Page 1

Wacom Digitizer

Implementation Guide

Component Business Division

Wacom Co., Ltd.

1 • 30.10.2007 • Wacom Confidential

Page 2

Contents

1. Principle of Wacom EMR

2. General Specification

3. Structure

4. Digitizer Lineup

5. Display Lineup

6. Customizing Digitizer

7. System Designing (EM noise)

8. System Designing2 (metal parts)

9. System Calibration

10.Driver

2 • 30.10.2007 • Wacom Confidential

Page 3

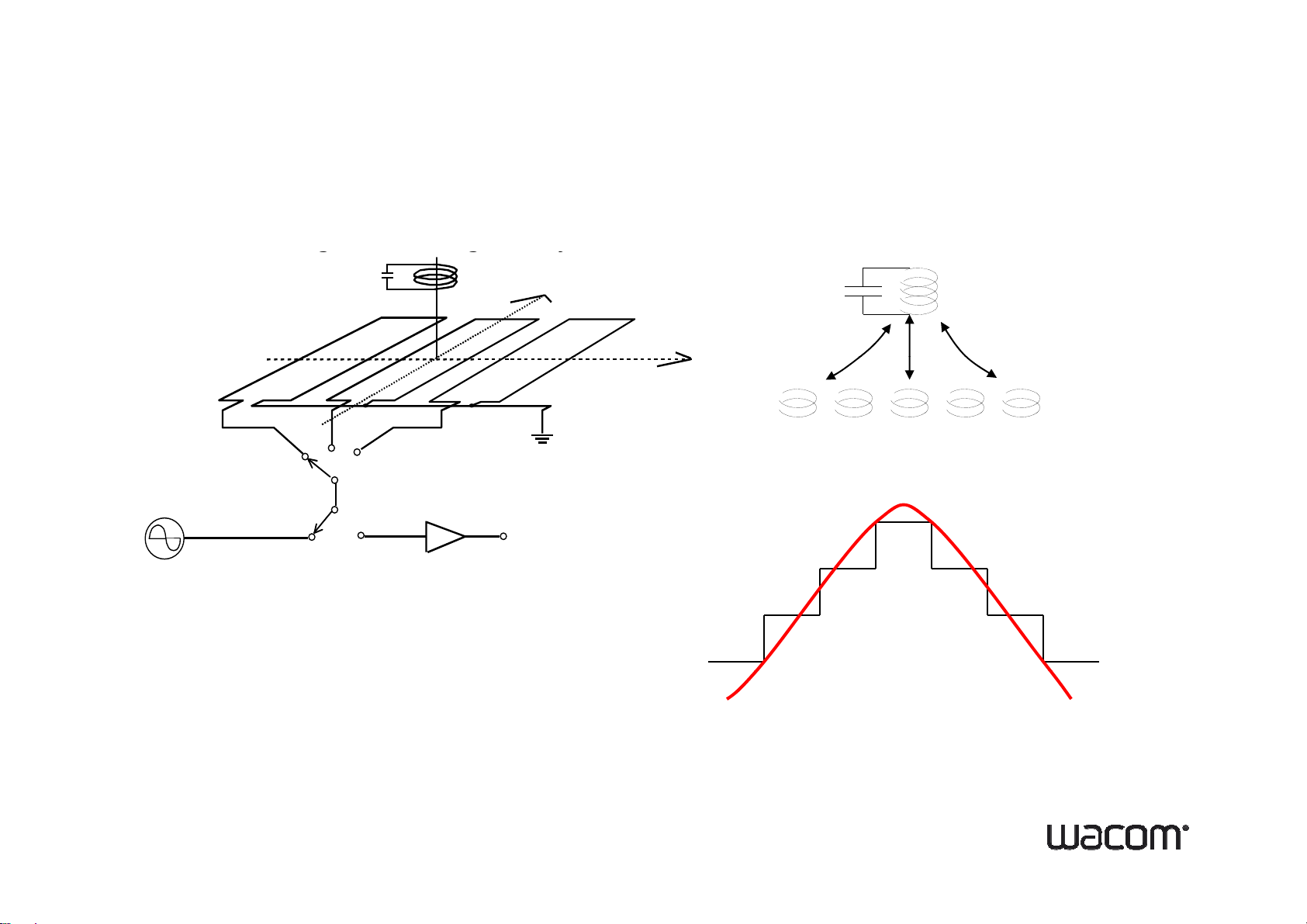

1. Principle of Wacom EMR

ggy

X axis

Receiver

High frequency

source

Re ceiving and transmitting coil in stylus

Y axis

Coil swit c hing

V

transmit/receive

Antenna coil

Pen

Sensor Board

Signal strength

3 • 30.10.2007 • Wacom Confidential

Page 4

2. General Specification

W

Digiti

it

Coordinate Accuracy

±

0.4mm (see Note 1 and 2)

p

p

Note 3: Th

acom

Technology EMR (Electro-Magnetic Resonance)

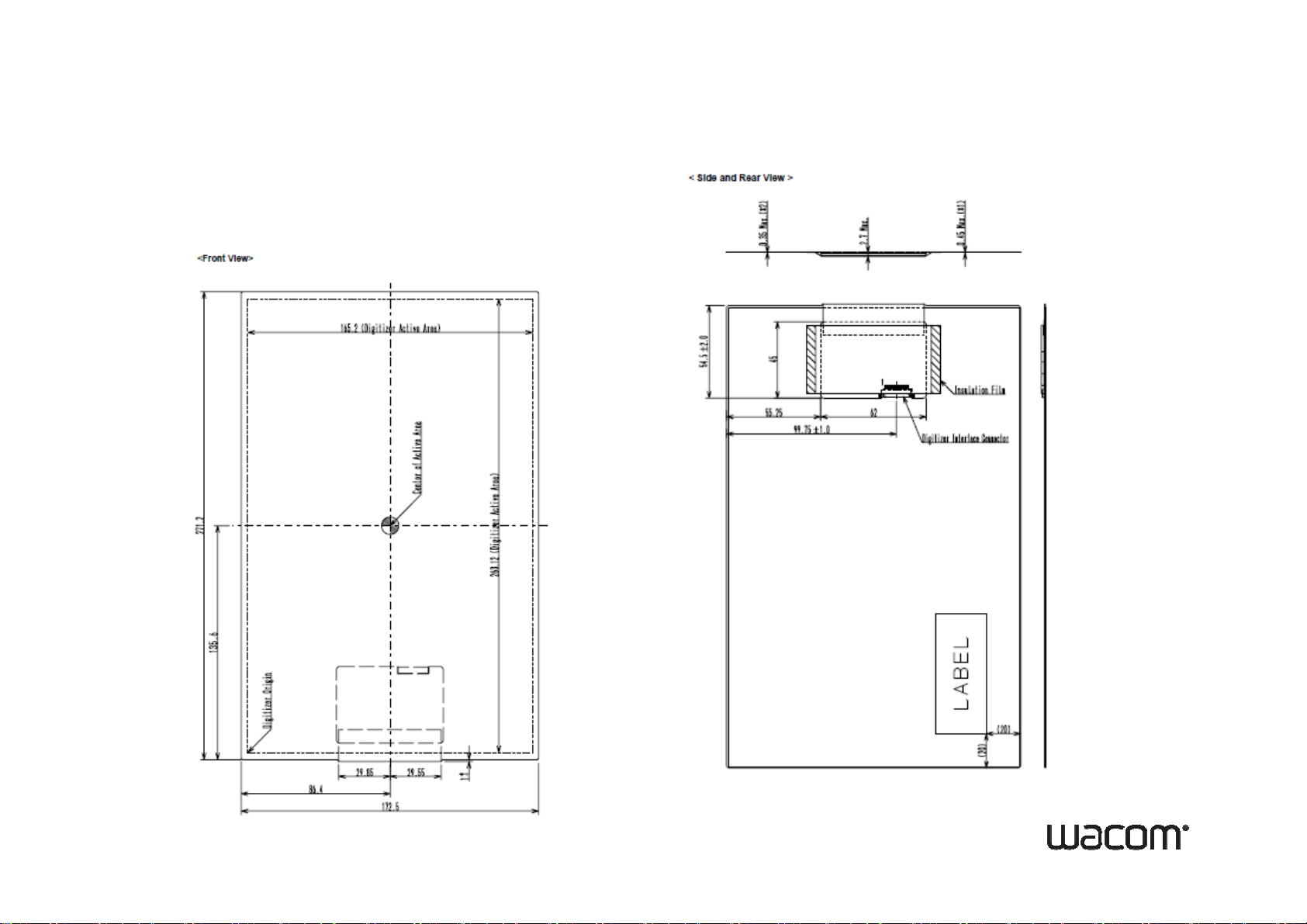

Active Area 263.12 * 165.2 mm for SU5E-12W16AS-00X

Resolution 0.01mm (2540 ppi)

Coordinate Deviation When Tilting Pen

Detectable Pen tilt

Detectable Height 4 to 14mm above the Sensor Board (see Note 1)

Position Report Rate 133 pps

Pressure Resolution 256 levels @ full scale

zer Un

±3mm (tilted ±50º from vertical) (see Note 3)

U

to 50°from vertical

Power Consumption 35mA (max.70mA) @133pps

Note 1: The digitizer sensor unit and pen only, at ordinary temperature.

Note 2: The pen held vertically at 7mm high from sensor board.

4 • 30.10.2007 • Wacom Confidential

e pen held in the center of the active area.

Page 5

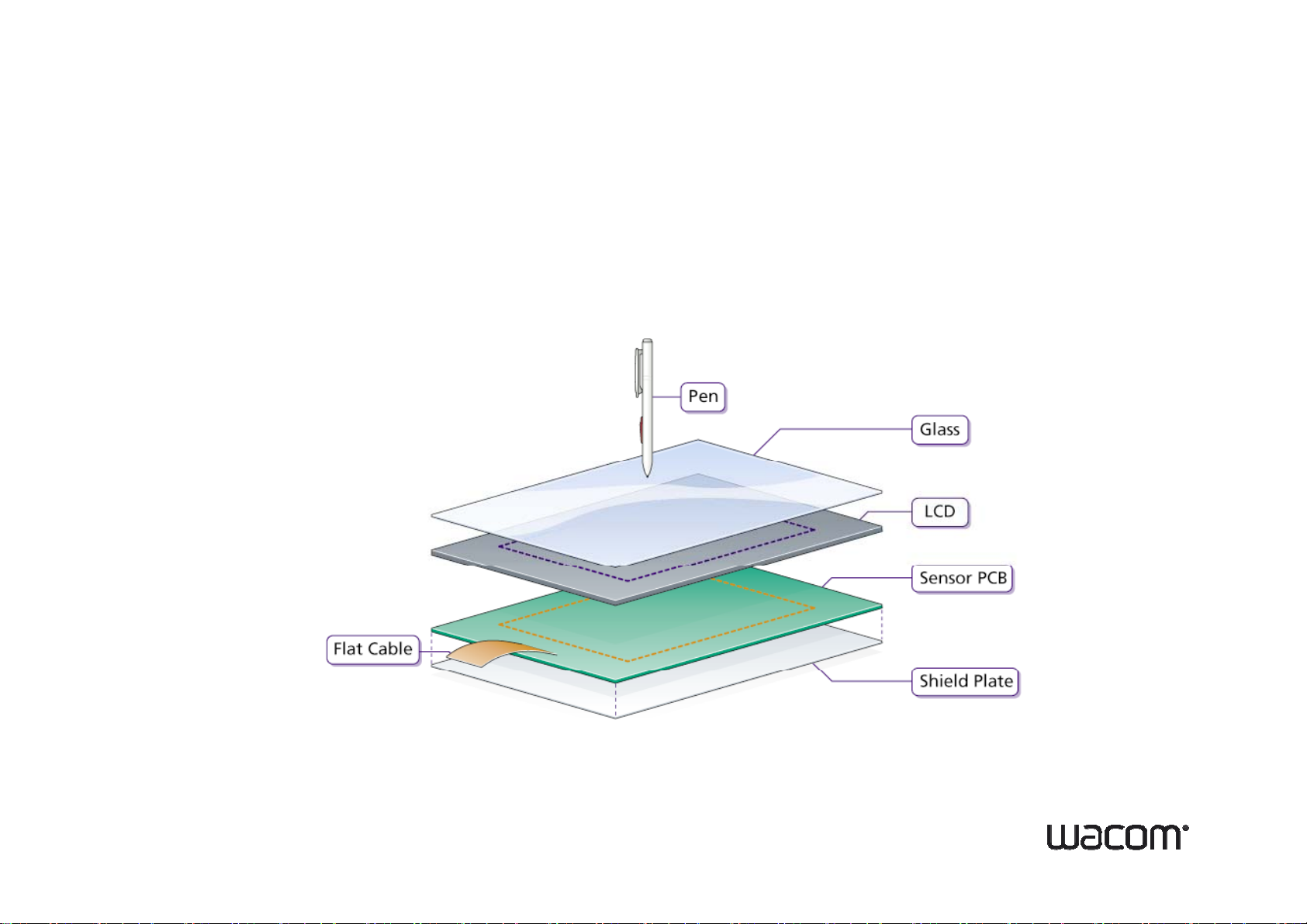

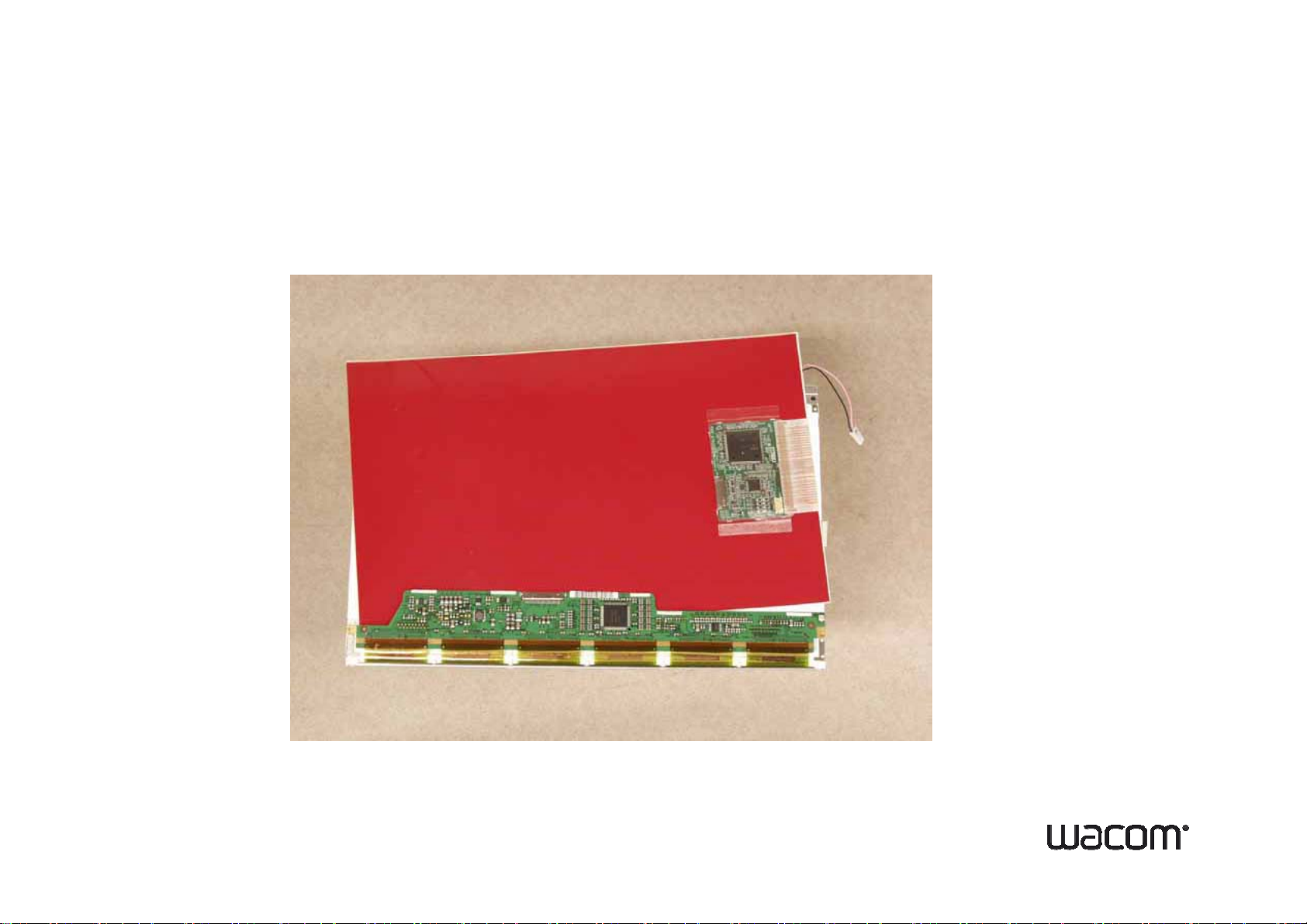

3-1. Structure

EMR digitizer be inserted under the LCD

5 • 30.10.2007 • Wacom Confidential

Page 6

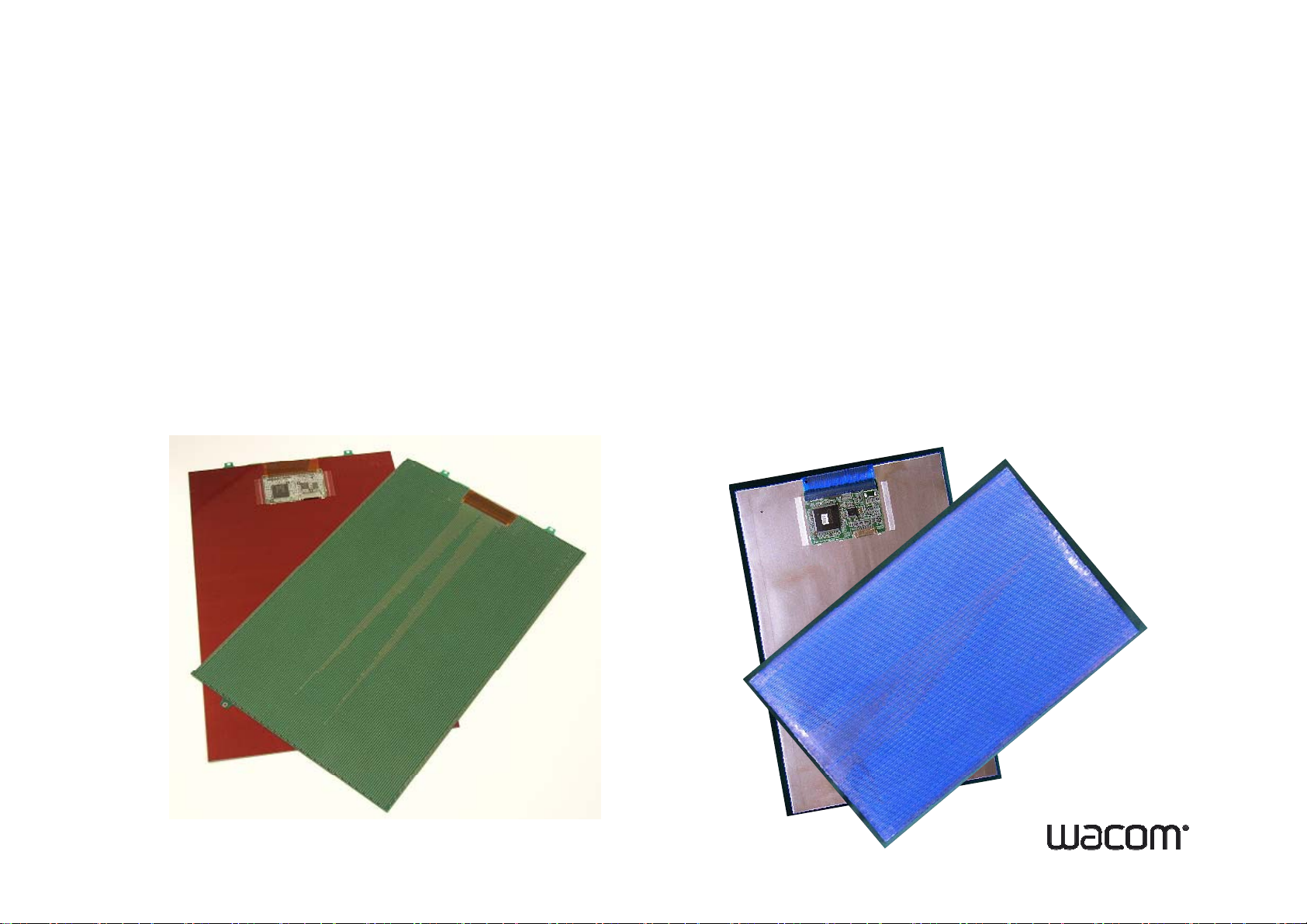

3-2. Structure

EMR digitizer be inserted under the LCD

6 • 30.10.2007 • Wacom Confidential

Page 7

4-1. Digitizer Lineup

Sensor : G4 ・・・ glass epoxy sensor

G4.5 ・・・ glass epoxy sensor

G5 ・・・ PET film or FPC (Polyimide)

G4/G4.5

7 • 30.10.2007 • Wacom Confidential

G5

Page 8

4-2. Digitizer Lineup

G5 sensor

8 • 30.10.2007 • Wacom Confidential

Page 9

4-3. Digitizer Line up

y

y

Technology :

1. EMR onl

2. Resistive-DualTouch・・・ sensor + Resistive Touch screen interface

3. Capacitive-DualTouch・・・ sensor + Capacitive Touch screen interface

EMR only R-Dual C-Dual

9 • 30.10.2007 • Wacom Confidential

Page 10

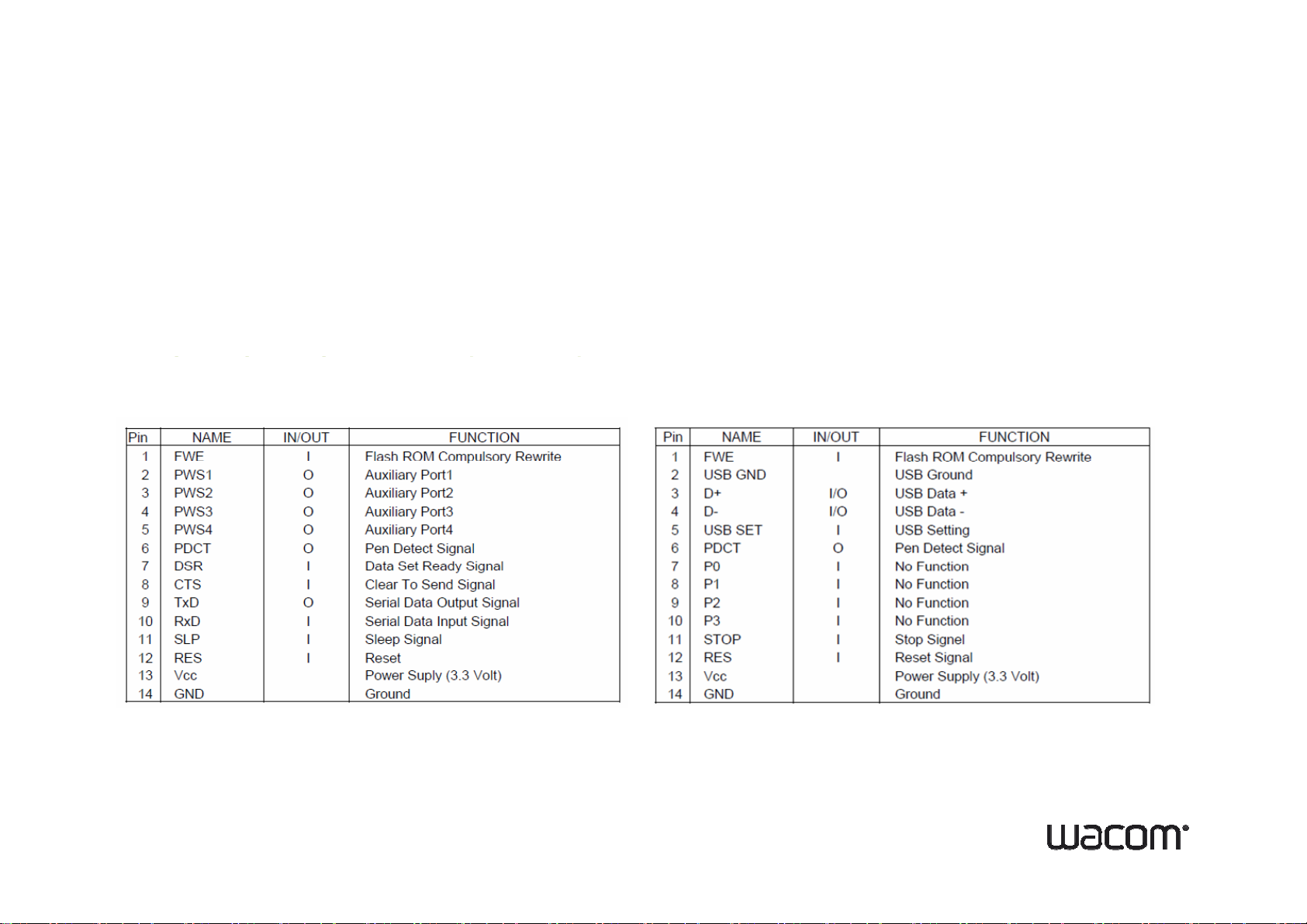

4-4. Digitizer Lineup

Si

(UART)

Interface : UART, USB

gnal assignment

Signal assignment (USB)

10 • 30.10.2007 • Wacom Confidential

Page 11

4-5. Digitizer Lineup

11 • 30.10.2007 • Wacom Confidential

Page 12

5. Display Lineup

LCD---Kangaroo type ・E-ink display

12 • 30.10.2007 • Wacom Confidential

Page 13

6-1. Customizing Digitizer

y

r

y

Condition for digitizer customization

1. Minimum Volume: 30K/

2. There will be NRE and Tooling Cost

ea

13 • 30.10.2007 • Wacom Confidential

Page 14

6-2. Customizing Digitizer

3

Non

active area must be at least 4mm at each side

tli

Sensor Board Design

1. Must be square shape

rectangle

2. Must be flat

OK

square round

NG

heart

.

14 • 30.10.2007 • Wacom Confidential

-

ou

ne

active area

digitizer

at least

4mm

Page 15

6-3. Customizing Digitizer

g

g

LCD outline

digitizer outline

Sensor Board Design (continued)

4. Di

1mm

itizer active area needs at lease 1mm buffer from LCD active

area at each side

1mm

LCD active area

1mm

1mm

digitizer active area

15 • 30.10.2007 • Wacom Confidential

Page 16

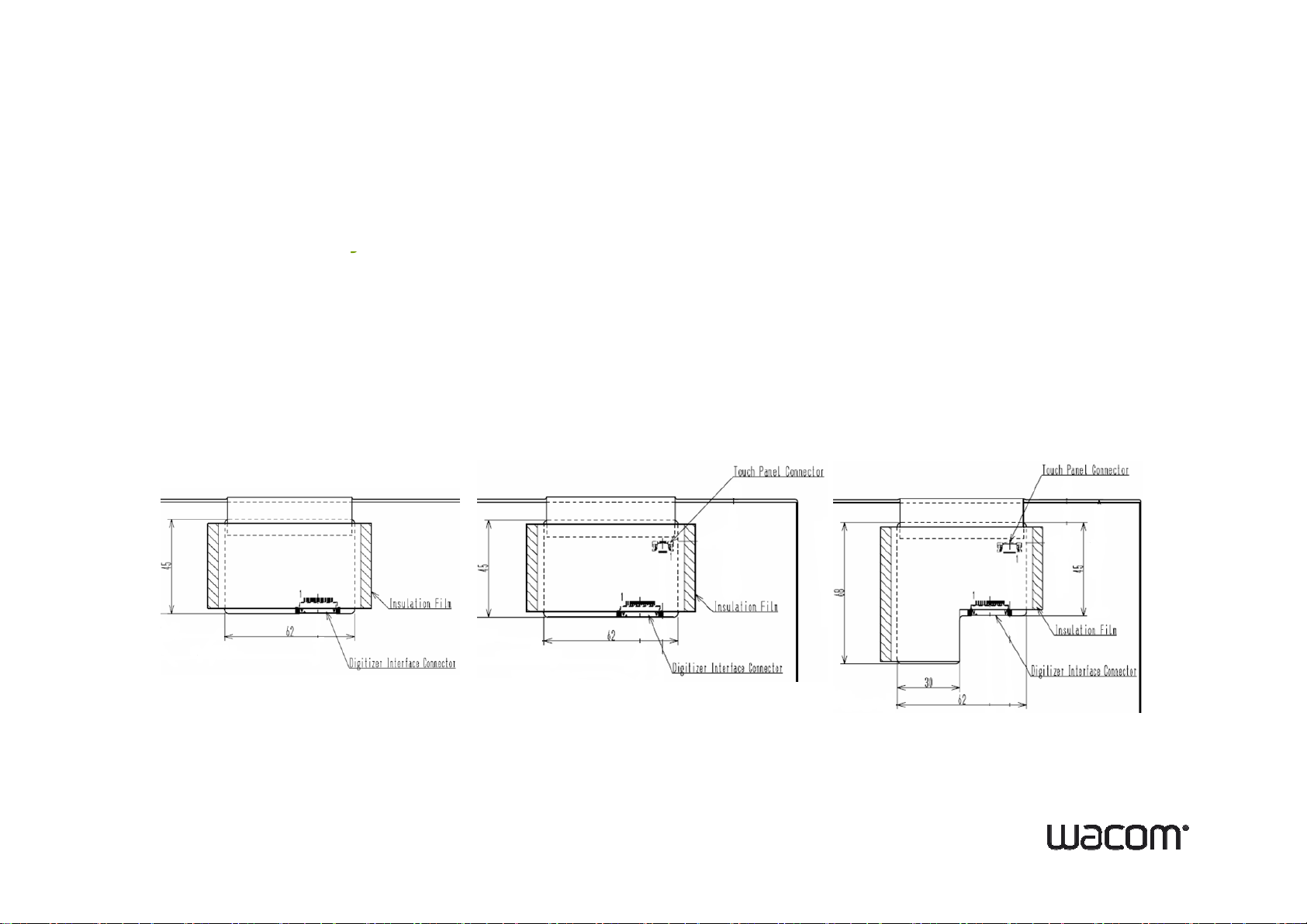

6-4. Customizing Digitizer

y

yg

C

iti

DF19L

14P

1H (HIROSE)

t

Baby Board Design

Onl

Interface connector

Counterpart connector: DF19-14S-1S, DF19G-14S-1C (HIROSE) or

standard design available.

onnector on dig

equivalent

zer:

-

-

or equivalen

16 • 30.10.2007 • Wacom Confidential

Page 17

6-5. Customizing Digitizer

D

1

Confi

t

3

ES sample shipment

8-10 weeks

7

CS

8-10

evelopment Schedule

No. Step Lead Time

rm custom design requiremen

2 Release of tentative shipping specification

*handmade sample with default firmware

4 Customer confirmation of shipping specification

5 System calibration 2 weeks

6 Customer approval of ES sample

sample shipment

*tooled sample with final calibrated firmware

At the same time as ES sample shipment

weeks

8 Release of final shipping specification

8 Customer approval of MP

9 MP shipment 8-10 weeks

Note: Lead time stated here is only reference and may change depending on digitizer design. Please confirm the final

development schedule with Wacom sales.

17 • 30.10.2007 • Wacom Confidential

At the same time as CS sample shipment

(including shipping specification, FW and CS sample)

Page 18

7-1. System Designing

Some transformers or coils in the power unit generates EM noise

To

prevent

this

•

Inverter

of

LCD

back

light

Prevention of EM noise problem

• Use transformers or coils that won’t allow magnetic flux leakage.

• Place them underneath the shield or in a distance as much as possible from the

sensor board.

• Position them so that EM noise flux did not across the sensorboard.

EM noise source

.

• DC to DC converter in power circuit

18 • 30.10.2007 • Wacom Confidential

Page 19

7-2. System Designing

!

an affection of the EM noise from the Inverter

EM Noise Countermeasure

LCD

View B-B’

Digitizer

or

Digitizer is sensitive to Electromagnetic Noise.

B

B’

Inverter

Shield

IMPORTANT

Inverter is one of the strongest EM source.

Shielding the inverter with shield plate*1, would improve

19 • 30.10.2007 • Wacom Confidential

As far as you can,please

SEPARATE the Digitizer Unit

.

from the Inverter

Page 20

7-3. System Designing

g

gpg

EM Noise Countermeasure2

PC Case

COIL

Like DC-DC Converter

In case of PC in one body, motherboard is located right beneath the

Di

itizer unit. Coils in the power unit generates the EM noise and it will

cause of inaccuracy of the Digitizer.

Shield the COIL with shield plate*1 for better Digitizer quality.

LCD

Digitizer

20 • 30.10.2007 • Wacom Confidential

Page 21

7-4. System Designing

Example of Noise Shield1

Noise Source Shielded

21 • 30.10.2007 • Wacom Confidential

Page 22

7-5. System Designing

Example of Noise Shield2

Noise Source Shielded

22 • 30.10.2007 • Wacom Confidential

Page 23

8-1. System Designing2

To

prevent

this

Reduction of metal influence

Some metal structure reduces digitizer signal which causes coordinate error.

• Do not use metal for upper case.

• Contact Wacom to make Error calibrated firmware data.

Metal influence source

• LCD metal bezel and lamp cover

• Upper case ( if it is made of metal )

23 • 30.10.2007 • Wacom Confidential

Page 24

8-2. System Designing2

EM signal decrease

Minimize Metal influence

LCD Upper Bezel

LCD Lamp cover

Upper case

24 • 30.10.2007 • Wacom Confidential

Metal on the digitizer will disturb the EM signal from the pen.

Page 25

8-3. System Designing2

Bad Example of Metal Parts1

Full Metal Upper Case

25 • 30.10.2007 • Wacom Confidential

Page 26

8-4. System Designing2

Bad Example of Metal Parts2

Wrapped by Metal Sheet

26 • 30.10.2007 • Wacom Confidential

Page 27

9-1. System Calibration

3

Coordinate accuracy

Calib

US$1,200

lib

Wacom will do following evaluation in order to prevent

adverse affect from EM noise and metal parts

1. EM noise environment

2. Coordinate stability

.

Wacom will provide FW data and evaluation report.

Calibration work will take approximately 1-2 weeks.

27 • 30.10.2007 • Wacom Confidential

ration work charge is

per ca

ration.

Page 28

9-2. System Calibration

•

Wacom will search the EM noise and measure the level

EM noise environment

• EM noise which mimic pen signal can cause digitizer malfunction.

.

28 • 30.10.2007 • Wacom Confidential

Page 29

9-3. System Calibration

Coordinate stability

EM noise can cause vibration of coordinate detected by digitizer (jitter).

Wacom quantifies the level of jitter by take 100 coordinate data at each

spot and calculating standard deviation and max deviation from mean

location.

29 • 30.10.2007 • Wacom Confidential

Page 30

9-4. System Calibration

C

lib

oordinate accuracy before ca

Metal parts or EM noise will disturb digitizer signal and can cause the

deterioration of digitizer accuracy.

Digitizer signal can be compensated by calibration up to certain level.

W acom measures the accuracy before and after calibration.

ration

30 • 30.10.2007 • Wacom Confidential

Page 31

9-5. System Calibration

Coordinate accuracy after calibration

31 • 30.10.2007 • Wacom Confidential

Page 32

9-6. System Calibration

1

Final design

3

criteria for syste

desig

ed

3

c te a o syste des g s o o ed

When several LCDs are applied for one model, FW needs to be

Before sending calibration machine, please check

below items.

.

2. Tooled product

. All

4. All accessories (eg. AC adaptor) are enclosed

5. Valid OS is installed

6. Wacom stylus (which pen to use with)

7. Assembly drawing to show LCD and digitizer position

Note:

Calibration is required for each design. Any material or design

changes will need another calibration.

m

n is follow

created for each LCD.

32 • 30.10.2007 • Wacom Confidential

Page 33

10. Driver

Symbian

Note:

Device Driver

Windows Vista, Windows XP, Windows 2000, Windows CE ,

for dual touch, standard interface is USB

33 • 30.10.2007 • Wacom Confidential

Loading...

Loading...