Page 1

Companion"

ClearStar™

For

Use

With

REF

M771

Enteral

For

Enteral

Notfor

Pump

SERVICE

MANUAL

Use

Only

Parenteral

Use

62-115.0550.02

(10/2000)

[1]

—İ

(4)

*

COMPANION”

Rea

MO

non

sm

^

RUN

værne

BE

Page 2

TABLE

OF

CONTENTS

Section

1.1-

Indications

1.2-

Precautions

1.3-

1.6-

Scope

1.4-

About

1.5-

User

Warnings,

1.7-

Instrument

1.7.1-

1.7.2-

1.7.3-

Section

Section

1-

Introduction

ForUse

...............

.....

.....

This

Manual

Gualifications

Cautions,

Installation

Unpacking,

Li

..........

and

Procedure

Inspection

Pump

Operational

2-

Specifications

3-

Theory

Test

of

Operation

ーー

Notes

......

ーー

ne

....

.....

.

.................

o

ーーーーー

k

PN

Li .

Lies

Lili

Lil

이

анна

.

-

-

11

12

1213

13

„134

1-4

21,2

3-1

3.1-

General

3.2-

Charger

3.2.1-

3.2.2-

3.2.3-

3.2.44.

3.2.5-

3.3-Pump

3.3.1-

3.3.2-

3.3

3.3.4-

33.5-

General

AC

Switching

Output

Control

Controller

Reference

Battery

3+

Low

Controller

Memory

33 6 Motor

3.3.7.

3.3.8-

3.39.

3.3.10-

TDC/BDC

Motor

Clog

Fluid

ων

Power

κκ κκ ων

Board

ον

.............

-

o

-

. = .

Input/Rectification

Converter

Rectifier

Circuits

Board

Voltages/Supplies

Stage

and

Filter

Operation

0

...

........

ーー

ーー

M-

. .

Battery/Shutdown

„=

ーー

Driver & Speed

Position

Runaway

Clearing,

Empty

Detection

Occlusion,

Detection

Control

Detection

de

Motor

....

&

Cassette

ーー

. .

Brake

Not

Present

ーー

トーー

、

ーー

ーー

..

…

.....

s.

Detector...

di

Less

-

ーー

A

32

3-2

33

e

34

e

3-5

0

3-6

37

E]

3-8

3-8/9

3

3-9/10

-

3-10711

32

Companion”

Clear

Star”

Enteral

Nutrition

Pump

i

62-HF-0550.02

{Rex.1012000)

Page 3

TABLE

OF

CONTENTS

3.3.11-

3.3.12-

3.3.13-

3.3.14-

3.4-

Pump

Section

4.1-

Equipment

4.1.1-

4.1.2-

4.1.3-

4.2-

Preventative

42.1-

4.2.2-

42.3-Labels

4.3-

Performance

43.1-

4.3.2-

43.3-

43.4-

43.5

4.3.6-

43.7-

43.8.

43.9-

4.3.10-

43.11-

4.3.12-

Beeper

Backlight

Touchpanel

Control

Display

4-

Tools

Test

Consumables

Inspecting

Cleaning

Setup

Power

AC/Battery

Touchpanel

Inactivity

Cassette

Empty

Clog

Distal

Audible

Occlusion

Delivery

Controller

Driver

Keypad

Dial

Board

Maintenance

Required

Required

Equipment & Materials

Maintenance

The

Fxterior

and

Sanitizing

、

Verification

...,

On

Sell-Test

Power

Keypad

Alarm

Not

Present

Alarm

Clearing

Occlusion

Mode

Alarm

Bvent

Accuracy

.....

Li Li

ーー

Tests

...

..

..

....

Alarm.

-

.......

Alarm

Volume

Recorder

이니

.

Lee

Required

ーーー

ーー

............

ーー

.

ーー

.

G

Li

ーー

ーー

o

russes

ーー

ーー

de

di

.

…

ο...

.

ーーー

ーーー

ーー

…

-

-

ーー

-

Li

„311

311012

…

.

a

=

114-718

3-11

3-12

3-12

44

41

41

4-1

42

42

42

43

44

44

44

da

4-5

45

AS

46

46

47

47

4-89

4.4-

Electrical

4.4.1-

4.4.2-

4.4.3-

Companion”

Leakage

Ground

Dielectric

ClearStar”

Safety

Freel

Tests

Current

Impedance

Withstand

Nutrition

Pup

....................

....

ーー

Test

de

i

ーー

ーー

ーー

.

62-HF-0550.02

-

49

4-10

ATO

410/11

(Rev.

1077000)

Page 4

TABLE

OF

CONTENTS

Section

5.1-

Technical

5.2-

Diagnostic

5.3-

Self

Test

5.4-

Alert

5.5.

Miscellaneous

Section

6.1-

Disassembly

6.1.1-

6.2-

Pump

6,2,1-

6.2.2-

6.23-

6.2.4-

6.2.5-

6.2.6-

6.2.7-

6.2.8-

6.2.9-

6.2.10-

6.2.11-

Problems

6-

General

Disassembly

Removing

Remove

Removing

Remove

Removing

Removing

Removing

Removing

Removing

Removing

Removing

5-

TROUBLESHOOTING

Assistance

Mode

Problems

DISASSEMBLY

INSTRUCTIONS

Recorder

........

Problems

and

Recalibration

....

Procedure

Battery

Battery

Control

Back

Piezo

Battery

Drive

Reed

Access

(Item

Knob

Case

Subassermbly

Buzzer

Clip

Main

PC

Board

System

Switch

Piston &

Front

Touchpanel

GUIDE

.......................................

.................

..

HERE

.........

AND

.....

.

ον

RECALIBRATION

Instructions

mr

=

.

ーー

.

-

eee

a

ーー

.

Door,

(Item

3)

ren

4) .....

Assembly

Subassembly

Assembly

Assembly

(items

Bracket

Cap

Assembly

(Item

27)

(Item

5)

(Item

(Item

8)

(Item

12-19)

Assembly

.

(Item

(Item

14)

Overlay

..........

6)

ーーー

9)

18)

de

.

5-1

5-1

51,23

-

.

5-4/5/6/718

ーーー・

..

5-3/4

5-89

6-1

61

61

6-1

6-2

62

TE

62

63

......63

63

.e

63

..64

64

61

8,3-

Charger

6.3.1-

Removing

Removing

6.3.2-

Remove

Removing

6.3.3-

6.3.4-

6.3.5-

6,3.6-

Companion”

Removing

Removing

Removing

Removing

ClearStar”

Disassembly

Rear

Rear

Switching

Switching

Power

Appliance

Pole

DC

Enteral

Nutrtia Pemp

Procedure

Cover

Cover

(item

(Item

Power

Power

Cord

(Item

Outlet

Clamp

Power

(Item

Connector Subassembly

.............

5) - Domestic

........

5) - International

Supply

Board

Supply

(Item

Board

(Item

1) - Domestic

Assembly

(Item

2) - International

6) - Domestic

6) - international

-

14-19)

(Item

10) 6-6

ir

ーーーーーーー

ーー

ーー

...........

ーー

52HFO550.02

6-4/5

....

(Rev.

1012000)

84

65

65

65

65

656

66

Page 5

6.4-

Recalibration

6.4.1-

$

42:

6.4.3-

Optics

6.4.4-

6.4.5-

6.4.6-

TOC/BDC

Default

Power

TABLE

..........................

General

Distal

Oeclusion

6.4.2.1-

6.4.2.2-

Recalibration

Recalibration

. -

Position

Value

Supply

Calibration

(Charger)

OF

Detector

Detector

—

using

No

using

Standard

Mode

CONTENTS

eee

ーー

Standard

Pumps

Pumps

ーー

ーー

Qe

ーー

ーー

ーー

ーー

o

66

67

6-718/9/10

.

6718/9

6-9/10/11/12

6-12/13

6-13/14/15

を

13716

61617

Section

7.1-

Label

7.11.

7.1.2-

7.1.3-

7.1.4-

71.5-

7.1.6-

7.1.7-

Figure

Figure

Figure

7.2-

Exploded

Figure

7-

Parts

Electrical

Placement

Parts

List - Canada

Parts

List - German

Parts

List - Spanish

Parts

List - Australia

Parts

List - Europe

Paris

List - Ttalian

Parts

List - U.K.

7-1-

Pump

7-2-

Domestic

7-3-

International

7-4-

Pump

-

Domestic

-

International

Label

Backpack

Mechanical

Exploded

Backpack

List,

(Code

Mechanical

Schematic

(Code

(Code

(Code

(Code

(Code

Placement...

Backpack

Views

Backpack

13)

15)

22)

(Code

View

27)

36)

42)

54)

Label

Label

Exploded

Exploded

...

Placement

...........

Drawings

......................

이이

....

.........

........

Placement

Li

ーー

View

View

..

and

a

ーー nu

-

ーー

ーー

ーー

ーー

ーー

-

es

m

ーーーーー

.

........

oo.

7-7

74

TA

71

Bl

72

„12

22

73

73

74

75

76

thru

12

7-8

7-10

TAZ

7.3-Electronics

i

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Companion”

7-9-

7-10-

7-11-

7-12-

7-13-

7-14-

7-15-

7-16-

Ciearstar”

............

-

Electrical

-

Main

Board

Main

Board

Main

Board

Domestic

Domestic

Intemational

International

Power

Powor

Fora

Supply

Nutrition

Block

Supply

Diagram

Assembly

Lilectsical

Electrical

Display

Display

Display

Display

Board

Board

Pump

Schematic

Board

Board

Board

Board

Assembly

Electrical

de

ーー

(Digital)

Schematic

Assembly

Electrical

(Analog)

Schematic

Assembly

Electrical

........

Schematic

ーーー

o

......

Schematic

W

.......

.

62-HF.0560.02

1021...

-=

ーー

7-13

ーーーーー

thru

7-14

7-15

„7.16

7-17

a

7-19

7-20

7-21

T

(ev.

10/2000)

23

テ

3

Page 6

Section

1

INTRODUCTION

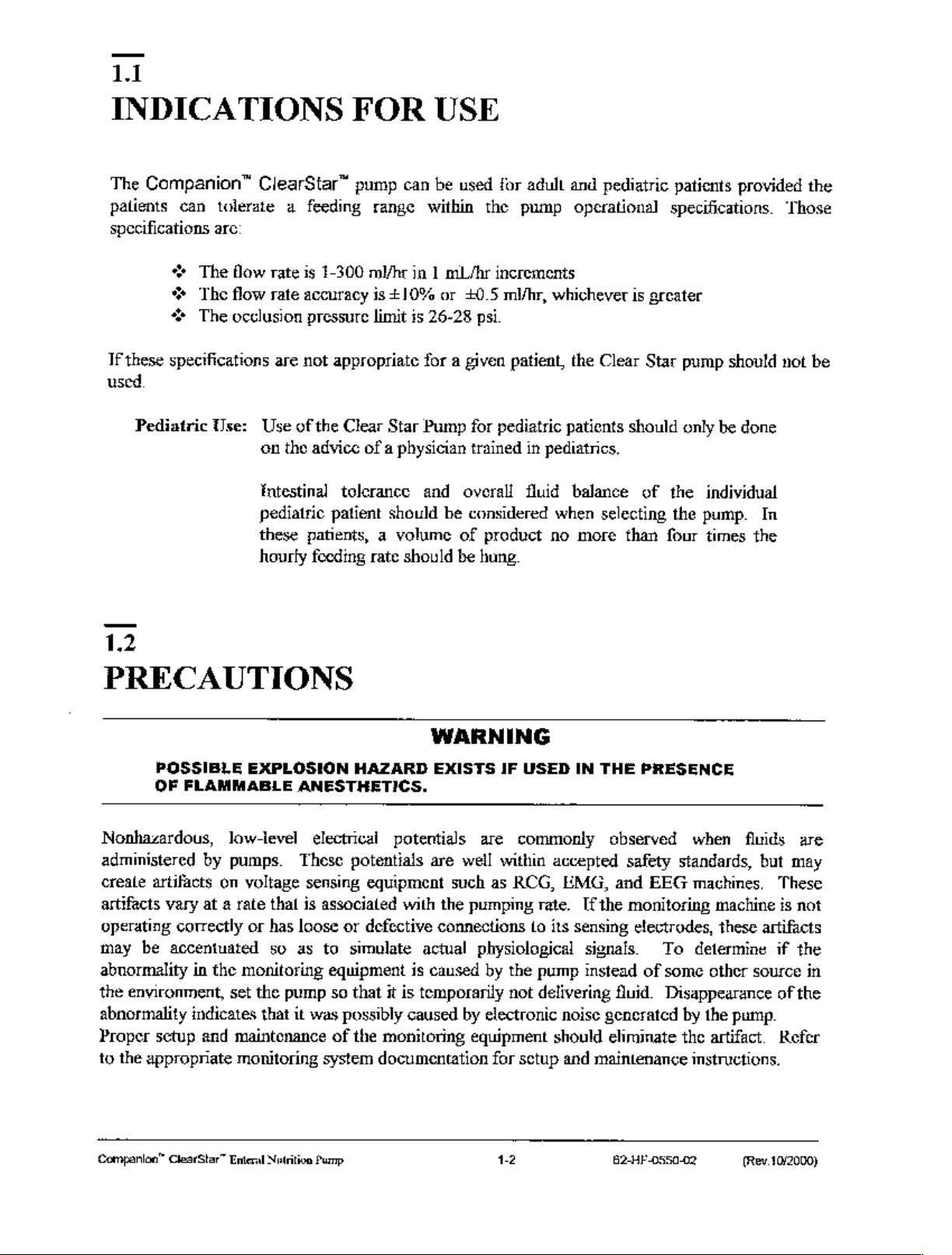

This

manual

Companion”

and

understood

The

Companion”

infusion

controls.

safety

1V

alarms

pole),

bellows

was

prepared

ClearStar™

before

pump

The

which

pump

function

The

pump

to

deliver

for

servicing

ClearStar™

provides

will

operate

when

utilizes

measured amounts

use

as a reference

Enteral

Nutrition

the device.

Enteral

accurate

on

AC power

the

pump

a

specially

is

used

designed

of

enteral

document

Pump.

Nutrition

delivery

by an

tt is

important

Pump

rates,

or

battery

ambulatory

administration

fluid.

for

personnel

is a microprocessor

casy-to-read

(i.e.:

the

patient

set,

who

will

service

that

this

manual

controlled

displays,

fluid

delivery

or

is

including

and

system

mounted

a

cassette

be

the

read

simple

and

on

an

with

CAUTION:

(standard

mixed

products,

into

solutions).

This

pump

infant

is

designed

formula,

to

or

reconstituted

deliver

only

powder

liquid

enteral

that

feeding

has

been

product

thoroughly

Figure

Companion”

ClearStar™

1-1,

Companion™

Entasl

Nuvition

Pump

ClearStar™

ta

Enteral

Nutrition

62-HF-0560.02

Pump

‘Rev.

1072000)

Page 7

11

INDICATIONS

The

Companion”

patients

specifications

TF these

can

The

The

+

The

specifications

used.

Pediatric

Use:

ClearStar”

tolerate a feeding

are

flow

flow

occlusion

Use

on

Intestinal

pediatric

these

hourly

FOR

rate

is

1-300

rate

accuracy

pressure

are

not

appropriate

of

the

Clear

the

advice

tolerance

patient

patients,

feeding

USE

pump

can

be

used

range

m¥/hr

is

limit

within

in 1 mL/hr

+10%

is

26-28

or

the

increments

+0.5

psi.

for a given

Star

Pump

of a physician

for

pediatric

trained

and overall

should

a

volume

rate

be

considered

of

should

be

hung.

product

for

adult

and

pump

ml/hr,

patient,

operational

whichever

the

Clear

patients

in

pediatrics,

fluid

balance

when

selecting

no

more

pediatric

patients

specifications.

is

greater

Star

pump

should

of

only

the

the

than

four

provided

should

be

done

the

Those

not

be

individual

pump.

times

In

the

12

PRECAUTIONS

POSSIBLE

OF

FLAMMABLE

Nonhazardous,

administered

create

artifacts

operating

may

abnormality

the

abnormality

Proper

to

artifacts

vary

correctly

be

accentuated

in

environment,

indicates

setup

the

appropriate

EXPLOSION

low-level

by

pumps.

on

voltage

at a rate

or

has

the

monitoring

set

the

that

and

maintenance

monitoring

HAZARD

ANESTHETICS.

electrical

These

thal

is

loose

so

as to

potentials

sensing

equipment

associated

or

defective

simulate

equipment

pump

so

that

it

was

possibly

of

the

system

WARNING

EXISTS

potentials

are

such

with

the

connections

actual

is

caused

it

is

temporarily

caused

monitoring

documentation

IF

USED

are

commonly

well

within

as

RCG,

pumping

rate.

Lo

physiological

by the

by

electronic

pump

not

delivering

equipment

for

sctup

IN

THE

PRESENCE

observed

accepted

EMG,

its

sensing

safety

and

EEG

[fthe

monitoring

electrodes,

signals.

instead

of

fluid.

noise

generated

should

eliminate

and

maintenance

when

standards,

machines.

To

determine

some

Disappearance

by the

the

fluids

machine

these

other

source

are

but

may

‘These

is

not

artifacts

if

the

in

of

the

pump.

artifact.

Refer

instructions.

Cempanioar

clearstar

Enteral

Norton

Pump

12

82-HF-0550-02

Rev.10:2000)

Page 8

All

enteral

consideration

more

than

This

pump

infant

‘Not

For

pumps

four

is

designed

formula,

Parenteral

have

in

feeding

times

or

reconstituted

Use

the

the

potential

volume-Sonsitive

hourly

feeding

to

deliver

only a liquid

powder

to

bolus-feed

patents.

rate

should

cnicral

product

that

or

overdelivor,

In

these

patients,

be

hung,

feeding

has

product:

been

thoroughly

which

a

standard

is

an

volume

of

product

liquid

mixed.

important

no

product,

Confirm

jejunostomy,

Verify

proper

gastrostomy,

the

following

A

Companion”

Cassette

When

Flow

uan

Pump

is

on

rate

dial

placement

before

properly

AC

power,

is

set

is

turned

13

SCOPE

The

material

performing

interpreting

Replacement

Recalibration

the

Companion”

contained

preventive

system

of

alarms, and

parts

Instructions.

ClearStar”

and

function

etc.).

initiating

ClearStar”

seated

at

the

to

in

maintenance,

Failure

to

feeding:

Pump

in

pump

pump

is

fully

seated

prescribed

mL/hr.

RUN

this

manual

is

periodic

troubleshooting

is

limited

Specific

to

those

instructions

Enteral

Nutrition

of

patient's

do

so

may

Sot

is

being

in

charger.

limited

to

testing

to

the level

parts

listed

for

operating

Pump

Operating

enteral

result

feeding

in

vomiting

used.

technical

functions,

in

information

various

of

subassembly

Section

this

product

Manual

tube

(nasogastric,

and/or

aspiration,

necessary

service

replacement.

6,

Disassembly

are

contained

for

tests,

and

in

14

ABOUT

The

purpose

Companion™

replaceable

information

Companion*

Clearsiar*

THIS

for

this

CiearStar™

components

on

operating

Enteral

MANUAL

Service

and

instructions.

Nutrition

Manual

Enteral

assemblies.

Pup

is

Feeding

Refor

to

provide

Pump,

troubleshooting

to

the

13

instructions

pump

necessary

alarms,

Operating

exnrossom

and

Manual

for

testing

replacing

for

{Rev.1012000)

the

field

detailed

Page 9

This

manual

is

organized

into

seven

sections

as

follows:

Section

Section

Section

Section

Section

Section

Section

I:

2:

3:

4:

5:

6:

7:

15

USER

The

Companion”

supervision

trained

in

QUALIFICATIONS

of

licensed

the

use

of

Introduction

Specifications

Theory

Maintenance

Troubleshooting

Disassembly

Parts

ClearStar™

physicians,

the

pump

of

Operation

and

and

List,

Drawings

Enteral

and

and

the

administration

Service

Guide

Recalibration

and

Nutrition

by

licensed

Tests

Instructions

Electrical

or

Schematics

Pump

certified

of

is

for

health

enteral

fluids

use

at

care

the

direction

professionals

of

who

are

or

SERVICE

BIOMEDICAL

TECRINICIANS

PERSONNEL.

DAMAGE,

ACTION

USER-SERVICEABLE

LISTED

INSTRUCTIONS

ENGINEERS

(BMET),

TO

DO

UNLESS

IN

SECTION

AVIOD

NOT

FULLY

ROSS

PERFORM

TRAINED

PARTS

6,

WARNING

ARE FOR

(BME),

OR

PERSONAL

ANY

AND

ARE

USE

BIOMEDICAL

ABBOTT

LIMITED

ONLY

INJURY

REPAIR

AUTHORIZED

BY

FIELD

OR

OR

TO

QUALIFIED

ELECTRONIC

SERVICE

INSTRUMENT

CORRECTIVE

TO

DO

THOSE

ITEMS

SO.

Companion”

CiearStar”

Emoral

Nuscicn

Pus

14

2HF.0650

02

(Rev.

102000)

Page 10

16

WARNINGS,

Throughout

and

notes.

CAUTION:

statement,

failure.

this

manual,

Pay

attention

A

WARNING

MUSF

WARNING

FATAL.

BE

A

CAUTION

It

contains

Neglecting

CAUTIONS,

three types

to

all

CONTAINS

OBSERVED

MESSAGES

information

a

CAUTION

of

alert

alert

messages.

WARNING

A

AT

ALI,

CAN

BE

message

that

message

messages

‘They

are

SPECIAL

TIMES.

DANGEROUS

usually

could

could

appears

prevent

result

AND

are

used.

described

SAFETY

FAILURE

irreversible

in

serious

NOTES

They

as

follows:

EMPHASIS

AND

POTENTIALLY

in

front

injury.

arc

TO

damage

warnings,

OBSERVE

of a procedure

cautions,

AND

or

hardware

or

NOTE;

A

NOTE

procedure.

17

INSTRUMENT

PROCEDURE

The

Instrument

pump

the

provided

operation

pump

has

below.

Installation

test.

not

been

message

highlights

INSTALLATION

Procedure

It is

recommended

damaged

during

information

consists

that

shipping.

of

three

these

steps

Procedures

that

helps

steps;

be

unpacking,

followed

for

performing

explain a concept

inspection,

in

order

to

ensure

thesc

or

and

that

steps

are

a

Companion”

CiearStar”

Estecal

Nutitan

Pump

15

62-HF-0550.02

(Rer102909

Page 11

1.7.1

UNPACKING

Use

care

when

for

returning

Center,

in

the

pump

event

unpacking

to

the

the

Ross

that

the

pump,

pump

Retain

Products

is

damaged

the

Division

packing

slip

Service

or

fails

the

operational

and

save

Center

or

Abbott

all

original

packing

International

self-test.

material

Service

NOTE:

installation

Product

damage

process.

172

INSPECTION

Inspect

to

overlay,

LABELS

contact

further

the

packing

be

damaged

LCD,

are

present.

the

Ross

instructions.

container

in

any

clamp

Products

173

PUMP

OPERATIONAL

may

occur

thoroughly

way. Verify

arm

assembly,

Should

Division

the

pump

that

power

Service

TEST

unless

or

proper

for

possible

there

is

no

cord,

backpack

Center

care

damage.

damage

etc,

Ensure

appear

or

Abbott

is

cxercised

Do

to

the

that

to

be

International

during

not

use

pump

all

WARNING

damaged,

the

unpacking

the

pump

or

backpack

&

or

labels

Service

and

if

it

appears

enclosure,

CAUTION

are

missing,

Center

for

NOTE:

The

on

greater

Tests).

outlet),

Do

not

following

all

pumps

level of

Test

1.

Rotate

Verify

а.

Verify

У

Y

Y

Y

Companion”

Clear Star”

place

in

service

procedure

to

ensure

detailed

is

to

the

pump

that

the

the

Numeric

IL

LCD

LOW

is

that

testing

be

performed

control

pump

following

digits

indicators

BATTERY,

Backlighting

Buzzer

(3

beeps).

Eales!

Nubiton

if

pump

the

minimal

the

unit

may

on

dial

goes

through a self-test

is

displayed

display

and

is

illuminated.

Pomp

fails

the

operational

recommended

has

not

been

be

performed,

batlery

from

power

POWER

on

the

(8888)

display

(RUN,

SELECT

RUN)

self-test

level

of

testing

damaged

per

(i.e.:

OFF

(CHARGE)

during

Section

power

sequence.

LCD:

ml/hx,

16

LOW

or

appropriate

that

should

shipping

4.3

(Performance

cord

not

plugged

to

the

SET

ALARM,

ICONs.

67-HF-055002

be

and handling. A

RATE

OCCL,

performed

Verification

into an

AC

position

EMPTY,

(Rcv.1072000)

Page 12

b.

Verify

Y

Y

+

©.

When

LCD:

+

У

У

2,

Depress

a.

Verify

3.

Depress

a.

Verify

4.

Depress

a.

Verify

proper

“rATE”

“LOSE”

“Ed”

self test

Set

Rate

“BATTERY”

Backlighting

the

the

and

that the Set

and

that

memory

and

Set

Rate

and

Set

Dose

and

Volume

is

completed,

“value”

backlight

and

is

OFF.

keypad.

backlighting

hold

the

increment

Rate

hold

the

decrement

the

Set

Rate

retention.

The

LCD

“value”

“value”

Fed

“value”

verify

the

following

“mit?”

illuminates

(

“value”

“value”

for

approximately

+)

keypad.

increments

(

+)

keypad.

decrements

displays

the

following

information

15

seconds

(scrolls

(scrolls

@ 3 speeds).

@ 3 speeds).

information:

is

displayed

on

the

NOTE:

recommended

into

The

lead-acid

that the

service.

battery

battery

may

be

charged

not be

fully

for a minimum

charged

upon

of 8 hours

receipt.

before

Therefore,

pump

it

is

placed

is

Companion”

ClearStar”

Enteral

Notrton Pump

1

82-HF.0550.02

(Rev.10/2000)

Page 13

Section

2

SPECLFICATIONS

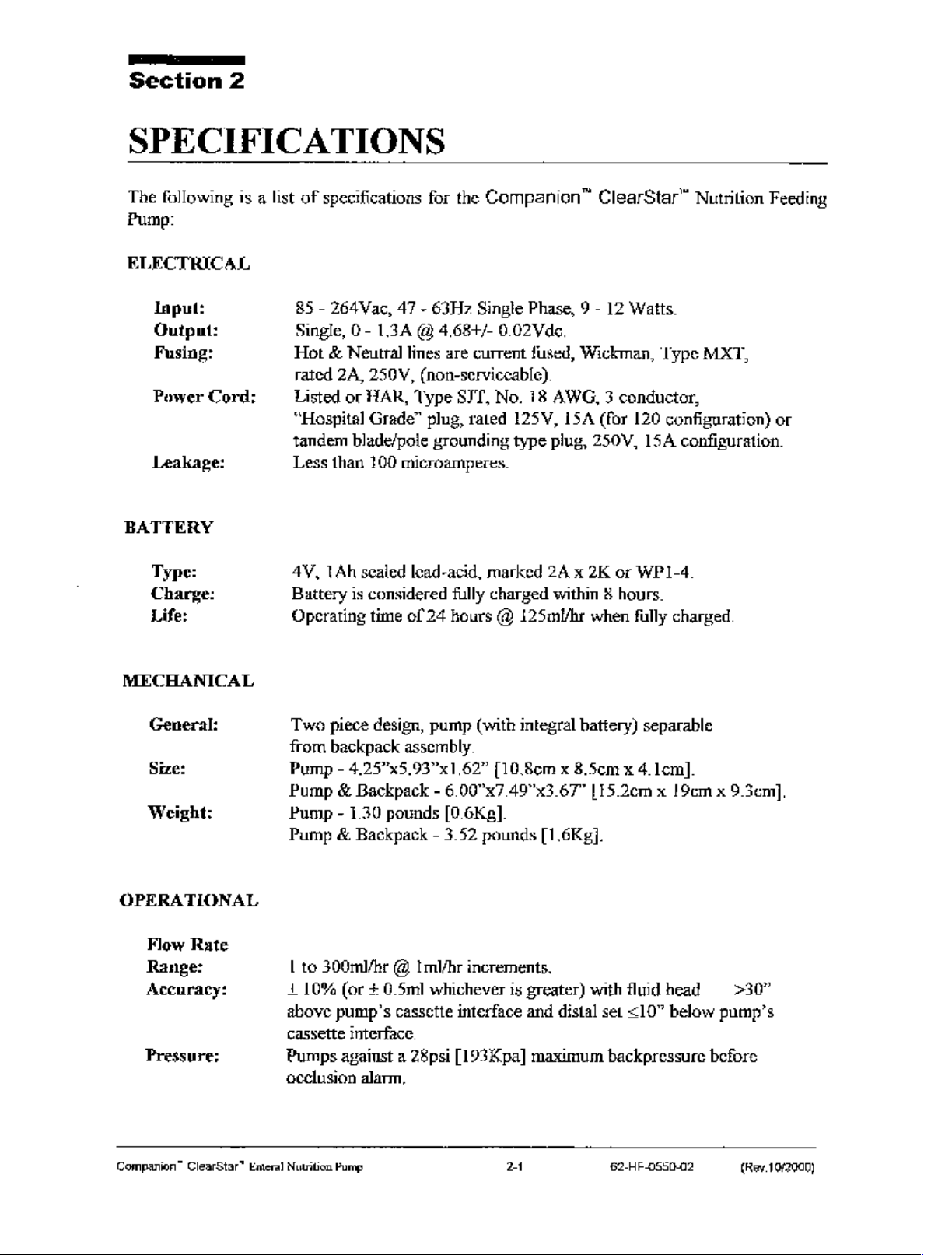

The

following

Pump:

ELECTRICAL

is a list

of

specifications

for

the

Companion™

ClearStar™

Nutrition

Feeding

Input:

Output:

Fusing:

Power

Cord:

Leakage:

BATTERY

Type:

Charge:

Life:

MECHANICAL

General:

Size:

Weight:

85 - 264Vac,

Single,

Hot

ge

Neutral

rated

2A,

Listed

or

“Hospital

tandem

Less

than

AY,

TAh

Buttery

Operating

Two

piece

from

backpack

Pump - 4.25"x5.93"x1,62"

Pump & Backpack - 6.00"x7.49"x3.67"

Pump - 1.30

Pump & Backpack - 3.52

47 - 63Hz

0 - 1.3A @ 4,68+/-

lines

250V,

HAR,

Grade”

(non-scrviceable).

‘Type

plug,

blade/pole

100

microamperes.

sealed

is

lead-acid,

considered

time

of

24

design,

pump

Single

Phase, 9 -

0.02Vde.

are

current

SIT,

rated

grounding

fully

hours @ 125ml/hr

(with

fused,

No.

18

125V,

type

marked

charged

integral

assembly.

[10.80m x 8.5cm x 4.1cm]

pounds

[0.6Kg]

pounds

12

Watts.

Wickman,

‘ype

AWG, 3 conductor,

15A

(for

120

configuration)

plug,

250V,

24 x 2K

ISA

or

WP1-4

within 8 hours,

when

fully

battery)

separable

115.20m x 19cm x 9.3cm]

[1.6K].

MXT,

or

configuration.

charged.

OPERATIONAL

Flow

Rate

Range:

Accuracy:

Pressure:

Companion”

ClearStar”

1

to

300m/hr @ 1m/hr

1

10%

above

cassette

Pumps

occlusion

Enteral

Nutrition

(or + 0.Sml

pump's

interface.

against

whichever

cassette

a

28psi

alarm,

Pump

increments,

is

greater)

interface

[193Kpa]

and

distal

maximum

24

with

fluid

head

set

<10”

below

backpressure

名

hrFoss0g2

pamp’s

before

>30”

(Rev

1042000)

Page 14

ENVIRONMENT

Temperatures

Hu

REGULATORY

n

Oto

110

60

to

deg F [-17.8

90

deg F [15.6

to

43

to

32.2

deg.C] @ 15

to

deg.C] @ 30

90%RH

to

90%RH

(storage)

(operating)

Standards:

Classification:

Designed

TEC601-1,

Class 1 (type

‘Type

Drip

and

CSA

BF

(degree

Proof

(IPX1).

mannfactured

22.2

No.601.1,

of

protection

of

protection

to

meet

18C601-1-2,

against

against

requirements

electrical

electrical

of

UL2601-1,

and

TEC601-1-4」

shock).

shock).

Companion

ClearStar™

intera!

Nutrition

Pump

22

62.HF-0550-02

‘Rev.

10/2000)

Page 15

Section

3

THEORY

This

section

Nutrition

describes

Pump.

D

OF

the

‘The

theory

General

i

Charger

31

GENERAL

The

Companion”

rotor/silicone

containing

disposable

contacting

tubing

a

comprossible

cassetle

the

administration

microcontroller.

conditions,

and a rechargeable

ClearStar”

combinations

is

inserted

reciprocating

of

enteral

The

pump

OPERATION

theory

of

Power

membrane

feedings,

also

of

operation

operation

details

Board

Enteral

and

syringe

and a pressure

into the

piston

sealed

(drive

at

rates

contains

icad-acid

for

the

the

following

D

Pump

CI

Pump

Nutrition

Controller

Display

Pump

type

infusion

actuated

pump

cavity

system).

of 1 to

various

sensors,

battery,

Companion”

major

topics:

Board

Board

replaces

pump

combination

with

the

compressible

Control

300

ml/hr,

lor

use

and

is

in

order

in

portable

ClearStar”

conventional

systems

check

measurement

monitored

to

detect

operating

peristaltic

with a cassette

valve.

membrane

by

an

flow

modes.

Enteral

The

of the

8-bit

alert

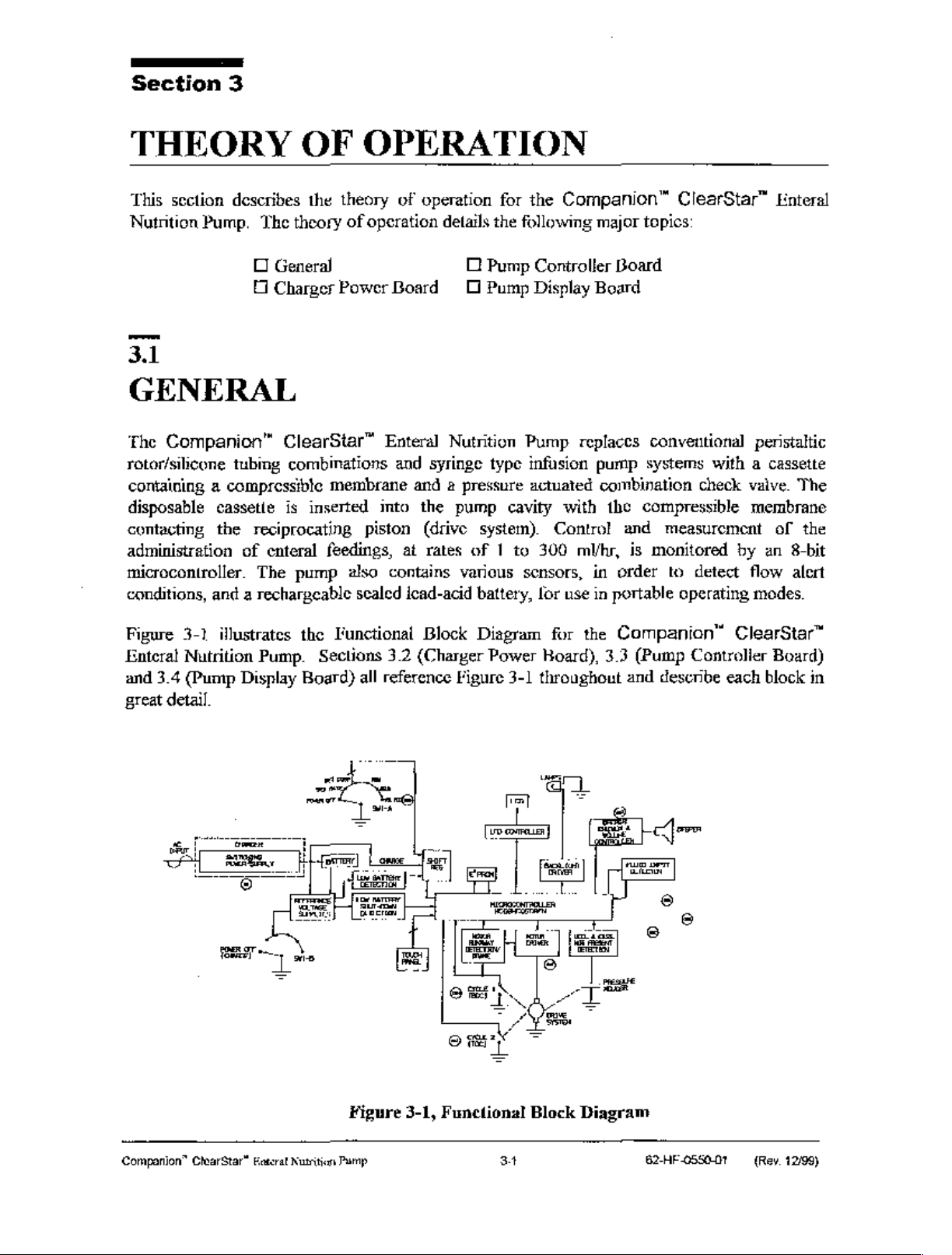

Figure

Enterat

and

great

3-1

Nutrition

3.4

(Pump

detail.

illustrates

Display

the

Pump.

Sections

Board)

Functional

all

Block

3.2

(Charger

reference Figure

Diagram

Power

3-1

for the

Hoard),

throughout

Companian™

3.3

(Pump

and

describe

ClearStar™

Controlier

Board)

each

block

in

Companion”

CloarStar®

Hateat

Nuria

Figure

Pump

3-1,

Functional

Block

34

Diagram

B2HE.OSSOOT

(Rev

12/09)

Page 16

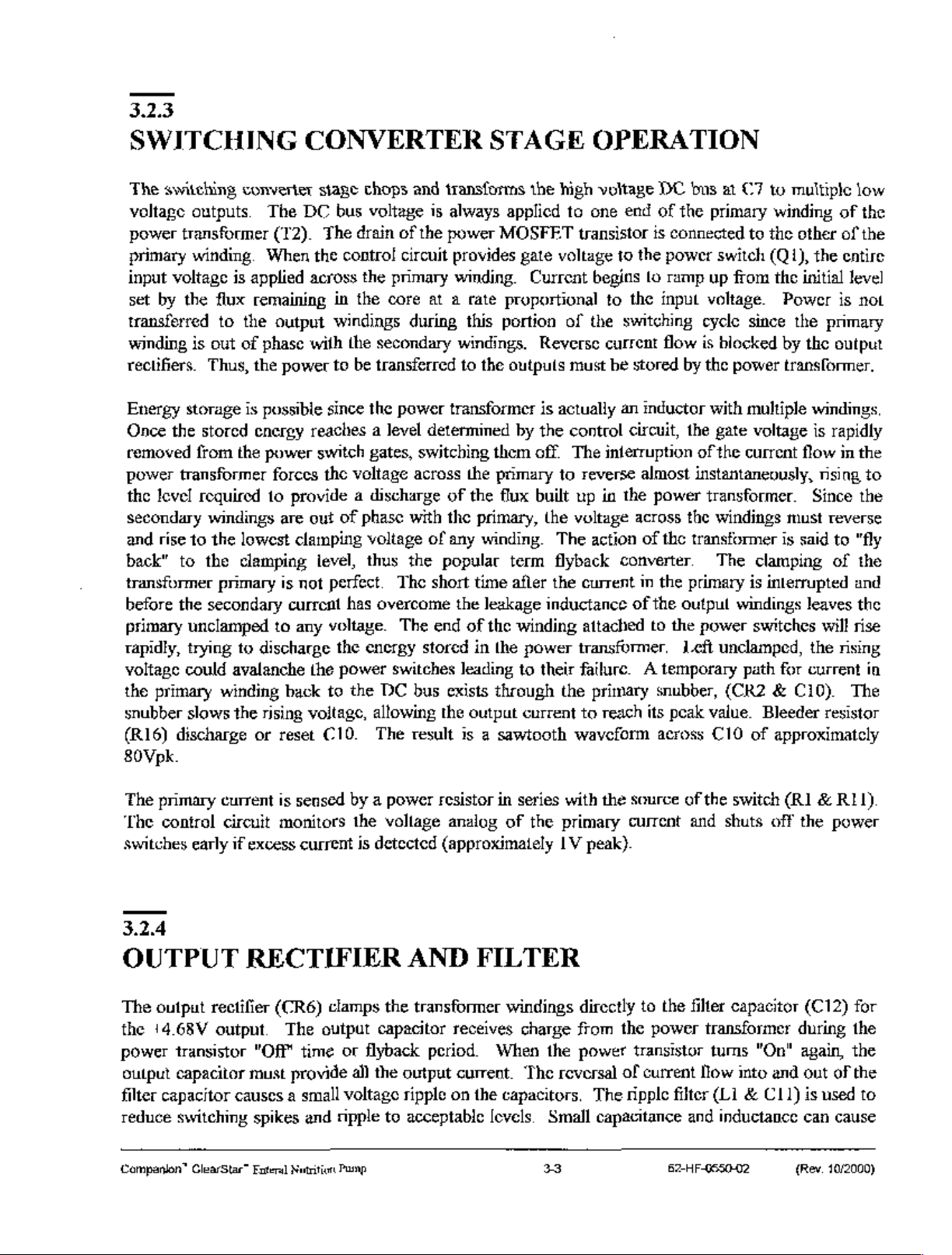

32

CHARGER

3.2.1

GENERAL

The

de.

switching

(JEC601-1-2)

-

264Vac @ 47 - 63H

charger

lead-acid

The

power

constant

as

an

indicator

output

overload.

eventually

Refer

to

requirements.

provides

enough

battery.

supply

has

4.68 + .02Vde,

for

battery

Under

hiccup.

Section

The

6.4.5

POWER

power

system

for

supply

The

single

power

two

separate

from 0 -

charging.

an

overload

will

the

power

BOARD

is

designed

power

phase,

to

supply

while

simultaneously

outputs.

13A.

The

The

primary

or

short

automatically

supply

calibration

lo

is

designed

providing

operate

The

first

second

output

output

circuit

recover

meet

condition

UL2601

to

operate

a

regulated

the

is

the

is

called

is

fully

once

the

procedure.

output

pump

primary

“LINE

protected

the

output

fault

(TEC601-1)

al

line

voltages

voltage

and

charge

output,

SENSE”

against

voltage

has

been

safety

ranging

of

the

4V,

used

and

short

will

removed.

and

EMC

from

85

4.68Vdc.

1Ab

to

provide

is

only

circuit

foldback

The

sealed

a

used

and

and

322

AC

The

85

protection

or

Under

voltage

excessive

Joules

with both

line-to-ling,

within

the

The

large

frequency.

INPUT/RECTIFICATION

input

voltage

to

264

Vac,

from

short

circuit

normal

transients

non-cepetitive

of

total

common

respectively.

the

FCC

AC

mains

input

voltage

electrolytic

The

is

applied

of

47

fire

hazard

output

conditions,

on

the

energy.

mode

and

VDE

is

provided

is

then

capacitors

peak

ripple

to

the

EMI

filter

to

63

Hz,

with

under

catastrophic

conditions

the

control

input

power

voltage

Input

current

(C5 & C6)

These

class B limits

to

discharge

rectified

(C7)

component

are

transients

then

and

components

the

through a full-wave

to

provide

is

through

less

than

failure

circuits

clamped

of

less

passes

differential

attenuate

for

conducted

EME

capacitors

DC

typically

the

fuses

5%

distortion.

conditions.

provide

overcurrent

by a metal

than

250

through a common-mode

filter

switching

emissions.

when

bridge

voltage

with a small

O

to

20%

(F1 & F2).

The

‘The

The

two

2A

fuses

will

protection.

oxide

varistor

microseconds

capacitor

frequency

The

the

AC

rectifier

(CR1,

ripple

of

the

peak-input

(M1).

duration

EMI

(C1) from

and

bleeder

power

is

7, 9 &10)

voltage

voltage.

input

voltage

input

not

open

Moderate

‘The

and limited

chokes

line-to-ground

rectifier

resistor

must

be

fuses

provide

on

overload

energy

MOV

clamps

to

10

(11 & T3)

and

harmonics

(R22)

to

across

interrupted.

and

at

twice

filtered

the

by

input

Companion”

ClearStat™

Entel

Nuttion

Pump

32

52-HF-055002

{Rex.

10/2000)

Page 17

323

SWITCHING

‘The

switching

voltage

power

primary

input

set

outputs.

transformer

winding.

voltage

by the

transferred

winding

is

rectifiers.

Energy

Once

storage

the

removed

power

transformer

the level

secondary

and

rise

to

back"

to

transformer

before

primary

rapidly,

the

unclamped

trying

voltage could

the

primary

snubber

(R16)

80Vpk

slows

discharge

converter

The

(12).

When

is

applied

flux

remaining

to

the

output

out

of

phase

Thus,

the

is

possible

stored

from

energy

the

power

forces

required

to

windings

the

lowest

the

clamping

primary

secondary

to

to

discharge

avalanche

winding

the

rising

or

CONVERTER

stage

chops

DC

bus

The

drain

the

control

across

in

the

the

windings

with

the

power

to

be

since

reaches a level

switch

the

voltage

provide a discharge

are

out

of

phase

clamping

level,

is

not

perfect.

currestt

any

back

has

voltage.

the

energy

the

power

to

the

voltage,

reset

CIO.

and

transforms

voltage

secondary

transferred

the

is

always

of the

primary

core

power

circuit

provides

winding.

at a rate

during

this

windings.

to

power

transformer

determined

gates,

switching

across

of

with

the

voltage

thus

overcome

DC

allowing

The

of

any

the

popular

The

short

the

The

end

of

stored

switches

bus

leading

exists

the

result

is a sawtooth

STAGE

the

high

applicd

MOSFET

gate

proportional

portion

the

outpuls

by

them

the

primary

the flux

primary,

winding.

term flyback

time

afler the

leakage

the

winding

in

the

to

through

output

to

voltage

Current

of

Reverse

must

is

actually

the

control

off.

to

built

the

The

inductance

power

their

the

current

OPERATION

voltage

one end

transistor

begins

to

the

current

be

The

interruption

reverse

up

in

voltage

action

current

attached

transformer.

failure.

primary

to

reach

waveform

DC

bus

of

the

is

connected

to

the

power

to

ramp

the

input

voltage.

switching

stored

an

inductor

circuit,

cycle since

flow

is

by the

the

of

almost

the

across

of the

instantaneously,

power

transformer.

the

transformer

converter.

in

the

primary

of

the

outpul

to

the

power

Left

A

temporary

snubber,

its

poak

value.

across

at

C7

to

multiple

primary

switch

up

blocked

with

gate

the

winding

to

the

other

(Qi),

the

ftom

the

initial

Power

the

primary

by

the

power

transformer.

multiple

voltage

current

windings,

is

flow

rising

Since

windings

The

windings

unclamped,

must

reverse

is

said

clamping

is

interrupted

leaves

switches

path

will rise

the

for

current

(CR2 & C10).

C10

of

Bleeder

approximately

resistor

low

of

the

of the

entire

level

is

not

output

rapidly

in

the

to

the

to

"fly

of the

and

the

rising

in

The

The

primary

‘The

control

switches

current

circuit

early

324

OUTPUT

The

output

the

14.68V

power

output

filter

capacitor

reduce

Companion”

rectifier

output.

transistor

capacitor

switching

ClearStac”

is

sensed

monitors

if

excess

current

by a power

the

is

detected

RECTIFIER

(CR6)

"OA"

must

causes

spikes

Futeral

clamps

The

output

time

or

flyback

provide

a small

and

Nutrition

all

voltage

ripple

Pump

the

resistor

vollage

analog

(approximately

AND

the

transformer

capacitor

period.

output

ripple

to

acceptable

FILTER

receives

When

current.

on

the

levels.

in

series

of

windings

capacitors.

with

the

primary

ГУ

peak)

directly

charge

‘The

from

the

power

reversal

The

Small

23

capacitance

the

source

current

the

transistor

of

ripple

of

the

switch

and shuts

to

the

filter

capacitor

power

transformer

tums

current

Now

into

filter

(Li & C11)

and

inductance

62-HF-0650-02

(RI & REL)

off the

power

(C12)

during

"On"

again,

and

out

is

used

can

(Rev.

10/2000)

for

the

the

of the

to

cause

Page 18

reverse voltage

levels,

a

dissipative

spikes

snubber

in

excess

(R19 & C9)

of

the

rating

of

the

is

connected

rectifier.

across

To

snub

the

anode

the

spike

to

cathode

voltages

of

CR6

to

acceptable

CONTROL

The

output

The

output

ratio

applied

conducts

CR6

anode through

photodiode

of

U1,

too

narrow

allowing

to a maximum

supply,

by

the

Modulation

charge

the

same

The

current

of

UI-1,

3.3V.

oscillator

reset

by the

switching

discharge

voltage

voltage

to

current

of

U2

At

approximately

(Output

U1-1

reverse

implementation

of the

through

instant

signal

the

output

Once

this

repeats

oscillator

frequency

time

of

CIRCUITS

is

controlled

is

sensed

the

reference

through

CRS

causes

#1

to

be

pulled

of

approximately

current

of

pulse

R7.

If

(U1-6),

is

compared

drive

level

is

the

same

and

timing

through

of

the

optocoupler

to

prevent

base

current

1V

on

U1-1,

too

low)

up

to

flows

back

03 & Q4.

width

the

occurs

voltage

turning

to a portion

is

latched

reached,

cycle

cap

discharge.

the

maximum

cap)

directly

U4

less

the

47%

into

and

the

resistor

(2.50V

current

to

flow

the

collector

5.00V

"On"

the

inside

at

UI-1

the

power

“Of”,

U1-4

switches

with

the

‘Thus,

duty

thus

scts

the

transformer

divider

reference).

photodiode

drawn

in

the

output

pulses

current

reference

time.

output

terminal

UL. A flip-flop

is

of

sufficient

transistors

of

the

voltage

The

timing

to a rapid

output

driver

the

cycle

(R25,

When

(U2).

from

output

The

battery

transistor

are

at

minimum

flows

of

Ul

(Pin

When

mains

of

the

is

magnitude,

"On".

capacitor

at

1-1.

‘The

discharge

latched

oscillator

cannot

operates

exceed

voltage

17 & 9).

U4-R

photodiode

at

through

8)

power

power

set

as

is

the

of

by

R7

is

the

the

The

above

output.

width.

the

U2

increasing

not

supply

timing

output

primary

When

continues

"ON"

the

to

charge

mode

back

by

an

at

twice

50%

(typically

for

all

other

divider

2.5V,

of

which

photo

supplied

current

ramp

internal

sets

the

the

cathode

U2

is

connected

The

current

pulls

down

Ifthe

pulse

transistor

the

pulse

to

is

kept

below

cap

(C13)

driver

goes

begins

reaches

to

approximately

to

1.6V.

The

flip-flop

the

actual

less

due

outputs.

voltage

pin

to

in

the

pin

1

width

of

U2

is

width

the

power

30h

A.

begins

to

the

to

high

at

ramp

level

timing

that

is

power

to

the

Excessive

until

fold

(approx.

startup

has

been

appears

If

the

begins

approximately

repeat

Companion”

current

the

next

back.

The

10V),

lhreshhold

(voltage

normal

bias

turning

is

removed.

to

be

providing

voltage

to

of

the

conduct

0.7V,

until

the

fault

ClearStar”

Baterat

"On"

voltage

reached

If

the fault

main

(CR8).

the

is

Nuition Pomp

at

U1-3

pulse,

also

Ul

"Of".

(approx.

is

short

bursts

output

When

SCR

latches

removed

or

more

than

1'V)

The

driver

foids

back

The

16V).

stil!

present,

of

power

increases

sufficient

pulses

(TP1

startup

Normal

the

or

"hiocuping“

beyond

current

“On”, shorting

the

power

supply

causes

become

to

TPS),

capacitor

shutdown

safe

is

the

outpul

so

narrow

to

the

begins

switching

operation

cycle

limits,

is

the

repaired,

the

available

output

34

driver

under

to

recharge

will

repeat.

overvoltage

to

causing a “hiccup”

62-HF-0550-02

to

switch

that

the

transformer

voltage

lockout

through

will

commence

The

power

protection

raise the

gate

off

point

R2

supply

zener

of

cycle

(Rev.

and

latch

voltages

of

U1

until

the

if

the

fault

thus

diode

SCRI

that

to

will

1072000)

Page 19

33

PUMP

‘The

following

CONTROLLER

is

an

board assembly

3.3.1

REFERENCE

The

pump

position

rotary

when

from

the

As

stated

charger

51230105,

source

discharged.

provides

(U6,

U7 & U8),

the

Low

is

activated

other

than

switch,

the

or

to

SW1,

control

pump

above,

battery

Q12.

drain.

filtering

dial

main

when

Q12

This

‘he

supply

to

power

beeper,

Battery & Low

"POWER

BOARD

in-depth description

VOLTAGES

when

the

OFF

activating

is

placed

board,

the

requires

helps

eliminate

infrared

Battery

four

in

except

control

is

pawer

dial

routed

à

minimum

protect

voltage

VI

contact

emitter/detector,

Shutdown

of

the

various

/

SUPPLIES

control

dial

{attached

(CHARGE)".

separate voltage

the

"POWER

used

for

js

rotated

through

{o a position

rotary

threshold

against

conditions

is

produced

bounce

during

detection

subsystems

to

rotary

Charger

OFF

battery

output

supplies

(CHARGE)"

charging,

other

switch,

voltage

where

at

the

drain

SW1,

Vos

the

switching

motor

run

and

circuits

that

make

switch,

or

battery

(V0,

VI, V2,

position,

than

"POWER

turning

of

2V

sealed

of

lead-acid

of

Qi2.

SWI.

led

backlight.

up

the

SWI)

power

is

is

and

1.2VREF).

all

power

OFF

on

the

p-channel

for

current

battery

The

luf

V1

supplies

VI

pump

controller

rotated

routed

to

any

through

Note,

is

removed

(CHARGE),

mosfet,

to

flow

from

is

completely

capacitor,

power

is

monitored

C17,

to

ICs

by

A

12

volt

reference

independent

voltage

Low

Supply

electrolytic

critical

Shutdown

to

the

voltage

voltage

to

the

Baitery

voltage

regulator

source

of

variations

empty,

Shutdown

VO

is

capacitor,

operating

or

information,

rotation

microcontroller

board.

Supply

required

V2

the

voltage

so

supplies

majority

V2

that

the

power

of

inputs

VO

to

LM385BM-1

(1.2VREF).

in

load

current

occlusion,

detection

generated

C4.

of

control

(U3),

is

generated

lines

the

pull-up

lines

going

cassette

circuits,

directly

VO

is

required

to

the

dial

reset

supervisor

directly

going

to

resisters

to

the

2,

D8,

is

used

along

DB

maintains

or

supply

not

present,

from

supply

so

2s to

EEPROM

to

the

when

"POWER

(U1),

from

supply

the

microcontroller

for the

rotary

microcontroller

the

voltage,

clog

VI,

via

maintain

main

power

OFF

(CHARGE)"

EEPROM

VI,

are

dial

input

(3)

with

V1

to

provide a stable

load

voltage

VI.

clearing,

LA

diode

power

is

at a constant

1.2VRFF

motor

PRLL5817,

during

the

discontinued,

position.

(US),

via

at

JA

diode

the

same

(SW

shift

register

PRLIS817,

potential

A),

touch

supplics

run

and

Low

Dl,

and a 6804f

saving

operation,

via

Low

VO

supplies

(US),

D2.

as

the

panel

overlay,

1.235

volt

1.2

volts,

a

roference

Battery

/

of

Battery

power

and

display

V2

is

VO

supply.

and

Companion”

ClearStar™

Fatral

Nuuitiat

Pump 35

62-HF-055007

(Rex.

1072000)

Page 20

332

BATTERY

A 4 volt, I ampere

#WP1-4)

unique

charge

voltage

of

60 - 90

an

extremely

is

utilized

features

current

charging

degree

hour

during

that

hetp

automatically,

circuit.

Fahrenheit),

low

rate of

applications.

The

4V,

1Ah

0.02Vdc

battery.

current.

battery

placed across

Charging

The

cell,

sealed

1A

(2)

lead-acid

occurs

slo-blo

shorted

333

LOW

BATTERY

rechargeable,

portable

to

simplify

therefore

Second,

temperature

self-discharge,

battery

it's

terminais.

directly

fuse

is

utilized

input

connector,

/

SHUTDOWN

sealed

pumping

the

due

to

lead-acid

operating

charger

only

requiring

the

pumps

compensation

which

is

constant

This

through a 1A

to

is

is

the

protect

and

(3)

battery

modes,

circuitry.

the

practical

highly

voltage

most

slo-blo

suitable

suitable

fusc,

against

shorted

(Sonnenschein

Lead-acid

First,

lead-acid

implementation

application

is

not

necessary.

for

charged,

method

with

the

following

components

#2A x 2K

batterics

batteries

have

seif

of a single

(L.e.:

operating

Third,

low

or

intermittent

with a constant

to

recharge a sealed

the

battery

fault

on

main

the

voltage

regulating

conditions;

board

or

Long,

several

regulate

level

constant

temperature

batteries

have

usage

of

4.68

+

lead-acid

charge

(1)

shorted

assembly.

‘There

0.2 volts,

audible

circuit,

automatically

volts.

The

CMOS

reference

Ut gocs

hysteresis

The

R40. A CMOS

with

of

latched

diode

are

two

at

becper).

Low

This

provents

Low

Battery

voltage

voltage

HIGH

for

Low

Battery

reference

ОТВ

goes

in

DS

and

the

separate

which

point

This

Battery

shuts

down

excessive

Detection

comparator

1.2VREF.

and

initiates

proper

triggering

Shutdown

voltage

voltage

HIGH

HIGH

state

comparator

circuits.

the

circuit

Shutdown

the

The

pump

goes

is

therefore

Circuit,

pump

in a safe

battery

Circuit

monitors

TLC374CD,

If

the

output

a

LOW

of

U7:A.

Circuit

comparator

1.2VREF.

and

initiates a LOW

via

positive

also

TLC374CD,

If

the

U7:C.

first

circuit

into an

discharge

17:A,

of

BATTERY

monitors

detects

alarming

called

goes

the

into

manner,

V1

whenever

and

protects

through a voltage

compares

the

voltage

alarm.

V1

U?:B,

output

feedback

of

the

BATTERY

diode

voltage

when

the

condition

Low

Battery

an

alarming

battery

pumping

the

output

divider

falls

battery

Detection

condition

divider,

voltage

(visual

vollage

circuitry.

resistors

of the

below

‘The 1 megaohm

through a vollage

compares

divider

SHUTDOWN

DS.

The

the

motor

divider,

output

falls

below

alarm.

run

circuit

falls

below

"LOW

1.2

resistor,

BATTERY"

Circuit.

(audible

falls

voltage

volts,

resistors

of

the

1.2

The

is

The

beeper)

below

R36

3,65 + 0.2

and

divider

the

output

R26,

provides

R38

voltage

volts,

the

comparator

also

disabled

3.95

4.

and

second

and

R39.

A

with

of

and

divider

output

is

via

‘Companion

ClearStar"

Enteral

Nutrition

Pump

38

62-HF-0550.02

{Rev.

1012000)

Page 21

334

CONTROLLER

The

microconiroller

technology,

life.

The

the circuit

The

microcontroller

includes

the

message

The

single

has

31

functions.

crystal

and

was

which

microcontroller

and a reset

visual,

audible,

"FL"

chip

bi-directional

The

oscillator

compiled

utilizes

helps

software

is

displayed

microcontroller

ClearStar

connections,

via the

355

high-density,

to

minimize

complementary

power

requirements

#MC68HC705C9A-CEN,

threshold

RAM

I/O

Byte

of

then

and

I/O

on

the

contains

lines

that

pump

also utilizes the

and

power-saving

Craft

2.93V

is

exceeded,

performs

an

initialization

verification.

LCD.

15,932

control

bytes

and

onboard

stop function.

C6805

code

development

metaloxide

and

U3,

is

initialized

via

the

microcontroller

routine and a self

X€

bere

should

of

EPROM

monitor

various

microcontroller

system.

semiconductor

provide

maximum

when

be

an

error

and 352

power

bytes

pumping

watchdog

Software

was

(HCMOS)

battery

(VO)

supervisory

test

function,

associated

of

RAM,

and

user

written

operating

is

applied

chip,

which

with

RAM,

SPT,

interfacing

timer,

in

on-chip

C-language

to

UL

and

MEMORY

Besides

microcontroller

EEPROM

memory,

features

The

The

operating

power

Shutdown

C4,

code

the

15,932

bytes

communicates

device.

internally

an

endurance

nonvolatile

1.

general

2.

diagnostic

encountered

3.

occlusion

4.

general

reset, Set

70ms,

5.

TDC & BDC

and

nonvolatile

parameters

shutdown),

(POWER

maintains

(if

any)

the

and

‘Ihe

organized

of 10°

EEPROM

user

operating

recorder - error

while

event

default

Rate — 300ml/hr,

XDUCER=

delay values

LLEPROM

are

one

OFF,

supply

checksum

recorder - event

information

to

of

EPROM

nonvolatile

and

serially,

via

EEPROM,

256 x 16

data

changes

is

used

to

save,

information

event

in

operation,

number

-

when

Set

Dose = Oml,

49,

and

and

the

requires

changed,

two

low

voltage,

(sel

15ms

or a fault

16

bit

values

battery

shutdown,

VO,

long

rale + set

352

byles

of

RAM

the

serial

peripheral

#NM93CS66LMS8X,

and

can

operate

with

40

years

the

following

-

Set

Rate,

dala

{fault

& duration of

activated

in

data

information:

Sct

Dose

codes

the

diagnostic

Volume

XDUCER

in

order

are

enough

dose + volume

gain

value

to

erase and

condition

saved

or

(~

occurs

into

motor

mnaway),

80ms)

fed)

that

are

onboard

interface

all

modes

the

(SPI),

U4,

contains

down

to

retention.

and

Volume

Fl - F21)

clog

clearing

&

Fed — Oml,

are

stored

write a single

during

non-volatile

the

to

save

the latest

Fed

used

in

seconds

occlusion

TDC & BDC

in

secured

16

bit

normal

EEPROM.

680

electrolytic

volume

information.

microcontroller,

the

with a nonvolatile

4096

27V.

hits

The

of

device

values,

to

identify

are

event

recorders

delay

errors

saved,

are

valucs

=

memory.

value.

pumping

When

the

(excluding

During

power

capacitor,

fed

value,

fault

Companionr

Clearslar”

Erenl

Rioriion

Purp

#7

62-HF-0550-02

(Rev.

1072000)

Page 22

336

MOTOR

The

motor

supplied

LOW,

{pin

voltage

UZ),

power

al

the

Rotational

supplied

BDC

implemented

normal

selected

resistor

to

3.15

potentiometer

to

through

14)

triggers

is

to

the

transistor,

collector.

to

to

TDC

feeding versus

for

values

volts.

DRIVER

drive

circuit

the

motor

diode

feedback,

non-inverting

speed

it.

Motor

in

in

order

R10,

and

Timing

controlled

and

DAN202KT146,

LOW,

through a digital

Q10,

A

100

of

the

speed

900ms

to

occluded

R11

and

the digital

feedback

&

SPEED

consists

allowing

of a motor

driver.

The

the

pnp

motor

D6.

power

controlled

input

of

comparator

ON

and

OFF

very

quickly

electrolytic

de

gearmotor

is

adjusted

and

from

provide

capacitor,

is

directly

(i.e.:

TDC

to

BDC

stability

in

conditions),

the

value

of

the

potentiometer

is

monitored

via

the

microcontroller.

CONTRO:

voltage

The

Vin

transducer

‘The

digital

may

via

regulator,

drive

circuit

output

transistor

resistive

U7:C,

in

C9,

dependent

applicd

in

900ms.

is

activated

of

voltage

MIE371,

voltage

The

comparator

order

to

is

needed

upon

to

the

Constant

output

value

of

Vm

potentiometer,

vary

between 0 to

CYCLF1 & CYCLE2

which

maintain

for

due

regulates

when

the

comparator

Q10,

to

conduct,

divider

filtering

the

gearmotor)

to

is

determined

U2.

network

is

in

effect

a

constant

to

input

motor

so

motor

speed

changes

Since

R10 & R11

10K,

Vm

reedswitches,

the

voltage

/RUN

1LC374CD,

(810,

tuming

(Vm)

linc

triggers

The

collector

RII,

the

(regulated)

help

reduce

voltage,

the

piston

control

in

motor

by

the

can

vary

ripple.

Vm,

travels

was

load

(i.e.

resistor

values

are

fixed

between

with

the

U7:C,

and

pap

voltage

from

2.03

digital

The

motor

electromechanical

pnp

transistor,

pnp

power

supply

voltage,

erosion

Vm,

of

the

MMBT4403LT1,

transistor

MJH371,

337

TDC/BDC

A

normal

seconds

and

which

selected

The

monitors

activated

The

the

TDC

reedswitch

200ms,

expires.

stop

pumping

(for

at

the

bottom

the

piston

by

the

cycle

begins

the

(shorted)

microcontroller

position,

for

entered

The

at

true

TDC

POSITION

cycle consists

flow

rates

between

dead

center

spends

user.

with

CYCLE2

activation.

during

/RUN

position

at

the

the

piston

reedswitch

at

the

beginning

enables

Once

the

the

/RUN

When

pump

signal

is

disabled and

(+.001”)

is

current

motor

Q8,

Q10.

limited

ta

400mA.

commutator

and

1.80

bias

resistor,

DETECTION

of

the

piston

250 - 300m1/hr)

(BDC)

BDC

position

position

at

the

BDC

for

an

of

the

/RUN

signal

signal

activated,

calibration).

stopping

or

3.1

for

the

is

determined

position,

open

condition.

motor

cycle,

allowing

is

enabled,

the

microcontroller

The

motor

the

/BRAKE