coffee grinders

instructions manual

RETAIL

R140

R120

R100

R80

R8

index

1. SAFETY MEASURES 1

2. DESCRIPTION 2

3. INSTRUCTIONS 3

4. IDENTIFICATION 3

5. TECHNICAL CARACTERISTICS 4

6. INSTALLATION 6

7. REGULATION 7

8. OPERATION 10

9. CONFIGURATION 12

10. CLEANING 13

11. MAINTENANCE 15

12. EC CONFORMITY 18

1. SECURITY

NOTE: The manufacturer will not be held responsible for any damages resulting from

improper use of the equipment, or for not following the safety measures as outlined

below.

Safety measures incorporated into our grinders:

• Special screw to maintain the hopper xed in place.

• Access restrictor in the grind group.

Owners: Please pay careful attention with the following instructions:

• The grinder should be used exclusively for the function for which it was

designed: grinding whole bean coffee.

• Do not use this grinder to grind other types of food products such as dry fruit,

sugar or spices.

• Children should be supervised to ensure that they do not play with the

appliance.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

• Any other use of the machine will be considered improper and dangerous.

• Do not put liquids in contact with internal or external parts of this grinder while

ON or OFF, with the exception of parts expressly outlined in the “CLEANING”

section of this manual. If liquids do come in contact with the grinder,

immediately disconnect electrical connection and carefully clean the affected

areas. If it is necessary to access the interior parts of the grinder, contact your

local service professional.

• In case of any damage to parts or components, we recommend contacting your

local service professional to help with repair or replacement of such parts,

thereby guaranteeing the maintenance of the security standards of the grinder.

• If the supply cord is damaged, it must be repalced by the manufacturer, its

service agent or similarly qualied persons in order to avoid a hazard.

• Only an authorized distributor should replace the main power cable of the

grinder.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

1

SOUND DECIBEL LEVEL

The level of sound emitted in different models is:

Sound decibel level With coffee

R8 68,2 dB

R80 70 dB

R100 70,6 dB

R120 78,4 dB

R140 78,7 dB

ψ

R120

R140

ψ

79,6 dB

80,6 dB

2. DESCRIPTION

Your new grinder has been designed using the most sophisticated technologies in

existence. The result is a product of high quality that offers the assurance of the best

results possible. Our products are manufactured by hand, one by one, following the

strictest quality requirements. In the manufacturing process, we use only the highest

quality materials (aluminum, stainless steel, etc.) especially designated for being in

contact with food stuff.

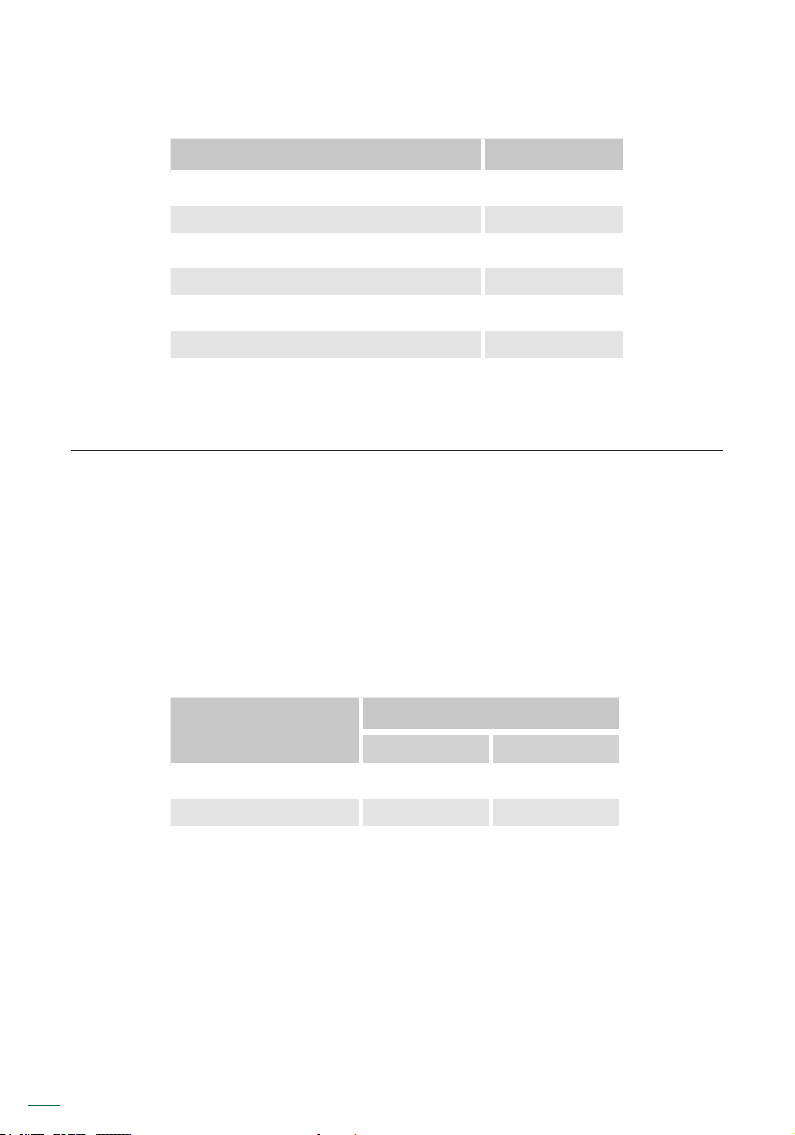

For the optimum functionality of the grinder models described in this user manual,

the maximum work cycles are as follows:

Model

R8, R80, R100 1 minute 2 minutes

R120, R140 2 minutes 1 minute

R120 ψ, R140

2

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

ψ

Working cycle

ON OFF

continuous continuous

3. INSTRUCTIONS

3.1. This manual is designed to provide the necessary information to correctly

install, use and maintain the grinder, as well as to highlight precautions for users to

keep in mind. To ensure the best operation of the coffee grinder, please follow the

instructions as outlined in this manual. This manual should be saved for the life of the

grinder, and should always be at the disposal of the operator.

3.2. This manual contains special terminology such as:

• Words in BOLD indicate important points or terminology.

• Numbers in parenthese after a word, indicate the location of this item in a parts

diagram.

Example: ( ) - Hopper lid

• Icons:

Information Atention

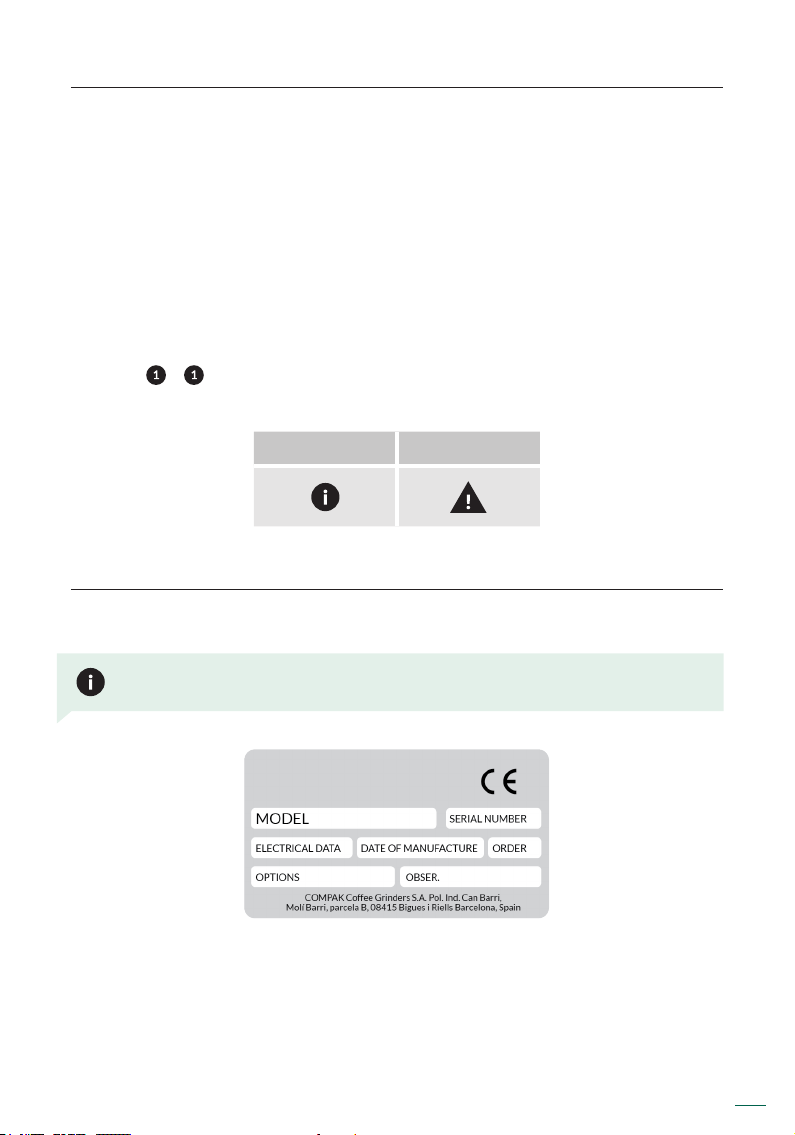

4. IDENTIFICATION

In the grinder information plaque is the following manufacturing/product information.

NOTE: The manufacturer reserves the right to change components/congurations of

any model, according to the different geographic market demands.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

3

5. TECHNICAL CARACTERISITICS

5.1. Usage

The coffee grinders are intended for use on commercial premises and facilities where

ground coffee is required, or in small stores that sell coffee. The grinder must only be

used to grind coffee beans. Any use other than this will be considered improper and

dangerous.

NOTE: The manufacturer will not be held responsible for any damages resulting from

improper use of the equipment, or for not following the safety measures as outlined

below.

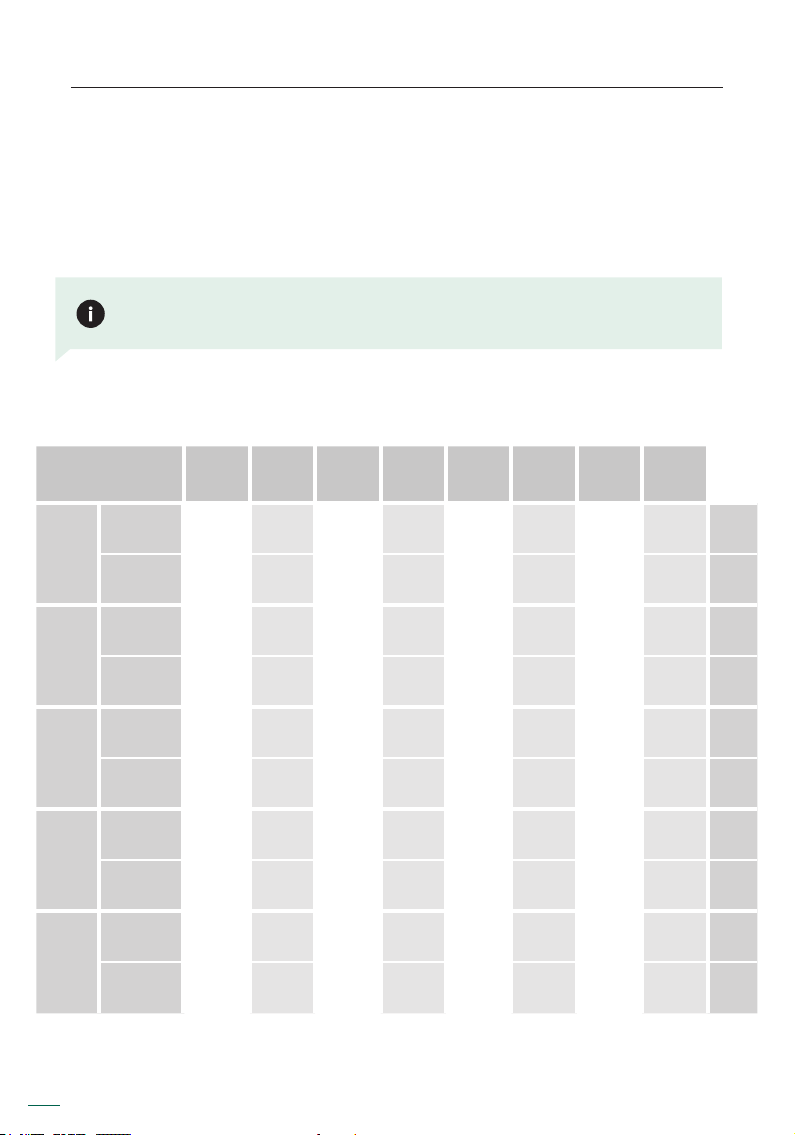

5.2. Technical data

Model

R8

R80

R100

R120

R140

Electric

power

Spin

speed

Electric

power

Spin

speed

Electric

power

Spin

speed

Electric

power

Spin

speed

Electric

power

Spin

speed

100 V

50 Hz

1.270 1.530 1.580 1.500 1.290 1.310 rpm

1.250 1.540 1.600 1.600 1.325 1.330 rpm

1.125 1.540 1.600 1.600 1.325 1.330 rpm

100 V

60 Hz

600 700 700 730 610 630 (W)

750 810 860 735 730 840 (W)

850 1.000 1.325 930 950 975 (W)

110 V

60 Hz

1.000 1.050 1.000 1.700 1.000 1.000 (W)

1.130 1.400 1.150 1.400 1.400 1.650 rpm

220 V

60 Hz

230 V

50 Hz

240 V

50 Hz

ψ

380 V

50 Hz

1.600 1.600 (W)

1.400 1.620 rpm

208 V

60 Hz

ψ

4

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

Model

R8 R80 R100 R120 R140

Ø Burrs

Production*

50Hz

Production*

60Hz

Hopper

capacity

Net weight

Height

Width

Depth

* Production is based on a medium-roasted coffee and an Espresso grind.

3.26

83

1.1

0,5

1.17

0,53

2.2

1,1

46.2

21,1

23.20

595

8

205

12.28

315

in mm in mm in mm in mm in mm

23.20

8

12.28

3.14

80

1.1

0,5

1.17

0,53

2.2

1,1

48.57

22,08

595

205

315

23.20

8

12.28

3.93

100

2.2

1

2.64

1,2

2.2

1,1

55.19

22,09

595

205

315

30.22

9

14.82

4.7

120

3.30

1,5

4

1,85

4.85

2,2

81.57

37,08

775

230

380

30.22

9

14.82

5.5

140

4.4

2

6.5

2,95

4.85

2,2

80.08

36,4

in

mm

lb/min

Kg/min

lb/min

Kg/min

lb

Kg

lb

Kg

775

230

380

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

5

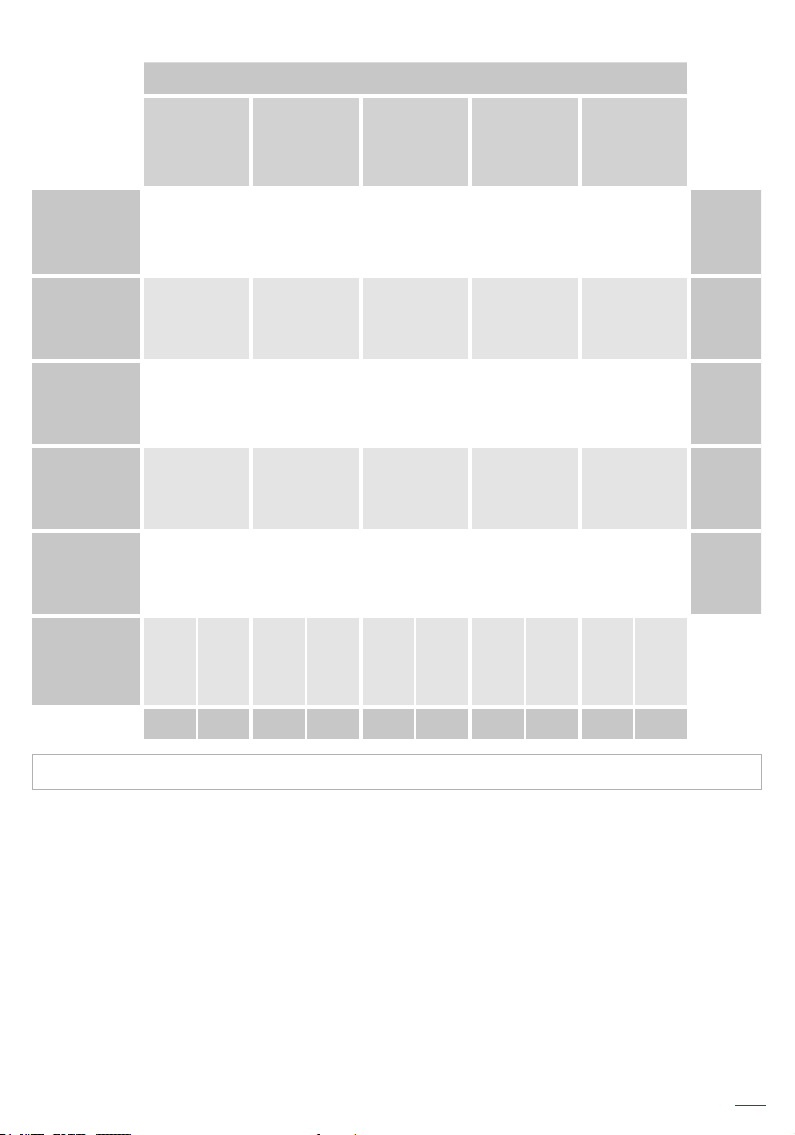

6. EXTERNAL COMPONENTS

6

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

7. INSTALLATION

7.1. General warnings

The person installing the grinder should carefully read this instruction manual

before installation. The installation of this machine should be completed by

qualied and authorized personnel, and all norms of safety and sanitation should be

followed.

7.2. Important warnings

The operator of the grinder should be a responsible adult, and a never a minor

or person incapable of safely using such equipment. When using the grinder,

the following precautions should be followed:

• No bare feet.

• No wet hands or feet.

• Do not submerge in water.

• Do not expose the grinder to sun or other atmospheric conditions.

• Do not place any type of object in the coffee entrance or exit while the grinder

is running. (It should be kept in mind that the cutting burrs continue turning for

a couple revolutions after the grinder is powered off).

• To disconnect the grinder, use the main power switch and never the power

cable, to avoid a possible short circuit.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

7

7.3. Where to use

The grinder should be installed on a at, stable surface. The minimum

dimensions of the work space should be as follows:

Model

R8, R80, R100 R120, R140

Height

Width

Depth

28.35

720

9.45

240

13.78

350

35.43

900

10.43

265

16.34

415

in

mm

in

mm

in

mm

7.4. Grinder installation

Before grinder installation, the following should be considered:

• The grinder information plaque data coincides with the electrical system on

site.

• The electrical outlet coincides with the grinder plug.

• The electric power at the location of installation should meet the minimum

required to properly run the grinder.

• The installation site should have the proper electrical overload protections.

• The grinder should be properly grounded as specied by local code.

The three-phase models are sold without the plug. In these models, you will be given

an uncovered power cable.

8

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

Please, check that the three-phase factory installation is correct.

Make sure our socket is EN 60529 and has 3F+N+T and the distribution of the

connection should be as in Figure 2.

Obtain 380V 50Hz or 220V 60 Hz between phases ( ) and 230V 50Hz or 110V

60Hz between Phase and Neutral ( - ).

In order for a correct grind, the burrs have to turn in a counter-clockwise direction.

When plugging in a three-phase grinder for the rst time, check that the burrs turn in

the right direction by opening the cover and looking into the hopper.

If the direction of the burrs is not correct, unplug the grinder and, with the help of a

at-head screwdriver, turn the phase reversal device 180º as soon shown in Figure 1.

When you plug the grinder in again, it should turn counter-clockwise.

NOTE: The coffee grinder should be used in areas with a room temperature below

30/35ºC ( 86/95ºF ) and should not be installed in places (SUCH AS INDUSTRIAL

KITCHENS) where cleaning with water jets is used.

8. OPERATION

8.1. Main switch

The main swith ( ) has 2 positions of use, ON–OFF

ON: Working

OFF: Not working

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

9

8.2. Hopper placement

Remove the upper body ( ) by unscrewing the two screws on the backside of the

grinder.

Place the hopper ( ) on the upper body and make sure that the hinge of the hopper

lid ( ) lines up with the backside of the grinder. Push down and turn clockwise until

the hopper clicks into place on the upper body ( ) (Fig. 4 & 5).

Turn the upper body around and x the hopper to the grinder body with the safety

screw that comes along with the grinder (Fig. 3).

NOTE: The manufacturer cannot accept responsibility for any damage casued by

improper use of the machine.

8.3. Use

Open the hopper lid ( ), ll the hopper ( ) with coffee and close the lid. Once the

coffee is inside the hopper, it can not be removed.

Press the bag support handle ( ) and put the empty bag around the coffee discharge

tube ( ), then release the handle so the bag remains xed in place.

10

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

Push the start button ( ) on the left of the front setting dial ( ) and the grinding

process will start (the selected grinding choice icon will ash). Once you have ground

the desired quantity of coffee, push the grinding stop button ( ) on the right of the

front setting dial ( ).

Remove the bag, holding it with one hand and with the other, push the bag support

handle ( ) down to release it.

Push the handle two or three more times against the outlet to remove so that any

remaining traces of coffee which may have stuck to the discharge tube ( ).

NOTE: The amount of coffee ground will depend on the chosen grinding point.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

11

1 coffee bean

100 - 300 particles

French Press

500 - 800 particles

Filter

1,000 - 3,000 particles

Mocha

3,500 particles

Espresso

15,000 - 35,000 particles

Turkish

9. VIBRATING PLATE

9.1. Vibrating plate

The grinder comes with an extension to distance the bag shaker from the machine,

allowing the possibility to use bigger bags (>0.55 lb for R80 & R100 and >1.1 lb for

R120 & R140) and therefore grinder larger amounts coffee.

To put the extension in place, remove the screw ( ) on the lower part of the bag

shaker as indicated in Fig. 7 and put the adapter in place. Reconnect the bag shaker

using the same screw.

12

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

10. CLEANING

10.1. General warnings

To guarantee the correct operation of the machine as well as the quality of the

ground coffee, periodically clean the parts that come into contact with the coffee (at

least once a week).

Before performing any type of maintenance work, the following indications must be

taken into consideration:

• Always turn off the machine using the general switch ( ).

• Disconnect the machine from the power supply.

• Do not submerge the grinder in water or use power washing devises.

• The appliance is not to be cleaned with a water jet.

10.2. Bean hopper cleaning

It is recommended that the grind chamber be cleaned monthly with a cleaner as

recommended by Compak. This process will eliminate smelly residues from the

coffee remains, which can negatively affect the quality of the brewed coffee.

The steps to follow are:

• Grind out the remaining coffee in the grind chamber.

• Pour 60 gr of grinder cleaning product into the bean hopper ( ).

• Grind the cleaning product at a medium course grind setting until it is passed

through the system and nothing remains in the grind chamber.

• Clean the hopper ( ) and rell with coffee beans.

• Discard the rst 2-3 doses of coffee to assure that the residual cleaning product

is removed from the grind chamber and set the grind regulator to the desired

setting ( ).

Following these steps will ensure that the grinder is clean and ready for use.

We do not recommend the taking apart of the grind assembly unless changing burrs,

or removing a blockage/obstruction in the grind chamber. Removal of the grind

assembly should be performed by a qualied service technician.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

13

10.3. Cleaning the coffee discharge tube

To clean the tube ( ) use the brush that comes with the grinder and insert it several

times to remove any coffee remains.

ALERT: It is recommended to follow the cleaning instruction described in this point

at least once a month.

10.4. Cleaning the outside of the grinder

To clean the outside, use a dry brush and then a cloth that has been slightly

dampened in soapy water.

NOTE: FAILURE to perform these cleaning operations will affect the taste and

aroma of the coffee.

14

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

11. MAINTENANCE

11.1. General warning

Before performing any type of maintenance you should:

• Always turn OFF the main power switch to the off position ( ).

• If the grinder is jammed, unplug it from the power source and contact an

authorized service technician.

Not following these warnings can compromise the safety of the grinder as well as

the user.

11.2. General maintenance of the grind chamber

To guarantee the efciency and correct operation of the grinder, it is essential to

follow manufacturer instructions and ensure that all maintenance work is carried

out by qualied staff.

Dull burrs will result in; a lower quality grind, greater heat generation in the coffee

and grinder, increased electrical consumption, and nally it puts additional stress on

the grinder motor.

NOTE: Based on extensive experience and a medium-hard coffee blend, we

recommend replacing the burrs according to the following table:

Kg / lb of ground coffee

R8 800 Kg / 1322.77 lb

R80 6.800 Kg / 14,991.43 lb

R100 10.000 Kg / 22,046.23 lb

R120 12.000 Kg / 26,455.47 lb

R140 15.000 Kg / 33,069.34 lb

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

15

11.3. Grinding group maintenance

Not following the recommended burr life guidelines can compromise the safety of

the grinder.

These operations should be done by a qualied service tecnician.

• To effect grinding group maintenance work, the following instructions should be

followed:

• Turn the front setting dial ( ) all the way to the left.

• Turn the machine off, using the ON-OFF switch ( ).

• Disconnect the cable from the power supply.

• Remove hopper ( ) from upper body ( ) according to section 7.

• Dismantle upper body ( ), by unscrewing the two rear screws. Remove the four

setting screws ( ) of the upper burr holder from the grinding cup (Allen wrench

4), according to Fig. 8.

• Replace the burrs by unscrewing them from their upper and lower supports.

During this operation, it is recommended to block the rotation of the lower burrs

with a at-head screwdriver.

• Clean the coffee remains from burr holders.

• Take out the used burrs and put in the new ones.

• Assemble to setting screws ( ) of the upper burr holder to the grinding cup.

16

ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 18/07/2016 | K04673

11.4. Reset the burrs to the 0 / Calibration

Position 0 is the point in which the burrs no longer touch.

Following these instructions allows the user to make small adjustments to adapt the

desired particle size for each of the types of coffee referenced on the front control

knob ( ).

• Turn the front dial ( ) clockwise until the burrs are as close as possible without

touching.

• Loosen, with the help of the key wrench that comes with the grinder, the screw

( ), until the chain is released.

• Turn the front dial ( ) clockwise as far as possible.

• Tighten the screw ( ).

• Assemble the upper body ( ), tightening the two rear screws and replace the

hopper.

K04673 | v. 18/07/2016 | Ref. quality process 002/03 | ORIGINAL INSTRUCTIONS

17

12. EC CONFORMITY

In accordance with European commu-nity directives, quality certicates have been

applied. All materials have been adapted and technical reports are available at our

ofces.

04/108/EC on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

06/42/EC amending Directive 89/392/EC on the approximation of the laws of the

Member States relating to machinery

REG. 1935/2004 amending Directive 89/109/CE on the approximation of the laws

of the Member States relating to material and objects destinated to make contact

with nutritional products.

03/108/EC amending Directive 2002/96/EC on waste electrical and electronic

equipment (WEEE).

06/95/EC of 12/12/2006 on the harmonization of the laws of Member States

relating to electrical equipment designed for use within certain voltage limits.

02/96/EC of 27/01/2003 on the approximation of the laws of the Member States on

waste electrical and electronic equipment (WEEE).

11/65/EU related to the restriction on the usage of certain dangerous

substances with electrical equipment and electronics.

Environment

Do not throw the applianceaway with the normal household waste; hand it in at

an ofcial recycling collection point. By doing this, you will help to preserve the

environment.

The Legal Representative

Jesús Ascaso

Compak Coffee Grinders, s.a.

18

Molí Barri, Parcela B - Pol. Ind. Can Barri - 08415 Bigues i Riells - Barcelona - Spain

Ph. 34 93 703 13 00 - Fax 34 93 703 13 23 - www.compak.es

Loading...

Loading...