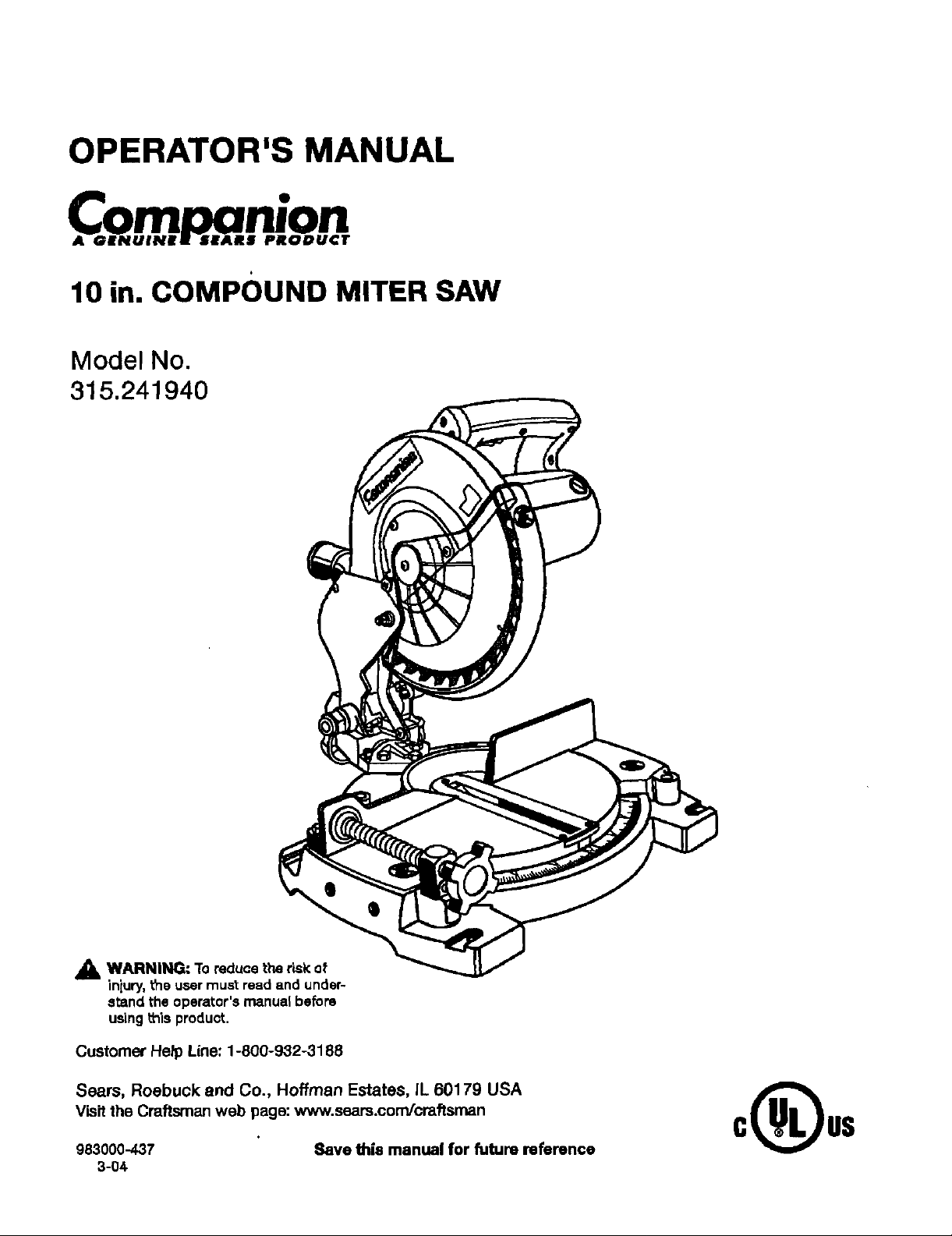

Companion 315241940 Owner’s Manual

OPERATOR'S MANUAL

4

10 in. COMPOUND MITER SAW

Model No.

315.241940

WARNING: To reducethe risk of

iniury, the usermust read and under-

stand the operator's manuatbefore

usingthis product,

Customer Hetp Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-437

3-04

Save this manual for future reference

• Warrantyand introduction................................................................................................................................................. 2

• General Safety Rules..................................................................................................................................................... 3-4

• SpecificSafety Rules..................................................................................................................................................... 4-5

• Symbols......................................................................................................................................................................... 6-7

• Electrical............................................................................................................................................................................ 8

• GlossaryofTerms.............................................................................................................................................................. g

• Features..................................................................................................................................................................... 10-12

• ToolsNeeded ................................................................................................................................................................. 12

• LooseParts .................................................................................................................................................................... 13

• Assembly................................................................................................................................................................... 13-20

• Operation................................................................................................................................................................... 20-26

• Adjustments.............................................................................................................................................................. 27-28

• Maintenance................................................................................................................................................................... 29

• PartsOrdering/Service................................................................................................................................................... 30

ONE YEAR FULL WARRANTY ON COMPANION TOOL

If this Companiontool failsdueto a defect inmaterial orworkmanshipwithinoneyearfromthe date of purchase,

RETURN IT TO THE NEARF__TSEARS STORE IN THE UNITED ffrATE8, and Sears willreplaceit, free of charge.

Thiswarranty isvoid ifthistool isusedforcommercialorrentalpurposes.

This warrantygivesyouspecificlegalrights,and you may also haveotherrightswhich varyfromstate to state.

Sears, Roebuck and Co., Dept. 8t7 WA, Hoffmen Eatates, IL 60179

This tool has many featuresformaking its usemorepteas_ntand enjoyable. Safety, performance,end dependability

havebeen given top pr)oriL'yinthe designof thisproduct making )t easyto maintainand operate.

2

,_ WARNING: Read and understand all inatrucl

tlone. Failureto followall inst_'uctionslistedbelow,

may rssuttin etecLricshock,fire and/or serious

persona_iniury.

READ ALL iNSTRUCTIONS

• KNOW YOUR POWER TOOL. Readthe operator's

manualcarefully.Learnthe eawls applicationsand limi-

tationsas well as the specificpotentialhazardsrelated

to thistool.

• GUARD AGAINST ELECTRICAL SHOCK BY PRE-

VENTING BODY CONTACT WITH GROUNDED

SURFACES. For examp]e, pipes, radiators,ranges,

refrigeratorenclosures.

• KEEP GUARDS IN PLACE and In goodworking order.

• REMOVE ADJUSTING KEYS AND WRENCHES.

Formhabit of checkingto see that keys and adjusting

wrenchesare removedfrpm tool beforeturningit on.

• KEEP WORK AREA CLEAN. Clutteredareas and

benchesinvite _ccidenta.00 NOT _aavetoolsor

piscesofwood on the saw whila It is in operation.

• DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not usa power tools in damp or wet focations or

expose to rain.Keep the work areawell tit.

• KEEP CHILDREN AND VISITORS AWAY.All visitors

shouldwear safety glassesand be kept a safe dLs-

lance fromwork area. Do notlet visitorscontact toolor

extensioncordwhite operating.

• MAKEWORKSHOPCHILDPROOFwith padlock.sand

masterswitches, or byremovingsLarterkeys.

• DON'T FORCE TOOL. [t will do thejob better and

eater at the feed rate for which it was designed.

• USE RIGHT TOOL. Don't force the tool orattachment

to do aiob it was not designed for. Don't use Rfor a

purposenot intended.

• USE THE PROPER EXTENSION CORD. Make sure

yourextensioncord is ingoodcondition.Use onlya

cordheavy enoughto carrythe currentyour product

will draw. An undersizedcord willcause a drop In line

voltageresultingin lossof powerand overheating.A

wire gaugesize (A.W.G.)of at least 14 is recommended

for an extensioncord 25 feet or less in length.If in

doubt, use the next heaviergauge.The smallerthe

gauge number,the heavierthe cord.

• DRESS PROPERLY. Do not wear loose clothing,

gloves,neckties,orjewelry.They can getcaught

and drawyou intomovingparts.Rubber glovesand

nonskidfootwear arerecommendedwhen working

outdoors.Alsowear protectiveha'rrcoveringto contain

long hair.

• ALWAYSWEAR SAFETY GI.ASSEB WITH SIDE

SHIELDS. Everydayeyeglasseshave onlyimpact-

resistantlenses, they are NOT satety glassas.

• SECURE WORK. Use clampsor a vise to hold work

when practical.It's saferthan usingyour hand and

|rees both hands to operate tool

• DON'T OVERREACH. Keep properfootingand bah

ance at all times.

• MAINTAIN TOOLS WITH CARE. Keep toolssharpand

cleanfor better and saferperformance.Follow instruc-

tionsfor lubricating and changingaccessories.

• DISCONNECT TOOLS. When not inuse, before ser-

vicing,or when changingattachments,blades, bits,

cutters,etc., all tools shouldbe disconnected.

• AVOID ACCIDENTAL STARTING. Be sureswitch isoff

when pluggingin anytool.

• USE RECOMMENDED ACCESSORIES. The use of

improper accessories may riskinjury.

• NEVER STAND ON TOOL, Seriousinjury could occur

if the tool istipped or ifthe cutting tool is unintention-

ally contacted.

• CHECK DAMAREO PARTS. _fore furtherLLSeOf

the tOO[,a guardor otherpertthat is dsmeged should

be carefullychecked to determine that it willoperate

properlyand performitsintendedfunction.Check for

alignmentof moving pe_Ls,binding ofmoving parts,

breakageof parts,mounting and any ot_er conditions

that may aff'ecf:its operation.A guardorotherpart that

isdamaged mustbe properlyrepairedor replacedby

an authorized service centertoavoidrisk of personal

injury.

• USE THE RIGHT DIRECTION OF FEED. Feed work

intoa blade or cutter againstthe directionof rotation of

bladeor cutter only.

• NEVERLEAVETOOL RUNNING UNATrENDED,

TURN THE POWER OFR Don't leave tooluntilit

comesto a completestop.

II PROTECT YOUR LUNGS. Weara face ordust mask if

the cuttingoperationisdusty.

• PROTECT YOUR HEARING. Wear hearingprotection

duringsxtandsd periodsof operation.

• DO NOT ABUSE CORD. Neveryankcord to discon-

nect from receptacle.Keep cordfrom heat, oil,and

sharp edges.

• USE OUTDOOR EXTENSION CORDS. When'Lociis

uead outdoors,usa onlyextensioncordswith ap-

provedgroundconnectionthat are intendedfor use

outdoorsand somarked.

• KEEP BLADES CLEAN, SHARP, AND

WTTH SUFFICIENT SET. Sharpbladesminimizestalll

ingand kickback.

• BLADE COASTS AFTER BEING TURNEDOFR

• NEVER USE IN AN EXPLOSNE ATMOSPHERE.

Normal sparkingof themotorcould ignite fumes.

3

• INSPECT TOOL CORDS PERIODICALLY. Ifdamaged,

have repaired by a qus_od sarvicat_.hn_lan at _n

authorizedservicefae){ity.The conductor with insula-

tion having an outersurface that is greenwithorwith-

out yellow eVipse isthe equipment-groundingconduc-

tor.If repairor replacementof the electric cordor plug

isnecessary,do not connectthe equipment-grounding

conductorto a[[ve terminal Repair orreplace a dam-

aged or worn cord immediately.Stay constantlyaware

ofcordlocationand keep it well away from the rotating

b_da.

• INSPECT EXTENSION CORDS PERIODICALLY and

replaceif damaged.

• KEEP TOOL DRY,CLEAN, AND FREE FROM OIL

AND GREASE. Always use a dean c_othwhen clean-

ing. Never use brake fluids, gasoline,petroleum-based

products, orany solvents to clean tool

• STAYALERT AND EXERCISE CONTROL, Watch

what you are doingand use common sense. Do not

operatetoo{when you aretired. Do not rush.

• DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defectiveswitchesreplaced byan

authorizedservice center.

• USE ONLY CORRECT BLADES. Do not useb{ades

with incorrectsize hoise.Never use bladewashersor

b_de boltathat are defective or {nCOTT_"_."[hemBx_-

mum b%adaeapad_ ofyoursaw Is 10 in. (254 ram).

• BEFORE MAKING ACUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

• BESURE BLADE PATH IS FREE OF NAILS. Inspect

for and remove atfna_sfrom lumber beforecutting.

• NEVER TOUCH BLADE orothermoving partsduring

UaS.

• NEVER STARTATOOLWHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKP|ECE.

• DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR AI_Y

MEDICATION.

• WHEN SERVICING useonly identic_ replacement

parts.Use ofanyother pads may createa hazard or

cause productdarr_ge.

• CHECKWITH AQUALIFIED ELECTRICIAN orservice

personnelJfthegroundinginstructionsarenot com-

pletelyunderstoodor it indoubt as to whether thetoot

LSproperlygrounded.

• USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories

that are not listed may cause the risk of personal

injury.Instructions for safe use of accessories are

included with the accessory.

• DOUBLE CHECK ALL SETUPS, Make sure blade is

tight and not making contact w)th saw or workpiece

before connecting to power supply,

• FIRMLY CLAMP OR BOLTyour miter sew to a work- •

benchor table at approximatelyhip height.

• KEEP HANDS AWAY FROM CUTrlNG AREA. Do not

reach underneath wor!<or in bladecuttingpath wlth

yourhands and fingersfar any reason.Alwaysturn the

power off.

• ALWAYS SUPPORT LONG WORKIPIECES whilecut-

tingto minimizeriskof blade pinchingand kloid0aok. •

Saw mayslip, walk or slide whilecutting long orheavy

boards.

• ALWAYS USE A CLAMP to secure the workplece

when possible.

• BE SURE THE BLADE CLEARS THE WORKPIECE.

Neverstart the sewwith the bladetouchingthe

wcrkpiece. Allow motorto come up to fullspeed

before startingcut.

• MAKE SURE THE MITER TABLE AND SAW ARM

(BEVEL FUNCTION) ARE LOCKED IN POSITION

BEFORE OPERATING YOUR SAW. Lock the miter

table bysecurelytightening the miterlocklevers. Lock

the saw arm (bevelfunction}bysecurelytighteningthe

bevel lockknob.

NEVER USE A LENGTH STOP ON THE FREE SCRAP

END OF A CLAMPED WORKPIECE. NEVER hold

onto orbind the free scrap end of theworkplace in any

operat'_r_. If=_work clamp and length stopare used

together,they must both be installedon the same side

ofthe sew _ablato preventthe sew from catchingthe

looseend and kickingup.

NEVER out more than one piece at a time. DO NOT

STACK more than oneworkpiece on the saw table at a

time.

NEVER PERFORM ANY OPERATION FREEHAND.

Alwaysplacethe workpJeceto becut on the miter

table and positionit f'_mlyagainstthe fence ase back-

stop.Alwaysusethe fence.

NEVER handholda workpieoethat istoo smallto be

clamped. Keep handsriser of the cutting arcs.

NEVER reachbehind, under,orwithinthreeinches

ofthe blade and its cuttingpath w_h yourhands and

fingersfor any reason.

• NEVER reach to pick up a workpiece, a piece of scrap,

or anything e_ssthat is in or near the cutting path of the

b_de,

• AVOID AWKWARD OPERATIONS AND HAND PO-

SITIONS where a sudden slip couldcause your hand

to move intothe blade. ALWAYS make sure you have

good balance. NEVER operateyourmiter saw onthe

flooror in a crouchedposition.

• NEVER stand or haveany part of your bodyin line wfth

the path of the saw blade.

• ALWAY8 releasethe power switch and allow the

saw blade to stop rotating beforeraising itout of the

workpiece.

• DO NOT TURN THE MOTOR SWITCH ON AND OFF

RAPIDLY. "l%hiscou(dcausethe saw blade to loosen

and could createa hazard. Shouldthis ever occur,

stand cTserand at_owthe saw blade to come to s com-

plete stop. Disconnectyoursawfromthe powersupply

and socurolyretightenthe blade bolt.

• IFANY PARTOF THIS MITER SAW IS MISBING or

shouldbreak, band, orfail in anyway, or shouldany

electricalcomponent fail to perform properly,shut off

the power switch,remove the miter saw plug(Tomthe

power sourceand have damaged, missing, or failed

parts replaced beforeresumingoperation.

• ALWAYSSTAY ALERT] Do not allowfamiliarity (gained

from frequentuse ofyour saw)to seuse a careless

mistake. ALWAYS REMEMBER that a carelessfraction

of a second is sufficientto inflictsevere injury.

• MAKESURETHEWORKAREAHASAMPLE LIGHT-

ING to see the work andthat no obstructionswit] inter-

tara with saf_ oper-tion BEFORE psrtorr_in(.}any work

usingyour saw.

• ALWAYSTURN OFF THE SAW before disconnecting

it to avoid accidentalstartingwhen reconnectingto

power suppty.NEVER leave the saw unattendedwhile

connected toa powersource.

• THIS TOOL should havethe following markings:

a) Wear eye protection.

b) Keep hands out of path of saw blade

c) Do not operate saw withoutguardsinpJaos.

d) Do not perform any operation freehand.

e) Never reach aroundsew b{ade.

f) Turnoff tool and walt for saw blade to stop before

moving work.pieceorchang(rigsettings.

g) Disconnectpower (or unplugtool as applicab{e)

beforechangingbladeor servicing.

h) No loadspeed.

• ALWAYS carrythe tool onlyby the carrying handle.

• SAVETHESE INSTRUCTIONS, Referto them

frequently and use to instructother usem.If you loan

someonethistool, loan them thessinstructionsalso.

WARNING: S(xr_ dust created by powersand{ng,sawing, gr(nding, drii{(ng, end otherconstruction_ctNitiea con-

tains chemicals knownto cause cancer, birthdefects orother reproductiveharm.Some examples ofthesechem-

icalsare:

• leadfrom lead-based paints,

• crystallinesilicafrom bricksand cement and othermasonryproducts,and

• arsenicand chromium fromchemically-treated {umber.

Yourrisk(Tomtheseexposures varies,dependingon how oftenyou do thistype of work.Toreduceyourexposure

to these chemicals: work ina well ventilatedarea, and work with approved safety equipment,suchas those dust

masks that are speciallydesignedto filteroutmicroscopicparticles.

5

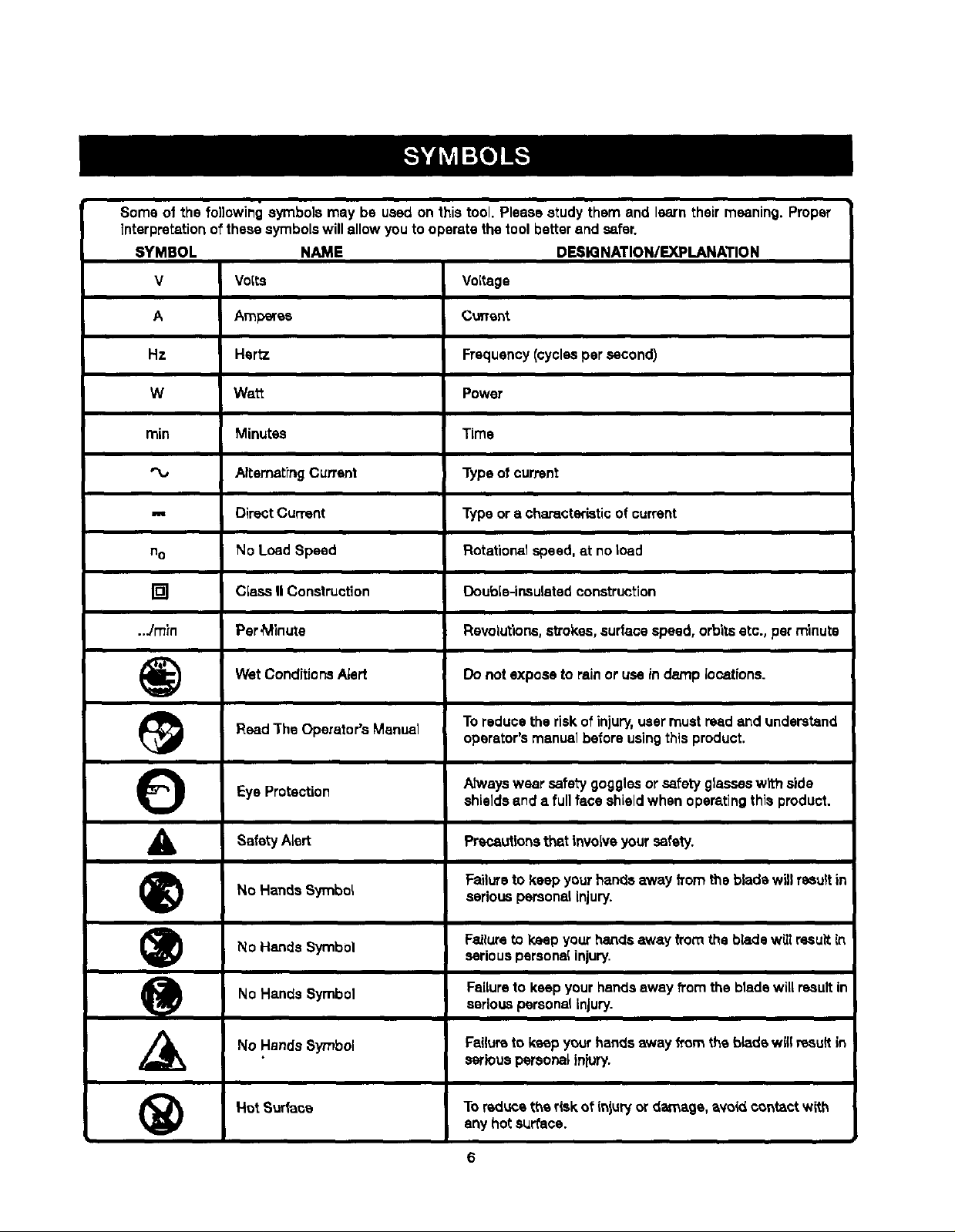

Someof the followingsymbols may be used on this tool. Pleasestudy them and learntheir meaning. Proper

interpretation of these symbolswillallow you tooperate thetool betterand s,_fsr.

SYMBOL NAME OESIQNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency(cyclesper second)

W Watt Power

rain Minutes Time

AitemetingCurrent Type of current

•- DirectCurrent Type or a characteristicof current

no No Load Speed Rotationalspeed,at notoad

[] ClassII Construction Daub[s-insulatedconstruction

..Jmin Per.Minute Revolutions,stTokes,surface speed, orbitsetc., per minute

WetConditionsAJert Do notexpose to rainor use in damp locations.

Read The Operator's Manual Toreducethe riskof injury,usermustread and understand

Eye

Protection Atwayswear safety gogglesor safety glasseswith side

Safety Atert Precautionsthat involve

No Hands Symbo_ seriouspersonatinjury.

(_ Failureto keep yourhandsaway from the bladew_lresult_n

e Failureto keepyour handsawayfromthe bladewill resultin

(_ Ho'_Surface To reducethe riskof {niuryordt_'_age,avoid contactw_th

No Hands Symbol serious persona{injury,

No Hands Symbol seriouspersona{injury.

No HandsSymbol Failureto keep y_ur hands away fromthe blade wi{{resultin

operator'smanual beforeusingthis product.

shieldsand a fullface shieldwhen operatingthis product.

yoursafety.

Failureto keepyour handsawayfromthebladewillrseu_tin

seriouspersona_in,P/.

anyhot surface.

6

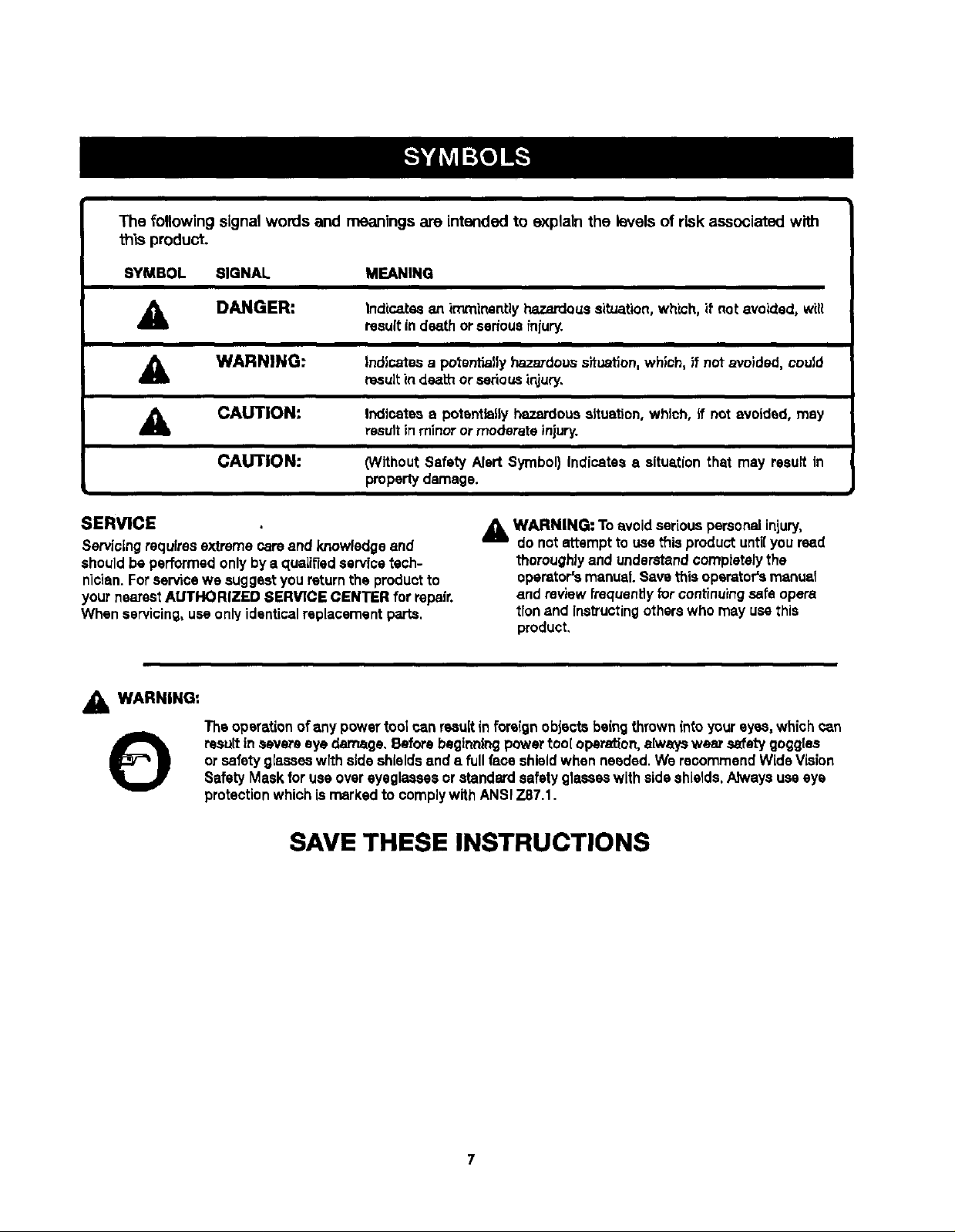

The following signal words and meanings are intended to explain the levels of risk associated with

this product.

SYMBOL SIGNAL MEANING

A DANGER:

WARNING:

CAUTION:

CAUTION:

SERVICE

Servicingrequiresextremecareand knowledgeand

shouldbe performedonlyby a qualifiedservicetech-

nician.For servicewe suggestyoureturnthe productto

your nearestAUTHORIZED SERVICE CENTER for repair.

When servicing,use onlyidenticalreplacementparts.

& WARNING:

The operationof any powertool can resultin foreign objectsbeingthrowninto youreyes, whichcan

resultin severe eye damage, Before beginningpower too[ operation,always wear safetygoggles

O

or safety g[aseeswlthside shieldsand a fullface shieldwhen needed.We reoommendWide Vision

Safety Mask for useover eyeglasses or standard safety glasseswith side shields.Alwaysuse eye

protectionwhichis marked to complywith ANSI Z87.1.

Indica.tssan imrninantlyil_.ardous situation,which, if not avoided, will

resultin death orseriousfniury.

Indicates a potentiallyhazardoussituation,which, if not avoided, could

resultin death or seriousinjury,

Indicates a potentially hazardoussituation,which, ifnot avoided, may

resultinminorormoderate injury.

_/ithout Safety Alert Symbol) Indicates a situs,tion that may result in

propertydamage.

WARNING: To avoidseriouspersonalinjury,

do not attempt to use thisproductuntilyouread

thoroughlyand understandcomptetalythe

operator'smanual.Save this operators manual

and review frequently for continuingsafe opera

tfonand Ins_'uctingotherswho may usethis

product,

SAVE THESE INSTRUCTIONS

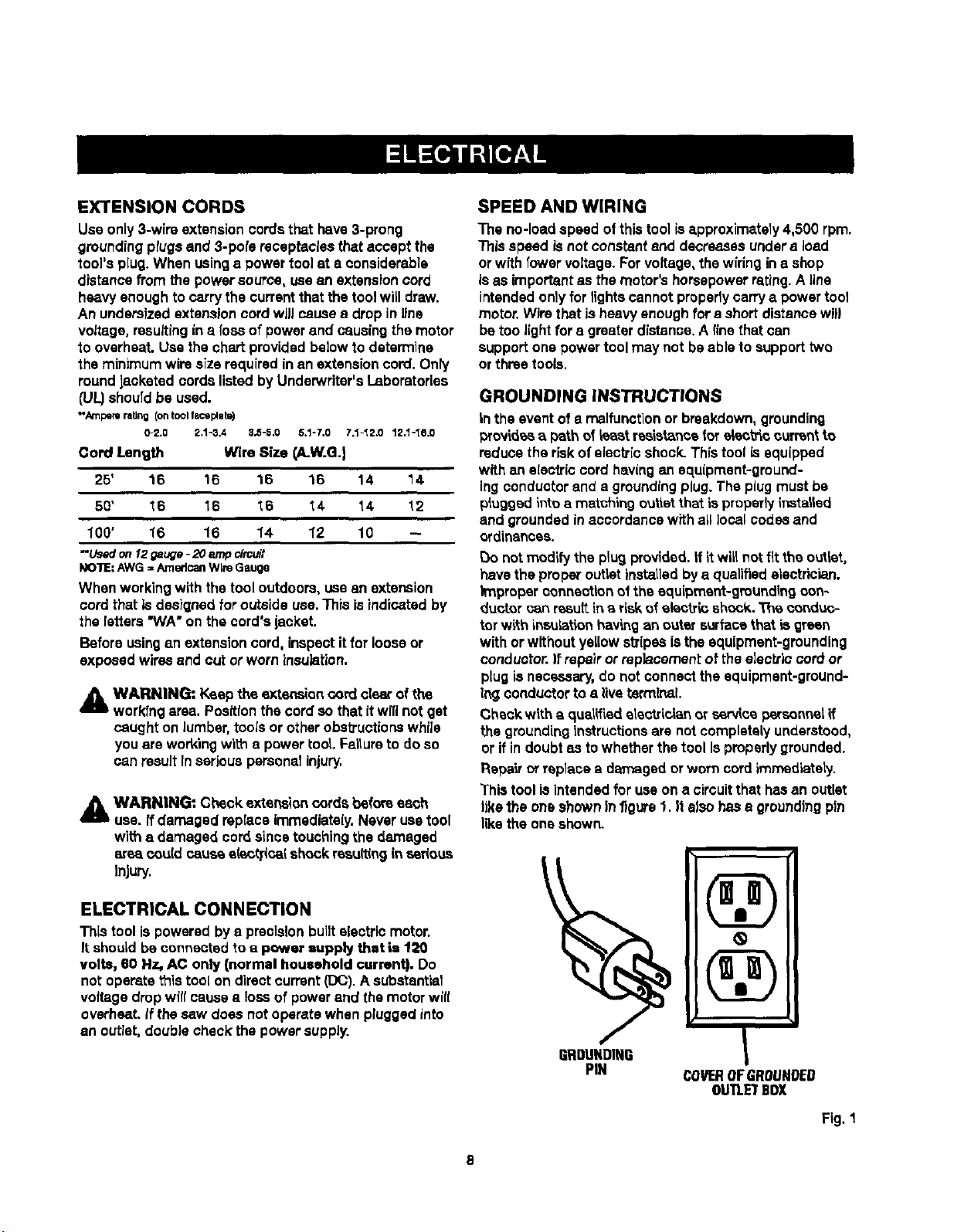

EXTENSION CORDS

Use only 3-wire extensioncordsthat have3-prong

groundingplugsand 3-pole receptaclesthat accept the

tool's plug. When usinga power tool at s considerable

distancefrom the powersource, use an extensioncord

heavyenough to carrythe currentthat the toolwill draw.

An undersizedextensioncord will causea drop in line

voltage, resultingina foes of powerand causingthe motor

to overheat.Use the chart providedbelowto determine

the minimumwire size requiredin an extensioncord. Only

roundJacketedcordslistedby Underwriter'sLaboratories

(UL)shouldbe used.

-Ampe_ rating (ontool facep!ete)

0-2.0 2.%3,4 3,5-5.0 5.1-7,0 7.%_ 2.0 12,1-'{0,0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 _6 _4 14 12

100' 16 16 14 12 10 --

--Ueed on12 gauge - 20 amp circuit

NO'RE:AWG = Amedcan Wire Gauge

When working with thetool outdoors,use an extension

cord that isdesigned for outside use.Thisisindicated by

the letters"WA" on the cord's jacket.

Before using an extensioncord. inspectitfor looseor

exposed wiresand cut or worn insulation.

A WARNING: Keep the extension cord clearof the

workrngarea. Positionthe cord so that it wiflnotget

caught on lumber,toolsorotherobstructionswhile

youare workingwith a power tool.Failureto doso

can result fnseriouspersonal injury.

WARNING: Check extensioncordsbefore each

use. If damaged replace immediately.Neveruse tool

with a damaged cordsince touchingthe damaged

are_ cou(dcause s(oc_cat shock resu(tinginserious

Injury.

SPEED AND WIRING

The no-loadspeed of thistool isapproximately4,500 rpm.

7his speed isnot constant and decreasesundera Iced

or with fewer voltage. Forvoltage, the widng ina shop

isas importantas the motor'shorsepowerrating.A line

intendedonly for lightscannot properlycarrya powertool

motor.Wirethat isheavyenoughfor a shortdistancewill

betoo lightfora greaterdistance.A finethat can

supportone power toolmay not be able to support two

or three tools.

GROUNDING INSTRUCTIONS

in the event of a malfunctionor breakdown,grounding

provides _ pathof k_astresistancefor electriccurrentto

reducethe riskof electricshock.Thistool isequipped

with an electric cordhaving an equipment-ground-

ingconductoranda groundingplug.Theplugmustbe

plugged intoa matchingoutletthat isproperlyinstalled

and groundedinaccordancewith all local codesand

ordinances.

Do notmodify the plu9 provided.Ifit winnotfit the outlet,

havethe properoutletinstalledbya qualifiedelectrician.

improper connectionof the equipment-groundingcon-

ductor can re,sultina riskof eiectr_ shock.The cond_,-

tor with insulation hav_ngan outersurface that is green

with orwithout yellowsffipesis the equipment-grounding

conductor.)f repairor replacementof the electriccordor

plugis necessary,do notconnect the equipment-ground-

ingconductorto a live tarmlna}.

Check with a qualified electrician _r ser_ce persone_elif

the groundinginstructionsare notcompletelyunderstood,

or if indoubt as to whether the tool Is properlygrounded.

Repairor replace a damaged orworn cordimmediately.

Thistool isintendedfor use on a circuitthat hasan outlet

likethe one shown infigure 1, It else has s groundingpin

likethe one shown.

ELECTRICAL CONNECTION

This tool is poweredby a precisionbuiltelectricmotor.

It should beconnected to a power supply that is t20

volts, 60 Nz, AC only (normal household current). Do

not operatethis toot on direct current(DC). A substantial

voltagedropwiltcausea lossof powerand the motorwltl

overheat,If the saw does notoperate when pluggedinto

an outlet,double check the powersupply.

GBDUNDING I

PIN COVEROFGROUNDED

OUTLETBOX

Fig. 1

8

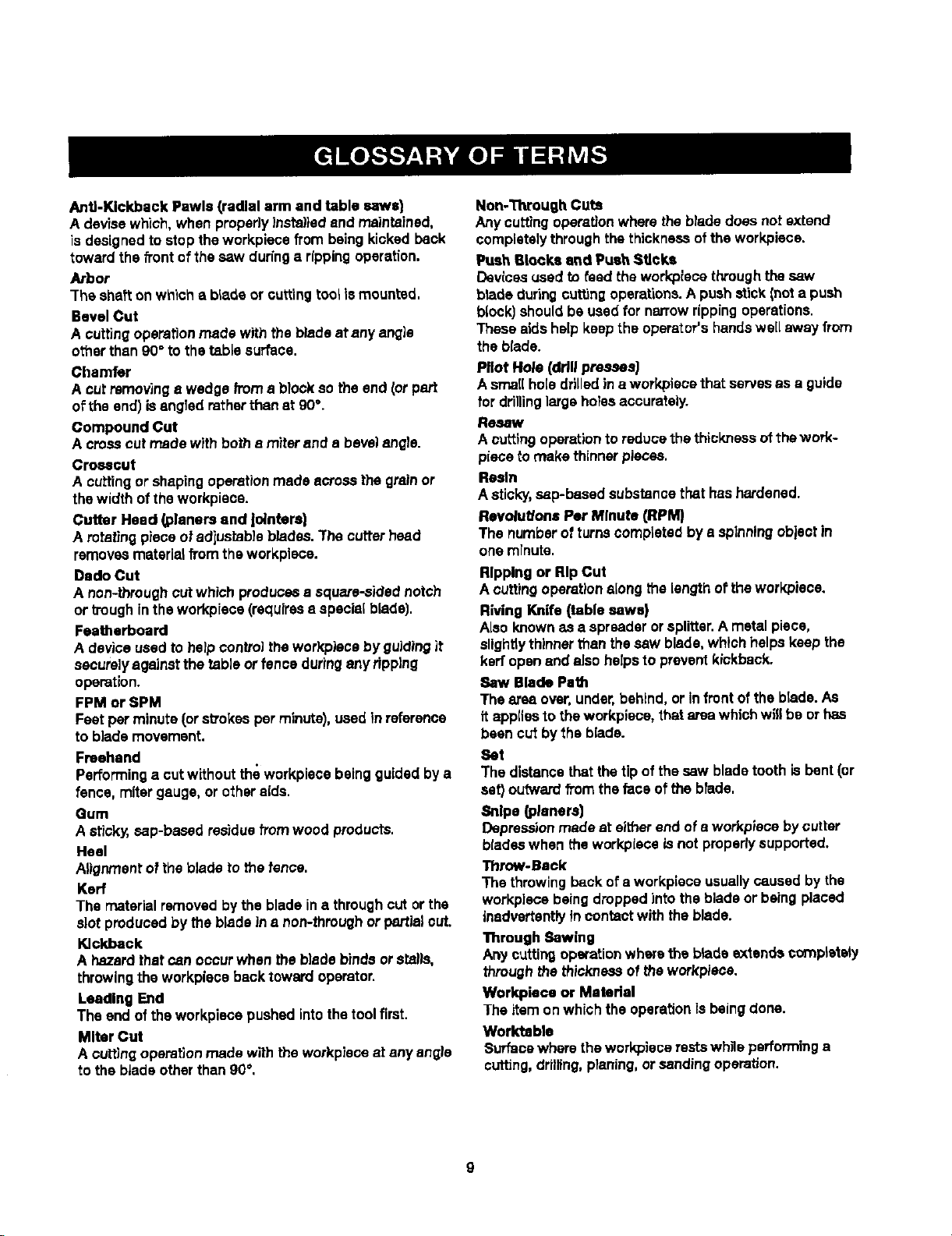

Anti-Kickback Pawls (radial arm and table saws)

A dev?sewhich,when property ?nste]ladand maintained,

isdesigned to stop the workplace from being kiokedback

towardthe front ofthe saw duringa rippingoperation.

Arbor

The shaft onwhich a blade or cutting tool is mounted,

Bevel Cut

A cuttingoperationmade with the blade atany angle

otherthan 90" to thetable surface.

Chamfer

A cut removinga wedge from• block sothe end (or part

ofthe end) isangled ratherthan at 90°.

Compound Cut

A crosscut madewithboth e miterend a bevel angle.

Crosscut

A cuttingor shaping operationmade acrossthe grainor

thewidth of theworkpieee.

Cutter Head (Planers and Io/ntera|

A rotating plaoeof adiustablablades.The cutter heed

removesmaterialfrom the workplece.

Dedo Cut

A non-throughcutwhich producese squara-sJdsdnotch

or hough inthe work,piece (requiresaepsolaiblade).

Featherboard

A device used to helpcentre] the workpJecaby guiding Jt

securelyagainst the table or fence duringany ripping

operation.

FPM or SPM

Feet per minute (orstrokes perminute),used in reference

to blade movement.

Freehand

Performinga cutwithout the workplacebeing guided by a

fence, mitergauge, or other aids.

Gum

A sticky,esp-bassd residuefrom wood products,

Heel

Alignmentof the blade to thefence.

Kerr

The material removedby the blade ina throughout orthe

slot producedby the bladeina non-through or pertlalcut.

Klckback

A hazard that can occur when theblade bindsor stalls,

throwingthe workpleoe back towerd operator.

Leedlng End

The end ofthe workpieoepushedintothe tool first.

Miter Cut

A cuttingoperationmade with theworkp?eoeat any angle

tothe bladeother than 90°,

Non-Through Cuts

Any cuttingoperationwhere the blade does not extend

completelythroughthe thickness ofthe workpiecs.

Push Blocks and Push Sticks

Devicesused to feed the work:piecethroughthe saw

blade duringcuttingoperations.A push stick(nota push

block)shouldbe used for narrowrippingoperations.

These aids help keep the operator'shands well away from

theblade.

Pilot Hole (drillpresses]

Asmall hole drilledina workpiecethat servesasa guide

for drillinglarge holesaccurately.

Ra_w¢

A cuttingoperationto reducethethickness of the work-

piece to make thinnerpieces,

Resin

A sticky,eep-based substanoethat hashardened.

Ravoful_tonsPar Minute (RPM)

The numberof turnscompleted by a spinning object in

one minute.

Ripping or Rip Cut

A cuttingoperationalong the lengthof theworkplace.

Riving Knife (table saws)

Alsoknown as a spreaderor splitter. A metal piece,

slightlythinnerthan the sew blade,whichhelps keepthe

kerr open and also helpsto preventkickback.

_v Blade Path

The areaover, under,behind,orinfrontof the blade. As

it appliesto the wcrkpiece, that areawhich will be or has

been cut by the blade.

Set

The distancethat thetipof thesaw blade tooth is bent (or

set) outwardfrom the face of the blade.

Snips (planers}

DeprassJonmade at either end of s workplace by cutter

bladeswhen the workpiece isnot properlysupported.

Throw-Beck

The throwingback of a workpiece usuallycaused by the

wcrkplacsbeing droppedintothe blade or being placed

inadvertentlyincontact with the blade.

Through Sawing

Any cuttingoperationwhere the blade extends completely

through the thickness of the wcrkpleca.

Work.piece or Material

The item on whichthe operationis beingdone.

Worktable

Surfacewhere theworkpiecerests whileperforatinga

cutting,drilling,planing,or sandingoperation.

g

Loading...

Loading...