Companion 32010831 Owner’s Manual

Operator's Manual

p nion

7 1/4-in. Circular Saw

Model No.

320.10831

• SAFETY

CAUTION: Read understand and follow

all Safety Rules and Operating Instructions

in this manual before using theeproduct.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• OPERATION

• MAINTENANCE

• ESPAI_OL

Warranty................................................................................................... Page 2

General Safety Rules............................................................................. Pages 2 - 4

SpecificSafetyRules............................................................................. Pages 5 - 6

Symbols............................................................................................. Page 6

Specifications........................................................................................... Page 7

Features................................................................................................... Page 7

Operation............................................................................................. Pages 8 - 9

Maintenance.................................................................................... ,........Page 10

Accessories.............................................................................................. Page 11

Service Numbers .......................................................................................... Back C<_ver

ONE FULL YEAR WARRANTY ON COMPANION TOOL

If thisCompaniontool failsdueto a defecl inmaterialor workmanshipwithinone

yearfrom the date of purchase, RETURN ITTO THE NEAREST SEARS STORE

tNTHE UNITED STATES,and Sears wfflreplaceit, freeof charge.

Thiswarranty is void ifIbistool is usedfor commercialorrentalpurposes.

Thiswarranty gives you specificlegalrights,and you mayalso haveotherdghts

whichvary from state to slate.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

READ ALL INSTRUCTIONS THOROUGHLY

To operate thistool, read thisoperating manualand all the labels affixedto the drcblar

sawcarefully befere using.Keepthis manualavailablefor futurereference.

IMPORTANT

This toolshould onlybe servicedby a quailed servicetechnician.

Keep your work area dean and well lit. Cluttered benchesand dark areas

inviteaccidents.

Do not operate power tools in explosive atmospheres, such as in the presence

of ffammoble liquids, gases, or dust. Power toolscmafe sparkswhich may ignite

the dustor fumes.

Keep bystanders, children and visitors away While operating a power tool.

Distractionscan cause you to losecootrbl.

Use clamps or other practical ways to secure and support the workp|ece

to a stable platform. Hbldingthe work byhand or againstyour bodyisunstableand

may lead to leasof control.

Do not force the toot. Use the correct tool for your applfuctlon. The correcttool

willdothe job better and safer at the rate forwhich itis designed.

rl= _1_: 1:11._:111 =1tti :lit ti:l.'r,!tSL

Do not use tool ff switch does not turn it on or off. Any tool that cannotbe

controlledwith the switchls dangerousand must be repaired.

Disconnect the plug from the power source before making any ad|ustmenta,

changleg accessories, or storing the tool. Such preventivesafetymeasures reduce

the riskof startingthe toolaccidenlail_

Store Idle tools out of reach of children and other untrained persons. Toolsare

dangerousIn the handsof untrainedusers.

Maintain tools with care. Keep cutting tools sharp and clean. Properlymaintained

tools,with sharpcuttingedgesare less likelyto hindand are eaaierto control

Check for mleaitgnment or hlndtng of moving parts, breakage of parts, and any

other condition that may aft_'t the tool's operation. If damaged, have the tool

servleed before using. Many accidentsare causedby poorlymaintained tools.

Use only accesaorles that are recommended bythe manufacturer for your

model. Accessoriesthatmaybe suitablefo_one tool, maybecomehazardouswhen

usedon another tool.

Do not aRer or misuse tool. These tools are precisionbuilt.Any aiteraticn or

modificationnot spedifiedismisuseand may resultina dangerouscondition.

read all Instructions, safely rules and warnings. Failure to comply can resutt in fire

electric shock, or serious personal injury. Save the Owner's Manual and review

I A_ CAUTION: Do not attempt to operate this tool until you have thoroughly

frequently for reference.

I A_, WARNING: When using power tools, basic safety precautions shouldalways be followed to reduce the risk of fire, dieotdc shod<, and personal injury.

Stay alert, watch whet you are doing and use common sense when operating a

power tool. Oo not use tool while Ifred or under the influence of drags, alcohol,

or medication. A moment of inattenlicn while operafing power tools may result in

serious personal Injury.

Dress properly. Do not wear loose clothing or Jewelry. Contain long hair. Keep

your hair, cdothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving paris.

Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools

with your finger on the switch or plugging in tools that have the switch on invites

accidents.

Do not overreach. Keep proper footing and balance st all times. Proper footing

and balance enables better control of the tool in unexpected situations.

Use safety equiprrmnL Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Before connecting the toni to a power soume (receptacle, outlet, etc.), be sure

voltage supplied is the same as that specified on the nameplate of the tool. A power

source with voltage greater than that specified for the tool can result in serious injury

to the user, as we{t as damage to the tool.

[e]:1_1:::_:II_'fd g q lt'i i.'llJg_l_q,ln

propelledinto youreyes, resulllogin severeeye damage.When operating

powertoof, always wear safety gogglesorsafelyglasseswith side shieldsand a

I \ WARNING: The operation of anytoolcan resultinforeignobjects being

fullface shieldwhen needed.

on.A wrench ora keythat is left attached to a rotatingpart of thetool mayresult

I _ WARNING: Remove adjustingkeys or switchesbefore turning the tcol

inpersonalinjury.

A_ WARNING: If any partsare missing,de nof operatethe tooluntilthe missing

parts have been replaced.Doing socould resultin seriouspersonalinjury.

ELECTRICAL SAFETY

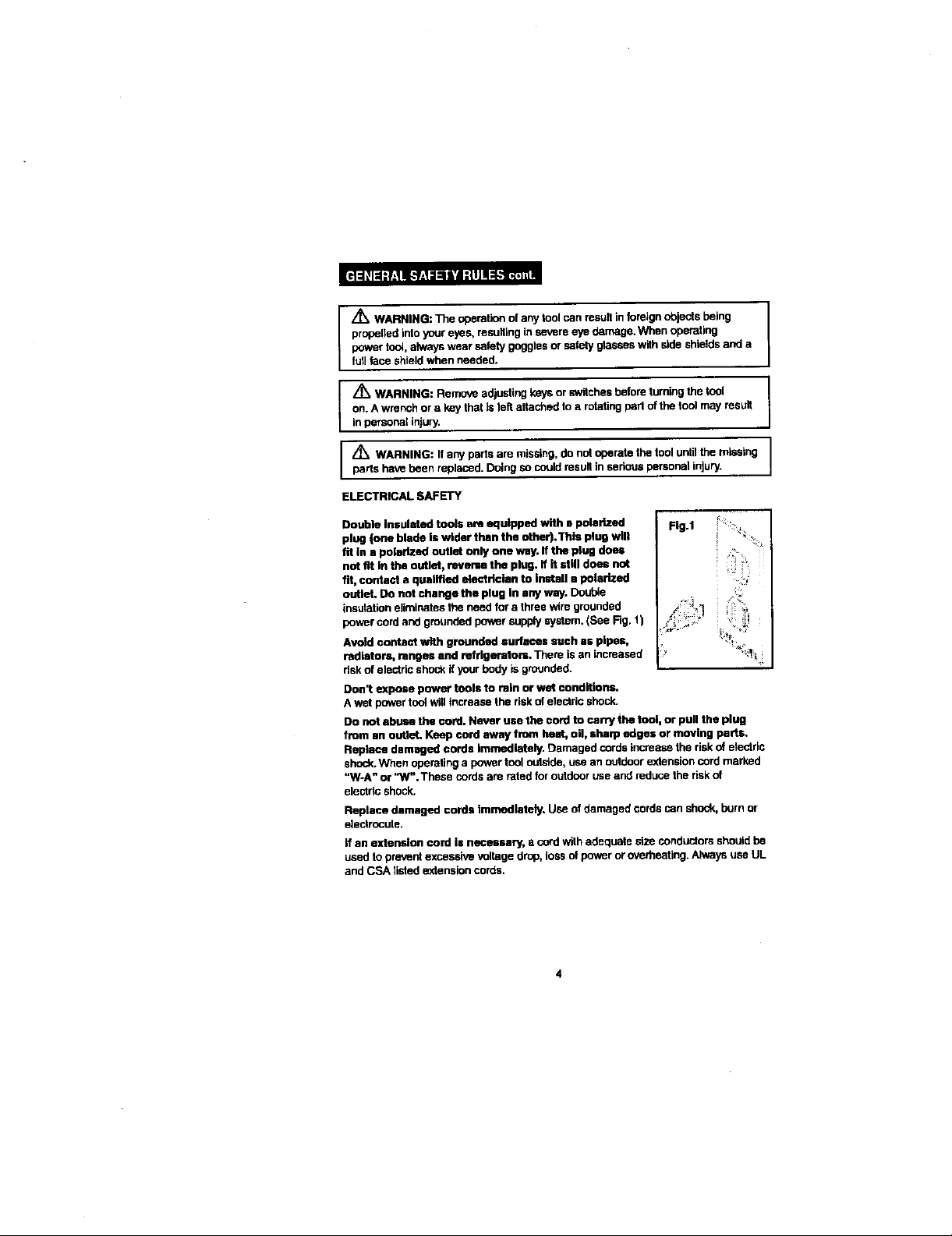

Double Insulated tools am equipped with • polarized .1 ":

plug (one blade Is wider than the other).Thls plug wilt

fit in a polarized outlet only one way. If the ptug does

not fit In the outlet, reverse tbe plug. if if ettll does not _ _

fit, contact a quatified etectricfen to install a polarized

outlet. Do not change the plug in any way. DouSe •

insulation eliminates the need fo)"a three wire grounded

power cord and grounded power supply system. (See Fig. 1) !_ _,

Avoid contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is grounded.

Don't expose power tools to rain or wet conditions.

A wet power tool wilt increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the toet, or pull the plug

from an outlet. Keep cord away from heat, oil, sharp edges or moving parts.

Repfece damaged cords immediately. Damaged cords increase the risk ol electric

shock.When operating a power tool oulside, use an outdoor extension cord marked

"W-A" or"W".These cords are rated for outdoor use and reduce the risk of

electric shock.

Replace damaged cords immediately. Use of damaged cords can shock, burn or

siectrocule.

If an extension cord is necessary, a cord with adequate size conductors should be

used to prevent excessive voltage drop, loss of power or overheating. Always use UL

and CSA listed extension cords.

Fig 4

•/_ WARNING: Keep hands away from cutting area and blade. Keep your

second hand on auxiliary hancte, or motor housing, If both hands am holding

the saw, they can't be cut by the blade.

Keep your body positioned to either side of the sew blade, _ not in line with

the saw blade. KICKBACK could cause the saw to jump backwards.

Do not reach underneath the work piece. The guard can nut protect you from the

blade below the work piece.

Check lower guard for proper closing before each use. Do not operate saw if

lower guard does not move freely and close instantly. Never clamp or tie the

lower guard into the open position. Ifsaw is ac_lentally dropped, lower guard

may be bent. Raise the iewer guard with the rettacting handle and make sure it

moves freely and does not touch the blade or any other part, in all angles and depths

of cut.

Check the operation and condition of the lower guard spring. If the guard and

the spring are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts, gummy depeslls, or a buildup

of debris.

Lower guard should be retracted manually only for special cuts such as

"pocket cuts" and "compound cuts". Raise lower guard by retracting handle.

As soon as blade enters the material, lower guard must be released. For all

other sawing, the lower guard should operate automatically.

Always observe that the lower guard Is covering the blade before placing saw

down on bench or floor. An unprotected, coasting blade will cause the saw to walk

backward, cutting whate_er is in its path. Be aware of the time it takes for the blade

to stop after swifch is released.

NEVER hold piece being cut in your heeds or across your leg. It is important to

support the work piece properly to minimize body exposure, blade binding, or less of

control

Hold tool by Insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a "li_"

wire will also make exposed metal paris of the tool "li_e" and shock the operator,

Always use blades with correct size and shape (diamond vs. round) arbor

holes. Blades thai do not match the mouotJng hardware of the sew will run

ecceutrically causing fuss of coutml.

Never use damaged or incorrect blade washers or bolts. The b4ade washers and

bolt wore specially designed for your saw, for optimum performance and safely of

operation.

Maintain a firm grip with both hands on the saw and position your body and

arm to allow you to resist KICKBACK forces. KICKBACK forces can be controlled

by the operator, if proper precautions are taken.

When blade is binding, or when hltarrxJpting a cut for any raeson, re/ease the

trigger and hold the saw motionless In the material until the blade comes to a

complete stop. Never attempt to remove the saw from the work or pull the saw

backward while the blade is in motion or KICKBACK may occur. Investigata and

take corrective actions Io ctim_te the cause ol blade binding.

5

II."! ".l=[NI_1[II.'f.'| I111li'|: I I I I _.1 _mira

When restarting a saw in the work piece, center the saw blade in the kerr and

check that saw teeth are not engaged Into the msterlal. If saw blade is binding, it

may walk up or KICKBACK from the work piece as the saw is restarted.

Support large panels to minimize the risk of blade pinching end KICKBACK.

Large panels tend to sag under their own weight. Supports must be pisced under the

panel on both sides near the line of cut and near the edge of the panel.

Do not use dull or damaged blade. Unsharpened or improperly set b_ades produce

nan'ow kerfs causing excessive friction, blade binding and KICKBACK.

Blade depth and bevel adjusting locking levers must be tight and secure

before making cut. If t_ade adjustment shifts while cutting, itmay cause binding and

KICKBACK.

Use extra caution when making a "pocket cut" into existing walls or other

blind areas. The protruding bfede may cut objects that can cause KICKBACK.

Do not use blades made of high-allay, high-speed steel (HSS).

Do not usa the circular saw near fumes or combustible liquids.

Secure small pieces of wood firmly before working. Never hold them in your

hand.

Never slow the blade down with your hands or by applying pressure to the

side of the blade.

Never apply forcel Move the clrcufer saw forward gently and steadily.

Important:Someof the followingsymbolsmay be usedon yourtool. ptease

studythem and learn theirmeaning,properinterpretationof these symbolswill

allow you to operate the tool better and safer.

SYMBOL

V

A

Hz

min

n0

/mln

NAME

Volts

Amperes

Hertz

Minutes

Aiternating Current

;No Load Speed

Revolutions or Reciprocation

Per Minute

Safety Alert Symbol

_rotection

DESIGNATION/EXPLANATION

Voltage

Current

Frequency(cycles per second)

Time

Type ora characterislicofcurrent

Rotationalspeed, at no load

Revolutions,strokes,sudace

speed, orbitsst¢, per minute

Indicatesdanger,warning or

caution.It means attention!ll

AJwayswear safetygear

©

Wet Condition Alert

Do net exposeto rainor usein

damplocations.

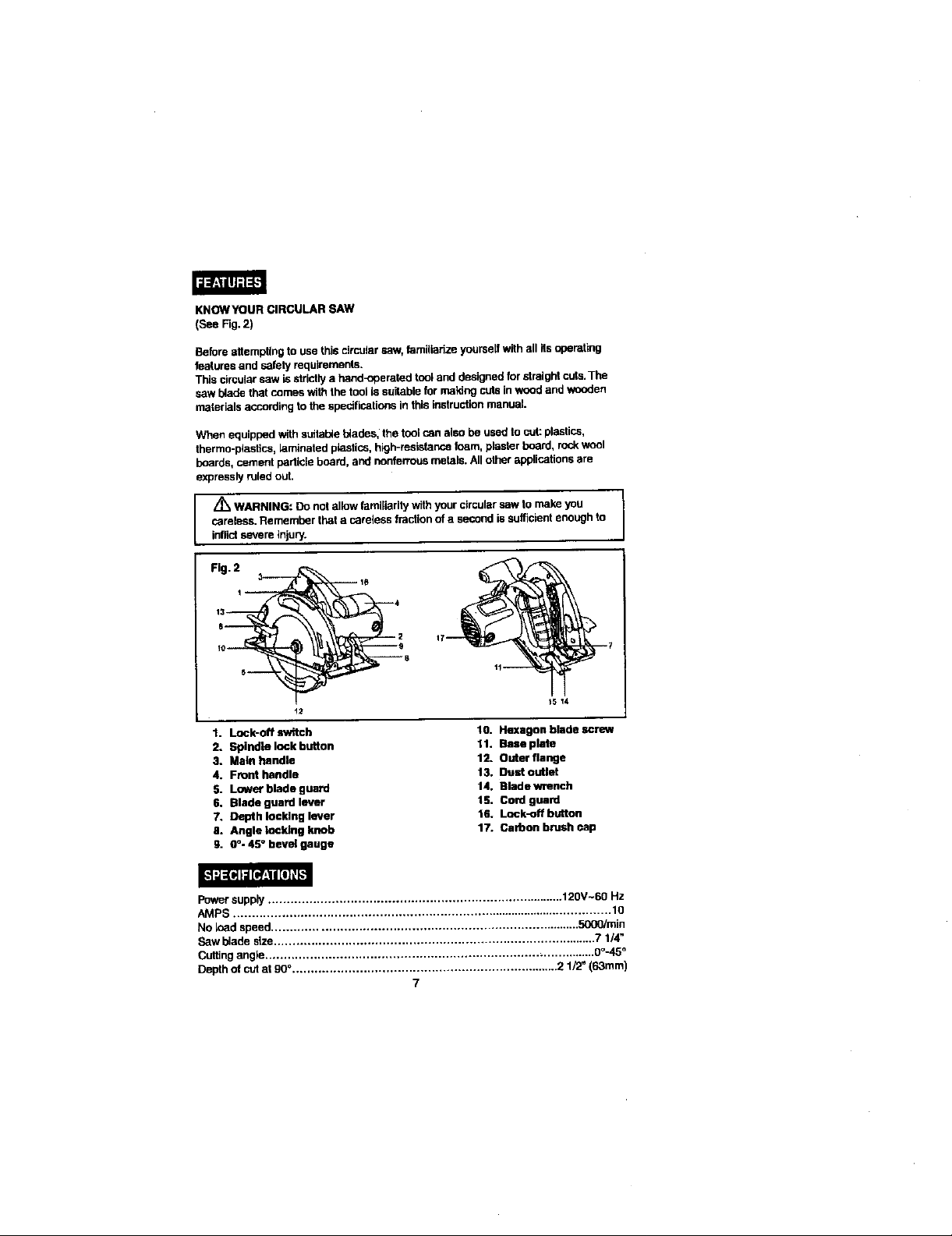

KNOWYOURCIRCULARSAW

(SeeFig.2)

Beforeattempting to usethis circularsaw,familiarizeyourselfwithalllfs operating

features and safetyrequirernen_s.

This circular saw is strictlya hend_Yperatedtcol anddesigned forstraightcuts.The

sawt_ade thatcomes with the tool18suitablefor matdngcufein woad and wooden

materials accordingtothe specificationsinthis instructionmanual.

When equippedwithsuitableblades,the tool can also be used to cut:plastics,

thermo-piastics,laminatedplastics, high-resistanceloam,plasterboard, rockwool

boards,cement particleboard, and nonferrousmetals.Allother applicationsare

expresslyruledout.

WARNING: Do not allow femlliarity with your circular saw to make you

careless. Remember that a carefree traclion of a second is sufifo_ent enough to

inliict severn injury.

Fig. 2

3----

1--

4

10

1. Lock-oft sw_tch

2. Spindle lock button

3. Main handle

4. Front handle

5. Lower blade guard

6, Blade guard lever

7. Depth Io©ldnglever

8. Angle k_ldng knob

5

_5 14

10. Hexagon b_de sq:rew

11. Base plste

12. Onter flange

13. Dust outlet

14, Blade wrench

15, Cord guard

16. Lock-off button

17. Carbon brush cap

g. o°- 45 _bev_ gauge

I.'1"J:l[_llg[If_ I[I}_1€

Powersupply ................................................................................ 120V-60 Hz

AMPS ........................................................................................................ 10

No _oadspeed................................................................................... 5000/min

Sawblade sfz_....................................................................................... 7 I/4"

Cuttingangie......................................................................................... 0°-45°

Depthof cutat 90°........................................................................ 2 1/2" (63mm)

7

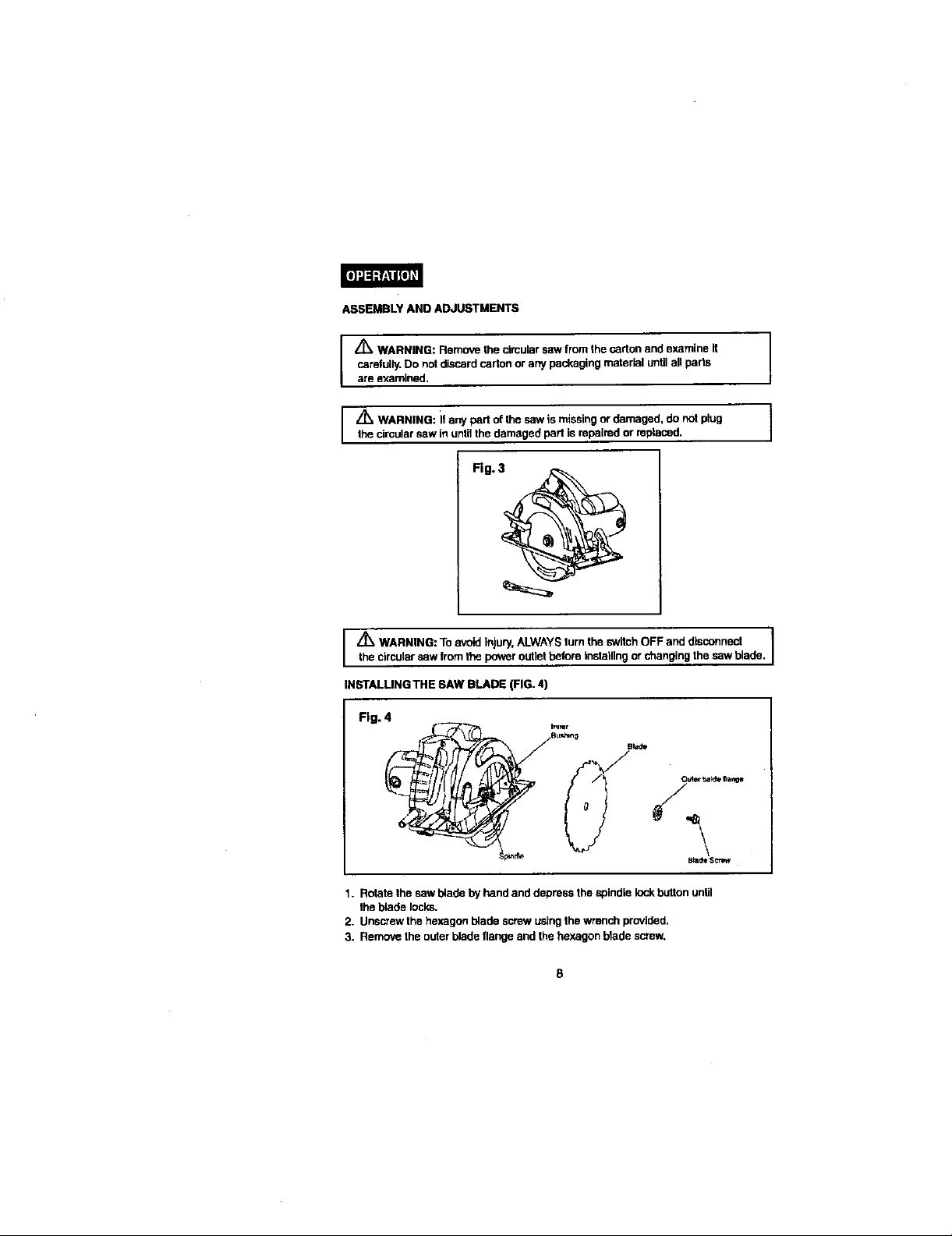

ASSEMBLYANDADJUSTMENTS

carefully. Do not discard carton or any packaging material until all parts

I 1_ WARNING: Remove the circular saw from the carton and examine fl

are examined•

Z_ WARNING: If any part of Ihe saw is missing or damaged, do not plug I

the circular saw in until the damaged part is repaired or replaced.

A_ WARNING:To avoidinjury,ALWAYSturnthe b"WgChOFF and disconnect

the circularsaw fromthe poweroutletbeforeinstatllngorchangingthe saw bade.

INSTALLINGTHE SAW BLADE (FIG. 4)

Fig. 4

I

1. Rotate Ihe sawblade byhand and depressthe spindle lockbuttonunlil

the blade locks.

2. Unsmewthe hexagon blade screwusingthe wrenchprovided.

3. RemoveIhe outer blade flangeand the hexagon blade screw.

8

Loading...

Loading...