Companion 17221399 Owner’s Manual

Operator's Manuam

@

21399-MANUAL

Save this manual for future reference.

CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions in

this manual before using this product.

Sears, Roebuck and COo,Hoffman Estates, UL60179 U.SoA.

P/N 21399-MANUAL

LISTED

tgDV

oSAFETY

e FEATURES

oASSEMBLY

oADJUSTMENT

oOPERATRON

o MAnNTENANOE

AOCESSORBES

Warranty. ....................................................................... Page 2

Safety Instructions .................................................... Pages 3 - 11

Safety Symbols ..................................................... Page 6

Glossary of Terms ................................................... Page 12 o 13

Product Specifications and Unpacking ......................... Page 14

Carton Contents ................................................... Page 14

Loose Parts and Tools Needed ..................................... Page 14 o 15

Description .................................................................... Page 15 - 16

Assembly ............................................................ Pages 17 - 19

Adjustments .................................................................. Pages 20 - 22

Operation .................................................................. Pages 23 =24

Maintenance ................................................................. Pages 25 - 26

Accessories ........................................................ Page 26

ONE YEAR FULL WARRANTY ON COMPANION TOOL

If this Companion tool fails due to a defect in material or workmanship within one year from the

date of purchase, CONTACTTHE NEAREST SEARS PARTS & REPAIR CENTER at

I=800o4oNIY-HOME ®and Sears will replace it, free of charge. This warranty applies only while

this product is in the United States.

This warranty is void if this tool is used for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

SAVE THESE INSTRUCTmONS!

READ ALL UNSTRUCTmONS!

2

Z_ WARNmNG: BE SURE to read and understand all safety instructions in this manual,

including all safety alert symbols such as DANGER, WARNING and CAUTHON, BEFORE

using this tool. Failure to follow all instructions listed below may result in electric shock,

fire and/or serious personal injury.

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols

and the explanations with them, deserve your careful attention and understanding. The safety

warnings DO NOT by themselves eliminate any danger. The instructions and warnings they give

are no substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates danger, warning or caution. May

be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to

yourself or to others. Always follow the safety precautions to reduce the risk

of fire, electric shock and personal injury.

WARNRNG: Failure to obey a safety warning can result in serious injury to

yourself or to others. Always follow the safety precautions to reduce the risk

of fire, electric shock and personal injury.

WEAR YOUR

CAUTaON: Failure to obey a safety warning may result in property damage or

personal injury to yourself or to others. Always follow the safety precautions to

reduce the risk of fire, electric shock and personal injury.

NOTE: Advises you of information or instructions vital to the operation or

maintenance of the equipment.

Z_ _'V'ARNmNG: The operation of any tool can result in foreign objects

being thrown into your eyes, which can result in severe eye damage.

Before beginning power tool operation, ALWAYS wear safety goggles

or safety glasses with side shields and a full face shield when needed.

We recommend A Wide Vision Safety Mask for use over eyeglasses or

standard safety glasses with side shield, both available at Sears Retail

Stores. ALWAYS wear eye protection which is marked to comply with

ANSI Z87.1.

3

ELECTRICAL SAFETY

General Electrical Connections

Z_ DANGER: To reduce the risk of electrocution:

1. Use only identical replacement parts when servicing. Servicing should be performed

by a qualified service technician.

2. DO NOT use in rain or where floor is wet. This tool is intended for indoor use only.

110=120 Volt, 60 Hz. Tool Brfformation

The plug supplied on your tool may not fit into the outlet you are planning to use.Your local

electrical code may require slightly different power cord plug connections. If these differences exist,

make the proper adjustments per your local code before your tool is plugged in and turned on.

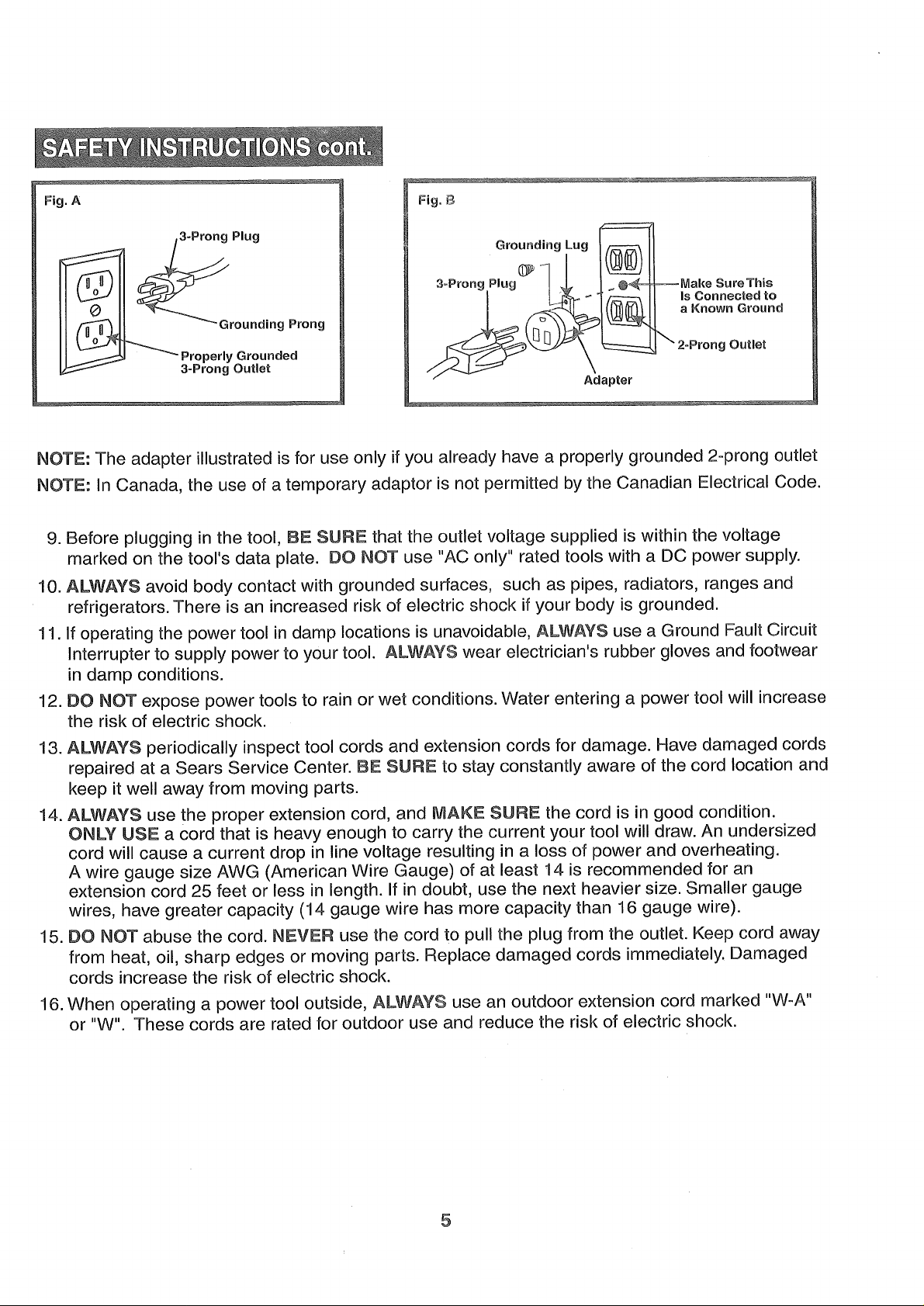

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having

an equipment-grounding conductor and a grounding plug, as shown (Fig. A). The plug must be

plugged into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

DO NOT modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a

qualified electrician.

A temporary adapter may be used to connect this plug to a 2=prong outlet as shown (Fig. B) if a

properly grounded 3-prong outlet is not available. This temporary adapter should be used only until

a properly grounded 3-prong outlet can be installed by a qualified electrician. The green colored

rigid ear, lug or the like, extending from the adapter must be connected to a permanent ground such

as a properly grounded outlet box.

Improper connection of the equipmentlgrounding conductor can result in a risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow stripes is

the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary,

DO NOT connect the equipment-grounding conductor to a live terminal.

/4kxWARNHNG: DO NOT permit fingers to touch the terminals of the plug when inserting or

removing the plug to or from the outlet. '_ .....

If the grounding instructions are not completely understood, or if you are in doubt as to

whether the tool is properly grounded, check with a qualified electrician or service personnel.

I part of the tool c°z_WARNIN-_---G: I_f not properly grounded, t i-s tool can caue an electrica s-hock__particul---_arl_ "_-

when used in damp Iocat ons, n proximity to plumbing, or out of doors. If an electrical shock

occurs, there is the potential of a secondary hazard, such as your hands contacting a moving

ausing serious injury.

4

Fig. A

Fi 9. B

Grounding Lug .....-----_,

Plug

3-Pro.gp,.g I

_ _Grounding Prong

_Make SureThis

Is Connected to

a Known Ground

_ 2=Prong Outlet

"o"

NOTE: The adapter illustrated is for use only if you already have a properly grounded 2-prong outlet

NOTE: In Canada, the use of a temporary adaptor is not permitted by the Canadian Electrical Code.

9. Before plugging in the tool, BE SURE that the outlet voltage supplied is within the voltage

marked on the tool's data plate. DO NOT use "AC only" rated tools with a DC power supply.

10. ALWAYS avoid body contact with grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

11. If operating the power tool in damp locations is unavoidable, ALWAYS use a Ground Fault Circuit

Interrupter to supply power to your tool. ALWAYS wear electrician's rubber gloves and footwear

in damp conditions.

12. DO NOT expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

13. ALWAYS periodically inspect tool cords and extension cords for damage. Have damaged cords

repaired at a Sears Service Center. BE SURE to stay constantly aware of the cord location and

keep it well away from moving parts.

14. ALWAYS use the proper extension cord, and MAKE SURE the cord is in good condition.

ONLY USE a cord that is heavy enough to carry the current your tool will draw. An undersized

cord will cause a current drop in line voltage resulting in a loss of power and overheating.

A wire gauge size AWG (American Wire Gauge) of at least t4 is recommended for an

extension cord 25 feet or less in length. If in doubt, use the next heavier size. Smaller gauge

wires, have greater capacity (14 gauge wire has more capacity than 16 gauge wire).

15. DO NOT abuse the cord. NEVER use the cord to pull the plug from the outlet. Keep cord away

from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

16. When operating a power tool outside, ALWAYS use an outdoor extension cord marked "W°A"

or "W". These cords are rated for outdoor use and reduce the risk of electric shock.

5

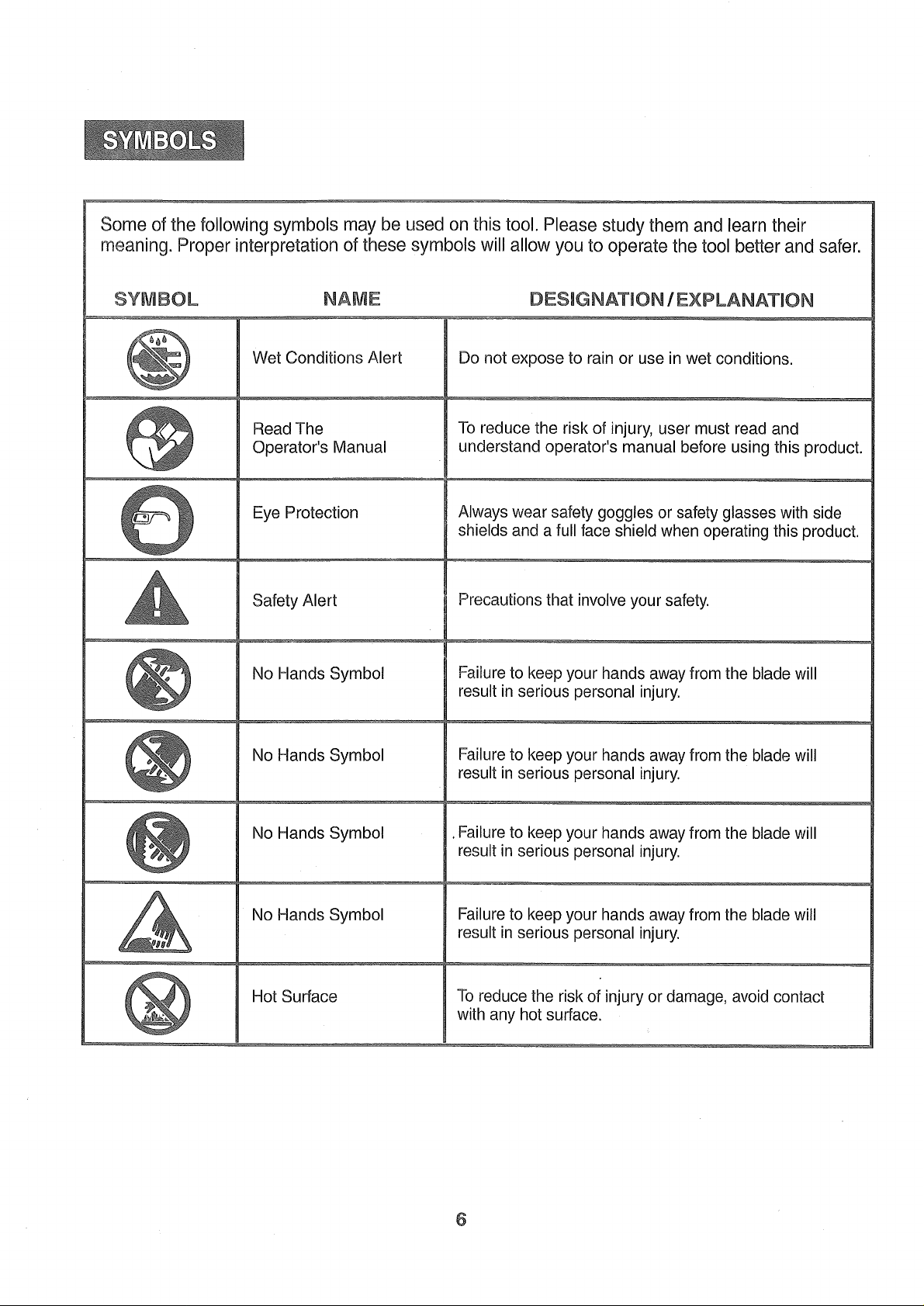

Some of the following symbols may be used on this tool. Please study them and learn their

moaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL

@

0

NAME

Wet Conditions Alert

Read The

Operator's Manual

Eye Protection

Safety Alert

No Hands Symbol

DESIG NAT_ON / EXPLANATION

Do not expose to rain or use in wet conditions.

To reduce the risk of injury, user must read and

understand operator's manual before using this product.

Always wear safety goggles or safety glasses with side

shields and a full face shield when operating this product.

Precautions that involve your safety.

Failure to keep your hands away from the blade will

result in serious personal injury.

@

No Hands Symbol

No Hands Symbol

No Hands Symbol

Hot Surface

Failure to keep your hands away from the blade will

result in serious personal injury.

,Failure to keep your hands away from the blade will

result in serious personal injury.

Failure to keep your hands away from the blade will

result in serious personal injury.

To reduce the risk of injury or damage, avoid contact

with any hot surface.

6

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. DO NOT leave tools or pieces of wood on the

tool while it is in operation. Cluttered benches and dark areas invite accidents.

2. DO NOT operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

3. ALWAYS keep bystanders, children and visitors away while operating a power tool. Distractions

can cause you to lose control.

4. ALWAYS make your workshop childproof with padlocks and master switches or by removing

starter keys.

5. ALWAYS make sure the work area has ample lighting so you can see the work and that there are

no obstructions that will interfere with safe operation BEFORE using your tool.

PERSONAL SAFETY

1. ALWAYS know your power toot. Read the operator's manual carefully, learn the tool's applications

and limitations, as well as the specific potential hazards related to this tool.

2. ALWAYS stay alert, watch what you are doing and use common sense when operating a power

tool. DO NOT use toot while tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal injury.

3. ALWAYS dress properly. DO NOT wear loose clothing, gloves, neckties, rings, bracelets or other

jewelry that can get caught and draw you into moving parts. Non-slip footwear is also recommended.

Pull back long hair. Keep your hair, clothing and gloves away from moving parts. Loose clothing,

jewelry or long hair can be caught in moving parts.

4. ALWAYS remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is

left attached to a rotating part of the tool may result in personal injury.

5. ALWAYS wear safety glasses with side shields. Everyday eyeglasses have only impact resistant

lenses, they are NOT safety glasses.

6. ALWAYS wear a dust mask to keep you from inhaling fine particles.

7. ALWAYS protect your hearing. Wear hearing protection during extended periods of operation.

8. ALWAYS secure your work. Use clamps or a vise to hold work when practical. It is safer than

using your hand and frees both hands to operate tool.

9, DO NOT overreach. ALWAYS keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

10o ALWAYS avoid accidental starting. BE SURE switch is in the "Off" position before plugging in.

11o NEVER stand on tool. Serious injury could occur if the tool is tipped or if the tool is accidentally contacted.

TOOL USE AND CARE SAFETY

1. NEVER leave the tool running unattended. ALWAYS turn it off. DO NOT leave the tool until it

comes to a complete stop.

2o DO NOT use the tool if the switch does not turn it "On" or "Off". Any tool that cannot be controlled

with the switch is dangerous. ALWAYS have defective switches replaced at a Sears Service Center.

3. ALWAYS disconnect the plug from the power source before making any adjustments, changing

accessories or storing the tool. Such preventive safety measures reduce the risk of starting the

tool accidentally.

4. ALWAYS store idle tools out of the reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

7

TOOL USE AND CARE SAFETY cont.

5. ALWAYS maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools

with sharp cutting edges are less likely to bind and are easier to control. Follow instructions for

lubricating and changing accessories.

D

DO NOT force the tool; it will do the job better and more safely at the rate for which it was designed.

7.

ALWAYS use the right tool for the job. DO NOT force the tool or attachment to do a job it

was not designed for. Use it only the way it was intended.

m

Before using this tool, ALWAYS check for damaged parts, including guards for prop operation

and performance. Also ALWAYS check the alignment of moving parts, binding of moving parts,

breakage of parts, tool stability, mounting and any other condition that may affect the tool's

operation. If damaged, have the tool serviced at a Sears Service Center before using. Many

accidents are caused by poorly maintained tools.

I Z_WARNING: Use of accessories that are not recommended for use with this tool may createa hazardous condition.

9. Only use accessories that are recommended for this tool. Using. improper

accessories may cause the risk of serious injury. See accessones section of this manual

for proper accessories.

ADDmONAL SPECIFIC SAFETY RULES FOR BAND SAWS

i Z_WARN"NG: DO NOT °perate y°ur band saw until it is c°mpletely assembled and installedlaccording to the instructions.

.

Know your power tool. Read operator's manual carefully. Learn the applications and limitations,

as well as the specific potential hazards related to this tool. Following this rule will help reduce

the risk of electric shock, fire or serious injury.

.

ALWAYS firmly clamp or bolt your tool to a workbench or worktable at approximately hip height.

3.

ALWAYS be sure that all adjustments are secure BEFORE operating tool.

4.

ALWAYS USE SAFETY GOGGLES WHEN OPERATING YOUR BAND SAW. KEEP FINGERS

AWAY FROM THE BLADE.

.

To avoid injury from unexpected movement, MAKE SURE your band saw is on a firm, level

surface and properly secured to prevent rocking or shifting. MAKE SURE there is adequate

space for handling your workpiece without obstruction. Bolt the band saw to the support surface

to prevent slipping, moving or sliding during operation. Turn the band saw OFF and unplug the

power cord BEFORE moving the band saw.

i

8

ADDHTHONAL SPEC_FHC SAFETY RULES FOR BAND SAWS conto

.

To avoid injury from jams, slips or thrown pieces, use ONLY the right size and style of blade.

7.

Use ONLY recommended accessories. MAKE SURE the blade teeth point downward toward

the top of the worktable.

8.

ALWAYS be sure the band saw blade path is free of nails. ALWAYS carefully inspect lumber

and remove all nails BEFORE sawing.

9.

ALWAYS adjust the upper blade guide and blade guard to barely clear the workpiece. (Blade

guides, thrust bearing and blade tension must be properly adjusted to avoid accidental blade

contact, to minimize blade breakage and to maximize blade support.)

10. DO NOT remove the band saw's blade guard. NEVER operate the band saw with any guard or

cover removed. MAKE SURE that all guards are operating properly BEFORE each use.

11. ALWAYS be sure that the band saw blade clears the workpiece. NEVER start the band saw

with the blade touching the workpiece. ALWAYS allow the motor to come up to full speed

BEFORE starting to saw.

12. ALWAYS support long workpieces to minimize the risk of the band saw blade binding, breaking

or throw back. The band saw blade may slip or slide while working with long or heavy boards.

13. BE SURE the worktable lock handle is tightly secured BEFORE turning on the band saw.

14. Use extra care and caution with large, very small or awkwardly shaped workpieces. Make relief

cuts when cutting long curves.

15. USE extra external supports to prevent workpieces from tipping off the top of the worktable. DO

NOT use another person as a substitute for an extension of the worktable or as an additional

support for the workpiece.

16. NEVER saw more than one piece at a time. DO NOT STACK more than one workpiece on the

worktable at a time.

17. NEVER do layout, assembly or setup work on the worktable when the band saw is on or while

the blade is moving.

18. ALWAYS avoid awkward operations and hand positions where a sudden slip could cause your

hand to move into the band saw blade. ALWAYS make sure that you have good balance.

NEVER operate your band saw on the floor or in a crouched position.

19. NEVER stand or have any part of your body in line with the path of the band saw blade.

20. ALWAYS plan intricate, close and fine work carefully BEFORE you turn on the band saw so that

you DO NOT pinch the blade as you make your cut.

21. ALWAYS secure small workpieces with jigs and fixtures. DO NOT hand-hold small workpieces

that can draw your fingers under the blade guard. ALWAYS support round-shaped workpieces

properly (with a "V" block or clamped to the miter gauge) to prevent the workpiece from rolling

on the worktable or the blade from biting into the workpiece accidentally.

22. ALWAYS use clean and sharp band saw blades. Sharp blades minimize stalling, blade drifting

and kickback.

9

Loading...

Loading...