Compact Power BOXER 999-823 User Manual

COMP ACT

COMP ACT

COMP ACT

COMP ACT

BIG POWER IN ALL PLACES

TM

Part No. 999-823

Serial No.s 005 and Higher

118 Operator’s Manual

118 Operator’s Manual

MANUFACTURED BY:

MODEL NO.

S.N.

ENGINE SERIAL NO.

WEIGHT

POWER

COMPACTPOWER EQUIPMENT

800-476-9673

cpiequipment.com

DATE OF MANUFACTURE

MERTZ MANUFACTURING LLC

PONCA CITY, OKLAHOMA, USA

LB

KG

HP

KW

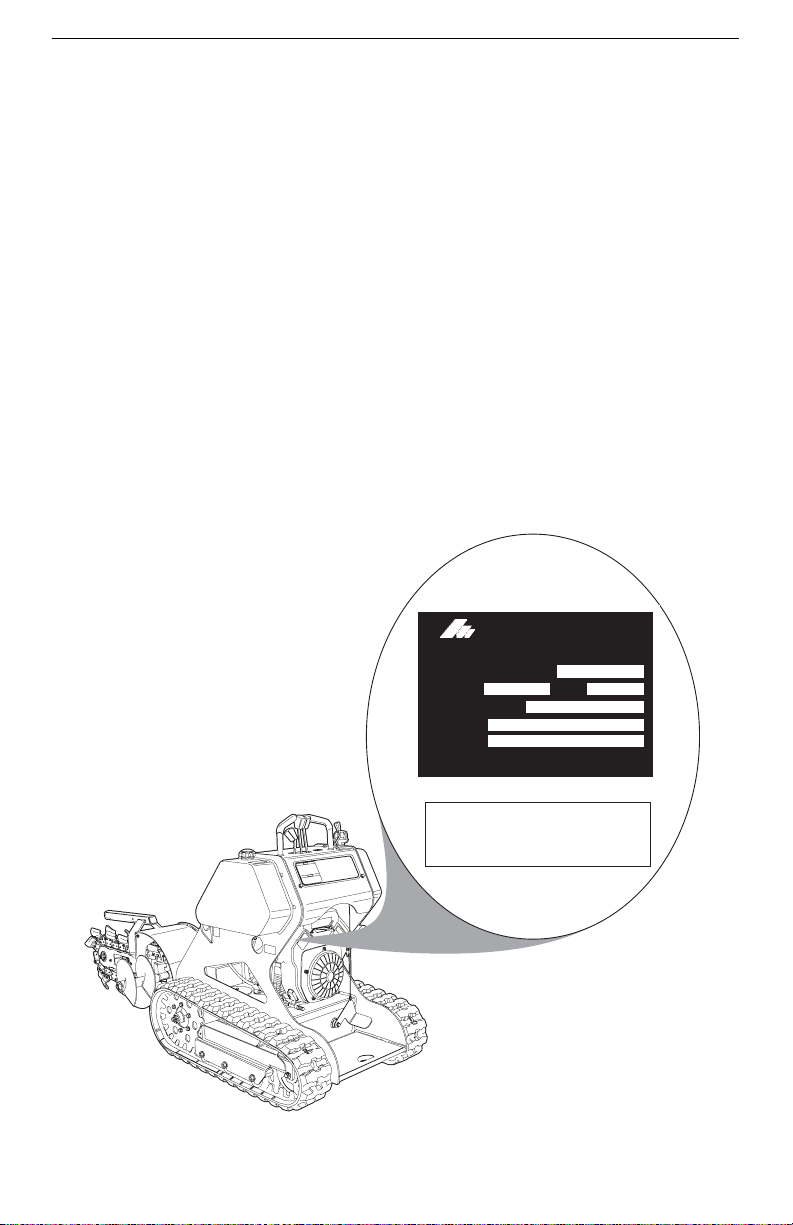

Write your machine’s Serial Number in the space below for future reference. The

serial number is located on the metal tag on the left side of the machine. Remove the

service access panel to locate the Serial Number plate.

MANUFACTURED BY:

MERTZ MANUFACTURING LLC

PONCA CITY, OKLAHOMA, USA

DATE OF MANUFACTURE

ENGINE SERIAL NO.

Record SERIAL Number here

COMPACTPOWER EQUIPMENT

800-476-9673

cpiequipment.com

2418

Boxer Product Warranty

WARRANTY AND LIABILITY LIMITATIONS

Mertz Manufacturing, LLC warrants each new Compact Utility Trencher manufactured

(hereinafter referred to as the equipment) by us to be free from defects in materials and

workmanship, for a period of one (1) year or 1000 operational hou rs, whichever occurs

first from the date of delivery. This warranty is effective provided that the equipment

warranted hereunder is operated by the purchaser in accordance with generally

approved practices, is properly maintained in accordance with the instructions

contained in this owner's manual, and is operated within the manufacturer's rated

capacity limitations.

Any parts of the equipment found to be defective within the warranty period shall be

repaired or replaced, at Mertz Manufacturing, LLC's sole option. Repairs must be

performed at Mertz Manufacturing, LLC facilities or at an authorized dealer facility.

Any part or parts proving d efective with in the above specified time will be repaired or

replacement parts furnished, F.O.B. Ponca City, Oklahoma, providing such parts are

returned, transportation prepaid, and found to be defective by the manufacturer.

The purchaser is responsible to keep maintenance records to substantiate proper

maintenance. If a defect becomes apparent, it is the purchaser's responsibility to

notify Mertz Manufacturing, LLC or an authorized dealer of said defect. The

purchaser agrees to return the defective equipment or parts to Mertz Manufacturing,

LLC or to an authorized dealer facility, freight prepaid, within fifteen (15) days after

the defective condition is discovered.

All warranties, if any, extended to Mertz Manufacturing, LLC by manufacturers and

suppliers of component parts, accessories, or other goods included in the

manufacturing of Mertz Manufacturing, LLC products will be assigned, if

contractually permitted, to the purchaser. Specific component warranty details will be

provided to the purchaser upon request.

This warranty excludes the following: maintenance items including, but not lim it ed

to, seals, track grousers, roller bearings, filters and spark plugs, equipment that has

been repaired, replaced, or altered by someone other than Mertz Manufacturing, LLC

or an authorized service facility without prior approval from Mertz Manufacturing,

LLC unless, however; if Mertz Manufacturing, LLC, in its sole opinion, determines

that the defective condition of the equipment was in no way caused by or was

attributable to said repairs, replacements, or alternatives.

Mertz Manufacturing, LLC and the purchaser agree that, in consideration of the

above expressed warranty, all other warranties other than title, either expressed or

implied, whether arising under law or equity including warranties of merchant ability

and fitness for a particular purpose are excluded from this contract, further, the

foregoing warranty is made solely to the first purchaser and may not be transferred in

any form.

The sole liability of Mertz Manufacturing, LLC and the exclusive remedy of the

purchaser arising out of the manufacture, sale, or use of the equipment provided

i

hereunder, on warranties or otherwise, shall be limited to the cost of repair or

replacement of defective parts as herein specified. Further Mertz Manufacturing,

LLC's maximum liability hereunder arising from any cause whatsoever, including but

not limited to, breach of contract or tort (including negligence), shall not exceed the

contract price of the equipment furnished hereunder. Mertz Manufacturing, LLC shall

not be responsible for work done, equipment or parts furnished, or for parts or repairs

made by others unless the work is specifically ordered by Mertz Manufacturing, LLC.

In no event shall Mertz Manufacturing, LLC be liable for removing defective parts or

for reinstalling said parts when repaired or replaced by anyone other than Mertz

Manufacturing, LLC or an authorized service facility or for any costs incurred with

such removal or reinstallation.

CONSEQUENTIAL DAMAGES

Notwithstanding any other provision of this agreement, in no event shall Mertz

Manufacturing, LLC be liable, whether arising under contract, tort (including

negligence) or otherwise, for loss of anticipated profits, loss of use of capital or

revenue, non-operational expenses, increased expense of operation cost of

purchased or replacement equipment, damage to loads or contents of the equipment,

transportation expenses due to repairs, claims of customers, cost of money, or for any

special, incidental or consequential loss or damage of any nature arising at any time

or from any cause whatsoever.

This Warranty Agreement shall be governed by, and construed and enforced in

accordance with the laws of the State of Oklahoma. Any litigation under this warranty

will be held in Kay County in accordance with the laws of Oklahoma.

Mertz Manufacturing, LLC P.O. Box 150 Ponca City, OK 74602

PO BOX 150 (74602) / 1701 N WAVERLY / PONCA CITY, OK 74601. PHONE:

(580) 762-5646 / FAX: (580) 767-8411 / NT FAX: (580) 765-3934

www.boxerok.com

ii

TRACK LIMITED PRORATED WARRANTY POLICY STATEMENT

Compact Power Inc provides a limited warranty to the original purchaser that the

original tracks used on consumer products sold by Compact Power or its authorized

Distributor/Dealer, and manufactured by its subsidiary Mertz Mfg., will be free from

defects in material and workmanship for a period of one (1) year after the date of

purchase or 400 hours of use, whichever occurs first. Compact Power or its

authorized Distributor/Dealer will replace any track found to be defective in either

material or workmanship, using the below described prorated discount structure, and

subject to the conditions, limitations, and exclusions set forth herein.

The one year or 400 hours of use duration of this warranty applies only if the product

is put to ordinary and reasonable use.

Genuine manufacturer supplied replacement track(s) not purchased with the original

product purchase, but which are later purchased and used with that product, are

warranted to be free from defects in material and workmanship for a period of sixty

(60) days after the date of the “parts” purchase or 100 hours of use. The purchaser of

these replacement tracks must be able to document the time frame and hours of use

for the replacement tracks. Compact Power or its authorized Distributor/Dealer will

repair or replace any such track free of charge during that period.

Prorated discount structure: If the original track becomes unserviceable within the

first 100 hours of use, Compact Power or its authorized Distributor/Dealer will

replace that track at no cost including replacement labor. If the original track

becomes unserviceable within the first 200 hours of use, Compact Power or its

authorized Distributor/Dealer will replace the track with a prorated discount from the

cost of the track and no charge for the replacement labor. If the track becomes

unserviceable within the first 400 hours of use, Compact Power or its authorized

Distributor/Dealer will replace the track with a prorated discount from the cost of the

track with no replacement labor paid.

This warranty is subject to the following conditions, limitations,

and exclusions:

This warranty is valid only if the following conditions are met:

The warranty registration card must be completed and returned t o manufact urer of the

product.

The purchaser must perform maintenance and minor adjustments explained in the

owner's manual.

The purchaser must promptly notify Compact Power or its authorized Distributor/

Dealer service representative o f th e nee d for w arr anty serv ice.

This warranty is subject to the following limitations:

The purchaser must transport the product to and from the place of warranty repair. Any

expense for travel or mileage is the responsibility of t he purch aser.

iii

Warranty service must be performed by Compact Power or its authorized Dealer's

service representative

The following items are not covered by this Track Limited Warranty:

Parts that are not genuine original manufacturer se rvic e p arts ar e not co vered by thi s

warranty.

Products which are damaged and sold as salvage units or in an “as is” condition are not

covered by this warranty.

Any defect which is the result of misuse, alteration, improper assembly, improper

adjustment, neglect, accident, or damage caused by natural calamity beyond human

control such as fire, flood, etc. is not covered by this warranty.

EXAMPLE OF THE 'PRORATED' COMPUTATIONS OF THIS TRACK

LIMITED WARRANTY:

First, divide the number of hours on the original tracks, the hours on the unit, by 400

to determine the “wear percentage factor.” Next, subtract the result from 1 to

determine the “prorated discount” to be applied to the cost of the track.

If a unit has 150 hours and requires a new track; divide 150 by 400 which equals .38

the “wear percentage factor.” Subtract that number from 1 which equals .62, or 62%

the “prorated discount.” In this case, the dealer will receive a warranty credit in the

amount of his cost for the track less 62%. If the hours are less that 200 on the original

track, a labor allowance of ½ hour will also be credited. No replacement labor will be

paid if hours are over 200.

,

,

LIMITATION OF REMEDY AND DAMAGES

Compact Powers liability under this warranty, and under any implied warranty that

may exist, is limited to repair of any defect in workmanship, and repair or

replacement of any defective part. Compact Power shall not be liable for incidental,

special, or consequential damages (including lost profits). Some states do not allow

the exclusion of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

DISCLAIMER OF FURTHER WARRANTY

Compact Power makes no warranty, express or implied, other than what is

expressly made in this warranty. If the law of your state provides that an implied

warranty of merchantability, or an implied warranty of fitness for particular

purpose, or any other implied warranty, applies to Compact Power, then any

such implied warranty is limited to the duration of this warranty. Some states do

not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. This warranty gives you specific legal rights,

and you may also have other rights which vary from state to state.

iv

Boxer Warranty Registration

Dear Customer,

Mertz Manufacturing, LLC wishes to thank you for your purchase. We are

committed to providing our customers with the finest products and product

support available in any market today. To do this, we need to update our

database with some specific information. Currently, the warranty start date is

listed as the date the Boxer Tren cher left Mertz Manufacturing, LLC. T his may

be several months before you ever received the product. Mertz

Manufacturing, LLC will restart the warranty date if you will complete the

information below and return this form to us. We will continue to use the date

the Boxer Trencher left the factory as the warranty start date of record until we

are told differently through receipt of this form. Not returning the form could

result in your being denied some of your warra nty entitlements. To have Mertz

Manufacturing, LLC reset the warranty start date, please complete the form

below and mail or fax it back to: Mertz Manufacturing, LLC, P.O. Box 150,

Ponca City, OK 74602, Fax: 580-767-8411.

Please take the time to complete and return this warranty form.

Fold

Name: _______________________________________________________

Address:______________________________________________________

City: ____________________ State: Zip: ___________________

Telephone No. _________________________________________________

Location Purchased: ____________________________________________

Date Purchased: __________ Salesman: __________________________

____ I have received a copy of the Owners Manual for my engine.

____ I need a copy of the Owners Manual for my engine.

Signed: ______________________________________________________

Model No. _______________ Serial No. ___________________________

v

Affix

Stamp

Here

Mertz Manufacturing, LLC

P.O. Box 150

Ponca City, OK 74602

vi

Safety Introduction

Be Prepared - Get to Know All Operating and Safety Instructions

This is the Safety Alert Symbol.

Wherever it appears, either in this manual or on safety signs on the machine, you should be

alert to the potential for personal injury or accidents. Always observe safety precautions and

follow recommended procedures.

Learn the Signal Words Used with the Safety Alert Symbol

The words “DANGER”, “WARNING”, and “CAUTION” are used throughout this manual

and on labels on the machine indicate hazards or unsafe practices. All three statements indicate

that safety is involved. Observe the precautions indicated whenever you see the Safety Alert

symbol no matter which signal word appears next to the Safety Alert symbol.

DANGER

INDICATES A HAZARDOUS SITUATION THAT, IF NOT AVOIDED, IS VERY

LIKELY TO CAUSE DEATH OR EXTREMELY SERIOUS INJURY. IT MAY ALSO

BE USED TO ALERT AGAINST EQUIPMENT THAT MAY EXPLODE OR

DETONATE IF HANDLED OR TREATED CARELESSLY.

WARNING

Indicates a hazardous situation that, if not avoided, could result in serious injury or

death. It may also be used to alert against a highly unsafe practice.

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury. It may also be used to alert against a generally unsafe practice.

NOTICE

This type of statement is used to draw attention to a procedure that needs to be followed to

prevent machine damage.

vii

viii

Table of Contents

Boxer Product Warranty...................................................................................... i

Track Limited Warranty Policy Statement .......................................................iii

Safety Introduction ........................................................................................... vii

Be Prepared - Get to Know All Operating and Safety Instructions.........vii

Learn the Signal Words Used with the Safety Alert Symbol...................vii

Section 1 – Safety Precautions...................................................................... 1–1

GENERAL SAFETY ................................................................................... 1–1

OPERATING SAFETY ............................................................................... 1–2

SERVICE & MAINTENANCE SAFETY......................................................1–4

ELECTRICAL SYSTEM HAZARDS ........................................................... 1–4

Battery Hazards................................................................................... 1–5

Jump Starting/Battery Charging Hazards............................................1–5

Hydraulic System Hazards .................................................................. 1–6

Fueling Hazards .................................................................................. 1–7

Section 2 – Operating Controls ..................................................................... 2–1

Component Locations ................................................................................ 2–1

Right Front View.................................................................................. 2–1

Left Rear View..................................................................................... 2–2

Operating Controls .............................................................................. 2–3

Safety Decals ...................................................................................... 2–4

Operating Controls Description ........................................................... 2–5

Section 3 – Pre-Start Inspection and Operation........................................... 3–1

Pre-Start Inspection.................................................................................... 3–1

Daily Service Checks ................................................................................. 3–1

Operating Instructions ................................................................................ 3–7

Machine Start-up................................................................................. 3–7

Machine Shut-down............................................................................. 3–8

Transportation ..................................................................................... 3–8

Lifting Procedures................................................................................ 3–9

Machine Travel Controls .......................................................................... 3–10

Operating Instructions .............................................................................. 3–15

Section 4 – Routine Service and Maintenance............................................. 4–1

Daily Maintenance Procedures .................................................................. 4–2

New Machine Brake-in Maintenance Procedures ...................................... 4–8

Weekly Maintenance Procedures............................................................. 4–11

Monthly Maintenance Procedures............................................................ 4–12

Annual Maintenance Procedures............................................................. 4–16

General Maintenance...............................................................................4–18

Draining Fuel Tank............................................................................ 4–18

Adjusting Digging Chain Tension ...................................................... 4–20

Trencher Boom Replacement............................................................ 4–22

Replacing the Digging Teeth............................................................. 4–24

Replacing the Drive Sprocket............................................................ 4–25

Chain Configuration........................................................................... 4–27

Chain Master Link.............................................................................. 4–28

ix

Configuring the Chain........................................................................ 4–29

Parts List .................................................................................................. 4–30

Boxer 118 Hydraulic Interconnect Diagram.............................................. 4–32

Section 5 – Troubleshooting.......................................................................... 5–1

Section 6 – General Specifications ............................................................... 6–1

Noise Data.................................................................................................. 6–2

x

Section 1 – Safety Precautions

Since Mertz Manufacturing has no direct control over machine application or operation,

following the proper safety practices is the responsibility of the owner and/or operator.

Remember that this unit is only as safe as those who operate it. Safety tips shown throughout

this Operator's Manual must be followed at all times.

GENERAL SAFETY

• Never operate the Boxer without first completely reading and understanding this Owner's

Manual.

• Only authorized, qualified, and trained personnel are allowed to operate this machine.

• Never operate the machine under the influence of alcohol, awareness altering drugs, or

medications that would affect your ability to operate safely.

• KEEP CHILDREN CLEAR FROM THE WORK SITE AREA AT ALL TIMES!

• NEVER ALLOW A CHILD TO OPERATE OR RIDE ON THE MACHINE

• Serious injury or death involving children can occur. Stay ALERT and be aware of your

surroundings at all times. Stop operations if children wander onto the job site. Resume work

only when the operating area is clear.

• Keep all non-operating personnel away from the machine during operation.

• Passengers must never be allowed to ride on the machine.

• Wearing protective clothing and gear, such as hard hats, safety glasses, safety shoes, hearing

protection, breathing protection, and long pants and shirts is highly recommended. Do not

operate in clothing or shoes which will expose skin or feet to possible flying debris.

• Clothing should be relatively close fitting. Loose clothing, rings, and other jewelry should be

avoided because of the danger of catching them on machine parts or controls or on any

rotating parts, either on the machine or any attachment.

• Keep hands/fingers clear from all rotating parts.

• Never touch engine parts or machine components while they are hot.

• Always perform the “Standard Shut Down Procedure” shown in this manual, if the unit will

be left unattended for any length of time.

• Use only original BOXER or approved replacement parts. Imitation parts may lead to unit

damage and/or injury to personnel. The machines' warranty may be voided if unauthorized

parts are used.

1-1

Safety Precautions

OPERATING SAFETY

• Plan ahead and learn as much as possible about your job-site area before beginning any work.

• Know the exact location of overhead power lines or obstructions.

• Have all buried lines such as; gas, electric, water, telephone and cable TV, marked by the

proper authorities.

• Prior to use, perform the "Pre-Start Inspection" and Daily Maintenance to make sure that the

unit is in safe operating condition.

• Never operate a malfunctioning unit!

• Keep hands, gloves, shoes, control knobs, and operator platform clean. Slippery controls can

cause you to lose control, which may result in an accident.

• Always keep a firm grip on the hand rails located at the operator's platform during travel and

operation to prevent falling off the unit.

• When working on an unfamiliar construction site, review, understand and follow job site

safety rules.

• Keep the work site clear of all non-operating personnel. Should a person enter the work area,

stop machine operation until the work area is clear.

• Prior to unloading the unit and starting to work, inspect the path you will travel and work site

area for potential hazards. Some of the hazardous conditions you may encounter are:

–Holes

– Deep ditches or excavations

– Drop-offs

– Soft un-compacted soil

– Culverts

– Deep mud / Standing Water

– Large rocks

– Slippery surfaces

– Steep slopes

– Tall grass, trees, or shrubs

If any of these conditions exist, correct the hazard or obstruction. If any of these conditions

can not be corrected, avoid operating or traveling near them.

• Be extremely cautious traveling through or near trees, brush, shrubs or any obstacles which

might obscure your vision. These might hide potential hazards, such as the edge of a steep

slope, deep holes, large rocks, etc.

• Never operate near a ditch or embankment where loose or soft ground conditions could cause

the surface to give way under the machine causing it to become unstable.

• Never exceed the rated capacity of the machine.

• Operate all controls slowly and smoothly and never abruptly stop any function. This can

cause the machine to become unstable.

• Always look in the direction of travel.

• Come to a complete stop prior to reversing travel directions.

• Reduce speed and proceed with caution when traveling in reverse or turning.

• Never travel with the trencher boom raised. Lower the boom as soon as possible and travel

with the boom at the lowest safe height.

• Approach corners slowly, turning too fast or sharp may cause the machine to tip over.

• Stay alert when operating near traffic or roadways.

1-2

Safety Precautions

• If the unit should begin to tip or become unstable, DO NOT try to stabilize the unit with your

legs or arms.

• If the unit is involved in an accident or inadvertently damaged during operation, stop and

perform a thorough inspection. Make sure the unit is in safe operating condition prior to

resuming work.

• Be alert to any unusual reaction to any of the controls. If anything unusual is noticed, shut the

machine down and thoroughly inspect it to determine the cause of the problem. Do not

operate the machine until all required repairs have been made.

• If the unit must be left unattended, shut the machine down and make sure that it can not be

started by an unauthorized individual.

• Operating on steep slopes can be dangerous and there is a greater risk of the machine tipping

over or becoming unstable. The list of rules below must be understood and followed for

maximum safety:

– Avoid excessively steep slopes or unstable surfaces. If travel on a slope is necessary, keep

the load low and proceed with extreme caution.

– DO NOT travel ACROSS excessively steep slopes under any circumstances.

– Travel straight up and down slopes with the heavy end of the machine pointing up the

incline. When the machine has no load, the operator's platform end of the machine is

considered the heavy end.

– Turning on slopes is not a recommended practice, however if you must turn on slopes;

reduce travel speed to as slow as possible, and exercise extreme caution. A void sharp turns

or sudden movements.

– Wet or slick ground conditions should be avoided as reduced traction could cause the

machine to slide down the slope.

– Never park the unit on a slope.

1-3

Safety Precautions

SERVICE & MAINTENANCE SAFETY

Maintenance work can be hazardous if not done in a careful manner. All personnel should

realize the hazards and strictly follow safe mainte nan ce p ractic es. Fail ure to comply wit h the se

safety precautions may result in serious personal injury and/or death.

• Use only BOXER supplied or approved replacement parts. Imitation parts may lead to unit

damage and/or injury to personnel. Warranty may be voided if unauthorized parts and are

used.

• Wear the proper protective clothing and personal safety equipment necessary to perform the

maintenance or service required.

• Keep the machine free of grass, leaves, or other debris build-up.

• Clean up oil or fuel spillage.

WARNING

Fuel or oil leaks or spills can create a fire or explosion hazard.

• Prior to performing maintenance or service, park the unit in a level area away from

obstructions and/or work site hazards.

• Be sure the area has adequate light and is well ventilated. NEVER operate the machine

inside a closed area.

• Clean-up any oil, grease, mud, water, or snow which might cause the floor surface to become

slippery.

• If the machine requires maintenance, take the machine out of service and attach a "Do Not

Operate" tag at the control panel and remove the ignition key.

• If maintenance or repairs require the boom to be raised, securely support the boom.

• Know where all pinch points and rotating parts on the unit are. These areas must be avoided

to prevent serious injury.

• Remove only those guards or covers on the component being serviced and replace them

immediately upon completion of the work.

• Never attempt to adjust or service engine or machine components while they are hot.

ELECTRICAL SYSTEM HAZARDS

• Prior to working on the electrical system:

– Disconnect battery cables, removing the battery ground cable first.

– When re-connecting the battery, connect the battery ground cable last.

– Never allow battery cables to contact hydraulic lines or rub against sharp edges.

1-4

Safety Precautions

Battery Hazards

Before working with batteries, the following are important points about battery safety that you

should be aware of:

• Batteries are always surrounded by extremely explosive gases. This is especially true when

the battery is being charged. T o avoid explosion:

– Do not smoke near batteries.

– Keep arcs, sparks and open flames away from batteries.

– Perform battery service work only in a well ventilated area .

• Make sure to dispose of batteries according to local regulations.

• Electrolyte Hazards:

NOTICE

The batteries on the machine may be either be “wet cell” or gel cell.

It is still important to know and follow these warnings and cautions.

• Battery electrolyte in standard “wet cell” batteries contains sulfuric acid which is poisonous

and can cause severe chemical burns. To avoid personal injury:

– Wear a face shield to prevent sulfuric acid contact with your eyes

– Wear chemical resistant gloves and clothing to keep acid off your skin and clothing.

– Since wet cell batteries give off explosive gases, use a flashlight to check the electrolyte

level, not an open flame such as a match.

– Never check the battery by placing a metal object across the battery posts. The resulting

spark could ignite anything flammable, causing fire or an explosion.

– If electrolyte is splashed into your eyes, flush them immediately with clean water and seek

medical attention.

– If electrolyte is swallowed, seek medical attention immediately.

– If electrolyte is splashed onto exposed skin or clothing, flush and clean the area

immediately with clean water and seek medical attention if necessary.

Jump Starting/Battery Charging Hazards

Follow the instructions for jump starting or battery char ging in the engine owner 's manual. You

must be at the operator's platform when attempting to start the unit with booster batteries and

jumper cables so that you are at the controls when the engine starts.

Here are some general safety rules you must follow for jump starting the machine:

• Make sure to connect the positive jumper cable to the positive (RED) terminal on the battery.

• Connect the negative cable to the engine, machine chassis or the furthest ground point away

from the battery. Never make the final connection at the starter or dead battery. Sparks may

ignite the explosive gases surrounding the battery.

• When disconnecting cables after jump starting, remove the negative cable first and then the

positive cable.IMPORT ANT: DO NOT let the cable clamps touch when disconnecting them.

• Severe damage can occur to the booster battery or machine.

• Never charge a battery or attempt to jump start a frozen battery. The sudden surge in

electrical power could cause the battery to explode.

1-5

Safety Precautions

Hydraulic System Hazards

The hydraulic system is under pressure whenever the engine is running and may hold pressure

even after the engine is shut off. Cycle all hydraulic controls after the trench boom is resting o n

the ground. Some components will retain residual or trapped pressure. Use extreme caution

when removing any hydraulic component.

During inspection of the hydraulic system:

• Cycle all hydraulic controls to release residual pressure.

• Wait for the hydraulic fluid to cool down before disconnecting any hydraulic lines. Hot

hydraulic fluid can cause severe burns.

WARNING

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use cardboard

or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are injected with

hydraulic oil or any other fluids, immediately seek treatment by a doctor trained in the

treatment of penetrating fluid injuries.

• Hydraulic fluid can cause permanent eye injury. We ar s afe ty glasses or a full face shield to

provide appropriate eye protection.

• When venting or filling the hydraulic system, loosen the filler cap slowly to allow any

pressure in the hydraulic tank to be released and remove the cap gradually.

1-6

Safety Precautions

Fueling Hazards

Most fuels are highly flammable. Observe the following precautionary practices to reduce the

possibility of a serious accident:

• Always refuel the unit in an open, well ventilated area away from sparks or open flames.

DANGER

Gasoline Engines:

• Shut the engine off before attempting to fuel the machine. Never refuel a unit while

it is running.

• Allow engine to cool before re-fueling

• Always use a funnel or pour spout when filling the tanks.

• Under certain circumstances a static charge can develop and ignite the fuel. Make

sure that you are standing on the ground when filling the fuel tanks.

• If you are filling the fuel tanks from a service vehicle, make sure to connect the

service vehicles ground cable to the machine before beginning the fueling process.

• Keep the fuel nozzle in constant contact with the rim of the machines fuel tank.

• When filling a portable gas container, always place it on the ground. Never fill a

portable fuel container while it is inside a vehicle, truck, pick-up bed, or any

surface.

• To avoid static sparks when using a portable fuel container, only fill the container

when it is positioned on the ground and keep the fuel contain er nozzle in contact

with the tank opening during filling.

• Make sure to move the unit from the transport truck or trailer and only refuel the

unit on the ground, using an approved container.

• Keep sparks and flames away from fuel.

• Do not smoke while refueling or when handling the fuel container.

• Never cut or weld on or near fuel lines, tanks or containers.

• Never overfill the tank.

• Clean up spilled fuel immediately.

• Store fuel in an approved container and keep out of the reach of children.

1-7

Safety Precautions

1-8

Section 2 – Operating Controls

Component Locations

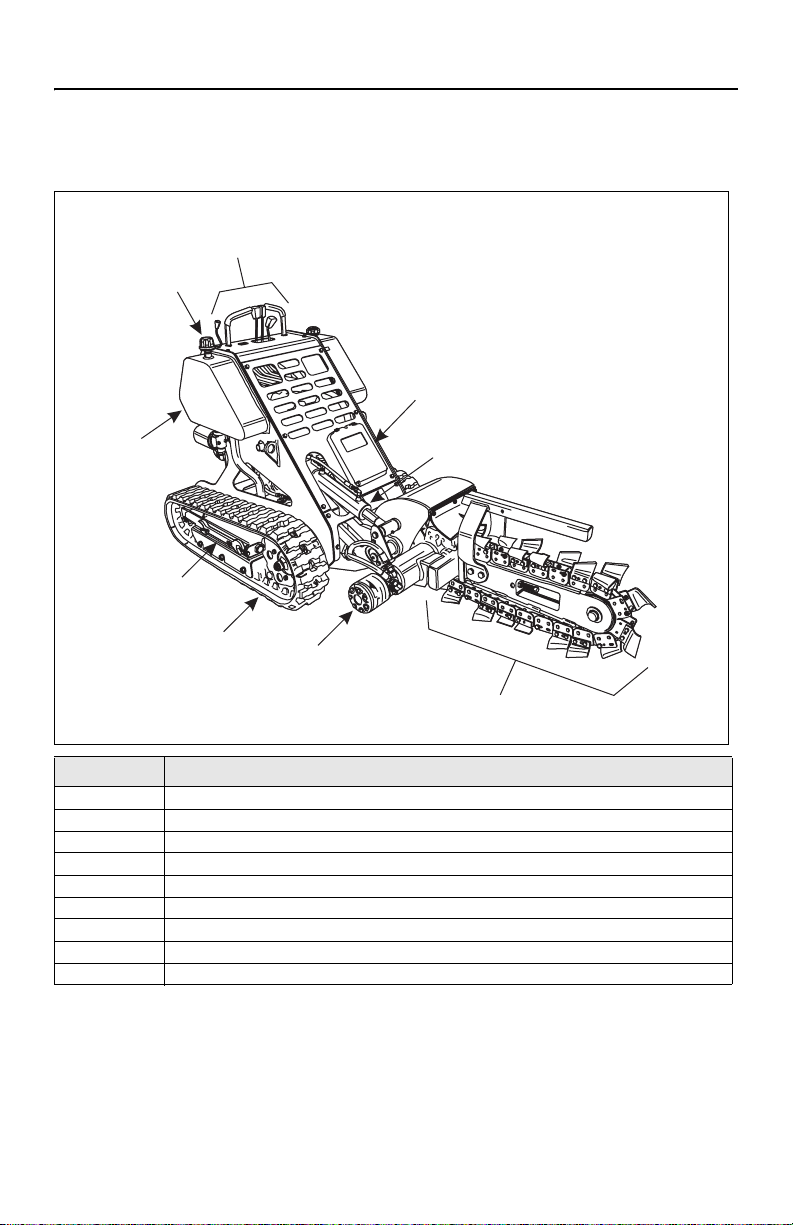

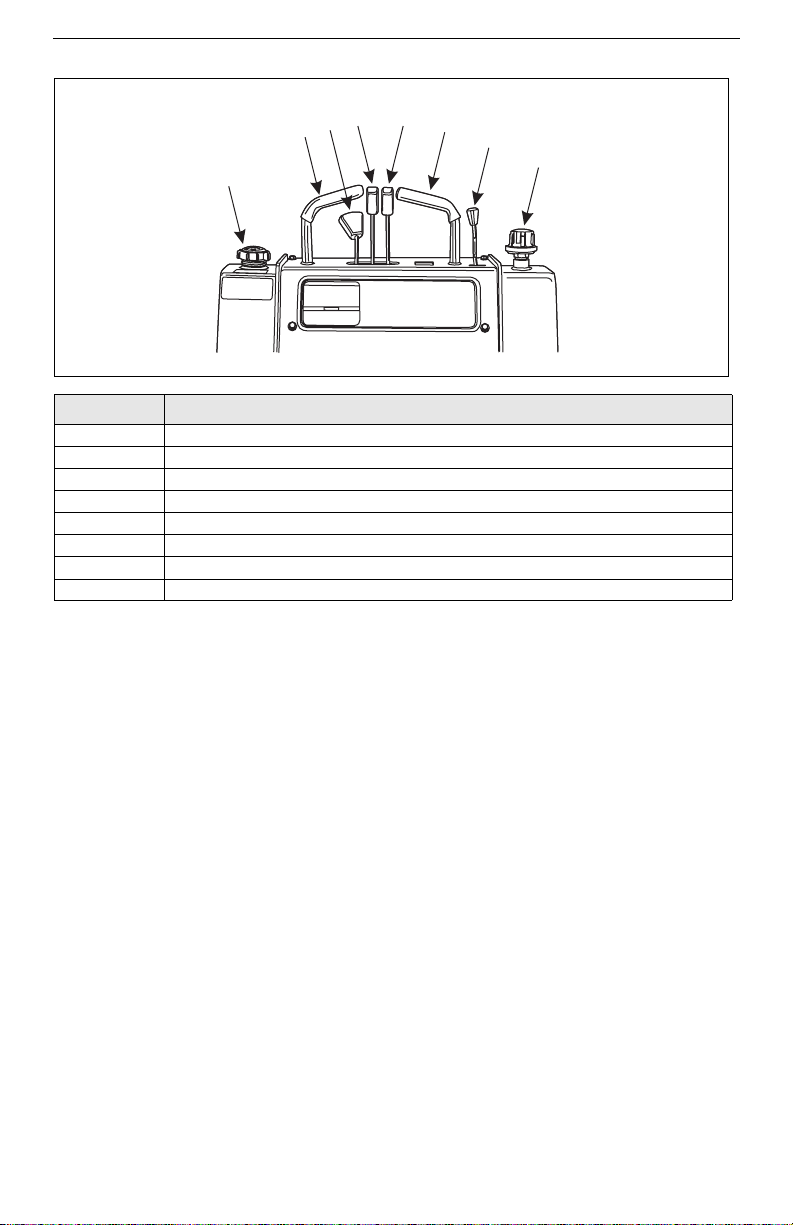

Right Front View

1

2

9

3

8

4

5

Item No. Description

1 Operating Controls

2 Hydraulic Fluid Level Dipstick and Tank Fill Port

3 Hydraulic Tank

4 Track Adjusting Wrench

5 Right Hand Track Drive

6 Trencher Drive Motor

7 Trencher Assembly

8 Boom Raise Cylinder

9 Manual Holder

6

7

2149

2-1

Operating Controls

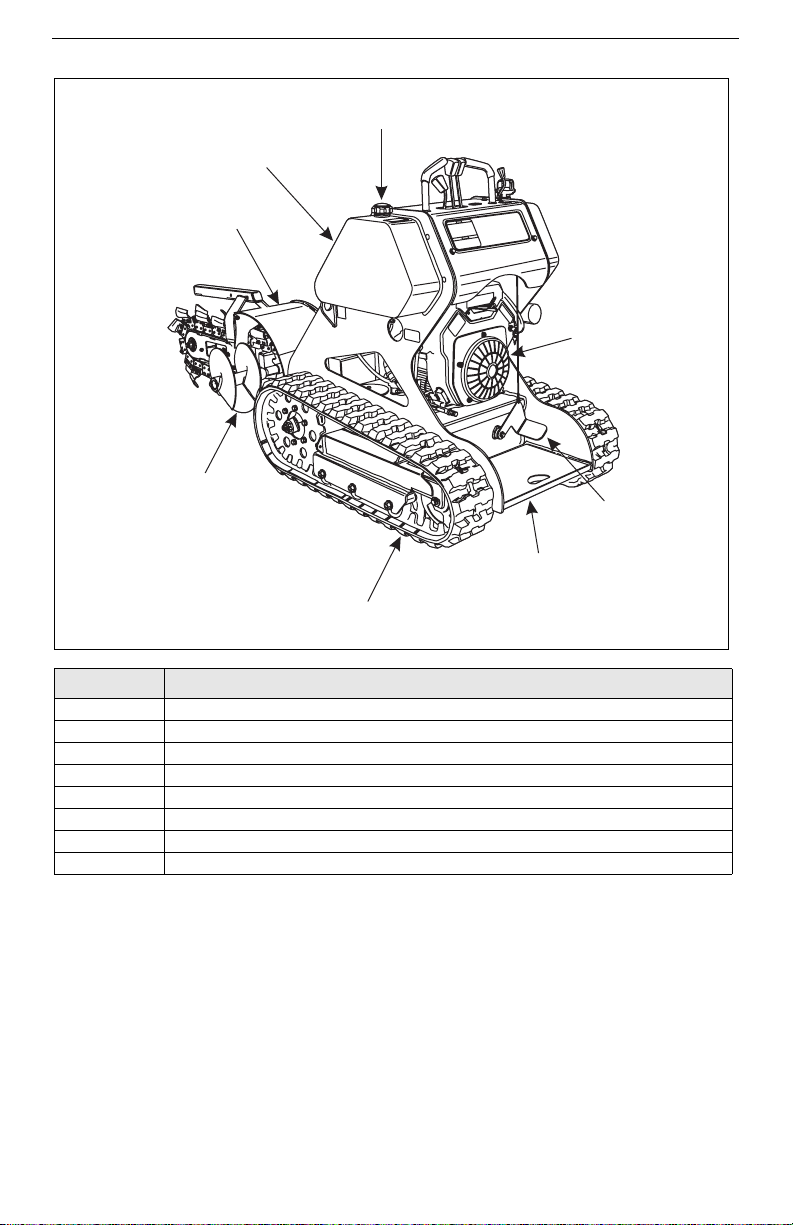

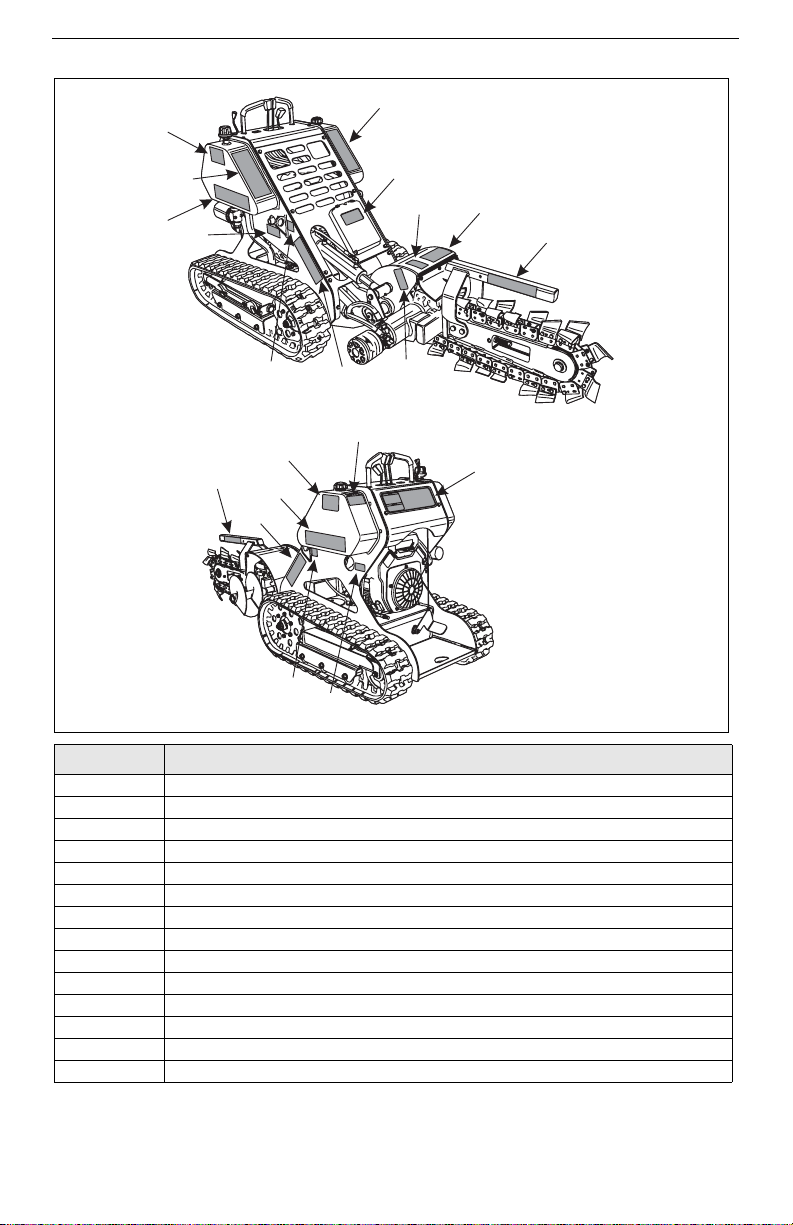

Left Rear View

1

2

3

8

4

7

6

5

Item No. Description

1 Fuel Gauge and Fuel Filler Cap

2 Gas Tank

3 Rock Guard

4 Spoils Auger

5 Left Track Assembly

6 Operator's Platform

7 Trencher Activation Lock Lever

8 Engine

2-2

2420

Operating Controls

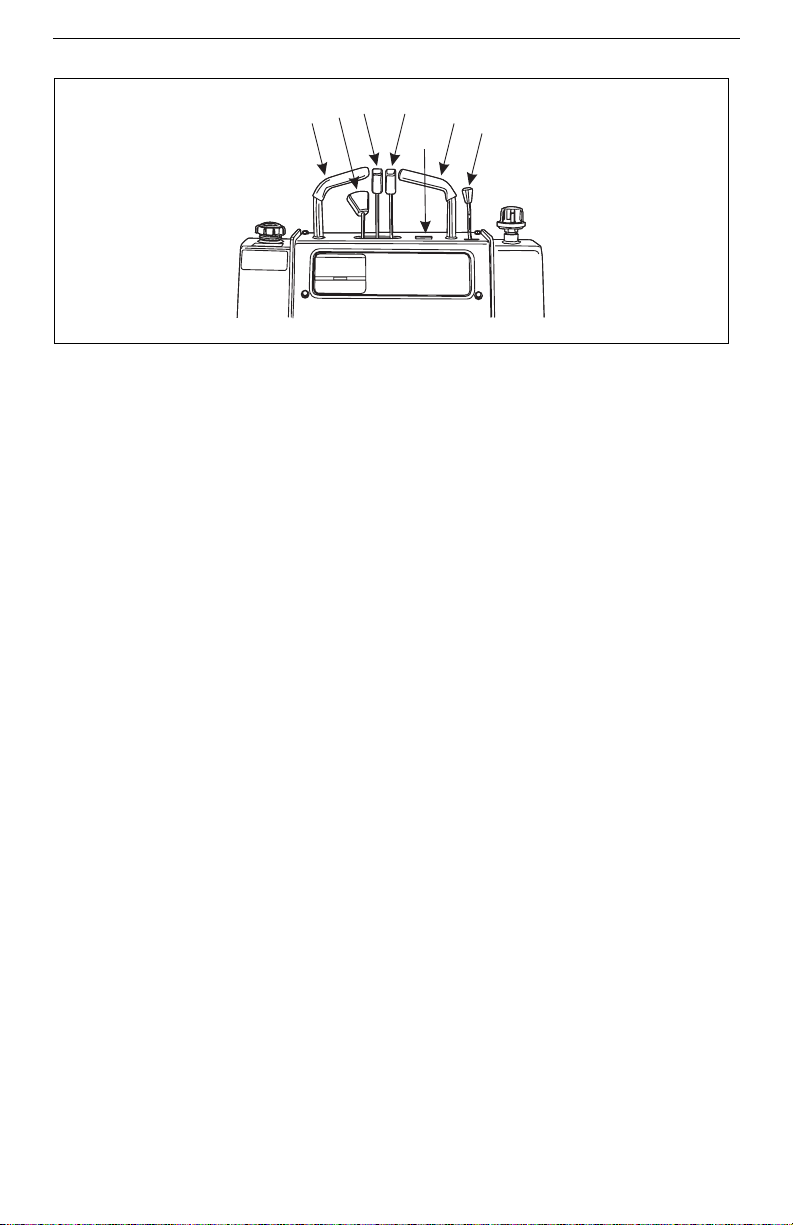

45

3

2

1

Item No. Description

1 Fuel Gauge and Fuel Filler Cap

2 Left Hand Grip

3 Trencher Boom Raise and Lower Control Lever

4 Left Travel Control Lever

5 Right Travel Control Lever

6 Right Hand Grip

7 Trencher Activation Control

8 Hydraulic Filler Cap and Dipstick

Operating Controls

6

7

8

2424

2-3

Operating Controls

Safety Decals

2

1

1

3

4

5

11

10

9

8

6

7

12

2

8

3

13

6

5

14

2421

Item No. Description

1 118 Model Number

2 Keep Distance Warning

3 CPI Logo

4 Burn Hazard Warning

5 Tie Down and Lifting Hazard Decals

6 Boxer Logo

7 Crush Hazard Decal

8 Stand Clear Warning Decal

9 Entanglement Hazard Decal

10 Shock Hazard Decal

11 Read Manual Decal

12 Fuel Explosion Hazard Warning Decal

13 Operating Instruction Decal

14 Fuel Shut Off Warning

2-4

Operating Controls

Operating Controls Description

23

1

5

5

6

4

Boom Raise and Lower – This lever controls the raising and lowering of the trencher

1.

boom assembly.

Left Travel Motor Control – Pushing the lever forward rotates the left side track for

2.

forward travel. Pulling the lever backwards rotates the left side track for reverse travel.

Right Travel Motor Control – Pushing the lever forward rotates the right side track for

3.

forward travel. Pulling the lever backwards rotates the right side track for reverse travel.

Engine Hour Meter Gauge

4.

5. Hand Grip

6. Trencher Operation –

the control lever, the operator my step on the operator presence control lever and hold the

lever in the downwards position. This allows the trencher control lever to be moved.

a. The center and forward position of the trencher control lever is the Neutral position. With

the lever in this position, the trencher chain will not move.

b. The main operating position is when the trencher control lever is moved to the right into

the Forward position. The control will remain in this position until it is moved back into

the Neutral position or you step off of the operator presence control.

c. If it is required, the trencher chain can be reversed by moving the control lever to the left

hand side of the slot. The control lever will not remain in this position, and if you let it go,

the lever will return to the neutral position.

There are three positions for the T rench er Control Lever. To activate

2425

2-5

Loading...

Loading...