Companion 875181180 Owner’s Manual

Owner's Manual

ompanio0n

PNEUMATIC

GRAVITY FEED SPRAY GUN

Model No.

875.181180

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

• Safety

• Warranty

• Features & Operation

• Maintenance

• EspaSol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

www.sears.com

ReadOperating Instructions

Pleasebecome familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

impact resistanteye protection should meet or exceed the

standards set forth in ANSIZ87.1, Occupational and

EducationalEyeand FaceProtection. Look for marking Z87.1

on your eye protection to ensure that it isan approved style.

Hearing Protection isRecommended

Hearing protectionshould be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Processnoise, reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area.if you are unable to

determine your noise level exposure, we recommend the use

of hearing protection.

Avoid Prolonged Exposureto Vibration

Pneumatic tools can vibrate during use. Prolonged exposure

to vibration or very repetitive hand and arm movements can

cause injury. Discontinue the use of any tool if you experi-

ence tingling, numbness, discomfort or pain in your hands

or arms. You should consult your physician before resuming

useof tool.

100 PSIG Maximum

This tool is designed to operate at an air pressure of 45-60

pounds per square inch gauge pressure (100 PSIG)

maximum, at the tool. Useof higher air pressure can, and

may cause injury, Also, the useof higher air pressure places

the internal components under loads and stressesthey were

not designed for, causing premature tool failure.

NOTE: THE AIR SUPPLY SHOULD BECLEAN, DRY AND

PREFERABLYLUBRICATED. FOR BEST RESULTSDRAIN THE

MOISTURE FROM YOUR COMPRESSOR DAILY.

[ IIWARNING] Somedustcreated

by power

sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth

defects or other reproductiveharm. Some examples of these

chemicals are:

Leadfrom lead based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposureto

these chemicals: work ina well ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic particles.

!_CAUTIONI

TO AVOID CREATING AN EXPLOSIVEATMOSPHERE,

WORK ONLY IN WELL-VENTILATEDAREAS.

USE OF NIOSH APPROVED FACE MASK IS RECOM-

MENDED TO PREVENT INHALATION OF TOXIC MATE-

RIAL. DO NOT ATTEMPT TO UNCLOG (BACK FLUSH)

SPRAY GUN BY SQUEEZING TRIGGER WHILE HOLDING

FINGER IN FRONT OF FLUID NOZZLE.

I WARNING The following hazards can

occurduring the normal use of this product:

Risk of Explosionor Fire - Flammable

Materials

When paints or materials are sprayed, they

are broken into very small particles and

mixed with ain This will cause certain paints

and materials to become extremely

flammable and could results in serious injury or death.

How to prevent it:

Never spray near open flames or pilot tights in stoves or

heaters. Never smoke while spraying.

Provide ample ventilation when spraying indoors,

Riskof Explosion - Incompatible

Materials

[_ The solvents 1,1,1 - Trichlorethylene

hazard that could result in serious injury or death.

and protective clothing designed for use with your specific

application and spray materials. Some masks provide only

limited protection against toxic materials and harmfut paint

solvents. Consult with a Safety Expert or industrial Hygienist

if uncertain about your equipment or materials.

Riskfrom FlyingObjects:

Certain parts are under pressure whenever the gun is

connected to a pressurized air line. Theseparts may be

propelled if the gun is disassembled. Compressed air may

propel dirt, metal shavings, etc. and possibly cause an injury.

Prolonged exposure to air spraycan result in permanent

damage to hearing.

How to prevent it:

Disconnect the gun from the air line or completely depres-

surize the air line whenever the gun is to be disassembled.

Never point any nozzle or sprayer toward a person or part of

the body. Always wear ANSI 278.1 safety approved goggles

or glasses when spraying. Always wear hearing protection

when operating spray equipment.

DO not use pressure that exceeds the operating

pressure of any of the parts (hoses, fittings, etc.) in the

painting system. Keep hose away from sharp objects.

Bursting air hoses may cause injury. Examine air hoses

and Methylene Chloride can chemi-

callyreact with the aluminum used in

most spray equipment, an this gun

and cup, to produce and explosion

Riskto Breathing

cause lung damage, and burns if inhaled or

allowed to come into contact with skin or

Some paints, coatings and solvents may

eyes.

How to prevent it:

Use a NIOSHapproved mask or respirator

regularly and replace if damaged.

Afways use a pressure regulator on

the air supply to the spray gun.

(2)

DO NOT ATTEMPT TO UNCLOG (RACK FLUSH) SPRAY GUN

BY SQUEEZING TRIGGER WHILE HOLDING FINGER IN

FRONT OF FLUID NOZZLE.

Pressure may vary according to viscosity of material used.

Maximum working pressure of gun is 100 psig. DO NOT

EXCEED PRESSURE LIMIT OF GUN OR ANY OTHER

COMPONENT IN SYSTEM]

Prior to daily operation, make certain that all connections

and fittings are secure. Check hose and all connections for

a weak or worn condition that could render system

unsafe. All replacement components such as hose or

fittings must have a working pressure equal to or greater

than system pressure.

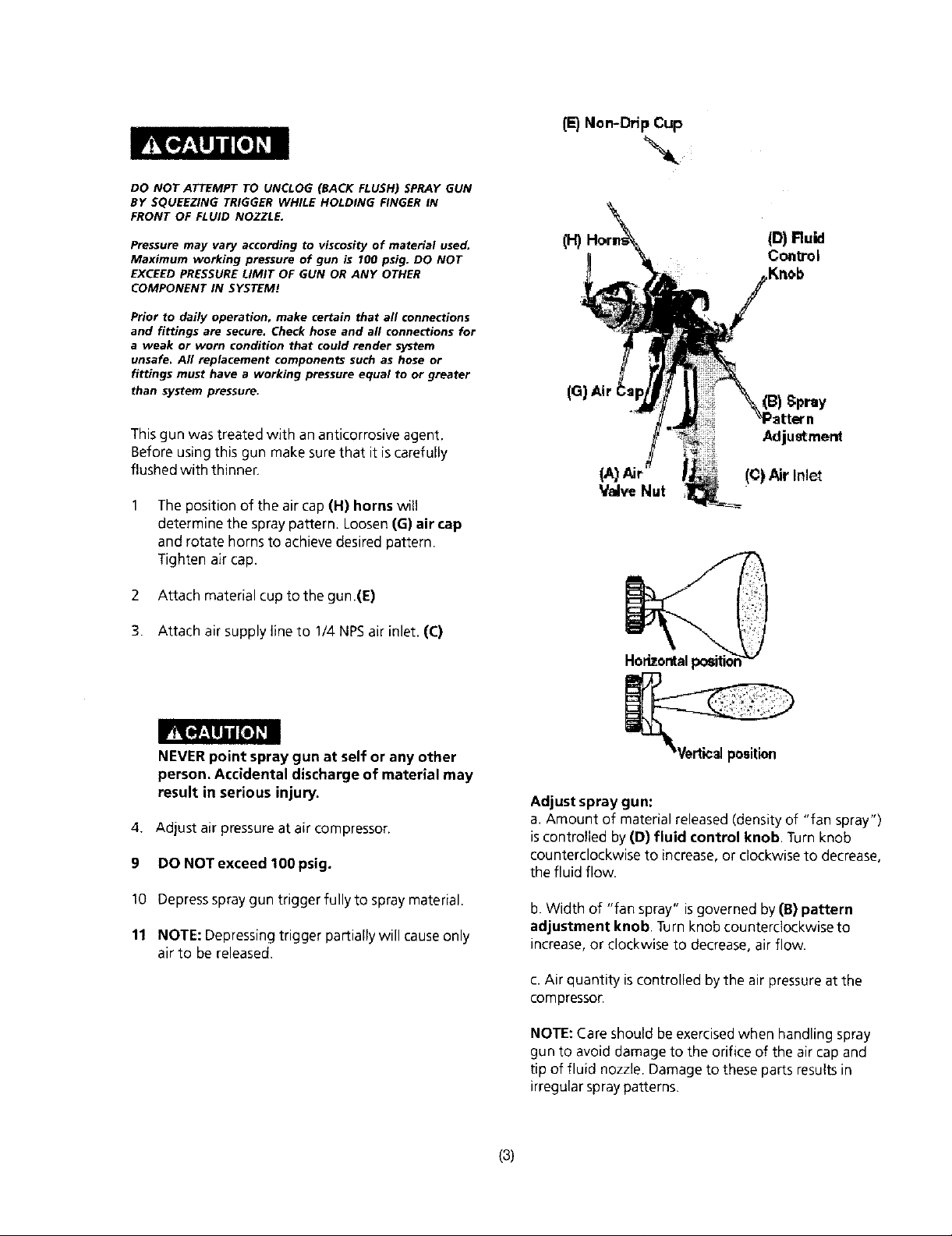

(D)R-id

Control

Knob

_;pray

This gun was treated with an anticorrosive agent.

Before using this gun make sure that it is carefully

flushed with thinnen

The position of the aircap (H) horns will

determine the spraypattern. Loosen (G) air cap

and rotate horns to achieve desired pattern.

Tighten air cap.

2 Attach material cup to the gun.(E)

3. Attach air supply line to 1/4 NPS air inlet. (C)

NEVER point spray gun at self or any other

person, Accidental discharge of material may

result in serious injury,

4. Adjust air pressure at air compressor.

9 DO NOT exceed 100 psig.

Adjustmont

!¢) Air Inlet

Valve Nat

Horizontal

Adjust spray gun:

a. Amount of material released(density of "fan spray")

iscontrolled by(D) fluid control knob. Turn knob

counterclockwise to increase, or clockwise to decrease,

the fluid flow.

10 Depress spray gun trigger fully to spray material.

11 NOTE: Depressing trigger partially will cause only

air to be released.

b. Width of "fan spray" isgoverned by (B) pattern

adjustment knob, Turn knob counterclockwise to

increase,or clockwise to decrease,air flow.

c. Air quantity is controlled by the air pressure at the

compressor.

NOTE: Care should be exercised when handling spray

gun to avoid damage to the orifice of the air cap and

tip of fluid nozzle. Damage to these parts results in

irregular spray patterns.

(3)