CNG DISPENSER

SERVICE

MANUAL

CNG Dispenser Service Manual

Version 1.1.4

Date: 8th December 2017

Conditions of Use

Conditions of Use

▪ Read this manual completely before working on,

or making adjustments to, the Compac

equipment

▪ Compac Industries Limited accepts no liability for

personal injury or property damage resulting

from working on or adjusting the equipment

incorrectly or without authorization.

▪ Along with any warnings, instructions, and

procedures in this manual, you should also

observe any other common sense procedures

that are generally applicable to equipment of this

type.

▪ Failure to comply with any warnings,

instructions, procedures, or any other common

sense procedures may result in injury, equipment

damage, property damage, or poor performance

of the Compac equipment

▪ The major hazard involved with operating the

Compac C4000 processor is electrical shock.

This hazard can be avoided if you adhere to the

procedures in this manual and exercise all due

care.

▪ Compac Industries Limited accepts no liability for

direct, indirect, incidental, special, or

consequential damages resulting from failure to

follow any warnings, instructions, and

procedures in this manual, or any other common

sense procedures generally applicable to

equipment of this type. The foregoing limitation

extends to damages to person or property

caused by the Compac C4000 processor, or

damages resulting from the inability to use the

Compac C4000 processor, including loss of

profits, loss of products, loss of power supply,

the cost of arranging an alternative power

supply, and loss of time, whether incurred by the

user or their employees, the installer, the

commissioner, a service technician, or any third

party.

▪ Compac Industries Limited reserves the right to

change the specifications of its products or the

information in this manual without necessarily

notifying its users.

▪ Variations in installation and operating conditions

may affect the Compac C4000 processor's

performance. Compac Industries Limited has no

control over each installation's unique operating

environment. Hence, Compac Industries Limited

makes no representations or warranties concerning

the performance of the Compac C4000 processor

under the actual operating conditions prevailing at

the installation. A technical expert of your choosing

should validate all operating parameters for each

application.

▪ Compac Industries Limited has made every effort to

explain all servicing procedures, warnings, and

safety precautions as clearly and completely as

possible. However, due to the range of operating

environments, it is not possible to anticipate every

issue that may arise. This manual is intended to

provide general guidance. For specific guidance and

technical support, contact your authorised Compac

supplier, using the contact details in the Product

Identification section.

▪ Only parts supplied by or approved by Compac may

be used and no unauthorised modifications to the

hardware of software may be made. The use of nonapproved parts or modifications will void all

warranties and approvals. The use of non-approved

parts or modifications may also constitute a safety

hazard.

▪ Information in this manual shall not be deemed a

warranty, representation, or guarantee. For warranty

provisions applicable to the Compac C4000

processor, please refer to the warranty provided by

the supplier.

▪ Unless otherwise noted, references to brand names,

product names, or trademarks constitute the

intellectual property of the owner thereof. Subject to

your right to use the Compac C4000 processor,

Compac does not convey any right, title, or interest

in its intellectual property, including and without

limitation, its patents, copyrights, and know-how.

▪ Every effort has been made to ensure the accuracy

of this document. However, it may contain technical

inaccuracies or typographical errors. Compac

Industries Limited assumes no responsibility for and

disclaims all liability of such inaccuracies, errors, or

omissions in this publication.

Product Identification

Product Identification

Validity

Compac Industries Limited reserves the right to revise or change product specifications at any

time. This publication describes the state of the product at the time of publication and may not

reflect the product at all times in the past or in the future.

Models Covered

Standard

High Flow

Ultra-High Flow

Laser

L-CNG15

L-CNGD15

L-CNG50

L-CNGD50

L-CNG50-15

L-CNG80

L-CNGD80

L-CNG80-15

Legend

LGDCNG15

LGDCNGD15

LE3KG25D

LGDCNG50

LGDCNGD50

LGDCNG50-15

LGDCNG80

LGDCNGD80

LGDCNG80-15

Manufactured By:

The Compac CNG dispenser is designed and manufactured by Compac Industries Limited

52 Walls Road, Penrose, Auckland 1061, New Zealand

P.O. Box 12-417, Penrose, Auckland 1641, New Zealand

Phone: + 64 9 579 2094

Fax: + 64 9 579 0635

www.compac.co.nz

Copyright ©2015 Compac Industries Limited, All Rights Reserved

Document Control

Document Control

Document Information

Document Details

CNG Dispenser Service Manual

File Name and Location

G:\Masters\Manuals\Authorised Manuals\CNG

Manuals

Current Revision Author(s)

J Jang

Authorised By

W Zheng

Release Date:

27/01/2016

Revision History

Version

Date

Author(s)

Revision Notes

1.0.0

12/01/2010

R Lacey

Added document control

information

1.0.2

08/09/2010

R Lacey

Added troubleshooting

hyperlinks

1.0.3

10/02/2011

R Lacey

Added RS485 MOD-BUS &

Micro Motion wiring

1.0.4

13/04/2011

R Lacey

Added RS485 wiring

diagram

1.0.5

11/05/11

A.Kingstone

Corrected part numbers

1.0.6

10/02/2014

R Lacey

Added 350 Bar solenoid

information

1.0.7

14/04/2014

R Lacey

Added new Temperature

Pressure Board

connections

1.0.8

05/05/2014

R Lacey

Added Er FLO error

message

1.0.9

12/06/2015

R Lacey

Added information about air

actuated valve supplement

1.1.0

21/07/2015

R Lacey

Included Isolation valve and

gas operated valve

servicing instructions

1.1.1

20/11/2015

H Kleyer

Updated C4000 Power

Supply diagram

Document Control

1.1.2

10/03/2016

H Kleyer

Updated manual for Mk2

C4000 Power Supply

1.1.3

10/03/2016

H Kleyer

Updated PID

1.1.4

22/01/2018

J Jang

Updated manual

1.

Contents

Contents

Conditions of Use ................................................................................................. 1

Product Identification .......................................................................................... 2

Document Control ................................................................................................ 3

Contents ............................................................................................................... 1

Safety ................................................................................................................... 4

Mechanical Safety ..................................................................................... 4

Electrical Safety ........................................................................................ 5

Introduction .......................................................................................................... 6

Refuelling Modes ................................................................................................. 7

Dispenser Operation ............................................................................................ 8

Turning the Dispenser on ......................................................................... 8

Refuelling a Vehicle ............................................................................................. 9

Fast Fill Refuelling Process .................................................................... 10

Temperature Compensated Refuelling Process..................................... 11

Reading the Dispenser Totals ................................................................. 12

Electronics ......................................................................................................... 13

C4000 Processor ..................................................................................... 13

Menu Options ..................................................................................................... 15

Unit Price ............................................................................................................ 16

To set the unit price: ............................................................................... 16

Sequencing Rate ................................................................................................ 17

Hose Number ...................................................................................................... 18

To Set the dispenser hose numbers: ...................................................... 18

Software Version HIA29.24.9CNG onwards: ........................................... 18

Dispenser Software ........................................................................................... 19

To Identify the software Program Version Number: .............................. 19

End of Sale Indicators ........................................................................................ 20

To View the End of Sale indicators: ........................................................ 20

Dispenser Passcode .......................................................................................... 22

To Set the Dispenser Passcode: ............................................................. 22

To Disable the Dispenser Passcode: ...................................................... 22

2.

Contents

Troubleshooting ................................................................................................. 23

Fault Codes ........................................................................................................ 25

Indicator LED’s ................................................................................................... 27

Servicing ............................................................................................................ 31

Degassing the Dispenser ........................................................................ 31

Schedules Servicing ................................................................................ 32

Checking Dispenser Operation ............................................................... 33

Checking the Sealing of the Solenoid .................................................... 33

Checking the Setting and Sealing of the Regulator ............................... 33

Checking the Over-Pressure Switch Operation (Fast Fill & Temperature

Compensated Units Only)........................................................................ 34

Checking the Dispenser for Leaks ......................................................... 35

Checking the Refuelling Hoe for Leaks .................................................. 36

Checking the Isolation Ball Valve Sealing and Operation ..................... 36

Checking the Three-Way Refuelling Valve Sealing and Operation ....... 37

Draining the Coalescing Filter ................................................................ 37

Filter Element Replacement ......................................................... 38

Solenoid Valve Seal Replacement .......................................................... 39

Solenoid Coil Replacement ..................................................................... 42

Complete Solenoid Valve Replacement .................................................. 43

Regulator Valve Seal Replacement ........................................................ 44

Isolation Valve Seal Replacement .......................................................... 46

Gas Operated Valve (option) Seal Replacement .................................... 48

Bleed Valve Replacement ....................................................................... 52

Pressure Relief Valve Replacement ....................................................... 52

KG80 Meter Replacement ....................................................................... 52

Compac Breakaway Seal Replacement ................................................. 53

Three-Way Refuelling Valve Seal Replacement ..................................... 55

Compac Refuelling Valve Exploded View ............................................... 57

3.

Contents

Refuelling Hose Replacement ................................................................. 58

Power Supply Fuse Replacement ........................................................... 58

Power Supply Replacement .................................................................... 60

Processor Board Replacement ............................................................... 61

Temperatuer Pressure Board Replacement (Fast Fill & Temperature compensation

Units Only) ............................................................................................... 62

Dispenser Software Upgrade/Replacement ........................................... 63

Meter Replacement ................................................................................. 65

Unserviceable Parts List ......................................................................... 65

Dispenser Calibration ........................................................................................ 66

Meter Calibration .................................................................................... 66

Pressure Transducer Calibration (Fast Fill & Temperature Compensated Units Only)

................................................................................................................. 68

Ambient Temperature Sensor Calibration .............................................. 69

Appendix ............................................................................................................ 70

Specifications .................................................................................................... 71

Model Specifications .............................................................................. 71

Technical Specifications ......................................................................... 72

Component Specifications ...................................................................... 74

Mechanical Drawings ........................................................................................ 77

Dispenser Component Locator ............................................................... 77

4.

Safety

Safety

DANGER PRECAUTIONS

You must adhere to the following safety precautions at all times when working on the

Compac equipment. Failure to observe these safety precautions could result in

damage to the dispenser, injury, or death.

Make sure that you read and understand all safety precautions before operating the

Compac equipment

Failure to take adequate safety precautions could result in explosion, injury and loss of

life.

System Design

Ensure the system design does not allow the dispenser inlet pressure to

exceed its rating. The dispenser does not include any safeties to protect

against excessive inlet pressure. If necessary, suitable protective devices

should be fitted prior to the dispenser inlet.

Mechanical Safety

Observe the following electrical precautions:

▪ Never tighten a fitting under pressure, even if a fitting or joint is leaking.

Always depressurise the line first.

▪ Never disassemble a fitting under pressure. Always depressurise the line first.

▪ Be very careful when disassembling frozen pipework, as gas pressure may be

trapped and suddenly released. Always depressurise the line before using.

▪ Never reuse any O-ring seals that have been in a high pressure gas

atmosphere and then exposed to air. These o-rings swell and cannot be

reused. Always make sure you have a new seal kit available to replace the

seals before disassembly.

▪ Make sure that all internal surfaces are cleaned and that sliding surfaces are

lightly greased with O-ring lubricant before reassembly. Dust and dirt entering

components reduce the life span of the components and can affect operation.

▪ Ensure the service area is thoroughly cleaned before initiating service on CNG

components. Dust and dirt entering the components reduce the life span of the

component and affect future operations.

5.

Safety

Electrical Safety

Observe the following electrical precautions:

▪ Always turn off the power to the CNG Dispenser before removing the box lid.

Never touch wiring or components inside the CNG Dispenser with the power

on.

▪ Never power up the CNG dispenser with the flameproof box lid removed.

▪ Always turn off the power to the dispenser before removing or replacing

software or memory IC’s

▪ Always take basic anti-static precautions when working on the electronics,

i.e., wearing a wristband with an earth strap. The Compac CNC dispenser is

designed to provide safe and reliable dispensing of CNG fuels. They are

available in either single or dual hose configurations and with different flow

rates.

▪ Compac CNG dispensers are controlled by a C4000 board which has many

programmable features to suit your individual operation.

6.

Introduction

Introduction

The Compac CNC dispenser is designed to provide safe and reliable dispensing of CNG

fuels. They are available in either single or dual hose configurations and with different

flow rates.

Compac CNG dispensers are controlled by a C4000 board which has many

programmable features to suit your individual operation.

This manual contains the information required to operate and maintain your dispenser.

Due to ongoing improvements and customised designs, there may be software

features that are not available on your particular unit.

For clarity, this manual will refer to the "Dollars" display. If you do not use dollars

please substitute this for your local currency.

7.

Refuelling Modes

Refuelling Modes

Fixed Pressure Refuelling

The fuel is dispensed through a fixed pressure regulator. When fuel flow reaches a

minimum rate. The fuel flow is shut off. Refer to Fixed Pressure Refuelling.

Fast Fill Refuelling

To enable fast refuelling, the pressure in the tank is measured then a small amount of

precisely measured fuel is dispensed into the tank and the pressure rise is measured.

From these figures, the volume of the tank is calculated, and the tank filled rapidly to

this level. When the tank is full the flow is shut off by a solenoid valve. Refer to Fast Fill

Refuelling Process.

Temperature Compensated Refuelling

In cold environments, a tank filled to maximum pressure may exceed its maximum

pressure if the temperature rises. To prevent overfilling, a thermometer measures

ambient temperature and reduces the maximum fill pressure to eliminate this

possibility. Refer to Temperature Compensated Refuelling Process.

8.

Dispenser Operation

Dispenser Operation

Turning the Dispenser on

When the power is applied to the dispenser, the display will show PA:Use and

count down from 60seconds. This start-up procedure ensures the dispenser is

functioning properly before gas is dispensed.

Dispenser will be ready to use when the display indicates 0.00

NOTE: Before starting a fill, the software checks the status of the Stop switch. If the

switch is latched on, the display will flash STOP and will not allow the fill to proceed

until the switch is reset. The switch can be reset by rotating the Stop switch in a

clockwise direction.

9.

Refuelling a Vehicle

Refuelling a Vehicle

There can be up to three storage banks for CNG refuelling. During filling the dispenser

sequences through these banks from low to high as the pressure in the vehicle

cylinder increases and the flow rate drops.

Appropriate personal safety equipment should be worn whilst refuelling a vehicle.

To refuel a vehicle

▪ Press the start button or remove the nozzle from the holster to initiate a fill.

▪ The display will show 888888 and clear, at this point both the gas and

value totals will display 0.00

▪ Connect the refuelling nozzle to the vehicle.

▪ Open the nozzle refuelling valve to commence filling.

▪ The dispenser will emit a long beep signalling the end of the fill, at this point

the gas total display flashes Fin.

▪ Close the refuelling valve.

NOTE: Closing the valve shuts off the gas from the dispenser. It also vents the gas

between the refuelling valve and coupling to the dispenser vent point.

▪ Disconnect the nozzle from the vehicle.

▪ Return the refuelling nozzle to the nozzle holder.

10.

Refuelling a Vehicle

Fast Fill Refuelling Process

The fast fill refuelling process uses pressure sensors to calculate the quantity of gas

required to fill a vehicle to a configurable target fill pressure (FPA).

The technical operation of a fast fill dispenser is as follows:

▪ Press the start button or remove the nozzle from the holster to initiate a fill.

o The display will indicate 888888 then clear, at this point both the

gas and value totals will display 0.00.

▪ Connect the refuelling nozzle to the vehicle.

▪ The refuelling valve is opened and when flow is detected the solenoids shut

immediately. Pressure reading and amount dispensed is recorded.

▪ The solenoids are opened and filling continues as follows:

o If

was less than 50bar , the fill will continue for 20

seconds.

o If

was greater than 50bar but less than 100bar ,

the fill will continue for 14 seconds.

o If

was greater than 100bar but less than 150bar

, the fill will continue for 10 seconds.

o If

was greater than 150bar but less than 180bar

r, the fill will continue for 6 seconds.

▪ The solenoids shut and pressure reading

and amount dispensed

are recorded.

▪ The amount of gas

to completely fill the vehicle to FPA is calculated as

follows:

▪ The dispenser fills to

and stops. This is the end of the fill.

11.

Refuelling a Vehicle

Temperature Compensated Refuelling Process

The technical operation of a temperature compensated dispenser is as follows:

▪ Press the start button or remove the nozzle from the holster to initiate a fill.

The display will indicate 888888 and then clear, at this point both the

gas and value totals will display 0.00.

▪ Connect the refuelling nozzle to the vehicle.

▪ The refuelling valve is opened and when flow is detected the solenoids shut

immediately. Pressure reading and amount dispensed are

recorded.

▪ The compensated fill pressure Ptc is calculated. If the vehicle is within 20 bar

of this pressure, no filling takes place.

▪ The solenoids are opened, and filling continues as follows:

o If

was less than 50bar , the fill will continue for 20

seconds.

o If

was greater than 50bar but less than 100bar

, the fill will continue for 14 seconds.

o If

was greater than 100bar but less than 150bar

, the fill will continue for 10 seconds.

o If

was greater than 150bar but less than 180bar

r, the fill will continue for 6 seconds.

▪ The solenoids shut and pressure reading

and amount dispensed

are recorded.

▪ The amount of gas

to completely fill the vehicle to is calculated as

follows:

▪ The dispenser fills to

and stops. This is the end of the fill.

12.

Refuelling a Vehicle

Reading the Dispenser Totals

To read the dispenser totals:

▪ Quickly press the Start button or nozzle switch five times on the side of

the dispenser you wish to view the totals for. The total is 10 digits long. The

four most significant digits are displayed on the top line and the number wraps

to the second line showing the six least significant digits.

The dispensed amount will be shown on the display for 10 seconds.

This will be shown as:

d Followed by a 10-digit total (eg. d**********).

The dispensed quantity will then be shown next and will be displayed for 10

seconds.

This will be shown as:

L Followed by a 10-digit total (eg. L**********).

NOTE: From software version HIA29.25.3CNG onwards the decimal place has been

removed from the tote. There will be two digits on the top ($) display and six digits on

the lower (kg) display. For dual dispensers, the A or B side will be indicated in the unit

price display.

13.

Electronics

Electronics

C4000 Processor

The Parameter switch is located on the C4000 processor board and allows you to

adjust the unit price, horse number, sequencing rate and password.

The Parameter switch also enables you to view the Dispenser Software Version and

End of Sale Indicators.

The Compac C4000 is a microprocessor-based circuit board designed for use in liquid

and gaseous fuel metering. One C4000 head is used for a single or dual LPG

dispenser. The C4000 accepts inputs from the V50 meter. It converts the V50 meter

output to litres, which are corrected to litres at 15°C and displayed with the price and

total of the sale on the retail LCD display.

NOTE: Wait at least 30 seconds from powering up the C4000 before starting a fill.

Failure to do this will result in a "density” error.

The parameter and K-Factor switches are used to configure the dispenser’s C4000

processor. Changes made can affect how the dispenser operates and can result in it

becoming inoperable. Only make changes when you understand what you are

changing.

The parameter and K-Factor switches are located on the C4000 board, which is in the

dispenser cabinet and covered by a metal panel. The K-Factor switch is sealed to

prevent tampering.

14.

Electronics

PARAMETER

K-FACTOR

15.

Menu Options

Menu Options

Listed below is the order in which the Parameter switch menu options are presented.

There are different menu options depending on the current setting of the C

configuration code.

The X indicates that you can achieve the displayed menu option, regardless of what

the indicated part is set to. You may need to change the C configuration in order to

access the parameter code you require.

C Configuration

Set-Up Code

Code Description

CXXX61

P

Software Program version

Pr

Unit Price

SE9

CNG Sequencing rate

(FAS,nOr,SLO)

Pn

Hose Number

Code

Dispenser Passcode

CXXX62

P

Software Program version

PrA

Unit Price Side A

PrB

Unit Price Side B

PnA

Hose Number Side A

PnB

Hose Number Side B

Code

Dispenser Password

To change the value of a selected digit, hold down the K-Factor switch. This will cause

the digit to cycle through (0,9). Releasing the K-Factor switch will select the digit.

The K-Factor switch must be resealed after use to prevent unauthorised access.

NOTE: Before altering any K-Factor switch settings, ensure the nozzles are hung up,

and the dispenser is idle.

16.

Unit Price

Unit Price

The unit price (Pr, PrA and Prb) is used to calculate the total value of the

quantity dispensed. The unit price can be different on each side of a dual hose

dispenser.

PR or PrA is the unit price for side A of the dispenser.

Prb is the unit price for side B of the dispenser

The unit price can be set at the dispenser or set remotely with the Compac Dispenser

Monitor.

NOTE: If the unit price is not set Error 3 will be displayed and the dispenser

will not operate.

To set the unit price:

▪ Make sure that the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch until the required unit price is

displayed. (Pr, PrA or Prb)

▪ Enter in the unit price.

NOTE: Each press of the Parameter switch passes you over a digit in a setting,

making the digit blink. Holding the switch down for more than a second changes

whichever digit is currently displayed. If you want to pass over a setting without

changing any digits, keep pressing and releasing the switch.

▪ Let the menu time out so that the value and quantity amounts are displayed.

17.

Sequencing Rate

Sequencing Rate

NOTE: Only available on CNG dispensers. Appropriate software required.

The sequencing rate (SE9) enables you to set the percentage level of maximum flow

that sequencing occurs to the next pressure bank.

These are three settings to choose from;

▪ FAS: Switching to the next higher-pressure bank occurs at 40% of the

maximum flow rate for a particular bank.

▪ nOr: Switching to the next higher-pressure bank occurs at 30% of the

maximum flow rate for a particular bank.

▪ SLO: Switching to the next higher-pressure bank occurs at 20% of the

maximum flow rate for a particular bank.

NOTE: From software version HIA29.25.3CNG onwards the sequencing rates are as

follows:

▪ FAS: Switching to the next higher-pressure bank occurs at 60% of the

maximum flow rate for a particular bank or when the flow rate drops to

,

whichever occurs first.

▪ nOr: Switching to the next higher-pressure bank occurs at 30% of the

maximum flow rate for a particular bank or when the flow rate drops to

,

whichever occurs first.

▪ SLO: Switching to the next higher-pressure bank occurs at 20% of the

maximum flow rate for a particular bank or when the flow rate drops to

,

whichever occurs first.

NOTE: The dispenser leaves the factory with the FAS setting.

To set the sequencing rate:

▪ Make sure that the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch (17 or more times) until SE9 xxx is

displayed.

▪ Enter the sequencing rate. Each press of the Parameter switch passes you

over a digit in the setting, making the digit blink. Holding the switch down for

more than a second changes whichever digit is currently displayed. If you

want to pass over a setting without changing any digits, keep pressing and

releasing the switch.

▪ The displayed sequencing rate is now selected, and operation of the dispenser

will be affected immediately. The displays will reset after a 10 second timeout.

18.

Hose Numb

er

Hose Number

The Hose Number (Pn, PnA and Pnb) identifies the dispensers hose(s) when the

dispenser is communicating to a forecourt controller such as the Compac Dispenser

Monitor.

Pn or PnA is the hose number of side A of the dispenser.

Pnb is the hose number side B of the dispenser

When using forecourt controller all dispenser hoses must have unique numbers.

To Set the dispenser hose numbers:

▪ Make sure that the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch until the required hose number is

displayed. (Pn, PnA or Pnb).

▪ Enter the hose number.

NOTE: Each press of the Parameter switch passes you over a digit in a setting,

making the digit blink. Holding the switch down for more than a second changes

whichever digit is currently displayed. If you want to pass over a setting without

changing any digits, keep pressing and releasing the switch.

▪ Let the parameter menu time out so that the value and quantity amounts are

displayed

Software Version HIA29.24.9CNG onwards:

From this version of software onwards the hose number(PN) display has been modified

to also display the following information:

▪ A count of the total error 9 faults in the unit shown in the price display.

▪ The display will also flash in the

screen, the last recorded reason for the

end of sale and the last recorded error 9.

This information can be used as a diagnostic aid to check whether error 9 faults are

occurring on a regular basis.

19.

Dispenser Software

Dispenser Software

The dispenser software version (P) is the version number of the software currently

loaded in the dispensers C4000.

See Dispenser Software Upgrade/Replacement for instructions on Upgrading dispenser

software.

To Identify the software Program Version Number:

▪ Make sure the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch once or until P is displayed. The

system enters a diagnostic mode whereby it displays the software program

version and performs a display segment test. It cycles through this program

for approximately 10 seconds before reverting to the normal display.

When displaying the program version data, the display panel shows P in the Dollars

screen and XXXXX. In the kilograms screen where XXXXX is the abbreviated

program version number. From example: Software version HIA29.26.0CNG will read

29260.

20.

End of Sale Indicators

End of Sale Indicators

The end of sale indicator allows you to determine the reason why the last fill ended.

This can be very useful for fault finding and diagnostics.

Recent versions of CNG software will flash the end of sale indicator in the price per

litre window at the end of each fill during normal operation. Older versions of software

will need to use the procedure below to view the end of sale indicator.

To View the End of Sale indicators:

▪ Press and release the Parameter switch until the required hose number (Pn,

PnA or Pnb) is displayed.

▪ The number in the unit price display is the end of sale indicator for the hose

number shown

See the table below for the meaning of the number displayed.

Number

Meaning

Checks

1

Nozzle switch de-activated (does not

apply to push to start dispensers).

2

Preset or temperature compensated value

reached. Normal end of sale message

for temperature compensated and Fast

Fill dispensers.

3

Fill timed out. Start button pressed, or

nozzle lifted, without flow.

Check inlet gas pressure.

Check solenoid operation.

Refer Solenoid Problems

Check nozzle and breakaway

for blockages.

4

The dispenser was stopped by a remote

device such as a Point of Sale (POS) or

Compac Communicator.

Check that the point of sale is

not sending a stop command

and is correctly configured.

5

Maximum display value reached.

Check display resolution (Sr)

setting. Refer Display

Resolution

7

An error has occurred. The error will be

shown on the main display.

Check error code reason.

Refer Error Codes

8

Outputs sequenced normally and

dispenser finished on the low flow cutoff

setting. Normal end of sale message for

regulator controlled dispensers

21.

End of Sale Indicators

Number

Meaning

Checks

12

Parity error on main display. This is

caused by a fault in the display or a bad

connection in the display wiring loom.

Check displays are dry and all

connections tight. Try

swapping with another display

if available.

14

Main display not detected. This is caused

by a fault in the display or a bad

connection in the display wiring loom.

See above.

20

The pressure at the first measurement

was within 20bar of the calculated

maximum pressure.

Check for blockage in the fuel

delivery hose, breakaway or

vehicle pipework.

21

The pressure at the second measurement

exceeded the calculated maximum

pressure.

Check for blockage in the fuel

delivery hose, breakaway or

vehicle pipework.

22

The pressure at the third measurement

exceeded the calculated maximum

pressure.

Check for blockage in the fuel

delivery hose, breakaway or

vehicle pipework.

25

Stop switch operated.

Check the stop switch wiring

and switch operation. Refer

CNG Dispenser Electrical

Schematic.

26

Twin pressure sensor values (when fitted)

do not agree.

Check pressure sensor

calibration.

30

Maximum flow rate exceeded.

31

Over-pressure switch has been activated.

32

Dispenser on Hold. (No fuel will be

dispensed).

22.

Dispenser Passcode

Dispenser Passcode

The dispenser passcode (Code and PASS ) enables you to limit the access to

sensitive settings found under the parameter and K-factor switches.

If set, only the dispenser software version can be viewed.

NOTE: If the dispenser is connected to the forecourt PC, you can access the dispenser

information via the Compac Dispenser Monitor program, even if the dispenser is

passcode is enabled.

To Set the Dispenser Passcode:

▪ Make sure that the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch until Code is displayed.

▪ Enter the new passcode.

NOTE: Each press of the Parameter switch passes you over a digit in a setting,

making the digit blink. Holding the switch down for more than a second changes

whichever digit is currently displayed. If you want to pass over a setting without

changing any digits, keep pressing and releasing the switch.

▪ Let the menu time out so that the value and quantity amounts are displayed.

The dispenser is now passcode protected. Store the passcode in a secure place.

To Disable the Dispenser Passcode:

▪ Make sure that the dispenser is idle, with the nozzle in its holster.

▪ Press and release the Parameter switch until PASS is displayed.

▪ Enter the current password.

NOTE: Each press of the Parameter switch passes you over a digit in a setting,

making the digit blink. Holding the switch down for more than a second changes

whichever digit is currently displayed. If you want to pass over a setting without

changing any digits, keep pressing and releasing the switch.

▪ Press and release the Parameter switch until Code is displayed.

▪ Clear the password by setting it to 000000.

NOTE: Each press of the Parameter switch passes you over a digit in a setting,

making the digit blink. Holding the switch down for more than a second changes

whichever digit is currently displayed. If you want to pass over a setting without

changing any digits, keep pressing and releasing the switch.

▪ Let the menu time out so that the value and quantity amounts are displayed.

The dispenser passcode is now disabled.

23.

Troubleshooting

Troubleshooting

This troubleshooting section outlines issues that you may encounter when using the

dispenser, and provides recommended actions.

For sites where the temperature falls below –10°C, power should only be removed

from the dispenser for servicing.

Problem

Likely Cause(s)

Recommended Action

For all problems not listed here please contact your service agent

After powering the

dispenser, PA:uSE is

displayed on the

countdown from 60 does

not start.

For push to start dispensers

the start button is held

down.

Release the start

button.

The nozzle is not stowed, or

the nozzle switch is active.

Correctly stow the

nozzle.

The C4000 electronics are

not working. The indicator

LEDs are off and nothing

happens when you lift the

nozzle (i.e., no beeps or

888888s are

displayed).

Unacceptable voltage spikes

are causing the fuses on the

C4000 to blow.

Fit a voltage-stabilising

UPS to the dispenser.

Contact your service

agent.

There is low input voltage.

Turn the dispenser off

and then on again.

Check power supply to

dispenser.

A display LCD segment is

always on or always off.

Display is faulty.

Contact your service

agent

When the start

button is pressed the

dispenser does not

display the 88888s

and reset for the next fill.

The dispenser number has not

been set.

Set the dispenser

number.

The start button or

nozzle switch is faulty, stuck,

or broken.

Check that the nozzle

switch is operating

correctly and is not

broken. Check the

nozzle switch

mechanism is free to

move in and out.

Contact your service

agent.

The connection between the

forecourt controller and

dispenser communications

connection is faulty.

Checkthe forecourt

controller.

Contact your service

agent.

24.

Troubleshooting

Problem

Likely Cause(s)

Recommended Action

The dispenser is under

filling the vehicle

The pressure in the storage

cascades is lower than target

filling pressure.

This is not a dispenser

fault.

If cascade pressure is

above target filling

pressure, please contact

your service agent.

The preset display is

flashing after a fill.

The preset amount has been

exceeded.

NOTE: The preset display will

stop flashing when the next fill

is started

If problem continues

contact your service

agent.

Gas flows but does not

read up on the display.

The C4000 needs to be reset.

Re-power dispenser.

If problem continues

contact your service

agent

The dispenser stops at

9999.99,

99999.9, or

999999 units

according to where the

decimal point is set.

The dispenser will stop

dispensing if either the money

or the quantity displays ever

reach these values.

Hang up the nozzle to

reset the display and

restart.

This is not a dispenser

fault.

NOTE: When fixing a Compac CNG Dispenser fault, please follow the recommendations

and safety information in this manual. Failure to do this may cause injury or void the

warranty.

25.

Fault Codes

Fault Codes

Fault codes indicate any problems with the dispenser. These problems are indicated

to you by codes displayed on the screen.

After you have physically corrected a fault, you need to clear the fault message

displayed on the control panel before normal operation can resume.

You can clear all fault codes by quickly pressing the start button or nozzle switch five

times. This also displays the tote information, which remains on the screen for 10

seconds for each section of tote data.

NOTE: You should read and understand all safety precautions before operating or

maintaining the Compac CNG Dispenser.

NOTE: When fixing Compac CNG Dispenser faults, please follow the recommendations

in this manual. Otherwise you may injure yourself and void the warranty.

Fault Code

Likely Cause

Recommended Action

Err 3

Loss of price in the

C4000 head.

If the dispenser is connected to a site Controller,

the price on the dispenser should be set to

0.00 and the pricing should be sent from the

Controller.

This procedure is outlined in the Hose Price

section.

If the dispenser is not connected to a site

Controller, the price must be set on the

dispenser.

This procedure outlined in Hose Price section.

Loss of hose number

in the C4000 head.

Check that the hose number has been set.

This procedure is outlined in the Hose Number

section.

Err 8

Excessive reverse

flow.

Repower dispenser

If problem persists contact your service agent.

Err 9

Gas metering error

Re-power the dispenser.

If problem persists contact your service agent

Err 10

No Configuration

data

Contact your service agent

Err 12

EPROM failure.

Contact your service agent

26.

Fault Codes

Fault Code

Likely Cause

Recommended Action

Err 13

The temperature

pressure interface

board is

disconnected or has

failed.

Contact your service agent

Err 14

The temperature

probe has been

disconnected, or is

connected with wire

links still in place.

Contact your service agent

Err 15

The pressure probe

has been

disconnected.

Contact your service agent

PA:uSE

The dispenser is in

start-up mode.

Hang up the nozzle.

The PA:uSE message stays on the display

for 60 seconds, then changes to 0.00.

When the display changes to 0.00, the

dispenser is ready to dispense gas.

STOP

The Stop switch

is latched on.

Establish why the Stop switch was

operated.

If safe, reset the switch by rotating the button

clockwise.

PrSErr

There is a pressure

difference of 10 bar

or more between the

pressure probes.

Contact your service agent

:0.0

The dispenser's

power supply has

been turned off and

back on since the

last transaction.

The colon disappears when the nozzle is lifted

for the next transaction.

Ab d

PE d

PE P

PS d

PS P

The display has an

error

Check for moisture or humid environment

Contact your service agent

27.

Indicator LEDs

Indicator LEDs

LED indicators are used to provide power, output status, and diagnostic information.

28.

Indicator LEDs

29.

Indicator LEDs

30.

Indicator LEDs

Indicator

LEDs

LED

Reference

Description

Power

D1

Indicates power is being supplied

to the processor board. If it is not

lit there is a fault on the processor

power supply.

RXD

D6

Flashes when polling information is

being received.

TXD

D7

Flashes when polling information is

being sent.

Diagnostic

D18

Provides diagnostic information

(see below).

Diagnostic

LED

The diagnostic LED D18 flashes in three different states when the

processor is working properly, as outlined in the table below.

State

LED Flashes

When

1

Slowly and

consistently.

The hose is idle and in stand-alone

mode.

2

Slowly but

erratically.

The hose is idle and

communicating with a Controller.

3

Quickly.

The start button is being pressed

or the nozzle has been lifted from

its holster.

31.

Servicing

Servicing

Degassing the Dispenser

When replacing or servicing dispenser hydraulics the dispensers must be de-gassed.

Degass the Dispenser

- Isolate the dispenser by closing the inlet gas supply valves at the base of the

unit or at the priority panel.

- Fill one or more CNG bottles until the dispenser pipework is completely

depressurized. Ensure that the isolation valve remains open during this

process.

Open the bleed valve on the utility manifold (where fitted) to remove any remaining gas

inside the dispenser.

32.

Servicing

Schedules Servicing

Weekly-checks

- Check the sealing and operation of the three-way refuelling valve.

- Check the sealing and operation of the solenoids.

- Check the sealing and setting of the regulator.

- Drain the Coalescing Filter.

Suggested 6-monthly or 400 compressor run hour service

Check the dispenser for leaks.

Check the Coalescing filter elements, replace if necessary.

Check damage and electrical continuity of Refuelling Hoses

Replace Breakaway seals.

Replace 3-way refuelling valve seals and inspect ball for scratches and wear.

Replace ball if necessary.

Replace refuelling probe O-rings. Check that the probe is not damaged or bent,

replace if necessary.

OEM Nozzles and Breakaways - Refer to manufacturer’s instructions.

Suggested yearly or 8000 compressor run hour service

In addition to all the checks listed in the 6-month service, carry out the following:

Dismantle and clean the solenoid valves. Replace the seals and O-rings.

Dismantle and clean the regulator valves. Replace the seals and O-rings.

Check the dispenser calibration. Meter Calibration.

Check the C4000 Processor Board is clean, dry and dust free.

Check the UPS and voltage stabiliser supplying power to the dispenser is working

according to the manufacturer’s specifications.

Check the C4000 flameproof box lid is bolted down tight and all glands are tight.

Check the zero point and calibration of the dispenser pressure transducers (fast fill &

temperature compensation only).

33.

Servicing

Checking Dispenser Operation

To check that the dispenser is operating correctly:

1. Fill two gas bottles.

2. Check that:

- The bottles fill to the desired pressure.

- The dispenser fills to the preset value.

- The displays and gauges are working

Checking the Sealing of the Solenoid

- De-gas the hose by opening the 3 way valve.

- When the hose is empty check that the flow has stopped. If the flow does not

stop, the seals in the final stage solenoid will need to be replaced.

Checking the Setting and Sealing of the Regulator

Before you start, make sure you have:

An 8mm hex key

NOTE: When you are undertaking this check, the dispenser must be turned on and

pressurised.

To check the setting and sealing of the regulator:

- Hang up the nozzle and check that the three-way valve is closed.

- Press the start button to initiate a fill and open the solenoids

- Check that the pressure gauge is at the setpoint reading (typically 200 bar).

- Check that the pressure gauge reads at a steady state, rather than creeping after

a fill.

If the pressure gauge is not reading the correct setpoint:

▪ Insert an 8mm hex key into the top of the regulator body.

▪ Adjust the pressure up clockwise or down anticlockwise to 200 bar.

If the pressure on the gauge does not remain stable, the regulator valve seal is

leaking and will have to be replaced.

34.

Servici

ng

Valve Adjuster (use 8 mm Hex Key)

Checking the Over-Pressure Switch Operation (Fast Fill & Temperature

Compensated Units Only)

To check the operation of the Over-Pressure cut off:

- Access the K-Factor switch on the C4000 processor.

- Obtain the over-pressure settings, PLa (for side A) and PLb (for side B),

as per the K-Factor Switch Settings section.

- Set the over-pressure cut-off point to below the regulator pressure or target

fill pressure (FPA, FPb).

- For example, if the regulator pressure is 220 bar, then set the over-pressure

to 100 bar. An exact value is not required; just make sure that the value is

significantly lower than the regulator pressure.

- Start a fill. The dispenser should stop shortly after the fill begins.

- Check the dispenser End of Sale indicator states that the fill has ended

because of over-pressure. End of Sale Indicators.

- Reset the over-pressure cut-off point to its original value.

35.

Servicing

Checking the Dispenser for Leaks

Before you start, make sure you have:

- Soapy water

To check the dispenser for leaks:

CAUTION: Be careful not to spray or drip water into any of the dispenser electronics

when checking for leaks.

- Apply soapy water to all joins in the assemblies and fittings on the inside and

outside of the dispenser, including the hose.

If bubbles form, there is a leak with that assembly or fitting. The fitting may require

tightening, or the seals might need to be replaced.

DANGER: You must isolate the gas supply and depressurise the dispenser before

disassembling any component or adjusting any fitting. Serious injury may result if

components are removed while the dispenser is under pressure.

- Threaded SAE Fittings.

- Adjustable Threaded SAE Fittings.

- Compression Fittings.

- To remedy a leak, refer to the appropriate section, depending on the leak is

location.

- After checking for leaks, wipe any excess water off the dispenser to prevent

corrosion.

36.

Servicing

Checking the Refuelling Hoe for Leaks

Before you start, make sure you have:

- Soapy water

To check the refuelling hose:

- Visually check the refuelling hose for damage, such as fraying and cuts.

- Apply soapy water to all valves and connections.

If bubbles form, there is a leak in that assembly or fitting. The fitting may require

tightening or the seals might need to be replaced.

DANGER: You must isolate the gas supply and depressurise the dispenser before

disassembling any component or adjusting any fitting. Serious injury may result if

components are removed while the dispenser is under pressure.

Replace the hose if it is damaged or leaking.

Checking the Isolation Ball Valve Sealing and Operation

Before you start, make sure you have:

- Soapy water

To check the operation of the isolation ball valve:

- Close the isolation valve.

- Open the dispenser access door.

- Open the bleed valve on the utility manifold block (where fitted) and bleed the gas

from the refuelling hose.

- Close the bleed valve once the hose is degassed.

- Start a fill.

If the pressure gauge starts to move, the isolation ball valve is leaking or passing

gas.

- Apply soapy water to the valve.

If bubbles form, there is a leak in the assembly or fitting. The fitting may require

tightening or the seals might need to be replaced.

For servicing refer to Isolation Valve Seal Replacement.

37.

Servicing

Checking the Three-Way Refuelling Valve Sealing and Operation

Before you start, make sure you have:

- Soapy water

Check the Sealing of the Three-Way Refuelling Valve

To check the sealing of the three-way refuelling valve, apply soapy water to the

valve.

If bubbles form, there is a leak, in which case you should replace the three-way

refuelling valve seals.

Check the Operation of the Three-Way Refuelling Valve

To check the operation of the three-way refuelling valve, do a test fill to check that

the valve is filling the vehicle, and venting properly when you disconnect it from the

vehicle.

If bubbles form, there is a leak, in which case you should replace the three-way

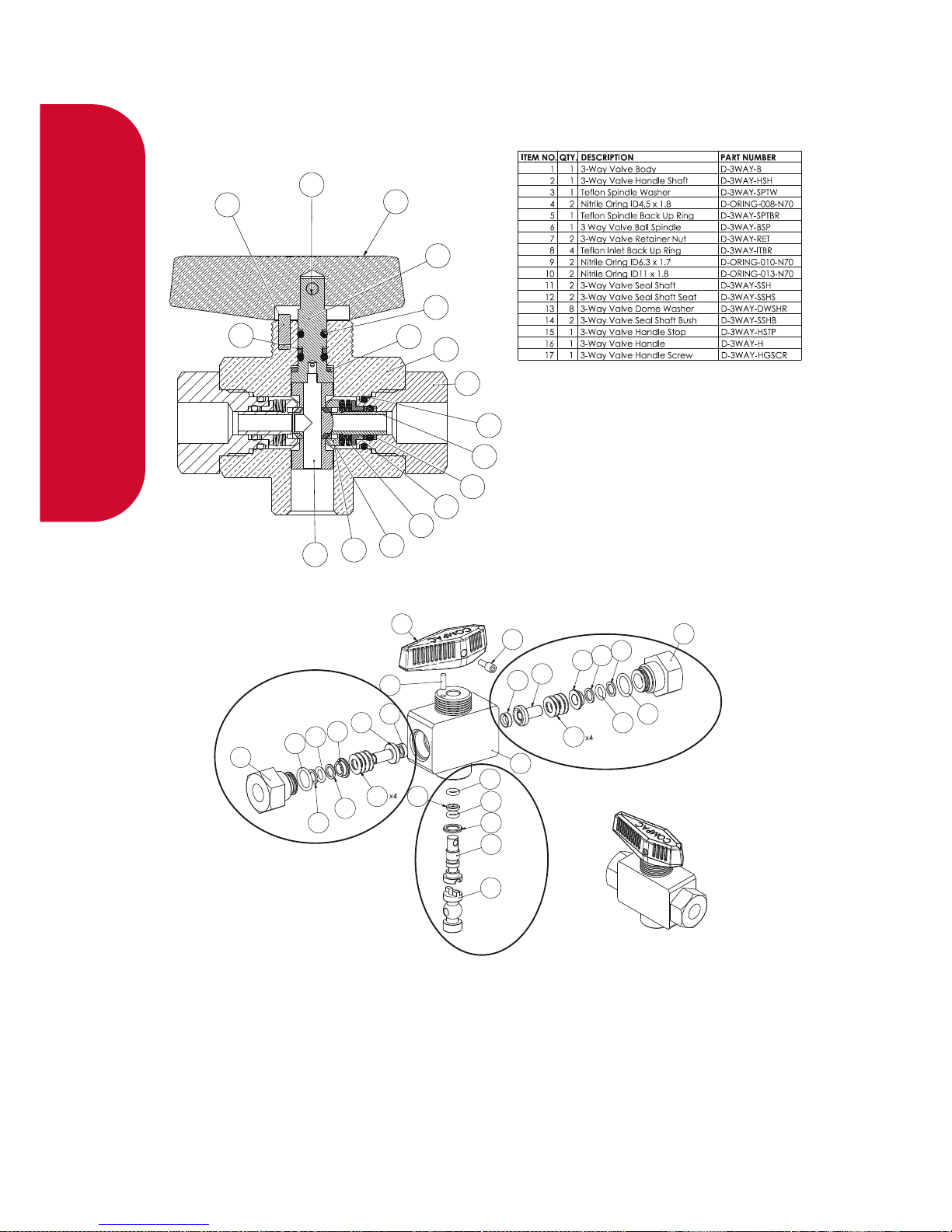

refuelling valve seals.

Draining the Coalescing Filter

Before you start, make sure you have:

- A 3/16" hex key

To drain the coalescing filter:

- De-gas the dispenser.

- Open the dispenser access doors.

- Unscrew the drain plug from the bottom of the filter cover.

- Allow all oil and water to drain from the filter*.

- If excessive amounts of oil and water are present, remove and replace the

coalescing filters.

- Screw in the drain plug and repeat steps 1 to 4 for all additional filters.

Note: Make sure you dispose of any fluids responsibly.

38.

Servicing

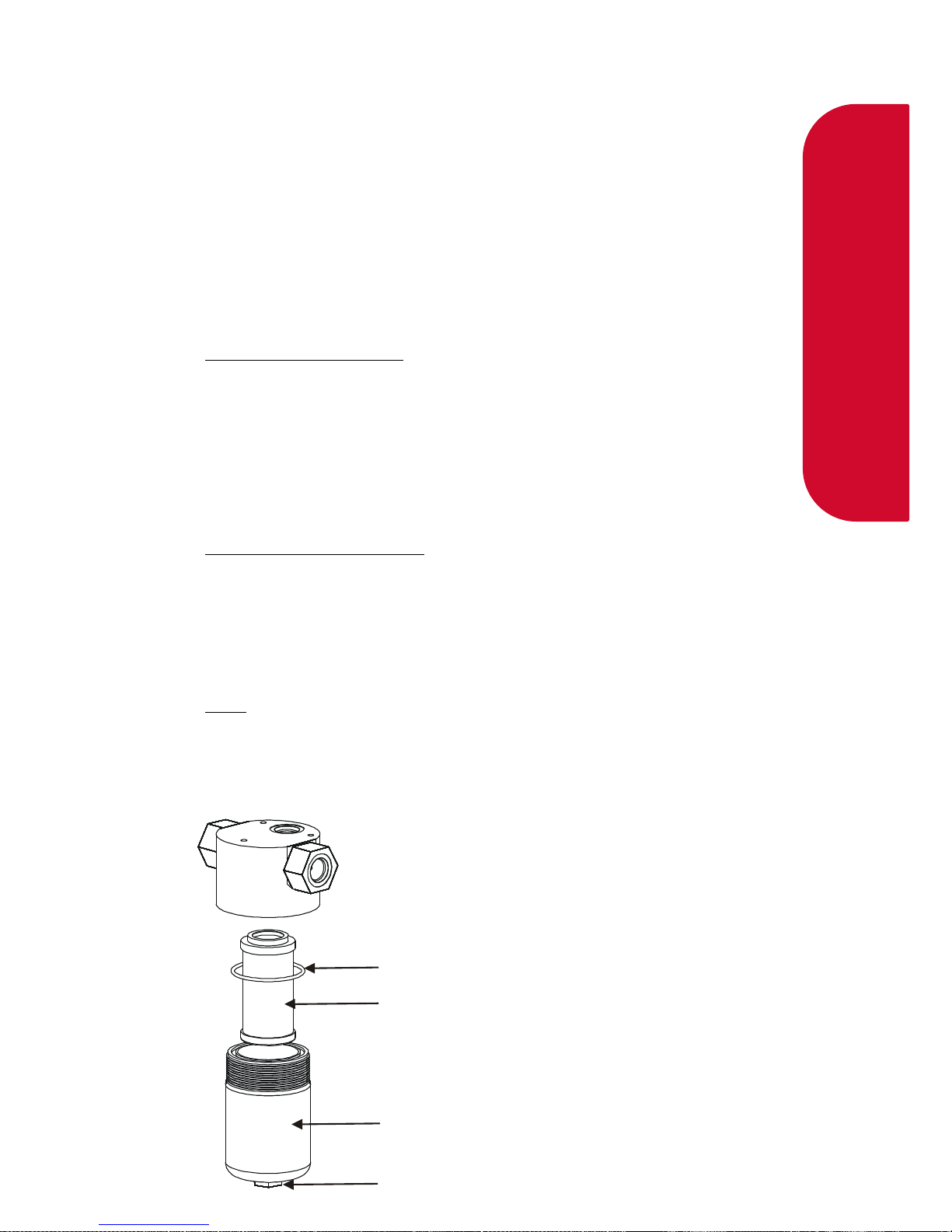

Filter Bowl O-ring Seal

Filter Element

Filter Bowl

Drain Plug

Filter Element Replacement

The coalescing filters are designed to trap dirt, moisture, oil, and other debris that

may damage the valve seals.

Before you start, make sure you have:

- A seal kit - Part number FC-FIL-0001

▪ 1 x filter

▪ 1 x filter bowl O-ring seal

- O-ring lubricant

Remove the coalescing filter

- Degas the dispenser.

- Drain the coalescing filters if they have not been drained already.

- Unscrew the filter bowl(s) with a spanner on the 22mm hex nut at the base of

the filter bowl.

- Remove the filter element.

- Clean all oil and dirt off the components with a clean cloth.

Install the new coalescing filter

- Insert the new filter element and lubricated filter bowl O-ring seal.

CAUTION: O-rings that are subjected to natural gas at high pressure swell when

exposed to air. Once swollen, they cannot be reused and must be replaced.

NOTE: Always use O-ring lubricant to prevent damage to the O-rings.

- Screw in the filter bowl(s)

- Check the dispenser for leaks.

39.

Servicing

Solenoid Valve Seal Replacement

These instructions refer to the current Compac S2-350 solenoid valve. The

solenoids are available in several types: Standard, high oil and low temperature.

Always quote the dispenser serial number when ordering parts and check the

model number on the valve body before installation.

NOTE: For applications where the gas has a high oil content, a special piston with

an O ring seal is available. If you are having problems, discuss this option with your

service agent. If the special piston is used for low oil content gas, no harm will

occur, but the service life of the seal may be shortened.

Before you start, make sure you have:

- A seal kit - Part number FC-SK-0001

▪ 1 x Teflon valve seal

▪ 1 x solenoid top O-ring seal

▪ 1 x gas return line O-ring seal

- O-ring lubricant

- Solenoid piston - Part number FC-VLV-PSTN-0001 (optional standard)

- Solenoid piston – Part number FC-VLV-PSTN-S2 (optional high oil)

- Solenoid top service kit standard. Part number FC-SVK-0003 (replace valve top

if leak detected through stem)

- Solenoid top service kit - low temperature option (-40 degrees C). Part number

FC-SVK-0004 (replace valve top if leak detected through stem).

CAUTION: Never remove or service the stem. If it is leaking, it must be replaced

using the appropriate top service kit.

CAUTION: Cleanliness is essential. When working on the open solenoid assembly,

cover the opening with a cloth to prevent dust and dirt from entering.

CAUTION: O-rings that are subjected to natural gas at high pressure swell when

exposed to air. Once swollen, they cannot be reused and must be replaced.

CAUTION: The Nitrile O-rings have a life span of over 10 years from cure date but

improper handling of these O-rings before use can shorten their useful life. O-rings

will deteriorate if exposed to ozone or ultraviolet light so keep in original packaging

and away from UV light. If in unsure about their condition, do not use old O-rings

and order new ones.

NOTE: It is not necessary to remove the solenoid body from the dispenser to service

the solenoid seals.

40.

Servicing

Remove the Old Solenoid Valve Seals

- De-gas the dispenser.

- Switch off the power supply to the dispenser.

DANGER: Never remove any electrical components without first switching off the

power to the dispenser. Failure to turn off the power could result in an electric

shock.

- Unscrew the solenoid coil retaining nut and move the coil out of the way.

- Remove the six cap screws from the solenoid top.

NOTE: Do not remove the angled grub screw from the solenoid top. This is epoxied

in place during manufacture and should never be removed.

- Remove the solenoid top and remove the old top O-ring seal and gas return O-

ring.

- Remove the solenoid spring.

- Screw an M6 cap screw into the solenoid piston to withdraw it from the

solenoid body.

41.

Servicing

- Taking care not to damage the piston, hold the flat part of the piston with a

spanner to prevent rotation, then unscrew the M6 x 12 mm cap screw from

the bottom of the piston. This releases the solenoid seal retainer and valve

seal.

- Discard the old valve seal.

- Clean all oil and dirt off the components with a clean cloth and check that

the bleed hole is not blocked.

- While the solenoid is apart, inspect the solenoid piston centre seal and piston

for wear, scratching or damage. Replace piston if required.

Install new Solenoid Valve Seals

- Place the new valve seal and seal retainer on the cap screw.

- Taking care not to damage the piston, hold the flat part of the piston to prevent

rotation, and then screw the M6 cap screw into the bottom of the piston.

- Insert a new gas return O-ring.

- Insert the piston back into the solenoid body.

- Insert the solenoid spring.

- Replace the solenoid top O-ring seal.

- Place the solenoid top back on the solenoid body, making sure that the locating

dowel is engaged.

- Screw in and tighten the six cap screws.

- Replace the solenoid coil.

- Re-power and re-gas the dispenser then check for leaks and correct operation of

the valve.

42.

Servicing

Solenoid Coil Replacement

Before you start, make sure you have:

- Replacement solenoid coil FC-COIL-0005 (Compac S2-350).

NOTE: Solenoid coils are not interchangable between models. Make sure you order

the correct one by quoting the dispenser serial number. To replace obsolete coils,

the entire solenoid will need replacing.

Remove the Solenoid Coil

- De-gas the dispenser.

- Switch off and isolate the power supply to the dispenser.

DANGER: Never remove any electrical components without first switching off the

power to the dispenser. Failure to turn off the power could result in an electric

shock.

- Remove the flameproof box lid to gain access to the C4000 power supply

board.

- Disconnect the appropriate solenoid coil wiring from the C4000 power supply

board.

CAUTION: Take basic anti-static precautions by wearing a wristband with an earth

strap.

- Loosen the gland on the flameproof box that is clamping the solenoid coil lead

and pull the lead out of the gland.

Undo the nut on the top of the solenoid valve that is securing the coil and remove

the coil from the top of the valve

Install the New Solenoid Coil

- To install a new solenoid coil, reverse the procedure above.

NOTE: Before replacing the lid on the flameproof box, make sure that the O-ring is

not damaged and is seated properly in its groove. If the O-ring is damaged and

needs replacing, replace it with an O-ring of the same size and specification (176

N70).

43.

Servicing

Complete Solenoid Valve Replacement

These instructions refer to the current Compac S2-350 solenoid valve. This

replaces all previous solenoids.

Before you start, make sure you have:

- Solenoid valve standard 350 bar model (FC-VALVE-0035) or

- Solenoid valve 350 bar O ring seal option for high oil content gasses (FC-

VALVE-0036) or

- Solenoid valve 350 bar low temperature option (FC-VALVE-0037)

NOTE: Solenoid valves are supplied without coils. If you need the coil it must be

ordered as well.

CAUTION: Cleanliness is essential. When working on the open pipes and

solenoids, cover the openings with a clean, lint-free cloth to prevent dust and dirt

from entering.

Remove the Old Solenoid Valve

- De-gas the dispenser.

- Switch off the power supply to the dispenser.

DANGER: Never remove any electrical components without first switching off the

power to the dispenser. Failure to turn off the power could result in an electric

shock.

- Undo the nut and remove the solenoid coil.

- Undo the gland nuts connecting the solenoid valve to the pipework and

manifold and remove valve

Replacing Solenoid Valve

- Ensuring all surfaces are clean and any sealing plugs are removed from

the valve, reconnect the pipework and tighten the gland nuts.

- Replace the solenoid coil.

- Repower and re-gas the unit, check for leaks and test for correct

operation.

44.

Servicing

Regulator Valve Seal Replacement

Before you start, make sure you have:

- A regulator seal kit - Part Number FC-SK-0002

▪ 2 x regulator O-ring seals

▪ 2 x Teflon back-up ring

▪ 1 x Teflon valve seal

- O-ring lubricant

Remove the Old Regulator Valve Seals

- De-gas the dispenser.

- Open the dispenser access doors.

- Unscrew the spring tube by placing a 1 ¼" spanner on the machine hex nut

at the top of the spring tube.

NOTE: Do not unscrew the valve adjustment nut. The spring remains at the set

tension.

- Unscrew the bottom plug in the regulator body.

- Using a hex key inserted into the base of the piston to stop the piston from

twisting sideways and being damaged, push the piston downwards out the

bottom of the regulator body.

- Hold the piston by the 8mm flat and remove the M6 cap screw from the

bottom.

NOTE: The M6 cap screw has a special hole through it. Never substitute it for a

normal cap screw.

45.

Servicing

Install New Regulator Valve Seals

- Install the new valve seal. Make sure that the larger flat side of the

seal faces upwards.

NOTE: O-rings that are subjected to natural gas at high pressure swell when

exposed to air. Once swollen, they cannot be reused and must be replaced.

CAUTION: The Nitrile O-rings have a life span of over 10 years from cure

date but improper handling of these O-rings before use can shorten their

useful life. O-rings will deteriorate if exposed to ozone or ultraviolet light so

keep in original packaging and away from UV light. If in unsure about their

condition, do not use old O-rings and order new ones.

- Lever off the two regulator O-rings and two Teflon back-up rings.

- Install two new regulator O-rings and two new Teflon back-up seals.

The back-up rings go on the outside of the O-rings.

NOTE: Always use O-ring lubricant on the O-rings to increase the service life.

- Reassemble the piston.

- Push the piston back up into the regulator body with a hex key.

NOTE: Keep the piston straight, rotate it clockwise to prevent the new O-ring

from catching or ripping.

- Screw in the bottom plug.

- Screw on the spring tube until tight.

Check the setting and sealing of the regulator for correct pressure.

A

B

DETAIL B

Regulator O-Ring

Teflon Back-Up Ring

DETAIL A

Teflon Back-Up Ring

Regulator O-Ring

Make sure that the

flat face of the seal

faces up

46.

Servicing

Isolation Valve Seal Replacement

NOTE: Please make sure you identify the valve before disassembling it to make

sure you have the correct seal kit available.

Complete valve is part number FC-Valve-0001

Before you start

Obtain the following replacement parts and equipment:

- FC-SK-0010 Parker Isolation Valve Seal Kit

- Refer to Spare Parts list for other items that you may need.

Remove the isolation valve seals.

CAUTION: Take care when disassembling the valve, as a lot of parts look

similar.

- De-pressurise the valve and remove it from the pipework.

- Remove the handle and panel nut to remove it from the cabinet.

- Disassemble the valve, as per the drawing below.

- Undo the packing nut and remove packing washers, packing and stem.

- Undo the end connectors and remove the seals, seat assembly and ball

Clean all components with a clean dry lint free rag.

CAUTION: O-rings that are subjected to Natural Gas at high pressure. Swell

when exposed to air. Once swollen they must be replaced.

- Blow compressed air (100 psi) through all ports to remove any impurities

that may damage the seals in operation.

CAUTION: Wear appropriate safety eye wear when using compressed air.

47.

Servicing

Replace the isolation valve seals

CAUTION: Take care to keep all parts clean while assembling.

- Apply a light coating of approved grease to the ball then replace the ball

and ball seat sub-assemblies, making sure the slot in the ball is at the

top.

- Making sure the retainer seal and end connector O ring are in place,

screw in the end connectors. Do not tighten yet.

- Locate the stem in the ball slot then replace the stem washers, stem

packing and packing nut.

- Open and close the valve a few times to seat the ball valve before

tightening the end connectors and packing nut.

- Reattach the valve to the cabinet and reconnect the pipework.

- Reapply gas to the valve and check for leaks.

48.

Servicing

Gas Operated Valve (option) Seal Replacement

CAUTION: Follow all safety precautions listed at the front of this manual.

Before doing any work on the valve, ensure that the power is off and the

system pressure is reduced to atmospheric levels. Ensure that the pressure is

removed from both the inlet and outlet ports of the valve and from the air

supply line.

Before you start

Obtain the following replacement parts and equipment:

- FC-SK-0029 Oasis Gas Operated Valve Seal Kit

Always quote model and serial number of your dispenser when ordering.

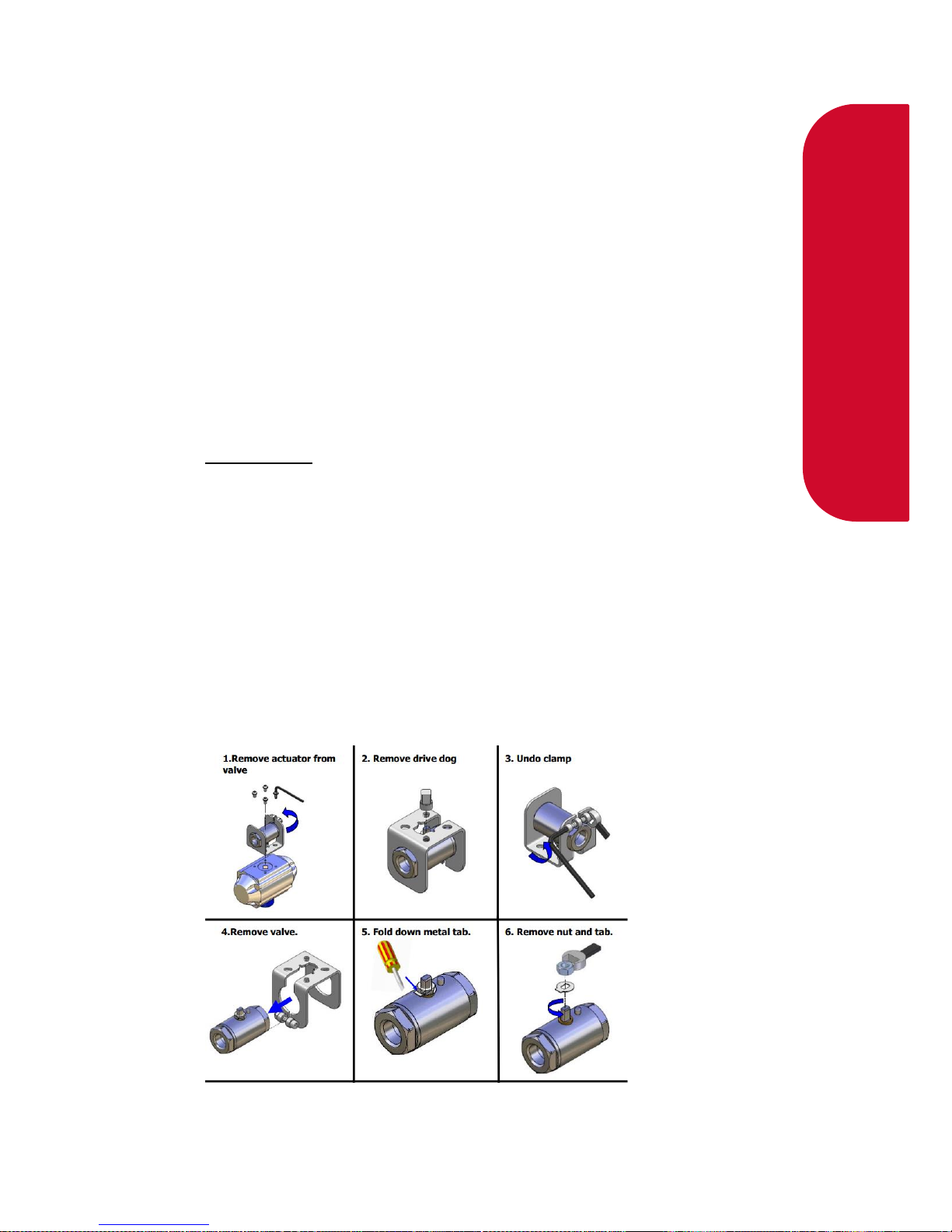

Diassembly

CAUTION: Take care when disassembling the valve, as a lot of parts look

similar.

- Undo the pipework and remove the valve and actuator.

- Undo the four Allen screws and remove the actuator from the valve

- Remove the drive dog (note orientation)

- Undo clamp (note orientation of clamp in relation to flow direction)

- Remove valve from the clamp

- Fold down metal locking tab

- Remove nut and tab

49.

Servicing

- Use a pick to pull out the stem seal and discard.

- Undo the end cap, remove the valve seat and discard it.

- Turn the valve stem to the “Closed” position then tap on the end of the ball

valve with a wooden or soft plastic dowel (BV ASST) to remove it. Discard

the ball.

- Push the valve stem down into the valve and remove it from the valve

body. Discard the valve stem.

1. With a pick, carefully remove the second valve seat taking care not to

scratch the internal surfaces of the valve. Discard the valve seat.

2. Remove and discard the O-ring from the end cap.

50.

Servicing

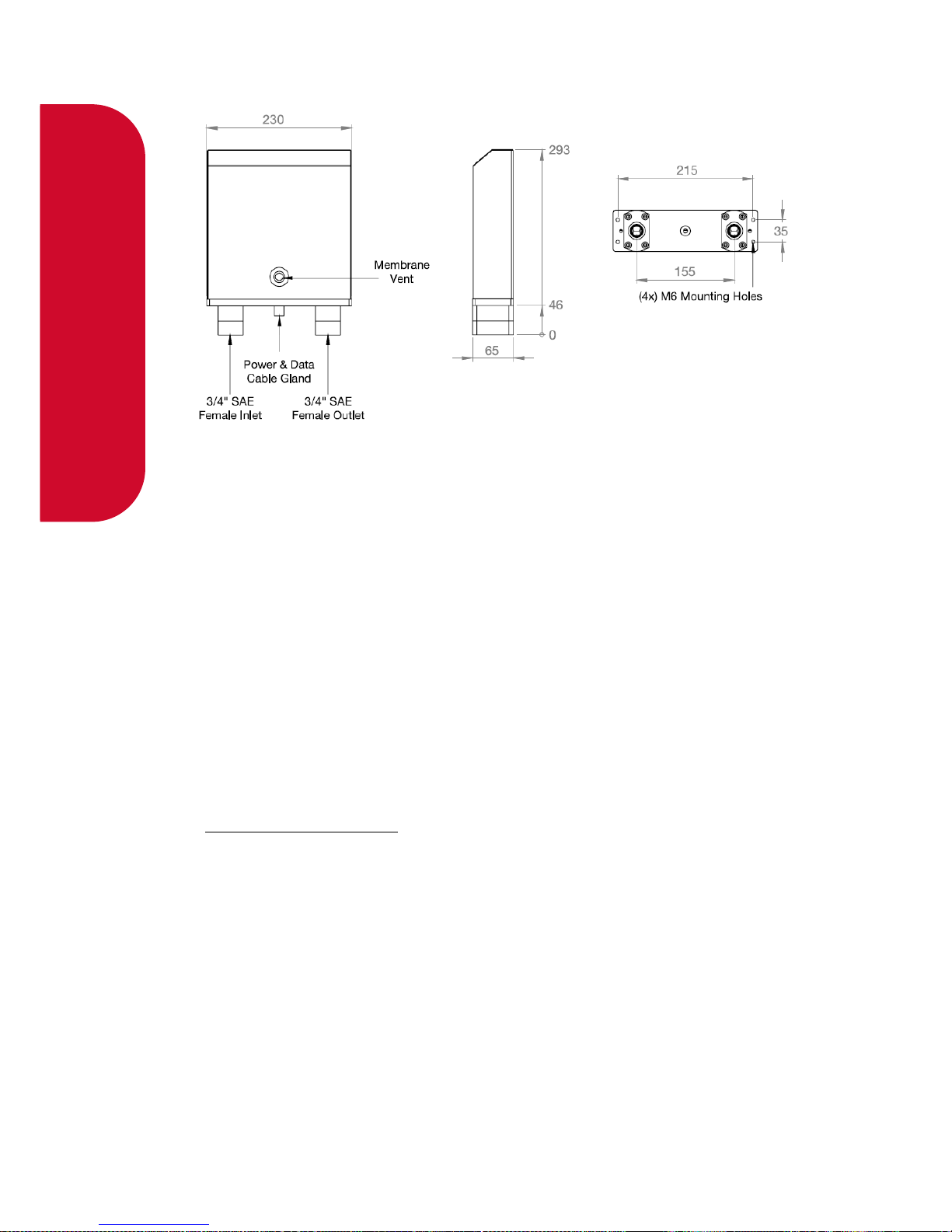

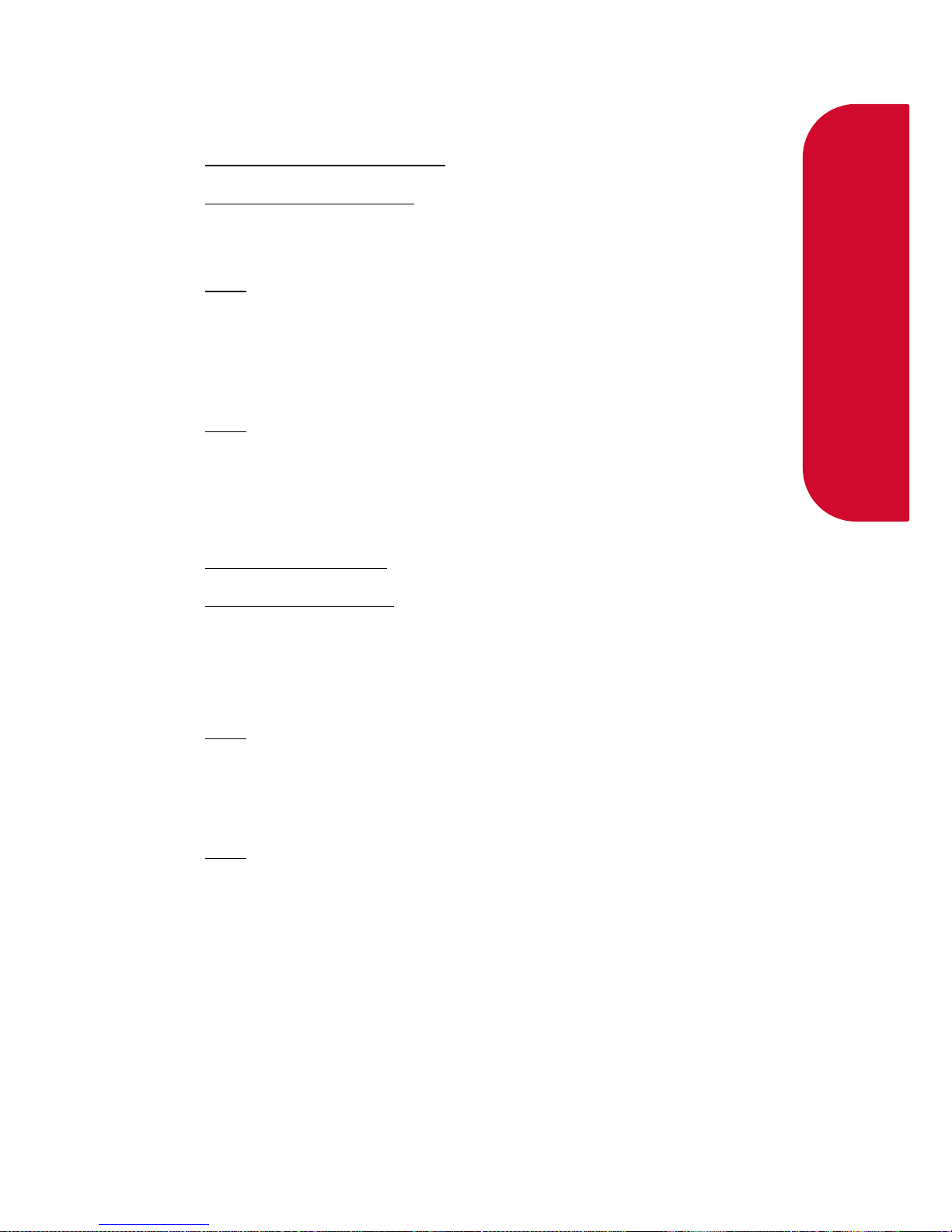

Service kit

Suggested service tools

Replacement

- Thoroughly clean and dry the valve body and end cap.

- Place the new O-ring on the end cap and lubricate with the supplied

grease. Put an anti-seize compound on the threads.

- Fit the new valve seat making sure it is seated properly. Insert the valve

stem into the valve body and pull it upwards until it clicks into place.

51.

Servicing

- With the valve stem in the “Closed” position, insert the ball so the slot

engages with the stem.

- Insert the second valve seat

- Install the end cap and tighten to 60 N/m

- Install the valve stem gland then the lock tab and nut. Tighten nut to 3

N/m and bend the lock tab to stop the nut undoing

- Hold the valve stem with pliers and open and close the valve four or

more times to bed in the seal. Leave the valve in the closed position

- Reinstall the bracket, drive dog and air actuator

- Reinstall the assembled valve and connect pipework

- Repower the dispenser and check for correct operation of the valve and

for any leaks

DANGER: Do not use thread tape or sealing compounds on parallel SAE

fittings.

CAUTION: O-rings that are subjected to natural gas at high pressure swell

when exposed to air. Once swollen, they cannot be reused and must be

replaced.

52.

Servicing

Bleed Valve Replacement

The bleed valve seldom gives problems and is not serviceable

For a replacement valve and instructions if required, contact your Compac

service agent with your Model and Serial numbers

Pressure Relief Valve Replacement

The pressure relief valve seldom gives problems and is not serviceable

For a replacement valve and instructions if required, contact your Compac

service agent with your Model and Serial numbers

KG80 Meter Replacement

Removal

This section describes how to replace the KG80Meter.

- Shut off gas supply and degas the meter.

- Remove the inlet and outlet pipes from the old meter.

- Unscrew the SAE fittings from the meter inlet and outlet.

- Take note of the position and orientation of the communications plug

then unplug the meter cable from the C4000 processor board and cut

any cable ties that hold it in place.

- Undo the four bolts that hold the meter on the dispenser frame.

- Remove the old meter.

Replacement

- Secure the new meter to the dispenser frame using the four bolts.

- Plug the communications cable into the C4000 processor board.

- Screw the SAE fittings into the meter inlet and outlet.

- Install the inlet and outlet pipes.

- Cable tie the communications cable to avoid pulling or damage to it.

- Pressurise the meter and check for leaks.

- Calibrate the meter in accordance with the instructions in the

dispenser service manual.

53.

Servicing

Compac Breakaway Seal Replacement

This section describes how to replace the seal in a QBCI model breakaway.

The Compac Breakaway QBCI is only used on 15 kg/min models or on

models where the vent is returned to the dispenser.

The excess flow end (female) and check valve end (male) should not require

servicing. Both have metal to metal seats that are not affected by dirt.

Before you start, make sure you have:

Obtain the following replacement parts and ancillary equipment:

- A seal kit - Part number FC-SK-0011

▪ 3 x O-rings

▪ 2 x probe O-rings

- O-ring lubricant

Reassemble the Breakaway

In the event of a breakaway, check the O-rings in the male end of the

breakaway for damage.

If they are damaged, replace the breakaway QBCI seals by following the

steps below.

54.

Servicing

Replace the Breakaway Seals

To replace the breakaway seals:

- Remove the old O-rings.

NOTE:If you are dismantling the quick breakaway valve, make sure that you

have a spare seal kit available. O-rings that are subjected to natural gas at

high pressure swell when exposed to air and must be replaced.

- Replace the old O-rings with the new lubricated O-rings.

NOTE: Always use O-ring lubricant to prevent the O-rings from being

damaged.

If the breakaway parts under gas pressure for no apparent reason check that

the pressure relief hole is clear. If the pressure relief hole is blocked, gas

pressure will force the male and female ends apart.

Reconnect the Breakaway

To reconnect the breakaway:

- Make sure that both male and female receptacle breakaway parts are

clean before reassembly.

- Check that the pressure relief hole is clear.

NOTE: If the pressure relief hole is not clear, gas pressure will force the male

and female ends to part.