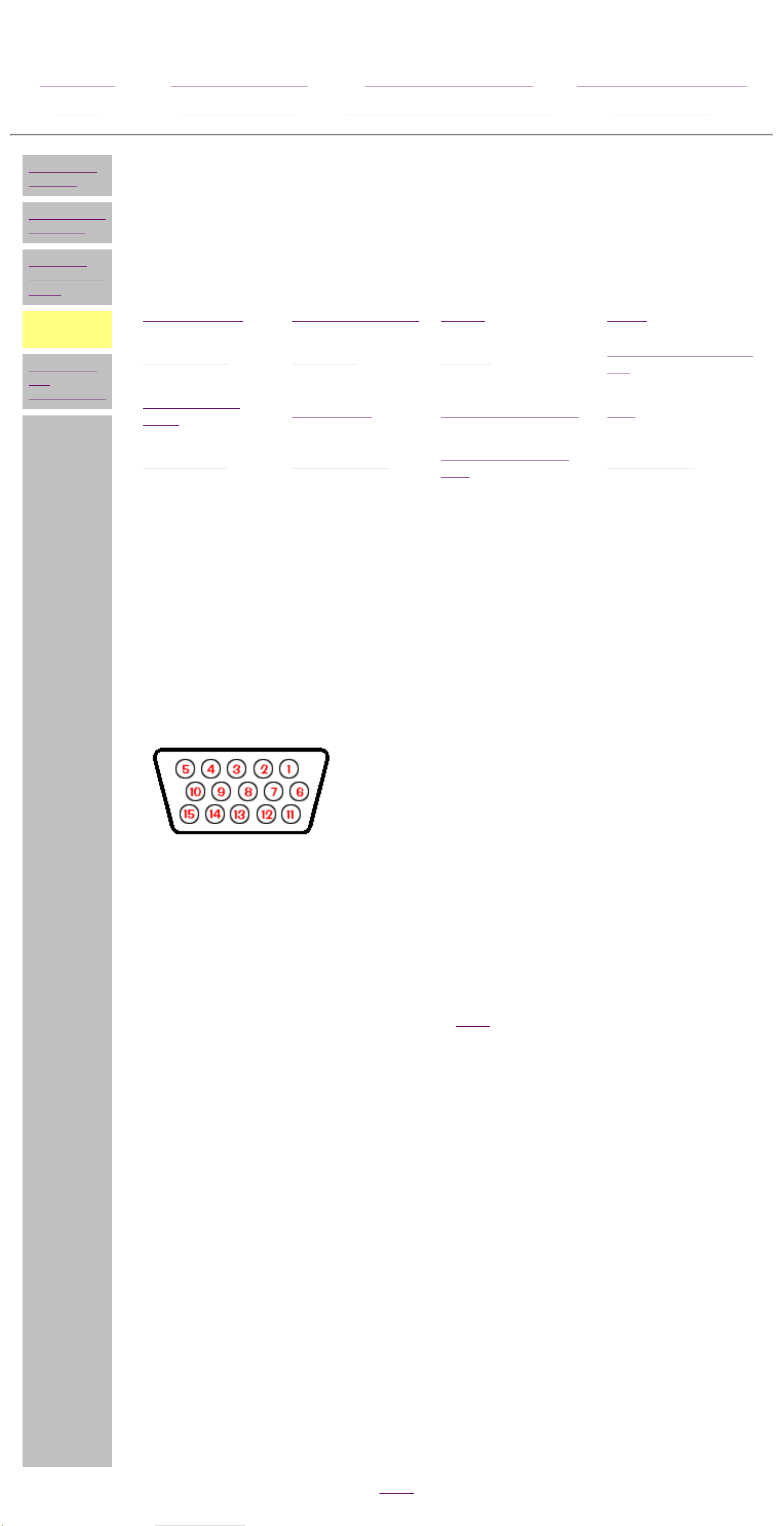

VGA Monitor

Pin Signal Pin Signal

1

2

3

Red Analog

Green Analog

Blue Analog

9

10

11

+5 VDC

Ground

Volume Down

4

5

6

7

8

Volume Up

Ground

Ground Analog

Ground Analog

Ground Analog

Return to

the top.

12

13

14

15

DDC Data

Horizontal Sync

Vertical Sync

DDC Clock

CD Drive Data Cable

Pin Signal Pin Signal Pin Signal Pin Signal

1

2

3

RESET

GND

DD7

11

12

13

DD3

DD12

DD2

21

22

23

DMARK

GND

-DIOW

31

32

33

INTRQ

-IOCS16

DA0

4

DD8

14

DD13

24

GND

34

-PDIA6

5

6

7

8

DD6

DD9

DD5

DD10

15

16

17

18

DD1

DD14

DD0

DD15

25

26

27

28

-DIOR

GND

IORDY

SPSYNC

35

36

37

38

DA0

DAZ

-CS1FX

-CS3FX

9

DD4

19

GND

29

-DMACK

39

-DASP

10

DD11

20

(KEY)

30

GND

40

GNP

Return to

the top.

Page 22

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description

Home Troubleshooting

Models and

features

PRODUCT DESCRIPTION

Power Cord Set Requirements

CPU controls

and lights

Keyboard

controls and

lights

Rear CPU

connectors

Power cord

set

requirements

● The auto-detect feature on the computer permits it to operate from any

line voltage between 120 and 240 volts AC.

● The power cord set (flexible cord and wall plug) received with the

computer meets the requirements for use in the country where the

computer was purchased.

● Power cord sets for use in other countries must meet the requirements

of the country where you use the computer. For more information on

power cord set requirements, contact your Compaq authorized dealer,

reseller, or service provider.

Removal &

Replacement

Jumper & Switch

Information

Illustrated Parts

Catalog

Specifications

l

General Requirements

The requirements listed below are applicable to all countries:

1

The length of the power cord set must be at least

6.00 feet (1.8 m) and a maximum of 9.75 feet (3.0

m).

2

All power cord sets must be approved by an

acceptable accredited agency responsible for

evaluation in the country where the power cord set

will be used.

3

The power cord set must have a minimum current

capacity of 10A and a nominal voltage rating of 125

or 250 volts AC, as required by each country's power

system.

4

The appliance coupler must meet the mechanical

configuration of an EN 60 320/IEC 320 Standard

Sheet C13 connector, for mating with appliance inlet

on the Switch Box.

Country-Specific Requirements

Country Accredited Agency

Australia EANSW* Italy IMQ*

Country Accredited

Agency

Austria OVE* Japan JIS***

Belgium CEBC* Norway NEMKO*

Canada CSA** Sweden SEMKO*

Denmark DEMKO* Switzerland SEV*

Finland SETI* United

Kingdom

BSI*

France UTE* United States UL**

Germany VDE*

* The flexible cord must be <HAR> Type HO3VV-F, 3conductor, 1.0 mm2 conductor size. Power cord set fittings

(appliance coupler and wall plug) must bear the certification

mark of the agency responsible for evaluation in the country

where it will be used.

** The flexible cord must be Type SJT-2 or equivalent, No. 18

AWG, 3-conductor. The wall plug must be a two-pole

grounding type with a NEMA 5-15P (15A, 125V) or NEMA 615P (15A, 250V) configuration.

*** The appliance coupler, flexible cord, and wall plug must

bear a "T" mark and registration number in accordance with

the Japanese Dentori Law. Flexible cord must be Type VCT or

VCTF, 3-conductor, 0.75mm2 conductor size. The wall plug

must be a two-pole type with a Japanese Industrial Standard

C8303 (15A, 125V) configuration.

Page 23

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Jumper & Switch

Home Troubleshooting

Information

Illustrated Parts

Catalog

Specifications

REMOVAL & REPLACEMENT PROCEDURES - INDEX PAGE

This section provides general service information for Compaq 2200 and 2400 Series

Computers.

Adherence to the procedures and precautions described in this section is essential

for safe and proper service.

Preliminary considerations

electrostatic discharge

service particulars

preparation for disassembly

serial number

Hood

Button / headphone board

Riser card (backplane)

Power supply

Mass storage devices

drive cage

CD drive

diskette drive

hard drive

expansion bay cover

Front bezel

Internal speakers (ES models)

Fax-modem

NIC card (Network Interface Connector

card)

System board components

battery

memory module

processor

I/O panel

system board

Page 24

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Jumper & Switch

Home Troubleshooting

Information

DISASSEMBLY

SEQUENCE

REMOVAL & REPLACEMENT PROCEDURES

Preliminary Considerations - Index Page

Preliminary

considerations

For maximum safety and efficiency, please read and understand these sections

Hood

Button board

Front bezel

before attempting to repair or replace any components.

Electrostatic discharge

Service particulars

Illustrated Parts

Catalog

Specifications

Speakers

Fax-modem

NIC card

Riser card

Mass storage

devices

Power supply

System board

components

Preparation for disassembly

Serial number

Page 25

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

Mass storage

devices

REMOVAL & REPLACEMENT

Riser Card (Backplane)

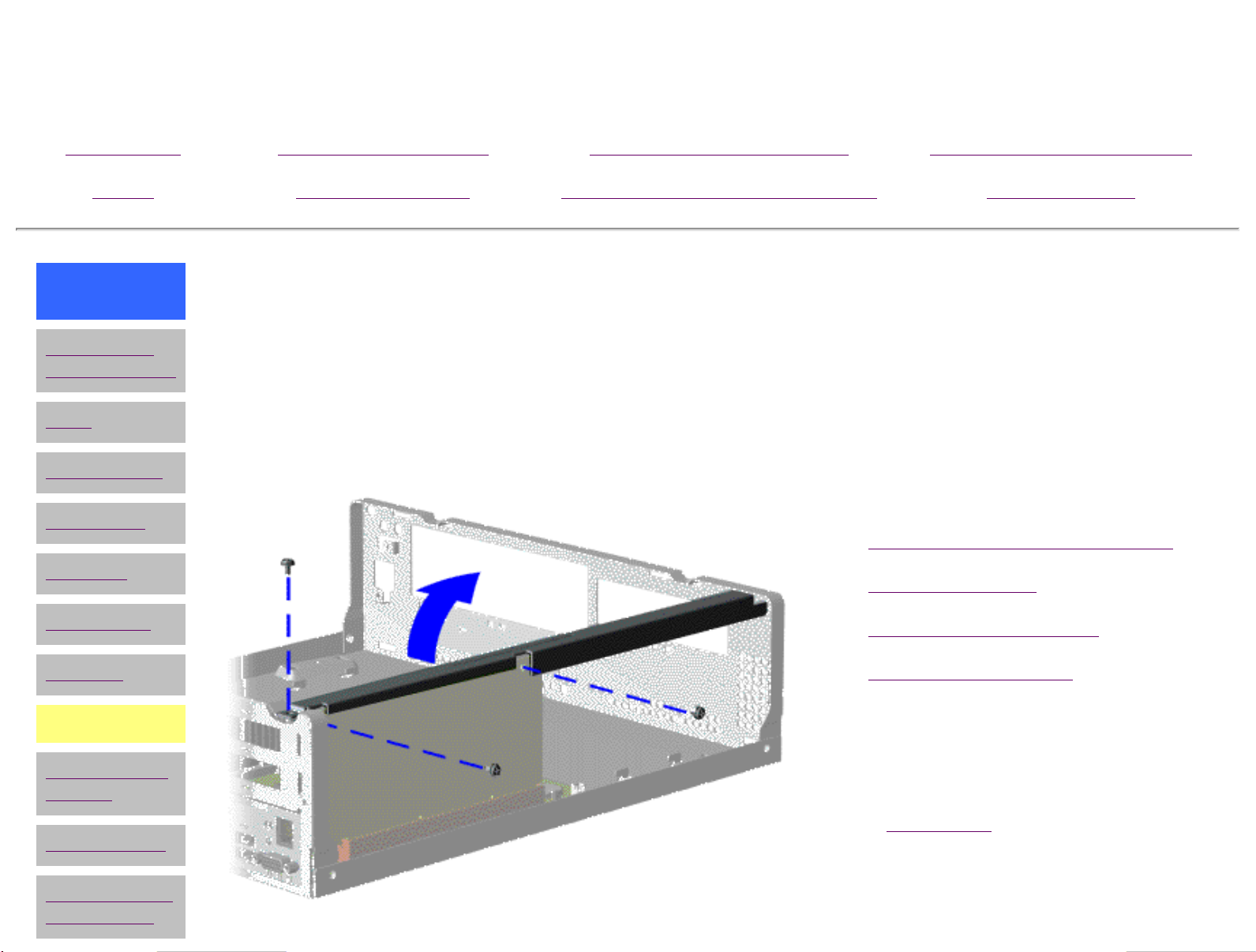

There are six steps in this sequence.

Perform preparation procedures.

1

Remove the hood.

2

Remove the fax-modem.

3

Remove the NIC card, if present.

4

Remove the three screws holding

5

the riser card to the cross-brace

bar.

Power supply

System board

components

NEXT STEP

Page 26

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Jumper & Switch

Information

REMOVAL &

REPLACEMENT

Riser Card (Backplane),

continued

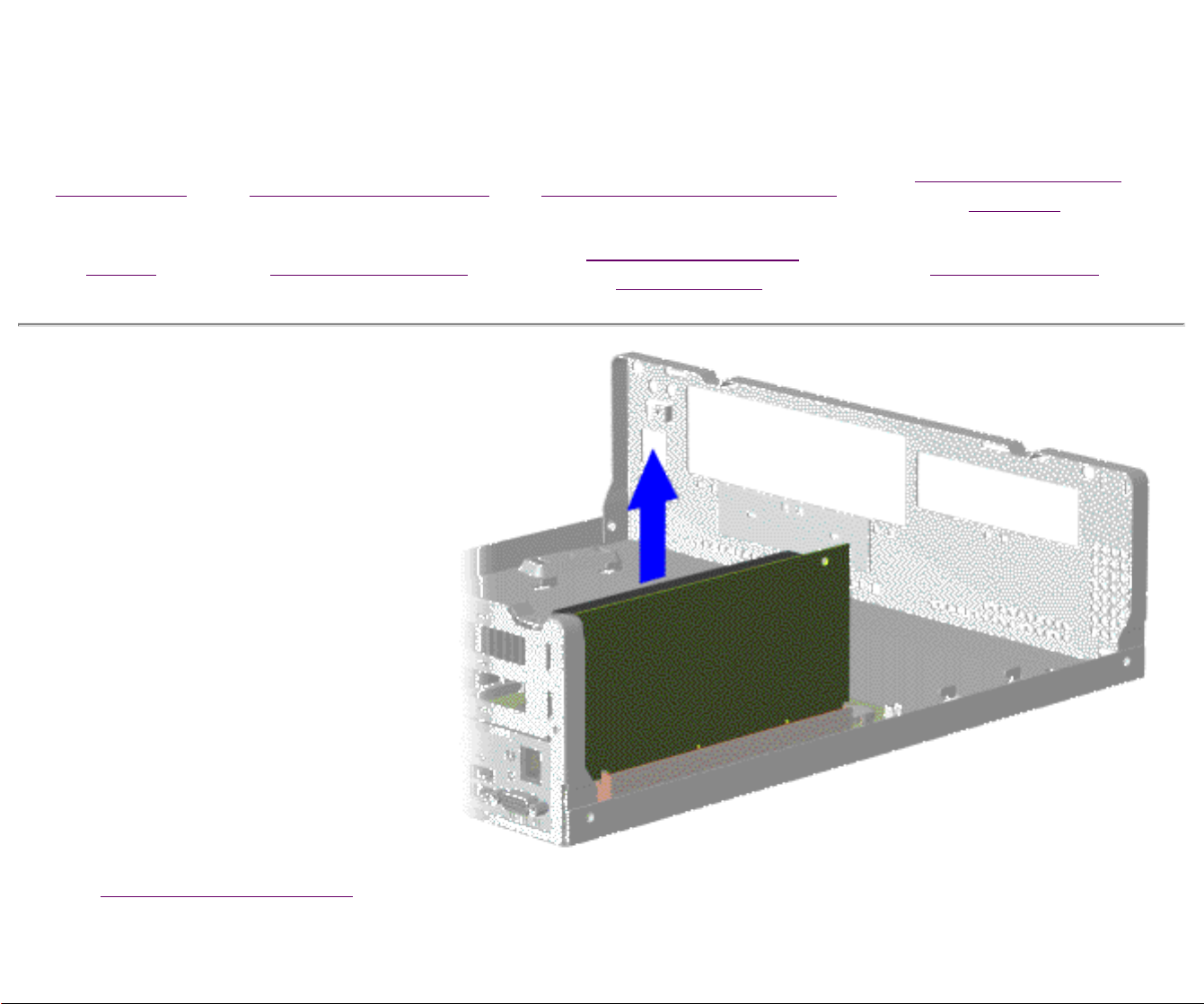

Pull the riser card out of the

6

system board.

Illustrated Parts

Catalog

Specifications

END OF SEQUENCE

To replace the riser card, reverse

this sequence.

Return to section index

Page 27

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

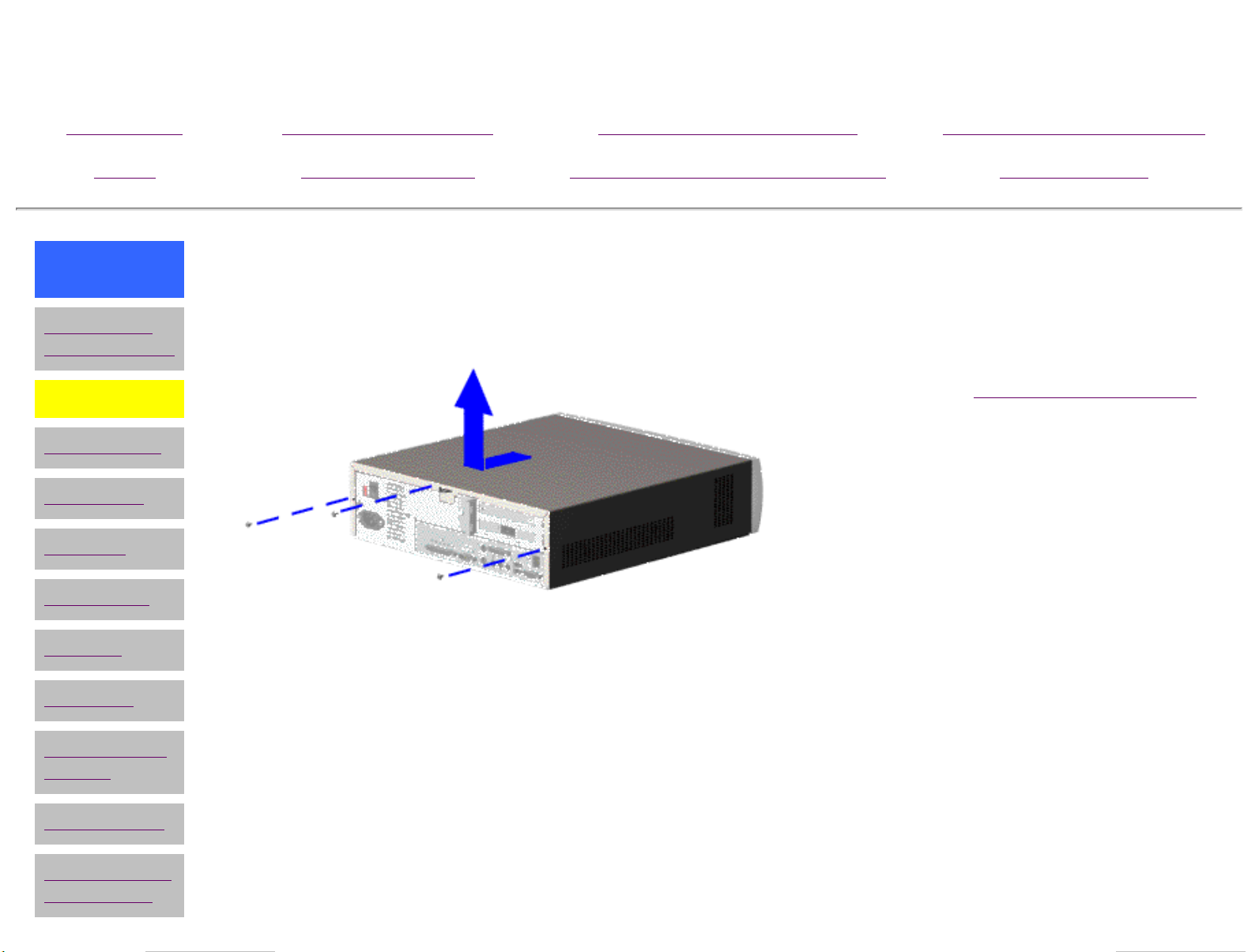

Hood

1

Perform the

2

Remove the three screws at the

preparation procedures

back of the computer which hold the

hood to the chassis

3

Grasp the handles on the bottom of

the hood, pull back slightly, and lift

the hood off the computer

To replace the hood, reverse this

sequence.

Mass storage

devices

Power supply

System board

components

Page 28

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

Button / Headphone Board

1

Perform preparation procedures.

2

Remove the hood.

3

Disconnect the button board

cable from the system board (at

J27).

4

Remove the two screws from

the button board assembly.

5

Pull the assembly from the rear

of the front bezel.

Mass storage

devices

Power supply

System board

components

END OF SEQUENCE

To replace the button board assembly,

reverse this sequence.

Page 29

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

Front Bezel

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the

button/headphone board.

4

Remove the drive cage.

5

Release the six latches, then

remove the front bezel from

the chassis.

Mass storage

devices

Power supply

System board

components

To replace the front bezel, reverse

this sequence.

Page 30

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

Internal Speakers (ES models)

There are four steps in this

sequence.

Perform preparation

1

procedures.

Remove the hood.

2

Unplug the speaker cord from

3

the connector (J25 for L, J26

for R) on the system board.

NEXT STEP

Mass storage

devices

Power supply

System board

components

Page 31

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

REMOVAL & REPLACEMENT

Internal Speakers (ES models), continued

Squeeze the plastic speaker casing at the bottom

4

(or squeeze the speaker tabs under the chassis), then

pull the speaker vertically out of the chassis .

END OF SEQUENCE

To replace a speaker, reverse this sequence.

Return to section index

Page 32

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

Fax/modem

NOTE

Your modem may look

different and be in the upper

option slot.

1

Perform preparation procedures.

2

Remove the hood.

3

Remove the screw holding the option

card retainer bracket to the chassis.

4

Remove the option card retainer

bracket, then carefully pull the

fax/modem board out of the riser

card.

Mass storage

devices

Power supply

System board

components

l

To replace the fax/modem, reverse this

sequence.

IMPORTANT

When replacing the

fax/modem, download

the latest software from

SoftPaq. If QuickRestore

is used, it may not have

the 56K or V.90 upgrade

software included.

Page 33

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

NIC card (2416ES models)

NOTE

Your NIC card may look

different and be in the upper

option slot

Perform preparation procedures.

1

Remove the hood.

2

Remove the screw holding the option

3

card retainer bracket to the chassis.

Remove the option card retainer

4

bracket, then carefully pull the NIC

card off the riser card.

Mass storage

devices

Power supply

System board

components

END OF SEQUENCE

To replace the NIC card, reverse this

sequence.

Page 34

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

Mass Storage Devices - Index Page

The mass storage devices are located in a drive cage, which needs to be taken out of the

chassis before removing a drive.

Removing the drive cage

Hard drive

Diskette drive

CD drive

Expansion bay cover

Mass storage

devices

Power supply

System board

components

Page 35

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting

Drive cage

Diskette drive

Hard drive

CD drive

Expansion

bay

Mass storage

devices index

page

REMOVAL & REPLACEMENT

Mass Storage Devices

Removing the Drive Cage

Jumper & Switch

Information

Specifications

There are five steps in this sequence.

1

Perform preparation

procedures.

2

Remove the hood.

3

Disconnect the cables from the

diskette drive.

NEXT STEP

l

or Go back to Removal

and Replacement main

page.

Page 36

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Jumper & Switch

Home Troubleshooting

Information

REMOVAL &

REPLACEMENT

Mass Storage Devices

Removing the Drive Cage

(continued)

Illustrated Parts

Catalog

Specifications

Unplug the cables to the CD

4

drive and hard drive

NEXT STEP

Page 37

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Jumper & Switch

Information

REMOVAL &

REPLACEMENT

Mass Storage Devices

Removing the Drive Cage

(continued)

Remove the four screws

5

holding the drive cage to the

chassis, then slide the cage

toward the rear of the chassis

and lift out.

Illustrated Parts

Catalog

Specifications

END OF SEQUENCE

To replace the drive cage, reverse

this sequence.

Return to mass storage devices

index page

Page 38

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Drive cage

Diskette Drive

Hard drive

CD drive

Expansion bay

Mass storage

devices index

page

l

REMOVAL & REPLACEMENT

Mass Storage Devices

Hard Drive

There are seven steps in this

sequence.

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the drive cage from

the chassis.

4

Remove the CD drive.

5

Remove the two screws holding

the hard drive to the left side

of the cage.

NEXT STEP

Page 39

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

REMOVAL & REPLACEMENT

Mass Storage Devices

Hard Drive, continued

6

Remove the recessed third screw, using an

8" magnetic Philips screwdriver.

7

Slide the drive out of the cage.

END OF SEQUENCE

To replace the hard drive, reverse this sequence.

Page 40

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Drive cage

Diskette drive

Hard drive

CD drive

Expansion bay

Mass storage

devices index

page

l

REMOVAL & REPLACEMENT

Mass Storage Devices

CD Drive

NOTE

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the drive cage from

the chassis.

Click

to remove a CD that

has jammed in the

drive.

here to see how

4

Remove the two screws

holding the CD drive in place,

then slide the drive out from

the front.

To replace the CD drive, reverse this

sequence.

END OF SEQUENCE

Page 41

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Drive cage

Diskette drive

Hard drive

CD drive

Expansion bay

Mass storage

devices index

page

l

REMOVAL & REPLACEMENT

Mass Storage Devices

Expansion Bay Cover

The expansion bay is used to hold extra drives, such as a Zip drive or an additional hard

drive.

Jumper & Switch

Information

Illustrated Parts

Catalog

Specifications

There are five

steps in this

sequence.

Perform

1

preparation

procedures.

Remove the

2

hood.

Remove the

3

drive cage.

Pull out the

4

plastic bay

cover.

NEXT

STEP

Page 42

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement

Home Troubleshooting

Jumper & Switch

Information

REMOVAL &

REPLACEMENT

Mass Storage Devices

Expansion Bay Cover

Pry out the metal bay cover

5

with a standard screwdriver

and discard it.

Illustrated Parts

Catalog

Specifications

END OF SEQUENCE

Return to index page

Page 43

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

Mass storage

devices

REMOVAL & REPLACEMENT

Power Supply

1

Perform preparation

procedures.

2

Remove the hood.

3

Unplug all cables attached to

the power supply.

4

Remove the two screws that

secure the power supply to the

rear of the chassis.

NOTE

Your power supply

may look different

from the one

shown.

Power supply

System board

components

l

5

Slide the power supply back

and remove from the chassis.

END OF SEQUENCE

To replace the power supply, reverse

this sequence.

Page 44

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

DISASSEMBLY

SEQUENCE

Preliminary

considerations

Hood

Button board

Front bezel

Speakers

Fax-modem

NIC card

Riser card

REMOVAL & REPLACEMENT

System Board Components - Index Page

● I/O panel

● Processor and heatsink

● Memory module

● RTC battery

● System board

Mass storage

devices

Power supply

System board

components

Page 45

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

I-O panel

Processor

Memory

module

Battery

System

board

System

board

components

index page

l

REMOVAL & REPLACEMENT

System Board Components

I/O Panel

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the fax-modem.

4

Remove the NIC (if present).

5

Remove the riser card.

6

Remove the system board.

7

Remove the eight screws

holding the I/O panel to the

chassis.

8

Gently push the I/O panel into

the chassis and lift out.

To replace the I/O panel, reverse this

sequence.

Page 46

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

I-O panel

Processor

Memory

module

Battery

System

board

System

board

components

index page

l

REMOVAL & REPLACEMENT

System Board Components

Processor and heatsink

1

Perform preparation procedures.

2

Remove the hood.

3

Remove the clip

.

4

Lift the heat sink

NOTE

The processor may come

out directly with the heat

sink.

from the heat sink

from the processor.

5

Raise the ZIF socket lever

processor out of the socket.

To reinstall the processor, rub a thermal

transfer crayon on the bottom of the

heatsink, then reverse the steps above.

(The thermal transfer crayon replaces the

thermal pad used with earlier processors.)

and lift the

Page 47

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

I-O panel

Processor

Memory

module

Battery

System

board

System

board

components

index page

l

REMOVAL & REPLACEMENT

System Board Components

Memory Module (DIMM)

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the modem or NIC

card

4

Release the end latches of the

socket

DIMM from the system board

.

and unplug the

To replace the DIMM, reverse this

sequence.

Page 48

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

I-O panel

Processor

Memory

module

Battery

System

board

System

board

components

index page

REMOVAL & REPLACEMENT

System Board Components

Battery

1

Perform preparation procedures.

2

Remove the hood.

3

Push out the battery socket latch and

lift the RTC battery out of the socket.

To replace the RTC battery, reverse this

sequence.

l

WARNING: The clock/CMOS

lithium battery may explode

if mistreated. Do not abuse.

Use only replacement

batteries supplied by Compaq

Computer Corporation.

Page 49

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

I-O panel

Processor

Memory

module

Battery

System

board

System

board

components

index page

l

REMOVAL & REPLACEMENT

System Board Components

System Board

There are ten steps in this sequence.

1

Perform preparation

procedures.

2

Remove the hood.

3

Remove the fax-modem.

4

Remove the NIC card (if

present).

5

Remove the riser card.

6

Remove the drive cage.

7

Disconnect the

cable from J27.

8

If there are internal speakers,

disconnect the speaker cables

from J25 and J26.

button board

9

Disconnect the power, CD &

hard drive, and CD audio

cables.

NEXT STEP

Page 50

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

REMOVAL & REPLACEMENT

System Board Components

System Board (continued)

10

Remove the four screws holding the system

board to the chassis, then slide the board away

from the I/O panel and lift it off the chassis.

END OF SEQUENCE

To replace the system board, reverse this sequence.

NOTE

The system board spare part kit does not

include the processor or DIMM. These

components must be transferred from the

old system board to the new system

board.

Page 51

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

ILLUSTRATED PARTS CATALOG - INDEX PAGE

NOTE:

System unit

Mass storage devices

Cables

Processors & boards

Keyboards

The computer

requesting information or ordering spare parts.

serial number should be provided to Compaq whenever

Monitors

Miscellaneous parts

Return kits

Documentation & software

Page 52

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

System Unit

To see the description and spare part number for an item, place your cursor over the item and leave

it there briefly.

l

Page 53

Maintenance and Service Guide

Hard drives:

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

l

ILLUSTRATED PARTS CATALOG

Mass Storage Devices

To see the description and spare part number for an item, place your cursor over the item and

leave it there briefly.

[FrontPage Save Results

Component]

Page 54

Maintenance and Service Guide

Asia/Pacific 137256-001

Australia 285811-001

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Cables

To see the description and spare part number for an item, place your cursor over the item and leave

it there briefly.

l

Page 55

Maintenance and Service Guide

100 MHz SDRAM DIMM:

56-DF V.90 fax-modems:

System boards:

Processors (heat sink and clip spared separately):

Riser Cards:

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Processors & Boards

To see the description and spare part number for an item, place your cursor over the item

and leave it there briefly, or use the drop-down menu provided below some of the items.

[FrontPage Save Results Component]

l

[FrontPage Save Results Component]

[FrontPage Save Results Component]

[FrontPage Save Results Component]

Page 56

Maintenance and Service Guide

Easy Access Internet Keyboards:

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Keyboards

To see the description and spare part number for an item, place your cursor over the

item and leave it there briefly.

Page 57

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

l

ILLUSTRATED PARTS CATALOG

Monitors

Description Spare Part

Number

Compaq Presario MV

monitors

MV400

North America

Northern Hemisphere

Southern Hemisphere

326902-001

326902-022

326902-B34

MV500

Northern Hemisphere

TCO95

Southern Hemisphere

340707-001

340707-026

340707-B34

MV700

Northern Hemisphere

EMEA

Southern Hemisphere

340708-001

340708-026

340708-B34

Attachable speakers (not

320426-001

shown)

Monitor audio cable (not

268244-001

shown)

Page 58

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Miscellaneous Parts

Description Spare Part Number

Mouse 337416-001

Mouse with Scroll 334689-001

Internal speakers for

educational units 337377-001

SPS Battery 234556-001

RTC battery 337356-001

Heatsink, clip, and

thermal crayon

Miscellaneous

hardware/plastics kit 337368-001

337369-001

l

Page 59

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Return Kits

Description Spare Part Number

Return kit for 2200, 2400 Series computers 337376-001

Carton and buns (international) for above models 337376-002

Return kit with packing, Compaq Presario MV400 monitor 341082-001

Return kit with packing, Compaq Presario MV500 monitor 341083-001

Return kit with packing, Compaq Presario MV700 monitor 341084-001

l

Page 60

Maintenance and Service Guide

Asia (English) 337383-371

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

System unit

Mass storage

devices

Cables

Processors &

boards

Keyboards

Monitors

Miscellaneous

Return kits

Documentation

& software

ILLUSTRATED PARTS CATALOG

Documentation & Software

Description Spare Part Number

Manual Kit 319172-002

QuickRestore Kit (click on the box for a list)

Quick Reference Guide (1 each) 162212-001

Quick Reference Guide (5 pack) 106854-001

Quick Reference Guide (1 each, quarterly subscription) 184960-001

Quick Reference Guide (5 pack, quarterly subscription) 184961-001

QuickFind for North America, Latin America, Asia/Pacific 137906-xxx**

QuickFind for Europe, Middle East, Africa 137907-xxx**

l

**QuickFind is updated monthly. To complete the QuickFind part number, add the suffix from the table below for the

desired month. If you do not specify the 3-digit suffix, the default is the month in which the order is placed.

Suffix Month Suffix Month Suffix Month Suffix Month

-001 January -004 April -007 July -010 October

-002 February -005 May -008 August -011 November

-003 March -006 June -009 September -012 December

Page 61

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

TROUBLESHOOTING - INDEX PAGE

Clearing CMOS

Power-On Self Test (POST)

Setup and Compaq Utilities

Preparing the computer

Setup

Compaq Utilities options

Computer checkup (TEST)

View system information (INSPECT)

Diagnostic error codes

Troubleshooting without diagnostics

Checklist for minor problems

Hardware installation

Power

USB

Monitor

Diskette drive

Hard drive

CD drive

DVD drive

Resolving hardware conflicts

Page 62

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Clearing

CMOS

Power-On Self

Test (POST)

Setup and

Compaq

Utilities

Diagnostic error

codes

Troubleshooting

without

diagnostics

l

TROUBLESHOOTING

Clearing CMOS

If the power-on password is unknown, clearing CMOS will disable the password and allow the computer

to be operated.

1

Complete the

for disassembly

procedures.

2

Remove the hood.

3

To clear CMOS and disable

the password, move the

jumper at J17 from pins 12 to pins 2-3 for 10

seconds, then return to

pins 1-2.

preparation

Page 63

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Clearing CMOS

Power-On

Self Test

(POST)

Setup and

Compaq

Utilities

Diagnostic error

codes

Troubleshooting

without

diagnostics

l

TROUBLESHOOTING

Power-On Self Test (POST)

POST is a series of diagnostic tests that run automatically when the system is turned on. After the

computer is turned on, POST checks the following assemblies to ensure that the computer system is

properly functioning:

■ Keyboard

■ System board

■ Memory modules

■ Video memory

■ Diskette drives

■ Hard drive

■ Power supply

POST also detects the type of mass storage devices installed in the computer.

If POST finds an error in the system, an error condition is indicated by an audible and/or visual

message. The table below gives explanations of the error codes and a recommended course of action.

NOTE

If your model doesn't have internal speakers, an external speaker must

be plugged into the speaker output connector to hear any beeps during

POST.

Click a link below to find the probable cause and recommended action for a given error message.

IMPORTANT

Retest the system after completing each step. If the problem has

been resolved, do not proceed with the remaining steps.

Diskette Drive A or B Error Keyboard Controller Error System BIOS Shadowed

Extended RAM failed at

offset nnn

Keyboard Error System Cache Error

Failing Bits nnn Operating System Not

Found

System CMOS Checksum Bad

Fixed Disk 0 or 1 Failure Parity Check 1 System RAM Failed at Offset, nnn

Fixed Disk Controller Failure Parity Check 2 System Timer Error

Incorrect Drive A Type Real Time Clock Error UMB Upper Limit Segment

Invalid NVRAM Media Type System Battery is Dead Video BIOS Shadowed

Address nnn

POST Messages

Error message Probable Cause Recommended Action

Diskette Drive A or

B Error

Extended RAM

failed at offset nnn

Failing Bits nnn nnn is a map of the bits at the RAM

Drive A: or B: is present, but fails the

BIOS POST diskette tests

Extended memory not working or not

configured properly

address which failed the memory test

1. Run

2. Replace the signal cables.

3. Replace the drive.

1. Replace the memory modules.

2. Replace the

1. Run Setup.

2. Replace the

Setup.

system board.

system board.

Fixed Disk 0 or 1

Failure

Fixed Disk

Controller Failure

Hard drive is not working or not

configured properly

Hard drive is not working or not

configured properly

1. Run Setup.

2. Replace the signal cable.

3. Replace the

1. Run Setup.

2. Replace the

hard drive.

system board.

Incorrect Drive A

Type

Type of diskette in drive A: not

correctly identified

1. Run Setup.

2. Replace the

diskette drive.

Invalid NVRAM

Media Type

Keyboard Controller

Error

Problem with NVRAM (CMOS) access Replace the system board.

Keyboard, I/O keyboard controller (on

system board), or mouse error

1. Replace the keyboard.

2. Replace the mouse.

3. Replace the

system board.

Keyboard Error Keyboard, I/O keyboard controller (on

Operating System

Not Found

Parity Check 1 Parity error found in the system bus 1. Run

system board), or mouse error

Operating system cannot be located on

either drive A: or C:

Parity Check 2 Parity error found in the I/O bus 1. Run Setup.

1. Replace the keyboard.

2. Replace the mouse.

3. Replace the system board.

Run Setup.

Setup.

2. Replace the

3. Replace the

2. Replace the

memory modules.

system board.

ISA board (modem).

Real Time Clock

Error

Real-time clock fails BIOS test Replace the system board.

System Battery is

Dead

System BIOS

Shadowed

System Cache Error RAM cache failed the BIOS test Run

System CMOS

Checksum Bad

System RAM Failed

at Offset, nnn

System Timer Error DMA, timers, etc. Replace the

UMB Upper Limit

Segment Address

nnn

RTC battery is dead 1. Replace the

2. Run

System BIOS copied to Shadow RAM Status message. No action required.

CMOS is corrupted or modified

incorrectly

System RAM failed Replace

Displays the address nnn of the upper

limit of Upper Memory Blocks,

indicating released segments of the

BIOS

Run Setup.

Status message. No action required.

Setup.

Setup.

memory modules.

RTC battery.

system board.

Video BIOS

Shadowed

Video BIOS successfully copied to

shadow RAM

Status message. No action required.

Page 64

Maintenance and Service Guide

Compaq 2200 and 2400 Series Computers

MSG Index Product Description Removal & Replacement Illustrated Parts Catalog

Home Troubleshooting Jumper & Switch Information Specifications

Clearing CMOS

Power-On Self

Test (POST)

Setup and

Compaq

Utilities

Diagnostic error

codes

Troubleshooting

without

diagnostics

l

TROUBLESHOOTING

Setup and Compaq Utilities

This section explains how to use Setup and Compaq Utilities which should be accessed in

the following instances:

■ When a system configuration error is detected during the Power-On Self-Test

(POST)

■ To change factory default settings for some of the computer features

■ To change the system configuration, which is sometimes necessary when you add

or remove optional hardware

■ To set system configuration features

Click a link below to go to the appropriate subsection:

● Preparing the Computer

● Setup

● Compaq Utilities Options

● Computer Checkup (TEST)

● View System Information (INSPECT)

Preparing the Computer

If you encounter an error condition, complete these steps before starting problem isolation procedures:

1

Ensure proper ventilation. The computer should have a 3-inch (7.6 cm) clearance

at the back of the system unit.

2

Turn off the computer and peripheral devices.

CAUTION: Always ensure that the power is off before

disconnecting or reconnecting the mouse, keyboard, or any other

peripheral devices. Disconnecting or connecting the keyboard or

mouse while the unit power is on can damage the system board.

3

Disconnect any peripheral devices other than the monitor and keyboard. Do not

disconnect the printer if you want to test it or use it to log error messages.

4

Install loop-back and terminating plugs for complete testing.

Go back to the top.

Setup

The Setup utility gives a snapshot of the computer's hardware configuration, aids in troubleshooting,

and sets custom features. Setup recognizes a new internal component or an external device and

automatically updates the configuration screens. Use the Setup utility to:

■ Modify settings for audio, storage, power management, communications, and

input devices

■ Get an overall picture of the computer's hardware configuration

■ Verify configuration parameters in determining problems

■ Set time and date

Running Setup

To access the Setup utility, turn on the computer and press the F10 key when the block cursor

appears in the upper-right corner of the screen. The following menu will appear:

NOTE

The actual menu displayed on your computer may